IF303

VERSION 3

I F303ME

smar

Specifications and information are subject to change without notice.

Up-to-date address information is available on our website.

web: www.smar.com/contactus.asp

www.smar.com

Kpvtqfwevkqp"

"

INTRODUCTION

The IF303 is a converter mainly intended to interface analog transmitters to a Profibus PA network.

The IF303 receives up to three current signal typically 4-20 mA or 0-20 mA, and makes them

available to Profibus PA system. The digital technology used in the IF303 enables an easy interface

between the field and the control room and it has several interesting features that reduce

considerably the installation, operation and maintenance costs.

The IF303 is part of SMAR's complete 303 line of Profibus PA devices.

Profibus PA, is not only a replacement for 4-20 mA or intelligent/smart transmitter protocols, it

contains much more.

The digital technology used in the IF303 enables the choice of several types of transfer functions, an

easy interface between the field and the control room and several interesting features that

considerably reduce the installation, operation and maintenance costs.

Some of the advantages of bi-directional digital communications are known from existing smart

transmitter protocols: Higher accuracy, multi-variable access, remote configuration and diagnostics,

and multi-dropping of several devices on a single pair of wires.

The system controls variable sampling, algorithm execution and communication so as to optimize

the usage of the network, not loosing time. Thus, high closed loop performance is achieved.

Using Profibus technology, with its capability to interconnect several devices, very large control

schemes can be constructed. In order too be user friendly the function block concept was introduced

The IF303, like the rest of the 303 family, has some Function Blocks built in, like Analog Input and

Totalizer Blocks.

The need for implementation of Fieldbus in small as well as large systems was considered when

developing the entire 303 line of Profibus-PA devices. They have common features and can be

configured locally using a magnetic tool, eliminating the need for a configuration tool or console in

many basic applications.

Get the best result of the IF303 by carefully reading these instructions.

NOTE

In case of using Simatic PDM as the configuration and parameterization tool, Smar

recommends that the user does not apply the option "Download to Device". This function

can improperly configure the field device. Smar recommends that user make the use of

the option "Download to PG / PC" and then selecting the Device Menu, use the menus of

the transducer, function and display blocks acting specifically, according to each menu

and method for reading and writing.

This product is protected by US patent number 5,706,007.

KKK"

KH525"/"Qrgtcvkqp"cpf"Ockpvgpcpeg"Kpuvtwevkqp"Ocpwcn"

t

r

c

r

y

This Manual is compatible with version 3.XX, where 3 denotes software version and XX software release. The

indication 3.XX means that this manual is compatible with any release of software version 3.

Waiver of responsibility

The contents of this manual abides by the hardware and software used on the current equipmen

version. Eventually there may occur divergencies between this manual and the equipment. The

information from this document are periodically reviewed and the necessary or identified corrections

will be included in the following editions. Suggestions for their improvement are welcome.

Warning

For more objectivity and clarity, this manual does not contain all the detailed information on the

product and, in addition, it does not cover every possible mounting, operation or maintenance

cases.

Before installing and utilizing the equipment, check if the model of the acquired equipment complies

with the technical requirements for the application. This checking is the user’s responsibility.

If the user needs more information, or on the event of specific problems not specified or treated in

this manual, the information should be sought from Smar. Furthermore, the user recognizes that the

contents of this manual by no means modify past or present agreements, confirmation or judicial

relationship, in whole or in part.

All of Smar’s obligation result from the purchasing agreement signed between the parties, which

includes the complete and sole valid warranty term. Contractual clauses related to the warranty are

not limited nor extended by virtue of the technical information contained in this manual.

Only qualified personnel are allowed to participate in the activities of mounting, electrical connection,

startup and maintenance of the equipment. Qualified personnel are understood to be the persons

familiar with the mounting, electrical connection, startup and operation of the equipment or othe

similar apparatus that are technically fit for their work. Smar provides specific training to instruct and

qualify such professionals. However, each country must comply with the local safety procedures,

legal provisions and regulations for the mounting and operation of electrical installations, as well as

with the laws and regulations on classified areas, such as intrinsic safety, explosion proof, increased

safety and instrumented safety systems, among others.

The user is responsible for the incorrect or inadequate handling of equipments run with pneumati

or hydraulic pressure or, still, subject to corrosive, aggressive or combustible products, since thei

utilization may cause severe bodily harm and/or material damages.

The field equipment referred to in this manual, when acquired for classified or hazardous areas, has

its certification void when having its parts replaced or interchanged without functional and approval

tests by Smar or any of Smar authorized dealers, which are the competent companies for certifying

that the equipment in its entirety meets the applicable standards and regulations. The same is true

when converting the equipment of a communication protocol to another. In this case, it is necessar

sending the equipment to Smar or any of its authorized dealer. Moreover, the certificates are

different and the user is responsible for their correct use.

Always respect the instructions provided in the Manual. Smar is not responsible for any losses

and/or damages resulting from the inadequate use of its equipments. It is the user’s responsibility to

know and apply the safety practices in his country.

NOTE

KX"

Vcdng"qh"Eqpvgpvu"

TABLE OF CONTENTS

UGEVKQP"3"/"KPUVCNNCVKQP"000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000"303"

GENERAL ..................................................................................................................................................................................... 1.1

MOUNTING .................................................................................................................................................................................. 1.1

ELECTRIC WIRING ...................................................................................................................................................................... 1.1

TOPOLOGY AND NETWORK CONFIGURATION ....................................................................................................................... 1.3

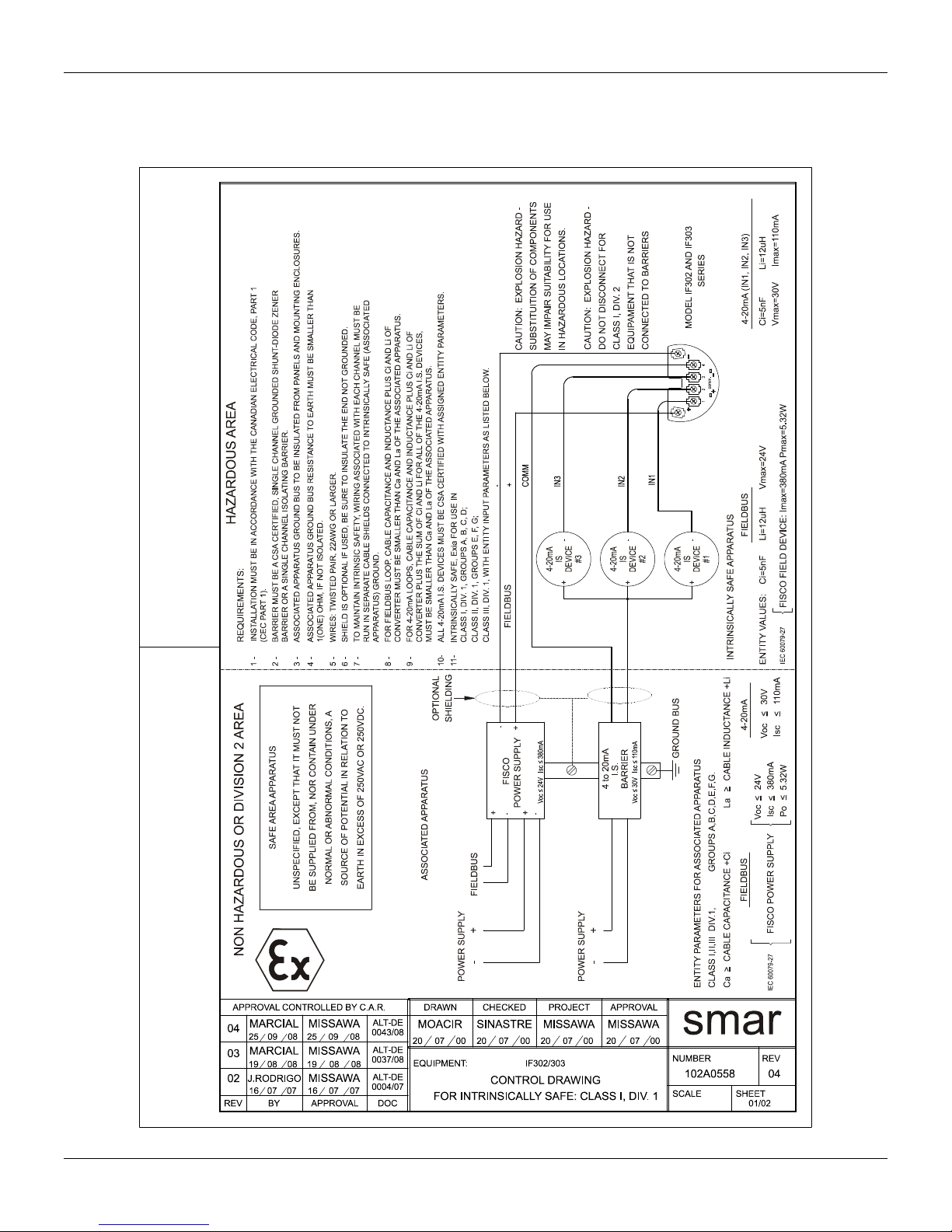

INTRINSIC SAFETY BARRIER .................................................................................................................................................... 1.4

JUMPER CONFIGURATION ........................................................................................................................................................ 1.5

POWER SUPPLY ......................................................................................................................................................................... 1.5

INPUT WIRING ............................................................................................................................................................................. 1.5

INSTALLATION IN HAZARDOUS AREAS ................................................................................................................................... 1.7

EXPLOSION/FLAME PROOF ....................................................................................................................................................... 1.7

INTRINSICALLY SAFE ................................................................................................................................................................. 1.7

UGEVKQP"4"/"QRGTCVKQP"0000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000"403"

FUNCTIONAL DESCRIPTION – ELECTRONICS .......................................................................................................................... 2.1

UGEVKQP"5"/"EQPHKIWTCVKQP"00000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000"503"

TRANSDUCER BLOCK .................................................................................................................................................................. 3.1

HOW TO CONFIGURE A TRANSDUCER BLOCK......................................................................................................................... 3.1

TERMINAL NUMBER ..................................................................................................................................................................... 3.1

FUNCTIONAL DIAGRAM OF THE CURRENT TO PROFIBUS PA TRANSDUCER BLOCK ......................................................... 3.2

CURRENT TO PROFIBUS PA TRANSDUCER BLOCK GENERAL PARAMETER DESCRIPTION .............................................. 3.2

TRANSDUCER BLOCK PARAMETER ATTRIBUTES .................................................................................................................... 3.4

IF303 - CYCLIC CONFIGURATION................................................................................................................................................ 3.5

HOW TO CONFIGURE THE ANALOG INPUT BLOCK .................................................................................................................. 3.9

HOW TO CONFIGURE THE TOTALIZER BLOCK ....................................................................................................................... 3.12

CURRENT TRIM ........................................................................................................................................................................... 3.16

VIA LOCAL ADJUSTMENT .......................................................................................................................................................... 3.19

TRANSDUCER DISPLAY – CONFIGURATION ........................................................................................................................... 3.20

DISPLAY TRANSDUCER BLOCK ................................................................................................................................................ 3.21

DEFINITION OF PARAMETERS AND VALUES .......................................................................................................................... 3.21

PROGRAMMING USING LOCAL ADJUSTMENT ........................................................................................................................ 3.26

QUICK GUIDE – LOCAL ADJUSTMENT TREE ........................................................................................................................... 3.28

J1 JUMPER CONNECTIONS ....................................................................................................................................................... 3.29

W1 JUMPER CONNECTIONS ..................................................................................................................................................... 3.29

CYCLICAL DIAGNOSIS ................................................................................................................................................................ 3.31

UGEVKQP"6"/"OCKPVGPCPEG"RTQEGFWTGU0000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000"603"

GENERAL ..................................................................................................................................................................................... 4.1

TROUBLESHOOTING .................................................................................................................................................................. 4.1

DISASSEMBLY PROCEDURE ..................................................................................................................................................... 4.2

REASSEMBLY PROCEDURE ...................................................................................................................................................... 4.2

BOARDS INTERCHANGEABILITY .............................................................................................................................................. 4.3

EXPLODED VIEW ........................................................................................................................................................................ 4.3

ACCESSORIES AND RELATED PRODUCTS ............................................................................................................................. 4.3

SPARE PARTS LIST .................................................................................................................................................................... 4.4

UGEVKQP"7"/"VGEJPKECN"EJCTCEVGTKUVKEU"00000000000000000000000000000000000000000000000000000000000000000000000000000000000000000"70 3"

ORDERING CODE ......................................................................................................................................................................... 5.2

CRRGPFKZ"C"/"EGTVKHKECVKQPU"KPHQTOCVKQP"00000000000000000000000000000000000000000000000000000000000000000000000000000000000000"C03"

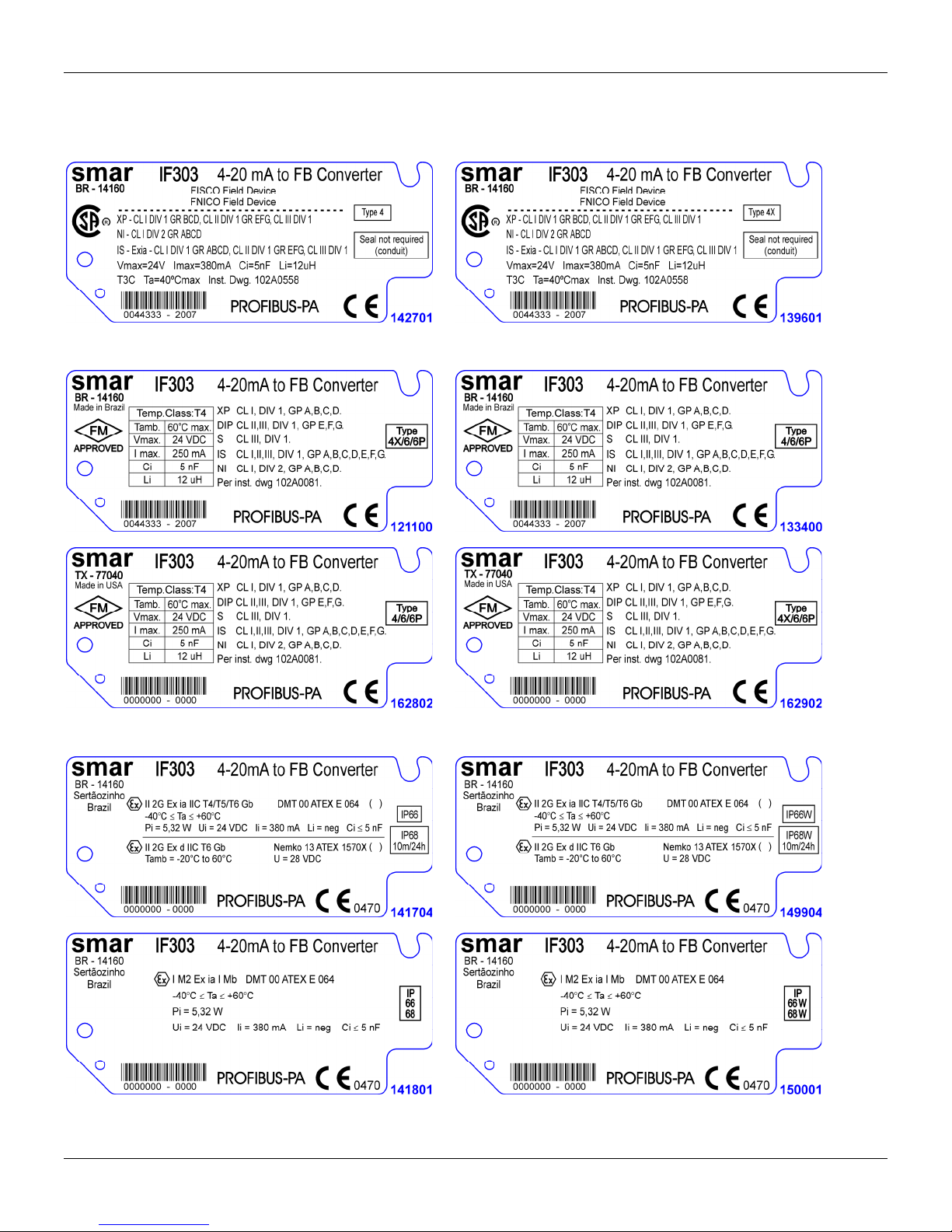

EUROPEAN DIRECTIVE INFORMATION ...................................................................................................................................... A.1

HAZARDOUS LOCATIONS GENERAL INFORMATION ................................................................................................................ A.1

HAZARDOUS LOCATIONS APPROVALS ..................................................................................................................................... A.2

IDENTIFICATION PLATE ............................................................................................................................................................... A.5

CONTROL DRAWING .................................................................................................................................................................... A.7

CSA (CANADIAN STANDARDS ASSOCIATION) ..................................................................................................................................... A.2

FM APPROVALS (FACTORY MUTUAL) ................................................................................................................................................... A.3

NEMKO (NORGES ELEKTRISKE MATERIELKONTROLL) ..................................................................................................................... A.3

EXAM (BBG PRÜF - UND ZERTIFIZIER GMBH) ..................................................................................................................................... A.3

CEPEL (CENTRO DE PESQUISA DE ENERGIA ELÉTRICA) ................................................................................................................. A.4

X"

KH525"/"Qrgtcvkqp"cpf"Ockpvgpcpeg"Kpuvtwevkqp"Ocpwcn"

CRRGPFKZ"D"⁄"UTH"⁄"UGTXKEG"TGSWGUV"HQTO"0000000000000000000000000000000000000000000000000000000000000000000000000000000000000"D03"

RETURNING MATERIALS ............................................................................................................................................................. B.2

KX"

"

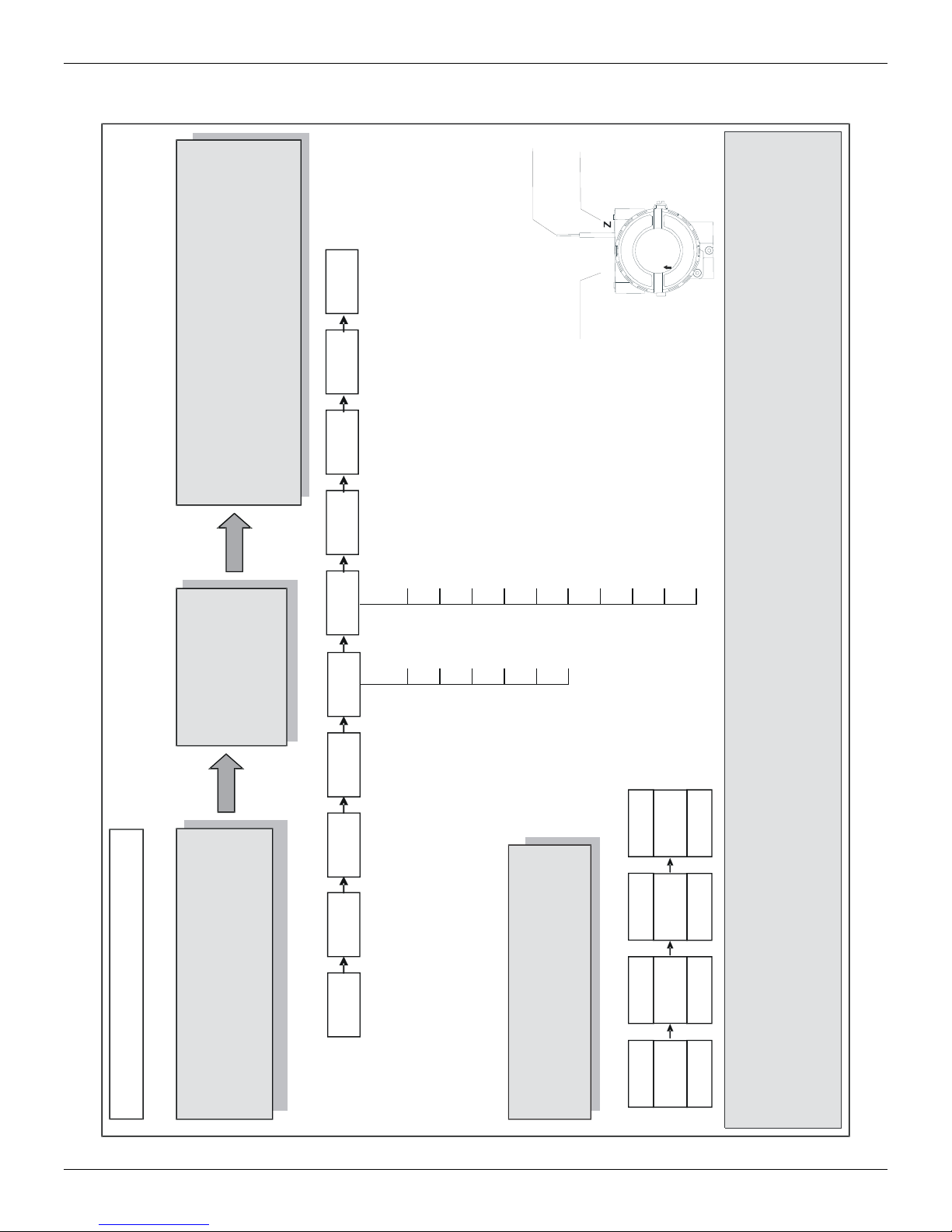

Kpuvcnncvkqp"Hnqyejctv"

Start

Kpuvcnncvkqp"Hnqyejctv"

Was the converter

configured on the bench

to match the application?

No

Configure the engineering unit.

Configure the terminal(s)

and input scale(s) .

(Section 3 - Calibration)

Configure the LCD reading.

(Section 3 - Configuration)

Simulate the value(s) in the 4 a

20 mA input and verify the

signal(s) in Fieldbus.

Yes

Install the converter on the field

following the instructions below.

Install the preferably

on wether-protected areas.

Check the area classification

Install the (mechanically

and electrically) according to the

application after checking the best

(Section 4 - Maintenance).

converter

and its practices.

converter

position for the LCD

Is the indication correct?

No

See section 4 - Maintenance

Yes

Power-up the properly.

IF303 needs a external power supply

for supply the equipment .

converter

4 - 20 mA

OK

XKK"

KH525"/"Qrgtcvkqp"cpf"Ockpvgpcpeg"Kpuvtwevkqp"Ocpwcn"

XKKK"

Section 1

General

Mounting

Electric Wiring

INSTALLATION

NOTE

The installation carried out in hazardous areas should follow the recommendations of the IEC60079-14

standard.

The overall accuracy of measurement and control depends on several variables. Although the

converter has an outstanding performance, proper installation is essential, in order to maximize its

performance.

Among all factors, which may affect converter accuracy, environmental conditions are the most

difficult to control. There are, however, ways of reducing the effects of temperature, humidity and

vibration.

Locating the converter in areas protected from extreme environmental changes can improve the

converter performance.

In warm environments, the converter should be installed to avoid as much as possible, direct

exposure to the sun. Installation close to lines and vessels subjected to high temperatures shou ld

also be avoided.

Use of sunshades or heat shields to protect the converter from external heat sources should be

considered, if necessary.

Humidity is fatal to electronic circuits. In areas subjected to high relative humidity, the O-rings for the

electronics cover must be correctly placed. Removal of the electronics cover in the fiel d should be

reduced to the minimum necessary, since each time it is removed the circuits are exposed to the

humidity. The electronic circuit is protected by a humidity proof coatin g, but frequent exposures to

humidity may affect the protection provided. It is also important to keep the covers tightened in

place. Every time they are removed, the threads are exposed to corrosion, since painting cannot

protect these parts. Code-approved sealing methods on conduit enteri ng the converter should be

employed.

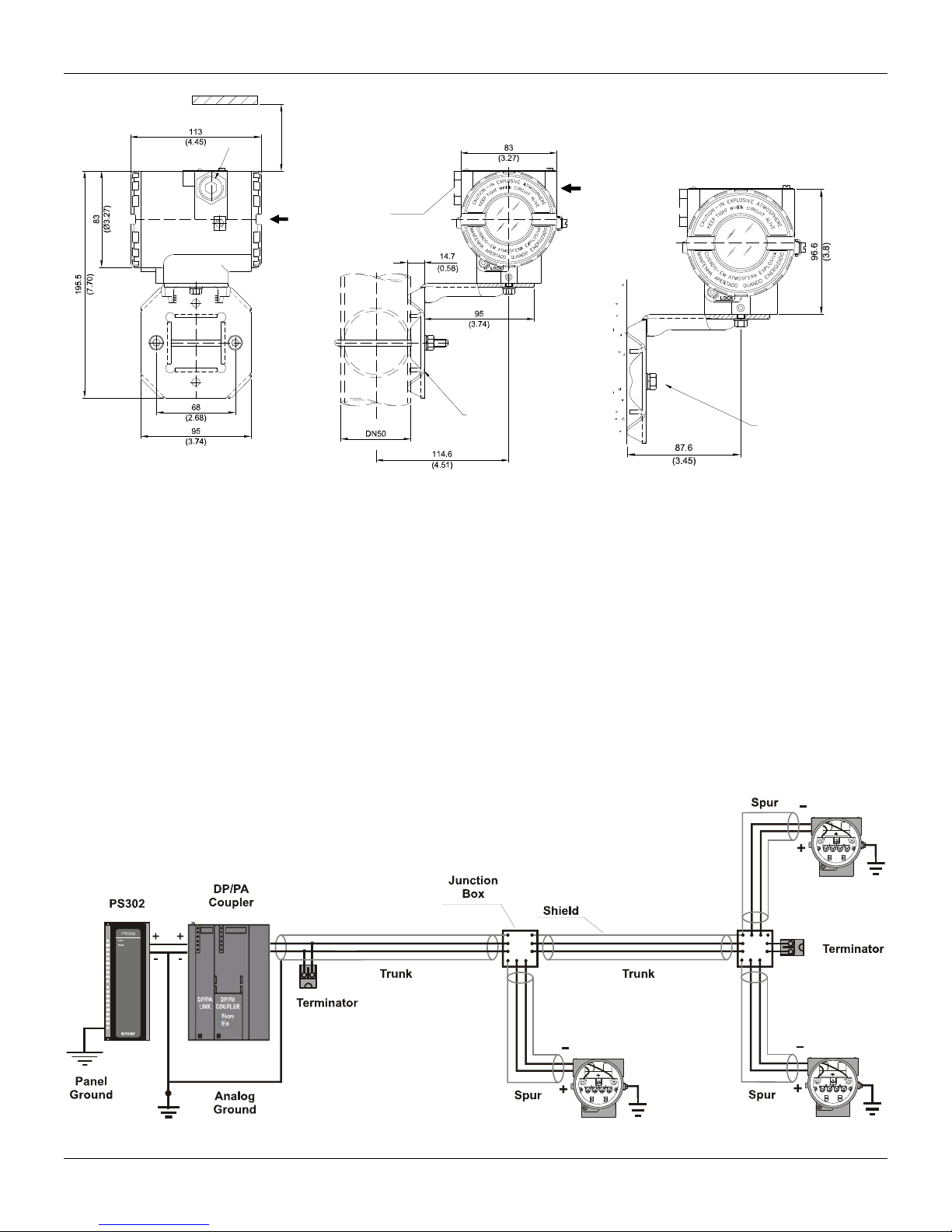

Using the bracket, the mounting may be done in several positions, as shown on Figure 1.3 Dimensional Drawing and Mounting Positions.

For better visibility, the digital indicator may be rot ated in steps of 90° (See Section 4 - Maintenance

Procedures).

Access the wiring block by removing the Electrical Connection Cover. This cover can be locked

closed by the cover locking screw (See Figure 1.1 - Cover Locking) To release the cover, rotate the

locking screw clockwise.

Cable access to wiring connections is obtained by one of the two conduit outlets. Con duit threads

should be sealed by means of code-approved sealing methods. The unused outlet connection

should be plugged accordingly.

The wiring block has screws, on which fork or ring type terminals can be fastened, see Figure 1.2 Terminal

Block.

1.1

IF303 - Operation and Maintenance Instruction Manual

A

COVER

LOCKING

SCREW

Figure 1.1 - Cover Locking

For convenience there are three ground terminals: one inside the cover and two externa ls, located

close to the conduit entries.

PROFIBUS PA

ND POWER SUPPLY

TERMINALS

GROUND

TERMINAL

INPUT

TERMINALS (3)

COMUNICATION

TERMINALS

INPUT

GROUND

TERMINAL

Figure 1.2 - Terminal Block

The IF303 uses the 31.25 kbi t/s voltage mode option for the phys ical signaling. All other devices on

the same bus must use the same signaling.

Various types of Fieldbus devices may be connected on the same bus.

The IF303 is powered via the bus. The limit for such devices is according to the DP/PA coupler

limitations for one bus (one segment) for non-intrinsically safe requirement.

In hazardous area, the number of devices ma y be limited by intrins ically safe restrictions, according

to the DP/PA coupler and barriers limitations.

The IF303 is protected against reverse polarity, and can withstand ±35 VDC without damage, but it

will not operate when in reverse polarity.

NOTE

Please refer to the General Installation, Operation and Maintenance Procedures Manual for more details.

1.2

PLUG

ALLOW 150 MM MINIMUM FOR LOCAL

ZERO AND SPAN ADJUSTMENT WITH

MAGNETIC TOOL.

COMMUNICATIONS

TERMINAL

PLUG

CONDUIT

CONNECTION

WALL OR

PANEL MOUNTING

Installation

PIPE 2"

Figure 1.3 - Dimensional Drawing and Mounting Positions

Topology and Network Configuration

Bus topology (See Figure 1.4 - Bus Topology) and tree top ology (See Figure 1.5 - Tree Topology)

are supported. Both types have a trunk cable with two terminations. The devices are c onnected to

the trunk via spurs. The spurs may be integrated in the device giving zero spur length. A spur may

connect more than one device, depending on the lengt h. Active couplers may be used to extend

spur length.

Active repeaters may be used to extend the trunk length.

The total cable length, including spurs, between any two devices in the Fieldbus sho uld not exceed

1900m.

The connection of couplers should be kept less than 15 per 250m. In folowing figures DP/PA link

depends on the application needs.

MOUNTING

BRACKET

FOR WALL MOUNTING

2 EXPANSION ANCHOR 2 HEXAGON SCREW -

FOR PANEL MOUNTING

2 BOLT AND NUTS - 1/4”X30

NOT INCLUDED

S8

3/16”X70

Figure 1.4 - Bus Topology

1.3

IF303 - Operation and Maintenance Instruction Manual

Intrinsic Safety Barrier

When the Fieldbus is in an area requiring intrinsic safety, a barrier must be inserted on the trunk

between the power supply and the DP/PA coupler, when it is Non-Ex type.

Use of DF47 is recommended.

Jumper Configuration

In order to work properly, the jumpers J1 and W1 located in the IF303 main board must be correctly

configured (See Table 1.1 - Description of the Jumpers).

J1 This jumper enables the simulation mode parameter in the AI block.

W1 This jumper enables the local adjustment programming tree.

Power Supply

The IF303 receives power from the bus via the si gnal wiring. The power supply may come from a

separate unit or from another device such as a controller or DCS.

The voltage should be between 9 to 32 Vdc for non-intrinsic safe applications.

A special requirement applies to the power supply used in an intrinsica lly safe bus and depends on

the type of barrier used.

Use of PS302 is recommended as power supply.

Figure 1.5 - Tree Topology

Table 1.1 - Description of the Jumpers

1.4

Input Wiring

CO

Installation

The IF303 accepts up to three current inp uts in the range 0-20 mA or 4-20 mA. The three inputs

have a common ground and they are protected from rever se polarity signal. The inputs should be

connected as per Figure 1.6 - Input Wiring.

4 to 20mA

1

TRANSMITTER 1

PROFIBUS PA

+

Power

Supply

-

TR = Transmitter

+

+

+

4-20mA

TR

TR

TR

2

IF303

3

4

Note that IF303 can operate with 0-20 mA or 4-20mA transmitters (See Figure 1.7 - Connection).

11

-

-

-

CHANNEL1

22

CHANNEL 2

3

CHANNEL 3

44

COMMON

Figure 1.6 - Input Wiring

TRANSMITTER 2

TRANSMITTER 3

+

0-20mA

+

0-20mA

-

0-20mA

-

4-wire 0-20mA Transmitters or

0-20mA Current Generator

POWER

SUPPLY

CHANNEL1

CHANNEL 2

3

CHANNEL 3

+

COMMON

NNECTION

Figure 1.7 - Connection

Avoid routing input wiring close to power cables or switching equipment.

WARNING

Apply in the inputs of the conversor only current levels. Don't apply tension levels,

because the shunt resistors are of 100R 1W and tension above 10 Vdc it can damage

them.

1.5

IF303 - Operation and Maintenance Instruction Manual

Installation in Hazardous Areas

Explosions could result in death or serious injury, besides financial damage. Installation of this

converter in explosive areas must be carri ed out in accordance with the local standards and the

protection type adopted .Before continuing the i nstallation make sure the certificate parameters are

In accordance with the classified area where the equipment will be installed.

The instrument modification or parts replacement suppl ied by other than authorized representativ e

of Smar is prohibited and will void the certification.

The converters are marked with options of the protection type. T he certification is valid only when

the protection type is indicated by the user. Once a particular type of protection is selected, any

other type of protection can not be used.

The electronic housing and the sensor installed in haz ardou s areas must h ave a minim um of 6 full y

engaged threads. Lock the housing using the locking screw (Figure 1.1).

The cover must be tighten with at least 8 turns to avoi d the penetration of humidity or corrosive

gases. The cover must be tighten until it touches the housing. Then, tight en more 1/3 turn (12 0) to

guarantee the sealing. Lock the covers using the locking screw (Figure 1.1).

Consult the Appendix A for further information about certification.

Explosion/Flame Proof

In Explosion-Proof installations the cable entries must be connected or c losed using metal cable

gland and metal blanking plug, both with at least IP66 and Ex-d certification.

The standard plugs provided by Smar are certifie d according to CEPEL certificate. If the plug

needs to be replaced, a certified plug must be used.

The electrical connection with NPT thread must use waterproofing sealant. A non-hardening

silicone sealant is recommended.

For NEMKO ATEX certificate please to follow the installation guide lines in hazardous locations

below: Group II Category 2G, Ex d, Group IIC, Temperature Class T6, EPL Gb U = 28VDC

Ambient Temperature: -20 to 60ºC for T6

Environmental Protection: IP66/687 or IP66W/687W

The electrical connection available are ½ - 14NPT and M20x1,5.

Cable entries must be connected or closed using metal cable gland and metal blanking plug,

both with at least IP66 and Ex-d certification or any appropriate ATEX approved metal cable

gland and metal blanking plug. Do not remove the transmitter covers when power is ON.

Intrinsically Safe

In hazardous zones with intrinsically safe or non-incendive requirements, the circuit entity

parameters and applicable installation procedures must be observed.

To protect the application the transmitter must be connected to a barrier. Match the parameters

between barrier and the equipment (Consider the cable parameters). Associated apparatus

ground bus shall be insulated from panels and mounting enclosures. Shield is optional. If used, be

sure to insulate the end not grounded. Cable capacitance and inductance plus Ci and Li must be

smaller than Co and Lo of the associated Apparatus.

It is not recommended to remove the transmitter cover when the power is ON.

WARNING

WARNING

WARNING

1.6

Section 2

OPERATION

The IF303 accepts signals from mA generators such as most conventional transmitters. It is

therefore ideal for interfacing existing equipment to a Fieldbus system.

Functional Description – Electronics

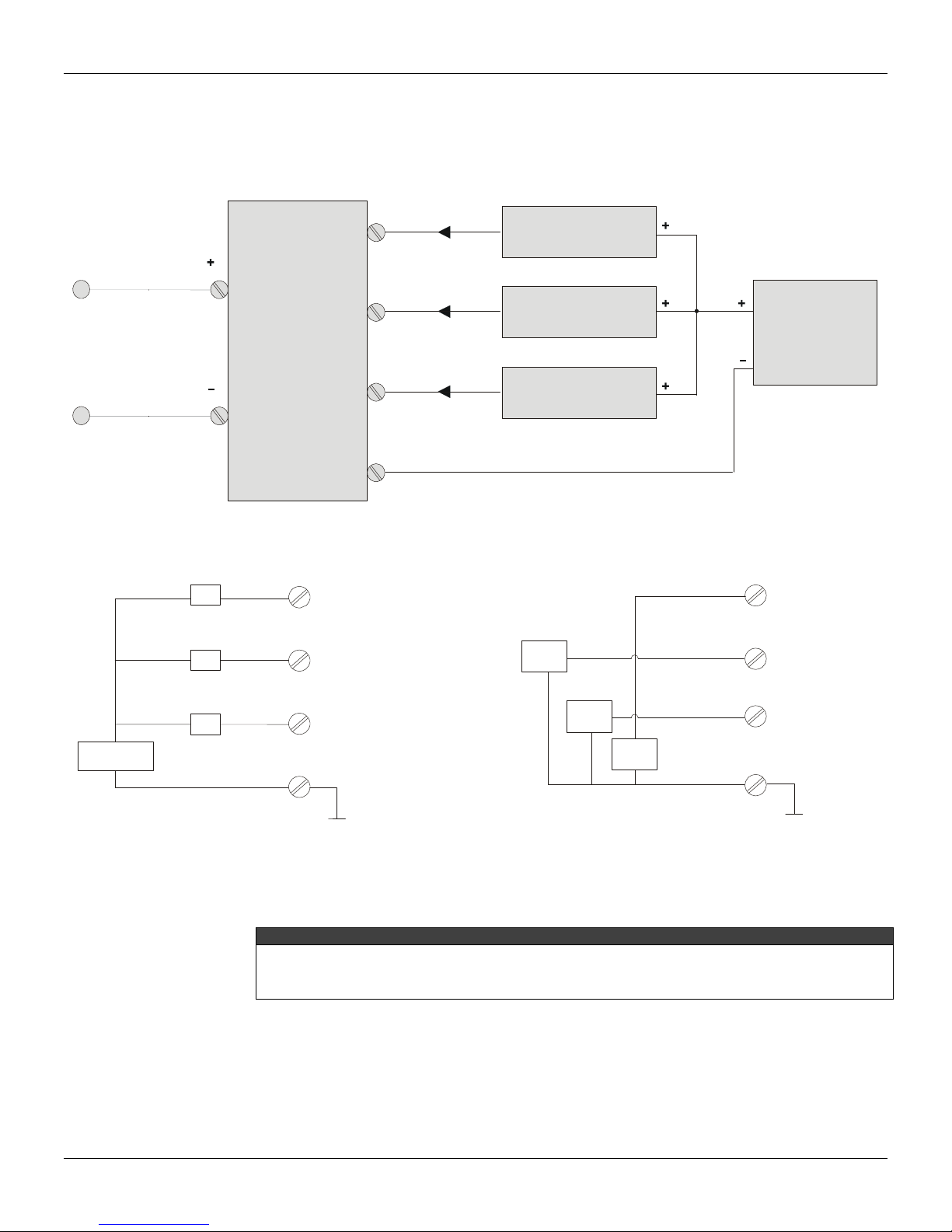

See Figure 2.2 - IF303 Block Diagram. The function of each block is described below.

MUX Multiplexer

The MUX multiplexes the input terminals to ensure that all three channels reach the A/D converter.

A/D Converter

The A/D converts the input signals to a digital format for the CPU.

Signal Isolator

Its function is to isolate the data signal between the input and the CPU.

(CPU) Central Processing Unit, RAM and FLASH

The CPU is the intelligent portion of the converter, being responsible for the management and

operation of block execution, self-diagnostics and comm unication. The program is stored in Flash

memory. For temporary storage of data there is a RAM. The data in the RAM is lost if the po wer is

switched off, however the device also has a nonvolatile EEPROM where data that must be retained

are stored. Examples of such data are: calibration, configuration and identification data.

Communication Controller

It monitors line activity, modulates and demodulates the signal from network line.

Power Supply

Takes power of the loop-line to power the converter circuitry.

Power Isolation

Just like the signals from the input section, the power to the input section must be isolated.

Display Controller

Receives data from the CPU and drives the Liquid Crystal Display.

Local Adjustment

They are two switches that are magnetically activated. They can be activ ated by the magnetic tool

without mechanical or electrical contact.

2.1

IF303 – Operation and Maintenance Instruction Manual

A

A

POWER

SUPPLY

SIGNAL

SHAPING

Figure 2.1 - LCD Indicator

MAIN CIRCUIT BOARD INPUT CIRCUIT BOARD

POWER

ISOLATION

SUPPLY

FIRMWARE

DOWNLOAD

INTERFACE

FLASH

RAM

MODEM

LOCAL ADJUST

CPU

EEPROM

S

I

G

N

L

I

S

O

L

T

I

O

N

(*) Resistor Shunt

(3 x 100R)

DISPLAY BOARD

DISPLAY

CONTROLLER

Apply in the inputs of the conversor only current levels. Don’t apply tensio n levels, because the shunt resistors are of 100R

1W and tension higher than 10 Vdc can damage them.

2.2

Figure 2.2 - IF303 Block Diagram

WARNING

Section 3

CONFIGURATION

One of the many advantages of using Fieldbus technologies is that device configuration is

independent of the configuration software. The IF303 may be configured by a third party terminal or

operator console as Smar’s configurators ProfibusView or AssetView for FDT.

The IF303 contains three input transducer blocks, one ph ysical block, on e display transdu cer block ,

three analog input and three totalizer function blocks.

Function Blocks are not covered in this manual. For further explanation and details of function

blocks, see the “Function Blocks Manual”.

In order to assure correct values in the offline configuration, when using download function of

Simatic PDM, please make sure you have done the upload firstly.

Offline Configuration

1. First run “Download to PG/PC” option to assure valid values.

2. Run after the Menu Device option to configure the required parameters using the related menus.

It is not advisable to use the “Download to Device” option. This function can misconfigure the equipment.

Transducer Block

Transducer block insulates function block from the specific I/O hardware, such as sensors and

actuators. Transducer block controls access to I/O through manufacturer specific implementation.

This permits the transducer block to execute as frequently as necessary to obtain good data from

sensors without burdening the function blocks that use the data. It also insulates the function blocks

from the manufacturer specific characteristics of certain hardware.

By accessing the hardware, the transducer block can get data from I/O or passing control data to it.

The connection between Transducer block and Input/Output Function blocks is called channel.

Normally, transducer blocks perform functions, such as linearization, characterization, temperature

compensation, control and exchange data to/from hardware.

How to Configure a Transducer Block

The transducer block has an algorithm, a set of contained parameters and a cha nnel connecting it to

a function block. The algorithm describes the behavior of the transducer as a data transfer functio n

between the I/O hardware and other function block. The set of contained parameters, it means, you

are not able to link them to other blocks, defines the user interface to the transducer block. They can

be divided into Standard and Manufacturer Specific.

The standard parameters will be present for such class of device, as pressure, temperature,

actuator, etc., whatever is the manufacturer. Oppositely, the manufacturers specific ones are

defined only by its manufacturer. As common manufacturer specific parameter s, we have calibration

settings, material information, linearization curve, etc.

When deforming a standard routine as a calibr ation, user is conducted step by step by a method.

The method is generally defined as guide line to help the user to make common tasks. The

Configuration Tool identifies each method associated to the parameters and enables the interface

to it.

Terminal Number

It is the parameter, which makes reference to a physical input, which in the turn, is sent internally

from the specified transducer output to function block.

It starts at channel one (1) for transducer number one until channel three (3) for transducer number

three.

NOTE

3.1

IF303 – Operation and Maintenance Instruction Manual

The channel number of the AI block and TOT block is related to the transducer’s terminal number.

Channel number 1, 2, 3 corresponds bi-univocally to the terminal block with the same number.

Therefore, all user has to do is choosing c ombinations: (1.1), (2.2), (3,3) for (CHANNEL, BLOCK)

respectively.

Functional Diagram of the Current To PROFIBUS PA Transducer Block

Figure 3.1 - Functional Diagram of the Current To PROFIBUS PA Transducer Block

Current To PROFIBUS PA Transducer Block General Parameter Description

Parameter Description

BACKUP_RESTORE

3.2

This parameter allows to save and to restore data according to factory and user calibration

procedures. It has the following options:

1, "Factory Cal Restore",

2, "Last Cal Restore",

3, "Default Data Restore",

4, "Shut-Down Data Restore",

11, "Factory Cal Backup",

12, "Last Cal Backup",

14, "Shut-Down Data Backup",

Configuration

Parameter Description

0, "None".

CAL_MIN_SPAN

CAL_POINT_HI

CAL_POINT_LO

This parameter contains the minimum calibration span value allowed. This minimum span

information is necessary to ensure that when calibration is done, the two calibrated points (high

and low) are not too close together. Unit derives from SENSOR_UNIT.

This parameter contains the highest calibrated value. For calibration of the high limit point you

give the high measurement value (pressure) to the sensor and transfer this point as HIGH to the

transmitter. Unit derives from SENSOR_UNIT.

This parameter contains the lowest calibrated value. For calibration of the low limit point you give

the low measurement value (pressure) to the sensor and transfer this point as LOW to the

transmitter. Unit derives from SENSOR_UNIT.

Linearization Type:

LIN_TYPE

LOW_FLOW_CUT_OFF

0 – No Linearization

10 – Square Root

This is the point in percent of flow till that the output of the flow function is set to zero. It

is used for suppressing low flow values.

This is the point of the flow function where the curve changes from linear to square root

FLOW_LIN_SQRT_POINT

MAINT_DATE

EEPROM_FLAG This parameter is used to indicate EEPROM saving process.

FACTORY_GAIN_REFERENCE Factory calibration reference value.

MAIN_BOARD_SN This is the main board serial number.

MAX_SENSOR_VALUE

MIN_SENSOR_VALUE

ORDERING_CODE Indicates information about the sensor and control from production factory.

PRIMARY_VALUE

PRIMARY_VALUE_TYPE

PRIMARY_VALUE_UNIT

SECONDARY_VALUE_1 This parameter contains the current value and status available to the Function Block.

SECONDARY_VALUE_1_UNIT

SECONDARY_VALUE_2

SECONDARY_VALUE_2_UNIT

SCALE_IN

SCALE_OUT

SENSOR_HI_LIM This parameter contains the sensor upper limit value. Unit derives from SENSOR_UNIT.

SENSOR_LO_LIM This parameter contains the sensor lower limit value. Unit derives from SENSOR_UNIT.

SENSOR_UNIT

SENSOR_SN The serial number of sensor.

SENSOR_VALUE

TERMINAL_NUMBER

function.

The input has to be done in percent of flow.

The date of last maintenance.

Holds the maximum process SENSOR_VALUE. A write access to this parameter resets to the

momentous value. The unit is defined in SENSOR_UNIT.

Holds the minimum process SENSOR_VALUE. A write access to this parameter resets to the

momentous value. The unit is defined in SENSOR_UNIT.

This parameter contains the measured value and status available to the Function Block. The unit

of PRIMARY_VALUE is the PRIMARY_VALUE_UNIT.

This parameter contains the application of the device.

> 128: manufacturer specific

This parameter contains the engineering units index code for the primary value. In this case the

unit code is mA (1211).

This parameter contains the current units of the SECONDARY_VALUE_1. In this case the unit

code is mA (1211).

This parameter contains the measured value after input scaling and status available to the

Function Block. The related unit is the SECONDARY_VALUE_UNIT_2. In this case the unit code

is % (1342).

This parameter contains the units of the SECONDARY_VALUE_2 defined by the manufacturer. In

the this case the unit code mA (1211).

This is the input conversion of the current into PRIMARY_VALUE using the high and low scale.

The related unit is the PRIMARY_VALUE_UNIT.

This is the output conversion value using the high and low scale. The related unit is the

PRIMARY_VALUE_UNIT.

This parameter contains the engineering units index code for the calibration values. In this case

the unit code is mA (1211).

This parameter contains the raw sensor value. The uncalibrated measurement value from the

sensor. Unit derives from SENSOR_UNIT.

The terminal number, which references a channel value, which is sent via internal, manufacturerspecific from AI function block to the specified transducer. It starts at one (1) for transducer

3.3

IF303 – Operation and Maintenance Instruction Manual

Parameter Description

number one until three (3) for transducer number three.

TRIMMED_VALUE

XD_ERROR

This parameter contains the sensor value after the TRIM processing. Unit derives from

SENSOR_UNIT.

Indicates the condition of calibration process according to:

{16, "Default value set"},

{22, "Applied process out of range"},

{26, "Invalid configuration for request"},

{27, "Excess correction"},

{28, "Calibration failed"}

Table 3.1 - Parameter Description

Transducer Block Parameter Attributes

Relative

Index

Parameter Mnemonic

8 SENSOR_VALUE Simple Float D 4 r C/a 0 - M (B)

9 SENSOR_H I_LIM Simple Float N 4 r C/a 0 - M (B)

10 SENSOR_LO_LIM Simple Float N 4 r C/a 0 - M (B)

11 CAL_POINT_HI Simple Float N 4 r,w C/a 20.0 - M (B)

12 CAL_POINT_LO Simple Float N 4 r,w C/a 4.0 - M (B)

13 CAL_MIN_SPAN Simple Float N 4 r C/a 0 - M (B)

14 MAINT_DATE Simple Octet String S 16 w,w C/a O(B)

15 SENSOR_UNIT Simple Unsigned 16 N 2 r,w C/a 1211 - M (B)

16 SENSOR_SN Simple Unsigned 32 N 4 r,w C/a - M (B)

17 TRIMMED_VALUE Record DS-33 D 5 r C/a 0.0 - M (B)

18 PRIMARY_VALUE Record DS-33 D 5 r C/a 0.0 - M (B) 1

PRIMARY_VALUE_UN

19

IT

PRIMARY_VALUE_TY

20

PE

SECONDARY_VALUE

21

_1

SECONDARY_VALUE

22

_1_UNIT

SECONDARY_VALUE

23

_2

SECONDARY_VALUE

24

_2_UNIT

25 SCALE_IN Array Float S 8 r,w C/a

26 SCALE_OUT Array Float S 8 r,w C/a

MAX_SENSOR_VALU

27

E

Object

Type

Simple Unsigned 16 N 2 r,w C/a - - M (B)

Simple Unsigned 16 N 2 r,w C/a 255 - M (B)

Record DS-33 D 5 r C/a 0.0 - O (B)

Simple Unsigned 16 N 2 r,w C/a mA - O (B)

Record DS-33 D 5 r C/a 0 - O (B)

Simple Unsigned 16 N 2 r,w C/a % - O (B)

Simple Float N 4 r,w C/a 0.0 - O (B)

Data Type Store Size Access

... Standard Parameter 1

Additional Parameter for Transducer Block

Parameter

usage/

Type of

transport

Default

value

20.0

4.0

20.0

4.0

Down-

load

Order

Mandatory /

Optional

(Class)

- O(B)

- O(B)

View

3.4

Configuration

Relative

Index

33-40 RESERVED

Parameter Mnemonic

28 MIN_SENSOR_VALUE Simple Float N 4 r,w C/a 0.0 - O (B)

29 TERMINAL_NUMBER Simple Unsigned 8 S 1 r,w C/a 0 - O (B)

30 LIN_TYPE Simple Unsigned 8 S 1 r,w C/a 0 - O (B)

LOW_FLOW_CUT_OF

31

F

FLOW_LIN_SQRT_POI

32

NT

41 BACKUP_RESTORE Simple Unsigned 8 S 1 r,w C/a 0 - O (B)

42 XD_ERROR Simple Unsigned 8 D 1 r C/a 0x10 - O (B)

43 MAIN_BOARD_SN Simple Unsigned 32 S 4 r,w C/a 0 - O (B)

44 EEPROM_FLAG Simple Unsigned 8 D 1 r C/a FALSE - O (B)

FACTORY_GAIN_REF

45

ERENCE

46 ORDERING_CODE Array Unsigned 8 S 50 r,w C/a - - O (B)

Object

Type

Simple Float S 4 r,w C/a 0 - O (B)

Simple Float S 4 r,w C/a 0 O (B)

Simple Float S 4 r,w C/a 0 - O (B)

Data Type Store Size Access

Parameter

usage/

Type of

transport

Default

value

Down-

load

Order

Mandatory /

Optional

(Class)

Table 3.2 - Parameter Attribute

See FUNCTION BLOCKS PROFIBUS PA manual for more parameters information, by visiting our

web page on the Internet: http://www.smar.com.

IF303 - CYCLIC CONFIGURATION

The PROFIBUS DP and PROFIBUS PA protocols have mechanisms against communication

failures between the slave device and the network master. For example, during initialization, these

mechanisms are used to check these possible errors. After po wering up the field device (slave), it

can cyclically exchange information with the class 1 mast er, if the parameterization for the slave is

correct. This information is obtained using the GSD files (supplied by the device man ufacturer, it

contains their descriptions). Through the commands below, the master executes all initialization

process with the PROFIBUS PA device:

Get_Cfg: uploads the slave configuration on the master and checks network configuration;

Set_Prm: writes to the slave parameters and executes the parameterization network;

Set_Cfg: configures the slaves according to i ts outputs and inputs;

Get_Cfg: another command, where the master checks the slave configuration.

All these services are based on the information obt ained from slave gsd files. The GSD file from

IF303 shows details such as, hardware and software revision, device bus timing and i nformation

about cyclic data exchange.

IF303 has 6 function blocks: 3 AIs (Analog Input) and 3 TOTs (Totalizer). It also has the empty

module for applications where not all function blocks are necessary. The following cyclic order of the

blocks should be respected: AI_1, AI_2, AI_3 and T OT_1, TOT_2, TOT_3. Suppose, only the AIs

blocks are necessary, then configure this way: AI_1, AI_2, AI_3, EMPTY_MODULE,

EMPTY_MODULE, EMPTY_MODULE.

Nevertheless, if you want to work only 1 AI and 1 TOT, configure them this way: AI_1,

EMPTY_MODULE, EMPTY_MODULE and TOT_1, EMPTY_MODULE, EMPTY_MODULE.

Most PROFIBUS configuration tools use two directories where the different manufacturers’ GSD’s

and BITMAPS files are stored. The GSD’s and BITMAPS for Smar devices can be obtained through

the website: (https://www.smar.com), select "Download" option in the product specific page.

The following example shows the necessary steps to integrate the IF303 on a PROFIBUS system.

View

3.5

IF303 – Operation and Maintenance Instruction Manual

These steps are valid for the entire 303 line of Smar devices:

Copy the IF30 3 gsd file to the research directory of the PROFIBUS configuration tool, usually

called GSD;

Copy the IF303 b itmap file to the research director y of the PROFIBUS configuration tool usually

called BMP;

After choos ing the master, define the communication rate. Do not forget that the cou plers may

have the following fixed communication rates 45,45 kbits/s (Siemens) or 9 3,75 kbits/s (P+F) and

variable comm rates up to 12 Mbit/s as instance: SK2 and SK3 from P+F, link IM157 from

Siemns and Smar’s controllers with embedded couplers (DF95 or DF97);

Add the IF303 and specify its physical bus address;

Choose the cyclic configuration via parameterization using the gsd file that depends on the

application, as detailed previously. For every AI (Analog Input) block, the IF303 provides the

process variable to the master in 5 bytes value, being the first four according to float poin t data

type and the fifth byte is the status that brings the measure quality of this information.

In the TOT (Totalizer) block, the user can choose the totalization value (Total) and the

integration is made considering the operati on mode (Mode_Tot). It allows defining of how the

totalization will be, with the following options: only positive value of the flow, only negative values

of the flow, or both. In this block, the user can reset the totalization and configure the preset

value through the Set_Tot parameter. The reset option is very used in batch processes;

It allows activating the condition of watchdog, which the device goes to a fail safe condition,

when a loss of communication is detected with the master.

Using ProfibusView, AssetView for FDT from Smar or Simatic PDM configuration software from

Siemens, for instance, user may configure parameters of the Input Transducer block. See Figure 3.2

- Function and Transducers Blocks.

3.6

Figure 3.2 – Function and Transducers Blocks – ProfibusView

Configuration

Figure 3.3 – Function and Transducers Blocks – Simatic PDM

To make the configuration of Transducer Block, select on the main menu:

Figure 3.4 - Transducer Block – ProfibusView.

3.7

IF303 – Operation and Maintenance Instruction Manual

Figure 3.5 - Transducer Block - Simatic PDM

When the user chooses "Square Root", he needs to configure more two parameters: Low Flow

Cutoff" and "Flow Lin Sqr Point". For details, please see last figure and the diagram of Transducer

Block.

In terms of Square Root, we have the following feature:

Y

10. I (%)

Y =

Square Root

Low_Lin_Sqrt_Point = Z

Y = I (%).Q

10. Z

Q =

Z

Figure 3.6 – Square Root Calculation.

Low_Flow_Cut_Off

I (%)

3.8

How to Configure the Analog Input Block

The Analog Input block takes the input data from the Transducer block, selected by channel

number, and makes it available to other function blocks at its output. T he transducer block provides

the input unit of the Analog Input, and when the unit is cha nged in the transducer, the PV_SCALE

unit is changed too. Optionally, a filter may be applied in the process value signal, whose time

constant is PV_FTIME. Considering a step change to the input, this is the time in seconds to the PV

reaches 63,2% of the final value. If the PV_FTIME value is zer o, the filter is disabled. For more

details, please, see the Function Blocks Specifications.

To configure the Analog Input Block select on the main menu. Using this window, the user can

configure the block mode operation, selects the channel, scales and unit for input and output value

and the damping.

Configuration

Figure 3.7 – Basic Settings for Analog Input Block – ProfibusView.

3.9

IF303 – Operation and Maintenance Instruction Manual

Figure 3.8 – Basic Settings for Analog Input Block - Simatic PDM.

Selecting the page "Advanced Settings", the user can configure the conditions for alarms and

warnings, as well the fail safe condition. Please, see the next window:

3.10

Figure 3.9 - Advanced Settings for Analog Input Block – ProfibusView.

Configuration

Figure 3.10 - Advanced Settings for Analog Input Block - Simatic PDM.

Figure 3.11 - Configuration for Analog Input Block – ProfibusView.

3.11

IF303 – Operation and Maintenance Instruction Manual

Figure 3.12 - Configuration for Analog Input Block - Simatic PDM.

How to configure the Totalizer Block

The Totalizer function block obtain the input data from the T ransducer block, selected by channel

number, and integrates over the time. This block is normally used to totalize flow, giving total mass

or volume over a certain time, or totalize power, giving the total energy.

The Totalizer Function Block integrates a variable (e.g flo w rate or power) in function of the time to

the corresponding quantity (e.g., volume, mass or distance). The rate unit of the Totalizer is

providing by the transducer block. Internally, the time units are converted in rate units per second.

Each rate, multiplied by the block execution time, gives the mass, volume or energy incr ement per

block execution.

The TOTAL is the totalized quantity. The en gineering unit used in th e output is the UNIT_TOT. The

unit of the output must be compatible with the unit of t he input provided by the transducer by the

channel. Then, if the input the rate is mass flow (like Kg/s, g/min, ton/h) the unit of the output must

be mass (like kg, g, ton, lb, etc.). For more details, please, see the Function Blocks Specifications.

To configure the Totalizer Block select on the main menu. Using this window, the user can configure

the block mode operation, selects the channel, totalizer mode and unit for the total. The user can

choose up to 3 Totalizer Blocks:

3.12

Configuration

Figure 3.13 - Basic Settings for Totalizer Block – ProfibusView

Figure 3.14 - Basic Settings for Totalizer Block - Simatic PDM

3.13

IF303 – Operation and Maintenance Instruction Manual

Choosing the "Advanced Settings" window, the user can set alarm and warning limits, as well the

fail safe condition:

Figure 3.15 - Advanced Settings for Totalizer Block - ProfibusView.

3.14

Figure 3.16 - Advanced Settings for Totalizer Block - Simatic PDM

Configuration

In the screen Config Block Mode the user can adjust the operation of the block.

Figure 3.17 - Totalizer Block Configuration - ProfibusView.

Figure 3.18 - Totalizer Block Configuration - Simatic PDM.

3.15

IF303 – Operation and Maintenance Instruction Manual

Current Trim

Figure 3.19 - Set/Preset Configuration for Totalizer Block - ProfibusView

Figure 3.20 - Set/Preset Configuration for Totalizer Block - Simatic PDM

The IF303 provides the capability of making a TRIM in the input channels, if necessar y.

TRIM procedure is necessary if the indication readin g of the transducer block outp ut differs from the

actual physical output. The reason may be:

User's current meter differs from the factory standard.

Converter had its original characterization signal shifted by over-load or by long term drift.

3.16

Configuration

User can check the calibration of the transducer output by measuring t he actual current in the input

and compare it with the indication of the device (an appropriate meter must be used). If a mismatch

is detected, a TRIM can be done.

TRIM can be done in two points:

Lower TRIM: Is used to TRIM the lower value of the input range.

Upper TRIM: Is used to TRIM the upper value of the input value.

These two points define the linear characteristic of the output. TRIM in one point is independent

from the other.

There are at least two ways of doing the T RIM: using local adjustment or using a Configuration

Tool (see below examples using ProfibusView).

When doing the TRIM, make sure you are using an appropriate meter (with the necessary

accuracy).

Via ProfibusView, AssetView for FDT or Simatic PDM

The channel number of the AI block is related to the transducer ’s terminal block number. Channel

number 1,2,3 corresponds bi-univocally to the terminal block with the same number. Therefor e, all

the user has to do is to select combinations: (1, 1), (2, 2), (3, 3), for (CHANNEL, TERMINAL

NUMBER).

It is possible to calibrate the current inputs of the transmitter by means of parameters

CAL_POINT_LO and CAL_POINT_HI.

Let’s take the lower value as an example:

Supply 4 mA or the lower value to the terminal block and wait until the readout of parameter

PRIMARY_VALUE stabilizes.

Write 4.00 or the lower value in parameter CAL_POINT _LO. For each value written a calibration is

performed at the desired point.

Figure 3.21 - Lower Current Calibration - ProfibusView.

3.17

IF303 – Operation and Maintenance Instruction Manual

Figure 3.22 – Lower Current Calibration - Simatic PDM.

Let’s take the upper value as an example:

Supply 20 mA or the upper value to the terminal block and wait until the readout of parameter

PRIMARY_VALUE stabilizes.

Write 20.00 or the upper value in parameter CAL _POINT_HI. For each value written a calibration is

performed at the desired point.

The user can

select Lower

or Upper Trim.

The Upper Sensor

Limit and the

Upper Calibration

Point.

The current value

and status.

The operation

result.

3.18

Figure 3.23 - Upper Current Calibration -

ProfibusView.

Configuration

It is recommended, for every new calibration, to saving the existent TRIM data by means of parameter

BACKUP_RESTORE, using option "Last Cal Backup".

Via Local Adjustment

The IF303 has 3 input transducers and it is provided by SMAR with default settings. T he factory

setting establishes only the transducers #1 as default for local adjustment. In order to configure the

others via local adjustment, user shall configure them in the display trans ducer via Configuration

Tool, according specific instructions for this transducer block.

In order to enter the local adjustment mode, place the magnetic to ol in orifice “Z” until flag “MD”

lights up in the display. Remove the magnetic tool from “Z” and place it in orifice “S” until the

message “LOC ADJ” is displayed. The message will be displayed during approximately 5 s econds

after the user has removed the magnetic tool from “S”. By placing the magnetic t ool t he user will be

able to access the local adjustment tree in the monitoring mode.

Browse to parameter P_VAL (PRIMARY_VALUE).

Supply 4.0mA or the lower value to the terminal block and wait until the read of the parameter

stabilizes in the display.

Browse to parameter “LOWER”. After that, in order to start calibration, the user will act on the

parameter “LOWER” by placing the magnetic tool in “S” down to 4.0 mA.

Let’s take the upper value:

Supply 20.0mA or the upper value to the terminal block and wait until the readout of parameter

P_VAL stabilizes, and then actuate parameter UPPER up to 20.0.

TRIM mode exits via local adjustment automatically when the magnetic tool is not used during

approximately 16 seconds.

Keep in mind that even when parameters LOWER or UPPER present the desired value, they must be

actuated so that calibration is performed.

Limit Conditions for Calibration:

For every writing operation in the transducer blocks there is a code indication for the operation

associated with the writing method. These codes appear in parameter XD_ERROR every time a

calibration is performed. Code 16, for example, indicates a successfully performed operation.

Lower:

Figure 3.24 - Upper Current Calibration - Simatic PDM.

WARNING

NOTE

3.19

IF303 – Operation and Maintenance Instruction Manual

0.0mA < NEW_ LOWER < 9.0mA

Otherwise, XD_ERROR = 22

Upper:

15.0 mA < NEW_UPPER < 22.0mA

Otherwise, XD_ERROR = 22.

Codes for XD_ERROR:

16: Default Value Set

22: Out of range

26: Invalid Calibration request

27: Excessive Correction

Transducer Display – Configuration

Using the ProfibusView, AssetView for FDT,

possible to configure the Display Transducer block. As d escribed above it is a transducer due the

interfacing of its block with the LCD hardware.

Transducer Display is treated as a normal block by any configuration tool. It means, this block has

some parameters and those ones can be configured according to customer's needs.

Customer can choose up to six parameters to be shown at LCD display, they can be parameters

just for monitoring purpose or for acting locally in the fiel d devices by using a magnetic tool. The

seventh parameter is used to access the physical device address. The user can change this

address according to his application. To configure the Display Block select on the main menu:

NOTE

Simatic PDM or any other configuration tool is

3.20

Figure 3.25 - Display Block - ProfibusView.

Configuration

Display Transducer Block

Local adjustment is completely configured by configuration tool. It means, user can select the best

options to fit his application. From factory, it is configured with the options to set the Upper and

Lower TRIM, for monitoring the input transducer output and check the Tag. The converter is much

better configured by configuration tool, but the local functionality of the LCD permits an easy and

fast action on certain parameters, since it does not rely on communication and network wiring

connections. Among the possibilities by Local Adjustment, the following options can be emphasized:

Mode block, Outputs monitoring, Tag visualization and Tuning Parameters setting.

The interface is described in details on the "General Installation, Operation and Maintenance

Procedures Manual". Please take a detailed look at this manual in the chapter related to

"Programming Using Local Adjustment". The same handling methodology used for this transducer

display can also be used for the 303 Series field devices from Smar. So, since the user has learned

once, he is capable to handle all kind of field devices from SMAR.

All function block and transducers defined according PROFIBUS PA have a description of their

features written by the Device Description Language.

This feature allows third-parties configuration tools, enabled by Device Description Service

technology, interpreting these features and make them accessible to user Function Blocks

and Transducers of 303 Series have been defined rigorously according th e PROFIBUS PA

specifications in order to be interoperable to other parties.

In order to enable local adjustment using the magnetic tool, it is necessary ta previous setup of

parameters related with this operation via System Configuration.

There are six groups of parameters, which one may be pre-configured by the user in order to

enable, a possible configuration by means of the local adjustment. Use “NONE” option in t he "Select

Block Type" parameter to hide unnecessary itens to be displayed. Doing this, device will not take

the parameters related (indexed) to its Block as a valid parameter.

Definition of Parameters and Values

Select Block Type

This is the type of the block where the parameter is located. The user can choose: Transducer

Block, Analog Input Block, Totalizer Block , Physical Block or None.

Select/Set Parameter Type/Index

This is the index related to the parameter to be actuated or viewed (0, 1, 2…). For each block there

are some pre-defined indexes. Refer to the Function Blocks Manual to know available indexes to be

used.

Figure 3.26 - Display Block - Simatic PDM.

3.21

IF303 – Operation and Maintenance Instruction Manual

Set Mnemonic

Mnemonic for the parameter identification (it is allowed a maximum of 16 characters into the

alphanumeric field of the display). Choose the mnemonic, preferably with no more than 5 characters

in order to avoid the display rotation.

Set Decimal Step

It is the increment and decrement in decimal units when the parameter is Float or Float Status

value; integer, when the parameter is in whole units.

Set Decimal Point Place.

This is the number of digits after the decimal point (0 to 3 decimal digits).

Set Access Permission

Allows user to read, in the case of the “Monitoring” option, and to write when "action" option is

selected, then the display will show the increment and decrement arrows.

Set Alpha Numerical

These parameters include two options: value and mnemon ic . In option val u e, it is poss ible to displa y

both data in the alphanumeric and in the numeric fields; this way, in case of a data higher than

10000, it will be shown in the alphanumeric field. It is useful when we are s howing Totalization at the

LCD interface.

Selecting mnemonic, display may show the data in the numeric field and the mnemonic in the

alphanumeric field.

For devices where the software version is higher or equal to 1.10, please see the configuration of local

adjustment using the local adjustment, in the Installation, operation and maintenance procedures manual.

In case you wish to visualize a certain tag, opt for the index relative equal to "tag". To configur e

other parameters just select "LCD-II" up to "LCD-VI" windows:

NOTE

3.22

The option

"Write" should

be selected in

order to

execute the

upgrade of

local

adjustment

programming

tree.

After its step

all the

selected

parameters

will be shown

on the LCD

display.

Figure 3.27 - Parameters for Local Adjustment Configuration - ProfibusView.

Configuration

Figure 3.28 - Parameters for Local Adjustment Configuration - Simatic PDM.

The window "Local Address Change" allows the user "enable/disable" the access to changin g

the physical device address.

When the option

"enable" is

selected, the user

can change the

physical device

address.

Figure 3.29 - Parameters for Address Configuration - ProfibusView

3.23

IF303 – Operation and Maintenance Instruction Manual

Figure 3.30 - Parameters for Address Configuration - Simatic PDM.

When user is in the local adjustment, he can rotate parameters using the magnet screwdrive.

Normally; primary value (P_VAL) is the standard parameter to be shown. In case of setting another

parameter to be displayed, user shall changue “Access Permission” to “Monitoring”. T hus the last

parameter set to “Monitoring” will be displayed after removing the magnet tool.

Always on the LCD interface will be shown t wo parameters at the s ame time, s witching bet ween the

configured parameter at the LCD-II and the last monitoring parameter. If user do es not want to show

two parameters at the same time, it is only needed to set "none" when configure the LCD-II:

Selecting "None",

only the last

chosen monitoring

parameter will be

shown at LCD.

3.24

Figure 3.31 - Parameters for LCD-II Configuration - ProfibusView.

Configuration

Figure 3.32 - Parameters for LCD-II Configuration - Simatic PDM.

The user can select the "Mode Block" parameter at the LCD. In this case is necessar y to select the

index equal to "Mode Block":

With this

option, the

Mode Block

parameter is

shown at the

LCD.

Figure 3.33 - Parameters for Local Adjustment Configuration - ProfibusView.

3.25

IF303 – Operation and Maintenance Instruction Manual

Figure 3.34 - Parameters for Local Adjustment Configuration - Simatic PDM.

Programming Using Local Adjustment

The local adjustment is completely configured by configuration tool. It means, the user can select

the best options to fit his application. From factory, it is configured with the options to set the Upper

and Lower TRIM, for monitoring the input transducer output and check the Tag.

Normally, the converter is much better configured by configuratinon tool, but the local functionality

of the LCD permits an easy and fast action on certain parameters, since it does not rely on

communication and network wiring connections. Among the possibilities b y Local Adjustment, the

following options can be emphasized: Mode block, Outputs monitoring, Tag visua lizati on and T uning

Parameters setting.

The interface between the user is also described very detailed on the "General Installation,

Operation and Maintenance Procedures Manual" Pl ease take a detailed look at this manual in the

chapter related to "Programming Using Local Adjustme nt". It is significantly the resources on this

transducer display, also all the 303 Series field devices from SMAR has the same methodolog y to

handle with it. So, since the user has learned once, he is capable to han dle all kind of field devices

from SMAR. This Local adjustment configuration is a suggestion only. The us er may choose his

preferred configuration via configuration toll, simply configuring the displa y block).

The converter has two holes for magnetic switches activated by the magnetic tool located und er the

identification plate. These magnetic switches are activated by one magnetic tool (see figure 3.35).

This magnetic tool enables adjustment of the most important parameters of the blocks. It also

enables pre-configuration of the communication.

The jumper W1 on top of the main circuit board must be i n place for this f unction to be enab led and

the converter must be fitted with the digital display for access to the loc al adjustment. Without the

display the local adjustment is not possible.

3.26

Configuration

A

Fig. 3. 35 - Local Adjustment Holes

Table 3.4 shows the actions on the Z and S holes on the FY303 when Local Adjustment is enabled.

HOLE

Z Inicializes and rotates through the available functions.

S Selects the function shown in the display.

CTION

Table 3.4 - Purpose of the holes on the Housing

3.27

IF303 – Operation and Maintenance Instruction Manual

Quick Guide – Local adjustment Tree

UPDT

TGGL

ITEM

1) Browse until CONF option, select LCD2

2) Browse until BLOCK select the block that will be configured

3) Browse until PRMT and set the relative index of the parameter

4) Browse until ITEM and set the sub index ( if applicable )

5) Browse until UPDT,insert magnetic screw driver in Zero Hole

6) Reenter in Local Adjustment, browse until LCD2, now the

parameterisavailabletochange

3) HOW TO CONFIGURE A BLOCKPARAMETER

7) Repeat above steps for all the parameters to be configured

Magnetic Tool

1

S

Span Hole Zero Hole

ADDR

e

id

u

G

k

ic

u

-Q

e

re

T

2) HOW TO BROWSEAND

PRMT

AI1

AI2

PHY

TRD1

TRD2

TRD3

AI3

TOT1

TOT3

TOT2

BLOCK

LCD1

LCD2

LCD3

LCD4

LCD5

LCD6

Insert magnetic

Insert magnetic

CONF

screw driver in zero hole

and hold

screw driver in span hole

Browse:

SELECT MENU OPTIONS

Select:

and hold

UPPER ADDR

VARIABLES

UPPER ADDR

LOWER

ment

t

s

u

dj

lA

a

c

o

L

3.28

Follow Steps:

1) Insert magnetic screw driver in zero hole

2) Wait 3 seconds

3) Insert magnetics screw driver in span hole

1) HOW TO ACCESS LOCALADJUSTMENT TREE

4) Wait 3 seconds, then MD will appear on display

PVAL

LOWER

LCD1 LCD2 LCD4 LCD5

Follow Steps:

1) Browse until TGGL

2) Select 2

TIP: DISPLAY SWITCHING BETWEEN 2

3) Configure LCD 2 with the desired parameter

With TOGGLE 6

18 2 11 21

PVAL1

• CONF: option where it is possible to select the LCD to configure. Six options are available: from LCD1 up to LCD6;

• BLOCK: option where the user must select the function block that he desires to configure;

“Unit Index” and “Decimal Point”;

• PRMT: number correspondent to the relative index of the desired parameter into the chosen function block;

• ITEM: configure this option when a selected parameter has sub items to be configured, for example, the OUT_SCALE parameter is compounded by “EU at 100%”, “EU at 0%”,

• TGGL (Toggle): switches from 1 up to 6 configured parameters on the display.IfTGGLis equal to 2, for example, the display wil l switch between LCD1 and LCD2;

• UPDT: refreshes the display when one of the LCDs are configured. Finalize display configuration by setting "UPDT", after choosing the configuration for the local adjustment.

J1 Jumper Connections

If J1 (see figure 3.20) is connected to ON, then simulation mode in the AO block is enabled.

W1 Jumper Connections

If W1 (see figure 3.20) is connected to ON, the local adjustment programming tree is enabled and

then important block parameters can be adjusted and communication can be pre-configured via

local adjustment.

Configuration

In order to start the local

adjustment, place the

magnetic tool in orifice Z

and wait until letters MD

are displayed.

OFF ON

WR

J1

OFF ON

W1

LOC

ADJ

MAIN BOARD

Fig. 3.36 - J1 and W1 Jumpers

Place the magnetic tool in

orifice S and wait during 5

seconds.

Figure 3.37 - Step 1 - IF303

3.29

IF303 – Operation and Maintenance Instruction Manual

Remove the

magnetic tool from

orifice S.

Place the magnetic tool in

orifice Z. In case this is the first

configuration, the option shown

on the display is the TAG with

its corresponding mnemonic

configured by the Configuration

Tool. Otherwise, the option

shown on the display will be the

one configured in the prior

operation. By keeping the tool

inserted in this orifice, the local

adjustment menu will rotate.

Insert the magnetic

tool in orifice S once

more and LOC ADJ

should be displayed .

Figure 3.38 - Step 2 - IF303

This parameter is used to

calibrate the lower current

point. In order to range the

lower value, simply insert the

magnetic tool in orifice S as

soon as lower is shown on the

display. An arrow pointing

upward (↑) increment the value

and an arrow pointing

downward (↓) decrement the

value. Apply the 4.00 mA

current in the 1 and 4

terminals. Adjust the current

showed on the display to 4.00

mA..

In order to decrement

the lower value, place

the magnetic tool in

orifice Z to shift the

arrow to the downward

position and then, by

inserting and keeping

the tool in orifice S, it is

possible to decrement

the lower value.

3.30

Figure 3.39 - Step 3 - IF303

This parameter is used to

calibrate the upper current

point. In order to range the

upper value, simply insert the

magnetic tool in orifice S as

soon as upper is shown on the

display. An arrow pointing

upward (↑) increment the value

and an arrow pointing

downward (↓) decrement the

value. Apply the 20.0 mA

current in the 1 and 4

terminals. Adjust the current

showed on the display to 20.0

mA.

Figure 3.40 - Step 4 - IF303

Configuration

In order to decrement the

address value, place the

magnetic tool in orifice Z to

shift the arrow to the

downward position and

then, by inserting and

keeping the tool in orifice

S, it is possible to

decrement the address

value.

In order to decrement

the address value, place

the magnetic tool in

orifice Z to shift the

arrow to the downward

position and then, by

inserting and keeping

the tool in orifice S, it is

possible to decrement

the address value.

Figure 3.41 - Step 5 - IF303

1

In order to change the address

value, simply take off the

magnetic tool from orifice Z as

soon as ADDR is shown on

the display. An arrow pointing

upward (↑) increments the

address and an arrow pointing

1

downward (↓) decrements the

address. In order to increment

the address, insert the tool in

S up to set the value desired.

Cyclical Diagnosis

Figure 3.42 - Step 6 - IF303

NOTE

This Local adjustment configuration is a suggestion only. The user may choose his preferred configuration via

Configuration Tool, simply configuring the display.

Via cyclic communication is possible to verify diagnostics from the IF303 using the Profibus Master

Class 1 or even via acyclic communication via Master Class 2. The Profibus-PA dev ices provide up

to 4 standard diagnoses bytes via Physcial Block (see figure 3.43 and 3.44) and when the most

significant bit of the fourth Byte is "1", the diagnose will extend the information in more 6 bytes.

These Diagnosis bytes can also be monitored via cyclic tools.

Figure 3.43 – Cyclical Diagnosis

3.31

IF303 – Operation and Maintenance Instruction Manual

Figure 3.44 – Cyclic Diagnosis mapping for 4 bytes of Physical Block.

Unit_Diag_bit is described in the GSD file Profibus-PA device.

See below a description part of a GSD file for the 4 bytes and more detail:

;----------- Description of device related diagnosis: --------------------;

Unit_Diag_Bit(16) = "Error appears"

Unit_Diag_Bit(17) = "Error disappears"

;

;Byte 01

Unit_Diag_Bit(24) = "Hardware failure electronics"

Unit_Diag_Bit(25) = "Not used 25"

Unit_Diag_Bit(26) = "Not used 26"

Unit_Diag_Bit(27) = "Not used 27"

Unit_Diag_Bit(28) = "Memory error"

Unit_Diag_Bit(29) = "Measurement failure"

Unit_Diag_Bit(30) = "Device not initialized"

Unit_Diag_Bit(31) = "Device initialization failed"

;Byte 02

Unit_Diag_Bit(32) = "Not used 32"

Unit_Diag_Bit(33) = "Not used 33"

Unit_Diag_Bit(34) = "Configuration invalid"

Unit_Diag_Bit(35) = "Restart"

Unit_Diag_Bit(36) = "Coldstart"

Unit_Diag_Bit(37) = "Maintenance required"

Unit_Diag_Bit(38) = "Characteristics invalid"