Page 1

INSTALLATION AND OPERATION

Made Right in the U.S.A

Installation and

Service Manual

SHOWMATION

Automation Control System

Version 4.xx

Devices, Inc.

5945 Peachtree Corners East

Norcross, Georgia 30071

1-800-45-SMART or 770-449-6698

1

Page 2

Copyright 2000 by SMART Devices, Inc.

5945 Peachtree Corners East

Norcross, GA 30071-1337

SHOWMATION Automation Control System Ver. 4.xx

Table of Contents

Introduction Page 2

Electrical Interference Warning Page 3

Features Page 4

Description Page 5

Installation Page 6

Operating Instructions Page13

Front Panel Quick Reference Page 15

Notes Page 16

SMART products are designed to deliver unsurpassed quality in workmanship and performance.

The following information gives detailed instructions on the installation and operation of the

SMART SHOWMATION automation. We strongly encourage new owners of the SHOWMATION

to thoroughly read this entire manual before placing their new SMART product into service. This

will ensure that the SHOWMATION will be operated properly to give the superior performance

that it was designed to deliver.

For service or installation assistance,

please call our Technical Support Department

between the hours of 8 AM and 5 PM E.S.T., Monday - Friday

at 1-800-45-SMART

LIMITED WARRANTY: SMART products and accessories are warranted against malfunction or failure due to defects in workmanship or materials

for a period of one year from the date of shipment. If a problem occurs during the warranty period, the unit will be repaired, or replaced at our

option, without charge for materials or labor. If air freight is requested by the dealer, the difference between air and surface charges will be billed to

the dealer. This limited warranty does not cover products that have been abused, altered, modified, or operated in other than specified conditions.

Prior factory approval is required on all returns. Returned equipment or defective parts must be shipped freight prepaid to us by the dealer or

customer. Our limited warranty does not cover damages resulting from accident, misuse or abuse, lack of responsible care, or failures not attributable

to manufacturing defects, except as provided herein. SMART Devices, Inc. makes no warranties, express or implied, including warranties of

merchantability or fitness for a particular purpose. RETURN POLICY: Factory authorization MUST be obtained before returning any product. A

15% restocking charge will be issued on unused equipment (in original box) that is returned for credit. Credit is issued to the dealers account. The

credit may be used against future purchases and no cash transactions are offered. All returns must be shipped freight prepaid by the dealer.

Equipment returned without a factory RA (Return Authorization) will be refused.

Page 3

INSTALLATION AND OPERATION

Installation, Service, and Operation Manual

Showmation Automation Ver. 4.xx

INTRODUCTION

The SMART SHOWMATION is a full featured automation control system which controls all aspects

of your presentation when used in conjunction with the SMART SHOWGRAMMER II. It is also

available as a simpler stand alone automation which does not require the SHOWGRAMMER II. The

OPERATOR PANEL and the CONTROLLER are separate pieces which mount at any convenient

place in your console. A wall mount package is also available which houses the OPERATOR PANEL

and the CONTROLLER if console mounting is not desired or is not available.

A unique Annunciator Panel is available which utilizes a very simple 4 wire plus ground hookup,

unlike other panels which require multiple conductors and complicated hookups. This panel, called

the WATCHDOG may be used in multiples by simply extending the wiring from one to the next.

Companion Light Dimmer packages are also available which will handle 3 kiloWatts of lighting.

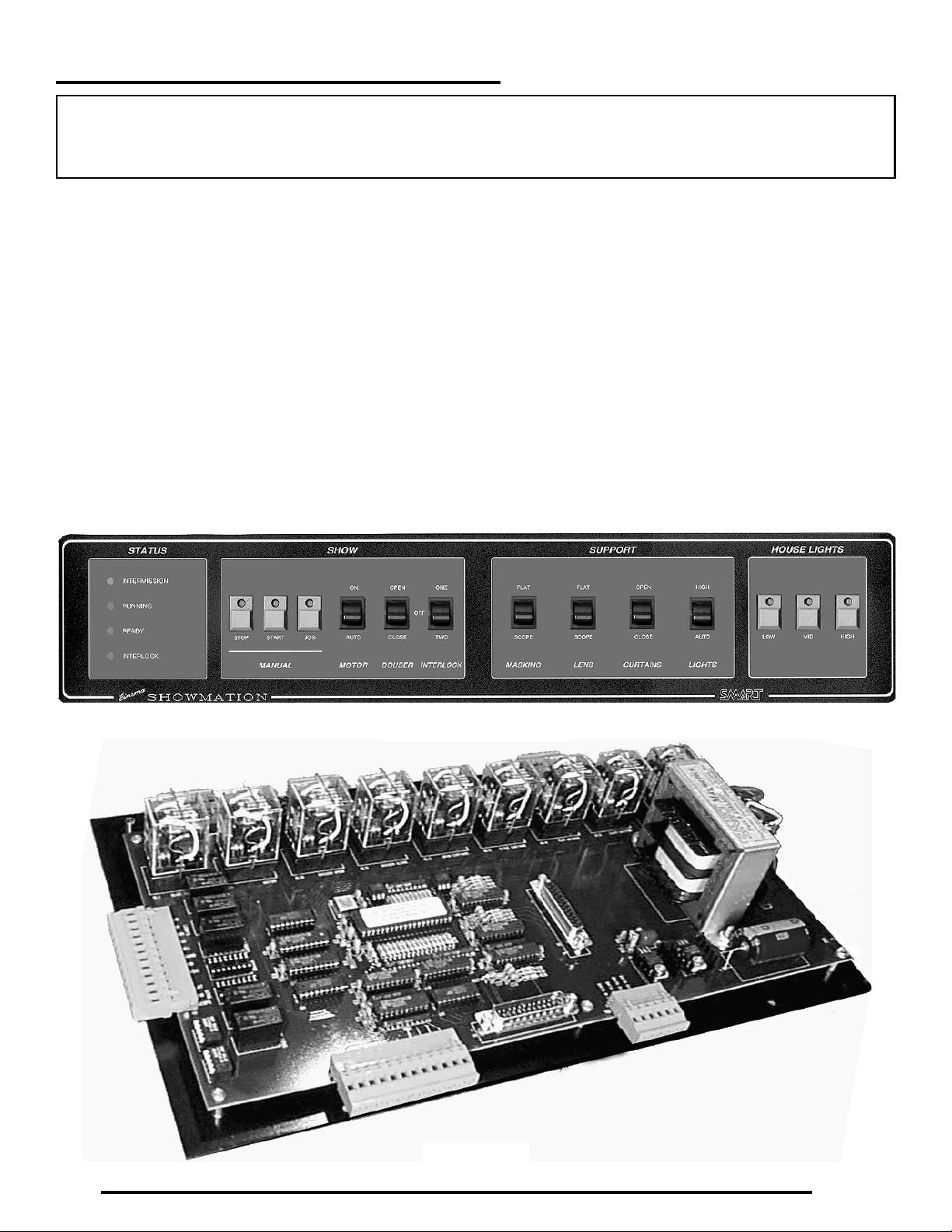

Operator Panel

Controller

3

Page 4

SHOWMATION AUTOMATION

ELECTRICAL INTERFERENCE WARNING

This device utilizes sophisticated computerized micro-controller devices and

!

other parts which may be susceptible to externally produced electro-magnetic

interference (EMI).This type of interference may be found in and around

projector lamphouses which are not very clean electrically and magnetically. It

is imperative to make certain that all sources of EMI are properly suppressed if

this device is to perform to its full potential. By far, the worst offender is the

Xenon lamp ignitor, and many lamphouses, especially older ones, have

extremely electrically dirty ignitors. Please see the diagram below for suggested

ways to clean up the lamphouse. Having an EMI suppressed system is your

responsibility, and SMART assumes no responsibility for failures due to

excessive interference.

LAMPHOUSE

XENON LAMP

Chassis

ground

points

4

IGNITOR

120 VAC Leads

3 capacitors

0.05uF to 0.1uF

at least 450 VDC

rating

LAMP DC LEADS

3 capacitors

0.1uF to 0.47uF

at least 450 VDC

rating

Keep all capacitor leads as

short as possible with the

most direct connection to

chassis ground, 2 to 3 inches

at most. Long leads will

degrade suppression. Mount

all capacitors as close as

possible to where leads exit

lamphouse.

Page 5

INSTALLATION AND OPERATION

FEATURES

Micro-Controller based

Simple Installation

All wiring on pluggable terminal strips and Faston connectors and DB25 computer type cables

Heavy duty 10 Amps continuous service relays for high current loads

1 Amp continuous service relays for low current loads

When several automations are wired together for interlock, two different interlocks may run

simultaneously

Each SHOWMATION has setup switches to properly identify itself to the WATCHDOG

annunciator panels

The OPERATOR PANEL has a scratchproof Lexan overlay which matches the SHOWGRAMMER II

All pushbuttons are high quality Schadow switches

A JOG pushbutton will run the motor as long as it is held in for ease of checking film threading. This

relieves wear and tear on the motor manual bypass switch

Light dimmer pushbuttons are available on the OPERATOR PANEL

Manual bypass switches are available for motor, douser, masking, lens, curtains, and lights

5

Page 6

SHOWMATION AUTOMATION

DESCRIPTION

This automation consists of two separate items, the Controller and the Operator Panel.

The Controller is the internal device which

mounts inside the console. It contains all the relays, wiring connectors for hookup to all the

projector and console devices, the power supply, and the micro-controller computer chip and

associated circuitry which performs all the automation functions. It also contains connectors

for hookup to the Operator Panel and to an optional SHOWGRAMMER II. This is all on a

large printed circuit board which is mounted on

a metal back plate. The back plate has four

mounting holes which will pass #8 machine

screws for securing the Controller to the inside

of the console. Alternatively, the Controller may

also be mounted in the optional Wall Mount

Package.

The Operator Panel is a 3½” high by 19” wide

rack mount assembly which mounts in any standard EIA rack mount opening. Many consoles

have provision for mounting such equipment.

The Operator Panel contains all the pushbuttons

and manual bypass switches for normal operation of a typical booth. It also contains LED indicators for the pushbutton switches and the system status. The Operator Panel has a reverse

silk-screened Lexan overlay which is very

scratch resistant and aesthetically appealing. It

contains all the legends for the switches, pushbuttons, and system status. The look matches

that of the optional SHOWGRAMMER II.

Connection from the Operator Panel to the Controller is through a DB25 Male to Female cable

for normal functions and through several wiring

harnesses for the manual bypass functions. The

harnesses are terminated to Faston connectors

on the Operator Panel end for ease of connec-

tion. The Controller end of the harnesses are terminated on Faston connectors for some functions and bare tinned wires for connection to the

pluggable connectors for other functions. These

pre-made harnesses make for an easy installation which was an important consideration in

the design.

Ease of operation was also a very important design factor, and the SHOWMATION is very

straightforward and easy to use. System Status

is easily discernible at a glance, and the operator

will appreciate the simplicity of operation.

Interlock capability is a part of the system and

goes beyond that of conventional automation

systems. The SHOWMATION has a three position Interlock selector switch with the center position being OFF, or no interlock. The UP position is Interlock 1 and the DOWN position is Interlock 2. Several automations can be wired for

interlock, and two different interlocks can be

run simultaneously with virtually any number

of screens participating. For example, lets say

that 6 screens are wired together for interlock.

Screens 1, 2, and 3 can run on Interlock 1 while

screens 5 and 6 are running on Interlock 2, and

Screen 4 is running standalone. This is accomplished by simply setting the Interlock selector

switch on each Operator Panel to the appropriate position. You can set up any combination of

screens for interlock in this way. While running,

the Interlock state can not be changed accidentally. The only time the Interlock state can be altered is in STOP mode. This prevents a condition in which film might be broken if one projector were to stop for some reason.

6

Page 7

!

INSTALLATION AND OPERATION

INSTALLATION

Take extra precautions when installing this piece of equipment. Remember that

you are dealing with dangerous voltages present inside the console. These voltages can be lethal. Even 120 VAC can KILL. Remove ALL power from the console preferably by shutting off the breakers at the main or sub panels that feed

this console. Take care when attaching high voltage wiring to the pluggable terminal strips on the automation. Do not leave any strands of wire hanging loose

which may short to the console case. Make sure that ALL connections are

TIGHT and SECURE. Leave NOTHING to chance. Remember what Murphy said: If

anything can go wrong, you will probably DIE. Well, that wasn’t exactly what he

said, but you get the point. Be careful!

Now that we have that out of the way, let’s get on to the installation.

First, we are assuming a console mounting

which will probably cover most situations. If

you are installing in a Wall Mount Package, the

steps are similar except that the Controller and

Operator Panel will be in the Wall Mount Package and you will be running wires between the

console and the Wall Mount Package.

Controller

Please refer to the diagrams that follow the Installation section for additional information on

mounting and connections to the Controller.

Find a suitable location in the console to mount

the Controller. This is not particularly critical

except for attempting to stay as far as possible

away from sources of EMI as described on Page

3 of this manual.

please do so NOW. The success of this installation may well depend on how well you have

cleaned up the console electrically.

The Controller does not generate an appreciable

amount of heat, but as with all electronic equipment, the cooler the better. So if airflow is available, take advantage of it and mount the Controller in the airflow path. Also try to locate the

Controller in close proximity to the majority of

the electrical connections to minimize the wire

lengths to the Controller.

If you have not read Page 3,

Position the Controller so that the power transformer is at the TOP or to the RIGHT. Use the

mounting holes on the metal back plate to mark

the hole positions for drilling. Drill the appropriate holes in the console mounting location

and secure the metal back plate and controller

with #8 machine screws, lockwashers, and nuts.

Follow the diagrams following the installation

section of this manual and locate the various

connection points for the Xenon Ignitor, motor,

slide projector, douser, etc. and wire each of

these items from the pluggable terminal strips

to the appropriate points in the console wiring.

Use wire sizes appropriate for the load you are

controlling.

Even with all the proper precautions taken to

minimize interference from the Ignitor, you

may still experience interference problems . If

so, contact the factory for an external relay/

cable set to use in the Ignitor circuit.

7

Page 8

SHOWMATION AUTOMATION

Configuration

Pulse or latch operation (Diagram on Page 11)

The Controller has several functions which may

be configured for either pulse or latch operation:

lens, masking, and lights. The Douser function

is always pulse mode, and the Curtains function

is always latch mode. There are 5 DIP switches

in the DIP switch package labeled SW2 which

are used to set these functions to either pulse or

latch modes. If the switch is UP (off) then the

mode is pulse. If the switch is DOWN (on), then

the mode is latch. In the pulse mode, the appropriate relay(s) will close for one second and then

open. In the latch mode, the relay(s) will close

and remain closed as long as that function is selected.

In Version 4.00 of the software, only the lens,

masking, and lights are selectable as pulse or

latch. The douser function is ALWAYS pulse

mode. The curtains function is ALWAYS latch

mode. Future versions of the software will allow the douser and curtains to be either pulse

or latch. The software version is listed on the

label on top of the micro-controller IC labeled

U8 on the Controller printed circuit board.

Annunciator ID (Diagram on Page 11)

There is another DIP switch package labeled

SW1 on the Controller printed circuit board.

These DIP switches set the Identification Code

for each Controller to allow proper communication with the optional WATCHDOG Annunciator Panel(s).

unique

ID Code so that the WATCHDOG Annunciator Panel(s) will be able to tell which

Controller is sending information about the

system status.

Each Controller must be set to a

SW1-1 SW1-2 SW1-3 SW1-4 SW1-5 ID Code

UP UP UP UP UP 1

UP UP UP UP DOWN 2

UP UP UP DOWN UP 3

UP UP UP DOWN DOWN 4

UP UP DOWN UP UP 5

UP UP DOWN UP DOWN 6

UP UP DOWN DOWN UP 7

UP UP DOWN DOWN DOWN 8

UP DOWN UP UP UP 9

UP DOWN UP UP DOWN 10

UP DOWN UP DOWN UP 11

UP DOWN UP DOWN DOWN 12

UP DOWN DOWN UP UP 13

UP DOWN DOWN UP DOWN 14

UP DOWN DOWN DOWN UP 15

UP DOWN DOWN DOWN DOWN 16

DOWN UP UP UP UP 17

DOWN UP UP UP DOWN 18

DOWN UP UP DOWN UP 19

DOWN UP UP DOWN DOWN 20

DOWN UP DOWN UP UP 21

DOWN UP DOWN UP DOWN 22

DOWN UP DOWN DOWN UP 23

DOWN UP DOWN DOWN DOWN 24

DOWN DOWN UP UP UP 25

DOWN DOWN UP UP DOWN 26

DOWN DOWN UP DOWN UP 27

DOWN DOWN UP DOWN DOWN 28

DOWN DOWN DOWN UP UP 29

DOWN DOWN DOWN UP DOWN 30

DOWN DOWN DOWN DOWN UP 31

DOWN DOWN DOWN DOWN DOWN 32

You should set each Controller’s ID Code to

match the screen number.

This way the

WATCHDOG Annunciator Panel(s) will indicate the system status properly for each screen

There are 32 possible codes which can be selected. To set a code, push the appropriate

switches DOWN (on). Use the following table to

determine the ID Codes for each Controller.

8

Operator Panel

Find a suitable place in the console for the Operator Panel to mount. The panel is a 3½” high by

19” wide rack mount which will fit any stan-

Page 9

INSTALLATION AND OPERATION

dard EIA rack opening. Plug the supplied DB25

male to female cable into the connector on the

Operator Panel circuit board. Plug the other end

of the cable into the connector on the Controller.

There are six wiring harnesses supplied which

are used to connect the Operator Panel manual

switches to the Controller. Each harness is labeled at each end. The ends that are labeled F1PANEL through F16-PANEL go to the FASTON connectors on the Operator Panel circuit

board.

nesses to the correct points at each end. Incorrect connections could result in dangerous

voltages being applied to places they should

not be. This could result in disastrous consequences. Please use the table on PAGE 12 for a

complete listing of all the harness connections.

After connecting these harnesses to the Operator Panel, connect the other ends to the appropriate points on the Controller. Two of the harnesses have bare tinned wires on the Controller

end for connection to the pluggable terminal

strips. These harnesses are for high lights and

lens flat or scope manual functions. They will be

wired to the terminal strips together with the

wires from the lens change controller and the

light dimmer unit(s).

SHOWGRAMMER II

Mount the SHOWGRAMMER II close to the

Operator Panel, preferably directly below it.

Plug the DB25 cable into the DB25 connector on

the Controller. Plug the other end of the DB25

cable into the DB25 connector on the Showgrammer II. See the SHOWGRAMMER II manual for hookup information regarding connections to the sound processor.

It is very important to attach these har-

Interlock Wiring

All interlock wiring should use 2 conductor plus

shield cable. Refer to the diagram on Page 11 for

the pluggable terminal strip labeled as TB3. You

will need 2 of the 2 conductor plus shield cables

to connect between each automation that you

desire to wire for interlock. The first cable will

connect Interlock 1 Start, Interlock 1 Stop, and

Interlock Common together. The second cable

will connect similar terminals for Interlock 2.

Use the the 2 conductors for the Start and Stop

functions, and the shield for the Interlock Common. If several automations are wired together

for Interlock the cables will just daisy chain

from one to the next and so on.

Annunciator Panel Wiring

The Annunciator Panel wiring is done similarly

to the Interlock wiring. You may use the same 2

conductor cable as for the interlock wiring if

you like.

The shields of the cables will connect to the Com

terminal on TB6 of each automation. The hot

conductors will attach to the Data terminals on

TB3 of each automation. Wire one cable to the

DATA IN LO and DATA IN HI terminals. Wire

the other cable to the DATA OUT LO and

DATA OUT HI terminals.

You may only wire up to 32 automations together. Run cables from any of the automations

to the location where the Annunciator panel

will be mounted.

On all DB25 connectors, secure the connectors

with the two thumb screws provided on each

connector.

9

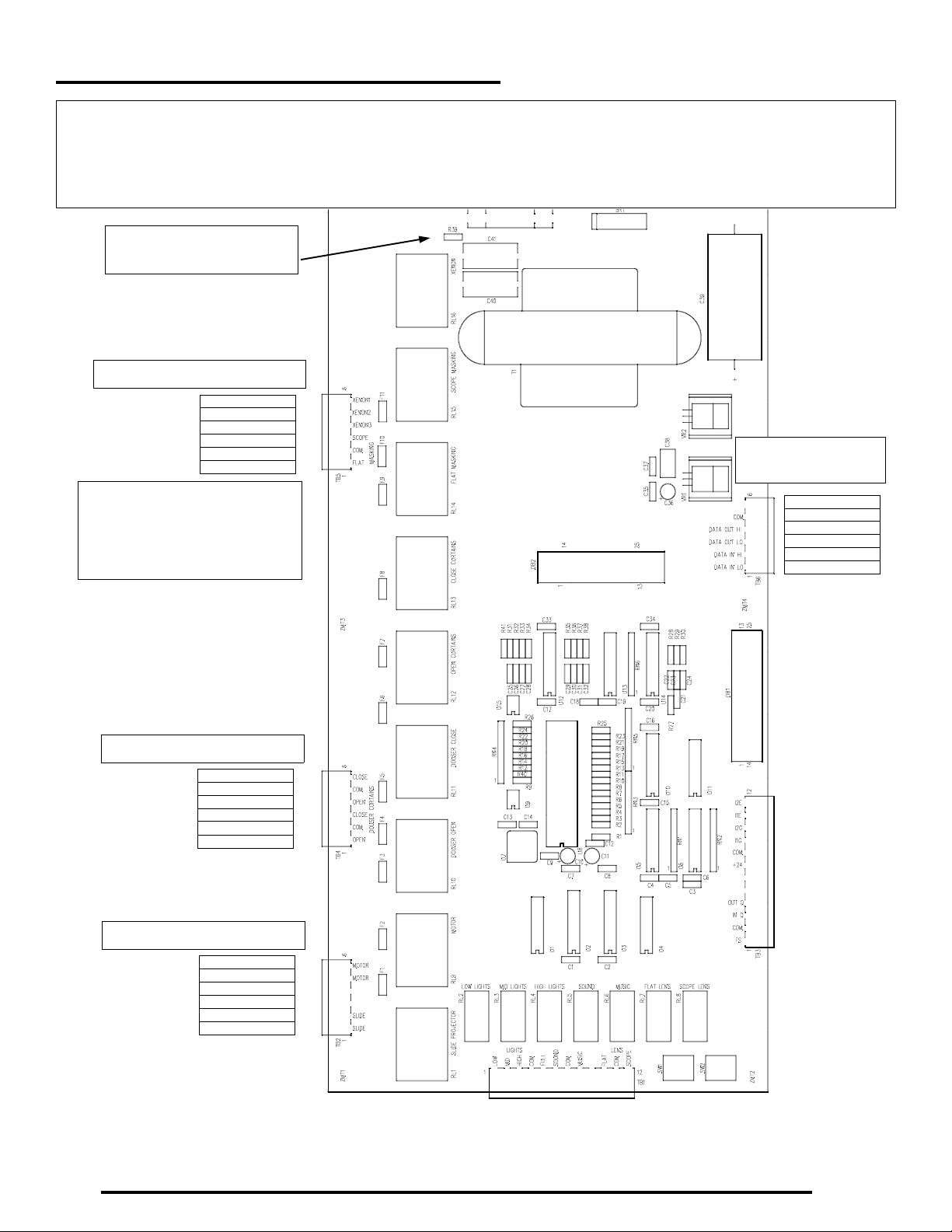

Page 10

SHOWMATION AUTOMATION

Controller Installation

Mount the Controller in the console as shown in this diagram. The power transformer should be at

the TOP or RIGHT. Please note that the the metal back plate is NOT symmetrical and cannot be

turned upside down. The PC board will only mount one way on the panel. There are four mounting

holes on the metal back plate which will pass #8 machine screws. These are accessible without

removing the PC board from the metal panel. The power cord may be plugged in or the plug may be

cut off for direct wiring to a 120VAC source.

Power Connections

F12 & F13

MDL2 Fuse Slow Blow

DB25 cable from

Operator Panel

DB25 cable from

Showgrammer II

10

Page 11

INSTALLATION AND OPERATION

Controller Wiring Information

This page shows the functions for the 6 position pluggable terminal strips. All relays are rated at 10

Amps. If you are controlling a higher current device, then use an external relay of the proper

capacity controlled by the on board relay. Use wire size appropriate for the load to be controlled.

R39 NOT installed unless

directed by the factory.

6 position connector - TB5

Xenon 1

Xenon 2

Xenon 3

Masking Scope

Masking Common

Masking Flat

Use the XENON 1 and XENON 2

terminals for the Ignitor control

circuit. Do NOT use XENON 3

except in special cases as

directed by the factory.

6 position connector

TB6

N/C

Com

Data Out Hi

Data Out Lo

Data In Hi

Data In Lo

6 position connector - TB4

Curtains Close

Curtains Common

Curtains Open

Douser Close

Douser Common

Douser Open

6 position connector - TB2

Motor

Motor

N/C

N/C

Slide Projector

Slide Projector

11

Page 12

SHOWMATION AUTOMATION

Controller Wiring Information

This page shows the functions for the 12 position pluggable terminal strips. Lights and Lens relays

are rated at 1 Amp. If you are controlling a higher current device, then use an external relay of the

proper capacity controlled by the on board relay. The Interlock functions on TB3 will be wired in the

field. Use one 2 conductor shielded cable for each of the two interlock functions. Connect the

shields to Interlock Common. Connect all like terminals together on the projectors you wish to be

interlocked.

Lens Scope

Lens Com

Lens Flat

N/C

Future 2

Com

Future 1

Lights Full

Lights Com

Lights High

Lights Mid

Lights Low

12 position connector - TB1

12 position connector - TB3

Interlock 2 Stop

Interlock 1 Stop

Interlock 2 Start

Interlock 1 Start

Interlock Common

+24

N/C

N/C

Outboard Cue

Inboard Cue

Common

Failsafe Switch (Open when

SW1

12345

DIP Switch for

selecting ID Number

threaded)

not

CURTAINS

MASKING

DOUSER

LIGHTS

SW2

LENS

12345

DIP Switch for selecting

Pulse or Latch

12

Page 13

INSTALLATION AND OPERATION

Operator Panel and Showgrammer Installation

Mount the Operator Panel and optional Showgrammer in the space provided in the console. Mount

the Operator Panel on top with the optional Showgrammer below it. Plug a Male to Female DB25

cable into the DB25 connector on the Showgrammer. Plug the other end into the DB25 connector

marked DB1 on the Controller. Plug the other Male to Female DB25 cable into the DB25 connector

on the Operator Panel. Plug the other end into the DB25 connector marked DB2 on the Controller.

There are several wiring harnesses with Faston connectors supplied. These must be attached between the Operator Panel and the Controller (Main Board). These harnesses are color coded to

show the appropriate points of connection at each end. Please refer to the chart below for the correct connections. Note that some wires are 16 Gauge and some are 24 Gauge.

Operator Panel

Terminal Designator

and Cable Color

F1 BLUE 24 W/FASTON TB1-4 BLUE 24 STRIPPED Lights Common

F2 RED 24 W/FASTON TB1-5 RED 24 STRIPPED Lights Full

F3 ORANGE 16 GA W/FASTON F6 ORANGE 16 GA W/FASTON Curtains Open

F4 WHITE 16 GA W/FASTON F7 WHITE 16 GA W/FASTON Curtains Common

F5 BROWN 16 GA W/FASTON F8 BROWN 16 GA W/FASTON Curtains Close

F6 BROWN 24 GA W/FASTON TB1-10 TB1-10-MAIN STRIPPED Lens Flat

F7 WHITE 24 GA W/FASTON TB1-11 TB1-11-MAIN STRIPPED Lens Common

F8 GREY 24 GA W/FASTON TB1-12 TB1-12-MAIN STRIPPED Lens Scope

F9 VIOLET 16 GA W/FASTON F9 VIOLET 16 GA W/FASTON Masking Flat

F10 GREEN 16 GA W/FASTON F10 GREEN 16 GA W/FASTON Masking Common

Controller (Main Board)

Terminal Designator

and Cable Color

Bypass Function

F11 PINK 16 GA W/FASTON F11 PINK 16 GA W/FASTON Masking Scope

F12 BLUE 16 GA W/FASTON F3 BLUE 16 GA W/FASTON Douser Open

F13 GREY 16 GA W/FASTON F4 GREY 16 GA W/FASTON Douser Common

F14 YELLOW 16 GA W/FASTON F5 YELLOW 16 GA W/FASTON Douser Close

F15 BLACK 16 GA W/FASTON F1 BLACK 16 GA W/FASTON Motor

F16 RED 16 GA W/FASTON F2 RED 16 GA W/FASTON Motor

13

Page 14

SHOWMATION AUTOMATION

OPERATING INSTRUCTIONS

Operation of the SHOWMATION is very

straightforward and simple. See the OPERATOR PANEL QUICK REFERENCE on Page 15

for a quick explanation of the Indicator LED’s,

Pushbuttons, and Switches.

Cues

When used in conjunction with a SHOWGRAMMER II, you have complete control of the film

presentation. This is done by setting the various

switches on the SHOWGRAMMER II and by

placing cues on the film at the appropriate

places to initiate the desired format, lens, masking, and lighting changes.

All cues are to be placed on the

the film when the SHOWMATION and SHOWGRAMMER II are used together. (When the

SHOWMATION is used as a standalone system,

then cues may also be placed on the outboard

side of the film. This is a special situation which

will be detailed in a separate manual for the

standalone SHOWMATION.)

This SHOWMATION system ALWAYS requires

a cue at PICTURE START. The douser will

open until the PICTURE START cue passes. This

is also a requirement for Interlock Operation, so

placing a cue at PICTURE START will serve

both purposes.

See the SHOWGRAMMER II manual for details

on programming the desired format, lens and

masking, and lighting changes. In addition to

the cue at PICTURE START, one cue will be required at every point in the film where you desire to make any change. Format, lens and

masking, and lighting changes may be done in

any combination on any cue. The START cue

will open the douser and advance the SHOWGRAMMER II to the START position. Format,

inboard

side of

not

lens and masking, and lighting changes which

have been programmed on the SHOWGRAMMER II START position will go into effect on the

FIRST cue. There may be

the Start cue to control format, lens and masking, and lighting changes.

For example, the START cue could be set up for

MONO, FLAT and MID lights. The next cue

could change to STEREO A, SCOPE, and MID

lights, the next cue could change to STEREO SR,

SCOPE, and LOW lights. The next cue could be

at the credits and could just change the house

lights to MID for early house lights.The next cue

placed at the end of the credits could change the

SHOWGRAMMER II to end of show which will

bring up MUSIC format and close the douser.

Then when the failsafe drops, the system will

stop and be ready for re-threading for the next

show.

If you have used

(PICTURE START plus four more) for format,

lens and masking, and lighting changes, there is

one more available cue which will tell the

SHOWGRAMMER II that the end of show is

here. This cue is not programmable on the

SHOWGRAMMER II, but the SHOWGRAMMER II will recognize this sixth cue and initiate

an end of show condition. This cue will be

placed at the end of credits.

As with other systems, make sure the cues are

properly applied and are in good condition. A

good presentation depends on the cues, and failure to pay good attention to this part of preparing your film will result in poor performance.

Operation

When the SHOWMATION is in intermission

mode, the INTERMISSION LED will be on. As

all five

available cues

more cues after

four

14

Page 15

INSTALLATION AND OPERATION

the film is threaded and the failsafe is raised, the

READY LED will come on. The system will not

start unless the READY LED is on. The RUNNING LED will be off at this point. In addition

the LED in the STOP pushbutton will be on. The

INTERLOCK LED will be off unless you have selected an interlock mode with the INTERLOCK

switch.

As an aid in threading, the SHOWMATION provides a JOG function. When you push the JOG

pushbutton, the motor will run. When you release

the JOG pushbutton, the motor will stop. Use this

feature rather than the MOTOR manual switch.

This saves wear and tear on the manual switch.

The STOP pushbutton will not normally be used

except when there is a problem. If you start the

show and the film is not feeding properly, for example, you may push the STOP pushbutton to

stop the projector. After the problem is corrected,

push the START pushbutton to re-start the show.

Once the film is threaded and you are ready to

start the show, push the START pushbutton. The

INTERMISSION LED and the STOP pushbutton

LED will go off and the RUNNING LED and the

START pushbutton LED will come on. The projector will start running and the lamp will strike.

When the PICTURE START cue comes along, the

douser will open.

At this point, no further attention is required unless a film break occurs. If the film breaks, the LED

in the STOP pushbutton will blink rapidly. Simply

repair the film and re-thread. Then push the

START button to re-start the show. After a 7 second delay, the douser will open automatically. If

you wish the douser to open sooner, press the JOG

pushbutton which doubles as a timer bypass

switch.

The manual switches are there in the event that

the SHOWMATION is not functioning correctly.

These are self-explanatory. Normally you should

not have to use the manual switches unless there

is a problem such as the lens and masking are not

in the correct format. In that case use the manual

switches to correct the problem.

The HOUSE LIGHTS pushbuttons may be used at

any time to change the house lights levels. Normally, the house lights levels are controlled by the

SHOWGRAMMER II programming and the cues

on the film, so it is usually not necessary to use

these pushbuttons unless there is a problem. The

LED’s in these pushbuttons will change as the

SHOWGRAMMER II programming dictates so

you may tell at a glance what the house lights levels are.

The LIGHTS switch should always be in the

AUTO position so that the SHOWMATION can

control the lights. However, in an emergency this

switch can be used to

house lights levels, and when placed in the HIGH

position will bring the house lights to full brightness.

Interlock

The SHOWMATION has a three position INTERLOCK selector switch with the center position being OFF, or no interlock. The UP position is Interlock 1 and the DOWN position is Interlock 2. Two

different interlocks can be run simultaneously

with virtually any number of screens participating. For example, lets say that 6 screens are wired

together for interlock. Screens 1, 2, and 3 can run

on Interlock 1 while screens 5 and 6 are running

on Interlock 2, and Screen 4 is running standalone.

This is accomplished by simply setting the Interlock selector switch on each Front Panel to the appropriate position. You can set up any combination of screens for interlock in this way. While running, the Interlock state can not be changed accidentally. The only time the Interlock state can be

altered is in STOP mode. This prevents a condition

in which film might be broken if one projector

were to stop for some reason.

override

the programmed

15

Page 16

SHOWMATION AUTOMATION

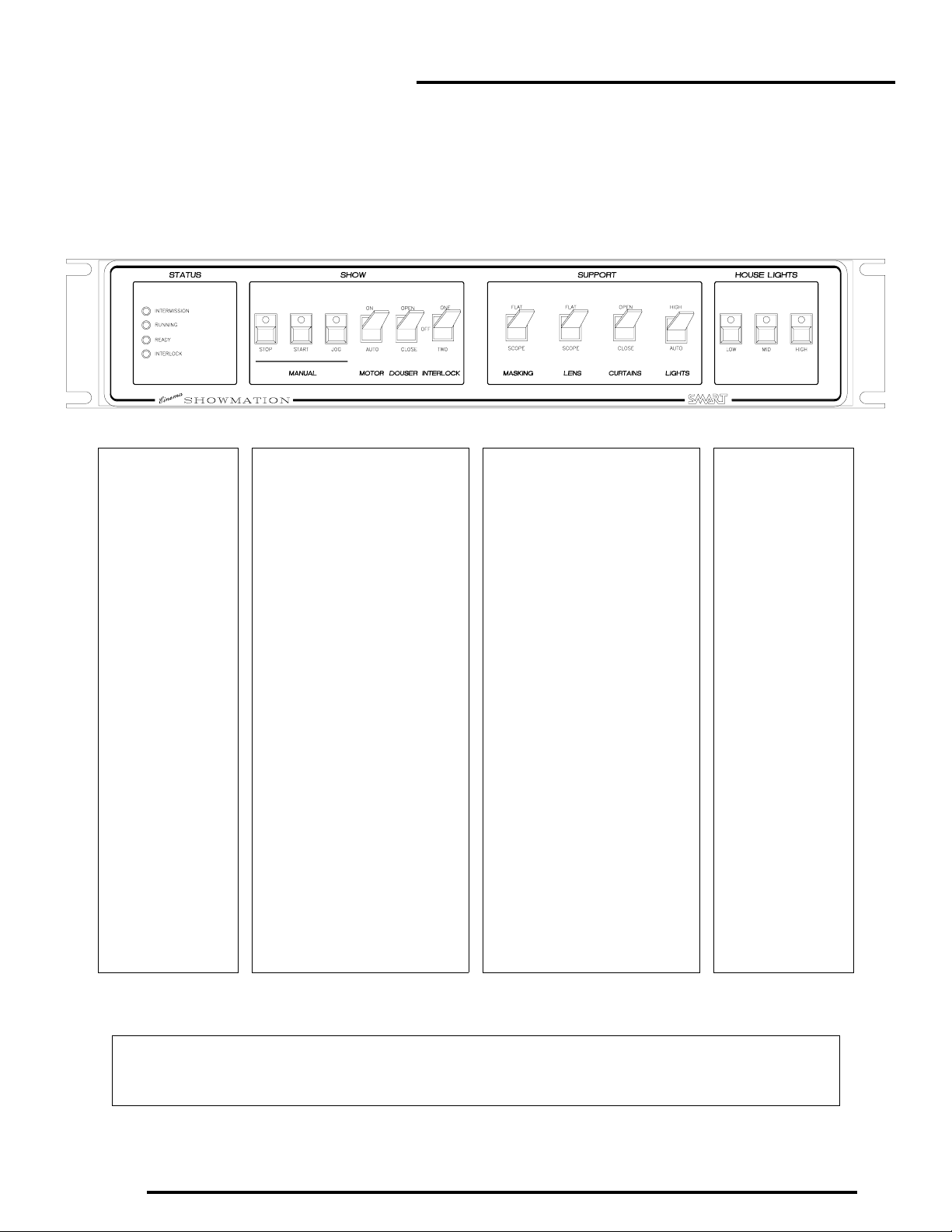

OPERATOR PANEL QUICK REFERENCE

The STATUS LED’s

indicate the current

state of the system.

The READY led is on

when the failsafe is

up.The system will not

start unless the

READY LED is on.

The RUNNING LED

comes on when the

show is started.

The INTERMISSION

LED is on between

shows.

The INTERLOCK LED

is on when one of the

two Interlocks is

selected

These switches and pushbuttons

control the major show functions.

The START pushbutton is used to

begin the show. The START LED

will be on while the show is running.

The STOP pushbutton will stop the

show, but will not normally need to

be pushed. The STOP LED will be

on during intermission and will be

rapidly blinking during a film break.

The JOG pushbutton is used to

momentarily run the motor to feed

film as an aid in threading up. Hold it

in to run the motor, and release it to

stop the motor. The JOG pushbutton

is also used as a timer bypass for

the 7 second douser open timer.

The MOTOR and DOUSER toggle

switches are for manual operation

and will not normally be used.

These toggle switches control the

show support functions.

The MASKING and LENS switches

are for manual operation and will not

normally be used unless the

masking or lens is set to the

incorrect format. Push these

switches to the FLAT or SCOPE

positions to select the

correct format.

The CURTAINS and LIGHTS

switches are for manual operation of

the curtains and for bringing the

house lights to maximum in an

emergency situation.

The HOUSE LIGHTS

pushbuttons can be

used to manually

select the lighting

levels desired.

The LED’s in the

pushbuttons indicate

the selected level.

Normally, the levels

are controlled by the

SMART

SHOWGRAMMER

which operates in

conjunction with the

automation system.

16

In a film break, the automation will shut down the projector. The STOP pushbutton will blink rapidly. After repairing the break

and re-threading, push the START pushbutton to re-start the show. Wait briefly to see that all is running OK and then push the

DOUSER toggle switch to the OPEN position to open the douser.

Loading...

Loading...