Page 1

Copyright 1995 by SMART Devices Inc.

5945 Peachtree Corners East

Norcross, GA 30071-1337

Table of Contents

SECTION 1 INTRODUCTION..............................................................2

SECTION 2 CARD DESCRIPTION......................................................3

SECTION 3 INSTALLATION.................................................................7

-

WIRING HOOKUP INSTRUCTIONS.................................7

SECTION 4 CALIBRATION..................................................................10

- B CHAIN CALIBRATION.................................................10

- A CHAIN CALIBRATION.................................................12

SECTION 5 OPERATING INSTRUCTIONS.........................................13

SECTION 6 SERVICE..........................................................................13

SECTION 7 SCHEMATICS ..................................................................16

LIMITED WARRANTY: SMART products and accessories are warranted against malfunction or failure due to defects in workmanship or

materials for a period of one year from the date of shipment. If a problem occurs during the warranty period, the unit will be repaired, or

replaced at our option, without charge for materials or labor. If air freight is requested by the dealer, the difference between air and surface

charges will be billed to the dealer. This limited warranty does not cover products that have been abused, altered, modified, or operated in

other than specified conditions. Prior factory approval is required on all returns. Returned equipment or defective parts must be shipped

freight prepaid to us by the dealer or customer.

Our limited warranty does not cover damages resulting from accident, misuse or abuse, lack of responsible care, or failures not attributable to

manufacturing defects, except as provided herein. SMART Devices, Inc. makes no warranties, express or implied, including warranties of

merchantability or fitness for a particular purpose.

RETURN POLICY: Factory authorization MUST be obtained before returning any product. A 15% restocking charge will be issued on unused

equipment (in original box) that is returned for credit. Credit is issued to the dealers account. The credit may be used against future purchases

and no cash transactions are offered. All returns must be shipped freight prepaid by the dealer. Equipment returned without a factory RA

(Return Authorization) will be refused.

SMART products are designed to deliver unsurpassed quality in workmanship and performance. The following information gives detailed instructions on the installation and operation of the SMART MOD V processor. We strongly encourage new owners of the MOD V to

thoroughly read this entire manual before placing their new SMART product into service.

This will ensure that the MOD V will be operated properly to give the superior performance

that it was designed to deliver.

For service or installation assistance, please call our

Technical Support Department between the hours of

8 a.m-5 p.m. E.S.T., Mon.-Fri.

1-800-45-SMART

Page 2

2

INTRODUCTION

The MOD V Stereo cinema processor is a full 8 channel

system delivering superior audio quality for any theatre.

This advanced processor comes standard with many features, yet is easy to operate, making the unit the best buy on

the market. The MOD V is fully compatible with all digital

formats, and was designed to easily process 70mm and

35mm magnetic soundtracks.

To achieve optimum results from your new MOD V cinema

processor, the theatre engineer installing the system should

be totally familiar with all features and adjustments. Careful

attention to detail and familiarity with the installation

instructions will allow you to offer a system that has a

sound quality second to none.

FEATURES

In addition to the standard features you find on other

processors, the MOD V offers many extras that makes operation easier and more flexible.

FADER CONTROL:

To begin, the MOD V has one MASTER FADER that controls the overall playback level for all 8 channels. This master fader is used as the volume control for all formats except

music mode. Seven trim controls on the front panel independently fine tune adjust (± 3 dB) the volume level of each

format. The music control on the front panel is the master

music level control. The trim faders allow matched levels

when the MOD V transitions between various formats. This

unique feature allows the MOD V to operate without constant attendance by a projectionist.

STATUS INDICATORS:

The operator control panel features a STATUS DISPLAY

readout that shows the mode the system is in at any time.

Red LED’s show which format is selected. The indicator

lights can be seen from a distance so it is not necessary to

be near the processor to verify the status. LED arrays on the

front panel indicate relative volume level for the five primary channels: Left, Center, Right, Left Surround and Right

Surround.

UPDATING FOR THE FUTURE:

Since the MOD V processor is totally modular, any new circuit developments or additional options may be added easily. This can be achieved by simply plugging in a new card

into the existing card cage when a factory exchange or

update promotion is offered. The system can stay up with

current and future technology at minimum expense.

MOD V COMPONENTS:

There are two main components included in the MOD V

system: the power supply and the card cage. There are also

several optional plug-in cards to give the system more features and greater flexibility. The system cannot operate

without the two main components, but can operate without

the options.

— POWER SUPPLY:

A heavy duty fully-regulated power supply is furnished with

the MOD V processor. This bipolar supply is heavily filtered and supplies ample current for both the positive and

negative 20 VDC supplies. This external power supply minimizes the chances of hum pickup when high gain electronic

circuits are placed in the same chassis as a power supply.

Also, the large power capacity of the supply provides a very

“stiff” voltage to all cards in the MOD V to prevent power

sag (momentary drop of the supply output due to heavy

loads). This gives excellent transient peak response and

superior stability.

— CARD CAGE:

The “working” part of the MOD V system is housed in a

card cage rack mount assembly that contains plug-in component cards for easy servicing and future expansion of the

system. A theatre may elect to start with a basic OPTICAL

STEREO sound system, update to a digital stereo system,

and eventually an eight channel system with sub-woofer.

The SMART MOD V is fully equipped to handle your

expansion needs. The MOD V will easily handle magnetic

soundtracks with the addition of external magnetic preamps

and two more noise reduction cards that easily plug into the

main card cage.

Installation and Service Manual

MOD V Digital/Optical Stereo Cinema Processor

Page 3

3

INSTALLATION & OPERATION

CARD DESCRIPTION

Each circuit card in the MOD V has its own on-board voltage regulators that stabilizes the circuits locally as well as filter

unwanted signals that may be present on the main power busses.

Test points are included on some cards for the sound engineer to access vital circuit points with his scope or meter. These

terminals will accept a meter probe or “alligator” clip.

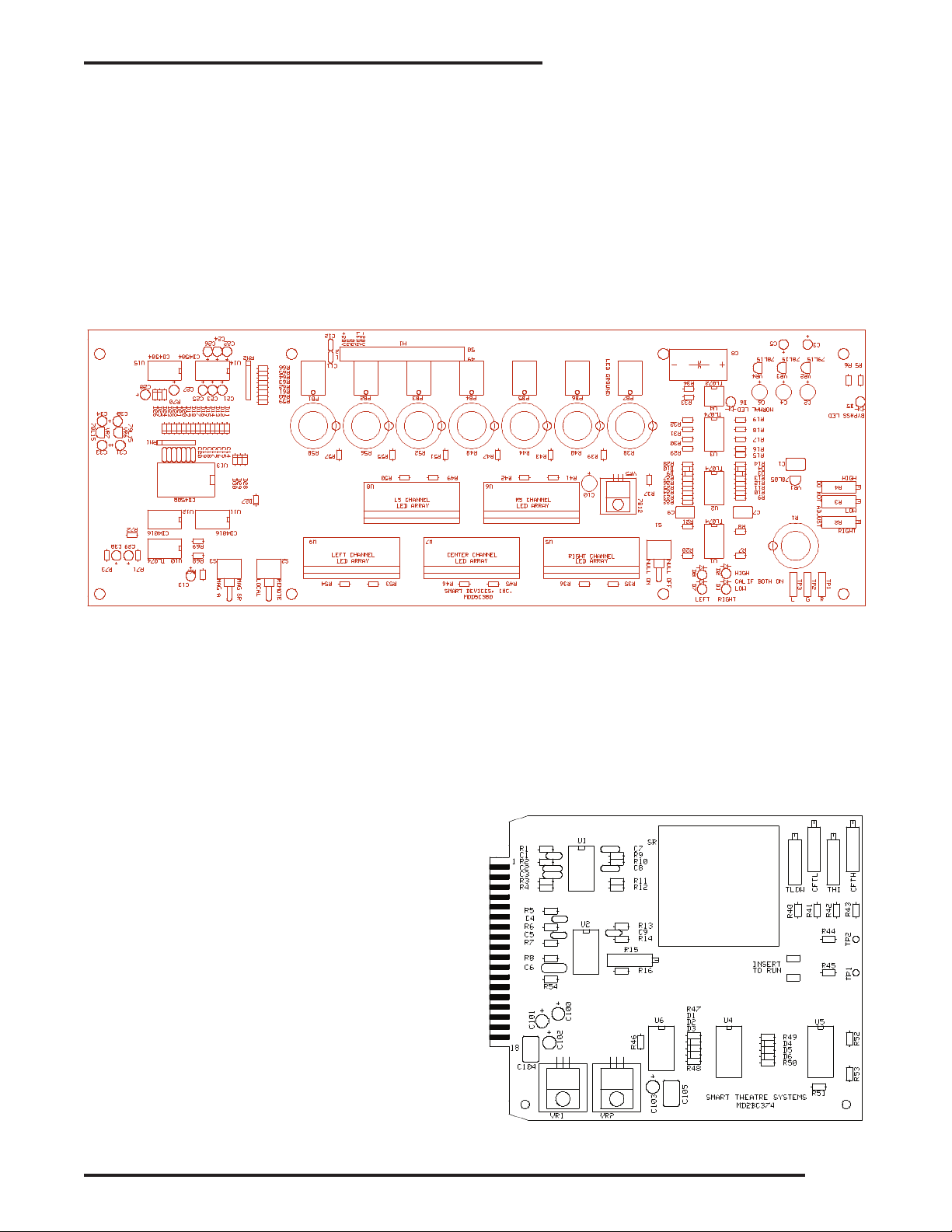

FRONT DISPLAY CARD:

MOD5X380

The front panel is where the Master Film Fader and individual Format Trim Level controls are located. This important card

has three switches (located on the inside of the unit) which are used for selecting various modes. To access these switches,

just pull the front panel forward from the top. The hinged front panel allows easy access to these switches.

The NULL switch is used during setup to change the LEFT SURROUND LED ARRAY circuit to indicate when a proper

surround null has been achieved. It should normally be left in the OFF position. The VOLUME switch selects either local

volume control or remote volume control. The third switch (only on the “C” version or later of the circuit board) is the

MAGNETIC NR switch which is used to select Type A or Type SR noise reduction for MAG prints. This switch is normally

set to MAG A.

Test points 1-3, located on the front right hand side of the board, is where you will find a convenient location for probing the

left and right outputs of the preamp card. The four red LED’s next to the preamp test points are used for setting preamp levels during setup.

NOISE REDUCTION CARDS:

MD2BX374

The SMART noise reduction cards provide noise reduction

for decoding Dolby type A stereo prints and Spectral

Recording (SR) encoded prints. The noise reduction circuitry

is automatically switched to the proper mode when selected

by the format switches on the front of the processor. There

are four trimpots and two test points on each NR card. These

are for factory use only. Do not attempt to adjust these

trimpots or use the test points. Two of the NR cards (slots 1

and 2) are dual purpose. They are used for both optical

stereo and for mag soundtracks, left and right channels. The

other two cards (slots 3 and 4) are strictly for mag use only,

center and surround channels. These two are optional and are

not shipped with every MOD V, since they are only used for

sound systems equipped for magnetic prints.

Page 4

4

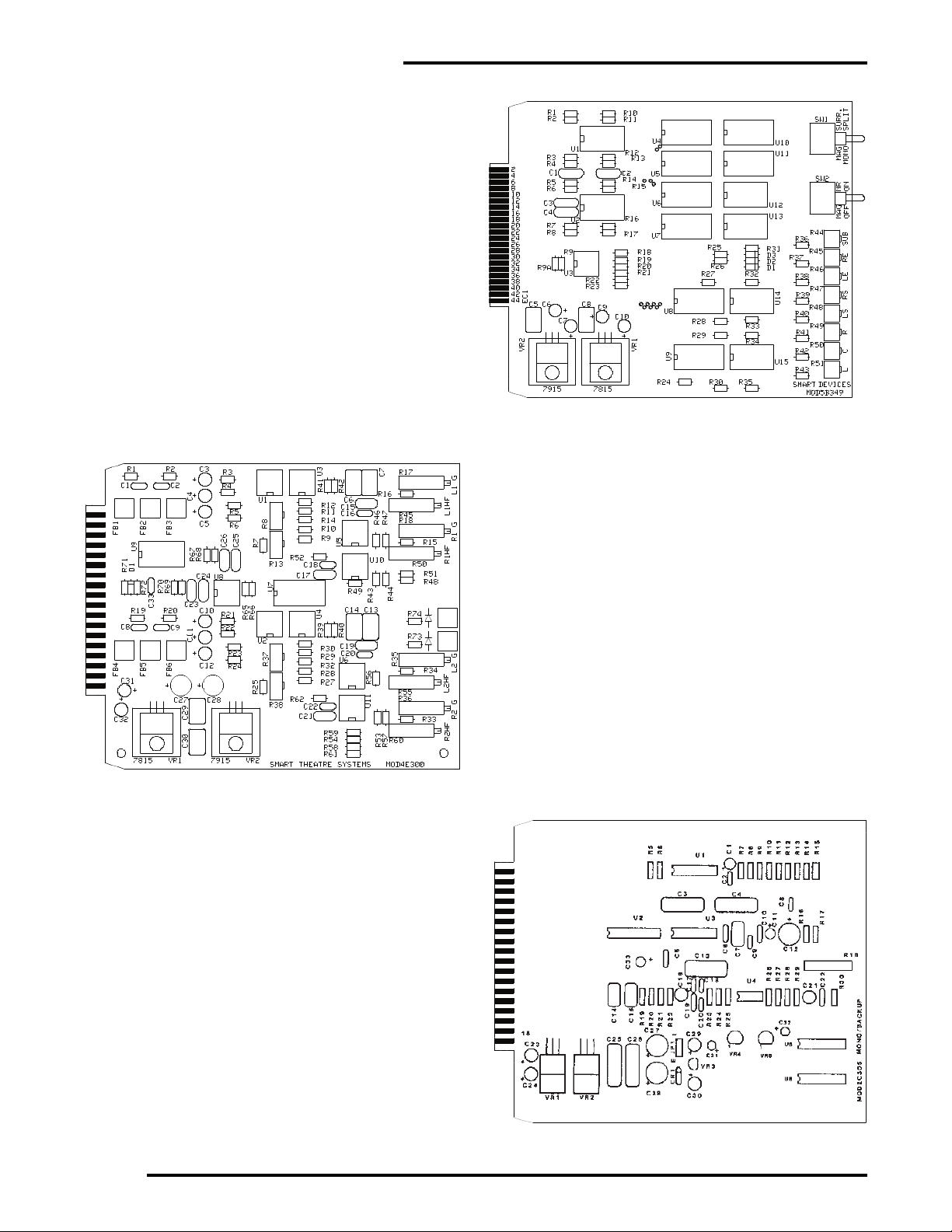

EXTERNAL INPUT/NR SWITCHING CARD:

MOD5X349

This card handles several functions related to external magnetic and digital signal sources, NR switching, and magnetic modes. Source selection of digital or magnetic signals is

provided by electronic switching I.C’s. These determine

which signals appear on the main signal busses of the MOD

V. This is dependent on which format is selected. The Left

and Right NR cards are switched between optical and mag

sources, again dependent on the selected format.

This card also has 2 toggle switches to select various magnetic sound modes. The bottom switch selects MAG NR

ON or OFF. Since most mag prints use NR encoding

(Dolby 70), this switch is normally ON (up position). The

top switch selects mag mono surrounds or split surrounds.

Because most mag prints do not have split surrounds, this

switch should normally be left in MONO (down position).

DUAL PROJECTOR PREAMP CARD:

MOD4X300

There are 2 stereo solar cell preamplifiers in the MOD V:

each preamplifier channel is equipped with slit-loss correction. The Stereo-optical preamplifiers on this card increase

the incoming level from the stereo solar cells. Electronic

changeover circuitry between stereo pairs is built on the

card to allow use in dual projector booths. If the MOD V is

installed in a single projector booth, leave the second projector inputs unconnected.

The Dual Projector Preamp Card has two solar cell preamplifier gain controls and two slit-loss correction circuits for

each projector. There is sufficient gain built into the preamps for narrow slit optical sound lenses when the exciter

lamp is run at 80% of its rated value. The card is silk

screened to make it easier to see the location of each preamplifier gain and slit-loss correction control pot.

MONO/BACKUP CARD:

MOD2X305

The MONO card provides the necessary frequency response

shaping and level shifting to provide a quality mono signal

from mono prints. In addition, a special open ended noise

reduction circuit called Dynamic Noise Reduction is used to

eliminate much of the “hiss” and film scratch noise often

present on film. This card also provides the necessary drive

signal for the optional stereo synthesizer portions of the

MOD V.

The MONO card contains the necessary circuitry for the

emergency backup system in the event of loss of sound

within the MOD V processor. The multi-turn pot on this

card is for setting the emergency backup level.

Page 5

5

INSTALLATION & OPERATION

MATRIX CARD:

MOD4X317

This is the heart of the stereo conversion process. The Wide

Trac Deluxe Matrix card takes the signal from the preamp

and noise reduction circuits and converts the two channel

soundtrack into the four channels required for normal stereo

mode. There is a surround null adjustment trimpot on the

matrix card which the installer can adjust to minimize surround channel crosstalk without disturbing the input signal

calibration settings of the preamplifier and noise reduction

circuits.

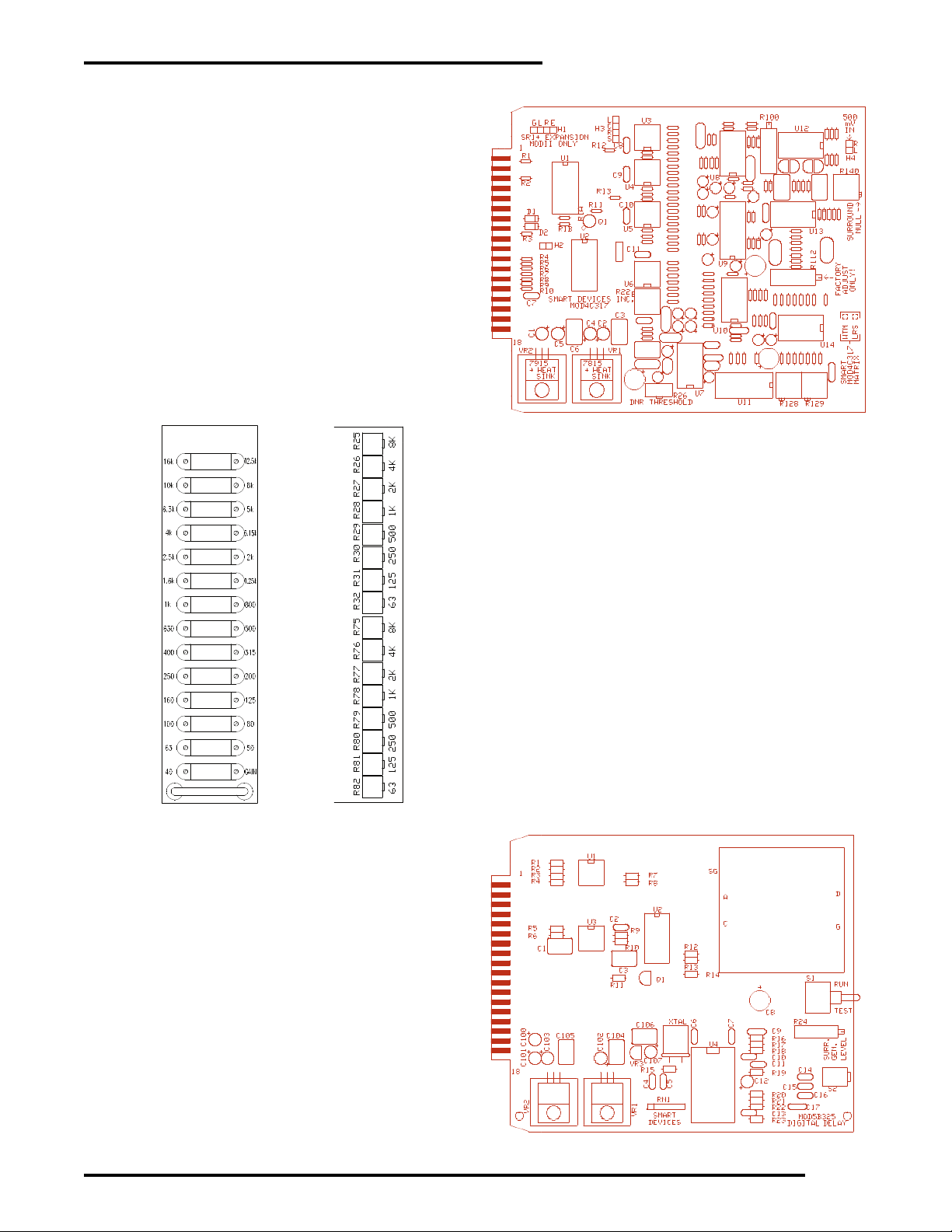

1/3 OCTAVE EQUALIZER CARDS:

MOD4X320

Three one third octave room tuning equalizers are used for the

front stage speakers. Each adjustable frequency band in the

front stage EQs may be cut or boost ± 10 dB. A +6 dB gain

adjustment is also on each card. For overall unity gain, leave the

gain pot in the CCW position. For unity gain on each of the frequency band adjustments, leave the pot in the mid position. All

pots are the single turn type.

DUAL CHANNEL ONE OCTAVE EQUALIZER CARD:

MOD4X324

This card is for the Left and Right Surround Channels. Circuitry

and operation is similar to the stage channel EQs except that it

uses one octave EQs and there is no gain adjustment pot. The

top eight trimpots are for Left Surround, and the bottom eight

are for Right Surround.

DIGITAL TIME DELAY/SURROUND GENERATOR

CARD:

MOD5X325

The digital time delay portion of the MOD V system is contained on this card, along with the optional Stereo

Generator Surround Module. The surround channel passes

through the time delay whenever any Stereo-Optical format

or Stereo Generator format is selected by the operator.

35mm magnetic, 70mm magnetic, Music or digital inputs

are NOT time delayed. There is a rotary switch on this card

that is used to set the time delay setting. The rotary switch

has 16 positions: 0-9 & A-F. Position 0 is 10 milliseconds

of delay, which is the minimum delay setting. Each position

clockwise adds 10 milliseconds of delay for a maximum

setting of 160 milliseconds (position F).

Note: Earlier units used an analog time delay card. This

card had dip switches that set the time delay. All switches

down (on position) produced a minimum delay of 35 milliseconds. Each dip switch flipped up (off position) added

10 milliseconds of additional delay.

1/3 Octave EQ One Octave EQ

Page 6

6

OUTPUT/MUSIC CARD:

MOD5X331

Eight channels of audio, comprised of the primary stereo

channels (Left, Center, Right, Sub, Left Surround and Right

Surround), along with the Left-Extra and Right-Extra channels, pass through the MASTER VCA (Voltage Controlled

Amplifiers). The digital inputs also allow for separate Left

Surround and Right Surround channels in addition to a separate subwoofer input. The VCAs exhibit very close tracking between channels and are controlled by the MASTER

FILM FADER and individual FORMAT LEVEL TRIMS

contained on the front panel. Music Fade-in and Fade-out,

controlled by the automation or front panel format switch,

is also on the output card along with a special music matrix

to generate a four channel non-sync sound from a standard

two channel music tape or CD player.

FRONT STEREO GENERATOR CARD (optional):

MOD2X340

A deluxe Stereo Generator (synthesizer) is offered as an

optional feature of the MOD V system. The synthesized

front channel circuits are included on this card. The optional

surround generator is part of the DELAY/SURROUND

GENERATOR card in another part of the system. The output levels for the three stage synthesizer channels should be

adjusted ONLY after the main stereo-optical channels have

been correctly adjusted. The synthesizer levels should be set

to be the same as other stereo channels so that a transition

between film format modes will appear smooth to the audience without large level changes. Three multi-turn pots are

located on the front of the Stereo Generator PC board to

adjust the Left, Center, and Right channel outputs.

SUB WOOFER/BASS EXPANDER CARD:

MOD5X346

The last PC board on the far right of the MOD V card cage

contains the subwoofer output circuitry and the EMERGENCY BYPASS switch. Switching the MOD V into

emergency bypass mode is as simple as flipping the red

bypass switch. The bypass audio level is set by a multi-turn

pot on the Mono Backup card.

This card is equipped with an optical expander circuit that

works only when optical sound formats have been selected

(Stereo, SR & Stereo Generator), and not on Magnetic,

Digital inputs, or non-sync music. The small ON-OFF toggle switch on the front of the PC board turns the subwoofer

circuit on or off. The Sub-Bass optical expander expands

the output level at a 1.5 to 1 ratio in the low frequencies.

The Sub-Bass card is equipped with a five band 1/3 octave equalizer. The frequency adjustments are 31, 40, 50, 63 and 80

Hz. This gives good coverage of the sub-bass region.

Page 7

7

INSTALLATION & OPERATION

Bandpass shaping for the low frequency subwoofer output is selectable with various settings of the DIP switches at the front

of the PC card. The High Pass filter has a fixed slope of 12 dB/octave, and the Low pass filter is 18 dB/octave. The following

combinations of switches will configure the filters for the desired LF bandpass output.

DIP SWITCH SETTINGS FOR VARIOUS FREQUENCY BANDPASS CHARACTERISTICS

ALL switches UP for wide-band frequency response. Useful when feeding a sub-woofer power amplifier that has built-in filters.

ALL F1 switches DOWN - ALL other switches UP for 10-65 Hz

response to sub-woofer output.

F2 switches DOWN with ALL other switches UP will give a 10-200 Hz

response.

ALL F1 switches and HPF (high pass filters) DOWN, with F2 switches

up for 25-80 Hz frequency response.

ALL F2 and HPF switches DOWN with F1 switches up results in 35225 Hz bandpass.

If ALL DIP switches are set to the DOWN position, the output response

will be 23-68 Hz.

The Subwoofer/Bass expander card has individual output level adjustments for

Optical, Digital, Magnetic, and Music Formats. Each format sub-bass level may be set separately.

PROCESSOR PLACEMENT IN THE RACK:

Before mounting the MOD V processor in the equipment

rack or projector console, be sure to select a well ventilated

area that allows cool air to circulate around the individual

components. In SMART prewired rack systems, the Power

Supply is mounted on the floor of the rack, and the rackmounted processor is placed at eye level for easy visibility

of the system operation status.

Make sure that the processor is not immediately adjacent to

hum producing components. Run the factory-supplied

power supply wiring harness along the left side of the

equipment cabinet (when viewed from the rear) to the MOD

V processor. Dress the wires for appearance and craftsmanship. The wiring harness has a connector that plugs into the

back of the MOD V. Make sure to observe polarity. As you

are looking at the back of the MOD V, the far left connector

is where the power supply harness plugs in. The power supply wires will exit from the bottom of the connector. The

red wire should go to the terminal marked +20 VOLTS, the

black wire to PS GROUND, and the yellow wire to -20

VOLTS. Remember to check all connections before applying power to the system. A wire that is reversed could be

very destructive to the system.

EMERGENCY SUPPLY:

The emergency power supply is contained within the Main

Power Supply. There is a white wire with a red stripe that is

part of the power supply harness and it should be connected

to the MOD V terminal marked BYPASS DC, and the black

lead should connect to the terminal marked BYPASS GND.

WIRING HOOKUP INSTRUCTIONS:

EASY HOOKUP:

All connections are made to rear of the MOD V with plugin Entrelec connectors (supplied). Inputs, Outputs, Power

and Control connections are carefully laid out in groups.

Please do not bundle the wires together with tie-wraps.

Make sure each group has good separation between lowlevel and high-level signals.

SOLAR CELL HOOKUP:

Connect the wire from the left solar cell (red) to the corresponding LEFT projector input terminal of the MOD V.

Connect the wire from the right solar cell (green) to the

RIGHT projector input terminal. The common solar cell

lead (black) should be connected to the NEUTRAL projector input terminal, and the shield of the cable to the

GROUND terminal. Be sure to cut off the shield at the projector end so that a ground loop is not created. Only the

shield on the MOD V end of the cable should be grounded.

It is good practice to tape or shrink wrap the end of the

shielded cable at the sound head to prevent any stray shield

wires from grounding out to the sound head case.

INSTALLATION INSTRUCTIONS

Page 8

8

DOUBLE CHECK your work to see that the solar cell leads

arrive at the proper terminals. A reversal of leads will cause

very strange results. You may hear the center channel information through the surround speakers, the surround through

the stage, and the left channel out of phase with the right.

This is a common error, so verify correct wiring before proceeding.

AUTOMATION TERMINALS:

A momentary ground contact to one of the format terminals

on the automation inputs of the MOD V will switch the

processor to any desired format, including music. When the

MOD V is in music mode and any one of the film formats

are pulsed, the film sound will appear at the main outputs,

and the music will slowly fade out. While the processor is in

one of the film formats and the music terminal is pulsed, the

MOD V will fade from the film mode to music.

OUTPUTS:

The 8 channel outputs are labeled LEFT, LEFT EXTRA,

CENTER, RIGHT, RIGHT EXTRA LEFT SURROUND,

RIGHT SURROUND, SUB+ and SUB-. Shielded cable

should be run between these terminals and the next piece of

equipment in the sound system (equalizer, amplifier, etc.).

Convenient GROUND terminals are provided near the outputs. A balanced subwoofer output is available on the MOD

V. The balanced output provides an easy means to mono

bridge the sub amplifier.

CHANGEOVER WIRING OF DUAL PROJECTOR PREAMPS:

Changeover between projectors is done electronically in the

MOD V. This necessitates that BOTH exciter lamps be lit at

the same time. No exciter light changeover is provided in

the unit. An exciter light changeover has at least 3 dB more

circuit noise than an electronic changeover and is NOT recommended in high quality systems.

Projector changeover is accomplished by using only a single

pair of wires and either a manual switch or relay contacts in

the automation system. A relay closure in the automation

equipment will execute a changeover by grounding the

CHANGEOVER terminal. Run a pair of twisted unshielded

wires to the “dry” contacts of the automation projector

changeover relay. Connect one wire from the other end of

the pair to the CHANGEOVER terminal of the MOD V

only. Ground the other wire of the pair to the nearest ground

terminal on the MOD V. When the automation relay closes,

projector TWO of the MOD V will be “enabled,” and the

first pair of stereo preamplifiers (PROJ 1) will be “disabled.” Releasing the relay will cause the reverse action to

occur. In other words, PROJ 1 is always ON until the

CHANGEOVER terminal is grounded. The

CHANGEOVER terminal must be held low to activate

PROJ 2. It is not a pulse input.

DIGITAL INPUTS:

The MOD V system has 8 inputs on the rear barrier strip

labeled for each channel of a digital decoder. There is also a

DB25 input connector that can be used for digital inputs

(see the REAR CHASSIS DB25 SECTION for specific

pinout designation). The Digital inputs accept any high

level multi-channel source and route the signals through the

MOD V, which includes the Master Fader and EQs.

Another application of the Digital Input terminals is for

external sync sources. Sound-Interlock from a 35mm reproducer or a single 16mm projector may be fed into the

Digital inputs and selected with the front panel DIGITAL

program switch on the MOD V front panel.

MUSIC INPUT:

The non-sync music inputs for the MOD V feature a special

music matrix decoder that separates in-phase and out-ofphase signals on a standard two channel recording (CD

player or tape) and creates four channels of auditorium

music. Connect your stereo music source to the LEFT and

RIGHT MUSIC inputs on the MOD V.

Occasionally, a theatre may use a monaural sound player

such as a background music cartridge player that does not

have stereo capabilities. A jumper on the OUTPUT CARD

in the MOD V is moved to the MONO position for this use.

The music source should then be connected to both LEFT

and RIGHT MUSIC inputs. Music will appear on all stage

channel and surround speakers when mono material is feeding the sound system.

REAR CHASSIS DB25 CONNECTORS:

The computer type DB25 connectors on the back of the

processor are for special inputs and outputs. On the far left

(as you view the rear of the chassis) there is a DB25 connector that provides monitor outputs of all channels for a

THX booth monitor/crossover package. Output pinout of

the DB25 connector is compatible with a THX monitor.

You may use a shielded SERIAL computer cable to make

Page 9

9

INSTALLATION & OPERATION

the connection between the MOD V and a THX monitor.

The cable should have a male DB25 on one end, and female

on the other end. You must use a cable in which all pins of

the DB25 are connected. Some computer cables do not connect all pins. The middle DB 25 connector provides inputs

for 70mm magnetic signals from external preamps. The far

right DB25 connector is an alternative input connection for

a digital decoder (i.e. DTS, Dolby Digital). See below for

specific pinout configuration.

The MONITOR DB25 outputs:

Pin 2 Left

Pin 16 Left Extra

Pin 5 Center

Pin 8 Right

Pin 19 Right Extra

Pin 23 Left Surr.

Pin 24 Right Surr.

Pin 25 Sub+

Pin 12 Sub Pins 3, 10, 11, 14, 17 & 20 Ground

The MAGNETIC DB25 inputs:

Pin 1 Left

Pin 2 Center

Pin 3 Right

Pin 4 Surround

Pin 5 Left Extra

Pin 6 Right Extra

Pins14-20 Ground

The DIGITAL DB25 inputs

Pin 1 Left

Pin 3 Center

Pin 5 Right

Pin 6 Left Surr.

Pin 7 Right Surr.

Pin 8 Sub

Pin 12 Digital

Pin 13 Stereo A / Stereo SR *

Pin 14 Ground

*see Default Optical Selection below

DEFAULT OPTICAL SELECTION:

External Digital Decoders available on the market (i.e.

DTS) have a function that instructs the processor to switch

to an optical format in the event that the digital decoder fails

or loses time code. When this happens, the digital decoder

will pulse a special terminal to ground to alert the processor

to switch to the optical format.

On the MOD V Digital DB25 input connector, this terminal

is the Stereo A / Stereo SR pin (see above). The MOD V

will switch to either Stereo A or Stereo SR depending on

the location of a 0 ohm resistor jumper located on the lower

right side of the back motherboard.

The MOD V is shipped to default to Stereo A in the event

of a digital decoder problem. In this default mode, J1 has a

0 ohm resistor installed and J 2 does not. For a default setting of Stereo SR, you must remove the 0 ohm resistor

jumper on J1 (it must be desoldered) and one must be

installed on J2 (soldered in place). The factory default setting of Stereo A should be adequate for most theatres.

However, if a Stereo SR default is desired, then all plug-in

cards must be removed along with the internal tray in order

to access the back motherboard. Use extreme care when

removing and plugging in the circuit cards. Make sure

power is removed from the system before doing so.

MUTING FUNCTION:

A convenient mute terminal on the back of the MOD V

allows all output channels of the MOD V to be silenced

whenever this terminal is grounded.

Note: On earlier units, the MUTE terminal was mistakenly

marked as GROUND. This terminal is the sixth one from

the left on the far left entrelec connector as viewed from the

rear of the MOD V.

REMOTE FADER OPERATION:

The volume control of the MOD V can be operated remotely at another location, independent of the MASTER FILM

FADER. This can be accomplished by adding a remote, linear taper 10k ohm pot (to act as a volume control) between

the REM SEND and GROUND terminals on the back of the

MOD V. Connect the wiper of the remote pot to the REM

RETURN terminal. (See diagram.)

The toggle switch on the left hand side of the front panel

display board, labeled VOLUME SELECT, allows the operator to select either local or remote volume control of the

MOD V. This switch is easily accessible by opening the

hinged front panel.

Note: Remote operation is for film formats only, and will

not affect the music level.

GROUNDING

On the left rear side of the MOD V (see below), next to the

power supply terminals, a special ground wire has been

added to allow jumpering of the MOD V circuit ground to

the system chassis ground. Normally, this wire is left

unconnected which separates circuit ground from chassis

ground. In most cases, this will result in the least amount of

ground loop problems.

In the event of ground problems, this wire may be connected to any terminal marked GROUND on the rear of the

MOD V. This will then jumper the circuit ground to chassis

ground. Take special caution when diagnosing ground problems; what may work with one sound system may not necessarily work with another.

Rear view of MOD V showing the special ground wire.

Page 10

10

CALIBRATION

The Sound Systems should be turned on for at least one

hour before alignment. All doors should be closed and the

exhaust fan should be running if the MOD V is placed in an

equipment rack.

Note: Before plugging or unplugging cards in the MOD V

during calibration, be certain power is removed from the

MOD V. Otherwise, damage to cards or the processor may

result!

EQUIPMENT REQUIRED:

Sound Pressure level meter, real time analyzer with a calibrated microphone, dual trace oscilloscope, multimeter, a

tuning wand and appropriate test loops.

B CHAIN CALIBRATION:

PRELIMINARY:

It is desirable to have a SMART PINK NOISE GENERATOR CARD and, optionally, an EXTENDER CARD for

performing the calibration and testing of the MOD V. Note:

Make sure the SMART Pink Noise Generator Card has the

following minor modification: There must be a jumper wire

between pins 4 & 5 of the edge connector as viewed from

the component side. This allows the Surround switch to

simultaneously feed pink noise to both Left and Right

Surround channels. A future version of the Pink Noise

Generator card will have separate Left and Right Surround

switches.

The PINK NOISE card may be plugged directly in without

the extender card, but it is easier if the extender card is used

with the PINK NOISE card. The PINK NOISE card plugs

into the MATRIX CARD position for setting house EQ levels and into the PREAMP CARD position for setting subbass levels. The PINK NOISE CARD has seven switches.

The bottom switch is used to select NORMAL or CHOOCHOO modes. The top six switches are used to turn individual channels on and off. These channel switches are

three position, with center position being off, the top position giving an in phase signal and the bottom position giving an out of phase signal. There is a built-in high quality

pink noise source which feeds these switches.

If a Pink Noise Card is not available for the MOD V calibration, then an external pink noise source may be used

instead. Feed the external pink noise source into the DIGITAL inputs on the rear of the MOD V for the following

checks. Set the pink noise source level for .55 volts RMS.

You must use an analog meter to measure this voltage level.

Special Note: The factory settings for digital levels on the

External Input/NR Switching Card should be left as they are

while using an external pink noise source. This will ensure

that the house levels are set correctly. Normally, the digital

input levels on the External Input/NR Switching card do not

need adjustment, but if they must be adjusted, do so AFTER

setting house levels. See the DIGITAL LEVEL SETTINGS

at the end of the B CHAIN CALIBRATION section for

more information.

For the following procedures, select STEREO by pushing

the appropriate button on the front panel. Also, set the front

panel MASTER FILM FADER to the CAL line, and the

trim faders to the 12 o’clock position.

EQUALIZATION AND HOUSE LEVELS:

The equalizers are normally shipped with the individual

trimpots set for a flat frequency response. The 1/3 octave

equalizers used for the stage channels are capable of cutting

and boosting each frequency band ± 10 dB. The individual

trimpots are single turn types, with the mid position of each

pot being flat (unity gain).

The dual-channel surround equalizer card is a full octave

band type. All frequencies on this card are also cut and

boost ± 10 dB with single turn trimpots.

Remove the MATRIX CARD from its slot and set it aside.

Plug the PINK NOISE CARD into the MATRIX CARD

slot. Make sure the NORMAL/CHOO-CHOO switch is in

the NORMAL position. Turn on the appropriate switch on

the PINK NOISE CARD for the channel you wish to equalize. Perform the equalization and then adjust the output

trimpot on the OUTPUT/MUSIC CARD so that 85 dBC spl

is measured in the auditorium. Do this for the five main

channels (Left, Center, Right, Left Surround & Right

Surround). If more gain is needed, then the gain pot on the

ISO Cinema playback standard states that 1/3 octave bands

should be tuned for flat response to 2 kHz, with a 3

dB/octave rolloff above 2K.

The optional extender card can be used with the Pink Noise

Card to calibrate the MOD V. This allows easier access to

the Pink Noise Card.

10

5

0

-5

-10

-15

31.5 63 125 250 500 1K 2K 4K 8K 16K

Page 11

11

INSTALLATION & OPERATION

stage EQs can be used which gives an additional 6 dB of

gain. However, do not boost the gain on the EQ cards unless

it is absolutely necessary.

The 1/3 octave stage channel equalizers in the MOD V

allow the same tuning results obtained in professional room

tuning filter sets used in high-end sound playback applications. Sound contractors learned, a long time ago, that

boosting frequency bands adjacent to bands that are cut

introduce a phase shift that the ear is very sensitive to.

Although the test instruments show a nice curve, the sound

has a coloration that is not natural. For this reason, we

encourage you to apply the minimum amount of boost and

cut whenever needed. Never over-equalize the system. All

frequencies may be cut and boosted by as much as 7 dB in

each of the 1/3 octave bands without creating the above

problems. The use of bass and treble controls on the equalizer has also been avoided to further minimize phase shift.

Each filter section uses a single turn trimpot for adjustment.

The equalizers are factory set for flat response during final

QC test.

Before attempting to equalize be sure the stage speaker connections are properly polarized, the polarity of the components in each speaker system is correct, and the speaker

devices are mechanically aligned according to the manufacturer’s recommendations. Remember that equalizers are

used to tune the room, NOT to correct poor speaker installation and alignment.

If LE and RE are being used, turn on the pink noise for

these channels (one at a time) and adjust the output trimpots

for 85 dBC spl. There are no equalizers for the LE and RE

channels.

SUB-BASS LEVELS:

Remove the PREAMP CARD from

its slot and set it aside. Remove the

PINK NOISE CARD from the

MATRIX CARD slot and plug it into

the PREAMP CARD slot. Do not

plug the MATRIX CARD back in yet.

Turn on the LEFT and RIGHT pink

noise switches. Adjust the individual

EQ adjustments on the Sub-Bass Card

for a flat low frequency response from

the subwoofer. Each EQ pot allows a

± 10 dB range. Adjust the OPTICAL

LEVEL trimpot on the Sub-Bass Card

for 90 dBC spl from the subwoofer. In

Music or Mag modes, adjust Music or

Mag pots for the desired sub levels. In

Digital mode, set Dig sub pot per digital processor instructions.

OPTIONAL GENERATOR FUNCTIONS:

If your MOD V is equipped with the optional stereo and

surround generator modules, then do the following adjustments:

Install the J1 jumper on the Front Stereo Generator Card to

the rear two pins to prevent high frequency attenuation

when in Generator mode. Insure that the Pink Noise

Generator Card is plugged into the preamp slot. Switch on

the pink noise for the Left and Right channels (in phase),

and flip the Digital Time Delay/Surround Generator Card

switch to the TEST position. Turn the surround amp off.

Now adjust the Left, Center and Right generator levels on

the Front Stereo Generator Card to read 82 dBC in the auditorium. To do this, switch the power amplifiers off and set

gains one channel at a time, by switching on only the amplifier for that channel being adjusted. Once stage levels are

balanced, switch all power amps on and check to insure that

a sound pressure level of 85 dBC is obtained. Turn off the

stage amps and turn on the surround amp. Adjust the level

pot on the Digital Time Delay/Surround Generator Card for

an auditorium level of 85 dBC. Flip the RUN/TEST switch

back to RUN and turn all amps back on. Remove the Pink

Noise Generator Card.

Plug the MATRIX and PREAMP Cards back into their

appropriate slots.

MUSIC LEVELS:

Set the MUSIC LEVEL control on the front panel to the 3

o’clock position. Select Music mode and turn on the music

source that is feeding the MOD V. Turn the left and right

music level trimpots on the Output/Music Card to obtain a

normal house level. These trimpots are factory set and may

not need adjustment. DO NOT TURN THESE UP TOO

HIGH as music-to-film crosstalk may occur. Adjust the

trimpots so that right and left music are set to the same

level. The music circuit in the MOD V has a simple matrix

which generates four channels of music from any 2-channel

stereo music source.

TIME DELAY:

Locate the 325 DIGITAL TIME

DELAY/SURROUND GENERATOR

Card. The bottom of this card has a

rotary switch. Each position clockwise

on the rotary switch equals 10 mSec

(milliseconds) of delay. Position 0 is

the minimum delay setting which

equals 10 mSec of delay. Position 1

produces a total of 20 mSec of delay,

position 2, 30 mSec, etc. The maximum amount of delay possible is 160

mSec. Measure the distance in feet

from the ideal seat (which is usually

2/3 of the way back from the stage

speakers, centered side to side) to the

stage speakers. Now measure the distance from the ideal seat to the nearest surround speaker. Subtract the two measurements. Now add 20 to this number to get the

delay (in milliseconds) required in the auditorium. Set the rotary switch to the nearest setting in milliseconds.

DIGITAL LEVEL SETTINGS:

Incoming signals from the Digital input terminals SHOULD be trimmed externally to match

levels from the Stereo-Optical signals. These

adjustments can be made at the output of the

external digital processor or interlock audio

tape machine (see manufacturer’s manual). If

necessary, additional digital level adjustments

can be made on the MOD V EXTERNAL

INPUT/NR SWITCHING CARD, which has

eight trimpot adjustments for cutting or boosting the input level of each individual digital

channel. Normally, this card is set for unity

POSITION DELAY

0 10

1 20

2 30

3 40

4 50

5 60

6 70

7 80

8 90

9 100

A 110

B 120

C 130

D 140

E 150

F 160

Page 12

12

gain. Make sure that all other B-chain calibration adjustments have been made prior to adjusting the digital input

levels on the External Input/NR Switching Card (see special

note in the PRELIMINARY section of the B CHAIN CALIBRATION).

A CHAIN CALIBRATION:

PRELIMINARY:

1. Clean soundhead optics, exciter lamp, optical lens and

solar cell before attempting a soundhead alignment.

2. Set exciter lamp voltage for at least 80% of rated voltage.

BXM 9 volt 4 amp — 7.2 volts

BXN 10 volt 5 amp — 8 volts

Most foreign 6.3 volt 4 amp — 5 volts

3. Make sure film/cell spacing is approximately 1mm with

the slit image striking the top one-third of solar cell.

4. Connect scope and real time analyzer to the left and right

preamp outputs on the rear terminals of the MOD V, or at

the test points (mini-banana jacks) on the front panel display board.

5. Locate gain controls on 300 Preamp Card. Turn gain

controls fully clockwise.

6. Turn the MASTER FILM FADER all the way down to

avoid excessive noises in the auditorium

for the next steps.

SOUNDHEAD ALIGNMENT:

1. Play a S.M.P.T.E. Buzz Track loop.

Adjust the lateral film guide assembly or

exciter lamp assembly. Monitor the preamp signals with the oscilloscope. Adjust

for minimum signal on the left and right

channels. Refer to specific instructions in

the projector soundhead manual. Minor

variations in alignment procedure depend

on the individual mechanical design of the soundhead.

2. Play CAT.# 97 Stereo Cell Alignment Film. Move solar

cell laterally and vertically until you have achieved minimum crosstalk between channels (see above right).

3. Repeat steps 1 and 2 until no further improvement can be

obtained.

4. Play Pink Noise side of CAT.# 69 Test Film. Switch

scope to X/Y Mode. Adjust soundhead optical lens azimuth

for narrowest diagonal trace. Observe the real time analyzer

and focus the lens for maximum high frequency output

while maintaining the best azimuth. This is not easy, but it

is one of the most critical adjustments affecting the overall

system performance and is often not done as well as it

should be.

5. Adjust the vertical and lateral alignment of the EXCITER

LAMP for maximum output on both channels. This is especially critical with a narrow slit optical lens because there is

a much smaller “window” for the light to pass through.

6. Check the high frequency output on both channels. Make

sure the response is the same on both channels. With a nar-

row slit optical lens, the response should be flat within ± 3

dB to about 12 kHz with NO slit loss correction. If not, this

MUST be corrected before proceeding with the next steps.

It is not permissible to use slit loss correction to correct

poor high frequency response caused by misalignment of

the optical soundhead. An EXCITER LAMP out of alignment, the barrel of the optical lens crooked, or oil in the

optical lens will all affect output and balance.

OPTICAL PREAMP CALIBRATION:

Run the pink noise side of the CAT. # 69 loop. Observe the

frequency response on your RTA which is still connected to

the preamp testpoints. Adjust the left and right slit loss correction trimpots on the PREAMP CARD for optimum flat

high frequency response. Do not over adjust the slit loss

correction in an effort to obtain extended response. This will

result in an undesirable frequency response peak.

Note: While adjusting the slit loss correction, aim for as flat

a high frequency response as possible. If one of the preamp

channels is slightly worse than the other, then adjust the better responding preamp to match the lesser. This will ensure

that the matrix steering in the MOD V will be as accurate as

possible.

While running the Dolby CAT. # 69 loop, tone side.

Observe the preamp calibration LED’s on the front panel

display board. These LED’s are located near the right front

of the display board, component side. Adjust the LEFT and

RIGHT trimpots on the PREAMP CARD until both LED’s

Low crosstalk between channels.

The preamp calibration LED’s

Page 13

13

INSTALLATION & OPERATION

for left and both LED’s for right are on simultaneously.

There are preamp testpoints located just to the right of the

calibration LED’s to which you may hook up an AC voltmeter to accurately measure the preamp levels. The correct

level for Dolby tone is 707 mV AC.

SURROUND NULL:

Make sure the MATRIX CARD is plugged back into its

slot. Set the SURROUND NULL switch on the Front Panel

Display Card to ON. While running the CAT. # 69 Dolby

tone adjust the NULL trimpot on the MATRIX CARD for a

minimum signal observed on the Left Surround LED array

on the front of the MOD V. Switch the Surround Null back

to off when finished.

BYPASS:

Listen to the CENTER channel on the booth monitor.

Switch from normal to backup (the Red switch on the SubBass Card) and adjust the backup level pot on 305 Mono

Card to achieve equal levels while switching from Normal

mode to Backup mode while running a film soundtrack.

This completes the “A” Chain and BYPASS calibrations.

OPERATING INSTRUCTIONS

The MOD V system is one of the easiest systems to operate.

The Manager/Operator of the sound booth should review

the operation instructions to assure that emergency functions are also understood, should they ever be needed.

TURNING ON THE SYSTEM:

The sound engineer who installed the sound system has provided a way to apply power to the system through a master

power switch or circuit breaker. Also, several of the individual components in the equipment rack have their own power

switches. Become familiar with all switches or breakers that

control power to the sound equipment.

If the components are normally turned on individually, it is

important that the processing components are turned on first

and the power amplifiers are turned on after all other components are on for a few seconds. This will allow time for

the low level circuits to stabilize so that the power amplifiers will not pass a “turn-on thump” to the auditorium

speakers. Repeat in reverse order when turning off the system.

MUSIC SELECTION:

It is likely that the sound system will be turned on before

the arrival of the first audience of the day. The MOD V

powers up in Music mode. If the music player (CD player or

tape machine) is running, music will be heard in the audito-

rium and on the booth monitor. MUSIC may also be selected by pressing the front panel Music button.

PROGRAM SELECTION:

The automation should be set to select the proper formats

when needed. However, any format may be overrided by

simply pushing one of the Format buttons located on the

front of the MOD V.

EMERGENCY BYPASS SWITCH:

The MOD V contains a backup system that will keep the

show sound on the screen in the event of a failure of the

processor. This special circuitry is located on the MONO

card in the main card cage unit and is activated by the red

NORMAL-BACKUP switch located on the Sub-Bass

Expander card at the far right slot in the MOD V chassis.

MASTER FILM FADER:

This control is located on the MOD V Front Panel and is

used to set the system level for any film format, but not for

music level.

FORMAT LEVEL TRIMS:

These front trim controls can be used to make minor volume

changes to any of the formats. The MUSIC control serves as

the master fader for music level, and is a full range volume

control.

AUTOMATIC SURROUND GENERATOR:

The MOD V system may contain an optional surround generator for monaural soundtracks when the system is placed

into the GEN mode of operation. This circuit needs no

adjustment by the installer or operator.

SERVICE

CAUTION:

Service instructions are included for use by qualified personnel only. To avoid electrical shock, do not perform servicing other than that described within the Operating

Instructions unless you are qualified to do so. Refer all such

servicing to qualified service personnel.

Repairs to this product should be performed in accordance

with applicable safety standards, and should be performed

only by a trained service technician.

Most components used in the MOD V are available locally

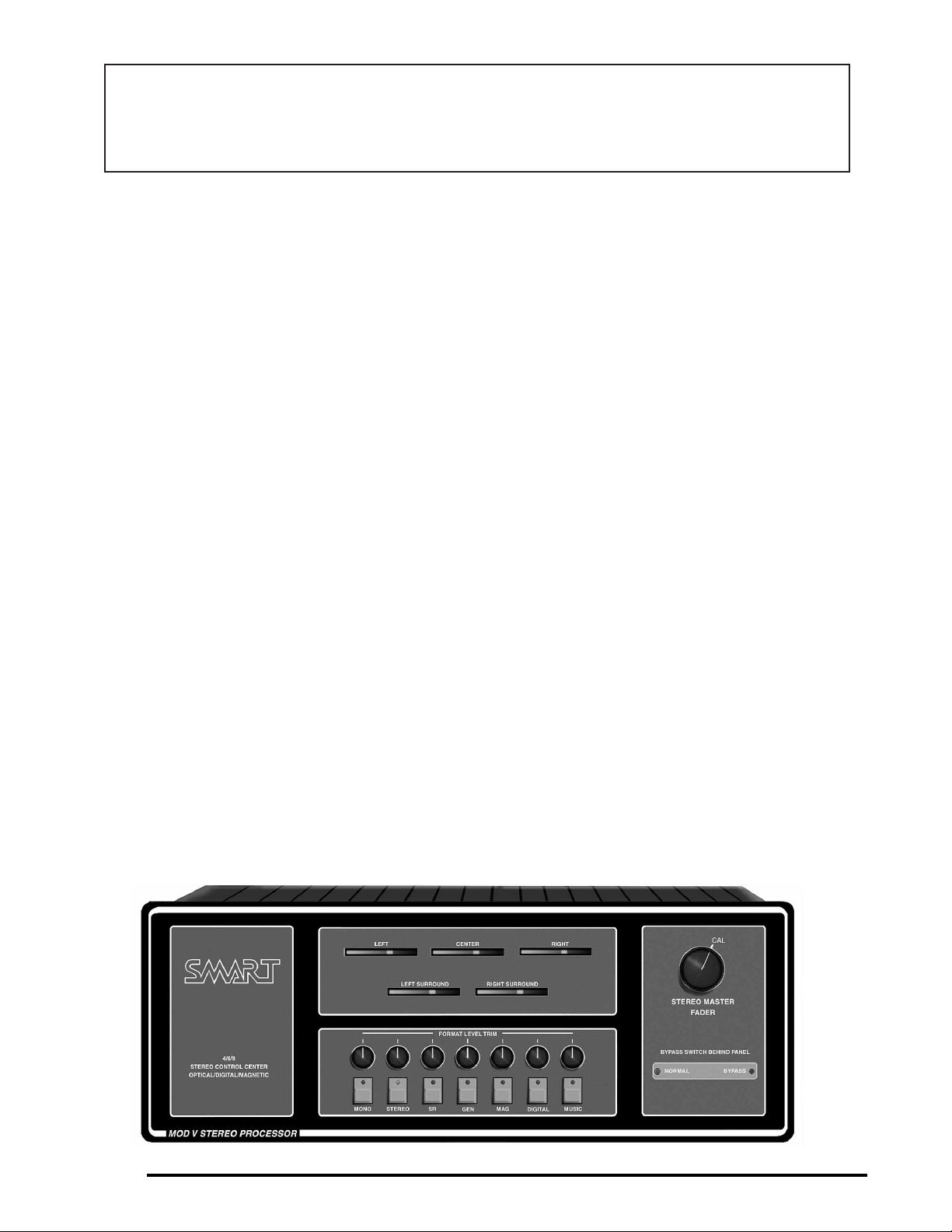

The front of the MOD V is where the Master Film Fader,

Format Level Trims, Format Select Buttons, and individual

channel LED indicators are located.

Page 14

14

from a radio parts supplier. Refer to the schematic diagrams

for information regarding specific circuits. IC sockets are

used to facilitate easy removal and replacement of any

Integrated Circuit, should this ever become necessary.

Each unit is “burned in” for a minimum of 5 days before

Q.C. testing and packaging. This ensures that the MOD V

purchased by the customer will be free of defect. However,

in the event of a failure of one or more functions of the

MOD V, a service call will result by the owner. Before calling the unit defective, always check for obvious causes of

the symptoms first:

1. Is the unit receiving AC. power? (Control panel lit.)

2. Has the power supply fuse blown? (Replace with

applicable fuse type and rating.)

3. Are all controls in their normal operating mode?

4. Is the supporting equipment functioning properly?

(Amplifiers, equalizers, exciter lamp supply, etc.)

When all symptoms point to an internal problem, your only

choice is to substitute with a spare (or similar piece of

equipment) and have the unit fixed by SMART Devices or

another competent repair facility.

TROUBLESHOOTING:

A quick check of the power supply voltages will indicate if

the power supply is operating properly. Place your service

meter negative lead on a convenient GROUND point (such

as a terminal strip ground). Switch your voltmeter to the

PLUS 30 volt DC range or higher and measure the positive

voltage input at the power supply terminal on the MOD V.

It should be 20 volts DC. Now measure the negative voltage

from the power supply. It should be -20 volts DC. If you

cannot obtain the voltages mentioned, you may have a

shorted connecting cable or a bad power supply.

Disconnect the low voltage cable by unplugging the power

plug at the processor end and make the tests again on the

power supply terminals. BE CAREFUL NOT TO SHORT

THE PINS ON THE POWER SUPPLY TERMINALS

WHILE MAKING THESE TESTS. A MOMENTARY

SHORT COULD PRODUCE A DANGEROUS SPARK

BEFORE THE SUPPLY GOES INTO SELF-PROTECT.

When you are satisfied that the voltages are correct, go to

the schematic diagram and study the circuit layout. The

most practical way to troubleshoot audio circuits is through

signal tracing. Put an audio signal into the input and follow

the signal with a scope until the signal stops. This method

allows you to locate a defective component in the related

section.

Since the MOD V uses a bi-polar supply, each audio IC

opamp output should measure nearly 0 volts DC with no

signal. That is, you should be able to probe each output pin

with your service meter and see a minimum DC offset. If

the opamp is showing a few volts at the output pin, it is likely that a bad capacitor or resistor is causing an input bias

that forces the output of the amplifier to shift. A defective

IC could also be the culprit. Note: SOME OF THE IC’s

OPERATE ON A SINGLE-ENDED SUPPLY. These chips

get their current from the positive supply rail with a ground

return. Single-ended chips may show a very large offset

voltage at their outputs. Also check for a hairline short in

the PC card foil traces. Here are several tips that will aid in

troubleshooting:

1. Make sure the switches are in the proper position

before testing the unit.

2. Very hot IC’s usually indicate an internal short.

3. An open resistor may lead you to believe that an IC

is defective. Use a substitute device to see if the problem is in the device itself or elsewhere.

4. Shorted input capacitors may bias an IC opamp OFF.

5. Be sure IC’s are firmly in their sockets. They can be

vibrated loose during shipment.

The following paragraph applies to earlier units equipped

with the analog time delay card — MOD2X335:

Signal tracing procedures may also be employed when servicing the time delay portion of the SURROUND CHANNEL(s). A signal at the input, through the filter circuit, the

delay chip, and the anti-alias filter will reveal where the signal has stopped. Refer to the schematic for pin identification

of the signal flow. The HFE4047 clock associated with the

delay chip must be operating properly for the audio signal to

pass through the delay chip. An oscilloscope will reveal

high level square wave pulses on pins 10 and 11 of the 4047

when this device is operating. If either phase of the clock

fails, no audio can pass. We suggest you NOT REMOVE

the delay chip itself unless you are positive it has failed.

This component is very expensive and can be easily

destroyed by stray static caused by handling. The BIAS pots

near the chips are factory set to each individual chip, and

should not be moved unless the IC must be replaced by a

new device.

The MATRIX CARD and NOISE REDUCTION CARDS

in the MOD V contain many components and IC’s that are

factory calibrated. The Matrix Card is not intended to be

serviced without special test equipment and test fixtures. A

defective card may be exchanged with a new one from the

factory. We do suggest, though, that the MOD V be

returned to the factory for servicing if a failure is verified.

An important part of any pre-service call is to make sure

that the operator or other theater personnel is fully familiar

with the operation of this equipment. Often service calls are

The MOD V Power Supply should be the first item checked

when troubleshooting the MOD V system.

Page 15

15

INSTALLATION & OPERATION

made unnecessarily because the operator was not trained

with the correct operation procedures.

MANY IC DEVICES CAN BE DESTROYED BY HANDLING. CMOS logic devices and Bi-FET opamps are very

static sensitive. They are safe when plugged into their sockets, but removal can expose the inputs to conduct static

electricity from tools, your hands, or other static generating

components. USE PROPER HANDLING PROCEDURES

when removing IC’s from their sockets.

This manual is included with each shipment so that you can

leave a copy with the theatre owner or operator.

SERVICE ACCESS:

The MOD V contains up to 16 plug-in printed circuit cards,

depending on the system configuration. These cards should

be removed ONLY WHEN MAIN POWER HAS BEEN

REMOVED. Plugging in a card with power present can

cause a jolt to the input regulators, causing them to fail. It

should never be necessary to remove the main “Mother

Board” that lies at the rear of the card cage.

To replace LED’s in, or otherwise service the front panel,

the printed circuit card must be detached from the front

panel. First, remove the 50 pin ribbon cable. Then, remove

the 8 screws holding it to standoffs mounted on the rear of

the front panel. It is NOT necessary to remove the knobs on

the Fader pots before attempting to release the card. After

the screws have been removed, slowly and carefully pull the

card back from the front panel so that all and LED’s are

clear of their holes.

To reassemble the unit, follow the directions in reverse.

Before tightening the screws holding the card to the standoffs, make sure the LED’s are seated squarely in their front

panel holes.

P.C. CARD COMPONENT REPLACEMENT:

All IC’s in the MOD V PC cards are socketed and can easily be replaced from the top surface of the boards.

WARNING:

Disconnect the power supply from the AC power line

before replacing components to avoid the danger of electrical shock.

If any of the CMOS logic chips are replaced, use reasonable

care to avoid damage due to static electricity. If the relative

humidity is below 50%, use a grounded workbench and

make sure that the PC board is grounded to it. To prevent

static damage to a chip, do not touch any of the leads unless

you are also touching the workbench, or you are connected

to it through a standard high-resistance grounded wrist

strap. (Such wrist straps are connected to ground through a

1 megaohm or more resistor, greatly reducing danger to personnel due to electric shock.)

Other components that are soldered in place may be

replaced following the instructions covered in this section.

If filter capacitors are to be replaced, fasten them securely

to the board using the original factory installation as a

model. This will prevent them from breaking loose from

vibration in the future.

REPLACEMENT PARTS:

If you have difficulty finding parts for this or any other

SMART product, The SMART Technical Support

Department stands ready to supply you with the required

parts at a fair price. Please contact us at the address on the

title page of this manual.

REPLACEMENT OF COMPONENTS ON PRINTED

CIRCUIT BOARDS:

It is important to use the correct technique for replacing

components mounted on PC boards. Failure to do so will

result in possible circuit damage and/or intermittent problems.

The circuit boards used in the MOD V are the double-sided

plated-through type. This means that there are traces on

both sides of the boards, and that the through-holes contain

a metallic plating in order to conduct current through the

board. Because of the plated-through holes, solder often

creeps 1/16” up into the hole, requiring a sophisticated technique of component removal to prevent serious damage to

the board.

COMPONENT REMOVAL:

If the technician has no practical experience with the

demanding technique of removing components from double-sided PC boards without board damage, it is wiser to cut

each of the leads of the defective component from its body

while the leads are still soldered to the board. The component is then discarded, and each lead is heated independently and pulled out of the board with long nose pliers. Each

hole may be cleared of solder by using solder wick or by

carefully heating with a low-wattage soldering iron and

sucking out the remaining solder with a spring-activated

desoldering tool. THIS METHOD IS THE BEST

METHOD OF CLEARING A PLATED-THROUGH

HOLE OF SOLDER.

Another technique is:

1. Use a 30 watt soldering iron to melt the solder on the

underside (solder side) of the PC board. Do not use a soldering gun or high wattage iron! As soon as the solder is

molten, vacuum it away with a spring activated desoldering

tool like the Edsyn “Soldapult.” Do not overheat the board!

Overheating will almost surely damage the board by causing the conductive foil to separate from the board. Use a

pair of fine needle-nose pliers to wiggle the lead horizontally until it can be observed to move freely in the hole.

2. Repeat step 1 until each lead to be removed has been

cleared of solder and is free to move.

3. Now lift the component out of the holes.

COMPONENT INSTALLATION:

1. Bend the leads of the replacement component until it

will fit easily into the appropriate PC board holes. Using a

good brand of rosin-core solder, solder each lead to the bottom side of the board with a 30 watt soldering iron. Make

sure that the joint is smooth and shiny. If no damage has

been done to the plated through hole, soldering the topside

pad is not necessary. However, if the removal procedure did

not progress smoothly, it would be wise to solder each lead

at the topside to avoid potential intermittent problems.

Loading...

Loading...