TT303

PROFIBUS PA TEMPERATURE

TRANSMITTER

OPERATION & MAINTENANCE

INSTRUCTIONS MANUAL

TT303

VERSION 3

APR / 15

T T 3 0 3 M E

web: www.smar.com/contactus.asp

www.smar.com

Specifications and information are subject to change without notice.

Up-to-date address information is available on our website.

smar

Introduction

III

INTRODUCTION

The TT303 is from the first generation of Profibus PA devices. It is a transmitter mainly intended for

measurement of temperature using RTDs or thermocouples, but can also accept other sensors with

resistance or mV output such as: pyrometers, load cells, resistance position indicators, etc. The

digital technology used in the TT303 enables a single model to accept several types of sensors, an

easy interface between the field and the control room and several others features that considerably

reduces the installation, operation and maintenance costs.

The digital technology used in the TT303 enables the choice of several types of transfer functions,

an easy interface between the field and the control room and several interesting features that

considerably reduce the installation, operation and maintenance costs.

The TT303 is part of Smar's complete 303 line of Profibus-PA devices.

Some of the advantages of bi-directional digital communications are known from existing smart

transmitter protocols: Higher accuracy, multi-variable access, remote configuration and diagnostics,

and multi-dropping of several devices on a single pair of wires.

The system controls variable sampling, algorithm execution and communication so as to optimize

the usage of the network, not loosing time. Thus, high closed loop performance is achieved.

Using Profibus technology, with its capability to interconnect several devices, very large control

schemes can be constructed. In order too be user friendly the function block concept was

introduced.

The TT303, like the rest of the 303 family, has some Function Blocks built in, like Analog Input.

The need for implementation of Fieldbus in small as well as large systems was considered when

developing the entire 303 line of Profibus-PA devices. They have common features and can

configured locally using a magnetic tool, eliminating the need for a configuration tool or console in

many basic applications.

Now, thanks to Fieldbus, the transmitter accepts two channels, i.e., two measurements. This

reduces the cost per channel. Other function blocks are also available. They allow flexibility in

control strategy implementation.

Get the best result of the TT303 by carefully reading these instructions.

WARNING

In case of using Simatic PDM as the configuration and parameterization tool, Smar recommends that

the user does not apply the option "Download to Device". This function can

improperly configure the field device. Smar recommends that user make the use of the option

"Download to PG / PC" and then selecting the Device Menu, use the menus of the transducer,

function and display blocks acting specifically, according to each menu and method for reading and

writing.

TT303 – Operation and Maintenance Instruction Manual

IV

Waiver of responsibility

The contents of this manual abides by the hardware and software used on the current equipment

version. Eventually there may occur divergencies between this manual and the equipment. The

information from this document are periodically reviewed and the necessary or identified corrections

will be included in the following editions. Suggestions for their improvement are welcome.

Warning

For more objectivity and clarity, this manual does not contain all the detailed information on the

product and, in addition, it does not cover every possible mounting, operation or maintenance

cases.

Before installing and utilizing the equipment, check if the model of the acquired equipment complies

with the technical requirements for the application. This checking is the user’s responsibility.

If the user needs more information, or on the event of specific problems not specified or treated in

this manual, the information should be sought from Smar. Furthermore, the user recognizes that the

contents of this manual by no means modify past or present agreements, confirmation or judicial

relationship, in whole or in part.

All of Smar’s obligation result from the purchasing agreement signed between the parties, which

includes the complete and sole valid warranty term. Contractual clauses related to the warranty are

not limited nor extended by virtue of the technical information contained in this manual.

Only qualified personnel are allowed to participate in the activities of mounting, electrical connection,

startup and maintenance of the equipment. Qualified personnel are understood to be the persons

familiar with the mounting, electrical connection, startup and operation of the equipment or other

similar apparatus that are technically fit for their work. Smar provides specific training to instruct and

qualify such professionals. However, each country must comply with the local safety procedures,

legal provisions and regulations for the mounting and operation of electrical installations, as well as

with the laws and regulations on classified areas, such as intrinsic safety, explosion proof, increased

safety and instrumented safety systems, among others.

The user is responsible for the incorrect or inadequate handling of equipments run with pneumatic

or hydraulic pressure or, still, subject to corrosive, aggressive or combustible products, since their

utilization may cause severe bodily harm and/or material damages.

The field equipment referred to in this manual, when acquired for classified or hazardous areas, has

its certification void when having its parts replaced or interchanged without functional and approval

tests by Smar or any of Smar authorized dealers, which are the competent companies for certifying

that the equipment in its entirety meets the applicable standards and regulations. The same is true

when converting the equipment of a communication protocol to another. In this case, it is necessary

sending the equipment to Smar or any of its authorized dealer. Moreover, the certificates are

different and the user is responsible for their correct use.

Always respect the instructions provided in the Manual. Smar is not responsible for any losses

and/or damages resulting from the inadequate use of its equipments. It is the user’s responsibility to

know and apply the safety practices in his country.

WARNING

This Manual is compatible with version 3.XX, where 3 note software version and XX software release. The

indication 3.XX means that this manual is compatible with any release of software version 3.

Table of Contents

V

TABLE OF CONTENTS

SECTION 1 - INSTALLATION ................................................................................................. 1.1

GENERAL ........................................................................................................................................................................ 1.1

MOUNTING ..................................................................................................................................................................... 1.1

NETWORK WIRING ........................................................................................................................................................ 1.1

SENSOR WIRING ........................................................................................................................................................... 1.4

TOPOLOGY AND NETWORK CONFIGURATION .......................................................................................................... 1.6

INTRINSIC SAFETY BARRIER ....................................................................................................................................... 1.7

JUMPER CONFIGURATION ........................................................................................................................................... 1.7

POWER SUPPLY ............................................................................................................................................................ 1.7

INSTALLATION IN HAZARDOUS AREAS ...................................................................................................................... 1.8

EXPLOSION/FLAME PROOF ......................................................................................................................................... 1.8

INTRINSICALLY SAFE .................................................................................................................................................... 1.8

SECTION 2 - OPERATION ...................................................................................................... 2.1

FUNCTIONAL DESCRIPTION - HARDWARE ................................................................................................................. 2.1

TEMPERATURE SENSORS ............................................................................................................................................ 2.2

THE DISPLAY .................................................................................................................................................................. 2.5

MONITORING .................................................................................................................................................................. 2.5

ALARM ............................................................................................................................................................................. 2.6

SECTION 3 - CONFIGURATION ............................................................................................. 3.1

TRANSDUCER BLOCK .................................................................................................................................................... 3.1

HOW TO CONFIGURE A TRANSDUCER BLOCK .......................................................................................................... 3.1

FUNCTIONAL DIAGRAM OF THE TEMPERATURE TRANSDUCER BLOCK ................................................................ 3.2

TEMPERATURE TRANSDUCER BLOCK GENERAL PARAMETER DESCRIPTION ..................................................... 3.2

TEMPERATURE TRANSDUCER BLOCK GENERAL PARAMETER ATTRIBUTES ....................................................... 3.5

TT303 - CYCLIC CONFIGURATION ................................................................................................................................ 3.6

SENSOR TRANSDUCER NUMBER .............................................................................................................................. 3.10

JUMPER CONFIGURATION .......................................................................................................................................... 3.11

HOW TO CONNECT TWO SENSORS ........................................................................................................................... 3.12

COMPENSATION OF LINE RESISTANCE FOR RTD DOUBLE SENSOR OR OHM SENSOR .................................... 3.12

COMPENSATION OF COLD JUNCTION ....................................................................................................................... 3.12

CALIBRATION IN TT303 BY THE USER ....................................................................................................................... 3.12

HOW TO CONFIGURE THE ANALOG INPUT BLOCK .................................................................................................. 3.14

PROGRAMMING USING LOCAL ADJUSTMENT .......................................................................................................... 3.17

LOCAL ADJUSTMENT TREE - QUICK GUIDE .............................................................................................................. 3.19

J1 JUMPER CONNECTIONS ......................................................................................................................................... 3.20

W1 JUMPER CONNECTIONS ....................................................................................................................................... 3.20

LOCAL PROGRAMMING TREE ................................................................................................ ..................................... 3.20

TRANSDUCER DISPLAY – CONFIGURATION ............................................................................................................. 3.22

DISPLAY TRANSDUCER BLOCK .................................................................................................................................. 3.23

DEFINITION OF PARAMETERS AND VALUES ............................................................................................................ 3.24

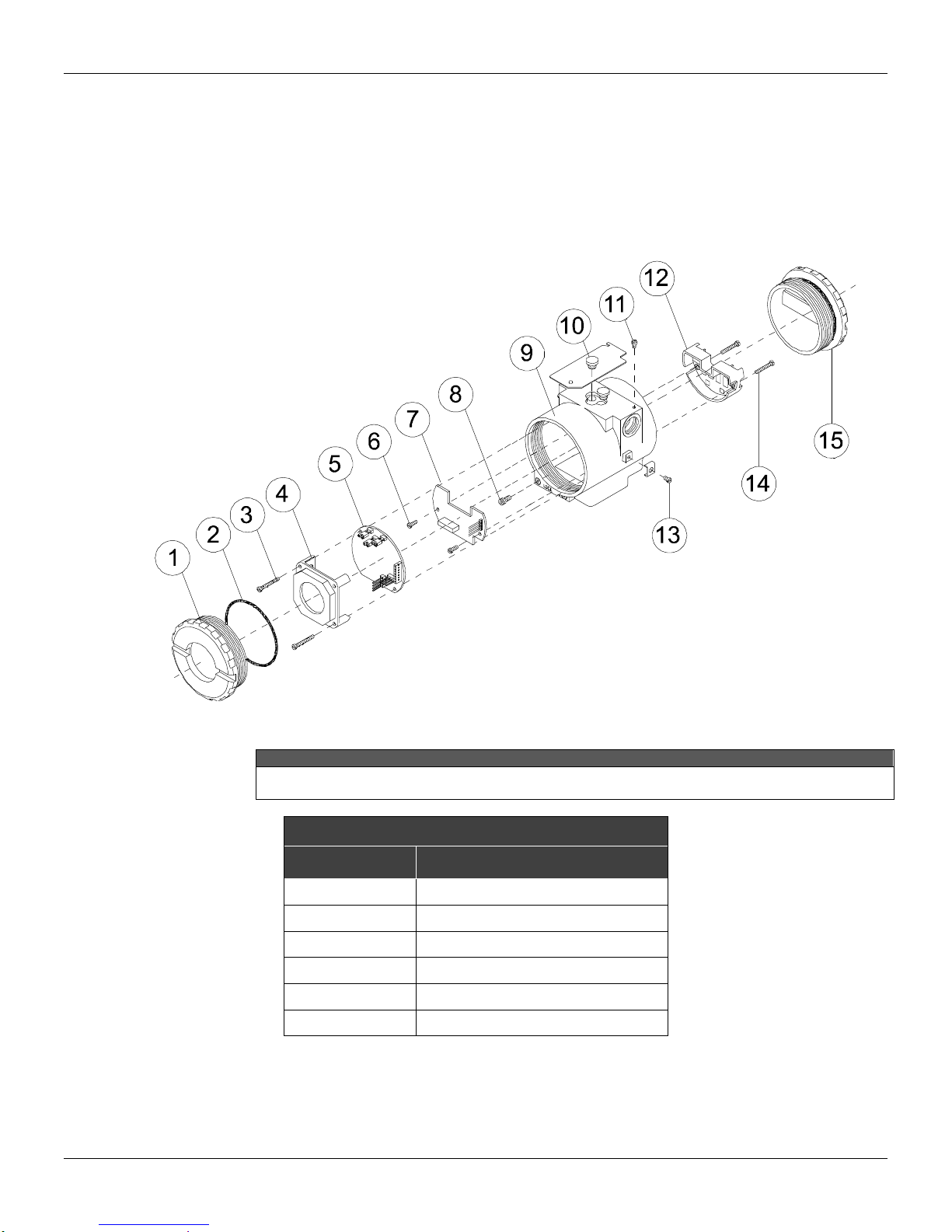

SECTION 4 - MAINTENANCE PROCEDURES ....................................................................... 4.1

TROUBLESHOOTING ...................................................................................................................................................... 4.1

DISASSEMBLY PROCEDURE ......................................................................................................................................... 4.2

SENSOR .......................................................................................................................................................................................... 4.2

ELECTRONIC CIRCUITS ................................................................................................................................................................. 4.2

REASSEMBLE PROCEDURE .......................................................................................................................................... 4.2

INTERCHANGEABILITY .................................................................................................................................................. 4.2

RETURNING MATERIALS ............................................................................................................................................... 4.3

SECTION 5 - TECHNICAL CHARACTERISTIC ...................................................................... 5.1

ORDERING CODE ........................................................................................................................................................... 5.4

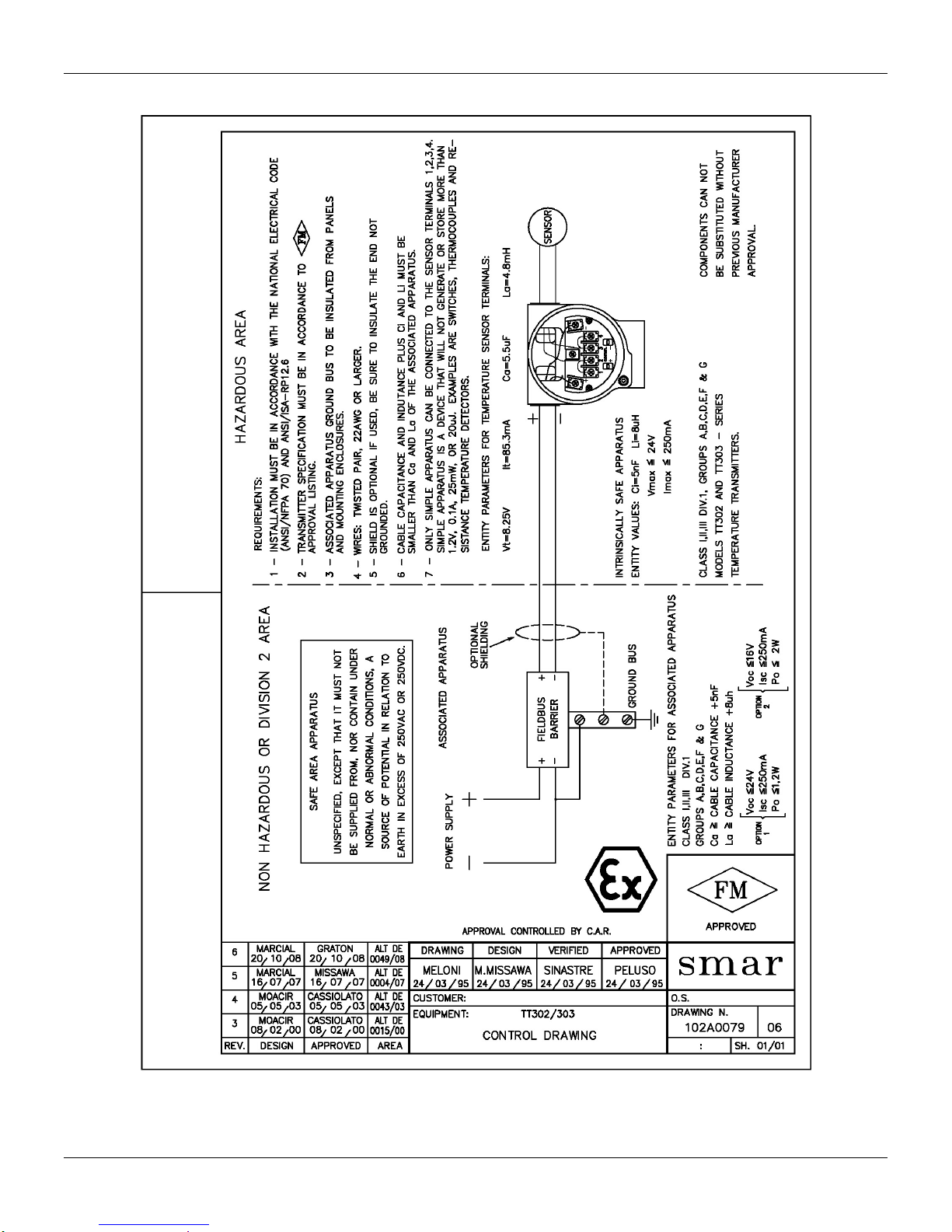

APPENDIX A - CERTIFICATIONS INFORMATION ................................................................ A.1

EUROPEAN DIRECTIVE INFORMATION ........................................................................................................................ A.1

HAZARDOUS LOCATIONS CERTIFICATIONS ............................................................................................................... A.1

NORTH AMERICAN CERTIFICATIONS ........................................................................................................................................... A.1

SOUTH AMERICAN CERTIFICATIONS ........................................................................................................................................... A.1

TT303 – Operation and Maintenance Instruction Manual

VI

EUROPEAN CERTIFICATIONS ................................................................................................................................ ....................... A.2

ASIA CERTIFICATION ..................................................................................................................................................................... A.2

IDENTIFICATION PLATE AND CONTROL DRAWING .................................................................................................... A.2

IDENTIFICATION PLATE ................................................................................................................................................................. A.2

CONTROL DRAWING ...................................................................................................................................................................... A.5

APPENDIX B – SRF – SERVICE REQUEST FORM ............................................................... B.1

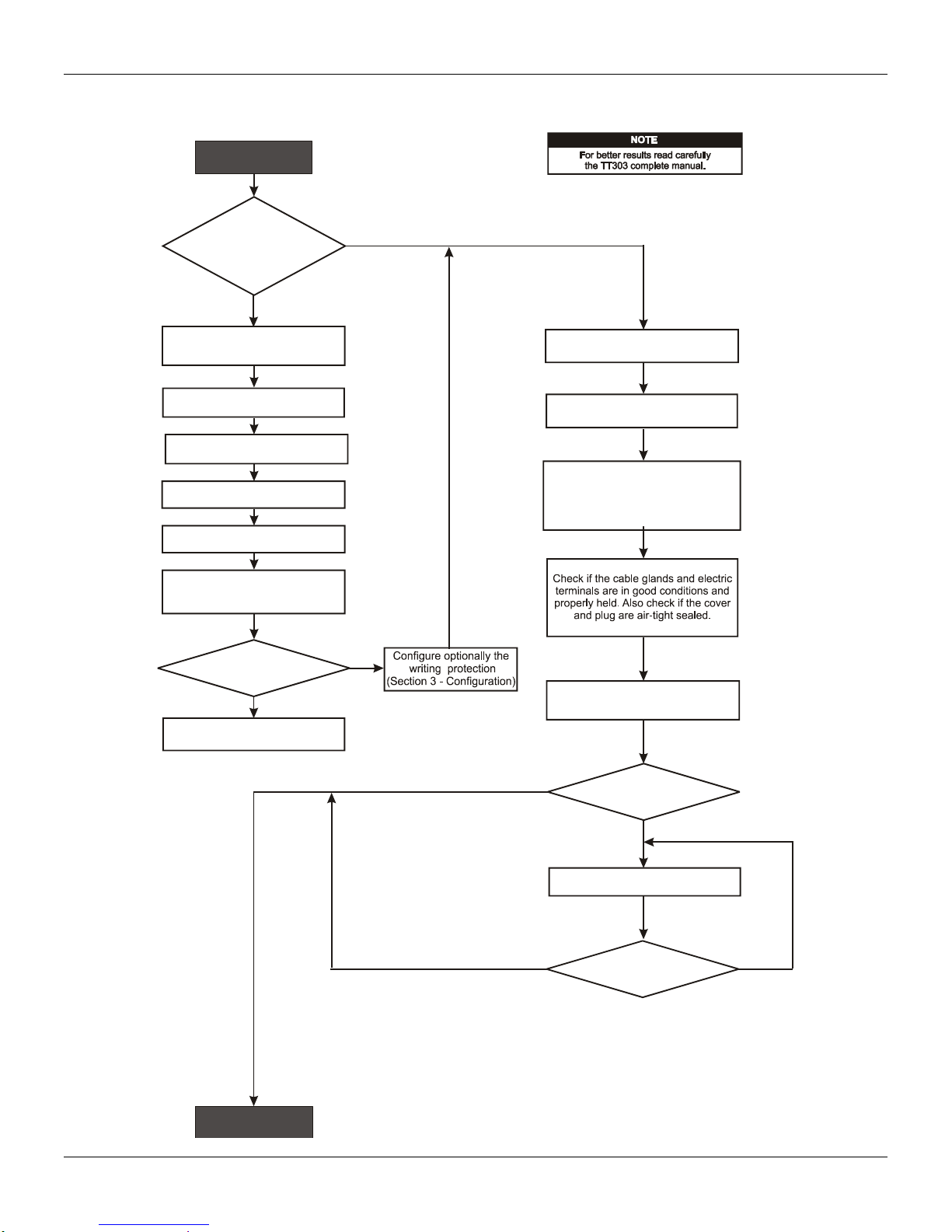

Installation Flowchart

VII

Installation Flowchart

Yes

Was the transmitter

configured on the bench

to match the application?

Configure the range and unit

(AI block)

Simule the value(s)

of the work range in the sensor(s)

conection terminal(s)

mV or Ohm

Start

No

No

OK

Yes

No

Yes

No

Yes

Configure the

1 and

3 - Configuration)

sensor and its

connections (Section

Section

Configure the measuring type

(differantial, dual, backup, or single)

Configure the Damping (AI block)

(Section 3 - Configuration)

Configure the LCD reading

(Section 3 - Configuration)

See manual

(Section 5 - Maintenance)

Is the reading correct?

Check the area classification

and its practices.

Install the transmitter preferably

on weather- protected areas.

Install the transmitter

(mechanically and electrically)

according to the application after

checking the best position for the LCD

(Section 5 - Maintenance)

Power the transmitter properly.

Is the transmitter

reading correct?

Do lower and upper trimTrim

Did you correct the

transmitter reading?

TT303 – Operation and Maintenance Instruction Manual

VIII

Section 1

General

Mounting

Network Wiring

INSTALLATION

The overall accuracy of temperature and other measurements depends on several variables.

Although the transmitter has an outstanding performance, proper installation is essential in order to

maximize its performance.

Among all factors which may affect transmitter accuracy, environmental conditions are the most

difficult to control. There are, however, ways of reducing the effects of temperature, humidity and

vibration.

Locating the transmitter in areas protected from extreme environmental changes can minimize

temperature fluctuation effects.

In warm environments, the transmitter should be installed in such a way as to avoid, as much as

possible, direct exposure to the sun. Installation close to lines and vessels subjected to high

temperatures should also be avoided. For temperature measurements, sensors with cooling-neck

can be used or the sensor can be mounted separately from the transmitter housing.

Use of sunshades or heat shields to protect the transmitter from external heat sources should be

considered.

Humidity is fatal for electronic circuits. In areas subjected to high relative humidity, the O-rings for

the electronic housing covers must be correctly placed and the covers must be completely closed by

tightening them by hand until you feel the O-rings being compressed. Do not use tools to close the

covers. Removal of the electronics cover in the field should be reduced to the minimum necessary,

since each time it is removed, the circuits are exposed to humidity. The electronic circuit is protected

by a humidity proof coating, but frequent exposure to humidity may affect the protection provided. It

is also important to keep the covers tightened in place. Every time they are removed, the threads

are exposed to corrosion, as painting cannot protect these parts. Code-approved sealing methods

should be employed on conduit entering the transmitter.

Connecting the sensor as close to the transmitter as possible and using proper wires (See Section 2

- Operation), can decrease measurement error.

The transmitter may be mounted in two basic ways:

Separated from the sensor, using optional mounting brackets.

Mounted on the sensor assembly.

It can be mounted in several different positions using the bracket, as shown in Figure 1.3. As shown

in Figure 1.3 one of the conduit inlets for electrical connection is used to mount the sensor integral

to the temperature transmitter.

For better visibility, the digital display may be rotated in steps of 90º (see Figure 4.1).

Access the terminal block by removing the Electrical Connection Cover. This cover can be locked

closed by the cover locking screw (See Figure 1.1).To release the cover, rotate the locking screw

clockwise.

1.1

TT303 – Operation and Maintenance Instruction Manual

COVER

LOCKING

SCREW

WARNING

Do not connect the Fieldbus network wires to the sensor terminals. (Terminals 1, 2, 3 and 4).

ALLOW 150 MM MINIMUM FOR LOCAL

ZERO AND SPAN ADJUSTMENT WITH

MAGNETIC TOOL.

COMMUNICATIONS

TERMINAL

PLUG

CONDUIT

CONNECTION

MOUNTING

BRACKET

PIPE 2"

PLUG

WALL OR

PANEL MOUNTING

FOR WALL MOUNTING

2 EXPANSION ANCHOR 2 HEXAGON SCREW -

S8

3/16”X70

2 BOLT AND NUTS - 1/4”X30

NOT INCLUDED

FOR PANEL MOUNTING

POWER SUPPLY

AND COMMUNICATION

(FIELDBUS NETWORK)

TERMINALS

AUXILIARY

COMMUNICATION

TERMINALS

GROUND

TERMINALS

+

1 2 3

4

+

COMM

Figure 1.1 - Cover Locking

Cable access to wiring connections are obtained by one of the two conduit outlets. Conduit threads

should be sealed by means of code-approved sealing methods. The unused outlet connection

should be plugged accordingly.

The wiring block has screws on which fork or ring type terminals can be fastened (see Figure 1.2).

Figure 1.2 - Ground Terminals

For convenience, there are three ground terminals: one inside the cover and two externally,

located close to the conduit entries.

Figure 1.3 - Dimensional Drawing and Mounting Positions

1.2

Installation

NOTE

Please refer to the General Installation, Operation and Maintenance Procedures Manual for more

details.

WIRES

NOTE

Avoid routing sensor wiring close to power cables or switching equipment.

The TT303 uses the 31.25-kbit/s, voltage mode option for the physical signaling. All other devices

on the same bus must use the same signaling. All devices are connected in parallel along the same

pair of wires.

Various types of Fieldbus devices may be connected on the same bus. The TT303 is powered via

the bus. The limit for such devices is according to the DP/PA coupler limitations for one bus for nonintrinsically safe requirement.

In hazardous areas, the number of devices may be limited intrinsically safe restrictions, according to

the DP/PA coupler and barriers limitations.

The TT303 is protected against reverse polarity, and can withstand ±35 VDC without damage, but it

will not operate when in reverse polarity.

Use of twisted pair cables is recommended. It is also recommended to ground shield of shielded

cables at one end only. The non-grounded end must be carefully isolated.

The Figure 1.4 shows the correct installation of the conduit, in order to avoid penetration of water, or

other substance, which may cause malfunctioning of the equipment.

Sensor Wiring

Figure 1.4 - Conduit Installation Diagram

The TT303 accepts up to two sensors and may operate in one of three modes:

Single channel single sensor measurement;

Dual channel dual sensor measurement;

Single channel dual sensor differential measurement;

Single channel dual sensor backup measurement;

In accordance with connection and sensor types, the terminal blocks shall be wired as shown on the

figure 1.5.

1.3

TT303 – Operation and Maintenance Instruction Manual

2 - WIRE RTD OR OHM INPUT

4 - WIRE RTD OR OHM INPUT

DUAL OR DIFFERENTIAL

RTD OR OHM INPUT

DUAL OR DIFFERENTIAL

THERMOCOUPLE OR

MILLIVOLT INPUT

THERMOCOUPLE

INPUT

MILLIVOLT INPUT

3 - WIRE RTD OR OHM INPUT

1 2 3 4

1 2 3 4 1 2 3 4 1 2 3 4

1 2 3 4

1 2 3 4

1 2

DUAL OR DIFFERENCTIAL

RTD AND TC INPUT

3 41 2 3 4

10 M

DUAL OR DIFFERENTIAL

+

+

1 2

10 M

3 4

+

+

+

+

Figure 1.5 - Sensor Wiring

1.4

JUNCTION

BOX

SHIELD

SPUR

SPUR SPUR

TERMINATOR

Analog

Ground

+-+

-

Analog

Ground

+ - +

-

JUNCTION

BOX

TERMINATOR

COUPLER

Topology and Network Configuration

Bus topology (see Figures 1.6 and 1.7) are supported. Both types have a trunk cable with two

terminations. The devices are connected to the trunk via spurs. The spurs may be integrated in the

device giving zero spur length. A spur may connect more than one device, depending on the length.

Active couplers may be used to extend spur length.

Active repeaters may be used to extend the trunk length.

The total cable length, including spurs, between any two devices in the Fieldbus should not exceed

1900 m.

The connection of couplers should be kept less than 15 per 250 m. In following figures the

DP/PA link depends on the application needs.

Installation

Figure 1.6 - Bus Topology

Figure 1.7 - Tree Topology

1.5

TT303 – Operation and Maintenance Instruction Manual

J1

This jumper enables the simulation mode parameter in the AI block.

W1

This jumper enables the local adjustment programming tree.

Intrinsic Safety Barrier

When the Fieldbus is in an area requiring intrinsic safety, a barrier must be inserted on the trunk

between the power supply and the DP/PA coupler, when it is Non-Ex type.

Use of DF47 is recommended.

Jumper Configuration

In order to work properly, the jumpers J1 and W1 located in the TT303 main board must be correctly

configured (See Table 1.1).

Power Supply

The TT303 receives power from the bus via the signal wiring. The power supply may come from a

separate unit or from another device such as a controller or DCS.

The voltage should be between 9 to 32 Vdc for non-intrinsic safe applications.

A special requirement applies to the power supply used in an intrinsically safe bus and depends on

the type of barrier used.

Use of PS302 is recommended as power supply.

Table 1.1 - Description of the Jumpers

1.6

WARNING

Explosions could result in death or serious injury, besides financial damage. Installation of this

transmitter in explosive areas must be carried out in accordance with the local standards and the

protection type adopted .Before continuing the installation make sure the certificate parameters are

in accordance with the classified area where the equipment will be installed.

The instrument modification or parts replacement supplied by other than authorized representative

of Smar is prohibited and will void the certification.

The transmitters are marked with options of the protection type. The certification is valid only when

the protection type is indicated by the user. Once a particular type of protection is selected, any

other type of protection can not be used.

WARNING

Only use Explosion Proof/Flameproof certified Plugs, Adapters and Cable glands.

In Explosion-Proof installations the cable entries must be connected or closed using metal cable

gland and metal blanking plug, both with at least IP66 and Ex-d certification.

The standard plugs provided by Smar are certified according to CEPEL certificate. If the plug

needs to be replaced, a certified plug must be used.

The electrical connection with NPT thread must use waterproofing sealant. A non-hardening

silicone sealant is recommended.

For NEMKO ATEX certificate please to follow the installation guidelines in hazardous locations

below: Group II Category 2G, Ex d, Group IIC, Temperature Class T6, EPL Gb U = 28VDC

Ambient Temperature: -20 to 60ºC for T6

Environmental Protection: IP66/687 or IP66W/687W

The electrical connection available are ½ - 14NPT and M20x1,5.

Cable entries must be connected or closed using metal cable gland and metal blanking plug, both

with at least IP66 and Ex-d certification or any appropriate ATEX approved metal cable gland and

metal blanking plug. Do not remove the transmitter covers when power is ON.

WARNING

In hazardous zones with intrinsically safe or non-incendive requirements, the circuit entity

parameters and applicable installation procedures must be observed.

To protect the application the transmitter must be connected to a barrier. Match the parameters

between barrier and the equipment (Consider the cable parameters). Associated apparatus ground

bus shall be insulated from panels and mounting enclosures. Shield is optional. If used, be sure to

insulate the end not grounded. Cable capacitance and inductance plus Ci and Li must be smaller

than Co and Lo of the associated Apparatus.

It is not recommended to remove the transmitter cover when the power is ON.

Installation in Hazardous Areas

Explosion/Flame Proof

Installation

Intrinsically Safe

1.7

TT303 – Operation and Maintenance Instruction Manual

1.8

Section 2

OPERATION

The TT303 accepts signals from mV generators such as thermocouples or resistive sensors such as

RTDs. The criterion is that the signal is within the range of the input. For mV, the range is -50 to 500

mV and for resistance, 0-2000 Ohm.

Functional Description - Hardware

The function of each block is described below.

Figure 2.1 - TT303 Block Diagram

MUX Multiplexer

The MUX multiplexes the sensor terminals to the signal conditioning section ensuring that the

voltages are measured between the correct terminals.

Signal Conditioner

Its function is to apply the correct gain to the input signals to make them suit the A/D - converter.

A/D Converter

The A/D converts the input signal to a digital format for the CPU.

Signal Isolation

Its function is to isolate the control and data signal between the input and the CPU.

(CPU) Central Processing Unit, RAM, PROM and EEPROM

The CPU is the intelligent portion of the transmitter, being responsible for the management and

operation of measurement, block execution, self-diagnostics and communication. The program is

stored in a PROM. For temporary storage of data there is a RAM. The data in the RAM is lost if the

power is switched off. However there is a nonvolatile EEPROM where data that must be retained is

stored. Examples, of such data are trim, calibration, block configuration and identification data.

Communication Controller

It monitors line activity, modulates and demodulates communication signals and inserts and deletes

start and end delimiters.

2.1

TT303 – Operation and Maintenance Instruction Manual

Power Supply

Takes power of the loop-line to power the transmitter circuitry.

Power Isolation

Just like the signals to and from the input section, the power to the input section must be isolated.

Isolation is achieved by converting the DC supply into a high frequency AC supply and galvanically

separating it using a transformer.

Display Controller

Receives data from the CPU informing which segments of the Liquid Crystal Display, should be

turned on.

Local Adjustment

There are two switches that are magnetically activated. They can be activated by the magnetic tool

without mechanical or electrical contact.

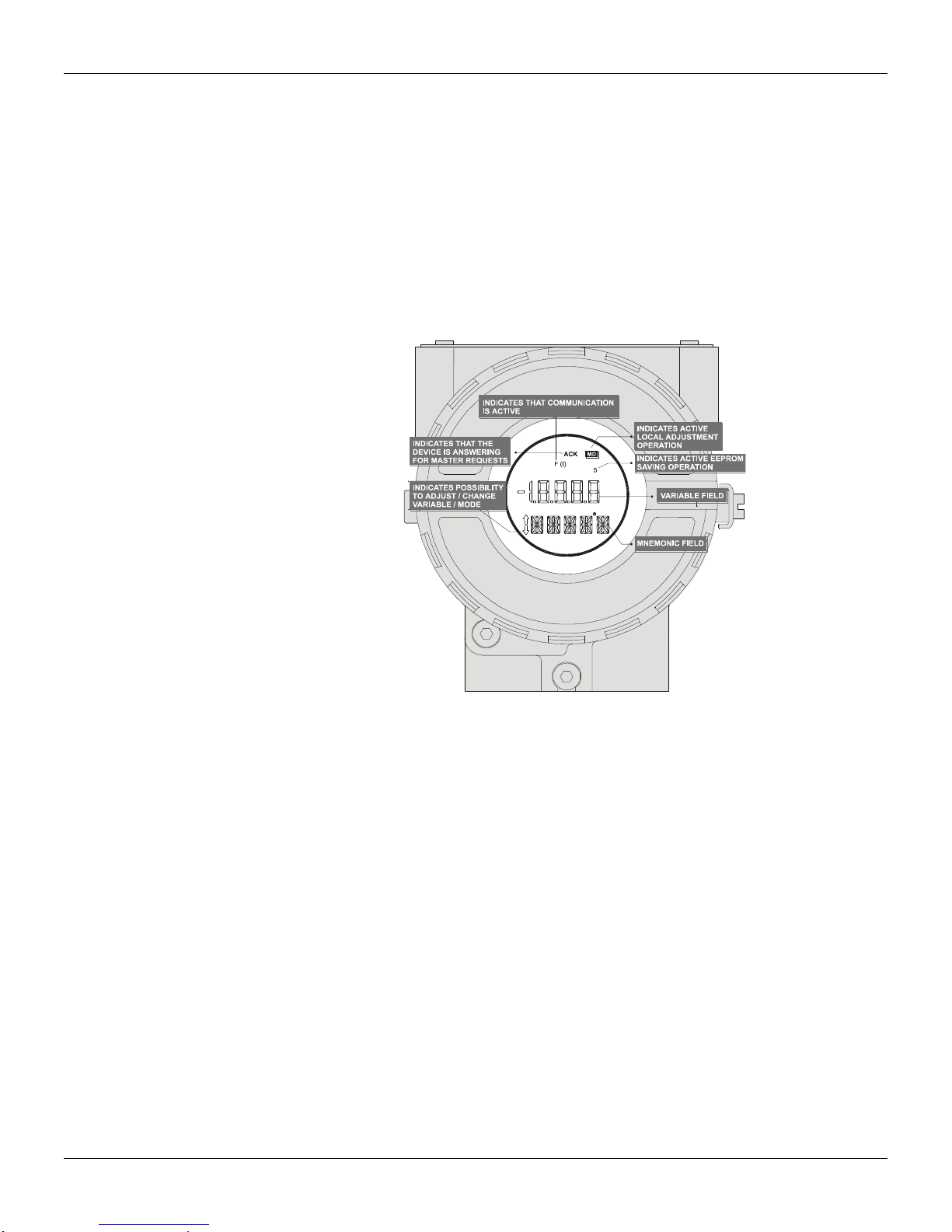

Figure 2.2 - LCD Indicator

Temperature Sensors

The TT303, as previously explained, accepts several types of sensors. The TT303 is specially

designed for temperature measurement using thermocouples or Resistive Temperature Detectors

(RTDs).

Some basic concepts about these sensors are presented below.

Thermocouples

Thermocouples are constructed with two wires made from different metals or alloys joined at one

end, called measuring junction or "hot junction". The measuring junction should be placed at the

point of measurement. The other end of the thermocouple is open and connected to the temperature

transmitter. This point is called reference junction or cold junction.

For most applications, the Seebeck effect is sufficient to explain thermocouple behavior as

following:

How the Thermocouple Works (Seebeck Effect)

When there is a temperature difference along a metal wire, a small electric potential, unique to every

alloy, will occur. This phenomenon is called Seebeck effect. When two wires of dissimilar metals are

joined at one end, and left open at the other, a temperature difference between the two ends will

result in a voltage since the potentials generated by the dissimilar materials are different and do not

cancel each other out. Now, two important things must be noted. First: the voltage generated by the

thermocouple is proportional to the difference between the measuring-junction and the cold junction

temperatures.

2.2

Operation

NOTE

Use thermocouple wires or appropriate extension wires all the way from sensor to transmitter.

R

V2

TRANSMITTER

2,1

3,4

R

RTD

I

Therefore the temperature at the reference junction must be added to the temperature derived from

the thermocouple output, in order to find the temperature measured. This is called cold junction

compensation, and is done automatically by the TT303, which has a temperature sensor at the

sensor terminals for this purpose. Secondly, if the thermocouple wires are not used, all the way to

the terminals of the transmitter (e.g., copper wire is used from sensor-head or marshaling box) will

form new junctions with additional Seebeck effects. It will be created and ruin the measurement in

most cases, since the cold-junction compensation will be done at the wrong point.

The relation between the measuring junction temperature and the generated millivoltage is tabulated

in thermocouple calibration tables for standardized thermocouple types, the reference temperature

being 0C.

Standardized thermocouples that are commercially used, whose tables are stored in the memory of

the TT303, are the following:

NBS (B, E, J, K, N, R, S & T)

DIN (L & U)

Resistive Temperature Detectors (RTDs)

Resistance Temperature Detectors, most commonly known as RTD’s, are based on the principle

that the resistance of metal increases as its temperature increases.

Standardized RTDs, whose tables are stored in the memory of the TT303, are the following:

JIS [1604-81] (Pt50 & Pt100)

IEC, DIN, JIS [1604-89] (Pt50, Pt100 & Pt500)

GE (Cu10)

DIN (Ni120)

For correct measurement of RTD temperature, it is necessary to eliminate the effect of the

resistance of the wires connecting the sensor to the measuring circuit. In some industrial

applications, these wires may be hundreds of meters long. This is particularly important at locations

where the ambient temperature changes constantly.

The TT303 permits a 2-wire connection that may cause measuring errors, depending on the length

of connection wires and on the temperature to which they are exposed. (see Figure 2.3).

In a 2-wire connection, the voltage V2 is proportional to the RTD resistance plus the resistance of

the wires.

V2 = [RTD + 2 x R] x I

Figure 2.3 - Two-Wire Connection

In order to avoid the resistance effect of the connection wires, it is recommended to use a 3-wire

connection (see Figure 2.4) or a 4-wire connection (see Figure 2.5).

In a 3-wire connection, terminal 3 is a high impedance input. Thus, no current flows through that

wire and no voltage drop is caused. The voltage V2-V1 is independent of the wire resistances since

they will be cancelled, and is directly proportional to the RTD resistance alone.

2.3

TT303 – Operation and Maintenance Instruction Manual

R

V2

V1

TRANSMITTER

2,1

4

3

R

RTD

I

R

V2

2

1

+

-

3

4

R

RTD

TRANSMITTER

I

TRANSMITTER

1,3

R

R

R

2

4

V1

V2

RTD2

RTD1

I

I

V2-V1 = [RTD + R] x I - R x I = RTD x I

Figure 2.4 - Three – Wire Connection

In a 4-wire connection, terminals 2 and 3 are high impedance inputs. Thus, no current flows through

those wires and no voltage drop is caused. The resistance of the other two wires is not of interest,

since there is no measurement registered on them. Hence the voltage V2 is directly proportional to

the RTD resistance.

(V2 = RTD x I)

Figure 2.5 - Four - Wire Connection

A differential or dual channel connection is similar to the two-wire connection and gives the same

problem (See Figure 2.6). The resistance of the wires will be measured and do not cancel each

other out in a temperature measurement, since linearization will affect them differently.

2.4

Figure 2.6 - Differential or Dual Connection

* PID IS OPTIONAL

M

A

Fix

F(t)

PID

SP

F(x)

35

PV

min

ACK

INDICATES THAT THE DISPLAYED

ALARM HAS NOT YET BEEN ACKNOWLEDGED

INDICATES ACTIVE SPECIAL

SENSOR LINEARIZATION

( NOT USED ON TT301 )

VARIABLE FIELD

UNIT PERCENT

UNIT MINUTES

UNIT AND FUNCTION FIELD

INDICATES THAT THE PROCESS

VARIABLE IS NOW DISPLAYED

INDICATES ACTIVE

MULTIDROP MODE

INDICATES ACTIVE

SETPOINT GENERATOR *

INDICATE PID

CONTROLLER MODE *

INDICATES ACTIVE

CONSTANT OUTPUT MODE

INDICATES CONTROLLER

IN AUTOMATIC *

INDICATES CONTROLLER

IN MANUAL *

INDICATES POSSIBILITY

TO ADJUST / CHANGE

VARIABLE / MODE

INDICATES THAT

THE SETPOINT

The Display

Operation

The digital indicator is able to display one or two variables which are user selectable. When two

variables are chosen, the display will alternate between the two with an interval of 3 seconds.

The different fields and status indicators are explained in Figure 2.7.

Monitoring

Figure 2.7 – Typical Monitoring Mode Display

During normal operation, the TT303 is in the monitoring mode. In this mode, indication alternates

between the primary and secondary variable as configured in DISPLAY. See Figure 2.8.

The display indicates engineering units, values and parameters simultaneously with most status

indicators. The monitoring mode is interrupted in two situations:

User performs complete local adjustment.

An alarm is activated.

Figure 2.7 – Display

2.5

TT303 – Operation and Maintenance Instruction Manual

ALARM 1

ALARM 2

Alarm

The two alarms are software alarms and have no contacts available on the transmitter. The alarms

are acknowledged by using the Local Adjustment or the Configurator, which can view and configure

alarms as well - see further Section III. During an alarm, the display will indicate which alarm has

been activated and if it has been acknowledged or not.

The transmitter display also indicates the alarms status as shown in Figure 2.9.

AL H means High Alarm, AL L means Low Alarm and ALO indicates Burnout failure. The ACK

indicates that the alarm has not yet been acknowledged.

When the alarm condition disappears, the "ACK" is switched off and the display returns to

monitoring mode.

For further information on alarm configuration, see Section III - Programming Using Terminal.

Figure 2.9 – Typical Alarm Condition Display

2.6

Section 3

CONFIGURATION

This section describes the characteristics of the blocks in the TT303. They follow the Profibus PA

specifications, but in terms of transducer blocks, the input transducer block and display, they have

some special features on top of this.

The TT303 contains two input transducer blocks, one resource block, one display transducer block.

For explanation and details of function blocks, see the “Function Blocks Instruction Manual”.

The 303 Smar family is integrated in Profibus View, from Smar and in the Simatic PDM, from

Siemens. It is possible to integrate any 303 Smar device into any configuration to ol for Profibus PA

devices. It is necessary to provide a Device Description or Drive acc ording to the configuration too l.

In this manual is taken several examples using Profibus View or Simatic PDM.

In order to assure correct values in the offline configuration, first run “Download to PG/PC” option to

assure valid values. After, run the Menu Device option to configur e the required parameters using

the related menus.

In offline configuration, it is not advisable to use the “Download to Device” option. This function can

misconfigure the equipment.

Transducer Block

Transducer block insulates function blocks from the specific I/O hardware, such as sensors,

actuators. Transducer block controls access to I/O through manufacturer specific implementation.

This permits the transducer block to execute as frequently as nec essary to obtain good data from

sensors without burdening the function blocks that uses the data. It also insulates the function block

from the manufacturer specific characteristics of certain hardware.

By accessing the hardware, the transducer block can get data from I/O or passing control data to it.

The connection between Transducer block and Function block is called channel. T hese blocks can

exchange data from its interface.

Normally, transducer blocks perform functions, such as linearization, characterization, temperature

compensation, control and exchange data to hardware.

How to Configure a Transducer Block

The transducer block has an algorithm, a set of contained p arameters, it means, yo u are not able t o

link these parameters to other blocks and publish the link via communication, and a channel

connecting it to a function block.

The algorithm describes the behavior of the transducer as a data transfer function between the I/O

hardware and other function block. The set of contained parameters defi nes the user interface to the

transducer block. They can be divided into Standard and Manufacturer Specific.

The standard parameters will be present for such class of device, as pressure, temperature,

actuator, etc., whatever is the manufacturer. Oppositely, the manufacturers specific ones are

defined only for its manufacturer. As common manufacturer specific parameters, we have calibration

settings, material information, linearization curve, etc.

When you perform a standard routine such as calibration, you are conducted step by step by a

method. The method is generally defined as guideline to help the user to make c ommon tasks. The

Configuration Tool identifies each method associated to the parameters and enables the i nterface

to it.

NOTE

3.1

TT303 – Operation and Maintenance Instruction Manual

x

Functional Diagram of the Temperature Transducer Block

Transducer BlockProcess Transducer Block AI FB(’s)

R.J.

Input

T1

T2

Input 1

Input 2

INPUT_RANGE,

SENSOR_CONNECTION,

COMP_WIRE1/2

RJ_TEMP

RJ_TYPE

R.J. Comp.

LIN

+

0

1 2 EXTERNAL_RJ_VALUE

Linearization

LIN

+

TAB_...

LIN

Arithmetic

BIAS_1

SECONDARY_VALUE_1

+

PRIMARY_VALUE

+

SECONDARY_VALUE_2

BIAS_2

SENSOR_MEAS_TYPELIN_TYPE,

Figure 3.1 – Functional Diafram of the Temperature Block

Temperature Transducer Block General Parameter Description

Temperature Transducer Block General Parameter Description formatted: font: Not Bold, English

(U.S.)

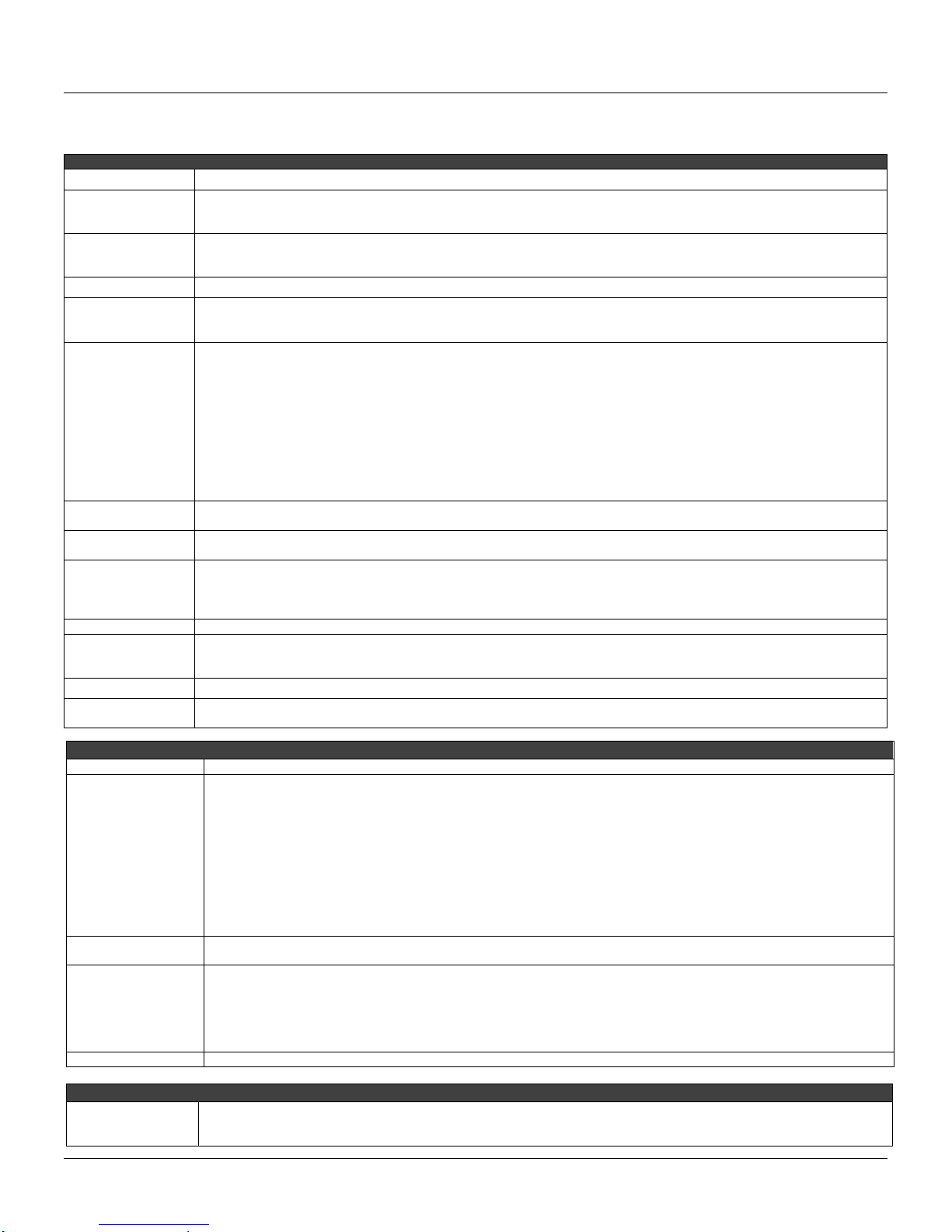

PARAMETER DESCRIPTION

BIAS_1

BIAS_2

INPUT_FAULT_GEN

INPUT_FAULT_1

Bias that can be algebraically added to process value of channel 1.

The unit of BIAS_1 is the PRIMARY_VALUE_UNI T.

Bias that can be algebraically added to process value of channel 2.

The unit of BIAS_2 is the PRIMARY_VALUE_UNI T.

Input malfunction: Diagnosis object for errors that concerns all values

0 = device OK

Bit:

0 = Rj error

1 = Hardware error

2 – 4 = reserved

5 – 7 = manufacturer specific

Byte:

0x00: status ok;

0x80: hardware failure

Input malfunction: Diagnosis object for errors that concern SV_1

0 = Input OK

Bit:

0 = underrange

1 = overrange

2 = lead breakage

3 = short circuit

4 – 5 = reserved

6 – 7 = manufacturer specific

Byte:

0x00: input ok;

0

x8800:: sseennssoorr ffaaiilluurree

0

3.2

INPUT_FAULT_2

INPUT_RANGE

LIN_TYPE

PARAMETER DESCRIPTION

Input malfunction: Diagnosis object for errors that concern SV_2

0 = Input OK

Bit and byte definition see INPUT_FAULT_1

Electrical input ran ge and mode. The ranges are manufacturer specific but range n is smaller than range n+1

if more than one range is supported for one input mode (e.g. range1=0...400

INPUT_RANGE is equal for channel 1 and 2.

Defined codes (other codes are reserv ed):

0 = mV range 1 => mV22

1 = mV range 2 => mV100

2 = mV range 3=> mV500

:

9 = mV range 10

128 =

:

137 = range 10

192 = mA range 1

193 = mA range 2

:

201 = mA range 10

240 = manufacturer specific

:

249 = manufacturer specific

250 = not used

251 = none

252 = unknown

253 = special

Remark:

When using codes 240..249 (manufacturer specific) interchangeability is not possible.

Select the type of sensor (Code) for Thermocouples, Rtd, Pyrometers or linear.

101 = RTD Pt50 a=0.003850 (IEC 751, DIN 43760, JIS C1604-97, BS1904)

102 = RTD Pt100 a=0.003850 (IEC 751, DIN 43760, JIS C1604-97, BS1904)

104 = RTD Pt500 a=0.003850 (IEC 751, DIN 43760, JIS C1604-97, BS1904)

107 = RTD Pt50 a=0.003916 (JIS C1604-81)

108 = RTD Pt100 a=0.003916 (JIS C1604-81)

120 = RTD Ni120 a=0.006720 (Edison curve #7)

121 = TC Type E, Ni10Cr-Cu45Ni (IEC584, NIST MN 175, DIN 43710, BS 4937, ANSI MC96.1, JIS

C1602, NF C42-321)

128 = TC Type B, Pt30Rh-Pt6Rh (IEC 584, NIST MN 175, DIN 43710, BS 4937, ANSI MC96.1, JIS

C1602, NF C42-321)

133 = TC Type J, Fe-Cu45Ni (IEC 584, NIST MN 175, DIN 43710, BS 4937, ANSI MC96.1, JIS C1602,

NF C42-321)

134 = TC Type K, Ni10Cr-Ni5 (IEC 584, NIST MN 175, DIN 43710, BS 4937, ANSI MC96.1, JIS C1602,

NF C42-321)

135 = TC Type N, Ni14CrSi-NiSi (IEC 584, NIST MN 175, DIN 43710, BS 4937, ANSI MC96.1, JIS

C1602, NF C42-321)

136 = TC Type R, Pt13Rh-Pt (IEC 584, NIST MN 175, DIN 43710, BS 4937, ANSI MC96.1, JIS C1602,

NF C42-321)

137 = TC Type S, Pt10Rh-Pt (IEC 584, NIST MN 175, DIN 43710, BS 4937, ANSI MC96.1, JIS C1602,

NF C42-321)

138 = TC Type T, Cu-Cu45Ni (IEC 584, NIST MN 175, DIN 43710, BS 4937, ANSI MC96.1, JIS C1602,

NF C42-321)

139 = TC Type L, Fe-CuNi (DIN 43710)

140 = TC Type U, Cu-CuNi (DIN 43710)

145 to 239 reserved

Manufacturer specific :

240 Cu10 GE, Edison #15

241 Ohm 100

242 Ohm 400

243 Ohm 2000

244 mV22

245 mV100

246 mV500

:

249 Manufacturer specific

250 Not used

251 None

252 Unknown

253 Special

range 1 = > Ohm 100

129 = range 2 = > Ohm 400

130 = range 3 = > Ohm 2000

Configuration

, range2=0...4k).

3.3

TT303 – Operation and Maintenance Instruction Manual

PARAMETER DESCRIPTION

Physical lower limit function of sensor (e.g. Pt 100 = -200°C) and input range. In the case of multichannel

LOWER_SENSOR_LIMIT

PRIMARY_VALUE

PRIMARY_VALUE_UNIT

SECONDARY_VALUE_1

(SV_1)

SECONDARY_VALUE_2

(SV_2)

SENSOR_MEAS_TYPE

UPPER_SENSOR_LIMIT

COMP_WIRE1 Value in OHM to compensate line resistance when the thermoresistance 1 is connected with 2 or 3 wires.

COMP_WIRE2 Value in OHM to compensate line resistance when the thermoresistance 2 is connected with 2 or 3 wires.

SENSOR_CONNECTION

PRIMARY_VALUE_RANGE

CAL_POINT_HI

CAL_POINT_LO

CAL_MIN_SPAN

CAL_UNIT

SENSOR_RANGE

SENSOR_SN The sensor serial number.

SECONDARY_VALUE The secondary value related to the sensor .

SECONDARY_UNIT The engineering units to be used with the secondary value related to the sensor.

MODULE_SN Indicates the number of the module.

SECONDARY_VALUE_ACTION

TWO_WIRES_COMPENSATION

SENSOR_TRANSDUCER_NUMBER Selects the Transducer 1 or 2.

FACTORY_DIGITAL_INPUTS Reads the digital inputs.

FACTORY_GAIN_REFERENCE Calibration point for Ohm and mV sensors.

FACTORY_TERMINAL_REFERENCE Calibration point for the Borne Resistance .

BACKUP_RESTORE

measurements (e.g. differential measurement) the meaning of LOWER_SENSOR_LIMIT is the limit of one

channel not the calculated limit of both channels.

The unit of LOWER_SENSOR_LIMIT is the PRIMARY_VALUE_UNIT.

Process value, function of SECONDARY_VALUE_1/2.

The unit of PRIMARY_VALUE is the PRIMARY_VALUE_ UNIT.

Show the unit code of the PRIMARY_VALUE and other values. The unit is select using

PRIMARY_VALUE_RANGE parameter.

Set of unit codes:

1000: K (Kelvin)

1001: °C (degree Celsius)

1002: °F (degree Fahrenheit)

1003: Rk (Rankine)

1281: (Ohm)

1243: mV (milivolt)

Process value connected to the channel 1 corrected by BIAS_1. The unit of SECONDARY_VALUE_1 is the

PRIMARY_VALUE_UNIT.

Process value connected to the channel 2 corrected by BIAS_2. The unit of SECONDARY_VALUE_2 is the

PRIMARY_VALUE_UNIT.

Mathematical function to calculate PRIMARY_VALUE (PV).

Defined codes:

128: PV = SV_1 - SV_2 Difference

manufacturer specific:

220: = Backup

230: = Process Temperature

Physical upper limit function of sensor (e.g. Pt 100 = 850°C) and input range. In the case of multichannel

measurements (e.g. differential me asurement) the meaning of UPPER_SENSOR_LIMIT is the limit of one

channel not the calculated limit of both channels.

The unit of UPPER_SENSOR_LIMIT is the PRIMARY_VALUE_UNIT.

Connection to the sensor, select for 2, 3 and 4 wires connection.

Defined codes:

0 = 2 wires

1 = 3 wires

2 = 4 wires

3 = 2 dual wires

The high and low range limits values, the engineering units and the number of digits to the right of the

decimal to be used to display the primary value.

This parameter contains the highest calibrated value. For calibration of the high limit point you give the high

measurement value (temperature) to the sensor and transfer this point as HIGH to the transmitter. Unit

derives from CAL_UNIT.

This parameter contains the lowest calibrated value. For calibration of the low limit point you give the low

measurement value (temperature) to the sensor an d tran sfer this point as LOW to the transmitter. Unit

derives from CAL_UNIT.

This parameter contains the minimum calibration span value allowed. This minimum span information is

necessary to ensure that when calibration is done, the two calibrated points (high and low) are not too close

together. Unit derives from CAL_UNIT.

The unit for calibration process:

{1000, "Kelvin"},

{1001, "Celsius"},

{1002, "Fahrenheit"},

{1003, "Rankie"}

{1243, "mV"}

{1281, "Ohm"}

The high and low range limits values, the engineering units and the number of digits to the right of the

decimal to be used to describe the operating limits for the sensor.

Allows to enable and to disable the cold junction.

{0, "Disable"},

{1, "Enable"}

Allows the compensation of line resistance for double RTD or Ohm sensors.

{0, "Disable"},

{1, "Enable"}

This parameter allows to save and to restore data according to factory and user calibration procedures. It has

the following options:

3.4

Configuration

PARAMETER DESCRIPTION

1, "Factory Cal Restore",

2, "Last Cal Restore",

3, "Default Data Restore",

11, "Factory Cal Backup",

12, "Last Cal Backup",

14, "Shut-Down Data Backup",

0, "None".

Indicates the condition of calibration process according to:

{16, "Default value set"},

XD_ERROR

{22, "Applied process out of range"},

{26, "Invalid configuration for request"},

{27, "Excess correction"},

{28, "Calibration failed"}

EEPROM_FLAG This parameter is used to indicate EEPROM saving process.

MAIN_BOARD_SN This is the main board serial number.

ORDERING_CODE Indicates information about the sensor and control from production factory.

Table 3.1 - Parameter Description

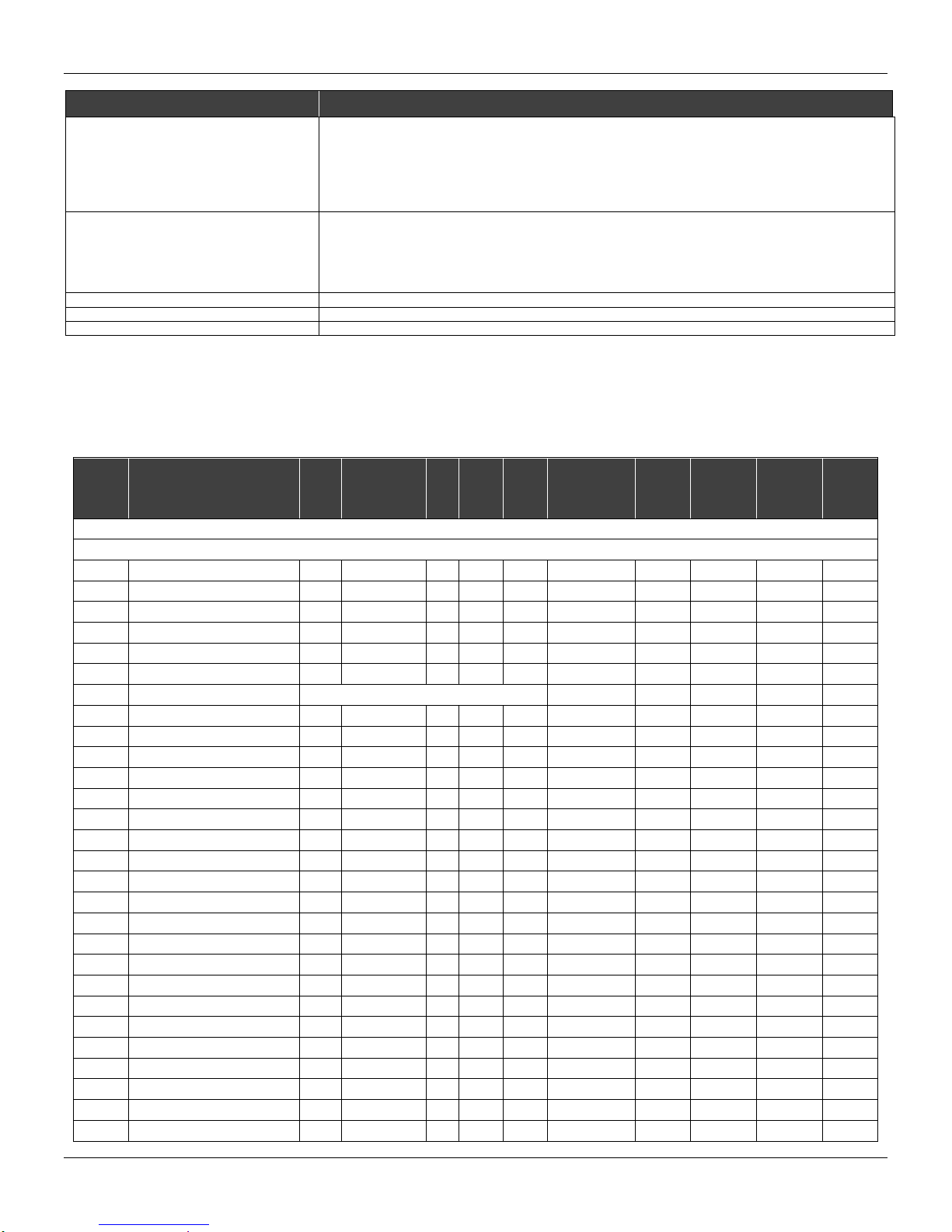

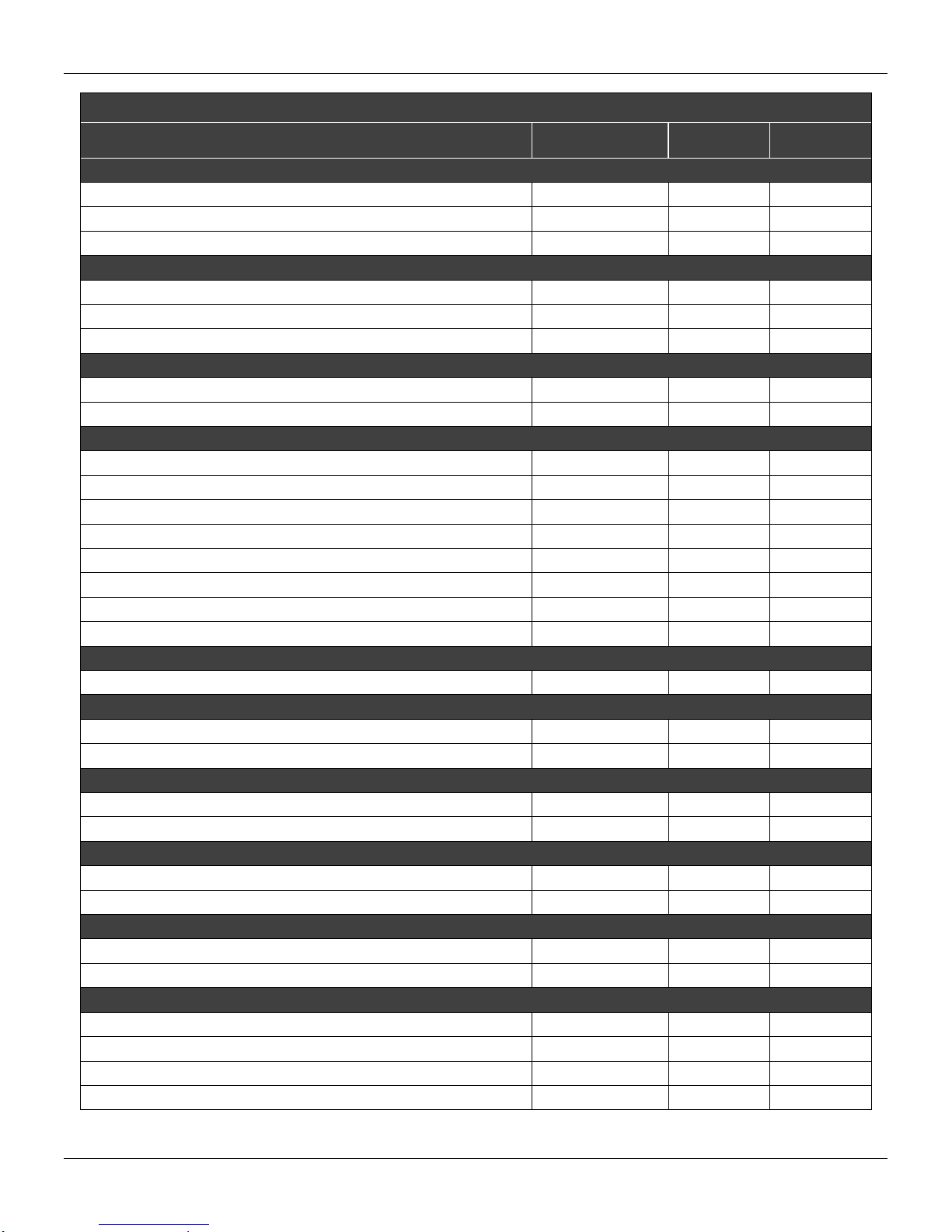

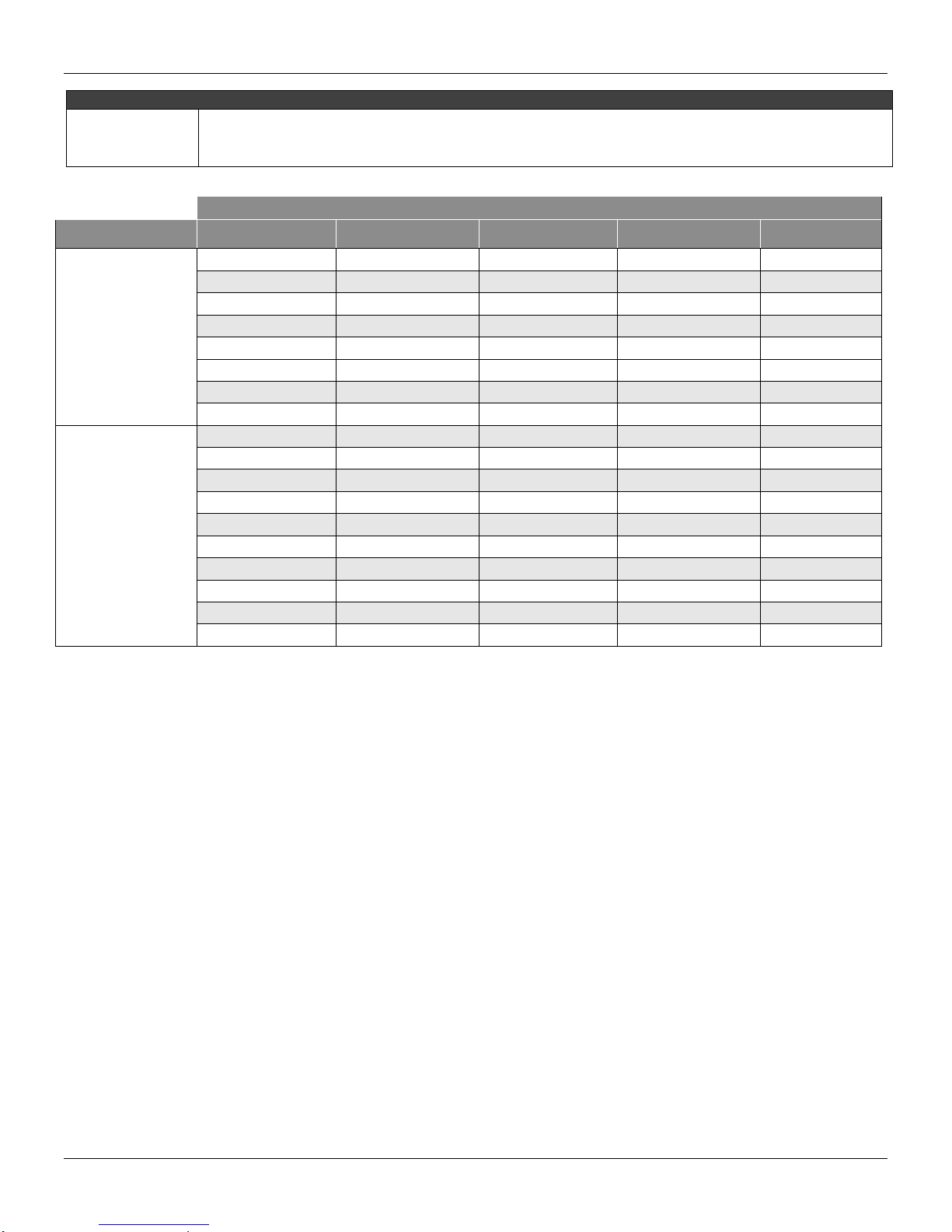

Temperature Transducer Block General Parameter Attributes

Temperature Transducer Block General Parameter Attributes

Relative

Index

... Standard Parameter see General Requirements

General Parameter for Temperature Transducer Block

8 PRIMARY_VALUE simple DS-33 D 5 r C/a M 1

9 PRIMARY_VALUE_UNIT simple Unsigned 16 S 2 r,w C/a 2 M

10 SECONDARY_VALUE_1 simple DS-33 D 5 r C/a M

11 SECONDARY_VALUE_2 simple DS-33 D 5 r C/a O

12 SENSOR_MEAS_TYPE simple unsigned 8 S 1 r,w C/a 3 M

13 INPUT_RANGE simple unsigned 8 S 1 r,w C/a 4 M

14 LIN_TYPE See General Requirements. 1 M

19 BIAS_1 simple Float S 4 r,w C/a 0.0 5 M

20 BIAS_2 simple Float S 4 r,w C/a 0.0 O

21 UPPER_SENSOR_LIMIT simple Float N 4 r C/a M

22 LOWER_SENSOR_LIMIT simple Float N 4 r C/a M

24 INPUT_FAULT_GEN simple unsigned 8 D 1 r C/a M 1

25 INPUT_FAULT_1 simple unsigned 8 D 1 r C/a M 1

26 INPUT_FAULT_2 simple unsigned 8 D 1 r C/a O

27-35 Not used

36 SENSOR_CONNECTION simple unsigned 8 S 1 r,w C/a 7 M

37 COMP_WIRE1 simple Float S 4 r,w C/a 0.0 8 M

38 COMP_WIRE2 simple Float S 4 r,w C/a 0.0 O

39 – 61 Not used

62 PRIMARY_VALUE_RANGE record DS-36 S 11 r,w C/a

63 CAL_POINT_HI simple Float S 4 r,w C/a 850.0

64 CAL_POINT_LO simple Float S 4 r,w C/a -200.0

65 CAL_MIN_SPAN simple Float S 4 r C/a 10.0

66 CAL_UNIT simple Unsigned 16 S 2 r,w C/a 1001

67 SENSOR_RANGE record DS-36 N 11 r C/a

68 SENSOR_SN simple Unsigned 32 S 4 r,w C/a

69 SECONDARY_VALUE simple DS-33 D 5 r C/a

70 SECONDARY_VALUE_UNIT simple Unsigned 16 S 2 r,w C/a 1001

Parameter Name

Object

type

Data type Store Size Access

Param. Usage/

Type of

Transport

Default

Value

Download

Order

Mandatory

Optional

(Class)

View

3.5

TT303 – Operation and Maintenance Instruction Manual

Relative

Index

71 MODULE_SN simple Unsigned 32 S 4 r,w C/a

72 SECONDARY_VALUE_ ACTION simple Unsigned 8 S 1 r,w C/a

73 TWO_WIRES_COMPENSA-TION simple Unsigned 8 S 1 r,w C/a

74 SENSOR_TRANSDUCER_

75 FACTORY_DIGITAL_INPUTS simple Float N 4 r,w C/a

76 FACTORY_GAIN_ REFERENCE simple Unsigned 8 S 1 r,w C/a

77 FACTORY_BORNE_

78 BACKUP_RESTORE simple Unsigned 8 S 1 r,w C/a

79 XD_ERROR simple Unsigned 8 D 1 r C/a

80 MAIN_BOARD_SN simple Unsigned 32 S 4 r,w C/a

81 EEPROM_FLAG simple Unsigned 8 D 1 r C/a

82 ORDERING_CODE simple Unsigned 8 S 50 r,w C/a

Parameter Name

NUMBER

REFERENCE

Object

type

simple Unsigned 8 S 1 r,w C/a

simple Unsigned 8 S 1 r,w C/a

Data type Store Size Access

Param. Usage/

Type of

Transport

Default

Value

Download

Order

Mandatory

Optional

(Class)

View

Table 3.2 - General Parameter for Temperature Transducer Block

TT303 - Cyclic Configuration

The PROFIBUS-DP and PROFIBUS-PA protocols have mechanisms against communication

failures between the slave device and the net work master. For example, during initialization, these

mechanisms are used to check these possible errors. After powering up the field devic e (slave), it

can cyclically exchange information with the class 1 master, if the parameterization for the slave is

correct. This information is obtained using the GSD files (supplied by the device manufacturer, it

contains their descriptions). Through the commands below, the master executes all initialization

process with the PROFIBUS-PA device:

Get_Cfg: uploads the slave configuration on the master and checks network configuration;

Set_Prm: writes to the slave parameters and executes the parameterization network;

Set_Cfg: configures the slaves according to its outputs and inputs;

Get_Cfg: another command, where the master checks the slave configuration.

All these services are based on the information obta ined from slave gsd files. The GSD file from

TT303 shows details such as, hardware and software revision, device bus timing and information

about cyclic data exchange. TT303 has 1 functional block: AI.

Most PROFIBUS configuration tools use two directories where the different manufacturers’ GSD’s

and BITMAPS files are stored. The GSD’s and BITMAPS for Smar devices can be obtained through

the website: (https://www.smar.com), on the ‘download’ link.

The following example shows the necessary steps to integrate the TT303 on a Profibus system.

These steps are valid for the entire 303 line of Smar devices:

Copy the TT303 gsd file to the research directory of the PROFIBUS configur ation tool, usually

called GSD;

Copy the TT303 bitmap file to the research directory of the PROFIBUS configur ation tool usuall y

called BMP;

After choosing the master, def ine the baud rate for the net work. Do not forget that couplers may

work with the following baud rate: 45.45 kbits/s (Siemens model), 93.75 kbits/s (P+F model) and

12 Mbits/s (P+F, SK2 model). The IM157 device link (Siemens model) may work up to 12

Mbits/s;

3.6

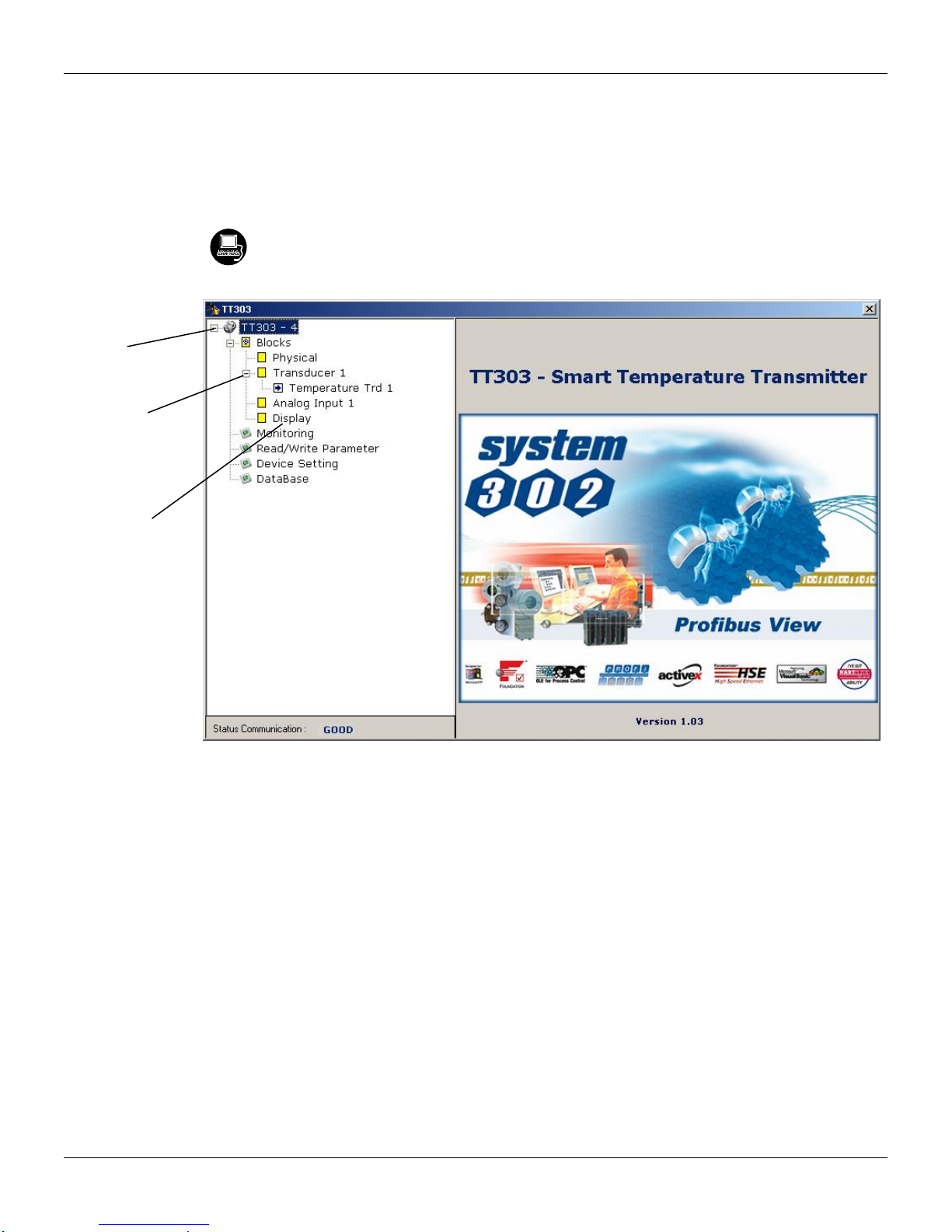

The device was

created as

TT303.

Here, you can

see all blocks

instantiated.

As you can see

the Transducer

and Display are

treated as

special type of

Function

Blocks, called

Transducer

Blocks.

Configuration

Add the TT303 and specify its physical bus address;

Choose the cyclic configuration via parameterization using the gsd file that depends on the

application, as detailed previously. For every AI (Analog Input) block, the TT303 provides the

process variable to the master in 5 bytes value, being the first four according to float point data

type and the fifth byte is the status that brings the measure quality of this information;

It allows activating the condition of watchdog, which the device goes to a fail safe condition,

when a loss of communication is detected with the master.

Configuration softwares like Profibus View from Smar or Simatic PDM (Process Device Manager)

from Siemens can configure many parameters of the Input Transducer block. See the figures 3.2

and 3.3.

Figura 3.2 – Profibus View – Function and Transducers Block

3.7

TT303 – Operation and Maintenance Instruction Manual

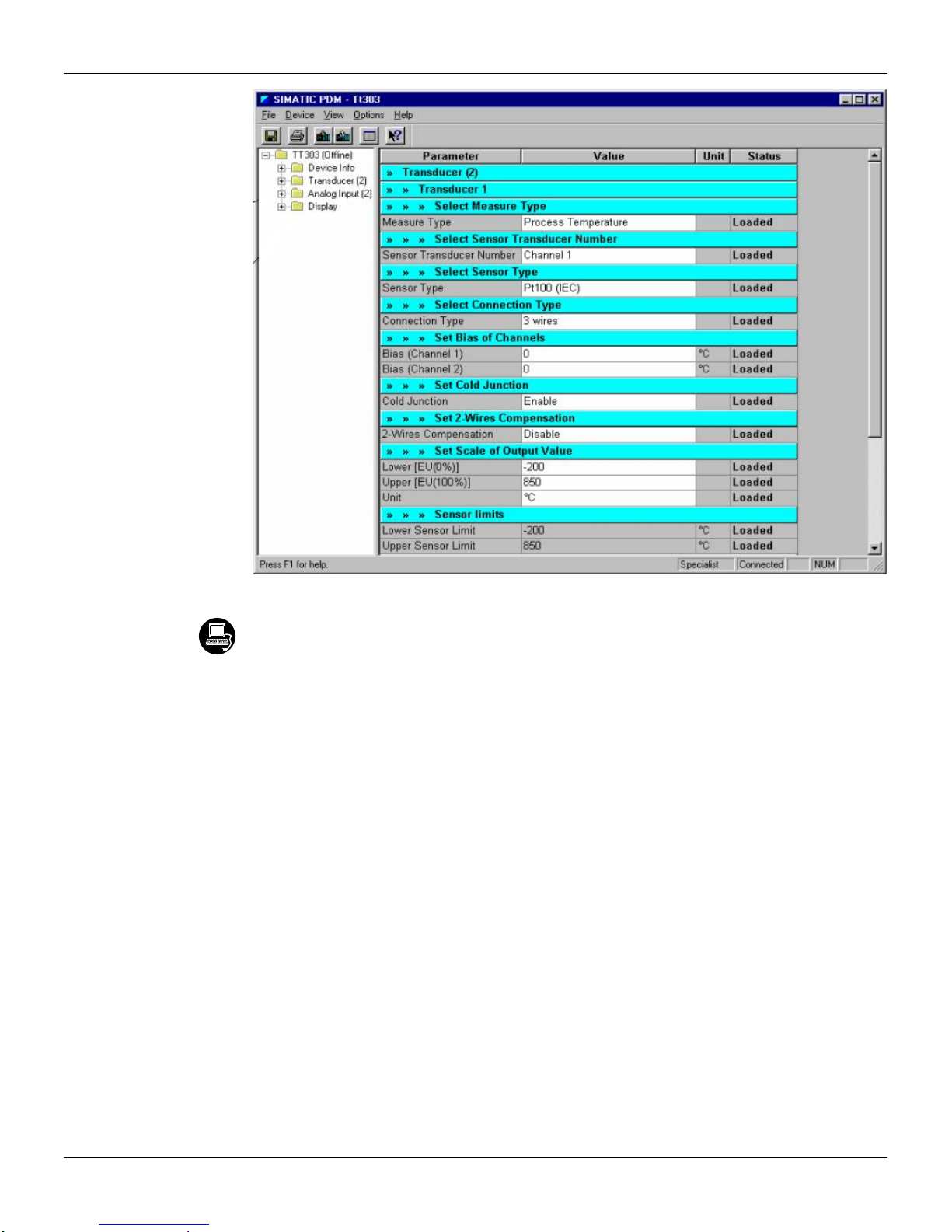

Figure 3.3 – PDM Simatic - Function and Transducers Blocks

Use this menu:

- To change the device address;

- To make the up/download of parameters;

- To configure the Transducer Blocks, Analog Blocks and Display Block;

- To calibrate the transmitter;

- To make the reset by software, to protect the device against writing and to

simulate the value from transducer block to analog block;

- To save and restore data calibration.

To make the configuration of Transducer Block, we need to select the Transducer 1 block on the

main menu.

3.8

p

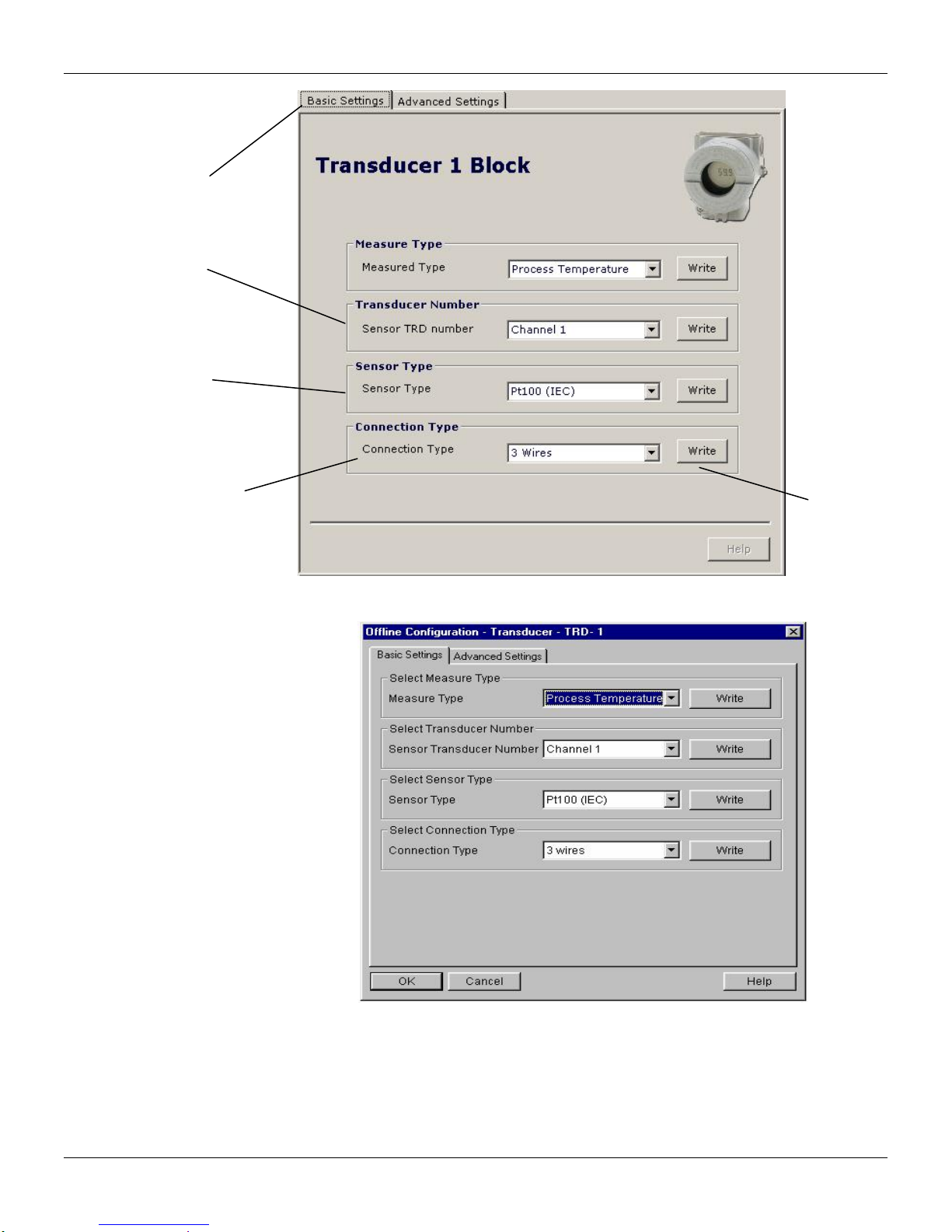

The user can select

the Measured type:

T1-T2, Process

Temperature or

.

Backu

The user can set the

sensor transducer

number.

Please, select sensor type

according to the

application and the

connection type.

Configuration

This parameter selects the

type of sensor connection.

The options here will depend

on Sensor Type chosen as

described above.

After selecting

the desired

option, this

key should be

pressed.

Figure 3.4 - Profibus View - Transducer Basic Settings

The user can configure the Transducer Block, accordin g to the selected Measure Type (when you

have selected "Process Temperature", it means that you will have two sensors, two transducer

blocks and two analog input blocks). Please, select the parameters according to your application.

Figure 3.5 – PDM Simatic - Offline Configuration - Transducer Basic Settings

3.9

TT303 – Operation and Maintenance Instruction Manual

It is possible to configure connection and sensor type by means of parameters SENSOR_TYPE and

SENSOR_CONNECTION. The connection and sensor types available are listed in the t ables Table

3.6 and Table 3.7.

Using the "Advanced Settings" window, the user can set the scaling and unit for the output value

according to the Transducer Block Diagram, bias of chann els and set the cold junction and 2- wires

compensation according to his application.

The user can

configure the

scale an unit

for the output

value.

The user can

configure the bias

of channels.

The user can set the

cold junction and the

2-wires compensation.

Figure 3.6 – Profibus View - Transducer Advanced Settings

Figure 3.7 – PDM Simatic - Offline Configuration - Transducer Advanced Settings

Sensor Transducer Number

The Sensor Transducer Number associates the sensor to the transducer. It can be set to channe l

one up to channel two, in case of dual sensor.

3.10

Jumper Configuration

In order to work properly, the jumpers J1 and J3 located in the TT303 main board must be correctly

configured.

J1 is responsible to enable the AI block simulate mode.

W1 is responsable to enable the local adjustment.

There are no 3 or 4 wire connections for mile-voltage sensors.

Configuration

NOTE

SENSOR_TYPE

Pt 100 IEC

Pt 100 JIS

Pt 500 IEC

Ni 120 DIN

Cu 10 CE

Pt 50 IEC

Pt 50 JIS

Ohm 100

Ohm 400

Ohm 2,000

TC B NBS

TC E NBS

TC J NBS

TC K NBS

TC N NBS

TC R NBS

TC S NBS

TC T NBS

TC L DIN

TC U DIN

mV 22

mV 100

mV 500

Table 3.3 - Sensor Type Table

CONNECTION

DOUBLE TWO WIRE

TWO WIRE

THREE WIRE

FOUR WIRE

Table 3.4 - Type of Connection Table

3.11

TT303 – Operation and Maintenance Instruction Manual

How to Connect Two Sensors

Transmitter series TT303 are capable of operating simultaneously with two sensors, using two

transducer blocks, if necessary. Configuration types in two sensors operation are as follows:

Differential – In this case there is only one transducer. Transducer output is the difference bet ween

the readout of sensor 1 (between terminals 3 and 4) and the readout of sensor 2 (between terminals

2 and 4).

Backup - In this case there is only one transducer.

If the first sensor (connected between terminals 3 and 4) opens, the second sensor (connected

between terminals 2 and 4) will supply the signal to the transducer.

Process Temperature - In this case there are t wo transducers. Each s ensor provides a signa l to its

respective transducer. In this case, please select the sensor connection to “2 dual wires ".

In order to be able to operate with sensors in the backup or differential modes, the user shall actuate

parameter MEASURED_TYPE. In order to operate with double sensors, the user shall actuate

parameter SENSOR_CONNECTION. Please see figure 3.4 e 3.5.

Compensation of Line Resistance for RTD Double Sensor or Ohm Sensor

TT303 allows connecting two sensors but it is possi ble just using 2 wires and this can cause an

error due to the absence of compensation of line resistance. T o minimize this error, there is the

TWO_WIRES_COMPENSATION parameter that enables the calculation of line resistance.

To make the compensation it is necessary to set RTD or Ohm with 2 dual wires in the LIN_TYPE

parameter (relative index 14) and then make a short circuit between 1 and 3 terminals. After that it is

necessary to make a short circuit between 3 and 4 terminals (in the wires in the sensor

location).Then enable the TWO_WIRES_COMPENSATION parameter (relative index 73). After that,

verify the PRIMARY_VALUE parameter.

Repeat the same procedure for the second transducer, keeping the s hort circuit between 1 and 3

terminals, but making a short circuit between 2 and 4 terminals. Please see figure 3.6 e 3.7.

Compensation of Cold Junction

TT303 allows the compensation of cold junction when the user select "Enable" according to the

Figure 3.6 e 3.7.

Calibration in TT303 by the User

The electronics of TT303 is very stable in time, not requiring further calibrations after manufacturer’s

calibration. However, should the client decide to use his r eference to calibrate the TT303 (which is

not recommendable), this may be done by means of parameters CAL_POINT_LO and

CAL_POINT_HI. When trim is performed, always use two points as reference; never consider onl y

one point as a reference. Using Profibus View or the Simatic PDM, the calibration is done

selecting at the main menu "Calibration - Transducer TRD1-Lower/Upper" or menu Calibration Transducer TRD2-Lower/Upper".

3.12

Configuration

The user can select

lower or upper

calibration.

The user can see the

lower sensor limit and

the actual calibrated

point. The user just

needs to inform the

desired point.

The user can see the

measured temperature

The user can verify

the calibration

operation result.

and its status.

Figure 3.8 – Profibus View - Lower Calibration Procedures

If the user to select the upper page (UPPER):

Figure 3.9 – PDM Simatic - Lower Calibration Procedure

3.13

TT303 – Operation and Maintenance Instruction Manual

p

The user can see

the upper sensor

limit and the actual

calibrated point. The

use just needs to

inform the desired

The user can

verify the

calibration

o

eration result.

The user can see

the measured

temperature and

its status.

Figure 3.10 – Profibus View - Upper Calibration Procedures

Every time the sensor is altered, TRIM values are reset. In the case of TC it is necessary to

disable the cold junction compensation before starting calibration procedures. Trim is not

available for TT using two sensors.

How to Configure the Analog Input Block

The Analog Input block takes the input data from the Transducer block, selected by channel

number, and makes it available to other function blocks at its output. The transducer bloc k provides

the input unit of the Analog Input, and when the unit is changed in the transduc er, the PV_SCALE

unit is changed too. Optionally, a filter may be applied in the process value signal, whose time

constant is PV_FTIME. Considering a step change to the input, this is the time in seconds to the PV

reaches 63.2% of the final value. If the PV_FTIME value is zero, the fi lter is disabled. For more

details, please, see the Function Blocks Specifications. To configure the Analog Input Block, please,

select the Analog Input Block, in the main menu. Select the analog block according to the

application. Using this window, the user can configure the block mode operation, selects the

channel, scales and unit for input and output value and the damping.

3.14

Figure 3.11 – PDM Simatic - Upper Calibration Procedure

NOTE

Configuration

The user can set

the block mode

operation.

The user

can select

PV, Sec

Value 1 or

Scale of input

value. The

unit comes

from the

Sec Value 2

for the

channel.

parameter.

transducer

block.

Scales and

unit for the

output value.

The user can

set the PV

damping value.

Figure 3.12 – Profibus View - Basic Settings for Analog Input Block

Figure 3.13 – PDM Simatic - Basic Settings for Analog Input Block

Selecting the page "Advanced Settings", the user can configure the conditions for alarms and

warnings, as well the fail safe condition. Please, see the window:

3.15

TT303 – Operation and Maintenance Instruction Manual

The user can set

Alarm/Warning limits.

The fail safe

conditions.

Figure 3.14 – Profibus View - Advanced Settings for Analog Input Block

3.16

Figure 3.15 – PDM Simatic - Advanced Settings for Analog Input Block

Configuration

The user can

set the mode

block

operation.

The user can

monitor the

output

parameter

and verify the

current state

alarm.

Figure 3.16 – Profibus View - Analog Input Block

Figure 3.17 – PDM Simatic - Online Configuration for Analog Input Block

Programming Using Local Adjustment

The local adjustment is completely configured by Profibus View or Simatic PDM or any other

configuration tool. It means that the user can select the best options to fit his application. From

factory, it is configured with the options to set the Upper and Lower trim, for monitoring the input

transducer output and check the Tag. Normally, the transmitter is much better configured by

configuratinon tool, but the local functionality of the LCD permits an easy and fast action on

certain parameters, since it does not rely on communication and network wiring connections. Among

the possibilities by Local Adjustment, the following options can be emphasized: Mode Block,

Outputs Monitoring, Tag Visualization and Tuning Parameters Setting.

3.17

TT303 – Operation and Maintenance Instruction Manual

User´s interface is also described very detailed on the "General Installation, Operation and

Maintenance Procedures Manual". Please take a detailed look at this manua l in the chapter related

to "Programming Using Local Adjustment". The resources on this transducer display are very

signifcant, and all of the Series 303 field devices from SMAR has the sa me methodology to handle

with it. So, since the user has learned once, he is capable to handle all kind of field devices from

SMAR. This Local Adjustment is a suggestion only. The user may choose his preferred

configuration via configuration toll, simply setting the display block).

The positioner has two holes for magnetic switches, located u nder the identification plate. These

magnetic switches are activeted by a magnetic tool.

This magnetic tool enables adjustment of the most important parameters of the blocks. It also

enables pre-configuration of the communication.

The jumper W1 on top of the main circuit board must be i n place and the positioner must be fitted

with digital display for access to the local adjustment. Without dis play, the local adjustment is not

possible.

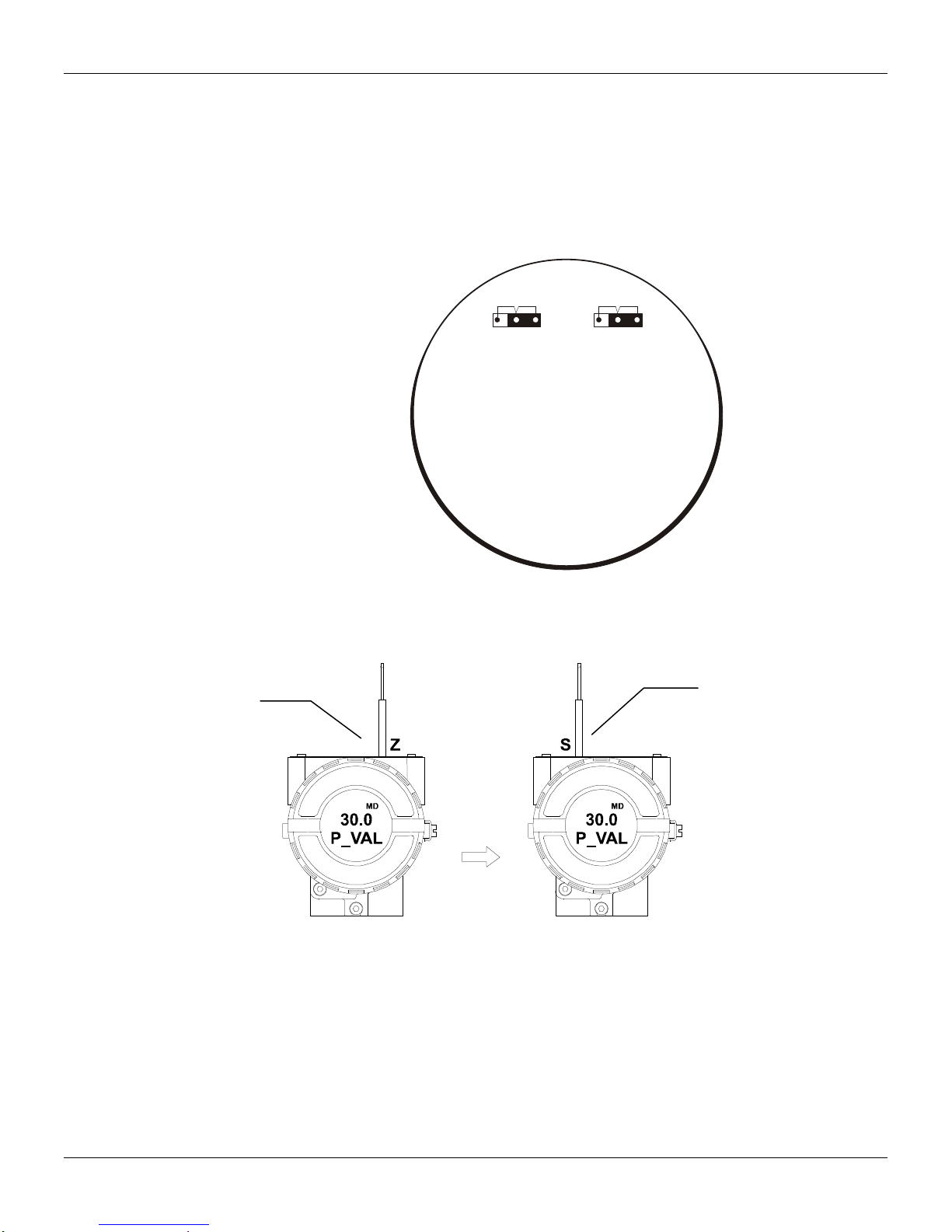

Figure 3.18 - Local Adjustment Holes

Table 3.5 shows the actions on the Z and S holes on the TT303 when Local Adjustment is enable d.

HOLE ACTION

Z

S

Inicializes and rotates through the available functions.

Selects the function shown in the display.

Table 3.5 - Purpose of the holes on the Housing

3.18

Local Adjustment Tree - Quick Guide

UPDT

Configuration

Magnetic Tool

Zero Hole

TGGL

S

ITEM

Span Hole

PRMT

AI

PHY

3) HOW TO CONFIGURE A BLOCK PARAMETER

1) Browse until CONF option, select LCD2;

2) Browse until BLOCK select the block that will be configured;

3) Browse until PRMT and set the relative index of the parameter;

4) Browse until ITEM and set the sub index ( if applicable );

5) Browse until UPDT, insert magnetic screw driver in Zero Hole;

6) Reenter in Local Adjustment, br owse until LCD2, now the

parameter is available to change;

7) Repeat above steps for all the parameters to be configured.

TRD

LCD1

LCD2

TOT

LCD3

LCD4

LCD5

LCD6

CONF BLOCK

31

Insert magnetic

Insert magnetic

SEC2

LCD6

2) HOW TO BROWSE AND

1) HOW TO ACCESS LOCAL ADJUSTMENT TREE

Local Adjustment tree – Quick Guide

SELECT MENU OPTIONS

Browse:

Follow Steps:

screw driver in zero hole

and hold.

Select:

screw driver in span hole

and hold.

VARIABLES

LOWER UPPER SEC1

LOWER UPPER SECV1 SECV2 ADDR

SEC2

PV%

18 31 12 11 29

PVAL

1) Insert magnetic screw driver in zero hole;

2) Wait 3 seconds;

3) Insert magnetics screw driver in span hole;

4) Wait 3 seconds, then MD will appear on display.

P_VAL

TIP: DISPLAY SWITCHING BETWEEN 2

Follow Steps:

1) Browse until TGGL;

2) Select 2;

3) Configure LCD 2 with the desired parameter.

With TOGGLE 6

LCD1 LCD2 LCD3 LCD4 LCD5

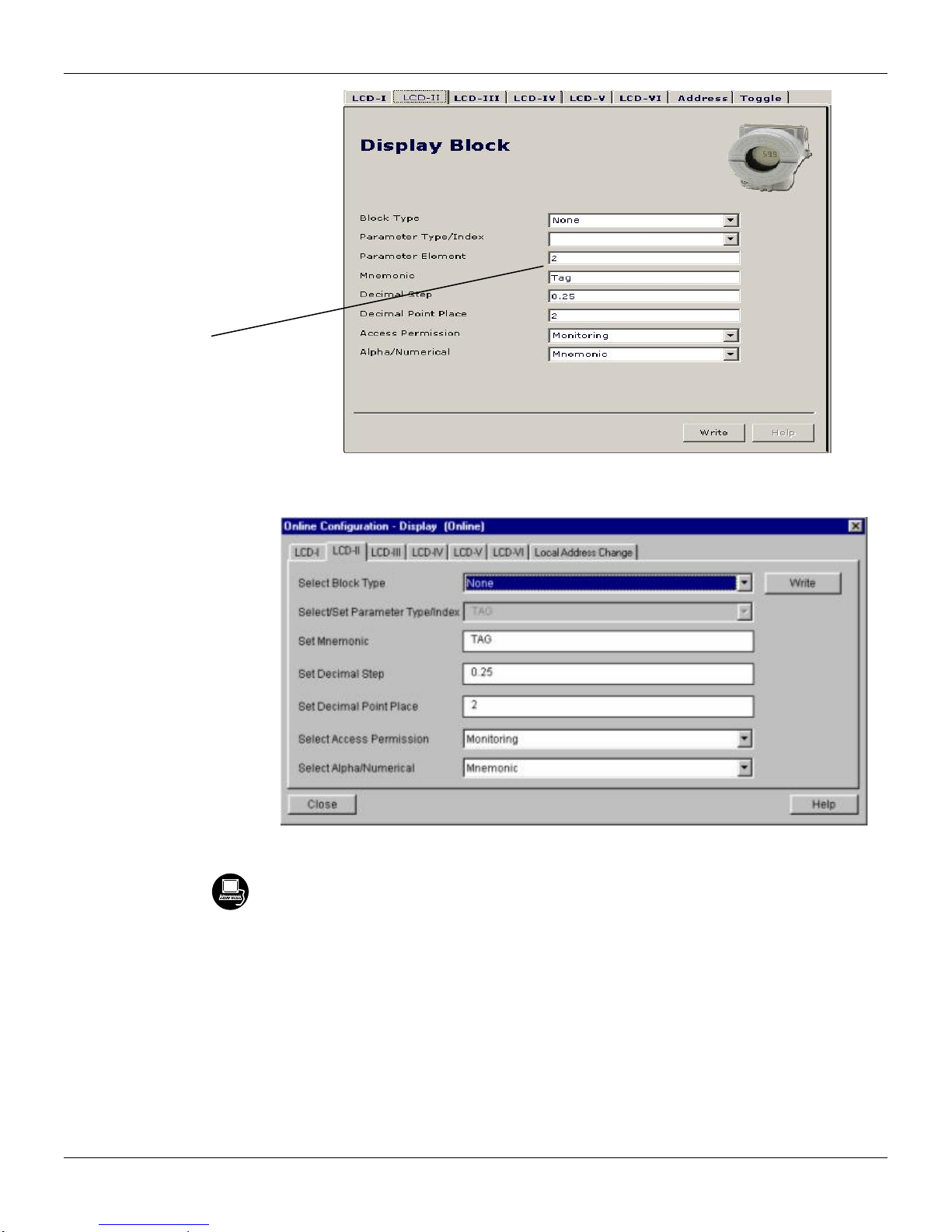

• CONF: option where it is possible to select the LCD to configure. Six options are available: from LCD1 up to LCD6;

• BLOCK: option where the user must select the function block that he desires to configure;

“Unit Index” and “Decimal Poin t ” ;

• TGGL (Toggle): switches from 1 up to 6 configured parameters on the display. If TGGL is equal to 2, for example, the display will switch between LCD1 and LCD2;

• PRMT: number correspondent to the relative index of the desired parameter into the chosen function block;

• ITEM: configure this option when a selected parameter has sub items to be configured, for example, the OUT_SCALE para meter is compounded by “EU at 100%”, “EU at 0%”,

• UPDT: refreshes the display when one of the LCDs are configured.Finalize display configuration by setting "UPDT", after choosing the configuration for the local adjustment.

3.19

TT303 – Operation and Maintenance Instruction Manual

A

J1 Jumper Connections

If J1 (see figure 3.14) is connected to ON, then simulation mode in the AI block is enabled.

W1 Jumper Connections

If W1 is connected to ON, the local adjustment programming tree is enabled and then important

block parameters can be adjusted and communication can be pre-configured via local adjustment.

Local Programming Tree

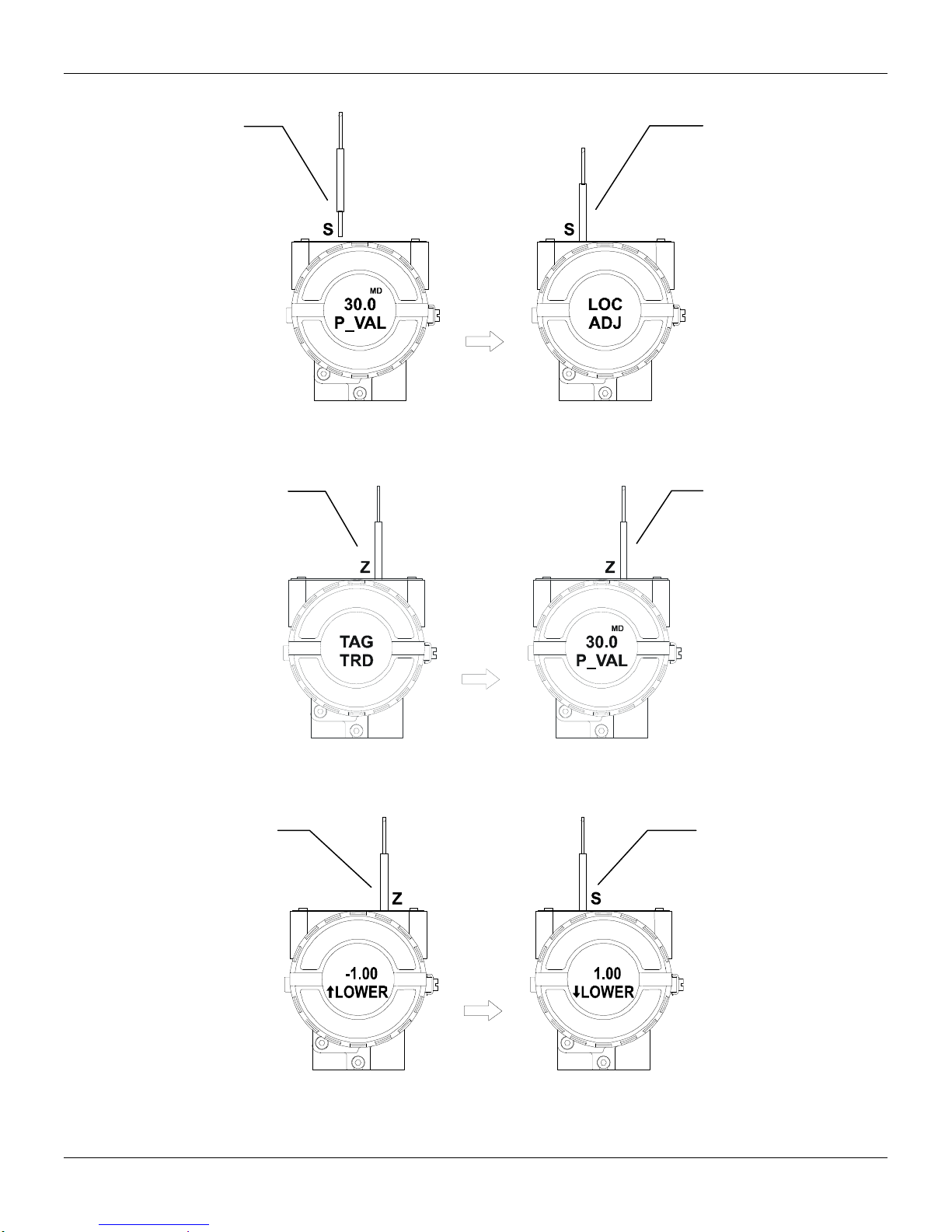

In order to start the

local adjustment,

place the magnetic

tool in orifice Z and

wait until letters MD

are displayed.

WR

OFF

ON

J1

OFF

W1

ON

LOC

DJ

MAIN BOARD

Figure 3.19 - J1 and W1 Jumpers

Place the magnetic

tool in orifice S and

wait during 5

seconds.

3.20

Figure 3.20 - Step 1 - TT303

Configuration

Remove the

magnetic tool

from orifice S.

Insert the

magnetic tool in

orifice S once

more and LOC

ADJ should be

displayed.

Figure 3.21 - Step 2 - TT303

Place the magnetic tool

in orifice Z. In case this

is the first configuration,

the option shown on the

display is the TAG with

its corresponding

mnemonic configured

by the CONFIGURATION TOOL.

Otherwise, the option

shown on the display

will be the one

configured in the prior

operation. By keeping

the tool inserted in this

orifice, the local