Tracer

Flowmeter

Operating Instructions (Ver 5.1)

®

Electronic Switching

with FCI (Fluid Characteristic Indication)

General

The Tracer Electronic Switching Flowmeter provides:

◆ 0 to 5V or 0 to 10V Selectable Flow Output

◆ 0 to 5V or 0 to 10V Selectable Temperature Output

◆ 1A, 30VAC/42VDC Programmable Switch for high

or low temperature and/or flow

◆ Fluid Flow Rate Display in gallons per minute

(gpm) or liters per minute (lpm)

◆ Fluid Temperature Display (°F or °C)

◆ BTU’s per Minute Display

◆ Fluid Characteristic Indication (Turbulent Flow or

“TFLOW” on display)

BTU Basics

To obtain the most accurate BTU calculation, use the Tracer

to measure the supply side water temperature (in °F) before

installing the Tracer in a cooling water return line.

BTU’s per minute calculation is based on the increase in water

temperature multiplied by the flow rate. The Tracer Electronic

Flowmeter calculates this information based on supply side

temperature entered manually. Due to inherent differences in most

thermometers, the most accurate BTU calculation will result from

using the same thermometer (inside the Tracer) to measure supply

and return line temperatures. Record the supply side temperature and

enter it using the “Set BTU/m Input Temperature” instructions on

page 3.

U.S. Patent No.

7,729,869

Application

Liquid running through the Tracer flowmeter

should be free of metal shavings. Loose

particles can interfere with moving

components causing extra maintenance

requirements.

Specifications

Flow

Size [NPT(F)] Range (gpm) Range (lpm)

3/8" 0.5 to 8 0 to 30

3/4" 2.0 to 20 8 to 76

1" 3.0 to 30 11 to 114

1-1/2" 6.5 to 60 25 to 228

2" 10.0 to 110 38 to 418

Accuracy ....................±5% of Full Range

Repeatability ..............±3% of Full Range

Environment

Tracer construction is water resistant, but the

electronics housing is not submersible.

Turbulent Flow

“TFLOW” notification appears on the display when Turbulent Flow

is likely inside the cooling circuit of the selected size.

Turbulent flow is the mixing and swirling of water inside a cooling

line that provides optimum heat transfer. Water flow rate greater than

the point of Turbulent Flow does not provide a proportional benefit.

Turbulent flow tracking allows technicians to apply mathematical

cooling principles to all machines in a water system. Visit the

Technical Documents section of www.smartflow-usa.com for a

detailed discussion of Turbulent Flow.

Input the percentage of glycol in cooling water (0%, 10%, 20% or

30%) for accurate Turbulent Flow Indication. See Setup Mode option

on page 5. Antifreeze compounds of ethylene or propylene glycol are

sometimes added to cooling waer. Glycol compounds have

substantially higher viscosity than water. As a result, higher flow

rates are required to reach Turbulent Flow when glycol is used.

151 Memorial Drive, Unit H - Shrewsbury, MA 01545 - Phone: (888) 792-2223 - sales@plastixs.com - www.plastixs.com

Form #146 (02.16)

Temperature

Operating Range............32 to 180°F (0 to 82°C)

Accuracy........................±2% of Display Value

Repeatability..................±1% of Display Value

Component Materials

Body (3/8" model) .........Nickel-Plated Brass

Body (3/4" thru 2")........Anodized Aluminum

Stainless Steel (optional)

Back Cover(3/8" only) ..Polysulfone

Impeller..........................Nylon 6/12

Magnet...........................Neodymium

Shaft...............................18-8 Stainless Steel

Electronics Cover ..........Nylon 6/6

Cable..............................9-Conductor, 24AWG

Operating

Internal Relay ................SPDT 1A, 30VAC/42VDC

Power Required .............8 to 28VDC

Maximum Pressure........100psi (7bar)

Installation Instructions

For best performance, mount the Tracer flowmeter vertically with the

flow entering the meter from the bottom. This provides full flow inside

the meter. We recommend a straight run of pipe equal to 10 pipe

diameters on the inlet side of the Tracer flowmeter and a straight run of

pipe equal to 5 pipe diameters on the outlet side of the flowmeter.

Use appropriate pipe sealant to prevent leakage on inlet and outlet

sides of the flowmeter. The Tracer flowmeter can be installed in any

orientation with the flow direction from either end of the flowmeter.

Attach the power and switching connections to the bare wires of the

cable according to the chart at right. Individual wires are 24AWG

stranded copper. Attach 8 to 28VDC power to the unit for correct

operation. Power supply other than 8 to 28VDC may damage the

electronics!

In normal operation, the internal relay is energized. If power to the unit

is lost, or if unit is turned off, relay state changes to signal an alarm.

Operating Instructions

When power is applied to the Tracer flowmeter, the software version

and the Tracer Unit Code (EP) will appear sequentially. Then the

screen will be blank. Press ON to activate the display.

There are three modes of operation for the Tracer Electronic

Flowmeter: User Mode, Setup Mode, and Calibration Mode. User

Mode displays all available process information. Setup Mode

configures the flowmeter for unit selection (°F, °C, lpm, and gpm)

and switching set points. Setup Mode also allows you to enter the

information required to calculate BTU’s per Minute.

Wire Color Function

Black DC Ground

(Ground for Analog Output)

Yellow +DC Input (8 to 28VDC)

Red Not used

Blue Not used

Orange Flow Analog Voltage Output (+)

Violet Temp. Analog Voltage Output (+)

Green Relay Common

Brown Relay Normally Open

Gray Relay Normally Closed

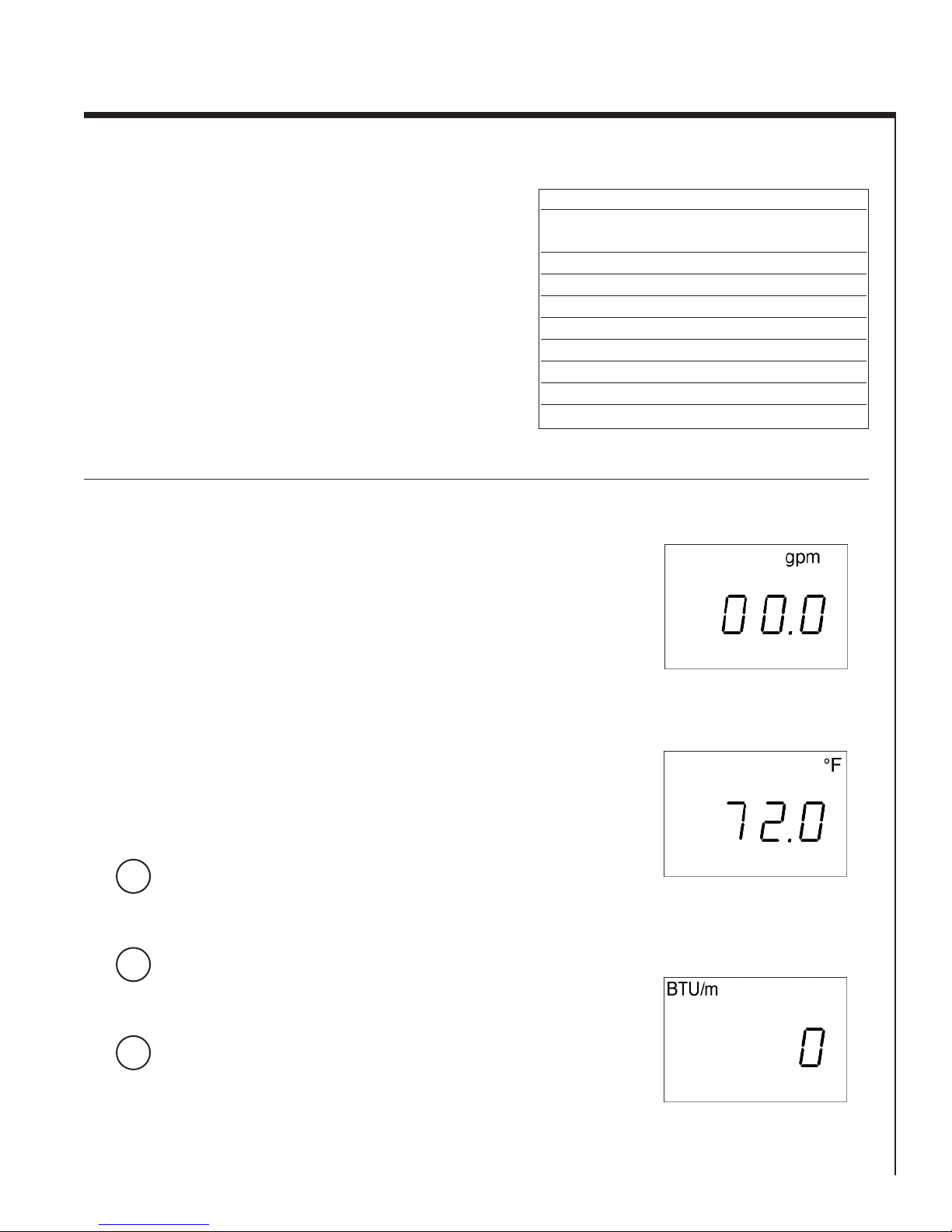

Figure 1

ON

Δ

Δ

User Mode

After pressing ON, press Δ or ∇ buttons repeatedly

to scroll continuously through displays of flow

rate, temperature and BTU/m. BTU/m will not

display until activated using the Setup Mode on

page 3.

View Flow Rate

Press ON. Flow rate and units (gpm or lpm) will be

displayed. See Figure 1.

View Temperature

Press Δ. Temperature and units (°F or °C) will be

displayed. See Figure 2.

View BTU/m (not visible until activated)

Press Δ. BTU's and units will be displayed. See

Figure 3. To activate, enter Setup Mode, and

follow instructions to set input temperature found

on page 3.

Figure 2

Figure 3

2

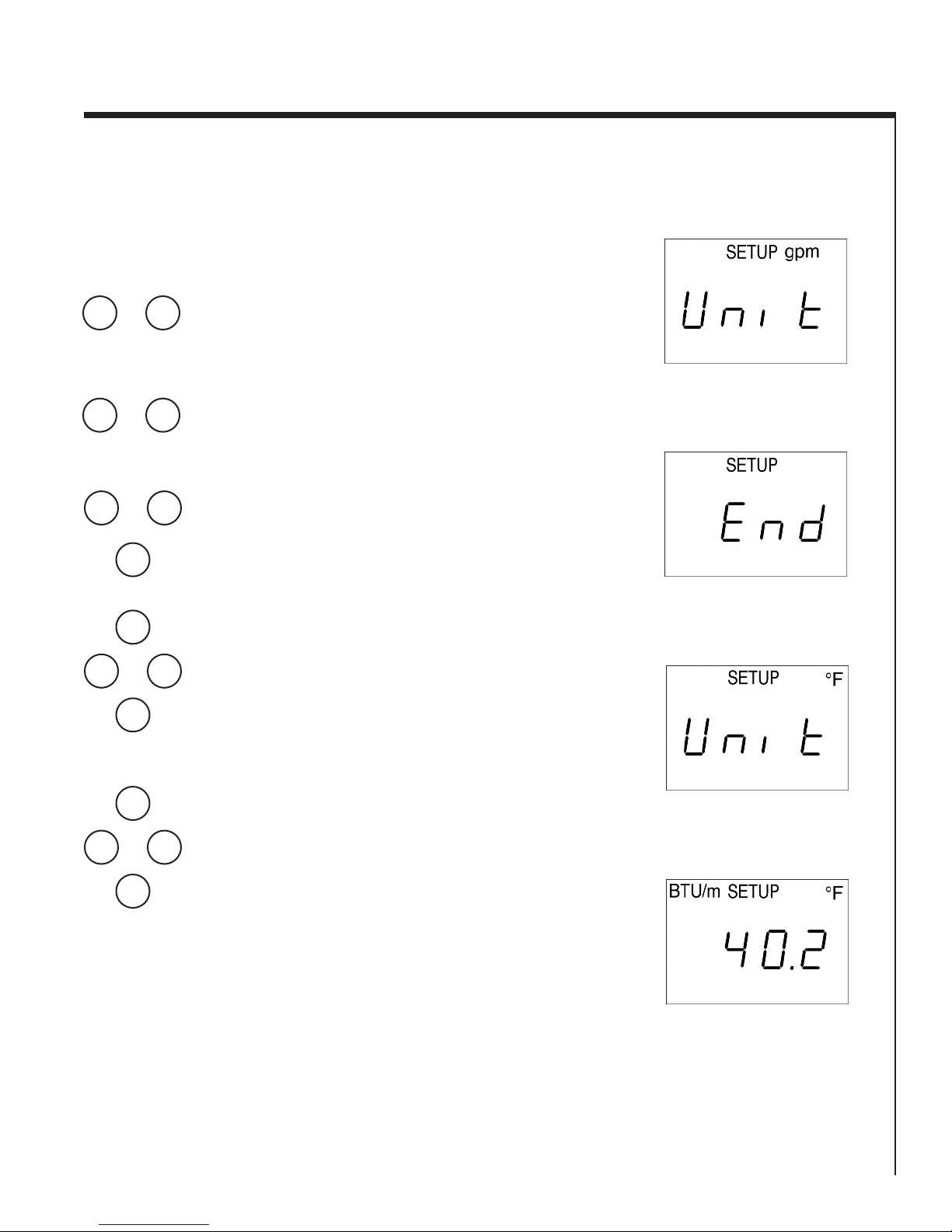

Setup Mode

Setup Mode allows the user to select English or Metric units, input

BTU/m inlet temperature, and set auto shut-off time. Δ and ∇ keys

scroll through all options inside each display selection. Turn the

display off before entering Setup Mode.

Enter Setup Mode

The display must be off to enter Setup Mode.

∇

and

Press and hold ∇, then press ON. Flow rate units

ON

plus "Unit" and "SETUP" will be displayed. See

Figure 4.

Select Flow Rate Units

Figure 4

∇

ON

∇

∇

or

ON

ON

or

ON

ON

or

ON

Press ∇ or Δ to change units to gpm or lpm. Press

Δ

ON when the desired unit is displayed. See Figure

4. Setup Mode will continue unless you exit.

Exit Setup Mode

Δ

Press ON repeatedly until the display reads “end”,

then press Δ. See figure 5. The display will read

"off", then press ON and the unit will return to user

mode.

Select Temperature Units

Enter Setup Mode (above). Press ON repeatedly

until the display shows “°F” or °C” in the upper

right corner and “unit” in the center. See Figure 6.

Δ

Press ∇ or Δ to change units. Press ON when

desired unit is displayed.

Setup Mode will continue unless you exit.

Set BTU/m Input Temperature

Enter Setup Mode (above). Press ON repeatedly

until the display shows “BTU/m” in the upper left

corner. See Figure 7. Press ∇ or Δ to change input

temperature (40 to 220°F or 4.4 to 104.4°C). Press

Δ

ON when desired unit is displayed.

Note: If you set the temperature input to less than

40°F or 4.4°C, the display will show “off” and

BTU/m display will deactivate.

Setup Mode will continue unless you exit.

Figure 5

Figure 6

Reactivate BTU/m

Follow the instructions to set (above) and press ∇

or Δ to display a value instead of “off”, and press

ON to set.

Figure 7

3

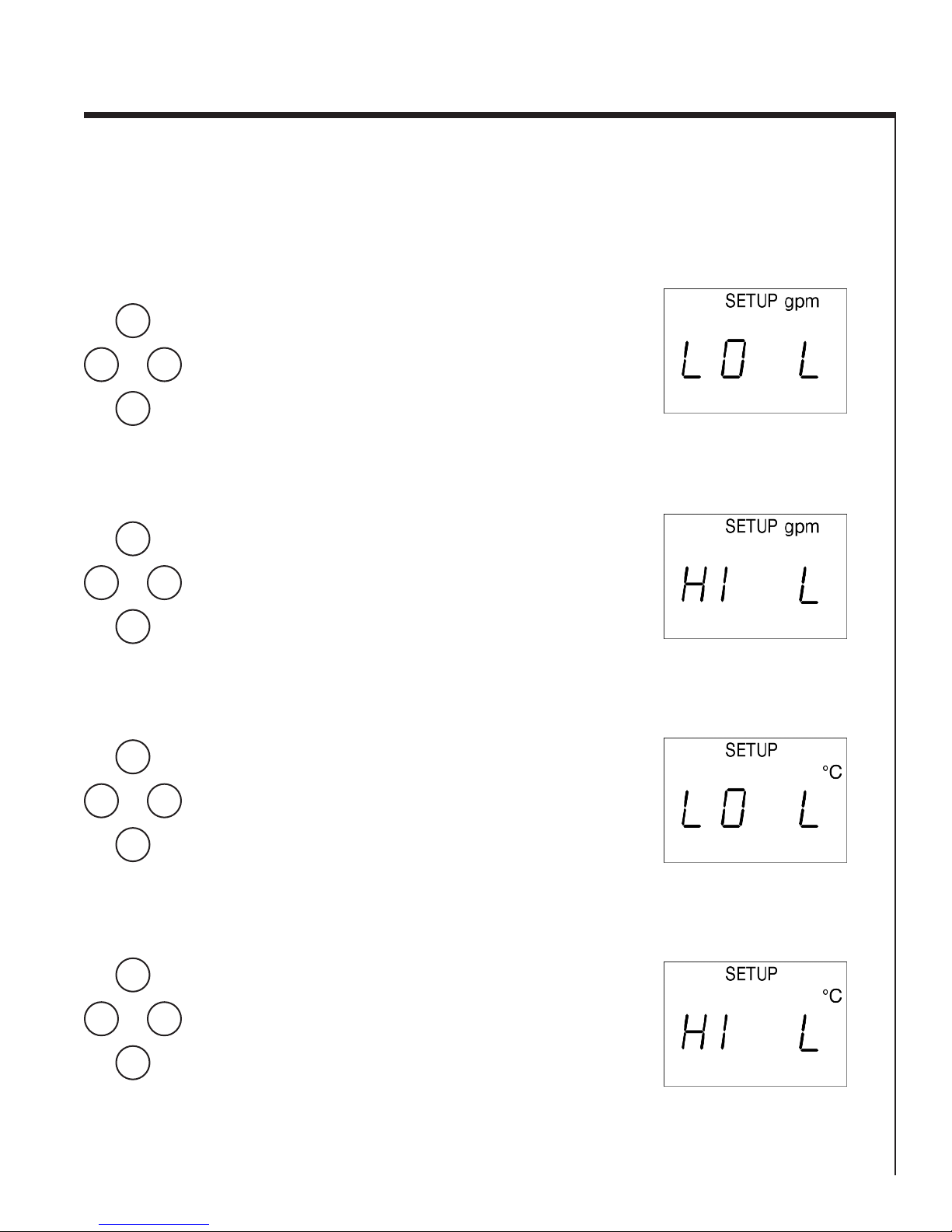

Switch Set Points

All switch set points are turned off when shipped from the factory. The switch actuates when sensed value(s) fall below

low level set point(s) and/or sensed values rise above high level set point(s). The switch returns to normal state when the

process fluid reaches programmed flow and/or temperature conditions. There is a 2 second delay to prevent switch chatter.

Any or all of the switches may be disabled or enabled at any time. An internal programming check prevents conflicting low

and high switch values. Always set the flow switching points using the same units as normal operating units.

Set Lo Limit Flow Switch Point

∇

∇

∇

ON

or

ON

ON

or

ON

ON

or

ON

Enter Setup Mode (see page 3). Press ON

repeatedly until the display shows “gpm” or “lpm”

in the upper right corner and “LO L” in the center.

See Figure 8. Press ∇ or Δ to set the flow rate at

Δ

which the Normally Open switch contact will

close. Press ON when desired value is displayed.

To turn off this set point, press and hold ∇ until the

display shows “OFF”.

Setup Mode will continue unless you exit.

Set Hi Limit Flow Switch Point

Enter Setup Mode (see page 3). Press ON

repeatedly until the display shows “gpm” or “lpm”

in the upper right corner and “HI L” in the center.

See Figure 9. Press ∇ or Δ to set the flow rate at

Δ

which the Normally Open switch contact will

close. Press ON when desired value is displayed.

To turn off this set point, press and hold Δ until the

display shows “OFF”, and press ON to set.

Setup Mode will continue unless you exit.

Set Lo Limit Temperature Switch Point

Enter Setup Mode (see page 3). Press ON

repeatedly until the display shows “°F” or “°C” in

the upper right corner and “LO L” in the center.

Δ

See Figure 10. Press ∇ or Δ to set the temperature

at which the Normally Open switch contact will

close. Press ON when desired value is displayed.

To turn off this set point, press and hold ∇ until the

display shows “OFF”.

Setup Mode will continue unless you exit.

Figure 8

Figure 9

Figure 10

Set Hi Limit Temperature Switch Point

ON

or

∇

ON

Enter Setup Mode (see page 3). Press ON

repeatedly until the display shows “°F” or “°C” in

the upper right corner and “HI L” in the center. See

Figure 11. Press ∇ or Δ to set the flow rate at

Δ

which the Normally Open switch contact will

close. Press ON when desired value is displayed.

To turn off this set point, press and hold Δ until the

display shows “OFF”, and press ON to set.

Setup Mode will continue unless you exit.

Figure 11

4

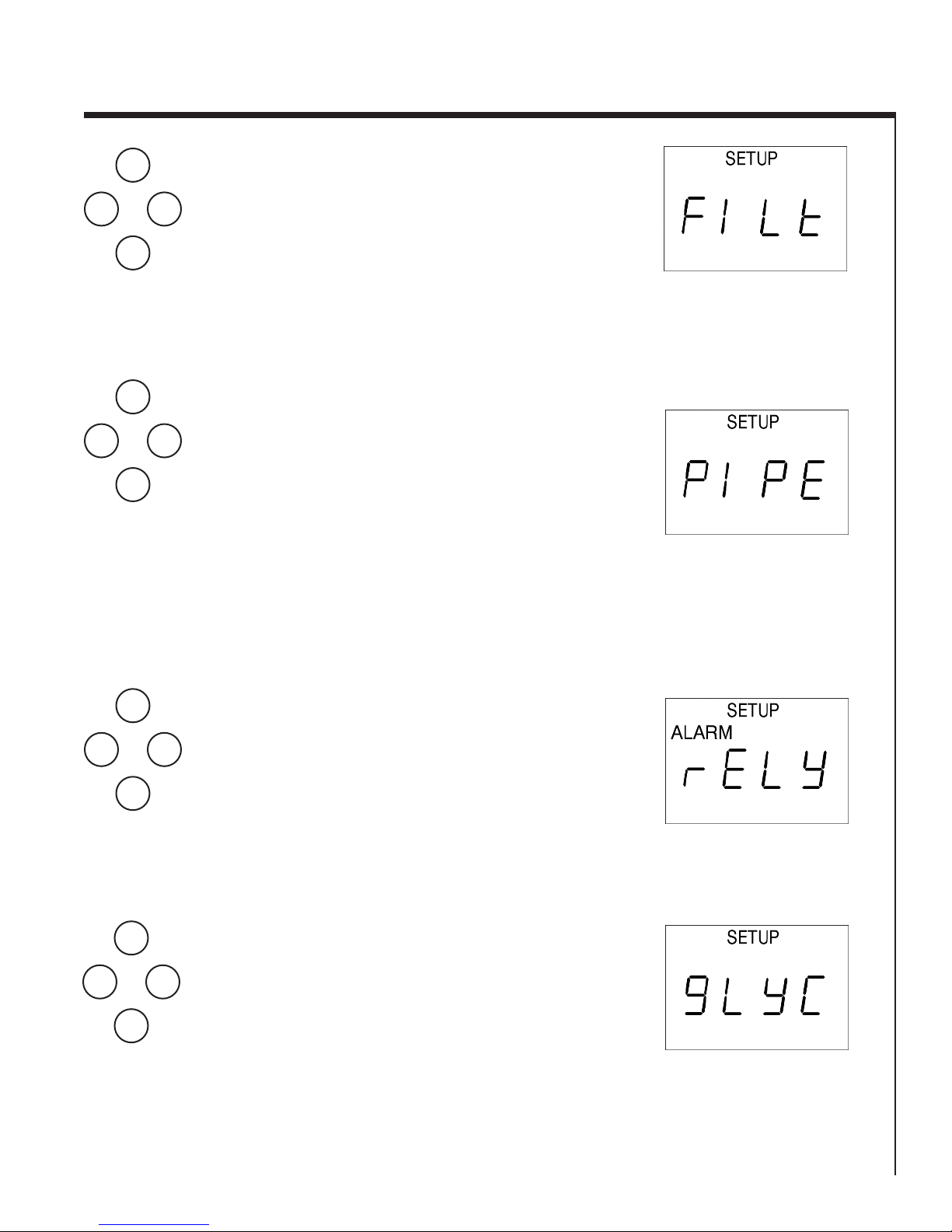

Set Flow Rate Display Filter

∇

∇

ON

or

ON

ON

or

ON

The Tracer flowmeter impeller changes speed as

the water is swirling and mixing while passing

through the meter. The filter program stabilizes the

Δ

display reading for the meter by averaging readings

from the impeller. Filter can be turned ON or OFF.

The recommended setting is ON.

Enter the Setup Mode (see page 3). Press ON

repeatedly until the display reads “Filt” (see figure

12) Press ∇ or Δ to toggle the filter setting ON or

OFF.

Change Cooling Line Size (Turbulent Flow)

Enter Setup Mode (see page 3). Press ON

repeatedly until the display shows “PIPE” (see

Δ

Figure 13). Press ∇ or Δ to change cooling line

size. Available sizes are: 0.250

0.375

0.750

1.000

1.500

2.000

Turbulent Flow display “TFLOW” and calculation

are adjusted automatically based on process

temperature and pipe size.

Figure 12

Figure 13

∇

∇

ON

or

ON

ON

or

ON

Select Relay Action to Set Points or

Turbulent Flow

Relay can be set to switch on user programmed set

points or on Turbulent Flow. Enter Setup Mode

(see page 3) Press ON repeatedly until the display

shows “rELY” (see Figure 14). Press ∇ or Δ to

Δ

change relay action to “ALARM” or “TFLOW”.

Alarm settings are programmed per instructions on

page 4 and are held in memory if “TFLOW”

setting is used. Factory default setting is

“ALARM”

Select Percentage of Glycol

Enter the percentage of glycol present for accurate

Turbulent Flow “TFLOW” Indication. Higher flow

rate is required to achieve Turbulent Flow when

glycol is present.

Δ

Enter Setup Mode (see page 3). Press ON until the

display shows “GLYC” (see Figure 15). Press ∇ or

Δ to indicate the correct glycol percentage: 0, 10,

20, or 30%. Press ON to set.

Figure 14

Figure 15

5

Analog Output Options

Output Voltage for flow and temperature are set independently. 0 to 5V or 0 to 10V output is selectable for flow or

temperature. The upper end of the effective flow range is also user-definable to give a more accurate flow and temperature

reading over the voltage output range. For Example: In a 1" cooling line you are using only half of the flow range. The

Tracer flowmeter can be set for 10V output at 15gpm instead of 30gpm to provide more precise voltage output.

∇

∇

∇

ON

or

ON

ON

or

ON

ON

or

ON

Select Flow Voltage Output

Enter Setup Mode (see page 3). Press ON

repeatedly until the display shows “AO F” (Analog

Δ

Output Flow) in the center. See Figure 16. Press ∇

or Δ to set 5 or 10 Volts as the upper end of the

output range. Press ON when desired value is

displayed.

Select Temperature Voltage Output *

Enter Setup Mode (see page 3). Press ON

repeatedly until the display shows “AO t” (Analog

Output Temperature) in the center. See Figure 17.

Δ

Press ∇ or Δ to set 5 or 10 Volts as the upper end

of the output range. Press ON when desired value

is displayed

Set Flow Output Upper Limit

Enter Setup Mode (see page 3). Press ON

repeatedly until the display shows “FS F” (Full

Δ

Scale Flow) in the center. See Figure 18. Press ∇

or Δ to set the upper limit of the flow output. Do

not set this value higher than the largest flow value

of the meter. Press ON when desired value is

displayed.

Figure 16

Figure 17

Figure 18

Set Temperature Output Upper Limit *

ON

or

∇

ON

Enter Setup Mode (see page 3). Press ON

repeatedly until the display shows “FS t” (Full

Δ

Scale Temperature) in the center. See Figure 19.

Press ∇ or Δ to set the upper limit of the

temperature output. Press ON when desired value

is displayed. Setup Mode will continue unless you

exit.

* Note: The low end of temperature output range =

0°F (-17.8°C)

Figure 19

6

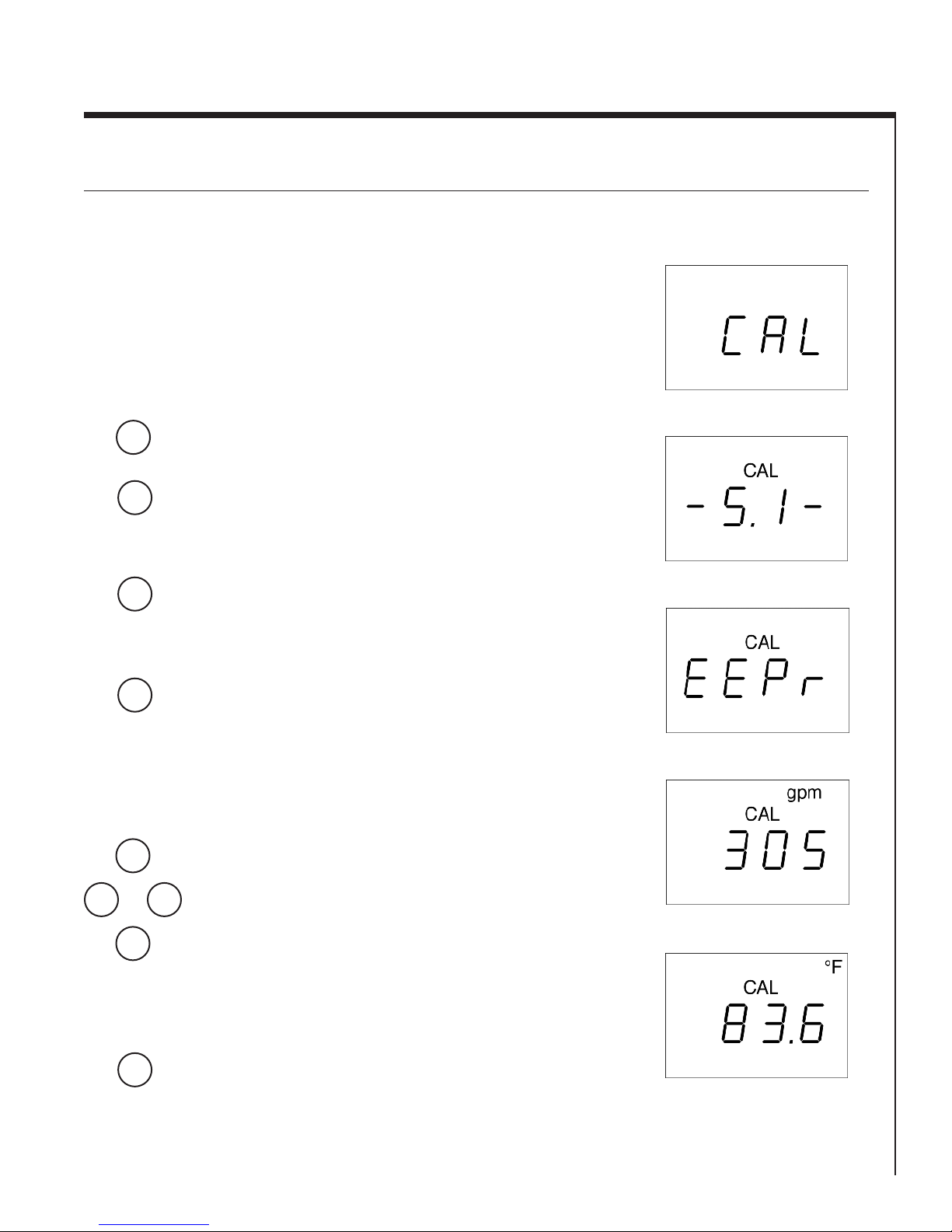

Calibration Mode

Calibration Mode allows the user to adjust the calibration values for

flow and temperature. Other functions include LCD self-test. There

are eight functions or displays available through this mode. The ON

button scrolls the menu through all functions until the user turns the

display off.

Turn the display off before entering Calibration Mode.

∇

hold

Δ

then

ON

ON

ON

ON

or

Start Calibration Mode

The display must be off to enter this mode. Press

and hold Δ, then press ON. CAL will be displayed.

See Figure 20. To scroll through the Calibration

Mode, press the ON button. If the ON button is not

pushed within three seconds, the display will

automatically shut off.

Software Version

By pressing ON once after entering Calibration

Mode, the software version will display. See Figure

21. There is no adjustment to be made.

EEPR

This function resets the calibration values to the

program defaults. See Figure 22. Do not reset

these values! This will re-program the Tracer

flowmeter back to pre-calibrated settings. The

flowmeter must be recalibrated if this is done.

Flow Calibration Value

Increase or decrease this number by using the

arrow keys. See Figure 23. Increasing the

calibration value by 20 units lowers the flow

display by .1 gpm. See the Flow Calibration

Procedure below.

Δ

Figure 20

Figure 21

Figure 22

Figure 23

ON

ON

Temperature Calibration Value

Increase or decrease this number by using the

arrow keys. See Figure 24. Increasing the

calibration value by 10 units raises the temperature

display by 1 degree F.

Temperature Slope Calibration Value

Do not adjust.

Figure 24

7

∇

ON

or

ON

Analog Output Calibration

This calibration compensates the output for

tolerances of electronic components. Analog

Output Calibration sets the upper end of the

temperature and flow output at exactly 10 Volts.

Flow (See Figure 25): Connect the Orange wire to

the + side of a voltmeter and the Black wire to

ground connection. Adjust the number on the

Tracer flowmeter using the arrow buttons until the

Δ

voltmeter reads exactly 10 Volts. Press the ON

button to scroll to the next function.

Temperature (See Figure 26): Connect the Violet

wire to the + side of a voltmeter and the Black

wire to ground connection. Adjust the number on

the Tracer flowmeter using the arrow buttons until

the voltmeter reads exactly 10 Volts. Press the ON

button to scroll to the next function.

LCD Test Screen

Figure 25

Figure 26

∇

∇

or

ON

or

ON

See Figure 27. By pushing either arrow button,

Δ

“test” will display. By pushing the ON button

while “test” is displayed, the LCD will run a selftest. See Figure 28 for LCD diagram.

End Screen

By pressing either arrow button the display will

Δ

change to “OFF”. Press the ON button to turn off

the display.

Flow Calibration

Procedure

Tools Required:

Five Gallon (minimum) Calibrated

Container (or weigh on an accurate

scale)

Stopwatch

Valved Water Supply

Figure 27

Figure 28

See Figure 29 for an example of the

test configuration.

Figure 29

8

Flow Calibration Procedure (continued)

Before you begin: Purge all the air from the system by running liquid

through the test apparatus.

For best results, take readings as close to full range as possible (at least 5

gpm for the 3/8"NPT, etc.).

1. If the display is off, push the ON button on the Tracer flowmeter.

2. Turn valve to full open position quickly and start timer

simultaneously.

3. Record flow display on the Tracer flowmeter.

4. When the liquid reaches the selected level in the container, stop

timing and close the valve.

5. Divide the volume from the container by time in minutes from the

timer to determine flow rate.

6. Plug the numbers into the following formula:

Tracer reading - manual reading = difference

Multiply the difference x 200.

7. Add the resulting number (positive or negative) to the Flow

Calibration Value in the Calibration Mode. Use the Calibration Mode

to change the flow calibration value, as shown on page 7.

8. Verify and reapt calibration if needed.

Temperature Calibration Procedure

Tools Required:

Accurate Temperature Measuring Device

Water Supply

See Figure 30 for an example of the test

configuration.

Temperature calibration must be

performed with liquid flowing through

the Tracer flowmeter.

1. Stabilize the temperature by allowing

water to run through the circuit for a

few minutes.

2. Press ON on the Tracer Flowmeter, then Δ to display the temperature.

3. Record the temperature shown.

6. Plug the numbers into the following formula:

Measuring device reading - Tracer Flowmeter reading = difference

Multiply the difference x 10.

7. Add the resulting number (positive or negative) to the Temperature

Calibration Value in the Calibration Mode. Use the Calibration Mode

to change the temperature calibration value, as shown on page 7.

8. Verify that Tracer agrees with calibration thermometer and repeat

calibration procedure if needed.

Figure 30

9

Maintenance Instructions

Calibration

Annual calibration is recommended. Return to the factory for calibration, or follow the

Flow and Temperature Calibration Procedures on pages 8 and 9.

Caution: Do not blow compressed air through the flowmeter. Damage to

the rotor and shaft may result.

Drain liquid from inside Tracer flowmeter when not in use to prevent build-up of scale

and mineral deposits.

Copper Plumbing Alert

DO NOT connect an aluminum body flowmeter directly to copper plumbing. Galvanic

corrosion is very likely to occur. Stainless steel body material is strongly recommended

for this application. Contact the factory for more information.

EMI/RFI

Electromagnetic Interference or Radio Frequency Interference may impair the proper

operation of the Switching Tracer. If the unit unexpectedly turns itself off, check the

area around the cable and electronic unit for pumps, heaters and electrical relays that

may emit EMI/RFI. Move the cable and electronic housing away from Thermal

Control Units, Heater Bands, Pumps, etc. If the problem persists, contact the factory.

Chemical Compatibility

The following is a list of chemicals that are not compatible with the

UDEL Polysulfone used in the Tracer Electronic Flowmeter. Contact

Burger & Brown Engineering for more detailed information.

Please contact us for further information.

Burger & Brown Engineering, Inc.

4500 E 142nd Street

Grandview, MO 64030

Tel: 816-878-6675

Fax: 816-878-6683

www.smartflow-usa.com

Limited Warranty

Seller warrants that this product supplied will conform to the description herein stated and that the product will be of standard quality.

This is the sole warranty made by Seller with respect to this product. Seller expressly disclaims any other express or implied warranties,

including, but not limited to, the implied warranty of merchantability and the implied warranty of fitness for a particular purpose.

Seller shall not be liable for any cost or damages, whether direct, incidental or consequential, including, but not limited to, any injury,

loss or damage resulting from the use of this product, regardless of whether any claim for such cost or damages is based on warranty,

contract, negligence, tort or strict liability. The sole liability of Seller is limited to repairing or replacing this product.

this warranty shall not apply to any products that have been repaired or altered by anyone other than Seller. The warranty shall not apply

to any products subject to misuse due to common negligence or accident, nor to any products manufactured by Seller which are not

installed or operated in accordance with the printed instructions of Seller or which have been operated beyond the rated capacity of the

goods. Seller states that the product’s useful safe life is 5 years. Actual life may vary widely depending on operating environment such as

temperature, pressure, and chemical exposure. Users are cautioned to refer to instructions for operating limits and a partial list of

incompatible chemicals.

Acetone, Methyl Ethyl

Ketone

Benzene

Carbon Tetrachloride

Chlorobenzene

Chloroform

Cyclohexanone

Esters

Freon TA

Methylene Chloride

Tetrachloroethylene

1,1,2,2-

Tetrachloroethane

Toluene

1,1,1-Trichloroethane

Trichloroethylene

Xylene

10

Loading...

Loading...