SMART desks Cirrus Ratchet Leg Stand Up Desk Assembly & Instruction Manual

SYM ECN DATE BY CHANGE

B

268 DS Dimension A was 4.026/06/12

DRAWING#

REVISION

SHEET

OF1 1

ASY 1131

B

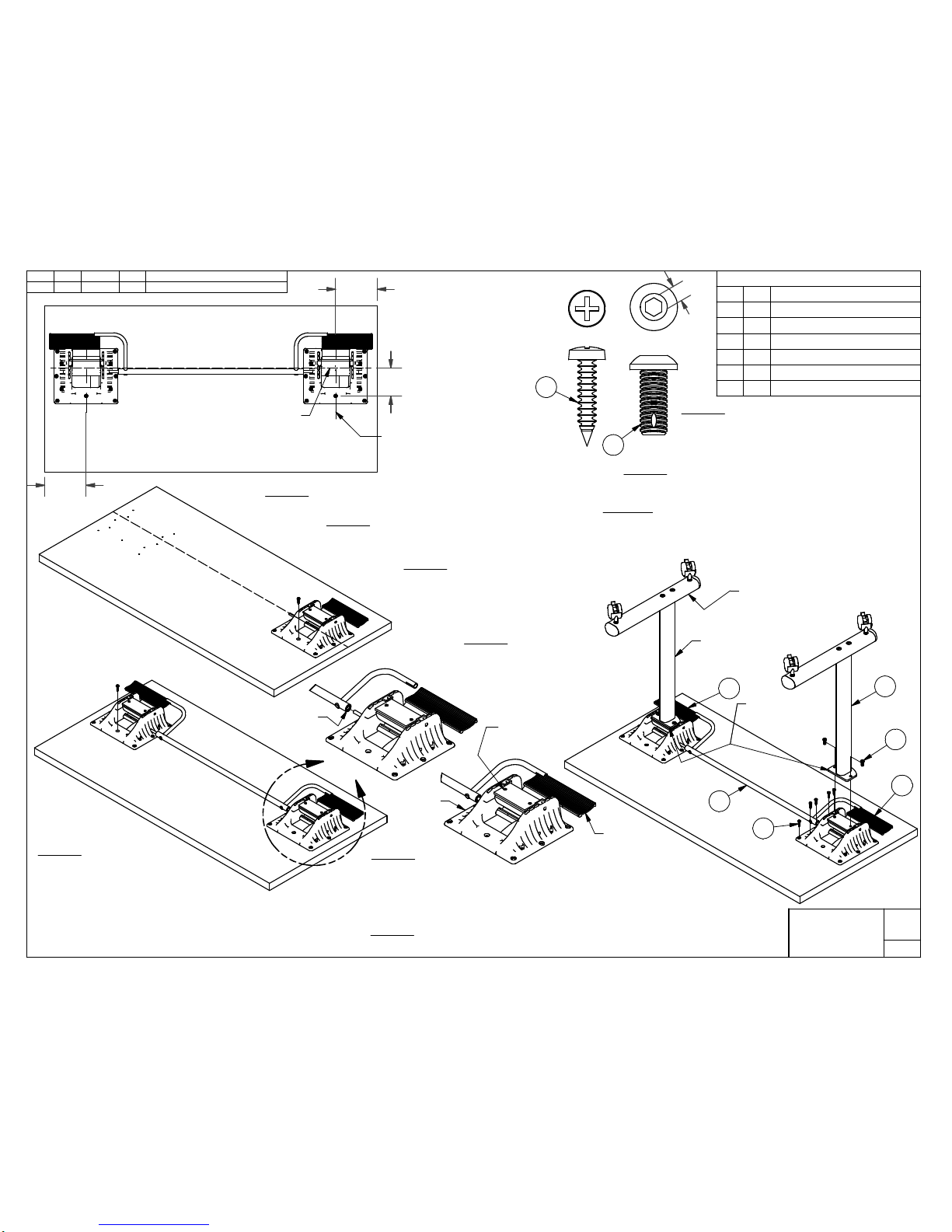

Parts List

DescriptionQtySeq

Genu-Flip Assembly LH11

Genu-Flip Assembly RH

12

Genu-Flip Swing Arm Assembly

13

Screw #12 X 1 PPH224

Screw 5/16-18 X 3/4" BHCS

45

End Base Assembly

26

A

6.00

Standard Distance from Edge

of Top to Center of Bases Shown

Dimension May Vary By Job

Desired Centerline of Bases

(View Shows Bases Offset 3"

From Centerline of Table Top)

Step # 1

Position Top Upside Down On Carpet or Other Non-abrasive Surface.

Step # 2

If Top Not Predrilled, Mark and Drill Two Ø1/8 Pilot Holes

1/2" Deep at the Locations Shown In View A.

Step # 4

Place the LH Genu-Flip Assembly (#1)

Onto the Top at Desired Location and

Attach It to the Top with One #12

Screw (#4) as Shown in View B.

Step # 10

Align the Two Thru Holes In One of the End Base Mounting Plates With

the Two Tapped Holes In the Genu-Flip Pivot Block. Hand Start a

5/16-18 Screw (#5) Thru the Mounting Plate and Into Each Tapped Hole.

Then, Using a 3/16" Hex Driver, Tighten Each 5/16-18 Screw To Between

20 and 25 Foot Pounds. Repeat Process for Each Base.

2

1

3

6

5

4

4

5

0.19

Step # 5

Align Center Bushing of

Swing Arm Assembly (#3) with

5/16 Diameter Pin That Extrudes Out

From the LH Genu-Flip Assembly (#1) and

Align the Center of Formed Tube on Swing Arm

Assembly with the the Rounded Profile of the Handle.

Slide Swing Arm Assembly Onto the LH Genu-Flip Assembly

Until the End Of Bushing Is Flush With the Edge of Genu-Flip Housing.

Step # 3

Verify That the Pivot Block In Both Genu-Flip

Assemblies Are Positioned As Shown Below.

If Not, Press the Genu-Flip Handle Down to

Allow the Block to Pivot and Rotate the Block

to This Position.

Handle

Pivot Block

With Two Tapped

Holes Up

6.00

Step # 8

If the Top Was Predrilled, Install the Remaining #12

Screws (#4). If the Top Was Not Predrilled, Use the

Genu-Flip Housing as a Template and Drill Ø1/8

Pilot Holes By 1/2" Deep Before Installing the

Remaining Screws.

If Installing Cantilevered End Bases,

the Shorter Side of the Mainbar

Needs to Be Positioned

Towards the Handle.

Genu-Flip

Housing

Step # 6

Using the Same Method as

Step #5, Align the RH Genu-Flip Assembly (#2) with the Other End of the Swing

Arm Assembly (#3). Slide the RH Genu-Flip Asssembly Into Swing Arm Assembly

Until the Pilot Hole in the Top Lines Up With the Hole In the Genu-Flip Housing as

Shown In View C. Install a #12 Screw (#4) to Secure Genu-Flip to Top.

Center Bushing

of Swing Arm

End Base Styles May

Vary From the

One Shown

View A

View B

View C

Step # 7

Verify That the Two Genu-Flip Assemblies Are Inline with Each Other.

Step # 9

If Not Already Pre-Assembled, Assemble the End Bases Per the

Base Assembly Instructions.

Mounting Plate and

Pivot Block Flush

on This Side

Up to 2.00 wide Column A = 4.02

2.13 to 2.50 wide Column A = 4.27

2.63 to 3.00 wide Column A = 4.52

3.63 to 4.00 wide Column A = 5.02

SYM ECN DATE BY CHANGE

A

-

DS

New Drawing

10/24/12

DRAWING#

REVISION

SHEET

OF1 1

ASY 1173

A

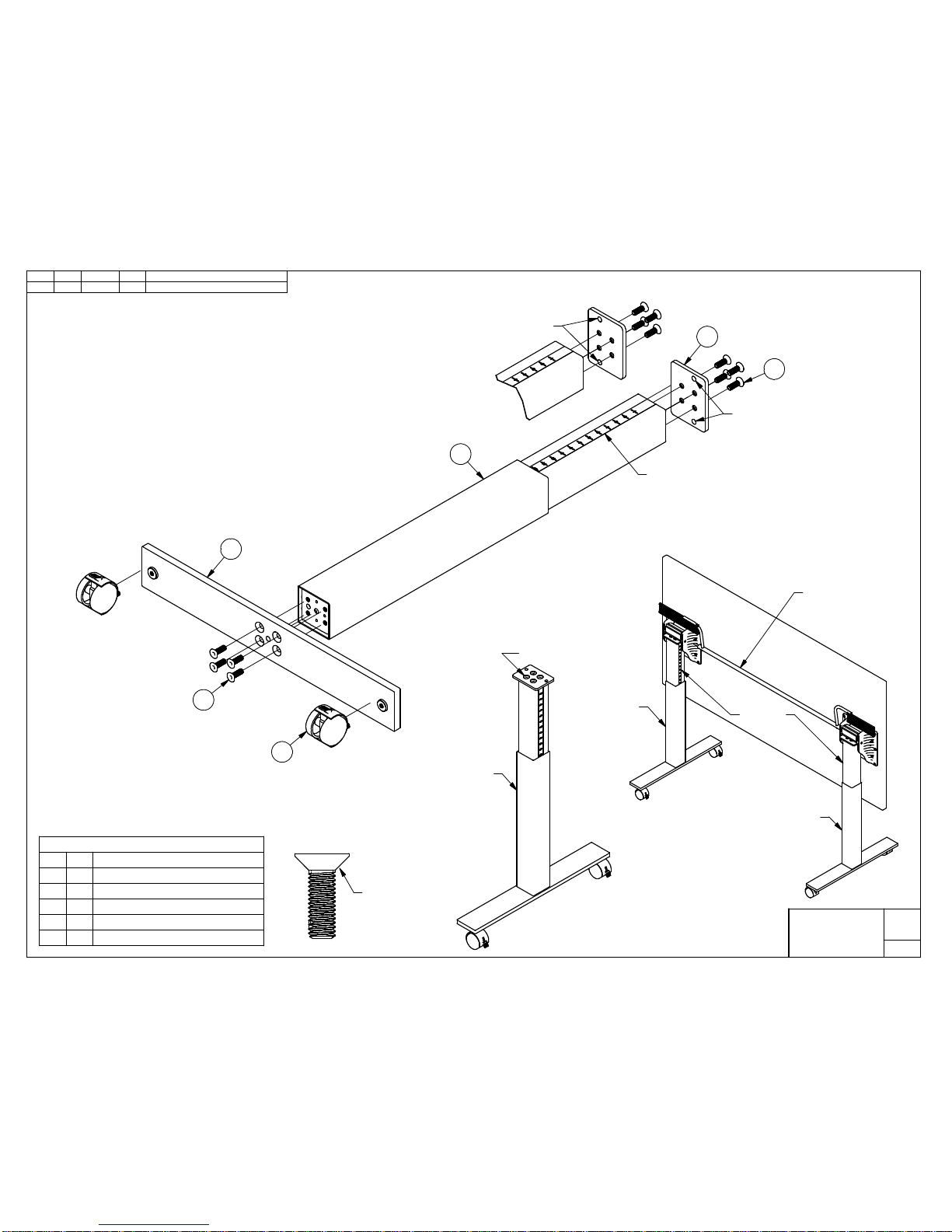

Parts List

DescriptionQtySeq

Mounting Plate11

Column Assembly, Ratchet

12

Mainbar Assembly

13

Screw, M8 x 25mm FHCS Hex Drive84

Leveler or Caster

25

M8 x 25mm

ASSEMBLY INSTRUCTIONS

1. Align the Four Holes in the Mounting Plate (#1) with the Four Tapped

Holes in the Column (#2). Insert Four M8 x 25mm Screws (#4) Thru

the Mounting Plate and Thread Into the Column. With a 5mm Hex

Drive, Tighten the Screws To 15 Foot Pounds of Force.

2. Align the Four Holes in the Mainbar (#3) with the Four Tapped Holes

in the Column as Shown. Insert Four M8 x 25mm Screws Thru the

Mainbar and Thread Into the Column. With a 5mm Hex Drive,

Tighten the Screws To 15 Foot Pounds of Force.

3. If Not Pre-Installed, Turn the Threaded End of the Levelers or Casters (#5)

Into the Threaded Inserts On the Bottom Side of the Mainbar.

1

2

4

5

4

3

Holes Location

for Side A

Decal for Height

Adjustment Positions

For Flip Mechanism

Assembly, See

Drawing ASY 1131

Side A

Side B

Decal

Countersunk Holes

Side A

Holes Location

for Side B

Loading...

Loading...