Page 1

EN

Accessories for Central Inverter

SUNNY STRING-MONITOR SSM16-11/SSM24-11

Installation Guide

SSM16-24-IA-IEN105120 | 98-4024820 | Version 2.0

Page 2

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Information on this Guide . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Appropriate Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Target Group Qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Symbols on the Type Label and the Sunny String-Monitor . . . . 13

3 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 SunnyString‑MonitorSSM16-11 / SSM24-11 . . . . . . . . . . . . 14

3.2 String Current Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 String Fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 Overvoltage Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5 Remote Tripping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5.1 Remote Tripping as a Shunt Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5.2 Remote Tripping as Undervoltage Release . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.6 Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Scope of Delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 Sunny String-Monitor SSM16-11 . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 Sunny String-Monitor SSM24-11 . . . . . . . . . . . . . . . . . . . . . . . 21

5 Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Base Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1.1 Selecting the Mounting Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1.2 Mounting the Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1.3 Mounting the Sunny String-Monitor on the Base. . . . . . . . . . . . . . . . . . . . . . 25

5.2 Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2.1 Selecting the Mounting Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2.2 Mounting the Sunny String-Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installation Guide SSM16-24-IA-IEN105120 3

Page 4

Table of Contents SMA Solar Technology AG

6 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.1 Overview of the Connection Area . . . . . . . . . . . . . . . . . . . . . . 29

6.2 Connecting the PV Strings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2.1 Calculating the Maximum Number of Strings per Measuring Input . . . . . . . 31

6.2.2 Connecting the PV Strings to Isolation Terminals. . . . . . . . . . . . . . . . . . . . . . 31

6.2.3 Connecting the PV Strings to the SUNCLIX DC Plug Connectors . . . . . . . . . 31

6.2.4 Connecting the PV Strings to Tyco, MC3, and MC4 Plug Connectors . . . . . 34

6.3 Connecting the DC Main Cable. . . . . . . . . . . . . . . . . . . . . . . . 34

6.4 Connecting the Grounding Cable. . . . . . . . . . . . . . . . . . . . . . . 35

6.5 Connecting the Data Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.5.1 Selecting the Data Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.5.2 Connecting the Data Cable Shield Contact . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.5.3 Connecting the Data Cable in the Sunny String-Monitor . . . . . . . . . . . . . . . 37

6.5.4 Connecting the Data Cable in the Sunny Central. . . . . . . . . . . . . . . . . . . . . 38

6.6 Connecting the Remote Tripping for the DC Circuit Breaker. . . 40

6.6.1 Dimensioning the Connection Cable for the Shunt Trip. . . . . . . . . . . . . . . . . 40

6.6.2 Connecting the Shunt Release. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.6.3 Connecting the Feedback Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.7 Installing the Theft Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2 Preparing and Carrying Out Commissioning . . . . . . . . . . . . . . 43

7.2.1 Requirements for Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2.2 Terminating the Data Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2.3 Noting the Serial Number of the Piggy-Backs for Data Processing. . . . . . . . 45

7.2.4 Filling In the Commissioning Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3 Switching On the Sunny String-Monitor . . . . . . . . . . . . . . . . . . 46

7.4 Reconnecting the DC Circuit Breaker after Tripping . . . . . . . . . 46

8 Disconnecting the Sunny String-Monitor . . . . . . . . . . . . . 47

4 SSM16-24-IA-IEN105120 Installation Guide

Page 5

SMA Solar Technology AG Table of Contents

9 Configuring the Sunny String-Monitor via

Sunny Central Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.1 Organizing the Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.2 Detecting Sunny String-Monitors. . . . . . . . . . . . . . . . . . . . . . . . 48

9.3 Setting the Parameters for the String Current Monitoring . . . . . 50

9.3.1 Setting the Number of Strings per Measuring Channel . . . . . . . . . . . . . . . . 50

9.3.2 Setting the Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.3.3 Setting the Tripping Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.3.4 Setting the Tolerance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.3.5 Setting the Monitoring Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.3.6 Setting the Nighttime Deactivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.3.7 Setting the Theft Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.4 Reading the Measured Values . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.4.1 Reading the Mean Values of the Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.4.2 Reading the Mean Values for the Individual Measuring Channels. . . . . . . . 52

9.5 Reading and Confirming Messages . . . . . . . . . . . . . . . . . . . . . 52

9.5.1 Resetting the Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.5.2 Reading and Confirming Current Messages. . . . . . . . . . . . . . . . . . . . . . . . . 52

9.5.3 Reading and Confirming the Event History . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10 Configuring the Sunny String-Monitor with

Sunny Data Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10.1 Organizing the Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . 53

10.2 Detecting the Sunny String-Monitor . . . . . . . . . . . . . . . . . . . . . 55

10.3 Setting Parameters for String Current Monitoring . . . . . . . . . . . 56

10.3.1 Overview of the Program Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.3.2 Setting the Number of Strings per Measuring Channel . . . . . . . . . . . . . . . . 57

10.3.3 Setting the Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.3.4 Setting the Monitoring Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.3.5 Setting the Tripping Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.3.6 Setting the Tolerance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.3.7 Setting the Nighttime Deactivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Installation Guide SSM16-24-IA-IEN105120 5

Page 6

Table of Contents SMA Solar Technology AG

10.3.8 Setting the Theft Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.4 Reading the Measured Values . . . . . . . . . . . . . . . . . . . . . . . . . 59

11 Configuring the Sunny String-Monitor with

Sunny WebBox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

11.1 Organizing the Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . 60

11.2 Sunny WebBox Interface Overview . . . . . . . . . . . . . . . . . . . . . 60

11.3 Detecting the Sunny Central . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

11.4 Detecting the Sunny String-Monitor . . . . . . . . . . . . . . . . . . . . . 61

11.5 Setting the Parameters for Sunny Central Control. . . . . . . . . . . 62

11.5.1 Setting the Number of Strings per Measuring Channel . . . . . . . . . . . . . . . . 62

11.5.2 Setting the Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

11.5.3 Setting the Monitoring Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.5.4 Setting the Tripping Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.5.5 Setting the Tolerance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.6 Setting the Parameters for the Sunny Central String Monitor

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.6.1 Setting the Number of Strings per Measuring Channel . . . . . . . . . . . . . . . . 64

11.6.2 Setting the Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.6.3 Setting the Communication Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

11.6.4 Setting the Monitoring Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

11.6.5 Setting the Tripping Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

11.6.6 Setting the Tolerance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

11.7 Reading the Measured Values . . . . . . . . . . . . . . . . . . . . . . . . . 66

11.7.1 Reading the Measured Values of the Groups. . . . . . . . . . . . . . . . . . . . . . . . 66

11.7.2 Reading the Measured Values for the Individual

Measuring Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

11.8 Acknowledging Error Messages. . . . . . . . . . . . . . . . . . . . . . . . 67

11.8.1 Acknowledging Error Messages with Sunny Central Control . . . . . . . . . . . . 67

11.8.2 Acknowledging Error Messages with the Sunny Central String Monitor

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6 SSM16-24-IA-IEN105120 Installation Guide

Page 7

SMA Solar Technology AG Table of Contents

12 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

12.1 LED signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

12.2 Communication and Operation Faults . . . . . . . . . . . . . . . . . . . 69

13 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

13.1 Sunny String‑Monitor SSM16-11 . . . . . . . . . . . . . . . . . . . . . . . 70

13.2 Sunny String‑Monitor SSM24-11 . . . . . . . . . . . . . . . . . . . . . . . 76

14 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Installation Guide SSM16-24-IA-IEN105120 7

Page 8

1 Information on this Guide SMA Solar Technology AG

1 Information on this Guide

Validity

This installation guide applies to the following devices:

•SunnyString‑MonitorSSM16‑11

•Sunny String-Monitor SSM24-11

Target Group

This manual is intended for skilled workers. Only qualified personnel are allowed to perform the tasks

set forth in this manual (see section 2.2”Target Group Qualification”,page10).

Additional Information

Additional information is available at www.SMA.de/en:

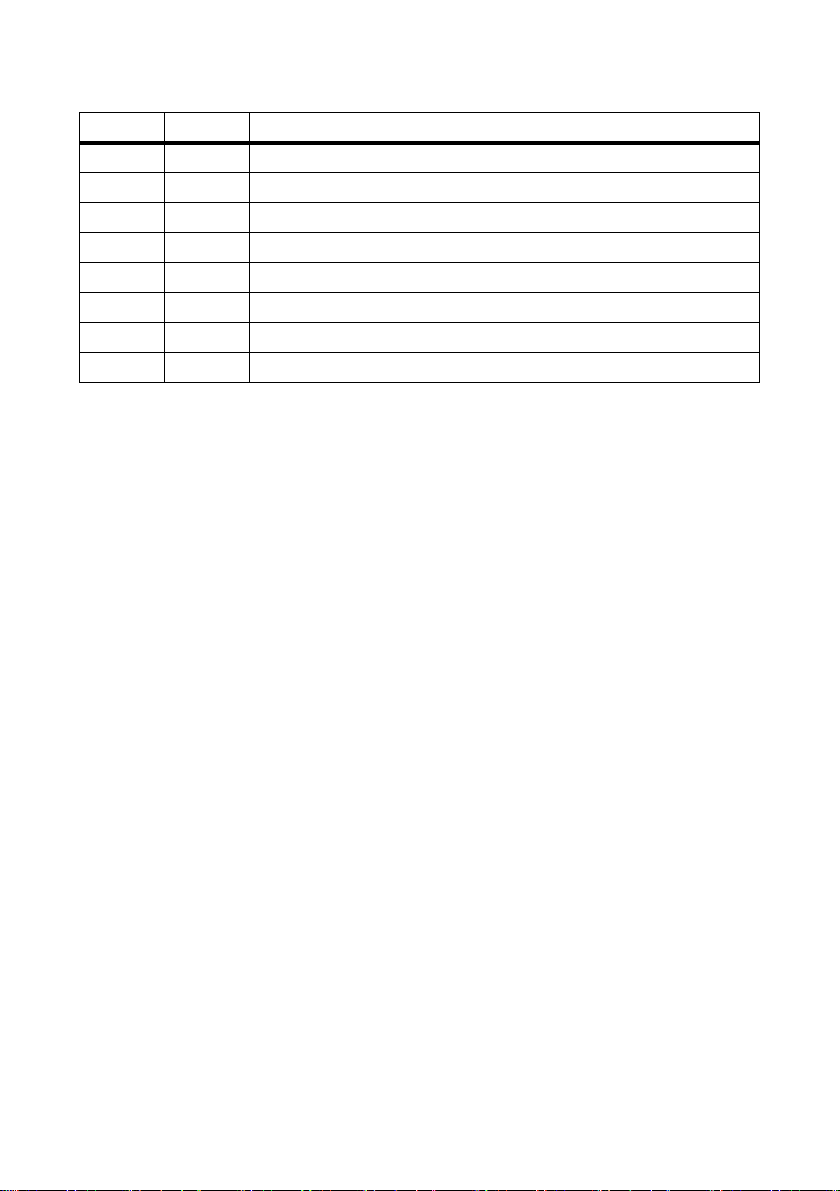

Document title Document type

Product Details ‒ Features and Mounting Options for

SUNNY STRING-MONITOR SSM 16-11

Product Details ‒Features and Mounting Options for

SUNNY STRING-MONITOR SSM 24-11

Plant communication in large-scale PV plants ‒

POSSIBILITIES OF PLANT COMMUNICATION

Technical Information

Technical Information

Technical Description

Utility Model

The Sunny String-Monitor SSM 16-11 and the Sunny String-Monitor SSM24-11 have pending utility

patents.

8 SSM16-24-IA-IEN105120 Installation Guide

Page 9

SMA Solar Technology AG 1 Information on this Guide

%"/(&3

8"3/*/(

$"65*0/

/05*$&

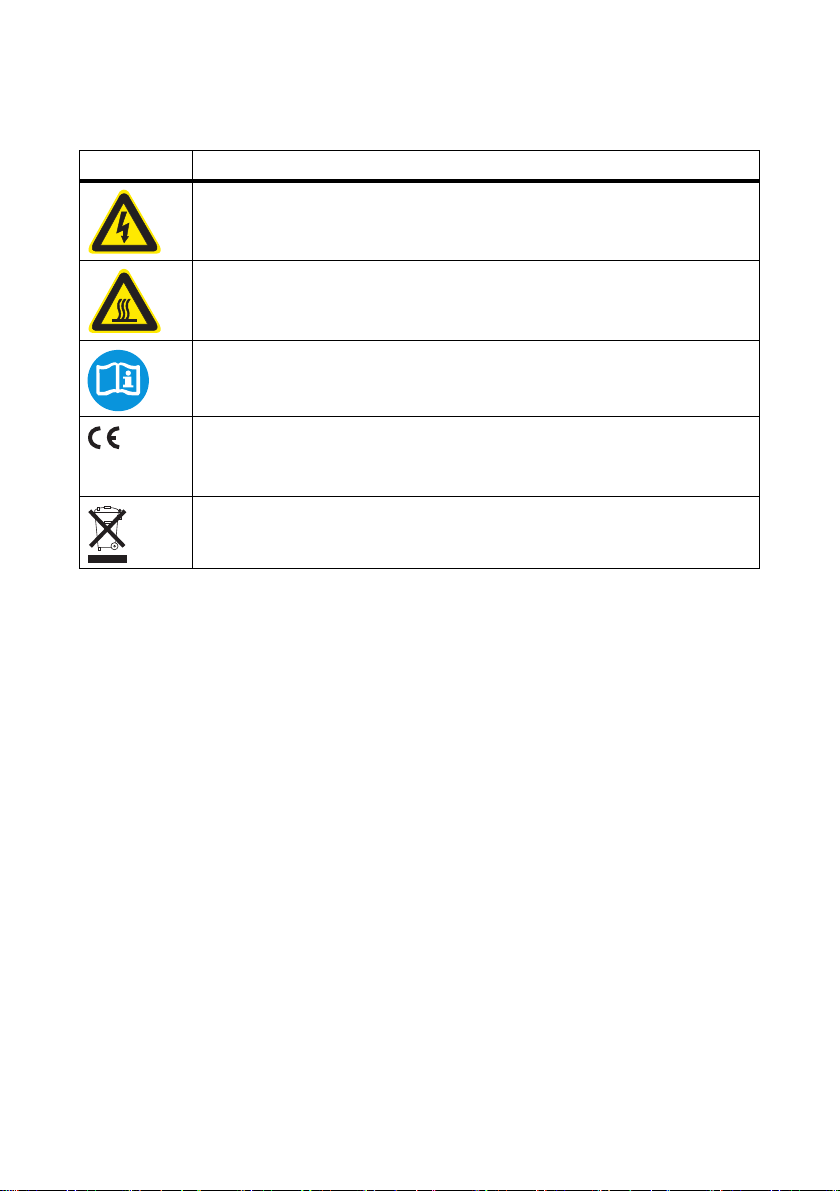

Symbols

Symbol Explanation

Indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

Indicates a hazardous situation which, if not avoided, could result in death

or serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor

or moderate injury.

Indicates a situation that can result in property damage if not avoided.

Indicates information that is important for a specific topic or objective, but

is not safety-relevant.

☐ Indicates a requirement for meeting a specific goal.

☑ Desired result.

✖ Undesired result. Followed by a solution on how to achieve the desired

result.

Typography

Typography Usage Example

"light" • Information displayed on

the inverter

•Elements on a software

interface

•Connections

bold • Elements from which you

should make a selection

•Elements which you

should input

> •Several elements which

you should select

[Button/key] • The button or key which

you should select or press

• The value can be read in the field

"Energy".

• Select Settings.

•Enter 10 in the "Minutes" field.

• Select Settings > Date.

• Select [Next].

Nomenclature

The manual deals with both the SunnyString‑Monitor SSM16-11 and the

SunnyString‑MonitorSSM24-11 and they are referred to as the Sunny String-Monitor.

Installation Guide SSM16-24-IA-IEN105120 9

Page 10

2 Safety SMA Solar Technology AG

2Safety

2.1 Appropriate Usage

The SunnyString‑Monitor is a DC sub-distributor to which several strings ca n be connected in paral lel.

The Sunny String-Monitor monitors the input current to the strings, detects failures and thus helps to

minimize power and yield losses.

Figure1:Principle of a grid-tie PV plant

Position Designation

APV array

B Sunny String-Monitor

C Sunny Central

D Transformer

E Power distribution grid

2.2 Target Group Qualification

All work on the plants may only be carried out by qualified technical personnel. Qualified means that

the personnel must possess training relevant to the task performed and must be familiar with the

content of this manual.

2.3 Safety Instructions

Following Instructions

Failure to follow this manual and the operating or safety instructions it contains may lead to severe

injury from electric shock.

• Only perform work as described in this manual. Observe all safety instructions.

• Keep the documentation for the Sunny String-Monitor and for the installed components with the

system documentation. They must be accessible at all times.

10 SSM16-24-IA-IEN105120 Installation Guide

Page 11

SMA Solar Technology AG 2 Safety

Electric Shock

The Sunny String-Monitor is connected to high voltages. Work on the Sunny String-Monitor is only

allowed if the power is disconnected and in compliance with the guidelines that apply at the

installation location.

• Disconnecting the device:

– Remove the DC fuses in the central inverter or main DC distributor, such as the Sunny Main

Box, in a no-load condition.

– Switch off the DC circuit breaker in the Sunny String-Monitor.

– Only open or close the isolation terminals in the Sunny String-Monitor in a no-load condition.

– Only insert or remove the fuses when wearing personal protective gear.

– Only plug in or unplug the Solar Plug when no load is present.

• Ensure that the device cannot be reconnected.

• Ensure that no voltage is present in the system.

• Ground and short-circuit.

• Cover or safeguard any adjacent live components. Protective covers must always be fitted.

If there is a grounding fault, grounded plant sections may be presumed live.

• Ensure there is no voltage present before touching.

Operating a damaged Sunny String-Monitor may cause severe injury from electric shock.

• The Sunny String-Monitor may only be used when it is technically faultless and safe to operate.

• Operate the Sunny String-Monitor only without visible damage and check regularly for visible

damage.

• E nsu re t hat all ext ernal safet y equipme nt i s fr eel y ac ces sib le a t all time s an d is reg ula rly che cke d

for proper functioning.

Burns

Some components, such as fuses, can become hot during operation.

• Wear safety gloves when working on the device.

Installation Guide SSM16-24-IA-IEN105120 11

Page 12

2 Safety SMA Solar Technology AG

Damage to the Sunny String-Monitor

If the Sunny String-Monitor or the PV plant are handled by persons unauthorized to do so, they might

sustain damage.

• Lock the Sunny String-Monitor after it has been put into operation.

• Remove the keys from the door locks.

• Keep the keys in a safe place.

Environmental Influences

When closed, the Sunny String-Monitor carries IP54 and is thus protected from dust and water.

• Do not carry out any assembly work in rain, fog or if humidity exceeds 95%.

• Close the doors of the Sunny String-Monitor after work on it is complete.

Electrostatic Discharge

Electrostatic discharge can destroy electronic component parts.

• When you work on the Sunny String-Monitor or its assemblies, observe the ESD safety

regulations and wear protective gloves.

• Conduct any electrostatic charges away from the electronic component parts before touching

them. To do this, touch the unpainted grounded parts of the housing, the PE connection, for

example.

12 SSM16-24-IA-IEN105120 Installation Guide

Page 13

SMA Solar Technology AG 2 Safety

2.4 Symbols on the Type Label and the Sunny String-Monitor

Symbol Explanation

Warning of dangerous electrical voltage.

The Sunny String-Monitor is connected to high voltages. All work on the

SunnyString-Monitor must only be carried out by electrically skilled persons.

Warning of hot surface.

The Sunny String-Monitor can become hot during operation. Avoid contact during

operation.

Take note of all the documentation supplied with the Sunny String-Monitor.

CE mark.

The Sunny String-Monitor complies with the requirements of the applicable EC

guidelines.

The Sunny String-Monitor must not be disposed of via domestic waste

arrangements.

Installation Guide SSM16-24-IA-IEN105120 13

Page 14

3 Product Description SMA Solar Technology AG

3 Product Description

3.1 SunnyString‑MonitorSSM16-11 / SSM24-11

The Sunny String‑Monitor is a DC sub-distributor to which several strings can be connected in parallel.

The Sunny String-Monitor monitors the input current to the strings and detects malfunctions.

Figure2:Structure of the Sunny String-Monitor

Position Designation

A Doors

B Switch cabinet lock

The string currents are monitored by the measuring board in the String Monitor Unit in the

SunnyString-Monitor. A Piggy-Back is integrated in the measuring board for data processing. The

data processing Piggy-Back manages the string currents and the parameterization of the measuring

board.

The string fuses in the Sunny String-Monitor protect the PV string modules from reverse currents.

3.2 String Current Monitoring

The string currents are monitored via the measuring board in the String Monitor Unit (SMU). The

String Monitor Unit measures the string currents and continuously calcu lat es t he a ver age cur ren ts. The

SMU compares the string currents with the mean values. If a string current exceeds or falls short of the

mean value by the set tolerance value, the warning 380 "SMU" is displayed.

You can adjust the parameters for monitoring the string current on the Sunny Central 100/200/250/

350 inverters and the Sunny Central in the HE-11 series on the int egrate d Sunny Centra l Contr ol data

logger or in the Sunny Data Control program on the PC. It is also possible to read mean values on

the Sunny Central Control and in the Sunny Data Control.

14 SSM16-24-IA-IEN105120 Installation Guide

Page 15

SMA Solar Technology AG 3 Product Description

With the Sunny Central inverters in the CP and the HE-20 series, you can set the parameters on the

PC via the WebBox interface and read the mean values and the messages.

With the parameterization, the Sunny String-Monitor can determine the total malfunction of a string

within a polling interval. Slightly elevated string currents are reliably detected in several polling

intervals and distinguished from typical current fluctuations of the PV array.

The following describes:

• The circumstances under which the string current is monitored

• The intervals at which data is transmitted

• Which parameters are important for the sensitivity with which the string current is monitored.

Requirements for Activating the String Current Monitoring

☐ The DC power of the PV array exceeds 5% of the nominal AC power of the Sunny Central.

P

> 0.05 * P

DC

Value Designation

P

DC

P

AC nom

PV array power

Sunny Central nominal AC power

☐ The string current mean value of the individual groups is equal or greater than 0.5 A.

I

M String

AC nom

≥ 0.5A

Value Designation

I

M String

Mean value of string-current from each group

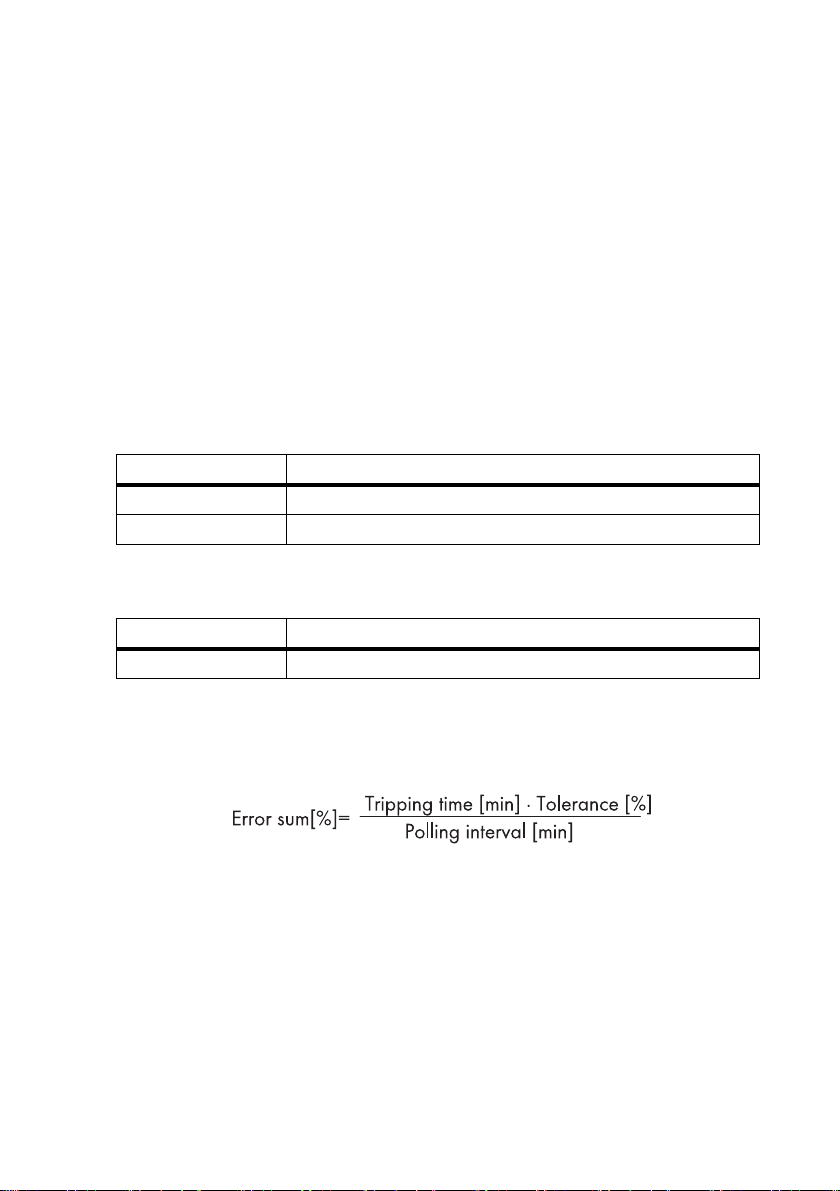

Error Sum

The error sum is a measure of the sensitivity of the string current monitoring. It can be parameterized

via the tripping time and tolerance, and is described by the following formula:

The individual error sums of the measuring channels are reset at 00:00 o'clock.

Installation Guide SSM16-24-IA-IEN105120 15

Page 16

3 Product Description SMA Solar Technology AG

Polling Interval

The Sunny String-Monitor continually measures the string currents and saves them in cycles. The data

logger reads these values every 5 minutes.

Tripping Time

The tripping time is the time span between the occurrence of a fault and the error message. The

tripping time is set to 180 minutes as default. You can set the parameters for the tripping time between

2 … 1440 minutes.

Tolerance

The tolerance indicates how much the string current may deviate fr om t he m ean value . Wh en t he s tring

current is outside of the tolerance limits, the data logger detects the deviation and stores it. The

tolerance can be set between 10% … 100%.

Grouping Strings

You can assign the strings to the 8 measuring channels in order to simplify monitoring. Should

individual PV strings be overshadowed, aligned differently or fitted with different modules, it is also

possible to group the individual measuring channels. This makes it possible to compare measuring

channels with the same properties.

Comparison

Every 5 minutes, the data logger compares the string-current with the mean value for the group. If the

string-current exceeds the tolerance limit, the data logger stores the deviation. If at the next poll, there

is still a deviation between the string-current and the mean value, the deviations are added together.

If the sum of deviations exceeds the error sum, the data logger sends the 380 "SMU" warning. When

the error is acknowledged, the error sum is reset, and the warning disappears from the display.

It is possible to see from the Sunny Central Control or via the Sunny WebBox which Sunny StringMonitor and which measuring channels are deviating from the mean value for the group.

Example:

It is assumed that at time t0 the mean value of a group is 5 A. The set tolerance is 10%. This means

that the tolerance range is from 4.5 A … 5.5 A. The tripping time is set to 10 minutes. The polling

interval is 5 minutes. The error sum can therefore be calculated as follows:

16 SSM16-24-IA-IEN105120 Installation Guide

Page 17

SMA Solar Technology AG 3 Product Description

All the string currents are now compared to this mean value in the 5 minute polling interval. If all the

string currents lie within the set tolerance of 10%, no addition is carried out.

If, however, a string shows a string current of 6 A, then the difference between the actual string

current of 6 A and the tolerance limit of 5.5 A is added to the total. The difference is 0.5 A, which

is a deviation of 10% from the mean value. This difference of 10% is now added to the total until

the error sum of 20% is reached.

The error sum is reached when the error remains the same for two polling intervals. The data logger

sends the warning 380 "SMU".

Installation Guide SSM16-24-IA-IEN105120 17

Page 18

3 Product Description SMA Solar Technology AG

If a string fails, the current difference in the above example is 4.5 A, which equates to a deviation

of 90% from the mean value. If the settings in the above example remain the same, i.e. tolerance at

10% and tripping time at 10 minutes, the error sum of 20% is already reached after the first polling

interval of 5 minutes. The data logger now sends an "SMU" warning.

3.3 String Fuses

The string fuses protect the modules of a PV plant from reverse currents.

Figure3:The principle of reverse current

Reverse current can occur when different open-circuit voltages are applied to modules connected in

parallel. In this event, the reverse current can be much higher than the module's short-circuit current.

The higher the reverse current, the higher the heat will rise in the modules of the faulty PV string.

Pronounced warming can destroy the modules of the faulty PV string.

Reverse current can have the following causes:

• Short circuit in one or more modules

• Short circuit in one or more cells in a module

• Double ground fault in a module

• Double ground fault in the cabling

The string fuses trip when the string current is too high and thus protect the modules of the faulty PV

string. The Sunny String-Monitor informs Sunny Central Control of the failure of the PV string.

In the case of grounded PV arrays, the positive or the negative pole can be grounded at the inverter.

To do this, cylindrical bridges are fitted in the Sunny String-Monitor instead of fuses.

18 SSM16-24-IA-IEN105120 Installation Guide

Page 19

SMA Solar Technology AG 3 Product Description

3.4 Overvoltage Protection

Integrated surge arresters provide overvoltage protection. The surge arresters protect the inverters

from transient overvoltages. The integrated surge arresters can be monitored in the Sunny StringMonitor. To guarantee the functionality of the integrated surge arrester, this must be connected to an

external grounding. The connection to ground is provided by a ground terminal.

3.5 Remote Tripping

3.5.1 Remote Tripping as a Shunt Trip

The DC circuit breaker is fitted optionally with a remote trigger which is configured as a shunt trip.

The remote trigger with the shunt trip is used to switch off the DC circuit breaker in an electrically

controlled way. Action of the shunt trip is configured at a voltage between 70% … 110% of the

nominal voltage of the shunt trip U

tripped. The DC circuit breaker is controlled via a make contact.

The function of the shunt trip is not guaranteed if a cable breaks, a connection is loose, voltage is too

low or the voltage supply fails. We recommend the use of an uninterrupted voltage supply. The

activation time for safely activating the shunt trip is at least 3 seconds.

After it has been triggered remotely, the DC circuit breaker must be connected again manually.

. If a voltage is present at the shunt trip, the DC circuit breaker is

N

3.5.2 Remote Tripping as Undervoltage Release

Th e DC cir cui t br eak er i s fi tte d optiona lly wit h a r emo te t rig ger whi ch i s co nfi gur ed as an un der vol tag e

release.

Remote tripping with the undervoltage release is used to switch off the DC circuit breaker in an

electronically controlled way. The DC circuit breaker is tripped when there is no voltage at the

undervoltage release, or if the voltage falls below 85% of the nominal release voltage UN. After

tripping, the DC circuit breaker can be connected again after the voltage rises above 85% of the

undervoltage release nominal voltage UN.

In order to avoid an inadvertent tripping, we recommend an uninterrupted power supply. The

undervoltage release is designed for continuous operation. Activation takes place via a normally

closed contact. The minimum interruption time for reliable tripping of the undervoltage release is

1 second.

After it has been triggered remotely, the DC circuit breaker must be connected again manually.

3.6 Type Label

The purpose of the type label is to identify the Sunny String-Monitor. You will find the type label on

the inside of the right door and on the right external wall of the Sunny String-Monitor. You will find the

following information on the type label:

• Type (Type/Model)

•Serial number (Serial No.) of the Sunny String-Monitor

Installation Guide SSM16-24-IA-IEN105120 19

Page 20

4 Scope of Delivery SMA Solar Technology AG

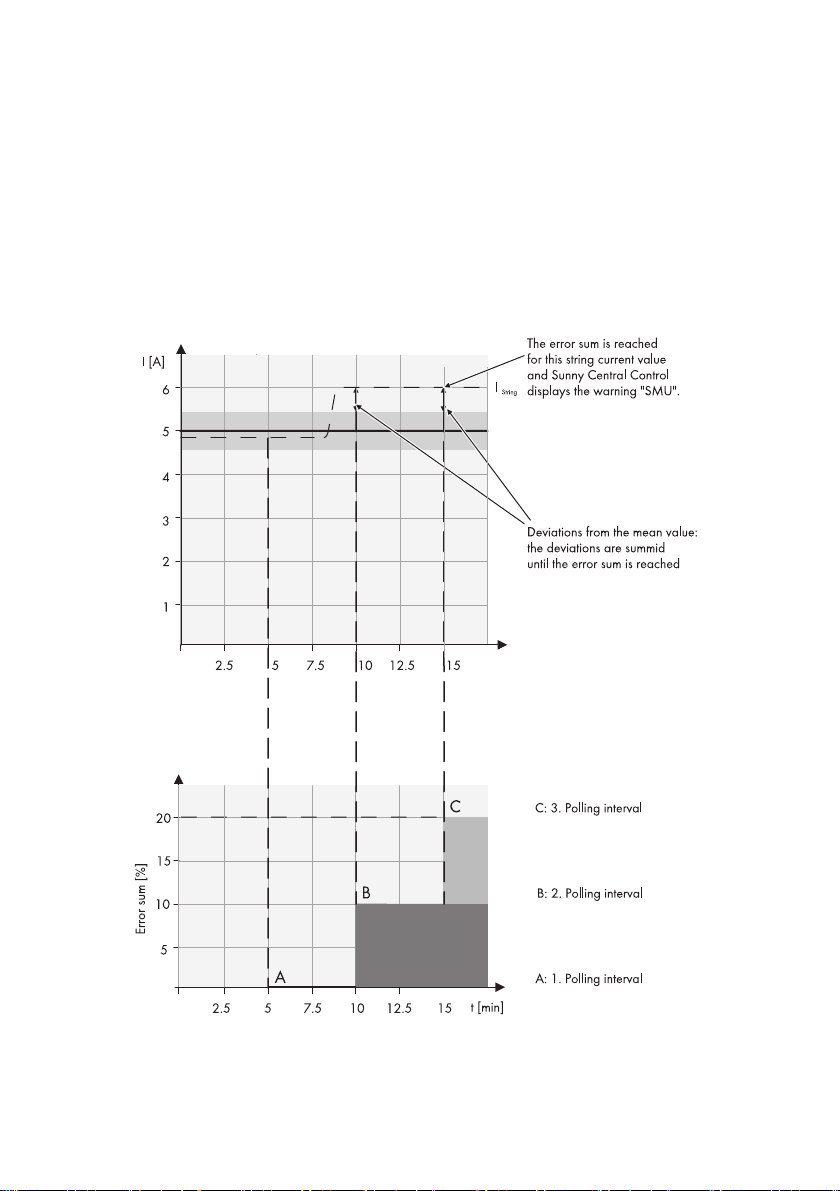

4Scope of Delivery

4.1 Sunny String-Monitor SSM16-11

Check the scope of supply for completeness and any visible external damage. Please contact your

supplier if the delivery is not complete or you find any damage.

Figure4:Sunny String-Monitor SSM16-11 - scope of delivery

Position Quantity Designation

A 1 Sunny String-Monitor SSM16-11

B1Base

*

C 1 Switch cabinet key

D2Mounting rail

E8Screw

F 0/16 Cylindrical bridges

G 16/32 Fuses

H 32/64 DC plug connector +pole

20 SSM16-24-IA-IEN105120 Installation Guide

*

*

*

*

*

Page 21

SMA Solar Technology AG 4 Scope of Delivery

Position Quantity Designation

I 32/64 DC plug connector -pole

K 32/64 Sealing plugs for DC plug connectors

*

*

L 1 Installation guide

M 1 Circuit diagram

*

optional

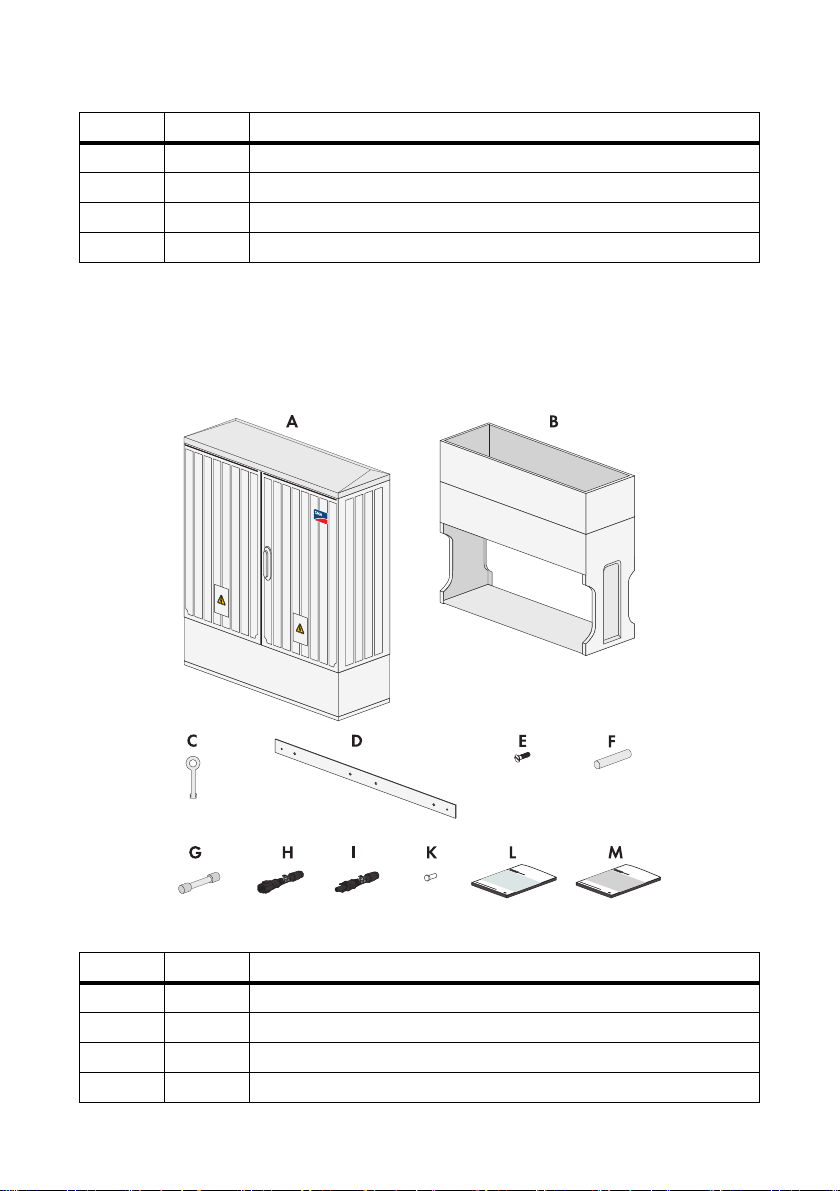

4.2 Sunny String-Monitor SSM24-11

Check the scope of supply for completeness and any visible external damage. Please contact your

dealer if the delivery is not complete or you find any damage.

Figure5:Sunny String-Monitor SSM24-11 - scope of delivery

Position Quantity Designation

A 1 Sunny String-Monitor SSM24-11

B1Base

*

C 1 Switch cabinet key

D2Mounting rail

Installation Guide SSM16-24-IA-IEN105120 21

*

Page 22

4 Scope of Delivery SMA Solar Technology AG

Position Quantity Designation

E8Screw

F 0/24 Cylindrical bridges

G 24/48 Fuses

H 48/96 DC plug connector +pole

I 48/96 DC plug connector -pole

K 48/96 Sealing plugs for DC plug connectors

*

*

*

*

*

*

L 1 Installation guide

M 1 Circuit diagram

*

optional

22 SSM16-24-IA-IEN105120 Installation Guide

Page 23

SMA Solar Technology AG 5 Assembly

%"/(&3

5Assembly

5.1 Base Mounting

5.1.1 Selecting the Mounting Location

Danger to life due to fire or explosion.

• Do not install the Sunny String-Monitor on flammable construction materials.

• Do not install the Sunny String-Monitor near highly flammable materials.

• Do not install the Sunny String-Monitor in potentially explosive areas.

Requirements:

☐ The mounting location is not an escape route, nor in a residential or office area.

☐ The mounting location must be easily accessible for maintenance work.

☐ The mounting location is shaded.

☐ The mounting location is protected from rain as far as possible.

Installation Guide SSM16-24-IA-IEN105120 23

Page 24

5 Assembly SMA Solar Technology AG

1 060 mm

595 mm

595 mm

245 mm

Figure6:Arrangement of the cables in the base area

Position Designation

APV+ string cable

B Grounding cable, RS485 communications cable, cable for remote tripping

(optional)

C DC main cable to Sunny Central

DPV‒ string cable

5.1.2 Mounting the Base

Figure7:Dimension of the support for the base

24 SSM16-24-IA-IEN105120 Installation Guide

Page 25

SMA Solar Technology AG 5 Assembly

/05*$&

/05*$&

1. Dig a pit. Note the depth of the pit on the base. Tip: the maximum depth of the pit is marked on

the sides of the Sunny String-Monitor.

2. Set the base in the pit with the side of the kick plate facing forwards.

3. Remove the upper kick plate.

4. Presort the output cables according to location and place in the base.

5. Half-fill the pit with gravel or sand. Use a grain from 2 mm … 4 mm.

6.

Penetrating moisture can lead to condensation, corrosion, and leakage currents.

Using the base filler stops condensation forming.

• Fill the remaining space around the base with base filler. Use a grain from 4 mm … 8 mm.

5.1.3 Mounting the Sunny String-Monitor on the Base

Damage to the cable glands and plug connections due to improper transport and

installation.

The cable glands and plug connections protrude from the enclosure.

• When transporting and mounting the Sunny String-Monitor, ensure that the cable glands and

plug connections are not damaged.

1. Loosen the 4 fixing screws on the bottom plate of

the Sunny String-Monitor.

2. Remove the upper kick plate.

3. Place the Sunny String-Monitor on the base.

4. Fix the Sunny String-Monitor to the base using the screws that were previously removed.

5. Insert all the output cables through bottom plate into the Sunny Strong-Monitor, and fasten to

the internal cable support rail.

6. In order to stop the kick plate from being opened by unauthorized persons, fit the two safety

bolts to the inner side of the bottom plate.

Installation Guide SSM16-24-IA-IEN105120 25

Page 26

5 Assembly SMA Solar Technology AG

%"/(&3

5.2 Wall Mounting

5.2.1 Selecting the Mounting Location

Danger to life due to fire or explosion.

• Do not install the Sunny String-Monitor on flammable construction materials.

• Do not install the Sunny String-Monitor near highly flammable materials.

• Do not install the Sunny String-Monitor in potentially explosive areas.

☐ The mounting location is not an escape route, nor in a residential or office area.

☐ The mounting wall can support the weight of the Sunny String-Monitor.

☐ The mounting location must be easily accessible for maintenance work.

☐ Mounting location is shaded.

☐ The mounting location is protected from rain as far as possible.

• Include external cable support rail.

• Mount the Sunny String-Monitor so that the connection area is pointing downward.

• Do not mount the Sunny String-Monitor flat on its back or leaning.

• If the PV array has a stand, place the

SunnyString‑Monitor on the PV array stand in the

shade.

26 SSM16-24-IA-IEN105120 Installation Guide

Page 27

SMA Solar Technology AG 5 Assembly

/05*$&

5.2.2 Mounting the Sunny String-Monitor

Damage to the cable glands and plug connections due to improper transport and

installation.

The cable glands and plug connections protrude from the enclosure.

• When transporting and mounting the Sunny String-Monitor, ensure that the cable glands and

plug connections are not damaged.

Required Material:

• 4 screws with a diameter of 8 mm. Consider the wall properties when choosing the screws.

•4 washers

• 4 screw anchors. Consider the wall properties when choosing the screw anchors.

Figure8:SSM 16-11 dimensions

Installation Guide SSM16-24-IA-IEN105120 27

Page 28

5 Assembly SMA Solar Technology AG

Figure9:SSM 24-11 dimensions

1. Mark the position of the holes.

2. Drill the holes in the indicated positions.

3. Insert the screw anchors.

4. Attach the mounting rails to the

SunnyString‑Monitor with the screws supplied

(torque: 15 Nm).

5. Fasten the Sunny String-Monitor to the wall or stand using suitable screws. The connection area

must point downwards.

6. Make sure that the device is securely in place.

28 SSM16-24-IA-IEN105120 Installation Guide

Page 29

SMA Solar Technology AG 6 Electrical Connection

6 Electrical Connection

6.1 Overview of the Connection Area

Figure10:Terminals for connections

Position Designation

A Main DC cable connection, − pole

B DC-string connections − pole

C Grounding cable connection

D Connection for remote tripping

*

E Data cable connection

F DC-string connections, +pole

G Main DC cable connection, +pole

*

optional

Installation Guide SSM16-24-IA-IEN105120 29

Page 30

6 Electrical Connection SMA Solar Technology AG

B

A

C

D

Figure11:View of the Sunny String-Monitor from below (example)

Position Designation

ADrainage channels

B Cable entry for connecting the string +pole

*

C Cable entry for connecting the incoming data cable

D Cable entry for connecting the outgoing data cable

E Cable entries for connecting to the remote tripping device

F Cable entry for connecting the main DC cable +pole

**

G Cable entry for connecting the main DC cable +pole

H Cable entry for connecting the grounding cable

I Cable entry for connecting the main DC cable − pole

K Cable entry for connecting the main DC cable − pole

L Cable entry for connecting the strings − pole

*

optionally with DC connector

**

optional

**

*

Figure12:Operating status LEDs

Position LED Meaning

A LED 1, green Digital input, optional for theft protection

B LED 2, green Surge arrester

30 SSM16-24-IA-IEN105120 Installation Guide

Page 31

SMA Solar Technology AG 6 Electrical Connection

Position LED Meaning

C LED 3, orange Data transmission

D LED 4, red Failure of the control board

6.2 Connecting the PV Strings

6.2.1 Calculating the Maximum Number of Strings per Measuring Input

You can connect several PV strings in parallel in the Sunny String-Monitor. The maximum number of

PV strings connected in parallel depends on the adjustable tolerance and can be determined as

follows:

N = maximum number of PV strings that can be connected in parallel.

You can adjust the "Tolerance" parameter through the Sunny Central Control, Sunny Data Control or

Sunny WebBox, depending on the type of inverter.

Maximum Number of Strings

If you connect more PV strings than the calculated maximum, it is not possible to detect the

failure of one PV string.

• Adhere to the maximum number of PV strings which can be connected in parallel.

6.2.2 Connecting the PV Strings to Isolation Terminals

1. For each cable entry, remove the filler-plugs from the cable glands.

2. Guide the strings through the cable glands into the enclosure interior. Make sure polarity is

correct when doing this.

3. Cut the wires to length and strip 12 mm off the insulation.

4. Connect the wires to the isolation terminals. Make sure polarity is correct when doing this.

5. Tighten the cable glands.

6.2.3 Connecting the PV Strings to the SUNCLIX DC Plug Connectors

Requirement:

☐ There is one SUNCLIX DC plug connector for each string cable.

☐ PV1-F cable is available.

Installation Guide SSM16-24-IA-IEN105120 31

Page 32

6 Electrical Connection SMA Solar Technology AG

+

++

+

+

Procedure:

• Assemble the SUNCLIX DC plug connectors

• Connect the SUNCLIX DC plug connectors to the Sunny String-Monitor

Assemble the SUNCLIX DC plug connectors

Figure13:SUNCLIX DC plug connector

Position Designation

A Negative DC plug connector

B Positive DC plug connector

Use the following procedure to assemble each DC plug connector.

1. Cut the wire to length and strip 12 mm off the insulation.

2. Guide the stripped wire all the way into the DC

plug connector. Ensure the correctness of the

polarity assignment and of the type of plug.

3. Push the clamping clip downward.

☑ The clamping clip snaps audibly into place.

☑ The stranded wire can be seen inside the

clamping clip chamber.

32 SSM16-24-IA-IEN105120 Installation Guide

Page 33

SMA Solar Technology AG 6 Electrical Connection

+

1

2

+

1

2

✖ Is the stranded wire not visible in the chamber?

The stranded wire is not correctly in place.

• Declamp the clamping clip. To do this insert

a screwdriver with a 3.5 mm blade into the

clamping clip and pry it out.

• Remove the wire and start again from step 2.

4. Push the bolted connection toward the thread and

screw it tight (torque of 2 Nm).

Connect the SUNCLIX DC plug connectors to the Sunny String-Monitor

1. Remove the transport plugs from all the DC plug connectors.

2. Connect the assembled DC connectors to the Sunny String-Monitor.

☑ The DC connectors click audibly into position.

3. Ensure that all DC connectors are securely in place.

4. Insert the sea ling pl ugs int o the DC connec tors th at

are not required. This way you seal the DC plug

connectors.

Sealing plug

The sealing plugs included in the delivery are meant only for the DC plug connectors.

• Do not insert the sealing plugs into the DC inputs on the Sunny String-Monitor.

Installation Guide SSM16-24-IA-IEN105120 33

Page 34

6 Electrical Connection SMA Solar Technology AG

/05*$&

5. Insert the DC plug connectors with sealing plugs into the remaining DC inputs on the Sunny

String-Monitor. This way you seal the Sunny String-Monitor.

6.2.4 Connecting the PV Strings to Tyco, MC3, and MC4 Plug Connectors

1. Remove the sealing plugs from the plugs.

2. Connect the DC plug connectors.

6.3 Connecting the DC Main Cable

Damage to the electronics due to wrong cable installation.

In order for the Sunny String-Monitor and Sunny Central to work properly, EMC guidelines must be

observed.

• Lay the DC main cable and the data cable se parate ly and at a distance greater than 400 mm

from one another.

Requirement:

☐ The correct terminal cross section for the main DC cable has been chosen.

Terminal Cross Section for Copper Cable

Connection

terminal

maximum

240 mm

maximum

300 mm

*

Sunny String-Monitor SSM16/24-11 with bottom plate: connection of 1 cable per DC terminal possible.

**

Sunny String‑Monitor SSM16/24-11 without bottom plate: connection of 2 cables per DC terminal possible.

34 SSM16-24-IA-IEN105120 Installation Guide

2

2

Number of

cables

*

1

**

2

*

1

**

2

Round,

single-strand

25 mm2…

2

50 mm

25 mm2…

2

50 mm

- 150 mm2…

2

70 mm

Terminal cross section

Round,

multi-strand

25 mm2…

240 mm

25 mm2…

120 mm

300 mm

70 mm2…

185 mm

2

2

2

2

single-strand

50 mm2…

50 mm2…

150 mm2…

95 mm2…

Sectoral,

185 mm

120 mm

185 mm

185 mm

2

2

2

2

Sectoral,

multi-strand

35 mm2…

35 mm2…

150 mm2…

95 mm2…

240 mm

120 mm

240 mm

185 mm

2

2

2

2

Page 35

SMA Solar Technology AG 6 Electrical Connection

Terminal Cross Section of Aluminum Cable

Connection

terminal

maximum

240 mm

maximum

300 mm

*

Sunny String-Monitor SSM16/24-11 with bottom plate: connection of 1 cable per DC terminal possible.

**

Sunny String‑Monitor SSM16/24-11 without bottom plate: connection of 2 cables per DC terminal possible.

2

2

Number of

cables

*

1

**

2

*

1

**

2

Round,

single-strand

25 mm2…

2

50 mm

25 mm2…

2

50 mm

- 150 mm2…

2

70 mm

Terminal cross section

Round,

multi-strand

25 mm2…

240 mm

25 mm2…

120 mm

300 mm

70 mm2…

185 mm

2

2

2

2

single-strand

50 mm2…

50 mm2…

150 mm2…

95 mm2…

Sectoral,

185 mm

120 mm

185 mm

185 mm

2

2

2

2

Sectoral,

multi-strand

95 mm2…

185 mm

50 mm2…

2

95 mm

150 mm2…

240 mm

95 mm2…

185 mm

1. Remove filler-plugs from the cable glands.

2. Guide the DC main cable through the cable glands into the enclosure interior. Make sure

polarity is correct when doing this.

3. Strip the main DC cable appropriately for terminal used and attach it to cage clamps. Tighten

to the torque specified.

Terminal Stripped insulation Torque

240 mm² terminal 35 mm 40 Nm

300 mm² terminal 45 mm 50 Nm

2

2

2

4. Make sure that it is securely in place.

5. Tighten the cable glands.

6.4 Connecting the Grounding Cable

To guarantee the functionality of the integrated surge arrester, this must be connected to an external

earth.

Requirement:

☐ Minimum cross section of the grounding cable 16 mm

1. Remove the filler-plugs from the cable gland.

2. Guide the grounding cable through the cable gland into the enclosure interior.

3. Strip the grounding cable 16 mm.

4. Connect the grounding cable to the ground terminal (torque: 3.5 Nm).

5. Tighten the cable gland.

Installation Guide SSM16-24-IA-IEN105120 35

2

Page 36

6 Electrical Connection SMA Solar Technology AG

/05*$&

6. Ground the grounding cable in the vicinity of the Sunny String-Monitor, for example, with a

ground rod.

6.5 Connecting the Data Cable

6.5.1 Selecting the Data Cable

Damage to the electronics due to wrong cable installation.

In order for the Sunny String-Monitor and Sunny Central to work properly, EMC guidelines must be

observed.

• Lay the AC/DC main cable and the data cable separately and at a distance greater than

400 mm from one another.

• Lay the data cable shield in the Sunny Central and in the Sunny String-Monitor.

The data cable of the RS485 communication and the power supply connects the Sunny StringMonitor to the Sunny Central.

• Use a shared cable of type Li2YCYv (TP) 4 x 2 x 0.5 mm for the data cable of the RS485

communication and the +55 VDC voltage supply.

6.5.2 Connecting the Data Cable Shield Contact

1. Remove the filler-plugs from the cable gland.

2. Guide the data cables through the cable gland into the enclosure interior.

3. Remove the data cable cover.

4. Loosen the thumbscrew on the shield clamp and

pull the cable through. Lay the cable shield on the

shield rails as you do so.

Maximum shield diameter 8 mm

5. Only tighten the shield clamps hand-tight. This prevents any damage to the insulation.

6. Tighten the cable gland.

36 SSM16-24-IA-IEN105120 Installation Guide

Page 37

SMA Solar Technology AG 6 Electrical Connection

6.5.3 Connecting the Data Cable in the Sunny String-Monitor

Parallel Connection of the Data Cables

• If you are using several Sunny String-Monitors, connect them in parallel. This way there

will be an incoming and an outgoing data cable at every Sunny String-Monitor. Only

one incoming data cable is connected to the last Sunny String-Monitor.

You can use the Sunny String-Monitor SSM as well as the Sunny String-Monitor SSM16-11 and the

Sunny String-Monitor SSM24-11 for string monitoring. These have various numbers of Piggy-Backs

for data processing.

• Sunny String-Monitor SSM: 1 Piggy-Back for data processing.

• Sunny String‑Monitor SSM16-11: 2 Piggy-Backs for data processing.

• Sunny String-Monitor 24-11: 3 Piggy-Backs for data processing.

Limited Number of Piggy-Backs for Data Processing per Hub

The voltage supply to the measuring boards via the communication cables limits the number

of Sunny String-Monitors that can be connected.

• Connect a maximum of 10 Piggy-Backs for data processing per hub.

Installation Guide SSM16-24-IA-IEN105120 37

Page 38

6 Electrical Connection SMA Solar Technology AG

S

Figure14:Connection of the data cables between the Sunny String-Monitors

1. Strip 8 mm from each wire in the data cable.

2. Remove the sticker from the communication terminal strip.

3. Connect the wires of the data cable to the connection terminals. Observe the terminal

allocation.

4. Conduct the wiring between the individual Sunny String-Monitors in a bu s. O bse rve the ter min al

allocation of the data cable.

6.5.4 Connecting the Data Cable in the Sunny Central

For the Sunny Central 100/200/250/350 and the Sunny Central in the HE--11 series the Sunny

String-Monitor data cable is connected to the hub. There are twocommunications connections to

which up to 10 Piggy-Backs each can be connected for data processing.

For the Sunny Centrals in the CP and HE-20 series the SunnyString‑Monitor can be connected to a

dedicated terminal strip (please consult the installation guides for t he releva nt c entral invert ers for how

to connect the Sunny String-Monitors to the Sunny Centrals of the CP and HE-20 series). There are

threecommunications connections to which up to 10 Piggy-Backs each can be connected for data

processing.

38 SSM16-24-IA-IEN105120 Installation Guide

Page 39

SMA Solar Technology AG 6 Electrical Connection

Figure15:Connection of the data cables between the Sunny Central in the HE-11 series and the

SunnyString‑Monitors

1. Guide the data cable into the Sunny Central (see the installation guide for the Sunny Central in

question).

2. Strip 8 mm from each wire in the data cable.

3. Remove the sticker on the connection area of the hub.

4. Connect the wires of the data cable to the connection terminals on the hub in accordance with

the Sunny Central circuit diagram. Observe the terminal allocation of the data cable.

Installation Guide SSM16-24-IA-IEN105120 39

Page 40

6 Electrical Connection SMA Solar Technology AG

6.6 Connecting the Remote Tripping for the DC Circuit Breaker

6.6.1 Dimensioning the Connection Cable for the Shunt Trip

The Sunny String-Monitor optionally includes a DC circuit breaker with a remote trigger. The remote

trigger consists of a shunt release and a feedback contact. The shunt release can be implemented as

a shunt trip or undervoltage release.

In order to achieve reliable tripping, the minimum cross section of the connection cable on the shunt

trip must be determined. The choice of connection cable cross section depends on the following

factors:

• The number of Sunny String-Monitors connected

• The length of the cable supplying the voltage

• The cable lengths between the Sunny String-Monitors connected

Figure16:Relationship between cable length, number of Sunny String-Monitors connected and cable crosssection.

1. Determine the number of DC circuit breakers.

2. Determine the greatest distance between the Sunny String-Monitors or the voltage supply and

the first Sunny String-Monitor.

3. Read off the minimum cable cross section from figure 16.

Example: Dimensioning a Connection Cable

In a PV plant there are 20 DC circuit breakers. The greatest distance between the

SunnyString‑Monitors is 150 m.

The cable cross section must be at least 4 mm

40 SSM16-24-IA-IEN105120 Installation Guide

2

.

Page 41

SMA Solar Technology AG 6 Electrical Connection

/05*$&

6.6.2 Connecting the Shunt Release

De pen din g on the ord er, the Sun ny S tri ng- Mon ito r in clu des a DC circuit breaker with a remote trigger.

In this case the DC circuit breaker is equipped with a shunt release and a feedback contact.

Destruction of the shunt release due to faulty cable dimensioning.

If the cable cross section is too small, the shunt release can malfunction and be destroyed.

• If the shunt release is implemented as a shunt trip, the connection cable must be correctly

dimensioned (see section 6.6.1”Dimensioning the Connection Cable for the Shunt

Trip”,page40).

• If the shunt release is implemented as an undervoltage release, observe the requirements for

the connection cable.

Line Fuse

• Furnish the connection cable of the remote trigger with a suitable line fuse.

Requirements for the connection cable of the undervoltage release.

☐ Cable cross section: at least 2.5 mm

☐ Total cable length: 1 000 m maximum.

1. Remove the filler-plugs from the cable gland.

2. Guide the connection cable through the cable gland into the enclosure interior.

3. Strip the connection cable 14 mm.

4. Connect the connection cable to the terminal strip

as shown in the circuit diagram.

2

.

5. Tighten the cable gland.

6.6.3 Connecting the Feedback Contact

1. Remove the filler-plugs from the cable gland.

2. Guide the connection cable through the cable gland into the enclosure interior.

3. Strip the connection cable 11 mm.

Installation Guide SSM16-24-IA-IEN105120 41

Page 42

6 Electrical Connection SMA Solar Technology AG

4. Connect the connection cable to the terminal strip as

shown in the circuit diagram.

5. Tighten the cable gland.

6.7 Installing the Theft Protection

On the Sunny Central 100/200/250/350 inverters and the Sunny Central inverters in the HE‑11

series you can activate the theft protection for the PV modules via the Sunny String-Monitor.

The contacts at the PV modules are connected to form a signal chain for the theft protection. Upon

interruption of the signal chain, an theft warning appears in the Sunny Central Control display, and

an e-mail message is sent immediately.

Installation of the cable gland and wiring is carried out by the customer.

Nighttime deactivation

The theft protection only functions if the nighttime deactivation has been deactivated. If the

nighttime deactivation is activated, the message is not sent until the supply voltage has been

switched on again.

• Deactivate the nighttime deactivation for theft protection (see section 9.3.6”Setting the

Nighttime Deactivation”,page51).

Requirement:

☐ The signal chain has a maximum 300 Ohm loop resistor.

1. Implement the contacts at the PV modules as normally closed contacts and connect to form a

signal chain.

2. Integrate the signaling contact for the theft

protection on the String Monitor Unit into the

monitoring circuit.

3. Activate the theft protection via the Sunny Central Control or via Sunny Data Control (see

section 9.3.7”Setting the Theft Protection”,page52 or section 10.3.8”Setting the Theft

Protection”,page59)

42 SSM16-24-IA-IEN105120 Installation Guide

Page 43

SMA Solar Technology AG 7 Commissioning

7Commissioning

7.1 Safety

Electric Shock

The Sunny String-Monitor is connected to high voltages. Work on the Sunny String-Monitor is only

allowed if the power is disconnected and in compliance with the guidelines that apply at the

installation location.

• Disconnecting the device:

– Remove the DC fuses in the central inverter or main DC distributor, such as the Sunny Main

Box, in a no-load condition.

– Switch off the DC circuit breaker in the Sunny String-Monitor.

– Only open or close the isolation terminals in the Sunny String-Monitor in a no-load condition.

– Only insert or remove the fuses when wearing personal protective gear.

– Only plug in or unplug the solar plug when no current is present.

• Ensure that the device cannot be reconnected.

• Ensure that no voltage is present in the system.

• Ground and short-circuit.

• Cover or safeguard any adjacent live components. Protective covers must always be fitted.

7.2 Preparing and Carrying Out Commissioning

7.2.1 Requirements for Commissioning

The commissioning report must be filled out during commissioning. The commissioning report is

enclosed with the Sunny Central.

Requirements:

☐ The DC circuit breaker is disconnected.

☐ The DC main cables are connected to the inverter or DC distribution box and are activated.

There is no reverse voltage from the inverter.

☐ All connections are made according to this manual (see section 6”Electrical

Connection”,page29).

☐ The ground underneath the Sunny String-Monitors is firm and can be walked on.

7.2.2 Terminating the Data Cable

In each case, the last Sunny String-Monitor of a string and the hubs in the Sunny Central are

terminated.

Installation Guide SSM16-24-IA-IEN105120 43

Page 44

7 Commissioning SMA Solar Technology AG

The Sunny String-Monitors are not terminated on delivery so that they can be configured as required

on site. The hubs in the Sunny Central are terminated on delivery.

Figure17:Termination of the data cable (example)

Requirement:

☐ All Sunny String-Monitors on a string are connected to the RS485 bus (see section

6.5.3”Connecting the Data Cable in the Sunny String-Monitor”,page37 and section

6.5.4”Connecting the Data Cable in the Sunny Central”,page38).

1. Plug the jumper on the upper String Mon itor Un it into

the last Sunny String-Monitor of each string.

44 SSM16-24-IA-IEN105120 Installation Guide

Page 45

SMA Solar Technology AG 7 Commissioning

A

B

C

2. When the jumpers of the String Monitor Units of the other Sunny String-Monitors of the string

have been plugged in, remove the jumpers.

3. Make sure that the terminating resistor at the hub in the Sunny Central is plugged into the

"485 Out" RJ45 socket.

7.2.3 Noting the Serial Number of the Piggy-Backs for Data Processing

The serial number of the Piggy-Backs for data processing serves to identify the String Monitor Unit.

The position of the serial number depends on the production version of the Piggy-Back for data

processing.

All the serial numbers of the Piggy-Backs for data processing in all the Sunny String-Monitors must be

written down in the commissioning report. You need the serial numbers for detecting the

SunnyString‑Monitors.

Figure18:Possible position of the serial number

Position Designation

A Serial number on the left

B Serial number in the centre

C Serial number on the right

• Identify the serial numbers and note them in the commissioning report.

7.2.4 Filling In the Commissioning Report

• Check the following points and document them in the commissioning report:

– Polarity of the DC voltages at the string inputs and at the DC main cables.

– All strings have similar voltage values.

– Check for the absence of ground faults on the strings and the DC main cables.

– Inspect the screw connections visually.

– Fuses correspond to the system design.

Installation Guide SSM16-24-IA-IEN105120 45

Page 46

7 Commissioning SMA Solar Technology AG

%"/(&3

–The terminal allocation of the data cable is correct.

– All protective covers are fitted.

7.3 Switching On the Sunny String-Monitor

Requirement:

☐ Voltage supply for the measuring boards is present.

1. Remove protective covers.

2.

Risk of lethal electric shock.

• Disconnect the voltage from the Sunny String-Monitor before inserting the string fuses.

3. Replace the protective covers.

4. Connect up the isolation terminals in a no-load condition.

5. Activate the DC circuit breaker.

☑ O n th e co ntr ol cir cui t bo ard LED s 1 and 2 gl ow gre en a nd L ED 3 gl ows ora nge per iodic all y.

Theft protection and surge arrester are intact. Data cable and control circuit board are ok.

✖ On t he c ontrol ci rcu it b oar d, a re L ED 1 or LED 2 no t li t up , has LED 3 not lit up a fte r 5 minute s,

is LED 4 lit up and red?

• See section 12”Troubleshooting”,page68.

7.4 Reconnecting the DC Circuit Breaker after Tripping

If the PV array has been disconnected from the inverter with the remote trip in the

SunnyString‑Monitor, you must switch the DC circuit breaker on again manually.

1. Search for the cause of the tripping, and remove it.

2. Open the Sunny String-Monitor.

3. Switch the DC circuit breaker manually from the tripped position to the off position.

4. Switch the DC circuit breaker manually from the off position to the on position.

☑ The DC circuit breaker is switched to "On".

✖ Not possible to turn the DC circuit breaker?

The shunt release is activated.

• If the shunt release is a shunt trip, make sure there is no current at the shunt trip.

• If the shunt release is an undervoltage release, make sure that there is a voltage at the

undervoltage release.

5. Close the Sunny String-Monitor.

46 SSM16-24-IA-IEN105120 Installation Guide

Page 47

SMA Solar Technology AG 8 Disconnecting the Sunny String-Monitor

%"/(&3

%"/(&3

8"3/*/(

%"/(&3

8 Disconnecting the Sunny String-Monitor

Risk of lethal electric shock.

• Pay attention to the safety rules.

– Disconnecting the device

– Ensure that the device cannot be reconnected

– Ensure that no voltage or current is present

– Cover or isolate adjacent live elements

Risk of lethal electric shock. The discharge time of the capacitors is longer than 5 minutes.

• After disconnection, wait until the capacitors have discharged.

Danger of burns from touching hot component parts.

• Wear gloves when working on the device.

1. If there is a DC circuit breaker on the Sunny String-Monitor, disconnect it. This ensures that there

is no current flowing through the Sunny-String-Monitor.

2. If there is no DC circuit breaker, disconnect the Sunny Central (see the installation guide for the

Sunny Central).

3. If there are fuses in the Sunny Central, remove them. Use an LV/HRC fuse handle to do this.

4. If there are no fuses in the Sunny Central, remove the fuses in the DC main distributor.

5.

Risk of lethal electric shock.

• Only open the isolation terminals in a no-load condition.

6. Disconnect all the DC plug connectors.

Installation Guide SSM16-24-IA-IEN105120 47

Page 48

9 Configuring the Sunny String-Monitor via Sunny Central Control SMA Solar Technology AG

9 Configuring the Sunny String-Monitor via Sunny

Central Control

9.1 Organizing the Configuration

On the Sunny Central 100/200/250/350 inverters and the Sunny Central in the HE‑11 series, you

can configure the Sunny String-Monitor through the Sunny Central Control data logger. The Sunny

Central Control is integrated in the central inverter.

Consult the user manual for the central inverter on how to operate the Sunny Central Control and on

the meaning of the keys.

Password Protection

The installer password must be entered in order to configure the Sunny Central String-Monitor

in the Sunny Central Control (please see the user manual for the central inverter).

9.2 Detecting Sunny String-Monitors

Procedure:

• Setting the serial interface

• Detecting the Sunny String-Monitor

• Updating identification of the String Monitor Units

Setting the serial interface

Parameters of the COM1 interface are predefined and factory-set:

• Medium: RS485

• Baudrate: 19200 Baud

•Protocol: SMA-Net

1. Select Device Set-up > Interfaces > Communication > COM1:SMUs.

☑ The interface parameters appear:

2. If the parameters are not set as described above, correct them.

48 SSM16-24-IA-IEN105120 Installation Guide

Page 49

SMA Solar Technology AG 9 Configuring the Sunny String-Monitor via Sunny Central Control

Detecting Sunny String-Monitor

1. When you first detect the Sunny String-Monitor, delete any Sunny String-Monitors already

detected.

•Select Device Set-up > SMUs > Devices > Registration.

• Select the String Monitor Unit you want.

• Select the ID submenu.

• Set the ID number to 99.

• Adopt all changes with the [Enter] key.

2. Select Device Set-up > SMUs > Devices > Detection.

☑ The Sunny Central Control begins detection of new devices automatically.

✖ Are there any problems in detecting the Sunny Central String-Monitors?

• See section 12”Troubleshooting”,page68.

3. Adopt the changes and save them with the [Enter] key.

4. Select Device Set-up > SMUs > Devices > Registration.

5. Compare the serial numbers displayed with the serial numbers you noted (see section

7”Commissioning”,page43).

☑ All the noted serial numbers are on the list.

✖ Not all noted serial numbers are on the list?

• Start again with step 2.

Updating identification of the String Monitor Units

To identify the String Monitor Units in the Sunny String-Monitor, each Piggy-Back for data processing

is assigned a number as an "SSM identifier". This makes troubleshooting easier, for example, in the

event of a string failure, or deviating string currents. The "SSM Identifier" does not correspond to the

network address which is automatically assigned upon detection. The Su nny Central Control support s

up to 40 "SSM Identifiers".

1. Select Device Set-up > SMUs > Devices > Parameters.

2. Select the String Monitor Unit you want.

3. Select the SSM Identifier parameter.

4. Give the String Monitor Unit you want a unique identification number between 1 and 40.

5. Adopt all changes with the [Enter] key.

Installation Guide SSM16-24-IA-IEN105120 49

Page 50

9 Configuring the Sunny String-Monitor via Sunny Central Control SMA Solar Technology AG

9.3 Setting the Parameters for the String Current Monitoring

9.3.1 Setting the Number of Strings per Measuring Channel

The number of strings per channel for the eight measuring channels can be selected from 1 to 4. The

default setting is "1". The maximum number of strings per channel is limited to 4.

The ideal number of strings for each measuring channel is 2. Depending on the system design it is

possible to connect more strings in parallel outside the Sunny String-Monitor and append them to a

measuring channel (see section 6.5.3”Connecting the Data Cable in the Sunny StringMonitor”,page37).

In the submenu No. of Str. All you can assign all channels of the Sunny String-Monitor to a string

number of 1 to 4.

No strings in a measuring channel

• If there are no strings connected to a measuring channel, assign this channel to the

0 group (see section 9.3.2”Setting the Groups”,page50).

1. Select Device Set-up > SMUs > Devices > Parameters.

2. Select the String Monitor Unit you want.

3. In the submenu No. Of Strings or No. of Str. All set the number of strings connected per

measuring channel used.

9.3.2 Setting the Groups

With Sunny Central Control one can subdivide the individual measuring channels of the connected

String Monitor Units into 3 groups, to make it possible to compare only th e measu ring ch annels which

have the same properties. The groups are monitored independently of each other, and each

individual measuring channel can be allocated freely to any group. An individual group must include

at least 4 measuring channels.

In the Group all chan. all the measuring channels of the String Monitor Unit can be assigned to a

group.

If you wish not to include individual channels from the String Monitor Unit in the string current

monitoring, these must be assigned to the 0 group, since string current monitoring is deactivated for

this group. This way, this measuring channel is not included in the mean value calculation.

1. Select Device Set-up > SMUs > Devices > Parameters.

2. Select the String Monitor Unit you want.

3. In the Group channel or Group all chan. submenu, set the group numbers for individual

measuring channels or for all of them.

50 SSM16-24-IA-IEN105120 Installation Guide

Page 51

SMA Solar Technology AG 9 Configuring the Sunny String-Monitor via Sunny Central Control

9.3.3 Setting the Tripping Time

Using the tripping time, you can set the sensitivity of the string current monitoring, since it is included

in the calculation of the error sum. The tripping time is set to 180 minutes as default.

1. Select Device Set-up > SMUs > Parameters.

2. In the Error Report Time submenu, set the value in minutes.

9.3.4 Setting the Tolerance

You can use the tolerance to set the sensitivity of the string current monitoring, since it is included in

the calculation of the error sum. The tolerance is set to 10% as default.

Since only a clear deviation of a measuring channel from a mean value is an indication of a faulty

string, whereas minor deviations can be considered normal, the tolerance value must be set

accordingly high.

1. Select Device Set-up > SMUs > Parameters

2. In the submenu tolerance grp, set the value per group.

9.3.5 Setting the Monitoring Period

You can define a monitoring period for each individual measuring channel on the Sunny StringMonitor. This allows you to filter out temporary effects such as shading on individual strings.

Under Monitoring On and Monitoring Off, one can set a specific time window for all measuring

channels of the Sunny String-Monitor for string current monitoring.

1. Select Device Set-up > SMUs > Devices > Parameters.

2. Select the String Monitor Unit you want.

3. In the submenu Monitoring (X) On and Monitoring (X) Off, one can set a specific time

window per measuring channel or for all the measuring channels of the Sunny String-Monitor.

9.3.6 Setting the Nighttime Deactivation

Nighttime deactivation in the Sunny Central is activated by default. Thus, the power supply to the

Sunny String-Monitors is deactivated in the Sunny Central as soon as the PV voltage has been under

250 V for one hour. The supply voltage switches itself on as soon as the PV voltage reaches 250V.

If nighttime deactivation is deactivated, the supply voltage to the Sunny String-Monitor remains on at

night. This means that theft protection can be activated and evaluated, see section 9.3.7”Setting the

Theft Protection”,page52.

1. Select Device Set-up > SMUs > Parameters.

2. In the submenu SMU Overn. Shut, set the nighttime disconnection.

Installation Guide SSM16-24-IA-IEN105120 51

Page 52

9 Configuring the Sunny String-Monitor via Sunny Central Control SMA Solar Technology AG

9.3.7 Setting the Theft Protection

Theft protection is deactivated by default in Sunny Central Control.

1. Select Device Set-up > SMUs > Parameters.

2. In the SMU Theft. submenu, set the theft protection.

9.4 Reading the Measured Values

9.4.1 Reading the Mean Values of the Groups

The mean values of the measuring channels for each group are displayed and updated at 5 minute

intervals.

•Select Device Set-up > SMUs > Measured Values and read the values.

9.4.2 Reading the Mean Values for the Individual Measuring Channels

The mean values for the individual measuring channels are updated and displayed at 5-minute

intervals.

•Select Device Set-up > SMUs > Devices > Measured Values and read the values.

9.5 Reading and Confirming Messages

9.5.1 Resetting the Messages

The individual meanings of the warnings and failures in the Sunny Central Control can be found in the

Sunny Central user manual.

Sunny Central Control resets messages which appear during a day automatically at midnight. These

messages can be read the next day in the event history. The individual error sums of the measuring

channels are reset at 00:00 o'clock.

9.5.2 Reading and Confirming Current Messages

1. Select Device Set-up > SMUs > Failure > actual Failures.

2. To confirm the message, select the submenuSMU Error quit. By doing this, you reset the error

sum.

9.5.3 Reading and Confirming the Event History

1. Select Device Set-up > SMUs > Failure > Hist. Failures.

2. To confirm the message, select the submenu SMU Error quit. By doing this, you reset the error

sum.

52 SSM16-24-IA-IEN105120 Installation Guide

Page 53

SMA Solar Technology AG 10 Configuring the Sunny String-Monitor with Sunny Data Control

10 Configuring the Sunny String-Monitor with Sunny

Data Control

10.1 Organizing the Configuration

For the Sunny Central 100/200/250/350 inverters and the Sunny Central of the HE‑11 series, you

can configure the Sunny String-Monitor with the Sunny Data Control program.

Sunny Data Control is a PC program by SMA Solar Technology AG with which you can store your

PV plant data in the long term and visualize it. Sunny Data Control can be downloaded free from

www.SMA.de/en (For information on how to use Sunny Data Control, see the Sunny Data Control

user manual at www.SMA.de/en).

Sunny Data Control Version

• Use Sunny Data Control up to version 3.9.3 to configure the Sunny String-Monitor.

Password Protection

In order to change parameters, entering the installer password is required. Contact the

SMA Serviceline about this (please see the user manual for Sunny Data Control at

www.SMA.de/en for information about password protection).

If you re-install Sunny Data Control on your PC, default values are set for this new version. To allow

communication with Sunny Central Control, these values must be modified as follows:

Property Default value Value for Sunny Central Control

Channel request 10 s 200 s

Storage time request 10 s 200 s

Detection Find First 5 s 10 s

Detection Find Next 7 s 10 s

Installation Guide SSM16-24-IA-IEN105120 53

Page 54

10 Configuring the Sunny String-Monitor with Sunny Data Control SMA Solar Technology AG

Figure19:Window for setting of required values

Position Designation

A Tree structure

B"Settings" area

C Parameters to be set

D"Value" field

E[OK] button