INTELLIGENT PRESSURE TRANSMITTER

MAR / 12

LD291

Version 6

LD291ME

smar

Specifi cations and info rm at i o n are subject to change without notice.

Up-to-date address information is available on our website.

web: www.sm ar.com/contactus. a sp

www.smar.com

Introduction

INTRODUCTION

The LD291 is a smart pressure transmitter for gauge and level measurement. It is based on a

field-proven capacitive sensor that provides reliable operation and high performance. The digital

technology used in the LD291 enables an easy interface between the field and the control room and

several interesting features that considerably reduce the installation, operation and maintenance

costs.

The LD291 is the economical alternativ e in routine gage pressure measurement. This lightweight

design eliminates the need for mounting brackets and transmitter supports in many applications.

The model LD291 offers digital HART

remote diagnostics. Also, an optional LCD meter can be added to provid e additional operatio ns and

local indication.

Its microprocessor- based electronics allow for total interchangeability with SMAR capacitive

sensors. It automatically corrects sensor characteristic changes caused by temperature fluctuations.

The LD291, besides the normal functions offered by other smart transmitters, offers the following

functions:

TABLE - the pr essure signal is custom linearized according to a 16-point table, enabling, e.g.,

conversion of level to volume of a horizontal cylindrical tank.

LOCAL ADJUSTMENT - not only for lower and upper value, but input/output function,

indication, as well.

PASSWORD - three levels for different functions.

OPERATION COUNTER - shows the number of changes in each function.

USER-UNIT - indication in engineering unit of the prop erty actually measu red, e.g., level, flo w or

volume.

WRITE-PROTECT- via hardware.

Get the best results of the LD291 by carefully reading these instructions.

Smar’s pressure transmitters are protected by U.S. patents 6,433,791 and 6,621,443.

based communication simplifying calibration and providing

III

LD291 - Operation and Maintenance Instruction Manual

r

r

This manual is compatible with version 6.XX, where 6 denote software version an d XX software

release. The indication 6.XX means that this manual is compatible with any rel ease of software

version 6.

To ensure that our products are safe and without risk to health, the man ual must be r ead c arefull y

before proceeding and warning labels on packages must be observed. Installation, operation,

maintenance and servicing must only be carried out by suitably trained personnel and in

accordance with the Operation and Maintenance Instruction Manual.

Waiver of responsibility

The contents of this manual abides by the hardware and soft ware used on the current equipment

version. Eventually there may occur divergencies between this manual and the equipment. The

information from this document are periodically r eviewed and the necessary or identified corrections

will be included in the following editions. Suggestions for their improvement are welcome.

Warning

For more objectivity and clarity, this manual does not contain all the detailed information on the

product and, in addition, it does not cover every possible mounting, operation or maintenance

cases.

Before installing and utilizing the equipment, check if the model of the acqu ired equipment complies

with the technical requirements for the application. This checking is the user’s responsibility.

If the user needs more information, or on the event of specific problems not specified or treated i n

this manual, the information should be sought from Smar. Furthermore, the user recognizes that the

contents of this manual by no means modify past or pres ent agreements, confirmation or judicial

relationship, in whole or in part.

All of Smar’s obligation result from the purchasing agreement signed between the parties, which

includes the complete and sole valid warranty term. Contractual clauses related to t he warranty are

not limited nor extended by virtue of the technical information contained in this manual.

Only qualified personnel are allowed to participate in the activities of mounting, electrical connection,

startup and maintenance of the equipment. Qualified personnel are understood to be the persons

familiar with the mounting, electrical connection, startup and operation of the equipm ent or othe

similar apparatus that are technically fit for their work. Smar provides specific training to instruct and

qualify such professionals. However, each country must comply with the local safety pr ocedures,

legal provisions and regulations for the mounting and oper ation of electrical installations, as well as

with the laws and regulations on classified areas, such as intrinsic safet y, explosion proof, incre ased

safety and instrumented safety systems, among others.

The user is responsible for the incorrect or inadequate handling of e quipments run with pneumatic

or hydraulic pressure or, still, subject to corrosive, aggressive or combustible products, since thei

utilization may cause severe bodily harm and/or material damages.

The field equipment referred to in this manual, when acquired for classified or hazardous areas, has

its certification void when having its parts replaced or interchanged without functional and approv al

tests by Smar or any of Smar authorized dealers, which are the competent companies for certifying

that the equipment in its entirety meets the applicable standards and regulations. The same is true

when converting the equipment of a communication protocol to another. In this case, it is necessary

sending the equipment to Smar or any of its authorized dealer. Moreover, the certificates are

different and the user is responsible for their correct use.

Always respect the instructions provided in the Manual. Smar is not responsible for any losses

and/or damages resulting from the inadequate use of its equipments. It is the user’s responsibilit y to

know and apply the safety practices in his country.

NOTE

WARNING

IV

Table of Contents

TABLE OF CONTENTS

SECTION 1 - INSTALLATION ................................................................................................................ 1.1

GENERAL ....................................................................................................................................................... 1.1

MOUNTING ..................................................................................................................................................... 1.1

ELECTRONIC HOUSING ............................................................................................................................... 1.8

WIRING ........................................................................................................................................................... 1.9

LOOP CONECTIONS ................................................................................................................................... 1.10

INSTALLATION IN HAZARDOUS AREAS ................................................................................................... 1.12

EXPLOSION/FLAME PROOF ...................................................................................................................... 1.12

INTRINSICALLY SAFE ................................................................................................................................. 1.12

SECTION 2 - OPERATION ..................................................................................................................... 2.1

FUNCTIONAL DESCRIPTION - SENSOR ..................................................................................................... 2.1

FUNCTIONAL DESCRIPTION - HARDWARE ............................................................................................... 2.2

FUNCTIONAL DESCRIPTION - SOFTWARE ................................................................................................ 2.3

THE DISPLAY ................................................................................................................................................. 2.5

SECTION 3 - CONFIGURATION ............................................................................................................ 3.1

CONFIGURATION FEATURES...................................................................................................................... 3.3

MANUFACTURING DATA AND IDENTIFICATION ....................................................................................... 3.3

PRIMARY VARIABLE TRIM - PRESSURE .................................................................................................... 3.3

PRIMARY VARIABLE CURRENT TRIM ........................................................................................................ 3.4

TRANSMITTER ADJUSTMENT TO THE WORKING RANGE ...................................................................... 3.5

ENGINEERING UNIT SELECTION ................................................................................................................ 3.6

TABLE POINTS .............................................................................................................................................. 3.7

EQUIPMENT CONFIGURATION ................................................................................................................... 3.8

EQUIPMENT MAINTENANCE ....................................................................................................................... 3.8

SECTION 4 - PROGRAMMING USING LOCAL ADJUSTMENT ........................................................... 4.1

THE MAGNETIC TOOL .................................................................................................................................. 4.1

SIMPLE LOCAL ADJUSTMENT ..................................................................................................................... 4.2

ZERO AND SPAN RERANGING .................................................................................................................... 4.2

COMPLETE LOCAL ADJUSTMENT .............................................................................................................. 4.3

LOCAL PROGRAMMING TREE ..................................................................................................................... 4.3

CONFIGURATION [CONF] ............................................................................................................................. 4.3

CONFIGURATION BRANCH (CONF) ............................................................................................................ 4.4

RANGE (RANGE) ........................................................................................................................................... 4.5

RANGE BRANCH (RANGE) ........................................................................................................................... 4.5

FUNCTION (FUNCT) ...................................................................................................................................... 4.7

PRESSURE TRIM [TRIM] ............................................................................................................................... 4.8

ESCAPE LOCAL ADJUSTMENT [ESC] ....................................................................................................... 4.10

SECTION 5 - MAINTENANCE PROCEDURES ..................................................................................... 5.1

GENERAL ....................................................................................................................................................... 5.1

DIAGNOSTIC WITH THE CONFIGURATOR ................................................................................................. 5.1

ERROR MESSAGES ...................................................................................................................................... 5.1

DIAGNOSTIC WITH THE TRANSMITTER .................................................................................................... 5.2

DISASSEMBLY PROCEDURE ....................................................................................................................... 5.4

REASSEMBLY PROCEDURE........................................................................................................................ 5.5

INTERCHANGEABILITY ................................................................................................................................ 5.5

RETURNING MATERIALS ............................................................................................................................. 5.6

ORDERING CODE FOR SENSOR ................................................................................................................ 5.9

SECTION 6 - TECHNICAL CHARACTERISTICS .................................................................................. 6.1

ORDERING CODE ......................................................................................................................................... 6.4

OPTIONAL ITEMS .......................................................................................................................................... 6.5

V

LD291 - Operation and Maintenance Instruction Manual

OPTIONAL ITEMS .......................................................................................................................................... 6.7

OPTIONAL ITEMS .......................................................................................................................................... 6.9

OPTIONAL ITEMS ........................................................................................................................................ 6.11

APPENDIX A - CERTIFICATIONS INFORMATIONS ............................................................................ A.1

EUROPEAN DIRECTIVE INFORMATION ..................................................................................................... A.1

OTHER APROVALS ....................................................................................................................................... A.1

FMEDA REPORT ....................................................................................................................................................... A.1

HAZARDOUS LOCATIONS CERTIFICATIONS ............................................................................................ A.1

NORTH AMERICAN CERTIFICATIONS .................................................................................................................... A.1

EUROPEAN CERTIFICATIONS ................................................................................................................................ A.2

SOUTH AMERICAN CERTIFICATIONS .................................................................................................................... A.2

ASIAN CERTIFICATIONS ......................................................................................................................................... A.3

IDENTIFICATION PLATE AND CONTROL DRAWING ................................................................................. A.3

IDENTIFICATION PLATE .......................................................................................................................................... A.3

CONTROL DRAWING ............................................................................................................................................... A.7

APPENDIX B – SRF – SERVICE REQUEST FORM ............................................................................. B.1

APPENDIX C – SMAR WARRANTY CERTIFICATE ............................................................................. C.1

VI

Start

Installation Flowchart

Was the transmitter

configured on the bench

to match the application?

No

Configure the transmitter

(Section 1 and 3)

Configure the engineering unit

(Section 3 - Configuration)

Configure the measuring range

to 0% (4mA) and 100% (20mA)

(Section 3 - Configuration)

Configure the Fail-Safe

value (Section 3 - Configuration)

Configure the Damping

(Section 3 ) - Configuration

Configure the LCD reading

(Section 3 ) - Configuration

Apply the pressure

Yes

Install the transmitter on the field

following the instructions below.

Install the transmitter preferably

on weather- protected areas.

Check the area classification

and its practices

Install the transmitter (mechanically

and electrically) according to the

application after checking the best

position for the LCD

(Section 5 )- Maintenance

Power the transmitter properly.

Is the reading correct?

No

See manual

(Section 5 ) - Maintenance

OK

Yes

Yes

Yes

Yes

Is the impulse line wett leg?

No

Is the transmitter

reading correct?

No

Apply the Zero Trim

Did you correct the

transmitter reading?

No

VII

LD291 - Operation and Maintenance Instruction Manual

VIII

Section 1

NOTE

The installation carried out in hazardous areas should follow the recommendations of the IEC6007914 standard.

General

Mounting

INSTALLATION

The overall accuracy of a flow, level, or pressure measurement depends on several variables. Although

the transmitter has an outstanding performance, proper installation is essential to maximize its

performance.

Among all factors, which may affect transmitter accuracy, environmental conditions are the most

difficult to control. There are, however, ways of reducing the effects of temperature, humidity and

vibration.

The LD291 has a built-in temperature sensor to compensate for temperature variations. At the f actor y,

each transmitter is submitted to a temperature cycle, and the characteristics under different

temperatures are recorded in the transmitter memory. At the field, this feature minimizes the

temperature variation effect.

Putting the transmitter in areas protected from extreme environmental changes can minimize

temperature fluctuation effects.

In warm environments, the transmitter should be installed to avoid, as much as possible, direct

exposure to the sun. Installation close to lines and vessels subjected to high temperatures should als o

be avoided. Use longer sections of impulse piping between tap and transmitter whenever the process

fluid is at high temperatures. Use of sunshades or heat shields to protect the transmitter from external

heat sources should be considered, if necessary.

Proper winterization (freeze pr otection) should be employed to prev ent freezing w ithin the measuring

chamber, since this will result in an inoperative transmitter and could even damage the cell.

Although the transmitter is virtually insensitive to vibration, installation close to pumps, turbines or other

vibrating equipment should be avoided.

The transmitter has been designed to be both rugged and lightweight at the same time. T his make its

mounting easier mounting positions are shown in Figure 1.1.

Should the process fluid contain solids in suspension, install valves or rod-out fittings at regular

intervals to clean out the pipes.

The pipes should be internally cleaned by using steam or compressed air, or by draining the line wit h

the process fluid, before such lines are connected to the transmitter (blow-down).

NOTE

When installing or storing the level transmitter, the diaphragm must be protected avoid scratchingdenting or perforation of its surface.

1.1

LD291 - Operation and Maintenance Instruction Manual

Figure 1.1(a) – Dimensional Drawing and Mounting Position for LD291

1.2

Installation

Figure 1.1(b) – Dimensional Drawing and Mounting Position for LD291 - Sanitary

1.3

LD291 - Operation and Maintenance Instruction Manual

Figure 1.1(c) – Dimensional Drawing and Mounting Position for LD291 – Sanitary

1.4

Installation

Figure 1.1(d) – Dimensional Drawing and Mounting Position for LD291 – Level

1.5

LD291 - Operation and Maintenance Instruction Manual

ELECTRIC

CONNECTION

MOUNTING

BRACKET IN ‘L’’‘

Mobile fixing flange

Sanitary

(OPTIONAL) O’RING

FIXED

Diaphragm protection

Mobile adjusting flange

ADJUSTABLE

ADJUSTABLE

VIEW BY ‘’A’’

4 M8 Screws

Diaphragm protection with screen

FIXED

Flange process tank

VIEW BY ‘’D’’

MACHINING DETAIL

OF FLANGE

PROBE

LENGTH

VIEW BY ‘’BB’’

VIEW BY ‘’C’’

- DIMENSIONS ARE IN mm (in)

Figure 1.1 (e) – Dimensional Drawing and Mounting Position for LD291 – Level (Insertion)

1.6

Installation

WARNING

NOTE

The figure 1.2 shows how to use the tool to fix the process transmitter tap.

Figure 1.2 – Fixing of the Transmitter in the Tap

Observe operating safety rules during wiring, draining or blow-down.

Normal safety precautions must be taken to avoid the possibility of an accident occurring when

operating in conditions of high pressure and/or temperature.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals.

Process leaks could result in death or serious injury

Do not attempt to loosen or remove flange bolts while the transmitter is in service.

Replacement equipment or spare parts not approved by Smar could reduce the pressure

retaining capabilities of the transmitter and may render the instrument dangerous.

Use only bolts supplied or sold by Smar as spare parts.

Some examples of installation, illustrating the position of the transmitter in relation to the taps, are

shown in Figure 1.3.

The location of pressure taps and the relative position of the transmitter are indicated in Table 1.1.

Process Fluid Location of Taps Location of LD291 in Relation to the Taps

Gas Top or Side Above the Taps.

Liquid Side Below the Taps or at the Piping Centerline.

Steam Side Below the Taps using Sealing (Condensate) Pots.

Except for dry gases, all impulse lines should slope at the ratio 1:10, in order to avoid trapping

bubbles in the case of liquids, or condensate for steam or wet gases.

Table 1.1 - Location of Pressure Taps

1.7

LD291 - Operation and Maintenance Instruction Manual

GAS

STEAM

LIQUID

DIAPHRAGM

SENSOR IN THE VERTICAL

HEAD OF THE FLUID

Figure 1.3 – Position of the Transmitter and Taps

NOTE

The transmitters are calibrated in the vertical position and a different mounting position displaces

the zero point. Consequently, the indicator will indicate a different value from the applied pressure.

In these conditions, it is recommended to do the zero pressure trim. The zero trim is to co mpens ate

the final assembly position and its performance, when the transmitter is in its final position. When

the zero trim is executed, make sure the equalization valve is open and the wet leg levels are

correct.

For the absolute pressure transmitter, the assembly effects correction should be done using the

Lower trim, due to the fact that the absolute zero is the reference for these transmitters, so there is

no need for a zero value for the Lower trim.

Electronic Housing

Humidity is fatal to electronic circuits. In areas subjected to high relative humidity, the O-rings for the

electronic housing covers must be correctly placed and the covers must be completely closed by

tighten them by hand until you feel the O-rings being compressed. Do not use tool s to close the cov ers.

Removal of the electronics cover in the field should be reduced to the minimum necessary, since each

time it is removed; the circuits are exposed to the humidity.

The electronic circuit is protected by a humidity proof coating, but frequent exposures to humidity may

affect the protection provided. It is also important to keep the covers tightened in place. Every time they

are removed, the threads are exposed to corrosion, since painting cannot protect these parts. Codeapproved sealing methods should be employed on conduit entering the transmitter.

The unused cable entries should be plugged and sealed accordingly to avoid humidity entering,

which can cause the loss of the product’s warranty.

1.8

WARNING

COVER

LOCKING

SCREW

(a)

(b)

COMUNICATION

TERMINAL

TES

COM

+

TES

TERMINAL

TERMINA

Wiring

Installation

The electronic housing can be rotated to adjust the digital display on a better position. To rotate it,

loose the Housing Rotation Set Screw, see Figure 1.4 (a). To prevent humidity entering, the electric

housing and the sensor joint must have a minimum of 6 fully engaged threads. The provided joint

allows 1 extra turn to adjust the position of the display w indow by rotating the housing clockwise. If the

thread reaches the end before the desired position, then rotate the housing counterclockwise, but not

more than one thread turn. Transmitters have a stopper that restricts housing rotation to one turn. See

Section 4, Figure 4.1.

Figure 1.4 - Cover Locking and Housing Rotating Set Screw (a) Electronic Board Side

(b) Terminal Connection Side

To release the cover that gives access to the wiring block, turn the cov er locking screw clock wise, see

the direction of the arrow in the figure 1.4.

Test and Communication terminals allow, respectively, to measure the current in the 4 - 20 mA loop,

without opening it, and to communicate with the transmitter. To measure it, connect a multi meter in the

mA scale in the "-" and "+" terminals, and to communicate, use a HART configurator in the "COMM"

and "-" terminals. The wiring block has screws on which fork or ring-type terminals can be fastened.

See Figure 1.6.

The LD291 is protected against reverse polarity

For convenience there are two ground terminals: one inside the cover and one external, located close

to the conduit entries.

Use of twisted pair (22 AWG or greater than) cables is recommended. Avoid routing signal wiring close

to power cables or switching equipment.

The Figure 1.6 shows the correct installation of the conduit, to avoid penetration of water, or other

substance, which may cause malfunctioning of the equipment.

GROUND

Figure 1.5– Wiring Block

1.9

LD291 - Operation and Maintenance Instruction Manual

CORRECT

WIRES

INCORRECT

250

SIGNAL LOOP BE GROUNDED A T ANY

POINT OR LEFT UNGROUND

CONFIGURATOR

POWER

SUPPLY

POWER

SUPPLY

1 13 14 15*

CONFIGURATOR

250

Loop Conections

Figure 1.6 - Conduit Installation

Connection of the LD291 should be done as in Figure 1.7. Connection in multi-drop configuration

should be done as in Figure 1.8. Note that a maximum of 15 transmitters can be connected on the

same line and that they should be connected in parallel.

Take care to the power supply as well, w hen many transmitter s are connected on the same line. T he

current through the 250 Ohm resistor will be high causing a high voltage drop. Therefore make sure

that the power supply voltage is sufficient.

The configuration can be connected to the communication terminals of the tra nsmit ter or at any poi nt of

the signal line by using the alligator clips. It is also recommended to ground the shield of shielded

cables at only one end. The ungrounded end must be carefully isolated.

Figure 1.8 – Wiring Diagram for the LD291 in Multidrop Configuration

1.10

Figure 1.7 – Wiring Diagram for the LD291

Installation

NOTE

Make sure that the transmitter is operating within the operating area as shown on the load curve

(Figure 1.9). Communication requires a minimum load of 250 Ohm.

Figure 1.9 – Load Curve

1.11

LD291 - Operation and Maintenance Instruction Manual

WARNING

The instrument modification or parts replacement supplied by other than autho rize d re prese ntati ve o f

Do not remove the transmitter covers when power is ON.

Installation in Hazardous Areas

Explosions could result in death or serious injury, besides financial damage. Installation of this

transmitter in explosive areas must be carried out in accordance with the local standards and the

protection type adopted .Before continuing the installation make sure the certificate parameters are I

n accordance with the classified area where the equipment will be installed.

Smar is prohibited and will void the certification.

The transmitters are marked with options of the protection type. The certification is valid only when

the protection type is indicated by the user. Once a particular type of protection is selected, any othe r

type of protection can not be used.

The electronic housing and the sensor installed in hazardous areas must have a minimum of 6 fully

engaged threads. Lock the housing using the locking screw (Figure 1.4).

The cover must be tightened with at least 8 turns to avoid the penetration of humidity or corrosive

gases. The cover must be tightened until it touches the housing. Then, tighten more 1/3 turn (120°) to

guarantee the sealing. Lock the covers using the locking screw (Figure 1.4).

Consult the Appendix A for further information about certification.

Explosion/Flame Proof

In Explosion-Proof installations the cable entries must be connected or closed using metal cable

gland and metal blanking plug, both with at least IP66 and Ex-d certification.

As the transmitter is non-ignition capable under normal conditions, the statement “Seal not

Required” could be applied for Explosion Proof Version (CSA Certification).

The standard plugs provided by Smar are certified according to the standards at FM, CSA and

CEPEL. If the plug needs to be replaced, a certified plug must be used.

The electrical connection with NPT thr ead m ust u se w aterproofing sealant. A non-hardening silicone

sealant is recommended.

WARNING

Intrinsically Safe

WARNING

In hazardous zones with intrinsically safe or non-incendive requirements, the circuit entity

parameters and applicable installation procedures must be observed.

To protect the application the transmitter must be connected to a barrier . Match the parameters

between barrier and the equipment (Consider the cable parameters). Associated apparatus ground

bus shall be insulated from panels and mounting enclosures. Shield is optional. If used, be sure to

insulate the end not grounded. Cable capacitance and inductance plus C

than Co and Lo of the associated Apparatus.

For free access to the Hart bus in the explosive environment, ensure the instruments in the loop

are installed in accordance with intrinsically safe or non-incendive field wiring pr actices. Use only

1.12

Ex Hart communicator approved according to the type of protection Ex-i (IS) or Ex-n (NI).

It is not recommended to remove the transmitter cover when the power is ON.

and Li must be smaller

i

Section 2

∆

d

A

C

×

≈

ε

ε

CL

d

d

A

d

d

A

CH ≈

∆−

×

∆+

×

≈

)

2

(

and

)

2

(

εε

OPERATION

Functional Description - Sensor

The LD291 Series Intelligent Pressure Transmitters uses c apacitive sensors (capacitive cells) as

pressure sensing elements, as shown in Figure 2.1.

Where,

P

and P2 are the pressures in chambers H and L

1

CH= capacitance between the fixed plate on P

CL= capacitance between the fixed plate on the P

d =distance between CH and CL fixed plates.

d= sensing diaphragm's deflection due to the differential pressure ∆P = P1 - P2.

The capacitance of a capacitor with flat, parallel plates is a function expressed by plate ar ea (A) and

distance (d) between the plates as:

Where,

= dielectric constant of the medium between the capacitor's plates.

CH and CL are capacitances from flat parallel plates with identical areas, then:

Figure 2.1 – Capacitive Cell

side and the sensing diaphragm.

1

side and the sensing diaphragm.

2

However, should the differential pressure (∆P) be applied to the capacitive cell not deflect the sensing

diaphragm beyond d/4, it is possible to assume ∆P as proportional to ∆d.

By developing the expression (CL - CH) / (CL + CH), it follows that:

2.1

LD291- Operation and Maintenance Instruction Manual

d

d

CHCL

CHCL

P

∆

=

+

−

=∆

2

P

H

P

L

PRESSURE

SENSOR

ELECTRONIC

CONVERTER

CONVERTER

TEMPERATURE

DIGITAL

DISPLAY

4-20 mA

PROCESSING UNIT

RANGES

SPECIAL FUNCTIONS

OUTPUT CONTROL

SERIAL COMMUNICATION

PROTOCOL HART

HART MODEM

D/A

CONVERTER

MATH

COPROCESSOR

DISPLAY

CONTROLLER

LOCAL ADJUSTMENTS

ZERO / SPAN

HT3012

POWER

SUPPLY

SENSOR

MAIN BOARD

OUTPUT

ELECTRONIC

CONVERTER

Because the distance (d) betw een the fixed plates CH and C L is constant, it is possible to conclude that

the expression (CL - CH) / (CL + CH) is proportional to ∆d and, therefore, to the different ial pressure to

be measured.

Thus it is possible to conclude that the capacitive cell is a pressure sensor formed by two capacitors

whose capacitances vary according to the applied differential pressure.

Functional Description - Hardware

Refer to the block diagram Figure 2.2. The function of each block is described below.

Figure 2.2 – LD291 Block Diagram Hardware

Oscillator

This oscillator generates a frequency as a function of sensor capacitance.

Signal Isolator

The Control signals from the CPU are transferred through optical couplers, and the signal from the

oscillator is transferred through a transformer.

(CPU) Central Processing Unit and PROM

The CPU is the intelligent portion of the transmitter, being responsible for the management and

operation of all other blocks, linearization and communication.

The program is stored in an external PROM. For temporary storage of data, the CPU has an internal

RAM. The data in the RAM is lost, if the power is switched off, however the CPU also has an internal

nonvolatile EEPROM where data that must be retained is stored. Examples of such data are:

calibration, configuration and identification data.

EEPROM

Another EEPROM is located within the sensor assembly. It contains data pertaining to the sensor's

characteristics at different pressures and temperatures. This characterization is done for each sensor at

the factory.

D/A Converter

Converts the digital data from the CPU to an analog signal with 14-bits resolution.

Output

Control the current in the line feeding the transmitters.

It acts as a variable resistive load whose value depends on the voltage from the D/A converter.

2.2

Modem

This system provider the data exchange between the serve-master digital communications. The

transmitter demodulates serial information transmitted by the c onfigurator from the current line, and

after treating it, modulates the response sending it over the line. A "1" is represented by 1200 Hz and

"0" by 2200 Hz. The frequency signal is symmetrical and does not affect t he DC -lev el of the 4-20 mA

signal.

Power Supply

Power shall be supplied to the transmitter circuit using the signal line (2-wire system). The transmitter

quiescent consumption is 3.6 mA; during operation, consumption may be as h igh as 21 mA, depen ding

on the measurement and sensor status.

The LD291 shows failure indication at 3.6 mA, if configured for low signal failure. At 21 mA, it will show

the indication when configured for high signal failure. In case of low saturation, it will indicate failure at

3.6 mA and for high saturation, 21 mA, and measurements, proportional to the applied pressure in the

range between 3.8 mA and 20.5 mA. 4 mA corresponds to 0% of the working range and 20 mA to100

% of the working range.

Power Supply Isolation

The sensor power supply is isolated from the main circuit by this module.

Display Controller

It receives the data from the CPU and actives the LCD segments. Also it actives the back plane and the

control signals for each segment.

Local Adjustment

Two switches magnetically activated. The magnetic tool without mechanical or electrical contact can

activate them.

Functional Description - Software

Refer to the Figure 2.3. The function of each Block is described below.

Factory Characterization

Calculate the actual pressure from the capacitances and temperature readings obtained from the

sensor using the factory characterization data stored in the sensor EEPROM.

Digital Filter

The digital filter is a low pass filter with an adjustable time constant. It is used to smooth noisy signals.

The Damping value is the time required for the output reaching 63.2% for a step input of 100%.

Customer Characterization

The characterization TRIM points (P1 to P5) can be used to complement the transmitter's original

characterization.

Pressure Trim

Here the values obtained by Zero Pressure TRIM and Upper Pressu re T RIM cor rects the tran smitt er f or

long term drift or the shift in zero or upper pressure reading due to installation or over pressure.

Ranging

It used to set the pressure values corresponding to the output 4 and 20 m A. T he L OWER-VALUE is the

point corresponding to 4 mA, and UPPER-VALUE is the point corresponding to 20 mA.

Function

Depending on the application, the transmitter output or controller PV may have the following

characteristics according to the applied pressure: Linear (for pressure, and level measurement).

The function is selected with FUNCTION.

Customer Linearization

This block relates the output (4-20 mA) to the input (applied pressure) a ccord ing to a look-up table from

2 to 16 points.

The output is calculated by the interpolation of these points. The points are given in the function

"TABLE POINTS" in percent of the range (Xi) and in percent of the output (Yi). It may be used to

linearize, e.g., a level measurement to volume or mass. In flow measurement it can be used to correct

for varying Reynolds number.

Operation

2.3

LD291- Operation and Maintenance Instruction Manual

SENDONDARY INDICATION

SENSOR

TABLE POINTS

T

P

DIGITAL FILTER

FACTORY

CHARACTERIZATION

CUSTOMER

CHARACTERIZATION

PRESSURE

TRIM

RAGING

CUSTOMER

LINEARIZATION

DAMPING

P1 - P5

ZPT

ZPT

SPT

SPT

PV* (PRESSURE)

LO

UP

OUTPUT

CURRENT

TRIM

4-20 mA

TABLE

CONST

OUTPUT

4 mA

20 mA

PV%

USER UNIT

PV**

PV**

DISPLAY

PV %

OUT

1 2

INDICATOR

NOTE:

* USER UNIT OFF

** USER UNIT ON

0%

100%

USER UNIT

ON/OFF

TEMP

PRIMARY INDICATION

2.4

Figure 2.3 – LD291 – Software Block Diagram

spare parts codes.

INDICATES ACTIVE

INDICATES THAT THE PROCESS

The Display

Operation

Output

Calculates the current proportional to the process variable or manipulated var iable to be tr ansmi tted on

the 4-20 mA output depending on the configuration in OP-MODE. This block also contains the constant

current function configured in OUTPUT. The output is physically limited to 3.6 to 21 mA.

Current Trim

The 4 mA TRIM and 20 mA TRIM adjustment is us ed to make the transmitter current comply with a

current standard, should a deviation arise.

User Unit

Converts 0 and 100% of the process variable to a desired engineering unit read out available for the

display and communication. It is used, e.g., to get a volume or from a level measurement , res pecti vely .

A unit for the variable can also be selected.

Display

Can alternate between two indications as configured in DISPLAY.

The integral indicator is able to display one or two variables, which are user selectable. When two

variables are chosen, the display will alternate between the two with an interval of 3 seconds.

The liquid crystal display includes a field with 4 1/2 numeric digits, a field with 5 alphanumeric digits and

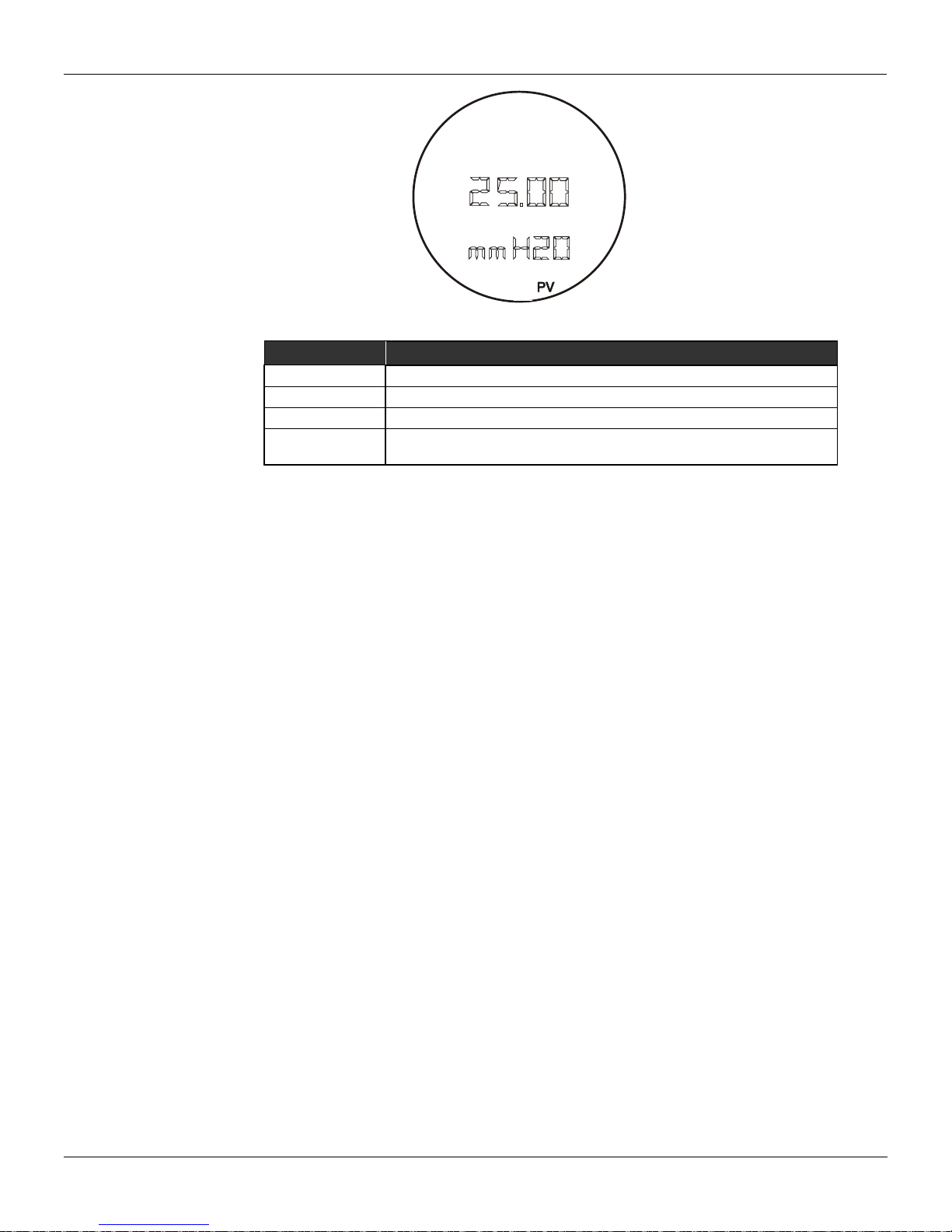

an information field, as shown on Figure 2.4.

DISPLAY V6.00

The display controller, from release V6.00 on, is integral to the main board. Please observe the new

Monitoring

During normal operation, the LD291 is in the monitoring mode. In this mode, indic ation alternates

between the primary and secondary variable as configured by the user. See Figure. 2.5. The display

indicates engineering units, values and parameters simultaneously with most status indicators.

The monitoring mode is interrupted when the user does complete local adjustment.

The display is also capable of displaying an error and other messages (See table 2.1).

TABLE FUNCTION

INDICATES ACTIVE

CONSTANT OUTPUT MODE

INDICATES POSSIBILITY

TO ADJUST / CHANGE

VARIABLES / OPTIONS

MD

Fix

F(x)

PV

Figure 2.4 - Display

%

INDICATES ACTIVE

MULTIDROP MODE

VARIABLE FIELD

UNIT PERCENT

UNIT AND FUNCTION FIELD

VARIABLE IS NOW DISPLAYED

2.5

LD291- Operation and Maintenance Instruction Manual

CHAR

LD291

Figure 2.5 – Typical Monitoring Mode Display Showing PV, in this case 25.00 mmH20

DISPLAY DESCRIPTION

INIT The LD291 is in initializing after power on.

FAIL SENS

SAT

The

Sensor failure. Refer to Section 5 - Maintenance.

Current output saturated in 3.8 or 20.5 mA. See Section 5 –

Maintenance.

is characterization mode. See Section 3 – Trim.

Table 2.1 - Display Messages

2.6

Section 3

k configuration for classified areas, the entity parameters a llow ed f or

≤

CONFIGURATION

The LD291 Intelligent Pressure T ransmitter is a digital instrument with the most up-to-date features a

measurement device can possibly have. Its digital communication protocol (HART

instrument to be connected to a computer in order to be configured in a very simple and compl ete w ay .

Such computers connected to the transmitters are called HOST comp uters . T hey can e ither be Prima ry

or Secondary Masters. Therefore, even the HART

being a master-slave t ype of protocol, it is po ssible

to work with up to two masters in a bus. The Primary HOST plays the supervisory role and the

Secondary HOST plays the Configurator role.

The transmitters may be connected in a point-to-point or multidrop type network. In a point-to-point

connection, the equipment must be in its "0" address so that the output current may be modulated in 4

to 20 mA, as per the meas urement. In a multidrop network, if the devices are recognized by their

addresses, the transmitters shall be configured with a network address between "1" and "15. In this

case, the transmitter’s output current is kept constant, with a consumption of 4 mA each. If the

acknowledgement mechanism is via Tag, the transmitter’s addresses may be "0" while their output

current is still being controlled, even in a multidrop configuration.

In the case of the LD291 the "0" address causes the LD291 to control its output current and addresses

"1" through "15" place the LD291 in the multidrop mode with current control.

NOTE

In the case of multidrop networ

the area shall be strictly observed. Therefore, the following shall be checked:

Ca ≥ Σ Cij + Cc La ≥ Σ Lij + Lc

) enables the

Voc

Where:

min [Vmaxj] Isc ≤ min [Imaxj]

Ca, La - Barrier Allowable Capacitance and Inductance

Cij, Lij - Non protected internal Capacitance/Inductance of transmitter j (j = 1 up to 15)

Cc, Lc - Cable capacitance and Inductance

- Barrier open circuit voltage

V

oc

- Barrier short circuit current

I

sc

- Maximum allowable voltage to be applied to the instrument j

Vmax

j

- Maximum allowable current to be applied to the instrument j

Imax

j

The LD291 Intelligent Pressure Transmitter includes a very encompassing set of HART Command

functions that make it possible to access the functionality of what has been implemented. Such

commands comply with the HART

Common Practice Controls Commands and Specific Commands. A detailed description of such

commands may be found in the manual entitled HART

protocol specifications, and are grouped as Overall Commands,

Command Specification - LD291 Intelligent

Pressure Transmitter.

Smar developed the CONF401 and HPC301 software, the first one w orks in Windows pl atfo rm (95, 98,

2000, XP and NT) and UNIX. The second one, HPC301, works in the most recent technology in PD A´s.

They bring easy configuration and monitoring of field devices, capacity to analyze data and to modify

the action of these devices. The operation characteristics and use of each one of the

configurators are stated on their respective manuals.

Figures 3.1 and 3.2 show the front of the Palm and the CONF401 screen, with the active configur atio n.

3.1

LD291- Operation and Maintenance, Instruction manual

Figure 3.1 – Smar’s Configurator

3.2

Figure 3.2 – Screen of the Configurator

Configuration Features

By means of the HART

be accessed:

Transmitter Identification and Manufacturing Data;

Primary Variable Trim – Pressure;

Primary Variable Trim – Current;

Transmitter Adjustment to the Working Range;

Engineering Unit Selection;

Linearization Table;

Device Configuration;

Equipment Maintenance.

The operations, which take place between the configurator and the transmitter do not interrupt the

Pressure measurement, and do not disturb the output signal. The configurator can be connected on the

same pair of wires as the 4-20 mA signal, up to 2 km away from the transmitter.

Configurator, the LD291 firmware allows the following configuration features to

Manufacturing Data and Identification

The following information about the LD291 manufacturing and identification data is available:

TAG - 8 character alphanumeric field for identification of the transmitter;

DESCRIPTOR

- 16 character alphanumeric field for additional identification of the transmitter. May be

used to identify service or location;

DATE - The date may be used to identify a relevant date as the last calibration, the next calibration or

the installation. The date is presented in the form of bytes where DD = [1,..31], MM = [1..12], AA =

[0,..255], where the effective year is calculated by [Year = 1900 + AA];

MESSAGE - 32 character alphanumeric field for any other info rmati on, s uch a s: the name of the person

who made the last calibration, some special care to be taken, or if a ladder is needed for accessing;

INTEGRAL METER – Installed, Inert, Special, Unknown and None;

SENSOR FLUID* - Silicone, Inert, Special, Unknown and None;

SENSOR ISOLATING DIAPHRAGM* - 316 SST, Hastelloy C, Monel, Tantalum and Special;

SENSOR TYPE* - It shows the sensor type;

SENSOR RANGE* - It shows the sensor range in engineering units chosen by use r. See Configuration

Unit.

Items marked with asterisk cannot be changed. They are read directly from the sensor memory.

Primary Variable Trim - Pressure

Pressure, defined as a Primary Variable, is determined from the sensor readout by means of a

conversion method. This method uses parameters obtained during the fabrication process. They

depend on the electric and mechanical characteristics of the sensor, and on t he te mpera ture chan ge to

which the sensor is submitted. These parameters are recorded in the sensor's EEPROM memory.

When the sensor is connected to the transmitter, such information is made available to the transmitter's

microprocessor, which sets a relationship between the sensor signal and the measured pressure.

Sometimes, the pressure show n on the transmitter's display is different from the appl ied p ressu re. T his

may be due to several reasons, among which the following can be mentioned:

Configuration

NOTE

3.3

LD291- Operation and Maintenance, Instruction manual

Some users prefer to use this feature for zero elevation or suppression when the measurement

For better accuracy, the trim adjustment should be made in the lower and upper values of the

certify that you are working with a pressure standard with accuracy 0.03% or better, otherwise the

The transmitter mounting position;

The user's pressure standard differs from the factory standard;

Sensor's original characteristics shifted by overpressure, over temperature or by long-term drift.

refers to a certain point of the tank or tap (wet tap). Such practice, however, is not recommended

when frequent laboratory calibrations are required, because the equipment adjustment refers to a

relative measurement, and not to an absolute one, as per a specific pressure standard.

The Pressure Trim, as described on this document, is the method used in order to adjust the

measurement as related to the applied pressure, as per the user's pressure standard. The most

common discrepancy found in transmitters is usually due to Zero displacement. This may be c orrected

by means of the Zero Trim or the Lower Trim.

There are four types of pressure trim available:

LOWER TRIM: Is used to trim the reading at the lower range. The user informs to the transmitter

the correct reading for the applied pressure via HART configurator.

Check on section 1, the note on the influence of the mounting position on the indicator.

NOTE

NOTE

operation range values.

UPPER TRIM: Is used to trim the reading at the upper range. The user informs the transmitter the

correct reading for the applied pressure via HART

The upper pressure trim shall always be done after the zero trim.

ZERO TRIM: is similar to the LOWER TRIM , but is assumed that the applied pressure is zero. T he

reading equal to zero must be active when the pressures of differential transmitter cameras are

equalized or when a manometric transmitter opened to atmosphere or when the absolute

transmitter is applied to the vacuum. Therefore, the user does not need to enter with any value.

CHARACTERIZATION: this is used to correct an eventual non-linearity intrinsic to the conversion

process. Characterization is done by means of a linearization table, with up to five points. The user

shall apply pressure and use the HART

point of the table. In most cases, characterization is not required, due to the efficiency of the

fabrication procedure. The transmitter will display "CHAR", thus indicating that the characterization

process is activated. The LD291 has a parameter to enable or disable the use of the

Characterization Table.

The characterization trim changes the transmitter characteristics. Read the instructions carefully and

transmitter accuracy will be seriously affected.

Primary Variable Current Trim

When the microprocessor generates a 0 % signal, the Digital to Analog converter and associated

electronics are supposed to deliver a 4 mA output. If the signal is 100 %, the output should be 20 mA.

There might be differences between the Smar current standards and your plant current Standard. In

this case, the Current Trim adjustment shall be used, with a precision Ammeter as measurement

reference. Two Current Tri m types are available:

configurator.

ATTENTION

configurators to inform the pressure value applied to each

WARNING

3.4

4 mA TRIM: this is used to adjust the output current value corresponding to 0 % of the

The transmitter presents a resolution that makes it possible to control currents as low as

measurement;

20 mA TRIM: this is used to adjust the output current value corresponding to 100 % of the

measurement.

The Current Trim shall be carried out as per the following procedure:

Connect the transmitter to the precision Ammeter;

Select one of the Trim types;

W ait a moment for the current to stabilize and inform the transmitter the current readout of the

precision Ammeter.

NOTE

microamperes. Therefore, when informing the current readout to the transmitter, it is recommended

that data input consider values up to tenth of microamperes.

Transmitter Adjustment to the Working Range

This function directly affects the transmitter's 4-20 mA output. It is used to define the transmitter's

working range; in this document it is referred to as the transmitter' s calibration. The LD291 transmitter

includes two calibration features:

CALIBRATION WITH REFERENCE: this is used to adjust the transmitter's working range, using a

pressure standard as a reference.

CALIBRATION WITHOUT REFERENCE: this is used to adjust the transmitter's working range,

simply by having limit values informed by the user.

Both calibration methods define the Working Range Upper and Lower values, in reference to some

applied pressure or simply informed by entered values. CALIBRATION WITH REFERENCE differs

from the Pressure Trim, since CALIBRATION WITH REFERENCE establishes a relationship between

the applied pressure and the 4 to 20 mA signal, and the Pressure Trim is used to correct the

measurement value.

In the transmitter mode, the Lower Value always corresponds to 4 mA and the Upper Value to 20 mA.

In the controller mode, the Lower Value corresponds to PV = 0 % and the Upper Value to PV = 100 %.

The calibration process calculates the LOWER and the UPPER values in a completely independent

way. The adjustment of value does not affect the other. The following rules shall, however, be

observed:

The Lower and Upper values shall be within the range limited by the Minimum and maximum

Ranges supported by the transmitter. As a tolerance, values exceeding such limits by up to 24 %

are accepted, although with some accuracy degradation.

The Working Range Span, determined by modulus of the difference between the Upper and Lower

Values, shall be greater than the minimum span, defined by [Transmitter Range / 120]. Values up

to 0.75 of the minimum span are acceptable with slight accuracy degradation.

NOTE

If the transmitter is operating with a very small span, it will be extremely sensitive to pressure

variations. Keep in mind that the gain will be very high and any pressure change, no matter how

small, will be amplified.

If it is necessary to perform a reverse calibration, that is, to w ork with an UP PER VALUE smaller than

the LOWER VALUE, proceed as follows:

Place the Lower Limit in a value as far from the present Upper Value and from the new adjusted

Upper value as possible, observing the minimum span allowed. Adjust the Upper Value at the

desired point and, then, adjust the Lower Value.

This type of calibration is intended to prevent the calibration from reaching, at any moment, values not

compatible with the range. For example: lower value equals to upper value or separated by a value

smaller than the minimum span.

Configuration

3.5

LD291- Operation and Maintenance, Instruction manual

Unit feature for such conversion.

This calibration procedure is also recommended for zero suppr ession or elevation in those cases where

the instrument installation results in a residual measurement in relation to a certain reference. This is

the specific case of the wetted tap.

In most applications with wetted taps, indication is usually expres sed as a percentage. Should

readout in engineering units with zero suppression be required, it is recommended to use the User

Engineering Unit Selection

Transmitter LD291 includes a selection of engineering units to be used in measurement indication.

For pressure measurements, the LD291 includes an option list with the most common units. The

internal reference unit is inH2O @ 20 oC; should the desired unit be other than this one, it will be

automatically converted using conversion factors included in Table 3.1.

As the LD291 uses a 4 ½ digit display, the largest indication will be 19999. Therefore, when selecting a

unit, make sure that it will not require readouts greater than this limit. For User reference, Table 3.1

presents a list of recommended sensor ranges for each available unit.

CONVERSION FACTOR NEW UNITS RECOMMEND RANGE

1.00000 Inches H2O at 20 oC 1, 2,3 & 4

0.0734241 Inches Hg at 0 oC all

0.0833333 Feet H2O at 20 oC all

25.4000 Millimeters H2O at 20 oC 1 & 2

1.86497 Millimeters Hg at 0 oC 1, 2, 3 & 4

0.0360625 Pound/square inch - psi 2, 3, 4, 5 & 6

0.00248642 Bar 3, 4, 5 & 6

2.48642 Millibar 1, 2, 3 & 4

2.53545 Gram/square centimeter 1, 2, 3 & 4

0.00253545 kilogram/square centimeter 3, 4, 5 & 6

248.642 Pascal 1

0.248642 KiloPascal 1, 2, 3 & 4

1.86497 Torr at 0 oC 1, 2, 3 & 4

0.00245391 Atmosphere 3, 4, 5 & 6

0.000248642 MegaPascal 4, 5 & 6

0.998205 Inches of water at 4 oC 1, 2, 3 & 4

25.3545 Millimeters of water at 4 oC 1 & 2

In applications where the LD291 will be used to measure variables other than pressure or in the cases

where a relative adjustment has been selected, the new unit may be display ed by means of the User

Unit feature. This is the case of measurements such as level, volume, and flow rate or mass flow

obtained indirectly from pressure measurements.

The User Unit is calculated taking the working range limits as a reference, which is, defining a value

corresponding to 0% and another corresponding to 100% of the measurement:

0% - Desired readout when the pressure is equal to the Lower Value (PV% = 0%, or transmitter

mode output equal to 4 mA).

100% - Desired readout when the pressure is equal to the Upper Value (PV% = 100%, or

transmitter mode output equal to 20 mA).

The user unit may be selected from a list of options included in the LD291. Table 3.2 makes it possible

to associate the new measurement to the new unit so that all supervisory systems fitted with HART

protocol can access the special unit included in this table. The user will be responsible for the

consistency of such information. The LD291 cannot verify if the values corresponding to 0 % and 100%

included by the user are compatible with the selected unit.

NOTE

Table 3.1 - Available Pressure Units

3.6

VARIABLE

UNITS

Pressure

inH2O, InHg, ftH2O, mmH2O, mmHg, psi, bar ,mbar, g/cm2, kg/cm2 , Pa,

kPa, Torr, atm, MPa, in H2O4, mmH2O4

3

Gal/h, Gal/d, ft3/h, m3/min, bbl/s, bbl/min, bbl/h, bbl/d, gal/h, Gal/s, I/h, gal/d

Velocity

ft/s, m/s, m/h

Volume

gal, liter, Gal, m3, bbl, bush, Yd3, ft3, In3, hl

Level

ft, m, in, cm, mm

Mass

gram, kg, Ton, lb, Sh ton, Lton

g/s, g/min, g/h, kg/s, kg/min, kg/h, kg/d, Ton/min, Ton/h, Ton/d, lb/s, lb/min,

lb/h, lb/d

SGU, g/m3, kg/m3, g/ml, kg/l, g/l, Twad, Brix, Baum H, Baum L, API, %

Solw, % Solv, Ball

Others

cSo, cPo, mA, %

special

5 characters

POINT

LEVEL (PRESSURE)

X

VOLUME

Y

1 - -10%

-

-0.62%

2

250 mmH2O

0%

0 m3

0%

3

450 mmH2O

10%

0.98 m3

5.22%

4

750 mmH2O

25%

2.90 m3

15.38%

5

957.2 mmH2O

35.36%

4.71 m3

25%

6

1050 mmH2O

40%

7.04 m3

37.36%

7

1150 mmH2O

45%

8.23 m3

43.65%

8

1250 mmH2O

50%

9.42 m3

50%

… … … … …

15

2250 mmH2O

100%

18.85 m3

100%

16 - 110%

-

106%

Volumetric Flow

Mass Flow

Density

Configuration

/min, gal/min, I/min, Gal/min, m3/h, gal/s, l/s, MI/d, ft3/s, ft3/d, m3/s, m3/d,

ft

Table Points

Table 3.2 – Available User Units

Should a special unit other than those presented on Table 3.2 be required, the LD291 allows the user

to create a new unit by entering up to 5 alphanumeric digits.

The LD291 includes an internal feature to enable and disable the User Unit.

Example: transmitter LD291 is connected to a horizontal cylindrical tank (6 meters long and 2 meters

in diameter), linearized for volume measurement using camber table data in its linearization table.

Measurement is done at the high-pressure tap and the transmitter is located 250 mm below the support

base. The fluid to be measured is water at 20 °C. Tank volume is: [(π.d

2

)/4].l = [(π.22)/4]π.6 = 18,85 m3.

The wet tap shall be subtracted from the measured pressure in order to obtain the tank level.

Therefore, a calibration without reference shall be carried out, as follows:

In Calibration:

Lower = 250 mmH

Superior = 2250 mmH

Pressure unit = mmH

O

2

O

2

O

2

In User Unit:

User Unit 0% = 0

User Unit 100% = 18.85 m³

User Unit = m³

When activating the User's Unit, LD291 it will start to indicate the new measurement.

If the option TABLE is selected, the output will follow a curve given in the option TABLE P OINTS . If you

want to have your 4-20 mA proportional to the volume or mass of fluid inside a tank, you must

transform the pressure measurement "X" into volume (or mass) "Y" using the tank strapping table, as

shown in Table 3.3.

As shown on the previous ex ample, the points may be freely distributed for any desired value of X . In

order to achieve a better linearization, the distribution should be concentrated in the less l inear part s of

the measurement.

Table 3.3 - Tank Strapping Table

3.7

LD291- Operation and Maintenance, Instruction manual

The LD291 includes an internal feature to enable and disable the Linearization Table.

Equipment Configuration

The LD291 enables the configuration of not only its operational services, but of instrument itself. This

group includes services related to: Input Filter, Burn Out, Addressing, Display Indication and

Passwords.

INPUT FILTER - The Input Filter, also referenced to as Damping, is a first class digital filter

implemented by the firmware, where the time constant may be adjusted between 0 and 128

seconds. The transmitter's mechanical damping is 0.2 seconds.

BURN OUT - The output current may be programmed to go to the maximum limit of 21 mA (Full

Scale) or to the minimum limit of 3.6 mA in case of transmitter failure. Configuring the BURNOUT

parameter for Upper or Lower may do this.

ADDRESSING - The LD291 includes a variable parameter to define the equipment address in a

DISPLAY INDICATION - the LD291 digital display is comprised of three distinct fields: an

HART

network. Addresses may go from value "0" to "15"; addresses from "1" to "15" are specific

addresses for multidrop connections. This means that, in a multidrop configuration, the LD291 will

display the message MDROP for addresses "1" to "15".

The LD291 is factory configured with address "0".

information field with icons indicating the active configuration stat us, a 4 ½ digit numeric field for

values indication and a 5 digit alphanumeric field for units and status information.

The LD291 may work with up to two display configurations to be alternately display ed at 2 second

intervals. Parameters that may be selected for visualization are those listed on Table 3.4, below.

WRITING PROTECTION - This feature is used to protect the transmitter configuration from

changes via communication. All configuration data are writing protected.

The LD291 include two write protection mechanisms: software and hardware locking; software

locking has higher priority.

When the LD291 writing software protection mechanism is enabl ed, it is possible, by means of

specific commands, to enable or disable the write protection.

PASSWORDS - this service enables the user to modify the operation passwords used in the

LD291. Each password defines the access for a priority level (1 to 3); such configuration is stored

in the LD291 EEPROM.

Password Level 3 is hierarchically upper to password level 2, which is upper to level 1.

Equipment Maintenance

Here are grouped maintenance services related with the collection of information required for

equipment maintenance. The following services are available: Order Code, Serial Number, O peration

Counter and Backup/Restore.

ORDER CODE - THE Order Code is the one used for purchasing the equipment, in accordance

with the User specification. There are 13 characters available in the LD291 to define this code.

CURRENT

CURRENT IN MILIAMPÈRES

CO Analog Output Current in mA

PR Pressre in pressure unit.

PV% Process Variable in percentage.

PV Process Variable in engineering units.

TE Ambient temperature.

NONE - No variable on display (only LCD_2)

ESC Escape.

Table 3.4 - Variables for Display Indication

3.8

11 12

EXAMPLE:

Configuration

1 2 3 4 5 6 7 8 9 10

13

L D 2 9 1 M 2 1I 1 1 0 1 H1

LD291 Intelligent Pressure Transmitter (D); Range: 1.25 to 50 kPa (2); Diaphragm of 316L SS,

Silicone Oil Fill Fluid (1), and Connection to the process with 316L SS (1I); with Digital Indicator (1);

Electrical Connection 1/2 - 14 NPT (0); with Local Adjustment (1); with Carbon Steel Bracket and

accessories (1); housing in SS (HI).

SERIAL NUMBER - Three serial numbers are stored:

Circuit Number - This number is unique to every main circuit board and cannot be changed.

Sensor Number - The serial number of the sensor connected to the LD291 and cannot be

changed. This number is read from the sensor every time a new sensor is inserted in the main

board.

Transmitter Number - the number that is written at the identification plate each transmitter.

NOTE

The transmitter number must be changed whenever there is the main plate change to avoid

communication problems.

OP_COUNT - Every time a change is made, there is an increment in the respective change

counter for each monitored variable, according to the following list. The counter is cyclic, from 0 to

255. The monitored items are:

LRV/URV: when any type of calibration is done;

Function: when any change in the transference function is done, e.g., linear, square root,

const, table;

Trim_4mA: when the current tri m i s done at 4 mA;

Trim_20mA: when the current tri m i s done at 20 mA;

Trim_Zero/Lower: when pressure trim is done at Zero or Lower Pressure;

Trim Upper Pressure: when the trim is done at Upper Pressure;

Characterization: when any change is made in any point of the pressure ch aracterization table

in trim mode;

Multidrop: when any change is made in the communication mode, for example, multidrop or

single transmitter;

Pswd/C-Level: when any change is made in the password or the level configuration.

BACKUP

When the main board is replaced, after assembling and powering it, the data saved in the sensor

memory are automatically copied to the main board memory.

RESTORE

This option allows copying or restoring the data saved in the sensor memory to the main board

memory.

3.9

LD291- Operation and Maintenance, Instruction manual

3.10

Section 4

COMPLETE

ADJUSTMENT

S - ACTION / SPAN

Z - MOVE AROUND / ZERO

The Magnetic Tool

PROGRAMMING USING LOCAL

ADJUSTMENT

Smar's magnetic tool is the second man machine interface. It comprises the advantage of the po werf ul

HHT and the convenience of the magnetic tool.

If the transmitter is fitted with a display, and configured for Complete Local Adjustment (using the

internal jumper), the magnetic tool is almost as powerful as the HHT. It eliminates the need for an H HT

in most basic applications.

If the transmitter is not fitted with a display, or is configured for Simple Local Adjustment (using the

internal jumper) the adjustment capability is reduced to ranging.

To select the function mode of the magnetic switches configures the jumpers located at the top of the

main circuit board as indicated in Table 4.1.

SI/COM OFF/ON NOTE WRITE PROTECT

SIMPLE LOCAL

ADJUSTMENT

LOCAL

Notes: 1 - If t he har dware protection is selected, the EEPROM will be protect ed.

2 - The local adjustment default condition is simple enabled and write protect disabled.

The transmitter has, under the identification plate, holes for two magnetic switches activated by the

magnetic tool (See Figure 4.1).

Disables Disables Disables

1 Enables

2

Disables Disables Enables

Table 4.1 – Local adjustment Selection

Disables

Disables Disables

Enables

Disables

Figure 4.1 – Local Zero and Span Adjustment and Local Adjustment Switches

4.1

LD291 - Operation and Maintenance Instruction Manual

Z

The holes are marked with Z (Zero) and S (Span) and from now on w ill be designated si mply by (Z) and

(S), respectively. Table 4.2 shows the action performed by the magnetic tool while inserted in (Z) and

(S) in accordance with the selected adjustment type.

Browsing the functions and their branches works as follows:

1. Inserting the handle of the magnetic tool in (Z), the transmitter passes from the normal

measurement state to the transmitter configuration state. The transmitter software automatically

starts to display the available functions in a cyclic routine.

2. In order to reach the desired option, browse the options, wait until they are disp layed and move the

magnetic tool from (Z) to (S). Refer to Figure 4.2 – Programming Tree Using Local Adjustment, in

order to know the position of the desired option. By placing the magnetic too l onc e aga in in (Z), it is

possible to browse for other options within this new branch.

3. The procedure to reach the desired option is similar to the one described on the previous item, for

the whole hierarchical level of the programming tree.

Action Simple Local Adjustment Complete Local Adjustment

S

For LD291 versions prior to a V6.00, the digital display shall be number 214-0108 as per spare

parts list for LD291 V6.XX.

For LD291 versions V6.XX, the digital display shall be number 400-0559, as per the updated

spare parts list

Simple Local Adjustment

The LD291 allows only the calibration of the values inferior and superior in this configuration.

Zero and Span Reranging

The LD291 can be very easily calibrated. It requires only Zero and Span adjustment in accordance with

the working range.

The jumpers shall be configured for simple local adjustment. In case the LD291 display is not

connected, the simple local adjustment is automatically activated.

Zero calibration with reference shall be done as follows:

Apply the Lower Value pressure.

Wait for the pressure to stabilize.

Insert the magnetic tool in the ZERO adjustment hole. (See Figure 4.1)

Wait about 2 seconds. The transmitter should be reading 4 mA.

Remove the tool.

Zero calibration with reference does not affect the span. In order to change the span, the following

procedure shall be observed:

Apply the Upper Value pressure.

Wait for the pressure to stabilize.

Insert the magnetic tool in the SPAN adjustment hole.

Wait 2 seconds. The transmitter should be reading 20 mA.

Remove the tool.

Zero adjustment causes zero elevation / suppression and a new upper value (URV) is calculated in

accordance with the effective span. In case the resulting URV is higher than the Upper Limit Value

(URL), the URV will be limited to the URL value, and the span will be automatically affected.

Selects the Lower Range Value Moves among all the options

Selects the Upper Range Value Activates the selected Functions

Table 4.2 - Local Adjustment Description

NOTE

4.2

Complete Local Adjustment

op to manual. And do not forget to return to auto after

Z

S

Z

NORMAL

DISPLAY

ACTION

S

Z

MOVE

AROUND

Z

ESC

ESCAPE

The transmitter must be fitted with the digital display for this function to be enabled. The following

functions are available for local adjustment: Constant Current, Table Points Adjustment, User Units,

and Fail-safe, Current Trim and Pressure, Address change and some items of function INFORMATION.

When programming using local adjustment, the transmitter wil l not pro mpt, "Control loop should be

in manual!" as it does when programming using the HART

before configuration, to switch the lo

configuration is completed.

Local Programming Tree

The local adjustment uses a tree structure where, by placing the magnetic tool in (Z) it is possible to

browse the options of a branch and by placing it in (S); details of the chosen option are shown. Figure

4.2 shows the LD291 available options.

WARNING

Programming Using Local adjustment

configurator. Therefore it is a good idea,

CONFIGURATION (CONF) - Is the option where the output and display related parameters are

configured: unit, primary and secondary display, calibration, and function.

TRIM (TRIM) – It is the option used to calibrate the "w ithout reference" characterization and the digital

reading.

ESCAPE (ESC) – It is the option used to go back to normal monitoring mode.

The local adjustment is actived by actuation in (Z).

Configuration [CONF]

Configuration functions affect directly the 4-20 mA output current and the display indication. The

configuration options implemented in this branch are the following:

Selection of the variable to be shown on Display 1 and / or Display 2;

Working range calibration of work. Options With and Without Reference are available;

Digital filter damping time configuration of the readout signal input.

Selection of the transference function to be applied to the measured variable.

Figure 4.2 – Local Adjustment Programming Tree – Main Menu

4.3

LD291 - Operation and Maintenance Instruction Manual

Figure 4.3 shows branch CONF with the available options.

Configuration Branch (CONF)

Display 1 (LCD_1)

Display 2 (LCD_2)

The procedure for selection is the same as for LCD_1, previous.

4.4

Figure 4.3 - Local Adjustment Configuration Tree

Z: Moves to the TRIM branch.

S: Enters the CONFIGURATION branch, starting with function display (LCD_1).

Z: Moves to the function Display 2 (LCD_2).

S: Starts selection of variable to be indicated as primary display.

After activating (S), you can move around the options available in t he following

table by activating (Z). See table 4.3.

The desired variable is activated using (S). Escape leaves primary variable

unchanged.

Z: Moves to the RANGE function.