Page 1

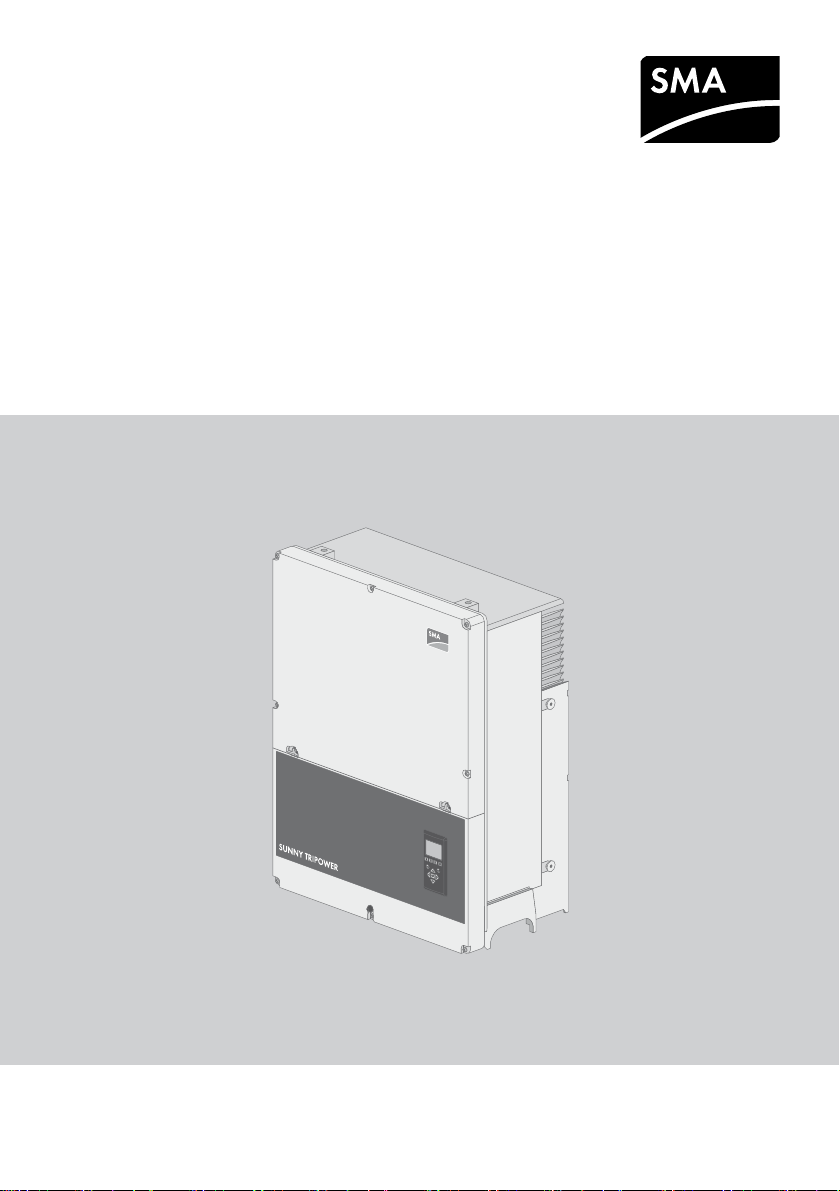

Installation Guide / Installationsanleitung /

Instrucciones de instalación / Instructions d’installation /

Istruzioni per l’installazione

SUNNY TRIPOWER 60

STP60-10-IA-xx-10 | 139R0102 | Version 1.0

Page 2

Page 3

SMA Solar Technology AG ENGLISH - Table of Contents

ENGLISH - Table of Contents

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.1 Overview of Installation Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.2 Purpose of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.3 Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.4 Inverter Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.5 Installation Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.1 Environment and Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.2 Mounting the Wall Mounting Bracket. . . . . . . . . . . . . . . . . . . . . . . . 22

2.3 Mounting the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.4 Disassembling the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.5 Access to the Installation Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.6 Grid Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.7 Cable Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.8 Ethernet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.9 PV Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.9.1 External PV Array Junction Boxes. . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.10 Closure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3 Initial Setup and Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

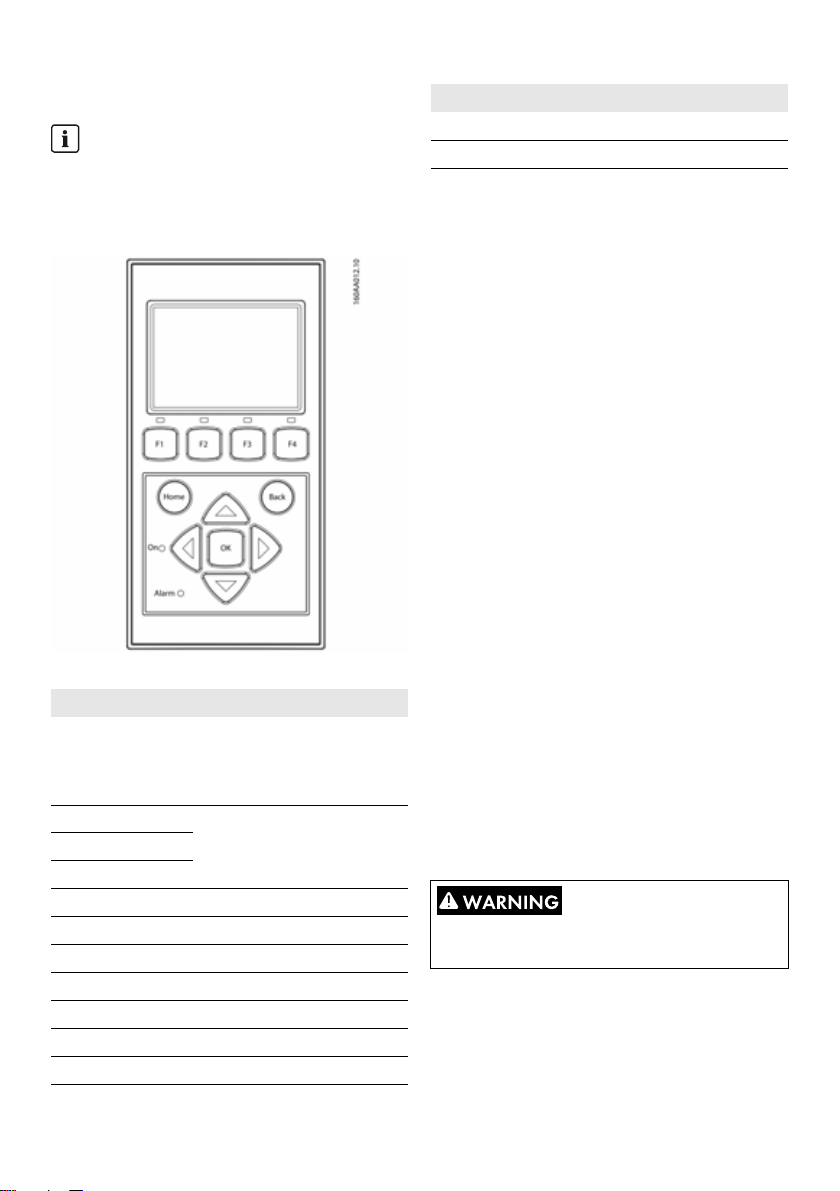

3.1 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.1.1 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.2 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.2.1 Initial Setup via LCS tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.2.2 Switching on the PV Load-Break Switch . . . . . . . . . . . . . . . . . . . . . . 31

3.2.3 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3 LCS tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3.1 Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4 Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Installationsanleitung STP60-10-IA-xx-10 3

Page 4

DEUTSCH - Inhaltsverzeichnis SMA Solar Technology AG

4.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.1 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.2 Trip Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.3 Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.4 Installation Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.5 Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.6 Specifications for Grid Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.7 Technical Data of the Communication Interface . . . . . . . . . . . . . . . . 51

5.8 Ethernet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.8.1 Network Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

DEUTSCH - Inhaltsverzeichnis

1 Einführung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1.1 Überblick über den Installationsbereich. . . . . . . . . . . . . . . . . . . . . . . 60

1.2 Zweck des Handbuchs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

1.3 Auspacken. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

1.4 Typenschild des Wechselrichters. . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

1.5 Installationsreihenfolge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.1 Umgebung und Abstände . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.2 Montage der Wandhalterung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

2.3 Montage des Wechselrichters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

2.4 Abbau des Wechselrichters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2.5 Zugang zum Installationsbereich. . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2.6 AC-Netzanschluss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2.7 Kabeleinführung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

2.8 Ethernet-Anschlüsse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

2.9 PV-Anschluss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4 STP60-10-IA-xx-10 Installationsanleitung

Page 5

SMA Solar Technology AG

2.9.1 Externe Generatoranschlusskästen . . . . . . . . . . . . . . . . . . . . . . . . . 71

2.10 Schließen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3 Ersteinrichtung und Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3.1 Benutzerschnittstelle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3.1.1 Betriebsarten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3.2 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3.2.1 Ersteinrichtung über LCS-Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.2.2 PV-Lasttrennschalter einschalten. . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.2.3 Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.3 LCS-Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.3.1 Erste Schritte. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4 Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.1 Fehlersuche und -behebung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.2 Wartung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5 Technische Daten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.1 Spezifikationen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.2 Abschalteinstellungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5.3 Konformität . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5.4 Installationsbedingungen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

5.5 Drehmomentspezifikationen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

5.6 Spezifikation für die Netzsicherungen. . . . . . . . . . . . . . . . . . . . . . . . 94

5.7 Technische Daten der Kommunikationsschnittstellen . . . . . . . . . . . . . 95

5.8 Ethernet-Anschlüsse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

5.8.1 Netzwerktopologie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6 Kontakt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Installationsanleitung STP60-10-IA-xx-10 5

Page 6

SMA Solar Technology AG

ESPAÑOL - Índice

1 Introducción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

1.1 Vista general de la planta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

1.2 Objetivo de estas instrucciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

1.3 Desembalaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

1.4 Placa de características del inversor . . . . . . . . . . . . . . . . . . . . . . . . 106

1.5 Orden de instalación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

2 Instalación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

2.1 Entorno y espacios libres. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

2.2 Montaje del soporte mural . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

2.3 Montaje del inversor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

2.4 Desmontaje del inversor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

2.5 Acceso al área de instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

2.6 Conexión de red de CA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

2.7 Entrada de cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

2.8 Conexiones de ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

2.9 Conexión FV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

2.9.1 Cajas de conexión del generador externas. . . . . . . . . . . . . . . . . . 115

2.10 Cerrar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

3 Configuración inicial y arranque . . . . . . . . . . . . . . . . . . . . . . 117

3.1 Interfaz de usuario. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

3.1.1 Tipos de funcionamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

3.2 Pantalla . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

3.2.1 Ajuste inicial mediante herramienta LCS . . . . . . . . . . . . . . . . . . . . 119

3.2.2 Ponga el interruptor-seccionador FV en posición ON . . . . . . . . . . 119

3.2.3 Arranque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

3.3 Herramienta LCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

3.3.1 Primeros pasos. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

4 Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

4.1 Resolución de problemas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

6 STP60-10-IA-xx-10 Installationsanleitung

Page 7

SMA Solar Technology AG

4.2 Mantenimiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

5 Datos técnicos. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

5.1 Especificaciones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

5.2 Ajustes de desconexión. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

5.3 Conformidad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

5.4 Condiciones de la instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

5.5 Especificaciones del par de apriete. . . . . . . . . . . . . . . . . . . . . . . . . 138

5.6 Especificaciones del circuito de la red eléctrica . . . . . . . . . . . . . . . 138

5.7 Especificaciones de la interfaz auxiliar . . . . . . . . . . . . . . . . . . . . . . 139

5.8 Conexiones de ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

5.8.1 Topología de red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

6 Contacto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

FRANÇAIS - Table des matières

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

1.1 Aperçu de la zone d’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

1.2 Objet du manuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

1.3 Déballage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

1.4 Plaque signalétique de l’onduleur . . . . . . . . . . . . . . . . . . . . . . . . . . 150

1.5 Séquence d’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

2.1 Environnement et distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

2.2 Montage du support mural . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

2.3 Montage de l’onduleur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

2.4 Démontage de l’onduleur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

2.5 Accès à la zone d’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

2.6 Raccordement au réseau AC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

2.7 Entrée des câbles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

2.8 Raccordements Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

2.9 Raccordement photovoltaïque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Installationsanleitung STP60-10-IA-xx-10 7

Page 8

SMA Solar Technology AG

2.9.1 Boîtiers de jonction externes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

2.10 Fermeture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

3 Configuration initiale et démarrage. . . . . . . . . . . . . . . . . . . . 161

3.1 Interface utilisateur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

3.1.1 Mode de fonctionnement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

3.2 Écran . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

3.2.1 Configuration initiale via l’outil LCS . . . . . . . . . . . . . . . . . . . . . . . . 163

3.2.2 Activation de l’interrupteur-sectionneur DC . . . . . . . . . . . . . . . . . . 163

3.2.3 Mise en service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

3.3 L’outil LCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

3.3.1 Premières étapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

4 Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

4.1 Recherche d’erreurs et dépannage . . . . . . . . . . . . . . . . . . . . . . . . . 170

4.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

5 Données techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

5.1 Spécifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

5.2 Réglages de déconnexion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

5.3 Conformité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

5.4 Conditions d’installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

5.5 Spécifications de couple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

5.6 Spécifications pour la protection du réseau . . . . . . . . . . . . . . . . . . 183

5.7 Spécifications de l’interface de communication. . . . . . . . . . . . . . . . 184

5.8 Raccordements Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

5.8.1 Topologie du réseau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

6 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

8 STP60-10-IA-xx-10 Installationsanleitung

Page 9

SMA Solar Technology AG

ITALIANO - Indice

1 Introduzione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

1.1 Panoramica sull’area di installazione.. . . . . . . . . . . . . . . . . . . . . . . 192

1.2 Scopo del presente manuale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

1.3 Disimballaggio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

1.4 Targhetta di identificazione dell’inverter . . . . . . . . . . . . . . . . . . . . . 194

1.5 Ordine d’installazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

2 Installazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

2.1 Ambiente e distanze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

2.2 Montaggio del supporto da parete. . . . . . . . . . . . . . . . . . . . . . . . . 198

2.3 Montaggio dell’inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

2.4 Rimozione dell’inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

2.5 Accesso all’area di installazione . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

2.6 Collegamento rete CA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

2.7 Introduzione dei cavi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

2.8 Collegamenti Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

2.9 Collegamento dell’impianto FV . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

2.9.1 Quadri di parallelo stringhe esterni . . . . . . . . . . . . . . . . . . . . . . . . 203

2.10 Chiusura. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

3 Setup iniziale e avviamento . . . . . . . . . . . . . . . . . . . . . . . . . . 205

3.1 Interfaccia utente . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

3.1.1 Modi di funzionamento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

3.2 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

3.2.1 Setup iniziale attraverso il tool LCS . . . . . . . . . . . . . . . . . . . . . . . . 207

3.2.2 Attivazione dell’interruttore del carico FV . . . . . . . . . . . . . . . . . . . 207

3.2.3 Messa in servizio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

3.3 Tool LCS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

3.3.1 Primi passi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

4 Servizio di assistenza tecnica . . . . . . . . . . . . . . . . . . . . . . . . . 214

4.1 Ricerca degli errori . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Installationsanleitung STP60-10-IA-xx-10 9

Page 10

SMA Solar Technology AG

4.2 Manutenzione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

5 Dati tecnici. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

5.1 Specifiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

5.2 Impostazioni di scollegamento . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

5.3 Conformità. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

5.4 Condizioni di installazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

5.5 Specifiche di coppia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

5.6 Specifiche interfaccia ausiliaria . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

5.7 Dati tecnici delle interfacce di comunicazione. . . . . . . . . . . . . . . . . 227

5.8 Collegamenti Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

5.8.1 Topologia della rete. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

6 Contatto. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

10 STP60-10-IA-xx-10 Installationsanleitung

Page 11

SMA Solar Technology AG

Legal Provisions

The information contained in this document is the

property of SMA Solar Technology AG. Publishing its

content, either partially or in full, requires the written

permission of SMA Solar Technology AG.

Any internal company copying of the document for

the purposes of evaluating the product or its correct

implementation is allowed and does not require

permission.

SMA Warranty

You can download the current warranty conditions

from the Internet at www.SMA-Solar.com.

Trademarks

All trademarks are recognized, even if not explicitly

identified as such. A lack of identification does not

mean that a product or symbol is not trademarked.

The BLUETOOTH® word mark and logos are

registered trademarks owned by Bluetooth SIG, Inc.

and any use of these marks by SMA Solar

Technology AG is under license.

Modbus® is a registered trademark of Schneider

El ect ric and is l icensed by t he M odb us O rga niz ati on,

Inc.

QR Code is a registered trademark of DENSO

WAVE INCORPORATED.

®

Phillips

and Pozidriv® are registered trademarks of

Phillips Screw Company.

Torx® is a registered trademark of Acument Global

Technologies, Inc.

SMA Solar Technology AG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

E-mail: info@SMA.de

© 2004 to 2015 SMA Solar Technology AG. All

rights reserved.

Installation Guide STP60-10-IA-xx-10 11

Page 12

SMA Solar Technology AG

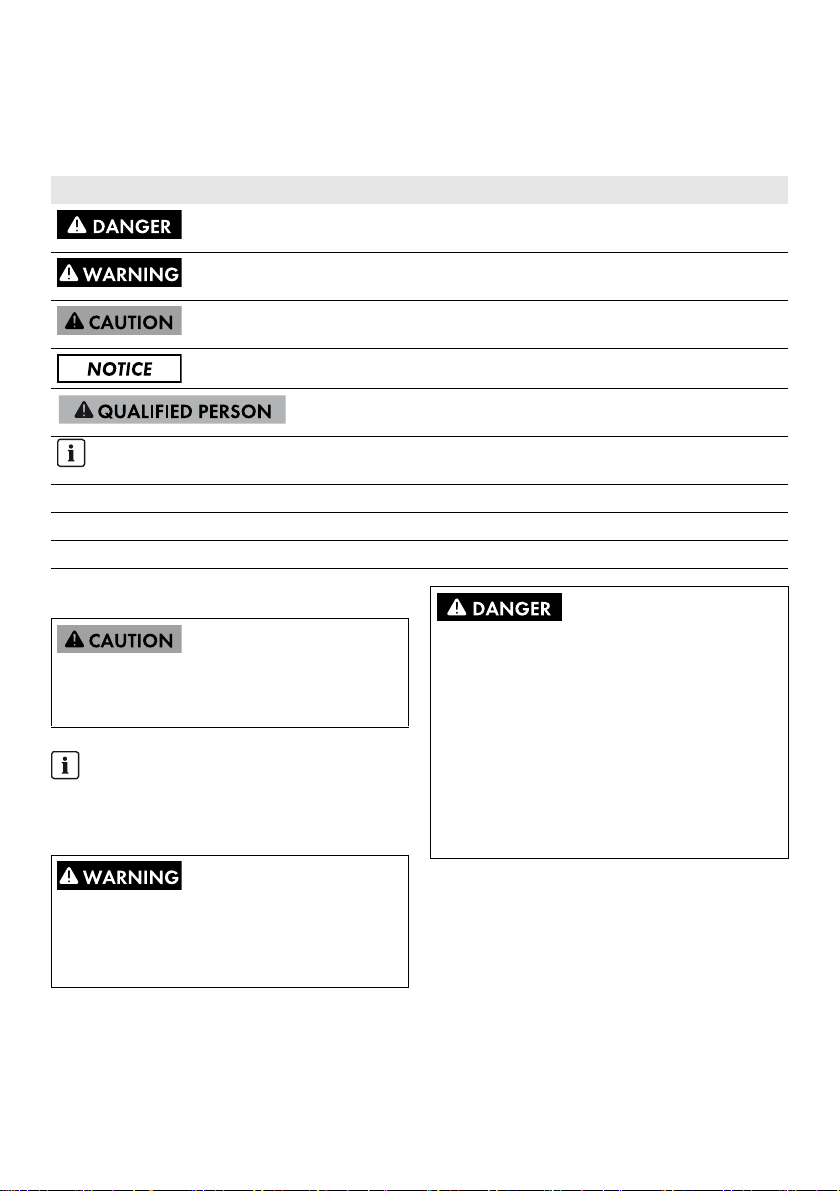

IMPORTANT SAFETY

INFORMATION

The following symbols are used in this document:

Symbol Explanation

Indicates a hazardous situation which, if not avoided, will result in death or

serious injury

Indicates a hazardous situation which, if not avoided, can result in death or

serious injury

Indicates a hazardous situation which, if not avoided, can result in minor or

moderate injury

Indicates a situation which, if not avoided, can result in property damage

Indicates that the following section contains tasks that must be performed by

qualified persons only

Information that is important for a specific topic or goal, but is not

safety-relevant

☐

☑ Desired result

✖ A problem that might occur

General Safety

Indicates a requirement for meeting a specific goal

Disconnecting the inverter

This manual contains important instructions that must be

followed during installation and maintenance of the

inverter.

Before Installation

Check the inverter and the packaging for damage. If

in doubt, contact the supplier before commencing

installation.

Installation

For optimum safety, follow the steps described in this

document. Keep in mind that the inverter has two voltage

carrying sides, the PV input and the utility grid.

12 STP60-10-IA-xx-10 Installation Guide

Before working on the inverter, disconnect it from the utility

grid by means of the main switch and switch off PV using

the integrated PV load-break switch (DC load-break

switch). Ensure that the inverter cannot be unintentionally

reconnected. Use a voltage detector to ensure that the

unit is disconnected and voltage free. The inverter can still

be charged with very high voltage at hazardous levels

even when it is disconnected from utility grid and PV

modules. Wait at least five minutes after disconnection

from the utility grid and PV modules before proceeding.

Page 13

SMA Solar Technology AG

RISK OF ELECTRIC SHOCK

These maintenance instructions are intended for use by

qualified personnel only. To reduce the risk of electric

shock, do not perform any maintenance work other than

that specified in the user manual unless you are qualified

to do so.

The inverter is not equipped with an transformer and is

intended to be installed according to NFPA 70, 690.35

with an ungrounded (floating) PV array.

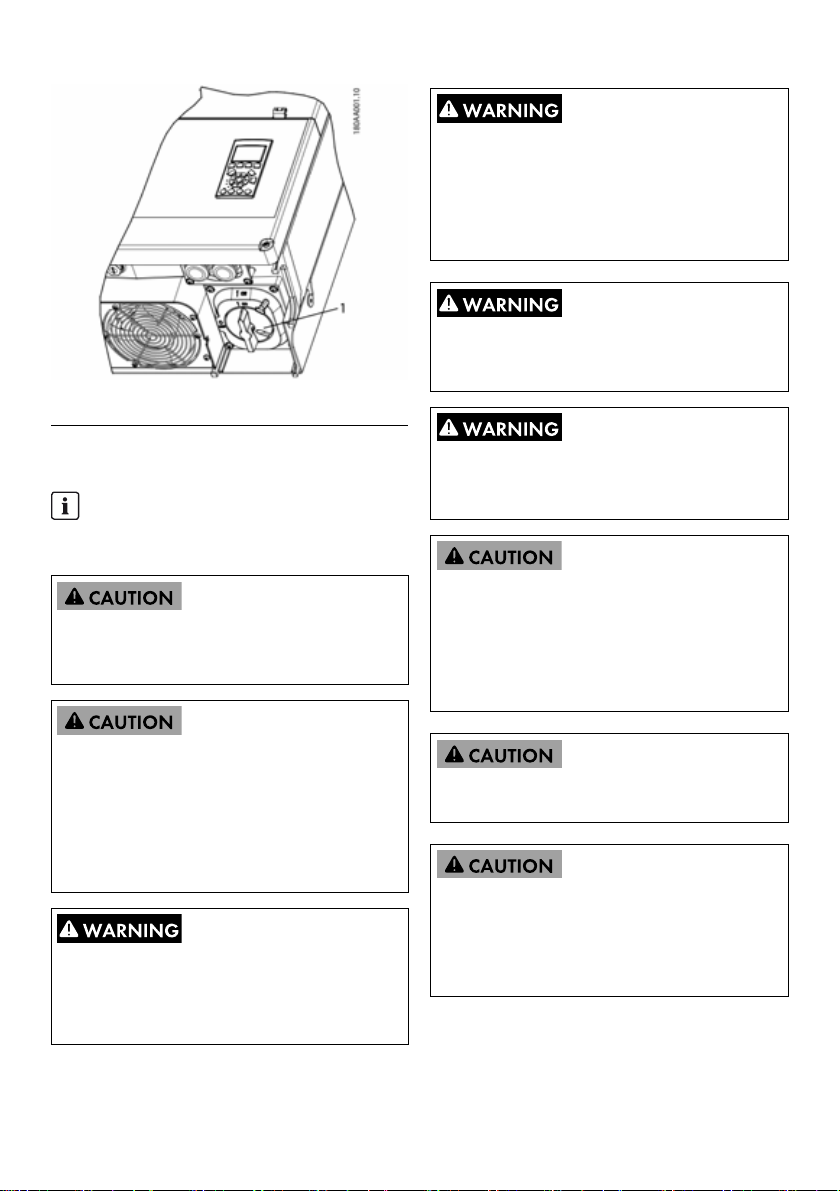

1 PV load-break switch

Figure 1.1

INFORMATION

The PV load-break switch can be secured in the ‘Off’

position using a padlock.

DC voltages up to 1,000 V are present in a PV system

even when the inverter is disconnected from the utility grid.

Faults or inappropriate use may lead to electric arcing.

MAINTENANCE AND MODIFICATION

Only authorized personnel are permitted to repair or

modify the inverter. To ensure personal safety, use only

original spare parts available from the supplier. If

no n-or igin al sp are p ar ts a re u se d, c omp li anc e wi th CE /U L

guidelines in respect of electrical safety, EMC and

machine safety is not guaranteed.

INSTALLER

Observe the National Electric Code, ANSI/NFPA 70.

Input and output circuits are isolated from the enclosure.

System grounding is the responsibility of the installer.

Input and output circuits are isolated from the enclosure.

System grounding, if required by the Canadian Electrical

Code, Part I, is the responsibility of the installer.

All persons responsible for the installation and

maintenance of inverters must be:

• Trained and authorized in general safety rules for

work on electric equipment.

• Familiar with local requirements, rules and

regulations for the installation.

The inverter does not provide overcurrent protection. This

must be provided by the installer. See table 5.8

The temperature of the cooling elements and components

in the inv ert er c an e xce ed 7 0°C /15 8°F . Th ere is a ri sk o f

burns.

The inverter is to be installed in such way that hot

components cannot be touched.

Installation Guide STP60-10-IA-xx-10 13

Page 14

SMA Solar Technology AG

INFORMATION

To reduce the risk of fire, connect the inverter only to a

circuit provided with 125 A maximum branch-circuit

overcurrent protection in accordance with the National

Electrical Code

®

, ANSI/NFPA 70.

This device has been tested and found to comply with

the thresholds for a Class B digital device, pursuant

to part 15 of the FCC Rules. These thresholds are

intended to provide an adequate level of protection

against harmful interference when using the device in

residential areas. The inverter generates, uses and

INFORMATION

Use 75°C or 90°C cables, either AWG copper or

AWG aluminum. See Section 2.7, page26.

can radiate radio frequency energy and, if not

installed and used in accordance with the

instructions, may cause harmful interference to radio

communications. However, there is no guarantee that

interference will not occur in a particular installation.

INFORMATION

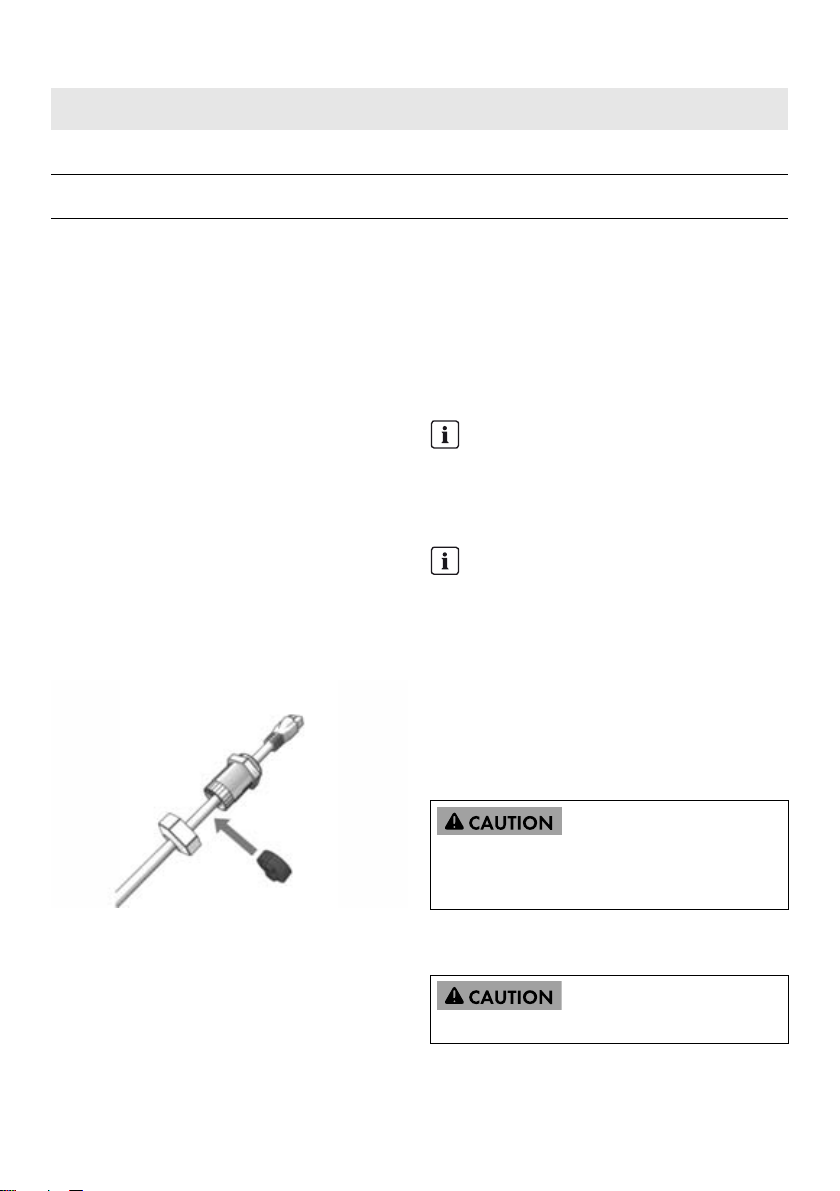

The symbol for grounding conductors used in this

manual is identified in figure 2.18.

The on/off symbol is identified in Section 3.2.2,

page31.

INFORMATION

For information about the operating temperature

range, see Section 5.4, page49.

If this device does cause harmful interference to radio

or television reception, which can be determined by

turning the device off and on, the user is encouraged

to try to c orr ect the int erf ere nce by o ne o r mo re o f th e

following measures:

• Reorient or relocate the receiving antenna.

• Increase the distance between the device and

receiver.

• Do not connect the device to a circuit for radio

or television receivers.

INFORMATION

This manual contains information about field wiring

connections and torque specifications. See Section

5.5, page50.

• Consult your distributor or a trained radio/TV

technician for help.

Symbols on the Inverter

Symbol Explanation

Danger to life due to electric shock

The product operates at high voltages.

All work on the product must be

carried out by qualified persons only.

Danger

This symbol indicates that the inverter

must be additionally grounded if

additional grounding or equipotential

bonding is required at the installation

site.

Danger to life due to high voltages in

the inverter; observe waiting time.

High voltages that can cause lethal

electric shocks are present in the live

components of the inverter.

Prior to performing any work on the

inverter, disconnect it from all voltage

sources as described in this document.

14 STP60-10-IA-xx-10 Installation Guide

Page 15

SMA Solar Technology AG 1 Introduction

Symbol Explanation

Risk of burns due to hot surfaces

The product can get hot during

operation. Avoid contact during

operation. Allow the product to cool

down sufficiently before carrying out

any work.

Observe the documentation

Observe all documentation supplied

with the product.

Compliance

Further information can be found in the download area of

www.SMA-Solar.com (see also Section 5, page45).

1Introduction

The STP 60 inverters are designed to act exclusively as

grid-tie inverters for PV systems. The inverter converts direct

voltage generated by a PV array to alternating current. The

device must be connected to the utility grid and a sufficient

number of PV modules in order to operate properly. The

STP 60 inverters are not suitable for any other applications

(such as operation with battery or wind turbine systems).

The STP 60 system consists of four main components:

• Sunny Tripower 60

• PV array junction box

The PV array junction box makes it possible to combine

the needed number of PV strings for the STP 60

inverter. A PV array junction box is needed for each

STP 60 inverter.

• SMA Inverter Manager

The SMA Inverter Manager is required for the

operation of the Sunny Tripower 60. Up to 42

Sunny Tripower 60 inverters can be connected to one

SMA Inverter Manager. The SMA Inverter Manager

handles all communication of the inverters. It serves as

central interface for data acquisition systems, upload to

cloud services and power-plant control.

• Local commissioning and service tool (LCS tool)

The LCS tool is required for commissioning and

servicing STP 60 inverters via the

SMA Inverter Manager. The LCS tool acts as the

primary user interface of the STP 60 system.

Installation Guide STP60-10-IA-xx-10 15

Page 16

1 Introduction SMA Solar Technology AG

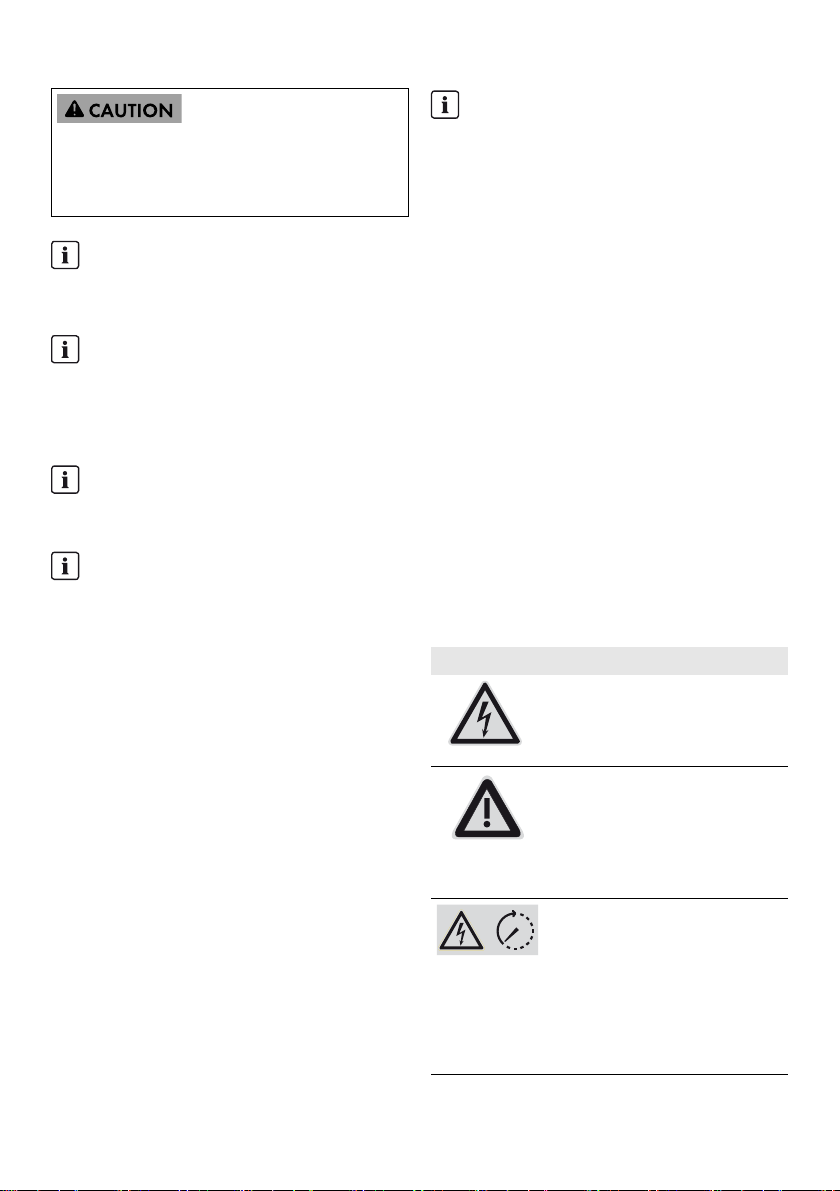

STP 60-10

STP 60-10

STP 60-10

DC COMBINER

DC COMBINER

DC COMBINER

1

12

1

12

1

12

1

23

4

5

6

7

8

9

10

11

12

INVERTER-

MANAGER

DC

AC

ETHERNET

RS485

I/O BOX

TRANSFORMER

STATION

PV STRINGS

PORTAL

LCS TOOL

ROUTER

GRID

MANAGEMENT

PV STRINGS

PV STRINGS

WEATHER

STATION

SCADA

SYSTEM

1.1 Overview of Installation Area

1PV strings

2 PV array junction box

3 Sunny Tripower 60

4 SMA Inverter Manager

5Router

6 LCS tool

7Portal

8 SCADA system

9 Weather station

10 I/O box

11 Grid management

12 Transformer station

16 STP60-10-IA-xx-10 Installation Guide

1.2 Purpose of the Manual

The installation manual provides information on the

installation and commissioning of the STP 60 inverter series.

Additional resources available:

• Quick reference guide for commissioning of the STP 60

inverters – for information required to commission the

STP 60 inverters as well as setup of inverter

communication.

• Installation manual of the SMA Inverter Manager and

the I/O box – for information required to commission

the STP 60 inverter as well as setup of inverter

communication

• Planning guidelines – for information required for

detailed inverter layout planning in a diversity of solar

energy applications.

Page 17

SMA Solar Technology AG 1 Introduction

• Service manual for replacing the fan – for information

required to replace a fan.

• Service manual for replacing the SPDs – for

information required to replace surge protection

devices.

These documents are available from the download area at

www.SMA-Solar.com or from the supplier of the PV inverter.

Figure 1.2 Sunny Tripower 60

Abbreviation Description

ANSI American National Standards Institute

AWG American Wire Gauge

cat5e Category 5 twisted pair cable (enhanced) for

DHCP Dynamic Host Configuration Protocol –

DGO Distribution Grid Operator

DSL Digital Subscriber Line

EMC (directive) Electromagnetic compatibility directive

ESD Electrostatic Discharge

FCC Federal Communications Commission

FRT Fault Ride Through

GSM Global System for Mobile Communications

HDD Hard Disk Drive

IEC International Electrotechnical Commission –

IT Isolated Terra

LCS Local Commissioning and Service

data transmission

enables automatic assignment of the network

address via the DHCP server

(standard for digital cellular mobile network)

international standards organization

Abbreviation Description

LED Light-Emitting Diode

LVD (Directive) Low voltage directive

MCB Circuit Breaker

MPP Maximum Power Point

MPPT Maximum Power Point Tracking determines the

NFPA National Fire Protection Association

P P is the symbol for active power and is

PCB Printed Circuit Board

PCC Point of Common Coupling - point of

PE Protective Grounding

PELV Protected Extra-Low Voltage

PLA Power Level Adjustment = Output power

P

nom

POC Point of Connection

P

STC

PV Photovoltaic, photovoltaic cells

RCD Residual-Current Device

RCMU Residual Current Monitoring Unit

R

ISO

ROCOF Rate of Change of Frequency

Q Q is the symbol for reactive power and is

S S is the symbol for apparent power and is

STC Standard Test Conditions

SW Software

THD Total Harmonic Distortion

TN-S Terra Neutral - Separate. AC Network

TN-C Terra Neutral - Combined. AC Network

TN-C-S Terra Neutral - Combined - Separate. AC

TT Terra Terra. AC Network

point of optimum PV power

measured in Watts (W).

interconnection

The point on the public electricity network to

which other customers are, or could be,

connected.

limitation

Power [W], Nominal active power

The point at which the PV system is connected

to the public utility grid.

Power [W], Standard Test Conditions

Insulation resistance

measured in reactive volt-amperes (VAr).

measured in volt-amperes (VA).

Network

Installation Guide STP60-10-IA-xx-10 17

Page 18

1 Introduction SMA Solar Technology AG

1.3 Unpacking

Content:

•Inverters

•Wall mounting bracket

• Accessories bag containing:

– 6 wall plugs 8 x 50 mm

– 6 mounting screws 6 x 60 mm

– 1 M25 cable gland with sealing grommet for

Ethernet cables

– 1 grounding bolt M6 x 12 mm

– For STP 60-10-US additionally included: 2 x cable

channel with conduit bracket (2")

• Installation manual

• Quick reference guide for installation

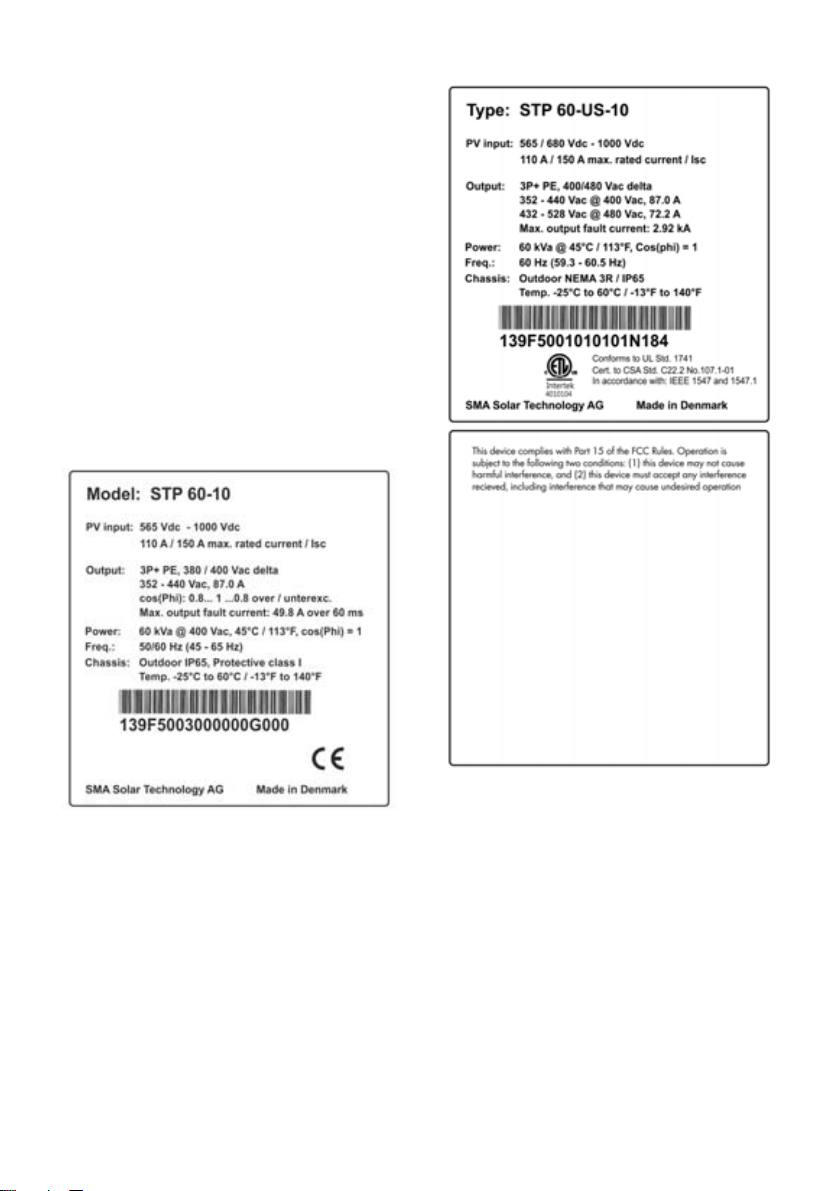

1.4 Inverter Type Label

Figure 1.4 Sunny Tripower 60-US type label

Figure 1.3 Sunny Tripower 60 type label

18 STP60-10-IA-xx-10 Installation Guide

The type label on the side of the inverter shows:

•Device type

• Important technical data

•Serial number, located under the bar code, for inverter

identification

Page 19

SMA Solar Technology AG 1 Introduction

1.5 Installation Sequence

1. Pay special attention to the important safety

information at the beginning of this manual.

2. Mount the inverter according to Section 2.1, page21,

Section 2.2, page22, Section 2.3, page23.

3. Open the inverter in accordance with Section 2.5,

page24.

4. Install the AC supply in accordance with Section 2.6,

page25.

5. Install Ethernet in accordance with Section 5.8,

page52.

6. Install the PV module in accordance with Section 2.9,

page27 using a PV array junction box.

7. Close the inverter in accordance with Section 2.5,

page24.

8. Turn on AC.

9. Finalize commissioning by using the Local

Commissioning and Service Tool (LCS tool). The tool is

available from the download area at

www.SMA-Solar.com. The hardware requirements for

the LCS tool are:

– PC with Windows

–1 GB HDD

–2 GB RAM

The LCS tool must be installed on a local PC drive. The

PC must be connected to the system network of the

SMA Inverter Manager. For setup via the LCS tool,

refer to Section 3.3, page31.

10. Switch on the PV system via the PV load-break switch.

11. Verify the installation by:

– Inverter display: LED "On" is permanently green.

– LCS tool: In the inverter view, the status is "On

grid".

12. The inverter is in operation now.

TM

7 and later

Installation Guide STP60-10-IA-xx-10 19

Page 20

1 Introduction SMA Solar Technology AG

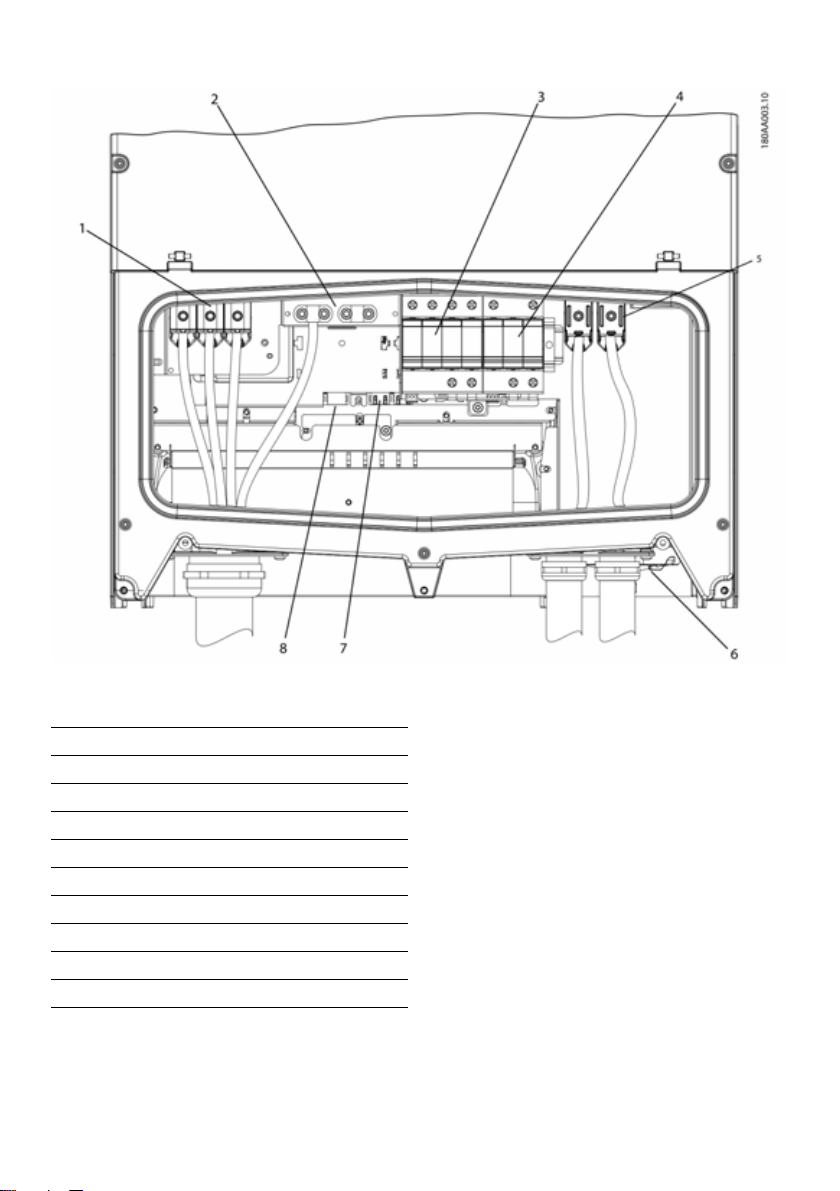

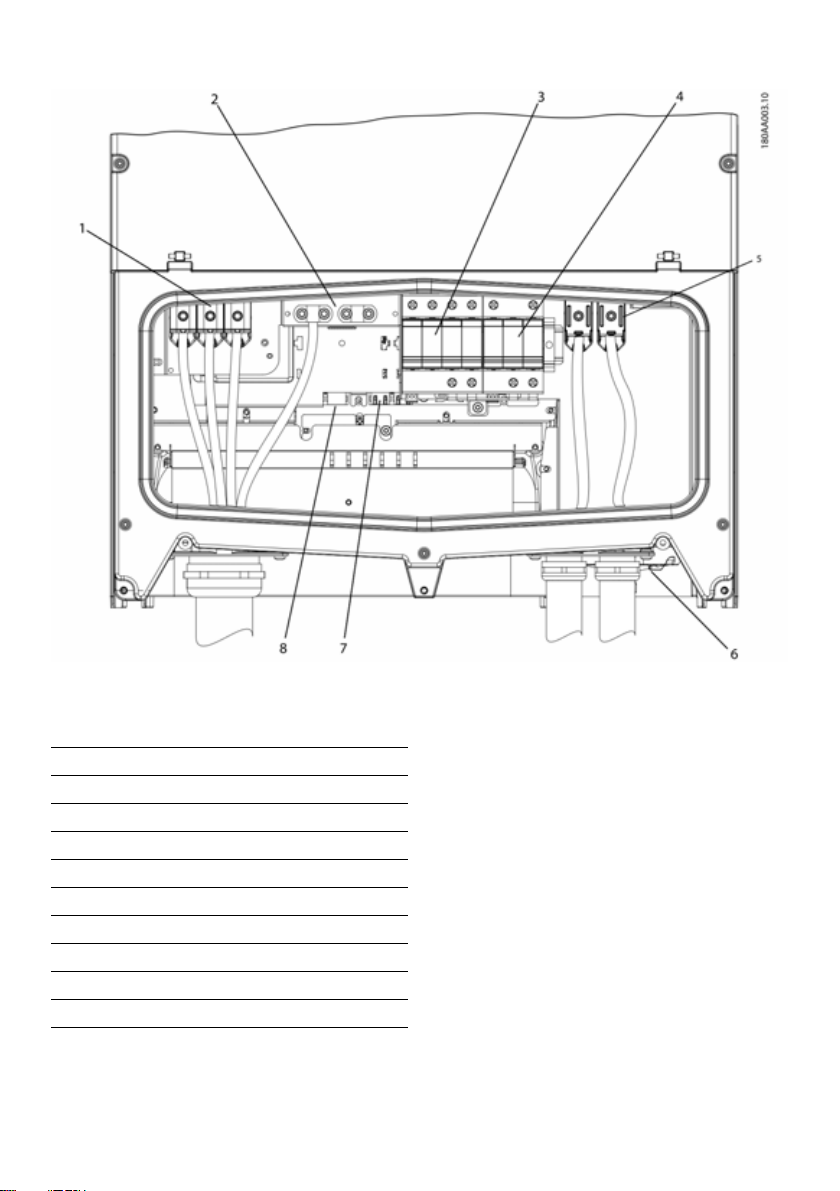

Figure 1.5 Overview of the installation area

PELV (safe to touch)

2 Device grounding

7 Ethernet interface x 2

8 RS-485 interface (not in use)

Live Parts

1AC terminals

5PV terminals

Other

3 AC overvoltage protection (SPDs)

4 DC overvoltage protection (SPDs)

6 PV load-break switch

Figure 1.2 Overview of the installation area

20 STP60-10-IA-xx-10 Installation Guide

Page 21

SMA Solar Technology AG 2 Installation

2Installation

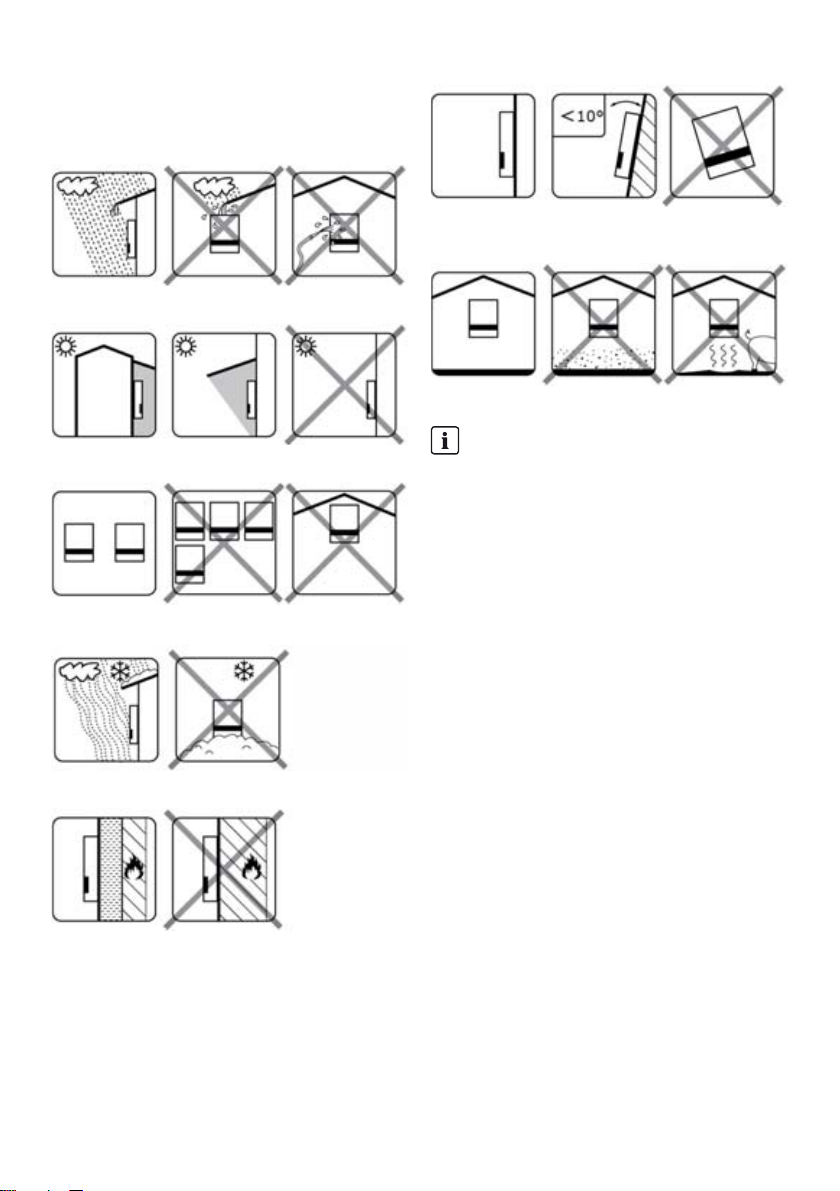

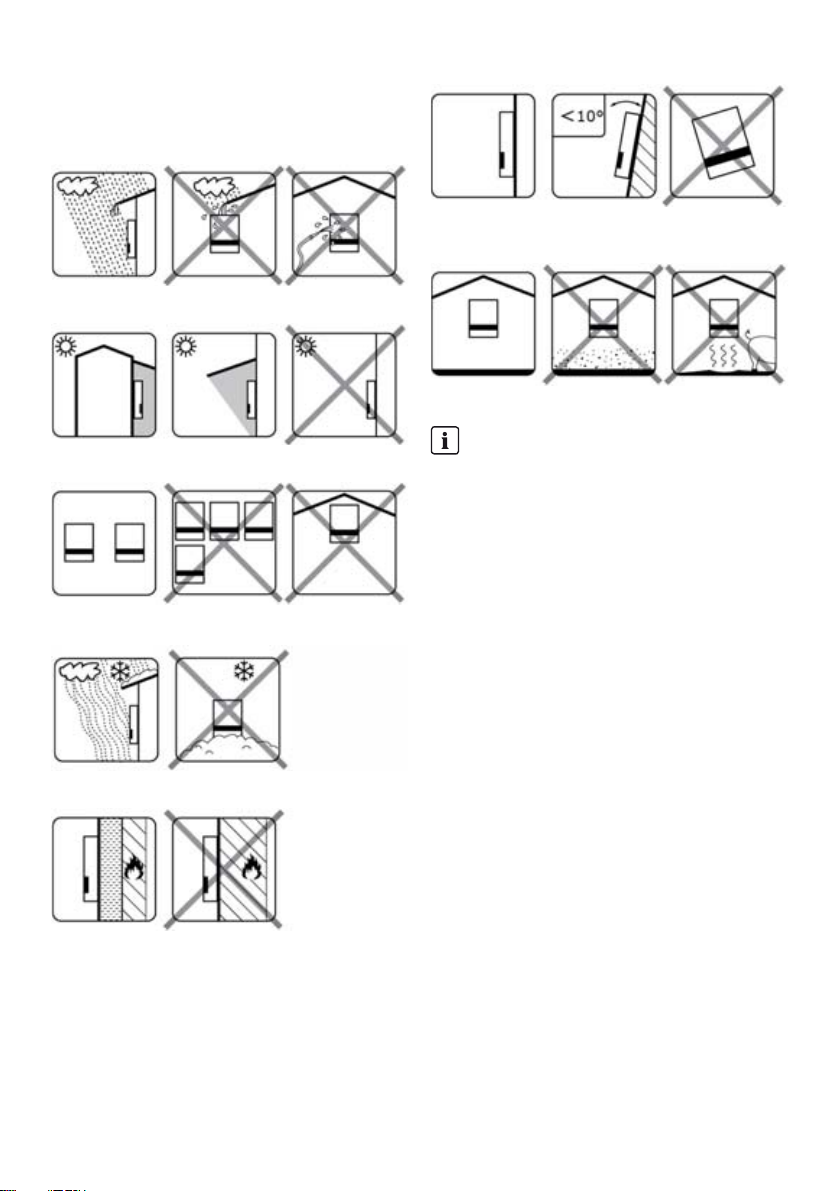

2.1 Environment and Clearances

Figure 2.6 Mount upright on vertical surface. Backwards tilt of up to

ten degrees is permitted.

Figure 2.1 Avoid constant contact with water

Figure 2.7 Prevent dust and ammonia gases

Figure 2.2 Avoid direct solar irradiation

Figure 2.3 Ensure adequate air flow

Figure 2.4 Ensure adequate air flow

Figure 2.5 Mount on non-flammable surface

INFORMATION

When planning the installation site, ensure that the

inverter product label and warning labels remain

visible. For detailed information, see Section 5,

page45.

Installation Guide STP60-10-IA-xx-10 21

Page 22

2 Installation SMA Solar Technology AG

2.2 Mounting the Wall Mounting

Bracket

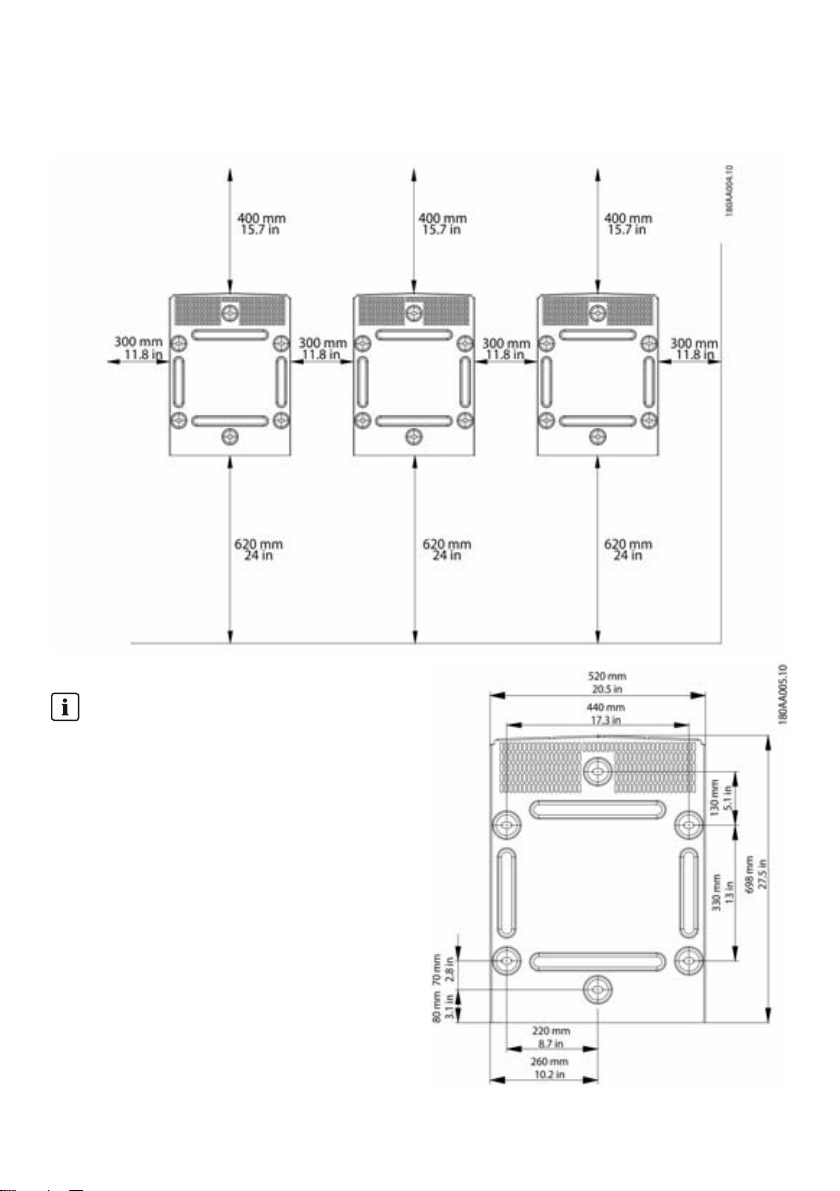

Figure 2.8 Safety clearances

INFORMATION

Ensure 620 mm/24 inches base clearance for

adequate airflow.

22 STP60-10-IA-xx-10 Installation Guide

Page 23

SMA Solar Technology AG 2 Installation

Figure 2.9 Wall mounting bracket

INFORMATION

Use of the wall mounting bracket delivered with the

inverter is mandatory. If the inverter is mounted

without the wall mounting bracket, the warranty

becomes void. It is highly recommended to use all six

mounting holes.

Mounting of the wall mounting bracket:

• Mount the wall mounting bracket in the defined

environment

• Use screws and wall plugs that can safely carry the

weight of the inverter.

• Ensure that the mounting plate is correctly aligned.

• Observe safe clearances when installing one more

inverters, to ensure adequate airflow. Clearances are

specified in figure 2.8 and on the mounting plate label.

• Mounting multiple inverters side by side in a single row

is recommended. Contact the supplier for guidelines

when mounting inverters in more than one row.

• Ensure adequate clearance at the front, for safe

installation and service access to the inverter.

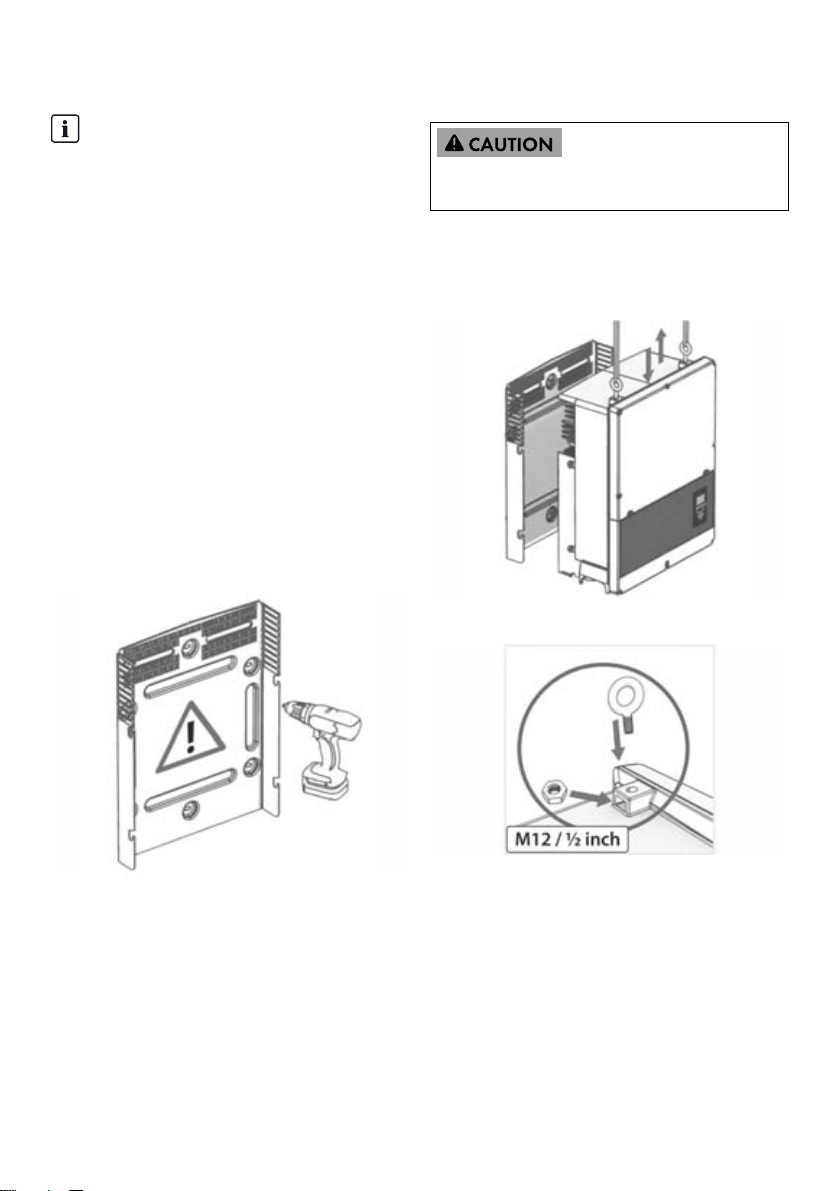

2.3 Mounting the Inverter

Refer to local health and safety regulations when

handling the inverter.

Procedure:

1. Lift the inverter. Locate the slots on the side of the wall

mounting bracket. Use M12 or ½ in lifting bolts and

matching nuts (not included in the scope of delivery).

Figure 2.11 Position the inverter

Figure 2.12 Lifting bolts

Figure 2.10 Mounting of the wall mounting bracket

2. On the inverter, position the side screws against the

wall mounting bracket slots.

3. Push the inverter as shown so the side screws slide into

the two lower slots and the two upper slots. See figure

2.13 and figure 2.14

Installation Guide STP60-10-IA-xx-10 23

Page 24

2 Installation SMA Solar Technology AG

2.5 Access to the Installation Area

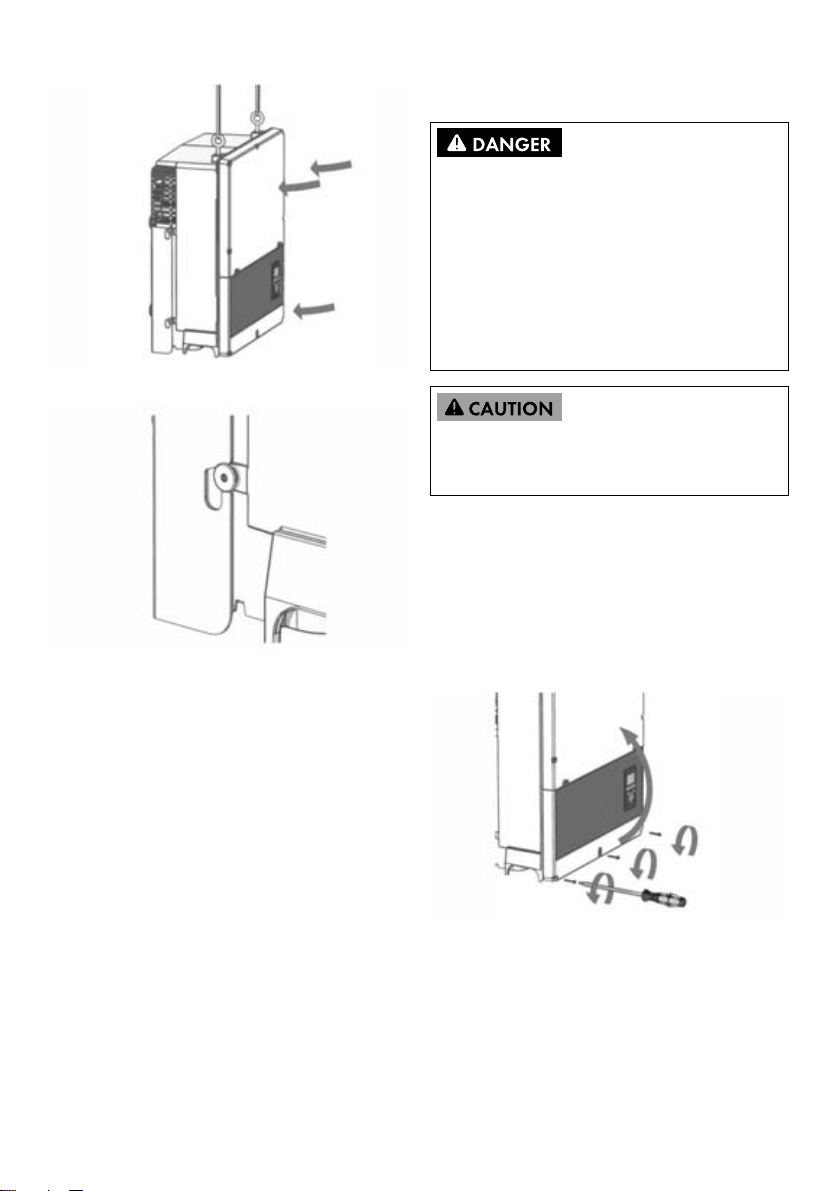

Before working on the inverter, disconnect it from the utility

grid by means of the main switch and switch off PV using

the integrated PV load-break switch (DC load-break

switch). Ensure that the inverter cannot be unintentionally

reconnected. Use a voltage detector to ensure that the

unit is disconnected and voltage free. The inverter can still

be charged with very high voltage at hazardous levels

even when it is disconnected from utility grid and PV

modules. Wait at least five minutes after disconnection

from the utility grid and PV modules before proceeding.

Figure 2.13 Sliding the screws into the slots

Observe ESD safety regulations. Discharge any

electrostatic charge by touching the grounded enclosure,

before handling any electronic component.

Procedure:

1. To open the cover, loosen the three lower front screws

using a TX 30 screwdriver. The screws are captive

screws and cannot fall out.

2. Ope n th e co ver and fla p it bac k. A mag net e nab les the

cover to stay open.

Figure 2.14 Detail of sliding into slot

3. To close the cover, lower it into place and fasten the

three front screws.

4. Check that the four side screws sit securely in the

mounting plate slots.

5. Release the inverter.

2.4 Disassembling the Inverter

Procedure:

1. Disassemble the inverter in the reverse mounting order.

2. Lif t an d sl ide the inv ert er o ut o f th e mo unt ing pla te s lot s.

3. Lift the inverter free of the mounting plate.

Figure 2.15 Loosen front screws and lift the cover

24 STP60-10-IA-xx-10 Installation Guide

Page 25

SMA Solar Technology AG 2 Installation

2.6 Grid Connection

These instructions for utility grid connection are for

qualified personnel only. To reduce the risk of electric

shock, do not perform any maintenance work other than

that specified in the user manual unless you are qualified

to do so.

For fuse and RCD information, refer to Section 5,

page45. AC fuse rating must not exceed the ampacity of

the conductors used.

INFORMATION

All electrical installations in the U.S. and Canada

must be made in accordance with the local standards

and National Electrical Code

the Canadian Electrical Code

®

ANSI/NFPA70 or

®

CSA C22.1.

• Before connecting the inverter to the utility grid,

contact your local grid operator. The electrical

conn ectio n of th e inve rter mus t be ca rried out by

qualified persons only.

• Ensure that no cables used for electrical

connection are damaged.

IMI Detection

The inverter has built-in IMI/RCMU (Insulation Monitoring

Interrupter / Residual Current Monitoring Unit) according to

the UL 1741 for non-isolated EPS interactive PV inverters. It

acts on continuous ground fault current and a sudden

change in the ground fault current. This functionality is

activated during normal operation.

Insulation Resistance Detection

The inverter has a built-in insulation resistance detection /

ISO circuit, which is certified according to the UL 1741 for

non-isolated EPS interactive PV inverters. The insulation

resistance detector performs a measurement of the

connected PV system resistance to ground before the

inverter connects to the grid. If the resistance is below the

gr id c ode set val ue, the inv erter wil l wa it a nd r e-m eas ure the

resistance after a short while. When the resistance is above

the grid code set value, the inverter performs a self-test and

connects to the grid.

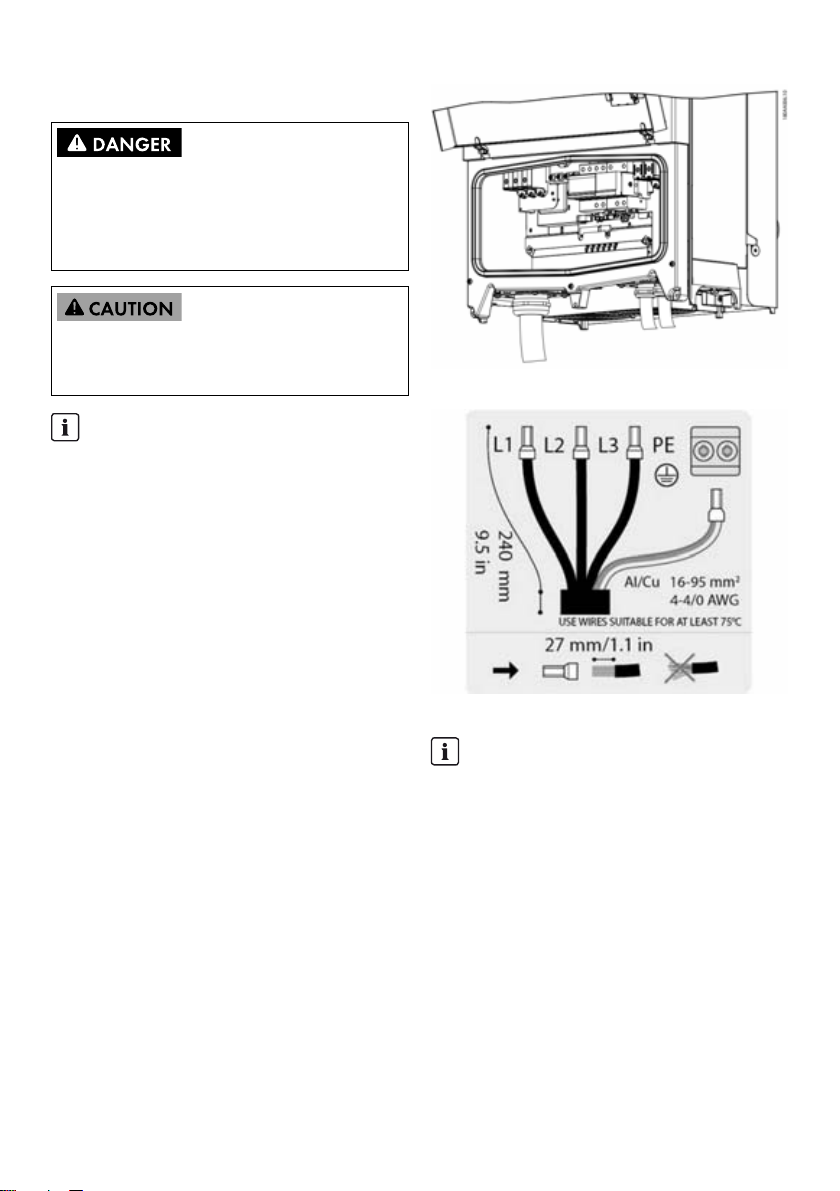

Figure 2.16 Installation area

Figure 2.17 AC cable wire strip

INFORMATION

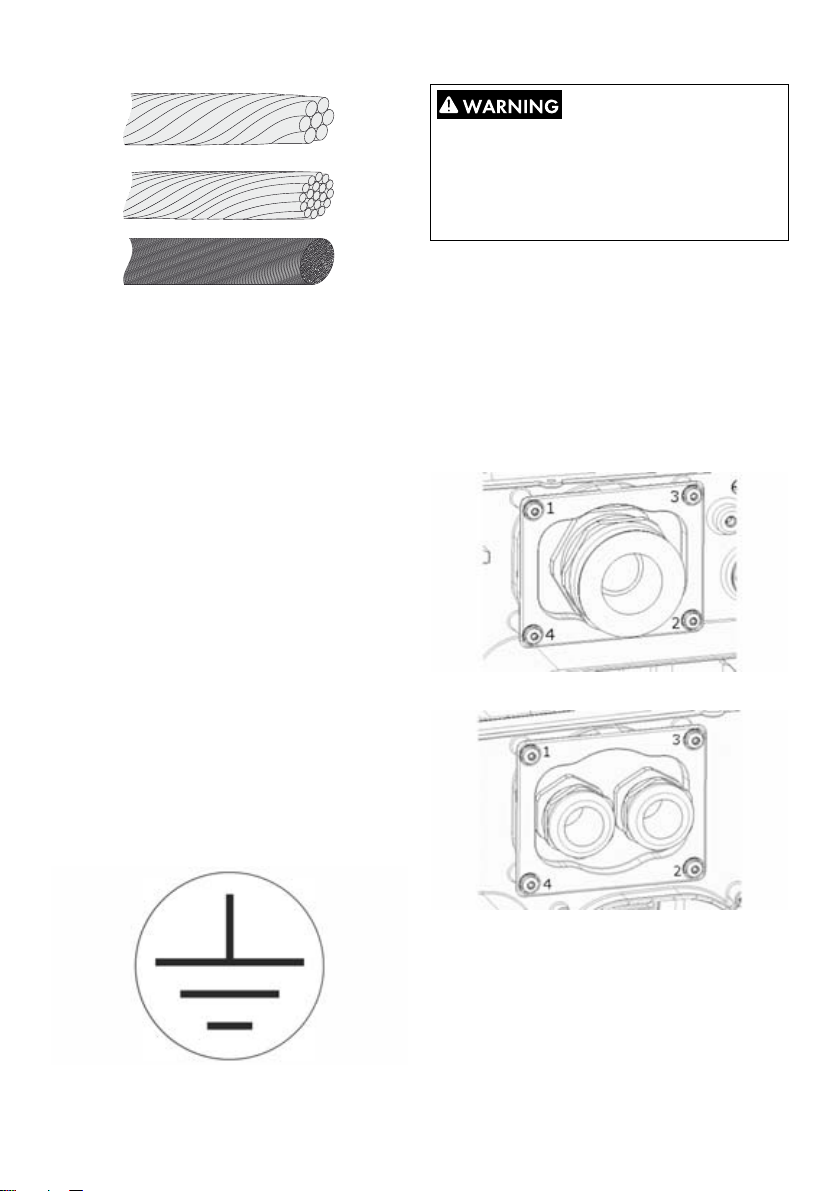

For AC connection, cables with multi-strand,

fine-strand or extra fine-strand conductors can be

used (see figure 2.18).

When using fine-strand or extra fine-strand

conductors, bootlace ferrules must be used for the

connection.

Installation Guide STP60-10-IA-xx-10 25

Page 26

2 Installation SMA Solar Technology AG

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the

inverter properly can result in death or serious injury.

• Ensure the correct grounding of the devices by a

certified electrical installer.

2.7 Cable Entry

Figure 2.18 Cables with different conductors (from top to bottom):

single strand, multi strand, fine stand and extra-fine strand

The STP 60 inverter must only be connected to a

three-phase grid.

On the AC cable, strip insulation on all four wires. The

protective conductor (PE) must be longer than the grid wires.

See figure 2.17.

1. Verify that the nominal voltage of the inverter matches

the grid voltage.

2. Ensure that the main circuit breaker is released, and

take precautions to prevent reconnection.

3. Open the front cover.

4. Insert the cable through the AC cable gland to the

connecting terminal plate.

5. Connect the three grid wires (L1, L2, L3) and the

grounding conductor (PE) to the connecting terminal

plate with the respective markings. The grounding

conductor is marked with the symbol shown in figure

2.19.

6. Optional: Make an extra PE connection at the

secondary PE grounding points using the external

device grounding bolt delivered with the inverter. See

figure 5.2.

7. All wires must be properly fastened with the correct

torque. See Section 5.5, page50.

Options for cable entry

• For STP 60-10: cable glands (pre-mounted)

• For STP 60-10-US: two-inch conduit adapters (included

in delivery)

When replacing the two-inch conduit adapters, ensure to

tighten the screws in the order shown in figure 2.19 and

figure 2.20. First tighten all screws with 0.75 Nm and then

2.5 Nm.

Figure 2.20 AC mounting bracket

Figure 2.21 DC mounting bracket

Figure 2.19 Protective conductor symbol

26 STP60-10-IA-xx-10 Installation Guide

Page 27

SMA Solar Technology AG 2 Installation

Terminal Range

AC+PE 16 to 95 mm²

PV 16 to 95 mm²

Table 2.1 Suitable conductor sizes

1)

Always observe the ampacity of cables used.

1)

6 to 4/0 AWG

6 to 4/0 AWG

Max. conductor

temperature rating

90ºC Al/Cu 37 to 44 mm

90ºC Al/Cu 14 to 21 mm

2.8 Ethernet Connections

For outdoor use, ensure that an appropriate cable is used.

If the cable is very stiff, an intermediate terminal should be

used in order to change from a stiff to a more flexible cable

before entering the inverter. For some cables it might be

sufficient to remove the hard outer mantle of the part of the

cable inside the inverter enclosure. This is to protect the

PCB-mounted RJ-45 Ethernet ports from excessive strain,

which could lead to damage or connection issues.

Procedure:

1. Do not remove the RJ-45 connector on the Ethernet

cable.

2. Run the cables through the base of the inverter via

cable glands. See figure 2.22.

3. Cut slice in rubber grommet. Place the grommet in the

gland to ensure proper seal.

4. Plug into the Ethernet connector.

Conductor

material

Cable sheath diameter with supplied

cable gland

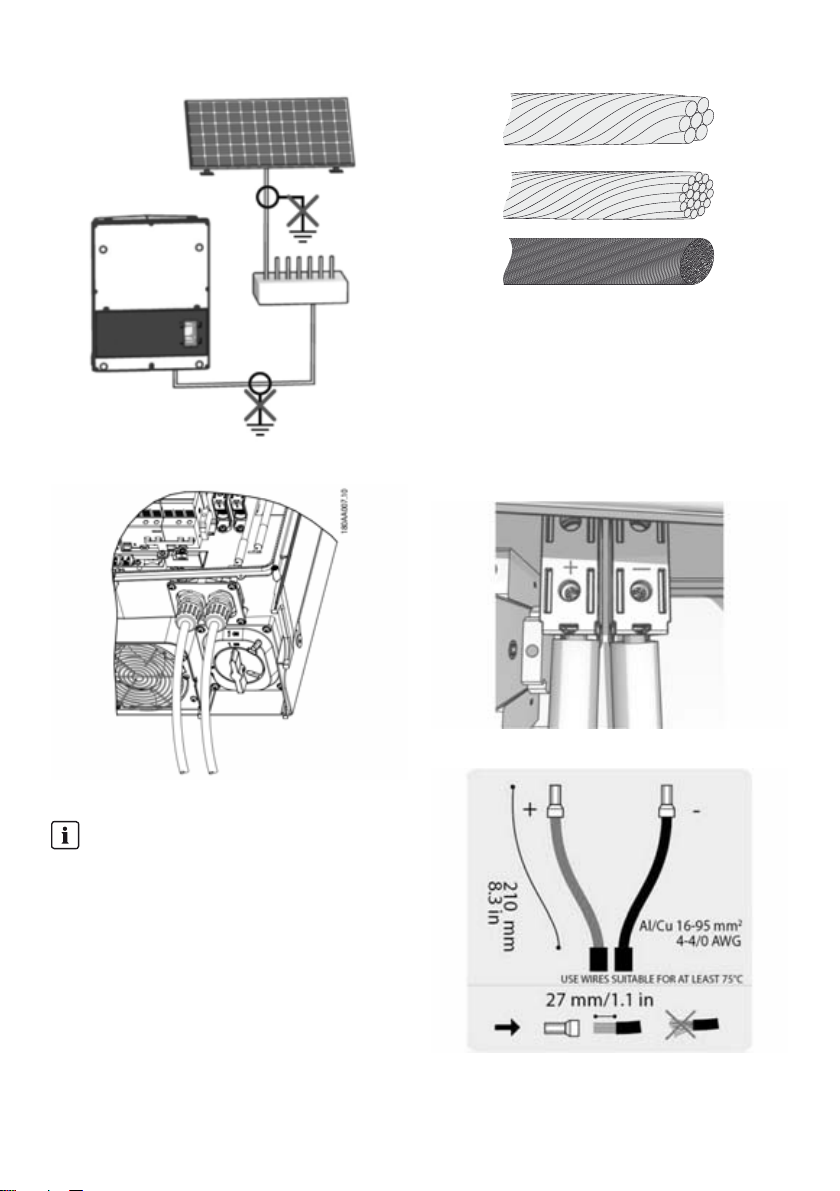

2.9 PV Connection

2.9.1 External PV Array Junction Boxes

PV str ing s mu st b e co nne cte d to the DC i npu t vi a an ext ern al

PV array junction box. The PV array junction box connects

the PV strings of the PV array and protects the individual

strings against overcurrent.

INFORMATION

The same number and type of modules must be

connected to all PV strings connected to the PV array

junction box. In addition, all connected modules must

have the same orientation.

INFORMATION

Observe correct fuse rating. Consult module

manufacturers' manuals for information on correct

string fuse rating.

Use a suitable voltage detector that can measure up to

1,000 V DC. Verify the polarity and maximum voltage of

the PV arrays by measuring the PV open-circuit voltage. The

inverter is protected against reversed polarity and will not

generate power until the polarity is correct.

The combined output from the DC combiner must be

connected to the DC input of the STP 60 inverter.

PV array is floating, with both the (+) and (-) conductors

connected to the inverters' PV inputs. Neither conductor is

connected to ground.

Figure 2.22 Run cables through cable glands

The DC power can be disconnected with the

inverter-integrated DC load-break switch.

Do NOT connect PV to ground!

Installation Guide STP60-10-IA-xx-10 27

Page 28

2 Installation SMA Solar Technology AG

Figure 2.26 Cables with different conductors (from top to bottom):

single strand, multi strand, fine strand and extra fine strand

1. On the inverter or PV array junction box turn the PV

load-break switch to Off position.

2. Connect the PV cables from the PV array junction box

to the inverter. Ensure correct polarity, see figure 2.27.

Figure 2.24 Do not connect PV to ground!

3. All wires must be properly fastened with the correct

torque. See Section 5.5, page50.

Figure 2.27 Connect to PV input

Figure 2.25: DC connection area

INFORMATION

Cables with multi-strand, fine-strand or extra

fine-strand conductors can be used for AC

connection (see figure 2.26).

When using fine-strand or extra fine-strand

conductors, bootlace ferrules must be used for the

connection.

Figure 2.28 DC label

28 STP60-10-IA-xx-10 Installation Guide

Page 29

SMA Solar Technology AG 3 Initial Setup and Start

Protection class of PV modules

The inverter must only be operated with PV modules of

protection class II, compliant with IEC 61730, application

class A.

Only connect PV modules to the inverter. Other energy

sources are not allowed.

PV modules generate a voltage when exposed to light.

2.10 Closure

1. Close the cover of the inverter installation area. Fasten

the three front screws. See Section 5.5, page50.

2. Turn on AC power.

3 Initial Setup and Start

3.1 User Interface

The user interface comprises:

• Local display, for all inverter variants. The local display

shows status information of the inverter. It is not

possible to configure or set up the STP 60 inverter via

the display. The "#" in the display explains the

operation modes.

• Local commissioning and service tool (LCS tool). The

LCS tool enables configuration of one or multiple

STP 60 inverters.

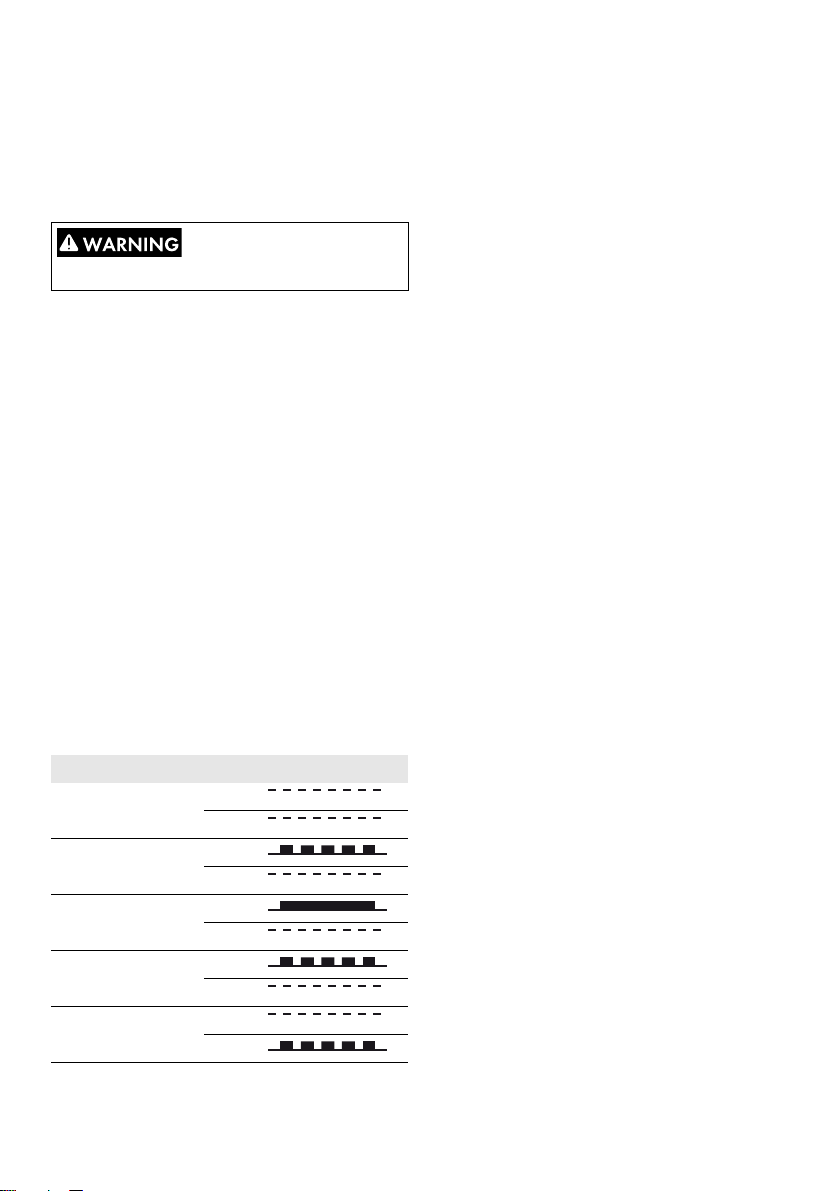

3.1.1 Operating Modes

The inverter has five operation modes, indicated by LEDs.

Status LEDs LEDs

Off grid Green

Red

Connecting Green

Red

On grid Green

Red

Internal inverter event Green

Red

Fail safe Green

Red

Off grid (standby) (LEDs off)

#0-51

When no power has been delivered to the utility grid for

more than ten minutes, the inverter disconnects from the grid

and shuts down. User and communication interfaces remain

powered for communication purposes.

Connecting (green LED flashing)

#52 to 53

The inverter starts up when the PV input voltage reaches the

minimum DC feed-in voltage. The inverter performs a series

of internal self-tests, including measurement of the resistance

between the PV arrays and ground. Meanwhile, it also

monitors the grid parameters. When the grid parameters

have been within the specifications for the required amount

of time (depends on grid code), the inverter starts feeding

into the utility grid.

On grid (green LED on)

#60

The inverter is connected to the utility grid and feeds into the

utility grid. The inverter disconnects when:

• it detects abnormal grid conditions (dependent on grid

code),

• an internal event occurs, or

• PV power is insufficient (no power is supplied to the

grid for ten minutes).

The inverter then enters connecting mode or off-grid mode.

Internal inverter event (green LED flashing)

#54

The inverter is waiting for an internal condition to be within

thresholds (for example when the temperature is too high)

before it re-connects to the utility grid.

Fail safe (red LED flashing)

#70

If the inv ert er d ete cts an e rror i n it s ci rcu its dur ing the sel f-test

(in connecting mode) or during operation, the inverter goes

into fail s afe mo de, disc onnec ting f rom t he gri d. The in verter

will remain in "fail safe" mode until power has been absent

for a minimum of ten minutes, or the inverter has been shut

down completely (AC+PV).

Table 3.1 Operating modes

Installation Guide STP60-10-IA-xx-10 29

Page 30

3 Initial Setup and Start SMA Solar Technology AG

3.2 Display

INFORMATION

It can take up to ten seconds until the display

activates, after start-up.

The integrated display on the inverter front gives the user

access to information about the PV system and the inverter.

Figure 3.1 Overview of display buttons and functionality

Display buttons and functionality

Button Function

F1 Adjust the contrast level of

display. Use arrow up/down

button while pressing the F1

button.

F2 No function

F3

F4

Home Return to main screen

OK No function

Arrow up A step up

Arrow down A step down

Arrow right Toggles screen right

Arrow left Toggles screen left

Back Return to main screen

Button Function

On - green LED

Alarm - red LED

Table 3.2: Display buttons and functionality

The screen structure is divided into three sections:

1. Main screen. Current and daily yield. This section

contains:

– Actual output power (kW)

– Yield of the current day (kWh)

– Total yield (kWh)

– Current date

– Current time

– Operating mode (#)

2. Inverter information. This section contains:

– Inverter device type

–Inverter name

–Serial number

– IP address

– MAC address of the SMA Inverter Manager

– Inverter software version

3. Actual values. This section contains:

– PV voltage and current

– Phase-to-phase voltages

– Phase currents

– Power frequency

3.2.1 Initial Setup via LCS tool

The LCS tool makes it possible to chose from a list of

predefined settings for different grids. All grid-specific limits

must be configured using the LCS tool.

After installation, check all cables and close the inverter.

Turn on AC power.

The correct selection of the grid code is essential to

comply with local and national standards.

30 STP60-10-IA-xx-10 Installation Guide

Page 31

SMA Solar Technology AG 3 Initial Setup and Start

3.2.2 Switching on the PV Load-Break Switch

Figure 3.2. PV load-break switch

Switch on the PV load-break switch on, either via inverter or

PV array junction box.

3.2.3 Commissioning

The inverter starts automatically if sufficient solar irradiation

is ava ila ble . Co mmi ssi oning tak es a few min ute s. D uri ng t his

period, the inverter performs a self-test.

INFORMATION

The inverter is equipped with reverse polarity

protection. The inverter does not generate feed-in

power until any reverse polarity is corrected.

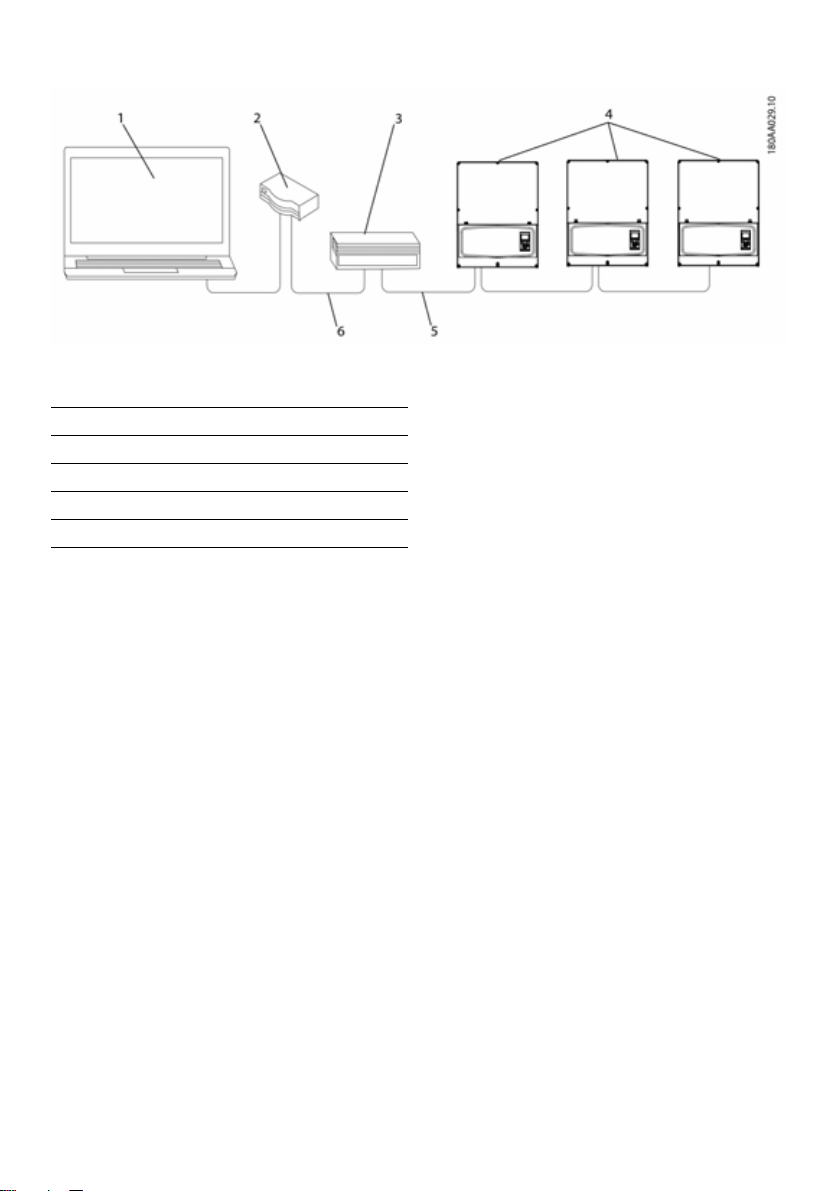

3.3 LCS tool

The STP 60 inverters and the SMA Inverter Manager must

be commissioned via the local commissioning and service

tool (LCS tool). Commissioning is required before the

STP 60 inverters are connected to the utility grid and start to

feed-in power.

The LCS tool is available in the download area at

www.SMA-Solar.com.

The hardware requirements for the LCS tool are:

• PC with Windows

•1 GB HDD

• 2 GB RAM

The LCS tool must be installed on a local PC drive. The PC

must be connected to the SMA Inverter Manager’s LAN 1

port via Ethernet.

TM

7 and later

INFORMATION

The SMA Inverter Manager must have an IP address

assigned by a DHCP server on port LAN 1.

It is important that the PC running the LCS tool is

connected to the same IP subnet as the

SMA Inverter Manager.

Port LAN 2 is intended for STP 60 inverters only.

Installation Guide STP60-10-IA-xx-10 31

Page 32

3 Initial Setup and Start SMA Solar Technology AG

Figure 3.3: Commissioning inverters via the LCS tool

1LCS tool

2Router/DHCP

3 SMA Inverter Manager

4 Sunny Tripower 60

5LAN 2

6LAN 1

32 STP60-10-IA-xx-10 Installation Guide

Page 33

SMA Solar Technology AG 3 Initial Setup and Start

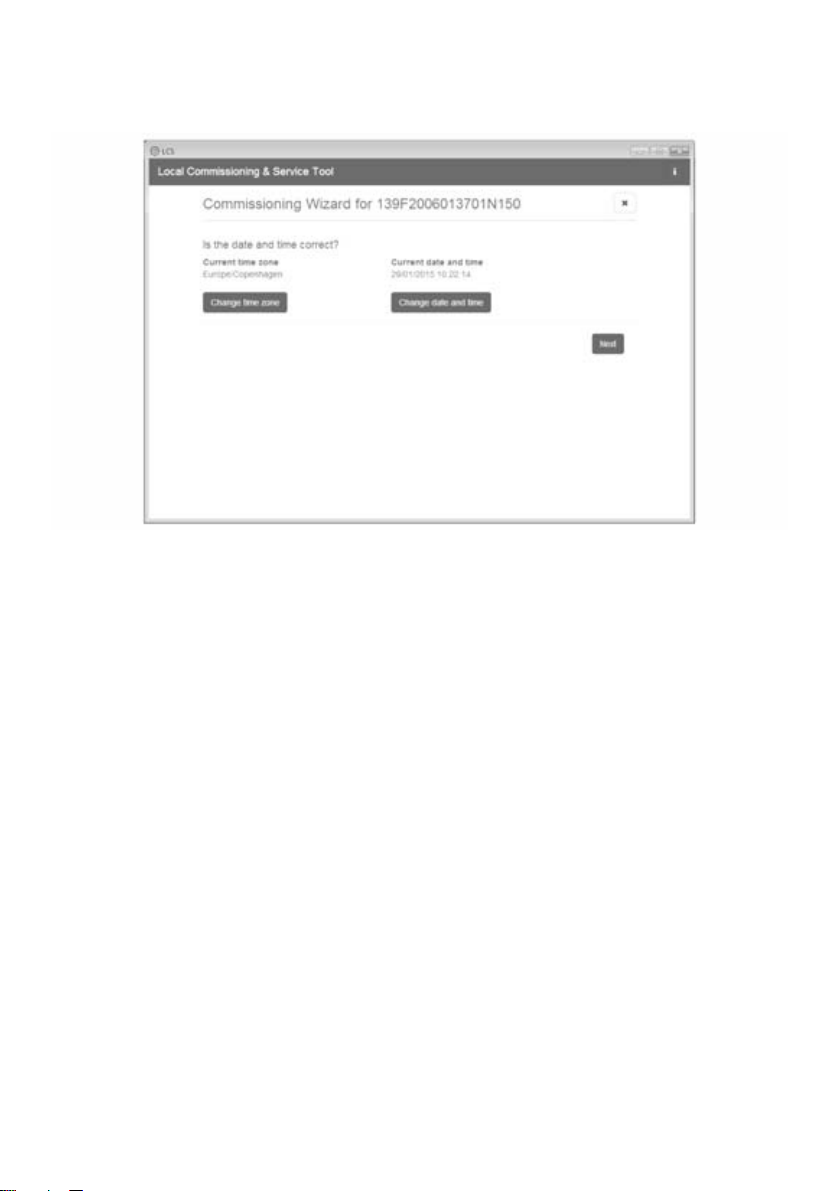

3.3.1 Getting Started

1. Start up the LCS tool. The tool displays a list of all

identified SMA Inverter Managers. It can take several

minutes before the LCS tool has identified all

SMA Inverter Managers.

2. The screen now shows a list of all

SMA Inverter Managers (see figure 3.4). To start the

wizard, click the SMA Inverter Manager to be

configured. By clicking the SMA Inverter Manager, the

inverters detected by the SMA Inverter Manager are

displayed. Uncommissioned inverters (no grid code

assigned) are presented with a blue square together

with their software version.

Figure 3.4 LCS tool - initial screen

Installation Guide STP60-10-IA-xx-10 33

Page 34

3 Initial Setup and Start SMA Solar Technology AG

3. Verify that date and time are correct. If not, set date

and time and continue. See figure 3.5.

Figure 3.5 LCS tool - Verifying date and time

4. A list of inverters identified by the selected

SMA Inverter Manager is shown. See figure 3.6

Make sure that the list of inverters is complete.

Make sure that all inverters are present. It is possible to

continue the configuration of the listed inverters even if not

all inverters are discovered. The undetected inverters can

always be configured later.

34 STP60-10-IA-xx-10 Installation Guide

Page 35

SMA Solar Technology AG 3 Initial Setup and Start

Figure 3.6 LCS tool - List of connected inverters

5. Select the desired country from the list of options

available for the inverters in the network. See figure

3.7.

Figure 3.7 LCS tool - Select country and grid code

6. Select the desired grid code from the list of options

available for the selected country. If needed, load a

customer-specific grid code by clicking the "Load"

button. See figure 3.7. The "Create" button is inactive

and cannot be used.

7. The LCS to ol prom pts for a c onfirmat ion of the selected

country and grid code. See figure 3.8. Incorrect

configuration can be changed using the "Back" button

and changing the settings in the previous windows.

Installation Guide STP60-10-IA-xx-10 35

Page 36

3 Initial Setup and Start SMA Solar Technology AG

Figure 3.8 LCS tool - Verification of country and grid code

8. The system now applies the selected grid code to the

SMA Inverter Manager and the discovered inverters.

Any inverter added at a later stage automatically

inherits the same grid code. Only one grid code is

possible per SMA Inverter Manager.

INFORMATION

It is essential to choose the correct grid code. The grid

code cannot be changed afterwards without

contacting SMA Solar Technology AG.

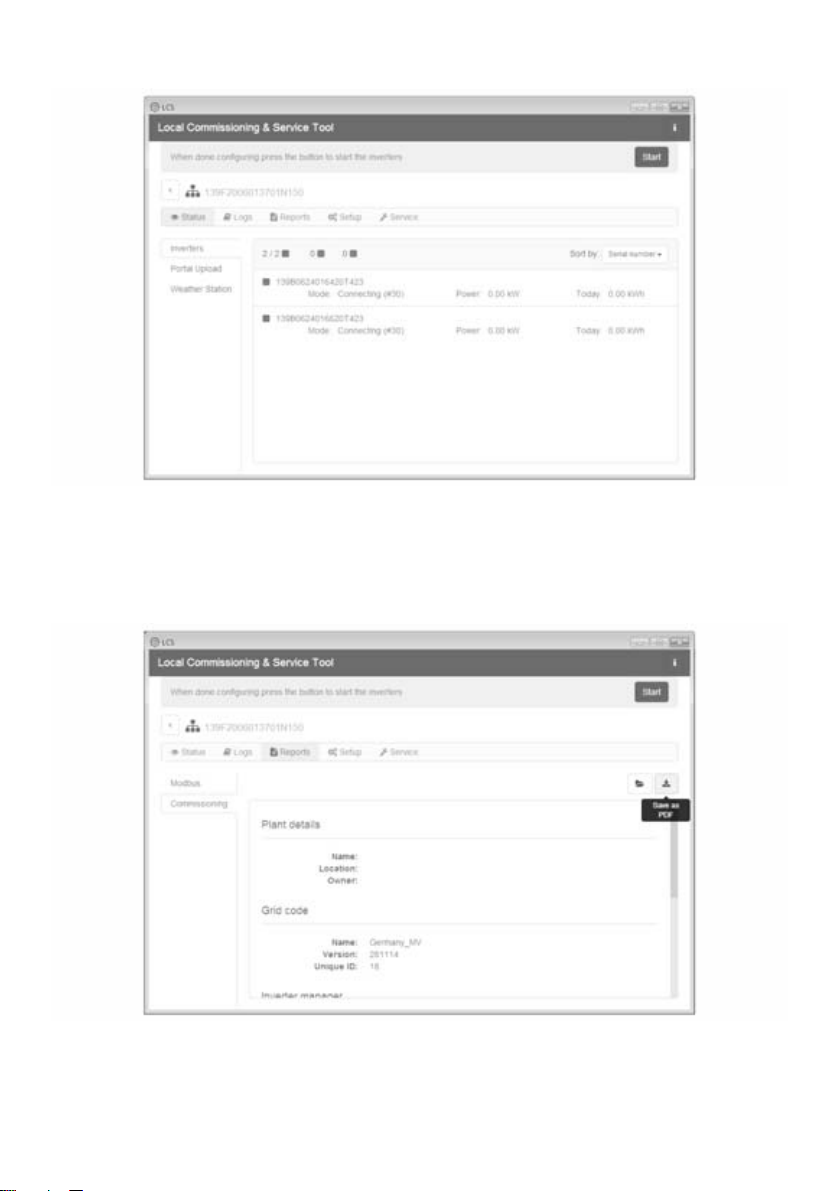

9. A green square identifies the commissioned inverters.

However, the inverters are not connected to grid

before a " Start" comm and is iss ued fro m the ba r below

the top menu. See figure 3.9.

36 STP60-10-IA-xx-10 Installation Guide

Page 37

SMA Solar Technology AG 3 Initial Setup and Start

Figure 3.9 LCS tool - List of all inverters connected to the

SMA Inverter Manager

10. If sufficient PV power is present and the grid code

conditions are met, the inverters are connected to the

grid.

Figure 3.10 LCS tool - Commissioning report

11. Upon commissioning, it is possible to download a

commissioning report under the menu "Reports". The

report contains information about inverter settings,

including actual disconnection values for each inverter.

See figure 3.10.

Installation Guide STP60-10-IA-xx-10 37

Page 38

3 Initial Setup and Start SMA Solar Technology AG

INFORMATION

If the desired grid code is not available, or if the LCS

tool displays a warning about incompatible software

versions, the grid code and software library must be

updated on the LCS tool.

It is possible to set up customer specific grid code files

with adapted setting values. For this purpose, please

contact SMA Technology AG.

38 STP60-10-IA-xx-10 Installation Guide

Page 39

SMA Solar Technology AG 4 Service

4Service

4.1 Troubleshooting

The information is organized in tables showing messages

appearing in the LCS tool, known as events. The tables

contain descriptions of events as well as explanations of

which actions to take when an event occurs.

Type of event Indicates whether the event relates to grid, PV, internal or fail safe issues.

ID The specific event ID.

Display Text shown in display.

Description Description of the event.

Measure Description of which action to take prior to contacting any other parties.

DGO If the prescribed action has not identified the malfunction, contact the DGO for further assistance.

Hotline If the prescribed action has not identified the malfunction, contact Service for further assistance

(see Section6 "Contact", page53).

PV If the prescribed action has not identified the malfunction, contact the PV module supplier for

further assistance.

Grid-Related Events

ID Status

message

1 to 6 Grid voltage too low. Check voltage and AC

7 to 9 Grid voltage average over 10

10 to 15 Grid voltage too high. Check voltage and AC

16 to18 The inverter has detected a

19, 22 Power frequency too low or

31 to 33 DC current share in utility grid

Installation Guide STP60-10-IA-xx-10 39

Description Measure DGO Hotline PV

-- -

-- -

-- -

-- -

-- -

minutes too high.

voltage peak on the grid.

too high.

is too high.

installation. If the voltage is zero,

check the fuses.

Check that the installation is

correct in accordance with the

installation manual. If so, request

a new grid code file with

increased voltage limit or reactive

power for voltage suppression.

installation.

Check voltage and AC

installation.

Check power frequency. - - -

For repeated daily occurrences,

perform onsite grid analysis.

Page 40

4 Service SMA Solar Technology AG

ID Status

Description Measure DGO Hotline PV

message

34 to 37 The residual-current monitoring

unit (RCMU) detected an

overcurrent.

Turn off both DC and AC supply

and wait until the display turns off.

Then turn on DC and AC supply

and obser ve if the eve nt reoc curs.

Visual inspection of all PV cables

and modules.

40 Utility grid

not OK.

The utility grid has been

outside the permissible range

for more than ten minutes

Check power frequency, grid

voltage, software version and

grid code setting.

(frequency and/or voltage).

41 to 43 Fault ride through. The inverter

has detected that grid voltage

was below or above a certain

If this event is reported several

times each day, perform onsite

grid analysis.

level.

48, 51 Power frequency too low or

too high.

54 to 56 DC current share in utility grid

is too high (stage 2).

61 Grid failure, open phase

detected.

Check power frequency and AC

installation.

For repeated daily occurrences,

perform onsite grid analysis.

If the event reoccurs several times

each day, contact the responsible

grid operator.

62 Grid failure. If the event reoccurs several times

each day, contact the responsible

grid operator.

64-81 Grid voltage on phase too low. Check voltage and AC

installation. If the voltage is zero,

check the fuses.

Figure 4.1 Grid-related events

-- -

-- -

-- -

-- -

-- -

-- -

-- -

40 STP60-10-IA-xx-10 Installation Guide

Page 41

SMA Solar Technology AG 4 Service

PV-Related Events

ID Status

103 PV current is

115,

260

258 PV voltage

278 DC voltage warning. Make sure that PV system and

Figure 4.2 PV-related events

message

too high/

waiting

PV ISO too

low

too high/

waiting

Description Measure DGO Hotline PV

Too many PV modules

connected in parallel. Should

only appear on newly installed

systems.

The resistance between the PV

strings and ground PE) is too

low for the inverter to be

commissioned. This will force

the inverter to make a new

measurement after ten minutes.

The DC voltage is too high. Make sure that PV system and

Check number of strings in

parallel and current ratings. Has

the current limit been exceeded?

Reconnect strings in parallel.

Make a visual inspection of all PV

cables and modules for correct

installation according to the

installation manual. The event

could indicate that the PE

connection is missing.

layout correspond to

recommendations in the manuals.

layout correspond to

recommendations in the manuals.

System-Related Events

ID Status

message

2000 Communication assembly is

2010,

2011

2012 to

2018

2030 Transmitting grid code to CPU

2050,

2051

2052,

2053

Description Measure DGO Hotline PV

booting.

The software update of the

main CPU has been started/is

finished.

The software update failed. Restart the software update. If an

failed.

Ethernet connection is active /

disconnected.

Transmitting the grid code from

SMA Inverter Manager to

STP 60-10 has been started /

stopped.

----

----

error occurs during the update,

contact the Service.

If the occurs repeatedly, contact

the Service.

No measures required. This error

identifies bad Ethernet cables.

----

-- -

-- -

-- -

-- -

-- -

-- -

-- -

Installation Guide STP60-10-IA-xx-10 41

Page 42

4 Service SMA Solar Technology AG

ID Status

Description Measure DGO Hotline PV

message

2054 Transmitting the grid code from

SMA Inverter Manager to

If the occurs repeatedly, contact

the Service.

STP 60-10 failed.

Table 4.3 System-related events

Internal events

ID Status

message

201 to

208

209,

210

211 Low fan

speed

213 to

215

216 to

218

219 to

221

225 to

240,

275

241,

242,

245,

249

248 Internal CPU error. Restart the inverter. If the event

252 to

254

243,

263

279 Temperature sensor error. If the event persists, call the

Description Measure DGO Hotline PV

The internal temperature of the

inverter is too high.

Make sure that there are no

objects or dust on the inverter and

that the air duct is not blocked.

Voltage in DC link is too high. If the event persists, reset the

inverter by disconnecting DC and

AC . If the ev ent is rep eat ed, check

the maximum PV voltage using the

display to see if it is above the

limits.

Fan speed is too low. Check whether the inverter fan is

blocked.

Internal error. Voltage

Contact the Service. - - measured before and after the

relay differs too much.

Current measured on AC side

Contact the Service. - - is too high.

Internal error. Voltage

Contact the Service. - - measured before and after the

relay differs too much.

Failure in memory/EEPROM. Restart the inverter. If the event

persists, call the Service.

Internal communications fault. Restart the inverter. If the event

persists, call the Service.

persists, call the Service.

Current measured on AC side

If the event repeats, call Service. - - is too high.

Internal error. Restart the inverter. If the event

persists, call the Service.

Service.

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

-- -

42 STP60-10-IA-xx-10 Installation Guide

Page 43

SMA Solar Technology AG 4 Service

ID Status

Description Measure DGO Hotline PV

message

280 Self-test 24-hour timeout.

None. - - Self-test must run at least once

per 24 hours.

281 Too many RCMU events

during th e past 24 h ours. Onl y

four automatic reconnect

Wait up to 24 hours. If event 34

also occurs, follow the action for

event 34.

attempts after event 34 is

allowed during a 24-hour

period. The inverter will

automatically try to reconnect

after a certain period.

282 Grid code settings invalid. Restart the inverter. If event

persists, ask Service to generate a

new grid code file or reselect a

standard grid code.

283 Gatedrive error. Restart the inverter. If the event

persists, call the Service.

323 Internal fan error. Maximum

If the event repeats, call Service. - - output power has been

reduced.

Table 4.4 Internal events

Events Caused by the Self-test

-- -

-- -

-- -

ID Description Measure DGO Hotline PV

100 PV input current is negative. Sensor fault. Check the polarity of the PV system. If

-- -

polarity is correct, call service.

264,

266

272 PV overvoltage protection device error.

273 Grid overvoltage protection device

274 Overvoltage protection device status

350 to

352

Measurement circuit test failed. Restart the inverter. If the event persists,

call the Service.

Replace PV overvoltage protection

Inverter will continue operation without

overvoltage protection.

device. See SPD replacement

instructions for details.

Replace PV overvoltage protection

error. Inverter will continue operation

without overvoltage protection.

device. See SPD replacement

instructions for details.

Restart the inverter. If the event persists,

unknown.

Residual-current monitoring unit (RCMU)

call the Service.

Contact the Service. - - self-test failed.

-- -

-- -

-- -

-- -

353 Current sensor test failed. Contact the Service. - - -

Installation Guide STP60-10-IA-xx-10 43

Page 44

4 Service SMA Solar Technology AG

ID Description Measure DGO Hotline PV

356–

361

366 Residual-current monitoring unit (RCMU)

Table 4.5 Events caused by the self-test

Transistor and relay test failed or inverter

relay has failed (contact assumed

welded).

self-test failed.

Contact the Service. - - -

Contact the Service. - - -

4.2 Maintenance

Ensure that the heat sink at the rear of the inverter is not

covered.

Clean the contacts of the PV load-break switch once a year.

Cl ean by c ycl ing the swi tch to o n and off positions ten times.

The PV load-break switch is located at the bottom of the

inverter.

For correct operation and a long service life, ensure free air

circulation for the following areas:

• around the heat sink at the top and side of the inverter

where the air exhausts, and

• to the fan at the inverter base.

To clear obstructions, clean using compressed air, a soft

cloth, or a brush.

Temperature of the heat sink can exceed 70°C.

44 STP60-10-IA-xx-10 Installation Guide

Page 45

SMA Solar Technology AG 5 Technical Data

5 Technical Data

5.1 Specifications

Parameter STP 60-10

AC

Nominal apparent power

Nominal active power

Reactive power range

1)

2)

1)

Nominal AC voltage (voltage range) 3P + PE (WYE) / 400-480 V (+/- 10 %)

Supported grounding systems TT, TN

Nominal AC current 3 x 87 A

Max. AC current 3 x 87 A (3 x 72 A @ 480 V)

AC total harmonic distortion (THD at nominal output power) < 1%

Inrush current 9.2 A/5 ms

Maximum residual output current 49.8 A RMS over three periods

Power factor – standard > 0.99 at nominal power

Displacement power factor - regulated 0.8 overexcited to 0.8 underexcited

Stand-by power consumption (for communication) 3 W

Nominal power frequency (range) 50/60 Hz (+/- 10%)

DC

Input voltage range 565 to 1,000 V at 400 Vac

680 to 1000 V at 480 Vac

Nominal DC voltage 630 V at 400 Vac

MPPT voltage range - nominal power 570 to 800 V at 400 Vac

Max. DC voltage 1,000V

Min power on the grid 100 W

Max. DC MPPT current

Max. DC short-circuit current

4)

4)