Page 1

Installation Manual

SMA SPEEDWIRE/WEBCONNECT Piggy-Back

SPW-WebconPB-IA-en-11 | Version 1.1 ENGLISH

Page 2

Legal Provisions SMA Solar Technology AG

Legal Provisions

The information contained in this document is the property of SMA Solar Technology AG. Publishing

its content, either partially or in full, requires the written permission of SMA Solar Technology AG.

Any internal company copying of the document for the purposes of evaluating the product or its

correct implementation is allowed and does not require permission.

SMA Warranty

You can download the current warranty conditions from the Internet at www.SMA-Solar.com.

Trademarks

All trademarks are recognized, even if not explicitly identified as such. A lack of identification does

not mean that a product or symbol is not trademarked.

The BLUETOOTH

and any use of these marks by SMA Solar Technology AG is under license.

Modbus® is a registered trademark of Schneider Electric and is licensed by the Modbus

Organization, Inc.

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

®

Phillips

and Pozidriv® are registered trademarks of Phillips Screw Company.

®

Torx

is a registered trademark of Acument Global Technologies, Inc.

SMA Solar Technology AG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

E-mail: info@SMA.de

© 2004 to 2014 SMA Solar Technology AG. All rights reserved.

®

word mark and logos are registered trademarks owned by Bluetooth SIG, Inc.

2 SPW-WebconPB-IA-en-11 Installation Manual

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Information on this Document. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Supported Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Qualifications of Skilled Persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Operating Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 SMA Speedwire/Webconnect Piggy-Back . . . . . . . . . . . . . . . . . . . . 11

4.2 Possible Network Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4 Cable Gland . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Inverter Connection Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Cable Requirements and Information on Routing . . . . . . . . . . . . . . . 17

5.3 Connecting the Cable to the Communication Terminal . . . . . . . . . . . 17

5.4 Installing the Piggy-Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1 Commissioning a Large-Scale PV Plant with Cluster Controller . . . . . 22

6.2 Commissioning a Small Plant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 Managing Small Plants with Sunny Explorer. . . . . . . . . . . . . . . . . . . 23

6.3.1 Functions and Parameter Settings in Sunny Explorer . . . . . . . . . . . . 23

6.3.2 Connecting to Sunny Explorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4 Plant Registration in Sunny Portal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4.1 Registering a Small Plant in Sunny Portal. . . . . . . . . . . . . . . . . . . . . 24

6.4.2 Registering a Large-Scale PV Plant with Cluster Controller in

Sunny Portal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installation Manual SPW-WebconPB-IA-en-11 3

Page 4

Table of Contents SMA Solar Technology AG

7 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.1 Removing the Piggy-Back. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.2 Disposing of the Piggy-Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.1 General Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.2 Performing a Piggy-Back Update. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4 SPW-WebconPB-IA-en-11 Installation Manual

Page 5

SMA Solar Technology AG 1 Information on this Document

1 Information on this Document

Validity

This document is valid for device type "SWPB-10.BG1" from hardware version A and firmware

version 1.00.00R.

Target Group

This document is for skilled persons. Only qualified personnel are allowed to perform the tasks

described in this manual (see Section2.3 "Qualifications of Skilled Persons", page8).

Symbols

Symbol Explanation

Indicates a hazardous situation which, if not avoided, will result in death

or serious injury

Indicates a hazardous situation which, if not avoided, could result in death

or serious injury

Indicates a hazardous situation which, if not avoided, could result in minor

or moderate injury

Indicates a situation which, if not avoided, could result in property damage

Information that is important for a specific topic or goal, but is not

safety-relevant

☐ Indicates an essential requirement for achieving a specific goal

☑ Desired result

✖ A problem that might occur

Installation Manual SPW-WebconPB-IA-en-11 5

Page 6

1 Information on this Document SMA Solar Technology AG

Typography

Typography Explanation Example

bold • Display messages

• Elements of a user interface

• Connections

• Elements to be selected

• Elements to be entered

> • Connects several elements

• The value can be read from the

Energy field.

• Select Settings.

•Enter the value 10 in the

Minutes field.

• Select Settings > Date.

that are to be selected

[Button/Key] • B utt on o r ke y to be s elec ted or

• Select [Next].

pressed

Nomenclature

Full designation Designation in this document

PV plant Plant

SMA Cluster Controller Cluster Controller

SMA Speedwire Speedwire

SMA Speedwire/Webconnect Piggy-Back Piggy-Back

SMA Webconnect function Webconnect function

SMA inverter Inverter

6 SPW-WebconPB-IA-en-11 Installation Manual

Page 7

SMA Solar Technology AG 2 Safety

2 Safety

2.1 Intended Use

The Speedwire/Webconnect Piggy-Back is a Speedwire communication interface with Webconnect

function for inverters.

Speedwire is a cable-based type of communication based on the Ethernet standard and the

communication protocol SMA Data2+. This enables inverter-optimised 10/100 Mbit data

transmission between Speedwire devices in PV plants.

The Webconnect function enables data transmission between a small plant and the Internet portal

Sunny Portal. In Sunny Portal, a maximum of four inverters can be combined in a Sunny Portal plant.

In Italy, the Speedwire/Webconnect Piggy-Back can be used for plants up to 6 kW that are

connected to the low-voltage grid. The Speedwire/Webconnect Piggy-Back implements grid

management for one inverter. The Speedwire/Webconnect Piggy-Back also receives specifications

fr om t he n etw ork ope rator vi a Et her net (in acc ord anc e with st andard CEI 0-21). The network operator

sends the control signals to the Speedwire/Webconnect Piggy-Back via a network operator gateway.

The Speedwire/Webconnect Piggy-Back fulfils the following tasks:

• Set-up of a Speedwire network in small and large-scale PV plants

• Data exchange with Sunny Portal:

– in small plants via a router with Internet connection

– in large-scale PV plants via the Cluster Controller

• Data exchange with Sunny Explorer

• Additionally for Italy:

– Implementation of grid management for one inverter

–Active power limitation of the connected active power

– Remote shutdown within 50 ms

– Narrowing of the frequency limits to between 49.5 Hz and 50.5 Hz

– Automatic narrowing of the inverter frequency limits to between 49.5 Hz and 50.5 Hz

when the connection to the network operator gateway is interrupted

The Speedwire/Webconnect Piggy-Back is available as a retrofit kit.

The inverter still complies with the standard after the product has been installed.

Installation Manual SPW-WebconPB-IA-en-11 7

Page 8

2 Safety SMA Solar Technology AG

The Speedwire/Webconnect Piggy-Back must only be operated with supported products

(see Section 2.2).

For safety reasons, it is not permitted to modify the product or install components that are not explicitly

recommended or distributed by SMA Solar Technology AG for this product.

The enclosed documentation is an integral part of this product.

• Read and observe the documentation.

• Keep the documentation in a convenient place for future reference.

Only use the Speedwire/Webconnect Piggy-Back in accordance with the information provided in the

enclosed documentation. Any other use may result in personal injury or property damage.

2.2 Supported Products

SMA inverter

The Speedwire/Webconnect Piggy-Back must only be used in the following inverters with at least the

given firmware version:

Sunny Boy / Sunny Mini Central From firmware version

SB 1300TL-10, SB 1600TL-10, SB 2100TL 4.30

SB 3300-11, SB 3800-11 4.02

SMC 6000A-11 4.33

SMC 7000HV-11 2.21

Firmware updates on the inverters can only be carried out by SMA Service. If your inverter is in need

of a firmware update, contact the SMA Service Line (see Section 10).

Additional SMA products

• Sunny Explorer from software version 1.05

Sunny Explorer is available free of charge at www.SMA-Solar.com.

• Cluster Controller

2.3 Qualifications of Skilled Persons

The work described in this document must be performed by skilled persons only. Skilled persons must

have the following qualifications:

• Training in the installation and commissioning of electrical devices and plants

• Knowledge of how to deal with the dangers and risks associated with installing and using

electrical devices and plants

• Knowledge of all applicable standards and directives

• Knowledge of how an inverter works and is operated

• Knowledge of and adherence to this document and all safety precautions

8 SPW-WebconPB-IA-en-11 Installation Manual

Page 9

SMA Solar Technology AG 2 Safety

2.4 Safety Precautions

Electric Shock

Lethal voltages are present in the conductive parts of the inverter.

• Prior to performing any work on the inverter, disconnect the inverter from any voltage sources

on the AC and DC sides (see inverter installation manual). Observe the waiting time to allow

the capacitors to discharge.

Burn Hazards

Some parts of the inverter enclosure can get hot during operation.

• During operation, touch the inverter on the enclosure lid only.

Environmental Influences

When close d and wi th the E SS plugged i n, the inverter has the degree of protection IP65. The inverter

is thus protected against dust intrusion and water penetration. Dust intrusion and water penetration

can damage the inverter.

• If the ESS is not plugged in, the inverter must be protected against dust and water.

• Firmly plug ESS in again after performing any work on the inverter.

2.5 Operating Information

Selecting a Suitable Internet Tariff for Small Plants

When using the new Webconnect function, a constant Internet connection is required.

De pen din g on the qu ali ty o f the Int ern et c onn ect ion , th e transm ission volume for an inverter is between

150 MB and 550 MB per month. When using the plant overview in Sunny Portal with live data

display, there is an additional data volume of 600 kB per hour.

• SMA recommends using an Internet tariff with a flat rate.

• Since Sunny Portal is permanently connected to the Internet, time-based billing systems should

be avoided. High costs could be incurred.

Installation Manual SPW-WebconPB-IA-en-11 9

Page 10

3 Scope of Delivery SMA Solar Technology AG

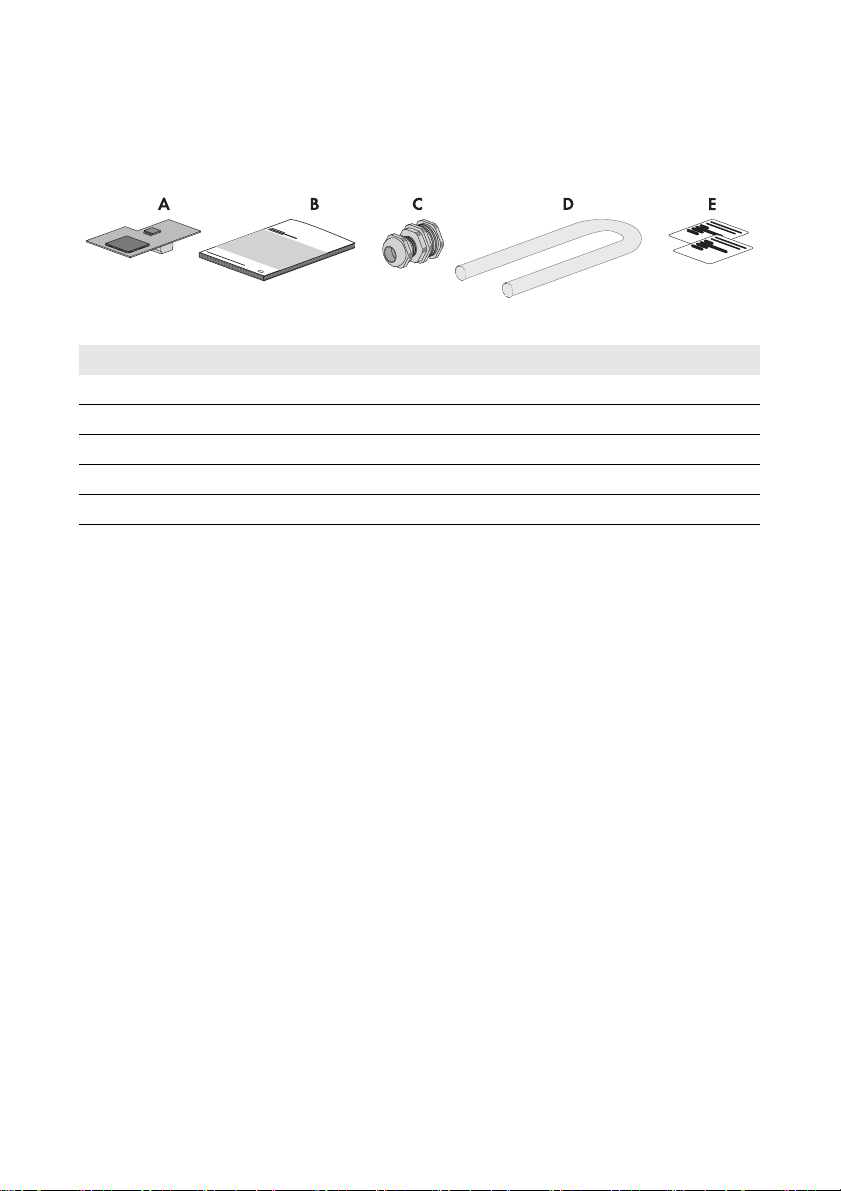

3 Scope of Delivery

Check the scope of delivery for completeness and any externally visible damage. Contact your

specialist dealer if the delivery is incomplete or damaged.

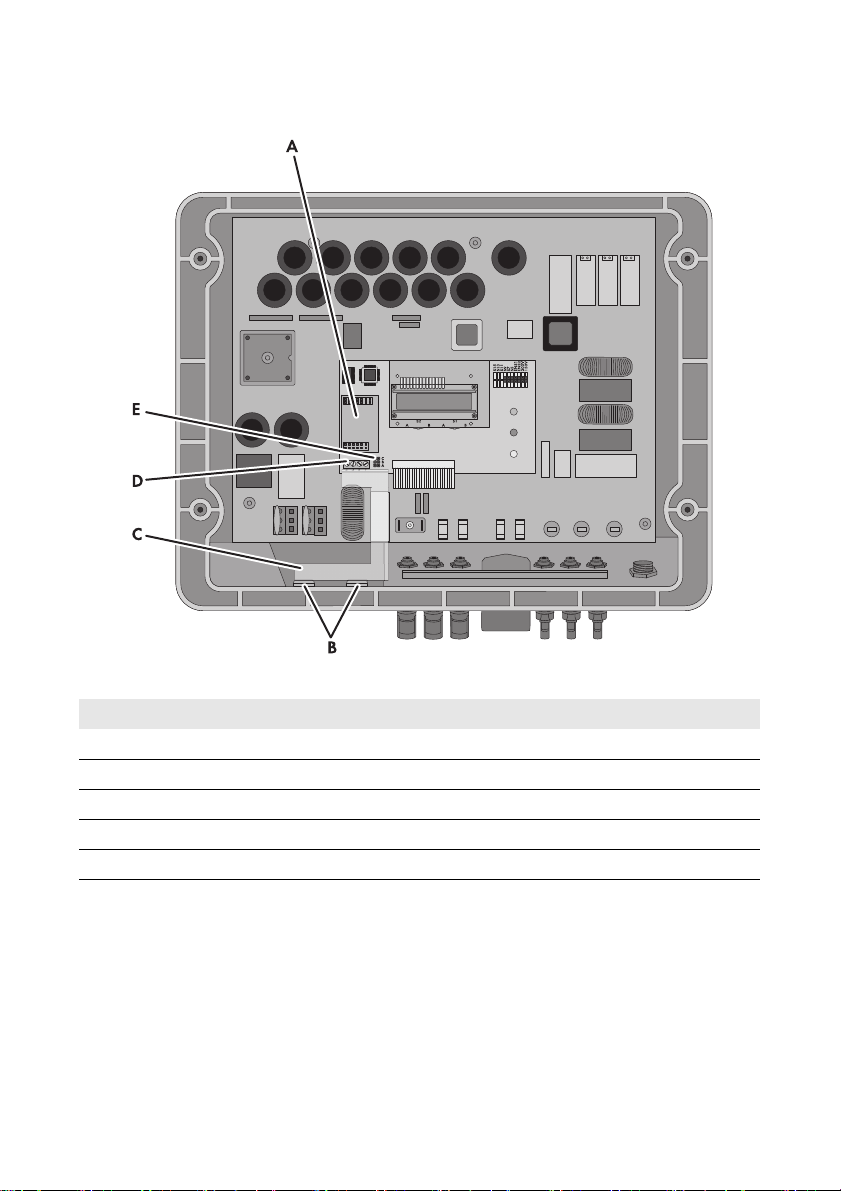

Figure1: Components included in the scope of delivery

Item Quantity Description

A 1 SMA Speedwire/Webconnect Piggy-Back (SWPB-10.BG1)

B 1 Installation manual

C 1 Cable gland

D1Silicone tube

E 2 Label with PIC and RID for registration in Sunny Portal

10 SPW-WebconPB-IA-en-11 Installation Manual

Page 11

SMA Solar Technology AG 4 Product Description

4 Product Description

4.1 SMA Speedwire/Webconnect Piggy-Back

The Speedwire/Webconnect Piggy-Back is a Speedwire communication interface with Webconnect

function for inverters.

Speedwire is a cable-based type of communication based on the Ethernet standard and the

communication protocol SMA Data2+. This enables inverter-optimised 10/100 Mbit data

transmission between Speedwire devices in PV plants.

The Webconnect function enables data transmission between a small plant and the Internet portal

Sunny Portal. In Sunny Portal, a maximum of four inverters can be combined in a Sunny Portal plant.

In Italy, the Speedwire/Webconnect Piggy-Back can be used for plants up to 6 kW that are

connected to the low-voltage grid. The Speedwire/Webconnect Piggy-Back implements grid

management for one inverter. The Speedwire/Webconnect Piggy-Back also receives specifications

fr om t he n etw ork ope rator vi a Et her net (in acc ord anc e with st andard CEI 0-21). The network operator

sends the control signals to the Speedwire/Webconnect Piggy-Back via a network operator gateway.

The Speedwire/Webconnect Piggy-Back fulfils the following tasks:

• Set-up of a Speedwire network in small and large-scale PV plants

• Data exchange in a large-scale PV plant with Cluster Controller via a router/network switch

• Data exchange with Sunny Portal:

– in small plants via a router with Internet connection

– in large-scale PV plants via the Cluster Controller

• Data exchange with Sunny Explorer

• Additionally for Italy:

– Implementation of grid management for one inverter

–Active power limitation of the connected active power

– Remote shutdown within 50 ms

– Narrowing of the frequency limits to between 49.5 Hz and 50.5 Hz

– Automatic narrowing of the inverter frequency limits to between 49.5 Hz and 50.5 Hz

when the connection to the network operator gateway is interrupted

The Speedwire/Webconnect Piggy-Back is available as a retrofit kit.

Installation Manual SPW-WebconPB-IA-en-11 11

Page 12

4 Product Description SMA Solar Technology AG

Figure2: Layout of the SMA Speedwire/Webconnect Piggy-Back

Item Description

A Female connector

Label with PIC and RID for Registration of a Small Plant in Sunny Portal

To activate the Piggy-Back in Sunny Portal, you will need the PIC and RID numbers printed on the

supplied label. After installation of the Piggy-Back, a label should be affixed on the exterior of the

inverter in the vicinity of the type label. Keep the other label in a safe place for future reference.

4.2 Possible Network Topologies

The possible network topologies depend on the devices used and on the number of network ports.

The Speedwire/Webconnect Piggy-Back is equipped with one network port. For further information

on network topologies, refer to the Technical Information "SMA Speedwire Fieldbus" at

www.SMA-Solar.com.

4.3 Type Label

Type Label

The type label clearly identifies the Speedwire/Webconnect Piggy-Back. The type label is located on

the front panel of the Speedwire/Webconnect Piggy-Back.

Figure3: Layout of the type label

Item Explanation

A Device type

B Serial number

C Hardware version

The information on the type label is required for safe use of the Speedwire/Webconnect Piggy-Back

and for reference if customer support from the SMA Service Line is needed. The type label must be

permanently affixed to the Speedwire/Webconnect Piggy-Back.

12 SPW-WebconPB-IA-en-11 Installation Manual

Page 13

SMA Solar Technology AG 4 Product Description

Supplementary Label with Data for Registration in Sunny Portal

The supplementary label is located on the front panel of the Speedwire/Webconnect Piggy-Back.

The data for registration in Sunny Portal is to be found on the supplementary labels supplied.

Figure4: Layout of the supplementary label

Item Explanation

A Identification key of the Piggy-Back for registration in Sunny Portal

B Registration ID of the Piggy-Back for registration in Sunny Portal

C MAC address of the Piggy-Back

Symbol on the Supplementary label

Symbol Description Explanation

CE marking The product complies with the

requirements of the applicable EU

directives.

4.4 Cable Gland

The cable gland provides a sturdy, tightly sealed connection of the network cables with the inverter

enclosure. The cable gland also protects the inverter from dust intrusion and moisture penetration.

Figure5: Product description: Cable gland

Item Description

ASwivel nut

B Adaptor PG16 to M16

CCounter nut

Installation Manual SPW-WebconPB-IA-en-11 13

Page 14

5 Connection SMA Solar Technology AG

5 Connection

5.1 Inverter Connection Area

SB 1300TL-10, SB 1600TL-10, SB 2100TL

Figure6: Overview of the connection area

Item Description

A Slot for Piggy-Back

B Opening in the inverter enclosure with filler plug

C Cable route to communication terminal

D Communication terminal

E Jumper slot for communication

14 SPW-WebconPB-IA-en-11 Installation Manual

Page 15

SMA Solar Technology AG 5 Connection

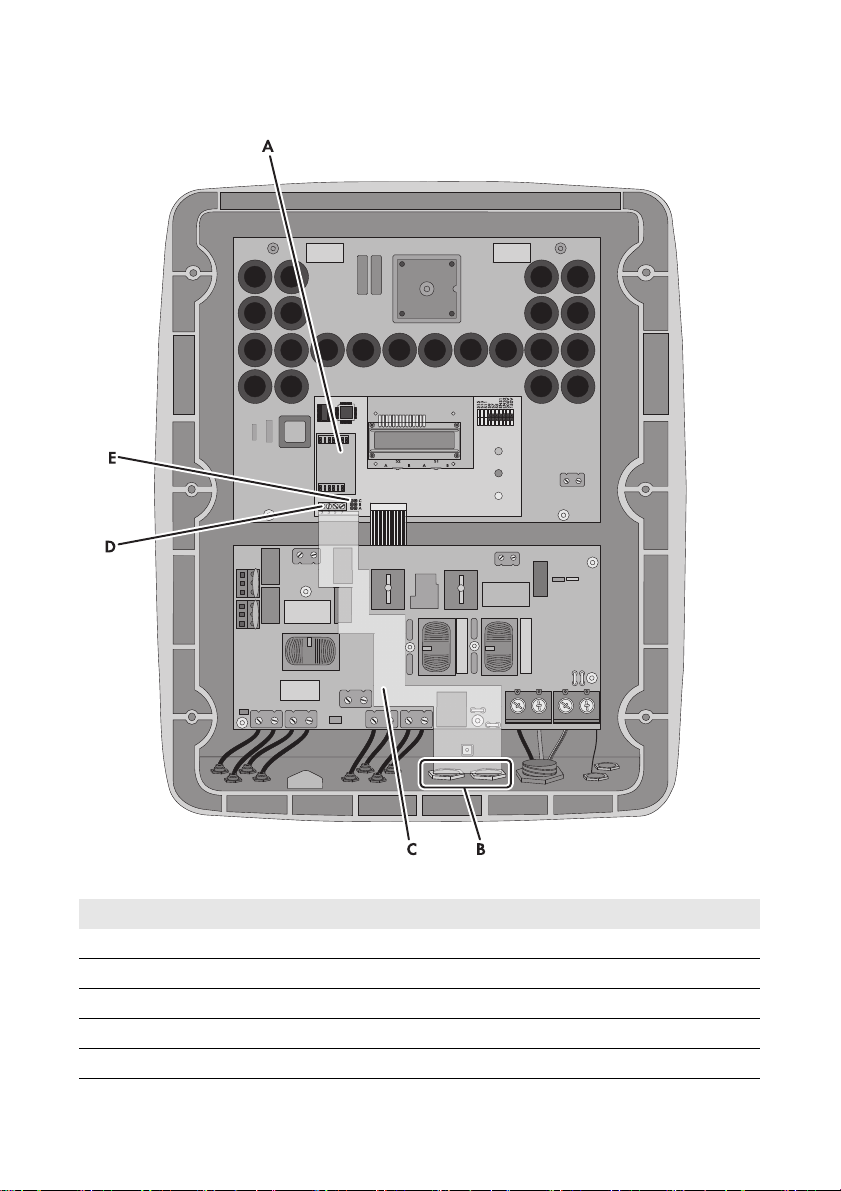

SB 3300-11, SB 3800-11

Figure7: Overview of the connection area

Item Description

A Slot for Piggy-Back

B Opening in the inverter enclosure with filler plug

C Cable route to communication terminal

D Communication terminal

E Jumper slot for communication

Installation Manual SPW-WebconPB-IA-en-11 15

Page 16

5 Connection SMA Solar Technology AG

SMC 6000A-11, SMC 7000HV-11

Figure8: Overview of the connection area

Item Description

A Slot for Piggy-Back

B Opening in the inverter enclosure with filler plug

C Cable route to communication terminal

D Communication terminal

E Jumper slot for communication

16 SPW-WebconPB-IA-en-11 Installation Manual

Page 17

SMA Solar Technology AG 5 Connection

5.2 Cable Requirements and Information on Routing

The cable length and quality have an effect on the signal quality in the Speedwire network. Observe

the following information and cable requirements:

Disturbance of data transmission due to AC Cables

When AC cables are in operation, they generate an electromagnetic field which may induce

interference in network cables during data transmission.

• Lay the network cables using suitable fastening material and with a minimum clearance

of 50 mm to the AC cables.

Cable requirements

☐ Cable length between two nodes: max. 100 m

☐ Cross-section: at least 2x2x0.22 mm

☐ Cable type: 100BaseTx, CAT5 with shielding S-UTP, F-UTP or higher

☐ UV-resistant for outdoor use

☐Type of plug: RJ45

SMA Solar Technology AG recommends the following cable types:

• For outdoor use: SMA COMCAB-OUTxxx

• For indoor use: SMA COMCAB-INxxx

The cables are available in the lengths xxx = 100 m, 200 m, 500 m, 1,000 m

2

or at least 2x2 AWG 24

5.3 Connecting the Cable to the Communication Terminal

Figures in this section

The work steps in this section are supported by figures of the inverter types SB 3300-11 and

SB 3800-11. The procedure for other inverter types is analogous (see Section 5.1).

Requirement:

☐ For Italy: There must be an available network operator gateway with network connection for

telecontrol protocol IEC 61850.

Additionally required material (not included in the scope of delivery):

☐ 1 network cable (see Section 5.2)

☐ 4 bootlace ferrules

☐ 1 RJ45 connector

Installation Manual SPW-WebconPB-IA-en-11 17

Page 18

5 Connection SMA Solar Technology AG

Procedure:

1.

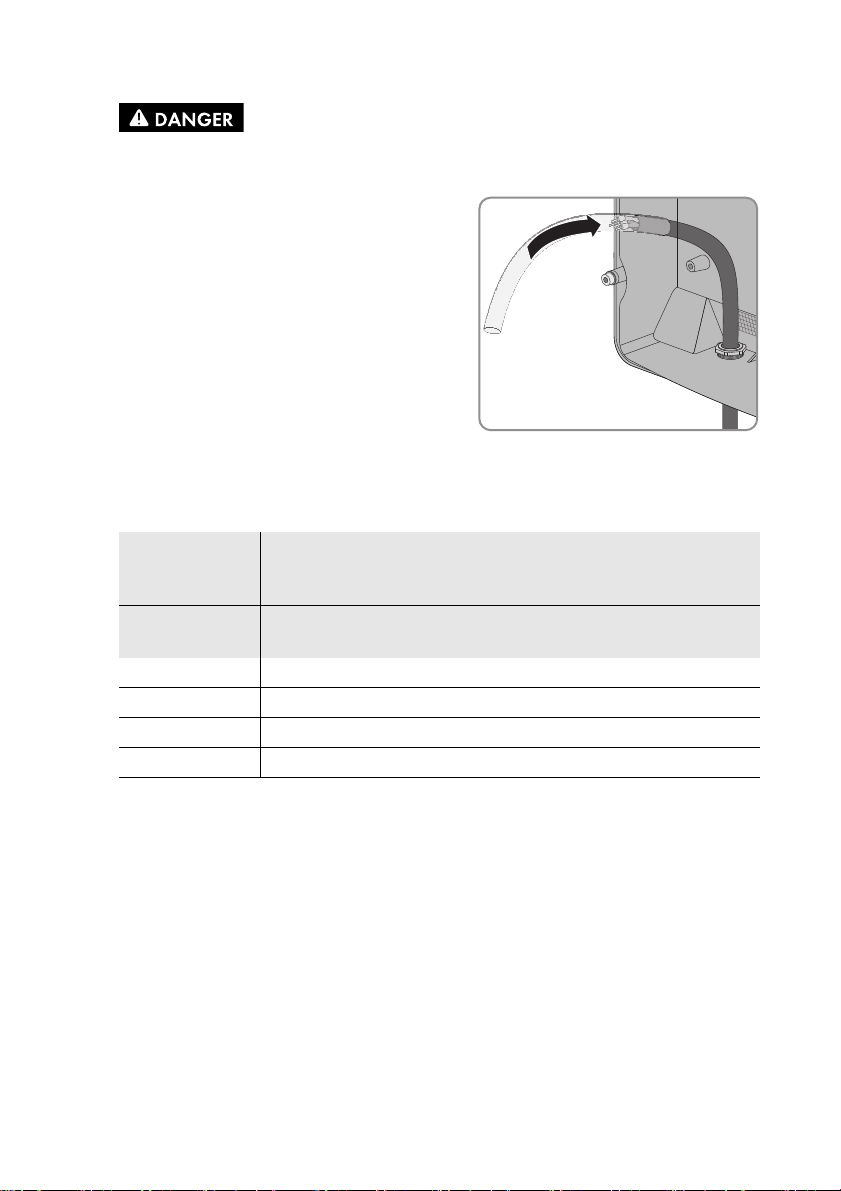

Danger to life due to electric shock when opening the inverter

Lethal voltages are present in the conductive parts of the inverter.

• Disconnect the inverter fro m any vo ltage sources on the AC and DC sides (see the inverter

installation manual). Observe the waiting time to allow the capacitors to discharge.

2. Open the inverter (see inverter installation manual).

3. Push one filler plug from the inside out of the bottom of the inverter enclosure.

4. Attach the cable gland to the enclosure opening

using the counter nut. Ensure that the grooved side of

the counter nut is facing the inverter enclosure.

5. Gauge the length from the communication terminal to the counter nut on the cable gland using

the cable, and mark the position on the cable. Be sure to take the permitted cable route into

account (see Section 5.1).

6. Below the marked position, remove 20 mm from the

cable sheath. This will enable contact between the

screening clamp and the cable shield in the cable

gland.

7. Unscrew the swivel nut of the cable gland but do not remove it.

18 SPW-WebconPB-IA-en-11 Installation Manual

Page 19

SMA Solar Technology AG 5 Connection

8. Gradually guide the end of the cable through the

cable gland into the inverter, until you can hear the

screening clamp grip onto the cable shield.

9. Tighten the swivel nut of the cable gland. This will prevent the cable from slipping and the

contact between screening clamp and cable shield being lost.

10. At the end of the cable, remove 40 mm from the cable sheath and cable shield. Make sure that

no pieces of cable are dropped into the inverter.

11. At the end of the cable, strip the insulation of the four required wires by 6 mm. Take the type of

cable into account, as listed below:

Network cable

Signal EIA/TIA 568A (8-wire)

Wire colour

Profinet (4-wire)

Wire colour

TD+ white/green yellow

TD- green orange

RD+ white/orange white

RD- orange blue

12. Shorten all other wires flush with the cable sheath.

13. Attach the bootlace ferrules to the wire ends.

Installation Manual SPW-WebconPB-IA-en-11 19

Page 20

5 Connection SMA Solar Technology AG

14.

Danger to life due to electric shock in case of incorrect cable insulation

If a cable is not correctly insulated, high voltages may occur on the cable outside the inverter.

• Lead the cable into the inverter through the

silicone t ube. Th e silicone tube mu st complete ly

cover the cable and the wires inside the inverter

enclosure.

• Cut the silicone tube to the required length, as

necessary.

• Fix the silicone tube in position with cable ties

at the beginning and end of the cable, as

necessary. Trim the ends of the cable ties. This

will prevent the ends of the cable ties causing

damage to hot components in the inverter.

15. Connect the wire ends to the communication terminal in the inverter at screw terminals 2, 3, 5

and 7 (torque: 0.23 Nm) (for position of the communication terminal, see Section 5.1).

Observe the permitted cable route (see Section 5.1) and the pin assignment as follows:

Inverter

Network cable

communication

terminal

Pin Signal EIA/TIA 568A (8-wire)

Wire colour

Profinet (4-wire)

Wire colour

2 TD+ white/green yellow

3 TD- green orange

7 RD+ white/orange white

5RD-orange blue

16. Make sure that there are no jumpers in the communication jumper slot (position of jumper slot

for communication, see Section 5.1).

20 SPW-WebconPB-IA-en-11 Installation Manual

Page 21

SMA Solar Technology AG 5 Connection

17. Attach an RJ45 connector to the other end of the cable (see manufacturer's manual). Observe

the pin assignment of the network cable, as follows:

Network cable

Signal Pin RJ45 plug EIA/TIA 568A (8-wire)

Wire colour

Profinet (4-wire)

Wire colour

TD+ 1 white/green yellow

TD- 2 green orange

RD+ 3 white/orange white

RD- 6 orange blue

18. Subject to the required network topology, connect the other end of the cable to a router,

network switch or Cluster Controller (see manual of the respective device). To do this, a router

with Internet connection must be connected to the plant.

5.4 Installing the Piggy-Back

1.

Danger to life due to electric shock when opening the inverter

Lethal voltages are present in the conductive parts of the inverter.

• If the inverter is closed, proceed as follows:

• Disconnect the inverter from any voltage sources on the AC and DC sides (see the

inverter installation manual). Observe the waiting time to allow the capacitors to

discharge.

• Open the inverter (see inverter installation manual).

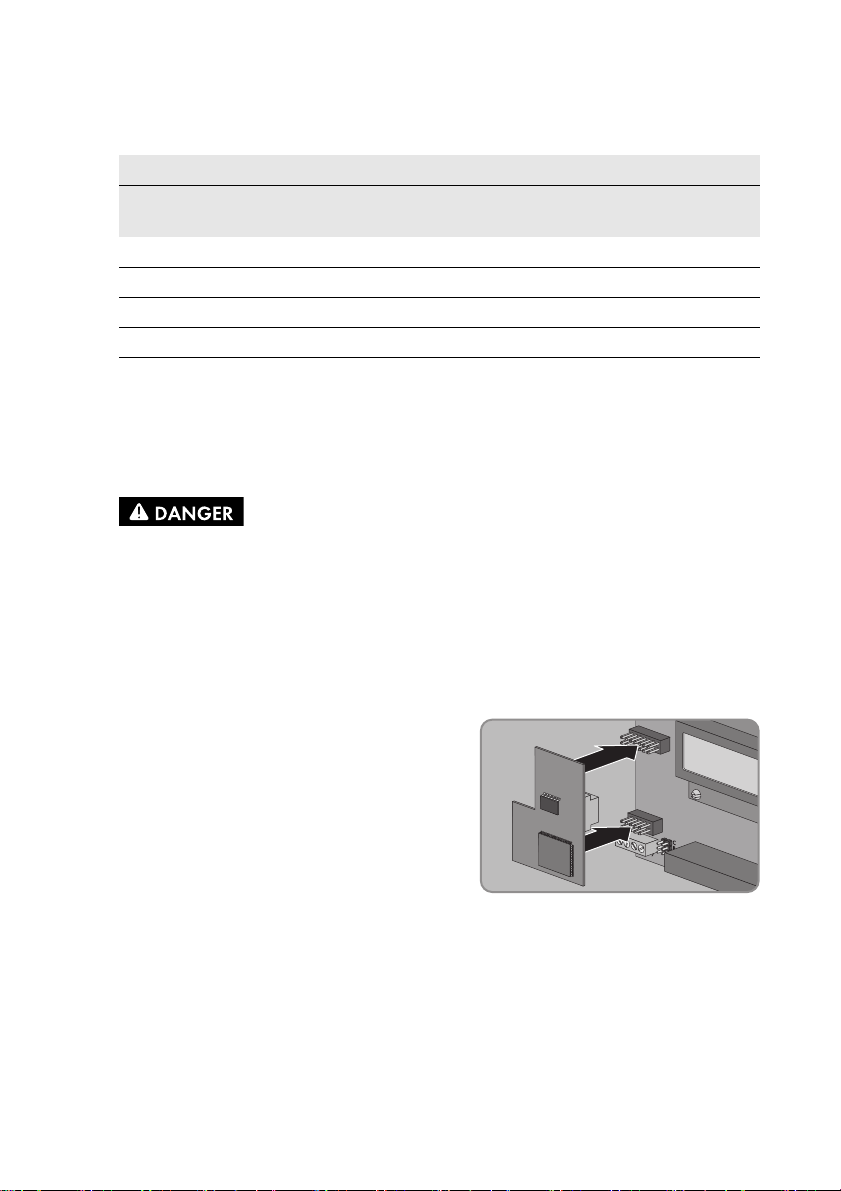

2. Plug the Piggy-Back into the female connectors at

the slot in the inverter (for position of slot, see

Section 5.1).

3. Stick one of the labels with the data for registration in Sunny Portal (PIC and RID) on the outside

of the inverter in the vicinity of the type label.

4. Close the inverter (see inverter installation manual).

Installation Manual SPW-WebconPB-IA-en-11 21

Page 22

6 Commissioning SMA Solar Technology AG

6 Commissioning

6.1 Commissioning a Large-Scale PV Plant with Cluster Controller

Requirements:

☐ The cable must be connected to the communication terminal (see Section 5.3).

☐ The Piggy-Back must be installed in the inverter (see Section 5.4).

☐ Subject to the required network topology, the Cluster Controller must be connected to the

Speedwire network (see Cluster Controller installation manual).

Procedure:

1. Commission all inverters with installed Piggy-Back (see inverter installation manual).

2.

Deactivating the Webconnect function of the inverters

In a large-scale PV plant with Cluster Controller, communication with Sunny Portal takes

place via the Cluster Controller itself.

For optimal operation of large-scale PV plants with Cluster Controller, deactivate the

factory-activated Webconnect function of the inverter with installed Piggy-Back

(see Cluster Controller user manual).

6.2 Commissioning a Small Plant

Requirements:

☐ The cable must be connected to the communication terminal (see Section 5.3).

☐ The Piggy-Back must be installed in the inverter (see Section 5.4).

☐ The plant must be connected to a router with Internet connection.

☐ DHCP must be enabled for the router.

☐ For Italy, in order to adjust the Sunny Explorer settings for receiving control signals from the

Piggy-Back, you must have a personal SMA Grid Guard code (see Sunny Explorer help).

Procedure:

1. Commission all inverters with installed Piggy-Back (see inverter installation manual).

2. For plants in Italy, in order to adjust the settings to receive control signals from the network

operator in the Piggy-Back, follow the steps below:

• Connect to Sunny Explorer (see Section 6.3.2).

• Enter your personal SMA Grid Guard code in Sunny Explorer (see Sunny Explorer help).

22 SPW-WebconPB-IA-en-11 Installation Manual

Page 23

SMA Solar Technology AG 6 Commissioning

• Set the following parameters in Sunny Explorer (for setting parameters in a device, see

Sunny Explorer help):

External Communication > IEC 61850 configuration

Parameter Value/Range Resolution Default

Application-ID 0 to 0x4000 1 0x4000

Goose-Mac address 01:0C:CD:01:00:00

…

01:0C:CD:01:02:00

•In the field Application-ID, enter the Application-ID of the network operator gateway.

You will receive this value from your network operator. You can enter a value between

0 and 16384. The value 16384 indicates deactivation.

•In the field Goose-Mac address, enter the MAC address of the network operator

gateway from which the Piggy-Back is to receive control commands. You will receive this

value from your network operator. If all MAC addresses are to be accepted in the

adjustable domain, enter 01:0C:CD:01:02:00.

1 01:0C:CD:01:02:00

6.3 Managing Small Plants with Sunny Explorer

6.3.1 Functions and Parameter Settings in Sunny Explorer

The following functions for plant management in Sunny Explorer are available:

• Overview of the plant status

• Graphic display of key plant data, device data and energy values

• Parameterisation of individual devices or an entire device class

• Simple diagnostics thanks to the display of faults and events

• Data export of inverter energy values and events in CSV format

• Piggy-Back update

You can change the following parameters in Sunny Explorer:

• Device name of the inverter

• Automatic IP configuration On/Off

• DNS-IP, gateway IP, IP address, subnet mask

• Webconnect function On/Off

• IEC 61850 configuration for plants in Italy up to 6 kW

Installation Manual SPW-WebconPB-IA-en-11 23

Page 24

6 Commissioning SMA Solar Technology AG

6.3.2 Connecting to Sunny Explorer

Requirements:

☐ The plant must be commissioned (see Section 6.2).

☐ The inverter with Piggy-Back must be in feed-in operation.

Procedure:

1. Connect the computer to the router/network switch with a network cable.

2. Start Sunny Explorer and create a plant (see Sunny Explorer help).

6.4 Plant Registration in Sunny Portal

6.4.1 Registering a Small Plant in Sunny Portal

Requirements:

☐ The small plant must be commissioned (see Section 6.2).

☐ The inverter with Piggy-Back must be in feed-in operation.

☐ The pla nt m ust be c onn ecte d to a ro ute r wi th p erma nen t In ter net connection (see router manual).

☐ PIC and RID must be available for the Piggy-Back.

☐ Your computer must have an Internet connection.

☐ JavaScript must be activated in the Internet browser.

Maximum permissible number of devices for a small plant in Sunny Portal

In Sunny Portal you can manage several plants. A maximum of four inverters with integrated

Piggy-Back is permissible per small plant.

Small plant with Piggy-Back cannot be combined with other plants

If you have already registered a plant in Sunny Portal with another communication device,

e.g. Sunny WebBox, you will still need to create a separate small plant with Piggy-Back. It is not

possible to combine the Piggy-Back and other communication devices within one plant in

Sunny Portal. Sunny Portal treats the existing plant and the new small plant with Piggy-Back as

separate plants.

• Create a new small plant with Piggy-Back.

Starting the Plant Setup Assistant in Sunny Portal

The Plant Setup Assistant is a step-by-step guide of the processes required for user registration and the

registration of your plant in Sunny Portal.

1. Open www.SunnyPortal.com.

2. Select [Plant Setup Assistant].

☑ The Plant Setup Assistant opens.

3. Follow the instructions of the Plant Setup Assistant.

24 SPW-WebconPB-IA-en-11 Installation Manual

Page 25

SMA Solar Technology AG 6 Commissioning

6.4.2 Registering a Large-Scale PV Plant with Cluster Controller in Sunny Portal

Requirements:

☐ The large-scale PV plant with Cluster Controller must be commissioned (see Section 6.1).

☐ The inverter with Piggy-Back must be in feed-in operation.

☐ The Cluster Controller must be connected to a router with Internet connection

(see Cluster Controller installation manual).

☐ Your computer must have an Internet connection.

☐ JavaScript must be activated in the Internet browser.

Procedure:

• For large-scale PV plants with Cluster Controller, register in Sunny Portal using the

Cluster Controller user interface (see Cluster Controller user manual).

Installation Manual SPW-WebconPB-IA-en-11 25

Page 26

7 Decommissioning SMA Solar Technology AG

7 Decommissioning

7.1 Removing the Piggy-Back

1.

Danger to life due to electric shock when opening the inverter

Lethal voltages are present in the conductive parts of the inverter.

• Disconnect the inverter fro m any vo ltage sources on the AC and DC sides (see the inverter

installation manual). Observe the waiting time to allow the capacitors to discharge.

2. Open the inverter (see inverter installation manual).

3. Remove the Piggy-Back from the communication

interface.

4. Release the screw terminals at the communication terminal in the inverter and remove the wires.

5. Remove the silicone tube from the cable.

6. Unscrew the swivel nut of the cable gland.

7. Pull the cable out of the inverter.

8. Unscrew the counter nut of the cable gland and remove the cable gland.

9. Seal the enclosure opening of the inverter with the corresponding filler plug.

10. Close the inverter (see inverter installation manual).

7.2 Disposing of the Piggy-Back

• Dispose of the Piggy-Back in accordance with the regulations for the disposal of electronic

waste applicable at the installation site.

26 SPW-WebconPB-IA-en-11 Installation Manual

Page 27

SMA Solar Technology AG 8 Troubleshooting

8 Troubleshooting

8.1 General Errors

Problem Cause and corrective measures

The inverter with Piggy-Back

cannot be accessed.

Piggy-Back update does not

initialise.

There is no Speedwire connection.

Corrective measures:

• Ensure that all network cable plugs are inserted and locked.

• Ensure that all inverters in the plant are in operation.

• Ensure that the plant router is switched on.

• Ensure that the Piggy-Back is connected correctly

(see Section 5.3).

• Ensure that the Cluster Controller is connected to the local

plant network (see Cluster Controller installation manual).

The firmware version of the inverter is not supported

(see Section 2.2).

Corrective measures:

• An inverter firmware update can only be carried out by

SMA Service. If your inverter is in need of a firmware

update, contact the SMA Service Line (see Section 10).

The software version of Sunny Explorer is older than version 1.05.

Corrective measures:

• Download Sunny Explorer from software version 1.05 from

www.SMA-Solar.com and install.

Firewall or IP filter settings are not correct.

Corrective measures:

• Adjust the firewall or IP filter settings (see firewall or router

manual).

The Piggy-Back does not have a valid IP address.

Corrective measures:

• Make sure DHCP is enabled for the router.

Inverters with retrofitted Piggy-Back shut down overnight. It is

therefore not possible to establish any connection to these

inverters.

As soon as the inverters switch on in the morning, they will be

accessible again.

The feed-in power of the inverter is less than 50 W.

Corrective measures:

• Carry out update once the feed-in power of the inverter is at

least 50 W.

Installation Manual SPW-WebconPB-IA-en-11 27

Page 28

8 Troubleshooting SMA Solar Technology AG

8.2 Performing a Piggy-Back Update

Piggy-Back updates are performed via Sunny Explorer. There is no need to replace the Piggy-Back.

Existing inverter settings and data are retained after the update. Only carry out an update providing

that the feed-in power of the inverter is sufficient (at least 50 W). After a successful update, restart

Sunny Explorer.

28 SPW-WebconPB-IA-en-11 Installation Manual

Page 29

SMA Solar Technology AG 9 Technical Data

9 Technical Data

General Data

Mounting location in the inverter

Voltage supply via the inverter

Mechanical Data

Width x height x depth 50 mm x 81 mm x 12 mm

Communication

Communication interface Speedwire/Webconnect

Maximum cable length 100 m

Ambient Conditions for Storage/Transport

Ambient temperature − 40°C to +70°C

Relative humidity, non-condensing 5% to 95%

Maximum height above sea level (MSL) 3,000 m

Installation Manual SPW-WebconPB-IA-en-11 29

Page 30

10 Contact SMA Solar Technology AG

10 Contact

If you have technical problems concerning our products, contact the SMA Service Line. We require

the following information in order to provide you with the necessary assistance:

• Type, serial number and firmware version of the inverter

• Type, serial number and firmware version of the Piggy-Back

• For large-scale PV plants: serial number and firmware version of the Cluster Controller

• For small plants: PIC and RID of the Piggy-Back

Australia SMA Australia Pty Ltd.

Sydney

Belgien/

Belgique/

België

Brasil Vide España (Espanha)

Česko SMA Central & Eastern Europe

Chile Ver España

Danmark Se Deutschland (Tyskland)

Deutschland SMA Solar Technology AG

España SMA Ibérica Tecnología Solar,

France SMA France S.A.S.

SMA Benelux BVBA/SPRL

Mechelen

s.r.o.

Praha

Niestetal

S.L.U.

Barcelona

Lyon

Toll free for

Australia:

International: +61 2 9491 4200

+32 15 286 730

+420 235 010 417

Medium Power Solutions

Wechselrichter:

Kommunikation:

SMA Online Service Center:

www.SMA.de/Service

Hybrid Energy Solutions

Sunny Island: +49 561 9522-399

PV-Diesel

Hybridsysteme:

Power Plant Solutions

Sunny Central: +49 561 9522-299

Llamada gratuita en

España:

Internacional: +34 902 14 24 24

Medium Power Solutions

Onduleurs :

Communication :

Hybrid Energy Solutions

Sunny Island : +33 472 09 04 42

Power Plant Solutions

Sunny Central : +33 472 09 04 43

1800 SMA AUS

(1800 762 287)

+49 561 9522-1499

+49 561 9522-2499

+49 561 9522-3199

900 14 22 22

+33 472 09 04 40

+33 472 09 04 41

30 SPW-WebconPB-IA-en-11 Installation Manual

Page 31

SMA Solar Technology AG 10 Contact

India SMA Solar India Pvt. Ltd.

Mumbai

Italia SMA Italia S.r.l.

Milano

Κύπρος/

Kıbrıs

Luxemburg/

Luxembourg

Magyarország lásd Česko (Csehország)

Nederland zie Belgien (België)

Österreich Siehe Deutschland

Perú Ver España

Polska Patrz Česko (Czechy)

Portugal SMA Solar Technology Portugal,

România Vezi Česko (Cehia)

Schweiz Siehe Deutschland

Slovensko pozri Česko (Česká republika)

South Africa SMA Solar Technology

United

Kingdom

Ελλάδα SMA Hellas AE

България Вижте Ελλάδα (Гърция)

Βλέπε Ελλάδα/

Bkz. Ελλάδα (Yunanistan)

Siehe Belgien

Voir Belgique

Unipessoal Lda

Lisboa

South Africa Pty Ltd.

Centurion (Pretoria)

SMA Solar UK Ltd.

Milton Keynes

Αθήνα

SMA Solar (Thailand) Co., Ltd. +66 2 670 6999

+91 22 61713888

+39 02 8934-7299

Gratuito em

Portugal:

Internacional: +351 2 12 37 78 60

08600 SUNNY

(08600 78669)

International: +27 (12) 643 1785

+44 1908 304899

801 222 9 222

International: +30 212 222 9 222

800 20 89 87

대한민국 SMA Technology Korea Co., Ltd.서울+82 2 508-8599

+971 2 234-6177 SMA Middle East LLC

!

Other

countries

Installation Manual SPW-WebconPB-IA-en-11 31

International SMA Service Line

Niestetal

Toll free worldwide: 00800 SMA SERVICE

(+800 762 7378423)

Page 32

SMA Solar Technology

www.SMA-Solar.com

Loading...

Loading...