SMA SSM-U-1610, SSM-U-2410, SSM-U-2415, SSM-U-3210, SSM-U-3215 Operating Manual

Operating Manual

SMASTRING-MONITOR

SSM-U-1610 / SSM-U-2410 / SSM-U-3210

SSM-U-1615 / SSM-U-2415 / SSM-U-3215

SSMUXX1015-BE-en-14 | Version 1.4

ENGLISH

Legal Provisions

The information contained in these documents is property of SMA Solar Technology AG. Any

publication, whether in whole or in part, requires prior written approval by SMA Solar Technology

AG. Internal reproduction used solely for the purpose of product evaluation or other proper use is

allowed and does not require prior approval.

SMA Warranty

You can download the current warranty conditions from the Internet at www.SMA-Solar.com.

Trademarks

All trademarks are recognized, even if not explicitly identified as such. Missing designations do not

mean that a product or brand is not a registered trademark.

Modbus® is a registered trademark of SchneiderElectric and is licensed by the

ModbusOrganization,Inc.

QRCode is a registered trademark of DENSOWAVEINCORPORATED.

Phillips® and Pozidriv® are registered trademarks of PhillipsScrewCompany.

Torx® is a registered trademark of AcumentGlobalTechnologies,Inc.

SMA Solar Technology AG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

Email: info@SMA.de

Copyright © 2016 SMA Solar Technology AG. All rights reserved.

Legal Provisions

SMA Solar Technology AG

Operating ManualSSMUXX1015-BE-en-142

Table of Contents

1 Information on this Document................................................. 6

1.1 Validity ............................................................................................... 6

1.2 Target Group ..................................................................................... 6

1.3 Additional Information....................................................................... 6

1.4 Symbols.............................................................................................. 6

1.5 Typographies..................................................................................... 7

1.6 Nomenclature.................................................................................... 7

2 Safety ........................................................................................ 8

2.1 Intended Use...................................................................................... 8

2.2 Safety Information ............................................................................. 9

2.3 Personal Protective Equipment.......................................................... 11

3 Scope of Delivery ..................................................................... 12

4 Product Overview .................................................................... 13

4.1 SMA String-Monitor .......................................................................... 13

4.2 External View of the DC Subdistribution .......................................... 14

4.3 Components of the DC Subdistribution............................................ 15

4.4 Terminals on the Electronic Assembly............................................... 17

4.5 Type Label.......................................................................................... 18

4.6 Symbols on the Product..................................................................... 19

4.7 LEDs on the Electronic Assembly ...................................................... 20

5 Mounting................................................................................... 21

5.1 Selecting the Mounting Location ...................................................... 21

5.2 Mounting the SMA String-Monitor on the Wall .............................. 23

6 Installation ................................................................................ 25

6.1 Overview of the Connection Area of the SMA String-Monitor ...... 25

6.2 Grounding ......................................................................................... 27

6.2.1 Information on Grounding ............................................................ 27

6.2.2 Grounding the Electronic Assembly ............................................. 27

6.2.3 Grounding the DC Surge Arrester................................................ 27

6.3 Installation of the DC Main Cables.................................................. 28

Table of Contents

SMA Solar Technology AG

Operating Manual 3SSMUXX1015-BE-en-14

6.3.1 Safety during Installation of the DC Main Cables....................... 28

6.3.2 Options for Installation of the DC Main Cables.......................... 29

6.3.3 Connecting the DC Main Cables to the Busbar using Terminal

Lugs................................................................................................. 29

6.3.4 Connecting the DC Main Cables to the Busbar using V Box

Terminals ........................................................................................ 32

6.3.4.1 Requirements and Conditions ................................................ 32

6.3.4.2 Installing the Box Terminal on the Busbar ............................. 33

6.3.4.3 Connecting Copper Cables to V-Box Terminal..................... 34

6.3.4.4 Connecting Aluminum Cables to V Box Terminal................. 35

6.4 Connecting the Ethernet Cables ....................................................... 36

6.5 Connection of Sensors ...................................................................... 38

6.5.1 Connecting Temperature Sensors................................................. 38

6.5.2 Connecting an Irradiation Sensor or Anemometer to the

Analog Input .................................................................................. 39

6.6 Connecting the Remote Terminal to the Digital Input...................... 41

6.7 Connecting the Remote Terminal to the Digital Output................... 41

6.8 Installation of the String Cables........................................................ 42

6.8.1 Requirements for Installation of the String Cables....................... 42

6.8.2 Installing the String Cables ........................................................... 43

7 Commissioning the DC Subdistribution .................................. 46

8 Disconnecting and Reconnecting ............................................ 47

8.1 Safety When Disconnecting and Reconnecting Voltage Sources.. 47

8.2 Disconnecting the DC Subdistribution.............................................. 48

8.3 Switching the DC Subdistribution Back On ..................................... 49

9 Troubleshooting........................................................................ 50

9.1 LED States........................................................................................... 50

9.1.1 Status LEDs of the SMA String-Monitor........................................ 50

9.1.2 LEDs of the Network Connection.................................................. 51

9.2 Performing an Update....................................................................... 52

10 Maintenance ............................................................................. 53

10.1 Safety during Maintenance .............................................................. 53

10.2 Maintenance Schedule and Consumables...................................... 54

Table of Contents

SMA Solar Technology AG

Operating ManualSSMUXX1015-BE-en-144

10.2.1 Notes on Maintenance Work....................................................... 54

10.2.2 Maintenance Work Every 24 Months ......................................... 54

10.3 Maintenance Work........................................................................... 55

10.3.1 Checking the DC Load-Break Switch............................................ 55

10.3.2 Checking the Protective Covers .................................................... 56

10.3.3 Performing the Visual Inspection................................................... 56

10.3.4 Checking the Condensate Drain................................................... 57

10.3.5 Checking the Vent Plug ................................................................. 57

10.3.6 Checking the Seals ........................................................................ 57

10.3.7 Checking the Labels ...................................................................... 58

10.3.8 Checking the LEDs ......................................................................... 59

10.3.9 Checking the Bolted, Clamp and Plug Connections ................... 59

10.3.10 Checking the Inline Fuse Connectors ........................................... 60

10.3.11 Checking the Ground Connection................................................ 60

10.4 Completing Maintenance Work....................................................... 60

11 Decommissioning ..................................................................... 61

11.1 Decommissioning the DC Subdistribution ........................................ 61

11.2 Disassembling the DC Subdistribution from the Wall...................... 61

11.3 Packing the DC Subdistribution ........................................................ 62

11.4 Storing the DC Subdistribution.......................................................... 62

11.5 Disposing of the DC Subdistribution................................................. 62

12 Periodic Actions ........................................................................ 63

12.1 Insert the cable into the inverter........................................................ 63

12.1.1 Leading Cables through Enclosure Opening with Membrane ... 63

12.1.2 Leading Cables through Enclosure Opening with Cable Gland 63

12.2 Disassembling and Mounting the Protective Covers....................... 64

13 Technical Data .......................................................................... 66

14 Accessories ............................................................................... 73

15 Contact ...................................................................................... 75

Table of Contents

SMA Solar Technology AG

Operating Manual 5SSMUXX1015-BE-en-14

1 Information on this Document

1.1 Validity

This document is valid for the SMAString-Monitor of the following device types from production

version A1:

• SSM-U-1610

• SSM-U-2410

• SSM-U-3210

• SSM-U-1615

• SSM-U-2415

• SSM-U-3215

Figures in this document are examples and identical with the device types SSM‑U‑1615/

SSM‑U‑2415/ SSM‑U‑3215.

1.2 Target Group

The tasks described in this document must only be performed by qualified persons. Qualified

persons must have the following skills:

• Knowledge of how the product works and is operated

• Training in how to deal with the dangers and risks associated with installing and using

electrical devices and systems

• Training in the installation and commissioning of electrical devices and systems

• Knowledge of all applicable standards and directives

• Knowledge of and adherence to this manual and all safety precautions

1.3 Additional Information

Links to additional information can be found at www.SMA-Solar.com.

1.4 Symbols

Symbol Explanation

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury

Indicates a hazardous situation which, if not avoided, can result in

death or serious injury

Indicates a hazardous situation which, if not avoided, can result in

minor or moderate injury

Indicates a situation which, if not avoided, can result in property

damage

1 Information on this Document

SMA Solar Technology AG

Operating ManualSSMUXX1015-BE-en-146

Symbol Explanation

Information that is important for a specific topic or goal, but is not

safety-relevant

Indicates a requirement for meeting a specific goal

Desired result

A problem that might occur

1.5 Typographies

Typographies Use Example

bold

• Display messages

• Elements on a user

interface

• Terminals

• Slots

• Elements to be selected

• Elements to be entered

• Set parameter WGra to

0.2.

>

• Connects several

elements to be selected

• Select PV system >

Detect.

[Button/Key]

• Button or key to be

selected or pressed

• Select [Start detection].

1.6 Nomenclature

In this document, the SMAString‑Monitor is also referred to as "DC subdistribution" or "product".

1 Information on this Document

SMA Solar Technology AG

Operating Manual 7SSMUXX1015-BE-en-14

2 Safety

2.1 Intended Use

The SMAString‑Monitor is a PV array junction box to which several strings can be connected in

parallel. The SMAString-Monitor monitors the input currents of the strings and detects failures, thus

helping to minimize power and yield losses.

The SMAString‑Monitor can be operated in large-scale PV power plants with central inverters from

SMA Solar Technology AG or other PV inverters.

The maximum current values for the SMAString-Monitor must not be exceeded.

The SMAString-Monitor should only be operated when the strings are fuse protected. SMA Solar

Technology AG guarantees safe operation of the SMAString-Monitor with inline fuse connectors as

string fuses, providing that the inline fuse connectors are connected directly to the DC connectors of

the string cables on the DC subdistribution. For any other type or location of the string fusing, SMA

Solar Technology AG cannot guarantee safe operation of the SMAString-Monitor or compliance

with the required thresholds. The inline fuse connectors are available as accessories.

The product is suitable for indoor and outdoor use.

All work on the product must only be performed using appropriate tools and in compliance with the

ESD protection regulations.

The installation of SMA accessories in the product is permissible without specific approval by SMA

Solar Technology AG, providing that the product supports the given SMA accessories (see

Section14, page73).

The product must only be used in countries for which it is approved or released by SMA Solar

Technology AG and the grid operator.

Use this product only in accordance with the information provided in the enclosed documentation

and with the locally applicable standards and directives. Any other application may cause

personal injury or property damage.

Alterations to the product, e.g. changes or modifications, are only permitted with the express written

permission of SMA Solar Technology AG. Unauthorized alterations will void guarantee and

warranty claims and in most cases terminate the operating license. SMA Solar Technology AG

shall not be held liable for any damage caused by such changes.

Any use of the product other than that described in the Intended Use section does not qualify as the

intended use.

The enclosed documentation is an integral part of this product. Keep the documentation in a

convenient place for future reference and observe all instructions contained therein.

The type label must remain permanently attached to the product.

2 Safety

SMA Solar Technology AG

Operating ManualSSMUXX1015-BE-en-148

2.2 Safety Information

This section contains safety information that must be observed at all times when working on or with

the product. To prevent personal injury and property damage and to ensure long-term operation of

the product, read this section carefully and observe all safety information at all times.

Danger to life from electric shock due to live voltage

High voltages are present in the live components of the product. Touching live components results

in death or serious injury due to electric shock.

• Wear suitable personal protective equipment for all work on the product.

• Do not touch any live components.

• Unless live voltage is absolutely necessary, always disconnect the product from voltage

sources before performing any work (see Section8 "Disconnecting and Reconnecting",

page47).

Danger to life from electric shock due to live DC cables

DC cables connected to PV modules that are exposed to sunlight are energized. Touching live

cables results in death or serious injury due to electric shock.

• Prior to assembling the DC cables, ensure that the DC cables are voltage-free.

• Wear suitable personal protective equipment for all work on the product.

Danger to life from electric shock due to damaged product

Operating a damaged product can lead to hazardous situations that result in death or serious

injuries due to electric shock.

• Only operate the product when it is in a flawless technical condition and safe to operate.

• Check the product regularly for visible damage.

• Make sure that all external safety equipment is freely accessible at all times.

• Make sure that all safety equipment is in good working order.

• Wear suitable personal protective equipment for all work on the product.

2 Safety

SMA Solar Technology AG

Operating Manual 9SSMUXX1015-BE-en-14

Danger to life from electric shock if the product is not locked

If the product is not locked, unauthorized persons will have access to live components carrying

lethal voltages. Touching live components can result in death or serious injury due to electric

shock.

• Always close and lock the product.

• Remove the keys.

• Store the keys in a safe place.

• Ensure that no unauthorized persons have access to the closed electrical operating area.

Danger to life from electric shock if the DC load-break switch is damaged

Switching the DC load-break switch at temperatures belowthe specified threshold may damage

the DC load-break switch. The threshold is: ‒25°C. In this case, reliable disconnection can no

longer be guaranteed.

If the DC load-break switch is switched in spite of visible damage, again the reliable

disconnection function cannot be guaranteed.

High voltages are present in components that are not properly disconnected. Touching live

components can result in death or serious injury due to electric shock.

• Do not switch the DC load-break switch at temperatures below the specified threshold. The

threshold is: ‒25°C.

• Do not switch the DC load-break switch if it is visibly damaged.

Damage to the PV system due to incorrectly rated fuses

If fuses are incorrectly rated, excessive reverse currents can destroy the PV modules.

• Observe the maximum current values for the product when rating the fuses.

2 Safety

SMA Solar Technology AG

Operating ManualSSMUXX1015-BE-en-1410

Property damage due to dust intrusion and moisture penetration

Dust or moisture intrusion can damage the product and impair its functionality.

• Do not open the enclosure during rainfall or when humidity exceeds the specified threshold.

The threshold for humidity is: 95 %.

• Only perform maintenance work when the environment is dry and free of dust.

• Operation of the product is only permitted when it is closed.

• If the installation or commissioning process is interrupted, mount all panels.

• Close and lock the enclosure.

• The product must always be closed for storage.

• Store the product in a dry and covered location.

• Temperature at the storage location must be in the specified range. The temperature range

is: ‒40°C to +70°C.

Damage to electronic components due to electrostatic discharge

Electrostatic discharge can damage or destroy electronic components.

• Observe the ESD safety regulations when working on the product.

• Wear suitable personal protective equipment for all work on the product.

• Discharge electrostatic charge by touching grounded elements. Only then is it safe to touch

electronic components.

2.3 Personal Protective Equipment

Always wear suitable protective equipment

When working on the product, always wear the appropriate personal protective equipment

for the specific job.

The following personal protective equipment is regarded to be the minimum requirement:

☐ In a dry environment, safety shoes of categoryS3 with perforation-proof soles and steel toe

caps

☐ During precipitation or on moist ground, safety boots of categoryS5 with perforation-proof

soles and steel toe caps

☐ Tight-fitting work clothes made of 100%cotton

☐ Suitable work pants

☐ Individually fitted hearing protection

☐ Safety gloves

Any other prescribed protective equipment must also be used.

2 Safety

SMA Solar Technology AG

Operating Manual 11SSMUXX1015-BE-en-14

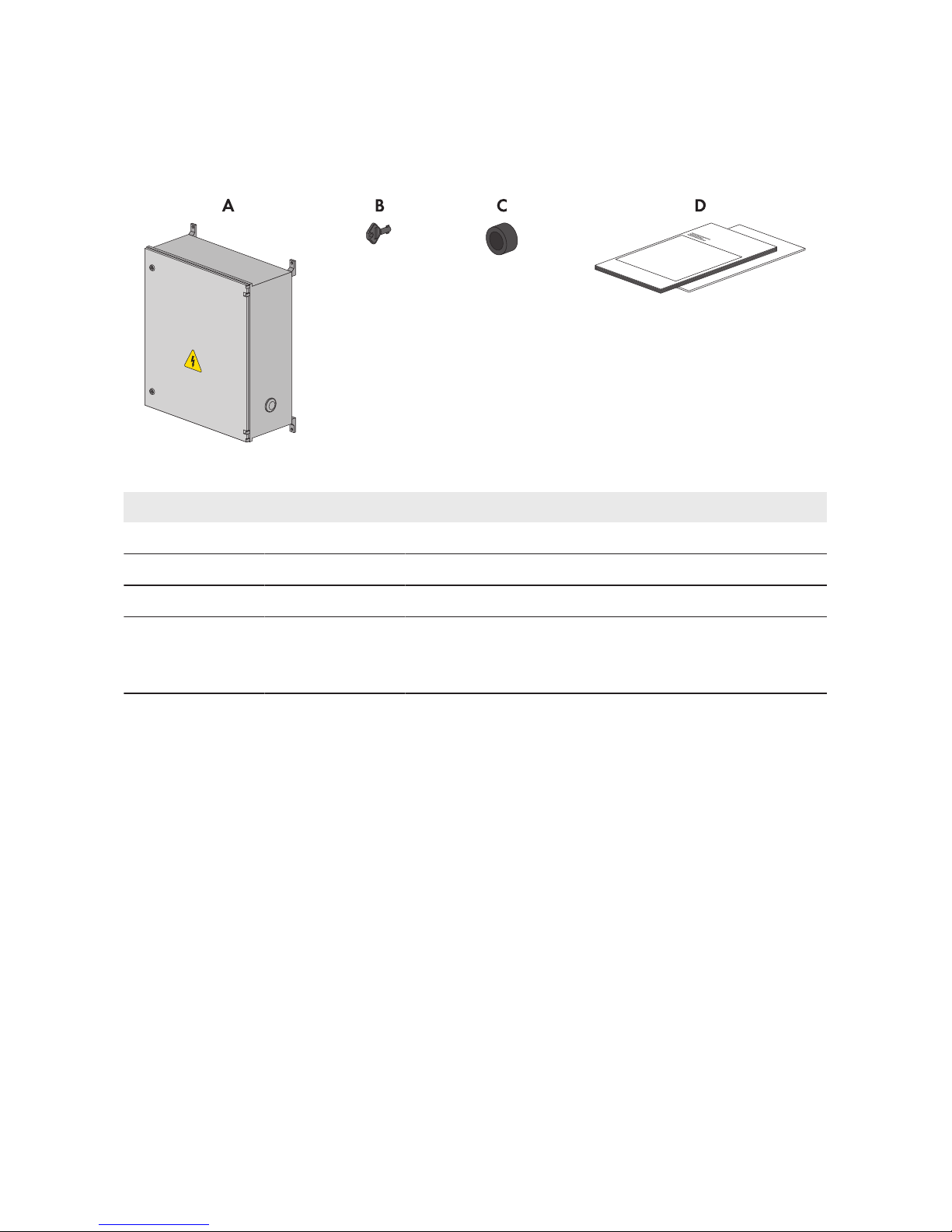

3 Scope of Delivery

Check the scope of delivery for completeness and any externally visible damage. Contact your

distributor if the scope of delivery is incomplete or damaged.

Figure 1: Components included in the scope of delivery

Position Quantity Designation

A 1 SMAString-Monitor

B 1 Switch cabinet key

C 4 Size-reducing seal inserts

D 1 Operating manual, circuit diagram, installation manual for

inline fuse connector and installation manual for PV connector

3 Scope of Delivery

SMA Solar Technology AG

Operating ManualSSMUXX1015-BE-en-1412

4 Product Overview

4.1 SMAString-Monitor

The SMAString‑Monitor is a PV array junction box to which several strings can be connected in

parallel. The SMAString‑Monitor can be operated in large-scale PV power plants with central

inverters from SMA Solar Technology AG or other PV inverters.

The essential tasks performed by the SMAString-Monitor are:

• to bundle the input currents of the strings

• Measuring of the input currents of the strings and transfer to the inverter

• to transmit information on the input currents of the strings

This enables failures to be recognized and power and yield losses to be minimized.

A distinction is made for the following SMA String-Monitor types:

Device types for rated voltage 1,000V

DC

Device types for rated voltage 1,500V

DC

Number of string inputs per

potential

SSM-U-1610 SSM-U-1615 16

SSM-U-2410 SSM-U-2415 24

SSM-U-3210 SSM-U-2415 32

Principle of a grid-tie PV system with SMAString-Monitor

Figure 2: Principle of a grid-tie PV system with SMAString-Monitor

Position Designation

A PV array

B SMAString-Monitor

C Sunny Central

D Transformer

E Utility grid

4 Product Overview

SMA Solar Technology AG

Operating Manual 13SSMUXX1015-BE-en-14

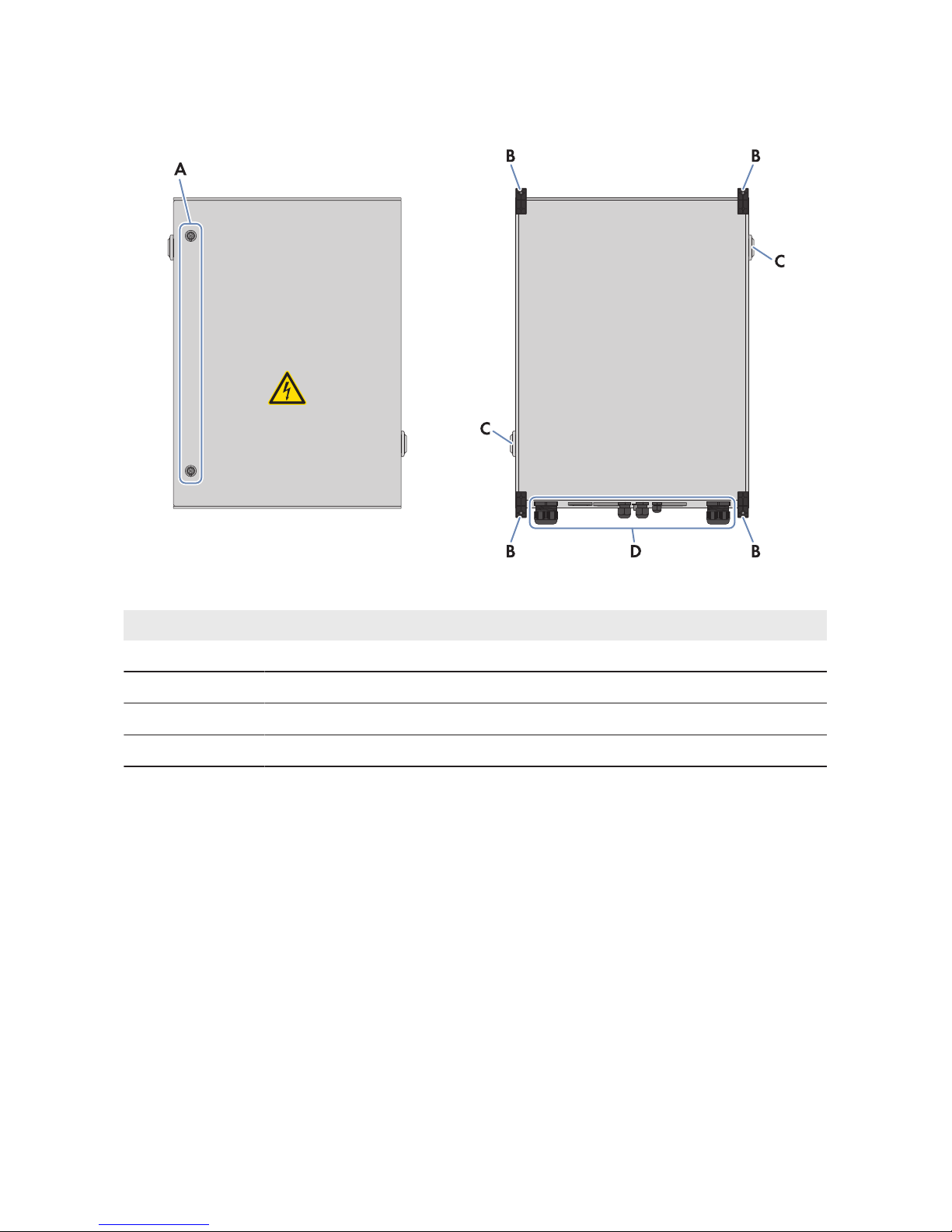

4.2 External View of the DC Subdistribution

Figure 3: External view of the DC subdistribution

Position Designation

A Lock cylinder

B Wall bracket lugs

C Vent plug

D Enclosure openings for introducing the cables

4 Product Overview

SMA Solar Technology AG

Operating ManualSSMUXX1015-BE-en-1414

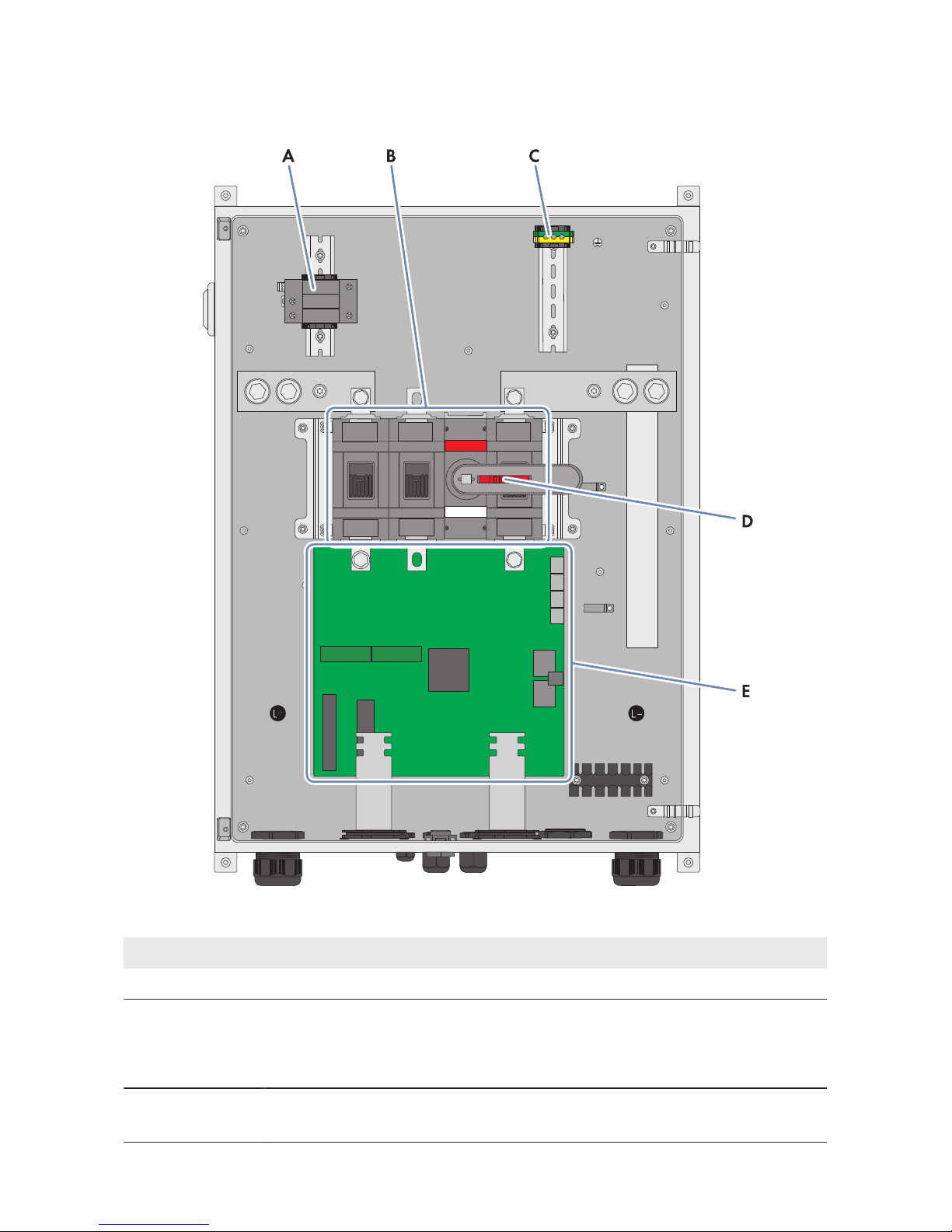

4.3 Components of the DC Subdistribution

Figure 4: Components of the DC subdistribution (SSM-U-1615 / SSM-U-2415 / SSM-U-3215)

Position Designation

A DC overvoltage protection

B DC load-break switch

• 2-pole at SSM-U-1610 / SSM-U-2410 / SSM-U-3210

• 3-pole at bei SSM-U-1615 / SSM-U-2415 / SSM-U-3215

C Terminal for connection of the DC overvoltage protection unit to the functional

grounding

4 Product Overview

SMA Solar Technology AG

Operating Manual 15SSMUXX1015-BE-en-14

Position Designation

D Rotary handle of the DC load-break switch

E Electronic assembly

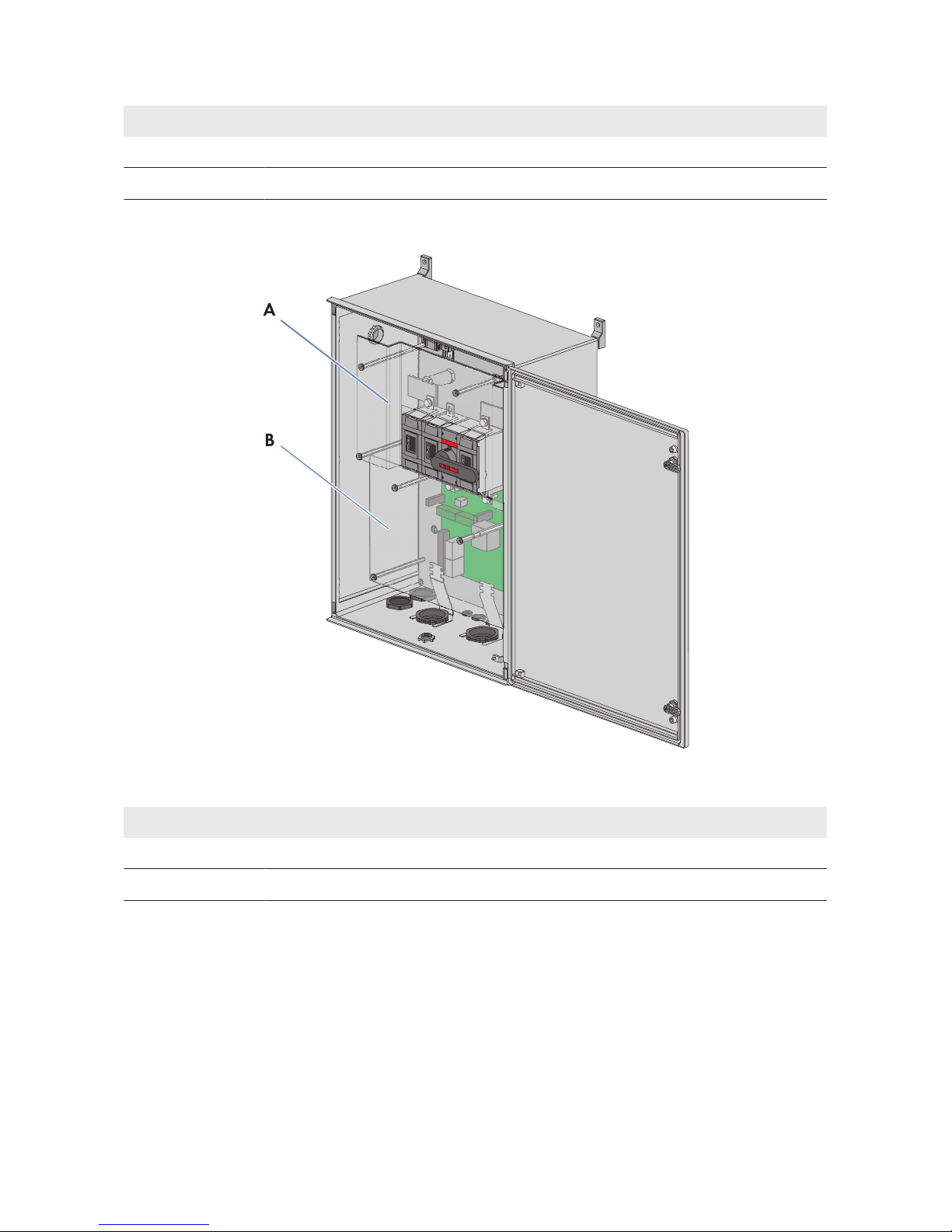

Protective covers

Figure 5: Position of the protective covers

Position Designation

A Top protective cover

B Bottom protective cover

4 Product Overview

SMA Solar Technology AG

Operating ManualSSMUXX1015-BE-en-1416

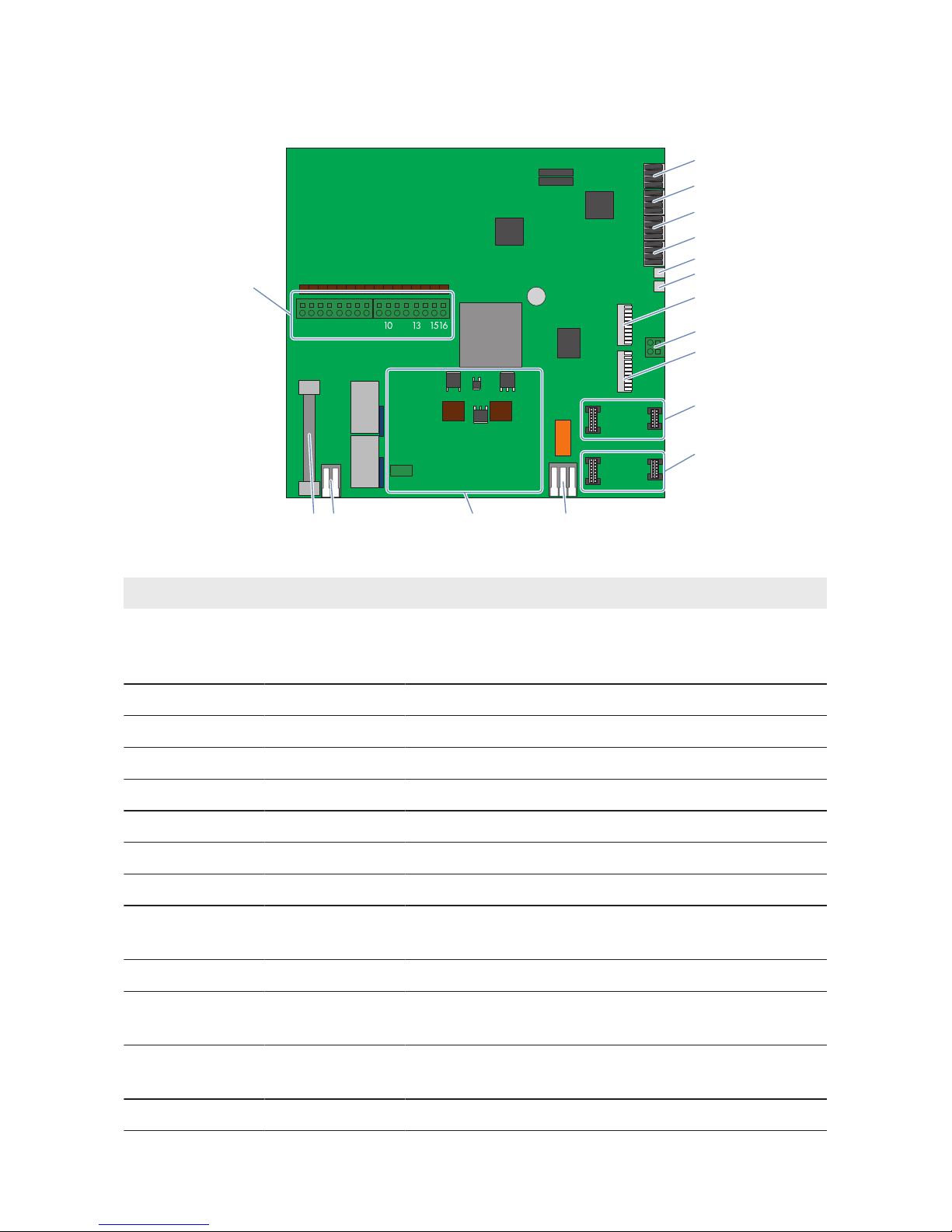

4.4 Terminals on the Electronic Assembly

12 345678 9 1112 14

A

B

C

D

E

F

G

H

K

L

M

N

OP

Q

I

Figure 6: Terminals on the electronic assembly

Position Designation Explanation

A ‒ Connection of string cable harnesses (PV+) and, depend-

ing on the version, of the plug-in board (MEU) for the num-

ber of PV inputs (factory installed)

B X1 Analog current input

C X2 Analog input temperature sensor external 1 (EXT 1)

D X3 Analog input temperature sensor external 2 (EXT 2)

E X4 Digital customer input

F X5 Digital input surge arrester DC

G X6 Status alarm contact DC load-break switch

H X7 Ethernet communication output LAN OUT

I X8 Terminal for the functional grounding cable of the elec-

tronic assembly

K X9 Ethernet communication input LAN IN

L LWLPB 1 Slot for the OF interface module (communication input

LWL IN)

M LWLPB 2 Slot for the OF interface module (communication output

LWL OUT)

N X10 Digital output of potential-free change-over contact

4 Product Overview

SMA Solar Technology AG

Operating Manual 17SSMUXX1015-BE-en-14

Position Designation Explanation

O ‒ Slot for the power supply assembly for external 230V

AC

supply voltage to the SMAString-Monitor via the inverter

P X14 Terminal for supply voltage of the SMAString-Monitor

from the PV field (PV-) (factory installed)

Q ‒ Fuse for the supply voltage of the SMAString-Monitor

from the PV field

4.5 Type Label

The type label clearly identifies the product.

You will require the information on the type label to use the product safely and when seeking

customer support from Service (see Section15, page75). The type label must remain

permanently attached to the product.

SMAString-Monitor

There are two type labels attached to the SMAString‑Monitor. The type labels are located on the

inside of the right-hand door and on the right-hand outside panel of the SMAString‑Monitor.

You can read off the following data from the type label:

• Date of manufacture (Fabrication Date)

• Serial number (SER)

• Device type (SSM-U-XXXX XX/XX/XX)

• Device-specific characteristics

Electronic assembly

There is one type label attached to the electronic assembly. The type label is located at the top left

of the electronic assembly.

You can read off the following data from the type label:

• Production version (FA)

• Serial number (SER)

• Assembly type and version (SSM30BASE.XXX)

Plug-in board (MEU) for the number of PV inputs

There is one type label attached to the plug-in board.

You can read off the following data from the type label:

• Production version (FA)

• Serial number (SER)

• Assembly type and version (SSM30MEU.XXX)

4 Product Overview

SMA Solar Technology AG

Operating ManualSSMUXX1015-BE-en-1418

4.6 Symbols on the Product

The following gives an explanation of all the symbols found on the SMAString-Monitor and on the

type label.

Symbol Designation Explanation

CE marking The product complies with the requirements of the applica-

ble EU directives.

DataMatrix code 2Dcode for device-specific characteristics

Degree of protec-

tionIP54

The product is protected against interior dust deposits and

splashing water from all angles.

Protection class II The product has a reinforced or double insulation be-

tween grid current circuit and output voltage.

WEEE designation Do not dispose of the product together with household

waste but in accordance with the locally applicable dis-

posal regulations for electronic waste.

Beware of dangerous

voltage

The product operates at high voltages. All work on the

product must be carried out by qualified persons only.

Beware of hot surface The product can get hot during operation. Avoid contact

during operation. Allow the product to cool down suffi-

ciently before carrying out any work. Wear personal pro-

tective equipment such as safety gloves.

Observe the documentation

Observe all documentation supplied with the product.

4 Product Overview

SMA Solar Technology AG

Operating Manual 19SSMUXX1015-BE-en-14

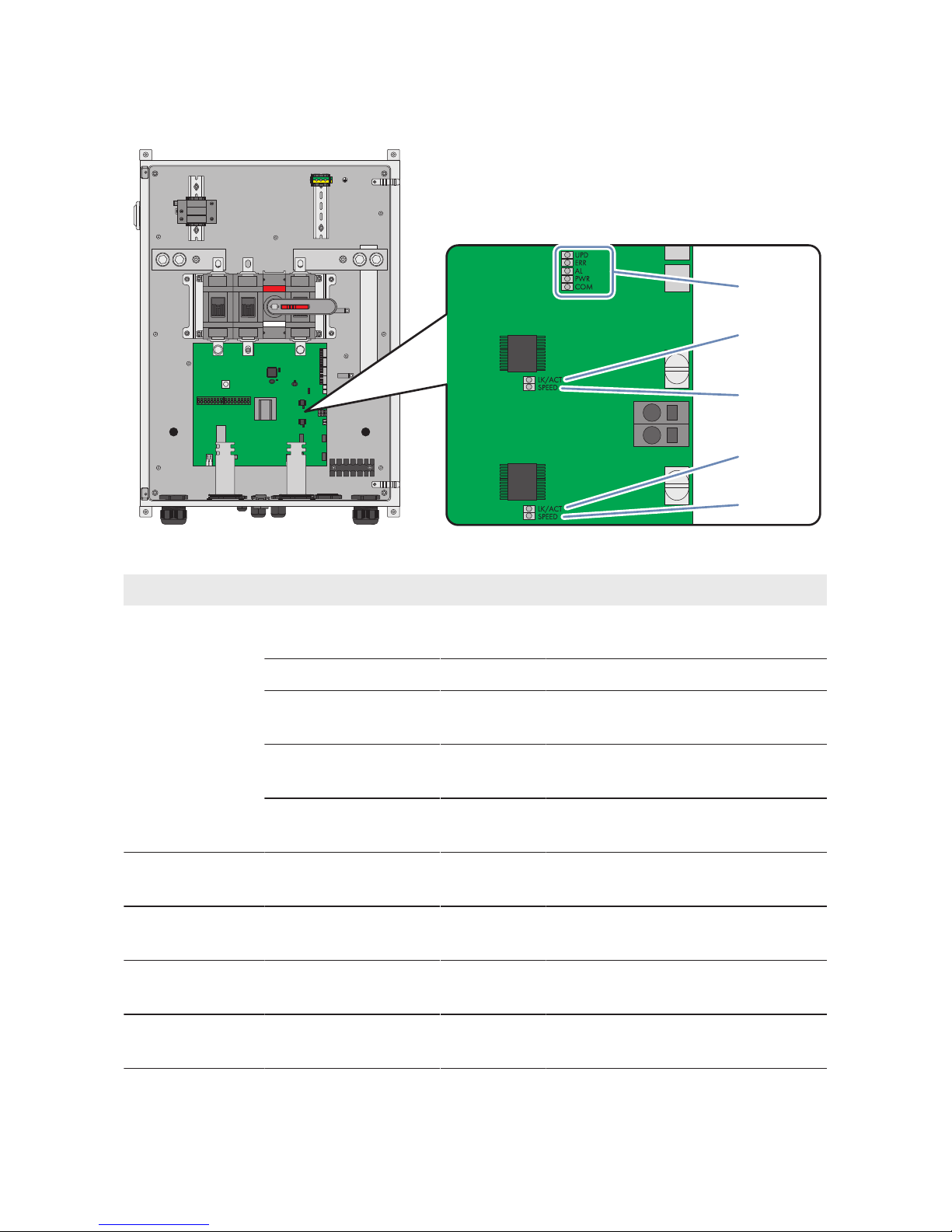

4.7 LEDs on the Electronic Assembly

L‒L+

LK/ACT

SPEED

LK/ACT

SPEED

UPD

ERR

AL

PWR

COM

A

B

C

D

E

Figure 7: LEDs on the electronic assembly

Position Designation Color Explanation

A UPD yellow Update status of the SMAString-Moni-

tor

ERR red Error in the SMAString-Monitor

AL green Firmware status of the SMAString-

Monitor

PWR green Voltage supply status of the

SMAString-Monitor

COM yellow Communication status of the

SMAString-Monitor

B LK/ACT green Status/activity of the network connec-

tion at the communication output

C SPEED yellow Speed of the network connection at

the communication output

D LK/ACT green Status/activity of the network connec-

tion at the communication input

E SPEED yellow Speed of the network connection at

the communication input

A description of the LED states will by given in (see Section9.1, page50).

4 Product Overview

SMA Solar Technology AG

Operating ManualSSMUXX1015-BE-en-1420

5 Mounting

5.1 Selecting the Mounting Location

Fire hazard due to wrong choice of mounting location

Despite careful construction, electrical devices can cause fires.

• Do not mount the DC sub-distribution on flammable construction materials.

• Do not mount the DC sub-distribution in areas containing highly flammable materials.

• Do not mount the DC sub-distribution in potentially explosive atmospheres.

Requirements for the mounting location:

☐ The mounting location can be outdoors or indoors.

☐ The mounting location must not be in a living or office area.

☐ The mounting location must not block any escape routes.

☐ The mounting location must be freely and safely accessible at all times without the necessity

for any auxiliary equipment (e.g. scaffolding or lifting platforms). Non-fulfillment of these

criteria may restrict servicing.

☐ The mounting location must be shaded, e.g. under a protective roof.

☐ The mounting location must be suitable for the weight and dimensions of the SMA

String‑Monitor.

☐ The mounting location must be suitable for the wind load.

☐ Mounting space below the SMAString-Monitor when using the inline fuse connectors:

at least 800mm.

Requirements for mounting the SMAString-Monitor

☐ Mount the SMAString-Monitor so that the connection area is facing downwards.

☐ Mount the SMAString-Monitor in a horizontal position.

☐ Do not mount the SMAString-Monitor in a twisted manner.

☐ Do not mount the SMAString‑Monitor in lying down or inclined position.

☐ An external cable support rail must be provided.

5 Mounting

SMA Solar Technology AG

Operating Manual 21SSMUXX1015-BE-en-14

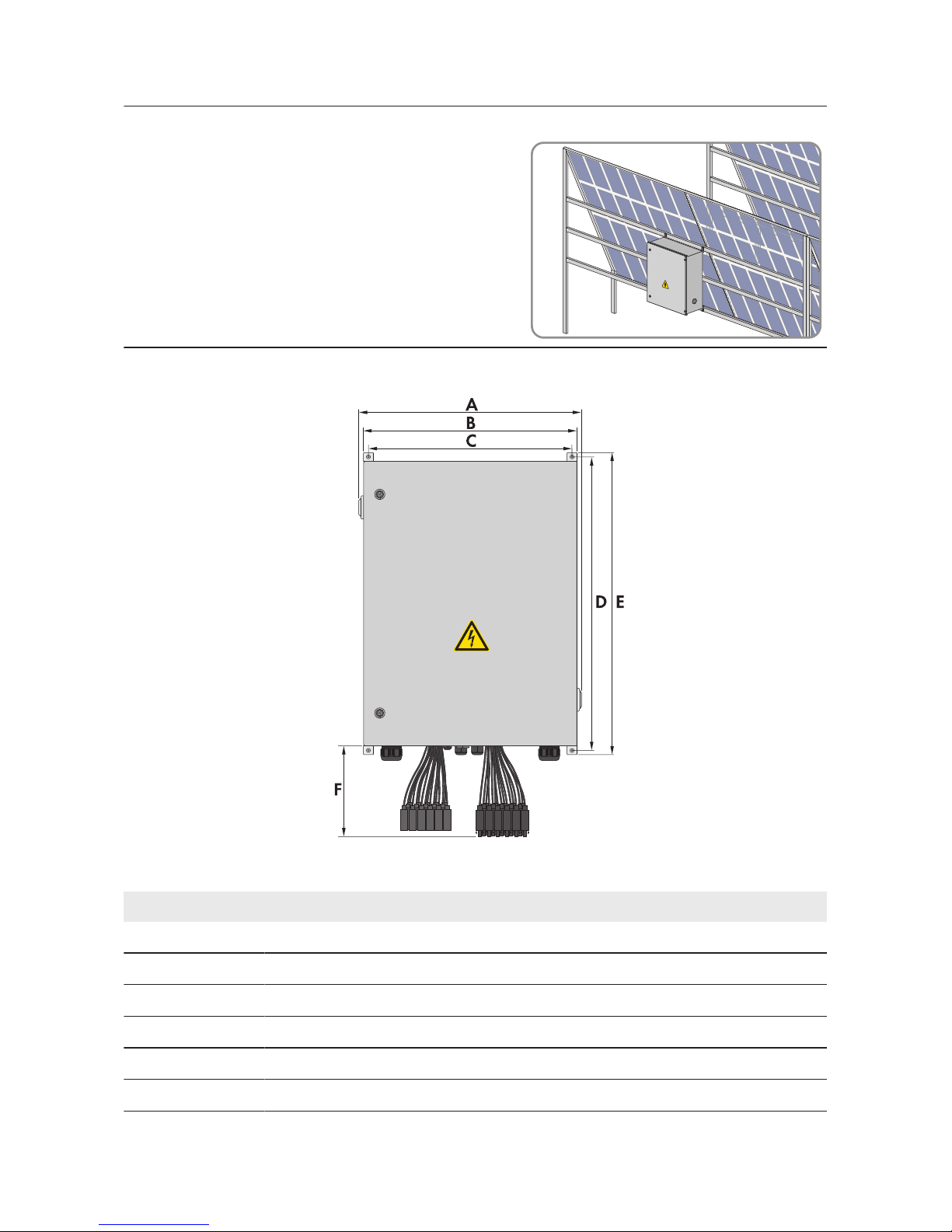

Example: Mounting on PV array substructure

• If the PV array is mounted on a free-standing

structure, the DC subdistribution can be fixed

to this structure in a shaded position. In this

case, make sure that there is no danger of

rainwater flowing off the module surface and

over the enclosure of the DC subdistribution.

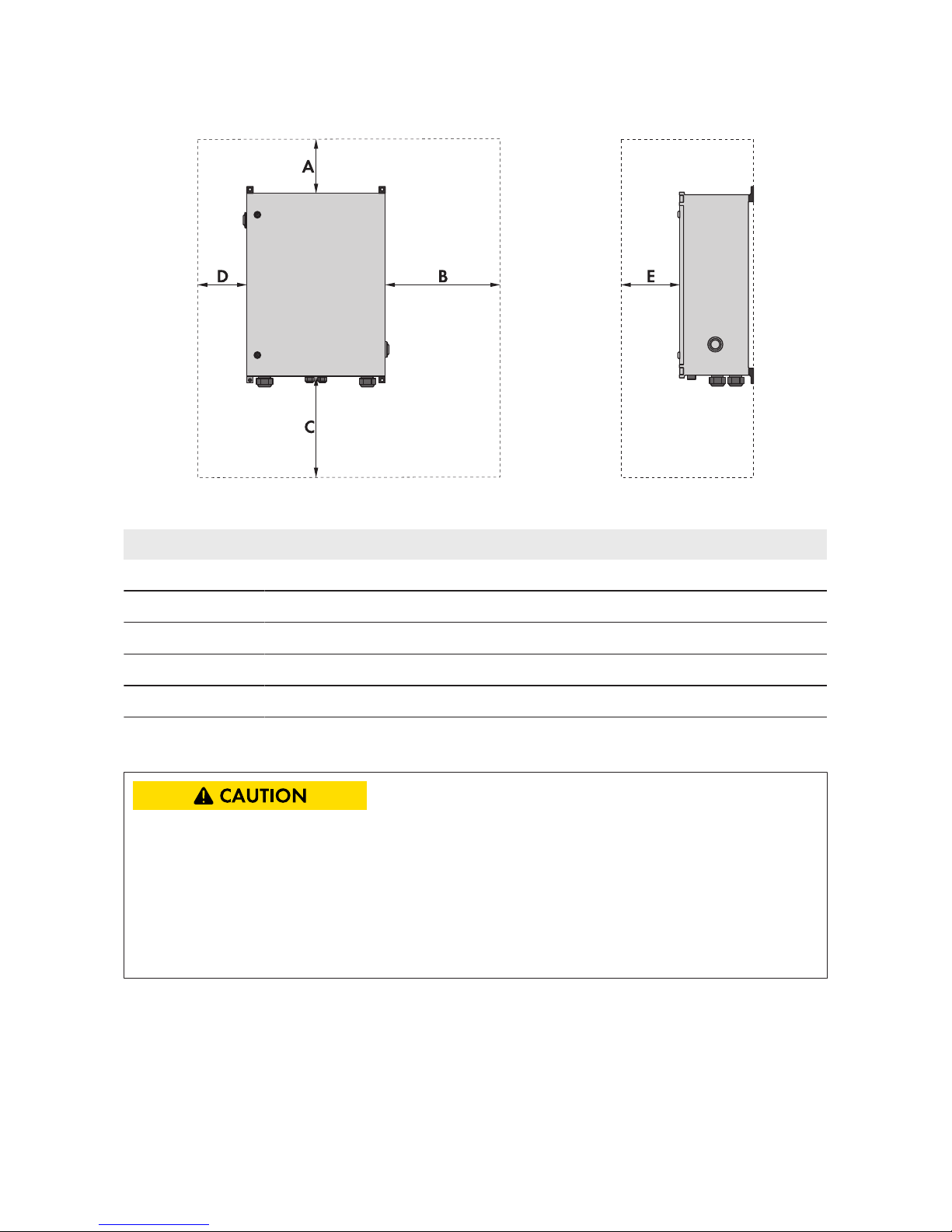

Dimensions and anchoring points:

Figure 8: Dimensions and anchoring points

Position Explanation

A 630.00mm

B 600.00mm

C 573.00mm (space between anchoring points)

D 825.60mm (space between anchoring points)

E 850.00mm

F 250.00mm

5 Mounting

SMA Solar Technology AG

Operating ManualSSMUXX1015-BE-en-1422

Observe minimum clearances:

Figure 9: Minimum clearances

Position Explanation

A 200mm

B 650mm

C 800mm

D 150mm

E 650mm

5.2 Mounting the SMAString-Monitor on the Wall

Risk of injury when lifting the DC sub-distribution, or if it is dropped

There is risk of injury if the DC sub-distribution is lifted incorrectly or dropped while being

transported or when attaching it to or removing it from the wall mounting bracket. Weight of the

DC sub-distribution without installed accessories: 35 kg.

• Two persons are required for mounting and disassembling the DC sub-distribution.

• Carefully lift and transport the DC sub-distribution.

Additionally required mounting material (not included in the scope of delivery):

• For mounting the DC subdistribution on a wall:

– 4 screws M6. Take the wall properties into account when selecting the screws.

– 4 washers

5 Mounting

SMA Solar Technology AG

Operating Manual 23SSMUXX1015-BE-en-14

– 4 screw anchors if necessary. Take the wall properties into account when selecting the

screw anchors.

• For mounting the DC subdistribution on the PV module substructure:

– 4 screws M6

– 4 washers

– 4 nuts

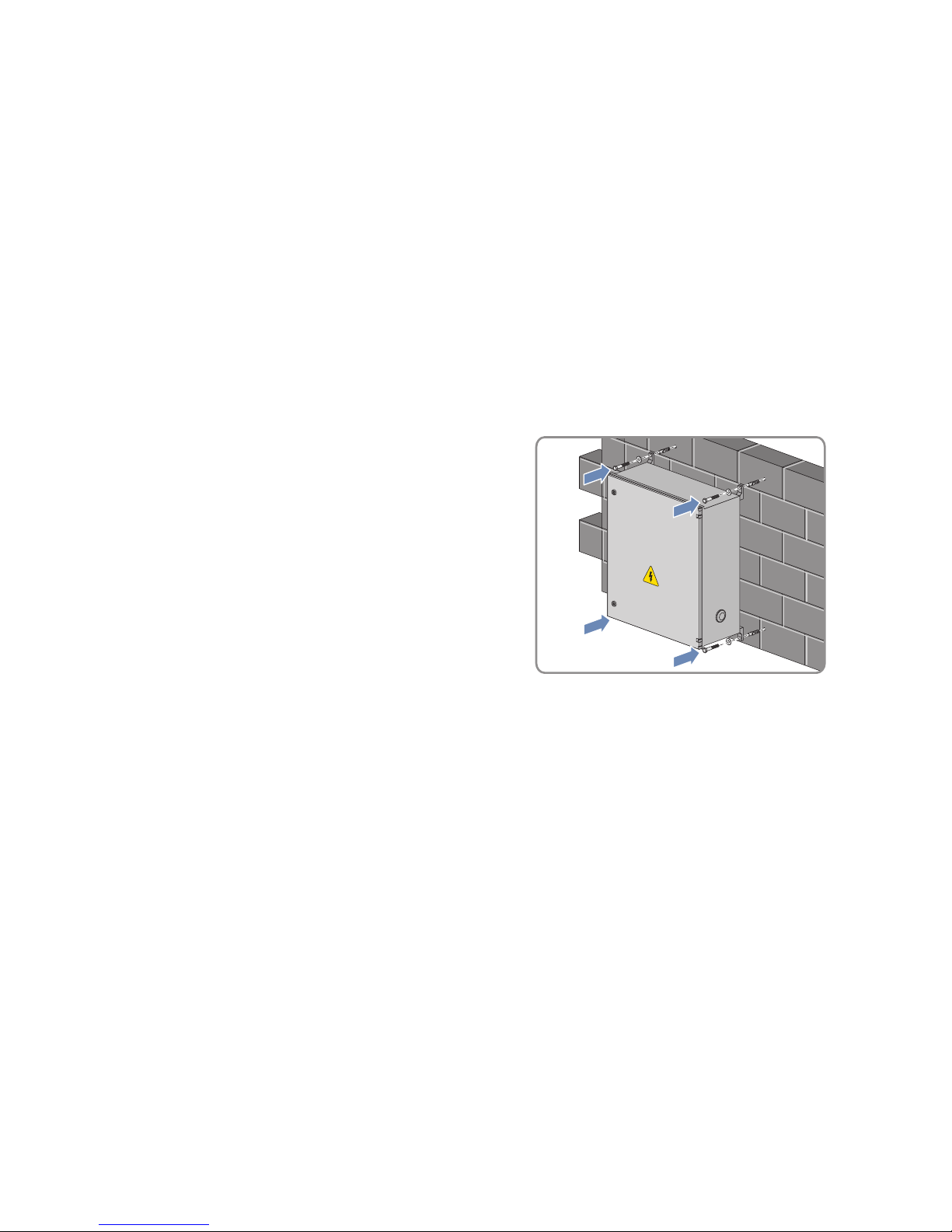

Procedure:

1. Close the DC subdistribution.

2. Mark the position of the drill holes on the wall or support structure.

3. Drill holes at the marked positions.

4. If necessary, insert screw anchors.

5. Fasten the DC subdistribution to the wall or

substructure using suitable screws and washers.

6. Ensure that the DC subdistribution is securely attached.

5 Mounting

SMA Solar Technology AG

Operating ManualSSMUXX1015-BE-en-1424

Loading...

Loading...