TT301

Intelligent Temperature Transmitter

with Control Capability Optional

OPERATION & MAINTENANCE

INSTRUCTIONS MANUAL

T T 3 0 1 M E

www.el-scada.ru

Introduction

INTRODUCTION

The TT301 is a transmitter mainly intended for measurement of temperature using RTDs or

thermocouples, but can also accept other sensors with resistance or mV output such as:

pyrometers, load cells, resistance position indicators, etc. The digital technology used in the TT301

enables the choice of several output functions, an easy interface between the field and the control

room and several interesting features that reduce considerably the installation, operation and

maintenance costs.

The TT301, besides the normal functions offered by other smart transmitters, offers the following

functions:

SPECIAL SENSOR: the output follows a mV or Ohm input according to a 16-point linearization

table.

PID OUTPUT CHARACTERIZATION: the PID output signal (MV) follows a curve determined by 16

points.

BACKUP SENSOR: the process measurement is realized by two sensors, but only one supplies the

temperature. If it failure the other take its place.

INPUT SELECTOR: the selection between two sensor to obtain the measure is configured by user

based in the conditions of maximum, minimum or average temperature of the sensor.

CONTROLLER: the process variable is compared to a setpoint. The deviation acts on the output

signal according to a PID algorithm (Optional).

BATCH : setpoint generator allowing pre-programmed recipes of up to 2-week duration in 16 points.

LOCAL ADJUST: allow to set lower and upper value, sensor type, operation mode, indication,

setpoint, PID parameters without a configurator.

PASSWORD : three configurable levels for different functions.

CHANGE COUNTER: indicates the number of changes in each functions.

SPECIAL- SENSOR-UNIT: allows the reading to be indicated by one of 100 standard engineering

units or any special unit with up to 5 characters.

Get the best results of the TT301 by carefully reading these instructions.

III

TT301 – Operation & Maintenance Instruction Manual

NOTE:

This Manual is compatible with version 4.XX, where 4 de notes software Version and XX software

"RELEASE". The indication 4.XXmeans that this manual is compatible with any release of software version

4.

Waiver of responsibility

The contents of this manual abides by the hardware and software used on the current equipment

version. Eventually there may occur divergencies between this manual and the equipment. The

information from this document are periodically reviewed and the necessary or identified corrections

will be included in the following editions. Suggestions for their improvement are welcome.

Warning

For more objectivity and clarity, this manual does not contain all the detailed information on the

product and, in addition, it does not cover every possible mounting, operation or maintenance

cases.

Before installing and utilizing the equipment, check if the model of the acquired equipment complies

with the technical requirements for the application. This checking is the user’s responsibility.

If the user needs more information, or on the event of specific problems not specified or treated in

this manual, the information should be sought from Smar. Furthermore, the user recognizes that the

contents of this manual by no means modify past or present agreements, confirmation or judicial

relationship, in whole or in part.

All of Smar’s obligation result from the purchasing agreement signed between the parties, which

includes the complete and sole valid warranty term. Contractual clauses related to the warranty are

not limited nor extended by virtue of the technical information contained in this manual.

Only qualified personnel are allowed to participate in the activities of mounting, electrical connection,

startup and maintenance of the equipment. Qualified personnel are understood to be the persons

familiar with the mounting, electrical connection, startup and operation of the equipment or other

similar apparatus that are technically fit for their work. Smar provides specific training to instruct and

qualify such professionals. However, each country must comply with the local safety procedures,

legal provisions and regulations for the mounting and operation of electrical installations, as well as

with the laws and regulations on classified areas, such as intrinsic safety, explosion proof, increased

safety and instrumented safety systems, among others.

The user is responsible for the incorrect or inadequate handling of equipments run with pneumatic

or hydraulic pressure or, still, subject to corrosive, aggressive or combustible products, since their

utilization may cause severe bodily harm and/or material damages.

The field equipment referred to in this manual, when acquired for classified or hazardous areas, has

its certification void when having its parts replaced or interchanged without functional and approval

tests by Smar or any of Smar authorized dealers, which are the competent companies for certifying

that the equipment in its entirety meets the applicable standards and regulations. The same is true

when converting the equipment of a communication protocol to another. In this case, it is necessary

sending the equipment to Smar or any of its authorized dealer. Moreover, the certificates are

different and the user is responsible for their correct use.

Always respect the instructions provided in the Manual. Smar is not responsible for any losses

and/or damages resulting from the inadequate use of its equipments. It is the user’s responsibility to

know and apply the safety practices in his country.

IV

Table of Contents

TABLE OF CONTENTS

SECTION 1 - INSTALLATION ...................................................................................................................................... 1.1

GENERAL ..................................................................................................................................................................................... 1.1

MOUNTING ................................................................................................................................................................................... 1.1

ELECTRONIC HOUSING ............................................................................................................................................................. 1.2

WIRING ......................................................................................................................................................................................... 1.2

LOOP CONNECTIONS ................................................................................................................................................................. 1.3

INSTALLATION IN HAZARDOUS AREAS .................................................................................................................................... 1.7

EXPLOSION/FLAME PROOF ....................................................................................................................................................... 1.7

INTRINSICALLY SAFE ................................................................................................................................................................. 1.7

SECTION 2 - OPERATION ........................................................................................................................................... 2.1

FUNCTIONAL DESCRIPTION-HARDWARE ................................................................................................................................ 2.1

FUNCTIONAL DESCRIPTION - SOFTWARE .............................................................................................................................. 2.4

TEMPERATURE SENSORS ......................................................................................................................................................... 2.5

THE DISPLAY ............................................................................................................................................................................... 2.7

MONITORING ............................................................................................................................................................................... 2.7

ALARM .......................................................................................................................................................................................... 2.8

SECTION 3 - CONFIGURATION .................................................................................................................................. 3.1

CONFIGURATION RESOURCES ................................................................................................................................................ 3.3

PROGRAMMING TREE ................................................................................................................................................................ 3.3

IDENTIFICATION AND MANUFACTURING DATA – INFO .......................................................................................................... 3.4

CONFIGURATOR - CONF ............................................................................................................................................................ 3.4

CALIBRATION – RANGE .............................................................................................................................................................. 3.4

MAINTENANCE - MAINT .............................................................................................................................................................. 3.4

SENSOR TYPES - SENSOR ........................................................................................................................................................ 3.5

CONECTION AND WORK MODEL .............................................................................................................................................. 3.7

SPECIAL SENSOR CONFIGURATION ........................................................................................................................................ 3.7

PID ………………………………………………………………………………………………………………………………………………3.8

MONITORING - MONIT ................................................................................................................................................................ 3.9

CALIBRATING THE TT301 ......................................................................................................................................................... 3.10

CALIBRATION WITHOUT REFERENCE .................................................................................................................................... 3.10

CALIBRATION WITH REFERENCE ........................................................................................................................................... 3.11

UNIT ............................................................................................................................................................................................ 3.11

DAMPING ................................................................................................................................................................................... 3.11

TRIM ........................................................................................................................................................................................... 3.11

ALARM ........................................................................................................................................................................................ 3.12

ALARM CONFIGURATION ......................................................................................................................................................... 3.12

ONLINE MULTIDROP OPERATION ........................................................................................................................................... 3.12

CONFIGURATION TT301 FOR MULTIDROP ............................................................................................................................ 3.13

MULTIDROP MODE CONFIGURATION .................................................................................................................................... 3.13

SECTION 4 - PROGRAMMING USING LOCAL ADJUSTMENT ................................................................................. 4.1

THE MAGNETIC TOOL ................................................................................................................................................................ 4.1

RERANGING USING THE LOCAL ZERO AND SPAN ADJUSTMENTS IN SIMPLE MODE ....................................................... 4.2

COMPLETE LOCAL ADJUSTMENT ............................................................................................................................................. 4.3

OPERATION [OPER] .................................................................................................................................................................... 4.4

BATCH [BATCH] ................................ ................................................................ ........................................................................... 4.5

TUNING [TUNE] ............................................................................................................................................................................ 4.6

CONFIGURATION [CONF] ........................................................................................................................................................... 4.9

SECTION 5 - MAINTENANCE PROCEDURES ........................................................................................................... 5.1

GENERAL ..................................................................................................................................................................................... 5.1

DIAGNOSIS WITH SMAR CONFIGURATOR ............................................................................................................................... 5.1

ERROR MESSAGES .................................................................................................................................................................... 5.1

DIAGNOSTICS WITH THE CONFIGURATOR ............................................................................................................................. 5.1

TROUBLESHOOTING WITH TRANSMITTER .............................................................................................................................. 5.2

DISASSEMBLY PROCEDURE ..................................................................................................................................................... 5.3

REASSEMBLY PROCEDURE ...................................................................................................................................................... 5.4

INTERCHANGEABILITY ............................................................................................................................................................... 5.4

RETURNING MATERIALS ............................................................................................................................................................ 5.4

V

TT301 – Operation & Maintenance Instruction Manual

SECTION 6 - TECHNICAL CHARACTERISTIC ........................................................................................................... 6.1

ORDERING CODE ....................................................................................................................................................................... 6.5

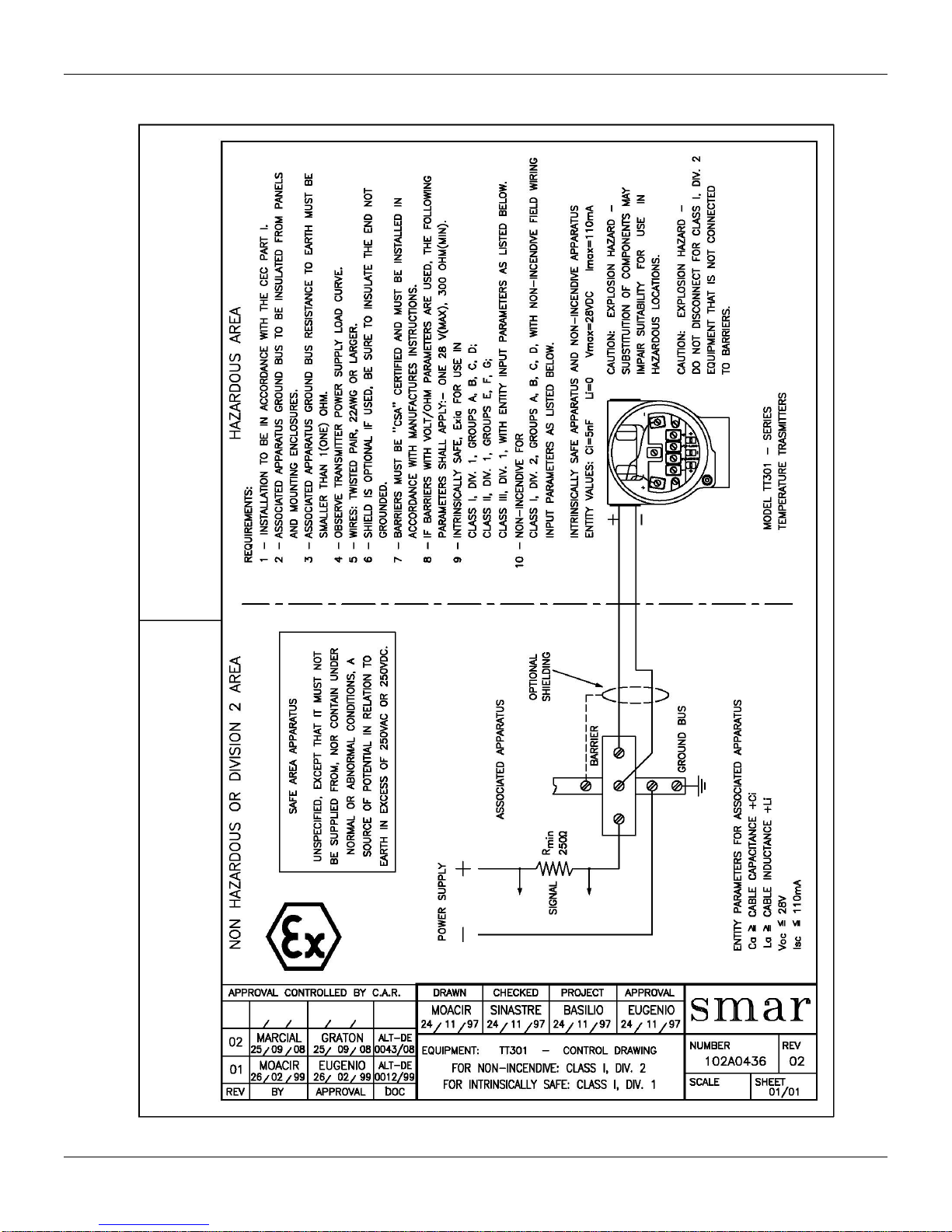

APPENDIX A - CERTIFICATIONS INFORMATION .................................................................................................... A.1

EUROPEAN DIRECTIVE INFORMATION ................................................................................................................................... A.1

OTHER CERTIFICATIONS .......................................................................................................................................................... A.1

IP68 REPORT: ........................................................................................................................................................................................... A.1

HAZARDOUS LOCATIONS CERTIFICATIONS .......................................................................................................................... A.1

NORTH AMERICAN CERTIFICATIONS .................................................................................................................................................... A.1

EUROPEAN CERTIFICATIONS................................................................................................................................................................. A.2

SOUTH AMERICA CERTIFICATION ......................................................................................................................................................... A.2

IDENTIFICATION PLATE AND CONTROL DRAWING ............................................................................................................... A.2

IDENTIFICATION PLATE .......................................................................................................................................................................... A.2

CONTROL DRAWING ................................ ................................................................................................ ............................................... A.5

APPENDIX B – SRF – SERCIVE REQUEST FORM................................................................................................... B.1

VI

Installation Flowchart

Yes

Was the transmitter

configured on the bench

to match the application?

Configure the action and

the limit (Seção 3).alarm

Simule the value(s)

of the work range in the sensor(s)

conection terminal(s)

mV or Ohm

Start

No

No

OK

Yes

No

Yes

No

Yes

Configure the transmitter 1

and 3 - Configuration)

(Section

Section

Configure the measuring range

to 0% (4mA) and 100% (20mA)

(Section 3 - Configuration)

Configure the Damping

(Section 3 - Configuration)

Configure the LCD reading

(Section 3 - Configuration)

See manual

(Section 5 - ) Maintenance

Is the reading correct?

Check the area classification

and its practices.

Install the transmitter preferably

on weather- protected areas.

Install the transmitter

(mechanically and electrically)

according to the application after

checking the best position for

the LCD (Section 5 - Maintenance)

Power the transmitter properly.

Is the transmitter

reading correct?

Do Zero and Span Trim

Did you correct the

transmitter reading?

Installation Flowchart

VII

TT301 – Operation & Maintenance Instruction Manual

VIII

Section 1

ALLOW 150 MM MINIMUM FOR LOCAL

ZERO AND SPAN ADJUSTMENT WITH

MAGNETIC TOOL.

COMMUNICATIONS

TERMINAL

PLUG

CONDUIT

CONNECTION

MOUNTING

BRACKET

PIPE 2"

PLUG

WALL OR

PANEL MOUNTING

FOR WALL MOUNTING

2 EXPANSION ANCHOR 2 HEXAGON SCREW -

S8

3/16”X70

2 BOLT AND NUTS - 1/4”X30

NOT INCLUDED

FOR PANEL MOUNTING

General

Mounting

INSTALLATION

The overall accuracy of temperature and other measurements depends on several variables. Although

the transmitter has an outstanding performance, proper installation is essential, in order to maximize its

performance.

Among all factors, which may affect transmitter accuracy, environmental conditions are the most

difficult to control. There are, however, ways of reducing the effects of temperature, humidity and

vibration.

Temperature fluctuation effects can be minimized by locating the transmitter in areas protected from extreme environmental changes.

In warm environments, the transmitter should be installed to avoid, as much as possible, direct exposure to the sun. Installation close to lines and vessels subjected to high temperatures should also be

avoided. For temperature measurements, sensors with cooling-neck can be used or the sensor can be

mounted separated from the transmitter housing.

Use of sunshades or heat shields to protect the transmitter from external heat sources should be

considered, if necessary.

The transmitter may be mounted in two basic ways, as follows:

Separated from the sensor, using optional mounting brackets;

Mounted on the sensor assembly.

Using the brackets, the mounting may be done in several positions, as shown on Figure 1.1.

Measurement error can be decreased by using proper wires (see Section II, Operation).

Figure 1.1 - Dimensional Drawing and Mounting Positions

1.1

TT301 – Operation & Maintenance Instruction Manual

WARNING

Do not remove the graphite grease from the covers, or they may jam.

WARNING

The unused cable entries should be plugged and sealed accordingly to avoid humidity entering,

which can cause the loss of the product’s warranty.

COVER

LOCKING

SCREW

(a) (b)

Electronic Housing

Humidity is fatal to electronic circuits. In areas subjected to high relative humidity, the O-rings for the

electronics cover must be correctly placed. Removal of the electronics cover in the field should be

reduced to the minimum necessary, since each time it is removed; the circuits are exposed to the

humidity.

The electronic circuit is protected by a humidity proof coating, but frequent exposures to humidity may

affect the protection provided. It is also important to keep the covers tightened in place. Every time they

are removed, the threads are exposed to corrosion, since painting cannot protect these parts. Sealing

methods should be employed on conduit entering the transmitter.

One of the conduit inlets for electrical connection is used to mount the sensor integral to the

temperature transmitter (see Fig. 1.1).

For better visibility, the digital indicator may be rotated in steps of 90o (see Section 5, Maintenance).

Reach the display and main board by removing the Cover with window. This cover should be locked

closed by the cover locking screw. To release the cover, rotate the locking screw clockwise. See figure

1.2.

Figure 1.2- Cover Locking and Housing Rotating Set Screw (a) Electronic Board Side

(b) Terminal Connection Side

Wiring

Access the wiring block by removing the Electrical Connection Cover. This cover can be locked closed

by the cover locking screw (Figure 1.2- b). To release the cover, rotate the locking screw clockwise.

The terminals in the superior part marked with () and (−) are to receive the powering from 12 to 45

Vdc. The inferior terminals marked with the numbers from 1 to 4 they are for the connections of the

different types of sensor.

Test and Communication terminals allow, respectively, to measure the current in the 4 - 20 mA loop,

without opening it, and to communicate with the transmitter. To measure it, connect a multimeter in the

mA scale in the "" and "" TEST terminals. To communicate with it, use a HART configurator

between "" and "" COMM terminals. The wiring block has screws on which terminals type fork or

ring can be fastened, see Figure. 1.3.

1.2

Installation

GROUND

TERMINAL

GROUND

TERMINALS

COMMUNICATION

TERMINALS

TEST

TERMINALS

+

+ +

1 2 3 4

C

O

M

M

T

E

S

T

WIRES

WARNING

Do not connect the Power Supply to the sensor terminals (Terminals 1, 2, 3 and 4).

CONFIGURATOR

250

Loop Connections

Figure 1.3 - Ground Terminal

The TT301 is protected against reversed polarity.

For convenience there are three ground terminals: one inside the cover and two external, located close

to the conduit entries.

Use of twisted pair (22 AWG) cables is recommended.

Avoid routing signal wiring close to power cables or switching equipment.

The Figure 1.3 shows the correct installation of the conduit, in order to avoid penetration of water, or

other substance, which may cause malfunctioning of the equipment.

Figure 1.4 - Conduit Installation Diagram.

Connection of the TT301 working as transmitter should be performed as in Figure 1.6.

Connection of the TT301 working as a controller (Optional) should be as indicated in Figure 1.5.

Figure 1.5 – Wiring Diagram for the TT301 Working as Transmitter

1.3

TT301 – Operation & Maintenance Instruction Manual

CONFIGURATOR

POWER

SUPPLY

250

WARNING

For proper operation, the configurator requires a minimum load of 250 Ohm between it and the

power supply.

TT301

# 2

TRANSMITTER

TT301

# 3

TRANSMITTER

TT301

# 15

TRANSMITTER

POWER

SUPPLY

250

CONFIGURATOR

TT301

TRANSMITTER

# 1

NOTE

Make sure that the transmitter is operating within the operating area as shown on the load diagram

(Figure 1.9). Communication requires a minimum load of 250 Ohm.

Figure 1.6 – Wiring Diagram for the TT301 Working as Controller

Connection of the TT301 in multidrop configuration should be done as in Figure 1.6. Note that a

maximum of 15 transmitters can be connected on the same line and that they should be connected in

parallel. When many transmitters are connected to the same line, calculate the voltage drop through

the 250 Ohm resistor and verify that the voltage of the power supply is enough (Figure 1.7).

Wiring diagram for the TT301 in multidrop.

Figure 1.7 - Wiring Diagram for the TT301 in Multidrop Configuration

The Configurator can be connected to the communication terminals of the transmitter or at any point of

the signal line by using the interface with alligator clips.

It is also recommended to ground the shield of shielded cables at only one end. The not grounded end

must be carefully isolated.

1.4

Installation

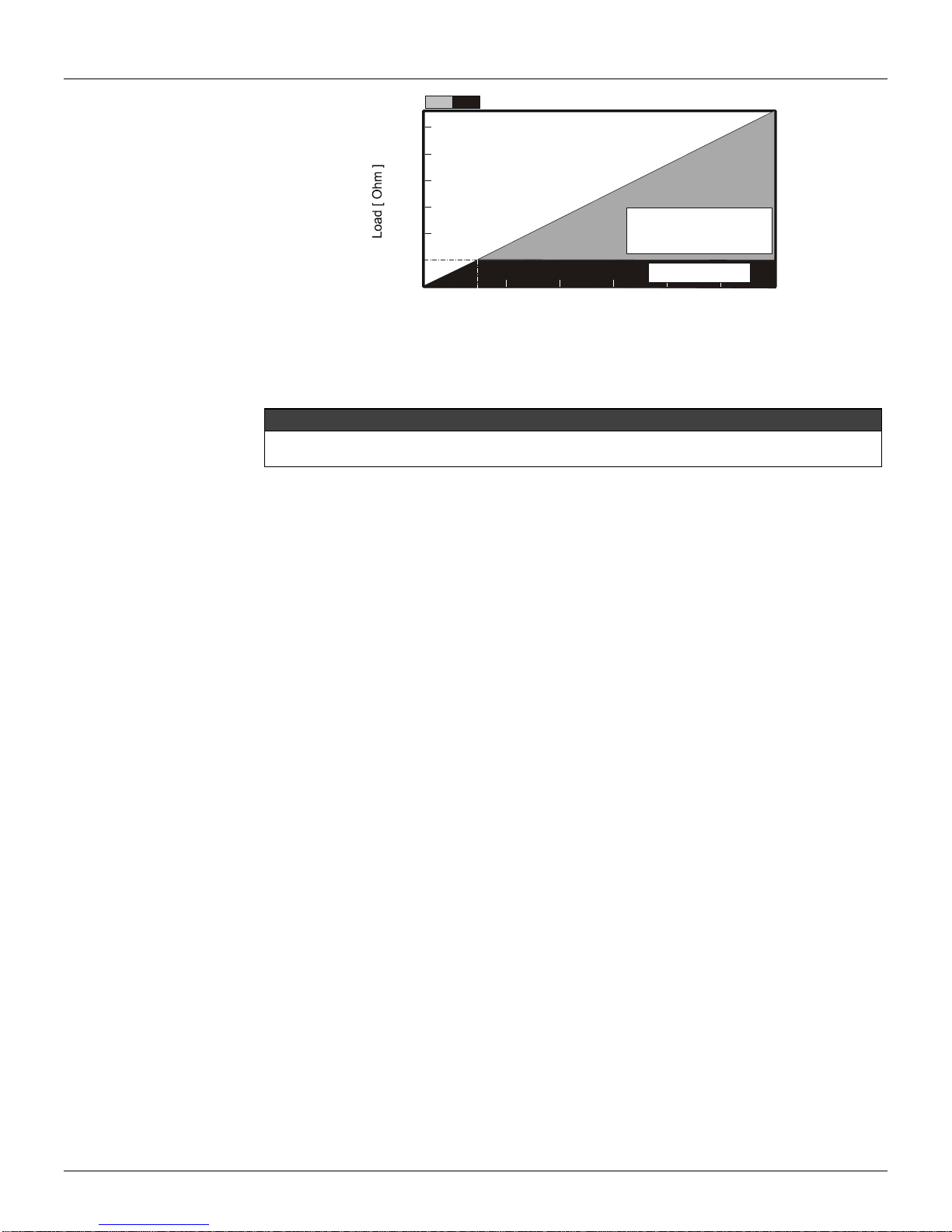

1650

1500

1000

500

0

12 20 30 40 45

250

Power Supply [ Volt ]

4-20mA only

Operating area

4-20mA and digital

communication

17

WARNING

When operating with two sensors, the sensors can not be both grounded. At least one has to be not

grounded for proper operation of TT301.

Figure 1.8 – Load Curve

The sensor should be connected as per Figure 1.8.

1.5

TT301 – Operation & Maintenance Instruction Manual

2 - WIRE RTD

OR OHM INPUT

3 - WIRE RTD

OR OHM INPUT

4 - WIRE RTD

OR OHM INPUT

THERMOCOUPLE OR

MILIVOLT INPUT

DIFFERENTIAL RTD

OR OHM INPUT

BACKUP, MINIMUM,

MAXIMUM OR AVERAGE

BACKUP, MINIMUM,

MAXIMUM OR AVERAGE

1

2

1

2

1 2

3

4

1 2

3

4

1 2

3

4

1 2

3

4 1 2

3

4

1 2

3

4

1 2

3

4

+

-

DIFFERENTIAL THERMOCOUPLE

OR MILIVOLT INPUT

1 2

3

4

+

-

+ +

- -

Figure 1.9 – Sensor Wiring

1.6

Installation in Hazardous Areas

WARNING

Explosions could result in death or serious injury, besides financial damage. Installation of this

transmitter in explosive areas must be carried out in accordance with the local standards and the

protection type adopted .Before continuing the installation make sure the certificate parameters are I n

accordance with the classified area where the equipment will be installed.

The instrument modification or parts replacement supplied by other than authorized representative of

Smar is prohibited and will void the certification.

The transmitters are marked with options of the protection type. The certification is valid only when the

protection type is indicated by the user. Once a particular type of protection is selected, any other type

of protection can not be used.

WARNING

Only use Explosion Proof/Flameproof certified Plugs, Adapters and Cable glands.

In Explosion-Proof installations the cable entries must be connected or closed using metal cable gland

and metal blanking plug, both with at least IP66 and Ex-d certification.

The standard plugs provided by Smar are certified according to CEPEL certificate. If the plug needs to

be replaced, a certified plug must be used.

The electrical connection with NPT thread must use waterproofing sealant. A non-hardening silicone

sealant is recommended.

For NEMKO ATEX certificate please to follow the installation guidelines in hazardous locations below:

Group II Category 2G, Ex d, Group IIC, Temperature Class T6, EPL Gb U = 28VDC

Ambient Temperature: -20 to 60ºC for T6

Environmental Protection: IP66/687 or IP66W/687W

The electrical connection available are ½ - 14NPT and M20x1,5.

Cable entries must be connected or closed using metal cable gland and metal blanking plug, both with

at least IP66 and Ex-d certification or any appropriate ATEX approved metal cable gland and metal

blanking plug. Do not remove the transmitter covers when power is ON.

WARNING

In hazardous zones with intrinsically safe or non-incendive requirements, the circuit entity parameters

and applicable installation procedures must be observed.

To protect the application the transmitter must be connected to a barrier. Match the parameters

between barrier and the equipment (Consider the cable parameters). Associated apparatus ground

bus shall be insulated from panels and mounting enclosures. Shield is optional. If used, be sure to

insulate the end not grounded. Cable capacitance and inductance plus Ci and Li must be smaller than

Co and Lo of the associated Apparatus.

For free access to the Hart bus in the explosive environment, ensure the instruments in the loop are

installed in accordance with intrinsically safe or non-incendive field wiring practices. Use only Ex Hart

communicator approved according to the type of protection Ex-i (IS) or Ex-n (NI).

It is not recommended to remove the transmitter cover when the power is ON.

Explosion/Flame Proof

Installation

Intrinsically Safe

1.7

TT301 – Operation & Maintenance Instruction Manual

1.8

Section 2

LOCAL ADJUST

MODEM

BELL 202

POWER

SUPPLY

OUTPUT

DISPLAY

CONTROLLER

AMBIENT

TEMPERATURE

SENSOR

DISPLAY BOARD

SUPPLY

SUPPLY

MAIN BOARDINPUT BOARD

MUX

SIGNAL

CONDI-

TIONER

TC

Ohm

RTD

mV

I

S

O

L

A

T

O

R

A/D

CONVER-

TER

D/A

CONVERTER

PROCESSING UNIT

RANGES

SPECIAL FUNCTIONS

PID (OPTIONAL)

OUTPUT CONTROL

SERIAL COMMUNICATION

HART PROTOCOL

POWER

ISOLATION

OPERATION

The TT301 accepts signals from mV generators such as thermocouples or resistive sensors such as

RTDs. The criterion is that the signal is within the range of the input. For mV, the range is -50 to 500

mV and for resistance, 0 to 2000 Ohm.

Functional Description-Hardware

Refer to the block diagram (Figure 2.1). The function of each block is described below.

Figure 2.1 – TT301 Block Diagram

MUX-Multiplexer

The MUX multiplexes the sensor terminals to the signal conditioning section ensuring that the voltages

are measured between the correct terminals.

Signal Conditioner

Its function is to apply the correct gain to the input signals to make them suit the A/D converter.

A/D Converter

The A/D converts the input signal to a digital format for the CPU.

Isolator

Its function is to isolate the control and data signal between the input and the CPU.

CPU - Central Processing Unit & PROM

The CPU is the intelligent portion of the transmitter, being responsible for the management and

operation of all other blocks: linearization, cold junction compensation and communication. The

program is stored in the PROM as well as the linearization data for the temperature sensors.

For temporary storage of data, the CPU has an internal RAM, the data in the RAM is lost if the power is

switched off, however the CPU also has an internal nonvolatile EEPROM where data that must be

retained is stored. Examples of such data are: calibration, configuration and identification data.

D/A Converter

Converts the digital data from the CPU to an analog signal with 14-bits resolution.

Output

Controls the current in the line feeding the transmitter. It acts as a variable resistive load whose value

2.1

TT301 – Operation and Maintenance Instruction Manual

depends on the voltage from the D/A converter.

Modem

Modulates a communication signal on the current line. A "1" is represented by 1200 Hz and a "0", by

2200 Hz. These signals are symmetric and do not affect the DC level of the 4-20 mA signal.

Power Supply

Power shall be supplied to the transmitter circuit using the signal line (2-wire system). The transmitter

quiescent consumption is 3.6 mA; during the operation, consumption may be as high as 21 mA,

depending on the measurement and sensor status.

The TT301, in the transmitter mode, shows failure indication at 3.6 mA if configured for low signal

failure; at 21 mA, if configured for high signal failure; 3.8 mA in the case of low saturation; 20.5 mA in

the case of high saturation and measurements proportional to the applied temperature in the range

between 3.8 mA and 20,5 mA. 4 mA corresponds to 0% of the working range and 20 mA to100 % of

the working range.

Power Isolation

Its function is to isolate power supply between the input and the CPU.

Display Controller

Receives data from the CPU informing which segments of the Liquid Crystal Display, should be turned

on.

Local Adjustment

Two switches that are magnetically activated. They can be activated by the magnetic tool without

mechanical or electrical contact.

2.2

Operation

C TEMP.

SENSOR

DIGITAL FILTER

INPUT

TRIM

RANGING

SPECIAL

SENSOR

PID

AUTO/MANUAL

ACTION

KP, TR, TD

A/M

MV

POWER-ON

SAFETY-OUT

HIGH

LOW

OUT RATE

MV-FEEDBACK

LIMITS

( BUMPLESS A/M )

OUTPUT

4-20mA

CURRENT

TRIM

DISPLAY

INDICATOR

SPAN

PAUSE

RESET

XMTR

CONST

4 mA

20 mA

1 2

OUT %

PRIMARY AND

SECONDARY

UNIT

DAMPING

SETPOINT

mA

SP

SP TRACKING

SP GENERAL

SP TABLE

PID BLOCK (OPTIONAL)

OP-MODE

PID

TIME

GENERATOR

ALARM

ACTION-0

ACTION-1

ACTION-2

LIMIT-1

LIMIT-2

SP ( ENG )

ERROR %

mA

PV%

OUT%

SP %

SP ( ENG )

PV ( ENG )

T. AMB.

ERROR %

TI

STANDARD SENSOR

LINEARIZATION

& CJ COMPENSATION

INPUT

ohm / mV

TI min

PV %

URV

LRV

BURNOUT

PV %

TYPE / CONNECTION

UNIT

TABLE

LRL / URL / MIN

TABLE

Figure 2.2 – Software Flow Chart

2.3

TT301 – Operation and Maintenance Instruction Manual

).

1

(

dt

dPV

Tdedt

Tr

eKpMV

Functional Description - Software

Refer to the block diagram (Figure 2.2). The function of each block is described below.

Input

Calculates the actual mV or Ohm from the value sensed by the input circuitry.

Digital Filter

The digital filter is a low-pass filter with an adjustable time constant. It is used to smooth noisy signals.

The Damping value is the time required for the output to reach 63.2% for a step input of 100%.

Input Trim

Here, the value obtained by READING-TRIM is used to correct the transmitter for long term drift.

Standard Sensor Linearization & Compensation

Here, the mV and Ohm measurements are linearized and cold-junction compensated according to the

sensor characteristics stored in the CPU. The CPU contains data about most standard sensors

available.

Ranging

It is used to set the process values corresponding to the output 4 and 20 mA in transmitter mode or

process variable 0 and 100% in PID mode. In transmitter mode the LOWER-VALUE is the point

corresponding to 4 mA, and UPPER-VALUE is the point corresponding to 20 mA. In PID mode, the

LOWER-VALUE corresponds PV = 0% and UPPER-VALUE corresponds to PV = 100%.

Time Generator (Optional)

Counts the time to be used by the Setpoint generator function. It may be paused by using PAUSE or

set to any value inside the table.

Setpoint (Optional)

Here, the setpoint is adjusted in PID. In this block, Setpoint tracking may be activated in SP-TRACK.

The setpoint may also be generated automatically by turning the SP-GENERATOR on. When running,

the setpoint generator will ramp and dwell the setpoint according to a table (recipe) configured in SPTABLE.

PID (Optional)

First the error is calculated as SP-PV or PV-SP depending on which action (direct or reverse) is

configured in ACTION. When Calendar Van Dussen function is used, the SP table points number is

limited to 14 points instead to 16.

TABLE POINTS

This block relates the output (%) with the input (%) according to a 16 table points. The output is

calculated through the interpolation of these points.

Auto/Manual (Optional)

The Auto/Manual mode is toggled in PID. In Manual, MV may be adjusted by the user in the INDIC

option. The SP-POWER-ON option is used here to determine in which mode the controller should be

upon powering it on.

Limits (Optional)

This block makes sure that the MV does not go beyond its minimum and maximum limits as

established by the HIGH-LIMIT and LOW-LIMIT. It also makes sure that the Rate-of-Change does not

exceed the value set in RATE-CHNG.

Output

Calculates the current proportional to the process variable or manipulated variable to be transmitted on

the 4-20 mA output depending on the configuration in OP-MODE. This block also contains the constant

current function configured in OUTPUT. The output is physically limited to 3.6 to 21 mA.

Current Trim

The 4 mA TRIM and 20 mA TRIM are used to make the transmitter current comply with a current

standard, should a deviation arise.

Display

Alternates two indications as configured in DISPLAY. The engineering unit for the process variable can

2.4

be selected in UNIT.

Temperature Sensors

The TT301, as previously explained, accepts several types of sensors. The TT301 is specially designed

for temperature measurement using thermocouples or thermoresistances (RTDs).

Some basic concepts about these sensors are presented below.

Thermocouples

Thermocouples are the mot widely used sensors in industrial temperature measurements.

Thermocouples consist of two wires made from different metals or alloys joined at one end, called

measuring junction. The measuring junction should be placed at the point of measurement. The other

end of the thermocouple is open and connected to the temperature transmitter. This point is called

reference junction or cold junction.

For most applications, the Seebeck effect is sufficient to explain thermocouple behavior:

How the Thermocouple Works

When there is a temperature difference along a metal wire, a small electric potential, unique to every

alloy, will occur. This phenomenon is called Seebeck effect.

When two wires of dissimilar metals are joined in one end, and left open in the other, a temperature

difference between the two ends will result in a voltage since the potentials generated by the dissimilar

materials are different and does not cancel each other out. Now, two important things must be noted.

First: the voltage generated by the thermocouple is proportional to the difference between the

measuring-junction and the cold junction temperatures. Therefore the temperature at the reference

junction must be added to the temperature derived from the thermocouple output, in order to find the

temperature measured. This is called cold junction compensation, and is done automatically by the

TT301, which has a temperature sensor at the sensor terminals for this purpose. Secondly, if the

thermocouple wires are not used all the way to the terminals of the transmitter (e.g. copper wire is used

from sensor-head or marshalling box) new junctions with additional Seebeck effects will be created and

ruin the measurement in most cases, since the cold-junction compensation will be done in the wrong

point.

The relation between the measuring junction temperature and the generated millivoltage is tabulated in

thermocouple calibration tables for standardized thermocouple types, the reference temperature being

0oC.

Standardized thermocouples which are commercially used, whose tables are stored in the memory of

the TT301, are the following:

NBS (B, E, J, K, N, R, S, T)

DIN (L, U)

GOST (L)

ASTM-E (W5Re/W26Re)

Thermoresistances (RTDs)

Resistance Temperature Detectors, most commonly known as RTD's, are based on the principle that

the resistance of a metal increases as its temperature increases.

Standardized RTDs, whose tables are stored in the memory of the TT301, are the following:

JIS [1604-81] (Pt50 & Pt100)

IEC, DIN, JIS [1604-89] (Pt50, Pt100, Pt500, Pt1000)

GE (Cu 10)

Edison Curve (Ni 120)

GOST (Pt50, Pt100, Cu50, Cu100)

IEC 751-95 (Pt100)

MILT (Ni120, Pt100)

For a correct measurement of RTD temperature, it is necessary to eliminate the effect of the resistance

of the wires connecting the sensor to the measuring circuit. In some industrial applications, these wires

may be hundreds of meters long. This is particularly important at locations where the ambient

temperature changes a lot.

The TT301 permits a 2-wire connection which may cause measuring errors, depending on the length of

connection wires and on the temperature to which they are exposed (see Figure 2.3).

Operation

2.5

TT301 – Operation and Maintenance Instruction Manual

R

V2

TRANSMITTER

2,1

3,4

R

RTD

I

R

V2

V1

TRANSMITTER

2,1

4

3

R

RTD

I

In a 2-wire connection, the voltage V2 is proportional to the RTD resistance plus the resistance of the

wires.

V2 = [RTD + 2x R] x I

Figure 2.3 – Two-Wire Connection

In order to avoid the resistance effect of the connection wires, it is recommended to use a 3-wire

connection (see Figure 2.4) or a 4-wire connection (see Figure 2.5).

In a 3-wire connection, terminal 3 is a high impedance input. Thus, no current flows through that wire

and no voltage drop is caused. The voltage V2-V1 is independent of the wire resistances since they will

be canceled out, and is directly proportional to the RTD resistance alone.

V2-V1 = [RTD + R] x I - Rx I = RTDx I

Figure 2.4 – Tree-Wire Connection

In a 4-wire connection, terminals 2 and 3 are high impedance inputs. Thus, no current flows through

those wires and no voltage drop is caused. The resistances of the other two wires are not interesting

since no measurement is done on them. Hence the voltage V2 is directly proportional to the RTD

resistance. (V2 = RTD x I).

2.6

Operation

R

V2

2

1

+

-

3

4

R

RTD

TRANSMITTER

I

TRANSMITTER

1,3

R

R

R

2

4

V1

V2

RTD2

RTD1

I

I

NOTE

The material, the gauge, and the length should be the same connections of 3 or 4 threads.

Figure 2.5 – Four-Wire Connection

A differential connection is similar to the two-wire connection and gives the same problem (see Figure

2.6). Terminal 3 is a high impedance input. Thus, no current flow through and no voltage drop is

caused, but the resistance of the other two wires will be measured and does not cancel each other out

in a temperature measurement, since linearization will affect them differently.

Figure 2.6 – Differential Connection

The Display

The digital indicator is able to display one or two variables which are user selectable. When two

variables are chosen, the display will alternate between the two with an interval of 3 seconds.

The different fields and status indicators are explained in Figure 2.7.

Monitoring

During normal operation, the TT301 is in the monitoring mode. In this mode, indication alternates

between the primary and secondary variable as configured in DISPLAY. See Figure 2.8.

The display indicates engineering units, values and parameters simultaneously with most status

indicators. The monitoring mode is interrupted in two situations:

User performs complete local adjustment.

An alarm is activated.

2.7

TT301 – Operation and Maintenance Instruction Manual

* PID IS OPTIONAL

M

A

Fix

F(t)

PID

SP

F(x)

35

PV

min

ACK

INDICATES THAT THE DISPLAYED

ALARM HAS NOT YET BEEN ACKNOWLEDGED

INDICATES ACTIVE SPECIAL

SENSOR LINEARIZATION

( NOT USED ON TT301 )

VARIABLE FIELD

UNIT PERCENT

UNIT MINUTES

UNIT AND FUNCTION FIELD

INDICATES THAT THE PROCESS

VARIABLE IS NOW DISPLAYED

INDICATES ACTIVE

MULTIDROP MODE

INDICATES ACTIVE

SETPOINT GENERATOR *

INDICATE PID

CONTROLLER MODE *

INDICATES ACTIVE

CONSTANT OUTPUT MODE

INDICATES CONTROLLER

IN AUTOMATIC *

INDICATES CONTROLLER

IN MANUAL *

INDICATES POSSIBILITY

TO ADJUST / CHANGE

VARIABLE / MODE

INDICATES THAT

THE SETPOINT

Alarm

Figure 2.7 – Display

Figure 2.8 – Typical Monitoring Mode Display

The two alarms are software alarms and have no contacts available on the transmitter. The alarms are

acknowledged by using the Local Adjustment or the Configurator, which can view and configure alarms

as well - see further Section III. During an alarm, the display will indicate which alarm has been

activated and if it has been acknowledged or not.

The transmitter display also indicates the alarms status as shown in Figure 2.9.

AL H means High Alarm, AL L means Low Alarm and ALO indicates Burnout failure. The ACK indicates

that the alarm has not yet been acknowledged.

When the alarm condition disappears, the "ACK" is switched off and the display returns to monitoring

mode.

For further information on alarm configuration, see Section III - Programming Using Terminal.

2.8

Operation

ALARM 1

ALARM 2

Figure 2.9 – Typical Alarm Condition Display

2.9

TT301 – Operation and Maintenance Instruction Manual

2.10

Section 3

NOTE

When configured in multidrop for the classified areas the entity parameters allowed for the area must be

strictly observed. So, verify that:

Ca Cij + Cc La Lij + Lc

Voc min [Vmaxj] Isc min [Imaxj]

Where:

Ca, La = capacitance and inductance permitted in bus;

Cij, Lij = transmitter capacitance and inductance r j (j=1, 155), without internal protection;

Cc, Lc = cable capacitance and inductance;

Voc = open circuit tension of the intrinsic safety barrier;

Isc = short circuit tension of the intrinsic safety barrier;

Vmax = maximum permissible tension to be applied on the r j transmitter;

Imax = maximum permissible tension to be applied on the r j transmitter.

CONFIGURATION

The Temperature Intelligent Transmitter TT301 is a digital device bearing the most advanced features a

measurement apparatus can offer. A HART digital communication protocol permits the device to be

connected to an external computer for a simple and complete configuration. These computers,

connected to the transmitters, are called HOST computers and may be a Primary or Secondary Master

type. Although HART may be a master/slave protocol, it may coexist with up to two masters in a field

bus. Generally, the Primary HOST stands for a Supervisory and the Secondary HOST is used as a

Configurator.

Transmitters, on the other hand, may be connected to a point-to-point or a multi-drop network. In a

point-to-point network, the equipment should have its address set at “0”, so that the output current is

modulated from 4 to 20 mA, according to the measurement performed. In a multidrop network, the

transmitters should be configured on a network address between “1” and “15”, if the identification

devices work via address. In this case, the transmitter’s output current must be constant, each

transmitter consuming 4 mA. If the identification mechanism is done via Tag, the transmitters may be

addressed at “0” and control their current output, even on a multidrop configuration.

The TT301 may be configured both for Transmitter and Controller and the HART addressing may be

used as follows:

TRANSMITTER MODE: The TT301 controls the current output, while the “1” to “15” addresses

adjust the TT301 on multidrop mode setting the output current control on 4 mA.

CONTROLLER MODE: The TT301 always controls the output current according to the value

calculated for the Manipulated Variable, regardless of its address value on the net.

The TT301 Intelligent Temperature Transmitter presents a comprehensive set of HART Commands that

permit accessing any implemented functionality. These commands comply with the HART protocol

specifications and are grouped in Universal Commands, Common Practice Commands and Specific

Commands.

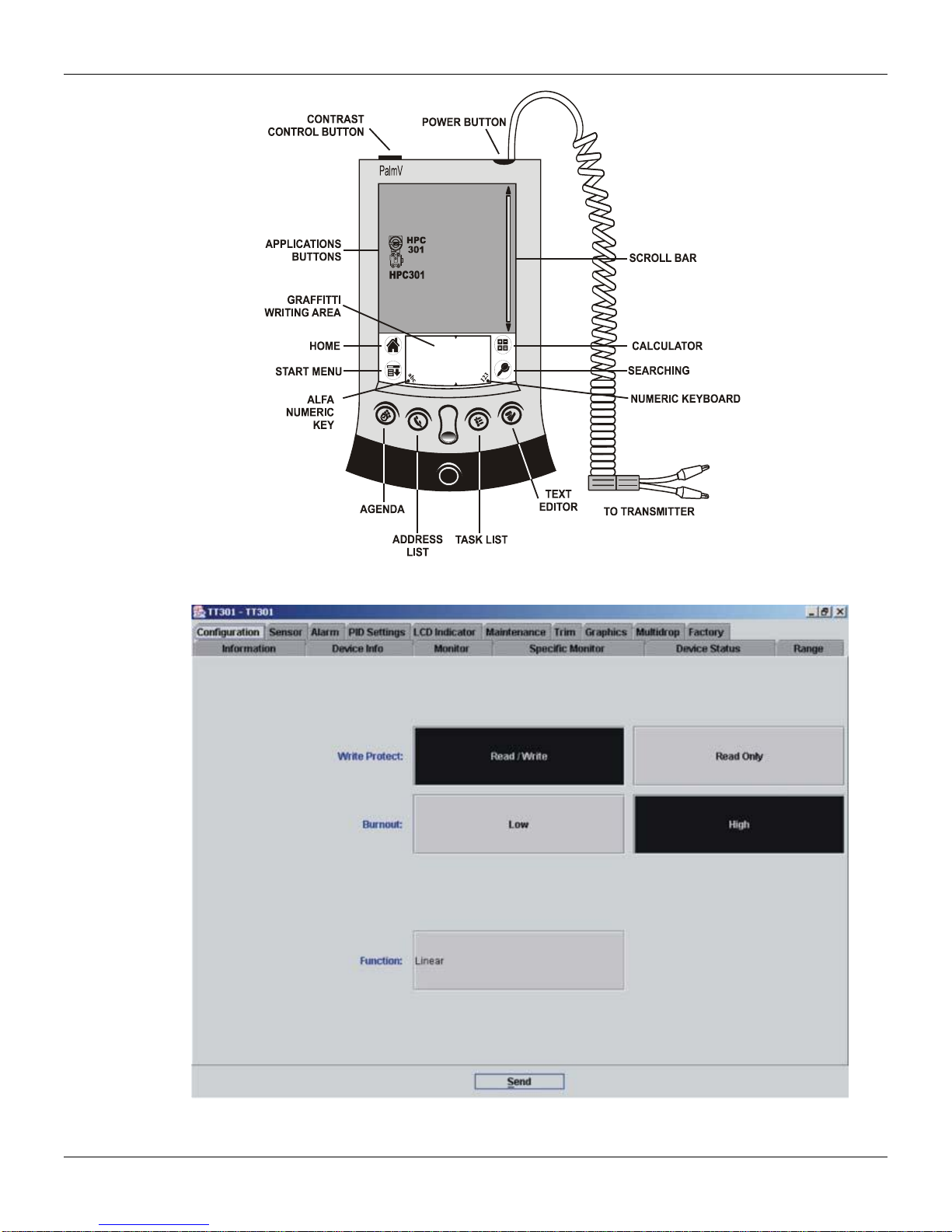

Smar developed the CONF401 and HPC301 software, the first one works in Windows platform (95, 98,

2000, XP and NT) and UNIX. The second one, HPC301, works in the most recent technology in PDA´s.

They bring easy configuration and monitoring of field devices, capacity to analyze data and to modify

the action of these devices. The operation characteristics and use of each one of the

configurators are stated on their respective manuals.

Figures 3.1 and 3.2 show the front of the Palm and the CONF401 screen, with the active configuration.

3.1

TT301 - Operation & Maintence Instruction Manual

Figure 3.1 - Configurator

3.2

Figure 3.2 – CONF401 Screen

Configuration Resources

WARNING

All transmitters are factory-configured without passwords. To avoid faulty operation on a few critical

levels on the programming tree, the configuration is recommended of all passwords before

operating. See option “PASSWORD”, on the maintenance section.

INFO CONF MAINT SENSOR PID RANGE TRIM ALARM FACTORY

TT301

MULTIDROP MONIT

Through the HART configurators, the TT301 firmware allows the following configuration resources to be

accessed:

Transmitter Identification and Manufacturer Data;

Primary Variable Trim – Temperature;

Secondary Variable Trim – Terminal Temperature;

Equipment Current Trim;

Transmitter Adjustment to Work range;

Engineering Unit Selection;

Set Point Generator Configuration;

PID Controller Configuration;

Equipment Configuration;

Equipment Maintenance.

The operations occurring between the configurator and the transmitter do not interrupt the temperature

measuring and do not disturb the output signal. The configurator may be connected on the same 4-20

mA signal cable to a maximum 2000 m distance from the transmitter.

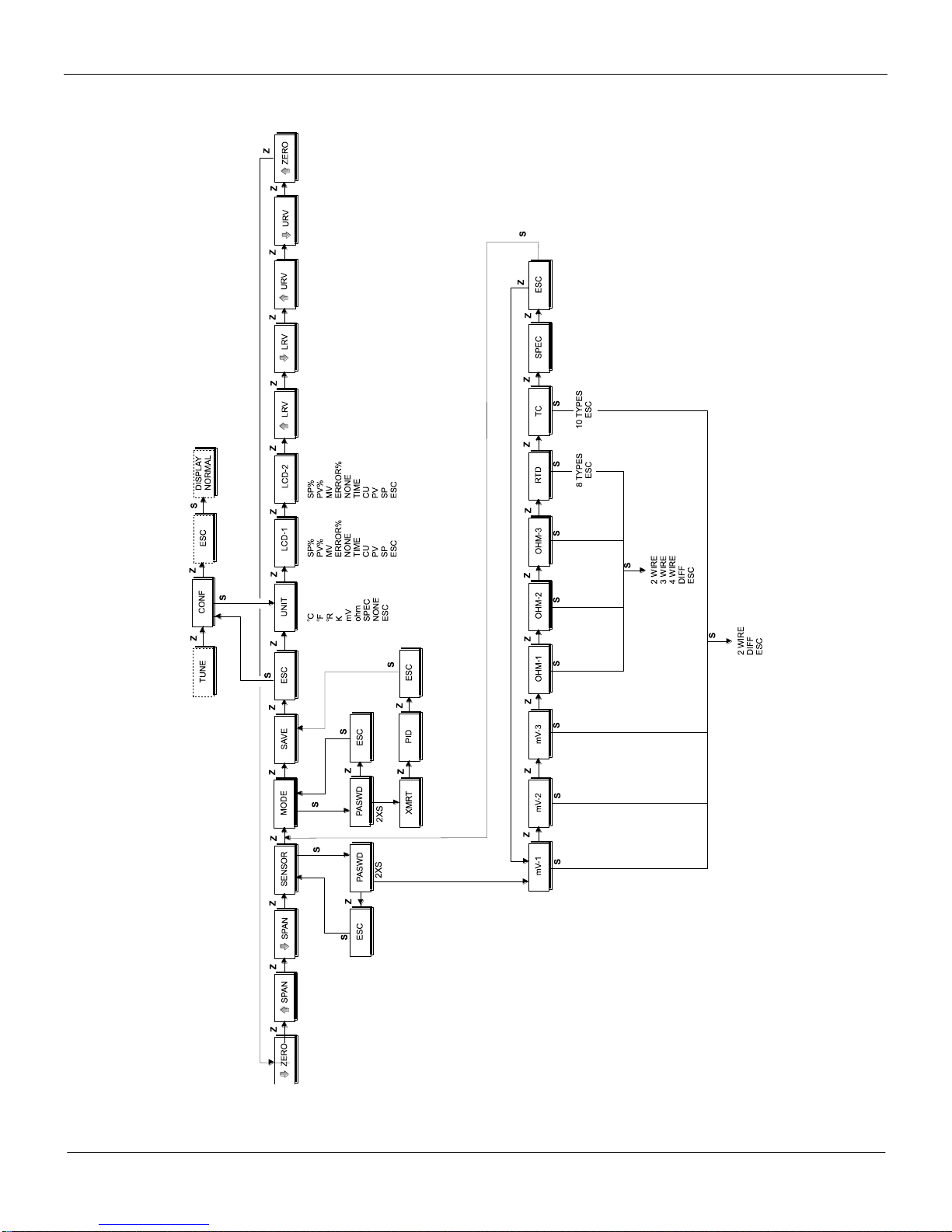

Programming Tree

The programming tree is a structure resembling a tree, with all the resources available in the software,

as shown on Figure 3.3.

DEVICE ADDRESS 0: Used when the Configurator is connected in parallel with a single transmitter

and this transmitter has 0 (zero) for address.

FROM: 0 TO 15: Used when the Configurator is connected in parallel with up to 15 several transmitters

and these transmitters are configured with different addresses (See Multidrop).

Programming Using Hand-Held Terminal

Figure 3.3 – Configuration Tree

INFO – The main information on the transmitter may be accessed here. They include: Tag,

Description, Message and Single ID.

CONF – This option permits Burnout and Display configurations

MAINT – This option tests the current loop, resets the operations equipment, sees the operations

counter and configures the password levels and ordering code.

SENSOR – This option permits configurate the sensor type and the connection to be used.

PID – This option connects and disconnects the programming function and adjusts and monitors all of

the control parameters.

MONIT – The user may monitor 4 of the transmitter dynamic variables and the current output.

RANGE – The following outputs related to the parameters may be configured: Lower Value, Upper

Value, Unit and damping.

TRIM – Adjusts the transmitter displaying to a current or an Ohm/mV standard.

ALARM – Any of the three available types of alarm may be configured. They may be used as an alert

tool to be activated when the PV is out the configured range.

FACTORY – Contains all parameters pre-configured at plant. This procedure is in-factory performed

and may not be adjusted by the user.

3.3

TT301 - Operation & Maintence Instruction Manual

*NOTE

This item may not be modified.

MULTIDROP – The user may track the equipments connected to the loop, thus detecting their

respective addresses. Also, an address is designated to each device to be connected to the

network.

Identification and Manufacturing Data – Info

The main information on the transmitter may be obtained here. They are: Tag, Description, Message,

Date and Single Identification. There is also a screen with important additional information on the

equipment. They are: Manufacturer, Type of equipment, Serial Number and Transmitter Firmware

Version, HART protocol Version and Hardware Revision.

The following information are available for the TT301 transmitter identification and manufacturer data:

TAG – Field with 8 alphanumerical characters for transmitter identification;

DESCRIPTION – Field with 16 alphanumerical characters for additional transmitter identification;

MESSAGE – Field with 32 alphanumerical characters for any other information, such as the name

of the last person to calibrate, some special caution to be observed or if a ladder is needed to

access the transmitter, for example.

MODIFICATION DATE – The date may be used to identify a relevant date, as the last calibration,

the next calibration or installation. The date is stored in the form of bytes, where DD = [1,..31],

MM = [1..12], AA = [0..255] and the effective year is calculated by [ year = 1900 + AA];

UNIQUE ID* - Information for reading only.

Configurator - Conf

This function affects the transmitter 4-20 mA output and display reading. It may alter the lower and

upper burnout, select the variables to be displayed and verify the status of writing protection.

Burnout – The burnout may occur when the sensor reading is out of range or the sensor is open. In

this case, the transmitter may be adjusted for maximum output limit at 21 mA, by configuring it on the

upper value, or the minimum limit at 3.6 mA configured on the lower value.

Calibration – Range

The Lower and the Upper Values are calibrated in this operational range, which also selects the unit

representing the process variable and the transmitter damping.

Maintenance - Maint

The maintenance option offers the user 5 choices to check his loop functionality, such as: restart the

equipment, test the current loop, verify the number of configurations performed, configure passwords

and verify the equipment order code. Below is a brief description of the characteristics

performed by the equipment Maintenance function:

Device Reset – The equipment is switched off and then on. The restarting option should be carried out

as a last resort, as it may destabilize the process control.

Loop Test – The current output may be adjusted to any desired value between 3.8 and 21.0 mA

regardless of the input value. There are a few stable current values for the loop test. The options

available are: 4, 8, 16 or 20 mA.

Operation Counter: The operation number counting is useful to indicate if somebody altered any

configuration on the equipment. Every time one of the parameters below is altered, the respective

alteration counter is activated. The monitored parameters are:

3.4

Range configuration (Lower/Upper)

Change to Constant Current

4 mA Trim

20 mA Trim

Sensor Trim

Burnout configuration

NOTE

Contact Smar in case you forgot or lost your password.

Sensor configuration

Auto/Manual shift (PID enabled)

Multidrop

Passwords: The options for password configuration and access level are: Info, Trim, Conf, Maint, PID

and Alarm.

There are three password levels. They are used to restrict the access to certain operations in the

programming tree. In the default condition no password is configured.

Each operation item may have a specified password level. The default password level is 0 (“Zero”), but

the adjustment of Info at level “1” and Maint at level “3” are feasible. These levels may be altered by

someone who knows the level “3” password. To cancel, just delete the current password and send

another blank one.

The level 3 password is hierarquically superior to the level 2 passwords, which, on its turn is superior to

level 1.

Ordering code – It contains the equipment ordering code.

Sensor Types - Sensor

It configures the TT301 input for the type of sensor in use and its connecting mode. The types covered

in this manual are:

RTD: Temperature Resistant Detector

Cu10 (GE)

Ni120 (Edison Curve #7)

Pt50, 100, 500, 1000 (IEC)

Pt50, 100 (JIS)

Pt50, PT100, Cu50, Cu100 (GOST)

Pt100 (IEC 751-95)

Ni120, Pt100 (MILT)

Configurable for 2, 3 or 4 wires, differential, backup, maximum, minimum or average

TC: Thermocouples

B, E, J, K, N, R, S e T (NBS)

L e U (DIN), K e S (IEC584)

L (GOST)

W5Re/W26Re (ASTM)

Configurable for 2, 3 or 4 wires, differential, backup, maximum, minimum or average

Ohm: Resistance Measuring

0 a 100 Ohm

0 a 400 Ohm

0 a 2000 Ohm

Configurable for 2, 3 or 4 wires, differential, backup, maximum, minimum or average

mV: Voltage Measuring

-6 a 22 mV

-10 a 100 mV

-50 a 500 mV

Configurable for 2 wires, differential, backup, maximum, minimum or average

Special: Special Sensor

Special Ohm

Special mV

It is used for special sensors like charge cells or position resistive indicators. This resource may turn

the TT301 into a mass, volume, position, etc. transmitter.

Cold Junction:

This option enables or not the cold junction for TC sensors. Do not use the "send" button. The alteration

is made automatically in the transmitter.

Programming Using Hand-Held Terminal

3.5

TT301 - Operation & Maintence Instruction Manual

VARIABLE

UNITS

Pressure

inH2O, InHg, ftH2O, mmH2O, mmHg, psi, bar, mbar, g/cm2, Pa, KPa,Ton, ATM

Volume Flow

ft3/min, gal/min, l/minin, Gal/min, m3/h, gal/s, l/s, Ml/d. ft/3s, ft3/d, m3/s, m3/d,

Gal/h, Gal/d, ft3/h, m3/min, bbl/s, bbl/min, bbl/h, bbl/d, gal/h, Gal/s, l/h

Speed

ft/s, m/s, m/h

Temperature

ºC, ºF, ºR, K

Voltage

mV, v

Volume

gal, l, Gal, m3, bbl, bush, Yd3, ft3, In3

Level &

Length

ft, m, in, cm, mm

Time

min, sec, h, dia

Weight

(Mass)

gram, Kg, Ton, lb, Shton, LTon

Mass Flow

g/s, g/min, g/h, kg/s, kg/min, kg/h, kg/d, Ton/min, Ton/h, Ton/d, lb/s, lb/min, lb/h,

lb/d, Ton/d

Temperature

SGU, g/cm3, kg/m3, g/ml, kg/l, g/l, TWARD, BRIX, Baum H, Baum L, API, %

Solw, % Solv, Ball

Others

Ohm, Hz, mA, %, pH, s, cPo

Special

5 characters

Conection and Work Model

After the selection of the sensor type is necessary to choose the way how sensors work. The available

options are: differential, 2 wires, 3 wires, 4 wires, backup, average, maximum and minimum. In the

options 2, 3 or 4 wires, only one sensor is connected in the device terminal. In the options differential,

backup, average, maximum and minimum are connected 2 sensors.

2, 3 and 4 wires: only one sensor will go to generate the process variable. If it ruptures, the burnout

indication will be showed.

Differential: In this mode, the TT301 will go to work with the measure difference between the sensors.

If one of them to ruptures, the burnout indication will be showed.

Backup: TT301 works with the reading of the first sensor (between 2 and 4 terminals). If this sensor

brokes, the second sensor (between 3 and 4 terminals) will replace it and show the process variable

reading. In this case, the reading of the first sensor will be discarded, even if this sensor returns to

operate again. The first sensor will back to operate again if either gives it a reset by software or

reenergize the device again. The message “S1BAD” will appear on LCD and the HART response code

“Non-PV out of limits” is set. In case of failure of the second sensor, the transmitter will continue to

operate normally but the message “S2BAD” will appear on LCD and the HART response code “Non-PV

out of limits” will be set.

Average: the final reading will be the average of the signals from two sensors. If the difference between

them is higher than a programmed value, an alarm will be generated. If one of them ruptures, the other

continues performing the process variable reading, and an alarm will be generated to inform this

situation. The message “S1BAD” or “S2BAD” will appear on LCD and the HART response code “NonPV out of limits” will be set.

Maximum and minimum: the process variable will be supplied by sensor that has either maximum or

minimum reading, respectively. If one of them ruptures, the other continues performing the process

variable reading, and an alarm will be generate to inform this situation. The message “S1BAD” or

“S2BAD” will appear on LCD and the HART response code “Non-PV out of limits” will be set.

Special Sensor Configuration

The special sensor is a function that permits sensors whose typical curves are not stored in the TT301

memory to be used or linearized. Table 3.1 shows the available units for special sensors.

Any sensor may be used, provided the TT301 accepts the signal range generated by the sensor. The

Ohm and mV sensors limitations may be seen on table 3.2.

To change the special sensor configuration select special on the sensor menu.

Table 3.1 – Special Sensor Available Units

3.6

Programming Using Hand-Held Terminal

WARNING

The special sensor function may not be used when the setpoint generating function is being used and

vice-versa.

CONNECTION TYPE

2, 3 OR 4 WIRES

DIFFERENTIAL (each input)

Ohm

0 < X < 2000

0 < X < 1000

mV

-6 < X < 500

10 < X < 250

dt

dPV

Tdedt

Tr

eKpMV .

1

The sensor typical curve may be scheduled on the TT301 EEPROM memory as a 16-point table. These

tables are usually supplied by the sensor manufacturer, but may also be obtained at a lab test.

The options for configuring the special sensor are:

Range – For the Ohm sensor there are 3 ranges: 0 to 100, 0 to 400 and 0 to 2000 ohm. For the mV

sensor there are also 3 ranges: -6 to 22, -10 to 100 and –50 to 500.

Connection – There are 4 options: differential, two wires, three wires and four wires.

X and Y Tables – The special sensor table points are inserted here. The sensor input is stored as an

X-variable. The chosen output is stored as a Y-variable (19999 ≤ Y ≤ +19999). The X-input should

always have growing values.

X = Ohm or mV terminal block input.

Y = Chosen output in engineering units.

Watch the following limitations for the X variable values:

PID

V.INF Calibration range lower limit. The least possible value for transmitter calibration when using this

special sensor.

V.SUP Calibration range upper limit. The most possible value for transmitter calibration when using this

special sensor.

Minimum Span The least possible span for transmitter calibration when using this special sensor.

Unit – Engineering Unit to be associated to the measured variable. If one from most of 100 units is

selected, the respective HART protocol code will be attributed to this parameter. This way, the whole

supervisory system having HART protocol may access the Unit menu.

This option adjusts the PID parameters including the Setpoint, change on auto/manual mode and the

tuning parameters.

The TT301 with an activated PID works as a controller/transmitter, while, deactivated, it works only as a

transmitter

The transmitter 4/20mA output may become a PID controller output, following the equation below:

Where:

e = PV – SP (Direct) or SP – PV (Reverse)

SP = Setpoint

PV = Process Variable

Kp = Proportional Gain

Td = Derivative Time

MV = Output

Tr = Integration Time

See below a list of configurations feasible on the PID function.

PID Controller – ON/OFF

Tuning Parameters – This feature configures the Kp, Tr and Td tuning parameters, as well as

Table 3.2 – Special Sensor Input Range

output limits and rate.

3.7

TT301 - Operation & Maintence Instruction Manual

VARIABLE

DESCRIPTION

CORRENTE

mA output.

*MV

Output percent.

PV

Process variable on the selected engineering unit.

TEMP

C Room temperature.

PV%

Process variable percent.

*SP%

Setpoint percent.

*SP

Setpoint on the selected engineering unit.

*TIME

Setpoint generator time in minutes.

*ER%

Deviation between SP and PV percents.

*NOTE

These items may only be selected on PID mode.

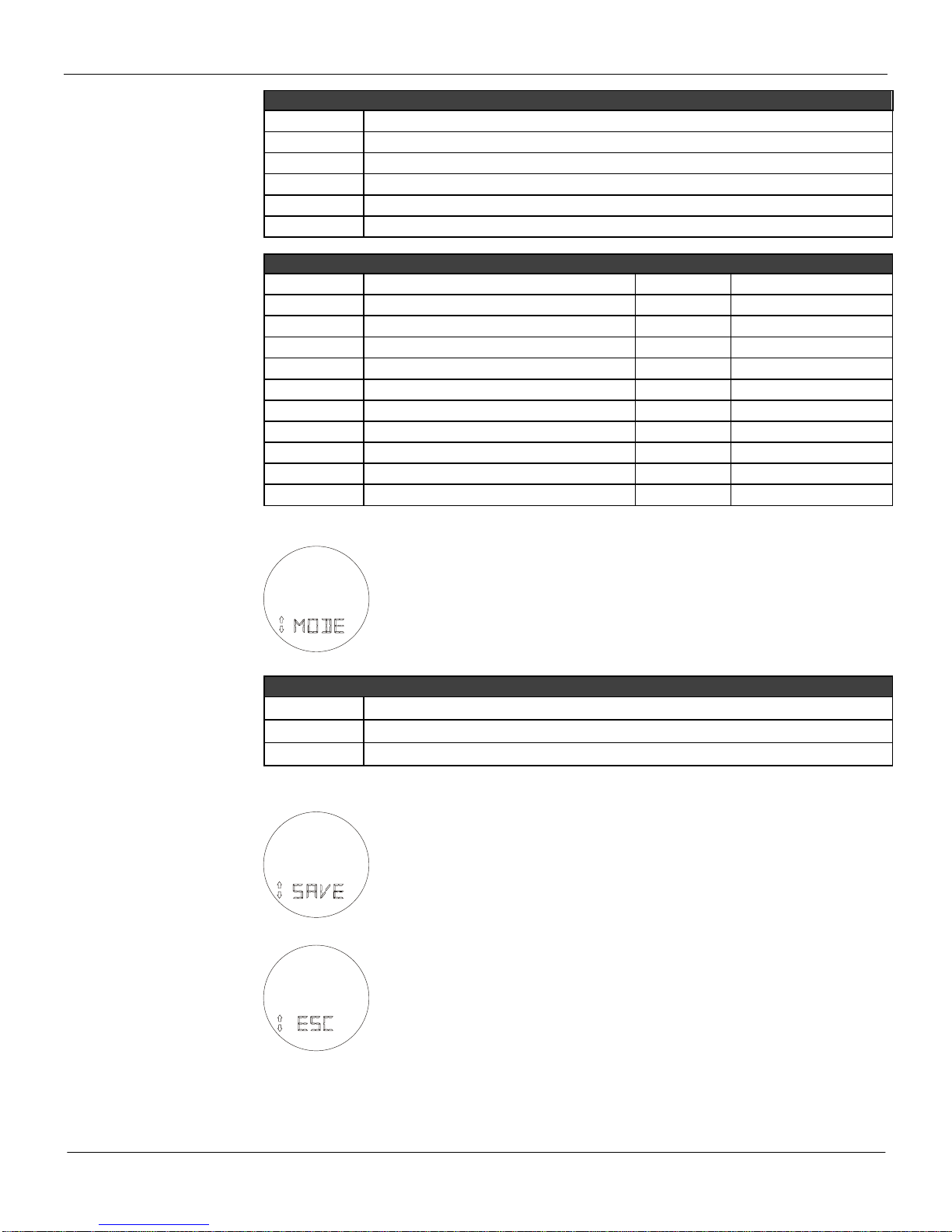

EXAMPLE

Set the first variable indication for PV percent and the second variable for current.

PV, SP, MV and Error Readings – Provides real-time variable value.

SP Tracking – When in MANUAL, the setpoint follows the PV. When the controller is switched to

AUTO, the last PV value before the switch will be regarded as SP.

Control Action – This option configures the transmitter Operation Mode. The options are:

Direct – The output increases when the PV rises.

Reverse – The output decreases when the PV does.

Control Mode – Selects Automatic and Manual.

MV Configuration – Adjusts the manipulated variable.

SP Configuration – The Setpoint is adjusted.

Control Limits – This option switches the SP Power On to automatic, manual and last value.

Safety value – The output after a power shortage or during a failure.

Rate / Alteration – The maximum allowed output change.

Lower Limit – The minimum allowed percent output.

Upper Limit – The maximum allowed percent output.

Setpoint Table – When the setpoint generator is activated, the setpoint varies according to a curve

table. The time is always read in minutes and the setpoint in percentage.

SP Generator – When activated, the setpoint varies with time according to the schedule on

TABELA_SP table.

Monitoring - MONIT

This function monitors the transmitter 4 dynamic variables and the output current on the configurator

display simultaneously.

Table 3.3 - Monitored Variables

The indications will always oscilate between the first and the second variable.

If the display should not indicate the oscillation, select the same indication in both variables, or select

“SEM” (“without”) on the second variable.

3.8

Calibrating the TT301

A transmitter calibration consists of configuring the input values related to 4 mA and 20 mA. The TT301

may do this in 4 different methods:

1 – By using the Configurator (no-reference method) whose calibration input is not required.

2 – By using the Configurator and an input signal as reference (referenced method).

3 – Local adjustment and an input signal as reference (simple local adjustment, with reference).

4 – Local adjustment and an input signal as reference (complete local adjustment, with reference).

5 – Local adjustment (complete local adjustment, without reference).

In transmitter mode, the lower value always corresponds to 4 mA and the upper value to 20 mA. In PID

mode, the lower value corresponds to PV=0 % and upper value to PV=100 %.

Calibration Without Reference

The TT301 may be configured to supply 4 to 20 mA, the equivalent to the temperature limits on the

user’s application, without the need to connecting a reference calibrating generator on its terminals.

This is possible because the TT301has linearization curves for several standard temperature

sensors in its memory. Let us suppose the transmitter range is calibrated from –100 to 300o C and

one must calibrate it on 0 to 100o C.

The transmitter generates a signal varying from 4 to 20 mA when the temperature oscillates between 0

and 100o C.

Watch that both the LOWER and UPPER values are entirely independent. Adjusting one does not

affect the other. However, the following rule must be observed:

a) Both values should not be less than the lower limit or in excess of the upper calibration limit.

b) The Upper value less Lower value span must be larger than the LOWER SPAN.

If a signal needs to be reverted, i.e., have an UPPER VALUE smaller than the LOWER VALUE,

proceed as follows:

Make the inferior value as close as possible to the Superior Value or vice-versa, observing the allowed

minimum span. Adjust the Superior Value with the desire value and, then, adjust the Inferior value.

Example: If the transmitter is calibration such as:

LOWER VALUE = 4 mA = 0 oC

UPPER VALUE = 20 mA = 100 oC and the values should change to:

LOWER VALUE = 4 mA = 100o C

UPPER VALUE = 20 mA = 0o C;

Considering that the Pt100 IEC Minimum Span is 10o C, the adjustments must be altered as follows:

a) LOWER VALUE = 90, or 100-10.

b) UPPER VALUE = 0 oC

c) LOWER VALUE = 100 oC

The table 3.4 shows graphycaly how to do this ranging.

Programming Using Hand-Held Terminal

3.9

TT301 - Operation & Maintence Instruction Manual

1 Step 2 Step 3 Step 4 Step

Get sensor

minimum span

Do Lower

Value = 90 ºC

Do Upper

Value = 0 ºC

100 ºC

Upper Value

90 ºC

Upper Value - Span

0 ºC

Lower Value

Minimum Span = 10 ºC

100 ºC

90 ºC

100 ºC

90 ºC

100 ºC

90 ºC

0 ºC 0 ºC0 ºC

Do Lower

Value = 100 ºC

Lower Value

Lower Value Lower Value

Lower Value

Lower Value

st sd

rd

th

Upper Value

Upper Value

Upper Value Upper Value

Table – 3.4 – Procedure to Range without Reference

Calibration With Reference

This is the most convenient way to calibrate a transmitter. Apply the signal for adjusting the 4 mA point

(PV=0 %). The Lower Value is altered but the span remains the same.

The same procedure is applied for the Upper Value.

LOWER VALUE = 0 Ohm

UPPER VALUE = 100 Ohm

Example: When measuring resistance the TT301 is calibrated as follows:

After the installation is done, the potentiometer (input sensor) was found to have a 5 Ohm residual

resistance when its indicator was on a zero position.

The Lower Value reference trim quickly corrects this problem, causing the Lower Value to equal 5 Ohm.

The Upper Value may be altered in the same way.

As mentioned before, the Ohm or mV sensor input may differ a little from its plant standard.

The Zero and Gain Trim may be used to adjust the transmitter reading to Engineering Units with its

plant standard, thus eliminating possible differences.

Unit

The Engineering Unit shown on the transmitter and the configurator displays may be altered. The units

are linked to a selected process variable.

The following units are available:

- For mV input: always mV.

- For Ohm input: always Ohm.

- For Thermocouple and RTD: Celsius, Fahrenheit, Rankine and Kelvin degrees.

Damping

The DAMPING option on the RANGE function enables electronic damping adjustment.

Trim

3.10

The damping may be adjusted between 0 and 32 seconds.

The TRIM function is used to adjust resistance, voltage and current reading to user standard. To

continue the TRIM adjustment, the control loop must be on MANUAL to avoid disturbances in the

process.

There are two options: Current signal and input reading.

Current TRIM (4-20 mA output)

When the microprocessor generates a 0 percent signal, the Digital-to-Analogic converter and related

electronic circuits must emit a 4 mA output. If the signal is 100 percent, the output must be 20 mA.

Differences may occur between the SMAR standard current and the plant standard. In this case, the

current TRIM adjustment should be used.

The Configurator will adjust the output signal and then it will ask again if the current is correct or not.

Input Reading TRIM

There may be differences between the SMAR resistance standard and mV and the plant standards. In

this event, the user TRIM adjustment may be used. The TRIM available are: Zero trim, the Gain trim

and Factory trim.

- Zero Trim – Calibrates the resistance or millivoltage lower value. The zero trim does not interfere with

the gain trim.

- Gain Trim – Calibrates the resistance or milivoltage upper value.

- Factory Trim – Recovers the Zero, Gain, and temperature sensor made in factory.

For zero or gain adjustment, a resistance or mV standard should be connected with a better than

0.02% accuracy.

If the transmitter is configured as either differential sensor, backup, average, maximum or minimum,

that is working with two sensors simultaneously, only the zero trim is available.

To perform zero trim, it should to short circuit the two sensors in the field and to enter with the value 0

(zero).

After perform the trim, remove the short circuit for the transmitter to read the sensors resistance without

the influence of the lines. The line maximum resistance should be less than 32 Ω for that zero trim

would be possible.

Temperature Sensor Trim

Althouth it is not necessary to perform the temperature trim of the terminal, it is possible a little

adjustment in the temperature measure through this menu.

Alarm

This function configures the three TT301 alarms, with independent configuration for alarms 1 and 2

action and limit. All the alarms may be monitored and identified through this function. Alarm zero

indicates burnout and may be activated in this function.