SMA SUNNY TRIPOWER 60, STP 60-10, SUNNY HIGHPOWER PEAK1, SHP 75-10 Installation Manual

Installation Guide / Installationsanleitung /

Instrucciones de instalación / Instructions d’installation /

Istruzioni per l’installazione

SUNNY HIGHPOWER PEAK1

SUNNY TRIPOWER 60

SHP75-10-STP60-10-IA-xx-18 | 139R0183 | Version 1.8

SMA Solar Technology AG

ENGLISH - Table of Contents

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.1 System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2 Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.3 Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.4 Inverter Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.5 Installation Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

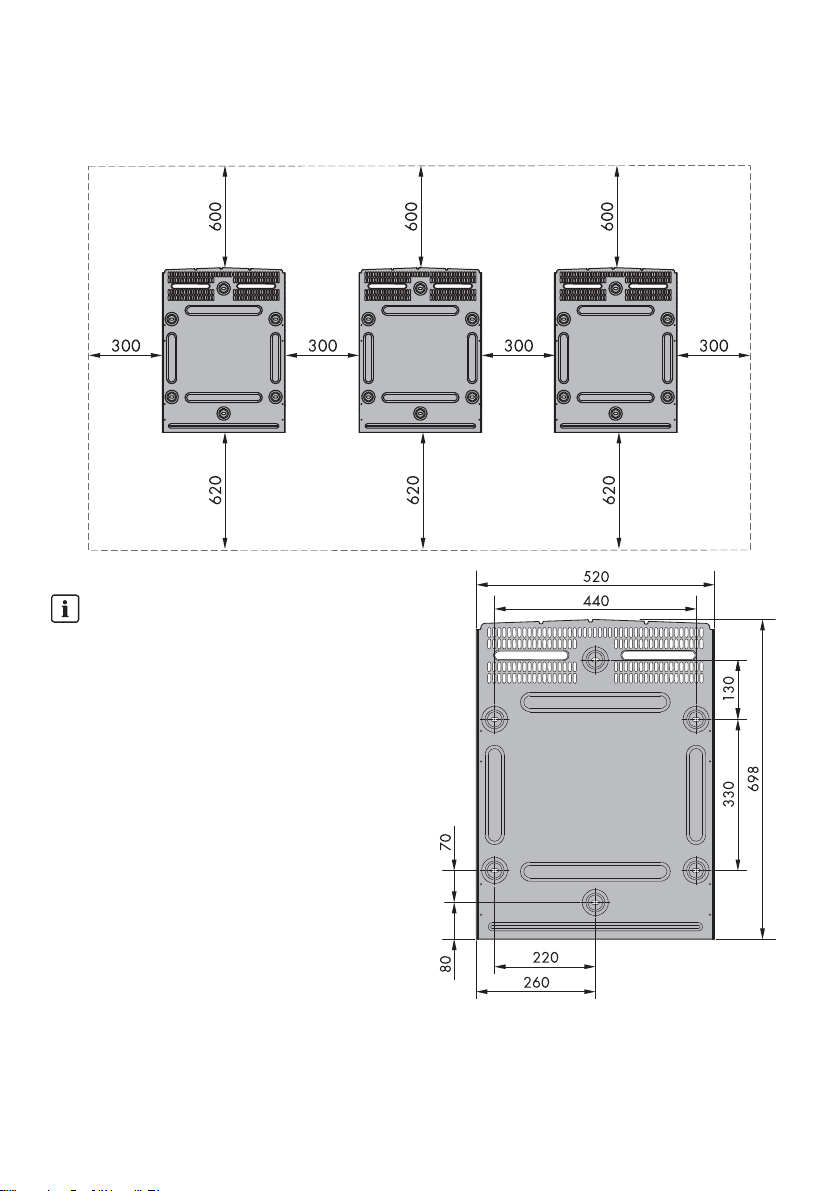

2.1 Environment and Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.2 Mounting the Wall Mounting Bracket. . . . . . . . . . . . . . . . . . . . . . . . 22

2.3 Mounting the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.4 Disassembling the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.5 Access to the Installation Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.6 AC Grid Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.7 Enclosure opening. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.8 Ethernet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.9 PV Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.9.1 External PV Array Junction Boxes. . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.10 Closing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3 Initial Setup and Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.1 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.1.1 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.2 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.2.1 Initial Setup via LCS-Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.2.2 Switching on the PV Load-Break Switch . . . . . . . . . . . . . . . . . . . . . . 32

3.2.3 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.2.4 Grid Code File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.2.5 Configuring the Fallback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4 Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1 Troubleshooting and Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installation Guide SHP75-10-STP60-10-IA-xx-18 3

SMA Solar Technology AG

4.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.1 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2 Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3 Installation Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4 Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.5 Specifications for Grid Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.6 Technical Data of the Communication Interface . . . . . . . . . . . . . . . . 46

5.7 Ethernet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.7.1 Network Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4 SHP75-10-STP60-10-IA-xx-18 Installation Guide

SMA Solar Technology AG

DEUTSCH - Inhaltsverzeichnis

1 Einführung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

1.1 Systemübersicht . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.2 Zweck der Anleitung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.3 Auspacken. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1.4 Typenschild des Wechselrichters. . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1.5 Installationsreihenfolge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2.1 Umgebung und Abstände . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2.2 Montage der Wandhalterung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.3 Montage des Wechselrichters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2.4 Abbau des Wechselrichters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.5 Zugang zum Installationsbereich. . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.6 AC-Netzanschluss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.7 Kabeleinführung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2.8 Ethernet-Anschlüsse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2.9 PV-Anschluss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2.9.1 Externe Generatoranschlusskästen . . . . . . . . . . . . . . . . . . . . . . . . . 63

2.10 Schließen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3 Ersteinrichtung und Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3.1 Benutzerschnittstelle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3.1.1 Betriebsarten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3.2 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3.2.1 Ersteinrichtung über LCS-Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.2.2 PV-Lasttrennschalter einschalten. . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.2.3 Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.2.4 Grid-Code-Datei. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3.2.5 Fallback konfigurieren . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4 Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.1 Fehlersuche und -behebung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Installation Guide SHP75-10-STP60-10-IA-xx-18 5

SMA Solar Technology AG

4.2 Wartung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5 Technische Daten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.1 Spezifikationen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.2 Konformität . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.3 Installationsbedingungen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.4 Drehmomentspezifikationen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.5 Spezifikation für die Netzsicherungen. . . . . . . . . . . . . . . . . . . . . . . . 81

5.6 Technische Daten der Kommunikationsschnittstellen . . . . . . . . . . . . . 82

5.7 Ethernet-Anschlüsse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.7.1 Netzwerktopologie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6 Kontakt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6 SHP75-10-STP60-10-IA-xx-18 Installation Guide

SMA Solar Technology AG

ESPAÑOL - Índice

1 Introducción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

1.1 Vista general del sistema. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

1.2 Fin de las instrucciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

1.3 Desembalaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

1.4 Placa de características del inversor . . . . . . . . . . . . . . . . . . . . . . . . . 90

1.5 Orden de instalación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

2 Instalación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

2.1 Entorno y espacios libres. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

2.2 Montaje del soporte mural . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

2.3 Montaje del inversor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

2.4 Desmontaje del inversor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

2.5 Acceso al área de instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

2.6 Conexión de red de CA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

2.7 Entrada de cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.8 Conexiones de ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.9 Conexión fotovoltaica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

2.9.1 Cajas de conexión del generador externas. . . . . . . . . . . . . . . . . . . 99

2.10 Cierre. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3 Configuración inicial y arranque . . . . . . . . . . . . . . . . . . . . . . 101

3.1 Interfaz de usuario. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3.1.1 Modos de funcionamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3.2 Pantalla . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

3.2.1 Ajuste inicial mediante LCS-Tool . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.2.2 Activación del interruptor-seccionador fotovoltaico. . . . . . . . . . . . 103

3.2.3 Puesta en marcha. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.2.4 Archivo del código de red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.2.5 Configuración del procedimiento de emergencia . . . . . . . . . . . . . 103

4 Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

4.1 Resolución de problemas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Installation Guide SHP75-10-STP60-10-IA-xx-18 7

SMA Solar Technology AG

4.2 Mantenimiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

5 Datos técnicos. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

5.1 Especificaciones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

5.2 Conformidad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

5.3 Condiciones de la instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

5.4 Especificaciones del par de apriete. . . . . . . . . . . . . . . . . . . . . . . . . 117

5.5 Especificaciones del circuito de la red eléctrica . . . . . . . . . . . . . . . 118

5.6 Especificaciones de las interfaces de comunicación . . . . . . . . . . . . 119

5.7 Conexiones de ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

5.7.1 Topología de red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

6 Contacto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

8 SHP75-10-STP60-10-IA-xx-18 Installation Guide

SMA Solar Technology AG

FRANÇAIS - Table des matières

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

1.1 Vue d’ensemble du système. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

1.2 Objet des ces instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

1.3 Déballage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

1.4 Plaque signalétique de l’onduleur . . . . . . . . . . . . . . . . . . . . . . . . . . 165

1.5 Ordre d’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

2.1 Environnement et distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

2.2 Montage du support mural . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

2.3 Montage de l’onduleur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

2.4 Démontage de l’onduleur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

2.5 Accès à la zone d’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

2.6 Raccordement au réseau AC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

2.7 Insertion de câbles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

2.8 Raccordements Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

2.9 Raccordement photovoltaïque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

2.9.1 Boîtiers externes de raccordement pour le générateur

photovoltaïque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

2.10 Fermeture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

3 Configuration initiale et démarrage. . . . . . . . . . . . . . . . . . . . 176

3.1 Interface utilisateur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

3.1.1 Modes de fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

3.2 Écran . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

3.2.1 Configuration initiale via LCS-Tool . . . . . . . . . . . . . . . . . . . . . . . . . 178

3.2.2 Activation de l’interrupteur-sectionneur PV . . . . . . . . . . . . . . . . . . . 178

3.2.3 Mise en service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

3.2.4 Fichier de codes réseau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

3.2.5 Configuration du repli automatique . . . . . . . . . . . . . . . . . . . . . . . . 179

4 Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

4.1 Recherche d’erreurs et dépannage . . . . . . . . . . . . . . . . . . . . . . . . . 180

Installation Guide SHP75-10-STP60-10-IA-xx-18 9

SMA Solar Technology AG

4.2 Entretien. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

5 Données techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

5.1 Spécifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

5.2 Conformité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

5.3 Conditions d’installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

5.4 Spécifications de couple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

5.5 Spécifications pour la protection du réseau . . . . . . . . . . . . . . . . . . 193

5.6 Spécifications de l’interface de communication. . . . . . . . . . . . . . . . 194

5.7 Raccordements Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

5.7.1 Topologie du réseau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

6 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

10 SHP75-10-STP60-10-IA-xx-18 Installation Guide

SMA Solar Technology AG

ITALIANO - Indice

1 Introduzione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

1.1 Panoramica del sistema. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

1.2 Scopo delle istruzioni . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

1.3 Disimballaggio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

1.4 Targhetta di identificazione dell’inverter . . . . . . . . . . . . . . . . . . . . . 127

1.5 Ordine d’installazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

2 Installazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

2.1 Ambiente e distanze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

2.2 Montaggio del supporto da parete. . . . . . . . . . . . . . . . . . . . . . . . . 130

2.3 Montaggio dell’inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

2.4 Rimozione dell’inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

2.5 Accesso all’area di installazione . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

2.6 Collegamento rete CA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

2.7 Introduzione dei cavi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

2.8 Collegamenti Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

2.9 Collegamento dell’impianto FV . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

2.9.1 Quadri di parallelo stringhe esterni . . . . . . . . . . . . . . . . . . . . . . . . 136

2.10 Chiusura. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

3 Setup iniziale e avviamento . . . . . . . . . . . . . . . . . . . . . . . . . . 138

3.1 Interfaccia utente . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

3.1.1 Modalità di funzionamento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

3.2 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

3.2.1 Setup iniziale attraverso LCS Tool . . . . . . . . . . . . . . . . . . . . . . . . . 139

3.2.2 Attivazione dell’interruttore del carico FV . . . . . . . . . . . . . . . . . . . 140

3.2.3 Messa in servizio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

3.2.4 File del codice di rete. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

3.2.5 Configurazione del fallback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

4 Servizio di assistenza tecnica SMA. . . . . . . . . . . . . . . . . . . . . 141

4.1 Ricerca degli errori . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Installation Guide SHP75-10-STP60-10-IA-xx-18 11

SMA Solar Technology AG

4.2 Manutenzione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

5 Dati tecnici. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

5.1 Specifiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

5.2 Conformità. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

5.3 Condizioni di installazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

5.4 Specifiche di coppia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

5.5 Specifiche dei fusibili di rete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

5.6 Dati tecnici delle interfacce di comunicazione. . . . . . . . . . . . . . . . . 155

5.7 Collegamenti Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

5.7.1 Topologia della rete. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

6 Contatti . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

12 SHP75-10-STP60-10-IA-xx-18 Installation Guide

SMA Solar Technology AG

Legal Provisions

The information contained in these documents is the

property of SMA Solar Technology AG. Any publication,

whether in whole or in part, requires prior written approval

by SMA Solar Technology AG. Internal reproduction used

sole ly for the pu rpose of pro duct e valua tion o r other p roper

use is allowed and does not require prior approval.

SMA Warranty

You can download the current warranty conditions from the

Internet at www.SMA-Solar.com.

Trademarks

All trademarks are recognized, even if not explicitly

identified as such. Missing designations do not mean that a

product or brand is not a registered trademark.

SMA Solar Technology AG

Sonnenallee 1

34266 Niestetal

Deutschland

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

E-mail: info@SMA.de

Copyright © 2019 SMA Solar Technology AG.

All rights reserved.

Nomenclature

Complete designation Designation in this

document

Sunny Highpower Peak1 Inverter, product

Sunny Tripower 60 Inverter, product

SMA Digital I/O Box I/O Box

IMPORTANT SAFETY

INFORMATION

The following symbols are used in this document:

Symbol Explanation

Indicates a hazardous

situation which, if not

avoided, will result in

death or serious injury

Indicates a hazardous

situation which, if not

avoided, can result in

death or serious injury

Indicates a hazardous

situation which, if not

avoided, can result in

minor or moderate injury

Indicates a situation

which, if not avoided, can

result in property damage

Indicates that the

following section contains

tasks that must be

performed by qualified

persons only

Information that is

important for a specific

topic or goal, but is not

safety-relevant

☐

☑ Desired result

✖ A problem that might

Indicates a requirement

for meeting a specific goal

occur

Installation Guide SHP75-10-STP60-10-IA-xx-18 13

SMA Solar Technology AG

A

General Safety

This manual contains important instructions that must be

followed during installation and maintenance of the

inverter.

Before Installation

Check the inverter and the packaging for damage.

If in doubt, contact the supplier before commencing

installation.

Installation/Service

For optimum safety, follow the steps described in this

document. Keep in mind that the inverter has two voltage

carrying sides, the PV input and the utility grid.

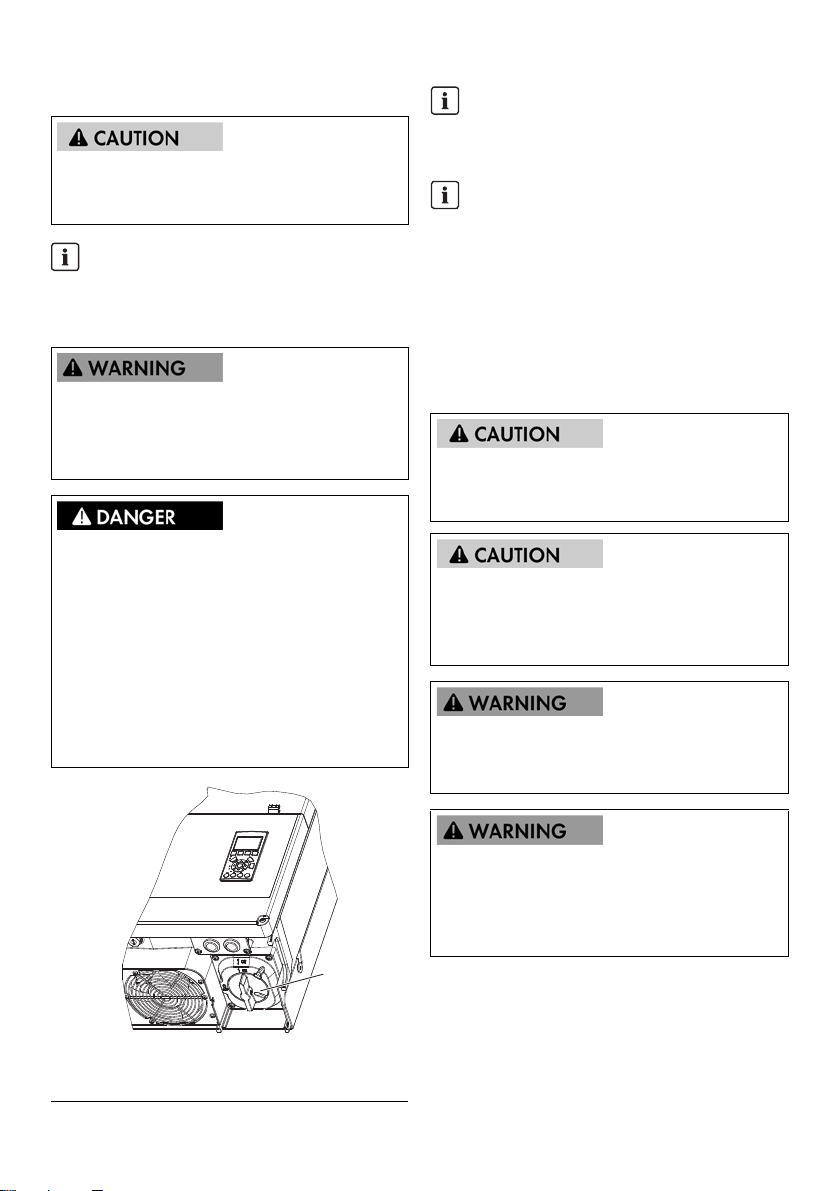

Disconnecting the inverter

Before working on the inverter, disconnect it from the utility

grid by means of the AC breaker and switch off PV using

the integrated PV load-break switch (DC load-break

switch). Ensure that the inverter cannot be unintentionally

reconnected. Use a voltage detector to ensure that the

unit is disc onnect ed and vol tage fr ee. The in verter ca n still

be charged with very high voltage at hazardous levels

even when it is disconnected from utility grid and PV

modules. Wait at least five minutes after disconnection

from the utility grid and PV modules before proceeding.

INFORMATION

The PV load-break switch can be secured in the "Off"

position using a padlock.

INFORMATION

Only for SHP 75-10:

The inverter is not intended to be used in living areas

and cannot provide protection of radio reception

against interference signals in such environments.

In accordance with EN55011:2016, the inverter

must only be operated at operation locations where

the distance between the inverter and

radio-communication installations is greater than

30 m and an own power transformer is used.

DC voltages up to 1000 V are present in a PV system

even when the inverter is disconnected from the utility grid.

Faults or inappropriate use may lead to electric arcing.

MAINTENANCE AND MODIFICATION

Only authorized personnel are permitted to repair or

modify the inverter. To ensure personal safety, use only

original spare parts available from the supplier.

INSTALLER

Input and output circuits are isolated from the enclosure.

System grounding is the responsibility of the installer.

RISK OF ELECTRIC SHOCK

This manual is intended for use by qualified personnel

only. To reduce the risk of electric shock, do not perform

any maintenance work other than that specified in the

manual unless you are qualified to do so.

Figure1: PV load-break switch

A PV load-break switch

14 SHP75-10-STP60-10-IA-xx-18 Installation Guide

SMA Solar Technology AG

Danger due to ground fault on DC side during

operation

Due to the transform erless topology of the product, the

occurrence of ground faults on DC side during operation

can lead to irreparable damage. Da mag es t o th e pr odu ct

due to a faulty or damaged DC installation are not

covered by warranty. The product is equipped with a

protective device that checks whether a ground fault is

present during the starting sequence. The product is not

protected during operation.

• Ensure th at the D C installation is ca rried out co rrec tly

and no ground fault occurs during operation.

The inverter is not equipped with a transformer and is

intended to be installed with an ungrounded (floating) PV

array.

Input and output circuits are isolated from the enclosure.

System grounding is the responsibility of the installer.

All persons responsible for the installation and

maintenance of inverters must be:

• Trained and authorized in general safety rules for

work on electric equipment.

• Familiar with local requirements, rules and

regulations for the installation.

The inverter does not provide overcurrent protection. This

must be provided by the installer. See table 5.8

The temperature of the cooling elements and components

in the inverter can exceed 70°C. There is a risk of burns.

The inverter is to be installed in such way that hot

components cannot be touched.

Damage to the product due to outgassing of

sealants

Sealants such as silicone, polyurethane foam or sealing

foam can outgas. Outgassing of sealants can damage the

product and impair its functionality.

• Do not use any sealants for sealing.

• Only use the provided material for sealing.

INFORMATION

The symbol for grounding conductors used in this

manual is identified in figure 2.18.

An ill ust rat ion of the DC d isc onn ect or c an be f oun d in

Section 3.2.2, page 32.

INFORMATION

For information about the operating temperature

range, see Section 5.3, page 44.

INFORMATION

This manual contains information about field wiring

connections and torque specifications. See Section

5.4, page 45.

Symbols on the inverter

Symbol Explanation

Danger to life due to electric shock

The product operates at high voltages.

All work on the product must be

carried out by qualified persons only.

Danger

This symbol indicates that the inverter

must be additionally grounded if

additional grounding or equipotential

bonding is required at the installation

site.

Danger to life due to high voltages in

the inverter; observe waiting time.

High voltages that can cause lethal

electric shocks are present in the live

components of the inverter.

Prior to performing any work on the

inverter, disconnect it from all voltage

sources as described in this document.

Installation Guide SHP75-10-STP60-10-IA-xx-18 15

1 Introduction SMA Solar Technology AG

Symbol Explanation

Risk of burns due to hot surfaces

The product can get hot during

operation. Avoid contact during

operation. Allow the product to cool

down sufficiently before carrying out

any work.

Observe the documentation

Observe all documentation supplied

with the product.

WEEE designation

Do not dispose of the product together

with the household waste but in

accordance with the disposal

regulations for electronic waste

applicable at the installation site.

The product complies with the

Moroccan safety and EMC

requirements for electrical products.

Compliance

Further information can be found in the download area of

www.SMA-Solar.com (see also Section 5, page 41).

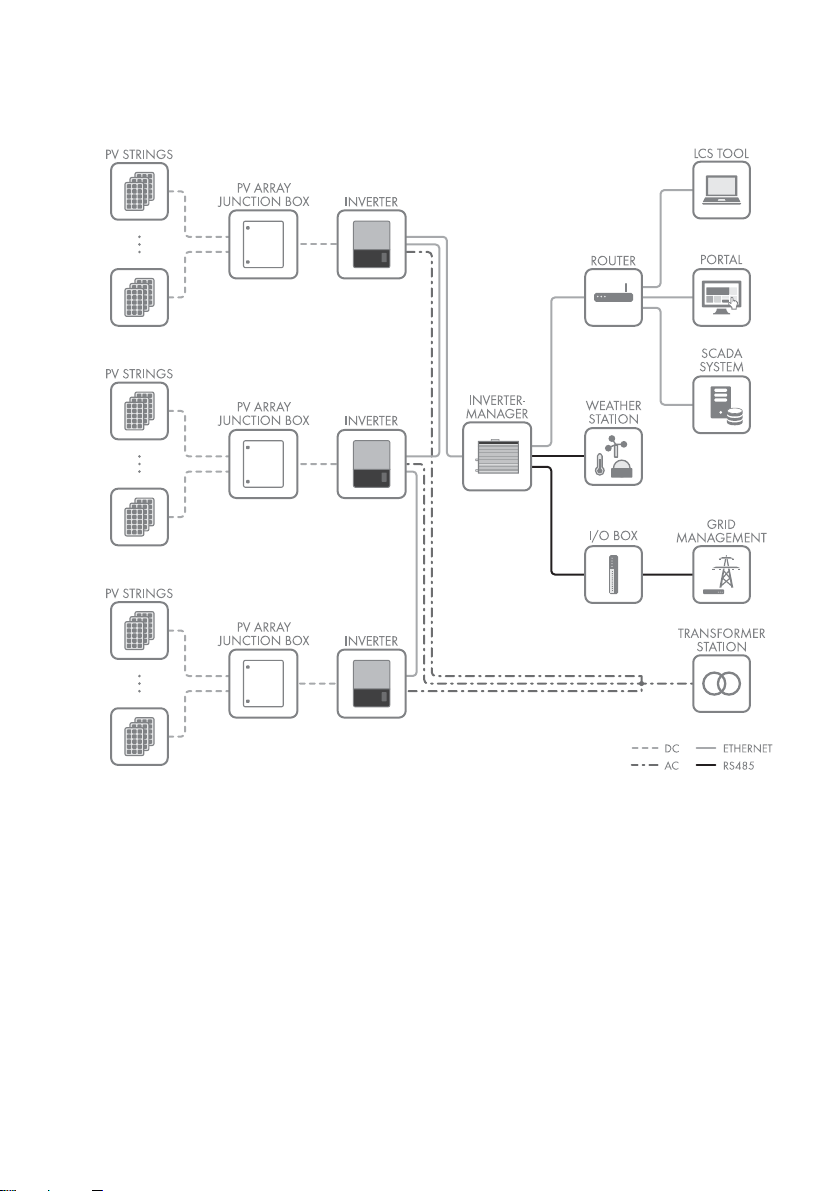

1 Introduction

The inverter is only designed for operation in grid-connected

PV systems. The inverter converts direct current from PV

modules into grid-compliant three-phase alternating current.

For operation, the inverter must be connected to a utility grid

and with a sufficient number of PV modules. The inverter is

not suitable for other applications (such as operation with

batteries or wind turbine systems).

The PV system consists of four main components:

• Inverter

• PV array junction box

The PV array junction box enables the bundling of the

necessary number of PV strings for the inverter. Each

inverter requires a PV array junction box.

• SMA Inverter Manager

The SMA Inverter Manager is always required for the

operation of the inverter. Up to 42 inverters can be

connection to each SMA Inverter Manager. The

SMA Inverter Manager handles all communication of

the inverters. It serves as central interface for data

acquisition systems, upload to cloud services and

power-plant control.

• Local commissioning and service tool (LCS-Tool)

The LCS-Tool is required for the commissioning and

servicing of the inverter via the SMA Inverter Manager.

The LCS-Tool is the primary user interface for the PV

system.

16 SHP75-10-STP60-10-IA-xx-18 Installation Guide

SMA Solar Technology AG 1 Introduction

1.1 System Overview

Figure 1.1 System overview

1.2 Purpose of This Manual

The manual contains information on the installation and

commissioning of the inverter.

The following additional materials are available:

• Qu ick ref ere nce gui de f or t he i nst all ati on o f th e in ver ter

- information necessary for commissioning and for

establishing communication.

• Installation manual for the SMA Inverter Manager and

the I/O Box - information necessary for commissioning

and for establishing communication.

Installation Guide SHP75-10-STP60-10-IA-xx-18 17

• Service manual for replacing the fan – for information

required to replace a fan.

• Service manual for replacing the SPDs – contains

information required to replace surge protection

devices.

These documents are available in the download area at

www.SMA-Solar.com. You can also request these from the

supplier of the inverter.

1 Introduction SMA Solar Technology AG

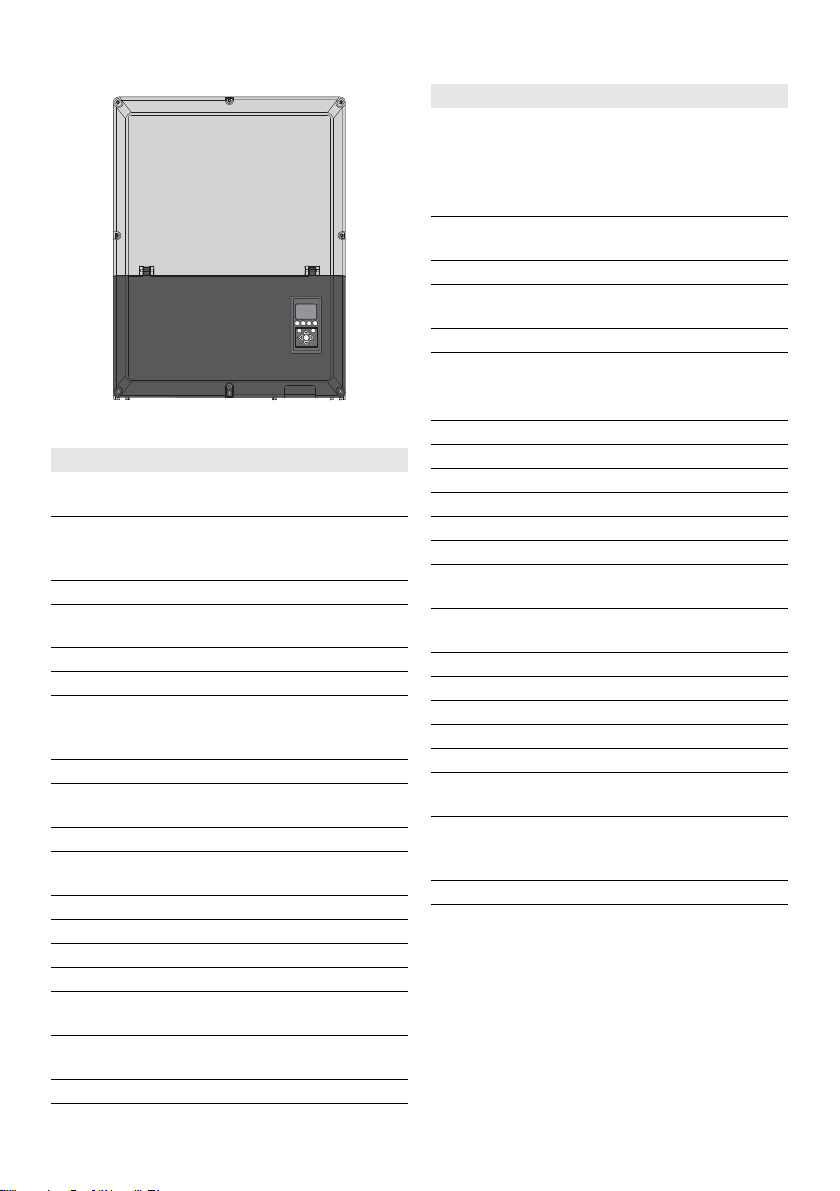

F1 F3 F4F2

OK

Home

Back

Alarm

On

Abbreviation Description

PCC Point of Common Coupling - point of

interconnection

The point on the public electricity network

to whi ch o the r cu sto mer s ar e, o r co uld be,

connected.

Grounding

Protective grounding

conductor

PELV Protected Extra-Low Voltage

PLA Power Level Adjustment = Output power

limitation

P

nom

Power [W], Nominal active power

POC Connection point

The point at which the PV system is

connected to the public utility grid.

Figure 1.2 Front view of the inverter

Abbreviation Description

cat5e Category 5 twisted pair cable (enhanced)

for data transmission

DHCP Dynamic Host Configuration Protocol –

enables automatic assignment of the

network address via the DHCP server

DSL Digital Subscriber Line

EMC

Electromagnetic compatibility directive

(directive)

ESD Electrostatic discharge

FRT Fault Ride Through

GSM Global System for Mobile

Communications (standard for digital

cellular mobile network)

HDD Hard Disk Drive

IEC International Electrotechnical Commission

– international standards organization

IT Isolated Terra

LCS Local commissioning and service tool

(LCS-Tool)

LED Light-Emitting Diode

P

STC

PV Photovoltaic, photovoltaic cells

RCD Residual-current device

RCMU Residual Current Monitoring Unit

R

ISO

ROCOF Rate of Change of Frequency

Q Q is the symbol for reactive power and is

S S is the symbol for apparent power and is

STC Standard Test Conditions

SW Software

THD Total Harmonic Distortion

TN-S Terra Neutral - Separate. AC Network

TN-C Terra Neutral - Combined. AC Network

TN-C-S Terra Neutral - Combined - Separate. AC

TT AC grid with separation between

DNO Distribution grid operator

Power [W], Standard Test Conditions

Insulation resistance

measured in reactive volt-amperes (VAr).

measured in volt-amperes (VA).

Network

operational ground of the generator and

ground of the load system

LVD (Directive) Low-voltage directive

MCB Miniature circuit breaker

MPP Maximum Power Point

MPPT Maximum Power Point Tracking

determines the point of optimum PV power

P P is the symbol for active power and is

measured in Watts (W).

PCB Printed circuit board

18 SHP75-10-STP60-10-IA-xx-18 Installation Guide

SMA Solar Technology AG 1 Introduction

1.3 Unpacking

Check the scope of delivery of each product for

completeness and any externally visible damage.

Contact your distributor if the scope of delivery is

incomplete or damaged.

The delivery may contain parts

that are not required for the installation.

Contents:

•Inverter

•Wall mounting bracket

• Accessories bag containing:

– 6 wall plugs 8 x 50 mm

– 6 mounting screws 6 x 60 mm

– 1 M25 cable gland with sealing grommet for

Ethernet cables

– 1 grounding bolt M6 x 12 mm

• Installation manual

• Quick reference guide for installation

1.4 Inverter Type Label

The type label uniquely identifies the inverter. You will

require the information on the type label to use the product

safely and when seeking customer support from the

SMA Service Line. You will find the following information on

the type label:

• Device type (Model)

• Serial number (Serial No.)

• Date of manufacture

• Device-specific characteristics

1.5 Installation Sequence

1. Pay special attention to the important safety

information at the beginning of this manual.

2. Mount the inverter according to Section 2.1, page 21,

Section 2.2, page 22, Section 2.3, page 23.

3. Open the inverter in accordance with Section

2.5, page 24.

4. Install the AC supply in accordance with Section

2.6, page 25.

5. Install Ethernet in accordance with Section

5.7, page 47.

6. Install the PV module in accordance with Section

2.9, page 28 using a PV array junction box.

7. Close the inverter in accordance with Section

2.5, page 24.

8. Turn on AC.

9. Finalize commissioning by using the Local

Commissioning and Service Tool (LCS-Tool). The tool is

available from the download area at

www.SMA-Solar.com. The hardware requirements for

the LCS-Tool are:

– PC with Windows

–1 GB HDD

– 2 GB RAM

The LCS-Tool must be installed on a local PC drive.

The PC mus t be con nected to the s ystem network of t he

SMA Inverter Manager. See Section 3.2.1, page 32

for configuring via the LCS-Tool.

10. Switch on the PV system via the PV load-break switch.

11. Verify the installation by:

– Inverter display: LED "On" is permanently green.

– LCS-Tool: In the inverter view, the status is

"On grid".

12. The inverter is in operation now.

TM

7 and later

Installation Guide SHP75-10-STP60-10-IA-xx-18 19

1 Introduction SMA Solar Technology AG

B

C

D

E

F

G

H

A

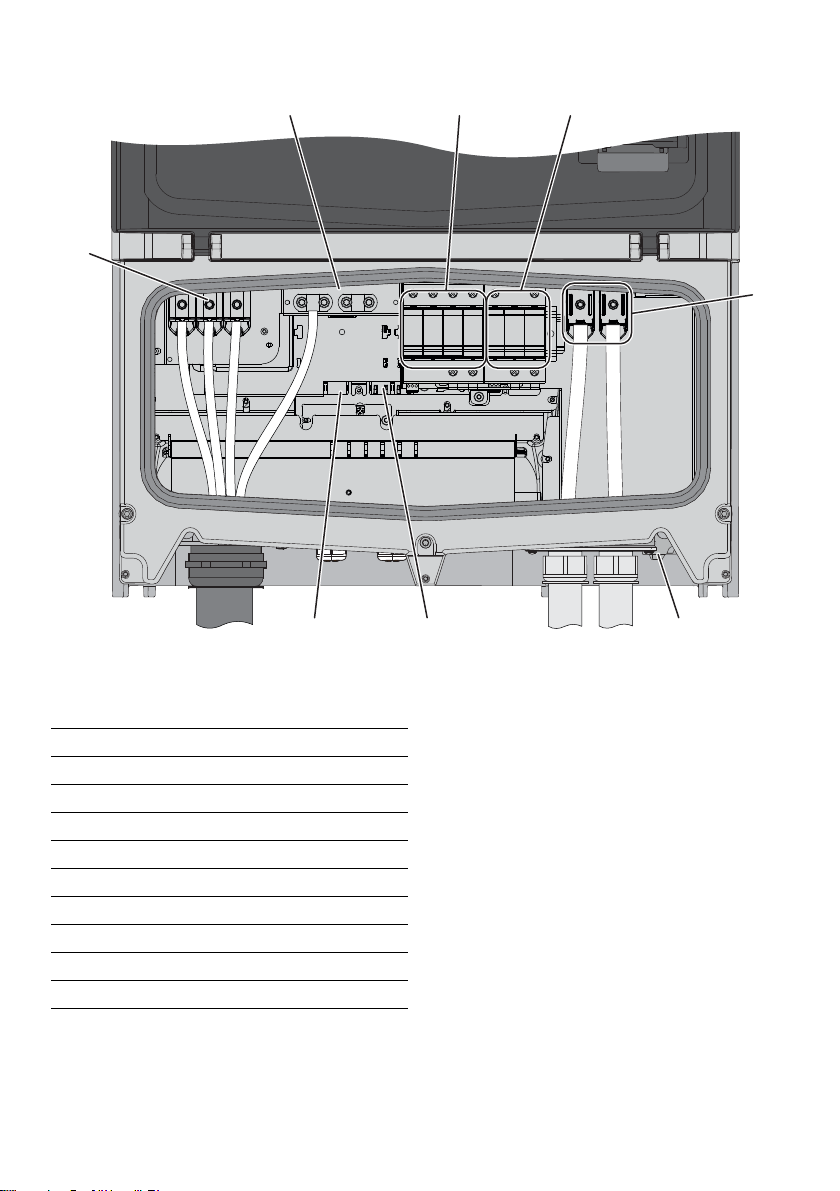

Figure 1.3 Overview of the installation area

PELV (safe to touch)

B Device grounding

G Ethernet interface x 2

H RS485 interface (not in use)

Live parts

AAC terminals

EPV terminals

Other

C AC overvoltage protection (SPDs)

D DC overvoltage protection (SPDs)

F PV load-break switch

Table 1.2 Overview of the installation area

20 SHP75-10-STP60-10-IA-xx-18 Installation Guide

SMA Solar Technology AG 2 Installation

2Installation

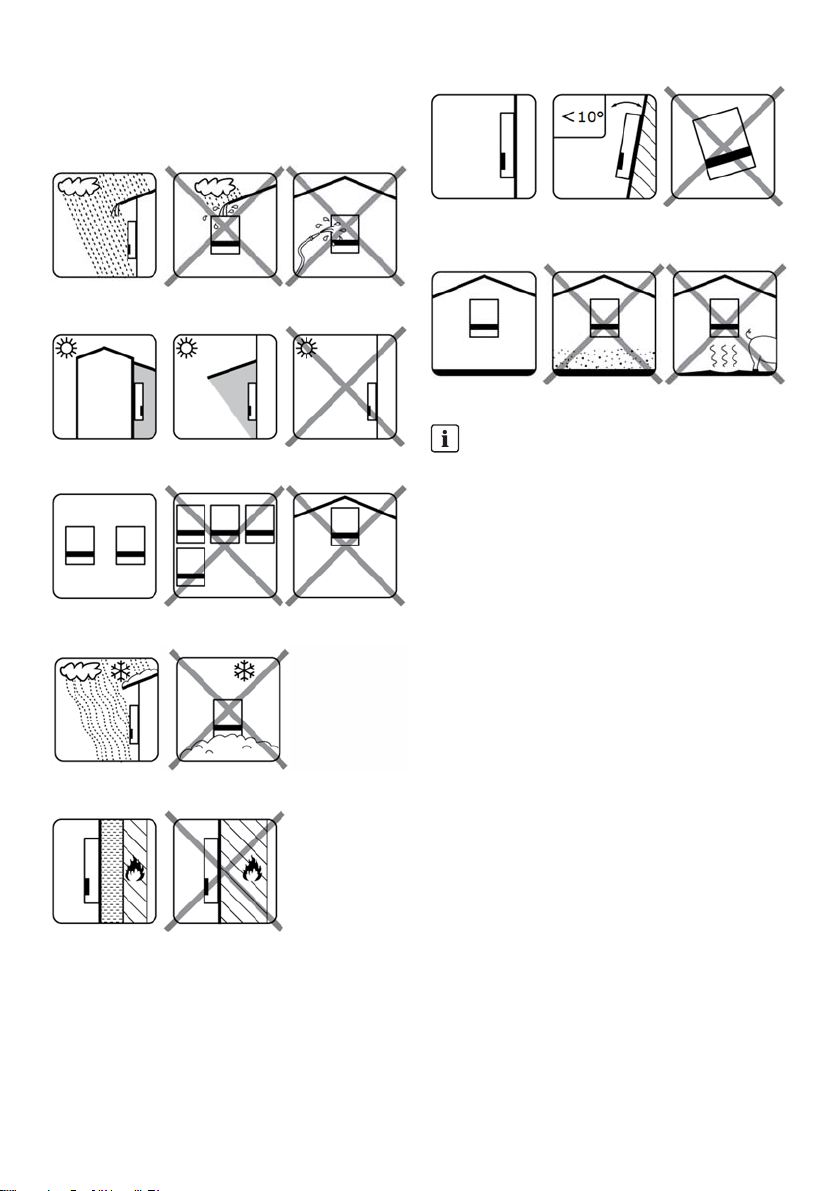

2.1 Environment and Clearances

Figure 2.6 Mount upright on vertical surface. A backward tilt of ten

degrees is allowed.

Figure 2.1 Avoid constant contact with water

Figure 2.7 Avoid dust and ammonia gases

INFORMATION

Figure 2.2 Avoid direct solar irradiation

Figure 2.3 Ensure adequate air flow

When selecting the installation site, ensure that the

product and warning messages on the inverter are

visible at all times. For details, refer to Section

5, page 41.

Figure 2.4 Ensure adequate air flow

Figure 2.5 Mount on non-flammable surface

Installation Guide SHP75-10-STP60-10-IA-xx-18 21

2 Installation SMA Solar Technology AG

2.2 Mounting the Wall Mounting Bracket

Figure 2.8 Safety clearances in mm

INFORMATION

The safety clearances to other objects must be

maintained to ensure sufficient air circulation (see

figure 2.8).

Figure 2.9 Dimensions of wall mounting bracket in mm

22 SHP75-10-STP60-10-IA-xx-18 Installation Guide

SMA Solar Technology AG 2 Installation

INFORMATION

Use of the wall mounting bracket delivered with the

inverter is mandatory. Warranty claims will expire if

the inverter is operated without the wall mounting

bracket. It is strongly recommended to use all six

mounting holes (see figure 2.10).

Mounting of the wall mounting bracket:

• Mount the wall mounting bracket in the designated

area.

• Use screws and wall plugs that can safely carry the

weight of the inverter.

• Ensure that the wall mounting bracket is correctly

aligned.

• When installing one or several inverters, observe the

safety clearances to ensure sufficient airflow.

Clearances are specified in figure 2.8 and on the wall

mounting bracket label.

• Mounting multiple inverters side by side in a single row

is recommended. Contact the supplier for guidelines

when mounting inverters in more than one row.

• Ensure adequate clearance at the front, for safe

installation and service access to the inverter.

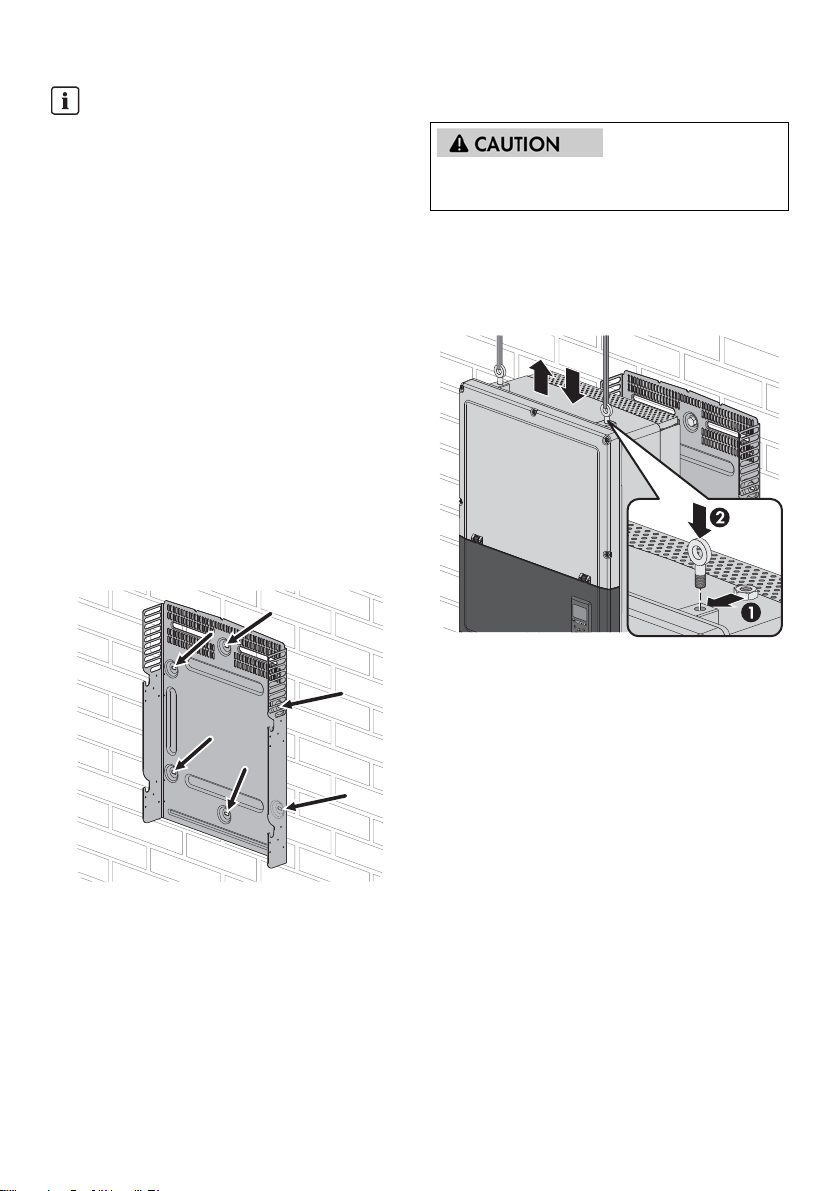

2.3 Mounting the Inverter

When handling the inverter observe the local health and

safety regulations.

Procedure:

1. Attach M12 lifting bolts and matching nuts to the

inverter (not included in the scope of delivery).

2. Lift the inverter.

Figure 2.11 Attaching the lifting bolts and lifting the inverter

3. Locate the slots on the side of the wall mounting

bracket.

4. On the inverter, position the side screws against the

wall mounting bracket slots. Push the inverter so the

side screws slide into the two lower slots and the two

upper slots.

Figure 2.10 Mounting of the wall mounting bracket

Installation Guide SHP75-10-STP60-10-IA-xx-18 23

2 Installation SMA Solar Technology AG

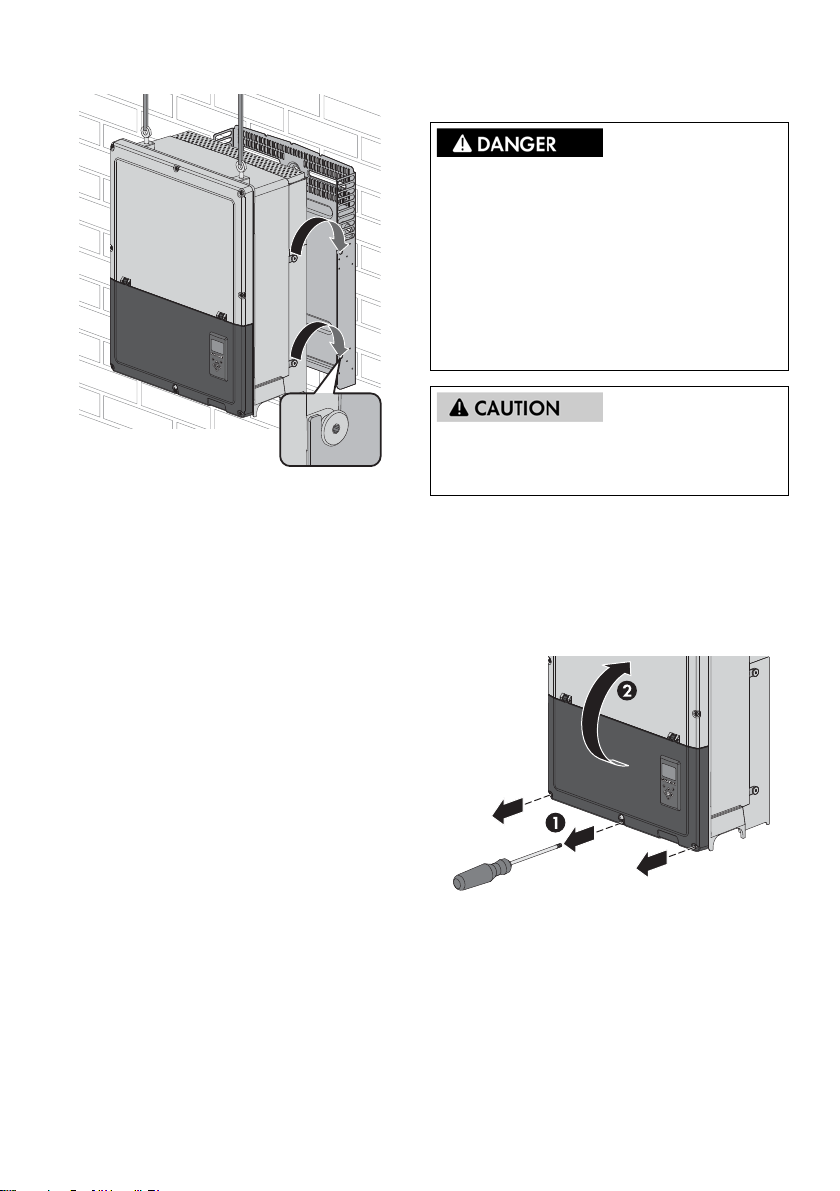

2.5 Access to the Installation Area

Before working on the inverter, disconnect it from the utility

grid by means of the AC breaker and switch off PV using

the integrated PV load-break switch (DC load-break

switch). Ensure that the inverter cannot be unintentionally

reconnected. Use a voltage detector to ensure that the

unit is disconnected and voltage free. The inverter can still

be charged with very high voltage at hazardous levels

even when it is disconnected from utility grid and PV

modules. Wait at least five minutes after disconnection

from the utility grid and PV modules before proceeding.

Observe ESD safety regulations. Discharge any

electrostatic charge by touching the grounded enclosure,

Figure 2.12 Hooking the inverter into the wall mounting bracket

5. Check that the four side screws sit securely in the wall

mounting bracket slots.

6. Release the inverter.

2.4 Disassembling the Inverter

Procedure:

1. Disassemble the inverter in the reverse mounting order.

2. Lift and slide the inverter out of the wall mounting

bracket slots.

3. Lift the inverter off the wall mounting bracket.

before handling any electronic component.

Procedure:

1. To open the cover, loosen the three lower front screws

using a TX 30 screwdriver. The screws are captive

screws and cannot fall out.

2. Raise the cover by 180 degrees. A magnet enables the

cover to stay open.

Figure 2.13 Loosen front screws and lift the cover

3. To close the cover, lower it into place and fasten the

three front screws.

24 SHP75-10-STP60-10-IA-xx-18 Installation Guide

SMA Solar Technology AG 2 Installation

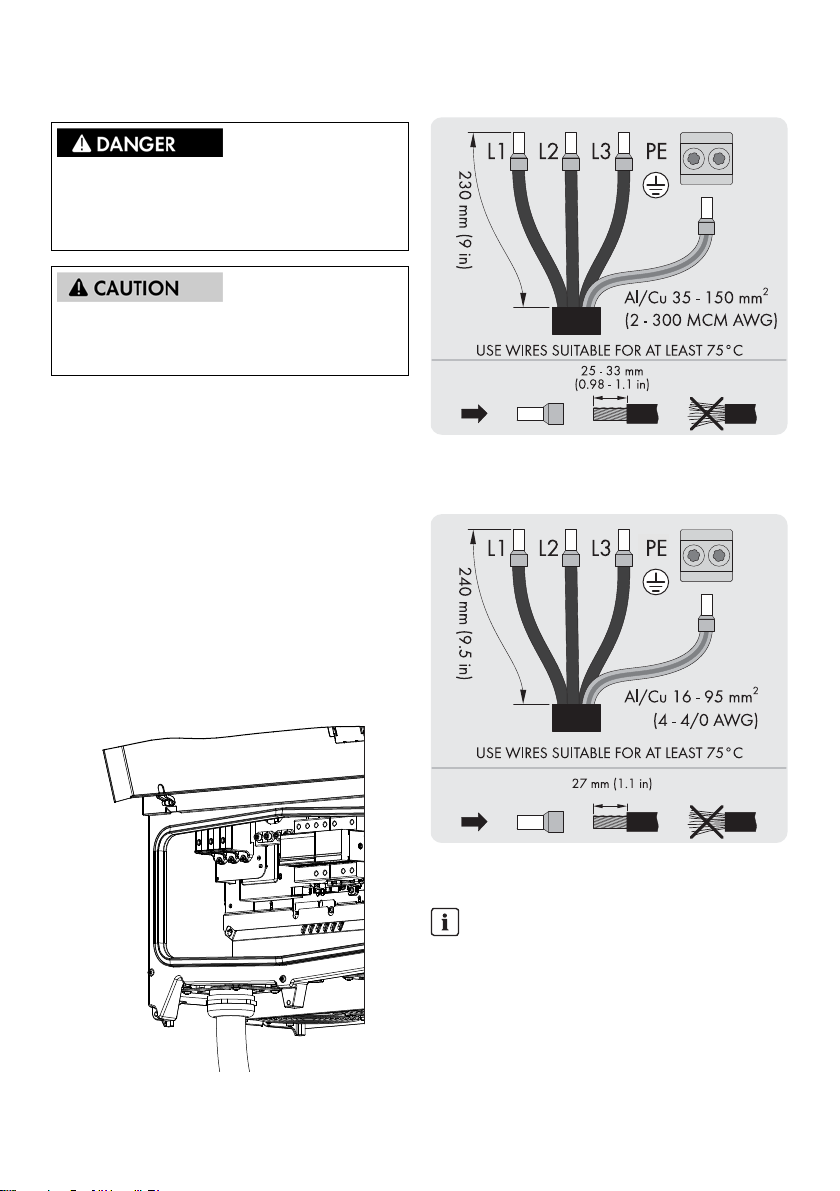

2.6 AC Grid Connection

These instructions for AC grid connection are for qualified

pe rso nne l on ly. To r edu ce t he r isk of e lec tri c sh ock , do not

perform any maintenance work other than that specified

in the manual unless you are qualified to do so.

For fuse and RCD information, refer to Section

5, page 41. AC fuse rating must not exceed the ampacity

of the conductors used.

IMI Detection

The inverter has a built-in IMI/RCMU (Insulation Monitoring

Interrup ter / Resi dual Curr ent Mon itorin g Unit). T he invert er

acts on residual DC current and a sudden change in the

ground fault current. This functionality is activated during

normal operation.

Insulation Resistance Detection

Th e in ver ter ha s a b uil t-i n in sul ati on res ist anc e de tec tio n. T he

insulation resistance detector performs a measurement of

the connected PV system resistance to ground before the

inverter connects to the grid. If the resistance is below the

gr id c ode set val ue, the inv erter wil l wa it a nd r e-m eas ure the

resistance after a short while. When the resistance is above

the grid code set value, the inverter performs a self-test and

connects to the grid.

Cable requirements SHP 75-10

Figure 2.15 AC cable SHP 75-10

Cable requirements STP 60-10

Figure 2.16 AC cable SHP 60-10

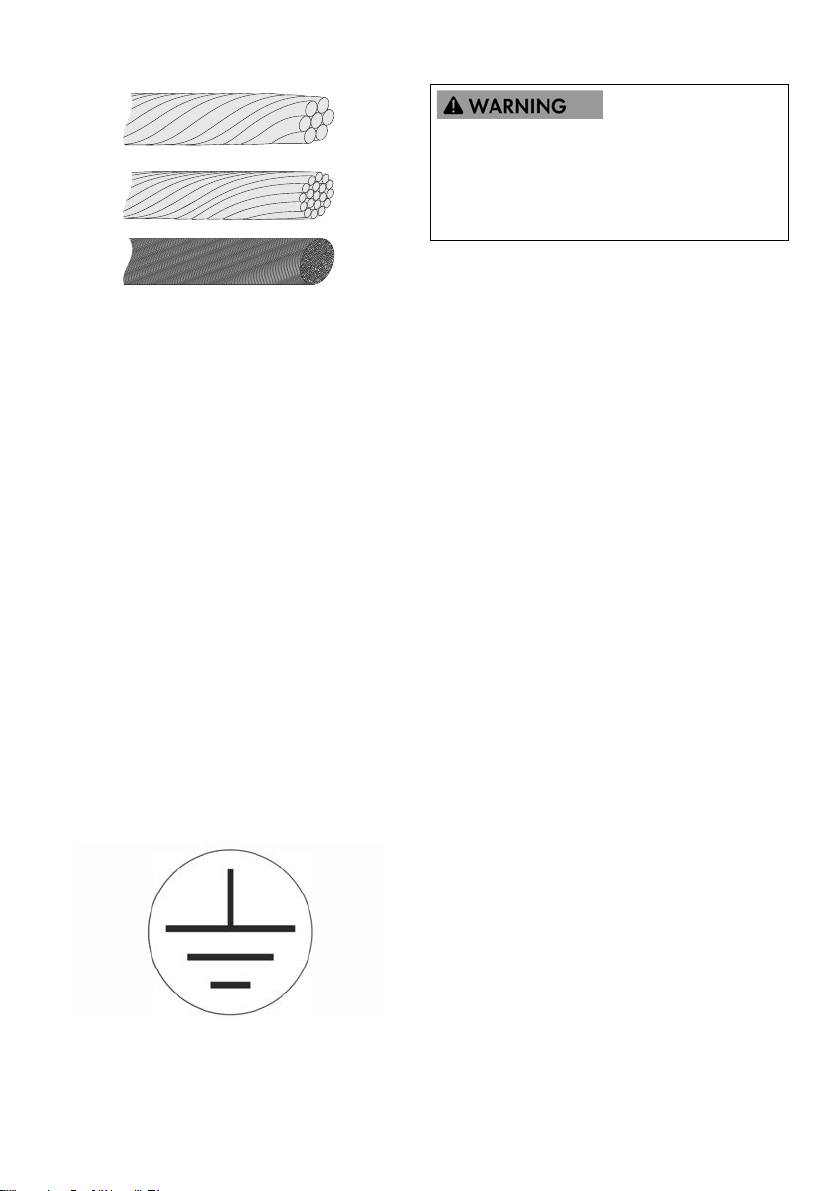

INFORMATION

Cables with multi-strand, fine-strand or extra

fine-strand conductors can be used for AC

connection (see figure 2.15 and 2.16). The cables

must be suitable for a temperature of at least 75°C.

When using fine-strand or extra fine-strand

conductors, bootlace ferrules must be used for the

Figure 2.14 Installation area

Installation Guide SHP75-10-STP60-10-IA-xx-18 25

connection.

2 Installation SMA Solar Technology AG

LEAKAGE CURRENT HAZARD

Insufficient grounding of the inverter can lead to serious

injuries or lethal injuries.

• Ensure the correct grounding of the devices by a

certified electrical installer.

Figure 2.17 Cables with different conductors (from top to bottom):

multi-strand, fine-strand and extra fine-strand

The inverter may only be connected to a three-phase utility

grid.

Strip off the insulation of all four AC cable conductors. The

protective conductor (PE) must be longer than the grid wires.

1. Verify that the nominal voltage of the inverter matches

the grid voltage.

2. Ensure that the main circuit breaker is released, and

take precautions to prevent reconnection.

3. Open the front cover.

4. Insert the cable through the AC cable gland to the

terminal block.

5. Connect the three grid wires (L1, L2, L3) and the

grounding conductor (PE) to the terminal block with the

respective markings. The grounding conductor is

marked with the symbol shown in figure 2.17.

6. Optional: Make an extra PE connection at the

secondary PE grounding points using the external

device grounding bolt delivered with the inverter. See

figure 5.2.

7. All conductors must be properly attached with the

correct tool (screwdriver bit, length min. 50 mm) and

correct torque, see Section 5.4, page 45.

Figure 2.18 Grounding conductor symbol

26 SHP75-10-STP60-10-IA-xx-18 Installation Guide

SMA Solar Technology AG 2 Installation

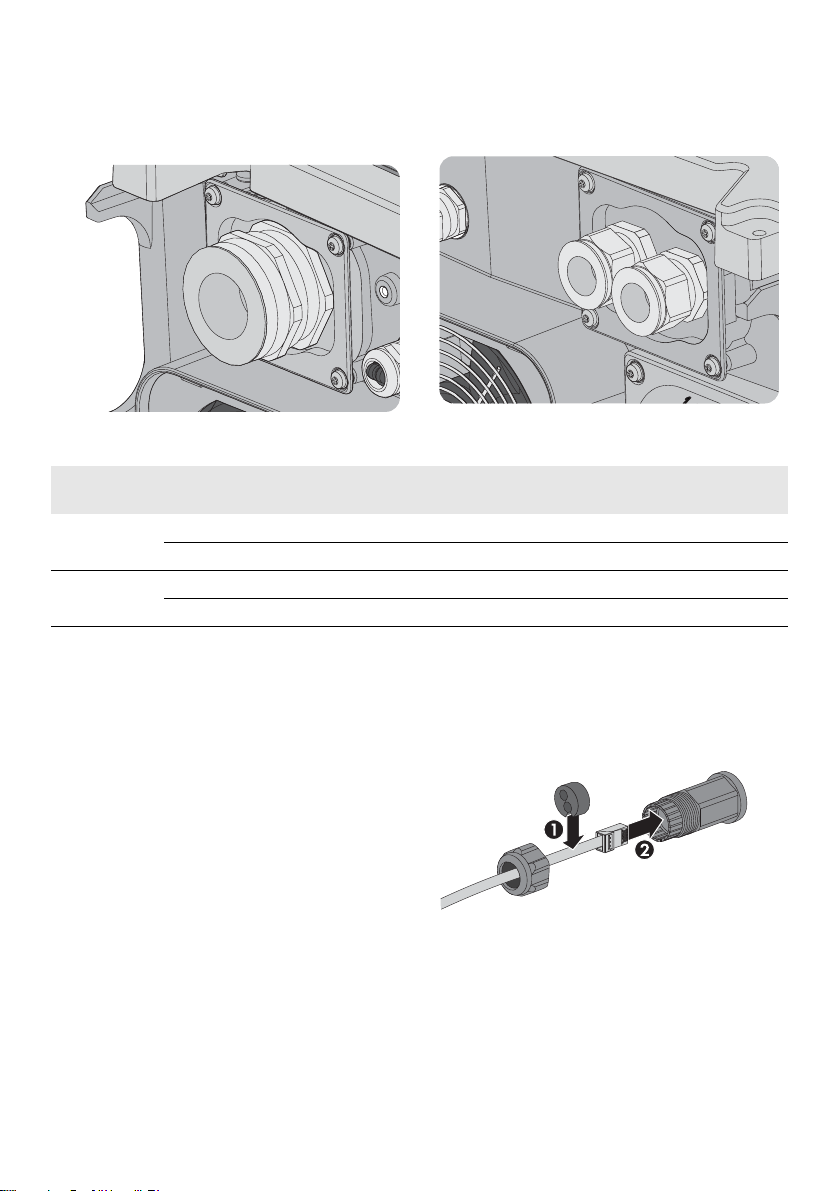

2.7 Enclosure opening

The mounting brackets for the cable glands are already

pre-mounted.

Figure 2.19 AC cable gland

Terminal Range

1)

Figure 2.20 DC cable gland

Line material Cable sheath diameter with

supplied cable gland

SHP 75-10 AC+PE 35 to 150 mm² Al/Cu 46 to 53 mm

PV 35 to 150 mm² Al/Cu 18 to 25 mm

STP 60-10 AC+PE 16 to 95 mm² Al/Cu 37 to 44 mm

PV 16 to 95 mm² Al/Cu 14 to 21 mm

Table 2.1 Suitable conductor sizes

1)

Always observe the ampacity of cables used.

2.8 Ethernet Connections

When used outdoors, make sure to use a suitable cable (see

Section 5.6 “Technical Data of the Communication

Interface”, page 47). If the cable is very stiff, an

intermediate terminal should be used to achieve greater

flexibility of the cable before it is connected to the inverter.

For some cables, it may be sufficient to remove the outer

hard sheath from the part of the cable that is inserted into

the inverter enclosure. In this way, the RJ45 Ethernet

connectors mounted on the printed circuit boards are

protected against excessive stress, which could lead to

damages or problems with the connection.

Procedure:

1. Do not remove the RJ45 connector on the Ethernet

cable.

2. Run the cables through the base of the inverter via

cable glands. See figure 2.20.

3. Cut slice in rubber grommet. Place the grommet in the

gland to ensure proper seal.

4. Plug into the Ethernet connector.

Figure 2.21 Run cables through cable glands

Installation Guide SHP75-10-STP60-10-IA-xx-18 27

2 Installation SMA Solar Technology AG

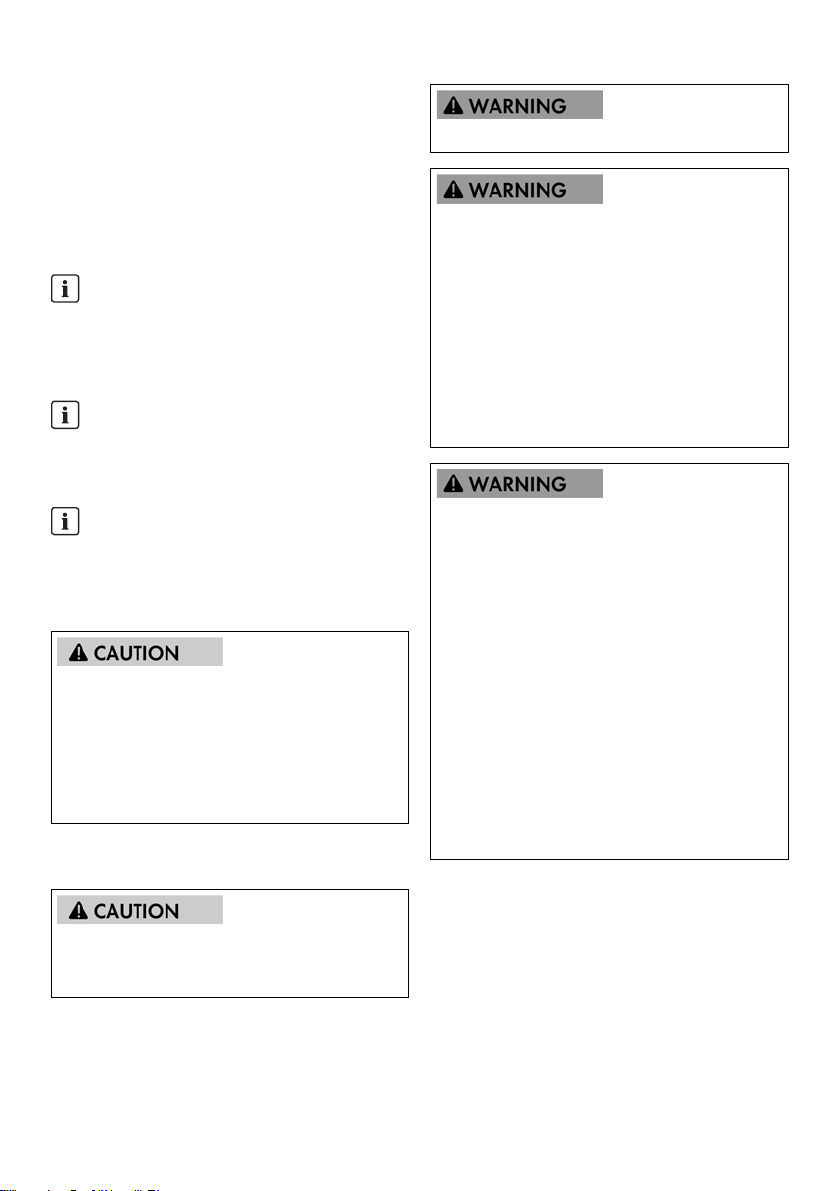

2.9 PV Connection

2.9.1 External PV Array Junction Boxes

PV str ing s mu st b e co nne cte d to the DC i npu t vi a an ext ern al

PV array junction box. The PV array junction box connects

the PV strings of the PV array and protects the individual

strings against overcurrent with appropriate fuse protection.

INFORMATION

The same number and type of modules must be

connected to all PV strings connected to the PV array

junction box. In addition, all connected modules must

have the same orientation.

INFORMATION

Observe correct fuse rating. Consult the module

manufacturer's manuals for information on correct

string fuse rating.

INFORMATION

Use a suitable voltage detector that can measure up

to 1000 V DC. Verify the polarity and maximum

voltage of the PV arrays by measuring the PV

open-circuit voltage.

The inverter is protected against short-term reverse

polarity. Not correcting reverse polarity results in

irreparable defects of the inverter and will void the

warranty.

• Make sure that the cables are properly connected to

the inverter so that the inverter can feed in DC input

voltage.

The combined power from the PV array junction box must

be connected to the DC input of the inverter.

Do NOT connect PV to ground!

Danger due to ground fault on DC side during

operation

Due to the transform erless topology of the product, the

occurrence of ground faults on DC side during operation

can lead to irreparable damage. Damages to the product

due to a faulty or damaged DC installation are not

covered by warranty. The product is equipped with a

protective device that checks whether a ground fault is

present during the starting sequence. The product is not

protected during operation.

• Ensure that the D C insta llation i s carri ed out cor rectly

and no ground fault occurs during operation.

Danger to life due to fire or explosion

In rare cases, an explosive gas mixture can be generated

inside the product in the event of an error. In this state,

switching operations can cause a fire or explosion. Death

or lethal injuries due to fire or flying debris can result.

• In case of error, only carry out corrective measures

specified by SMA Solar Technology AG (for

corrective measures see Section 4.1, page 34).

If no corrective measures are specified, do not

perform any actions on the product. Contact the

service.

• Disconnect the PV array from the product via an

external disconnection device. Do not operate the

DC load-break switch on the product

• Ensure that unauthorized persons have no access to

the product.

• Disconnect AC circuit breaker and secure against

reconnection.

PV array is floating, with both the (+) and (-) conductors

connected to the PV inputs of the inverter. Neither

conductor is connected to ground.

The DC power can be disconnected with the

inverter-integrated DC load-break switch.

28 SHP75-10-STP60-10-IA-xx-18 Installation Guide

SMA Solar Technology AG 2 Installation

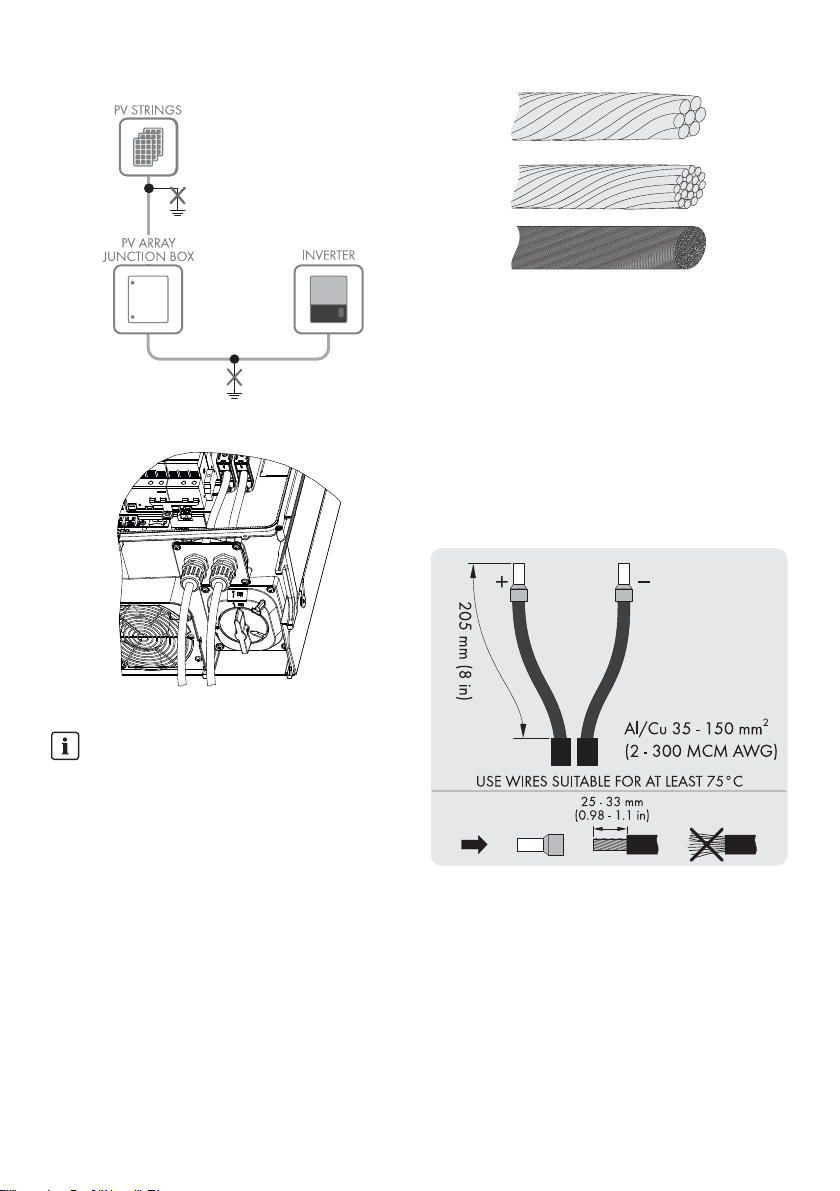

Figure 2.22 Do not connect PV to ground

Figure 2.23: DC connection area

INFORMATION

Cables with multi-strand, fine-strand or extra

fine-strand conductors can be used for AC

connection (see figure 2.23). The cables must be

suitable for a temperature of at least 75°C.

When using fine-strand or extra fine-strand

conductors, bootlace ferrules must be used for the

connection.

Figure 2.24 Cables with different conductors (from top to bottom):

multi-strand, fine-strand and extra fine-strand

1. Switch the PV l oad-br eak swi tch on t he invert er to "O ff"

and, if available, also on the PV array junction box.

2. Connect the PV cables from the PV array junction box

to the inverter. Ensure the correct polarity when doing

so.

3. All conductors must be properly attached with the

correct tool (screwdriver bit, length min. 50 mm) and

correct torque, see Section 5.4, page 45.

Cable requirements SHP 75-10

Figure 2.25 DC label SHP 75-10

Installation Guide SHP75-10-STP60-10-IA-xx-18 29

3 Initial Setup and Start SMA Solar Technology AG

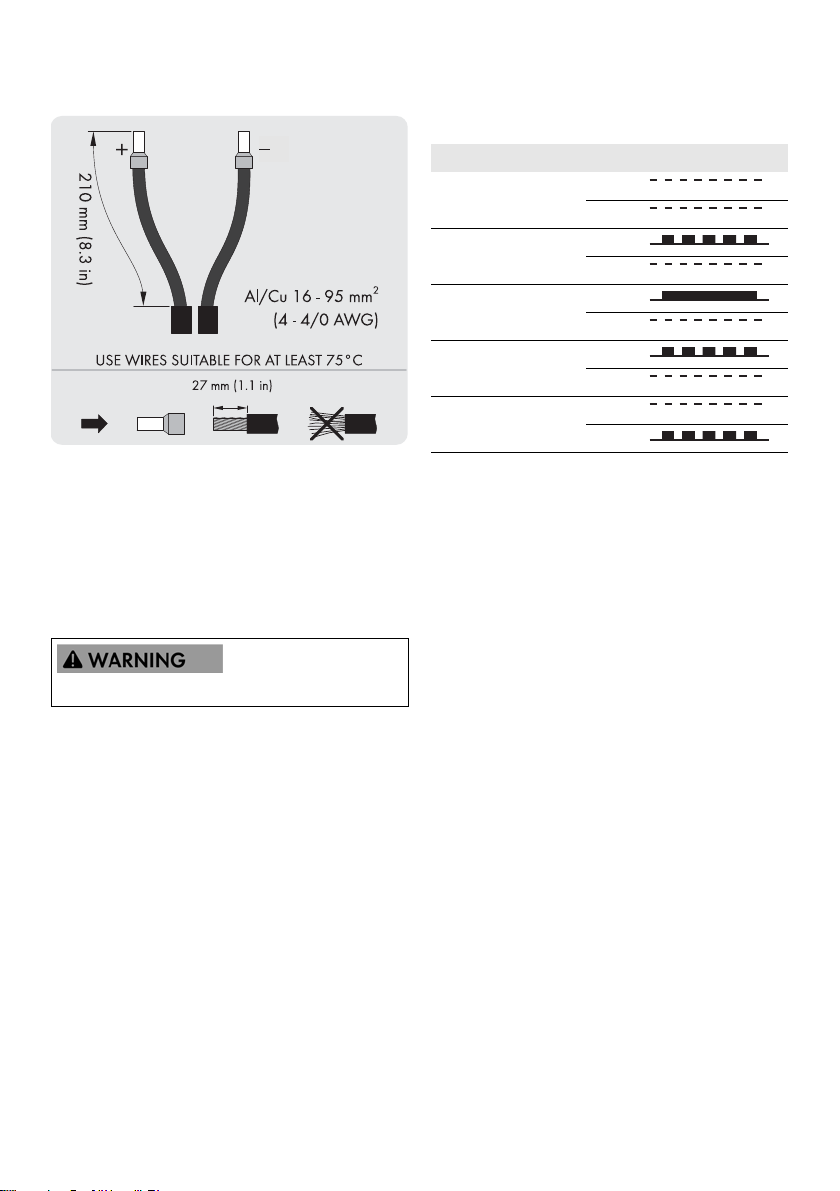

Cable requirements STP 60-10

Figure 2.25 DC label STP 60-10

Protection class of PV modules

The inverter must only be operated with PV modules of

protection class II, compliant with IEC 61730, application

class A.

Only connect PV modules to the inverter. Other energy

sources are not allowed.

3.1.1 Operating Modes

The inverter has five operation modes, indicated by LEDs.

Status LEDs LEDs

Off grid Green

Red

Connecting Green

Red

On grid Green

Red

Internal inverter event Green

Red

Fail safe Green

Red

Table 3.1 Operating modes

Off grid (LEDs off)

#0-51

If no electric current has been fed into the AC grid for more

th an ap pro x. ten minu tes, t he inv erter disco nnect s itse lf fro m

the utility grid and shuts down. User and communication

interfaces remain powered for communication purposes.

PV modules generate a voltage when exposed to light.

2.10 Closing

1. Close the cover of the inverter installation area. Fasten

the three front screws (see Section 5.4, page 45).

2. Turn on AC power.

3 Initial Setup and Start

3.1 User Interface

The user interface comprises:

• Local display, for all inverter variants. The local display

shows status information of the inverter. It is not

possible to set up or configure the inverter via the

display. The "#" in the display explains the operation

modes.

• Local commissioning and service tool (LCS-Tool). The

LCS-Tool can be used for configuring one or more

inverters.

30 SHP75-10-STP60-10-IA-xx-18 Installation Guide

Loading...

Loading...