SOFT-SERVE AND FROZEN YOGHURT FREEZER

USER GUIDE

(OPERATING MANUAL)

for

MODEL: EFE 2500 AP / APS / ANP / APH

Manual Number: V 005 – 19.08.2014

1

EFE 2500 AP/APS/ANP/APH

1.TABLE OF CONTENTS

1.TABLE OF CONTENTS ..................................................................................................................... 1

2.CONGRATULATIONS AND THANK YOU! ........................................................................................ 3

3.SYMBOLS IN MANUAL ................................................................................................................... 4

4.CONTACT DETAILS & HELP DESK .................................................................................................... 5

5.ELECTRICAL CONNECTION NOTICE ................................................................................................ 6

6. WARNINGS & SAFETY ................................................................................................................... 7

7. PARTS IDENTIFICATION ................................................................................................................ 9

7.1 Exploded View of Machine .................................................................................................... 9

7.2 Exploded View of Dispensing Head ...................................................................................... 15

7.3 Exploded View of Self Service Unit ...................................................................................... 16

7.4 Exploded View of Beater ...................................................................................................... 17

7.5 Exploded View of Dasher ..................................................................................................... 18

7.6 Exploded View of Aeration Pump ........................................................................................ 19

7.7 Exploded View of Compression Feed Pipe ........................................................................... 21

7.8 Exploded View of Liquid Level Sensor .................................................................................. 22

8. MACHINES WITH AIR-COOLED CONDENSER .............................................................................. 23

9. MACHINES WITH WATER-COOLED CONDENSER ........................................................................ 24

10. CONTROL DIAL .......................................................................................................................... 25

11. OPERATING PROCEDURE .......................................................................................................... 26

12. PREPARATION AND START UP PROCEDURE ............................................................................. 26

12.1 PREPARATION .................................................................................................................... 26

12.2 STARTING THE MACHINE ................................................................................................... 27

12.3 DISPENSING ICE CREAM ..................................................................................................... 30

13. STEP-BY-STEP CLEANING - SANITIZING PROCEDURE ................................................................ 30

13.1 CLEANING PROCEDURE ...................................................................................................... 31

13.2 BRUSH CLEANING PROCEDURE .......................................................................................... 33

13.3 SANITIZING PROCEDURE .................................................................................................... 36

14. STEP-BY-STEP ASSEMBLY PROCEDURE ..................................................................................... 37

14.1 DISPENSING HEAD ASSEMBLY ............................................................................................ 37

14.1.1 Dispensing Head O-Ring Assembly: ............................................................................ 37

14.1.2 Dispensing Head Piston – O-Ring Assembly: .............................................................. 37

14.1.3 Dispensing Head Piston Assembly: ............................................................................. 38

14.1.4 Dispensing Head Nozzle – O-Ring Assembly: .............................................................. 39

14.1.5 Dispensing Head Piston Lifter Assembly: .................................................................... 40

14.1.6 Dispensing Head Lifter Rod Assembly: ....................................................................... 40

14.1.7 Dispensing Head Assembled ....................................................................................... 41

14.2 BEATER ASSEMBLY ............................................................................................................. 41

14.2.1 Pusher Assembly: ........................................................................................................ 41

2

EFE 2500 AP/APS/ANP/APH

14.2.2 Blade Assemble Positions: .......................................................................................... 41

14.2.3 Seal Assembly:............................................................................................................. 43

14.2.4 Beater Assembled ....................................................................................................... 43

14.2.5 Dasher Assembly ......................................................................................................... 44

14.3 INSERTING THE ASSEMBLED BEATER INTO THE BARREL ................................................... 44

14.4 FITTING THE ASSEMBLED DISPENSING HEAD .................................................................... 45

14.4.1 Placing the Dispense Head: ......................................................................................... 46

14.4.2 Tightening the Screws: ................................................................................................ 46

14.4.3 Speed Adjustment: ...................................................................................................... 47

14.5 COMPRESSION FEED PIPE ASSEMBLY ................................................................................ 48

14.5.1 O-Ring Assembly: ........................................................................................................ 48

14.5.2 Pipe Connection Assembly: ......................................................................................... 48

14.5.3 Check Valve Assembly: ................................................................................................ 48

14.6 THE AERATION PUMP ASSEMBLY ...................................................................................... 49

14.6.1 Aeration Pump Cover Disassembled: .......................................................................... 49

14.6.2 Pump Cover O-Ring and Relief Spring Assembly ....................................................... 50

14.6.3 Feeder Tube Assembly ............................................................................................... 51

14.6.4 Aeration Pump Feeder Tube – Air Adjustment........................................................... 52

14.6.5 Pump Body Assembly .................................................................................................. 54

14.6.5.1 Pump Body Disassembled ........................................................................................ 54

14.6.5.2 Gears and O-Ring Assembly ..................................................................................... 54

14.6.5.3 Drive Shaft Assembly ............................................................................................... 55

14.6.6 Pump Body – Pump Cover Assembly .......................................................................... 55

14.7 ASSEMBLY OF PUMP TO THE MACHINE ............................................................................ 56

14.8 ASSEMBLY OF HOPPER AGITATOR TO THE MACHINE ....................................................... 57

14.9 LIQUID LEVEL SENSOR ASSEMBLY ...................................................................................... 60

14.10 HOPPER COVER ASSEMBLY .............................................................................................. 60

15. POSSIBLE FAILURES AND SOLUTIONS ....................................................................................... 61

16. ELECTRICAL CIRCUIT DIAGRAMS .............................................................................................. 63

WARRANTY DOCUMENT AND CONDITIONS ................................................................................... 62

3

EFE 2500 AP/APS/ANP/APH

2.CONGRATULATIONS AND THANK YOU!

Congratulations and thank you for acquiring a Soft-Serve Ice Cream Machine

manufactured especially in Turkey by Smach® Gıda Makine A.Ş.

If you encounter a problem with the Smach® Soft Serve Ice Cream Machine, please

contact your local service technician.

Please familiarize yourself with the machine by taking some time to study this manual. If

you get to know this little ice-cream factory, it has the potential of making good profit.

Notice and no warrantee: These pages are provided as a service and informational

purpose only, and on the assumption that the recipient of the Soft-Serve Freezer and the

operator of the Soft-Serve Freezer is competent to perform the required tasks, including,

but not limited to operation and/or repair of power equipment, for which the information is

provided, and that person is knowledgeable and mindful of proper safety precautions.

Neither Smach®, nor any of their respective employees make any claims about the

suitability or fitness of the information contained herein which is provided strictly on an "asis" basis, without any express or implied warranty, guarantee, assurance of quality,

conformity of specifications, reliability, functionality, or suitability. In no event shall

SMACH® and/or its employees be held liable, whether in contract or tort, to any party for

any direct, indirect, punitive, or consequential damages, including, but not limited to lost

profits and business interruption, arising out of any errors, typographical or otherwise,

inaccuracies, omissions, or delays arising out of or pertaining to the use, reliance on, or

inability to use any type of information, part, or good, even if notified in advance about the

possibility of such action. Information in this manual is subject to change without notice. All

rights reserved.

BEFORE USING THE MACHINE READ CAREFULLY THIS

MANUAL. PAY ATTENTION TO THE SAFETY INSTRUCTIONS.

4

EFE 2500 AP/APS/ANP/APH

3.SYMBOLS IN MANUAL

WARNING

When you see this symbol on your freezer or in this manual, be

alert to the potential for personal injury. Follow recommended

precautions and safe operating practices.

ELECTRIC DANGER

This symbol indicates the presence of electric shock hazards.

NOTE

It points out significant information for the stuff involved.

PROTECTIONS

This symbol means that operator must use protection against an

implicit risk of accident.

MACHINE OPERATOR

He/She is the person who has no specific expertise and she/he

will operate the freezer.

MAINTENANCE ENGINEER

He/She is a skilled engineer for the operation of the machine

under normal conditions; he/she is able to carry out interventions

on mechanical parts and all adjustments, as well as maintenance

and repairs. He/She is qualified for interventions on electrical and

refrigeration components.

5

EFE 2500 AP/APS/ANP/APH

4.CONTACT DETAILS & HELP DESK

Smach® Gıda Makine San.Tic.A.Ş

ADDRESS AND CONTACT DETAILS

Smach® Gıda Makine San.Tic.A.Ş

Guzelyurt Mah.5762 Sok.No 5/A

Orta Olcekli San.Bol.

Manisa/TURKEY

Tel: +90 236 233 39 29

Fax: +90 236 236 12 59

E-Mail: info@smach.com.tr

When calling Smach® have the following information ready:

1. Freezer Serial Number: Found on body panel

2. A brief description of the problem

6

EFE 2500 AP/APS/ANP/APH

5.ELECTRICAL CONNECTION NOTICE

1. Please make sure that the power supply conforms to the electrical data label (Rating

Plate).

2. Check the data label (Rating Plate) for the required circuit breaker amperage. Only plug

into an electrical wall socket that complies with the required amperage of the machine.

3. Machine should be installed according to the local authority electrical code/regulations it

is used in, as well as to other work health and safety requirements. If you are not sure,

please contact your local authority for details.

4. This symbol indicates the presence of electric shock hazards. Inside the

enclosures of the machine there are electrical shock hazards, therefore,

DO NOT remove any panels if you are not a qualified technician of an

authorized service provider.

5. WARNING: To avoid risk of injury from electric shock, if you are not a

qualified and duly authorized service technician, do not open the enclosure

panels on the sides and back of the machine.

6. The power supply must be properly grounded to prevent electrical shock. Check with a

qualified installer for compliance.

7. The fuse must be 220-240V, 50 Hz 16 Amp / 24 Amp or 380-400V, 50 Hz 32 Amp (

Before plugging in the machine, see metallised label on the back of the machine.)

7

EFE 2500 AP/APS/ANP/APH

6. WARNINGS & SAFETY

Read and understand all safety messages in this manual. Read and understand the safety

decals on your freezer. Take notice of the location of all decals on the freezer and keep

the safety decals in good condition. Check them periodically and replace missing,

damaged or illegible safety decals. The safety decals must remain in place and legible for

the life of the freezer.

Keep your Freezer clean and tidy! When it needs repairing, work with an authorized

SMACH® service agent.

Smach® is concerned about the safety of the person/s using the machine. Therefore

please take note and abide by amongst others, the following WARNINGS:

The weight of the machine is no less than 190 kg. The person who

carries the machine must be careful while moving the freezer.

Do NOT touch barrel feeder hole during cleaning.

Always follow local authority food safety and other health codes.

Always follow in-store operating and food hygiene safety and other

health code

Do not clean the machine with high-pressure water.

Use potable water to clean the parts.

Do NOT use the machine before studying this User Guide. Failure to

follow this instruction may result in equipment damage, poor

performance, health hazards or personal injury.

Only use food-grade lubricant when changing or replacing the O-

rings on the pistons.

A potential risk exists if the User Guide instructions and other safety

precautions are not strictly followed.

Do NOT allow anyone to attempt any repairs to the machine, unless

the main power supply to it has been disconnected from the power

supply point.

Never open the panels to reach inside the Freezer body. (Only by

authorized technicians)

Technical maintenance must be done by authorized technicians.

8

EFE 2500 AP/APS/ANP/APH

Do NOT allow untrained personnel to operate the Soft-Serve

Freezer.

Do NOT insert or remove the beater from the freezing barrel while

the Machine is connected to the power supply. First isolate the power

supply.

Do NOT remove the hopper cover (lid) unless you are filling or re-

filling the hopper with the mix.

Do NOT switch ON the Machine at the wall socket switch when the

following has not yet been done: (a) the beater is inserted properly

(b) the barrel head is fitted correctly and the four nuts screwed on

correctly and tightly, and (c) the barrel is flooded with Mix.

When removing, replacing or cleaning the removable parts do so with

caution because the beater blades have sharp edges that can easily

cause injury.

WINTER STORAGE

If the place of business is to be closed and the machine won’t run during

the winter months, it’s important to protect the freezer.

Disconnect the freezer from the main power source to prevent possible

electrical damage.

For WATER-COOLED freezers, disconnect the water supply. Use the air

pressure on the outlet side to blow out any water remaining in the condenser. This is

extremely important. Failure to follow this procedure may cause severe and costly damage

to the refrigeration system.

NOTICE: Smach® Gıda Makine A.Ş will not take any responsibility if the users do not follow

all the instructions as described in this User Guide.

9

EFE 2500 AP/APS/ANP/APH

7. PARTS IDENTIFICATION

7.1 Exploded View of Machine

Figure 1

10

EFE 2500 AP/APS/ANP/APH

NO

PART NAME

QUA.

1

Hopper Cover

2

2

Hopper Screw

2

3

Hopper Agitator Blades

2

4

Hopper Agitator Seal

2

5

Hopper

2

6

Stud

4

7

LED Indicator Light

2

8

Barrel

2

9

Selector Switch

2

10

Beater Seal

2

11

Beater

2

12

Scrapper Blade

10

13

Self Service Unit(Optional)

1

14

Plastic Pusher

2

15

Head Screws

4

16

Head Group

1

17

Dasher

2

18

Drip Tray_L

1

19

Drip Tray Holder

1

20

Drain

1

21

Photo Sensor

2

22

Front Panel

1

23

Right Panel

1

24

Base

4

25

Compression Feed Pipe Group_R

1

26

Pump Group

2

27

Compression Feed Pipe Group_L

1

28

Liquid Level Sensor

2

Table 1

11

EFE 2500 AP/APS/ANP/APH

Figure 2

12

EFE 2500 AP/APS/ANP/APH

NO

PART NAME

QUA.

1

Hopper Cover

2

2

Hopper Screw

1

3

Hopper Agitator Blades

1

4

Hopper Agitator Seal

1

5

Hopper

2

6

Stud

4

7

LED Indicator Light

2

8

Barrel

2

9

Selector Switch

2

10

Beater Seal

2

11

Beater

2

12

Scrapper Blade

10

13

Self Service Unit(Optional)

1

14

Plastic Pusher

2

15

Head Screws

4

16

Head Group

1

17

Dasher

2

18

Drip Tray_L

1

19

Drip Tray Holder

1

20

Drain

1

21

Photo Sensor

2

22

Front Panel

1

23

Right Panel

1

24

Base

4

25

Compression Feed Pipe Group_R

1

26

Pump Group

2

27

Compression Feed Pipe Group_L

1

28

Liquid Level Sensor

2

Table 2

13

EFE 2500 AP/APS/ANP/APH

Figure 3

14

EFE 2500 AP/APS/ANP/APH

NO

PART NAME

QUA.

1

Hopper Cover

2

2

Hopper

2

3

LED Indicator Light

2

4

Barrel

2

5

Selector Switch

2

6

Beater Seal

2

7

Beater

2

8

Scrapper Blade

10

9

Self Service Unit(Optional)

1

10

Plastic Pusher

2

11

Head Screws

4

12

Head Group

1

13

Dasher

2

14

Drip Tray_L

1

15

Drip Tray Holder

1

16

Drain

1

17

Photo Sensor

2

18

Front Panel

1

19

Stud

4

20

Right Panel

1

21

Base

4

22

Compression Feed Pipe Group_R

1

23

Pump Group

2

24

Compression Feed Pipe Group_L

1

25

Liquid Level Sensor

2

Table 3

15

EFE 2500 AP/APS/ANP/APH

7.2 Exploded View of Dispensing Head

Figure 4

NO

PART NAME

QUA.

1

Dispensing Head

1

2

4,8x3,53mm O-Ring NBR

1

3

Lifter Rod

1

4

Speed Adjuster

3

5

Piston Lifter

3

6

Piston

2

7

27,20x3,53mm O-Ring

4

8

Middle Piston

1

9

Middle Piston O-Ring

1

10

Nozzle

3

11

34,65 X 1,78mm O-Ring

3

12

89,69x5,33mm Silicon O-Ring

2

Table 4

16

EFE 2500 AP/APS/ANP/APH

7.3 Exploded View of Self Service Unit

Figure 5

NO

PART NAME

QUA.

1

Self Service Mounting Unit

1

2

Self Service Spring Pressure Pin

3

3

Self Service Screw M30

3

4

Self Service Spring

3

5

Rectangular Reed Sensor

3

Table 5

17

EFE 2500 AP/APS/ANP/APH

7.4 Exploded View of Beater

Figure 6

NO

PART NAME

QUA.

1

Beater

1

2

Metal Pusher

1

3

Scrapper Blades

5

4

Beater Seal

1

Table 6

18

EFE 2500 AP/APS/ANP/APH

7.5 Exploded View of Dasher

Figure 7

NO

PART NAME

QUA.

1

Dasher_Slot

1

2

Dasher Delrin Bushing

1

3

13,95 x 2,62 mm NBR O-Ring

1

Table 7

19

EFE 2500 AP/APS/ANP/APH

7.6 Exploded View of Aeration Pump

Figure 8

20

EFE 2500 AP/APS/ANP/APH

NO

PART NAME

QUA.

1

Pump Body

1

2

Driven Gear

1

3

Pump Cover

1

4

Pin

1

5

Pump Stopper Pin

1

6

Driven Gear Shaft

1

7

Driven Gear Bolt

1

8

Spring Support

1

9

Pressure Spring

1

10

Feeding Tube_L

1

11

Handle Knob

2

12

Driving Gear

1

13

Pump Seal

1

14

14,35 x 2,62 mm Silicon O-Ring Yellow

1

15

74 x 3 mm Silicon O-Ring

1

Table 8

21

EFE 2500 AP/APS/ANP/APH

7.7 Exploded View of Compression Feed Pipe

Figure 9

NO

PART NAME

QUA.

1

Compression Feed Pipe

1

2

13,95 x 2,62 mm O-Ring NBR

1

3

20,63 x 2,62 mm O-Ring

2

4

Pipe Connection Plastic

1

5

13,10 x 2,62 mm O-Ring Brown

1

6

Silicon Check Valve

1

Table 9

22

EFE 2500 AP/APS/ANP/APH

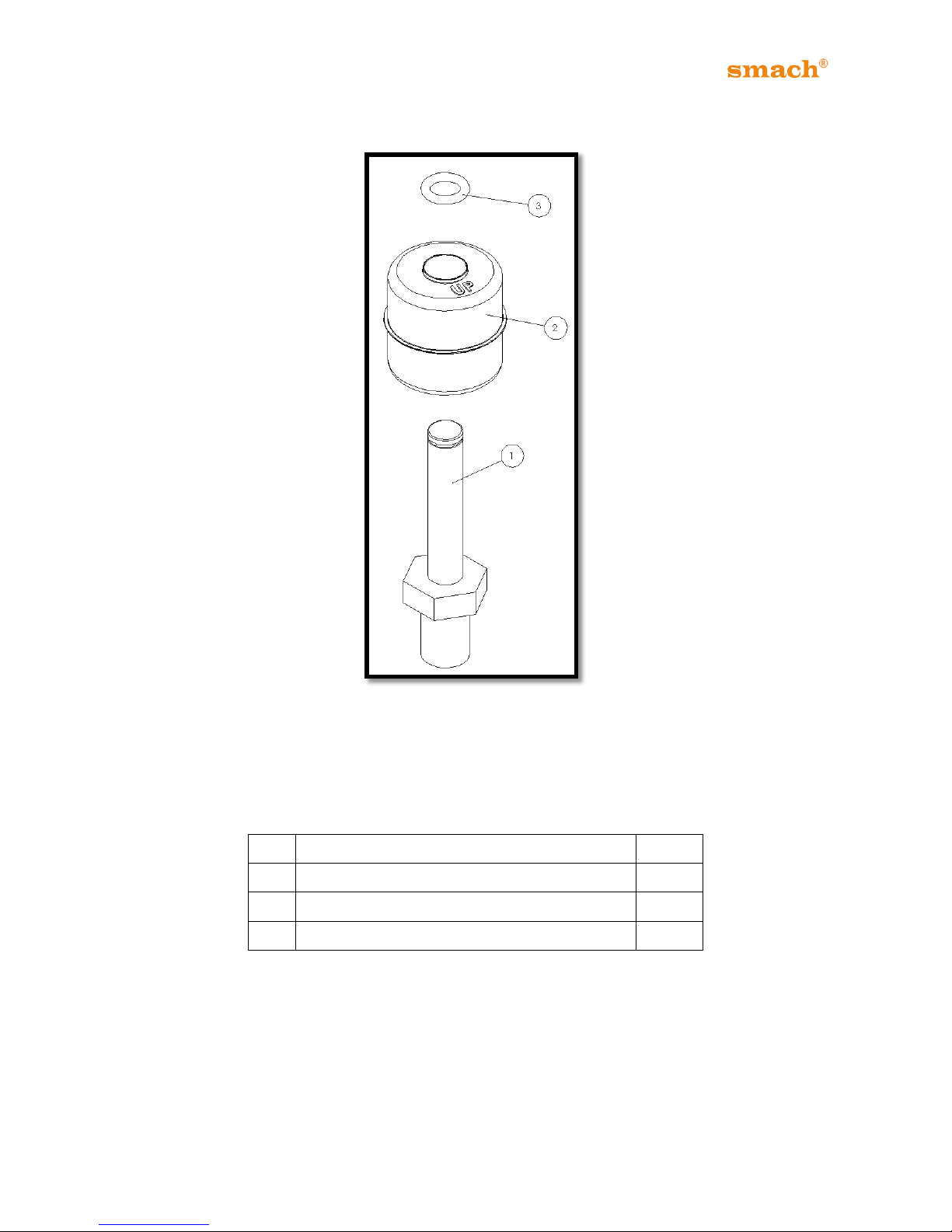

7.8 Exploded View of Liquid Level Sensor

Figure 10

NO

PART NAME

QUA.

1

PLS_045 Liquid Level Sensor Body

1

2

PLS Liquid Level Sensor Float

1

3

4,8 x 3,53 mm O-Ring Silicon Yellow

1

Table 10

23

EFE 2500 AP/APS/ANP/APH

8. MACHINES WITH AIR-COOLED CONDENSER

Figure 11

The freezer requires a minimum of 200 mm of clearance on both sides

and 500 mm in the rear of the unit. (Figure 11)

The clearance will allow sufficient amount of air flow across the condensers. Failure to

allow adequate clearance can reduce the refrigeration capacity of the freezers and cause

permanent damage to the compressors.

Position the machine for easy accessibility for cleaning, servicing and maintenance. A

clean environment is also essential for the proper performance of the freezer.

Attention: The freezer must not be exposed to direct sunlight. If it

stands in direct sunlight the performance will decrease. As the air

temperature increases the performance decreases. This is true for all

refrigeration equipment.

24

EFE 2500 AP/APS/ANP/APH

9. MACHINES WITH WATER-COOLED CONDENSER

Figure 12

Water-cooled machine must be connected to running water supply, or a

cooling tower. Water must have a pressure between 1-10 bar and a

delivery at least equal to the estimated hourly consumption.

Connect inlet pipe marked by plate “Water Inlet” to water supply installing a shut-off valve,

and outlet pipe marked by plate “Water Outlet” to a drain pipe, installing a shut-off valve.

If water valve is retarded, this operation will have to be carried out by skilled

personnel. Valve adjustment must be carried out in such a way that no

water flows when machine is off and lukewarm water flows when machine

is on.

Water consumption increases if temperature of entering water is above 20°C.

The filter should be cleaned every 3 months.

The use of potable water in the cooling system is recommended.

25

EFE 2500 AP/APS/ANP/APH

10. CONTROL DIAL

Figure 13

The CONTROL DIAL has the following selections:

STOP

In the STOP position No refrigeration occurs in hopper and barrel.

WASH

In the WASH position the Soft-serve in the barrel will be agitated, however no refrigeration

will occur.

STAND-BY

In the STAND BY position the barrel will retain frozen product in a semi-soft state for

prolonged periods of non-use. Both barrel and hopper will be chilled.

SOFT / HARD

Choose the SOFT / HARD selection depending on the type of Soft-Serve Product you

have chosen and the consistency you find more preferable.

26

EFE 2500 AP/APS/ANP/APH

11. OPERATING PROCEDURE

1. Always wash your hands with soap and potable water before assembling the machine.

(Preferably use new paper towels to dry your hands)

2. Only use the removable parts after they have been washed sanitized and air-dried.

3. Fit the beater assembly only when machine is off.

4. Follow all the instructions of this manual and the operating procedures of the store

owner, and at all times follow recognized in-store hygiene procedures, in particular those

in respect of dairy products.

5. Repairs must be done by the persons who are authorized by Smach®, if not, any

product failure warrantee will become invalid and void.

12. PREPARATION AND START UP PROCEDURE

12.1 PREPARATION

Make sure that all the removable parts have been washed with potable

water and sanitized, and then air dried before they are used.

Attention: NEVER ASSEMBLE OR DISASSEMBLE ANYTHING

UNLESS YOU HAVE:

1. Selected the STOP Mode.

2. Switched off the power at the wall and un-plugged the power cable.

27

EFE 2500 AP/APS/ANP/APH

You must use food grade lubricant to do the assembly described below.

Prepare the mixture as shown in product description.

12.2 STARTING THE MACHINE

Let the Barrel fill up with the MIX (The Barrel will be full when the air stops bubbling from

the Barrel)

Fill the hopper, up to the level of the suction tube handle (Figure 16). Do

NOT fill above the suction tube handle. It will leak into the drive

shaft and cause problems. Wait till all the air has bubbled out of the

barrel. The barrel will be full when the bubbling stops.

Figure 14 Figure 15

28

EFE 2500 AP/APS/ANP/APH

Figure 16

Carefully insert the Compression Feed Pipe into the Barrel Feeder Tube

hole on the floor of the hopper.

Now proceed to connect the Compression Feed Pipe assembly into position

by pressing the bottom end into the hole in the hopper floor. Initially keep it

at 90º to its final direction feed.

Then close the Hopper Cover and turn the control dial to the WASH mode to start the

aeration pump.

Figure 17

Wait 2 minutes and open the Hopper Cover. When you open the cover,

wash mode is automatically turned off and pump will stop in a few seconds.

If the mix is pumping out of the hole, as shown in the picture above, pump

is working properly. Wait the pump to stop (Figure 17) and then the

Aeration Pump Connecting Tube can be connected.

29

EFE 2500 AP/APS/ANP/APH

Figure 18

Now the pump has stopped pumping which indicates that the pump is off. Now connect the

aeration pump connecting tube.

Figure 19

Turn the aeration compression feed pipe towards the pump and connect.

Lock the plastic sliding fitting into position as shown on the picture.

Close the hopper cover and turn the freezer to WASH mode again and wait

2 minutes. Then discharge ice cream to take out pressure. Otherwise, the

barrel can freeze and it may damage the freezer. When you pull the

Dispensing Handle, if there is no pressure, you must check the pump

assembly.

30

EFE 2500 AP/APS/ANP/APH

After taking the pressure out, the freezer is ready to use. Place the Hopper

Cover, turn the control dial to SOFT or HARD mode and wait till the freezing

down has completed. The Freezer will stop and become quiet when the

Soft-serve is frozen down for the selected state of SOFT or HARD. (Once

the machine has reached the selected hardness the refrigeration

compressor will automatically stop for pre-set intervals).

12.3 DISPENSING ICE CREAM

After the Freezer has frozen down and stopped, pull the Dispensing Handle

and dispense about 300 grams of Soft-Serve into a washed and sanitized

beaker.

NOTICE: The temperature of the Soft-serve should be between: -6.5ºC

and -8.0ºC.

When a serve is dispensed the Freezer is automatically activated by the movement

detector switch when it senses the cone in hand being held below the dispense head

nozzle.

13. STEP-BY-STEP CLEANING - SANITIZING PROCEDURE

When properly used and cared for the machine will provide a consistent

quality Soft-Serve or Frozen Yoghurt. Like all equipment used to

manufacture food products it will require daily cleaning and regular

maintenance. A specified amount of care and attention is required

including but not limited to everything prescribed in this manual.

Attention: Because of bacteria population increases very fast, cleaning

and sanitizing is vital. Extra attention must be given for cleaning and

sanitizing properly.

31

EFE 2500 AP/APS/ANP/APH

13.1 CLEANING PROCEDURE

Follow these steps for cleaning: (All water used must be potable water)

1. Pull the handle to take ice cream for dispensing the pressure in the system.

2. Remove the compression feed pipe. Never remove the pipe without dispensing some

ice cream. Otherwise, the mix can squirt.

3. Remove the aeration pump.

4. Fit the Pump Cleaning Plug to the Pump Hole. (Figure 20)

Figure 20

5. Close the hopper cover and turn the machine to “WASH” mode and wait 3 minutes.

6. Place an empty container under the dispense head and drain the remaining Soft-

Serve and liquid into a clean, sanitized bucket. Immediately place a tight sealing lid

onto the bucket and store refrigerated (preferably below 5ºC)

7. Fill the hopper with cold water and allow the machine to run for 2-3 minutes before

draining the water into the bucket.

8. Refill the hopper with warm water and sanitizer as per the sanitizer manufacturer’s

instructions.

9. Fill the hopper with warm water. Allow the machine to run for approximately 5

minutes before draining the liquid into the bucket.

10. Repeat step 9 until the water runs clear.

11. Set the control DIAL to STOP mode and then switch off the power at the wall socket

and unplug the power cable.

12. Remove the screws of the Dispense Head.

13. Remove and disassemble the dispense Head, Piston, Beater and O-rings. (Please

use the o-ring remove apparatus. (Figure 21))

32

EFE 2500 AP/APS/ANP/APH

14. Remove and disassemble hopper agitator.

15. Remove the liquid level sensor. Remove the retaining ring and float.

16. Wash and sanitize all parts as per your local requirements and allow the parts to air-

dry. Do not use any chemicals other than the approved Sanitizer during the cleaning

process.

17. Assemble all the parts, ensuring the O-rings and their groves are properly lubricated.

18. Start by lubricating the harmonica-shaped Beater Shaft seal and slip it onto the

beater shaft:

a. Place the beater into the barrel and turn it slowly until it locks into position.

b. Place the dasher.

c. Lubricate the smaller O-rings, slip them onto the piston and place the piston

into the dispense head.

d. Lubricate the large O-ring and place into the back of the dispense head.

19. Place the dispense head back onto the machine and tighten the screws in a cross-

wise manner.

Do NOT touch barrel feeder hole during the cleaning process!

For optimal machine-performance, the condenser must be cleaned from

dust and dirt regularly by an authorized technician.

The nozzle must be cleaned and sanitized every 6 hours.

For water-cooled machines, the filter must be cleaned every 3 months.

Figure 21

33

EFE 2500 AP/APS/ANP/APH

13.2 BRUSH CLEANING PROCEDURE

*Optional – Smach® highly recommends the brush set for a proper detailed cleaning.

Figure 22

No

Part Name

Area of Usage

1

Brush - Ø90x120x440

Barrel, Hopper, Drip Tray

2

Brush - Ø40 x100x400

Head (Piston Grove), Barrel Feeder Hole

3

Brush - Ø20x90x450

Pump cover and Pump body holes, Outer Air

Tube, Scrapper Blades, Pusher, Dasher,

Head Screw Holes

4

Brush - Ø15x90x350

5

Brush – Ø9x110x350

Barrel Feeder Hole, Pump Feeder Tube,

Inner Air Tube, Compression Feed Pipe,

Head (Motion Pin Hole), Liquid Level Sensor

6

Triple Brush - Ø6 Ø5 Ø2

Pump Cover, Pump Feeder Tube, Air Tube,

Compression Feed Pipe, Head

7

Hand Brush - 30x35x170

Nozzle, Head (Back Side), Drip Tray, Pump

Table 11

34

EFE 2500 AP/APS/ANP/APH

Make sure all brushes are available for brush cleaning.

Figure 23

35

EFE 2500 AP/APS/ANP/APH

Figure 24

Figure 25

36

EFE 2500 AP/APS/ANP/APH

13.3 SANITIZING PROCEDURE

After cleaning procedure, hopper, barrel and all the removable parts must

be sanitized. It is recommended to use approved “SMACH

®

Sanitizer”

during disinfection. (Please contact SMACH® to provide approved

“SMACH

®

Sanitizer”.)

The SMACH® sanitizer is based on alcohol and QAC.

It is suitable for metals against corrosion.

It provides a fast and effective disinfection.

It is a volatile material, so it leaves no residue on the applied surface.

- Keep out of reach of children.

- Rinse well after application.

- Avoid eye contact. In case of contact, wash with water immediately.

- Avoid skin contact.

- Do not use for face, body, hand and food cleaning.

- Keep in a cool place.

- Do not expose to direct sunlight.

Directions to Use

It is a ready to use solution. Apply through spraying and wiping. It is recommended to wait

at least 5 minutes after spraying.

The sanitizing solution mustn’t be mixed with water.

During cleaning and sanitizing, follow all instructions given in this User

Guide, otherwise, Smach® Gıda Makine A.Ş will not take any responsibility

of unwanted results.

37

EFE 2500 AP/APS/ANP/APH

14. STEP-BY-STEP ASSEMBLY PROCEDURE

14.1 DISPENSING HEAD ASSEMBLY

14.1.1 Dispensing Head O-Ring Assembly: Again, place a small amount

of lubricant onto your index- and middle finger and hold the large

DISPENSING HEAD SEAL O-RING between the lubricated fingers and

your thumb. Gently pull the O-ring through your lubricated fingers until it is

entirely covered. The coating of lubricant should be thicker than on the

piston as it will prevent the O-ring from slipping during the latter stages of the assembly.

Place the O-ring gently into the designated groove of the Dispensing head and press firmly

into place.

Figure 26 Figure 27

14.1.2 Dispensing Head Piston – O-Ring Assembly: Assemble the

Dispensing Head piston using food grade lubricant. Slip the appropriate O-

rings onto the piston.

Place a small amount of lubricant onto your middle and index finger and

evenly coat the piston’s entire surface. The coating must be all-encompassing but must

not be too thick; a very thin layer will suffice

.

38

EFE 2500 AP/APS/ANP/APH

Figure 28 Figure 29

Figure 30 Figure 31

14.1.3 Dispensing Head Piston Assembly: Insert the lubricated piston

into the dispense head. This motion should be quite free and without too

much force. If the piston does not move freely, a little more Lubricant is

required.

In that case, remove the piston, add a little more lubricant as prescribed

above and re-insert.

39

EFE 2500 AP/APS/ANP/APH

Figure 32 Figure 33

14.1.4 Dispensing Head Nozzle – O-Ring Assembly: Lubricate the O-Ring and place it

gently into the designated groove on the nozzle. Then place the nozzle.

Figure 34 Figure 35

40

EFE 2500 AP/APS/ANP/APH

14.1.5 Dispensing Head Piston Lifter Assembly:

Figure 36

14.1.6 Dispensing Head Lifter Rod Assembly:

Figure 37 Figure 38

41

EFE 2500 AP/APS/ANP/APH

14.1.7 Dispensing Head Assembled:

Figure 39

14.2 BEATER ASSEMBLY

14.2.1 Pusher Assembly:

Figure 40 Figure 41

14.2.2 Blade Assemble Positions: Slots on the beater rings, shows blade

mounting positions.

42

EFE 2500 AP/APS/ANP/APH

Figure 42

Figure 43

The beater turns CLOCKWISE, so the blades should be mounted as

shown in the picture. Otherwise it may cause damage. Control the blades

carefully after mounting.

43

EFE 2500 AP/APS/ANP/APH

14.2.3 Seal Assembly: Lubricate the TWO faces of the Beater Drive Shaft

Seal and slip over the drive shaft.

Figure 44

14.2.4 Beater Assembled

Figure 45

44

EFE 2500 AP/APS/ANP/APH

14.2.5 Dasher Assembly

Figure 46 Figure 47

14.3 INSERTING THE ASSEMBLED BEATER INTO THE BARREL

Figure 48 Figure 49

Make sure the barrel is free of any obstruction before you insert the beater.

The beater must slide in easily with a final firm push and some turning to

align the shaft with the gearbox socket.

When it is pushed in the silicon seal will push it out a few millimeters like a

spring. Do not be concerned about this, as you place the dispensing head

on, the dispense head will push it into position.

45

EFE 2500 AP/APS/ANP/APH

Figure 50 Figure 51

After placing the beater, place the dasher. The front side of the dasher

should be placed upright as shown in the picture. You can now proceed to

put the dispensing head on as described below.

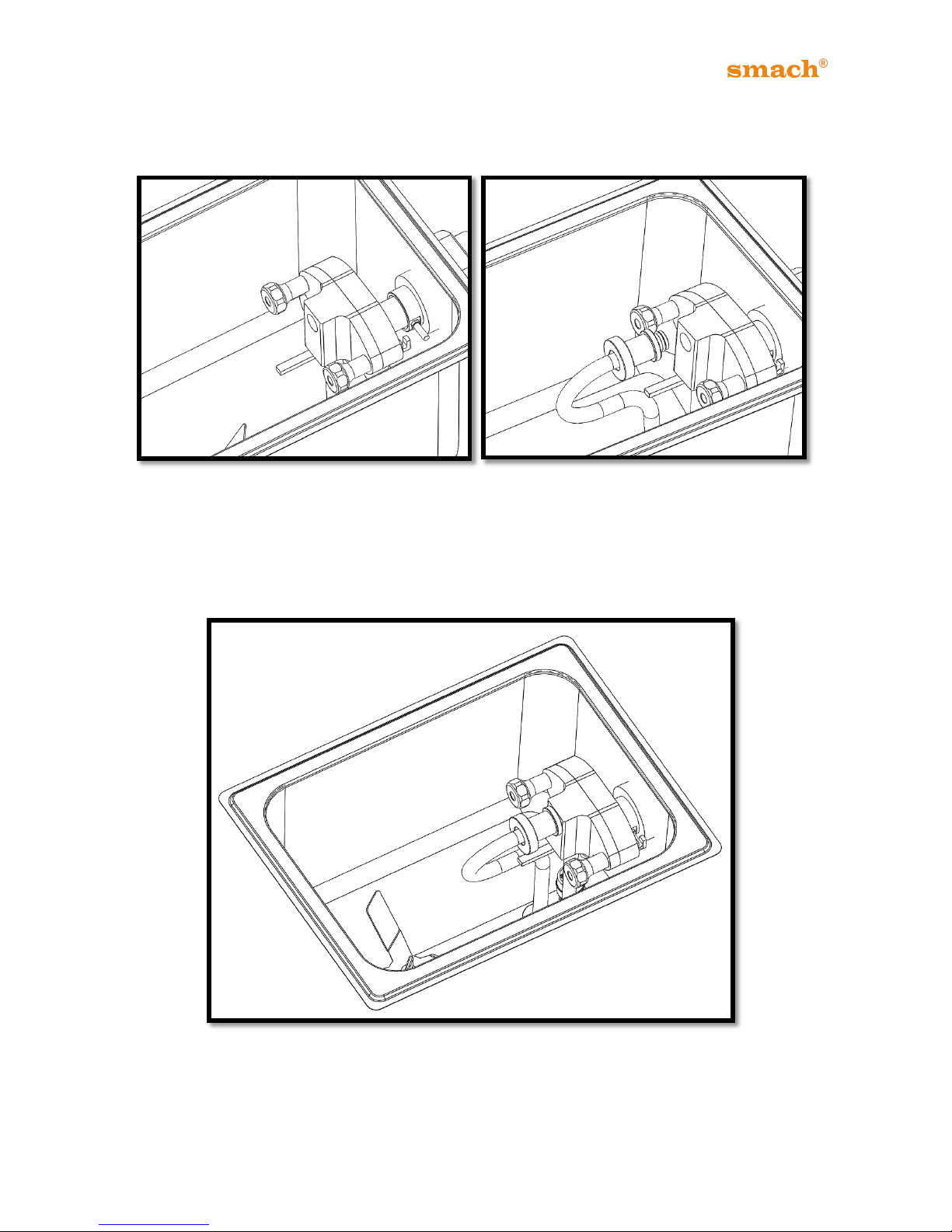

14.4 FITTING THE ASSEMBLED DISPENSING HEAD

Figure 52 Figure 53

46

EFE 2500 AP/APS/ANP/APH

14.4.1 Placing the Dispense Head:

Place the dispense head over the 4 fitting bolts. Make sure the dispense

handle is in the UP position so Soft-Serve liquid does not run out.

Figure 54 Figure 55 Figure 56

14.4.2 Tightening the Screws:

Tighten the 4 Dispense Head Screws in a cross order (i.e., left-hand top

and right-hand bottom and then right-hand top and left-hand bottom.

Figure 57

47

EFE 2500 AP/APS/ANP/APH

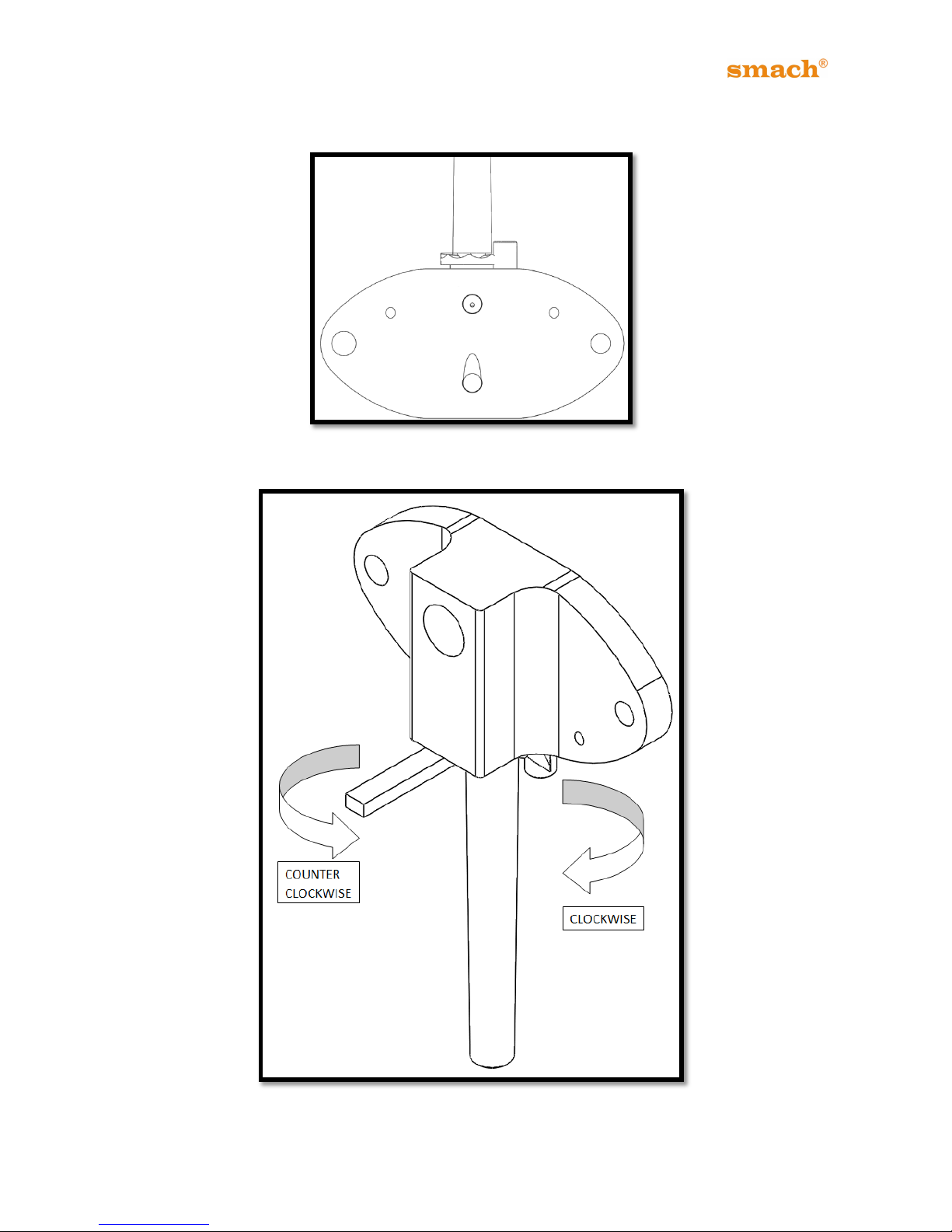

14.4.3 Speed Adjustment:

The speed (mass flow rate) of discharging ice cream can be adjusted with

“Speed Adjuster Screw”. When you turn the screw CLOCKWISE, mass flow

rate will decrease and ice cream discharge will be SLOWER. When you

turn the bolt COUNTER-CLOCKWISE, mass flow rate will increase and ice

cream discharge will be FASTER.

Figure 58

48

EFE 2500 AP/APS/ANP/APH

14.5 COMPRESSION FEED PIPE ASSEMBLY

14.5.1 O-Ring Assembly:

Lubricate and place the o-rings.

14.5.2 Pipe Connection

Assembly:

14.5.3 Check Valve

Assembly:

Figure 59 Figure 60 Figure 61

49

EFE 2500 AP/APS/ANP/APH

14.6 THE AERATION PUMP ASSEMBLY

14.6.1 Aeration Pump Cover Disassembled:

Figure 62

50

EFE 2500 AP/APS/ANP/APH

14.6.2 Pump Cover O-Ring and Relief Spring Assembly

Figure 63 Figure 64

Lubricate the O-Ring and place it gently to the O-Ring slot on the feeding tube. Then place

the “Pump Cover Relief Spring” (Pressure Spring) and the “Spring Support” as shown in

the picture.

51

EFE 2500 AP/APS/ANP/APH

14.6.3 Feeder Tube Assembly

Figure 65 Figure 66

Mount the “Feeder Tube” to the “Pump Cover”. Then turn the feeder tube CLOCKWISE.

Figure 67

52

EFE 2500 AP/APS/ANP/APH

14.6.4 Aeration Pump Feeder Tube – Air Adjustment

Figure 68

Figure 69

53

EFE 2500 AP/APS/ANP/APH

Figure 70

There are 6 different hole sizes as shown in the picture.

Turning the feeder tube CLOCKWISE, causes LARGER hole size and LOWER

OVERRUN.

Turning the feeder tube COUNTER-CLOCKWISE causes SMALLER hole size and

HIGHER OVERRUN.

54

EFE 2500 AP/APS/ANP/APH

14.6.5 Pump Body Assembly

14.6.5.1 Pump Body Disassembled

Figure 71

14.6.5.2 Gears and O-Ring Assembly

First mount the drive gear, then the driven gear. Grease the inner diameters with a little

grease. Don’t forget to lubricate the O-Ring before placing.

Figure 72 Figure 73

55

EFE 2500 AP/APS/ANP/APH

Figure 74 Figure 75

14.6.5.3 Drive Shaft Assembly

Grease the shaft with a little grease.

14.6.6 Pump Body – Pump Cover Assembly

Mount the Pump Cover and Pump Body and tighten the handle nuts.

Figure 76 Figure 77

56

EFE 2500 AP/APS/ANP/APH

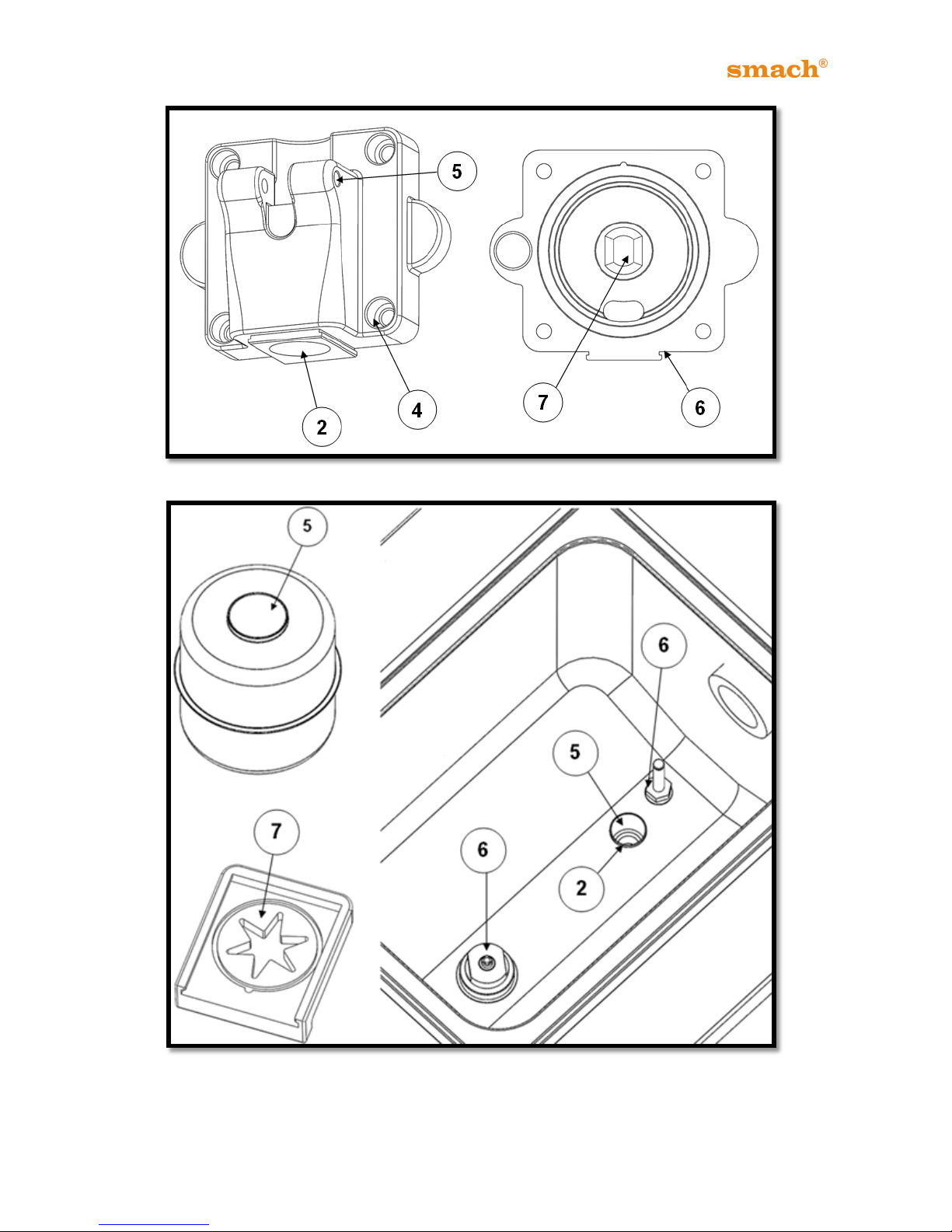

14.7 ASSEMBLY OF PUMP TO THE MACHINE

Figure 78 Figure 79

- The pump could be easily mounted by turning it. The pin must match with the slotted

part.

- Connect the Feeding Tube with the pump by turning and pushing forward.

Figure 80

57

EFE 2500 AP/APS/ANP/APH

14.8 ASSEMBLY OF HOPPER AGITATOR TO THE MACHINE

Figure 81

Figure 82

58

EFE 2500 AP/APS/ANP/APH

Figure 83

Lubricate the Agitator Seal and place it on the Agitator shaft.

Check the position of the seal. It must be placed as shown in the picture.

Figure 84 Figure 85

After placing Agitator Seal, place the Agitator Blades and tighten it with the Wing Screw.

59

EFE 2500 AP/APS/ANP/APH

Figure 86: Agitator Plug (for ANP and APH)

Figure 87 Figure 88

60

EFE 2500 AP/APS/ANP/APH

14.9 LIQUID LEVEL SENSOR ASSEMBLY

Place the liquid level sensor float on the body. Make sure the float is placed correctly. The

up side of the float is marked as shown in the picture. After placing float, place the O-Ring

to the groove.

Figure 89 Figure 90

14.10 HOPPER COVER ASSEMBLY

Place the HOPPER COVER in position. You should place the Hopper

Cover before running the machine. Otherwise the machine will lock itself

and won’t run.

61

EFE 2500 AP/APS/ANP/APH

15. POSSIBLE FAILURES AND SOLUTIONS

Attention: DO NOT ALLOW ANY TECHNICAL MAINTENANCE OR REPAIRS BEFORE

DISCONNECTING THE FREEZER FROM THE POWER SUPPLY.

If the solutions listed below in the Trouble Shooting guide do not resolve your operational

problems, call an authorized service agent for further assistance.

TROUBLESHOOTING GUIDE

Problem

Cause

Solution

1

Machine does not run

No electricity//power

Check if plugged in and switch on at wall

socket

Head and/or Hopper cover

aren’t closed.

Ensure that, the head and hopper cover

is closed.

No mix in the hopper.

Re-fill the hopper.

There is voltage fluctuation.

Plug off and wait for 30 seconds and

plug on again.

Check if there is another machine is

connected in the same socket.

2

Compressor starts, then

stops after a few

seconds.

a) Air-cooled machine: No air

circulation

b) Water-cooled machine: No

water circulation

a)Check the clearances around the

machine.

b)Check the water inlet, outlet and filter.

Check that pipe is not squashed nor

bent.

3

Machine fails to cut-off

when running on SOFT

or HARD mode

a) Air-cooled machine: Air

circulation is restricted.

b) Water-cooled machine:

Water circulation is restricted.

a)Check the clearances around the

machine.

b)Check the water inlet, outlet and filter.

Check that pipe is not squashed nor

bent.

Too much air in the freezerbarrel

Open Dispense head and drain-off ½

liter of product.

No mix in the Hopper

Re-fill the Hopper

4

Machine works, but no

product comes from the

Dispense Head.

Dispense head is blocked with

ice.

Place the machine onto Wash mode and

allow the product to thaw. Remove 1 liter

mix and re-start the machine.

Mixing instuctions of Soft-serve

was not followed

Drain the machine and re-fill with proper

mix.

The frozen product is too hard

Set the Control Dial to Wash mode and

allow the product to soften.

Pump is not working.

Re-assemble the pump properly. Check

all the parts assembled correctly.

Scrapper blades didn’t

assambled correctly.

Re-assemble the beater.

5

Machine runs, but

Product is too soft

Mixing instuctions of Soft-serve

was not followed

Drain the machine and re-fill with proper

mix.

Machine remained idle without

dispensing product for too long.

Remove 1 liter of frozen product and

allow the machine to recover.

Too much frozen product is

dispensed at a time.

Allow the machine to recover; then

continue to draw within the production-

62

EFE 2500 AP/APS/ANP/APH

limits for this model.

6

Mix leaks from the

Dispense Head

Piston O-rings are missing

Drain the machine and add piston Orings

Piston O-rings are worn

Drain the machine and replace the

piston O-rings

Nozzle O-ring is missing.

Add nozzle O-Ring.

Nozzle O-ring is worn.

Replace the nozzle O-Ring.

Dispense Head O-ring is

missing or displaced

Drain the machine and add or adjust Oring

Dispense Head bolts are not

tightened sufficiently or are

tightened unevenly

Tighten Disphense head screws evenly

and properly

7

Mix leaks from the Drip

Tube

Beater-seal is missing

Drain the machine and add Beater-Seal

Beater-seal is worn

Drain the machine and replace beaterseal.

63

EFE 2500 AP/APS/ANP/APH

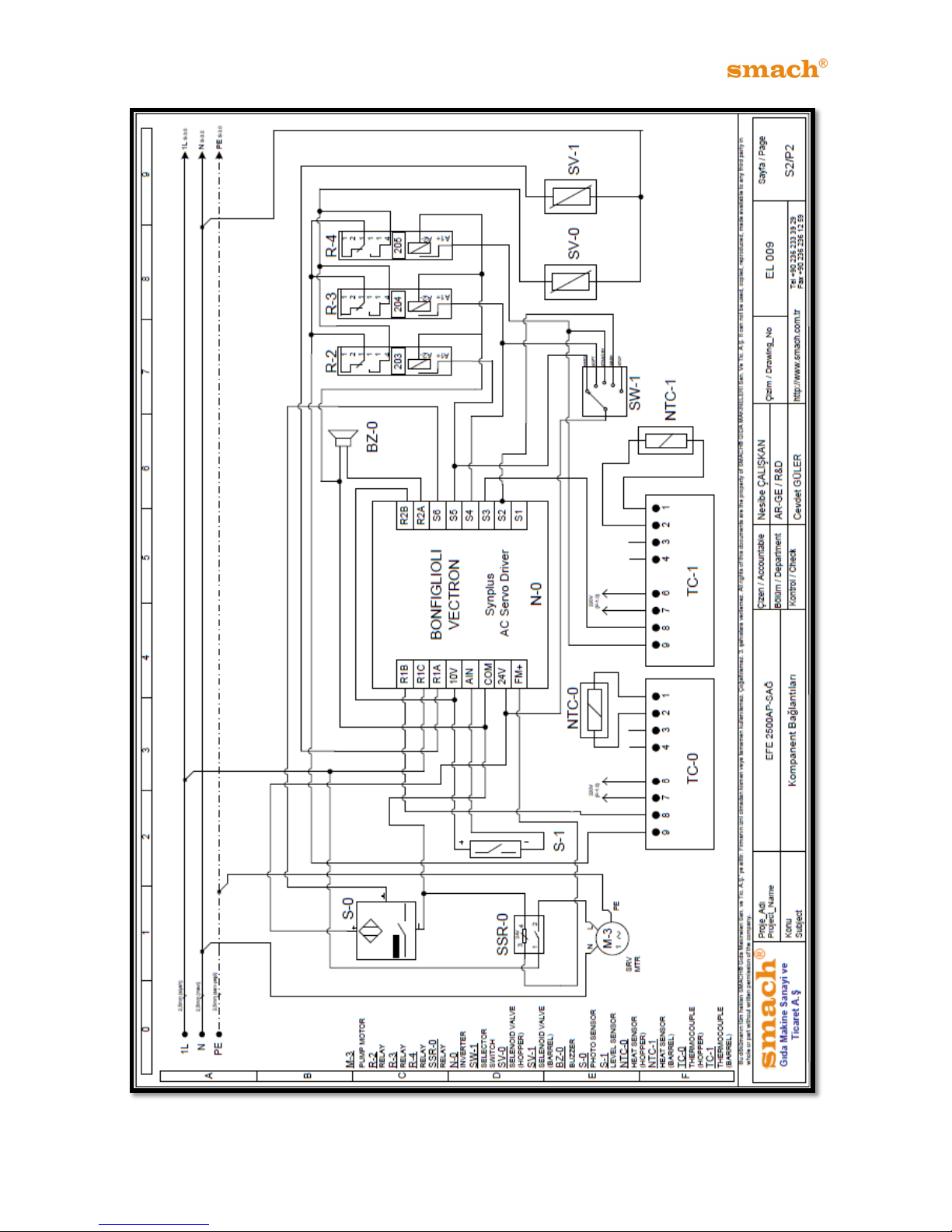

16. ELECTRICAL CIRCUIT DIAGRAMS

Figure 91

64

EFE 2500 AP/APS/ANP/APH

Figure 92

65

EFE 2500 AP/APS/ANP/APH

Figure 93

66

EFE 2500 AP/APS/ANP/APH

Figure 94

WARRANTY DOCUMENT AND CONDITIONS

MANUFACTURER

ADRESS: GUZELYURT MAH.5762 Sok.No:5/A

ORTA OLCEKLI SANAYI BOLGESI

MANISA

Tel: +90 236 233 39 29 / +90 236 233 62 04

Fax: +90 236 236 12 59

WARRANTY

MODEL NO: EFE 2500AP / APS / ANP / APH

International Warranty Period: 1 Year

Invoice Date/No:

Delivery Date:

SEAL&SIGNATURE

This warranty given by SMACH® GIDA MAKINE SAN.TIC.A.S does not apply in the following cases:

1) The failures results from misusage of product or usage of other applications.

2) After the delivery, the failures resulted from moving, carrying of the machine.

On the condition that any distortions made on warranty or on the serial number the

product will be out of the warranty.

Loading...

Loading...