Page 1

EN

PV Inverter

SUNNY TRIPOWER 15000TL Economic Excellence

SUNNY TRIPOWER 15000TL High Efficiency

SUNNY TRIPOWER 20000TL Economic Excellence

SUNNY TRIPOWER 20000TL High Efficiency

Installation Manual

STP20TLHE-IA-IEN122222 | IMEN-STP20TLHE | Version 2.2

Page 2

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Information on this Manual. . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Explanation of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.1 Symbols on the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.2 Symbols on the Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Identifying the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Sunny Tripower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 DC switch-disconnector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4 Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.5 Multi-Function Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.6 Feed-In Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.7 Reverse Current Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Selecting the Mounting Location. . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Mounting the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installation Manual STP20TLHE-IA-IEN122222 3

Page 4

Table of Contents SMA Solar Technology AG

6 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2 Overview of the Connection Area . . . . . . . . . . . . . . . . . . . . . . 27

6.3 Connection to the Electricity Grid (AC). . . . . . . . . . . . . . . . . . . 29

6.3.1 Conditions for the AC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.2 AC Connection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3.3 Connecting the Second Protective Conductor. . . . . . . . . . . . . . . . . . . . . . . . 33

6.4 Connecting the PV Array (DC) . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.1 Conditions for DC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.2 Assembling the DC Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4.3 Opening the DC Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4.4 Connecting the PV Array (DC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.5 Setting the Country Data Set and Display Language . . . . . . . . 42

6.5.1 Checking the Country Data Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.5.2 Extension of the Deactivation Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.5.3 Setting the country data set and language using rotary switches . . . . . . . . . 49

6.6 Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.6.1 Bluetooth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.6.2 Multi-Function Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.6.3 Communication Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.7 Activating and Deactivating the Reverse Current Protection

at Input Area A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.1 Commissioning the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2 Display Messages during the Start Phase. . . . . . . . . . . . . . . . . 57

8 Disconnecting the Inverter from Voltage Sources . . . . . . 58

9 Maintenance and Cleaning. . . . . . . . . . . . . . . . . . . . . . . . 61

9.1 Cleaning the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.2 Checking Heat Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4 STP20TLHE-IA-IEN122222 Installation Manual

Page 5

SMA Solar Technology AG Table of Contents

9.2.1 Cleaning the Ventilation Grids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.2.2 Cleaning the Fan on the Bottom of the Inverter. . . . . . . . . . . . . . . . . . . . . . . 62

9.2.3 Cleaning the Fan on the Left-hand Side of the Inverter Enclosure . . . . . . . . . 64

9.2.4 Checking the Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10.1 LED Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10.2 Event Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.3 Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

11.1 Checking the PV Array for Earth Faults . . . . . . . . . . . . . . . . . . . 75

11.2 Checking the Function of the Varistors . . . . . . . . . . . . . . . . . . . 77

12 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

12.1 Dismantling the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

12.2 Replacing the Enclosure Lid . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

12.3 Packing the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

12.4 Storing the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

12.5 Disposing of the inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

13 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

13.1 DC/AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

13.1.1 SUNNY TRIPOWER 15000TL Economic Excellence . . . . . . . . . . . . . . . . . . 85

13.1.2 Sunny Tripower 15000TL High Efficiency. . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13.1.3 Sunny Tripower 20000TL Economic Excellence . . . . . . . . . . . . . . . . . . . . . . 87

13.1.4 Sunny Tripower 20000TL High Efficiency. . . . . . . . . . . . . . . . . . . . . . . . . . . 88

13.2 General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

13.3 Protective Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

13.4 Licences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

13.5 Climatic Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

13.6 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Installation Manual STP20TLHE-IA-IEN122222 5

Page 6

Table of Contents SMA Solar Technology AG

13.7 Torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

13.8 Distribution systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

13.9 Data Storage Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

14 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

15 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6 STP20TLHE-IA-IEN122222 Installation Manual

Page 7

SMA Solar Technology AG Information on this Manual

1 Information on this Manual

1.1 Validity

This manual describes the procedure for mounting, installation, commissioning, maintenance and

troubleshooting of the following SMA inverters:

• Sunny Tripower 15000TL Economic Excellence (STP 15000TLEE-10)

• Sunny Tripower 15000TL High Efficiency (STP 15000TLHE-10)

• Sunny Tripower 20000TL Economic Excellence (STP 20000TLEE-10)

• Sunny Tripower 20000TL High Efficiency (STP 20000TLHE-10)

Store this manual where it will be accessible at all times.

1.2 Target Group

This manual is for the use of electrically skilled persons. The tasks described in this manual may be

performed by electrically skilled persons only.

1.3 Additional Information

You will find further information on special topics such as designing a miniature circuit-breaker or the

description of the parameters and measured values at www.SMA.de/en.

Refer to the user manual provided for detailed information on how to operate the inverter.

Installation Manual STP20TLHE-IA-IEN122222 7

Page 8

Information on this Manual SMA Solar Technology AG

1.4 Symbols Used

The following types of safety precautions and general information appear in this document:

DANGER!

DANGER indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING!

WARNING indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION!

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE!

NOTICE indicates a situation which, if not avoided, could result in property damage.

Information

An Information block provides valuable hints for the efficient installation and operation of

your product.

☑ This symbol indicates the result of an action.

8 STP20TLHE-IA-IEN122222 Installation Manual

Page 9

SMA Solar Technology AG Safety

2 Safety

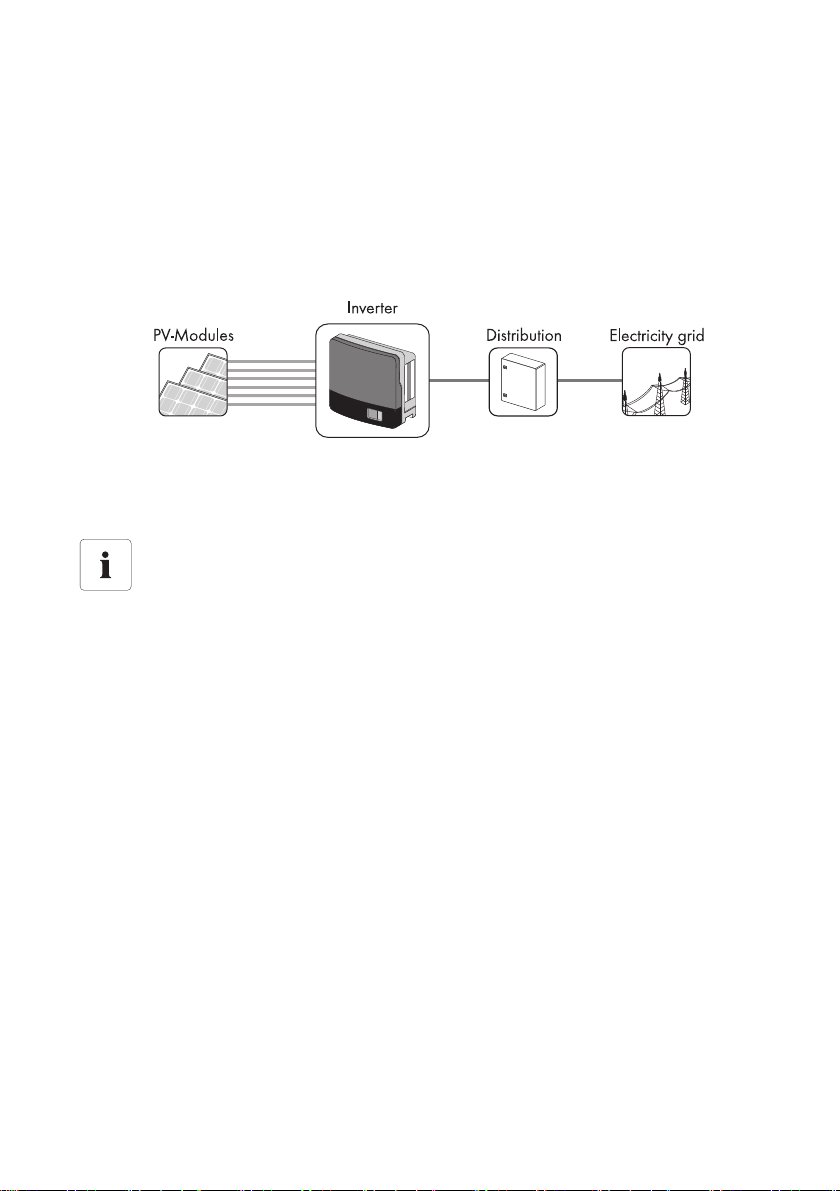

2.1 Intended Use

The Sunny Tripower is a PV inverter which converts the direct current of the PV array to grid-compliant

alternating current and performs three-phase feed-in into the electricity grid.

Principle of a PV plant with this Sunny Tripower

The Sunny Tripower is suitable for indoor and outdoor use.

The Sunny Tripower may only be operated with PV arrays (PV modules and cabling) of protection

class II. Do not connect any energy sources other than PV modules to the Sunny Tripower.

Capacitive Discharge Currents

PV modules with large capacities relative to earth, such as thin-film PV modules with cells

on a metallic substrate, may only be used if their coupling capacity does not exceed

500 nF.

During feed-in operation, a leakage current flows from the cells to earth, the size of which

depends on the manner in which the PV modules are installed (e.g. foil on metal roof) and

on the weather (rain, snow). This "normal" leakage current may not exceed 50 mA due to

the fact that the inverter would otherwise automatically disconnect from the electricity grid

as a protective measure. For further information on this subject see the Technical

Information "Capacitive Discharge Currents" at www.SMA.de/en.

When designing the PV plant, ensure that the values comply with the permitted operating range of all

components at all times. The free design program "Sunny Design" from version 2.0

(www.SMA.de/en/SunnyDesign) will assist you in this. The manufacturer of the PV modules must

have approved the PV modules for use with this Sunny Tripower. You must also ensure that all

measures recommended by the module manufacturer for long-term maintenance of the module

properties are taken (see also Technical Information "Module Technology" at www.SMA.de/en).

Do not use the Sunny Tripower for purposes other than those described here. Alternative uses,

modifications to the Sunny Tripower or the installation of components not expressly recommended or

sold by SMA Solar Technology AG void the warranty claims and operation permission.

Installation Manual STP20TLHE-IA-IEN122222 9

Page 10

Safety SMA Solar Technology AG

2.2 Safety Precautions

DANGER!

Danger to life due to high voltages in the inverter

High voltages which may cause electric shocks are present in the conductive parts of the

inverter.

• Prior to performing any work on the inverter, disconnect the inverter on the AC and

DC sides (see Section 8 "Disconnecting the Inverter from Voltage Sources"

(page58)).

CAUTION!

Risk of burns due to hot enclosure parts

During operation, the upper enclosure lid and the enclosure body may become hot.

• Only touch the lower enclosure lid during operation.

PV array earthing

Comply with the local regulations for earthing the modules and the PV array.

SMA Solar Technology AG recommends connecting the array frame and other electr ically

conductive surfaces so that there is continuous conduction and earthing them in order to

ensure maximum protection for property and persons.

10 STP20TLHE-IA-IEN122222 Installation Manual

Page 11

SMA Solar Technology AG Safety

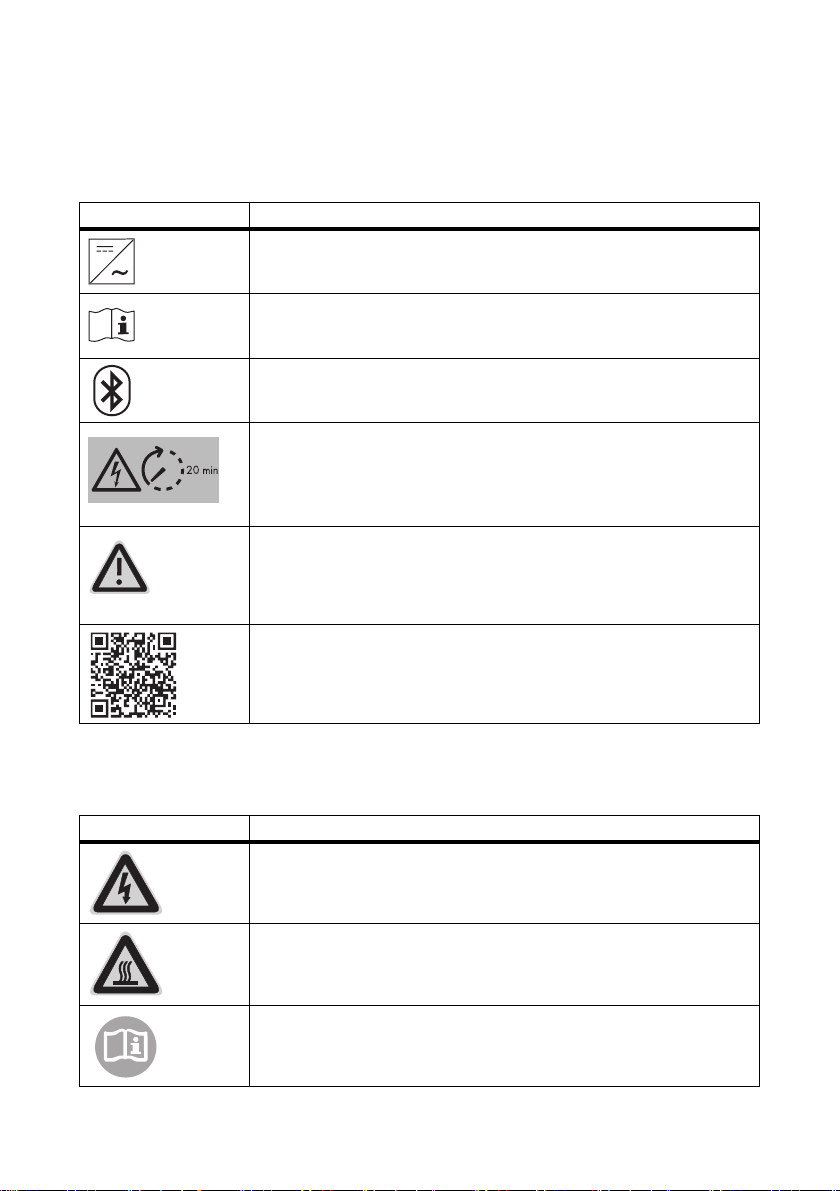

2.3 Explanation of Symbols

2.3.1 Symbols on the Inverter

Symbol Explanation

Operation display

Indicates the operating state of the inverter.

A disturbance has occurred.

Read section 11 "Troubleshooting" (page75) to remedy the disturbance.

SMA Bluetooth

Shows the status of Bluetooth communication.

Danger to life due to high voltages in the inverter

There is residual voltage in the inverter. The inverter takes 20 minutes to

discharge.

• Wait 20 minutes before you open the upper enclosure lid or the DC lid.

NOTICE, danger!

• Observe the connection requirements for the second protective

conductor in Section 6.3.1 "Conditions for the AC Connection"

(page29).

QR Code®* for SMA bonus programme

You will find information on the SMA bonus programme at

www.SMA-Bonus.com.

®

Wireless Technology.

* QR-Code is a registered trademark of DENSO WAVE INCORPORATED.

2.3.2 Symbols on the Type Label

Symbol Explanation

Beware of dangerous voltage.

The inverter operates at high voltages. All work on the inverter must be

carried out by skilled persons only.

Beware of hot surface.

The inverter can become hot during operation. Avoid contact during

operation.

Observe all documentation accompanying the inverter.

Installation Manual STP20TLHE-IA-IEN122222 11

Page 12

Safety SMA Solar Technology AG

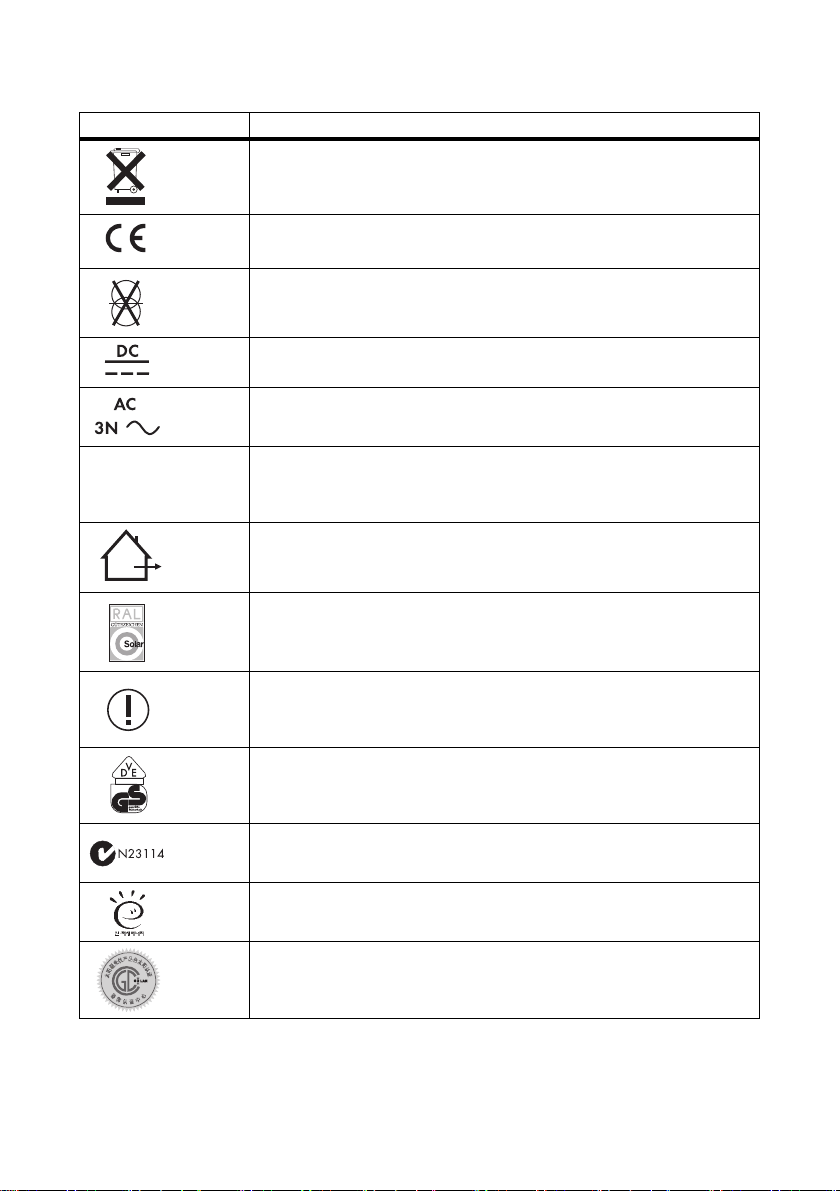

IP54

Symbol Explanation

The inverter must not be disposed of together with household waste. For

more information on disposal, see Section 12.5 "Disposing of the inverter"

(page84).

CE marking

The inverter complies with the requirements of the applicable EC directives.

The inverter does not have a transformer.

Direct current (DC)

Three-phase alternating current (AC) with neutral conductor

Protection rating IP54.

The inverter is protected against dust deposits in the interior and against

splashes of water from all angles.

Outdoor

The inverter is suitable for outdoor installation.

RAL quality mark for solar products

The inverter complies with the requirements of the German Institute for

Quality Assurance and Labelling.

Device class label

The inverter is equipped with a wireless component that complies with the

harmonised standards.

Certified safety

Th e in verter c omp lies wi th t he r equ irement s of the Eur ope an E quipment and

Product Safety Act.

Australian mark of conformity

Korean mark of conformity.

Chinese mark of conformity

12 STP20TLHE-IA-IEN122222 Installation Manual

Page 13

SMA Solar Technology AG Unpacking

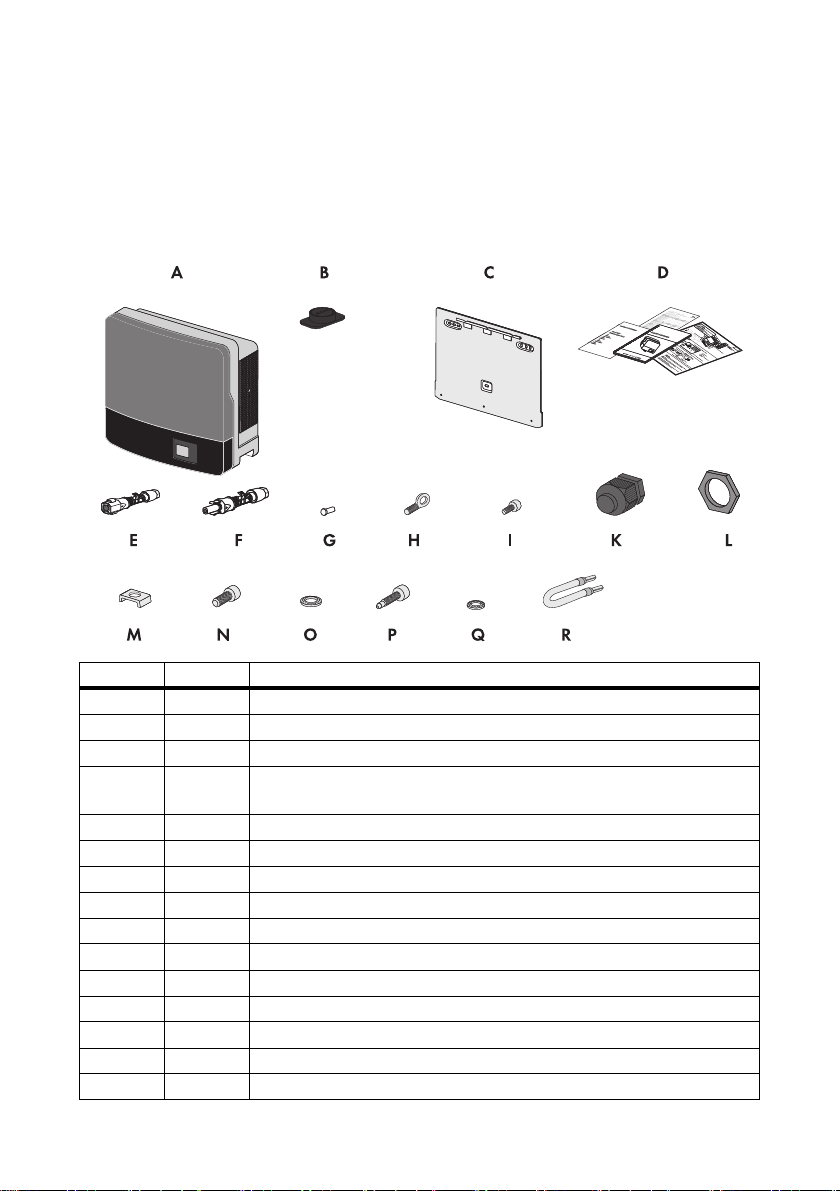

3 Unpacking

3.1 Scope of Delivery

Check the delivery for completeness and for any visible external damage. Contact your specialist

dealer if the delivery is incomplete or you find any damage.

Object Quantity Description

A 1 Sunny Tripower

B 1 Handle of the DC switch-disconnector*

C 1Back panel

D 1 Installation manual including user manual, document set with explanations

and certificates, supplementary sheet with the default settings

E 6 Negative DC connector

F 6 Positive DC connector

G 12 Sealing plugs

H 1 Eye bolt M8 for securing the inverter to the back panel

I 2 Cheese-head screw M5x10 for attaching the enclosure to the back panel

K 1 Cable gland for AC connection

L 1 Counter nut for cable gland at AC connection

M 1 Clamping bracket M6 for additional earthing

N 1 Cheese-head screw M6 for earth terminal

O 1 Conical spring washer M6 for earth terminal

P 2 Cheese-head screws M5x20 for upper enclosure lid (replacement)

Installation Manual STP20TLHE-IA-IEN122222 13

Page 14

Unpacking SMA Solar Technology AG

Object Quantity Description

Q 2 Conical spring washers M5 for upper enclosure lid (replacement)

R 1 Jumper cable for deactivating the reverse current protection

*optional

3.2 Identifying the Inverter

You can identify the inverter by the type label. The type label is located on the right-hand side of the

enclosure.

The serial number (Serial No.) and the type (Type/Model) of the inverter, as well as device-specific

characteristics are specified on the type label.

14 STP20TLHE-IA-IEN122222 Installation Manual

Page 15

SMA Solar Technology AG Product Description

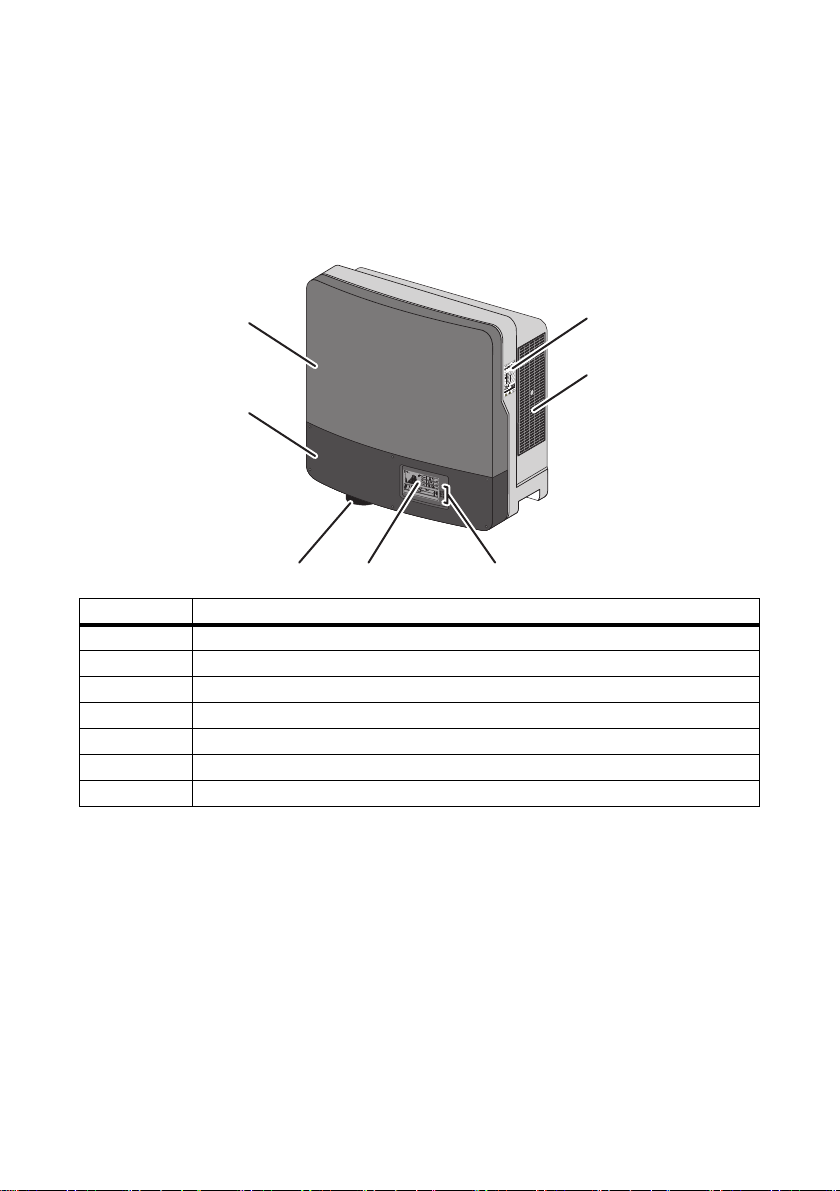

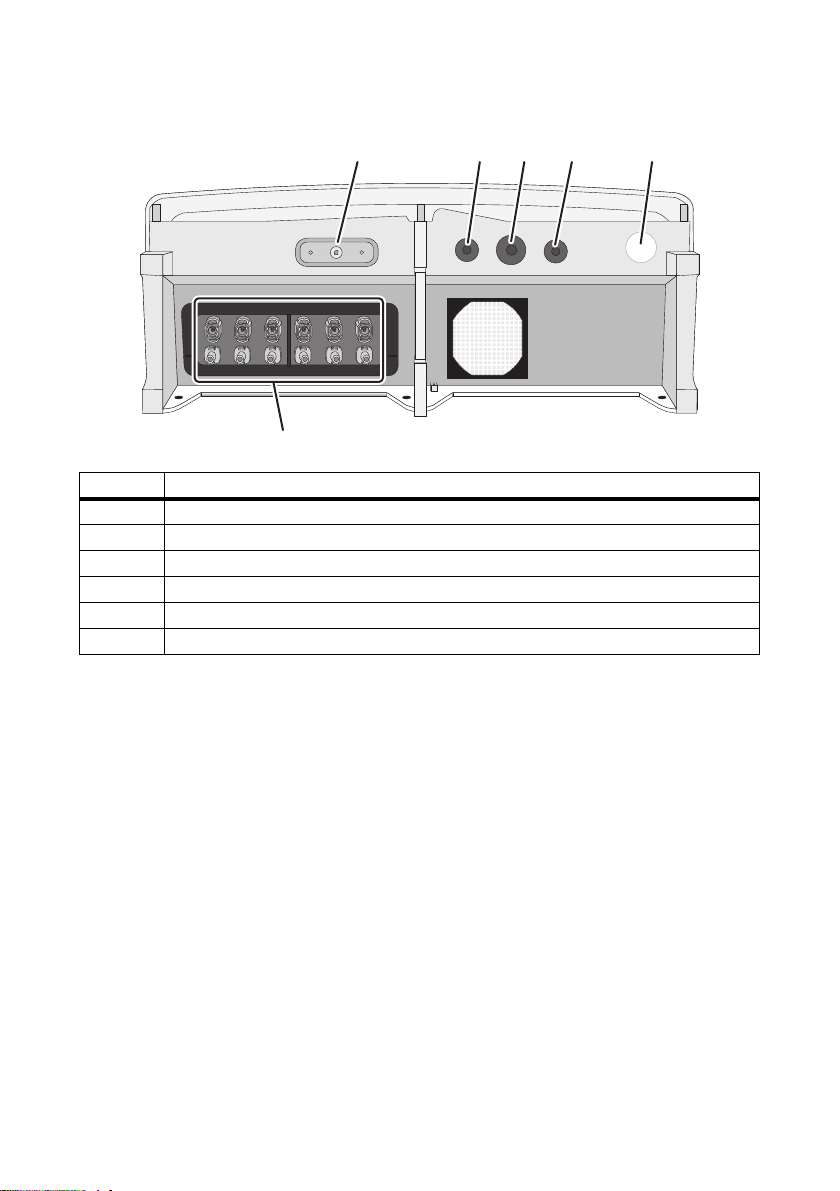

A

C

D

E

F

G

B

4 Product Description

4.1 Sunny Tripower

The Sunny Tripower is a PV inverter which converts the direct current of the PV array to grid-compliant

alternating current and performs three-phase feed-in into the electricity grid.

Position Description

A Type label

B Ventilation grid

C LEDs

D Display

E DC switch-disconnector*

F Lower enclosure lid

G Upper enclosure lid

*optional

Installation Manual STP20TLHE-IA-IEN122222 15

Page 16

Product Description SMA Solar Technology AG

kVAr

kVArh

kWh

MVArh

MWh

kW

kWh

A

B

C

D

E

F

G

H

K

L

M

I

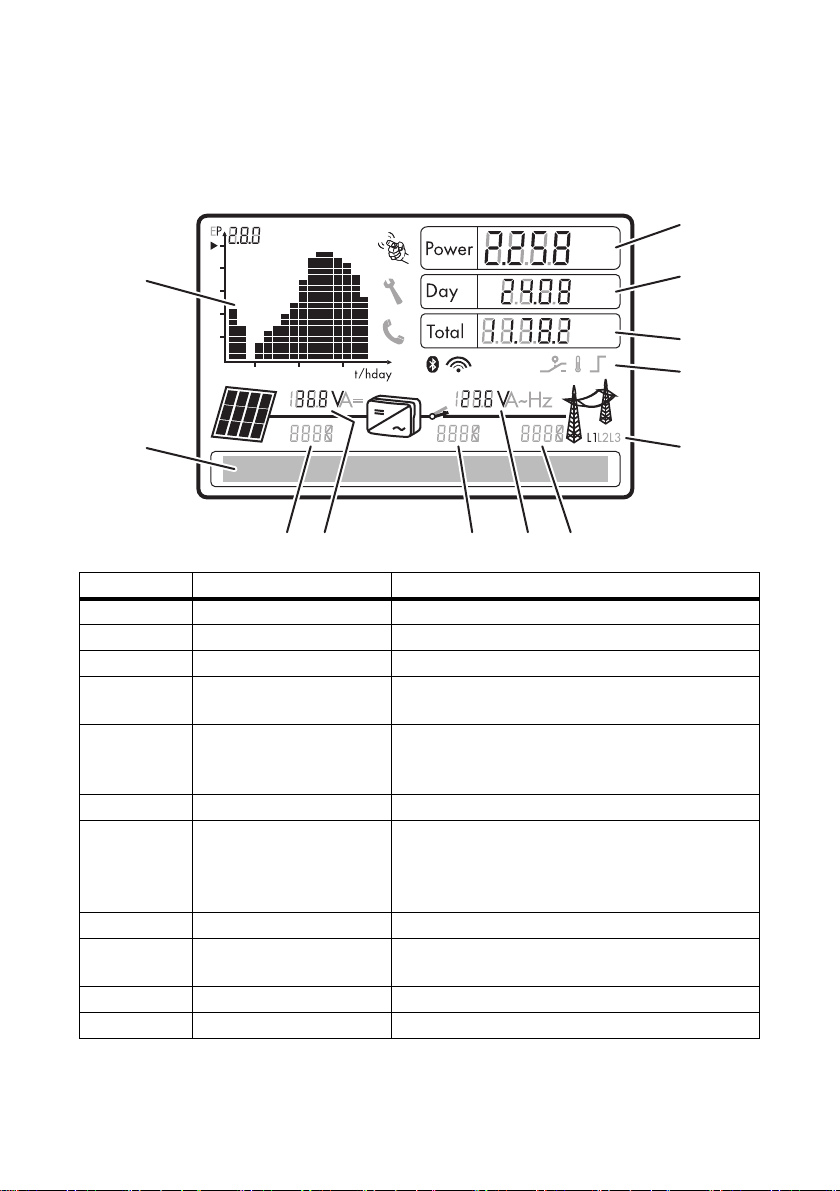

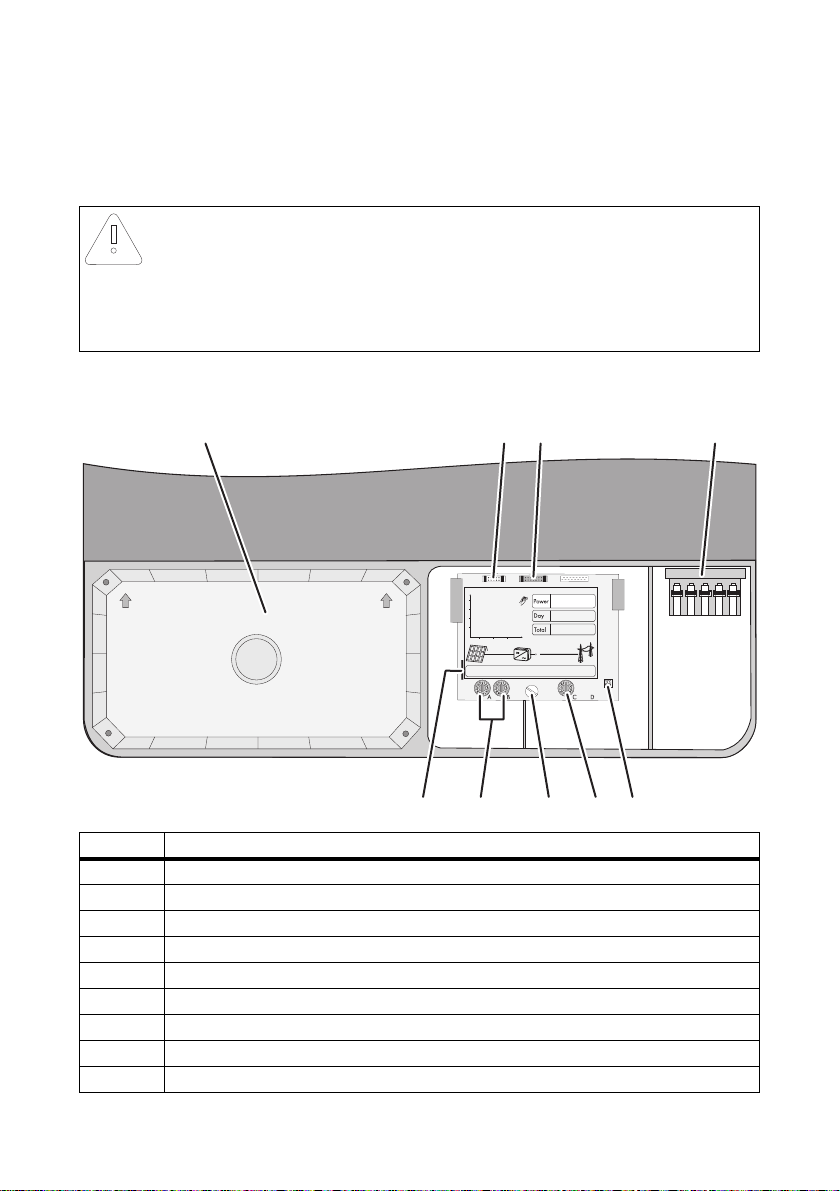

4.2 Display

The display shows the current operating data of the inverter (e.g. status, power, input voltage) as well

as faults and disturbances.

Position Description Explanation

A Power Displays the current power

B Day Displays the daily energy

C Total Displays the total amount of energy fed in until now

D Active functions The symbols indicate which communication or power

regulation functions are enabled.

E Phase assignment The phase assignment states the line conductor for

which output current or output voltage is currently

being displayed.

F Electricity grid event number Event number of a disturbance in the electricity grid

G Output voltage/output

current

H Inverter event number Event number of a device disturbance

I Input voltage/input current The display alternately shows the input voltage and

K PV array event number Event number of a disturbance in the PV array

L Text line The text line shows event messages.

The display alternately shows the output voltage and

the output current of the line conductor. The display

automatically switches between the 3 connected line

conductors.

the input current of the inverter.

16 STP20TLHE-IA-IEN122222 Installation Manual

Page 17

SMA Solar Technology AG Product Description

Position Description Explanation

M Power and yield curve The diagram shows the changes in power over the

last 16 feed-in hours or the energy yields over the last

16 days. Tap the display once to switch between

views.

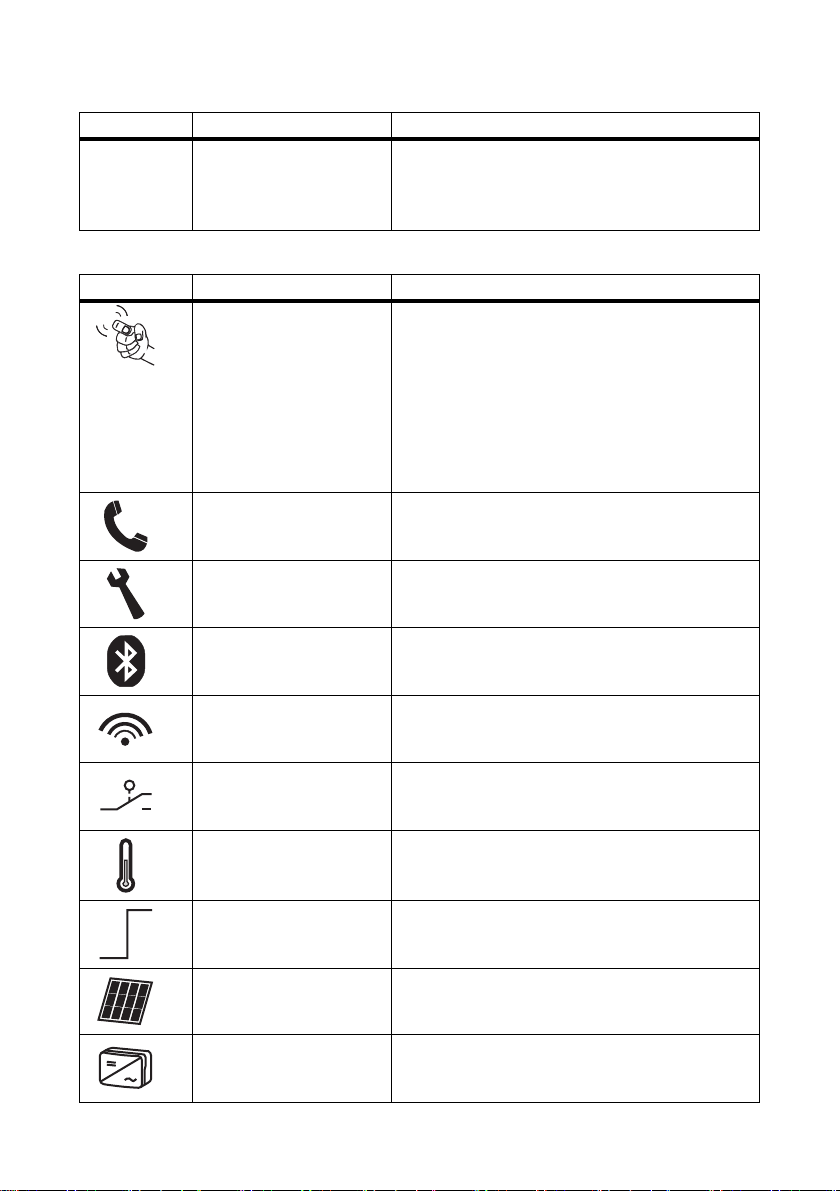

Symbols on the Display

Symbol Designation Explanation

Tap symbol You can operate the display by tapping it:

• Single tap: the backlight switches on or the

display scrolls one message further.

• Double tap: the display shows successively the

firmware version, the serial number or

de sig nat ion of th e in ver ter , th e Bluetooth Ne tID ,

the configured country data set and display

language.

Telephone receiver Device disturbance present. Contact the SMA Service

Line.

Spanner Signifies a disturbance that can be resolved on-site.

Bluetooth Bluetooth communication is enabled.

Bluetooth connection Bluetooth connection to other devices is active.

Multi-function relay The multi-function relay is active.

Temperature symbol The power of the inverter is limited due to excessive

temperature.

Power limitation The external active power limitation via the

Power Reducer Box is active.

PV array ‒

Inverter ‒

Installation Manual STP20TLHE-IA-IEN122222 17

Page 18

Product Description SMA Solar Technology AG

Symbol Designation Explanation

Grid relay When the grid relay is closed, the inverter feeds into

the grid. When the grid relay is open, the inverter is

disconnected from the electricity grid.

Electricity grid ‒

4.3 DC switch-disconnector

The DC switch-disconnector is optional. If you have ordered the inverter with DC switch-disconnector,

it will be pre-installed in the inverter on delivery.

Using the DC switch-disconnector, you can manually close or interrupt the electric circuit between the

PV array and the inverter. The DC switch-disconnector enables safe disconnection of the inverter from

the PV array. The disconnection takes place at all poles.

4.4 Communication

The inverter is equipped with a Bluetooth interface as standard. A multi-function relay and an

additional communication interface (e.g. RS485) can be retrofitted. The inverter can communicate

with special SMA communication products (e.g. data logger, software) or other inverters via the

communication interfaces (for information on supported communication products, see

www.SMA.de/en). You can only set the inverter's parameters using SMA communication products.

If you communicate via Bluetooth, you can protect the inverter with a plant password for the user and

a plant password for the installer. All inverters are delivered with the same factory-installed plant

passwords. You must change plant passwords using a communication product in order to protect the

PV plant from unauthorised access.

If you do not communicate via Bluetooth, deactivate the Bluetooth communication

(see Section 6.6.1 "Bluetooth" (page50)). This protects your PV plant from unauthorised access.

Various parameter displays

Depending on the type of communication, RS485 or Bluetooth, the parameters and

messages are displayed differently on the communication products.

Example: parameter display for testing the fan

• If you are using RS485: parameter "CoolSys.FanTst"

•If you are using Bluetooth: parameter "Fan test"

18 STP20TLHE-IA-IEN122222 Installation Manual

Page 19

SMA Solar Technology AG Product Description

4.5 Multi-Function Relay

The inverter may be equipped with a multi-function relay. The multi-function relay is an interface for

error messages or for controlling loads. Disturbances can be transmitted to a disturbance sensor.

For this purpose, the multi-function relay switches the disturbance sensor on and off. The multi-function

relay can control a load via a contactor. For this purpose, the inverter determines when the load is

switched on and off, depending on the operating parameters and measured values. You can

configure the multi-function relay for various operating modes (see Technical Description

"Multi-Function Relay and OptiTrac Global Peak" available at www.SMA.de/en).

4.6 Feed-In Management

The Sunny Tripower is capable of utilising reactive power and can feed reactive power into the grid

via the setting of a default value for the displacement power factor (cos φ). Additionally, this inverter

is also equipped with advanced feed-in management functions, e.g. power limitation and dynamic

grid support. You can enable and configure these functions depending on the requirements set by the

network operator.

You can find detailed information on setting the parameters of these functions in the Technical

Description "Measured Values and Parameters" at www.SMA.de/en in the "Technical Description"

category for the respective inverter.

Installation Manual STP20TLHE-IA-IEN122222 19

Page 20

Product Description SMA Solar Technology AG

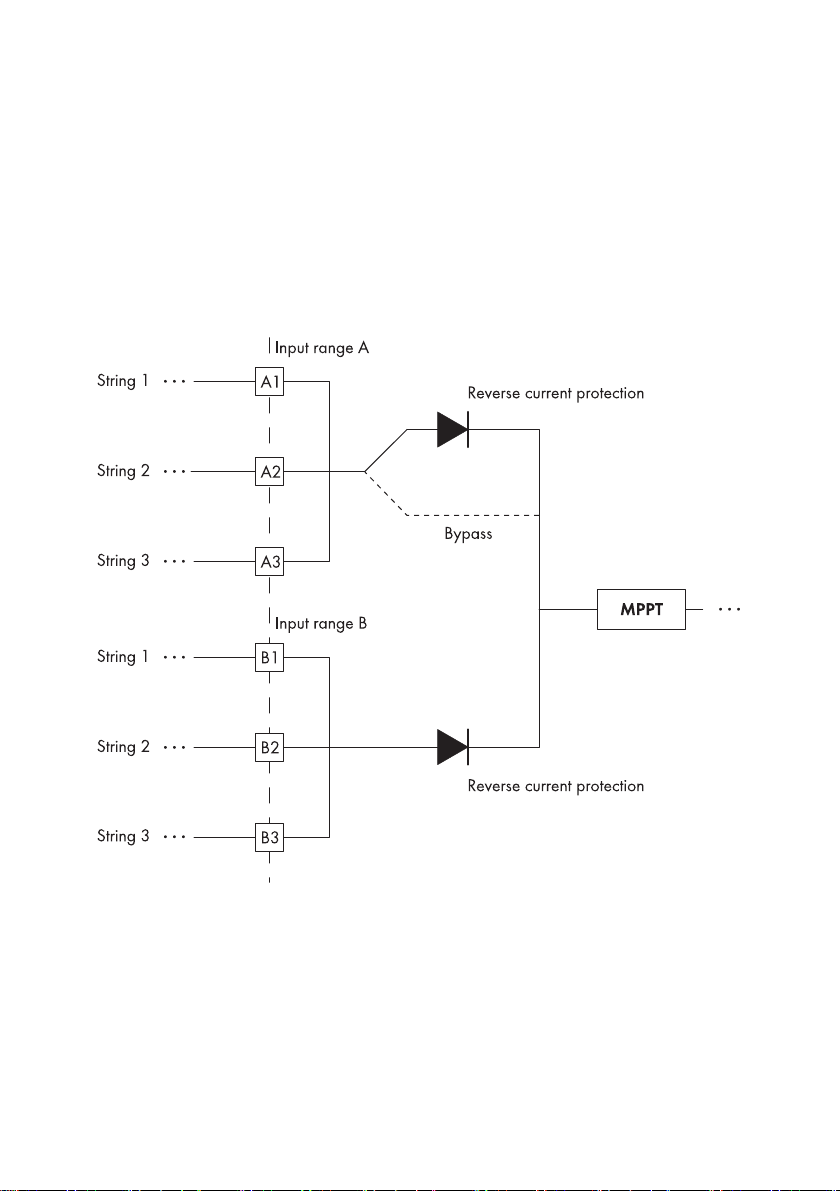

4.7 Reverse Current Protection

Every input area of the inverter is equipped with a diode as reverse current protection. A reverse

current between the input areas is therefore not possible.

If only input area A is used and the reverse current resistance of the PV modules is complied with, the

reverse current protection at input area A can be bypassed (see Section 6.7 "Activating and

Deactivating the Reverse Current Protection at Input Area A" (page52)). Bypassing the reverse

current protection slightly increases the inverter efficiency.

The reverse current protection at input area B cannot be deactivated.

20 STP20TLHE-IA-IEN122222 Installation Manual

Page 21

SMA Solar Technology AG Mounting

5 Mounting

5.1 Safety

DANGER!

Danger to life due to fire or explosion

Despite careful construction, electrical devices can cause fires.

• Do not mount the inverter on flammable construction materials.

• Do not mount the inverter in areas where highly flammable materials are stored.

• Do not mount the inverter in a potentially explosive atmosphere.

CAUTION!

Risk of injury due to the heavy weight of the inverter (approx. 53 kg)

• Take the weight of the inverter into account for transport.

• Select a suitable mounting location and mounting surface.

• When mounting the back panel, use fastening material suitable for the mounting

surface.

• Two people are needed to mount the inverter.

CAUTION!

Risk of burns due to hot enclosure parts

• Mount the inverter in such a way that it cannot be touched inadvertently.

5.2 Selecting the Mounting Location

Consider the following requirements when selecting the mounting location:

• The mounting method and location must be suitable for the weight and size of the inverter

(see Section 13 "Technical Data" (page85)).

• Mount on a solid surface.

• The mounting location must at all times be clear and safely accessible without the use of

additional aids such as scaffolding or lifting platforms. Non-fulfillment of these criteria may

restrict execution of service assignments.

Installation Manual STP20TLHE-IA-IEN122222 21

Page 22

Mounting SMA Solar Technology AG

max. 15°

300 mm

500 mm

50 mm

300 mm

300 mm

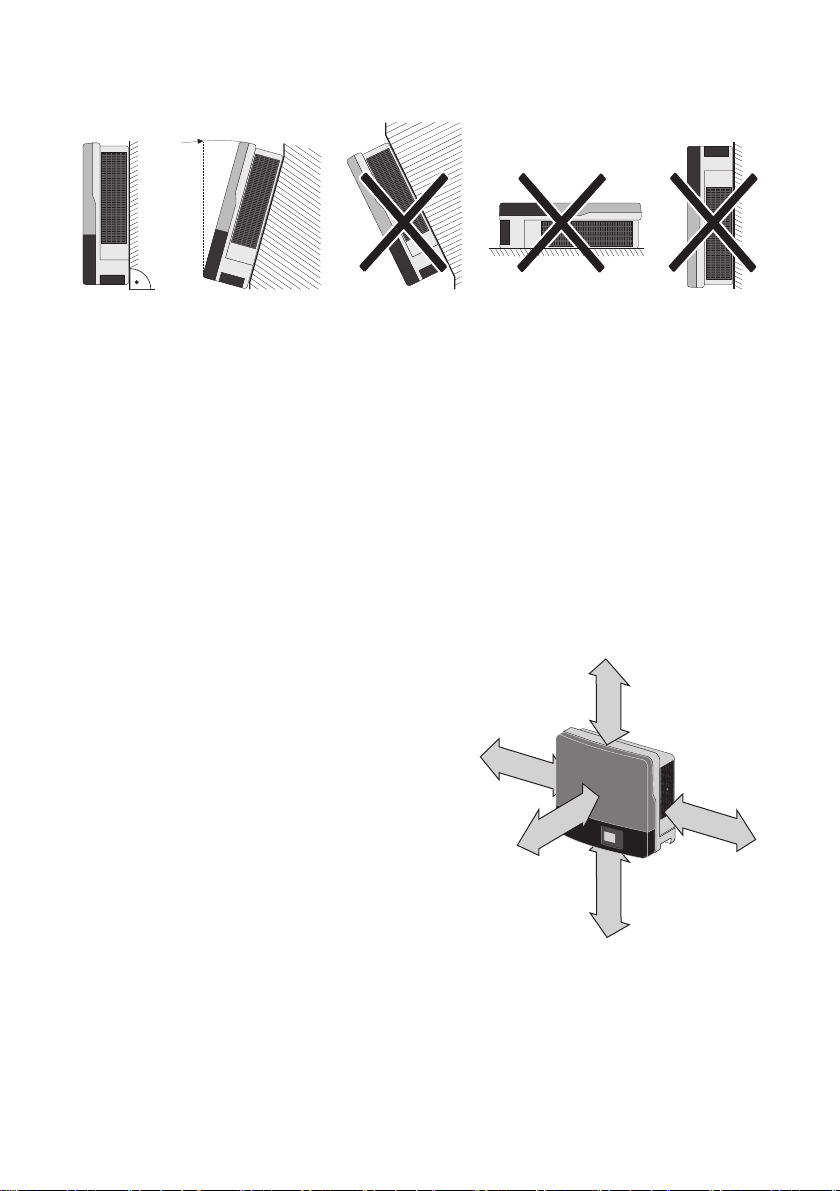

• Mount vertically or tilted backwards by max. 15°.

• The connection area must point downwards.

• Never mount the device with a forward tilt.

• Never mount the device with a sideways tilt.

• Do not mount horizontally.

• Mount the inverter at eye level. Given the weight of the device, this will facilitate disassembling

if service work is necessary.

• The ambient temperature should be below 40°C to ensure optimum operation.

• Do not expose the inverter to direct solar irradiation as this can cause overheating and lead to

power reduction.

• In living areas, do not mount the unit on plasterboard walls or similar in order to avoid audible

vibrations. When in operation, the inverter emits noise which may be perceived as annoying in

living areas.

• Observe the recommended clearances to the walls

as well as to other inverters or other objects as

shown in the diagram. This ensures adequate heat

dissipation and sufficient room to operate the

optional DC switch-disconnector.

• If multiple inverters are mounted in areas with high

ambient temperatures, increase the clearances

between the inverters and ensure an adequate

fresh-air supply. This prevents a reduction in inverter

power as a result of high temperatures (details on

tempe rature der ating can be fou nd in the Te chnical

Information "Temperature Derating" at

www.SMA.de/en).

22 STP20TLHE-IA-IEN122222 Installation Manual

Page 23

SMA Solar Technology AG Mounting

Display

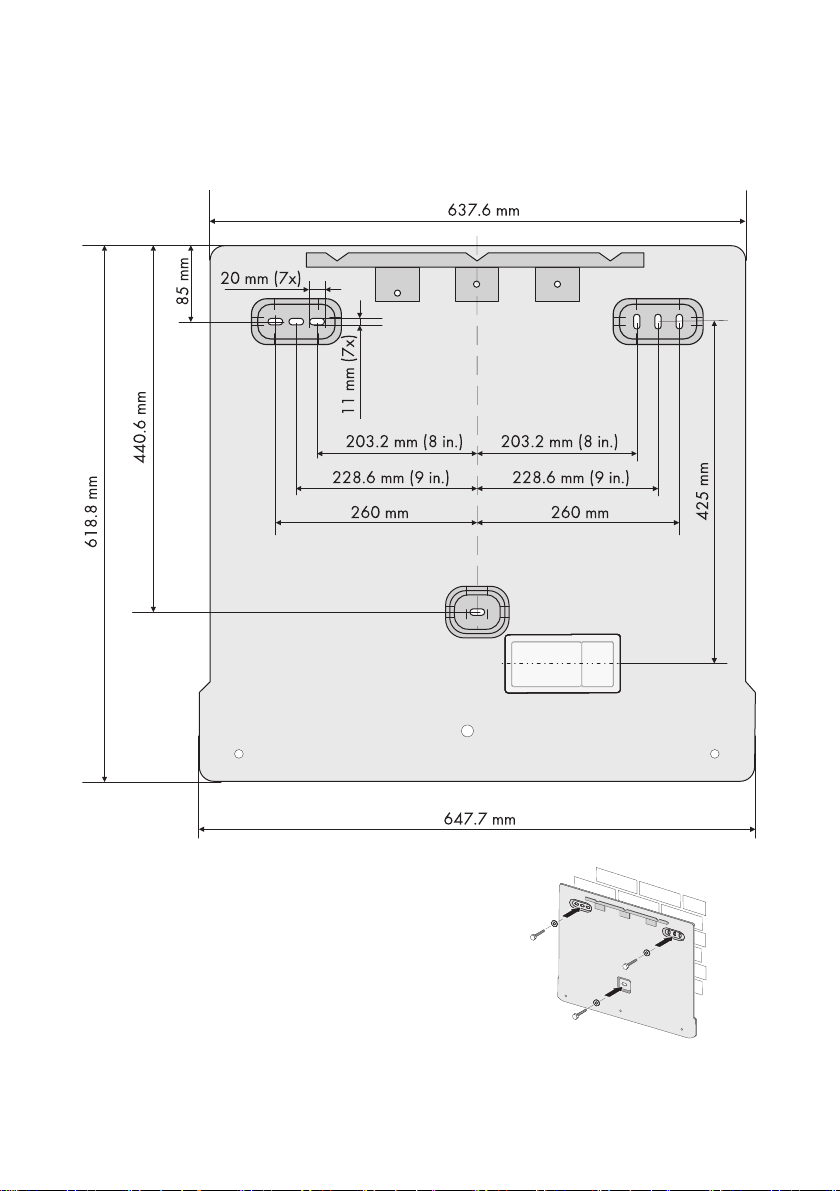

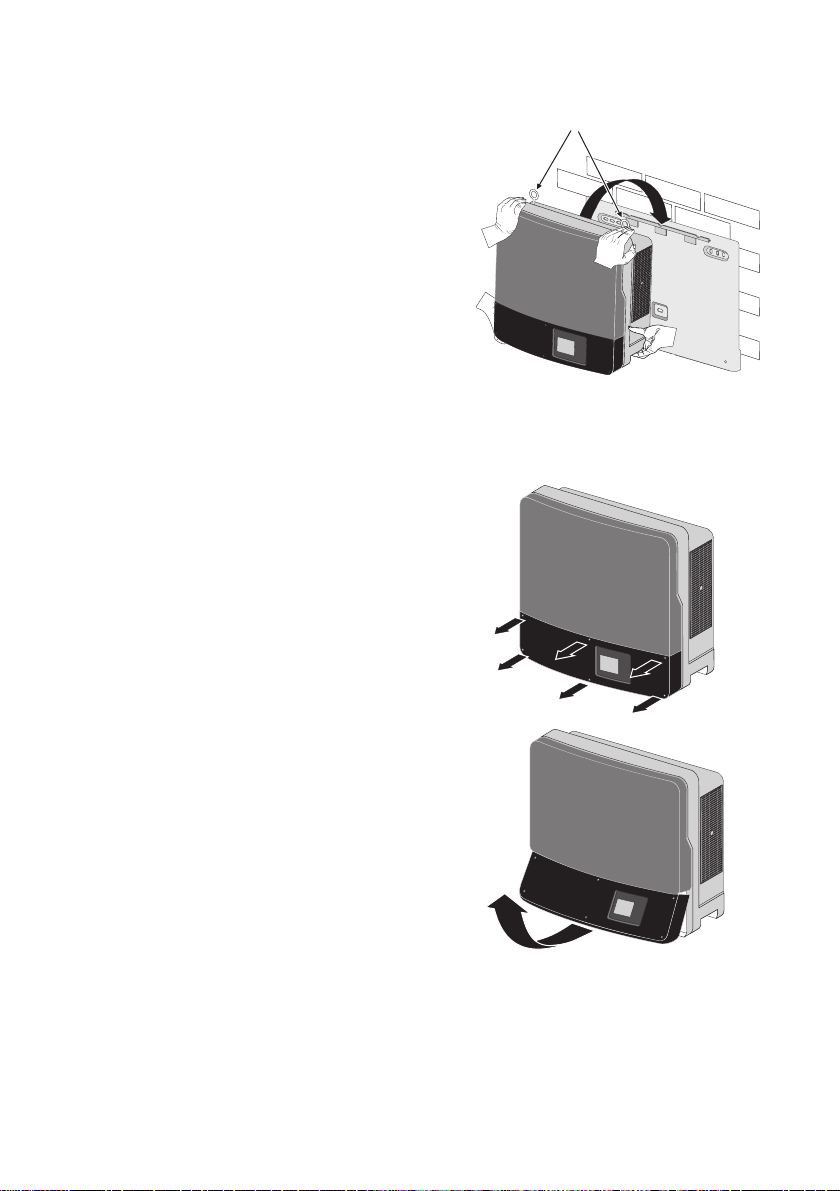

5.3 Mounting the Inverter

1. Use the back panel as a drilling template and mark the positions of the drill holes.

2. Mount the back panel.

For this, use 1 upper hole on the right and on the left

and the hole in the middle.

Installation Manual STP20TLHE-IA-IEN122222 23

Page 24

Mounting SMA Solar Technology AG

A

3. Hang the inverter in the back panel in such a way

that the enclosure of the inverter lies flush with the

back panel.

– For two people to transport the inverter, use the

recessed grips at the bottom and at the same

time hold the upper edge of the enclosure lid.

– For transport by crane, you can attach 2 ring

bolts to the top of the inverter

(see A: M10, diameter = 10 mm). To do this,

remove the filler-plugs and screw in the ring

bolts as far as they will go.

4. If necessary, remove the ring bolts after transport

and re-attach the filler-plugs.

5. Loosen all 6 captive screws of the lower enclosure

lid.

6. Lift and remove the lower enclosure lid from below.

24 STP20TLHE-IA-IEN122222 Installation Manual

Page 25

SMA Solar Technology AG Mounting

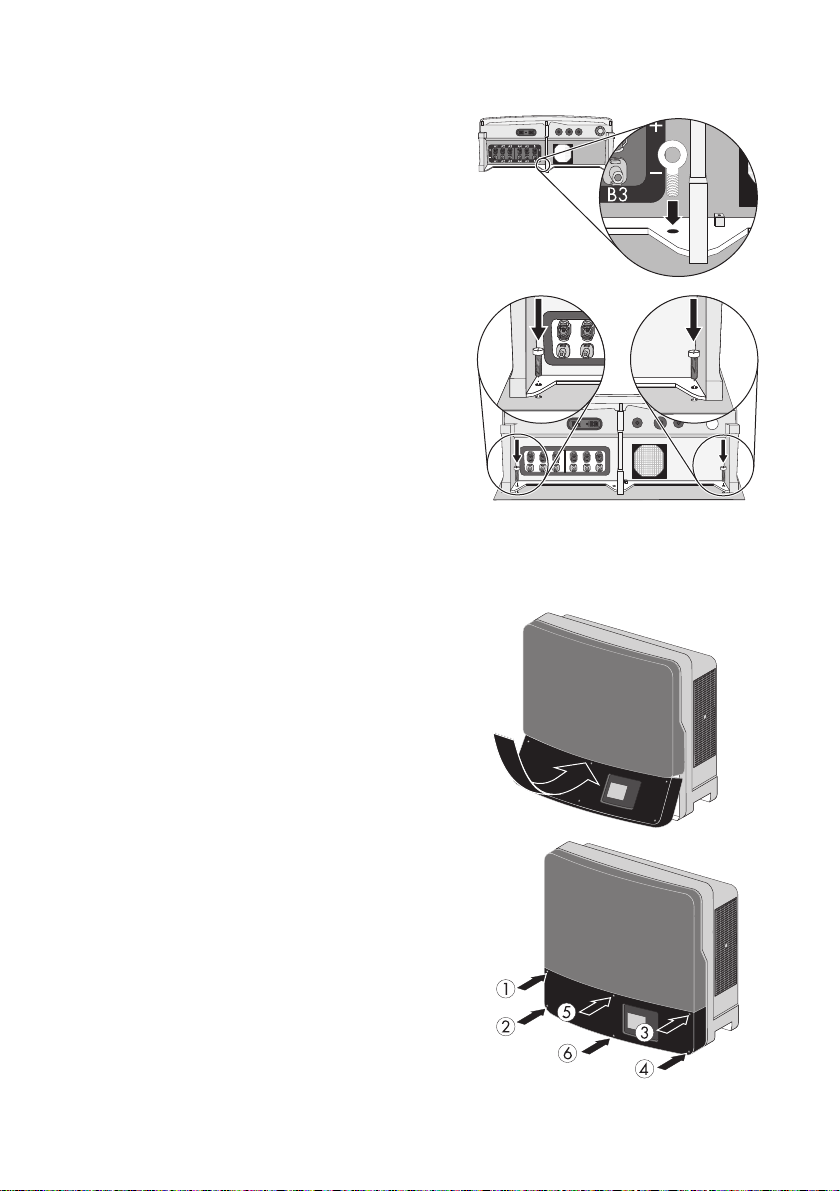

7. Screw the supplied eye bolt into the drill hole

provided in order to secure the enclosure against

removal. Only tighten the eye bolt hand-tight.

8. In order to secure the enclosure to the back panel,

fasten the underside of the enclosure with the two

M5x10 cheese-head screws supplied

(torque: 6.0 Nm).

9. Check to ensure that the inverter is securely in place.

☑ The inverter is now securely mounted to the wall.

If the inverter is not to be connected immediately, re-attach the lower enclosure lid:

– Dock the lower enclosure lid at an angle and

attach. The captive screws must protrude.

– Pre-screw all six screws and then tighten them in

the sequence shown on the right

(torque: 2.0 Nm).

Installation Manual STP20TLHE-IA-IEN122222 25

Page 26

Mounting SMA Solar Technology AG

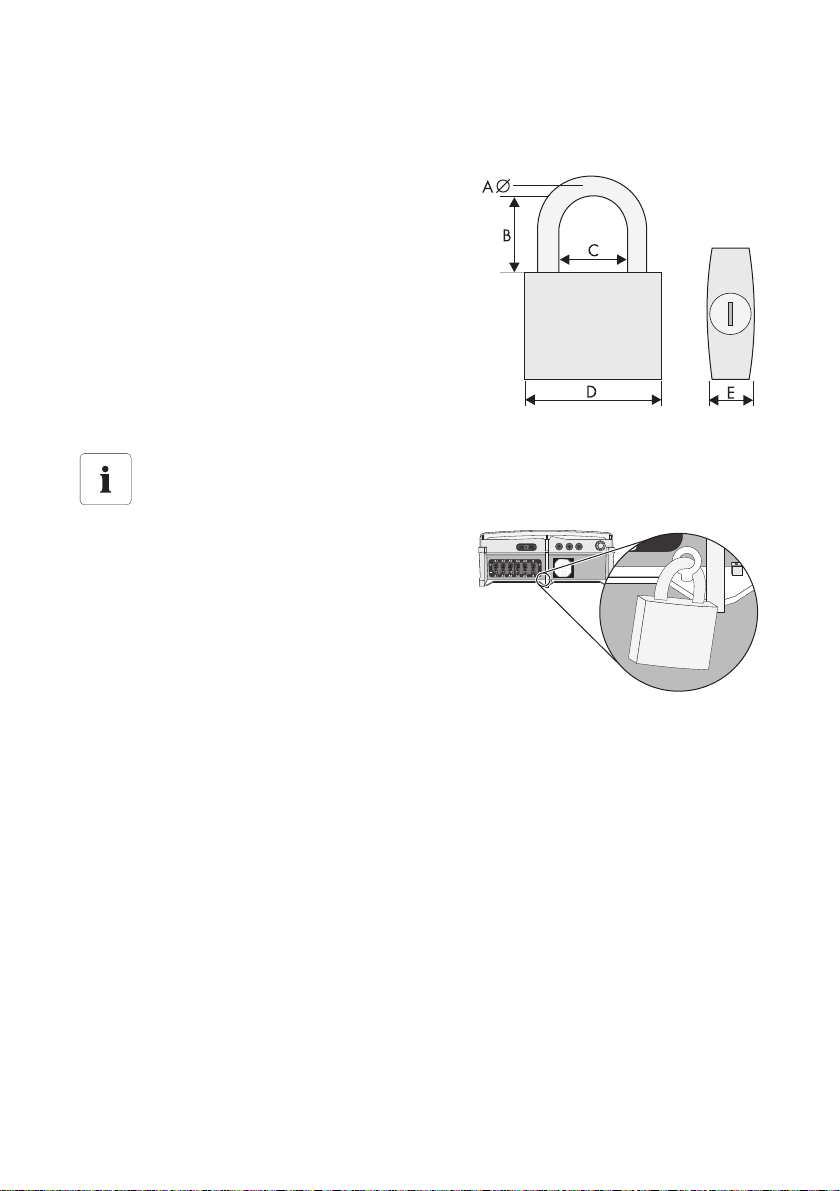

Optional Anti-Theft Protection

To protect the inverter from theft, you can secure it to the back panel with a padlock.

The padlock must meet the following requirements:

•Size:

A: 6 mm … 8 mm diameter

B: 23 mm … 29 mm

C: 23 mm … 28 mm

D: 39 mm … 50 mm

E: 13 mm … 18 mm

•Stainless

• Hardened shackle

• Secured lock cylinder

Storage of the key

Keep the key in a safe place in case it is needed for service purposes.

1. Put the shackle of the padlock through the eye of

the previously mounted eye bolt and close the

padlock.

☑ The inverter is now protected against theft.

26 STP20TLHE-IA-IEN122222 Installation Manual

Page 27

SMA Solar Technology AG Electrical Connection

L1

L2

L3

N

PE

A

B

C

D

EFGH

I

6 Electrical Connection

6.1 Safety

NOTICE!

Electrostatic discharge can damage the inverter

Internal components of the inverter can be irreparably damaged by electrostatic

discharge.

• Earth yourself before touching any components.

6.2 Overview of the Connection Area

Object Description

A DC lid

B Plug for connecting the optional multi-function relay

C Plug for connecting the optional RS485 communication module

D Terminal for grid connection

E Switch for changing the display language to English (for service purposes)

F Rotary switch for setting the Bluetooth NetID

G Screw for releasing and raising the display

H Rotary switch for setting the country data set and the display language

I Slot for SD card (for service purposes only)

Installation Manual STP20TLHE-IA-IEN122222 27

Page 28

Electrical Connection SMA Solar Technology AG

+ +

A1 A2 A3 B1 B2 B3

A1 A2 A3 B1 B2

B3

ABC D E

F

Object Description

A Jack for the handle of the DC switch-disconnector*

B Enclosure opening M20 for the optional multi-function relay

C Enclosure opening M32 for the optional communication via RS485

D Additional enclosure opening M20

E Enclosure opening M32 for the AC connection

F DC connectors for connecting the strings

* optional

28 STP20TLHE-IA-IEN122222 Installation Manual

Page 29

SMA Solar Technology AG Electrical Connection

6.3 Connection to the Electricity Grid (AC)

6.3.1 Conditions for the AC Connection

You must comply with the connection requirements of your network operator.

Residual-current protective device

The inverter is equipped with an integrated all-pole-sensitive residual-current monitoring unit. The

inverter can automatically differentiate between residual currents and normal leading leakage

currents.

If the network operator stipulates a residual-current protective device, you must use a residual-current

protective device that triggers in the event of a residual-current of 100 mA or more.

Further information on the use of a residual current protective device can be found in the Technical

Information "Criteria for selecting an RCD" at www.SMA.de/en.

Cable requirements

• External diameter: 14 mm … 25 mm

• Conductor cross-section: max. 16 mm²; with bootlace ferrule: max. 10 mm².

• Stripping length: 12 mm

• The cable must be dimensioned in accordance with the local and national regulations for the

dimensioning of cables. The requirements for the minimum conductor cross-section derive from

these regulations. Examples of factors influencing cable dimensioning are: nominal AC current,

type of cable, routing method, cable bundling, ambient temperature and maximum desired line

losses (for calculation of line losses, see design software Sunny Design from software version

2.0 at www.SMA.de/en).

Connection of a second protective conductor

In some installation countries, a second protective conductor is required to prevent a touch current in

the event of a malfunction in the original protective conductor.

For installation countries falling within the scope of validity of the IEC standard 62109, the following

requirements are applicable:

• Installation of the protective conductor on the AC terminal with a conductor cross-section of at

least 10 mm² Cu.

or

• Installation of a second protective conductor on the earth terminal with the same cross-section

as the original protective conductor on the AC terminal (see Section 6.3.3 "Connecting the

Second Protective Conductor" (page33)).

In each case, observe the applicable regulations for the site.

Installation Manual STP20TLHE-IA-IEN122222 29

Page 30

Electrical Connection SMA Solar Technology AG

Load disconnection unit

You must install a separate, 3-phase miniature circuit-breaker for each inverter in order to ensure

that the inverter can be securely disconnected under load. The maximum permissible fuse protection

can be found in Section 13 "Technical Data" (page85).

DANGER!

Danger to life due to fire.

When more than one inverter is connected in parallel to the same miniature circuit-breaker,

the protective function of the miniature circuit-breaker is no longer guaranteed. It can result

in a cable fire or destruction of the inverter.

• Never connect multiple inverters to the same miniature circuit-breaker.

• Observe the maximum permissible fuse protection of the inverter when selecting the

miniature circuit-breaker.

DANGER!

Danger to life due to fire.

When a generator (inverter) and a load are connected to the same miniature circuitbreaker, the protective function of the miniature circuit-breaker is no longer guaranteed.

The current from the inverter and the electricity grid can accumulate to overcurrents which

are not detected by the miniature circuit-breaker.

• Never connect loads between the inverter and the miniature circuit-breaker without

fuse protection.

• Always protect loads separately.

NOTICE!

Damage to the inverter caused by use of screw-type fuses as load-disconnect

units!

A s cre w-t ype fus e, e .g. DIA ZED fus e or NEO ZED fus e, i s no t a s witch-disconnector and thus

may not be used as a load disconnection unit. A screw-type fuse only acts as cable

protection.

If the inverter is disconnected under load using a screw-type fuse, the inverter may be

damaged.

• Use o nly a switc h-disconnecto r or a mi niatu re circuit-bre aker as a load discon necti on

unit.

30 STP20TLHE-IA-IEN122222 Installation Manual

Page 31

SMA Solar Technology AG Electrical Connection

6.3.2 AC Connection Procedure

1. Check the line voltage and compare it with the permissible voltage range (see Section 13

"Technical Data" (page85)).

2. Disconnect the miniature circuit-breaker from all three line conductors and secure against

reconnection.

3. Loosen all 6 captive screws of the lower enclosure

lid.

4. Lift and remove the lower enclosure lid from below.

Installation Manual STP20TLHE-IA-IEN122222 31

Page 32

Electrical Connection SMA Solar Technology AG

L1 L2 L3 N

N

PE

L3

L1

L2

5. Check that the country setting of the inverter is correct by using the supplementary sheet

provided with the default settings.

If the inv erter is not set to th e de sir ed c oun try data set , adjust the country data set using the rotary

switches as described in Section 6.5 "Setting the Country Data Set and Display Language"

(page42).

6. Remove the adhesive tape from the AC enclosure opening.

7. Insert the AC cable gland from the outside into the

enclosure opening and tighten it from the inside

with the counter nut.

8. Pull the cable through.

9. Raise all 5 terminals of the AC terminal as far as they will go.

NOTICE!

Risk of fire when connecting 2 conductors

If 2 conductors are connected to one terminal, a poor electrical contact can result in

overheating or a risk of fire.

• Never connect more than one conductor per terminal.

10. Connect L1, L2, L3, N and the protective conductor

(PE) to the AC terminal in accordance with the

labelling.

– To do this, the PE insulated conductor must be

5 mm longer than the L and N insulated

conductors.

– L and N must not be swapped.

– The direction of rotation of L1, L2 and L3 is not

relevant.

CAUTION!

Danger of crushing when terminals snap shut

The terminals close by snapping down fast and hard.

• Press the terminals down with your thumb, do not grip on either side of the terminal.

• Keep fingers away from the terminals.

32 STP20TLHE-IA-IEN122222 Installation Manual

Page 33

SMA Solar Technology AG Electrical Connection

11. Close all terminals of the AC terminal again until they snap into place.

12. Tighten the swivel nut firmly to the cable gland.

DANGER!

Danger to life due to high voltages in the inverter

• Do not switch on the miniature circuit-breaker until the PV array has been connected

and the inverter is securely closed.

6.3.3 Connecting the Second Protective Conductor

If the installation requires, the earth terminal can be used to connect a second protective conductor

or as equipotential bonding.

1. Take t he cla mping brac ket, chees e-head scr ew M6

an d co nic al s pri ng w ash er M 6 ou t of the acc ess ory

kit.

2. Insert the stripped earthing cable (D) under the

clamping bracket (C) (maximum conductor crosssection 16 mm²).

3. Fasten terminal (C):

– Attach conical spring washer on the screw.

Here, the grooved side of the conical spring

washer must point to the screw head.

– Tighten the screw (torque: 6.0 Nm).

☑ The teeth of the conical spring washer are

pushed into the clamping bracket. The

conductive earthing cable is conductively

connected to the enclosure.

Installation Manual STP20TLHE-IA-IEN122222 33

Page 34

Electrical Connection SMA Solar Technology AG

6.4 Connecting the PV Array (DC)

6.4.1 Conditions for DC Connection

The inverter has 2 input areas, "A" and "B", each with its own reverse current protection. In total, up

to 6 strings can be connected.

• Requirements for the PV modules of the connected strings:

– Same type

– Same quantity of PV modules connected in series

– Identical alignment

– Identical tilt

• T he c onn ect ing cab les of t he P V mo dul es m ust be e quipped wit h connectors. The DC connectors

for DC connection are included in the scope of delivery.

Use of Y adaptors

Y adaptors must not be visible or freely accessible in close proximity to the inverter.

• The DC electric circuit must not be interrupted by Y adaptors.

• Observe the procedure for disconnecting the inverter as described in

Section 8 "Disconnecting the Inverter from Voltage Sources" (page58).

34 STP20TLHE-IA-IEN122222 Installation Manual

Page 35

SMA Solar Technology AG Electrical Connection

• If the inverter is not equipped with a DC switch-disconnector but this is mandatory in the country

of installation, install an external DC switch-disconnector.

• The following limit values at the DC input of the inverter must not be exceeded:

Maximum input voltage Maximum input current

1,000 V (DC) 36 A (DC)

No mixed connections between input areas

For instance, if the positive pole of a string is connected at input area A and the negative

pole of the same string is connected at input area B, this is called a mixed connection.

Only connect strings at 1 input area and never mix the input areas A and B!

Otherwise, the inverter no longer fulfills the requirements of the EMC Directive (Directive

on the electromagnetic compatibility of a device) and forfeits its operation licence.

Installation Manual STP20TLHE-IA-IEN122222 35

Page 36

Electrical Connection SMA Solar Technology AG

6.4.2 Assembling the DC Connectors

For connection to the inverter, all connection cables of the PV modules must be equipped with the DC

connectors provided.

To assemble the DC connectors, proceed as follows. Ensure the connectors have the correct polarity.

The DC connectors have the symbols "+" and "‒".

Cable requirements

• Use a PV1-F cable.

Procedure

1. Lead the stripped cable all the way into the plug.

2. Press the clamping bracket down.

☑ The clamping bracket snaps audibly into place.

36 STP20TLHE-IA-IEN122222 Installation Manual

Page 37

SMA Solar Technology AG Electrical Connection

+

3. Ensure that the cable is correctly positioned:

Result Measure

☑ If the stranded wire is visible in the chamber

• Proceed to Step 4.

of the clamping bracket, the cable is

correctly positioned.

☑ If the stranded wire is not visible in the

chamber, the cable is not correctly

positioned.

• Loosening the clamping bracket: insert a

screwdriver (blade width: 3.5 mm) into the

clamping bracket and lever it out.

• Remove the cable and go back to step 1.

4. Push the swivel nut up to the thread and tighten (torque: 2.0 Nm).

Installation Manual STP20TLHE-IA-IEN122222 37

Page 38

Electrical Connection SMA Solar Technology AG

6.4.3 Opening the DC Connector

1. Unscrew the swivel nut.

2. Unlocking the DC connector: insert a screwdriver

(blade width: 3.5 mm) into the snap slot on the side

and lever it out.

3. Carefully pull the DC connector apart.

4. Loosening the clamping bracket: insert a

screwdriver (blade width: 3.5 mm) into the

clamping bracket and lever it out.

5. Remove the cable.

38 STP20TLHE-IA-IEN122222 Installation Manual

Page 39

SMA Solar Technology AG Electrical Connection

6.4.4 Connecting the PV Array (DC)

DANGER!

Danger to life due to high voltages in the inverter

• Before connecting the PV array, ensure that the AC miniature circuit-breaker is

disconnected from all 3 line conductors and that it cannot be reconnected.

NOTICE!

Destruction of the inverter due to overvoltage

If the voltage of the PV modules exceeds the maximum input voltage of the inverter, it can

be destroyed by the overvoltage. This will void all warranty claims.

• Do not connect strings to the inverter that have an open-circuit voltage greater than

the maximum input voltage of the inverter.

• Check the plant design.

NOTICE!

Excessive voltages can destroy the measuring device

• Only use measuring devices with a DC input voltage range up to at least 1,000 V.

1. Check the connection cables of the PV modules for

correct polarity and make sure that the maximum

input voltage of the inverter is not exceeded.

At an ambient temperature over 10°C, the openci rcu it v olt age of t he P V mo dul es s hou ld n ot e xce ed

90% of the maximum input voltage of the inverter.

If this is not the case, review the plant design and

the PV module circuitry. Otherwise, the maximum

inverter input voltage may be exceeded at low

ambient temperatures.

2. Check the strings for earth faults as described in

Section 11.1 "Checking the PV Array for Earth

Faults" (page75).

Installation Manual STP20TLHE-IA-IEN122222 39

Page 40

Electrical Connection SMA Solar Technology AG

+

+

A1 A2 A3 B1 B2 B3

+

1

2

+

+

3. Check the assembled DC connectors for correct

polarity and connect them to the inverter.

☑ The DC connectors click audibly into position.

To release the DC connectors, see Section 12.1

"Dismantling the Inverter" (page81).

4. In order to seal the inverter, all unneeded DC inputs must be closed with DC connectors and

sealing plugs:

Sealing plugs

Do not insert the sealing plugs directly into the DC inputs on the inverter.

– For unused DC plug connectors, push down the

clamping bracket and push the swivel nut up to

the thread.

– Insert the sealing plug into the DC connector.

– Fasten the DC connector (torque: 2.0 Nm).

40 STP20TLHE-IA-IEN122222 Installation Manual

Page 41

SMA Solar Technology AG Electrical Connection

+

A1 A2 A3 B1 B2 B3

– Insert the DC connectors with sealing plugs into

the corresponding DC inputs on the inverter.

☑ The DC connectors click audibly into position.

5. Ensure that all DC connectors are securely in place.

☑ You can now commission the inverter as described in Section 7 "Commissioning" (page55).

The following connections and settings are optional.

Installation Manual STP20TLHE-IA-IEN122222 41

Page 42

Electrical Connection SMA Solar Technology AG

AB

E

1

2

ON

79

6.5 Setting the Country Data Set and Display Language

The inverter can be configured for various countries. This can be done prior to commissioning via

2 rotary switches on the display or after commissioning by configuring the "CntrySet" or "Set country

standard" parameter using a communication product (e.g. Sunny WebBox or Sunny Explorer).

For devices ordered without any specified country of installation, the default country setting is

"VDE-AR-N4105-HP" and the display language is set to German.

Both rotary switches are set to 0 upon delivery. If you have ordered the inverter with specific country

settings, they will have already been preset at the factory via a communication product. In this case,

you will not be able to recognise the current setting by the switch position.

If changes are made via the rotary switches or via a communication product, the default grid

parameters are overwritten. They cannot be restored, and must be re-entered via a communication

product.

The display language can be changed at any time using the rotary switches, independent of the grid

parameters. This means that the default grid parameters remain unchanged, but the display messages

are shown in the set language.

Changes will be accepted immediately after switching the miniature circuit-breaker on. If an

unprogrammed switch setting is selected, the inverter displays an error message. The last valid setting

is retained.

42 STP20TLHE-IA-IEN122222 Installation Manual

Page 43

SMA Solar Technology AG Electrical Connection

SMA Grid Guard-Protected Country Data Sets

In some countries, the local connection conditions demand a mechanism which prevents the

parameters for the feed-in from being changed. Therefore, certain country data sets are protected

against unauthorised changes. They can only be unlocked with a personal access code - the

SMA Grid Guard code.

SMA Grid Guard-protected country data sets are automatically blocked for 10 feed-in hours after

commissioning, or after the last alteration. If the country data set is changed after these 10 feed-in

hours, the inverter does not accept the changes and displays the error message "Grid param. locked".

If, however, a later change to the country data set only relates to a change of the display language

via the rotary switches in the inverter, this change is immediately applied.

It is also p ossible to conf igure country d ata sets (p aramet er "CntrySet" or "Set country standard"), and

to lock or unlock these manually via a communication product. To block a data set, enter the digit

sequence "54321" instead of the password into the SMA Grid Guard code field. The data set can

only be unlocked by entering a personal, 10-digit SMA Grid Guard code which is valid for a

maximum of 10 feed-in hours. The application form for the personal access code is available at

www.SMA.de/en, in the "Certificate" category of the respective inverter.

The language can be configured without a password, regardless of the country data set.

Changing parameters in SMA Grid Guard-protected country data sets

If the parameters within protected country data sets are changed, these are no longer

protected and instead of the standard, "ADJ" or "Special setting" is displayed. In this case,

a change to parameters is not locked automatically after 10 feed-in hours, but has to be

locked manually. To manually lock the parameters, set the SMA Grid Guard Code to

"54321".

Further information on parameter settings

For detailed information on making adjustments and changing parameters, see the

corresponding user manual for your communication product.

The last change (executed via rotary switch or communication product) is always verified and

activated if applicable. Consequently, the switch position may not necessarily show the actual country

configuration.

Installation Manual STP20TLHE-IA-IEN122222 43

Page 44

Electrical Connection SMA Solar Technology AG

6.5.1 Checking the Country Data Set

Make sure that the inverter is set to the installation country.

Before commissioning:

• Check that the country data set of the inverter is correct by using the supplementary sheet

provided and comparing this to the default settings of the inverter.

After commissioning:

• Check that the country data set is correct using the display message during (re-)commissioning

(see Section 7 "Commissioning" (page55)).

• Check that the country data set is correct by tapping the display twice and viewing the display

messages of the start-up phase again.

or

• Check that the country data set is correct using the "SMA grid guard" measurement channel via

an SMA communication product.

Display language

Once you have configured the country data set, you can always set the display language

later using rotary switch B. However, you have to then set rotary switch A to "0" in order to

keep the country data set.

The settings of each country data set are specified in the operating parameters. The parameters can

be read out using a communication product. The description of the operating parameters is available

at www.SMA.de/en in the category "Technical Description" of the respective inverter.

(A) (B) Country data set Display language

SMA Grid Guard

Country

protection

0 0 Default settings Default settings Dependent on

parameter set

0 1 Retained English Dependent on

parameter set

0 2 Retained German Dependent on

parameter set

0 3 Retained French Dependent on

parameter set

0 4 Retained Spanish Dependent on

parameter set

0 5 Retained Italian Dependent on

parameter set

0 6 Retained Greek Dependent on

parameter set

0 7 Retained Czech Dependent on

parameter set

44 STP20TLHE-IA-IEN122222 Installation Manual

Dependent on

parameter set

Dependent on

parameter set

Dependent on

parameter set

Dependent on

parameter set

Dependent on

parameter set

Dependent on

parameter set

Dependent on

parameter set

Dependent on

parameter set

Page 45

SMA Solar Technology AG Electrical Connection

(A) (B) Country data set Display language

SMA Grid Guard

Country

protection

0 8 Retained Korean Dependent on

parameter set

0 9 Retained Portuguese Dependent on

parameter set

0 A Retained Dutch Dependent on

parameter set

0 B Retained Slovenian Dependent on

parameter set

0 C Retained Bulgarian Dependent on

parameter set

0 D Retained Polish Dependent on

parameter set

Dependent on

parameter set

Dependent on

parameter set

Dependent on

parameter set

Dependent on

parameter set

Dependent on

parameter set

Dependent on

parameter set

1 0 VDE0126-1-1 German Yes Germany,

Switzerland

a)

1 6 VDE-AR-N4105-HP

German Yes Germany

1 8 VDE0126-1-1 French Yes Switzerland,

France

b)

1 9 VDE 0126-1-1/UTE

French Yes France

2 0 VDE0126-1-1 Italian Yes Switzerland

2 8 AS4777.3 English No Australia

3 2 CEI0-21Ext

c)*

Italian Yes Italy

4 0 RD1663-A Spanish Yes Spain

4 1 RD1663/661-A Spanish Yes Spain

4 8 PPC Greek No Greece

4 9 PPC English No Greece

5 1 KEMCO 502_2009 English No South Korea

5 2 KEMCO 502_2009 Korean No South Korea

5 A G59/2 English No England

Installation Manual STP20TLHE-IA-IEN122222 45

Page 46

Electrical Connection SMA Solar Technology AG

(A) (B) Country data set Display language

SMA Grid Guard

Country

protection

6 0 EN50438 German Yes Various EU

6 1 EN50438 English Yes

countries

6 2 EN50438 French Yes

6 3 EN50438 Italian Yes

6 4 EN50438 Spanish Yes

6 5 EN50438 Greek Yes

6 6 EN50438 Czech Yes

6 7 EN50438 Portuguese Yes

6 8 EN50438 Bulgarian Yes

6 9 EN50438 Polish Yes

7 4 PPDS Czech Yes Czech

Republic

7 5 PPDS English Yes Czech

Republic

76PPDS German Yes Czech

Republic

7 8 C10/11* French Yes Belgium

7 9 C10/11* English Yes Belgium

7 A C10/11* German Yes Belgium

A 0 MVtg-Directive German Yes Germany

A 1 MVtg-Directive English Yes Flexible

A2MVtg-Directive French Yes France

A 3 MVtg-Directive Spanish Yes Spain

A 4 MVtg-Directive Czech Yes Czech

Republic

A C SI 4777* English Yes Israel

B 0 MVtg-Directive int German Yes Germany

B 1 MVtg-Directive int English Yes Flexible

B2MVtg-Directive int French Yes France

B 3 MVtg-Directive int Spanish Yes Spain

B 4 MVtg-Directive int Czech Yes Czech

Republic

B 8 IEC61727/MEA English No Thailand

B C IEC61727/PEA English No Thailand

C0Customer English No Flexible

C 1 Customer German No Flexible

C 2 Customer French No Flexible

46 STP20TLHE-IA-IEN122222 Installation Manual

Page 47

SMA Solar Technology AG Electrical Connection

(A) (B) Country data set Display language

SMA Grid Guard

Country

protection

C 3 Customer Spanish No Flexible

C 4 Customer Italian No Flexible

C 5 Customer Greek No Flexible

C 6 Customer Czech No Flexible

D 0 Off-Grid60* English No Flexible

D 1 Off-Grid60* German No Flexible

D 2 Off-Grid60* French No Flexible

D 3 Off-Grid60* Spanish No Flexible

D 4 Off-Grid60* Italian No Flexible

D 5 Off-Grid60* Greek No Flexible

D 6 Off-Grid60* Czech No Flexible

E 0 Off-Grid50* English No Flexible

E 1 Off-Grid50* German No Flexible

E 2 Off-Grid50* French No Flexible

E 3 Off-Grid50* Spanish No Flexible

E 4 Off-Grid50* Italian No Flexible

E 5 Off-Grid50* Greek No Flexible

E 6 Off-Grid50* Czech No Flexible

F0SD-Card SD-Card No Flexible

a) Setting in accordance with VDE- AR-N-4105 for PV plants > 13.8 kVA (Germany)

b) Special setting: Bluetooth transmission power reduced (in accordance with French standards)

c) Setting according to CEI 0-21 for PV plants with external grid and plant protection > 6 kVA (Italy)

*Planned

If the inverter is not set to the installation country, there are several ways of configuring the required

country data set:

• Setting via 2 rotary switches, as described in Section 6.5.3 "Setting the country data set and

language using rotary switches" (page49).

• Alternatively you can conduct the settings via the "CntrySet" or "Set country standard"

parameters with a communication product, once you have commissioned the inverter.

•If you require adjusted parameter settings for your installation site, you can change these with

the help of a communication product.

Installation Manual STP20TLHE-IA-IEN122222 47

Page 48

Electrical Connection SMA Solar Technology AG

6.5.2 Extension of the Deactivation Limits

The deactivation criteria (voltage, frequency) are specified via country parameters.

The inverters have the additional country data set "MVtgDirective/Medium-Voltage Directive

(Germany)". This parameter expands the deactivation limits of the inverter for voltage and frequency

to a maximum/minimum. This country setting may only be selected if the plant or the inverter is

operated with external three-phase decoupling protection, which will automatically disconnect the

inverter from the electricity grid if non-permissible voltage and frequency values occur.

Device protection is still guaranteed.

DANGER!

Electric shock due to missing external decoupling protection.

If you set the country data set "MVtgDirective/Medium-Voltage Directive (Germany)", you

may only operate the inverter with external 3-phase decoupling protection. Without

external three-phase decoupling protection, the inverter will not disconnect from the

electricity grid when the standard requirement is exceeded.

• Install external 3-phase decoupling protection.

48 STP20TLHE-IA-IEN122222 Installation Manual

Page 49

SMA Solar Technology AG Electrical Connection

E

7

9

O

N

E

7

9

O

N

7

9

ON

E

6.5.3 Setting the country data set and language using rotary switches

1. Disconnect the inverter (see Section 8 "Disconnecting the Inverter from Voltage Sources"

(page58)).

DANGER!

Danger to life due to high voltages in the event of electricity grid failure

If you set the inverter to "Off-Grid50/Island mode 50 Hz" or "Off-Grid60/Island mode

60 Hz" , you may no t operate t he inverter on t he ele ctricity grid, but only on the stand-al one

grid, because the inverter does not then satisfy any country-specific standards or directives.

If there is an electricity grid failure, this prevents danger of backfeed.

• If the inverter is set to "Off-Grid50/Island mode 50 Hz" or "Off-Grid60/Island mode

60 Hz", never operate the inverter directly on the electricity grid.

2. Set the rotary switches A and B with a screwdriver

(blade width: 2.5 mm) to the desired position

(see table in Section 6.5.1 "Checking the Country

Data Set" (page44)).

Temporarily setting the display language

to English

• To set the display language to English,

push the left switch 1 up until it locks into

pl ace. Us e an obj ect with a s mall ti p, e.g.

a ballpoint pen to do this.

• To reset the display language back to

the original language, push the left

switch 1 down until it locks into place.

Use an object with a small tip, e.g. a

ballpoint pen to do this.

3. Commission the inverter (see Section 7 "Commissioning" (page55)).

Installation Manual STP20TLHE-IA-IEN122222 49

Page 50

Electrical Connection SMA Solar Technology AG

E

7

9

O

N

6.6 Communication

6.6.1 Bluetooth

Communication via Bluetooth with a communication product is activated as standard. Networking

with other inverters via Bluetooth is deactivated by default.

The following setting options are possible via a rotary switch.

Switch position

Setting

(NetID)

0 Bluetooth communication is deactivated.

1Communication via Bluetooth with communication product possible, no

networking with other inverters (default settings)

2…F Networking via Bluetooth with other inverters is activated.

If you do not communicate using Bluetooth, deactivate the Bluetooth communication on your inverter.

This protects your PV plant from unauthorised access.

In order to restrict communication via Bluetooth between the inverters of your PV plant and those of

neighbouring systems, you can assign an individual NetID to the inverters of your PV plant (switch

position 2 … F). However, this is only necessary if neighbouring plants are located within a radius of

500 m.

So that all inverters in your PV plant are detected by your communication product, all inverters must

have the same NetID.

1. Determine a free NetID using Sunny Explorer (see Sunny Explorer user manual).

2. Disconnect the inverter (see Section 8 "Disconnecting the Inverter from Voltage Sources"

(page58)).

3. Set the arrow on the right-hand rotary switch C to

the required position using a screwdriver

(blade width: 2.5 mm).

4. Commission the inverter (see Section 7 "Commissioning" (page55)).

Acceptance of settings

The Bluetooth settings will only be accepted upon commissioning the inverter.

50 STP20TLHE-IA-IEN122222 Installation Manual

Page 51

SMA Solar Technology AG Electrical Connection

6.6.2 Multi-Function Interface

The inverter is equipped with a slot for multi-function interfaces. This slot is designed to connect a

simple multi-function relay or an SMA Power Control Module. The interface can either be retrofitted,

installed at the factory according to a specific order, or included in the regular scope of delivery.

Multi-Function Relay

You can configure the multi-function relay for various operating modes. The multi-function relay is

us ed, for exa mpl e, t o switch fau lt i ndi cat ors on o r of f (f or i nformation on installation and configuration,

see installation manual of the multi-function relay).

SMA Power Control Module

The SMA Power Control Module enables the inverter to implement grid management services and is

equipped with an additional multi-function relay (for information on installation and configuration,

see installation manual of the SMA Power Control Module).

6.6.3 Communication Interface

The inverter can optionally be fitted with an extra communication interface (e.g., RS485). This

communication interface enables the inverter to communicate with special SMA communication

products or other inverters (for information on supported products, see www.SMA.de/en).

The interface can either be retrofitted, installed at the factory acco rdi ng t o a s pec ifi c order, or i ncl ude d

in the regular scope of delivery.

You can only set the operating parameters of the inverter via SMA communication products. You can

set the country data set of the inverter via the two rotary switches in the inverter only prior to

commissioning or within the first ten operating hours.

Display of parameters

Depending on the type of communication, RS485 or Bluetooth, the parameters and

messages are displayed differently on the communication products.

Example of how the country data set parameter is displayed:

• For communication with RS485: "CntrySet" parameter

•If you are using Bluetooth: parameter "Set country standard"

Installation Manual STP20TLHE-IA-IEN122222 51

Page 52

Electrical Connection SMA Solar Technology AG

6.7 Activating and Deactivating the Reverse Current Protection at Input Area A

The reverse current protection is activated upon delivery. If you are using both in put areas, the r everse

current protection must be activated at both input areas.

If you are using only input area A, you can deactivate the reverse current protection at input area A,

which will slightly increase the inverter efficiency.

The reverse current protection at input area B cannot be deactivated.

The procedure for deactivating and reactivating the reverse current protection at input area A is

described below.

Requirements for deactivating the reverse current protection:

• Input area B must not be used.

• The reverse current resistance of the PV modules must be complied with.

Procedure

1. When the inverter is in operation, disconnect the inverter (see Section 8 "Disconnecting the

Inverter from Voltage Sources" (page58)).

2. Loosen the screws of the upper enclosure lid.

For this purpose, use an Allen key (AF 4).

3. Pull the upper enclosure lid forwards to remove it.

Jumper cable

Use only the supplied jumper cable to deactivate the reverse current protection.

4. Deactivating or activating the reverse current protection at input area A:

– To deactivate the reverse current protection,

insert both ends of the jumper cable into the

yellow terminals as far as they will go. Do not

kink the cable.

52 STP20TLHE-IA-IEN122222 Installation Manual

Page 53

SMA Solar Technology AG Electrical Connection

– To activate the reverse current protection,

remove both ends of the jumper cable from the

yellow terminals consecutively. To do so, insert

a screwdriver (blade width: 3.5 mm) into the

rectangular opening on the terminal and

remove the cable end.

5. For STP 15000TLHE-10 / STP 20000TLHE-10:

Make sure that all 4 EMC seals are present in the

upper enclosure lid and that they are correctly

positioned. The metal braiding of the EMC seals

must point outwards.

EMC seals

EMC seals are only installed in inverters of type STP 15000TLHE-10 / STP 20000TLHE-10.

Without EMC seals, the STP 15000TLHE-10 / STP 20000TLHE-10 no longer fulfil the

requirements of the EMC Directive (Directive on the electromagnetic compatibility of a

device) and forfeit their operating licence.

• Contact the SMA Service Line if one or more EMC seals is missing.

6. Pr e-sc rew all scr ews and t he c orr esp ondi ng c oni cal

sprin g washers for th e upper enc losure lid and then

tighten them in the sequence shown on the right

(torque: 6.0 Nm). The toothing of the conical spring

washers must point towards the enclosure lid.

The scope of delivery of the inverter includes a

spare screw and conical spring washer.

Installation Manual STP20TLHE-IA-IEN122222 53

Page 54

Electrical Connection SMA Solar Technology AG

DANGER!

Danger to life due to live enclosure lid

The earthing of the upper enclosure lid is ensured by the toothed conical spring washers.

• For all 6 screws attach the conical spring washers with the toothing facing towards

the enclosure lid.

54 STP20TLHE-IA-IEN122222 Installation Manual

Page 55

SMA Solar Technology AG Commissioning

7 Commissioning

7.1 Commissioning the Inverter

1. The following conditions must be fulfilled before commissioning:

– Correct mounting (see Section 5)

– Correct country setting (see Section 6.5).

– AC cable correctly connected (see Section 6.3)

– DC cable correctly connected (PV strings) (see Section 6.4)

– Unused DC inputs are closed using the cor res pon din g DC pl ug c onnectors and sealing plugs

(see Section 6.4.4)

– All enclosure openings are closed.

– The miniature circuit-breaker is of the correct size.

2. Dock the lower enclosure lid at an angle and

attach. The captive screws must protrude.

3. Pre-screw all six screws and then tighten them in the

sequence shown on the right (torque: 2.0 Nm).

For this purpose, use an Allen key (AF 3).

4. If an external DC switch-disconnector is installed, switch it off.

Installation Manual STP20TLHE-IA-IEN122222 55

Page 56

Commissioning SMA Solar Technology AG

5. If the inverter is equipped with an integrated DC switch-disconnector, plug the handle in and

switch it on.

– Set the handle of the DC switch-disconnector to

position "0" so that the captive screws are visible

in the handle.

– Align the handle of the DC switch-disconnector

in such a way that the sharp side of the handle

points to the left.

– Insert the handle of the DC switch-disconnector

in the socket on the bottom of the i nverter. T o do

this, the switch position "0" must be visible from

the front.

– Secure the handle of the DC switch-

disconnector with the 2 captive screws

(torque: 2 Nm). For this purpose, use an

Allen key (AF 3).

– Switch on the DC switch-disconnector.

6. Switch on the miniature circuit-breaker.

☑ Green LED is lit: commissioning was successful.

or

☑ Green LED flashes if irradiation is insufficient: grid connection conditions have not yet been

reached. Wait for sufficient irradiation.

or

☑ Red LED is lit: a disturbance has occurred. Eliminate the error (see Section 11

"Troubleshooting" (page75)).

7. If a multi-function relay is connected, switch on the supply voltage.

8. For communication via Bluetooth, make the following settings:

– Change the plant time (see the manual of the communication product).

– Change the passwords (see the manual of the communication product).

56 STP20TLHE-IA-IEN122222 Installation Manual

Page 57

SMA Solar Technology AG Commissioning

FW PACK XXXX HP XXXX

SN 2100237148 NetIDA

Sprache Deutsch

7.2 Display Messages during the Start Phase

Illustrated display messages

The display messages illustrated in this section serve as examples and, depending on the

country setting, may differ from the display messages on your inverter.

• Firstly, the firmware version of the internal

processors appears in the text line.

• After an interval of 5 seconds, or after tapping on

the enclosure lid, the serial number or designation

of the inverter and the NetID for communication via

Bluetooth will appear. The designation of the

inverter can be changed with a communication

product.

• After another 5 seconds, or by tapping the lid

again, the selected country data set will appear

(e.g. "VDE-AR-N4105-HP").

• After a further 5 seconds, or after a further tap,

the configured language is displayed

(example: "Sprache Deutsch" (Language German).

• During normal operation, the text line of the display will subsequently be clear. See Section 10

"Messages" (page66) for possible event messages which may be displayed in the text line and

their meaning.

Showing display messages again

If you want to view the display messages of the start phase again whilst in normal

operation, double-tap the display.

Installation Manual STP20TLHE-IA-IEN122222 57

Page 58

Disconnecting the Inverter from Voltage Sources SMA Solar Technology AG

8 Disconnecting the Inverter from Voltage Sources

DANGER!

Danger to life due to high voltages in the inverter

Death due to electric shock

The inverter operates at high voltages and must be disconnected prior to carrying out any

work on the device. In addition, if the DC connectors are pulled out without first switching

off the DC switch-disconnector, a dangerous electric arc can occur.

• Disconnect the inverter as described in this section.

CAUTION!

Risk of burns due to hot DC lid

During operation, the DC lid on the left-hand side of the connection area can become hot.

• Take care not to touch the DC lid when working in the connection area.

NOTICE!

Electrostatic discharge can damage the inverter

Internal components of the inverter can be irreparably damaged by electrostatic

discharge.

• Earth yourself before touching any components.

1. Disconnect the miniature circuit-breaker from all three line conductors and secure against

reconnection.

2. If a multi-function relay is connected, disconnect its supply voltage and ensure that the device

cannot be reconnected.

3. If an integrated or external DC switch-disconnector is connected, switch it off.

4. Wait until the LEDs, display and, if applicable, fault indicator have gone out.

5. If a DC switch-disconnector is installed, pull the

handle out. For this purpose, use an Allen key

(AF 3).

58 STP20TLHE-IA-IEN122222 Installation Manual

Page 59

SMA Solar Technology AG Disconnecting the Inverter from Voltage Sources

6. Loosen all six captive screws of the enclosure lid.

7. Lift and remove the enclosure lid from below.

8. Ensure that L1, L2 and L3 are disconnected from

voltage sources to N. For this purpose, use a test

probe with a maximum diameter of 2 mm.

Installation Manual STP20TLHE-IA-IEN122222 59

Page 60

Disconnecting the Inverter from Voltage Sources SMA Solar Technology AG

PE

9. Ensure that L1, L2 and L3 are disconnected from

voltage sources to PE.