Page 1

SC101 Core Shoulder

Service Manual

Page 2

Content

CH1 Serial Number Location 1

CH2 Safety Instruction 2

CH3 Preventive Maintenance 4

CH4 Specification and Assembly Guide 8

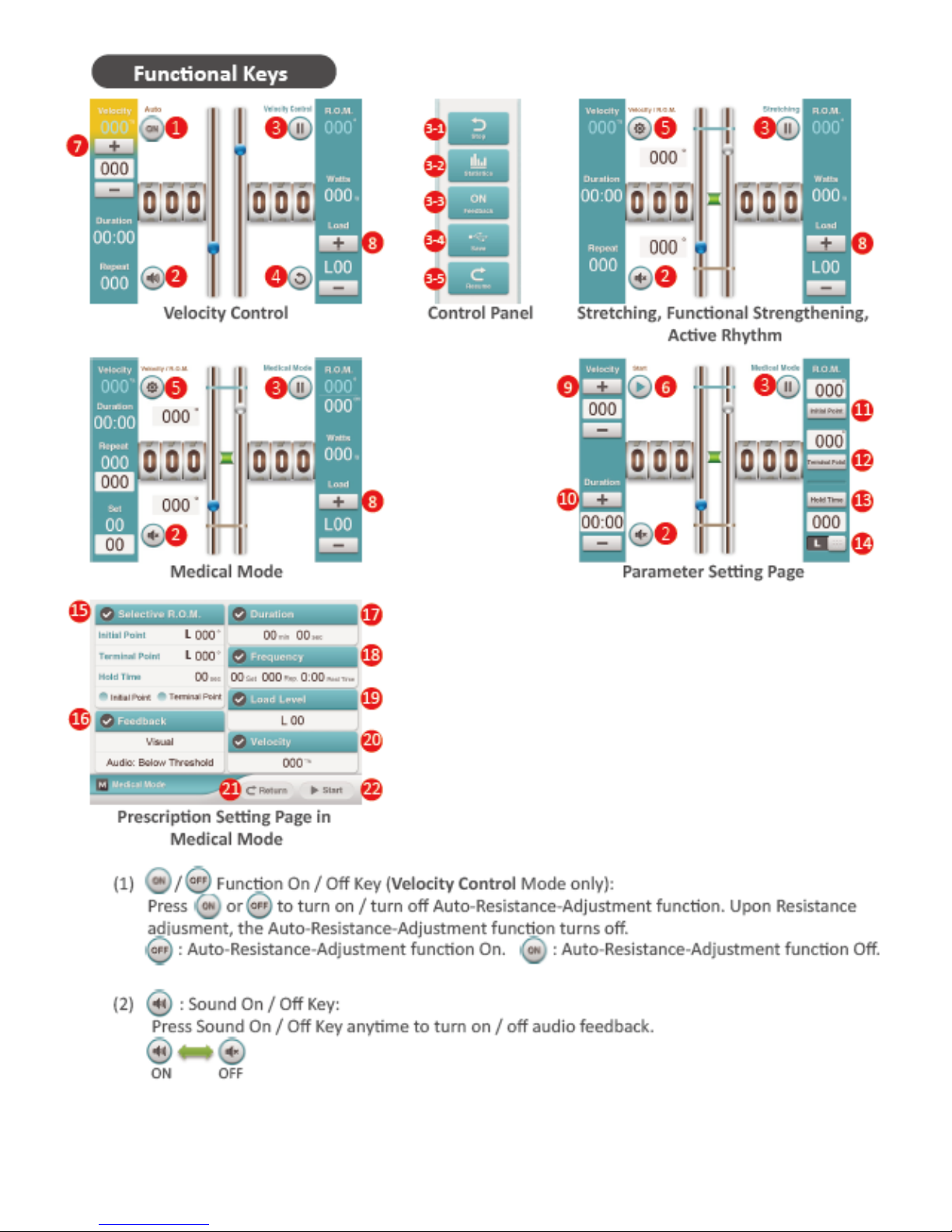

CH5 Console and Program Description 10

CH6 Engineer Mode 23

CH7 Troubleshooting 28

CH8 Parts Replacement 36

Page 3

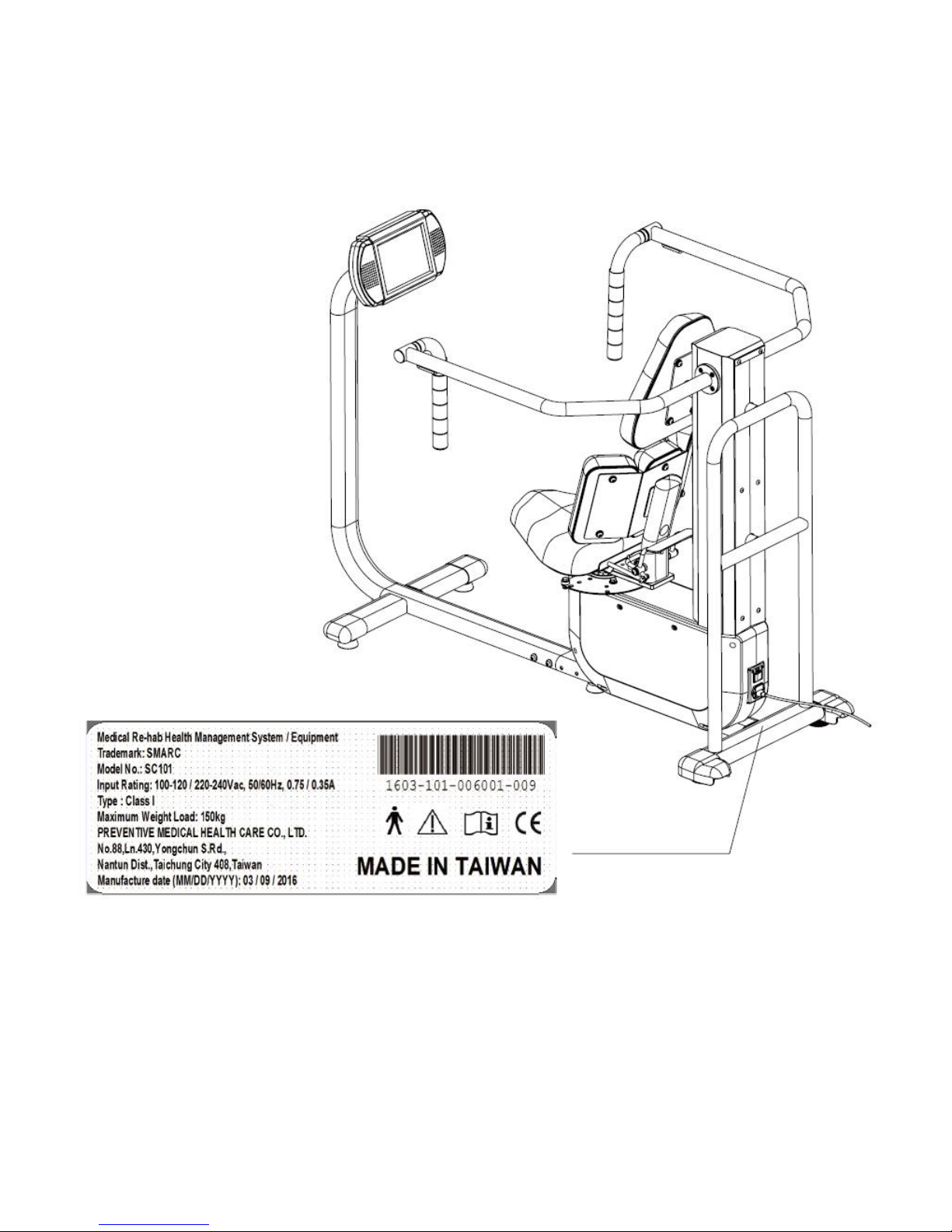

CH1 Serial Number Location

1

Page 4

Thank you for choosing SMARC products!

It is the owner’s responsibility to ensure that all users are fully informed of all warnings and precautions.

Please read this manual thoroughly before operating SMARC products. If you have any question

after reading this manual, please contact customer tech support at the local authorized dealers or

visit www.twpmhc.com for more details.

SAFETY

GENERAL SAFETY

1. Be cautious when getting on and off equipment seats to avoid falling.

2. Always set up all safety devices and pull the armrests down before exercising. For users with poor

control of trunk and limbs, make sure the seat is in locked position.

3. To prevent injuries, follow the instructions below:

• Never place hands close to the seat base when rotating the seat.

• Never place hands between the narrow spaces of the equipment or reach into the range of

motion limiters (eg. SC101, SC103, SC105, SC107 and SC108).

• Keep clear of the range of motion handles when the equipment is occupied.

• Be careful when operating the equipment to avoid tripping over equipment frames

(Stretching Tube of SC103 ).

• Do not sit on or lean against the armrests.

• If unusual situation has been observed (noises, no console display, loosen parts, and etc),

stop operation and contact local distributors immediately.

• Do not place the equipment outdoors or in area with high humidity.

4. Products are for continuous operation, and are not intended to be used in oxygen rich environment

nor to be sterilized. Do not perform servicing and maintenance while ME equipment is in

use.

ELECTRONIC SAFETY

1. This equipment must be grounded. If the equipment should malfunction or breakdown, grounding

provides a path to reduce the risk of electrical shock.

2. Please unplug the power cord wire to shut down the power.

3. Improper connection of the grounding conductor can result in risks of electric shock. Do NOT modify

the plug provided with the equipment. If it does not fit the outlet, have a proper outlet installed by a

qualified electrician.

4. Pulling on the cord can cause damage to the power cord. You should always pull on the actual plug.

5. With energy conservation in mind, the console will automatically go dark when SMARC product has

not been used for 30 minutes. Main Page will reappear when the equipment is used again.

6. WARNING: To avoid the risk of electric shock, the equipment must only be connected to supply

mains with protective earth.

7. SMARC products forms a ME SYSTEM when connected to a power supply, and can be operated at a

voltage of 115V or 230 V.

8. Do not position the ME Equipment that makes it difficult to disconnect the device (eg. to unplug).

9. The USB socket on SMARC console should ONLY be connected with USB flash drive provided by

PMHC and authorized dealer. It should ONLY be used with the purpose of exercise data download

and prescription upload. SMARC products are not suitable for connecting with any other electrical

equipment. Connecting with other devices might cause potential electromagnetic interference.

CH2 Safety Instruction

2

Page 5

PRECAUTION

FOR GENERAL CONSUMERS

1. If users experience any kind of discomfort, including chest pain, nausea, dizziness, shortness of

breath, severe joint pain or muscle pain, stop training immediately and consult physician or physical

therapist before continuing.

2. Warm up prior to exercise. Start exercise with light, repetitive, dynamic, site-specific movement.

3. Avoid over-stretching to prevent strain of soft tissues and joint instability.

FOR PATIENTS WITH MEDICAL NEEDS

Patients may operate SMARC products under supervision of physicians or physical therapists.

Users with following medical and therapeutic needs (especially over 40 years old) should consult

physician or physical therapist before operating.

1. Inflammation: Patients with inflammatory neuromuscular disease such as Guillain-Barre disease,

Polymyositis, and Dermatomyositis should use low Resistance training.

2. Severe cardiopulmonary disease: Patients with acute symptoms such as but not restricted to the

following should not attempt Resistance training.

• Coronary artery disease (unstable angina, myocardial infarction)

• Carditis

• Cardiomyopathy

• Aortic stenosis and Aortic dissection

• Decompensated congestive heart failure

• Severe pulmonary embolism

• Unstable hypertension

• Ventricular arrhythmia

3. When a hematoma or other indication of tissue trauma is observed.

4. Musculoskeletal Disorder: Patients who recently had a fracture, and bony union is not completed. A

bony block limits joint motion.

5. Neurological Disorder Patient: Only patients with good static sitting balance or Brunnstrom stage

above III are recommended using SMARC products.

6. Do not set high Resistance for children, elderlies, and patients with osteoporosis.

7. Be aware of medications a patient is using that can alter acute and chronic responses to exercise.

8. The equipment might emit low intensity electromagnetic pulse. Patients with concern should

consult physician or physical therapist before operating.

3

Page 6

1. General Maintenance

1) SMARC products require only the most basic general maintenance, performed on an asneeded basis every 6~8 months.

2) Minimum qualifications of SERVICE PERSONNEL: Only technicians trained by PMHC and

associated distributors are supposed to do maintenance. Please contact PMHC factory or

local authorized dealer for maintenance.

The MANUFACTURER will make available on request circuit diagrams, component part lists, descriptions,

calibration instructions, or other information that will assist SERVICE PERSONNEL to repair those parts

of ME EQUIPMENT that are designated by the MANUFACTURER as repairable by SERVICE PERSONNEL.

2. Recommended Cleaning (optional)

1) With the system turned OFF, wipe down all surfaces with a damp cloth. Neutral detergent

and water can be used to remove stains and scuff marks. Inspect all locking and adjustment

mechanisms for signs of damage.

2) NOTE: DO NOT use cleaning solutions containing ammonia or alcohol to clean. Neutral

detergent and water should be sufficient. Allow the system to dry thoroughly before

resuming operation.

CH3 Preventive Maintenance

4

Page 7

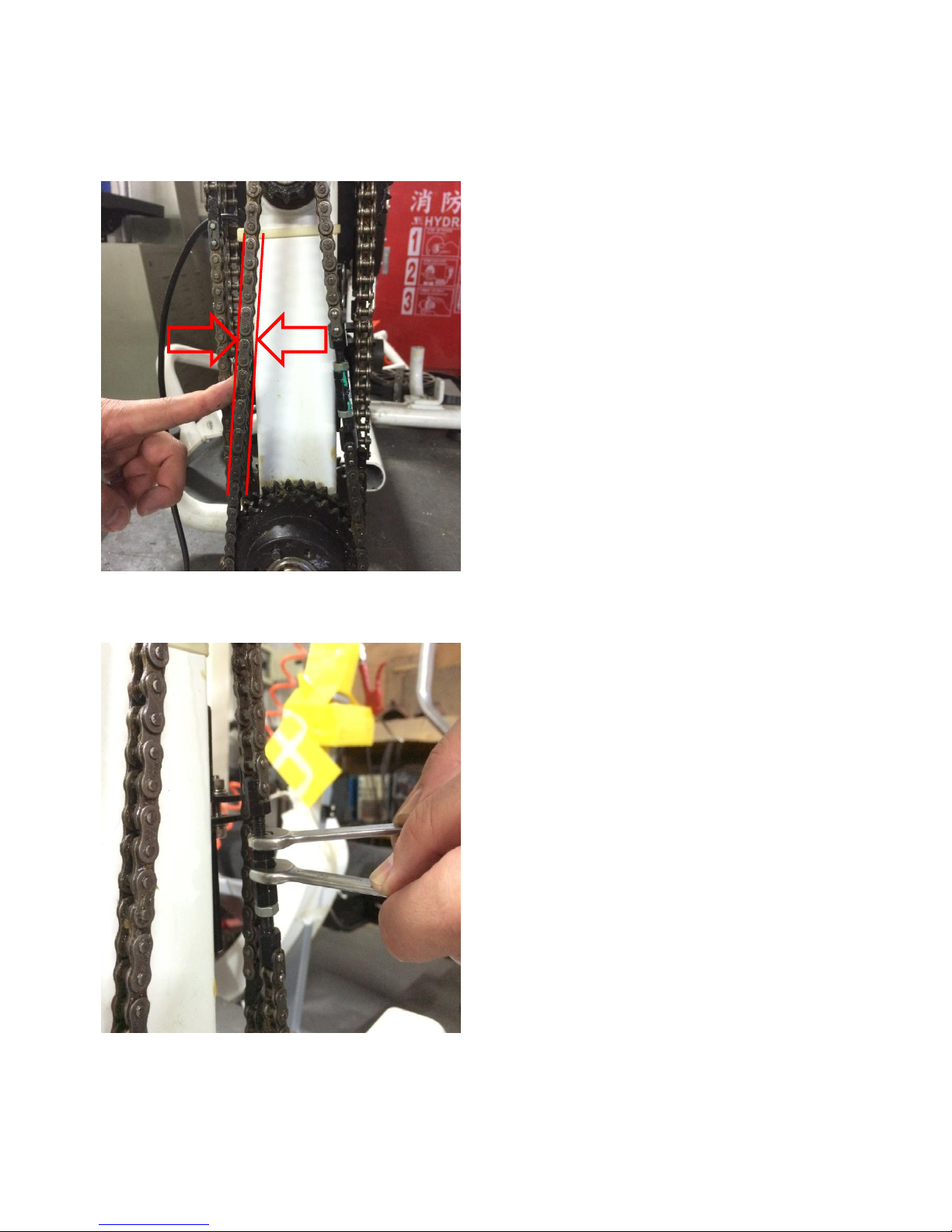

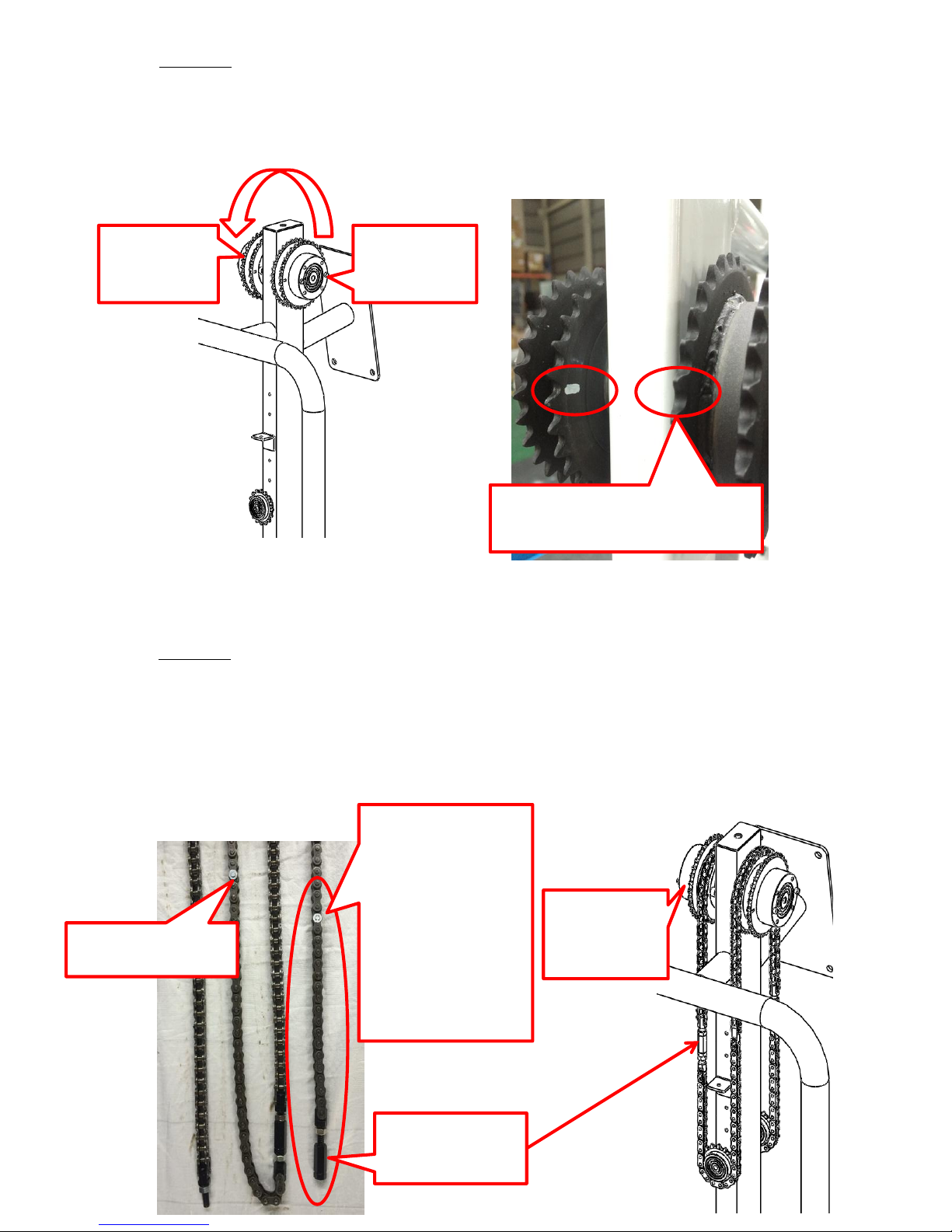

1) Applying grease

Chain Maintenance and Tightness Adjustment

Chain maintenance must be held at least once

ever 6 months, depending on the frequency of

use.

Please apply grease to chain links and sprocket

area as indicated on the left.

5

Page 8

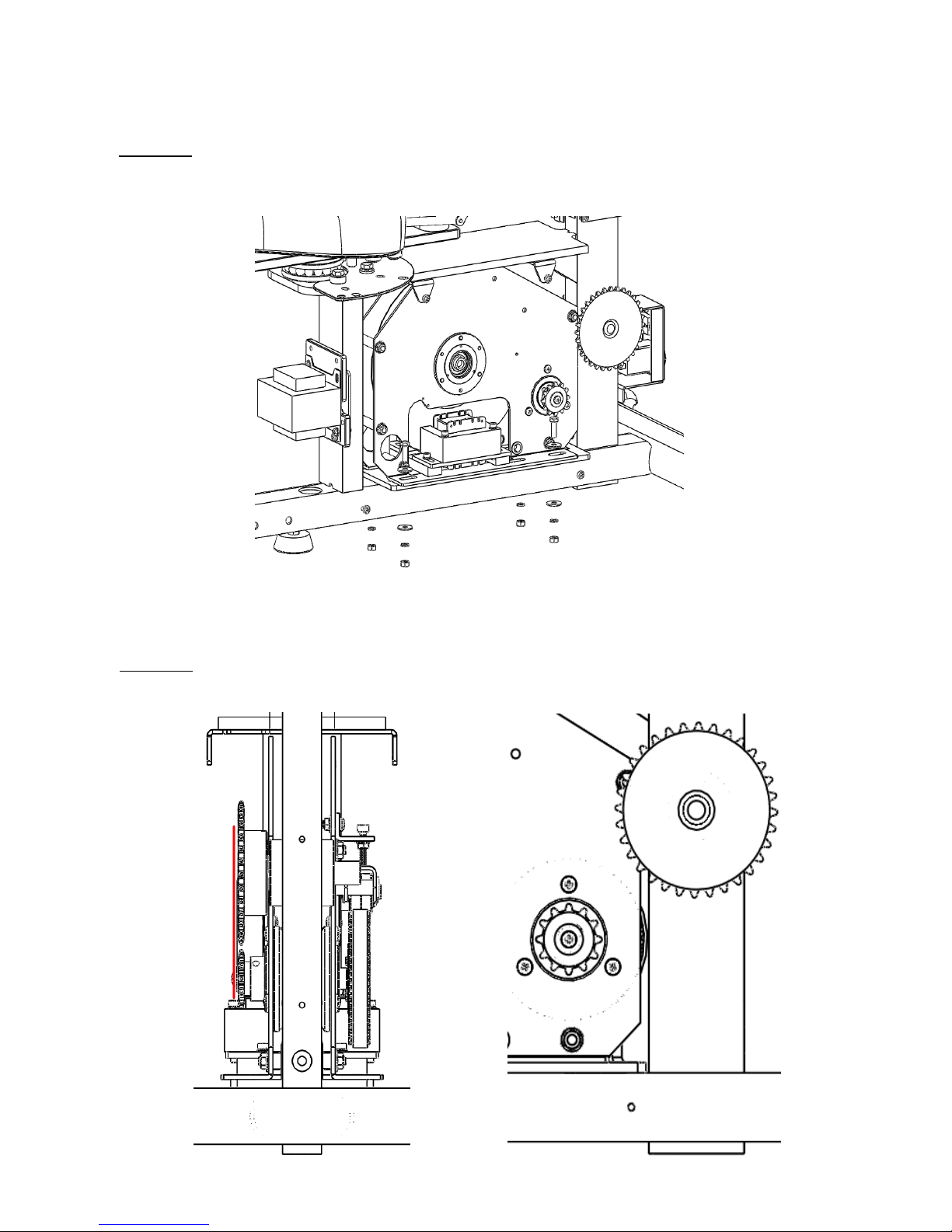

2) Tightness (tension) adjustment

Step1:Loosen the nuts above and beneath the “Turn Buckle”

Step2:Adjust the tightness (tension) of chain via turning the “Turn Buckle”

Chain Maintenance and Tightness Adjustment

Nut

Turn Buckle

6

Page 9

Step3:Check the tightness (tension) by pressing the chain. The standard tightness (tension) is

5~10 mm flexibility when pressed.

Step4:Tighten the nuts

Chain Maintenance and Tightness Adjustment

7

Page 10

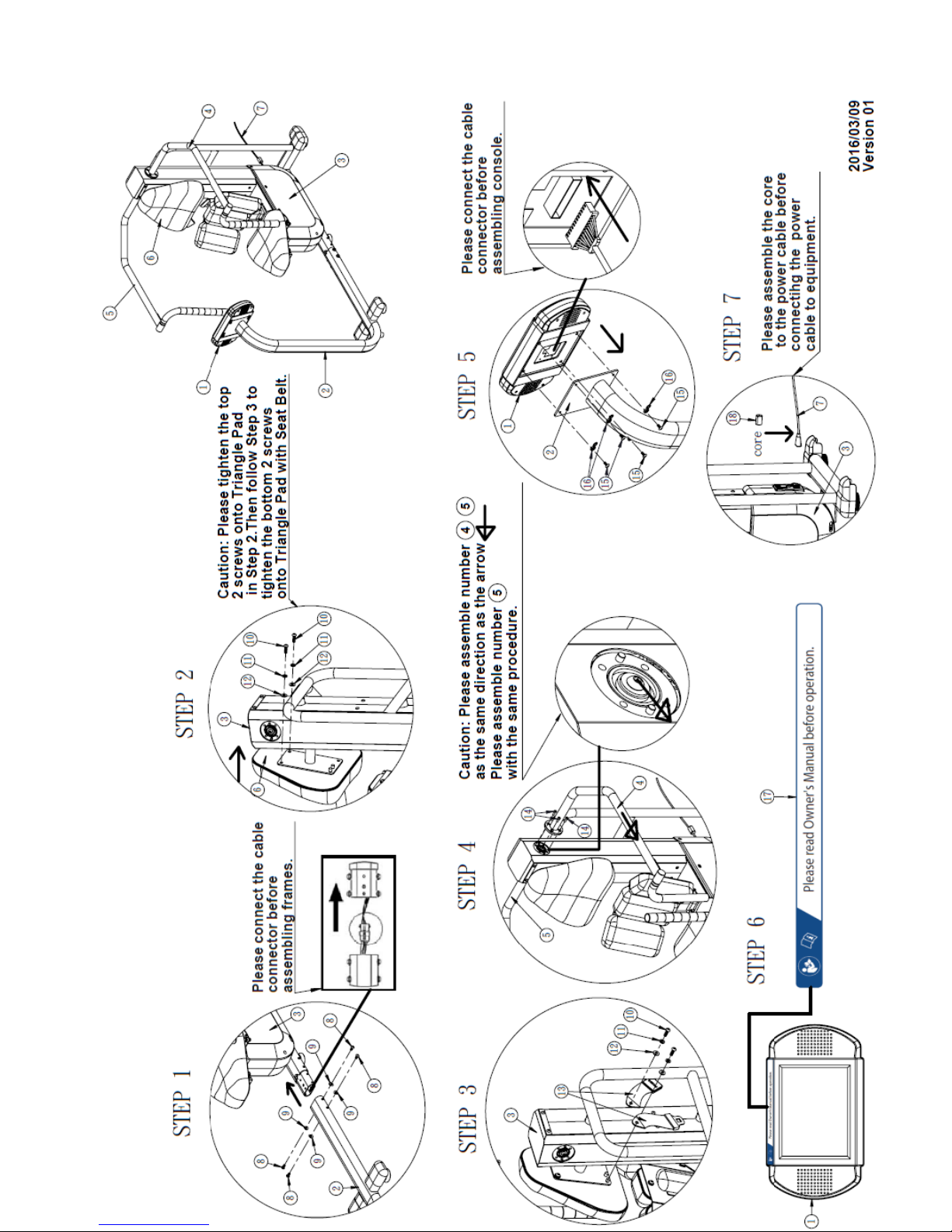

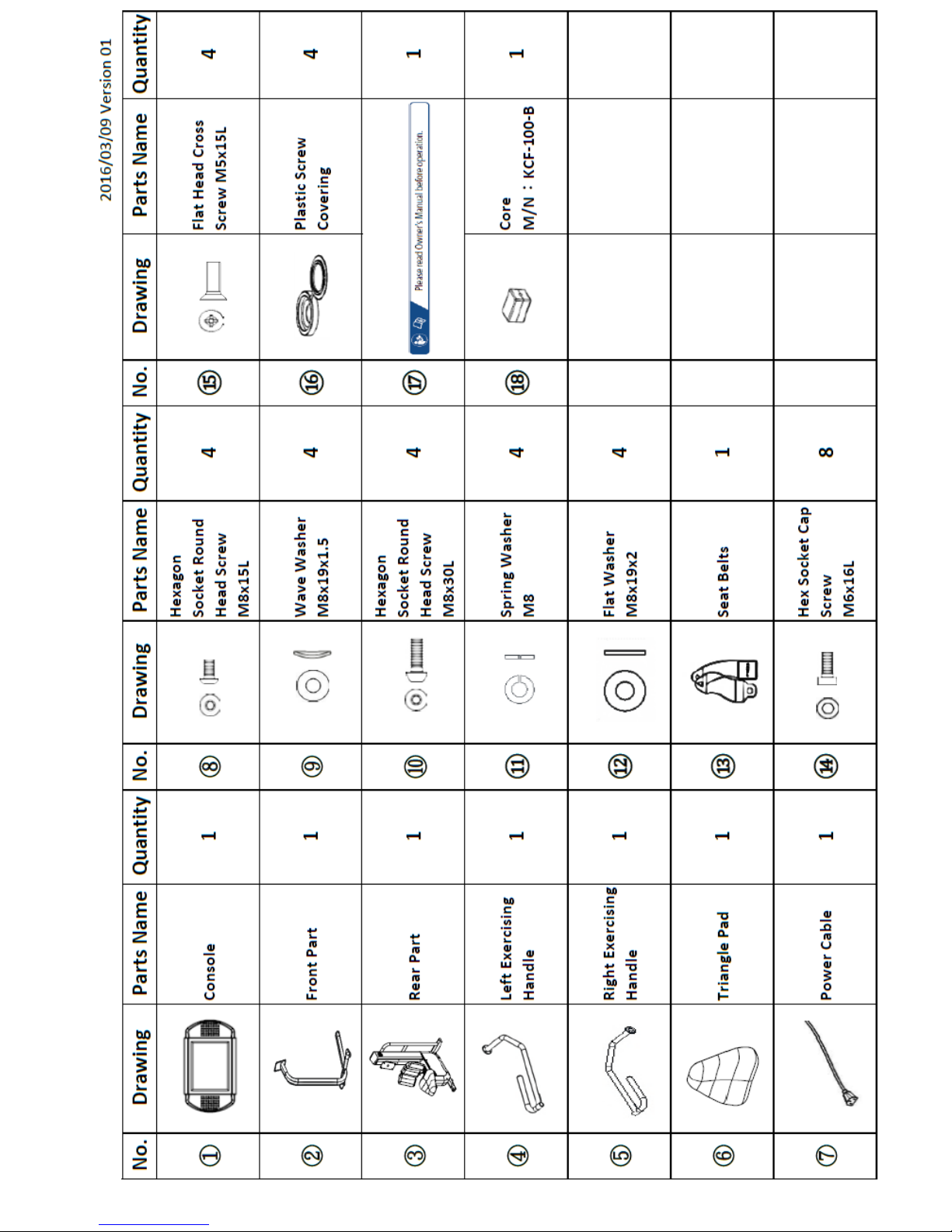

CH4 Specification and Assembly Guide

8

Page 11

9

Page 12

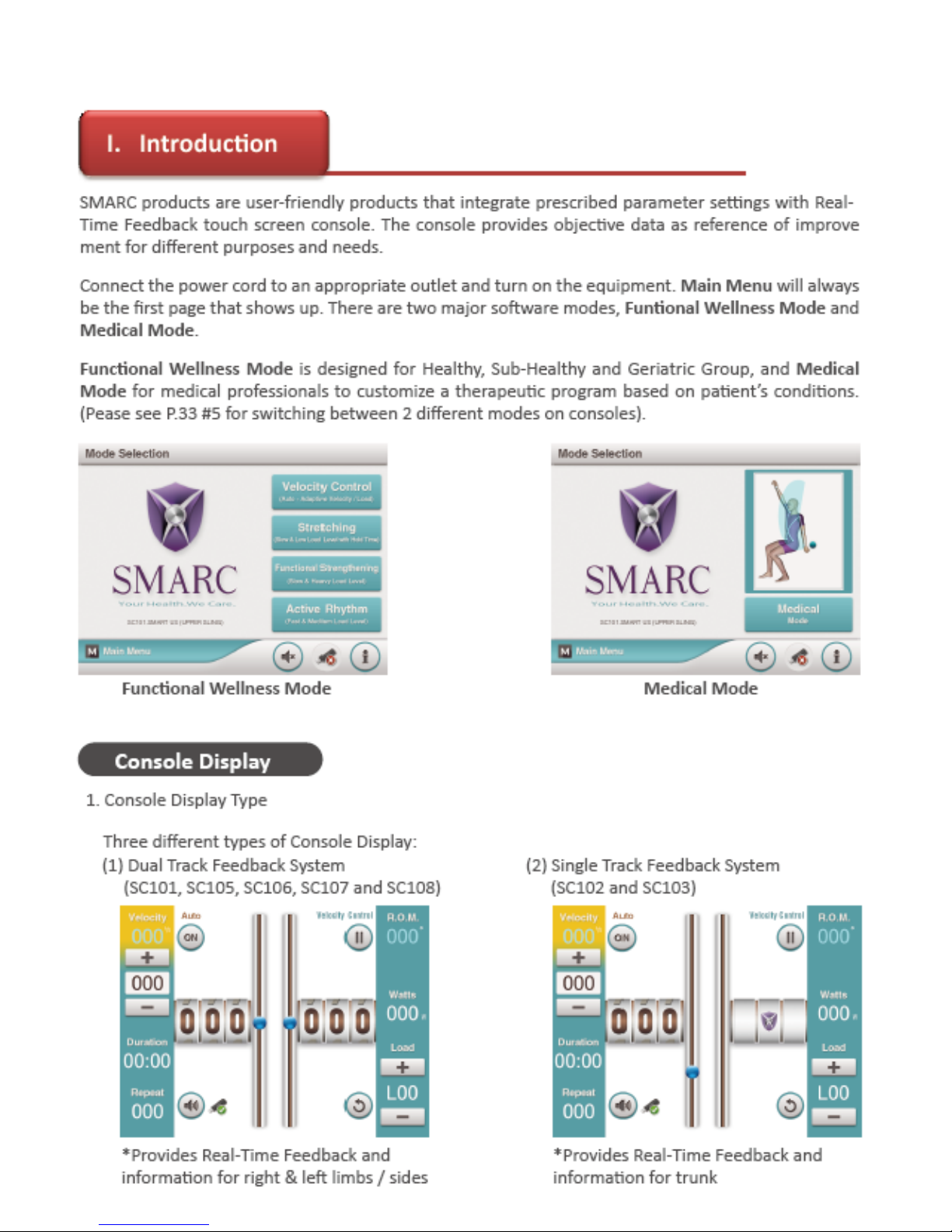

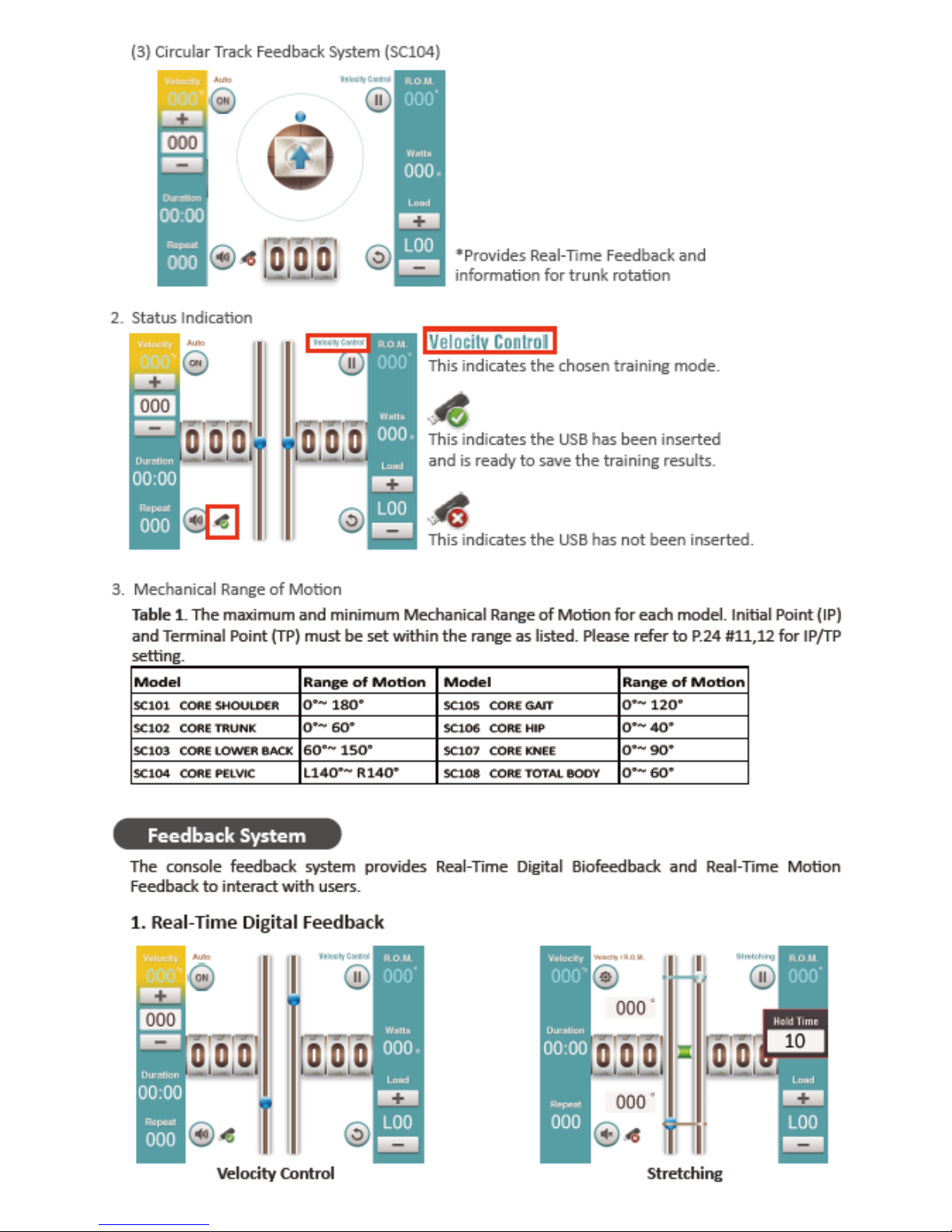

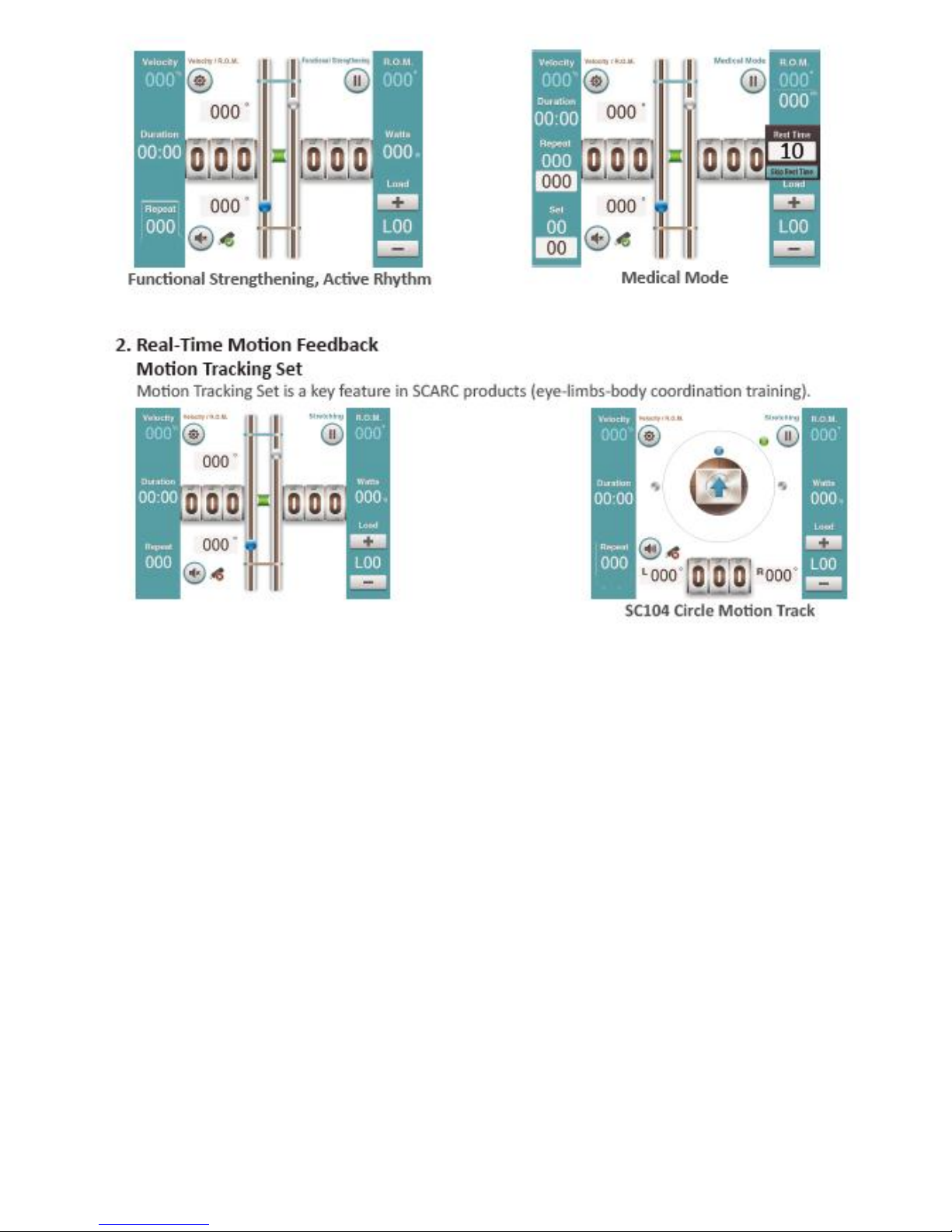

CH5 Console and Program Description

10

Page 13

11

Page 14

12

Page 15

13

Page 16

14

Page 17

15

Page 18

16

Page 19

17

Page 20

18

Page 21

19

Page 22

20

Page 23

21

Page 24

22

Page 25

CH6 Engineer Mode

Model Setting

Mode Setting

23

Page 26

24

Page 27

25

Page 28

26

Page 29

27

Page 30

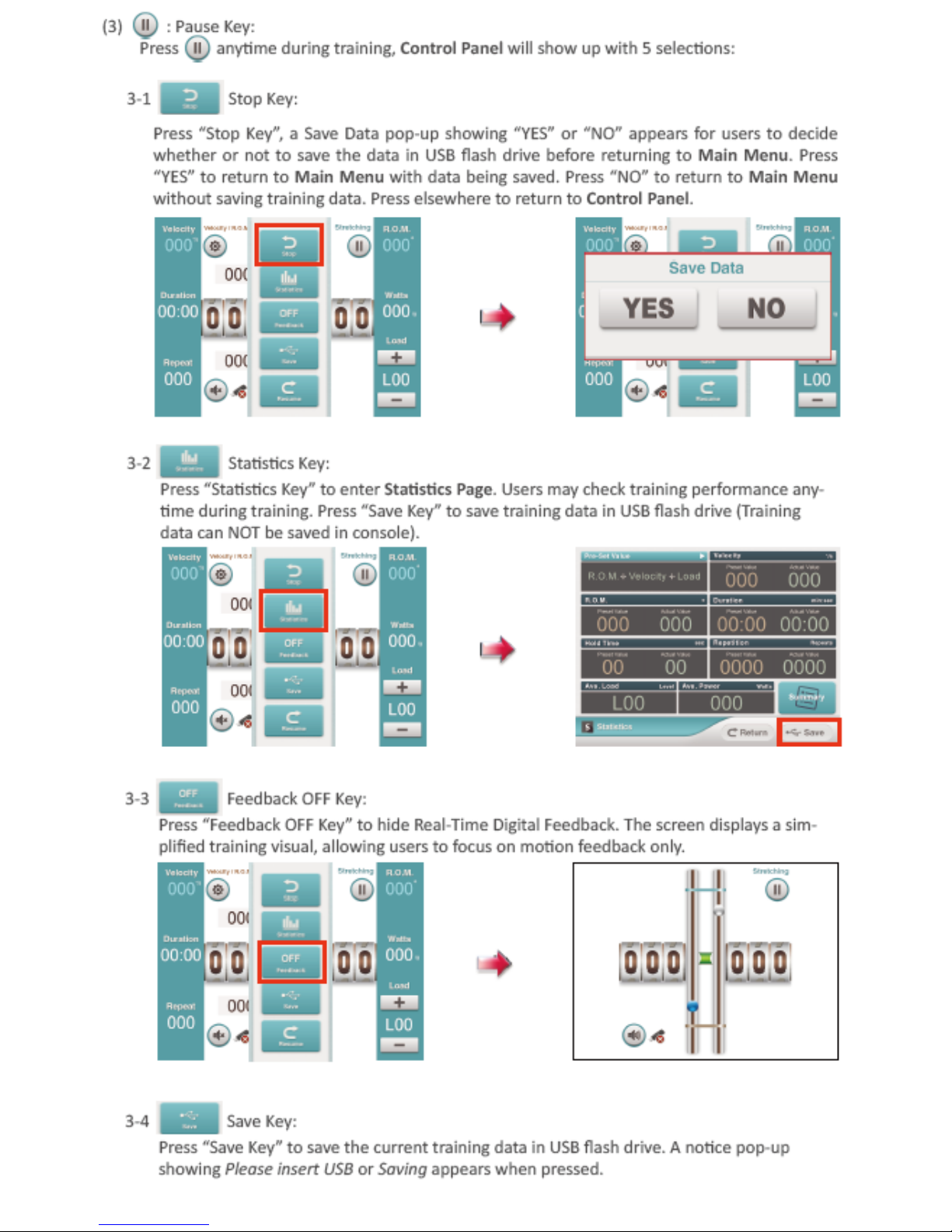

Lower Control Board Wires Installation

Encoder Wire

Console Wire

Lower Control

Board Power Wire

Generator

Power Cord

CH7 Troubleshooting

28

Page 31

1) No console display when powered on

1.1 Check the “Voltage Switch” if it has been switched to the appropriate

voltage, to 115V or 230V

1.2 Check the fuse if it is functioning

29

Page 32

1.3 Change a new console to eliminate console breakdown

1.4 Check if the Transformer wires and cables are loosened or damaged

1.5 Check the “Lower Control Board Power Wire is still in place

Check if there is power output

Make sure the wires are properly connected (the

power wire is inside the main frame tube)

30

Page 33

1.6 Check if the Console Wire has been properly connected to the

“Lower Control Board”

1.7 Check if the Console Wire has been properly connected to the

Console

31

Page 34

2) Console angle display error

2.1 Check if Console Wire has been properly connected to “Lower Control

Board”

2.2 Check if Encoder Wire has been properly connected to the “Lower

Control Board”

Angle display breakdown or

abnormal angle displayed

during exercise

32

Page 35

2.3 Check if Encoder Wire has been properly connected to the Encoder

2.4 Change Encoder or Encoder Set and see if the problem has been

solved upon changing

33

Page 36

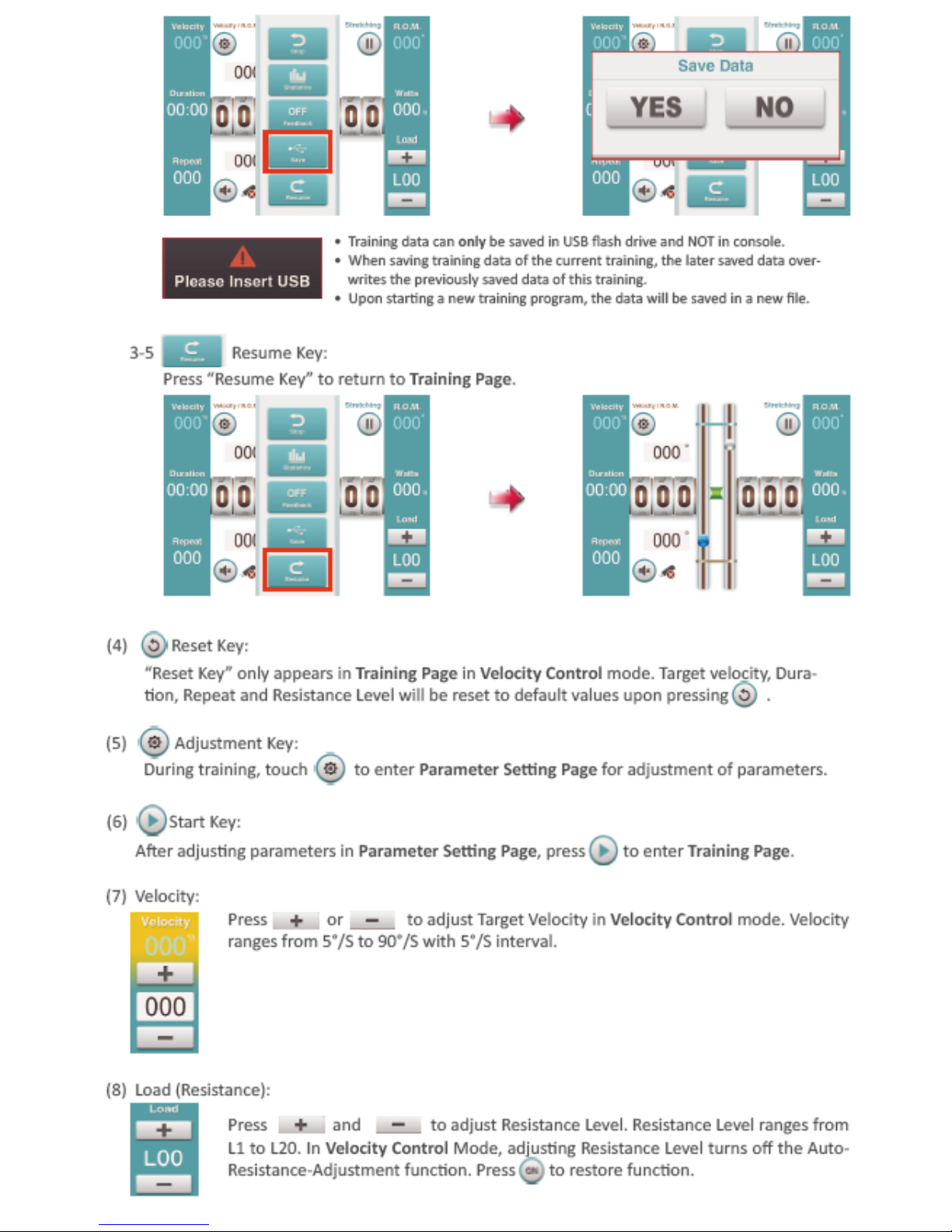

3) Resistance output error

3.1 Check if the Generator Power Cord has been properly connected

3.2 Check if power output is normal

Adjust Resistance

(Load)

Check if there is power

output

34

Page 37

3.3 Change another piece of “Lower Control Board” to see if

the problem has been solved upon changing

3.4 Change another piece of Generator to see if the problem has been

solved upon changing.

35

Page 38

I. Tools list

• Hex wrench x1 Set

• Diagonal pliers x1 pcs

• Needle-nose pliers x1 pcs

• Phillips screwdriver x1 pcs

• 10 mm Open ring wrench x2 pcs

• 13 mm Open ring wrench x2 pcs

• 10 mm Open end torque wrench x1 pcs

• Sprocket position adjustment tool

(replacement with ruler is acceptable) x1 pcs

• 4 mm T hex wrench x1 pcs

• Angle gauge x1 pcs

• Grease (No.2) As needed

• LOCTITE 243 As needed

CH8 Parts Replacement

36

Page 39

II. Cover Removal

1. Steel cover removal

Step 1:Remove Hex Socket Cap Screws and both exercise

handles.

Step 2:Remove Phillips Screws and the Steel Covers (top, right

and left).

37

Page 40

2. Plastic covers removal

Step 1:Remove Phillips screws on both sides of the cover.

Step 2:Remove the Plastic Covers.

38

Page 41

III. Chain Replacement

1.2 Exercise Handle Chain installation

Step 1: Install the Exercise Handle Chain with Turn Buckle facing

to the back of the equipment.

1. Driving Chain replacement

1.1 Driving Chain removal: Loosen the Chain Adjustment Set

(Turn Buckle) to remove the Chain.

Turn Buckle

Turn Buckle

39

Page 42

Step 3: Adjust the chain tightness by adjusting the Turn Buckle.

Apply Loctite 243 to Turn Buckle screw.

Step 2: Place and adjust the chain position. The white colored

labels on both the chain and the sprocket should align.

40

Page 43

2. Replace the Direction Turning Chain

2.1 Remove the Driving Chain:Loosen the Turn Buckle to remove

the Driving Chain.

2.2 Install the Direction Turning Chain

Step 1: There are two white colored labels on the Direction

Turning Chain. Upon installation, these labels should

align with the corresponding white colored labels on

the two sprockets.

41

Page 44

Step 2: Adjust both left and right sprockets where by the

white colored labels are facing towards the back end of

the equipment.

Step 3: Install the Direction Turning Chain, the white colored

label and the label on left sprocket should align, install

entire chain and the second label should also align to

the corresponding label on the right sprocket.

Left

sprocket

Right

sprocket

White colored labels

oriented in this position

Turn Buckle

Head

Left

sprocket

This white

colored label

should align

to the

corresponding

label on the

left sprocket

Second label

42

Page 45

Step 4: Adjust the chain tightness by adjusting the Turn Buckle.

Apply Loctite 243 to Turn Buckle screw.

Step 5: Swing the handles and check if the Turn Buckle

remained a safe distance to the sprocket.

43

Page 46

Step 6: Both handles should be able to position paralleled to

the ground simultaneously.

44

Page 47

IV. Generator and Generator Chain Replacement

1. Generator removal

Step 1: Remove Generator Fixation Screws.

Step 2: Loosen Generator Adjustment Screws, and push the

generator towards the direction of the arrow (as

indicated below).

45

Page 48

Step 3: Remove Chain Lock and remove chain.

Step 4:Remove Generator.

46

Page 49

2. Generator and Generator Chain installation

Step 1: Position the Generator on the frame, apply Fixation Screw

to settle the Generator.

Step 2: Ensure the Chain Gear is in parallel with Frame Gear

(can be observed looking sideway).

47

Page 50

Step 3:Install the chain and fix the Chain Lock.

Step 4: Adjust chain tightness by adjusting the Adjustment

Screws.

48

Page 51

Step 5: Fix the Generator with Hex Head Cap Screws, apply torque

force of 150 Kgf/cm to the screws.

49

Page 52

3. Apply Grease to Chain:

Step 1: After replacing the chains, apply grease to the chain

and sprocket keys.

50

Page 53

V. Wires and Parts Diagram

1. Wires and Parts connection diagram

51

Page 54

NO.

Parts Name Quantity

1.

WEE

-0000101-2

Electro

-Magnetic System - Short Axis Version 1

2.

WCM

-0000475-7

Encoder Control Set (A)

1

3.

WEE

-0000139-6

Console Set

1

4.

WEE

-0000140-9

Power Supply Unit

- Long 1

5.

WEE

-0000172-1

Transformer

1

6.

WEE

-0000084-6

Electro

-Magnetic System Cable-L400 1

7.

WEE

-0000156-7

Encoder

Cable-L350 1

8.

WEE

-0000124-5

Console Extension Cable

-L1900 1

9.

WEE

-0000159-8

Power Cord

-L900 1

10.

WEE

-0000006-2

Console Cable

-L1400 1

11.

WEE

-0000055-5

Lower

Control Board 1

3.

2.

11.

1.

4.

5.

2. Parts position

52

Loading...

Loading...