Page 1

MVME2502

Installation and Use

P/N: 6806800R96G

September 2019

Page 2

© 2019 SMART Embedded Computing™, Inc.

All Rights Reserved.

Trademarks

The stylized "S" and "SMART" is a registered trademark of SMART Modular Technologies, Inc. and “SMART Embedded

Computing” and the SMART Embedded Computing logo are trademarks of SMART Modular Technologies, Inc. All other names

and logos referred to are trade names, trademarks, or registered trademarks of their respective owners. These materials are

provided by SMART Embedded Computing as a service to its customers and may be used for informational purposes only.

Disclaimer*

SMART Embedded Computing (SMART EC) assumes no responsibility for errors or omissions in these materials. These

materials are provided "AS IS" without warranty of any kind, either expressed or implied, including but not limited to,

the implied warranties of merchantability, fitness for a particular purpose, or non-infringement. SMART EC further does

not warrant the accuracy or completeness of the information, text, graphics, links or other items contained within these

materials. SMART EC shall not be liable for any special, indirect, incidental, or consequential damages, including without

limitation, lost revenues or lost profits, which may result from the use of these materials. SMART EC may make changes to

these materials, or to the products described therein, at any time without notice. SMART EC makes no commitment to update

the information contained within these materials.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another document as a

URL to a SMART EC website. The text itself may not be published commercially in print or electronic form, edited, translated,

or otherwise altered without the permission of SMART EC.

It is possible that this publication may contain reference to or information about SMART EC products, programming, or services

that are not available in your country. Such references or information must not be construed to mean that SMART EC intends

to announce such SMART EC products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following notice shall apply

unless otherwise agreed to in writing by SMART Embedded Computing.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in

Technical Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and

Documentation clause at DFARS 252.227-7014 (Jun. 1995).

SMART Embedded Computing, Inc.

2900 S. Diablo Way, Suite 190

Tempe, Arizona 85282

USA

*For full legal terms and conditions, visit

www.smartembedded.com/ec/legal

Page 3

Table of Contents

About this Manual ...............................................................13

Safety Notes....................................................................19

Sicherheitshinweise .............................................................23

1 Introduction.................................................................27

1.1 Overview ...............................................................27

1.2 Standard Compliances ....................................................29

1.3 Mechanical Data .........................................................29

1.4 Ordering Information ......................................................30

1.5 Product Identification .....................................................30

2 Hardware Preparation and Installation ...........................................33

2.1 Overview ...............................................................33

2.2 Unpacking and Inspecting the Board .........................................34

2.3 Requirements ...........................................................34

2.3.1 Environmental Requirements ........................................35

2.3.2 Power Requirements ................................................36

2.3.3 Equipment Requirements.............................................37

2.4 Configuring the Board .....................................................37

2.5 Installing Accessories .....................................................38

2.5.1 Rear Transition Module ..............................................38

2.5.2 PMC/XMC Support..................................................39

2.5.3 Installation of MVME2502-HDMNTKIT1/MVME2502-HDMNTKIT2.............40

2.6 Installing and Removing the Board ...........................................43

2.7 Completing the Installation .................................................44

3 Controls, LEDs, and Connectors ...............................................45

3.1 Board Layout ...........................................................45

3.2 Front Panel .............................................................47

3.2.1 Reset Switch ......................................................48

3.3 LEDs ..................................................................48

3.3.1 Front Panel LEDs...................................................48

MVME2502 Installation and Use (6806800R96G) 3

Page 4

Table of Contents

3.3.2 On-board LEDs ....................................................50

3.4 Connectors .............................................................51

3.4.1 Front Panel Connectors ..............................................51

3.4.1.1 RJ-45 with Integrated Magnetics (J1) ...........................51

3.4.1.2 Front Panel Serial Port (J4) ...................................52

3.4.1.3 USB Connector (J5) .........................................53

3.4.1.4 VMEBus P1 Connector ......................................53

3.4.1.5 VMEBus P2 Connector ......................................55

3.4.2 On-board Connectors................................................56

3.4.2.1 SATA Connector (J3) ........................................56

3.4.2.2 PMC Connectors ...........................................57

3.4.2.3 JTAG Connector (P6) ........................................63

3.4.2.4 COP Connector P50(15) .....................................64

3.4.2.5 XMC Connector (XJ1) .......................................65

3.4.2.6 XMC Connector (XJ2) .......................................66

3.4.2.7 Miscellaneous P2020 Debug Connectors(P4) .....................66

3.5 Switches ...............................................................67

3.5.1 Geographical Address Switch (S1) .....................................67

3.5.2 SMT Configuration Switch (S2) ........................................69

4 Functional Description ........................................................71

4.1 Block Diagram ..........................................................71

4.2 Chipset ................................................................72

4.2.1 e500 Processor Core ................................................72

4.2.2 Integrated Memory Controller .........................................72

4.2.3 PCI Express Interface ...............................................73

4.2.4 Local Bus Controller (LBC) ...........................................73

4.2.5 Secure Digital Host Controller (SDHC) ..................................73

4.2.6 I2C Interface.......................................................73

4.2.7 USB Interface......................................................74

4.2.8 DUART...........................................................74

4.2.9 DMA Controller.....................................................74

4.2.10 Enhanced Three-Speed Ethernet Controller (eTSEC).......................74

4.2.11 General Purpose I/O (GPIO) ..........................................74

4.2.12 Security Engine (SEC) 3.1 ............................................75

4.2.13 Common On-Chip Processor (COP) ....................................76

4.2.14 P2020 Strapping Pins ...............................................76

4.3 System Memory .........................................................79

4 MVME2502 Installation and Use (6806800R96G)

Page 5

Table of Contents

4.4 Timers.................................................................79

4.4.1 Real Time Clock....................................................79

4.4.2 P2020 Internal Timer ................................................79

4.4.3 Watchdog Timer....................................................79

4.4.4 CPLD Tick Timer ...................................................79

4.5 Ethernet Interfaces .......................................................80

4.6 SPI Bus Interface ........................................................80

4.6.1 SPI Flash Memory ..................................................80

4.6.2 SPI Flash Programming ..............................................81

4.6.3 Firmware Redundancy ...............................................81

4.6.4 Crisis Recovery ....................................................82

4.7 Front UART Control ......................................................83

4.8 Rear UART Control .......................................................83

4.9 PMC/XMC Sites .........................................................84

4.9.1 PMC Add-on Card ..................................................85

4.9.2 XMC Add-on Card ..................................................85

4.10 SATA Interface ..........................................................85

4.11 VME Support ...........................................................85

4.11.1 Tsi148 VME Controller...............................................86

4.12 USB ..................................................................86

4.13 I2C Devices ............................................................86

4.14 Reset/Control CPLD ......................................................87

4.15 Power Management ......................................................88

4.15.1 On-board Voltage Supply Requirement ..................................88

4.15.2 Power Up Sequencing Requirements ...................................88

4.16 Clock Structure ..........................................................89

4.17 Reset Structure ..........................................................90

4.17.1 Reset Sequence....................................................90

4.18 Thermal Management .....................................................90

4.19 Real-Time Clock Battery ...................................................90

4.20 Debugging Support .......................................................91

4.20.1 POST Code Indicator................................................91

4.20.2 JTAG Chain and Board ..............................................91

4.20.3 Custom Debugging .................................................92

4.21 Rear Transition Module (RTM) ..............................................93

5 Memory Maps and Registers ...................................................95

5.1 Overview ...............................................................95

MVME2502 Installation and Use (6806800R96G) 5

Page 6

Table of Contents

5.2 MemoryMap............................................................95

5.3 Flash Memory Map .......................................................96

5.4 Linux Devices Memory Map ................................................96

5.5 Programmable Logic Device (PLD) Registers ..................................98

5.5.1 PLD Revision Register ...............................................98

5.5.2 PLD Year Register ..................................................98

5.5.3 PLD Month Register.................................................99

5.5.4 PLD Day Register ..................................................99

5.5.5 PLD Sequence Register..............................................99

5.5.6 PLD Power Good Monitor Register ....................................100

5.5.7 PLD LED Control Register ...........................................100

5.5.8 PLD PCI/PMC/XMC (Slot1) Monitor Register ............................101

5.5.9 PLD PCI/PMC/XMC (Slot2) Monitor Register ............................102

5.5.10 PLD U-Boot and TSI Monitor Register..................................103

5.5.11 PLD Boot Bank Register ............................................103

5.5.12 PLD Write Protect and I2C Debug Register ..............................104

5.5.13 PLD Test Register 1................................................105

5.5.14 PLD Test Register 2................................................106

5.5.15 PLD GPIO2 Interrupt Register ........................................106

5.5.16 PLD Shutdown and Reset Control and Reset Reason Register ..............107

5.5.17 EMMC Reset Register ..............................................108

5.5.18 PLD Watchdog Timer Refresh Register.................................109

5.5.19 PLD Watchdog Control Register ......................................109

5.5.20 PLD Watchdog Timer Count Register ..................................110

5.5.21 PLD Watchdog Timer Count Value Register .............................110

5.6 External Timer Registers .................................................111

5.6.1 Prescaler Register .................................................111

5.6.2 Control Registers ..................................................112

5.6.3 Compare High and Low Word Registers ................................112

5.6.4 Counter High and Low Word Registers .................................114

6 Boot System ...............................................................115

6.1 Overview ..............................................................115

6.2 Accessing U-Boot .......................................................115

6.3 Boot Options ...........................................................116

6.3.1 Booting from a Network .............................................116

6.3.2 Booting from an Optional SATA Drive ..................................117

6.3.3 Booting from a USB Drive ...........................................117

6 MVME2502 Installation and Use (6806800R96G)

Page 7

Table of Contents

6.3.4 Booting from an SD Card ............................................118

6.3.5 Booting VxWorks Through the Network .................................118

6.4 Using the Persistent Memory Feature .......................................119

6.5 MVME2502 Specific U-Boot Commands .....................................120

6.6 Updating U-Boot ........................................................123

7 Programming Model .........................................................125

7.1 Overview ..............................................................125

7.2 Reset Configuration .....................................................125

7.3 Interrupt Controller ......................................................129

7.4 I2C Bus Device Addressing ...............................................130

7.5 Ethernet PHY Address ...................................................131

7.6 Other Software Considerations .............................................131

7.6.1 MRAM ..........................................................131

7.6.2 Real Time Clock...................................................131

7.6.3 Quad UART ......................................................131

7.6.4 LBC Timing Parameters.............................................132

7.7 Clock Distribution .......................................................133

7.7.1 System Clock .....................................................134

7.7.2 Real Time Clock Input ..............................................134

7.7.3 Local Bus Controller Clock Divisor.....................................134

A Replacing the Battery ........................................................135

A.1 Replacing the Battery ....................................................135

B Related Documentation ......................................................139

B.1 SMART Embedded Computing Documentation ................................139

B.2 Manufacturers’ Documents ................................................139

B.3 Related Specifications ...................................................140

MVME2502 Installation and Use (6806800R96G) 7

Page 8

Table of Contents

8 MVME2502 Installation and Use (6806800R96G)

Page 9

List of Figures

Figure 1-1 Serial Number Location-ENP1 Variant ..................................30

Figure 1-2 Serial Number Location-ENP2 Variant ..................................31

Figure 3-1 Board Layout ENP1 Variant .......................................... 45

Figure 3-2 Board Layout ENP2 Variant .......................................... 46

Figure 3-3 Front Panel LEDs, Connectors and Switches ............................ 47

Figure 3-4 Front Panel LEDs .................................................. 48

Figure 3-5 On-board LEDs ................................................... 50

Figure 3-6 Geographical Address Switch ........................................ 68

Figure 3-7 SMT Configuration Switch Position ....................................69

Figure 4-1 Block Diagram .................................................... 71

Figure 4-2 SPI Device Multiplexing Logic ........................................ 82

Figure 4-3 Clock Distribution Diagram .......................................... 89

Figure 4-4 JTAG Chain Diagram .............................................. 92

Figure 4-5 RTM Block Diagram ................................................ 93

Figure A-1 Battery Location ENP1 Variant ...................................... 135

Figure A-2 Battery Location ENP2 Variant ...................................... 136

MVME2502 Installation and Use (6806800R96G) 9

Page 10

Table of Contents

10 MVME2502 Installation and Use (6806800R96G)

Page 11

List of Tables

Table 1-1 Board Standard Compliances ...........................................29

Table 1-2 Mechanical Data .....................................................29

Table 2-1 Environmental Requirements ...........................................35

Table 2-2 Power Requirements ..................................................36

Table 3-1 Front Panel LEDs ....................................................48

Table 3-2 On-board LEDs Status ................................................50

Table 3-3 Front Panel Tri-Speed Ethernet Connector (J1) .............................51

Table 3-4 Front Panel Serial Port (J4) .............................................52

Table 3-5 USB Connector (J5) ..................................................53

Table 3-6 VMEbus P1 Connector ................................................53

Table 3-7 VMEbus P2 Connector ................................................55

Table 3-8 Custom SATA Connector (J3) ...........................................56

Table 3-9 PMC J11/J111 Connector ..............................................57

Table 3-10 PMC J12/J222 Connector ..............................................59

Table 3-11 PMC J13/J333 Connector ..............................................60

Table 3-12 PMC J14 Connector ..................................................61

Table 3-13 JTAG Connector (P6) .................................................63

Table 3-14 COP Header (P50) ...................................................64

Table 3-15 XMC Connector (XJ1) Pin out ...........................................65

Table 3-16 XMC Connector (XJ2) Pin out ...........................................66

Table 3-17 P2020 Debug Header (P4) .............................................67

Table 3-18 Geographical Address Switch ...........................................68

Table 3-19 Geographical Address Switch Settings ....................................69

Table 4-1 P2020 GPIO Functions ................................................74

Table 4-2 P2020 Strapping Options ..............................................76

Table 4-3 P2020 I2C Port1 Devices ..............................................87

Table 4-4 P2020 I2C Port2 Devices ..............................................87

Table 4-5 Voltage Supply Requirement ............................................88

Table 4-6 Thermal Interrupt Threshold ............................................90

Table 4-7 POST Code Indicator on the LED ........................................91

Table 4-8 Transition Module Features .............................................93

Table 5-1 Physical Address Map .................................................95

Table 5-2 Flash Memory Map ...................................................96

Table 5-3 Linux Devices Memory Map ............................................96

Table 5-4 PLD Revision Register ................................................98

Table 5-5 PLD Year Register ....................................................98

Table 5-6 PLD Month Register ..................................................99

MVME2502 Installation and Use (6806800R96G) 11

Page 12

Table of Contents

Table 5-7 PLD Day Register ....................................................99

Table 5-8 PLD Sequence Register ...............................................99

Table 5-9 PLD Power Good Monitor Register ......................................100

Table 5-10 PLD LED Control Register ............................................100

Table 5-11 PLD PCI/PMC/XMC (Slot1) Monitor Register ..............................101

Table 5-12 PLD PCI/PMC/XMC (Slot2) Monitor Register ..............................102

Table 5-13 PLD U-Boot and TSI Monitor Register ...................................103

Table 5-14 PLD Boot Bank Register ..............................................103

Table 5-15 PLD Write Protect and I2C Debug Register ...............................104

Table 5-16 PLD Test Register 1 .................................................105

Table 5-17 PLD Test Register 2 .................................................106

Table 5-18 PLD GPIO2 Interrupt Register .........................................106

Table 5-19 PLD Shutdown and Reset Control and Reset Reason Register ................107

Table 5-20 PLD Shutdown and Reset Control and Reset Reason Register ................108

Table 5-21 PLD Watchdog Timer Refresh Register ..................................109

Table 5-22 PLD Watchdog Control Register ........................................109

Table 5-23 PLD Watchdog Timer Count Register ....................................110

Table 5-24 PLD Watchdog Timer Count Register ....................................110

Table 5-25 Prescaler Register ..................................................111

Table 5-26 Control Registers ...................................................112

Table 5-27 Compare High Word Registers .........................................113

Table 5-28 Compare Low Word Registers .........................................113

Table 5-29 Counter High Word Registers ..........................................114

Table 5-30 Counter Low Word Registers ..........................................114

Table 6-1 MVME2502 Specific U-Boot Commands .................................120

Table 7-1 POR Configuration Settings ...........................................125

Table 7-2 MVME2502 Interrupt List .............................................129

Table 7-3 I2C Bus Device Addressing ............................................130

Table 7-4 PHY Types and MII Management Bus Address ............................131

Table 7-5 LBC Timing Parameters ..............................................132

Table 7-6 Clock Distribution ...................................................133

Table 7-7 System Clock ......................................................134

Table B-1 SMART EC Documentation ...........................................139

Table B-2 Manufacturers’ Publications ...........................................139

Table B-3 Related Specifications ...............................................140

12 MVME2502 Installation and Use (6806800R96G)

Page 13

About this Manual

Overview of Contents

This manual is intended for users who install and configure MVME2502 product. It is

assumed that the user is familiar with the standard cabling procedures, configuration of

operating systems, U-Boot system and MVME Chassis.

The purpose of this manual is to describe MVME2502 product and the services it provides.

This manual includes description of MVME2502 product hardware, firmware and also

information about operating system.

This manual is divided into the following chapters and appendices.

About this Manual lists all conventions and abbreviations used in this manual and outlines

the revision history.

Safety Notes on page 19 summarizes the safety instructions in the manual.

Sicherheitshinweise on page 23 is a German translation of the Safety Notes chapter.

Chapter 1, Introduction on page 27 gives an overview of the features of the product,

standard compliances, mechanical data, and ordering information.

Chapter 2, Hardware Preparation and Installation on page 33 outlines the installation

requirements, hardware accessories, switch settings, and installation procedures.

Chapter 3, Controls, LEDs, and Connectors on page 45 describes external interfaces of the

board. This includes connectors and LEDs.

Chapter 4, Functional Description on page 71 includes a block diagram and functional

description of major components of the product.

Chapter 5, Memory Maps and Registers on page 95 contains information on system

resources including system control and status registers and external timers.

Chapter 6, Boot System on page 115 describes the boot loader software.

Chapter 7, Programming Model on page 125 contains additional programming information

for the board.

Appendix A, Replacing the Battery on page 135 contains the procedures for replacing the

battery.

Appendix B, Related Documentation on page 139 provides a listing of related product

documentation, manufacturer’s documents, and industry standard specifications.

MVME2502 Installation and Use (6806800R96G) 13

Page 14

l

About this Manual

Abbreviations

This document uses the following abbreviations:

Term Definition

COP Common On-Chip Processor

CPLD Complex Programmable Logic Device

DDR3 Double Data Rate 3

DUART Dual Universal Asynchronous Receiver Transmitter

EEPROM Erasable Programmable Read-Only Memory

FCC Federal Communications Commission

FPGA Field Programmable Gate Array

GPIO General Purpose Input/Output

HDD Hard Disk Drive

IEEE Institute of Electrical and Electronics Engineers

About this Manua

LBC Local Bus Controller

MCP Multi-Chip Package

MRAM Magnetoresistive Random Access Memory

PCI Peripheral Component Interconnect

PCI-E PCI Express

PCI-X Peripheral Component Interconnect eXtended

PIM PCI Mezzanine Card Input/Output Module

PLD Programmable Logic Device

PMC PCI Mezzanine Card (IEEE P1386.1)

PrPMC Processor PCI Mezzanine Card

RTC Real-Time Clock

RTM Rear Transition Module

SATA Serial Advanced Technology Attachment

SDHC Secure Digital Host Controller

SMT Surface Mounted Technology

14 MVME2502 Installation and Use (6806800R96G)

Page 15

Term Definition

UART Universal Asynchronous Receiver-Transmitter

VITA VMEbus International Trade Association

VME Versa Module Eurocard

XMC PCI Express Mezzanine Card

Conventions

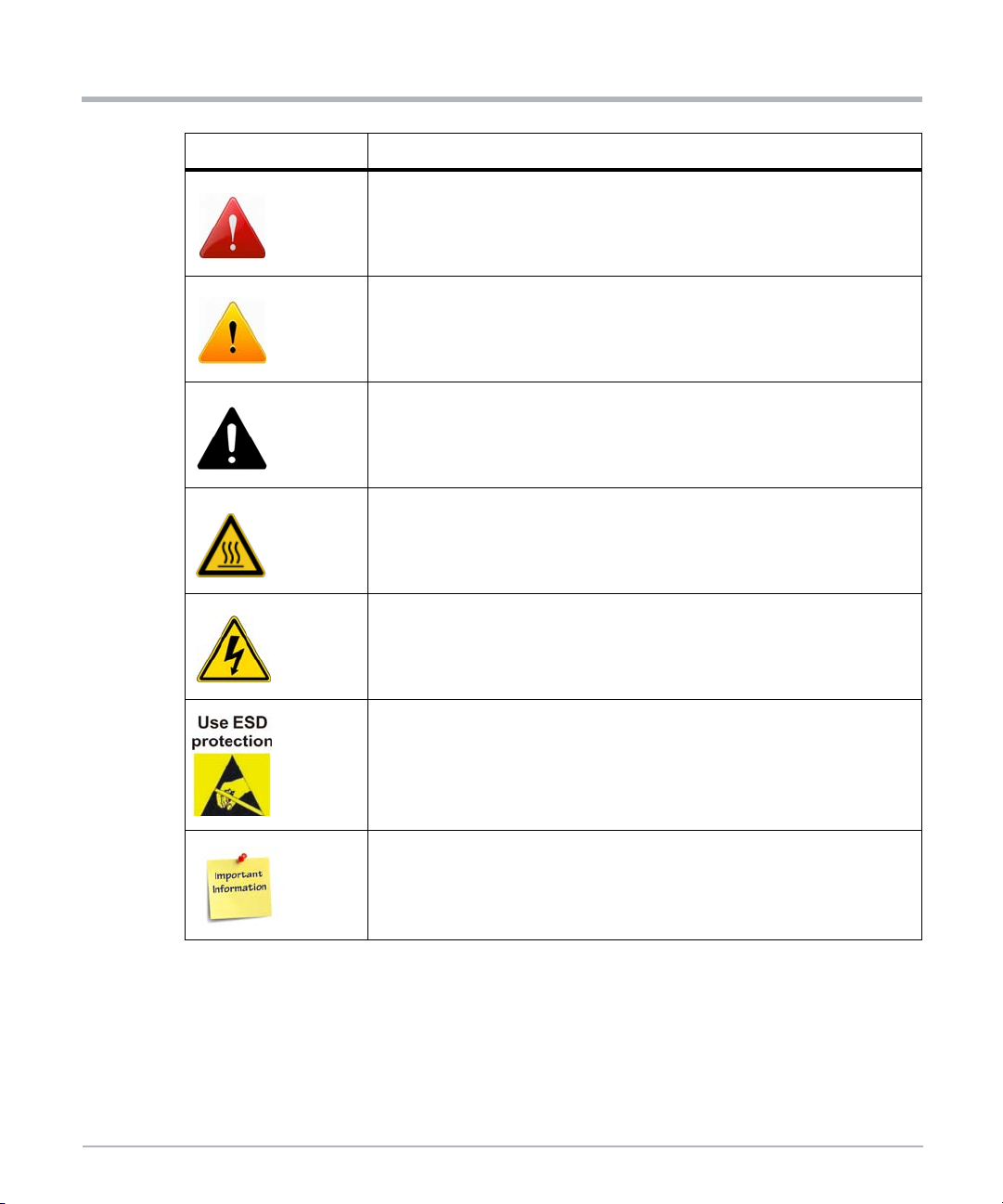

The following table describes the conventions used throughout this manual. .

Notation Description

About this Manual

0x00000000

0b0000

bold Used to emphasize a word

Screen

Courier + Bold

Reference

File > Exit Notation for selecting a submenu

<text> Notation for variables and keys

[text]

... Repeated item for example node 1, node 2, ..., node 12

.

.

.

..

Typical notation for hexadecimal numbers (digits are 0 through F), for

example used for addresses and offsets

Same for binary numbers (digits are 0 and 1)

Used for on-screen output and code related elements or commands.

Sample of Programming used in a table (9pt)

Used to characterize user input and to separate it from system output

Used for references and for table and figure descriptions

Notation for software buttons to click on the screen and parameter

description

Omission of information from example/command that is not necessary at

the time

Ranges, for example: 0..4 means one of the integers 0,1,2,3, and 4 (used

in registers)

| Logical OR

MVME2502 Installation and Use (6806800R96G) 15

Page 16

l

About this Manual

Notation Description

About this Manua

Indicates a hazardous situation which, if not avoided, could result in death

or serious injury

Indicates a hazardous situation which, if not avoided, may result in minor

or moderate injury

Indicates a property damage message

Indicates a hot surface that could result in moderate or serious injury

Indicates an electrical situation that could result in moderate injury or death

Indicates that when working in an ESD environment care should be taken

to use proper ESD practices

No danger encountered, pay attention to important information

16 MVME2502 Installation and Use (6806800R96G)

Page 17

Summary of Changes

This manual has been revised and replaces all prior editions.

Part Number Publication Date Description

6806800R96G September 2019

6806800R96F May 2016 Removed Declaration of Conformity.

6806800R96E April 2015 Updated Ta b le B . 1.

6806800R96D December 2014 Updated Boot Options and Crisis Recovery.

6806800R96C August 2014

6806800R96B April 2014

About this Manual

Re-branded to SMART Embedded Computing

template. Updated Conventions table; updated

Freescale to NXP; removed Ordering

Information table; added Ordering and Support

Information; updated RoHS compliance.

Added GBE_MUX_SEL in S2 to TSEC1 and

changed PHY addresses in Table 7-4 PHY

Types and MII Management Bus Address.

Re-branded to Artesyn template.

Added MVME2502 Declaration of Conformity on

page 22.

Added Flash Memory Map and updated SPI

Flash Memory, Reset Switch and PMC/XMC

Sites.

Added Installation of MVME2502HDMNKIT1

and MVME2502-HDMNKIT2.

6806800R96A October 2013 Initial Version

MVME2502 Installation and Use (6806800R96G) 17

Page 18

l

About this Manual

About this Manua

18 MVME2502 Installation and Use (6806800R96G)

Page 19

Safety Notes

This section provides warnings that precede potentially dangerous procedures throughout

this manual. Instructions contained in the warnings must be followed during all phases of

operation, service, and repair of this equipment. You should also employ all other safety

precautions necessary for the operation of the equipment in your operating environment.

Failure to comply with these precautions or with specific warnings elsewhere in this manual

could result in personal injury or damage to the equipment.

SMART Embedded Computing intends to provide all necessary information to install and

handle the product in this manual. Because of the complexity of this product and its various

uses, we do not guarantee that the given information is complete. If you need additional

information, ask your SMART EC representative.

This product is a Safety Extra Low Voltage (SELV) device designed to meet the EN609501 requirements for Information Technology Equipment. The use of the product in any other

application may require safety evaluation specific to that application.

Only personnel trained by SMART EC or persons qualified in electronics or electrical

engineering are authorized to install, remove or maintain the product.

The information given in this manual is meant to complete the knowledge of a specialist and

must not be used as replacement for qualified personnel.

Keep away from live circuits inside the equipment. Operating personnel must not remove

equipment covers. Only Factory Authorized Service Personnel or other qualified service

personnel may remove equipment covers for internal subassembly or component

replacement or any internal adjustment.

Do not install substitute parts or perform any unauthorized modification of the equipment or

the warranty may be voided. Contact your local SMART EC representative for service and

repair to make sure that all safety features are maintained.

EMC (Results below)

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by SMART EC could void the user's

authority to operate the equipment. Board products are tested in a representative system

MVME2502 Installation and Use (6806800R96G) 19

Page 20

Safety Notes

to show compliance with the above mentioned requirements. A proper installation in a

compliant system will maintain the required performance. Use only shielded cables when

connecting peripherals to assure that appropriate radio frequency emissions compliance is

maintained.

Operation

Product Damage

High humidity and condensation on the board surface causes short circuits.

Do not operate the board outside the specified environmental limits.

Make sure the board is completely dry and there is no moisture on any surface before

applying power.

Damage of Circuits

Electrostatic discharge and incorrect installation and removal can damage circuits or

shorten its life.

Before touching the board or electronic components, make sure that you are working in an

ESD-safe environment.

Safety Notes

Board Malfunction

Switches marked as “reserved” might carry production-related functions and can cause the

board to malfunction if their setting is changed.

Do not change settings of switches marked as “reserved”. The setting of switches which

are not marked as “reserved” has to be checked and changed before board installation.

Installation

Data Loss

Powering down or removing a board before the operating system or other software running

on the board has been properly shut down may cause corruption of data or file systems.

Make sure all software is completely shut down before removing power from the board or

removing the board from the chassis.

Product Damage

Only use injector handles for board insertion to avoid damage to the front panel and/or

PCB. Deformation of the front panel can cause an electrical short or other board

malfunction.

20 MVME2502 Installation and Use (6806800R96G)

Page 21

Product Damage

Inserting or removing modules with power applied may result in damage to module

components.

Before installing or removing additional devices or modules, read the documentation that

came with the product.

Cabling and Connectors

Product Damage

RJ-45 connectors on modules are either twisted-pair Ethernet (TPE) or E1/T1/J1 network

interfaces. Connecting an E1/T1/J1 line to an Ethernet connector may damage your

system.

Make sure that TPE connectors near your working area are clearly marked as

network connectors.

Verify that the length of an electric cable connected to a TPE bushing does not

exceed 100 meters.

Make sure the TPE bushing of the system is connected only to safety extra low

voltage circuits (SELV circuits).

Safety Notes

If in doubt, ask your system administrator.

Battery

Board/System Damage

Incorrect exchange of lithium batteries can result in a hazardous explosion.

When exchanging the on-board lithium battery, make sure that the new and the old battery

are exactly the same battery models.

If the respective battery model is not available, contact your local SMART EC sales

representative for the availability of alternative, officially approved battery models.

Data Loss

Exchanging the battery can result in loss of time settings. Backup power prevents the loss

of data during exchange.

Quickly replacing the battery may save time settings.

MVME2502 Installation and Use (6806800R96G) 21

Page 22

Safety Notes

Data Loss

If the battery has low or insufficient power the RTC is initialized.

Exchange the battery before seven years of actual battery use have elapsed.

PCB and Battery Holder Damage

Removing the battery with a screw driver may damage the PCB or the battery holder. To

prevent damage, do not use a screw driver to remove the battery from its holder.

Safety Notes

22 MVME2502 Installation and Use (6806800R96G)

Page 23

Sicherheitshinweise

Dieses Kapitel enthält Hinweise, die potentiell gefährlichen Prozeduren innerhalb dieses

Handbuchs vorrangestellt sind. Beachten Sie unbedingt in allen Phasen des Betriebs, der

Wartung und der Reparatur des Systems die Anweisungen, die diesen Hinweisen

enthalten sind. Sie sollten außerdem alle anderen Vorsichtsmaßnahmen treffen, die für den

Betrieb des Produktes innerhalb Ihrer Betriebsumgebung notwendig sind. Wenn Sie diese

Vorsichtsmaßnahmen oder Sicherheitshinweise, die an anderer Stelle diese Handbuchs

enthalten sind, nicht beachten, kann das Verletzungen oder Schäden am Produkt zur Folge

haben.

SMART Embedded Computing ist darauf bedacht, alle notwendigen Informationen zum

Einbau und zum Umgang mit dem Produkt in diesem Handbuch bereit zu stellen. Da es

sich jedoch um ein komplexes Produkt mit vielfältigen Einsatzmöglichkeiten handelt,

können wir die Vollständigkeit der im Handbuch enthaltenen Informationen nicht

garantieren. Falls Sie weitere Informationen benötigen sollten, wenden Sie sich bitte an die

für Sie zuständige Geschäftsstelle von SMART EC.

Das Produkt wurde entwickelt, um die Sicherheitsanforderungen für SELV Geräte nach der

Norm EN 60950-1 für informationstechnische Einrichtungen zu erfüllen. Die Verwendung

des Produkts in einer anderen Anwendung erfordert eine Sicherheitsüberprüfung für diese

spezifische Anwendung.

Einbau, Wartung und Betrieb dürfen nur von durch SMART EC ausgebildetem oder im

Bereich Elektronik oder Elektrotechnik qualifiziertem Personal durchgeführt werden. Die in

diesem Handbuch enthaltenen Informationen dienen ausschließlich dazu, das Wissen von

Fachpersonal zu ergänzen, können dieses jedoch nicht ersetzen.

Halten Sie sich von stromführenden Leitungen innerhalb des Produktes fern. Entfernen Sie

auf keinen Fall Abdeckungen am Produkt. Nur werksseitig zugelassenes

Wartungspersonal oder anderweitig qualifiziertes Wartungspersonal darf Abdeckungen

entfernen, um Komponenten zu ersetzen oder andere Anpassungen vorzunehmen.

Installieren Sie keine Ersatzteile oder führen Sie keine unerlaubten Veränderungen am

Produkt durch, sonst verfällt die Garantie. Wenden Sie sich für Wartung oder Reparatur

bitte an die für Sie zuständige Geschäftsstelle von SMART EC. So stellen Sie sicher, dass

alle sicherheitsrelevanten Aspekte beachtet werden.

EMV

Das Produkt wurde in einem SMART EC Standardsystem getestet. Es erfüllt die für digitale

Geräte der Klasse A gültigen Grenzwerte in einem solchen System gemäß den FCCRichtlinien Abschnitt 15 bzw. EN 55022 Klasse B. Diese Grenzwerte sollen einen

angemessenen Schutz vor Störstrahlung beim Betrieb des Produktes in Gewerbe- sowie

Industriegebieten gewährleisten.

MVME2502 Installation and Use (6806800R96G) 23

Page 24

Sicherheitshinweise

Das Produkt arbeitet im Hochfrequenzbereich und erzeugt Störstrahlung. Bei

unsachgemäßem Einbau und anderem als in diesem Handbuch beschriebenen Betrieb

können Störungen im Hochfrequenzbereich auftreten.

Wird das Produkt in einem Wohngebiet betrieben, so kann dies mit grosser

Wahrscheinlichkeit zu starken Störungen führen, welche dann auf Kosten des

Produktanwenders beseitigt werden müssen. Änderungen oder Modifikationen am

Produkt, welche ohne ausdrückliche Genehmigung von SMART EC durchgeführt werden,

können dazu führen, dass der Anwender die Genehmigung zum Betrieb des Produktes

verliert. Boardprodukte werden in einem repräsentativen System getestet, um zu zeigen,

dass das Board den oben aufgeführten EMV-Richtlinien entspricht. Eine

ordnungsgemässe Installation in einem System, welches die EMV-Richtlinien erfüllt, stellt

sicher, dass das Produkt gemäss den EMV-Richtlinien betrieben wird. Verwenden Sie nur

abgeschirmte Kabel zum Anschluss von Zusatzmodulen. So ist sichergestellt, dass sich die

Aussendung von Hochfrequenzstrahlung im Rahmen der erlaubten Grenzwerte bewegt.

Warnung! Dies ist eine Einrichtung der Klasse A. Diese Einrichtung kann im Wohnbereich

Funkstörungen verursachen. In diesem Fall kann vom Betreiber verlangt werden,

angemessene Maßnahmen durchzuführen.

Betrieb

Sicherheitshinweise

Beschädigung des Produktes

Hohe Luftfeuchtigkeit und Kondensat auf der Oberfläche des Produktes können zu

Kurzschlüssen führen.

Betreiben Sie das Produkt nur innerhalb der angegebenen Grenzwerte für die relative

Luftfeuchtigkeit und Temperatur. Stellen Sie vor dem Einschalten des Stroms sicher, dass

sich auf dem Produkt kein Kondensat befindet.

Beschädigung von Schaltkreisen

Elektrostatische Entladung und unsachgemäßer Ein- und Ausbau des Produktes kann

Schaltkreise beschädigen oder ihre Lebensdauer verkürzen.

Bevor Sie das Produkt oder elektronische Komponenten berühren, vergewissern Sie sich,

daß Sie in einem ESD-geschützten Bereich arbeiten.

Fehlfunktion des Produktes

Schalter, die mit 'Reserved' gekennzeichnet sind, können mit produktionsrelevanten

Funktionen belegt sein. Das Ändern dieser Schalter kann im normalen Betrieb Störungen

auslösen.

Verstellen Sie nur solche Schalter, die nicht mit 'Reserved' gekennzeichnet sind. Prüfen

und ggf. ändern Sie die Einstellungen der nicht mit 'Reserved' gekennzeichneten Schalter,

evor Sie das Produkt installieren.

24 MVME2502 Installation and Use (6806800R96G)

Page 25

Installation

Datenverlust

Das Herunterfahren oder die Deinstallation eines Boards bevor das Betriebssystem oder

andere auf dem Board laufende Software ordnungsmemäss beendet wurde, kann zu

partiellem Datenverlust sowie zu Schäden am Filesystem führen.

Stellen Sie sicher, dass sämtliche Software auf dem Board ordnungsgemäss beendet

wurde, bevor Sie das Board herunterfahren oder das Board aus dem Chassis entfernen.

Beschädigung des Produktes

Fehlerhafte Installation des Produktes kann zu einer Beschädigung des Produktes führen.

Verwenden Sie die Handles, um das Produkt zu installieren/deinstallieren. Auf diese Weise

vermeiden Sie, dass das faceplate oder die Platine deformiert oder zerstört wird.

Beschädigung des Produktes und von Zusatzmodulen

Fehlerhafte Installation von Zusatzmodulen, kann zur Beschädigung des Produktes und

der Zusatzmodule führen.

Lesen Sie daher vor der Installation von Zusatzmodulen die zugehörige Dokumentation.

Sicherheitshinweise

Kabel und Stecker

Beschädigung des Produktes

Bei den RJ-45-Steckern, die sich an dem Produkt befinden, handelt es sich entweder um

Twisted-Pair-Ethernet (TPE) oder um E1/T1/J1-Stecker. Beachten Sie, dass ein

versehentliches Anschließen einer E1/T1/J1-Leitung an einen TPE-Stecker das Produkt

zerstören kann.

Kennzeichnen Sie deshalb TPE-Anschlüsse in der Nähe Ihres Arbeitsplatzes

deutlich als Netzwerkanschlüsse.

Stellen Sie sicher, dass die Länge eines mit Ihrem Produkt verbundenen TPE-

Kabels 100 m nicht überschreitet.

Das Produkt darf über die TPE-Stecker nur mit einem Sicherheits-

Kleinspannungs-Stromkreis (SELV) verbunden werden.

Bei Fragen wenden Sie sich an Ihren Systemverwalter.

MVME2502 Installation and Use (6806800R96G) 25

Page 26

Sicherheitshinweise

Batterie

Beschädigung des Blades

Ein unsachgemäßer Einbau der Batterie kann gefährliche Explosionen und

Beschädigungen des Blades zur Folge haben.

Verwenden Sie deshalb nur den Batterietyp, der auch bereits eingesetzt wurde und

befolgen Sie die Installationsanleitung.

Datenverlust

Wenn Sie die Batter ie austauschen, können die Zeiteinstellungen verloren gehen. Eine

Backupversorgung verhindert den Datenverlust während des Austauschs.

Wenn Sie die Batterie schnell austauschen, bleiben die Zeiteinstellungen möglicherweise

erhalten.

Datenverlust

Wenn die Batterie wenig oder unzureichend mit Spannung versorgt wird, wird der RTC

initialisiert.

Sicherheitshinweise

Tauschen Sie die Batterie aus, bevor sieben Jahre tatsächlicher Nutzung vergangen sind.

Schäden an der Platine oder dem Batteriehalter

Wenn Sie die Batterie mit einem Schraubendreher entfernen, können die Platine oder der

Batteriehalter beschädigt werden.

Um Schäden zu vermeiden, sollten Sie keinen Schraubendreher zum Ausbau der Batterie

verwenden.

Umweltschutz

Entsorgen Sie alte Batterien und/oder Blades/Systemkomponenten/RTMs stets gemäß der

in Ihrem Land gültigen Gesetzgebung, wenn möglich immer umweltfreundlich.

26 MVME2502 Installation and Use (6806800R96G)

Page 27

Introduction

1.1 Overview

The MVME2502 is a VME form-factor single-board computer based on the NXP® QorIQ®

P2020 dual core processor which features e500 cores delivering an excellent performanceto-power ratio.The board has wide range of I/O options and is designed for applications

such as industrial control, semiconductor process equipment, radar, sonar and

transportation signaling.

The MVME2502 is designed to work in VMEbus chassis with a 3-row backplane connector

environment with a reduced I/O capacity and reduced peripheral power. It is also designed

to work in a more modern and higher performance VME chassis environment with a 5-row

backplane connector in the 2eVME or the 2eSST protocol mode.

The main features of the MVME2502board are as follows:

NXP QorIQ P2020 based 6U form-factor VME board

– 1000MHz to 1.2 GHz core frequency

– 512KB L2 cache

Chapter 1

– Three 10/100/1000 Mbps enhanced three-speed Ethernet controllers

(eTSECs)

– Two PCI-E 1.0a x1 interface controller

– One PCI-E 1.0a x2 interface controller

– USB 2.0 interface

– Enhanced secure digital host controller

– DDR3 memory controller at 800MT/s

– SPI interface (four chip selects, but only two are used on the board)

– Programmable interrupt controller

Dual PMC/XMC sites

– Site1:

PMC supporting PCI-X 64/33 interface

XMC supporting PCI-E 1.0a x2 interface

– Site2:

SATA Drive Kit

2GB DDR3-800 soldered chip memory with ECC

IEEE 1101.10 compliant or SCANBE ejector handles

MVME2502 Installation and Use (6806800R96G) 27

Page 28

Introduction

Introduction

Extended temperature and rugged variants

The front panel I/O configuration consists of two RJ-45 10/100/1000BASE-T

Ethernet ports, PMC/XMC front panel I/O (optional) a USB 2.0 port, a Micro DB9

RS-232 serial console port, and a reset/abort switch. It also has an LED to signal

board failure and another LED that can be configured in the LED register.

The rear I/O includes support for VMEbus (Legacy VME, VME 64, VME64x, and

2eSST), rear PMC/XMC I/O with P4 I/O, RTM I/O (through VME P2), two

10/100/1000BASE-T Ethernet, four UART, and RTM I2C/Presence/Power.

Persistent data storage: 512KB MRAM

User Flash: 8GB eMMC solid state storage

Boot Flash

– 16 MB SPI Flash (2x 8MB)

– Supports crisis recovery

2

I

C devices

– Real-time clock

– Board temperature sensor

– 8 KB VPD EEPROM

– Two 64 KB User EEPROM

MVME721E rear transition module I/O

– Two Gigabit Ethernet interfaces

– PMC I/O from PMC1

Operating system

– Based from BSP provided by NXP which is based from standard Linux version

2.6.32-rc3.

– Development tool is ltib 9.1.1 (Linux Target Image Builder) from NXP

– VxWorks

Boot firmware: U-Boot-based firmware image in 16MB SPI Flash. This flash is split

into two 8MB chips.

VMEbus interface

Controller: Tsi148 PCI-X to VMEbus bridge with support for VME64 and 2eSST

protocols

CPLD: Watchdog, timers, and registers

28 MVME2502 Installation and Use (6806800R96G)

Page 29

1.2 Standard Compliances

The product is designed to meet the following standards:

Table 1-1 Board Standard Compliances

Standard Description

EN 60950-1/A11:2009

IEC 60950-1:2005 2nd Edition

CAN/CSA C22.2 No 60950-1

FCC Part 15, Subpart B, Class A (nonresidential)

ICES-003, Class A (non-residential)

EMC Directive 89/336/EEC

EN55022 Class B

EN55024

AS/NZS CISPR 22, Class A

EN300386

ETSI EN 300 019 series Environmental Requirements

Safety Requirements (legal)

EMC requirements (legal) on system level (predefined

SMART Embedded Computing system)

Introduction

Directive (EU) 2015/863 (amending

Annex II to Directive 2011/65/EU)

Directive on the restriction of the use of certain hazardous

substances in electrical and electronic equipment

(RoHS).

1.3 Mechanical Data

The following table provides the dimensions and the weight of the board.

Table 1-2 Mechanical Data

Feature Value

Height 233.44mm (9.2 inches)

Depth 160.0mm (6.3 inches)

Front Panel Height 261.8mm (10.3 inches)

Width 19.8mm (0.8 inches)

Max. Component Height 14.8mm (0.58 inches)

Weight 400 grams (ENP1), 700 grams (ENP2)

MVME2502 Installation and Use (6806800R96G) 29

Page 30

Introduction

1.4 Ordering Information

Refer to the data sheet for the MVME2502 for a complete list of available variants and

accessories. Refer to Appendix B, Related Documentation or consult your local SMART

Embedded Computing sales representative for the availability of other variants.

For technical assistance, documentation, or to report product damage or shortages,

contact your local SMART EC sales representative or visit

https://www.smartembedded.com/ec/support/

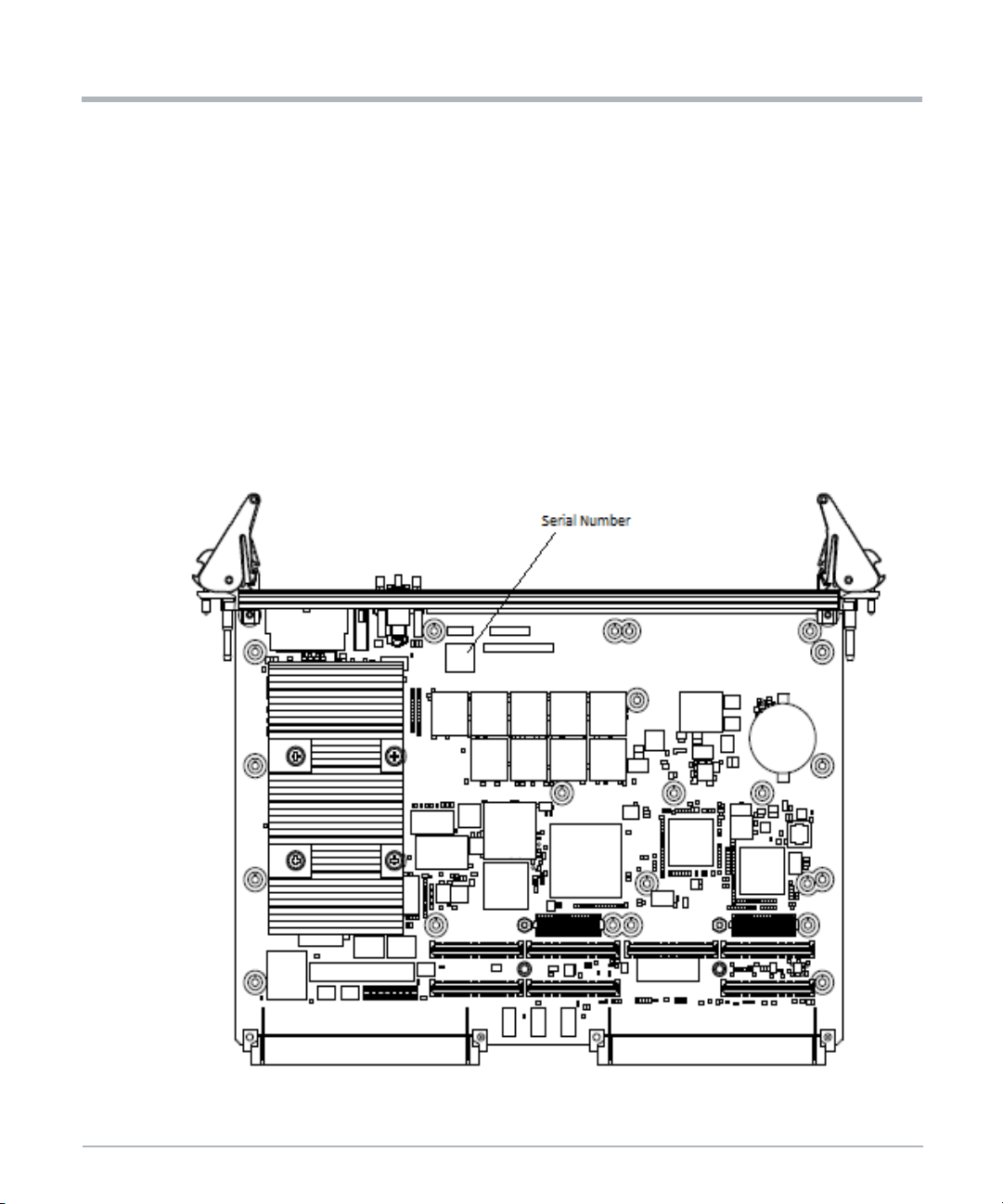

1.5 Product Identification

The following figures show the location of the serial number label.

Figure 1-1 Serial Number Location-ENP1 Variant

Introduction

30 MVME2502 Installation and Use (6806800R96G)

Page 31

Figure 1-2 Serial Number Location-ENP2 Variant

Introduction

MVME2502 Installation and Use (6806800R96G) 31

Page 32

Introduction

Introduction

32 MVME2502 Installation and Use (6806800R96G)

Page 33

Chapter 2

Hardware Preparation and Installation

2.1 Overview

This chapter provides unpacking instructions, hardware preparation, installation

procedures of the board. Installation instructions for the optional PMC/XMC modules and

transitions modules are also included.

A fully implemented MVME2502 consists of the base board and the following modules:

PCI Mezzanine Card (PMC) or PCI-E Mezzanine Card (XMC) for added versatility

Rear transition module

SATA kit

NOTE: MVME2502-HDMNKIT1/MVME2502-HDMNKIT2 is provided based on purchase

order.

The following are the steps to be performed before using the board. Be sure to read the

entire chapter, including all caution and warning notes, before you begin.

1. Unpack the hardware. Refer to Unpacking and Inspecting the Board on page 34.

2. Configure the hardware by setting jumpers on the board and the RTM. Refer to

Configuring the Board on page 37.

3. Install the rear transition module in the chassis. Refer to Rear Transition Module on

page 38.

4. Install PMC module (if required). Refer to PMC/XMC Support on page 39.

5. Install XMC span module (if required). Refer to PMC/XMC Support on page 39.

6. If purchased, install MVME2502-HDMNKIT1/MVME2502-HDMNKIT2. Refer to

Installation of MVME2502-HDMNTKIT1/MVME2502-HDMNTKIT2 on page 40.

7. Install the board in the chassis. Refer to Installing and Removing the Board on page 43.

8. Attach cables and apply power. Refer to Completing the Installation on page 44.

MVME2502 Installation and Use (6806800R96G) 33

Page 34

Hardware Preparation and Installation

Hardware Preparation and Installation

2.2 Unpacking and Inspecting the Board

Read all notices and cautions prior to unpacking the product.

NOTICE

Damage of Circuits

Electrostatic discharge and incorrect installation and removal can damage circuits

or shorten its life.

Before touching the board or electronic components, make sure that you are

working in an ESD-safe environment.

Shipment Inspection

To inspect the shipment, perform the following steps:

1. Verify that you have received all items of your shipment:

MVME2502 board

Quick Start Guide

Safety Notes Summary

Any optional items ordered

2. Check for damage and report any damage or differences to customer service.

3. Remove the desiccant bag shipped together with the board and dispose of it according

to your country’s legislation.

The product is thoroughly inspected before shipment. If any damage occurred during

transportation or any items are missing, contact customer service immediately.

2.3 Requirements

Make sure that the board meets the following requirements when operated in your

particular system configuration.

34 MVME2502 Installation and Use (6806800R96G)

Page 35

Hardware Preparation and Installation

2.3.1 Environmental Requirements

Operating temperatures refer to the temperature of the air circulating around the

board and not to the component temperature.

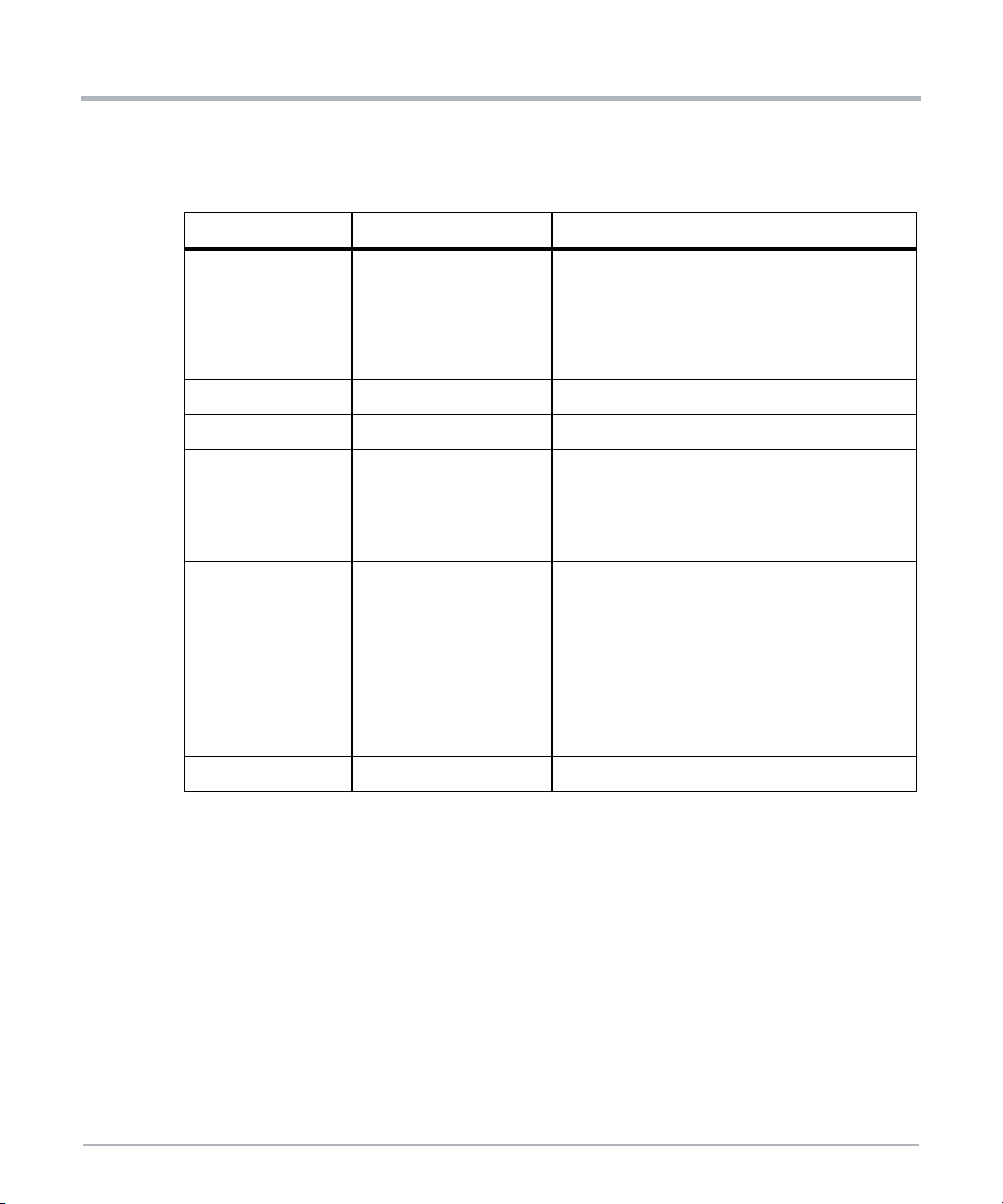

Table 2-1 Environmental Requirements

Characteristics Commercial Versions Extended Temperature Versions

Applicable Variants

Cooling Method

Operating Temperature 0°C to +55°C -40°C to +71°C

Storage -40°C to +85°C -50°C to +100°C

Vibration Sine

(10min/axis)

Vibration Random

(1hr/axis)

Shock 20g/11mS 30g/11mS

Humidity to 95% RH (non-condensing) to 100% RH (non-condensing)

1. ft3/min

2. Flat 15-1000Hz, -6db/octave 1000Hz - 2000Hz [MIL-STD 810F Figure 514.5C-17]

1

MVME2502-02120201E/S

MVME2502-02120202E/S

Forced Air Forced Air

2G, 5 to 500Hz 5G, 15 to 2000Hz

0.002g2/Hz, 15 to 2000Hz

MVME2502-02100202E

MVME2502-02100202S

0.04g2/Hz, 15 to 2000Hz

(8GRMS)

2

NOTICE

Product Damage

High humidity and condensation on the board surface causes short circuits.

Do not operate the board outside the specified environmental limits.

Make sure that the board is completely dry and there is no moisture on any surface

before applying power.

MVME2502 Installation and Use (6806800R96G) 35

Page 36

Hardware Preparation and Installation

2.3.2 Power Requirements

The board uses +5.0V from the VMEbus backplane. On-board power supply generates

required voltages for various ICs. The MVME2502 connects the +12V and -12V supplies

from the backplane to the PMC sites, while the +3.3V power supplied to the PMC sites

comes from the +5.0V backplane power. A maximum of 10A of +3.3V power is available to

the PMC sites, however the 90W +5.0V limit must be observed as well as any cooling

limitations.

The following table provides an estimate of the typical and maximum power required.

Table 2-2 Power Requirements

Hardware Preparation and Installation

Board Variant Maximum (Calculated)

MVME2502-02120201E 28.93W 21.8

MVME2502-02120201S 28.93W 21.8

MVME2502-02100202E 23.33W 16.6

MVME2502-02100202S 23.33W 16.6

The power is measured when the board is in standby (Linux prompt) mode. Power

will significantly increase when adding hard drives or a XMC/PMC card.

Typical (Measured

Operating)

The following table shows the power available when the MVME2502 is installed in either a

three row or five row chassis and when PMCs are present.

Chassis Type Available Power Power With PMCs

Three Row 70W maximum below 70W

Five Row 90W maximum below 90W

Keep below power limit. Cooling limitations must be considered.

36 MVME2502 Installation and Use (6806800R96G)

Page 37

Hardware Preparation and Installation

2.3.3 Equipment Requirements

The following are recommended to complete a MVME2502 system:

VMEbus system enclosure

System console terminal

Operating system (and/or application software)

Transition module and connecting cables

2.4 Configuring the Board

The board provides software control over most options. Settings can be modified to fit the

user's specifications. To configure, set the bits in the control register after installing the

board in a system. Make sure that all user-defined switches are properly set before

installing a PMC/XMC module. For more information, see Switches on page 67.

MVME2502 Installation and Use (6806800R96G) 37

Page 38

Hardware Preparation and Installation

2.5 Installing Accessories

2.5.1 Rear Transition Module

The MVME2502 does not support hot swap. Remove power to the rear slot or the system

before installing the module. A PCMI/O Module (PIM) needs to be manually configured and

installed before placing the transition module.

NOTICE

Damage of Circuits

Electrostatic discharge and incorrect installation and removal can damage circuits

or shorten its life.

Before touching the board or electronic components, make sure that you are

working in an ESD-safe environment.

Product Damage

Only use injector handles for board insertion to avoid damage to the front panel

and/or PCB. Deformation of the front panel can cause an electrical short or other

board malfunction.

Board Malfunction

Switches marked as “reserved” might carry production-related functions and can

cause the board to malfunction if their setting is changed.

Do not change settings of switches marked as “reser ved”. The setting of switches

which are not marked as “reserved” has to be checked and changed before board

installation.

Hardware Preparation and Installation

Installation Procedure

1. Turn OFF all equipment and disconnect the power cable from the AC power source.

2. Remove the chassis cover.

3. Remove the filler panel(s) from the appropriate card slot(s) at the rear of the chassis (if

the chassis has a rear card cage).

4. Install the top and bottom edge of the transition module into the rear guides of the

chassis.

5. Ensure that the levers of the two injector/ejectors are in the outward position.

6. Slide the transition module into the chassis until resistance is felt.

7. Move the injector/ejector levers in an inward direction.

38 MVME2502 Installation and Use (6806800R96G)

Page 39

8. Verify that the transition module is properly seated and secure it to the chassis using

two screws adjacent to the injector/ejector levers.

9. Connect the cables to the transition module.

Removal Procedure

1. Turn off the power.

2. Disconnect all the cables.

3. Press the red locking tabs (IEEE handles only) to eject the board.

4. Loosen and remove the screws adjacent to the injector/ejector levers that securing the

module to the chassis.

5. Move the injector/ejector levers in outward direction.

6. Slide the module from the chassis and make sure that no damage is caused to the pins.

7. Remove the transition module from the chassis and insert the filler panels.

2.5.2 PMC/XMC Support

Hardware Preparation and Installation

Installation Procedure

Read all notices and follow these steps to install a PMC on the baseboard.

NOTICE

Damage of Circuits

Electrostatic discharge and incorrect installation and removal can damage circuits

or shorten its life.

Before touching the board or electronic components, make sure that you are

working in an ESD-safe environment.

Product Damage

Inserting or removing modules with power applied may result in damage to module

components.

Before installing or removing additional devices or modules, read the

documentation that came with the product.

1. Attach an ESD strap to your wrist. Attach the other end of the strap to the chassis as a

ground. Make sure that it is securely fastened throughout the procedure.

2. Remove the PMC/XMC filler plate from the front panel cut-out.

MVME2502 Installation and Use (6806800R96G) 39

Page 40

Hardware Preparation and Installation

3. Slide the front bezel of the PMC/XMC into the front panel cut-out from backside. The

front bezel of the PMC/XMC module will be placed with the board when the connectors

on the module align with the connectors on the board.

4. Align the mating connectors properly and apply minimal pressure to the PMC/XMC until

it is seated to the board.

5. Insert the four PMC/XMC mounting screws through the mounting holes on the bottom

side of the board, and then thread the four mount points on the PMC/XMC. Fasten the

screws.

6. Install the board into the appropriate card slot. Make sure that the board is well seated

into the backplane connectors. Do not damage or bend connector pins.

7. Replace the chassis or system cover.

8. Reconnect the system to the power source and then turn on the system.

When removing the PMC/XMC, hold it by its long side and exert minimal force when

pulling it from the baseboard to prevent pin damage.

Hardware Preparation and Installation

2.5.3 Installation of MVME2502-HDMNTKIT1/MVME2502HDMNTKIT2

Installation Procedure

1. Attach washers and hex standoffs to HDD received with the MVME2502-HDMNTKIT1

or MVME2502-HDMNTKIT2.

40 MVME2502 Installation and Use (6806800R96G)

Page 41

Hardware Preparation and Installation

2. Assemble the SATA adapter board to the blade and ensure that it is properly aligned

with the standoff. Attach the screws to anchor the SATA adapter board to the blade.

NOTE: The 3.3V key must be removed to install the SATA kit.

3. Attach hex standoff to main board.

MVME2502 Installation and Use (6806800R96G) 41

Page 42

Hardware Preparation and Installation

4. Attach HDD with interface PCB to main board using screws as shown below:

Hardware Preparation and Installation

42 MVME2502 Installation and Use (6806800R96G)

Page 43

Hardware Preparation and Installation

2.6 Installing and Removing the Board

This section describes the recommended procedure for installing the board in a chassis.

Read all warnings and instructions before installing the board.

The MVME2502 does not support hot swap. Power off the slot or system and make sure

that the serial ports and switches are properly configured.

NOTICE

Damage of Circuits

Electrostatic discharge and incorrect installation and removal can damage circuits

or shorten its life.

Before touching the board or electronic components, make sure that you are

working in an ESD-safe environment.

Product Damage

Only use injector handles for board insertion to avoid damage to the front panel

and/or PCB. Deformation of the front panel can cause an electrical short or other

board malfunction.

Installation Procedure

1. Attach an ESD strap to your wrist. Attach the other end of the strap to an electrical

ground. Make sure that it is securely fastened throughout the procedure.

2. Remove VME filler panels from the VME enclosures, as appropriate.

3. Install the top and bottom edge of the board into the guides of the chassis.

4. Ensure that the levers of the two injector/ejectors are in the outward position.

5. Slide the board into the chassis until resistance is felt.

6. Simultaneously move the injector/ejector levers in an inward direction.

7. Verify that the board is properly seated and secure it to the chassis using the two

screws located adjacent to the injector/ejector levers.

8. Connect the appropriate cables to the board.

Removal Procedure

1. Turn off the power.

2. Disconnect all the cables.

3. Press the red locking tabs (IEEE handles only) to eject the board.

MVME2502 Installation and Use (6806800R96G) 43

Page 44

Hardware Preparation and Installation

4. Loosen and remove the screws adjacent to the injector/ejector levers that securing the

module to the chassis.

5. Move the injector/ejector levers in outward direction.

6. Hold top and bottom edges of the board and exert minimal force when pulling the board

from the chassis to prevent pin damage.

7. Carefully remove the board from the chassis and store the board in anti-static

envelope.

2.7 Completing the Installation

The board is designed to operate as an application-specific computer blade or an intelligent

I/O board/carrier. It can be used in any slot in a VME chassis. Once the board is installed,

you are ready to connect peripherals and apply power to the board.

NOTICE

Product Damage

RJ-45 connectors on modules are either twisted-pair Ethernet (TPE) or E1/T1/J1

network interfaces. Connecting an E1/T1/J1 line to an Ethernet connector may

damage your system.

Make sure that TPE connectors near your working area are clearly marked as

network connectors.

Verify that the length of an electric cable connected to a TPE bushing does not

exceed 100 meters.

Make sure the TPE bushing of the system is connected only to safety extra low

voltage circuits (SELV circuits).

If in doubt, ask your system administrator.

Hardware Preparation and Installation

The console settings for the MVME2502 are:

Eight bits per character

One stop bit per character

Parity disabled (no parity)

Baud rate of 9600 baud

Verify that hardware is installed and the power/peripheral cables connected are appropriate

for your system configuration.

Replace the chassis or system cover, reconnect the chassis to power source, and turn the

equipment power on.

44 MVME2502 Installation and Use (6806800R96G)

Page 45

Controls, LEDs, and Connectors

3.1 Board Layout

The following figure shows the components and connectors on the MVME2502 board.

Figure 3-1 Board Layout ENP1 Variant

Chapter 3

MVME2502 Installation and Use (6806800R96G) 45

Page 46

Controls, LEDs, and Connectors

Figure 3-2 Board Layout ENP2 Variant

Controls, LEDs, and Connectors

46 MVME2502 Installation and Use (6806800R96G)

Page 47

3.2 Front Panel

The following components are found on the MVME2502 ENP1 and ENP2 front panel.

Figure 3-3 Front Panel LEDs, Connectors and Switches

PMC/XMC 2

Controls, LEDs, and Connectors

PMC/XMC 1

USER 1

Serial Port

Reset Switch

FAIL

USB

ETH 1

ETH 2

MVME2502 Installation and Use (6806800R96G) 47

SPEED

ACT

SPEED

ACT

Page 48

Controls, LEDs, and Connectors

3.2.1 Reset Switch

The MVME2502 has a single push button switch that has both the abort and the reset

functions. Pressing the switch for less than three seconds generates an abort interrupt if

there is firmware that will read the GPIO2 (0xffdf0095) interrupt register. U-boot does not

implement any interrupts and also does not detect the interrupt or display anything when

the button is pressed.

Holding it down for more than three seconds will generate a hard reset. The VME

SYSRESET is generated if the MVME2502 is the VMEbus system controller.

3.3 LEDs

The MVME2502 utilize light emitting diodes (LEDs) to provide a visible status indicator on

the front panel. These LEDs show power failures, power up states, Ethernet link/speed,

Ethernet activity, SATA link and activity and PCIe valid lane status. There are few user

configurable LEDs. Each LED description is necessary for troubleshooting and debugging.

3.3.1 Front Panel LEDs

The front panel LEDs are shown in the next figure:

Controls, LEDs, and Connectors

Figure 3-4 Front Panel LEDs

PMC/XMC 2

PMC/XMC 1 USER 1 FAIL

SPEED

ETH 1

ACT

SPEED

ETH 2

ACT

Table 3-1 Front Panel LEDs

Label Function Location Color Description

Off

Yellow

USER 1 User Defined Front panel

Red

48 MVME2502 Installation and Use (6806800R96G)

By default

User Software Controllable. Refer to

the "User LED Register."

User Software Controllable. Refer to

the "User LED Register."

Page 49

Controls, LEDs, and Connectors

Table 3-1 Front Panel LEDs (continued)

Label Function Location Color Description

FAIL Board Fail Front panel

GENET1

SPEED

GENET1

ACT

GENET2

SPEED

GENET2

ACT

TSEC1

Link/Speed

TSEC1

Activity

TSEC2

Link/Speed

TSEC2

Activity

Front panel

Integrated

RJ-45 LED

Front panel

Integrated

RJ-45 LED

Front panel

Integrated

RJ-45 LED

(Left)

Front panel

Integrated

RJ-45 LED

Off

Red

Off

Amber

Green

Off

Blinking Green

Off

Amber

Green

Off

Blinking Green

Normal operation after successful

firmware boot.

One or more on-board power rails

has failed and the board has

shutdown to protect the hardware.

Normal during power up, during

hardware reset (such as a front

panel reset). May be asserted by the

BDFAIL bit in the Tsi148 VSTAT

register.

No link

10/100BASE-T operation

1000 BASE-T operation

No activity

Activity proportional to bandwidth

utilization

No link

10/100BASE-T operation

1000BASE-T operation

No activity

Activity proportional to bandwidth

utilization

MVME2502 Installation and Use (6806800R96G) 49

Page 50

Controls, LEDs, and Connectors

3.3.2 On-board LEDs

The on-board LEDs are listed below. The LEDs are located on the rear side of the board

just opposite of the battery location. To view the board, see Figure 3.1 on page 45.

Figure 3-5 On-board LEDs

Controls, LEDs, and Connectors

Table 3-2 On-board LEDs Status

Label Function Color Description

D9 Power Fail Red

D33 User Defined Amber

D34 User Defined Amber

D35 User Defined Amber

D36 Early Power Fail Amber This indicator is lit when the early 3.3V power supply fails.

D37 User Defined Amber Controlled by the CPLD

D38 User Defined Amber Controlled by the CPLD

50 MVME2502 Installation and Use (6806800R96G)

This indicator is illuminated when one or more of the onboard voltage rails fails.

Controlled by the CPLD. Used for boot-up sequence

indicator.

Controlled by the CPLD. Used for boot-up sequence

indicator.

Controlled by the CPLD. Used for boot-up sequence

indicator.

Page 51

3.4 Connectors

This section describes the pin assignments and signals for the connectors on the

MVME2502 board.

3.4.1 Front Panel Connectors

The following connectors are found on the outside of the MVME2502 board. These

connectors are divided between the front panel connectors and the backplane connectors.

The front panel connectors include the J1 and the J5 connectors. The backplane

connectors include the P1 and the P2 connectors.

3.4.1.1 RJ-45 with Integrated Magnetics (J1)

The MVME2502 uses an X2 RJ-45.

Table 3-3 Front Panel Tri-Speed Ethernet Connector (J1)

Pin Name Signal Description

1A GND

2A NC

Controls, LEDs, and Connectors

3A Port A TRD3 -

4A Port A TRD3 +

5A Port A TRD2 -

6A Port A TRD2 +

7A Port A TRD1 -

8A Port A TRD1 +

9A Port A TRD0 -

10A Port A TRD0 +

D1A Port A Green LED1 Anode / Yellow LED1 Cathode

D2A Port A Yellow LED1 Anode / Green LED1 Cathode

D3A Port A Green LED2 Anode / Yellow LED2 Cathode

D4A Port A Yellow LED2 Anode / Green LED2 Cathode

1B GND

2B NC

3B Port B TRD3 -

MVME2502 Installation and Use (6806800R96G) 51

Page 52

Controls, LEDs, and Connectors

Table 3-3 Front Panel Tri-Speed Ethernet Connector (J1) (continued)

Pin Name Signal Description

4B Port B TRD3 +

5B Port B TRD2 -

6B Port B TRD2 +

7B Port B TRD1 -

8B Port B TRD1 +

9B Port B TRD0 -

10B Port B TRD0 +

D1B Port B Green LED1 Anode / Yellow LED1 Cathode

D2B Port B Yellow LED1 Anode / Green LED1 Cathode

D3B Port B Green LED2 Anode / Yellow LED2 Cathode

D4B Port B Yellow LED2 Anode / Green LED2 Cathode

3.4.1.2 Front Panel Serial Port (J4)

Controls, LEDs, and Connectors

There is one front access asynchronous serial port interface labeled COMM1 that is routed

to the micro mini DB-9 front panel connector. A male-to-male micro-mini DB9 adapter cable

is available under SMART EC part number SERIAL-MINI-D (30-W2400E01A). The pin

assignments for these connectors are as follows:

Table 3-4 Front Panel Serial Port (J4)

Pin Signal Description

1NC

2RX

3TX

4NC

5 GND

6NC

7RTS

8 CTS

9NC

52 MVME2502 Installation and Use (6806800R96G)

Page 53

3.4.1.3 USB Connector (J5)

The MVME2502 uses upright USB receptacle mounted in the front panel.

Table 3-5 USB Connector (J5)

Pin Name Signal Description

1 +5V

2 Data -

3 Data +

4 GND

MTG Mounting Ground

MTG Mounting Ground

MTG Mounting Ground

MTG Mounting Ground

3.4.1.4 VMEBus P1 Connector

Controls, LEDs, and Connectors

The VME P1 connector is a 160-pin DIN. The P1 connector provides power and VME

signals for 24-bit address and 16-bit data. The pin assignments for the P1 connector is as

follows:

Table 3-6 VMEbus P1 Connector

Pin Row A Row B Row C Row D Row Z

1 DATA 0 BBSY DATA 8 +5V NC

2 DATA 1 BCLR DATA 9 GND GND

3 DATA 2 ACFAIL DATA 10 NC NC

4 DATA 3 BGIN0 DATA 11 NC GND

5 DATA 4 BGOUT0 DATA 12 NC NC

6 DATA 5 BGIN1 DATA 13 NC GND

7 DATA 6 BGOUT1 DATA 14 NC NC

8 DATA 7 BGIN2 DATA 15 NC GND

9 GND BGOUT2 GND GAP NC

10 SYSCLK BGIN3 SYSFAIL GA0 GND

MVME2502 Installation and Use (6806800R96G) 53