Page 1

ST-GP9750EB

WARNING! To Reduce Risk of Injury,

Owner’s Manual Prior to Use.

GP-9750EB

Owner’s Manual

NOTE: Retain Original Sales Receipt as Proof of Purchase!

User Must Read and Understand

Page 2

2

©2012 Smarter Tools, Inc. All Rights Reserved

Page 3

9750W Generator

Table of Contents

Introduction .............................................................. 04

Safety Guidelines – Definitions .............................. 05

General Precautions ................................................ 06

Carbon Monoxide .......................................... 06

Gasoline and Oil ............................................ 06

Hot Components ........................................... 07

Power Output ................................................ 07

Work Area ..................................................... 07

Electrical Safety ............................................ 08

Personal Safety ............................................. 08

General Use and Care .................................. 09

Servicing........................................................ 09

Installation ..................................................... 10

Mechanical .................................................... 10

Chemicals...................................................... 11

Noise ............................................................. 11

Extension Cords ............................................ 11

Controls and Features ............................................. 12

Generator ...................................................... 12

Control Panel ................................................ 13

Installation ................................................................ 14

General Location ........................................... 14

Wheel and Handle Kit Installation ................. 15

Support and Mounting ................................... 15

Grounding...................................................... 15

Connect the Battery ...................................... 16

Add Engine Oil .............................................. 16

Add Fuel ........................................................ 16

Operation .................................................................. 17

Starting .......................................................... 17

Surge Protection ........................................... 17

Capacity ........................................................ 17

Power Management ...................................... 18

Connecting Electrical Loads.......................... 18

Stopping the Engine ...................................... 18

Wattage Reference Guide ........................................ 19

WARNING!

ST-GP9750EB

GP-9750EB

Your Power Needs ......................................... 19

Inspection, Cleaning, and Maintenance ................. 20

Changing Oil .................................................. 20

Spark Plug ..................................................... 21

Air Filter .......................................................... 21

Spark Arrester (optional) ................................ 21

Cleaning ......................................................... 21

Maintenance Schedule .................................. 21

Storage .......................................................... 22

Transporting ................................................... 22

Specifications ............................................................ 23

Parts Lists .................................................................. 24

Crankcase Assembly ..................................... 24

Cylinder Head Assembly ............................... 25

Electric Starter Assembly ............................... 25

Camshaft Assembly ...................................... 26

Crankshaft Assembly ..................................... 26

Crankshaft Assembly and Piston ................... 27

Centrifuge Timing Implement Assembly ........ 27

Ignition Assembly ........................................... 27

Pull Start Assembly ........................................ 28

Engine Sprocket Cover .................................. 28

Carburetor Unit .............................................. 28

Air Filter Assembly ......................................... 29

Carburetor Assembly ..................................... 29

Generator ....................................................... 30

Gas Tank ....................................................... 30

Panel Assembly ............................................. 31

Muffler Assembly ........................................... 31

Motor Shield Assembly .................................. 31

Frame Assembly ............................................ 32

Exhalation System ......................................... 32

Troubleshooting ........................................................ 33

Warranty Identification ............................................. 34

Limited Warranty....................................................... 35

READ AND UNDERSTAND ALL SAFETY PRECAUTIONS IN THIS MANUAL BEFORE OPERATING.

FAILURE TO COMPLY WITH INSTRUCTIONS IN THIS MANUAL COULD RESULT IN PERSONAL

INJURY, PROPERTY DAMAGE, AND/ OR VOIDING OF YOUR WARRANTY. SMARTER TOOLS WILL

NOT BE LIABLE FOR ANY DAMAGE BECAUSE OF FAILURE TO FOLLOW THESE INSTRUCTIONS.

3

©2012 Smarter Tools, Inc. All Rights Reserved

Page 4

9750W Generator

Introduction

_________________________________________________________________________________________________

Congratulations on your purchase of a Smarter Tools

generator. Smarter Tools designs and builds gen er ato rs

to strict specifications. With proper use and maintenance,

this generator will bring years of satisfying service.

Portable Power Generator

This unit is an electric start, gasoline engine driven,

alternating current (AC) generator. It is designed to

supply electrical power for lighting, appliances, tools

and similar equipment.

Record the model and serial numbers as well as date and place of purchase for future reference.

Have this information available when ordering parts and when making technical or warranty inquiries.

Smarter Tools Customer Service

This Booklet

Every effort has been made to ensure the accuracy

and completeness of the information in this manual.

We reserve the right to cha nge, alter and/or improve

the product and this document at any time without prior

notice. For the most up to date information regarding

your Smarter Tools product please visit us at

www.usesmartertools.com

1-804-798-8588

Model Number

GP-9750EB

Serial Number

Date of Purchase

Purchase Location

4

©2012 Smarter Tools, Inc. All Rights Reserved

Page 5

Owner’s Manual

Safety Guidelines - Definitions

_________________________________________________________________________________________________

This manual contains important information that you need to know and understand in order to assure YOUR SAFETY and

PROPER OPERATION OF EQUIPMENT. The following symbols help you recognize this information. Please read the

manual and pay attention to these sections.

Save These Important Safety Instructions!

Read and understand all of these safety instructions. Be sure to retain them for future use.

WARNING!

WARNINGS INDICATE A CERTAINTY OR STRONG POSSIBILITY OF PERSONAL INJURY OR

DEATH IF INSTRUCTIONS ARE NOT FOLLOWED.

CAUTION:

CAUTIONS INDICATE A POSSIBILITY OF EQUIPMENT DAMAGE IF INSTRUCTIONS ARE NOT

FOLLOWED PROPERLY.

Note: Notes give helpful information.

WARNING!

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN SERIOUS

INJURY AND PROPERTY DAMAGE. READ AND UNDERSTAND ALL WARNINGS AND OPERATING

INSTRUCTIONS BEFORE USING THIS EQUIPMENT. BASIC SAFETY PRECAUTIONS SHOULD

ALWAYS BE FOLLOWED TO REDUCE THE RISK OF PERSONAL INJURY.

Save These Important Safety Instructions!

Read and understand all of these safety instructions. Be sure to retain them for future use.

5

©2012 Smarter Tools, Inc. All Rights Reserved

Page 6

Owner’s Manual

General Safety Precautions

_________________________________________________________________________________________________

WARNING!

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN SEVERE INJURY OR DEATH.

CAUTION:

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN ALSO RESULT IN DAMAGE TO THE EQUIPMENT

AND/OR THE ITEM YOU ARE WORKING ON OR WITH.

Carbon Monoxide

• Carbon Monoxide is an odorless and colorless gas. Breathing exhaust that contains this poisonous gas can cause

unconsciousness and may lead to death.

• The engine exhaust from this product contains chemicals recognized by the state of California to cause cancer,

birth defects, or other reproductive harm.

• When this tool is running, ensure that the area is well ventilated. Never run the engine in an enclosed area. Run

the engine in an open area or with an exhaust evacuation system in an enclosed area.

• NEVER use a generator inside homes, garages, crawlspaces, or other partially enclosed areas. Deadly levels of

carbon monoxide can build up in these areas. Using a fan or opening windows and doors does NOT supply

enough fresh air.

• ONLY use a generator outdoors and far away from open windows, doors, and vents. These openings can pull in

generator exhaust.

• Even when you use a generator correctly, CO may leak into the home. ALWAYS use a battery-po wer ed or

battery-backup CO alarm in the home.

• If you start to feel sick, dizzy, or weak after the generator has been running, move to fresh air RIGHT AWAY. See

a doctor. You could have carbon monoxide poisoning.

WARNING!

THE EXHAUST CONTAINS POISONOUS CARBON MONOXIDE GAS THAT CAN CAUSE LOSS OF

CONSCIOUSNESS AND MAY LEAD TO DEATH.

Gasoline and Oil

This product requires oil and fuel. THE ENGINE WILL NOT START WITHOUT OIL. Work in well ventilated area. Keep

cigarettes, flames or sparks away from the work area or where gasoline is stored.

WARNING!

GASOLINE IS EXTREMELY FLAMMABLE AND IS EXPLOSIVE UNDER CERTAIN CONDITIONS. KEEP

OUT OF REACH OF CHILDREN.

6

©2012 Smarter Tools, Inc. All Rights Reserved

Page 7

Owner’s Manual

General Safety Precautions (cont’d)

_________________________________________________________________________________________________

Gasoline and Oil (cont’d)

• Gasoline fuel and fumes are flammable and potentially explosive. Use proper fuel storage and handling

procedures. Always have multiple ABC class fire extinguishers nearby.

• Keep the generator and surrounding area clean at all times. Keep the generator at least 5 feet away from

buildings and other equipment during operation.

• Fuel or oil spills must be cleaned up immediately. Dispose of fluids and cleaning materials as per any local, state,

or federal codes and regulations. Store oily rags in a covered metal container.

• Never store fuel or other flammable materials near the generator.

• Do not smoke, or allow sparks, flames or other sources of ignition around the eng ine and fuel tank. Fuel vapors

are explosive.

• Keep grounded conductive objects, such as tools, away from exposed, live electrical parts and connections to

avoid sparking or arcing. These events could ignite fumes or vapors.

• Do not refill the fuel tank while the engine is running or while the engine is still hot. Do not operate the generator

with known leaks in the fuel system.

• Excessive buildup of unburned fuel gases in the exhaust system can create a potentia lly explosive condition. This

buildup can occur after repeated failed start attempts, valve testing, or hot engine shutdown. If this occurs, open

exhaust system drain plugs, if equipped, and allow the gases to dissipate before attempting to restart the generator.

• Use only engine manufacturer recommended fuel and oil.

Hot Components

WARNING!

HOT EXHAUST CAN BURN YOU. ENGINE AND EXHAUST SYSTE M PARTS BECOME VERY HOT AND

REMAIN HOT FOR SOME TIME AFTER THE ENGINE IS RUN. WEAR INSULATED GLOVES OR WAIT

UNTIL THE ENGINE AND EXHAUST SYSTEM HAVE COOLED BEFORE HANDLING THESE PARTS.

Power Output

This generator is not designed to power sensitive electronic equipment (including computers and medical devices) without

the addition of an approved line conditioner, which is sold separately.

CAUTION:

ATTEMPTING TO POWER SENSITIVE ELECTRONIC EQUIPMENT WITHOUT THE USE OF AN

APPROVED LINE CONDITIONER MAY CAUSE DAMAGE TO THE EQUIPMENT.

Work Area

• Keep your work area clean and well lit. Cluttere d benc hes and dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or

dust. Generators create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating a generator. Provide barriers or shields as needed.

7

©2012 Smarter Tools, Inc. All Rights Reserved

Page 8

Owner’s Manual

General Safety Precautions (cont’d)

_________________________________________________________________________________________________

Electrical Safety

• Keep all electrical equipment cle an and dr y. Replac e a n y wiring wher e the insu lat i on is cracked, cut eroded part

or otherwise degraded. Replace terminals that are worn, discolored, or corroded. Keep terminals clean and tight.

• Insulate all connections and disconnecte d wir es.

• Do not abuse the power cord. Keep power cords away from heat, oil, sharp edges, or moving parts. Replace

damaged power cords immediately. Damaged power cords increase the risk of electric shock.

• Do not operate the generator with wet hands. Do not expose generator to rain, snow or wet conditions. Water will

increase the risk of electric shock. The generator is a potential source of electrical shock if not kept dry.

• Do not attempt to connect or disconnect load connections while standing in water, or on wet or soggy ground.

• Do not touch electrically energized parts of the generator and interconnecting cables or conductors with any part

of the body, or with any non-insulated conductive object.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges, and refrigerators. There is an

increased risk of electric shock if your body is grounded.

• When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W”. These extension

cords are rated for outdoor use, and reduce the risk of electric shock.

• Grounded tools must be plugged into an outlet properly installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify the plug in any way. Do not use any adapter plugs.

• Double insulated tools are equipped with a polarized plug where one blade is wider than the other. This plug fits in

a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit,

contact a qualified electrician to install a polarized outlet. Do not change the plug in any way. Double insulation

eliminates the need for the three-wire grounded power cord and grounded power supply system.

• Before servicing equipment powered by the generator, disconnect the equipment from its power input.

• The generator must be earth-grounded for fixed installations in accordance with all relevant electrical codes and

standards before operation.

• Grounding provides a low-resistance path to carry electricity away from the user in the event of an electrical

malfunction.

• All connections and conduits from the generator to the load must only be installed by trained and licensed

electricians and in compliance with all relevant local, state, and federal electrical codes and standards, and other

regulations where applicable.

• Connect the generator only to a load or electrical system (110/120 volt) that is compatible with the electrical

characteristics and rated capacities of the generator.

• NEVER try to power building or home wiring by plugging the generator into a wall outlet, a practice known as

“backfeeding.” This is extremely dangerous and presents an electrocution risk to utility workers and neighbors

served by the same utility transformer. It also bypasses some of the built-in household circuit protection devices.

Personal Safety

CAUTION:

DO NOT SIT, STAND, OR PLACE OBJECTS ON TOP OF THE GENERATORS FUEL TANK.

REGARDLESS OF WHETHER IT IS RUNNING OR NOT.

• Stay alert. Watch what you are doing, and use common sens e when operating a generator. Do not use generator

while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating

generators may result in serious personal injury.

• Make note of the location of the engine power switch should you need to turn off the generator quickly.

• Dress properly. Contain long hair, clothing, jewelry, and gloves as they can be caught in moving parts.

• Avoid accidental starting. Make sure the power switch is in its “OFF” positi on, and disc onn ec t the spark plug wire

when not in use.

8

©2012 Smarter Tools, Inc. All Rights Reserved

Page 9

9750 Generator

General Safety Precautions (cont’d)

_________________________________________________________________________________________________

Personal Safety (cont’d)

• Remove adjusting keys or wrenches before turning the generator on. A wrench or a key that is left attached to a

rotating part of the generator may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times.

• Use safety equipment. Always wear eye protection. Wear ANSI approved safety impact eye goggles. Dust mask,

non-skid safety shoes, safety gloves, hard hat, or hearing protection must be used for appropriate conditions.

• Do not use the generator if the power switch does not turn it on or off. Any generator

that cannot be controlled with the power switch is dangerous and must be replaced.

• Do not force the generator. Use the correct generator for your application. The correct

generator will do the job better and safer at the rate for which it is designed.

• The generator weighs 187 lbs. Two or more people should assist when moving or lifting this product. Never lift the

Generator using the engine or alternator lifting lugs. Connect lifting equipment to the Frame of the generator.

Generator Use and Car e

• Make sure the power switch is in its “OFF” position and disconnect the spark plug wire before making any

adjustment, changing accessories, or storing the generator. Such preventive safety measures reduce the risk of

starting the generator accidenta lly.

• Store idle generators out of reach of children and other untrained persons. Generators are dangerous in the

hands of untrained users.

• Maintain generators with care. Do not use a damaged generator. Tag damaged generators “Do not use” until

repaired.

• Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the

generator’s operation. If damaged, have the generator serviced before using. Many accidents are caused by

poorly maintained generators.

• Use only accessories that are recommended by the manufacturer for your model. Accessories that may be

suitable for one generator may become hazardous when used on another generator.

Servicing

• Maintain labels and name plates on the generator and engine. These carry important information. If unreadable or

missing, contact Smarter Tools immediately for a replacement.

• Generator service must be performed only by qualified repair personnel. Service or maintenance performed by

unqualified personnel could result in a risk of injury.

• When servicing a generator, use only identical replacement parts. Follow all appropriate instructions in this

manual. Use of unauthorized parts or failure to follow maintenance instructions may create a risk of electric shock

or injury.

WARNING!

PEOPLE WITH PACE MA KERS SHOULD CONSULT THEIR PHYSICIAN(S) BEFORE USING THIS

PRODUCT. ELECTROMAGNETIC FIELDS IN CLOSE PROXIMITY TO A HEART PACEMAKER COULD

CAUSE INTERFERENCE TO OR FAILURE OF THE PACEMAKER.

9

©2012 Smarter Tools, Inc. All Rights Reserved

Page 10

Owner’s Manual

General Safety Precautions (cont’d)

_________________________________________________________________________________________________

Installation

• Ensure installation meets all applicable safety, and local and national electrical codes. Have installation performed

by a qualified, licensed electrician and building contractor.

• All electrical work, including the earth-ground connection, should be completed by a licensed electrician.

• Any separate fuel storage or generator supply facility must be built or installed in full compliance with all relevant

local, state, and federal regulations.

• It is recommended to use the generator only in well ventilated outdoor areas. A running gasoline engine will

generate carbon monoxide, a colorless, odorless gas that, if inhaled, can cause serious injury or death. If the

generator is installed indoors, exhaust fumes must be piped out of the building using leak-free, heat resistant

piping. Pipes and silencer should not use any flammable materials, nor should they be installed near the same.

Generator exhaust fumes must be within legal limits and installation must always meet local building codes.

• If the generator is installed outdoors, it must be weatherproofed and should be soundproofed. It should not be run

outdoors without protection of the generator and wiring conduit.

• Two or more people should assist when moving or lifting this product. Never lift the Generator using the engine or

alternator lifting lugs. Connect lifting equipment to the Frame of the generator.

• Before lifting the generator, ensure the lift rigging and supporting structure are in good condition, and are rated to

lift such a load.

• Keep all personnel away from the suspended generator during relocating.

• The supporting floor/ground surface should be level, and strong enough to safely hold the weight of the generator.

If the floor/grounded surface is not level, strong cross members should be placed under the full length of the

generator frame at its low side.

• For trailer installation, the generator should be mounted on the center point of the trailer, over the wheels. The

trailer must be capable of supporting the weight of the generator and all contents (tools, etc.)

• Install sound-and weath er -proofing only when it is not raining or snowing to avoid trapping m oist ure with in the

generator’s area.

Mechanical

• Always make sure the power switch is in its “OFF” position. Disconnect the spark plug wire, and allow the engine

to completely cool before carrying out maintenance.

• Check for damaged parts. Before using the generator, any part that appears damaged should be carefully

checked to determine that it will operate properly and perform its intended function. Check for alignment and

binding of moving parts, any broken parts or mounting fixtures, and any other condition that may affect proper

operation technician.

• The generator is designed with guards for protection from moving parts. In any case, care must still be taken to

protect personnel and equipment from other mechanical hazards when working around the generator.

• Do not operate the generator with safety guards removed. While the generator is running, do not att empt to reach

around the safety guard for maintenance or any other reason.

• Keep hands, arms, long hair, loose clothing, and jewelry away from moving parts. Be aware that when engine

parts are moving fast they cannot be seen clearly.

• Keep access doors on enclosures closed and locked when access is not required.

• When working on or around the generator always wear protective clothing including ANSI approved safety gloves,

safety eye goggles, and safety hat.

• Do not alter or adjust any part of the generator that is assembled and supplied by the manufacturer.

• Always follow and complete scheduled engine and generator maintenance.

©2012 Smarter Tools, Inc. All Rights Reserved

10

Page 11

Owner’s Manual

General Safety Precautions (cont’d)

_________________________________________________________________________________________________

Chemicals

• Avoid contact with hot fuel, oil, exhaust fumes, and hot solid surfaces.

Avoid body contact with fuels, oils, and lubricants used in the generator. If swallowed, seek medical treatment

•

immediately. Do not induce vomiting if fuel is swallowed. For skin contact, immediately wash with soap and water.

For eye contact, immediately flush eyes with clean water and seek medical attention.

Noise

Prolonged exposure to noise levels above 85dBA is hazardous to hearing.

Always wear ANSI approved ear protection when operating or working around the Generator when it is running.

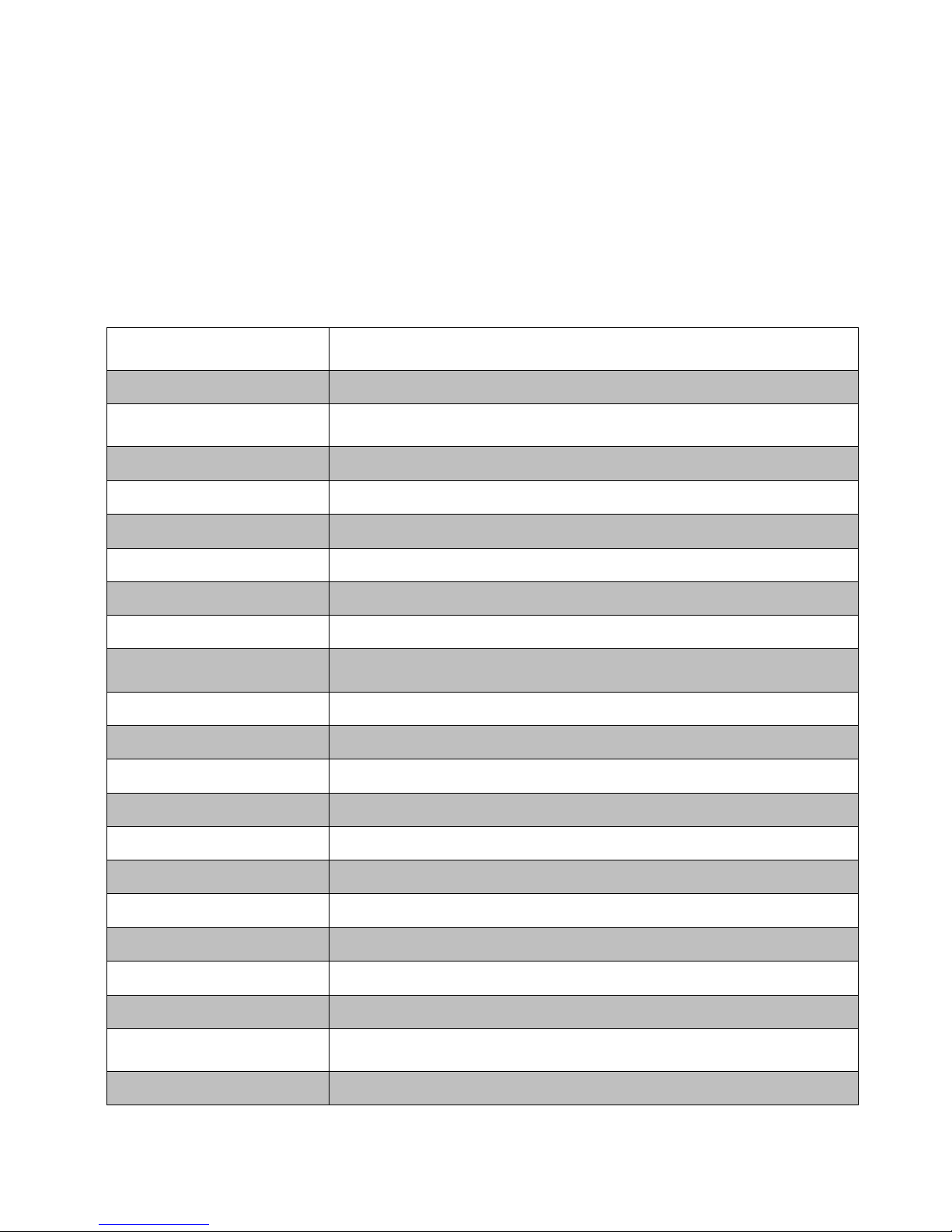

Extension Cords

If an extension cord (not included) is used, make sure to use only UL approved cords having the correct gauge and length

according to the following table:

Nameplate Amps Cord Lengths

(@full load)

0’-50’ 50’-100’ 100’-150’ 150’-200’

0-5 16 16 12 12

5.1-8 16 14 10 -

8.1-12 14 12 - -

12.1-15 12 10 - 15-20 10 10 - -

11

©2012 Smarter Tools, Inc. All Rights Reserved

Page 12

9750 Generator

Controls and Features

_________________________________________________________________________________________________

Familiarize yourself with the location and function of the controls and features before operating your generator. Save this

manual for future reference.

Generator

1. Fuel Gauge – Indicates amount of fuel in tank.

2. Fuel Tank – 7 gallon capacity

3. Choke – Used to start engine.

4. Fuel Valve – Turn this valve to the on position to

supply fuel to the engine

5. Air Filter – Protects the engine by filtering dust

and debris from the intake air.

©2012 Smarter Tools, Inc. All Rights Reserved

6. Recoil Starter – Used to start the engine.

7. Low Oil Shutdown – Senses the level of oil in

the crankcase and shuts the engine down if the

level falls too low.

8. Oil Filler Cap/Dipstick – Used to check and fill

engine oil.

9. Control Panel – See “Control Panel” page 13

12

Page 13

9750 Generator

Controls and Features (cont’d)

_________________________________________________________________________________________________

Control Panel

1. Engine Switch – Used to turn on and off the

engine. For electric models it is also used to

start the engine.

2. Hour Meter – Measures the number or hours

the engine has run and displays the voltage/Hz

produced by generator.

3. Circuit Breakers – Protects the generator

against electrical overload.

4. (2) 120V 20A Duplexes – These duplexes are

protected by a (2) 20A circuit breakers. Use

each duplex to operate 120 volt AC, single

phase, 60 Hz loads requiring up to 20 A or 2400

Watts of power.

5. 120/240V 30A Twist-Lock – Protected by a 30A

circuit breaker on each 120 Volt leg of the

receptacle. This receptacle powers 240 Volt AC,

60 Hz, single phase loads requiring up to 30A or

7200 Watts of power. If an L14-30P plug is wired

for only one 120 Volt leg (3-wire connection)

then this receptacle powers 120 Volt AC, 60 Hz,

single phase loads requiring up to 30A or 3600

Watts of power.

6. 120V 30A Twist-Lock– This outlet is pr otec te d

by a 30A circuit breaker. Use this Twist-Lock to

operate 120 volt AC, single phase, 60 H z loads

requiring up to 30A or 3600 Watts of power.

7. 12V DC Connectors – Use to operate 12V DC

8A devices.

8. General Specifications

9. Ground Terminal – Consult an electrician for

local grounding regulations.

13

©2012 Smarter Tools, Inc. All Rights Reserved

Page 14

14

©2012 Smarter Tools, Inc. All Rights Reserved

9750 Generator

Installation

_______________________________________________________________________________________

Note: Prior to powering tools and equipment, make sure the generator’s rated voltage, wattage,

and amperage capacity (120V-65AMPs) is adequate to supply all electrical loads that the unit will

power. If powering exceeds the generator’s capacity, it may be necessary to group one or more

of the tools and/or equipment for connection to a separate generator.

Electrical and other permits may be required for the installation of emergency power systems. Investigate your

local building and electrical codes before installing this unit. Installation must be completed by licensed

contractors.

WARNING!

THE GENERATOR WEIGHS APPROXIMATELY 190 POUNDS. USE CARE AND THE

PROPER LIFTING OR HOISTING EQUIPMENT WHEN MOVING IT TO THE INSTALLATION

LOCATION.

ALWAYS CONNECT HOSE LINES TO THE FRAME OF THE GENERATOR.

CAUTION:

DO NOT ADD OIL OR GASOLINE UNTIL INSTALLATION IS COMPLETE.

General Locatio n

CAUTION:

GENERATOR SHOULD ONLY BE OPERATED ON A LEVEL SERVICE. DO NOT OPERATE

GENERATOR ON LOOSE GROUND OR OBVIOUS INCLINES. THE LOW OIL SHUT DOWN

FEATURE MAY BE PREMATURELY ACTIVATED IN THESE CASES CAUSING THE UNIT TO

NOT START.

• Make sure to locate and install the generator outdoors where cooling air is readily available.

• Install th e g ene rato r so t hat th e air inlets and ou tle ts a re not blo cked by obstructions such as bushes,

trees, or snow drifts. Locating it in the path of heavy winds or snowdrift s may require th e pla cement of a

barrier for protection. In normal weather conditions, the air vent should face the prevailing wind direction.

• Install the generator on a concrete slab or other area where rain drainage or flood waters cannot reach it.

• Generator placement should allow four feet of access to all sides for maintenance.

• Place the generator as close as possible to the electrical tools and equipment being powered to reduce the

length of extension cords.

• If the generat or in locat ed indoo rs the engin e exhau st must be ven tilated t o the o utd oo r s u sing leak-proof,

heat resistant flexible metal, flex tubing.

Note: Generators used on construction sites may be subject to additional rules and regulations.

If you plan to use the generator on a construction site, please consult your local authority

regarding.

Page 15

15

©2012 Smarter Tools, Inc. All Rights Reserved

9750 Generator

Installation (cont’d)

_______________________________________________________________________________________

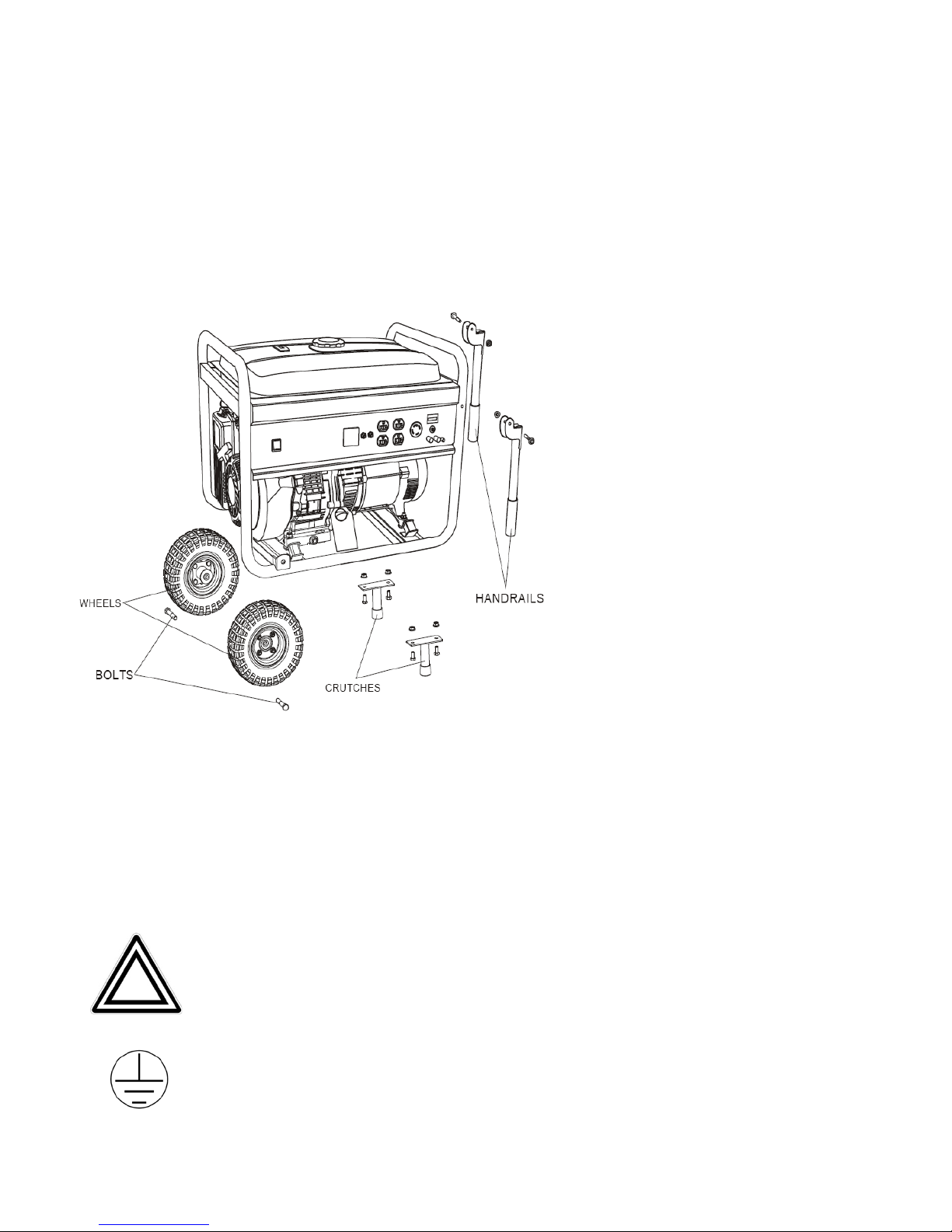

Wheel and Handle Kit Installation

(Installation requires a socket wrench with 10mm, 14mm, and 17mm sockets).

1. Before adding oil or gasoline

to the engine, tip the

generator slowly so that the

recoil and air filter are up.

2. Install the two wheels on the

generator using the (2) 17mm

2 ½” bolts provided. Make

sure the valve stem is facing

outward.

3. Tip the generator slowly so

that the recoil and air filter are

down.

4. Install the crutches on the

under frame with the (4) nuts

and 14mm 1” bolts provided.

5. Tip the generator slowly so

that is sits on both the wheels

and crutched.

6. Install the Handles on the right

side of the frame using the (2)

nuts and 10mm 1 ¾” bolts

provided.

Support and Mounting

Mount the generator on a concrete slab capable of supporting the weight of the generator. The slab must

extend on all sides beyond the frame by at least one foot. Contact a cement contractor for slab specifications

if necessary. Attach the frame to the concrete slab using 3/8” diameter expansion anchor bolts (not supplied).

Grounding

Note: It is recommended that only a trained and licensed electrician perform this procedure.

Connect a #8 AWG grounding wire (not included) from the ground connector on the generator to

a grounding rod (not included) that has been driven at least 24 inches deep into the earth. The

grounding rod must be an earth-driven copper or brass rod (electrode) which can adequately

ground the generator.

Page 16

16

©2012 Smarter Tools, Inc. All Rights Reserved

9750 Generator

Installation (cont’d)

_______________________________________________________________________________________

Note: The electric starter require a 12V battery with a minimum of 17AH. While higher Amp

Hour batteries may be used, do not attempt to start the engine using a battery rated for a lower or

higher Voltage.

Connect the Battery

1. Place battery into battery cradle and secure.

2. Remove the protective cover from the positive (red) battery lead. Positive lead is marked with a “+”.

3. Attach the positive lead to the positive terminal (marked with a “+”) on the battery with the phillipshead cap screw and secure with 8mm nut.

4. Remove the protective cover from the negative (black) battery lead. Negative lead is marked with a “-

”.

5. Attach the negative lead to the negative term inal (m arked with a “ -”) on the battery with the phillipshead cap screw and secure with 8mm nut.

CAUTION:

PRIOR TO FIRST USING THE GENERATOR, THE

ENGINE MUST BE FILLED WITH APPROXIMATELY 1

QUART OF HIGH QUALITY SAE 10W-30 GRADE

ENGINE OIL.

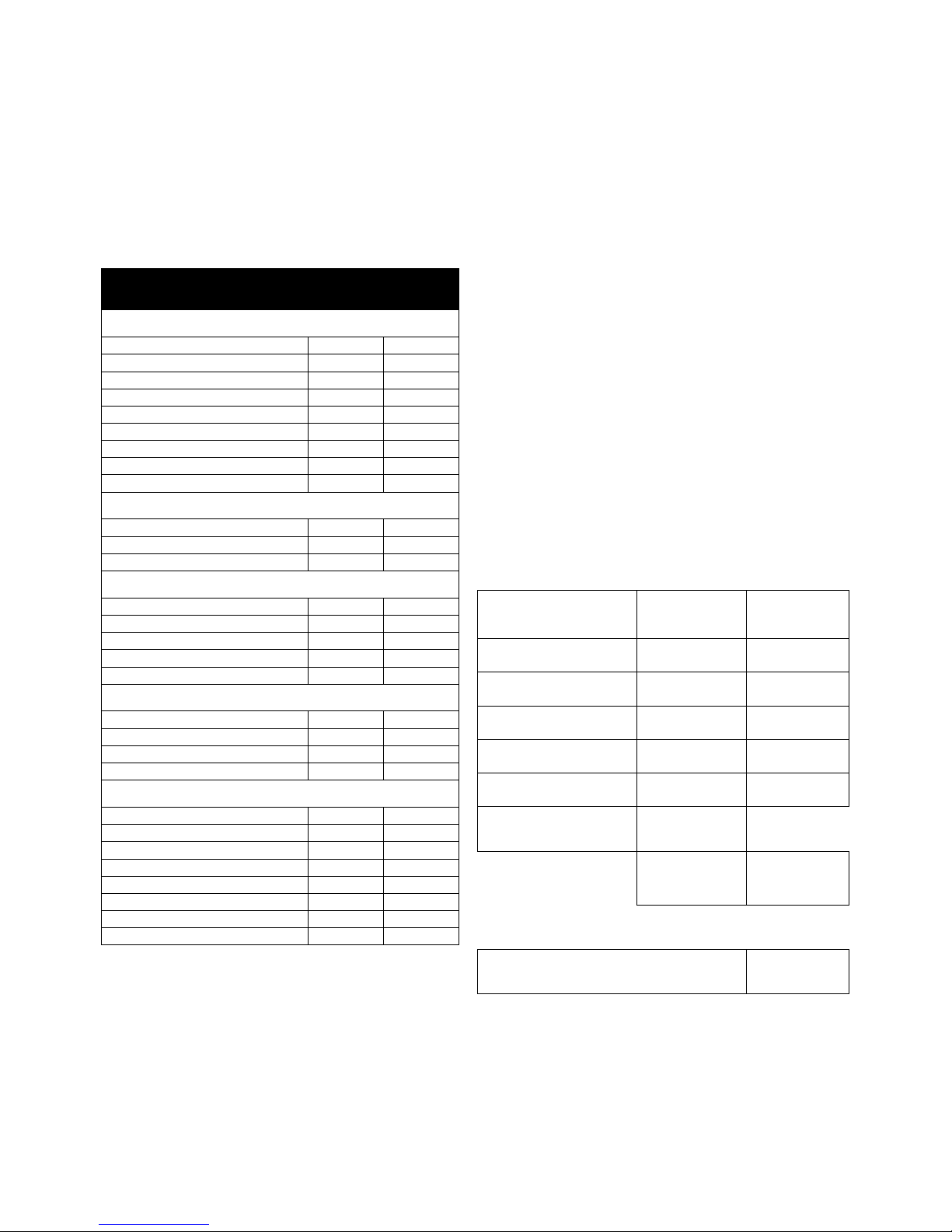

Add Engine Oil

1. Place the generator on a flat and level surface.

2. Remove oil fill cap/dipstick to add oil.

3. Add approximately 1 quart of high quality SAE 10W-30 grade

engine oil.

4. Check engine oil daily and add as needed.

Add Fuel

1. Use clean, fresh, regular unleaded fuel with a minimum octane

rating of 85.

2. DO NOT mix oil with fuel.

3. Clean area around the fuel cap.

4. Remove the fuel cap.

5. Be sure that the fuel strainer is in place.

6. Slowly add fuel to the tank. DO NOT overfill. Allow

approximately ¼ inch of space for fuel expansion.

7. DO NOT fill above fuel strainer.

8. Screw on the fuel cap and wipe away and spilled fuel.

WARNING:

THE GENERATOR MUST BE OFF AND COOLED

DOWN BEFORE REFILLING THE FUEL TANK.

Page 17

17

©2012 Smarter Tools, Inc. All Rights Reserved

9750 Generator

Operation

_______________________________________________________________________________________

Starting

1. Make sure the generator is on a flat and level surface.

2. Make sure the electrical powered tools/equipment that will be used are not plugged into the generator

while the engine is started.

3. Turn the 120 volt AC circuit breaker to its “ON” position.

4. Turn the fuel valve to the “ON” position.

5. Pull the choke rod out.

6. Turn the engine power switch to its “ON” position.

7. For “Electric Start” models turn key to the start position and hold until engine starts. If the engine fails

to start within 5 seconds, release the key and wait at least 10 seconds before attempting to start the

engine again.

8. For “Recoil Start”, hold the start handle loosely and pull it slowly several times to allow the gasoline to

flow into the engine’s carburetor. Then hold the start handle firmly and pull the rope hard and fast. Pull

the rope all the way out, using two hands if necessary. If necessary pull the rope several times until

the engine starts.

9. Allow the engine to idle unt i l warm. Then, slowly push choke rod in all the way.

Note: If the engine starts but does not run, make certain that the generator is on a flat, level

surface.

The engine is equipped with a low oil sensor that will prevent the engine from running when the oil

level falls below a critical threshold.

Surge Protection

CAUTION:

ATTEMPTING TO POWER SENSITIVE ELECTRONIC EQUIPMENT WITHOUT THE USE OF

AN APPROVED LINE CONDITIONER MAY CAUSE DAMAGE TO THE EQUIPMENT.

Electronic devices, including computers and many programmable appliances use components that are designed to

operate within a narrow voltage range and may be affected by momentary voltage fluctuations.

While there is no way to prevent voltage fluctuations, you can take steps to protect sensitive electronic equipment.

1. Install UL1449, CSA-listed, plug-in surge suppressors on the outlets feeding your sensitive equipment.

Surge suppressors come in single- or multi-outlet styles. They’re de sig ned t o pr ot e ct a gain st v i rtu ally all

short duration voltage fluctuations.

2. Obtain an Uninterruptible Power Supply (UPS) device. Mo st UPS device s come with a rechargeable

battery between the electronic equipme nt and pow er suppl y source. The device buffers the voltage and

protects against vi rtuall y all sho rt duration voltage fluctuations.

Capacity

Follow these simple steps to calculate the running and starting watts necessary for your purposes.

See page 16 for Wattage Reference Guide.

1. Select the electrical dev ices y ou plan on runni ng at the sa me time.

2. Total the running watts of these items. This is the amount of power you need to keep your items running.

3. Identify the highest starting wattage of all devices identified in step

a. Add this number to the number calculated in step

b. Surge wattage is the extra burst of power needed to start some electric driven equipment.

Following the steps li sted und e r “Pow e r Man age men t ” will gu a ran tee that o nly one device will be

starting at a time.

Page 18

18

©2012 Smarter Tools, Inc. All Rights Reserved

9750 Generator

Operation (cont’d)

_______________________________________________________________________________________

Power Management

Use the following formula to convert voltage and amperage to watts:

Volts x Amps = Watts

To prolong the life of your generator and attached devices, follow these steps to add electrical load:

1. Start the generator with no electrical load attached .

2. Allow the engine to run for several minutes to stabilize.

3. Plug in and turn on the first item. It is best to attach the item with the largest load first.

4. Allow the engine to stabilize.

5. Plug in and turn on the next item.

6. Allow the engine to stabilize.

7. Repeat steps 5-6 for each additional

Connecting Electrical Loads

1. Let the engine stabilize and warm up a few minutes after starting.

2. Prior to powering tools and equipment, make sure the generator’s rated voltage, and amperage

capacity (110/120VAC @ 65 AMPs, 12V DC @ 8 AMPs) is adequate to supply all electrical loads that

the unit will power. If powering exceeds the generator’s capacity, it may be necessary to group one or

more of the tools and/or equipment for connection to a separate generator.

3. Once the generator is running, simply connect the power cords of 110/120 volt AC powered tools and

equipment into the 110/120 volt AC dual outlets and/or the power cord of a 12V DC powered tool to

the DC terminals..

CAUTION:

MAKE SURE TO CONNECT THE POSITIVE (+) LEAD OF THE POWER CORD TO THE

POSITIVE (+) TERMINAL ON THE GENERATOR, AND CONNECT THE NEGATIVE (-) LEAD

OF THE POWER CORD TO THE NEGATIVE (-) TERMINAL ON THE GENERATOR.

4. If using only a 12V DC tool or equipment, turn the 110/120V AC circuit breaker to its “OFF” position.

5. DO NOT connect 3-phase loads to the generator.

6. DO NOT connect 50Hz loads to the generator.

7. DO NOT overload the generator.

Note: The DC terminals may be used for charging 12 volt automotive type batteries only.

Stopping the Engin e

1. Turn off and unplug all electrical loads. Never start or stop the generator with electrical devices

plugged in or turned on.

2. Let the generator run at no-load for several minutes to stabilize internal temperatures of the engine

and generator.

3. Turn the power switch to the “OFF” position.

4. Turn the fuel valve to the “OFF” position.

Page 19

19

©2012 Smarter Tools, Inc. All Rights Reserved

9750 Generator

Wattage Reference Guide

_______________________________________________________________________________________

These are estimates only. Check your tool or appliance

for exact wattage requirements. The wattages listed are

based on estimated wattage requirements. For exact

wattages, check the data plate or owner's manual on

the item you wish to power using the generator .

Operating voltage and frequency requirement of all

electronic equipment should be checked prior to

plugging to plugging them into this generator. Damage

may result if the equipment is not designed to operate

within a +/- 10% vo lta ge va riati on, and +/- 3 Hz

frequency variation from the generator specification

plate ratings.

Your Power Needs

Tool or Appliance

Running

Watts

Starting

Watts

1.

2.

3.

4.

5.

Total Running Watts

Highest

Starting

Watts

Total Running Watts

+ Highest Starting Watts

Item

Running

Watts

Starting

Watts

Essentials

Light Bulb

100

100

Refrigerator/Freezer

1200

2400

Sump Pump

600

1800

Well Pum p 1HP

2000

4000

Water Heater

4000 Security System

180

AM/FM Radio

300

Garage Door Opener ½ HP

500

600

Battery Charger 12V

110

Heating and Cooling

Air Conditioner 12000 BTU

1700

2500

Fan

300

600

Furnace Fan 1/3 HP

1200

2000

Home Appliances

Microwave

1000

Electric Range – One Element

1500 Electric Skillet

1250

Coffee Maker

1500

Clothes Washer

1200

Entertainment

CD/DVD Player

100 Stereo Receiver

450

Television 27”

500

PC with 15” Monitor

800

Job Site

Belt Sander 3”

1000

1500

Bench Grinder 6”

700

1500

Circular Saw

1500

1500

Compressor 1 ½ HP

1000

1000

Edge Trimmer

500

500

Hand Drill ½”

1000

1000

Paint Sprayer

600

1200

Table Saw

2000

2000

Page 20

20

©2012 Smarter Tools, Inc. All Rights Reserved

Owner’s Manual

Inspection, Cleaning, and Maintenance

_______________________________________________________________________________________

The owner/operator is responsible for all periodic maintenance.

WARNING!

MAKE SURE THE ENGINE POWER SWITCH IS IN ITS “OFF” POSITION. DISCONNECT THE

SPARK PLUG WIRE AND ALLOW SUFFICIENT TIME FOR THE ENGINE AND GENERATOR

TO COMPLETELY COOL BEFORE PERFORMING ANY INSPECTIONS, MAINTENANCE, OR

CLEANING.

•

Before each use, inspect the generator. Check for:

- Loose screws

- Misaligned or binding moving parts

- Cracked or broken parts

- Damaged electrical wiring

- Any other condition that may affect safe operation.

• If an engine problem occurs, have it checked by a qualified service technical before further use. DO

NOT use damaged equipment.

WARNING!

NEVER OPERATE A DAMAGED OR DEFECTIVE GENERATOR.

• Before each use, make sure the engine’s oil level is at manufacturer’s specification. If necessary, fill

the crankcase until the oil level is even with the oil fill hole. Make sure there is gas in the unit.

• Before each use, remove all debris with a soft brush, rag, or vacuum.

• Lubricate all moving parts using a premium quality, lightweight machine oil.

CAUTION:

DO NOT ATTEMPT TO ADJUST, MODIFY, OR DISABLE THE FACTORY INSTALLED

GOVERNOR. TAMPERING WITH THE FACTORY SET GOVERNOR WILL VOID YOUR

WARRANTY.

Note: Complete all scheduled maintenance in a timely manner. Routine maintenance will ensure

years of satisfying service out of your product

Changing Oil

Change oil when the engine is warm. Use SAE 10W-30 grade engine oil.

1. Remove the oil drain plug with a 17 mm socket and extension.

2. Allow the oil to drain completely.

3. Replace the drain plug.

4. Remove oil fill cap/dipstick to add oil.

5. Add approximately 1 quart of engine oil and replace oil fill cap/dipstick.

6. Dispose of used oil at an approved waste management facility.

Page 21

21

©2012 Smarter Tools, Inc. All Rights Reserved

Owner’s Manual

Inspection, Cleaning, and Maintenance

(cont’d)

_______________________________________________________________________________________

Spark Plug

1. Remove the spark plug cable from the spark plug.

2. Use the spark plug tool th at shipped with you r gen erat o r t o re move t he plu g.

3. Inspect the electrode on the plug. It must be clean and not worn to produce the spark required for ignition.

4. Make certain the spark plug gap is 0.7 - 0.8mm (0.028 - 0.031 in.).

5. Carefully thread the pl ug into the engine.

6. Use the spark plug tool to firmly install the plug.

7. Attach the spark plug wire to the plug.

Air Filter

1. Remove the air filter cover by releasing the snap clips on top and bottom.

2. Remove the foam element.

3. Wash in liquid detergen t and wa te r .

4. Squeeze thoroughly dry i n a c le an cloth.

5. Saturate in clean engine oil.

6. Squeeze in a clean, absorbent cloth to remove all excess oil.

7. Place the filter in the assembly.

8. Reattach the air filter cover and snap clips back in place.

Spark Arrestor (optional)

1. Allow the engine to cool completely before se rvicing the spa rk arreste r.

2. Remove the two screws holding the cover pl ate whi ch retain s the end o f the spark arrester to the muffler.

3. Remove the spark arrester screen.

4. Carefully remove the carbon deposits from the spark arrester screen with a wire brush.

5. Replace the spark arrester if it is damaged.

6. Position the spark arrester in the muffler and attach with the two screws.

Cleaning

• Use a damp cloth to clean exterior surfaces of the engine.

• Use a soft bristle brush to remove di rt and oil.

• Use an air compres sor to clea r dirt and debri s from the engine .

• DO NOT use a garden hose to clean the generator. Water can enter the generator t h rough t he cooli ng

slots and damage the generator windings.

Maintenance Schedule

Follow the se rvi ce in te rval s i n di cated in t he sched ul e below.

Service your generat or more fre quently when oper ating in adverse condi tio ns.

Every 8 hours of operation or daily

• Check oil level.

• Clean around air intake and muffler.

Every 50 hours of op er ati on or every season

• If operati ng und e r heavy load or in ho t env i ron ment s, d rain the old engin e oil and repla ce with

approximately 1 quart of high quality SAE 10W-30 grade engine oil.

• Remove, clean, re-dampen with motor oil and replace air filter.

Page 22

22

©2012 Smarter Tools, Inc. All Rights Reserved

Owner’s Manual

Inspection, Cleaning, and Maintenance

(cont’d)

_______________________________________________________________________________________

__________

Maintenance Sched ule (cont’d)

Every 100 hours of operation

• Drain the old engine oil and replace with approximately 1 quart of high quality SAE 10W-30 grade

engine oil.

• Remove spark plug. Remove any carbon deposits. Check for discoloration. Check spark plug gap

(0.7-0.8mm).

• Clean Spark Arrestor (if installed)

Every 150 hours of operation

• Remove, clean, and replace fuel filter.

Every 300 hours of operation

• Have a qualified, certified technician perform thorough maintenance on the generator and engine.

• For long term storage, either drain fuel into a suitable container or add a fuel preservative/stabilizer

(not included) to prevent fuel breakdown.

Storage

The generator should be started at least once every 14 days and allowed to run for at least 20 minutes. For

longer term storage, please follow these gu ideli nes .

1. Allow the engine to cool completely before storage.

2. Turn off the fuel supply at the fuel valve.

3. Drain all fuel completely from the fuel line and carburetor to prevent gum from forming.

4. Add a fuel stabilizer into the fuel tank.

5. Change the oil.

6. Remove the spark plug and pour about ½ ounce of oil into the cylinder. Crank the engine slowly to

distribute the oil and lubricate the cylinder.

7. Reattach the spark plug.

8. Slowly pull the starter grip until resistance is felt. At this point, the piston is coming up on its

compression stroke and both the intake and exhaust valves are closed. Storing the engine in this

position will help protect it from internal corrosion.

9. Clean the generator according to the instructions in the Maintenance section.

10. Store the unit in a clean, dry area.

11. Store in a clean, dry place out of direct sunlight.

Transporting

If the generator has been used, allow it to cool for at least 15 minutes before loading the generator on the

transport vehicle. A hot engine and exhaust system can burn you and can ignite some material. When

transporting the generator, turn the engine switch and fuel valve off, and keep the generator level to reduce

the possibility of fuel leakage.

Take care not to drop or strike the generator when transporting. DO NOT place heavy objects on the

generator.

Page 23

23

©2012 Smarter Tools, Inc. All Rights Reserved

Owner’s Manual

Specifications

______________________________________________________________________________________

ST-GP9750

ST-GP9750EB

Engine Type

4-Stroke OHV Air Cooled Single Cylinder EPA and CARB

Certified

Horsepower 15

Engine Displacement

(cc)

420cc

Running Watts 7800w

Starting Watts 9750w

Rated Frequency 60HZ

Rated Voltage 120V/240V

Rated Current 65A

Run Time 10hrs at 50% load

Receptacles (qty.)

(4) 120V AC; (1) 240V/120 AC; (1) 120V 30A AC; (1) 12V 10A

DC

Net/Gross Weight 185/187lbs.

Noise Level (dB) 73dB

Fuel Type Unleaded gasoline

Fuel Capacity (gal.) 7

Oil Level Meter Yes

Oil Type SAE 10W-30

Start Type Recoil (Electric on E and EB models)

AC Volt Meter Yes

Frame Construction Tubular Steel

Wheel & Handle Kit 10" No-flat Tires; Duel handles; 3 1/2" crutches

Dimensions L x W x H

(in.)

27" x 24" x 27"

Battery (optional) 12 Volt 17 Amp Hours Nut & Bolt Terminals

Page 24

Owner’s Manual

Troubleshooting

_________________________________________________________________________________________________

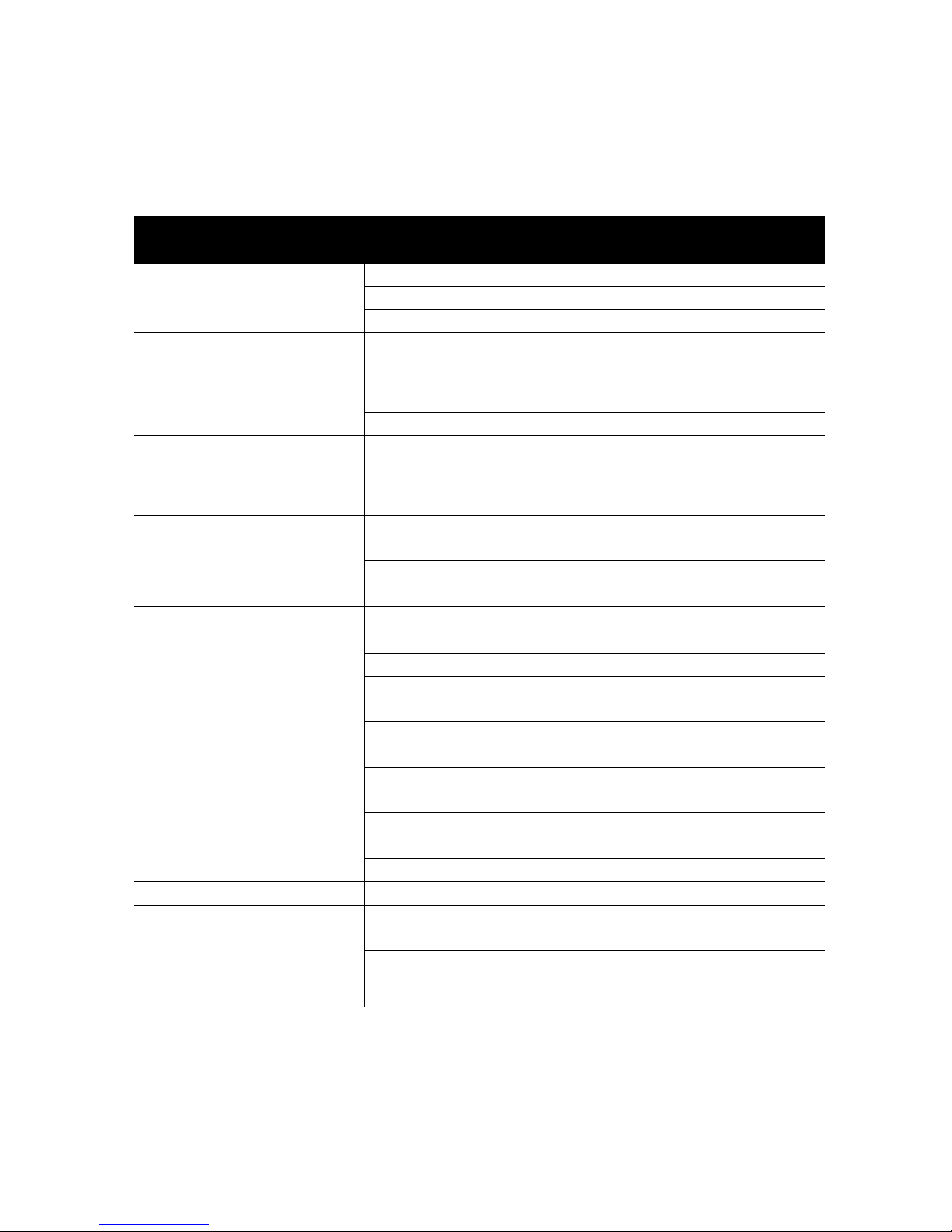

Problem Cause Solution

No Fuel Fill with fuel

Generator will not start

Generator will not start; Generator

starts but runs roughly

Generator shuts down during

operation

Faulty spark plug Replace spark plug

Unit loaded during start up Remove load from unit

Fill crankcase to the proper level

Low oil level

Choke in the wrong position. Adjust choke.

Spark plug wire loose Attach wire to spark plug

Out of fuel Fill fuel tank

Low oil level

Place generator on a flat, level

surface before restarting

Fill crankcase to the proper level.

Place generator on a flat, level

surface before starting

Generator cannot supply enough

power or overheating

No AC output

Generator gallops Engine governor defective Contact Smarter Tools

Repeated circuit breaker tripping

Generator is overloaded

Insufficient ventilation

Cable not properly connected Check all connections

Connected device is defective Replace defective device

Circuit breaker is open Reset circuit breaker

Capacitor defective

Faulty brush assembly

Faulty AVR

Loose wiring

Other Contact Smarter Tools

Overload

Faulty cords or device

Review load and adjust. See

“Power Management”

Check for air restriction. Move to a

well ventilated area

Replace capacitor.

Contact Smarter Tools

Replace brush assembly

Contact Smarter Tools

Replace AVR

Contact Smarter Tools

Inspect and tighten wiring

connections

Review load and adjust. See

“Power Management”

Check for damaged, bare or

frayed wires. Replace defective

device

33

©2012 Smarter Tools, Inc. All Rights Reserved

Page 25

Owner’s Manual

Warranty Identification

_________________________________________________________________________________________________

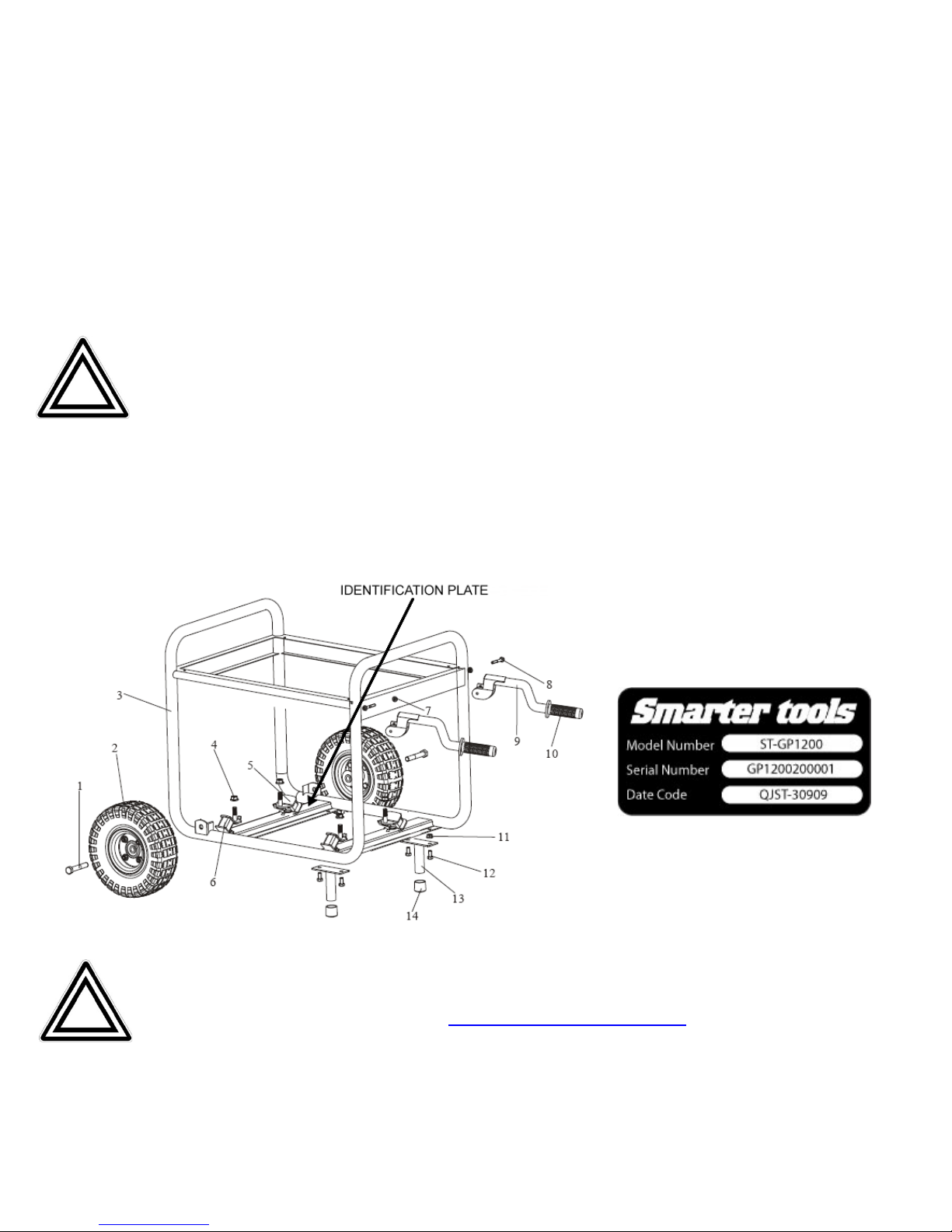

To assist in accurately determining whether your Smarter Tools product is still covered by manufacturer’s warranty and to

identify your product properly should you need to contact customer service an Hour Meter and Identification Plate have

been installed.

Hour Meter

The product’s Hour Meter can be found on the front control panel to the right of the power switch .

Note: The Hour Meter is tied directly to the product warranty. Attempting to disable or otherwise tamper with

the Hour Meter will VOID the manufacturer’s warranty.

Identification Plate

The product’s Identific ati on Plate can be found on t he l o wer-frame cross arm just behind the air filter. See figure below.

Note: Properly registering your product with Smarter Tools is the only way to ensure that your product will be

eligible for warranty replacement or repair should an unforeseen event cause the Identification Plate to be

unreadable. Register your product online at

registration card within 14 days or product purchase.

www.usesmartertools.com/register o r by mailing in your warran ty

34

©2012 Smarter Tools, Inc. All Rights Reserved

Page 26

LIMITED WARRANTY

Effective May 1, 2012. Replaces all undated warranties and all warranties

dated before May 1, 2012

Warranty Qualifications

Smarter Tools will register this warranty upon rece ipt o f

your Warranty Registration Card and a copy of your

sales receipt from one of Smarter Tools' retail locations

as proof of purchase.

Please submit your warranty regis trat ion and your proo f

of purchase within fourteen (14) days of the date of

purchase.

Repair/Replacemen t Warranty

Smarter Tools warrants to the original purchaser that the

mechanical and electrical components will be free of

defects in material and workmanship for a period of one

(1) year or 60 hours (measured by the factory installed

hour meter) from the original date of purchase (90 days

or 60 hours for commercial & industrial use).

Transportation charges on product submitted for repair

or replacement under this warranty are the sole

responsibility of the purchaser. This workmanship for a

period of warranty only applies to the original purchaser

and is not transferable.

Do not return the unit to the place of

purchase

Contact Smarter Tools’ Customer Service and Smarter

Tools will troubleshoot any issue via phone or e-mail. If

the problem is not corrected by this method, Smarter

Tools will, at its option, authorize evaluation, repair or

replacement of the defective part or component at a

Smarter Tools Service Center. Smarter Tools will

provide you with a case number for warranty service.

Please keep it for future reference. Repairs or

replacements without prior authorization, or at an

unauthorized repair facility, will not be covered.

Warranty Exclusi ons

This warranty does not cover the following repairs and

equipment:

Normal Wear

Generators need periodic parts and service to

perform well. This warranty does not cover

repair when normal use has exhausted the life of

a part or the equipment as a whole.

Installation, Use and M ai nt en ance

This warranty will not apply to parts and/or labor

if this generator is deemed to have been

misused, neglected, involved in an accident,

abused, loaded beyond the generator's limits,

modified, installed improperly or connected

incorrectly to any electrical component. Normal

maintenance such as spark plugs, air filters,

adjustments, fuel system cleaning and

obstruction due to buildup is not covered by this

warranty.

Other Exclusions

This warranty excludes:

• Merchandise sold as reconditioned, used as

rental equipment, or floor/display models sold

without packaging and/or miss ing parts or

components.

• Repair and transportation costs of merchandise

determined not to be defective.

• Cosmetic defects such as paint, decals, etc.

• Wear items such as filter elements, o-rings, etc.

• Accessory parts such as starting batteries, and

storage covers.

• Failures due to acts of God and other forces of

nature beyond the manufacturer's control.

• Problems caused by parts that are not original

Smarter Tools parts.

This warranty does not apply to generators used

for prime power in place of a utility.

Limits of Implied Warranty and

Consequential Da mage

Smarter Tools disclaims any obligation to cover any loss

of time, use of this product, freight, or any incidental or

consequential claim by anyone from using this

generator. THIS WARRANTY IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE.

A unit provided as an exchange will be subject to the

warranty of the original unit. The length of the warranty

governing the exchanged unit will remain calculated by

reference to the purchase date of the original unit.

This warranty gives you certain legal rights which may

change from state to state. Your state may also have

other rights you may be entitled to that are not listed

within this warranty.

Some states do not allow the exclusion, so it may not

apply to you.

Contact us at:

Smarter Tools Customer Service

12195 Harley Club Drive

Ashland, VA 23005

(804)798-8588

customerservice@usesmartertools.com

35

©2012 Smarter Tools, Inc. All Rights Reserved

Page 27

Loading...

Loading...