WASHING MACHINE

SERVICE MANUAL

CAUTION:

READ THIS SERVICE MANUAL CAREFULLY TO DIAGNOSE

TROUBLES CORRECTLY BEFORE OFFERING SERVICE.

CONTACT WITH YOUR SERVICE CENTER IF HAVE PROBLEM.

MODEL:

CL-AM100-S20PSF/1201

1 USER MANUAL

2 WIRING DIAGRAM / PCB LAYOUT / PROGRAM CHART

3 CAUTIONS FOR SAFETY

4 TEST MODE

5 DIASSEMBLY INSTRUCTION

6 ERORR CODES AND EXPLANATIONS

7 TROUBLE SHOOTING

8 HOW TO CHECK THE ELECTRIC PARTS

9 CHECK POINT AFTER SERVICE

10 EXPLOADED VIEW AND BOM LIST

Contents

2

UNPLUG POWER

• Unplug power cord for the work such as disassembling

which is not unnecessary to power on . Do not hold the plug

by a wet hand.

Failing to unplug may cause an electric shock.

WARNING

IMPORTANT SAFETY NOTICE

This service information is intended for individuals

possessing adequate backgrounds of electrical,

electronic and mechanical experience.

Any attempt to repair this appliance may result in

personal injury or property damage.

The manufacturer or seller can not be responsible for

the interpretation of this information, nor can it assume

any liability in connection with its use.

3

1 USER MANUAL

NOTE:

Please check the user manual about the installation,operation,

and spec etc.

4

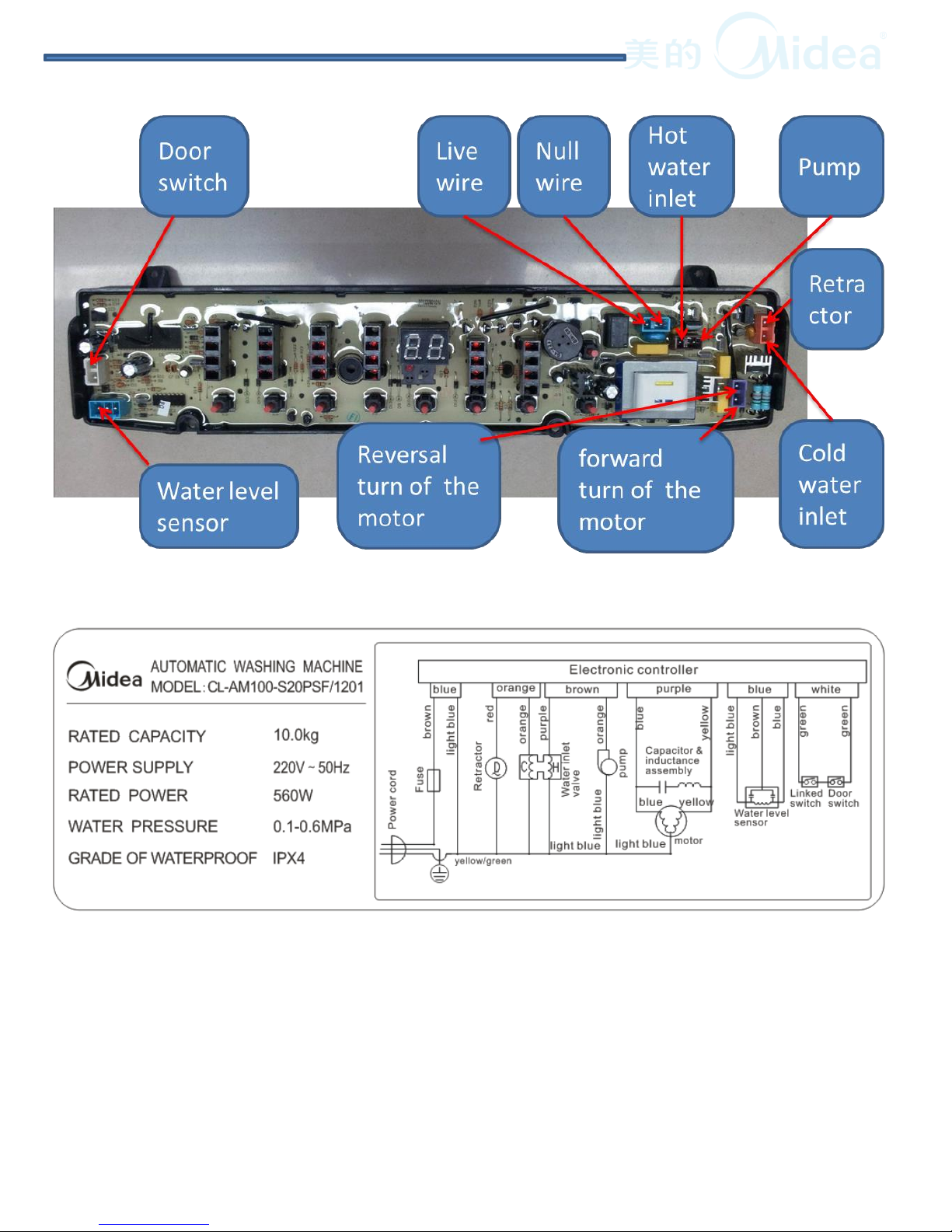

2 WIRING DIAGRAM / PCB LAYOUT / PROGRAM CHART

NOTE

发给客户时候增加客户化铭牌

电压不同,上下排水需区分

WARNING

OUT OF CHILD

• Advise the customer to keep children out of the work place.

Children may be injured with a tool or a disassembled part.

UNPLUG POWER

• Unplug power cord for the work such as disassembling which

is not unnecessary to power on . Do not hold the plug by a wet

hand.

Failing to unplug may cause an electric shock.

USE

REPAIR PARTS

• Use the specified repair parts when repairing the product.

Otherwise, a malfunction or a defect may occur.

Also, a short circuit, ignition or other danger to the customer

may occur.

CHECK

INSULATION

RESISTANCE

• After repair, measure insulation resistance between the

charging part (power cord plug) and the non-charging metallic

part (ground) with an insulation resistance meter (500V). The

resistance shall be 10M• or more.

Failing to check the insulation resistance may cause a short

circuit, electric

shock or other diseases to the customer.

DO NOT MODIFY

• Do not modify the product.

An electric shock or ignition may occur.

DO NOT

DISASSEMBLE AND

REPAIR

• Only a repair technician can disassemble and repair.

An electric shock, ignition or malfunction may cause injury.

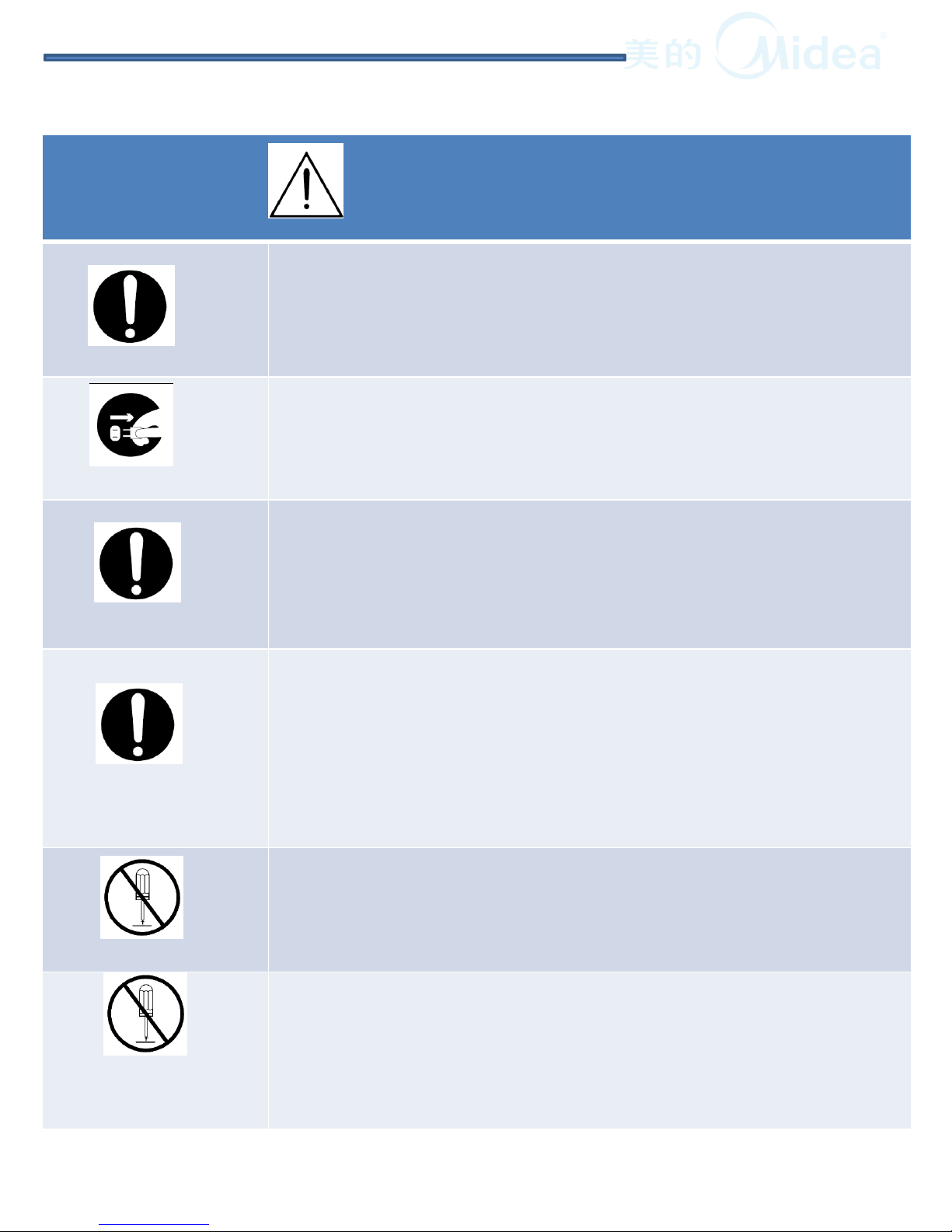

3 CAUTIONS FOR SAFETY

5

WARNING

USE EXCLUSIVE

SOCKET

• Use an exclusive A socket for the washing machine.

Otherwise, an electric shock or ignition may cause. Sharing the

same socket

with other instrument causes heating of a branch socket and

result in a fire.

CONNECT

GROUNDING WIRE

• Connect the grounding wire.

Failing to do so may cause an electric shock when a short

circuit occurs.

Consult an electric work shop or a sales shop.

DO NOT USE WET

PLACE

• Do not install in a bath room or a place exposed to wind or

rain.

An electric shock or a short circuit may cause a fire.

DO NOT SPLASH

WATER

• Do not pour or immerse electrical parts into water or liquid

solution.

An electric shock or ignition may occur.

REMOVE DUST

• Wipe off dust adhered to the plug of power cord.

Dust may cause a fire.

6

3 CAUTIONS FOR SAFETY

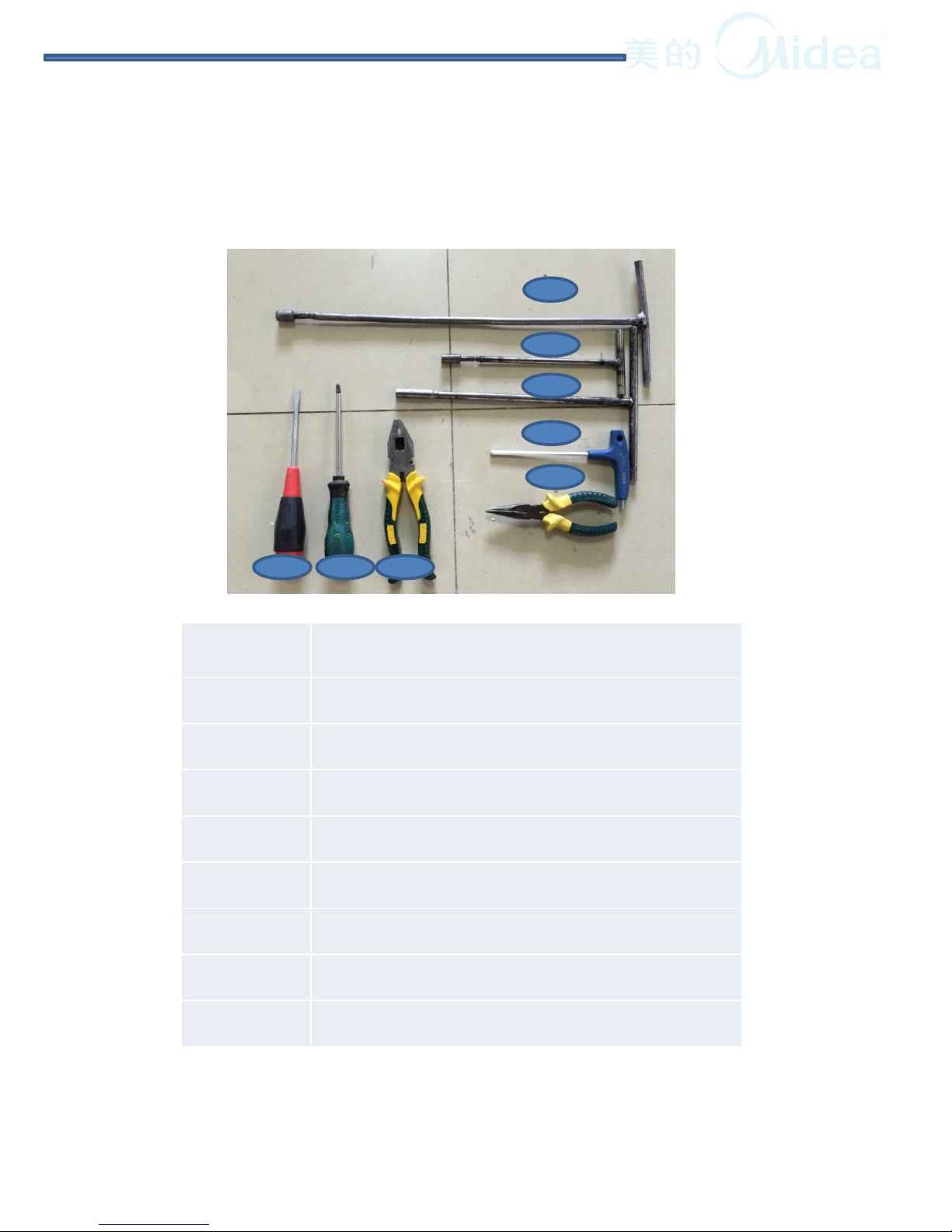

4 TEST MODE

8

1

2

3

4

5

678

Number

Tools

1

13# sleeve spanner

2

8# sleeve

spanner

3

10# sleeve

spanner

4

6# inner six angle wrench

5

Needle

nose pliers

6

pliers

7

cross screwdriver

8

slot type screwdriver

5 DIASSEMBLY INSTRUCTION

Service tools needed

UNPLUG POWER

• Unplug power cord for the work such as disassembling

which is not unnecessary to power on . Do not hold the plug

by a wet hand.

Failing to unplug may cause an electric shock.

WARNING

9

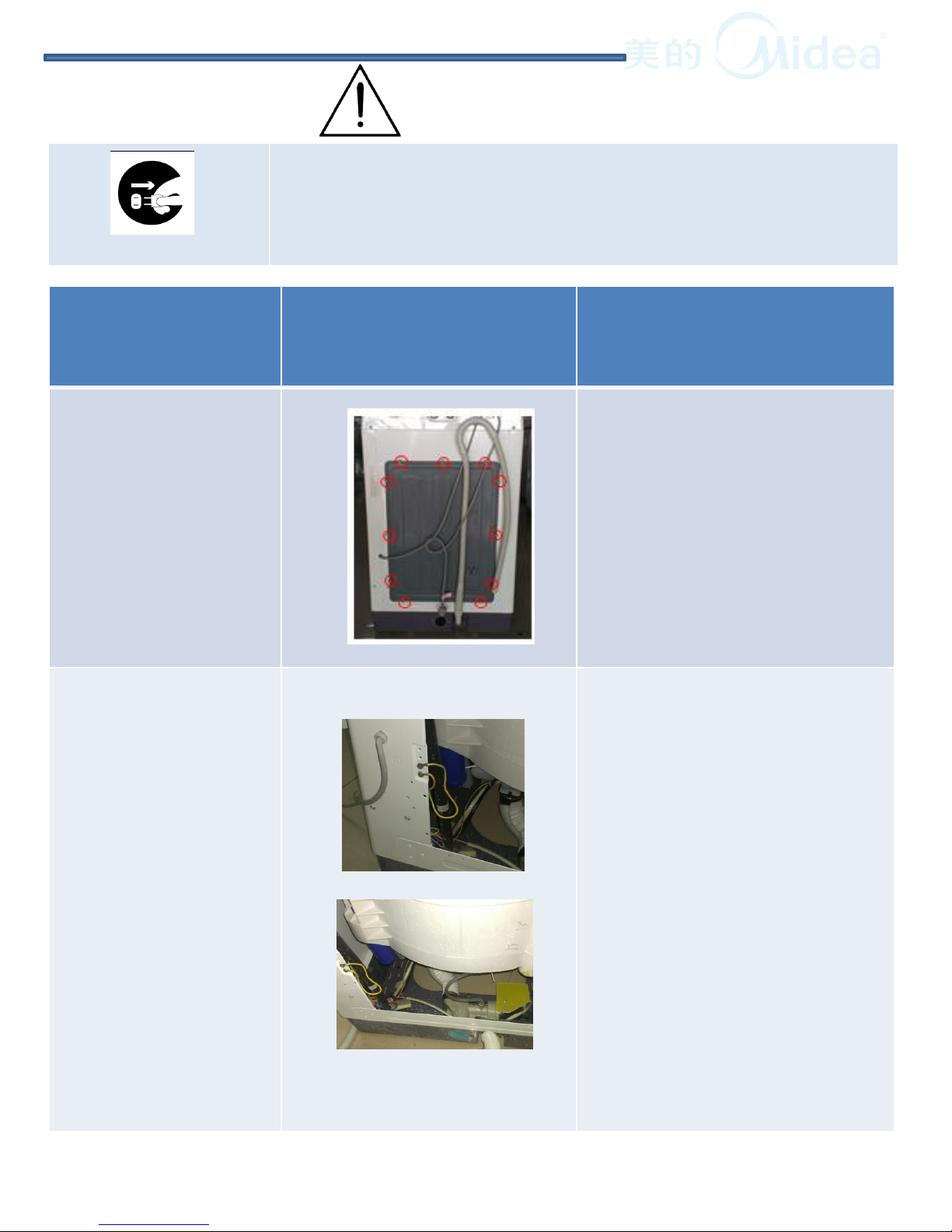

5 DIASSEMBLY INSTRUCTION

ITEM PICTURE HOW TO DISASSEMBLE

1.BACK COVER

①Unscrew the screws on the

back cover ( Red circle part) and

then take out the rear cover.

2. The earth screws,

capacitor screws, and

then pull out the air

pipe.

( make the air pipe

and

suspend poles

separate)

①Unscrew the earth screws to

make the earth wire

subassembly

and cabinet separate

②Unscrew the capacitor screws,

take down capacitor catch

③Pull out the air pipe to make

the air pipe and suspend poles

separate (When you install the

air pipe, you remember to coat

adhesive for preventing leakage)

ITEM PICTURE HOW TO DISASSEMBLE

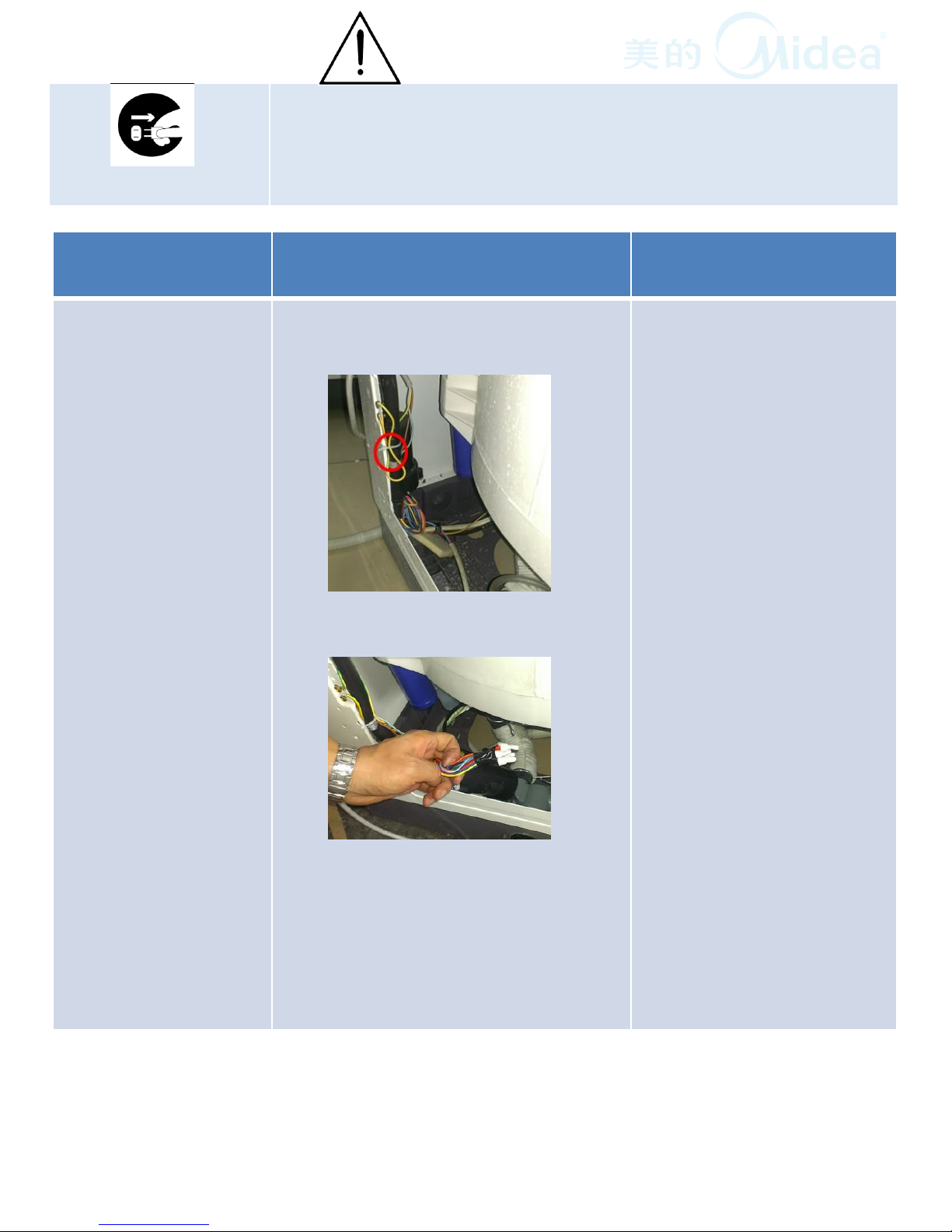

3

Pull the insulating

bag and

then remove the

wire

connector.

①

Put the Nylon

cable ties, pull the

insulating bag

②

Remove the

crimp terminal by

pliers .

UNPLUG POWER

• Unplug power cord for the work such as disassembling

which is not unnecessary to power on . Do not hold the plug

by a wet hand.

Failing to unplug may cause an electric shock.

WARNING

10

ITEM PICTURE HOW TO DISASSEMBLE

4 Top cover

①Unscrew the screws on the Top cover

(normally 2 sides 2 back. It varies

according to different designs)

②Take down the top cover, and put it

in the right place ( avoid to scratch the

top cover)

5 Remove the PCB

①Unscrew the controller board

screws, pull out the controller

board terminals(When you

plug wire and connect wires,

you must insert terminals to

the roots for not easily pulling.)

②Take down the controller board

and the front control panel

separately

UNPLUG POWER

• Unplug power cord for the work such as disassembling

which is not unnecessary to power on . Do not hold the plug

by a wet hand.

Failing to unplug may cause an electric shock.

WARNING

11

ITEM PICTURE HOW TO DISASSEMBLE

6 Take down the

back control

panel, cover switch,

water inlet valve,

water level sensor,

and internal wire

subassembly

①Remove the back control panel

screws, and take out the back

control panel.

②Remove the cover switch screws.

③Take down the water inlet valve.

④Remove the water level sensor

Screws.

⑤Take out the internal wire

Subassembly.

7 Door Lid

Use cross

screwdriver

①First remove the door bolt.

②Take down the lid

③Take out the spring

UNPLUG POWER

• Unplug power cord for the work such as disassembling

which is not unnecessary to power on . Do not hold the plug

by a wet hand.

Failing to unplug may cause an electric shock.

WARNING

12

ITEM PICTURE HOW TO DISASSEMBLE

8 outer tub cover

①Unscrew the outer tub

cover screws, and take

out the outer tub cover

9 Impeller

①

Unscrew the impeller

screws, and take out

the impeller

UNPLUG POWER

• Unplug power cord for the work such as disassembling

which is not unnecessary to power on . Do not hold the plug

by a wet hand.

Failing to unplug may cause an electric shock.

WARNING

13

ITEM PICTURE HOW TO DISASSEMBLE

10 Spin tub

①

Unscrew the spin tub bolts and

take

out the spin tub cover

11 Out

tub

①

Firstly make suspension rods

and the outer tub subassembly

separately.

(Remember the rods

installing order.

)

②

Take out the out tub

UNPLUG POWER

• Unplug power cord for the work such as disassembling

which is not unnecessary to power on . Do not hold the plug

by a wet hand.

Failing to unplug may cause an electric shock.

WARNING

14

ITEM PICTURE HOW TO DISASSEMBLE

12 Parts

attached

on the out tub

①

Remove the motor screws, and

take out motor.

②

Remove the bracket screws,

and take out bracket.

③

Remove the clutch body

subassembly screws, and take

out clutch body subassembly.

④

Firstly make retractor and the

clutch body subassembly

separately., remove retractor

screws, and take out retractor

13 Base plate

①

Remove the base plate screws,

and take out the base plate.

UNPLUG POWER

• Unplug power cord for the work such as disassembling

which is not unnecessary to power on . Do not hold the plug

by a wet hand.

Failing to unplug may cause an electric shock.

WARNING

15

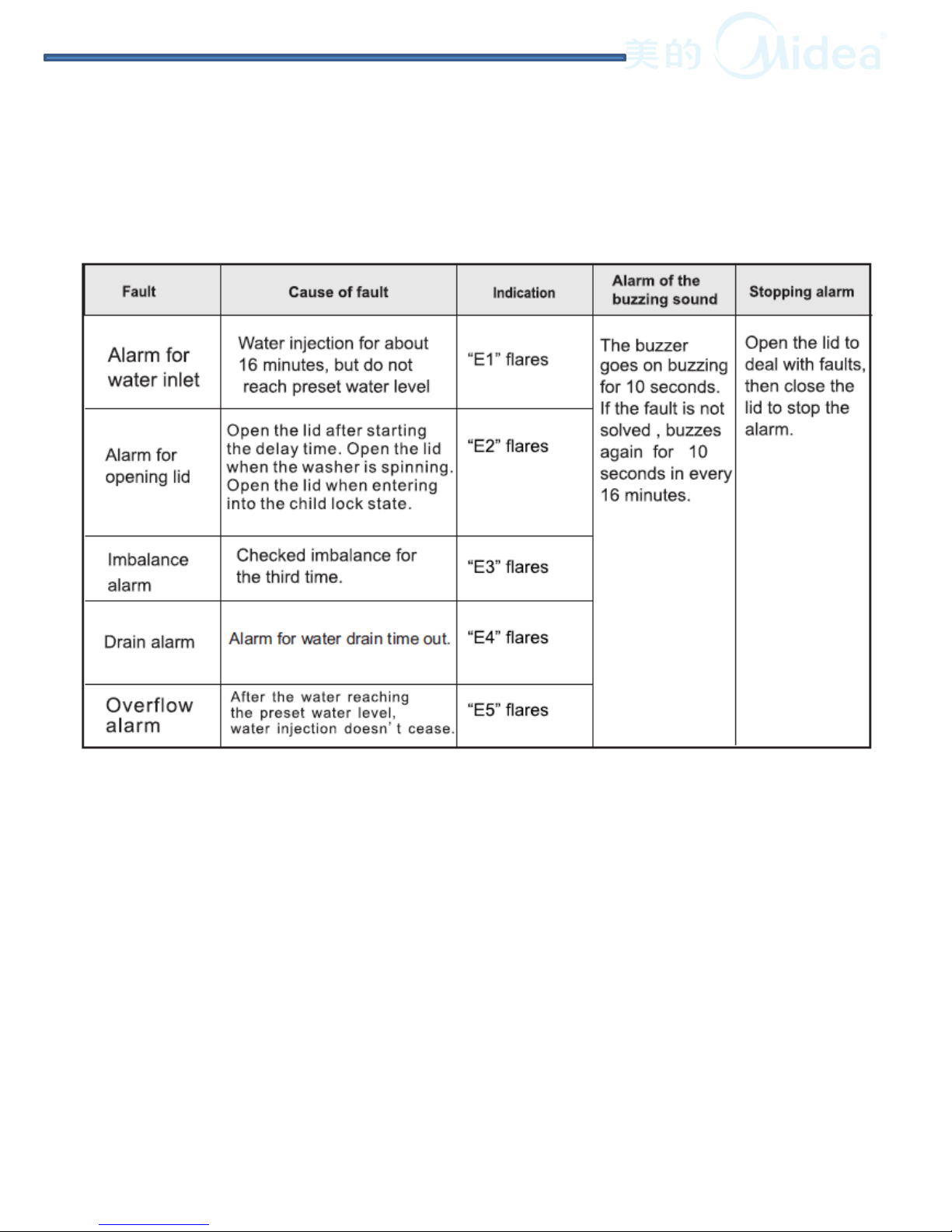

6 ERORR CODES AND EXPLANATIONS

16

Error Code

Unit Action

Description

PossibleCauses

Explanation

E1

Water is not

supplied

:

When water in the

tub didn`t achieve

the specified level in

30min,PCB will

display

“E1”.Remind the

timeout.

Some machine is

30min or more than

30min

There is no

water or

water is

very small

The water tap did not open

Check the tap have opened or not

Water pressure is small, into the

water is very small

Check the water pressure is smaller

than usual or not

water inlet valve is blocked, water

inflow is very small

When the water pressure normal

,

water inflow is small or not

Loose fill valve connected to the

power cord

Reconnect the power cord to check

whether can return to normal

Loose PCB connected to the

power cord

Reconnect the power cord to check

whether can return to normal

water inlet valve damage does

not work

Replace the inlet valve check

whether the function is OK

PCB failure

Replace the PCB check whether the

function is OK

Can't stop

the water

Water level sensor pressure pipe

is

loose,or water in the pipe

Check the water level sensor

pressure pipe is loose or leak

Water level sensor failure

Replace the Water level sensor

check whether the function is OK

PCB failure

Replace the PCB check whether the

function is OK

E2

Alarm for Lid open:

When the washing

machine in the

"spin" program,

safety switch is not

closed, cause the

machine alarm.

Cover is

opened

Cover is opened

Check that the lid is on or not

Cover is

closed

Safety switch contact undesirable

close the lid

,Check safety switch

contact undesirable or not

Safety switch and power cable

loose

Reconnect the power cord to check

whether can return to normal

PCB failure

Replace the PCB check whether the

function is OK

E3

Alarm for unbalance:

Ouer tub hit the

safety switch or

cabinet seriously,the

machine can`t spin

smoothly.

Machine is

unbalanced

Washing machine leg is

unbalanced

Check whether the machine is

unbalance or rock

clothes is unbalanced

Check whether the clothes is placed

evenly

The suspension failure

machine is

balanced,but it still

shaking seriously

Safety switch beam deformation

Safety switch beam deformation

17

6 ERORR CODES AND EXPLANATIONS

Error Code

Unit Action

Description

PossibleCauses

Explanation

E4

Alarm for not draining:

When water in the tub

didn`t drain out

absolutely in 10min,PCB

will display

“E4”.Remind the

timeout.

Some machine is 15min

or more than 15min

the water in the

tub didn`t drain

out absolutely

drain

-pipe is hung too

high

Drain pipe is not installed

correctly

Drain valve is blocked

Check whether there are

foreign bodies blocked drain in

drain valve

Drain valve is not fully

open

Bad fit with retractor and drain

valve

inner drain

-pipe is

blocked

Check that whether the drain

pipe have obvious bending

drain

-pipe is blocked

Check that whether the inner

drain pipe have obvious

bending

Drain pump filter is

blocked

Remove drainage pump filter

to check if there is any foreign

body blocked drain pump

Retractor is not open

Tractor has sound but can't

open the drain valve

The retractor is not running,

check whether the circuit is

normal

Replace the PCB check whether

the function is OK

Replace the retractor check

whether the function is OK

Drain pump cann`t drain

drain pump has sound but

can't drain normally

The drain pump is not running,

check whether the circuit is

normal

Replace the drain pump check

whether the function is OK

Replace the PCB check whether

the function is OK

PCB failure

Replace the PCB check whether

the function is OK

the water in the

tub is drain out

absolutely

Water level sensor

failure

Replace the water level sensor

check whether the function is

OK

PCB failure

Replace the PCB check whether

the function is OK

E5

Alarm for overflowing

:

When water level more

than the highest water

level,the machine will

alarm "E5",remind

Remind the overflowing

the water in the

tub is full

Inject extra water in the

washing machine

artificially

Inject extra water in the

washing machine artificially

Can't stop the

water

Water water inlet valve

can't turn off

water inlet valve can't stop the

water without power

the water level

is OK

Water level sensor

failure

Replace the water level sensor

check whether the function is

OK

PCB failure

Replace the PCB check whether

the function is OK

18

7 TROUBLESHOOTING

BEFORE SVC CHECKING

Before servicing ask the customer what the trouble is.

Check the work status of the problem.

Check the adjustments. (Power supply, water supply Installation

etc.

Check the troubles referring to the troubleshooting.

Decide service steps referring to disassembly instructions.

Check other related parts when do the service and repair.

After servicing, operate the appliance to see whether it works OK

or NOT.

7.1Washer Won't Start (Press the “POWER ”button, not light)

The most common part(s) or condition(s) which contribute to the

symptom Washer won't start are listed below. Check or test each item.

If you are still unable to solve the problem you may need to do

additional research and troubleshooting.

Causes Explanation

Incoming Power Problem

Check the power at the electrical outlet which the

washer is plugged into. Plug a lamp or radio into the

outlet to check it. If the outlet is dead, check the circuit

breakers or fuses for the home.

Power Cord

If power supply is OK, the power cord itself might be

defective. This is rare. You can check the power cord

with an Ohm meter for continuity.

Line Fuse

If the washer won't start the line fuse might have

blown, or the line fuse holder might be damaged and

need to be replaced.

Main Control Board(PCB)

If the washer won't start the main control board might

be defective.

19

7 TROUBLESHOOTING

7.2 Washer Fills slowly or not supply

(If the water supply is not finished in 30mins after the water supply

has started, the buzzer rings and “E1” is displayed on the indicator)

The most common part(s) or condition(s) which contribute to the

symptom Washer fills slowly are listed below. Check or test each item. If

you are still unable to solve the problem you may need to do additional

research and troubleshooting.

Causes Explanation

Low Water Pressure from

House Supply

If the washer fills very slowly, the water pressure from

the house might be too low. If the water inlet valve isn't

leaking and there are no other symptoms this problem

does not need to be corrected.

Water inlet hose

Make sure that water faucet is turned on and that the

screens on the hoses are not restricted.

Water inlet valve

(The voltage on the water

inlet valve is normal)

If the water pressure is good, try cleaning the screens

inside the water inlet valve hose connection ports. If

those are clean replace the water inlet valve.

Water level sensor or

control switch

(No voltage on the water

inlet valve)

A water lever control switch controls how much water

enters the washing machine by PCB. If the water level

control switch is defective, or more commonly, if the

small air pipe attached to the air bell restricted, The

switch will not be able to close the electrical contacts

to the washer fill valve.

CHECK THE AIR PIPE

CHECK THE WATER LEVERL SENSOR

CHECK THE PCB and the inner wire between PCB and

the sensor

20

7 TROUBLESHOOTING

7.3 Washer Overflowing (Water fills not stop)

The most common part(s) or condition(s) which contribute to the

symptom Washer overflowing are listed below. Check or test each item.

If you are still unable to solve the problem you may need to do

additional research and troubleshooting.

Causes Explanation

Water inlet valve

If the washer is overflowing and power is shut off to

the washer, the water inlet valve has failed. Replace it.

Water level sensor or

control switch

A water lever control switch controls how much water

enters the washing machine by PCB. If the water level

control switch is defective, or more commonly, if the

small air pipe attached to the air bell comes off, there

will no longer be pressure in the hose pushing on the

air tight diaphragm in the water level control switch.

The switch will not be able to open the electrical

contacts to the washer fill valve.

CHECK THE AIR PIPE

CHECK THE WATER LEVERL SENSOR

CHECK THE PCB and the inner wire between PCB and

the sensor

21

7 TROUBLESHOOTING

7.4 Washer Won't Agitate or some abnormal noise

The most common part(s) or condition(s) which contribute to the

symptom Washer won't agitate are listed below. Check or test each item.

If you are still unable to solve the problem you may need to do

additional research and troubleshooting.

Causes Explanation

Agitator or Impeller Kit

If the washer won't agitate this agitator repair kit may

solve the problem. The kit contains the components that

wear out over time. This is a relatively easy repair.

Door or Lid Latch

Assembly

The lid switch assembly might be defective. This is a very

common problem. The lid switch assembly can fail either

mechanically or electrically. Test any electrical switches

with an Ohm meter for continuity. The switches should

have continuity according to their design.

Motor Coupling

If the washer won't agitate the motor coupling might

have failed. The motor coupling connects the motor to

the washer transmission. It is designed to fail if the

washer is overloaded in order to protect both the motor

and transmission.

Drive Belt(V-BELT)

If the washer won‘t agitate the drive belt might have

worn out. Over time the drive belt will fail just from

normal use . Replace the belt every three or five years

depending on how much the washer is used.

Motor capacitor

The assembly of electric capacitor is mainly used to start

motor and control the motor rotation direction. If the

motor capacitor is defective the washer may not work at

all or function properly.

Drive Motor

This is not common. Check all of the other related parts to

this symptom before replacing the motor. If the motor is

visibly burned out or physically damaged it will have to be

replaced.

Main Control

Board(PCB)

If the washer won't Agitate the main control board might

be defective.

22

7 TROUBLESHOOTING

7.5 Washer Won't drain or some abnormal noise

The most common part(s) or condition(s) which contribute to the

symptom Washer won‘t drain are listed below. Check or test each item.

If you are still unable to solve the problem you may need to do

additional research and troubleshooting.

Causes Explanation

Clogged drain valve or

Hose

It's common for small socks or other small clothing items

to get into the water drain system and clog the hose

leading to drain valve or the drain valve itself. Remove the

hoses from the drain valve in order to remove the article

of clothing before replacing the drain valve.

Door or Lid Safety

switch Assembly

The lid switch assembly might be defective. This is a very

common problem. The lid switch assembly can fail either

mechanically or electrically. Test any electrical switches

with an Ohm meter for continuity. The switches should

have continuity according to their design.

Retractor

Retractor is consisted of motor and traction system, it can

drive the drain valve to drain water, and at the same time

control the clutch to achieve the conversion from washing

to spinning operation. If the washer won't drain, should

check the retractor.

Drain Pump

(Only for up drain

system)

It‘s common for a small sock or other article of clothing

to get caught in the drain pump .Check both for an

obstruction before check and replace the pump

Water level sensor or

control switch

If the water level control switch is defective, or more

commonly, if the small air pipe attached to the air bell

comes off, there will no longer be pressure in the hose

pushing on the air tight diaphragm in the water level

control switch. The switch will not be able to close the

electrical contacts to the drain valve.

CHECK THE AIR PIPE

CHECK THE WATER LEVERL SENSOR

CHECK THE PCB and the inner wire between PCB and the

sensor

23

7 TROUBLESHOOTING

7.6 Washer Won't spin or vibration, making noise

The most common part(s) or condition(s) which contribute to the

symptom Washer won‘t spin are listed below. Check or test each item.

If you are still unable to solve the problem you may need to do

additional research and troubleshooting.

Causes Explanation

Imbalance load

E4--Alarm for

imbalance

Is the laundry spread out evenly in the washer?

Is the washer set on a sturdy flat surface?

Washer vibration can occur if one of the leveling legs is

out of adjustment, be sure to adjust each leg until the

machine is level side to side and front to back

Won't drain

SEE 7.5 Washer Won't drain or some abnormal noise

Door or Lid Safety

switch Assembly

The lid switch assembly might be defective. This is a very

common problem. The lid switch assembly can fail either

mechanically or electrically. Test any electrical switches

with an Ohm meter for continuity. The switches should

have continuity according to their design.

Tub Seal and Bearing

Kit and Balance Ring

If the washer won't spin the tub seal and bearing kit and

Balance Ring might need to be replace. This is a very

involved repair and will require disassembling most of the

washer. If the bearing is bad the problem is going to get

worse very quickly and so either the kit will need to be

replaced or the washing machine.

The suspension rod

assembly

The suspension rod assembly connects the tub

subassembly to cabinet. It reduces the vibration of the

washer during washing and spinning.Washer vibration

can occur if one or more suspension rods are broken.

Check all four rods, replace any that are broken.

24

7 TROUBLESHOOTING

Causes Explanation

Motor Coupling

If the washer won't spin the motor coupling might have

failed. The motor coupling connects the motor to the

washer transmission. It is designed to fail if the washer is

overloaded in order to protect both the motor and

transmission.

Drive Belt(V-BELT)

If the washer won't spin, check the drive belt. If the belt is

broken or if it isn't tight on the pulleys the washer won't

spin properly.

Clutch

The clutch assembly makes the connection between the

transmission and the inner tub. As the clutch wears out it

may prevent the tub from spinning. The clutch is not

repairable, if it is loud or not working properly it will need

to be replaced.

Motor capacitor

The assembly of electric capacitor is mainly used to start

motor and control the motor rotation direction. If the

motor capacitor is defective the washer may not work at

all or function properly.

Drive Motor

This is not common. Check all of the other related parts to

this symptom before replacing the motor. If the motor is

visibly burned out or physically damaged it will have to be

replaced.

Main Control

Board(PCB)

If the washer won't spin the PCB also might be defective.

The motor control board provides power to the motor as

well as direction and force. If the motor control board is

defective the washer may not work at all or function

properly.

25

7 TROUBLESHOOTING

7.7 Electric leakage

The most common part(s) or condition(s) which contribute to the

symptom Electric leakage are listed below. Check or test each item.

If you are still unable to solve the problem you may need to do

additional research and troubleshooting.

Causes Explanation

Power cord

Power affected with damp or damaged

Incoming Power

Problem

Outlet ground connection not reliable

Earth Grounded wire

Make the ground connection reliable.

Motor

Motor affected with damp should be dried or replaced

Other parts have

electricity

Parts have water may leak electricity

26

7 TROUBLESHOOTING

7.8 Washer Leaking Water

The most common part(s) or condition(s) which contribute to the

symptom Washer Leaking Water are listed below. Check or test each item.

If you are still unable to solve the problem you may need to do

additional research and troubleshooting.

Causes Explanation

Water inlet hose

If the washer is leaking water, check the inlet hose, this is

the most common place for water to leak. Replace them

with stainless steel or some other, more durable hose.

Drain Hose

If the washer is leaking water check the drain hose. The

most common places for the hose to spring a leak is

from the connection to the valve out to the back of the

washer. Another common occurrence is when the

washer gets pushed too far back against the wall.

Tub Seal and Bearing

Kit

If the washer is leaking water the tub seal and bearing

kit might need to be replace. This is usually a very

involved repair and will require disassembling most of

the washer.

27

7 TROUBLESHOOTING

8 HOW TO CHECK THE ELECTRIC PARTS

28

Before repairing, use multimeter to judge circuit stand of fail

.

Part. Circuit Diagram/Principle Where, what & how to check?

Motor&

Capacitor

The assembly of electric

capacitor it is mainly used to

start motor and control the

motor rotation direction. And

different capacitance should

suit for different motor, or the

motor would not work

properly

Check resistance of the motor.

Check capacitance of the capacitor.

yellow

blue

Light

blue

blue

yellow

Test point

Normal value

Yellow-Blue

Indicating needle rises

and immediately

indicates ∞.

The needle

is stopped after it is

raised.

Means

Lack of capacitance of the

capacitor

.

The

needle doesn’t move Means

Capacitor is fully discharged.

Test point

Normal value

Yellow

—Light

blue

15

~25Ω

Blue

—Light blue

15

~25Ω.

29

8 HOW TO CHECK THE ELECTRIC PARTS

Part. Circuit Diagram/Principle Where, what & how to check?

Retractor

/Drain

motor

Retractor is consisted of motor

and traction system, it can

drive the drain valve to drain

water , and at the same time

control the clutch to achieve

the conversion from washing

to spinning operation .

Check resistance of the drain

motor

Drain

pump

Check resistance between terminals

Light

blue

red

Test point

Normal value

Red

-Light blue

5.5

—8.0KΩ

Test point

Normal value

Red

-Light blue

120

-170Ω

red

Light

blue

30

8 HOW TO CHECK THE ELECTRIC PARTS

Part. Circuit Diagram/Principle Where, what & how to check?

Inlet

Valve

Check resistance of the Inlet Valve

(

Coil)

Water

Level

Sensor

The water level sensor located

at the top frame ,consists of a

sensor and a pressure hose. It

can detect the pressure of

water and transfer the

information to PCB

Check frequency of the pressure

switch without load if wash is

proceeding without filling.

First

terminal

Second

terminal

First

terminal

Third

terminal

Test point

Normal value

1-24-

6KΩ

Test point

Frequency

(

KHZ

)

Water level

1

-2

26.70±0.

3

0.00

1

-2

24.05-

21.93

Full

31

8 HOW TO CHECK THE ELECTRIC PARTS

Part. Circuit Diagram/Principle

Where, what & how to

check?

Safety

Switch

The safety switch can cut off the

motor power when the cover is

lifted during spinning, another

function of the safety switch is to

prevent the tub from destroying

the cabinet, when the clothes in

the tub is out of balance

Check whether the lever of

the safety switch touches

the outer tub if touching

noise happens.

Check contact defect of the

safety switch, defect of

connection parts and

whether the lid is open if

door error is displayed.

32

9 CHECK POINT AFTER REPAIR

After repairing, be sure to make the following trial operation to see if

the washer operates normally.

Check Point Inspection & Judgement

1 Insulation resistance

Unplug the cord from the power outlet and turn on all

the timers. Then

measure the insulation resistance between the plug

(both of 2 pins) and

Grounding wire of the machine.

The measured value should be more than1M

In the following case, check sufficiently.

1)Replace the electrical part switch new ones.

2)Used in a moist place.

3)Used more than 5 years.

2 Safety designated

parts

Replace with the designated parts in the case the used

parts are not proper.

3 Wiring

Check to see if the lead wire is properly connected

without looseness or

Over tension and taping and setting are firmly performed.

washer.

4 Screws and Nuts

Check to see if the screws, nuts, etc are firmly tightened

and the screw locks are applied

5 Removal of useless

matter

Check to see if useless matters (Screws, bits of wire, etc.)

are left inside the machine.

6 Leakage of oil and

water

Check to see if oil or water leaks out around belowspinning, gear box, motors

7 Power-cord

Check to see if the cord, the plug, the outlet etc., are not

damaged. Do not use table

Tape with multi-wiring

8 Level Installation.

Check to see if the machine installed horizontally

33

10 EXPLOADED VIEW AND BOM LIST

Loading...

Loading...