Page 1

MC1600 Extreme Edge Server

Installation and Use

P/N: 6806870A02B

January 2020

Page 2

© 2020 SMART Embedded Computing™, Inc.

All Rights Reserved.

Trademarks

The stylized "S" and "SMART" is a registered trademark of SMART Modular Technologies, Inc. and “SMART Embedded

Computing” and the SMART Embedded Computing logo are trademarks of SMART Modular Technologies, Inc. All other names

and logos referred to are trade names, trademarks, or registered trademarks of their respective owners. These materials are

provided by SMART Embedded Computing as a service to its customers and may be used for informational purposes only.

Disclaimer*

SMART Embedded Computing (SMART EC) assumes no responsibility for errors or omissions in these materials. These

materials are provided "AS IS" without warranty of any kind, either expressed or implied, including but not limited to,

the implied warranties of merchantability, fitness for a particular purpose, or non-infringement. SMART EC further does

not warrant the accuracy or completeness of the information, text, graphics, links or other items contained within these

materials. SMART EC shall not be liable for any special, indirect, incidental, or consequential damages, including without

limitation, lost revenues or lost profits, which may result from the use of these materials. SMART EC may make changes to

these materials, or to the products described therein, at any time without notice. SMART EC makes no commitment to update

the information contained within these materials.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another document as a

URL to a SMART EC website. The text itself may not be published commercially in print or electronic form, edited, translated,

or otherwise altered without the permission of SMART EC.

It is possible that this publication may contain reference to or information about SMART EC products, programming, or services

that are not available in your country. Such references or information must not be construed to mean that SMART EC intends

to announce such SMART EC products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following notice shall apply

unless otherwise agreed to in writing by SMART Embedded Computing.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in

Technical Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and

Documentation clause at DFARS 252.227-7014 (Jun. 1995).

SMART Embedded Computing, Inc.

2900 S. Diablo Way, Suite 190

Tempe, Arizona 85282

USA

*For full legal terms and conditions, visit

www.smartembedded.com/ec/legal

Page 3

Table of Contents

About this Manual ...............................................................11

Safety Notes....................................................................15

Notice de Sécurité ...............................................................25

Sicherheitshinweise .............................................................37

1 System Overview ............................................................49

1.1 Introduction .............................................................49

1.2 Front Panel Interfaces ....................................................49

1.3 Cooling ................................................................50

1.4 Grounding ..............................................................51

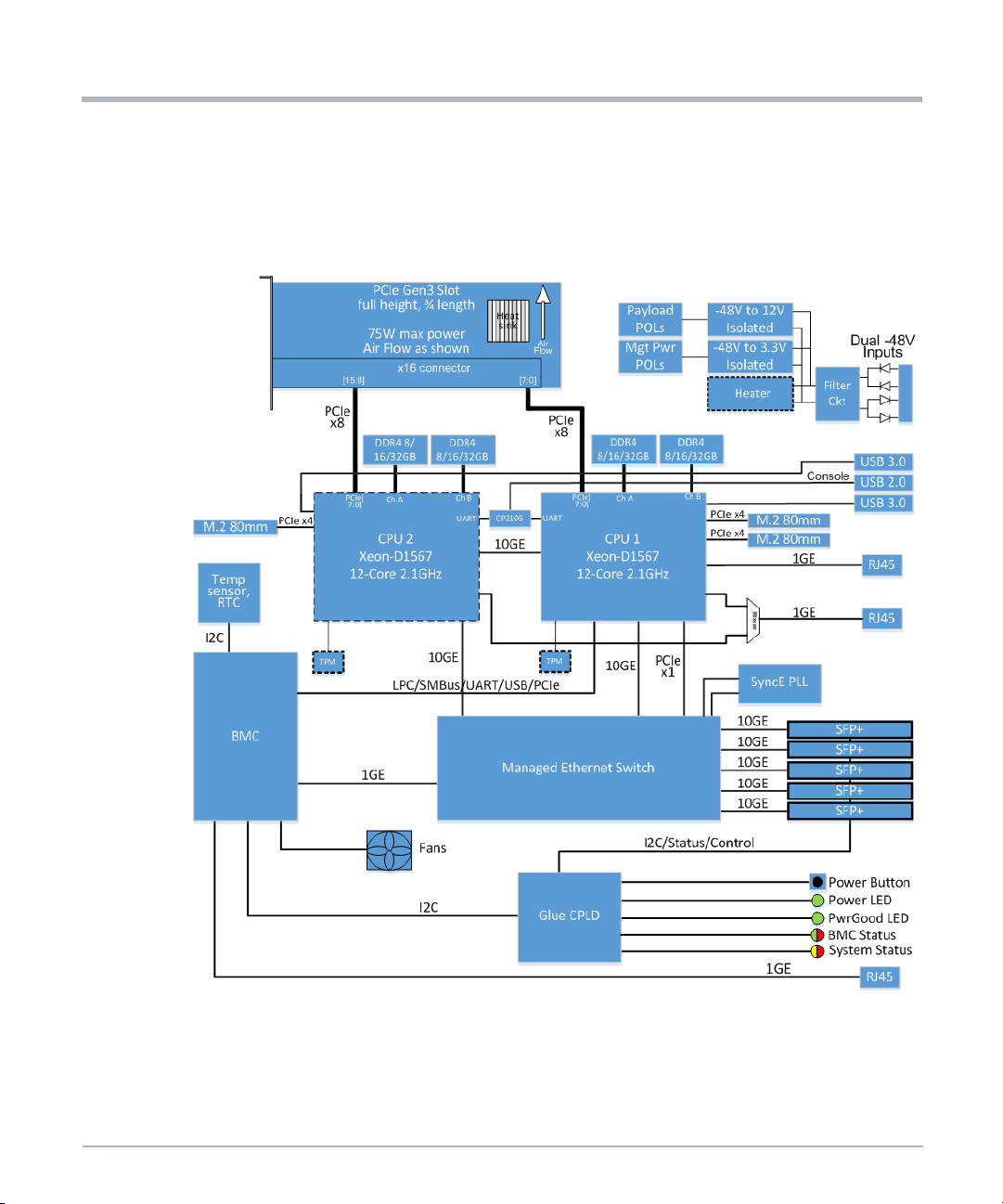

1.5 Block Diagram ..........................................................52

1.6 Extreme Edge Server Base Board ...........................................53

1.6.1 CPU SKU Support ..................................................54

1.6.2 Memory Controller ..................................................54

1.6.2.1 Real Time Clock ............................................55

1.6.2.2 Trusted Platform Module (TPM) ................................55

1.7 Interfaces ..............................................................55

1.7.1 PCI Express Interfaces ..............................................55

1.7.1.1 PCI Express Gen3 ..........................................55

1.7.1.2 PCI Express Gen2 ..........................................56

1.7.2 Ethernet Interface...................................................57

1.7.2.1 Gigabit Ethernet Controller ....................................57

1.7.2.2 PCIe-Based Gigabit Ethernet ..................................57

1.7.2.3 10 Gigabit Ethernet Controller .................................57

1.7.3 SPI Interface ......................................................57

1.7.4 USB Interface......................................................58

1.7.4.1 USB 3.0 Ports (xHCI) ........................................58

1.7.4.2 USB 2.0 Ports (EHCI) .......................................58

1.7.5 UART Interface ....................................................58

1.7.6 SMBus and I2C Interface .............................................59

1.7.7 LPC Interface ......................................................60

1.7.8 PECI Interface .....................................................60

1.8 10 Gigabit Ethernet .......................................................61

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 3

Page 4

Table of Contents

1.8.1 Ethernet Switch ....................................................61

1.8.2 SFP+ Ports........................................................62

1.8.3 Synchronous Ethernet and IEEE 1588 Support............................62

1.8.3.1 Synchronous Ethernet PLL ...................................62

1.8.3.2 IEEE 1588 Support .........................................63

1.9 PCIe Slot ...............................................................63

1.10 Storage ................................................................64

1.10.1 Supported NVMe Modules............................................64

1.11 Connectors .............................................................65

1.11.1 PCI Express Connector ..............................................65

1.11.2 -48V Power Connector...............................................68

1.11.3 SFP+ Module Connectors ............................................69

1.11.4 RJ-45 Ethernet Connectors ...........................................69

1.11.5 USB 2.0 Connector .................................................70

1.11.6 USB 3.0 Connectors ................................................70

1.11.7 DDR4 DIMM Connectors .............................................70

1.11.8 NVMe Module Connectors............................................74

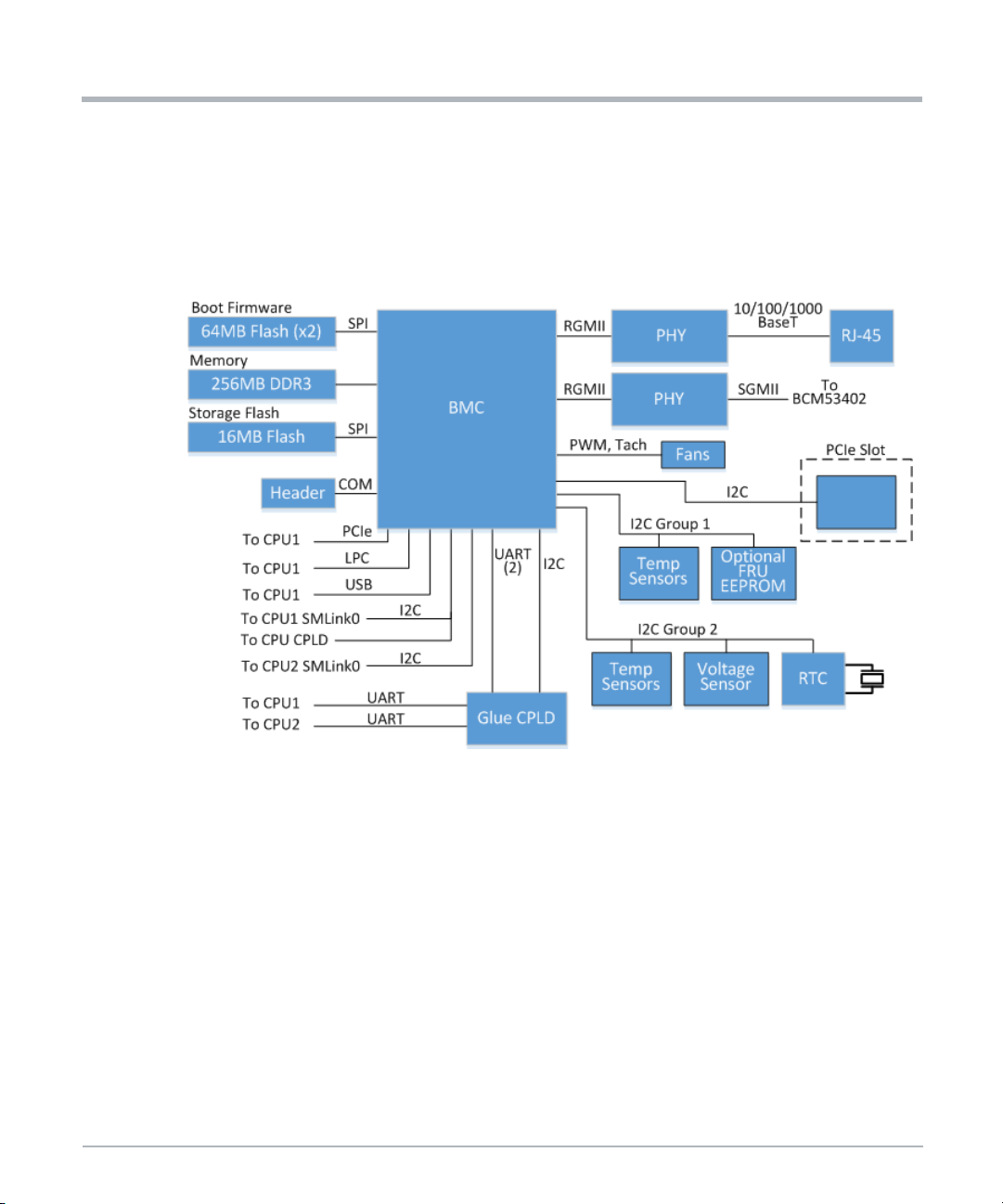

1.12 Baseboard Management Controller (BMC) ....................................76

1.12.1 BMC Subsystem Devices.............................................76

1.12.2 BMC Subsystem Features ............................................77

1.12.3 BMC Private I2C Buses ..............................................78

1.13 Programmable Logic ......................................................78

1.13.1 CPU CPLD ........................................................78

1.13.2 Glue CPLD ........................................................79

1.14 Power Supply ...........................................................80

1.14.1 Power Architecture..................................................80

1.14.2 Payload Power-Up Sequence .........................................80

1.14.3 -48V Power Domain.................................................81

1.14.3.1 Heater Circuit ..............................................81

1.15 Clock Structure ..........................................................81

1.15.1 Processor Clocks ...................................................81

1.15.2 Other Clocks ......................................................81

1.16 Reset Structure ..........................................................82

1.17 Debugging Support .......................................................82

1.17.1 POST Code Indicators ...............................................82

1.17.2 Dip Switches ......................................................82

1.18 Ordering and Support Information ...........................................82

4 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 5

Table of Contents

2 Site Preparation .............................................................83

2.1 Introduction .............................................................83

2.2 Unpacking the Extreme Edge Server .........................................83

2.3 Prepare the Installation Site ................................................83

2.3.1 Power Requirements ................................................84

2.3.2 Dimensions and Weight ..............................................84

2.4 ESD Prevention .........................................................85

2.5 Mounting Options ........................................................85

2.6 Electromechanical .......................................................86

2.7 Environmental ...........................................................86

2.7.1 Environmental Conditions ............................................86

2.7.2 Electronic Waste Disposal ............................................87

2.8 Regulatory Compliance ...................................................87

3 FRU Installation .............................................................89

3.1 Introduction .............................................................89

3.2 Install PCIe Card .........................................................89

3.3 SFP/SFP+ Modules ......................................................90

4 System Installation ...........................................................91

4.1 Introduction .............................................................91

4.2 Before Installation ........................................................91

4.3 Install the Extreme Edge Server in the Cabinet .................................91

4.3.1 Ground the Server ..................................................92

4.3.2 Connect to the Power Feed ...........................................92

4.3.3 Connect the Serial Console ...........................................93

4.3.4 Access the Console (BIOS and OS) ....................................93

4.3.5 4.3.5 Connection of a USB Device......................................94

4.3.6 Power Up .........................................................94

4.4 Removal ...............................................................94

4.4.1 Power Down the Server ..............................................94

4.4.2 Disconnect from the Power Feed.......................................95

4.4.3 Removing the Server ................................................95

5 Software Configuration .......................................................97

5.1 Introduction .............................................................97

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 5

Page 6

Table of Contents

5.2 Installed Software ........................................................97

5.2.1 Basic Blade Services (BBS)...........................................97

5.2.1.1 Default Network Configuration .................................97

5.2.1.2 Firmware Upgrade ..........................................99

5.2.1.2.1 BMC Upgrade .....................................99

5.2.1.2.2 BIOS Upgrade ....................................100

5.2.1.2.3 CPLD Upgrades ...................................102

5.2.1.2.4 CPU CPLD Upgrade Using fcu Utility: ..................103

5.2.1.3 Broadcom Switch ..........................................104

5.2.1.4 sfptool ...................................................108

5.2.2 Baseboard Management Controller (BMC) ..............................110

5.2.2.1 IPMI OEM Commands ......................................110

5.2.2.1.1 SMART EC IPMI OEM Command Summary .............111

5.2.2.1.2 Power Management ................................111

5.2.2.1.3 Chassis Power Policy ..............................114

5.2.2.1.4 Aggregated Temperature Sensors .....................116

5.2.2.1.5 Fan Control ......................................118

5.2.2.1.6 FRU Present State .................................118

5.2.2.1.7 Chassis Address Info ...............................120

5.2.3 AMI MegaRAC® Web GUI...........................................121

5.2.3.0.1 Invalid Certificate ..................................121

5.2.3.0.2 Login Page .......................................122

5.2.3.0.3 MegaRAC Dashboard ..............................122

A Related Documentation ......................................................123

6 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 7

List of Figures

Figure 1-1 Front Panel Connectors, PCIe Slot, LEDs, and Ground Point ................ 49

Figure 1-2 Front Panel LEDs .................................................. 49

Figure 1-3 Location of Serial and Assembly # Labels ...............................50

Figure 1-4 MC1600 Extreme Edge Server - Dual CPU Block Diagram ................. 52

Figure 1-5 High Level Broadwell-DE Block Diagram ................................ 53

Figure 1-6 CPU SMBus Architecture ........................................... 59

Figure 1-7 Synchronous Ethernet Clocking Architecture ............................ 62

Figure 1-8 BMC Block Diagram ................................................76

Figure 1-9 Power Architecture ................................................. 80

Figure 2-1 Location of Regulatory Labels ........................................88

Figure 5-1 Single CPU Variant ................................................ 98

Figure 5-2 Dual CPU Variant .................................................. 99

Figure 5-3 Insecure Connection Page - MegaRAC Web GUI ........................ 121

Figure 5-4 MegaRAC Login Page ............................................. 122

Figure 5-5 MegaRAC Dashboard ............................................. 122

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 7

Page 8

List of Figures

8 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 9

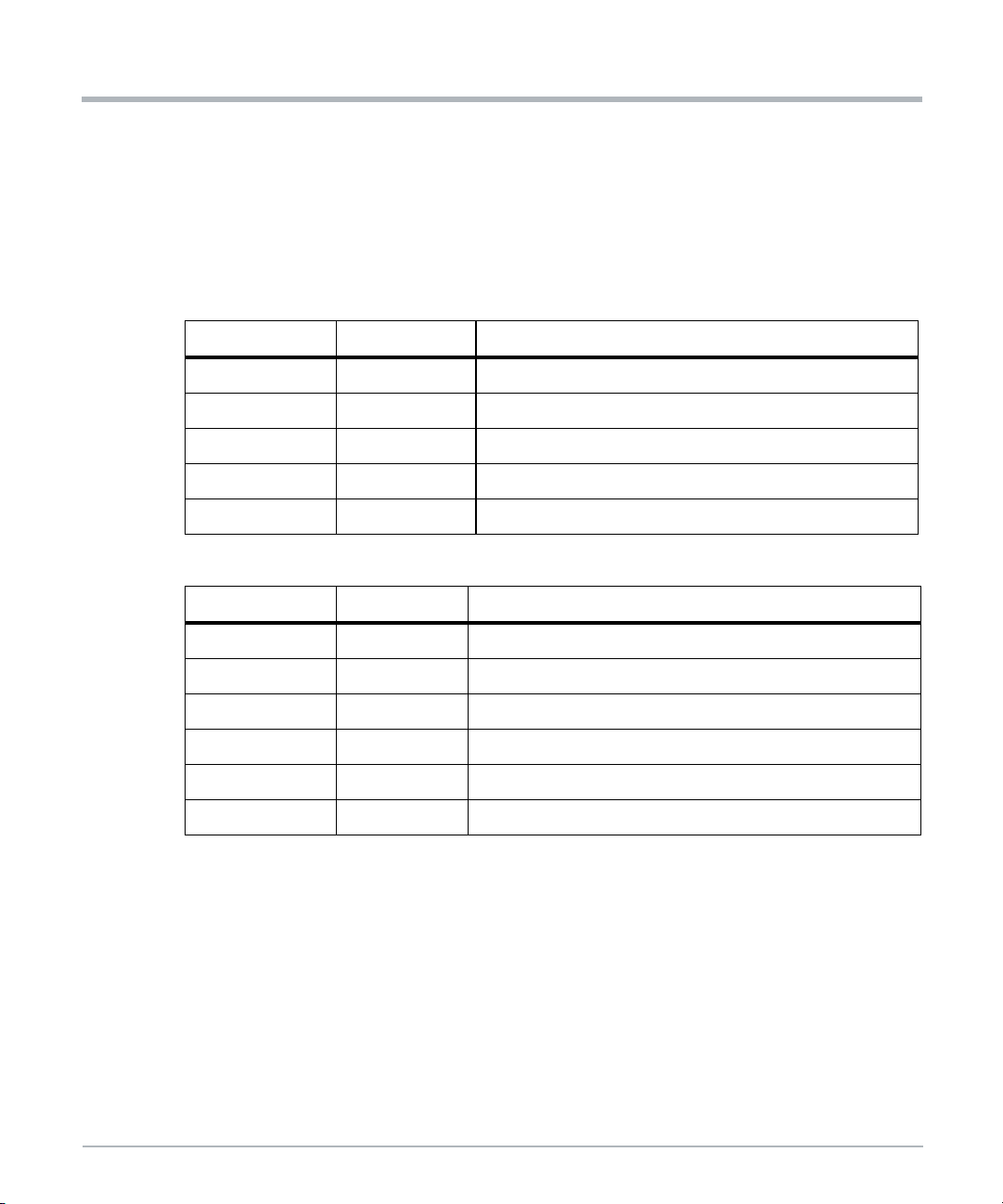

List of Tables

Table 1-1 Front Panel LED Description ............................................50

Table 1-2 CPU SKU Support ...................................................54

Table 1-3 ECC/Non-ECC DIMM Types ............................................54

Table 1-4 PCI Express Gen3 Interfaces to PCIe Connector ............................56

Table 1-5 PCI Express Gen3 Interfaces to M.2 Modules ..............................56

Table 1-6 PCI Express Gen2 (PCH) Interfaces ......................................56

Table 1-7 Ethernet Switch Port Assignments .......................................61

Table 1-8 M.2 NVMe Module Support ............................................64

Table 1-9 PCIe Slot Connector Pinout ............................................65

Table 1-10 Input Power Connector Pinout ..........................................68

Table 1-11 SFP+ Connector Pinout ...............................................69

Table 1-12 Ethernet RJ-45 Connector Pinout ........................................69

Table 1-13 USB 2.0 Connector Pinout .............................................70

Table 1-14 USB 3.0 Connector Pinout .............................................70

Table 1-15 DDR4 DIMM Pinout ..................................................70

Table 1-16 NVMe Module Pinout .................................................74

Table 1-17 BMC I2C Bus 8 Devices ...............................................78

Table 1-18 BMC I2C Bus 7 Devices ...............................................78

Table 2-1 System Power Requirements ...........................................84

Table 2-2 Dimensions and Weight of System .......................................84

Table 2-3 Environmental Conditions ..............................................86

Table 2-4 Regulatory Standards .................................................87

Table 4-1 Serial Port Configuration Parameters .....................................93

Table 5-1 Single CPU Variant ...................................................97

Table 5-2 Dual CPU Variant ....................................................98

Table 5-3 General OEM Command Structure ......................................111

Table 5-4 SMART EC IPMI OEM Command Summary ..............................111

Table 5-5 Set FRU Instance Power State ........................................112

Table 5-6 Get FRU Instance Power State .........................................113

Table 5-7 Set Chassis Power Policy .............................................114

Table 5-8 Get Chassis Power Policy .............................................115

Table 5-9 Set Aggregated Temperature Sensor ....................................117

Table 5-10 Get Aggregated Temperature Sensor ....................................118

Table 5-11 Get FRU Present State Version 0 .......................................119

Table 5-12 Get FRU Present State Version 1 .......................................119

Table 5-13 Set Chassis Address Info .............................................120

Table 5-14 Get Chassis Address Info .............................................120

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 9

Page 10

List of Tables

Table A-1 SMART EC Documentation ...........................................123

10 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 11

About this Manual

Overview of Contents

This manual is divided into the following sections.

Safety Notes on page 15 provides the safety information that should be observed while

operating the product.

Notice de Sécurité on page 25 provides a French translation of the safety notes section.

Sicherheitshinweise on page 37 provides a German translation of the safety notes section.

Chapter 1, System Overview on page 49 describes the MC1600 Extreme Edge Server’s

features and functionality. This chapter includes detail on front panel interfaces, cooling,

grounding, and the server’s base board. There is also information about the Baseboard

Management Controller (BMC) and ordering information.

Chapter 2, Site Preparation on page 83 provides information on unpacking the MC1600

Extreme Edge Server, safety precautions, and requirements for the product. Included are

the environmental and power requirements, mounting options, cooling considerations,

acoustic noise control, and dimensions and weight of the product.

Chapter 3, FRU Installation on page 89 describes the installation and removal of PCIe

cards and details of the SFP/SFP+ modules.

Chapter 4, System Installation on page 91 provides instructions for installing and removing

the MC1600 Extreme Edge Server in a rack or cabinet. It also gives information and

procedures for grounding, powering up and down, and disconnecting the server from the

power feed.

Chapter 5, Software Configuration on page 97 details about the preinstalled software and

firmware are presented in this chapter. CPU boot information and information on the Basic

Blade Services (BBS) which includes utilities for updating firmware and configuring

switches are described. System management and monitoring is discussed via the BMC

along with the standard IPMI implementation as well as some custom OEM commands.

Appendix A, Related Documentation on page 123 provides information on documentation

related to this product.

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 11

Page 12

l

About this Manual

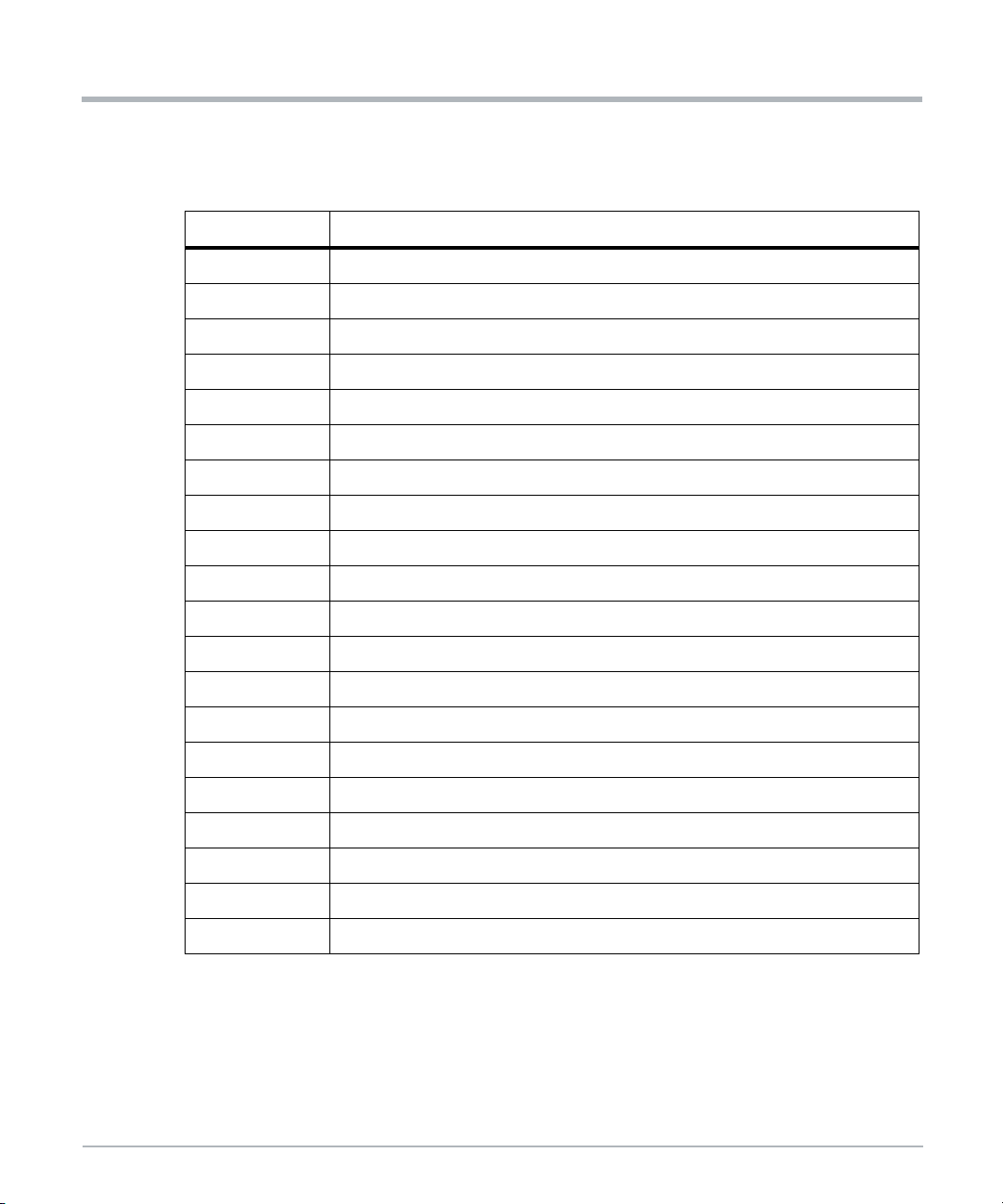

Abbreviations

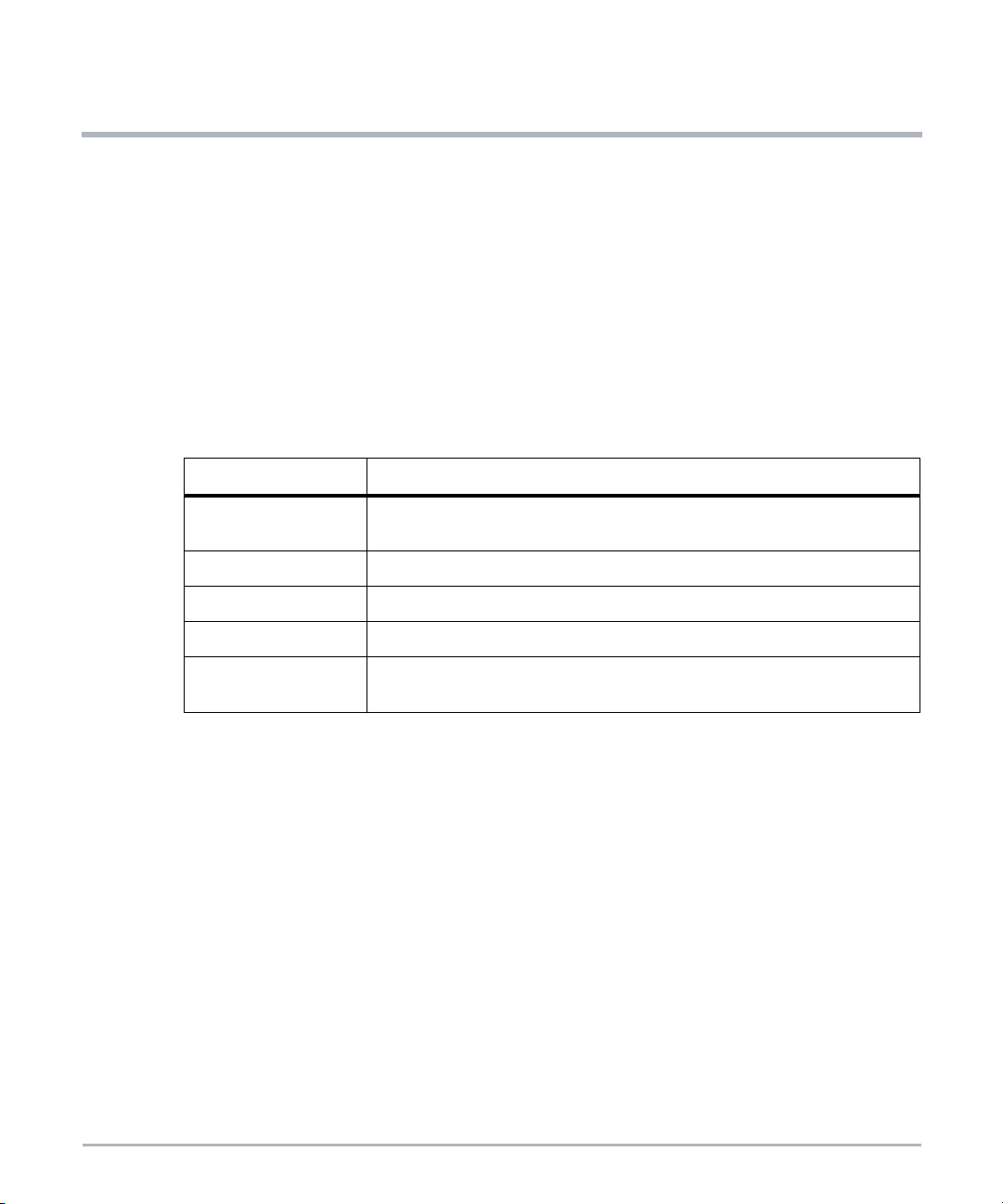

This document uses the following abbreviations:

Abbreviation Definition

BBS Basic Blade Services

BMC Baseboard Management Controller

BIOS Basic Input Output System

CPLD Complex Programmable Logic Device

CPU Central Processing Unit

EHCI Enhanced Host Controller Interface

ESD Electro-static Discharge

IIO Integrated IO

IPMI Intelligent Platform Management Interface

MISO Master Data In

About this Manua

MOSI Master Data Out

OEM Original Equipment Manufacturer

PCIe PCI Express

PEM Power Entry Module

SFP Small Form-factor Pluggable

SKU Stock Keeping Unit (Intel SKU Numeric Digits)

SPD Serial Presence Detection

SPI Serial Peripheral Interface

TPM Trusted Platform Module

xHCI eXtensible Host Controller Interface

12 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 13

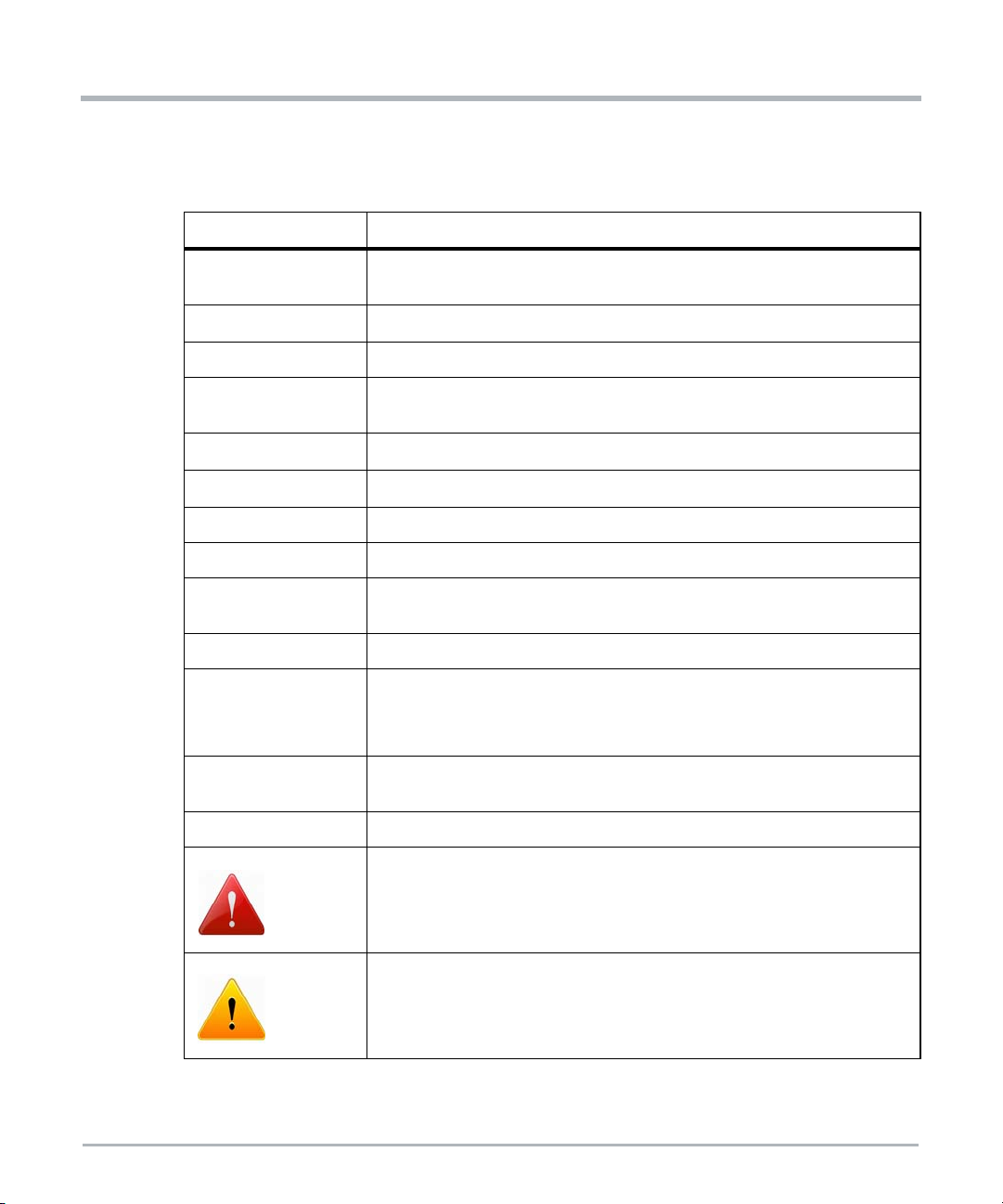

Conventions

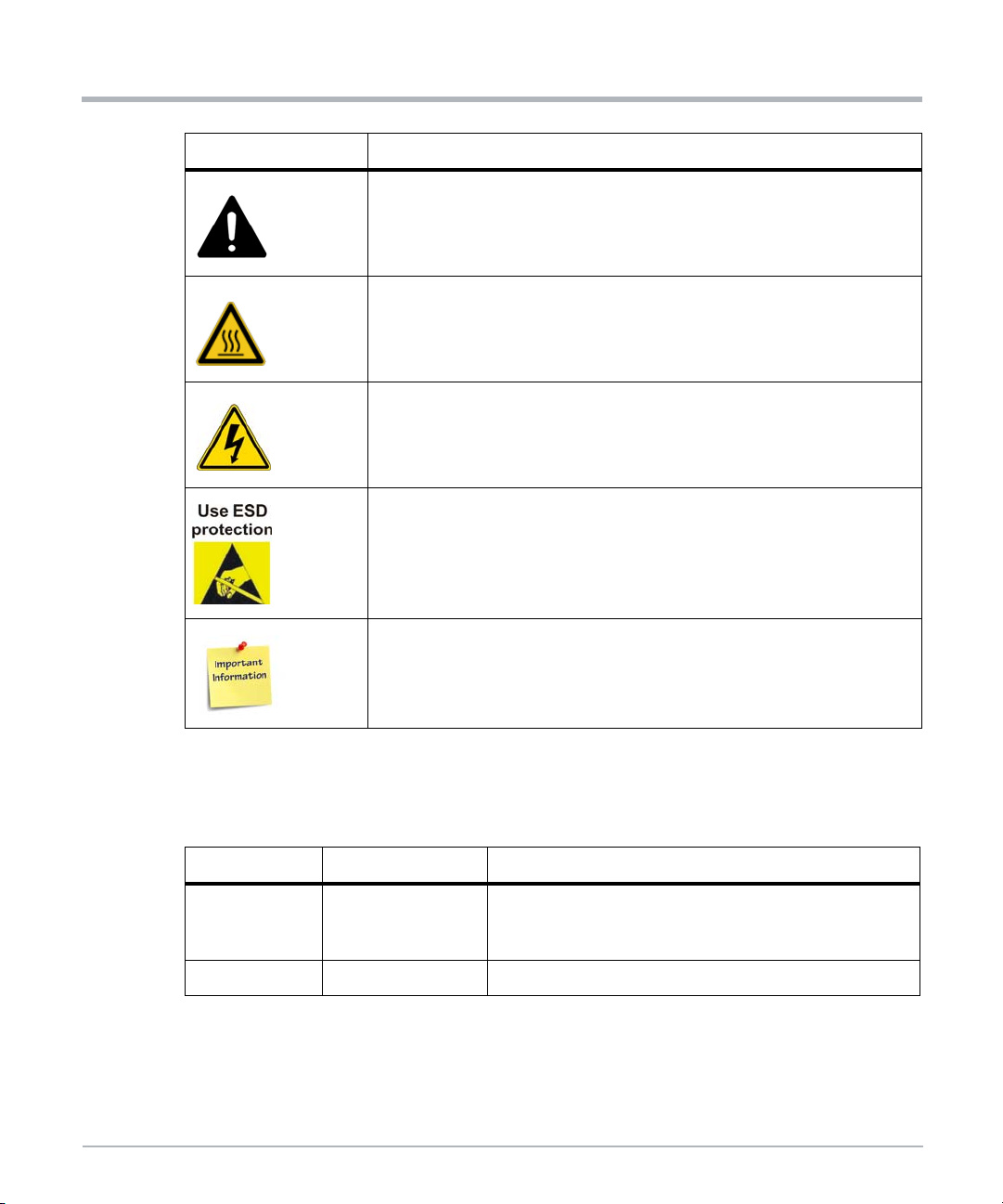

The following table describes the conventions used throughout this manual.

Notation Description

About this Manual

0x00000000

0b0000

bold Used to emphasize a word

Screen

Courier + Bold

Reference

File > Exit Notation for selecting a submenu

<text> Notation for variables and keys

[text]

... Repeated item for example node 1, node 2, ..., node 12

.

.

.

..

Typical notation for hexadecimal numbers (digits are 0 through F), for

example used for addresses and offsets

Same for binary numbers (digits are 0 and 1)

Used for on-screen output and code related elements or commands.

Sample of Programming used in a table (9pt)

Used to characterize user input and to separate it from system output

Used for references and for table and figure descriptions

Notation for software buttons to click on the screen and parameter

description

Omission of information from example/command that is not necessary at

the time

Ranges, for example: 0..4 means one of the integers 0,1,2,3, and 4 (used

in registers)

| Logical OR

Indicates a hazardous situation which, if not avoided, could result in death

or serious injury

Indicates a hazardous situation which, if not avoided, may result in minor

or moderate injury

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 13

Page 14

l

About this Manual

Notation Description

About this Manua

Indicates a property damage message

Indicates a hot surface that could result in moderate or serious injury

Indicates an electrical situation that could result in moderate injury or death

Indicates that when working in an ESD environment care should be taken

to use proper ESD practices

No danger encountered, pay attention to important information

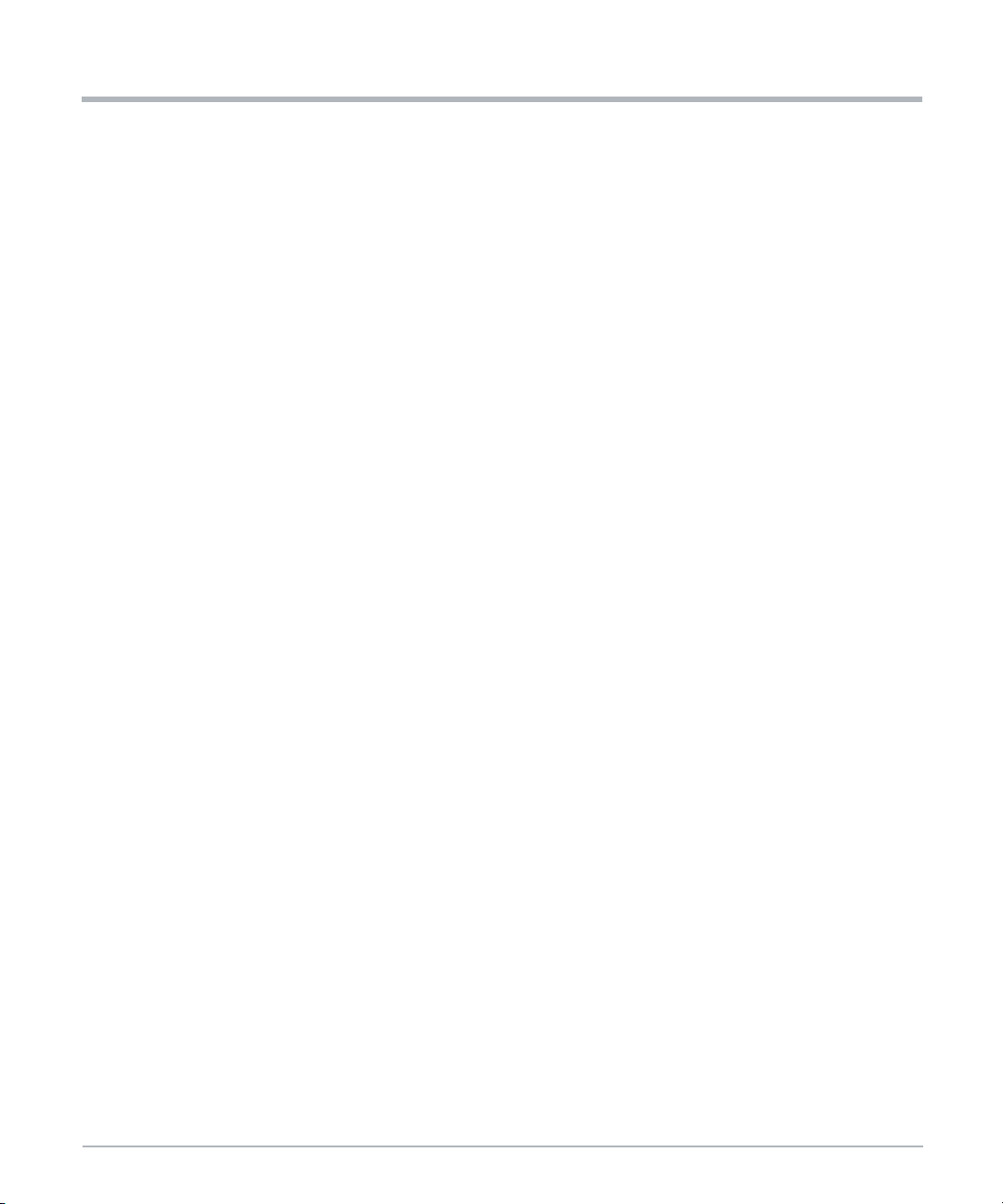

Summary of Changes

This manual has been revised and replaces all prior editions.

Part Number Publication Date Description

Rebrand to SMART Embedded Computing template.

6806870A02B January 2020

6806870A02A April 2019 Initial Release

14 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Updated Safety Notes in English and German; added

French Safety Notes.

Page 15

Safety Notes

This section provides warnings that precede potentially dangerous procedures throughout

this manual. Instructions contained in the warnings must be followed during all phases of

operation, service, and repair of this equipment. You should also employ all other safety

precautions necessary for the operation of the equipment in your operating environment.

Failure to comply with these precautions or with specific warnings elsewhere in this manual

could result in personal injury or damage to the equipment.

SMART Embedded Computing intends to provide all necessary information to install and

handle the product in this manual. Because of the complexity of this product and its various

uses, we do not guarantee that the given information is complete. If you need additional

information, ask your SMART EC representative.

The product has been designed to meet the standard industrial safety requirements. It must

not be used in safety critical components, life supporting devices, or on aircraft.

Only personnel trained by SMART EC or persons qualified in electronics or electrical

engineering are authorized to install, remove or maintain the product. The information given

in this manual is meant to complete the knowledge of a specialist and must not be used as

replacement for qualified personnel.

Keep away from live circuits inside the equipment. Operating personnel must not remove

equipment covers. Only factory authorized service personnel or other qualified service

personnel may remove equipment covers for internal subassembly or component

replacement or any internal adjustment.

Do not install substitute parts or perform any unauthorized modification of the equipment or

the warranty may be voided. Contact your local SMART EC representative for service and

repair to make sure that all safety features are maintained.

EMC

The product has been tested and found to comply with the limits for a Class A digital device

in this system, pursuant to part 15 of the FCC Rules, EN 55032 Class A respectively. These

limits are designed to provide reasonable protection against harmful interference when the

product is operated in a commercial, business or industrial environment.

The product conducts, radiates and uses radio frequency energy and, if not installed

properly and used in accordance with this user documentation, may cause harmful

interference to radio communications. Operating the product in a residential area is likely

to cause harmful interference. If this occurs, the user will be required to correct the

interference at the user's expense.

Changes or modifications not expressly approved by SMART EC could void the user's

regulatory compliance. Board products are tested in a representative system to show

compliance with the above mentioned requirements. A proper installation in a compliant

system will maintain the required performance.

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 15

Page 16

Safety Notes

Use only shielded cables when connecting peripherals to help assure that appropriate radio

frequency emissions compliance is maintained. For proper EMC shielding, only operate the

system with face plates installed and all vacant slots covered or populated with filler cards.

Grounding

If the product is not properly grounded, it may be damaged by electrostatic discharge.

The system contains EMI gaskets at the shelf and module level. Make sure that each of the

system's parts contact the EMI gasket.

The shelf is also fitted with an ESD jack/snap for use with conductive wrist straps. Make

sure the operator uses proper ESD protection.

This is a Class A product based on the standard of the Voluntary Control Council for

Interference by Information Technology Interference (VCCI). If this equipment is used in a

domestic environment, radio disturbance may arise. When such trouble occurs, the user

may be required to take corrective actions.

The equipment is suitable for installation in a Common Bonding Network (CBN) or Isolated

Bonding Network (IBN).

System Installation

Safety Notes

System Damage

To avoid system damage verify that the system environment meets the environmental and

power requirements given in this manual before installing the system. Before you set up

and cable your new system, consider these guidelines:

Restricted access location: Intended for installation in a restricted access location

with access by trained personnel only.

Detachable power supply cord set: The detachable power supply cord set is not

included in shipment. The detachable power supply cord set shall be an approved

type, acceptable to the authorities in the country where the equipment is installed.

Installation codes: Where applicable, this unit shall be installed in accordance with

the National Electrical Code (NEC).

Overcurrent protection: A readily accessible listed branch circuit overcurrent

protective device must be incorporated into the building wiring. For appropriate

AWG rating of the overcurrent protection device, see NEC Table 310.16 and other

national regulations.

The protective bonding conductor depends on your power distribution topology.

Make sure that you use an appropriate protective bonding conductor regarding the

rating of the branch circuit protection.

16 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 17

Safety Notes

Install the system safely. Make sure that cables and cords are out of the way.

Make sure that the set-up is comfortable for users.

System Damage

WARNING: The intra-building port (s) of the equipment or subassembly is suitable for

connection to intra-building or unexposed wiring or cabling only. The intra-building port (s)

of the equipment or subassembly MUST NOT be metalically connected to interfaces that

connect to the OSP or its wiring. These interfaces are designed for use as intra-building

interfaces only (Type 2 or Type 4 ports as described in GR-1089) and require isolation from

the exposed OSP cabling. The addition of primary protectors is not sufficient protection in

order to connect these interfaces metalically to OSP wiring.

System Damage

All interconnected equipment to this equipment (or to added subassemblies) is intended to

be within the same building. If this equipment (including any added subassemblies) is used

in inter-building connection, the connection shall be adequately protected against overvoltage/transient. And further Electrical Safety evaluation would be required.

System Damage

Environmental contamination can impair system operation.

Locate the system in a stable area free of excess movement and jarring and free of dust,

smoke, and electrostatic discharge (ESD). Make sure that the temperature does not

exceed the operating temperature given in the environmental requirements in this manual

and allow room for proper air flow for cooling.

Personal Injury or System Damage

A top-heavy rack can tip, causing damage to equipment and injury to personnel.

If your system is the only one in the rack, make sure to mount the system in the lowest part

of the rack. If several systems are installed in one rack, star t with the heaviest component

at the bottom. If the rack is equipped with stabilizing devices, make sure that they are

installed and extended so that the rack is secure. Then proceed to mount or service the

system.

Personal Injury or System Damage

Use caution when pulling the system out of the rack, as it could fall and cause personal

injury.

Personal Injury

The system is heavy and improper handling may lead to muscle strain or back injury.

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 17

Page 18

Safety Notes

System Damage

During handling, shipping, and assembly, it is possible that pins, mounting screws, fans,

and other items became loose or damaged.

Do not operate a damaged system, as it may damage the devices that interface with the

system.

Personal Injury

High leakage current can be hazardous and cause injury.

Make an earth ground connection before connecting power to the system.

System Damage

Wrong jumper settings can make the system inoperable. Never change the settings of the

jumpers.

Card Installation

Damage of Circuits

Electrostatic discharge and incorrect product installation and removal can damage circuits

or shorten their life.

Safety Notes

Before touching the product make sure that you are working in an ESD-safe environment.

Hold the product by its edges and do not touch any components or circuits.

Product Damage

Install PCI Express (PCIe) cards in the designated slots. Installing a card in the wrong slot

may cause card or system damage.

Installing or removing the card from the system while the system is powered up may

damage the card and the system.

When installing or removing the card from the system, power down the system first.

Data Loss

The MaxCore system does not support hot swap of PCIe cards. Before opening the top

cover of the system or before installing or removing any PCIe card, make sure the system

is powered off.

Disconnect the system from any AC or DC power or turn the system board power (payload

power) off through the Board Management Controller (BMC).

For more information, refer to the MC1600 Extreme Edge Server Installation and Use

manual.

18 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 19

Card Malfunctioning

Incorrect card installation and removal may result in card malfunction or damage the PCIe

slot. Ensure PCIe cards are properly seated.

Operation

System Overheating–Cooling Vents

Improper cooling can lead to card and system damage and may void the manufacturer’s

warranty.

To allow for proper cooling and undisturbed airflow through the system, always operate the

system in a horizontal position. Do not obstruct the ventilation openings at the front, rear,

or sides of the system. Keep the fresh air intake of the chassis completely clear. Make sure

that the fresh air supply is not mixed with hot exhaust from other devices.

Product Damage

High humidity and condensation on product surfaces causes short circuits.

Do not operate the system outside the specified environmental limits. Make sure the

system is completely dry and there is no moisture on any surface before applying power.

Do not star t the system below 0°C unless it is an extended-temperature model.

Safety Notes

Injury

Caution: The system may be equipped with multiple power feeds. All power connection

feeds must be disconnected to de-energize the system. To reduce the risk of personal

injury, disconnect the feeds when removing power from the system.

System Damage – Air Filters

Air contamination can pollute the air filter and obstruct the air intake of the system which

may cause system overheating and component damage.

To guarantee proper airflow through the system, replace the air filters (if equipped) at least

every six months. Artesyn recommends the air filters be replaced every 90 days.

Installations vary in physical location and cleanliness. Filter replacement may be required

more often in a dusty environment. Check air filters frequently after system installation to

determine how often they must be replaced. Establish a regular replacement schedule and

keep a log to record the date of each filter replacement.

Front Panel

The front panel, including the air filter (if equipped), is mounted to the system by alignment

pins and holding clips on both sides of the system. When mounting the front panel to the

shelf, align it accurately to avoid damage to the frame or front panel.

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 19

Page 20

Safety Notes

Earth Ground

This equipment is designed to permit the connection of the earthed conductor of the DC

supply circuit to the earthing conductor at the equipment. If this connection is made, all of

the following conditions must be met:

System Overheating

Safety Notes

This equipment shall be connected directly to the DC supply system earthing

electrode conductor or to a bonding jumper from an earthing terminal bar or bus to

which the DC supply system earthing electrode conductor is connected.

This equipment shall be located in the same immediate area (such as adjacent

cabinets) as any other equipment that has a connection between the earthed

conductor of the same DC supply circuit and the earthing conductor, and also the

point of earthing of the DC system. The DC system shall not be earthed elsewhere.

The DC supply source shall be located within the same premises as this

equipment.

Make sure you have an earth ground connection that is free of any disconnecting

device, such as a power switch or fuse, between the DC source and the earth

ground connector. A disconnecting device could result in the ground being

disconnected and the potential of injury from electrical shock.

If you set the fan speed manually through the Board Management Controller (BMC),

constantly monitor the system temperature to prevent overheating.

Make sure that the environmental and power requirements are met while operating the

system.

Injuries or Short Circuits

To avoid damage or personal injury, always check that no hazardous voltage is present

before servicing equipment.

Data Corruption

If power to the unit is removed while a firmware update is in progress to the product's flash

memory, the changes will not be saved or the flash memory may be corrupted. In such

case, the product is likely to remain in a non-operable state and will require reconditioning

by qualified repair services.

System Expansion

System Overload

To avoid an overload of the system, check the total power consumption of all components

installed. Make sure that the individual output current of any source stays within its

acceptable limits (see the technical specification of the respective source or component).

20 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 21

Loss of Safety Compliance–Using of Additional Plug-in Cards

The system may become noncompliant by the addition of plug-in cards. Regulatory

compliance is the responsibility of the system integrator.

Power Feed

Personal Injury

Touching the power feed with metallic objects on your hands, wrists, or hanging from your

neck may lead to severe personal injury through electric shock and burning when working

at the power feed or power input cables. Be extremely careful when using electrically

conductive tools near the PSUs/PEMs.

Short Circuits or Personal Injury

Make sure that the power feeds you plan to remove or attach are powered off and cannot

be switched on while you are working.

Make sure that all power feeds to the chassis are not energized. Be careful with the tools

used to prevent a short circuit.

Product Damage

Safety Notes

Improper cabling damages your product. Take extreme care not to reverse the polarity

when connecting the power cable.

Fans

System Damage

Insufficient cooling may damage the system.

When servicing, replace the fan tray (or fan modules) without delay.

Fan Replacement

When a fanis taken out of operation or is removed during a replacement procedure, system

management software may compensate for the loss by increasing the speed of any

remaining fans.

Running the fans at high speed for a long time may shorten the life of the fans and may

exceed allowable acoustic noise limits.

Replace the fan tray (or fan modules) without delay.

Personal Injury–Rotating Fans

Inserting tools or fingers into operational fans may cause personal injury.

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 21

Page 22

Safety Notes

Keep clear of the fans as long as they are rotating.

When the fan is removed, extreme care should be taken while handling the fan itself. The

centrifugal forces will make the unit difficult to handle.

Cabling

Personal Injury

The cabling should follow existing cable paths using existing or similar cable fastenings.

Never change the system's cabling as delivered by SMART EC. Check proper function of

the system after cabling extensions. To avoid personal injury, always ensure that cables

are securely installed so that no one can trip over them.

Personal Injury through Electric Shock

Touching contacts and cables during system operation can cause personal injury through

electric shock.

To avoid electric shock, make sure that contacts and cables of the system cannot be

touched while the system is operating. If in doubt concerning cabling, ask your local

SMART EC representative.

Safety Notes

Cable Damage

Do not fold cables. Folding a fiber cable damages the cable and inhibits the data

transmission.

RJ-45 Connector

System Damage

RJ-45 connectors on the system or on PCIe cards are either twisted-pair Ethernet (TPE) or

E1/T1/J1 network interfaces. Connecting an E1/T1/J1 line to an Ether net connector may

damage your system.

Make sure that TPE connectors near your working area are clearly marked as

network connectors.

Verify that the length of an Ethernet cable connected to a RJ-45 TPE connector

does not exceed 100 meters or approximately 328 feet.

Make sure the TPE connector of the system is connected only to Safety Extra Low

Voltage (SELV) circuits.

If in doubt, ask your system administrator.

For more information, see the documentation of the respective product.

22 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 23

Laser

Battery

Safety Notes

Personal Injury

If a label with the words CLASS 1 LASER PRODUCT is affixed to your system, the unit is

equipped with a laser device. These devices contain a laser system that produces visible

or invisible laser radiation (or both) and can be harmful to the eyes.

Seek supplemental information (power, wavelength, visibility, pulse duration, applicable

standards) prior to servicing equipment. Do not look at laser device with an optical

instrument at any time.

Blade Damage

Incorrect battery installation may result in a hazardous explosion and blade damage.

Always use the same type of lithium battery as is installed and make sure the battery is

installed as described in the manual.

Data Loss

Installing another battery type than the one mounted at product delivery may cause data

loss.

PCB and Battery Holder Damage

Do not use a screw driver to remove the batter y from its holder. Removing the battery with

a screw driver may damage the PCB or the battery holder.

Environment

Environmental Damage

Improper disposal of used products may harm the environment.

Always dispose of used products according to your country’s legislation and

manufacturer’s instructions.

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 23

Page 24

Safety Notes

Safety Notes

24 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 25

Notice de Sécurité

Cette section présente, à travers ce manuel, des avertissements qui précèdent les

procédures potentiellement dangereuses. Les instructions contenues dans les

avertissements doivent être suivies durant toutes les phases d’opération, de service et de

réparation de cet équipement. Vous devriez aussi employer toute autre précaution

nécessaire pour l’utilisation de l’équipement dans l’environnement d’opération. Le défaut

de se conformer à ces précautions ou aux avertissements spécifiques contenus ailleurs

dans ce manuel, peut engendrer des lésions corporelles ou dommages à l’équipement.

SMART Embedded Computing prévoit dans ce manuel de fournir toute l’information

nécessaire pour installer et manipuler le produit. En raison de la complexité de ce produit

et de ses diverses utilisations, nous ne pouvons pas garantir que les informations fournies

sont complètes. Si vous avez besoin d'information supplémentaire, contactez votre

représentant SMART EC.

Le produit a été conçu pour répondre aux exigences de sécurité standards de l’industrie. Il

ne doit pas être utilisé dans des composantes critiques pour la sécurité, des appareils de

maintien de vie ou sur un aéronef.

Seul le personnel formé par SMART EC ou les personnes qualifiées dans le domaine

de l'électronique ou du génie électrique sont autorisés à installer, retirer ou faire l’entretien

du produit. Les informations contenues dans ce manuel sont destinées à compléter les

connaissances d’un spécialiste et ne peuvent être utilisées en remplacement de personnel

qualifié.

Ne touchez pas les circuits sous tension à l'intérieur de l'équipement. Le personnel

d’opération ne doit pas enlever les couvercles de l’équipement. Seul le personnel de

maintenance autorisé par l'usine ou autre personnel de maintenance qualifié peut retirer

les couvercles des équipements pour le sous-assemblage interne ou pour le remplacement

de composantes, ou pour tout réglage interne.

N'installez aucune pièce de remplacement et n'effectuez aucune modification non

autorisée de l'équipement, sinon, la garantie pourrait être annulée. Contactez votre

représentant SMART EC local pour le service et la réparation, afin de vous assurer que

toutes les fonctions de sécurité soient maintenues.

Compatibilité électromagnétique (CEM)

Le produit a été testé et est déclaré conforme aux limites imposées à un appareil

numérique de classe A dans ce système, conformément à la section 15 de la

Réglementation FCC, EN 55032 classe A, respectivement. Ces limites sont conçues pour

offrir une protection raisonnable contre les interférences néfastes lorsque le produit est

utilisé dans un environnement commercial ou industriel.

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 25

Page 26

Notice de Sécurité

Le produit conduit, émet et utilise de l'énergie à radiofréquence et, s'il n'est pas installé

correctement et utilisé conformément à cette documentation de l’utilisateur, il peut causer

des interférences néfastes aux communications radio. Opérer ce produit dans une région

résidentielle est susceptible de causer des interférences néfastes. Si cela se produit,

l’utilisateur devra corriger les interférences à ses frais.

Les changements ou les modifications qui ne sont pas expressément approuvés par

SMART EC pourraient annuler la conformité réglementaire de l'utilisateur. Les cartes sont

testées dans un système représentatif pour démontrer la conformité aux exigences

mentionnées ci-dessus. Une installation adéquate dans un système conforme maintiendra

les performances requises.

Utilisez uniquement des câbles blindés lorsque vous connectez des périphériques pour

vous assurer que la conformité aux normes d'émission de radiofréquences est respectée.

Pour un blindage CEM adéquat, utilisez le système uniquement avec les plaques frontales

installées et tous les ports d’extension vacants couverts ou équipés de cartes obturatrices.

Mise à la terre

Si le produit n’est pas adéquatement mis à la terre, il peut être endommagé par une

décharge électrostatique.

Le système contient des joints EMI au niveau des étagères et des modules. Assurez-vous

que chacune des pièces du système est en contact avec le joint EMI.

Notice de Sécurité

L'étagère est également équipée d'une prise/déclic ESD pour une utilisation avec des

dragonnes conductrices. Assurez-vous que l'opérateur utilise la protection de décharge

électrostatique ESD appropriée.

Ceci est un produit de classe A basé sur la norme du Conseil volontaire de contrôle des

interférences (VCCI) par Information Technology Interference (Interférence des

technologies de l'information). Si cet équipement est utilisé dans un environnement

domestique, des perturbations radio peuvent survenir. Lorsque de tels problèmes

surviennent, l'utilisateur peut être amené à prendre des mesures correctrices.

L'équipement peut être installé dans un réseau de liaison équipotentielle (CBN) ou un

réseau de liaison isolé (IBN).

Installation du Système

Endommagement du système

Pour éviter tout endommagement du système, vérifiez que l’environnement du système

correspond aux exigences de puissance et environnementale fournies dans ce manuel,

avant d’installer le système. Afin de commencer l’installation et le câblage de votre

nouveau système, tenez compte de ces instructions :

26 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 27

Notice de Sécurité

Lieu à accès restreint : Conçu pour l’installation dans des lieux à accès restreint

avec un accès par du personnel compétent uniquement.

Cordon d'alimentation amovible: le cordon d'alimentation amovible n'est pas inclus

dans la livraison. Le cordon d'alimentation détachable doit être d'un type approuvé,

accepté par les autorités du pays où l'équipement est installé.

Codes d'installation: le cas échéant, cette unité doit être installée conformément

au Code national de l'électricité (NEC).

Protection contre la surintensité : Un dispositif de protection contre les

surintensités de circuit dérivé facilement accessible, doit être intégré au câblage

du bâtiment. Pour connaître le calibre AWG approprié du dispositif de protection

contre les surintensités, voir le tableau NEC, tableau 310.16, et les autres

réglementations nationales.

Le conducteur de liaison protecteur dépend de votre topologie de distribution

d’alimentation. Assurez-vousd’utiliser un conducteur de liaison protecteur adéquat

en ce qui concerne la valeur de la protection du circuit de dérivation.

Installez le système de façon sûre. Assurez-vous que les câbles et les cordons

soient hors de portée.

Assurez-vous que la configuration soit confortable pour les utilisateurs.

Endommagement du système

AVERTISSEMENT: le port intra-bâtiment de l'équipement ou du sous-ensemble convient

uniquement pour la connexion à un câblage intra-bâtiment ou à un filage non exposé

uniquement. Le por t intra-bâtiment de l'équipement ou du sous-ensemble NE DOIT PAS

être relié métalliquement à des interfaces qui se connectent à l'installation extérieure (OSP)

ou à son filage. Ces interfaces sont conçues pour être utilisées uniquement comme

interfaces intra-bâtiment (ports de type 2 ou de type 4 décrits dans le document GR-1089)

et nécessitent une isolation du câblage OSP exposé. L'ajout de protecteurs primaires ne

constitue pas une protection suffisante pour connecter ces interfaces de manière

métallique au câblage OSP.

Endommagement du système

Tous les équipements interconnectés à cet équipement (ou à des sous-ensembles ajoutés)

sont conçus pour être situés dans le même bâtiment. Si cet équipement (y compris tous

sous-ensembles ajoutés) est utilisé en connexion inter-bâtiments, la connexion doit être

correctement protégée contre les surtensions/transitoires. Une évaluation plus poussée de

la sécurité électrique serait requise..

Endommagement du système

La contamination environnementale peut nuire à l’opération du système.

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 27

Page 28

Notice de Sécurité

Placez le système dans une zone stable, sans excès de mouvement ni de coups,

poussière, fumée ou décharges électrostatiques (ESD).

Assurez-vous que la température ne dépasse pas la température de fonctionnement

indiquée dans les exigences environnementales de ce manuel, et laissez suffisamment de

place pour un flux d’air adéquat en vue du refroidissement.

Lésions corporelles ou endommagement du système

Un support lourd peut basculer, causant des dommages à l'équipement et des lésions

corporelles.

Si votre système est le seul du support, veillez à le monter dans la partie la plus basse du

support. Si plusieurs systèmes sont installés dans un seul support, commencez par la

composante la plus lourde placée en bas. Si le support est équipé de dispositifs de

stabilisation, assurez-vous qu'ils sont installés et déployésde façon à ce que le support soit

sécurisé. Ensuite, procédez au montage ou à la maintenance du système.

Lésions corporelles ou endommagement du système

Soyez prudent lorsque vous tirez le système de son support, puisqu’il peut tomber et

causer des lésions corporelles.

Lésions corporelles

Notice de Sécurité

Le système est lourd et une manipulation non conforme peut mener à une déchirure

musculaire ou une blessure dos.

Endommagement du système

Durant la manipulation, la livraison ou l’assemblage, il est possible que les broches, les vis,

les ventilateurs ou autres articles puissent se desserrer ou s’endommager.

N’opérez pas un système endommagé, puisqu’il peut endommager l’appareil qui sert

d’interface au système.

Lésions corporelles

Une fuite de courant élevé peut être dangereuse et causer des blessures

Effectuez une connexion de mise à la terre avant de connecter le bloc d'alimentation.

Endommagement du système

De mauvais réglages de câbles de démarrage peuvent rendre le système inutilisable. Ne

modifiez jamais les paramètres des câbles de démarrage.

28 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 29

Installation de la Carte

Endommagement des circuits

Les décharges électrostatiques, ainsi que l’installation inadéquate et le retrait du produit

peuvent endommager les circuits ou réduire leur durée de vie

Avant de toucher au produit, assurez-vous que vous travaillez dans un environnement

exempt de décharge électrostatique. Tenez le produit par ses extrémités et ne touchez

aucune composante ou circuit.

Endommagement du produit

Installez les cartes PCI Express (PCIe) dans les ports d’extension désignés. Installer une

carte dans le mauvais port d’extension peut causer des dommages à la carte ou au

système.

L’installation ou le retrait de la carte du système alors que le système est sous tension peut

endommager la car te et le système.

Lorsque vous installez ou retirez la carte du système, mettez en premier lieu le système

hors tension.

Perte de données

Notice de Sécurité

Le système MaxCore ne prend pas en charge le remplacement à chaud des cartes PCIe.

Avant d'ouvrir le couvercle supérieur du système ou avant d'installer ou de retirer une carte

PCIe, assurez-vous que le système est hors tension.

Déconnectez le système de toute alimentation CA ou CC ou mettez la carte système

(alimentation de la charge utile) hors tension via le Contrôleur de gestion de carte (BMC).

Pour plus d’information, référez-vous au manuel MC1600 Extreme Edge Server Installation

and Us.

Mauvais fonctionnement de la carte

L’installation ou le retrait inadéquat de la carte peut causer un mauvais fonctionnement de

la carte ou un dommage au port d’extension PCIe. Assurez-vous que les cartes PCIe sont

adéquatement installées.

Opération du Système

Surchauffe du système – Évents de refroidissement

Un refroidissement inadéquat peut endommager la carte et le système et annuler la

garantie fabricant.

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 29

Page 30

Notice de Sécurité

Pour permettre un refroidissement adéquat et une aération constante, opérez toujours le

système dans une position horizontale. N’obstruez pas les ouvertures de ventilation audevant, derrière ou sur les côtés du système. Gardez l’apport en air frais du châssis

complètement dégagé. Assurez-vous que l’apport d’air frais ne se mélange pas avec les

émanations de d’autres appareils.

Endommagement du produit

Une humidité élevée et la condensation sur la surface du produit crée des courts-circuits.

N’opérez pas le système en dehors des limites environnementales spécifiées. Assurezvous que le système soit complètement sec et qu'il n'y ait pas d'humidité sur aucune

surface, avant de mettre sous tension. Ne démarrez pas le système en dessous de 0 ° C

sauf s'il s'agit d'un modèle à température étendue.

Blessure

Avertissement : Le système peut être équipé de multiples PSUs. Toute source

d’alimentation de connexion doit être déconnectée pour mettre le système hors tension.

Pour réduire les risques de lésions corporelles, débranchez les sources lorsque vous

mettez le système hors tension.

Endommagement du système – Filtres à air

Notice de Sécurité

Une contamination de l’air peut polluer le filtre à air et obstruer l’apport en air du système

ce qui peut causer une surchauffe du système et endommager ses composantes.

Pour garantir une aération constante à travers le système, remplacez les filtres à air (si

équipé) au moins à tous les six mois. Artesyn recommande que les filtres à air soient

remplacés tous les 90 jours.

L’installation varie selon le lieu physique et la propreté. Le remplacement des filtres peut

être requis plus fréquemment dans un environnement poussiéreux. Vérifiez les filtres à air

fréquemment après l’installation du système pour déterminer à quelle fréquence ils doivent

être remplacés. Établissez un calendrier régulier de remplacement et gardez un registre de

la date de remplacement du filtre.

Panneau avant

Le panneau avant, incluant le filtre à air (si équipé), est monté au système par alignement

de broches et de clips de fixation des deux côtés du système. Lors du montage du panneau

avant sur l'étagère, alignez-le avec précision pour éviter d'endommager le cadre ou le

panneau avant.

Terre

Cet équipement est conçu pour permettre la connexion du conducteur mis à la terre du

circuit d'alimentation en CC au conducteur de mise à la terre de l'équipement. Si cette

connexion est établie, toutes les conditions suivantes doivent être remplies :

30 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 31

Notice de Sécurité

Cet équipement doit être connecté directement au conducteur de l’électrode de

mise à la terre du système d’alimentation en courant continu, ou à un cavalier de

mise à la terre d’une barre de terminal de mise à la terre ou d’un bus auquel

l’électrode du système d’alimentation en courant continu est connecté.

Cet équipement doit être situé dans la zone immédiate (telle que les armoires

adjacentes) de tout autre équipement ayant une connexion entre le conducteur mis

à la terre du même circuit d'alimentation en CC et le conducteur de terre, et

également du point de mise à la terre du système CC. Le système CC ne doit être

mis à la terre nulle part ailleurs.

La source d'alimentation en CC doit être située au même endroit que cet

équipement.

Assurez-vous que la connexion de mise à la terre soit exempte de tout dispositif

de déconnexion, tel qu'un commutateur d'alimentation ou un fusible, entre la

source CC et le connecteur de mise à la terre. Un dispositif de déconnexion

pourrait entraîner la déconnexion de la mise à la terre et un risque potentiel de

blessure par choc électrique.

Surchauffe du système

Si vous sélectionnez manuellement la vitesse du ventilateur [par le Contrôleur de gestion

de carte (BMC), surveillez constamment la température du système pour prévenir toute

surchauffe.

Assurez-vous que les exigences environnementales et de puissance sont rencontrés

lorsque vous opérez le système.

Blessures ou courts-circuits

Pour éviter tout dommage ou lésions corporelles, vérifiez toujours qu’aucun voltage

dangereux ne soit présent avant de réparer l’équipement.

Corruption des données

Si l'appareil est mis hors tension alors qu'une mise à jour du microprogramme est en cours

dans la mémoire flash du produit, les modifications ne seront pas enregistrées ou la

mémoire flash pourrait être corrompue. Dans un tel cas, le produit restera probablement

dans un état inutilisable et nécessitera un reconditionnement par des services de

réparation qualifiés.

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 31

Page 32

Notice de Sécurité

Expension du Système

Surcharge du système

Pour éviter une surcharge du système, vérifiez la consommation de puissance totale de

toutes les composantes installées. Assurez-vous que le courant de sortie individuelle de

toute source reste dans les limites acceptables (voir les spécifications techniques de la

source ou du composant correspondant).

Conformité de perte de sécurité - Utilisation de cartes enfichables supplémentaires

Le système peut devenir non conforme en ajoutant des cartes enfichables. La conformité

réglementaire est de la responsabilité de l'intégrateur de système.

Alimentation Électrique

Lésions corporelles

Toucher la source d'alimentation avec des objets métalliques sur les mains, les poignets

ou accrochés au cou peut entraîner des lésions corporelles graves par choc électrique et

brûlure lors du travail sur l’alimentation électrique ou les câbles d'alimentation. Soyez

extrêmement prudent lorsque vous utilisez des outils électriquement conducteurs à

proximité des blocs d’alimentation/module d’entrée d’alimentation.

Notice de Sécurité

Courts-circuits ou lésions corporelles

Assurez-vous que l’alimentation électrique que vous prévoyez de retirer ou attacher soit

hors tension et qu’elle ne peut pas être activée pendant que vous travaillez.

Assurez-vous que toutes les alimentations du châssis ne sont pas sous tension. Soyez

prudent en utilisant les outils utilisés pour prévenir les courts-circuits.

Endommagement du produit

Un calibrage non conforme peut endommager votre produit. Faites extrêmement attention

de ne pas renverser la polarité lorsque vous connectez le fil d’alimentation.

Ventilateurs

Endommagement du système

Un refroidissement insuffisant peut endommager le système.

Nehmen Sie deshalb den Austausch ohne Verzögerung vor.

32 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 33

Câblage

Notice de Sécurité

Remplacement de la ventilation

Lorsqu'un ventilateur est mis hors service ou est retiré au cours d'une procédure de

remplacement, le logiciel de gestion du système peut compenser cette perte en

augmentant la vitesse des ventilateurs restants.

Faire fonctionner les ventilateurs à haute vitesse pendant une longue période peut en

réduire la durée de vie et dépasser les limites de bruit admissibles.

Remplacez le plateau de ventilation (ou les modules de ventilation) sans délai.

Lésions corporelles – ventilateurs rotatifs

L'insertion d'outils ou de doigts dans les ventilateurs en marche peut causer des lésions

corporelles.

Restez à l'écar t des ventilateurs aussi longtemps qu'ils tournent.

Lorsque vous retirez le ventilateur, faites très attention lorsque vous le manipulez. Les

forces centrifuges rendront l'unité difficile à manipuler.

Lésions corporelles

Le câblage doit suivre les chemins de câbles existants en utilisant des fixations de câbles

existantes ou similaires. Ne changez jamais le câblage du système tel que fourni par

SMART EC. Vérifiez le bon fonctionnement du système après les extensions de câblage.

Pour éviter les lésions corporelles, assurez-vous toujours que les câbles soient

correctement installés de manière à ce que personne ne puisse trébucher dessus.

Lésion corporelle par choc électrique

Toucher les contacts et les câbles durant le fonctionnement du système peut provoquer

des lésions corporelles par choc électrique.

Pour éviter tout choc électrique, assurez-vous que les contacts et les câbles du système

ne peuvent pas être touchés pendant le fonctionnement du système. En cas de doute sur

le câblage, contactez votre représentant SMART EC local.

Dommages au câble

Ne pas plier les câbles. Le fait de plier un câble à fibre optique endommage le câble et

empêche la transmission des données.

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 33

Page 34

Notice de Sécurité

Les Connecteurs RJ-45

Endommagement du système

Les connecteurs RJ-45 du système ou des cartes PCIe sont des interfaces réseau

Ethernet à paire torsadée (TPE) ou E1/T1/J1. La connexion d'une ligne E1/T1/J1 à un

connecteur Ethernet peut endommager votre système.

Assurez-vous que les connecteurs TPE situés près de votre zone de travail soient

clairement identifiés comme étant des connecteurs réseau.

Vérifiez que la longueur d'un câble Ethernet connecté à un connecteur TPE ne

dépasse pas 100 mètres (environ 328 pieds).

Assurez-vous que le connecteur TPE du système soit uniquement connecté aux

circuits de sécurité très basse tension (SELV).

En cas de doute, demandez à votre administrateur de système.

Pour plus d'informations, voir la documentation du produit respectif.

Laser

Lésions corporelles

Notice de Sécurité

Batterie

Si une étiquette avec les mots PRODUIT LASER DE CLASSE 1 est apposée sur votre

système, l’unité est équipée d’un appareil laser. Ces appareils contiennent un système

laser qui produit des rayonnements visibles ou invisibles (ou les deux) et peut être nocif

pour les yeux.

Recherchez de l’information supplémentaire (puissance, longueur d'onde, visibilité, durée

d'impulsion, normes applicables) avant de faire le maintien de l'équipement. Ne regardez

jamais un appareil laser avec un instrument optique.

Endommagement de la lame

Une installation inadéquate de la batterie peut causer un risque d’explosion ou

d’endommagement de la lame.

Utilisez toujours le même type de batterie au lithium tel qu’installé et assurez-vous que la

batterie soit installée tel que décrit dans le manuel.

Perte de données

L'installation d'un autre type de batterie que celle montée à la livraison du produit peut

causer une perte de données.

34 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 35

Endommagement du PCB ou du support de batterie

N’utilisez pas de tournevis pour retirer la batterie de son support. Retirer la batterie avec

un tournevis peut endommager le PCB ou le support de batterie.

Environnement

Dommage Environnemental

Une disposition impropre des produits usagés peut être nocif pour l’environnement.

Éliminez les produits usagés toujours conformément à la législation de votre pays et aux

instructions du fabricant.

Notice de Sécurité

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 35

Page 36

Notice de Sécurité

Notice de Sécurité

36 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 37

Sicherheitshinweise

Dieses Kapitel enthält Hinweise, die potentiell gefährlichen Prozeduren innerhalb dieses

Handbuchs vorrangestellt sind. Beachten Sie unbedingt in allen Phasen des Betriebs, der

Wartung und der Reparatur des Systems die Anweisungen, die in diesen Hinweisen

enthalten sind. Sie sollten außerdem alle anderen Vorsichtsmaßnahmen treffen, die für den

Betrieb des Produktes innerhalb Ihrer Betriebsumgebung notwendig sind. Wenn Sie diese

Vorsichtsmaßnahmen oder Sicherheitshinweise, die an anderer Stelle diese Handbuchs

enthalten sind, nicht beachten, kann das Verletzungen oder Schäden am Produkt zur Folge

haben.

SMART Embedded Computing ist darauf bedacht, alle notwendigen Informationen zum

Einbau und zum Umgang mit dem Produkt in diesem Handbuch bereit zustellen. Da es sich

jedoch um ein komplexes Produkt mit vielfältigen Einsatzmöglichkeiten handelt, können wir

die Vollständigkeit der im Handbuch enthaltenen Informationen nicht garantieren. Falls Sie

weitere Informationen benötigen sollten, wenden Sie sich bitte an die für Sie zuständige

Geschäftsstelle von SMART EC.

Das Produkt wurde so entwickelt, dass es die Anforderungen für die von der Industrie

geforderten Sicherheitsvorschriften erfüllt. Es darf nicht in sicherheitskritischen

Komponenten, lebenserhaltenden Geräten oder in Flugzeugen verwendet werden.

Einbau, Wartung und Betrieb dürfen nur von durch SMART EC ausgebildetem oder im

Bereich Elektronik oder Elektrotechnik qualifiziertem Personal durchgeführt werden. Die in

diesem Handbuch enthaltenen Informationen dienen ausschließlich dazu, das Wissen von

Fachpersonal zu ergänzen, können dieses jedoch nicht ersetzen.

Halten Sie sich von stromführenden Leitungen innerhalb des Produktes fern. Entfernen Sie

auf keinen Fall Abdeckungen am Produkt. Nur werksseitig zugelassenes

Wartungspersonal oder anderweitig qualifiziertes Wartungspersonal darf Abdeckungen

entfernen, um Komponenten zu ersetzen oder andere Anpassungen vorzunehmen.

Installieren Sie keine Ersatzteile oder führen Sie keine unerlaubten Veränderungen am

Produkt durch, sonst verfällt die Garantie. Wenden Sie sich für Wartung oder Reparatur

bitte an die für Sie zuständige Geschäftsstelle von SMART EC. So stellen Sie sicher, dass

alle sicherheitsrelevanten Aspekte beachtet werden.

EMV

Das Produkt wurde getestet und erfüllt die für digitale Geräte der Klasse A gültigen

Grenzwerte gemäß den FCC-Richtlinien Abschnitt 15 bzw. EN 55032 Klasse A.Diese

Grenzwerte sollen einen angemessenen Schutz vor Störstrahlung beim Betrieb des

Produktes in einer gewerblichen, geschäftlichen oder industriellen Umgebung

gewährleisten.

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 37

Page 38

Sicherheitshinweise

Das Produkt leitet, strahlt und verwendet Hochfrequenzenergie und kann, wenn es nicht

ordnungsgemäß installiert und in Übereinstimmung mit dieser Bediehnungsanweisung

verwendet wird, schädliche Störungen des Funkverkehrs verursachen. Der Betrieb des

Produkts in einem Wohnbereich verursacht wahrscheinlich schädliche Interferenzen. In

diesem Fall muss der Benutzer die Störung auf seine Kosten beheben.

Änderungen oder Modifikationen, die nicht ausdrücklich von SMART EC genehmigt

wurden, können einzuhaltene Normen oder Vorschriften verletzen. Board Produkte werden

in einem repräsentativen System getestet, um die Einhaltung der oben genannten

Anfordernungen zu gewährleisten. Um die Leistungsfähigkeit zu erhalten is eine

ordungsgemäße Installation in einem konformen System erforderlich.

Um sicherzustellen, dass die entsprechenden Vorschriften für die Funkfrequenzen

einghalten werden, verwenden Sie beim Anschließen von Peripheriegeräten nur

abgeschirmte Kabel. Zur ordnungsgemäßen EMV-Abschirmung, ist das System nur mit

installierten Frontblenden zu betreiben und alle freien Steckplätze sind abzudecken oder

mit Steckkarten zu fuellen.

Erdung

Wenn das Produkt nicht richtig geerdet ist, kann es es durch elektrostatische Entladungen

beschädigt werden.

Das System enthält EMI-Dichtungen sowohl am System als auch an den einzelnen

Modulen. Stellen Sie sicher, dass alle Systemteile die EMV-Dichtung berühren.

Sicherheitshinweise

Am System befinden sich auch ESD-Kontakte fuer ESD-Bändern. Stellen Sie sicher, dass

jede Person, die mit dem System arbeitet, diese als ESD-Schutz benutzt.

Dies ist ein Klasse A Produkt, basierend auf dem Standard des „Voluntary Control Council

for Interference” (VCCI) von der „Information Technology Interference”. Wenn dieses Gerät

in einem häuslichen Umfeld verwendet wird, können Funkstörungen auftreten. Wenn

solche Probleme auftreten, muss der Benutzer möglicherweise Korrekturmaßnahmen

ergreifen.

Das Produkt ist für den Einsatz in Netzwerken mit gemeinsamem Potentialausgleich oder

mit isoliertem Potentialausgleich geeignet.

Systeminstallation

Beschädigung des Systems

Bevor Sie das System installieren, überprüfen Sie, ob die im Handbuch beschriebenen

Anforderungen erfüllt werden. Beachten Sie folgende allgemeinen Sicherheitshinweise vor

der Installation und Verkabelung des Systems:

Eingeschraenkter Zugangsbereich: Beabsichtigt für die Installation an einem

abgegrenzten Ort mit Zugang nur von geschultem Personal.

38 MC1600 Extreme Edge Server Installation and Use (6806870A02B)

Page 39

Sicherheitshinweise

Austauschbarer Netzkabelsatz: Der austauschbare Netzkabelsatz ist nicht im

Lieferumfang enthalten. Der austauschbare Netzkabelsatz muss ein zugelassenes

Modell sein und von der Behoerde dieses Landes, wo dieses Geraet installiert ist,

zugelassen sein.

Installationsvorschrift: Wo anwendbar, muss diese Einheit in Uebereinstimmung

mit der National Electrical Code (NEC) installiert werden.

Überstrom-Schutzeinrichtung: Eine leicht zugängliche Trennvorrichtung muss in

der Gebäudeverkabelung eingebaut sein. Einen angemessenen Wert für den

Leitungsquerschnitt können Sie der NEC (National Electrical Code) Tabelle 310.16

oder anderen nationalen Regelwerken entnehmen.

Der Erdungsleiter ist abhängig von der Spannungsverteilungstopologie innerhalb

Ihrer Anlage. Stellen Sie sicher, dass Sie einen angemessenen Erdungsleiter

gemäß der Auslegung des Zugangsleitungsschutzes verwenden.

Bauen Sie das System sicher ein. Stellen Sie sicher, dass Kabel und Leitungen

nicht im Weg sind.

Stellen Sie sicher, dass der Systemaufbau anwenderfreundlich ist.

Beschädigung des Systems

Die Gebäude-internen Schnittstellen ("intra-building ports" per GR-1089-CORE) der

Geräte oder Baugruppen sind nur für gebäudeinterne Verkabelung vorgesehen. Die

Schnittstellen sind als Typ 2 oder Typ 4 definiert (wie in GR-1089-Core beschrieben) und

erfordern eine Isolation zu Leitungen außerhalb des Gebäudes. Die Gebäude-internen

Schnittstellen dürfen keine elektrisch leitende Verbindung zu Leitungen außerhalb des

Gebäudes haben. Ein "Primary Protector" (wie in GR-1089-CORE beschrieben) ist keine

ausreichende Absicherung, um die Gebäude-internen Schnittstellen mit Leitungen

außerhalb des Gebäudes zu verbinden.

Beschädigung des Systems

Alle mit diesem Gerät verbundenen Geräte (oder hinzugefügte Unterbaugruppen) sollen

sich innerhalb desselben Gebäudes befinden. Wenn dieses Gerät (einschließlich eventuell

hinzugefügter Unterbaugruppen) für die Verbindung zwischen Gebäuden verwendet wird,

muss die Verbindung angemessen gegen Überspannung geschützt sein. Und eine weitere

Ueberpruefung der elektrischen Sicherheit wäre notwendig.

Beschädigung des Systems

Verschmutzungen können das System beschädigen.

Betreiben Sie das System an einem erschütterungsfreien Ort, an dem weder Staub, Rauch

noch elektrostatische Entladungen auftreten.

MC1600 Extreme Edge Server Installation and Use (6806870A02B) 39

Page 40

Sicherheitshinweise

Stellen Sie sicher, dass die Temperatur die Betriebstemperatur nicht überschreitet, die in

den Umgebungsbedingungen in diesem Handbuch angegeben ist, und lassen Sie einen

ausreichenden Luftstrom zum Kühlen..

Verletzungsgefahr und Beschädigung des Systems

Ein kopflastiger Schaltschrank kann umkippen, wodurch die Einrichtung beschädigt und

das Personal verletzt werden kann.

Bauen Sie das System deshalb ganz unten im Schrank ein, wenn es das einzige System

im Schrank ist. Wenn mehrere Systeme in einen Schrank eingebaut werden sollen,

platzieren Sie das schwerste System ganz unten und die leichteren weiter oben. Falls der

Schaltschrank mit Kippsicherungen ausgestattet ist, stellen Sie sicher, dass diese auch

installiert und ausgefahren sind, um einen sicheren Stand des Schranks zu gewährleisten.

Beginnen Sie erst danach mit dem Einbau oder der Wartung des Systems.

Verletzungsgefahr oder Beschädigung des Systems

Seien Sie vorsichtig, wenn Sie das System aus dem Rack ziehen, da es herunterfallen und

Verletzungen verursachen kann.

Verletzungsgefahr

Das System ist schwer, und eine unangemessene Handhabung kann zu Zerrungen oder

Rückenschäden führen.

Sicherheitshinweise

Beschädigung des Systems