Instruction Manual for SM-800A

COUNTER TOP MIXER

Installation, Operation and

Maintenance Instructions

SMAKY AB

Regulatorvägen 21, S-141 49 Huddinge, Sweden

Tel+ 46 8 657 9490

Fax+ 46 8 657 8980

http://www.smakymixers.com

e-mail: info@smaky.com

Revised in December, 2009

1

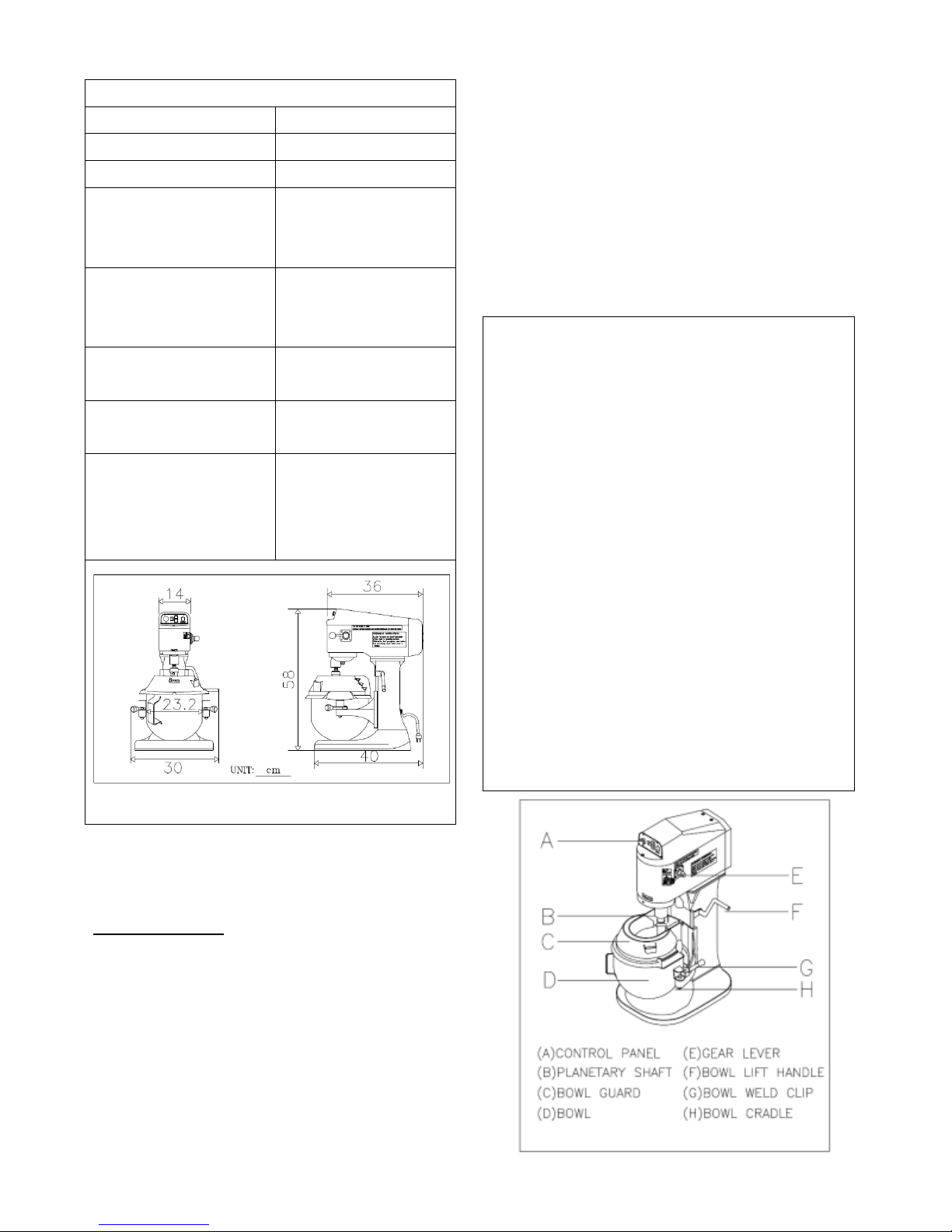

SM-800A

SPECIFICATION

Model

SM-800A

Bowl Size

8 Quarts (7.6 Liters)

Motor

1/4HP (0.20KW)

Electrics

110V/60HZ,

220V/50HZ

Single phase

Speeds

1st gear 132 rpm

2nd gear 235 rpm

3rd gear 421 rpm

Dimensions (cm)

(L x W x H)

40 x 30 x 58

47 x 36 x 66 carton

Weight

Gross 27kg

Net 25kg

Standard

Equipment

Pastry Knife, Stainless

steel bowl with Beater,

Whisk and Spiral

Dough hook.

Because of continual improvements, strict accuracy

of description cannot be guaranteed.

GUARANTEE

SMAKY provides one year guarantee, either

the date of dispatch from our factory, or the date of

purchase from one of our approved distributor.

SMAKY will replace any defected parts

resulted from faulty design, material or

workmanship. In addition to this, any repair must

be carried out by our authorized service agent.

All defective parts without any alteration or

repair can be returned to SMAKY or the nearest

authorized representative, postage paid within one

year warranty.

SM-800A is a desk top planetary mixer

designed for commercial use by the professional

caterer. It has a total bowl capacity of 8 Quarts,

combined with 3 speed gearbox to ensure that all

mixing requirements can be met.

CONTENTS

Specification.............................................. 1-2

Installation....................................................3

Electrical Connection.................................... 3

Safety............................................................3

Correct Use of the Mixer................................4

Tool Selection................................................4

Fitting the bowl.............................................4

Fitting the Mixing Tool..................................5

Speed selection...............................................5

Mixing Capacities...........................................5

Controls.........................................................6

Care of Your Mixer.........................................6

Fault Finding Chart........................................7

Maintenance...................................................7

Electrical Wiring Diagram............................8-9

Exploded View Drawing...........................10-16

2

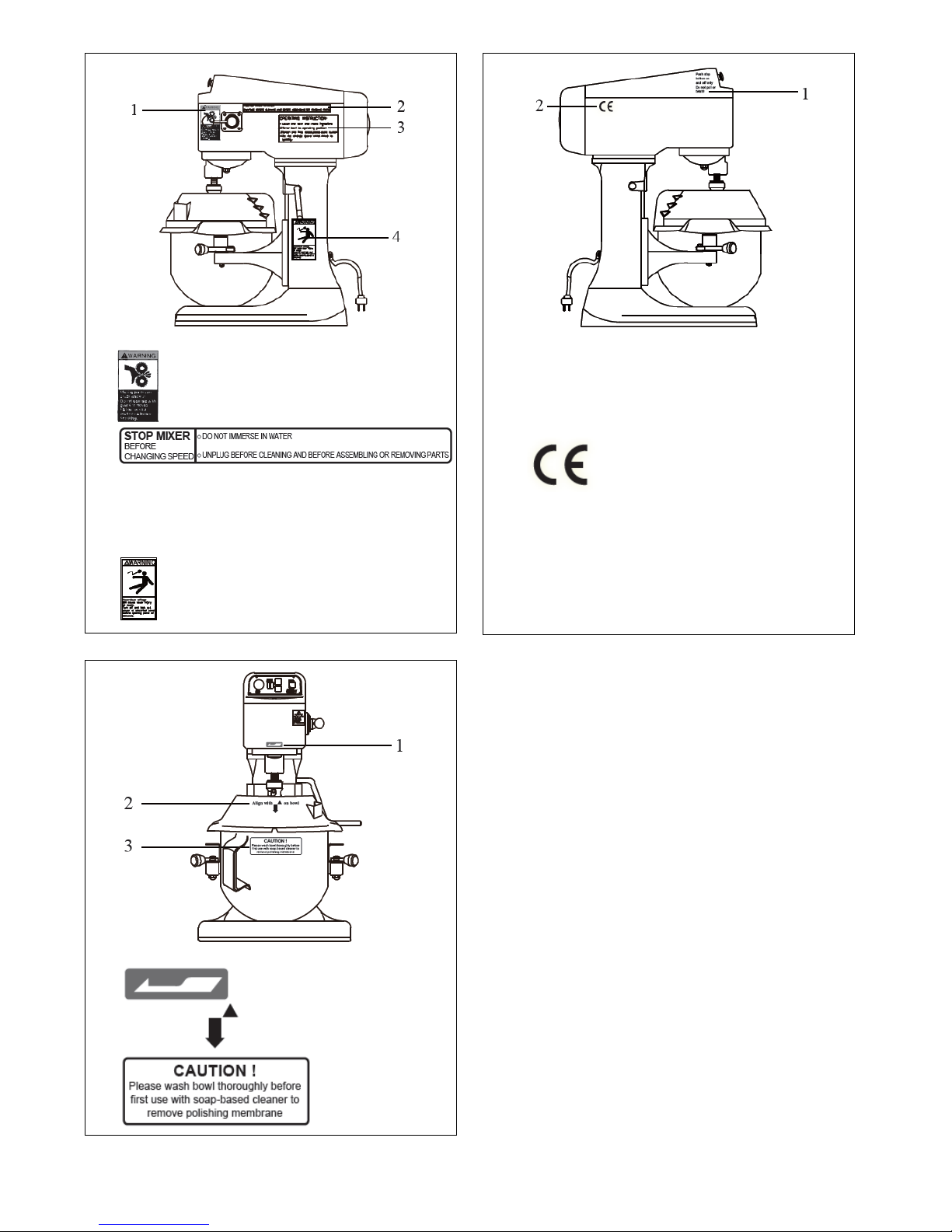

(1)

(2)

(3)

(4)

(1)

(2) Align with on bowl

(3)

(1) Push STOP button ON and OFF only

Do not pull or twist!!

(2)

Moving parts can crush and cut.

Do not operate with guard removed.

Follow lockout procedure before servicing.

OPERATING INSTRUCTION:

1. Lower the bowl and insert ingredient

2. Raise bowl to operating position

3. Select the first speed, press start button

4. Do not change gears whilst mixer is turning

Hazardous voltage will cause severe injury or

death. Turn off and lock out power at electrical

panel before opening panel or servicing.

3

INSTALLATION

The machine is supplied factory lubricated and

ready to run. It can be positioned on any substantial

work surface or bench which is capable of

supporting a load of 30kg. The transportation

should require two people. Please see Figure 1.

ELECTRICAL CONNECTION

Before connecting this machine to the

electrical supply, please check the details on the

rating plate (located on the rear of the machine)

corresponding to the details of your electrical

connection. The mixer is supplied with a trailing

lead fitted with a molded plug. If the style of plug is

unsuitable for the socket you plan to use, the plug

must be cut off and replaced with an appropriate

plug.

The mixer should be plugged into a switched

socket which isolates all poles and has a minimum

contact clearance of 3mm and located close to the

mixer for use in an emergency and to facilitate

servicing. (max.2 meters of cable) The machine

must be incorporated into a potential equalization

system. The leakage current for this appliance is no

greater than 1mA/KW. If the electrical supply cable

to the machine becomes damaged, it must be

replaced by a qualified electrician using cable

which is 0.75 or higher and suitable for a 1/4HP

motor load. The ground wire is fixed to the machine

and this connection must be kept intact. The mixer

MUST be grounded.

- The minimum requirement for all electrical

equipment is correct operation between air

temperature of +5°C and +4°C.

- Electrical equipment is capable of operating

correctly when the relative humidity does not

exceeding 95% at a maximum temperature of

+40°C.

- Electrical equipment is capable of operating

correctly at altitude up to 1000m.

- Electrical equipment is designed to withstand to

protected against the effects of transportation, and

storage temperature within a range of -25°C to

+55°C and for short periods not exceeding 24h at

up to +70°C.

BEFORE USING THE MIXER

Before using the mixer, please ensure that all

users are familiar with the correct operation of the

machine. In particular, care should be taken to

ensure that the bowl and mixing tools are correctly

fitted and the bowl cradle is in the raised position

prior to starting the machine.

SAFETY AT WORK

Never place your hand or any kitchen utensil

into the bowl when the mixer is in operation.

Please isolate the machine from the electrical

supply by removing the plug from the socket before

cleaning or dismantling.

A notice advising operators of the safe use of

this mixer is attached to the machine.

OFFICE, SHOPS AND RAILWAY

PREMISES ACT, 1963

The above Act requires that this machine and

attachments shall be operated only by a properly

instructed person or by an employee who is under

the supervision of a properly instructed person. The

instruction shall include indication of the possible

dangers arising and the precautions to be observed.

The Act also requires that no person under the age

of 18 shall clean a machine if this exposes him to

risk of injury from a moving part of that machine or

any adjacent machine.

4

CORRECT USE OF THE MIXER

It is the responsibility of the users to use the

mixer correctly within the recommended limitations.

Always follow the instructions on the side of the

machine when changing speed.

If the motor labors, stop the machine and

reduce the size of the mix immediately.

Damage resulting from improper use is not

covered by the SMAKY warranty.

For operator safety, the machines is fitted with

a bowl guard which is electrically interlocked to

ensure that the mixer cannot operate unless the

guard is correctly positioned and the bowl is

raised.

For additional safety the mixer has a no volt

release feature which means that in the event of a

power failure, the machine will only restart after the

control arrangement ensures that when the supply is

restored, the machine cannot restart on its own.

- Careful handling of bagged products by

minimizing the height above the bowl base from

which they are poured.

- Careful slitting of bags in the lower part of the

bowl to allow dust free discharge of flour as far as

possible.

- Use of Temporary bowl covers to minimize

openings through which flour may escape.

BOWL LIFT & BOWL GUARD

The bowl cradle and guard are electrically

interlocked so that the machine will only operate

with the bowl cradle in the raised position. In

addition to this, the bowl guard must be placed into

position by aligning the upside-down V cut into the

safety guard with the small raised portion on the lip

of the bowl.

Only once the bowl is raised and the guard

locked will the machine operate, thus ensuring total

user safety at all times.

Once the guard has been opened or the bowl

lowered, the machine can only be restarted by

pressing the start button. During the mixing process

additional ingredients can be added by means of the

chute located on the right hand side of the bowl

guard.

TOOL SELECTION

The beater, whisk and spiral dough hook are

meant for the work implied by their names.

Do not use the beater for dough making or the

whisk for anything other than whisking, aerating or

mixing light mixtures.

Table 1 shows the typical uses for each tool.

Beater: Firm mixes such as light

pastry, cakes biscuits, icings

fillings and mashed vegetables.

Spiral Dough Hook: Heavy mixes

such as dough, pie pastry and

sausage meat.

Whisk: Light mixes such as

whipped cream, mayonnaise, egg

whites, pancakes and soufflés.

Pastry knife

FITTING THE BOWL

With the bowl

cradle lowered, place

the chosen mixing tool

in the bowl and

position the bowl on

the cradle. There are

three location points

for the bowl:

(a) The locking pin at the rear of the bowl should

locate in the hole of the cradle.

(b) The two weld clips in the bowl handles must

engage on the locating pins located on

the cradle.

(c) Latching the bowl locking. Ensure that the bowl

is seated correctly on the cradle before securing the

bowl locking latches prior to use.

Table 1

5

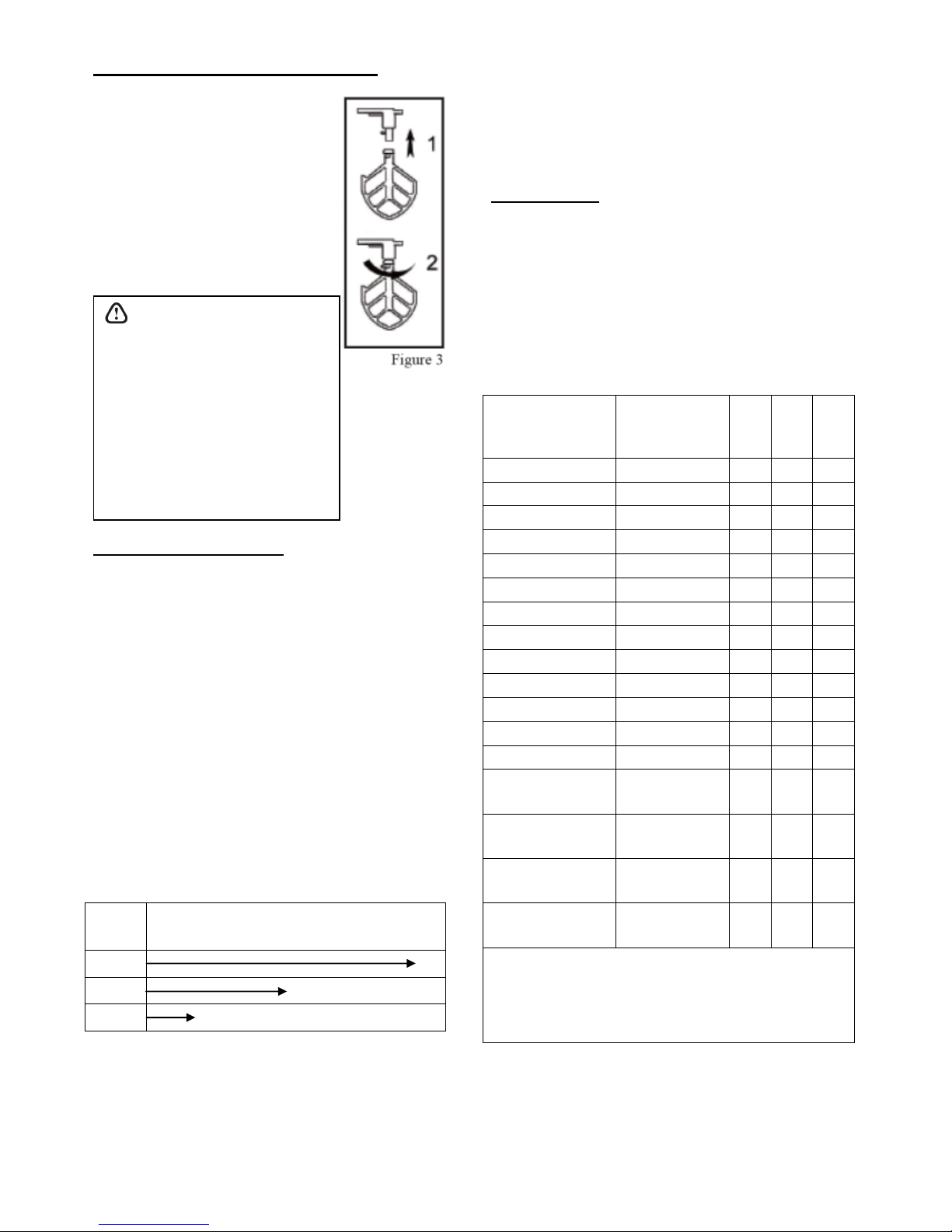

FITTING THE MIXING TOOL

Slide the bayonet fitting of

the tool onto the drive shaft and

twist clockwise to secure it in

position.

To remove the mixing tool,

slide the tool up the shaft slightly

and twist counter clockwise.

Please see figure 3.

SPEED SELECTION

Before changing speeds, the mixer must

always be stopped. The necessary speed can then be

selected before restarting the machine by pressing

the red start button.

The speed selected depends largely on the

quantity and consistency of the product. It is

recommended that mixing is always started at the

lowest speed and progressively increased to the

desired speed. In an emergency situation always use

the red emergency stop button to stop the machine.

Table 2 shows the recommended speeds for the

range of tools.

Recommended Speed

1st gear 2nd gear 3rd gear

Whisk

Beater

Hook

CAPACITY

The following table lists the recommended

capacities of finished weights of regular mixes.

Although the machine may be capable of mixing

larger quantities, it will lead to excessive and

premature wear and possible failure. Overloading

also results in lengthy processes and unsatisfactory

results.

Product

Maximum

Regular Mix

Whip

Beater

Spiral

Hook

Mashed potato

1,8 Kg

* *

Pie pastry

1,8 Kg

*

Cookies

-

*

Sponge cake

-

* *

Pound cake

-

*

Marshmallow

-

*

Fondant icing

1.3 Kg

*

Whipping cream

2 lit.

*

Egg whites

0.35 lit.

*

Mayonnaise

-

*

Batter

-

* *

Pasta, Egg noodle

900 g

*

Brioche (kg flour)

-

*

Raised Donut dough

(65% moisture content)

1 Kg

*

Heavy bread dough

(55% moisture content)

1.25 Kg

*

Pizza dough

(50% moisture content)

1.25 Kg

*

Pizza dough

(40% moisture content)

1 Kg

*

1. Recommended weight for a finished mix unless

otherwise stated.

2. Water content e.g. 25# flour / 12.5# water = 50%

moisture.

3. For pizza dough with lower moisture content, please

consult SMAKY

4. For higher gluten flour reduce dough batch by 25%.

Note: After cleaning,

please wipe the shaft with

Vaseline or oil for better

lubrication and preventing

rust.

Table 2

Table 3

6

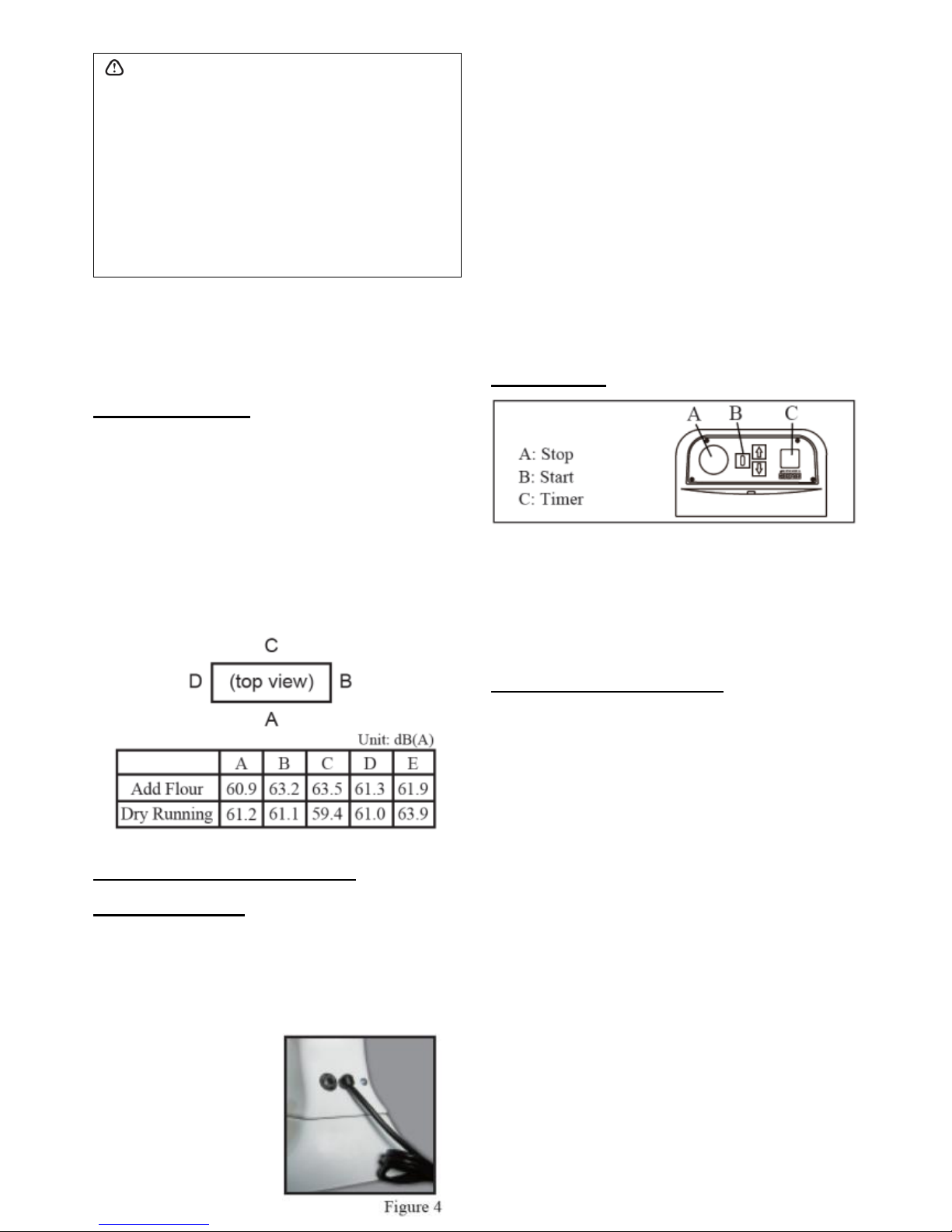

Noise Test Report

(1) Model No.: SM-800A

(2) Background noise:

Add Flour: background noise level is

54.0dB(A).

Dry running: background noise level is

52.6dB(A).

(3) Distance: 1m from the surface.

(4) Height: 1.6m from the floor.

Thermal overload protection

(circuit breaker):

The thermal overload protection (circuit

breaker) will shout off and stop the machine

automatically. If this occurs, please turn off the

mixer and reduce the size of the batch.

After waiting one

minute, reset the circuit

breaker (push in) and

turn on the mixer. If

mixers stop again,

reduce the batch further.

If this happens with an extremely small/light batch,

contact your nearest authorized service agent for

further information.

CONTROLS

The control panel is shown above, start the

mixer by pressing the “start” button. Always start

mixer at the first speed. Red button is for

emergency stop. Set timer at “99” for manual

operation. Set timer at 1-55 for automatic operation

CARE OF YOUR MIXER

The mixer is designed for minimum user

maintenance. It may be necessary from time to time

to apply a little oil to the rods on which the bowl

cradle slides. If so, use a little food quality lubricant,

ensuring that there is no excess oil that could

contaminate the food mix.

Water jet cleaning is not allowed. Clean the

mixer thoroughly after use. The body should be

wiped down with a damp cloth after first isolating

the machine from the electricity supply. Do not

spray the machine with or immerse it in water. Do

not forget to clean the rear of the machine and do

not allow the rear vents to become blocked as this

may result in overheating.

Pay particular attention to the bowl pins and

any surrounding areas of the cradle to prevent a

buildup of mix as this could prevent incorrect

location of the bowl. For the same reason, ensure

that the beater shaft and each of the sockets on the

tools are cleaned thoroughly. The bowl and tools

Note: To large a quantity is always

detrimental to the quality of the work and the

life of the mechanical parts of the beater and

may lead to abrupt stoppage.

7

should be washed in hot soapy water, rinsed and

dried before being put into storage. Do not wash the

tools in a dishwasher as the polished finish will be

adversely affected by the dishwashing chemicals.

- Steady state voltage: 0.9-1.1 of nominal voltage.

- Frequency: 0.99-1.01 of nominal frequency

continuously.

- Avoid exposing to vibration environment.

- Avoid exposing to direct sunlight or heat rays.

The overcurrent protection device should be rated

2A in supply side by user at least.

8

MAINTENANCE

Regular maintenance is necessary on all machines if they are to remain in good working order. It is

strongly recommended that this be carried out by trained technicians from a SMAKY appointed distributor.

GEARBOX LUBRICANT

Please refill the lubricant inside the gearbox every 5 years. We recommended that this servicing or

maintenance work must be carried out by trained technicians from a SMAKY appointed distributor.

CAUTION: Please use either Mobil lubricant “XHP 222” or Brugarolas “GRASA AGUILA PLEX

2-BOLSA” to refill the gearbox.

PLANETARY UNIT LUBRICANT

In case there is a strange noise coming from the planetary unit, please reapply grease to the planetary

unit. We recommended that this servicing or maintenance work must be carried out by trained technicians

from a SMAKY appointed distributor.

CAUTION: Please use TACBECON grease “DGK-100” to lubricate the planetary unit.

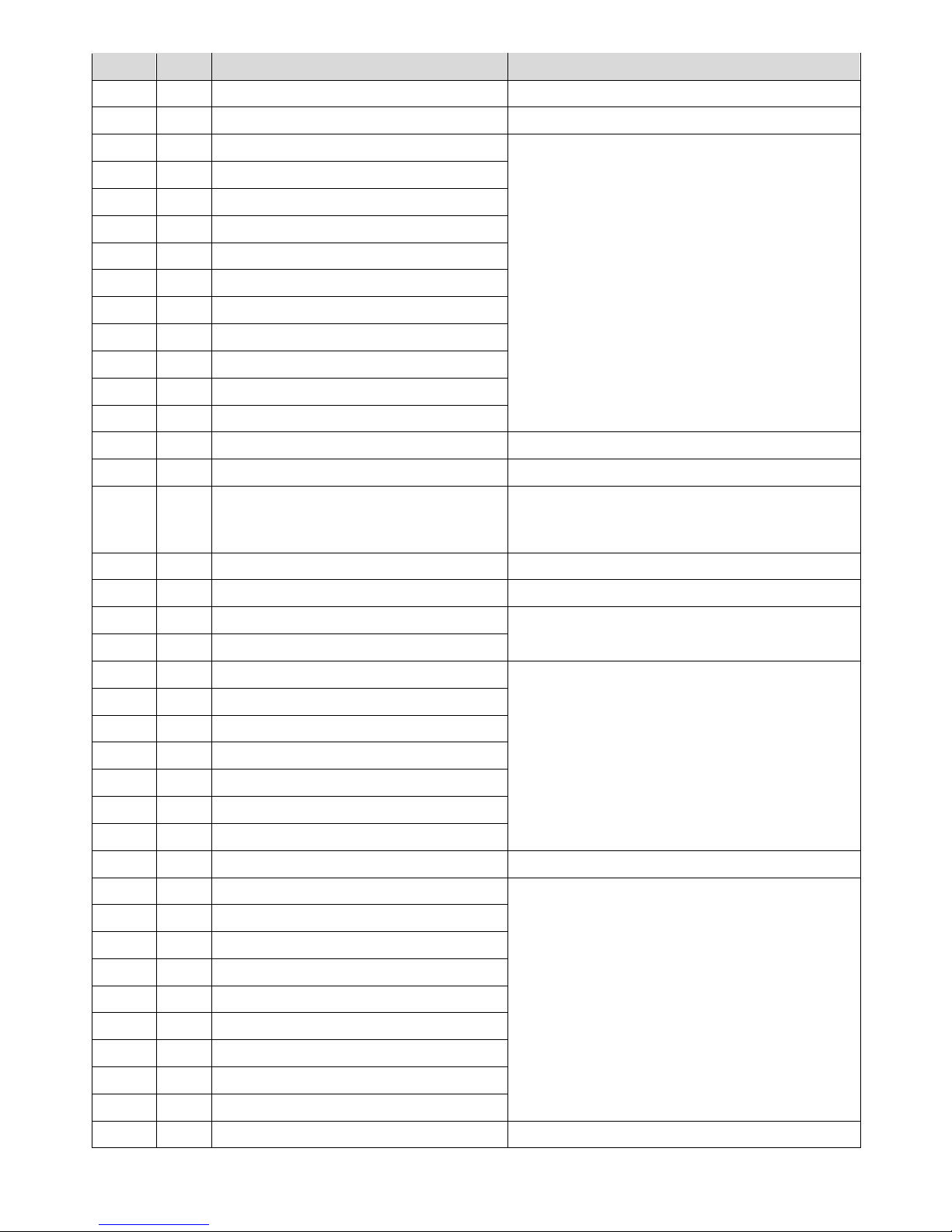

FAULT FINDING

FAULT

CHECK

POSSIBLE REASON AND ACTION

REQUIRED

No power to mixer

Check plug socket

Check wiring in plug

Check fuse in plug

Check or change cable

Check microswitch

Check motor carbon brush

Check circuit breaker over load or

short

Mixer not plugged into a live socket or not switched on

Plug incorrectly wired – rewire correctly

Possible faulty fuse – replace fuse

Cable damaged or split – replace cable

Limit switch damaged or faulty – replace switch

Motor carbon brush worn – replace carbon brush

Circuit breaker shut off or constantly short – reset or

replace the circuit breaker (automatically reset).

Mixer becomes noisy

Check bowl and tools

Check work surface

Check the wear of bearing

Ensure that bowl and tool are correctly seated.

Uneven surfaces create excessive resonance.

Worn bearings – replace bearings

Mixer loses power

Check capacity

Overloading of bowl – reduce load

Motor overheating

Check supply voltage

Voltage should correspond to rating plate

Oil on planetary shaft

Check oil seal

Worn oil seal – change oil seal

Mixing tools stuck on

planetary shaft

Check planetary shaft bent,

unclean or rusted.

Planetary shaft twisted or bent – please change planetary

shaft.

Planetary shaft rusted – please use descaler for derusting.

Turn planetary shaft anti-clockwise to meet square

groove, gently knock down mixing tools.

▲ It is recommended that any servicing or maintenance work must be carried out by a trained technician or

electrician.

▲ Isolate the mixer from the electricity supply by removing the plug from the socket before cleaning or

servicing.

▲ Isolate the mixer from the electricity supply by removing the plug from the socket after long

period of no use.

9

Item

Description

Aker

Part number

Qty

F1

Overload Protection

SANG MAO

110V/5A 220V/4A

1

F2

Microswitch of Safety Guard

ROUZET

125V/250V 5A

1

F3

Microswitch of Height Adjuster

Omron

V-212-1C6

1

FR1

Terminal Block

GEM

300V/12V

1

IC

IC Board

ZEON

2-MH 29009

1

S1

Emergency Stop Button

Switchlab

DC/6A 24V AC/5A 250V

1

S2

Start Button, Timer IC Control

Microchip

PAC 16C57-C/P

1

M1

Motor 1/4HP, 1PH, 120V, 50/60Hz

Shiun Jiann

1/4HP 120V/220V

1

10

11

12

ITEM

QTY.

DESCRIPTION

REMARK

1 2 screw:M5x20

2 1 screw:M4x30

3 1 transmission case cover

3_2

1

gasket

4 1 digital control panel

5 4

screw:M3x6

6 1 emergency stop button

7 4

hex screw:M6x16

8 4

spring washer:M6

9 2

pin:M6x15

10 1 transmission case

11 1 label, cleaning instructions

12 1 warning label

13 1 warning label

14 1 label, agitator direction

15 1 nut:M6

16 1 washer:M6x16x1

17 1 pinion beater:17T

18 1 ball bearing:#6001Z

19 1 planetary gear:56T

20 1 planetary holder

21 1 planetary holder cover

22 1 ball bearing:#6002Z

23 1 oil seal:32x17x7

24 1 planetary shaft

25

1

aluminum flat beater

1 stainless steel flat beater

Optional Accessory

26

1

aluminum dough hook

1 stainless steel dough hook

Optional Accessory

27 1 wire whip

Include item#28 & #29

28 3 hex screw:M4x10

29 1 stainless whip top

30 1 bowl

Bowl Assembly

31 1 bowl handles

32 1 bowl knob

33 2 bowl weld clip

34 4 screw:M6x13

35 3 screw:M2.6x4

36 1 key-way:4x8x8

37 1 planetary pin

13

ITEM

QTY.

DESCRIPTION

REMARK

38 1 spring, for planetary shaft

39 1 planetary washer:13.1x1

40 1 gear arm gasket

Gear Arm Assembly

41 1 o-ring:3x18

42 1 ball socket

43 2 spring

44 2 spring

45 1 gear arm plate

46 1 black plastic gear knob

47 1 gear arm plate

48 1 gear arm shaft

49 1 screw

50 4 nut:M4x10

51 4 nut:M10

52 1 pin:3x10

53 1 worm gear

Parts Configuration may vary. Please specify

frequency when ordering.

54 1 oil seal

55 1 ball bearing:#6203Z

56 1 motor shaft and core

Motor Assembly

57 1 motor coil

58 1 pin spring:6x12

Rear Cover of Motor Assembly

59 1 ball bearing:#6202Z

60 1 ***

61 1 ***

62 1 rear cover

63 4 screw:M5x50

64 4 spring washer:M5

65 1 bowl raise handle

66 1 pin spring

Bowl Lift Handle Assembly

67 1 bowl lift rod

68 1 pin spring:5x24

69 1 bowl lift connection

70 1 pin spring:3x18

71 2 washer:M8x16x15

72 1 spring washer:M5

73 1 washer:M8x16x1.5

74 1 nut:M8

75 1 mixer column

14

ITEM

QTY.

DESCRIPTION

REMARK

76 4 spring washer:M8

77 4 hex screw:M8x25

78 1 strain reliever

79 1 cord and plug

80 1 screw:M5x20

81 1 screw:M5x21

82 1 circuit breaker

83 1 motor capacitor

84 1 capacitor attachment

85 2 hex screw:M5x45

86 1 bowl cradle

87 2 screw:M4x4

88 1 clip

89 2 bolw locking latches

Bowl Clamp Assembly

90 2 plastic knobs

91 2 spring

92 2 washer:M5

93 4 nut-stop:M5

94 2 screw:M5x10

95 1 bowl lift bracket

96 2 bowl lock pins

97 2 spring washer:M8

98 2 nut-stop:M8

99 1 base

100

4

bottom rubber knobs

101

4

washer:M8x16

102

4

spring washer:M8

103

4

hex screw:M8x16

104

1

ball bearing:#6202

105

1

lead-in oil pad

106

1

bushing

107

1

first speed gear:46T

Parts Configuration may vary.

108

1

bushing

109

1

gear clutch:25T

110

1

third speed bushing

111

1

second speed bushing

112

1

second speed gear

Parts Configuration may vary.

113

1

bearing pad

114

1

ball bearing:#6203Z

115

1

oil sea:35x28x7

15

ITEM

QTY.

DESCRIPTION

REMARK

116

1

o-ring:S15

Parts Configuration may vary.

117

1

oil bushing- 28mm

118

1

o-ring:S15

Parts Configuration may vary.

119

1

s/s flat wahser:M8x22x2

120

1

screw and nut:M8

121

5

rollers:6.5x12.9

122

5

slice spring

123

1

clutch sleeve

124

1

drive shaft

125

1

key-way:5x5x18

126

2

key-way:4x4x28

127

1

key-way:5x5x26

128

1

ball bearing:#6200Z

129

1

transmission shaft

Parts Configuration may vary.

130

1

key-way:5x5x12

131

1

key-way:5x5x14

132

1

third speed gear:36T

133

1

bronze bushing

134

1

second speed gear

Parts Configuration may vary.

135

1

c-ring:S15

136

1

ball bearing:#6200Z

137

1

shifter yoke

Shifter Yoke Assembly

138

2

shifter yoke plunger

139

2

shifter yoke spirng

140

2

nut:M3

141

1

shifter guide rod

142

1

ball bearing:#6200Z

143

1

master shaft:18T

144

1

key-way:5x5x14

145

1

bronze worm gear

Parts Configuration may vary.

146

1

c-ring:S15

147

1

ball bearing:#6200Z

148

1

transmission case top

148_1

1

gasket

149

2

clip

Safety Guard Assembly (include Chute)

150

1

washer

151

1

screw

154

1

safety guard

154_1

1

chute of safety guard

152

1

microswitch

16

ITEM

QTY.

DESCRIPTION

REMARK

152_1

1

sleeve, for microswitch

152_2

1

nut

153

***

***

155

4

nut:M3

156

2

screw:M5

157

1

microswitch fixture

158

1

microswitch for bowl lifting

159

2

screw:M3

160

1

digital control board

161

4

washer:M6x1

162

4

screw:M3x10

163

1

fan-cooling

Loading...

Loading...