Page 1

Sunny Mini Central 5000/6000

Central inverter for homogeneous PV-plants

Installation Guide Version 1.2 SMC50_60-11:SE2006

IME-SMC50-60

Page 2

Page 3

SMA Technologie AG Explanation of Symbols used in this Document

Explanation of Symbols used in this Document

This symbol indicates information that is essential for a trouble-free

and safe operation of the product. Please read these sections carefully in order to avoid any damages of the equipment and for optimal personal protection.

This symbol indicates information that is required for the optimal operation of

the product. Read these sections carefully in order to ensure an optimal operation of the product and all its features.

This symbol indicates an example.

Installation Guide SMC50_60-11:SE2006 Page 3

Page 4

Legal Restrictions SMA Technologie AG

Liability exclusion

The information contained in this documentation are the property of SMA Technologie AG. No part of this

documentation may be published without written permission from SMA Technologie AG. A reproduction for

internal purposes for the evaluation of the product or an appropriate application is permitted and does not

require authorization.

All information are based on our "General Terms and Conditions of Delivery of SMA Technologie AG”.

The content of this documentation is reviewed continuously and adjusted, if necessary. SMA Technologie

AG provides this documentation without exclusion of deviations and without warranty of completeness. You

will find the current version on the Internet at www.SMA.de or can obtain it via the usual sales channels.

Warranty or liability claims for all kinds are excluded in case of damages due to:

• Inappropriate use of the product

• Operation of the product in an improper environment

• Operation of the product without considering the relevant safety regulations

• Non-fulfillment of the warnings or safety instructions described in the documentation for the product

• Operation of the product under faulty conditions concerning security and protection

• Arbitrary changing of the product or the provided software

• Failure of the product due to interference of connected or contiguous devices out of legal limit values

• Disasters and force majeure

Software Licensing

The use of the provided software by SMA Technologie AG is subject to the following conditions:

The software may be reproduced for internal purposes and installed on any number of computers. Provided

source codes can be changed and adjusted on the company’s own authority according to the internal

purpose. Driver may be ported to other operating systems as well. No part of the source codes may be

published without written permission of SMA Technologie AG. Sublicensing of the software is not

acceptable.

Liability limitation: SMA Technologie AG disclaims liability for any direct or indirect consequential damages

arising from the use of the software produced by SMA Technologie AG. The same applies for the provision

and/or non-provision of support.

Provided software not produced by SMA Technologie AG is subject to the respective licensing and liability

agreements of the manufacturer.

Trademarks

All brand and product names used herein are trademarks or registered trademarks of their respective

holders, although they may not be specifically designated as such.

SMA Technologie AG

Hannoversche Strasse 1-5

34266 Niestetal

Germany

Tel. (+49) 5 61 95 22 – 0

Fax (+49) 5 61 95 22 – 100

www.SMA.de

E-Mail: info@SMA.de

© 2005 SMA Technologie AG. All rights reserved.

Page 4 SMC50_60-11:SE2006 Installation Guide

Page 5

SMA Technologie AG Table of Contents

Table of Contents

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Device Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

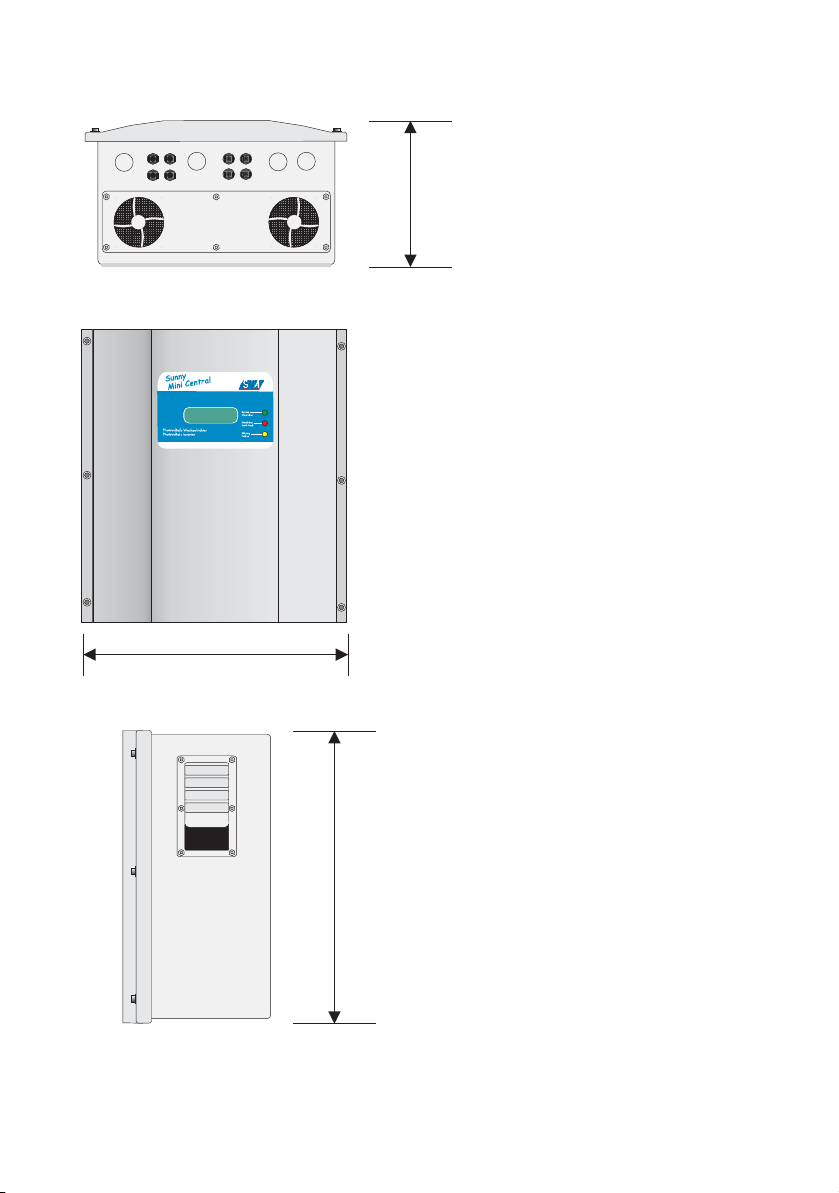

3.2 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.2.1 OptiCool Temperature Management . . . . . . . . . . . . . . . .13

4 Requirements for the Installation . . . . . . . . . . . . . . . . 15

4.1 Requirements: Mounting Place . . . . . . . . . . . . . . . . . . . . . . . .15

4.2 Requirements: PV-Modules. . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.3 String sizing of Sunny Mini Central PV plants . . . . . . . . . . . . .18

4.4 Requirements: Grid 230 V (AC) . . . . . . . . . . . . . . . . . . . . . . .18

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.2 Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.3 Reverse Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.4 Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6 Opening and Closing the Sunny Mini Central . . . . . . 35

6.1 Opening the Sunny Mini Central . . . . . . . . . . . . . . . . . . . . . .35

6.2 Closing the Sunny Mini Central . . . . . . . . . . . . . . . . . . . . . . .35

7 Technical Documentation . . . . . . . . . . . . . . . . . . . . . 37

7.1 Sunny Mini Central 5000. . . . . . . . . . . . . . . . . . . . . . . . . . . .37

7.1.1 Data PV Generator Connection . . . . . . . . . . . . . . . . . . . .37

7.1.2 Data Grid Connection. . . . . . . . . . . . . . . . . . . . . . . . . . .37

7.2 Sunny Mini Central 6000. . . . . . . . . . . . . . . . . . . . . . . . . . . .38

7.2.1 Data PV Generator Connection . . . . . . . . . . . . . . . . . . . .38

7.2.2 Data Grid Connection. . . . . . . . . . . . . . . . . . . . . . . . . . .38

7.3 Description of Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

7.4 Sunny Mini Central Operating Parameters . . . . . . . . . . . . . . .40

8 Checking the heat dissipation . . . . . . . . . . . . . . . . . . 43

8.1 Cleaning the fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

8.2 Testing the fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

8.3 Cleaning the Fins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

9 Exchanging Varistors . . . . . . . . . . . . . . . . . . . . . . . . 47

10 Sizing of a Circuit Breaker . . . . . . . . . . . . . . . . . . . . 51

11 Contact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Installation Guide SMC50_60-11:SE2006 Page 5

Page 6

SMA Technologie AG

Page 6 SMC50_60-11:SE2006 Installation Guide

Page 7

SMA Technologie AG Introduction

1 Introduction

The installation of the Sunny Mini Central may only be done by

qualified technicians. The installer must be approved by the utility

company. Please read the installation guide carefully before you

begin with the installation. The installation of utility interactive

power sources must be compliant with all applicable regulations of

the utility company and with all applicable regulations and

standards.

The Sunny Mini Central 5000/6000 is equipped with the SMA grid guard. This

is a type of independent disconnection device. It ensures that the Sunny Mini

Central 5000/6000 complies with the VDEW (Verband der

Elektrizitätswirtschaft – German Electricity Industry Association) regulations for

the connection and parallel operation of electrical power units to the lowvoltage grid of the electricity supply company and with DIN VDE 0126 (4.99)

which is a part of these regulations.

This installation manual is intended solely for qualified electricians. Its aim is to help

install and set up SMA Sunny Mini Central 5000/6000 inverters quickly and

correctly.

For detailed information on troubleshooting and on how to use the Sunny Mini

Central 5000/6000, including information about the different communication

options, please see the operating instructions.

The „Sunny Design“ tool will help to dimension and check the size of your strings with

respect to the inverter you intend to use. Further information about „Sunny Design“

is available at www.SMA.dSunny Mini CentralSunny Mini Centrale.

If you require further information, please call the Sunny Mini Central hotline on the

following number:

+49 561 95 22 - 499

Installation Guide SMC50_60-11:SE2006 Page 7

Page 8

Introduction SMA Technologie AG

Page 8 SMC50_60-11:SE2006 Installation Guide

Page 9

SMA Technologie AG Safety Instructions

2 Safety Instructions

Check your plant configuration and the

string sizing with „Sunny Design“ (available at www.SMA.de) or with the Sunny

Mini Central Hotline before you start with

the installation. Exceeding the specifications with the input voltage will destroy

P

h

B

o

e

t

t

r

o

i

e

b

v

o

O

l

P

t

p

a

h

e

r

i

o

a

k

t

t

-

i

o

o

W

n

v

o

e

l

c

ta

h

i

s

c

e

l

i

r

n

E

i

c

v

r

d

h

e

s

r

c

t

e

h

t

e

l

r

u

E

r

s

s

a

r

t

h

F

a

u

l

t

S

tö

r

u

n

g

F

a

i

l

u

r

e

Work on the Sunny Mini Central with the lid removed must be

carried out by a qualified electrician. Hazardous and even lethal

voltages can be encountered within the enclosure. Before working

on the Sunny Mini Central with the lid removed, the AC and DC

voltages MUST be disconnected from the Sunny Mini Central and it

must be sure that all capacitors are discharged.

the Sunny Mini Central. Overvoltage on

the DC side can even cause dangerous explosions of the Sunny Mini Centrals input

capacitors and explosions of the electrolytes coming from the exploded capacitors.

The Sunny Mini Central must be disconnected from the mains and

precautions must be taken to prevent the grid being reconnected.

In addition, the connections to the PV generator must be

disconnected.

After isolating the AC and DC voltage you must wait approx. 30

minutes for the capacitors in the Sunny Mini Central to discharge.

Only then is it safe to open the unit by removing the lid. You must

also make sure that no voltage is present in the device.

The electronics inside your Sunny Mini Central 5000/6000 is

vulnerable in terms of electrostatic discharge. Be sure to be

connected to ground (e.g. the enclosure of the Sunny Mini Central)

before handling anything within the enclosure of the Sunny Mini

Central.

Installation Guide SMC50_60-11:SE2006 Page 9

Page 10

Safety Instructions SMA Technologie AG

Page 10 SMC50_60-11:SE2006 Installation Guide

Page 11

SMA Technologie AG Overview

3 Overview

3.1 Device Description

The following figure shows the different components and connection areas of an

open Sunny Mini Central 5000/6000 inverter.

Varistors

page 47

Communication socket (RS232,

RS485, NLM Piggy-Back, radio)

Socket for display unit (Sunny

Display)

LEDs indicating

operating state

Communication

terminal

Socket for PLC

(Powerline Communication) power unit

Terminals (PE),

page 27

Terminals (AC),

page 27

PV input plug (DC),

page 29

Installation Guide SMC50_60-11:SE2006 Page 11

Cable gland for com-

munication

Cable gland for AC

connection cable

Page 12

Overview SMA Technologie AG

3.2 External Dimensions

250 mm

430 mm

600 mm

Page 12 SMC50_60-11:SE2006 Installation Guide

Page 13

SMA Technologie AG Overview

3.2.1 OptiCool Temperature Management

With the patented dual compartment cooling system

OptiCool, SMA now offers a technical solution combining both passive and active cooling systems. An "intelligent temperature management” is the result.

In order to achieve maximum efficiency the whole enclosure of the inverter becomes part of the cooling system. It does not only contain and protect the

components but also functions as a “cooling air distributor” and heat distributor.

The actual heat sink, as central component of the passive heat dissipation, is positioned within the enclosure

in such a way as to divide it into two compartments. The

highly sensitive electronics separated from the main

heat sources by the heat sink is securely protected from

external influences, such as moisture and dirt, in the

front waterproof compartment.

In the rear part, the temperature-intensive components,

such as chokes and transformers, which are either separately sealed or are intensive to ambient influences,

are installed.

A specifically designed active cooling system is positioned on the bottom of the rear compartment. Depending on the temperature of the power semiconductors

and the inductive components it is automatically activated and adjusts its speed according to the requirements

of a balanced heat dissipation within the device.

The air stream produced by the fans is effectively canalized through a stream tunnel. It dissipates the waste

heat of the heat sink as well as the components installed in this part.

Using OptiCool reduces the components' temperature in the entire inverter resulting

in high reliability and excellent overload performance. The efficiency of the inverter

and thus of the entire PV plant can therefore be increased.

Using a dual compartment system with a waterproof area for the electronics makes

the inverter suitable for inside as well as outside installation (near the PV generator).

Installation Guide SMC50_60-11:SE2006 Page 13

Page 14

Overview SMA Technologie AG

Page 14 SMC50_60-11:SE2006 Installation Guide

Page 15

SMA Technologie AG Requirements for the Installation

4 Requirements for the Installation

Please make sure to fulfill all conditions below before installing and commissioning

the Sunny Mini Central 5000/6000.

4.1 Requirements: Mounting Place

The Sunny Mini Central 5000/6000 has a relatively high weight of

63 kg. Please keep this in mind when selecting the place where and

how to mount the Sunny Mini Central 5000/6000.

The ambient temperature must be within -25°C and +60 °C.

The Sunny Mini Central 5000/6000 should be installed at a place

where it is not exposed to direct sunlight - otherwise this may reduce

the yield of the PV plant due to the higher temperature.

63 kg

The Sunny Mini Central is designed to be mounted on a vertical wall. For an optimum

energy yield and the most convenient operation, vertical installation at eye-level is

preferable. In case it is absolutely necessary to tilt the Sunny Mini Central to the back

the maximum angle is 45 °. If installing the unit outdoors, make sure that it is not

slanting forwards. We advise against installing the unit in a horizontal position

outdoors.

It is not reccomended to install the Sunny Mini Central lying on the back side with the

lid facing upwards.

Mount the Sunny Mini Central in a vertical

position or with a slight angle to the back.

Installation Guide SMC50_60-11:SE2006 Page 15

Do not mount the Sunny Mini Central with

an angle to the front or on the back.

Page 16

Requirements for the Installation SMA Technologie AG

Important for the selection of the location:

Unintended removal of the PV plug connectors can damage the

connectors and even result in serious injuries. Install the Sunny

Mini Central 5000/6000 at a place where an unintended removal

of the PV plug connectors (e. g. by children) is not possible.

Individual components in the Sunny Mini Central can reach a temperature of more than 60 °C.

Do not install the Sunny Boy on flammable construction materials,

in areas where highly inflammable materials are stored or in potentially explosive environments!

Please make sure there is a sufficient space for heat dissipation! In a normal environment the following clearances should be provided for the Sunny Mini Central 5000/

6000:

Minimum clearances

Lateral 30 cm

30

cm

Top 30 cm

Bottom 30 cm

Front 5 cm

30 cm

5

cm

30

cm

30 cm

If you decide to install the Sunny Mini Central 5000/6000 in an area with high ambient temperatures, you should enlarge the clearances. Otherwise the Sunny Mini

Central 5000/6000 could take air in from the devices next to it. Ensure sufficient ventilation.

Page 16 SMC50_60-11:SE2006 Installation Guide

Page 17

SMA Technologie AG Requirements for the Installation

In a living area the Sunny Mini Central 5000/6000

should not be mounted on plaster panels etc. in order

to avoid noises.

We recommend to install the inverter on a firm and sturdy surface.

The Sunny Mini Central 5000/6000 will emit a slight

noise during operation. This noise can be annoying

when the Sunny Mini Central is installed within a living

area.

Installation Guide SMC50_60-11:SE2006 Page 17

Page 18

Requirements for the Installation SMA Technologie AG

4.2 Requirements: PV-Modules

The Sunny Mini Central 5000/6000 is designed for the connection of large scales

with homogeneous structure (PV modules of the same type, same direction and slant).

The „Sunny Design“ tool will help to dimension and check the size of your strings with

respect to the inverter you intend to use. The „Sunny Design“ tool is available for

download at www.SMA.de.

The device has eight PV plug connectors (two for each string). The connecting cables

of the PV panel therefore have to be equipped with such plug connectors as well. A

connection kit for the connection of loose cable ends in a string can be purchased as

an accessory. In the following you find the SMA order numbers for the different PV

plug connectors:

• Multi-Contact 3 mm: „SWR-MC“

• Multi-Contact 4 mm: „MC-SET“

• Tyco: „TYCO-SET“

Limits for DC input

max. voltage 600 V (DC)

max. input current 26 A (DC)

The strings are connected in parallel inside the Sunny Mini Central 5000/

6000. Check if the cabling of the generator can handle high short-circuit currents. See also chapter 5.3 „Reverse Current” (page 30).

4.3 String sizing of Sunny Mini Central PV plants

Different from the Sunny Mini Centrals you are able to connect three or more strings

in parallel to the Sunny Mini Central 5000/6000. This sounds not very critical, but a

consequence is that failures which are not harmful in string plants have to be considered in plants with big generators: Because of short circuits. See also chapter 5.3

„Reverse Current” (page 30).

4.4 Requirements: Grid 230 V (AC)

The relevant technical regulations as well as specific requirements defined by the local public utility have to be

complied with. The terminals of the Sunny Mini Central

5000/6000 are suitable for cables with a cross-section

of up to 16 mm² . Their outer diameter should be between 11 mm and 25 mm. If you

choose a cable with a diameter less than 14 mm (at least 11 mm), you have to

change the rubber grommet of the connection. A smaller rubber grommet is included

in the shipping box.

The Sunny Mini Central 5000/6000 is connected with three wires (L, N, PE).

Page 18 SMC50_60-11:SE2006 Installation Guide

o

11 ... 25 mm

max. 16 mm²

Page 19

SMA Technologie AG Requirements for the Installation

Each connection to a Sunny Mini Central

5000/6000 must be equipped with a separrate circuit breaker 40 A. No other consumers may be connected to the cable.

Sizing of a circuit breaker for the AC line of a photovoltaic inverter for utility interaction

Several factors have to be considered when you define the size of the circuit

breaker for your PV plant:

• Cable type (material and isolation)

• Ambient temperature surrounding the cable (higher temperatures reduce the conducting capacity of the cable)

• Type of installation for the cable (can also reduce the conducting capacity of the

cable)

• Bundling of cables (can reduce the conducting capacity of the cable)

• Loop impedance [Z] (reduces the current that flows in case of a ground fault current through a body and has influence on the tripping characteristics of the circuit

breaker)

• Adequate clearance between the circuit breakers in order to avoid excessive

heating (automatic circuit breakers trip earlier when they are warmer).

• Fuse selectivity

• Protection class of the connected consumer (VDE 0100 Part 410 "Protection

against electric shock"

a

and/or the international standard IEC 60364-4-41:1992)

The following standards have to be complied with:

• DIN VDE 0298-4 ("Types of cable installation and conducting capacity")

1

• DIN VDE 0100 Part 430

("Protection measures for protection of cables

and conductors in terms of overcurrent") and/or the international standard IEC 364-4-43:1977 and IEC 364-4-473:1977

1

• VDE 0100 Part 410

("Protection against electric shock") and/or the inter-

national standard IEC 60364-4-41:1992

a. The standards mentioned above are to be only used as a guideline for your in-

stallation. The above mentioned standards apply for installations in Germany.

Please note that other standards will apply for different countries throughout the

world.

Installation Guide SMC50_60-11:SE2006 Page 19

Page 20

Requirements for the Installation SMA Technologie AG

An example for determining the rating of the AC circuit breaker is specified in detail

in chapter 10 „Sizing of a Circuit Breaker” (page 51).

The system impedance at the installation site of the Sunny Mini Central 5000/6000

must be less than 1 Ohms for the islanding detection and the fuses to work properly.

Furthermore you should have a suitable cable cross-section in order to keep the losses below 1 % at nominal power. The according losses with respect to cable length

and cross-section are illustrated below:

Losses of the Sunny Mini Central 5000

Do not use cables where losses will exceed 1.0 %

Losses

Length

The maximum cable lengths for the different cable cross-sections are as follows:

Conductor cross-

section

4.0 mm² 6.0 mm² 10.0 mm² 16.0 mm²

Max. length 12 m 18 m 31 m 49 m

Page 20 SMC50_60-11:SE2006 Installation Guide

Page 21

SMA Technologie AG Requirements for the Installation

Losses of the Sunny Mini Central 6000

1,4%

1,2%

1,0%

0,8%

0,6%

Losses

0,4%

0,2%

0,0%

0 m

4,0 mm²

5 m

10 m 15 m 20 m 25 m 30 m 35 m 40 m 45 m 50 m

Do not use cables where losses will exceed 1.0 %

6,0 mm²

10,0 mm²

Sunny Mini Central 6000

Length

16,0 mm²

The maximum cable lengths for the different cable cross-sections are as follows:

Conductor cross-

section

4.0 mm² 6.0 mm² 10.0 mm² 16.0 mm²

Max. length 10 m15 m25 m41 m

The Sunny Mini Central 5000/6000 is designed for 230 V grids. The voltage should

be within 198 V and 260 V and the frequency should be within 49.8 Hz and

50.2 Hz. All settings shown below are based on the German standard DIN VDE

0126. You are also able to use other settings.

Limits for AC output

Voltage range 198 V ... 260 V

Frequency range 49.8 Hz ... 50.2 Hz

Voltage range

(without anti-islanding)

Frequency range

(without anti-islanding)

180 V ... 260 V

45.5 Hz ... 54.5 Hz

The Sunny Mini Central 5000/6000 is equipped with an automatic 50 Hz / 60 Hz

utility frequency detection. It can therefore be connected to a 50 Hz or 60 Hz utility

without any further configuration changes. Pay attention to the local utility regulations in any case.

Installation Guide SMC50_60-11:SE2006 Page 21

Page 22

Requirements for the Installation SMA Technologie AG

Grid Impedance

In the following example the output power (Uac) is reduced to 260 V. You are also

able to reduce the output power of the Sunny Mini Central 5000/6000 according to

the national standards.

Because of a high grid impedance the Sunny Mini Central 5000/6000 can receive

a high AC voltage at the connection point. The output voltage (Uac) of the Sunny

Mini Central 5000/6000 is limited to 260 V. If the Sunny Mini Central 5000/6000

exceeds 260 V, it stops feeding to the grid immediately and indicates a „grid failure“.

Which power you can feed into the grid, without stopping operation because of high

AC voltages, is shown in the diagram below.

1,5

1,4

1,3

1,2

1,1

1,0

0,9

0,8

Grid Impedance [Ohm]

0,7

0,6

0,5

0 5 10 15 20 25 30

250 V 240 V 230 V 220 V 210 V 200 V

Power [kW] per Phase

To estimate how many Sunny Mini Central 5000/6000 can operate on one phase

you need the following values:

• Grid voltage without feeding

• Grid impedance at the connection point of the Sunny Mini Central 5000/6000

The diagram shows the respective curve for the AC voltage without feeding. The respective curve for power per phase (X axis) results in subject to the grid impedance

(Y axis).

Page 22 SMC50_60-11:SE2006 Installation Guide

Page 23

SMA Technologie AG Requirements for the Installation

Example

The grid voltage without feeding averages 230 V.

The grid impedance at the connection point averages 1.2 Ohm.

1,5

1,4

1,3

1,2

1,1

1,0

0,9

0,8

Grid Impedance [Ohm]

0,7

0,6

0,5

0 5 10 15 20 25 30

230 V

Power [kW] per Phase

The indicated power on the x axis complies approx. 6.2 kW per phase.

In consequence you should install only one Sunny Mini Central 5000/6000 per

phase. To install a plant with a higher power that does not stop feeding because of

AC over voltage, you should check the connection conditions of the Sunny Mini Central 5000/6000 (e. g. by using a cable with a higher cross-section).

Installation Guide SMC50_60-11:SE2006 Page 23

Page 24

Requirements for the Installation SMA Technologie AG

Page 24 SMC50_60-11:SE2006 Installation Guide

Page 25

SMA Technologie AG Installation

5 Installation

5.1 Mounting

For trouble-free mounting of the Sunny Mini Central

5000/6000 we recommend to use the bracket for wall

installation included in delivery. You can mount it vertically in firm concrete or stone walls with e. g. stainless

steel 8 mm x 50 mm hexagon screws according to DIN

571, an appertaining washer and with a 10 mm dowel.

Photovoltaik

B

e

trie

b

O

Photovoltaic inve

pe

ra

t

-W

io

n

echselrich

E

r

d

s

r

c

ter

hlu

te

E

r

ss

ar

th

F

a

u

lt

S

tör

u

n

g

F

a

i

lu

re

Keep the weight of the Sunny Mini Central 5000/6000

(63 kg) in mind.

For installing your Sunny Mini Central 5000/6000 on

wooden wall studs, use the four holes in the middle of

the wall-mounting bracket. Position the wall-mounting

bracket against a stake of the wall. Make sure that the

wall you choose to mount the Sunny Mini Central

5000/6000 on is sturdy enough to support its weight

U

tili

ty

In

ter

a

c

tiv

e

In

ve

r

t

er

(63 kg) over a long period of time and that the wall is

vertical.

1. Mount the bracket. To mark the positions for drill

holes you can also use the bracket as a drilling

template.

2. Hang the upper fixing straps of the Sunny Mini

Central 5000/6000 into the bracket (2) so that it

cannot be shifted sideways any more.

3. Secure the Sunny Mini Central 5000/6000

against lifting off by screwing the M6x10 screw

(included in delivery) into the lower middle fixing

strap (3).

4. Ensure the Sunny Mini Central 5000/6000 has

been tightly fastened.

2

1

1

3

Installation Guide SMC50_60-11:SE2006 Page 25

Page 26

Installation SMA Technologie AG

5.2 Electrical Installation

Check the correct polarity before you connect the PV strings!

The following figure shows the complete cabling of a Sunny Mini Central 5000/

6000:

++++

String 1

String 2

String 3

String 4

230 Vac:

---

-

NL1

Communication

max. 16 mm

32A

B

2

Page 26 SMC50_60-11:SE2006 Installation Guide

Page 27

SMA Technologie AG Installation

Connection of AC output

Please follow the steps below:

1. Check the grid voltage. If it is above 260 V

(German standard), the Sunny Mini Central

5000/6000 stops operation. The local public

utility company should solve this problem.

The maximum grid voltage for feeding

max. 260 V!

operation is 260 V!

2. Disconnect the grid (switch off the circuit breaker), secure it against accidental reactivation and

ensure that it is disconnected.

Off!

1. 2. 3.

Before opening the Sunny Mini Central

5000/6000 check whether the AC

output is safely isolated from supply!

3. Unscrew the lid from the enclosure of the Sunny

Mini Central 5000/6000 and remove the lid.

Photovoltaik-Wechselrichter

B

e

t

r

i

e

b

O

Photovoltaic inverter

p

e

r

a

t

i

o

n

E

r

d

s

c

h

l

u

E

s

s

a

r

t

h

F

a

u

l

t

S

t

ö

r

u

n

g

F

a

i

l

u

r

e

4. Connect the AC cable as illustrated in the figure

L

on the side. Use the cable gland that is included

in the delivery of your Sunny Mini Central

5000/6000. Phase (L) and Neutral (N) may not

be mixed up.

NL1

230 Vac:

N

Connection of „L“ and „N“

Installation Guide SMC50_60-11:SE2006 Page 27

Page 28

Installation SMA Technologie AG

5. Connect the PE conductor of the grid cable.

Connection of PE conductor

6. Fasten the lid to the enclosure of the Sunny Mini Central 5000/6000 by tightening the six screws. Don’t forget the lock washers. The notches of the lock washers

should face to the lid.

Do not switch on the circuit breaker yet! The Sunny Mini Central

5000/6000 may only be connected to the AC grid when the PV

strings have been connected and the device is tightly closed.

Page 28 SMC50_60-11:SE2006 Installation Guide

Page 29

SMA Technologie AG Installation

PV String (DC) Connection

Connect the PV strings as follows:

1. Check the PV generator connections on their

correct polarity and compliance with the maximum string voltage of 600 V DC, see chapter

4.2 „Requirements: PV-Modules” (page 18).

The voltage from the strings is very dangerous! Be very careful

and pay attention to all applicable safety regulations!

2. Measure the DC voltages between each PV plug

connector of a string and ground potential. Follow the safety instructions!

3. If the measured voltages are constant and their

total approximately corresponds to the open-circuit voltage of the string, a ground fault has occured in this string. The ratios of voltages

approximately indicate where the ground fault

can be found.

PE

When you have found a ground fault in a string, only connect it to

the Sunny Mini Central 5000/6000 after you have removed the

cause for the ground fault in the PV generator.

4. Repeat steps 2 and 3 for each string.

5. Connect the trouble-free PV strings to the Sunny

Mini Central 5000/6000. Make sure to connect

them with correct polarization.

++

-

-

6. Close off the unneeded DC input sockets using

the protective caps supplied in the accessories

kit.

Installation Guide SMC50_60-11:SE2006 Page 29

String A

String B

Page 30

Installation SMA Technologie AG

5.3 Reverse Current

Information about the design of generators for PV plants with

Sunny Mini Central

In contrast to the „Sunny Mini Central“ string inverters, mostly three and more strings

are connected in parallel within a PV generator of a „Sunny Mini Central 5000/

6000“ (SMC). In case of such large generators failures may occur that are uncritical

in string plants: module currents misrouted by short circuits can load a PV module with

a so called reverse current that may exceed the normal maximum current (short circuit current) of the PV module.

When can a reverse current occur?

In principal, a reverse current can only occur when modules are connected in parallel

and the open terminal voltage (open-circuit voltage Uoc) of the individual parallel

strings is different. In normal operation mode, this is mostly avoided due to the fact

that the strings are identical. Even in the special case of shadowing no considerable

reverse current occurs as shadowing has no significant impact on Uoc.

In normal operation no excessive reverse current can occur in a PV plant that has

been accurately designed!

Thus, a reverse current can only arise in case the open terminal voltage of a module

string is significantly below the open circuit voltage of the other strings connected in

parallel due to a failure in the PV generator (e.g. short circuit of one or several modules). At worst, the voltage applied to the defective string is in the range of the remaining generator's MPP voltage (UMPP). Due to the internal diode structure of the

PV cell a reverse current flows through the defective generator string. This reverse

current may cause an extreme heat all the way to the destruction of the string's modules depending on the current intensity!

The failures indicated below may result in reduction of the open terminal voltage of

a generator string and thus in a reverse current in case of connection in parallel:

• Short circuit of one or several modules,

• Short circuit of one or several cells in the module,

• Double ground fault of a module and/or the wiring.

Even if these failures are very unlikely and rare in the field precautions must be taken.

This failure involves a high potential for damages and dangers. All modules of the

affected Strings can be damaged and cause secondary damages due to the high

Page 30 SMC50_60-11:SE2006 Installation Guide

Page 31

SMA Technologie AG Installation

thermal impact. It is therefore not amazing that UL certifiers in the USA already consider this aspect and that the reverse current resistance is a value specified by default

in US datasheets of PV modules.

Current of the defective string =

Sum of the current of the other strings

+

-

L

N

Installation Guide SMC50_60-11:SE2006 Page 31

Page 32

Installation SMA Technologie AG

How can one avoid reverse currents within the modules?

Bypass diodes that are currently state of the art in module design have no impact on

the reverse current within the module but only reduce the effects of possible shadowing.

You have the following possibilities to cope with the reverse current problems:

1. String Technology

All components of a string (modules, cables, plug connectors) must be designed for

the remaining generator short-circuit current as reverse current. This always applies

in case of parallel connection of a maximum of two strings as the resulting reverse

current of a (damaged) string can achieve at most the value of the short circuit current

of the (faultless) string.

2. String Diodes

Due to so called string diodes connected in serial circuit with the individual strings

only the reverse current within the respective string is avoided. Disadvantage: the diode is permanently in serial circuit with the respective generator string and the respective string current flows through it. Respectively high permanent losses result. In

addition, failure of the diode may cause a loss of the protective function or failure of

the entire string.

3. String Fuses

String fuses connected in serial circuit with the individual strings allow to limit the reverse current in the respective string to the permitted maximum. The losses at the

string fuses are lower than the losses you would observe with string diodes. A string

fuse failure can be identified by a fuse control or an "intelligent" failure control of the

PV panel.

The first option is to be considered for the design of a cost-efficient plant. The Sunny

Mini Central 5000/6000 is therefore delivered with MC and Tyco plug connectors

that have a rating of 30 A current.

Design Tips

The following is specifically to be checked and/or ensured:

1. Do all strings have the same number of modules connected in serial circuit?

2. What is the maximum reverse current in a defective string under nominal conditions?

Example: Generator consisting of 4 strings of modules with short circuit current

of 5 A maximum reverse current is 3 x 5 A = 15 A.

3. Are the modules suitable for such a reverse current?

4. Are the plug connections of the modules and the inverter suitable for such a reverse current?

5. Is the string cabling suitable for such a reverse current?

Page 32 SMC50_60-11:SE2006 Installation Guide

Page 33

SMA Technologie AG Installation

5.4 Activation

You can activate the Sunny Mini Central 5000/6000 when:

• The lid has been tightly screwed on.

• The AC (grid) cable has been correctly connected.

• All the DC (PV) strings have been connected and all unused DC plug connectors

on the underside of the inverter have been closed with the protecting caps.

Proceedings for Activation

1. Switch the circuit breaker on.

2. Check whether the LEDs indicate trouble-free

operation of the Sunny Mini Central 5000/

6000 based on the following table. If this is the

case commissioning has been successfully completed.

If the lower yellow LED repeatedly blinks once a second for four

times, immediately disconnect the grid voltage and the PV generator from the Sunny Mini Central 5000/6000. The input voltage is

too high. The inverter might be damaged!

On!

Off

Check whether string voltages comply with limiting values stated in chapter 4.2 „Requirements: PV-Modules” (page 18). If the values are too high, the planner / installer

of the PV generator must modify the strings.

If the LED blinks again when the PV plant is reconnected to the inverter although

string voltages have been checked to be ok, disconnect the PV panel again and contact SMA Technologie AG (see chapter 11 „Contact” (page 55)).

Installation Guide SMC50_60-11:SE2006 Page 33

Page 34

Installation SMA Technologie AG

Green Red Yellow Status

off off OK (feeding)

permanently on

blinking fast

(3 x per second)

blinking slowly

(1 x per second)

shortly turns off

(approx. 1 x per

second)

off

permanently on

off off OK (Stop)

permanently on off failure

off off

permanently on permanently on failure

off off OK (derating)

permanently on off failure

off

permanently on

off failure

permanently on OK (Initialization)

OK (waiting, grid moni-

toring)

off OK (stand-by)

off / blinking failure

off failure

off / blinking failure

You will find a detailed description of failure messages and their causes in the „Operating Instructions“.

Page 34 SMC50_60-11:SE2006 Installation Guide

Page 35

SMA Technologie AG Opening and Closing the Sunny Mini Central

6 Opening and Closing the Sunny Mini Central

If the inverter has to be openend always follow the safety instructions given in chapter 2 „Safety Instructions” (page 9).

6.1 Opening the Sunny Mini Central

Caution: Stick to the order specified below!

1. Switch off the AC connection.

2. Prevent accidental reconnection!

3. Disconnect the PV generator from the Sunny Mini Central 5000/6000 by pulling

off all the connectors.

4. Wait 30 minutes! (This is necessary to let the internal capacitors discharge.)

5. Remove the six screws on the lid and pull the lid slightly forward.

6.2 Closing the Sunny Mini Central

Caution: Stick to the order specified below!

1. Attach the lid to the enclosure of the Sunny Mini Central 5000/6000 by tightening the six screws. Don’t forget the lock washers. The notches of the lock washers

should face to the lid.

2. Connect the PV generator.

3. Switch on the AC circuit breaker. This activates the Sunny Mini Central 5000/

6000.

4. Check whether the LEDs of the Sunny Mini Central 5000/6000 indicate troublefree operation.

Installation Guide SMC50_60-11:SE2006 Page 35

Page 36

Opening and Closing the Sunny Mini Central SMA Technologie AG

Page 36 SMC50_60-11:SE2006 Installation Guide

Page 37

SMA Technologie AG Technical Documentation

7 Technical Documentation

7.1 Sunny Mini Central 5000

7.1.1 Data PV Generator Connection

Max. input open-circuit voltage U

Input voltage, MPP operation U

Max. input current I

Max. input power P

Recommended generator

power

All-pole disconnector on DC input side DC plug connector

Surge voltage protection thermally monitored varistors

Voltage ripple U

Personnel protection Ground Fault monitoring

Internal consumption in operation < 7 W (stand-by)

Pole confusion prevention by short-circuit diode

7.1.2 Data Grid Connection

Nominal output power P

Permanent output power at 45 °C 5500 W

Peak output power P

Nominal output current I

Harmonic distortion of output

(with KUnom < 2 %, PAC > 0,5 PACnom)

Short-circuit resistance Imax = 30 A

Operating range, grid voltage U

Operating range, grid frequency f

All-pole disconnector on grid side independent disconnection device (MSD),

Phase difference (related to basic wave of

current)

Overvoltage category III

Test voltage 2 kV (1 s unit / 60 s type test)

Surge voltage test 4 kV (1.2/50 µs)

Internal consumption in stand-by 0.25 W

0 600 V (at -10 °C module temperature)

PV

PV

PV max

PV

PP

ACnom

ACmax

ACnom

T

HDIAC

AC

AC

cos Phi 1

250 V ... 600 V DC

(250 V DC at 230 V AC)

26 A

5750 W

6350 Wp

< 10 % of input voltage

(Riso > 2 MΩ)

5000 W

5500 W

21.7 A

4 %

198 ... 260 V AC

(adjustable 180 ... 265 V)

49.8 ... 50.2 Hz

(adjustable 45.5 ... 54.5 Hz)

(2 independant systems)

(serial interface: 6 kV)

Installation Guide SMC50_60-11:SE2006 Page 37

Page 38

Technical Documentation SMA Technologie AG

7.2 Sunny Mini Central 6000

7.2.1 Data PV Generator Connection

Max. input open-circuit voltage U

Input voltage, MPP operation U

Max. input current I

Max. input power P

Recommended generator

power

All-pole disconnector on DC input side DC plug connector

Surge voltage protection thermally monitored varistors

Voltage ripple U

Personnel protection Ground Fault monitoring

Internal consumption in operation < 7 W (stand-by)

Pole confusion prevention by short-circuit diode

0 600 V (at -10 °C module temperature)

PV

PV

PV max

PV

250 V ... 600 V DC

(250 V DC at 230 V AC)

26 A

6300 W

7000 Wp

PP

< 10 % of input voltage

(Riso > 2 MΩ)

7.2.2 Data Grid Connection

Nominal output power P

ACnom

Permanent output power at 45 °C 6000 W

Peak output power P

Nominal output current I

Harmonic distortion of output

(with KUnom < 2 %, PAC > 0,5 PACnom)

ACmax

ACnom

T

HDIAC

Short-circuit resistance Imax = 30 A

Operating range, grid voltage U

Operating range, grid frequency f

AC

AC

All-pole disconnector on grid side independent disconnection device (MSD),

Phase difference (related to basic wave of

cos Phi 1

current)

Overvoltage category III

Test voltage 2 kV (1 s unit / 60 s type test)

Surge voltage test 4 kV (1.2/50 µs)

Internal consumption in stand-by 0.25 W

5500 W

6000 W

24 A

4 %

198 ... 260 V AC

(adjustable 180 ... 265 V)

49.8 ... 50.2 Hz

(adjustable 45.5 ... 54.5 Hz)

(2 independant systems)

(serial interface: 6 kV)

Page 38 SMC50_60-11:SE2006 Installation Guide

Page 39

SMA Technologie AG Technical Documentation

7.3 Description of Devices

You will find a detailed device description in the Operating Instructions.

General Data

Protection Degree according to

DIN EN 60529 IP54

Dimensions (width x height x depth) approx. 430 mm x 600 mm x 250 mm

Weight approx. 63 kg

External interfaces

Data transmission via powerline optional

Data transmission via separate data cable optional,

RS232 / RS485, electrically separated

Data transmission via radio optional

Efficiency

Max. Efficiency ηmax 96 %

European weighted efficiency ηeuro > 95.1 %

The efficiency of the Sunny Mini Central depends on the input voltage coming from

the PV modules. The lower the input voltage, the higher the efficiency.

96

95

94

93

92

Overall efficiency [%]

91

90

0 2000 3000 4000 5000 6000

Installation Guide SMC50_60-11:SE2006 Page 39

250 V

300 V

400 V

500 V

Sunny Mini Central 5000 / 6000

1000

Output power [W]

Page 40

Technical Documentation SMA Technologie AG

7.4 Sunny Mini Central Operating Parameters

Any unauthorized modifications of the operating parameters can

• Result in serious injuries or casualties due to altered internal

safety precautions within the Sunny Mini Central

• Void the operating permission of the Sunny Mini Central

• Void the warranty of the Sunny Mini Central

Never change the operating parameters without explicit permission and instructions!

The parameters with a grey background are only visible when in installer mode.

Name Unit Range Default

Betriebsart/

Operating Mode

Default GER/ENS

dFac-MAX Hz/s 0.005 ... 4.0 0.25

dZac-MAX mOhm 0 ... 20000 350

E_Total kWh 0 ... 200000

Fac-Delta- Hz 0 ... 4.5 0.19

Fac-Delta+ Hz 0 ... 4.5 0.19

Fan test 0 1 0

h_Total h 0 ... 200000

Inst.-Code

NiTest/

testcurrent Zac

Riso kOhm 0 ... 10000 1000

Speicherfunktion/

Memory Function

Speicher /

Storage

T-Max-Fan °C 0 ... 100 90

T-Start s 5 ... 1600 10 / 300

T-Start-Fan °C 0 ... 100 70

T-Stop s 1 ... 1800 2

T-Stop-Fan °C 0 ... 100 50

Uac-Max / Vac-Max V 180 ... 300 260

Uac-Min / Vac-Min V 180 ... 300 198

Usoll-Konst/

Vconst-Setval

mA 0 ... 25000 16000

V 250 ... 600 600

MPP, UKonst, Stop,

Turbine, MPP

permanent / volatile permanent

MPP

none

Page 40 SMC50_60-11:SE2006 Installation Guide

Page 41

SMA Technologie AG Technical Documentation

The following parameters appear in parameter list but cannot be modified:

Name Unit Range Description

Plimit W 5000 /

6000

SMA-SN Serial Number of the Sunny Mini Central

Software-BFR Firmware version of the operation control unit

Software-SRR Firmware version of the current control unit

Upper limit of AC output power

(BFR)

(SRR)

Installation Guide SMC50_60-11:SE2006 Page 41

Page 42

Technical Documentation SMA Technologie AG

Page 42 SMC50_60-11:SE2006 Installation Guide

Page 43

SMA Technologie AG Checking the heat dissipation

8 Checking the heat dissipation

You only need to check the heat dissipation, in case you recognize that the fans are

severely clogged or the Sunny Mini Central is often in the operation mode Derating.

Whether the Sunny Mini Central works in the operation mode Derating or not, depends on the ambient temperature and the efficiency of the ventilation. I. e. a device

with clogged filters (insufficient ventilation) and a low ambient temperature, may seldom or even not change to the mode Derating. But a device with sufficient ventilation

and a high ambient temperature may relatively often change to the mode Derating.

8.1 Cleaning the fans

If the filters are only clogged with loose dust you can clean them with a vacuum cleaner. If the fans are still clogged, you have also the possibility to remove the fans for

cleaning them.

The fans are mounted on a plate on the bottom side of the Sunny Mini Central. To

clean the fans please follow the steps below:

1. Remove the six screws on the bottom side of the

Sunny Mini Central.

Pac 903W

Upv 330V

2. Carefully remove the plate with the fans and disconnect the cable leading to the inside of the inverter.

3. Unlock the connectors of the fans and remove

them carefully.

4. The fans are mounted to the plate with four nuts

each. Undo the four nuts and remove the fans, the

spacers and filters located behind each fan.

5. To clean the fans, spacers and filters use a soft

brush or cloth. Do not use air pressure for cleaning the fans. This will damage

the fans.

Installation Guide SMC50_60-11:SE2006 Page 43

Page 44

Checking the heat dissipation SMA Technologie AG

6. When the fans are clean, reinstall them using the above steps in reverse order.

Pay attention to the direction of the fans. Do not forget to reconnect the plugs of

the fans. After reinstalling the fans, check their function (see following chapter).

Page 44 SMC50_60-11:SE2006 Installation Guide

Page 45

SMA Technologie AG Checking the heat dissipation

8.2 Testing the fans

You can verify the operation of the fans in two ways:

• Set the parameter „Fan Test“ to „1“ (with Sunny Data, Sunny Data Control or

with the data logger Sunny Mini Central Control).

• Use the jumper on the control board of the Sunny Mini Central (see figure below).

For setting the jumper for the fan test, proceed as follows. Stick to the order specified

below!

1. Open the Sunny Mini Central 5000/6000 as described in chapter 6.1 „Opening the Sunny Mini Central” (page 35).

2. Put the jumper in the slot shown in the picture below. The jumper is included in

delivery

3. Close the Sunny Mini Central as described in chapter 6.2 „Closing the Sunny

Mini Central” (page 35) and switch it on again.

4. The Sunny Mini Central can not detect the jumper, until you deactivate and reactivate it.

Position of the jumper

After setting the jumper, switch on the Sunny Mini Central. Check the air flow of the

fans. The Sunny Mini Central aspirates the air from the bottom side and blows it out

on the sides of the device. Pay attention to strange sounds, they might be a hint for

an incorrect installation or a defective fan.

When you finished testing the fans you have to reset the parameter „Fan-Test“ to „0“,

or you have to remove the jumper.

Installation Guide SMC50_60-11:SE2006 Page 45

Page 46

Checking the heat dissipation SMA Technologie AG

8.3 Cleaning the Fins

The fins are mounted on both sides of the Sunny Mini Central. To clean the fins follow

the steps below.

1. Turn off the Sunny Mini Central by following the steps 1 to 4 of chapter 6.1

„Opening the Sunny Mini Central” (page 35)

2. Remove the six screws on both sides of the Sunny Mini

Central.

3. Take out the fins. Behind the fins are the filters. Clean

the filters and fins with a soft brush, cloth or air pressure.

4. When the fins and filters are clean, reinstall them using the above steps in reverse order. Don’t forget the

lock washers. The notches of the lock washers should

face to the enclosure.

Page 46 SMC50_60-11:SE2006 Installation Guide

Page 47

SMA Technologie AG Exchanging Varistors

O

9 Exchanging Varistors

The Sunny Mini Central 5000/6000 is a very complex technical device. Therefore

there are only a few possibilities to repair failures on site. Please do not try to make

repairs otherwise than described in this document. Make use of our exchange service

and the repair service of SMA Technologie AG.

If the red status LED is permanently on during operation please first make sure that

there is no ground fault in the PV generator.

1. Disconnect the grid (switch off the circuit breaker), secure it against accidental reactivation and

ensure that it is disconnected.

ff!

1. 2. 3.

Ensure that the AC voltage is off before

you open the Sunny Mini Central 5000/

2. Disconnect the PV plug connectors of all strings.

String A

String B

Disconnect the PV strings!

3. Measure voltages between one PV plug connector of each string and the ground potential. Follow all applicable safety instructions!

PE

++

6000!

-

-

Measure voltages between PV plug

connectors and the ground potential.

The voltage from the strings is very dangerous! Be very careful

and pay attention to all applicable safety regulations!

4. If the voltages measured are constant and their total is approximately equal to

the open-circuit voltage of the string, there is a ground fault in this string. Its approximate position can be deducted from the ratios of voltages.

Installation Guide SMC50_60-11:SE2006 Page 47

Page 48

Exchanging Varistors SMA Technologie AG

5. Repeat points 3 and 4 for each string.

If you have found a ground fault it is probably unnecessary to exchange the

varistors. Make sure to remove the ground fault instead. This should normally

be done by the installer of the PV plant. In this case proceed with point 10, but

without reconnecting the faulty string! Protect its PV plug connectors against

touching (e. g. by protective caps or insulation strip with sufficient electric

strength).

If you have not found any ground fault in the PV generators, probably one of

the thermally monitored varistors has lost its protective function. The varistors

are subject to wear and tear and their function is reduced in the course of their

aging or in case of repeated strain placed on them by surge voltages. You can

now check the varistors as described below while following the safety instructions given in chapter 2 „Safety Instructions” (page 9).

6. Unscrew the lid of the Sunny Mini Central 5000/6000 and remove it. Test safe

isolation from supply.

7. Test all varistors for an electric connection between terminals 2 and 3. If there

is no electric connection the varistor is useless. The position of varistors in the

Sunny Mini Central 5000/6000 can be seen in chapter 3.1 „Device Description” (page 11).

8. Replace the defective varistor by a new one as

shown in the figure on the left. Ensure correct

orientation of the varistor! Please contact SMA

if you have not received special tools to move

Unlock the varistor

with the

extractor tool

the terminals (included in delivery of replacement varistors). However, the terminal contacts

can also provisionally be released one by one

with a suitable screwdriver. The failure of a

varistor is normally due to circumstances that

apply to all varistors in a similar manner (tem-

Remove varistor

perature, age, induced surge voltages). We

therefore strongly recommend not only to exchange the defective one, but all two. These

varistors are specially manufactured for use in

3

2

1

the Sunny Mini Central 5000/6000 and are not

commercially available. They have to be purchased from SMA Technologie AG direct (SMA

order name:“SB-TV4“).

The wire with the little

dent must be inserted

into the terminal

number 1 when you

install the new varistor

Page 48 SMC50_60-11:SE2006 Installation Guide

Page 49

SMA Technologie AG Exchanging Varistors

In case there are no spare varistors available the Sunny Mini Central 5000/6000 still can feed electricity into the grid. The input is

not protected against overvoltages in this case. Replacement varistors should be obtained as soon as possible. In systems with a high

risk of overvoltages, the Sunny Mini Central 5000/6000 should not

be operated with defective varistors.

9. Attach the lid to the enclosure of the Sunny Mini Central 5000/6000 by tightening the six screws. Don’t forget the lock washers. The notches of the lock washers

should face to the lid.

10. Connect the faultless strings of the PV panel. Ensure correct allocation to strings.

-

11. Close off the unneeded DC input sockets using

++

-

the protective caps supplied in the accessories

kit.

String A

String B

12. Switch on the circuit breaker.

On!

13. Check whether the LEDs of the Sunny Mini Central 5000/6000 show trouble-free operation.

Off

If you have found neither a ground fault nor a defective varistor there probably is a

fault in the Sunny Mini Central 5000/6000. Please contact the SMA hotline in this

case to discuss further proceedings.

Installation Guide SMC50_60-11:SE2006 Page 49

Page 50

Exchanging Varistors SMA Technologie AG

Page 50 SMC50_60-11:SE2006 Installation Guide

Page 51

SMA Technologie AG Sizing of a Circuit Breaker

10 Sizing of a Circuit Breaker

Example for the sizing of a circuit breaker for the AC line of a photovoltaic inverter for utility interaction in terms of temperature.

Photovoltaic plant with 9 inverters type Sunny Mini Central SMC 6000 with 3

inverters per phase

P

h

B

o

e

t

r

t

i

o

e

b

v

o

O

l

P

t

p

a

h

e

r

i

o

a

k

t

t

-

i

o

o

W

n

v

o

e

l

c

t

a

h

i

s

c

e

l

i

r

n

E

i

v

c

r

d

h

e

s

r

c

t

e

h

t

e

l

r

u

E

r

s

s

a

r

t

h

F

a

u

l

t

S

t

ö

r

u

n

g

F

a

i

l

u

r

e

L1

L2

L3

P

h

B

o

e

t

r

t

i

o

e

b

v

o

O

l

P

t

p

a

h

e

r

i

o

a

k

t

t

-

i

o

o

W

n

v

o

e

l

c

t

a

h

i

s

c

e

l

i

r

n

E

i

v

c

r

d

h

e

s

r

c

t

e

h

t

e

l

r

u

E

r

s

s

a

r

t

h

F

a

u

l

t

S

t

ö

r

u

n

g

F

a

i

l

u

r

e

P

h

B

o

e

t

r

t

i

o

e

b

v

o

O

l

P

t

p

a

h

e

r

i

o

a

k

t

t

-

i

o

o

W

n

v

o

e

l

c

t

a

h

i

s

c

e

l

i

r

n

E

i

v

c

r

d

h

e

s

r

c

t

e

h

t

e

l

r

u

E

r

s

s

a

r

t

h

F

a

u

l

t

S

t

ö

r

u

n

g

F

a

i

l

u

r

e

...

P

h

B

o

e

t

r

t

i

o

e

b

v

o

O

l

P

t

p

a

h

e

r

i

o

a

k

t

t

-

i

o

o

W

n

v

o

e

l

c

t

a

h

i

s

c

e

l

i

r

n

E

i

v

c

r

d

h

e

s

r

c

t

e

h

t

e

l

r

u

E

r

s

s

a

r

t

h

F

a

u

l

t

S

t

ö

r

u

n

g

F

a

i

l

u

r

e

P

h

B

o

e

t

r

t

i

o

e

b

v

o

O

l

P

t

p

a

h

e

r

i

o

a

k

t

t

-

i

o

o

W

n

v

o

e

l

c

t

a

h

i

s

c

e

l

i

r

n

E

i

v

c

r

d

h

e

s

r

c

t

e

h

t

e

l

r

u

E

r

s

s

a

r

t

h

F

a

u

l

t

S

t

ö

r

u

n

g

F

a

i

l

u

r

e

P

h

B

o

e

t

r

t

i

o

e

b

v

o

O

l

P

t

p

a

h

e

r

i

o

a

k

t

t

-

i

o

o

W

n

v

o

e

l

c

t

a

h

i

s

c

e

l

i

r

n

E

i

v

c

r

d

h

e

s

r

c

t

e

h

t

e

l

r

u

E

r

s

s

a

r

t

h

F

a

u

l

t

S

t

ö

r

u

n

g

F

a

i

l

u

r

e

N

Required data of the used inverters:

• max. output current: 26 A

• max. permissible rating of the circuit breaker for one inverter: 40 A

The type of cable as well as the type of cable installation and several other conditions

have influence on the maximum rating of the circuit breaker for the inverter.

In this example we assume that the cable used (6 mm²) can be used for nominal currents up to 32.2 A in this example.

Selection of the circuit breakers:

• The maximum possible nominal current of the cable used and the maximum possible rating for the inverter now define the maximum possible nominal current of

the circuit breakers.

• 32 A are possible in our example for one inverter.

However, the thermal suitability of the line circuit breaker still needs to be checked.

Installation Guide SMC50_60-11:SE2006 Page 51

Page 52

Sizing of a Circuit Breaker SMA Technologie AG

Several aspects that have affect on the load must be considered when you select a

circuit breaker. These aspects are specified in the data sheets of the circuit breakers.

Example for the sizing of a 32 A circuit breaker with B characteristics for the

AC line of a photovoltaic inverter for utility interaction while the circuit breakers

are installed right next to each other without gap (with respect to the thermal

conditions).

One vendor of circuit breakers for example specifies the ratings for an ambient temperature of 50 °C.

Aspects that have an affect on the load specified in the data sheets:

• Reduction of the tolerable current because of continuous load > 1 h = 0.9

• Reduction of the tolerable current due to installation of 9 circuit breakers right

next to each other without gap = 0.77

• Increase of the tolerable current resulting from ambient temperatures of 40 °C in

the distribution box = 1.07

c

b

a

a. In photovoltaic applications continuous loads of over 1 h are possible.

b. The coefficient is 1 in case there is only one single circuit breaker.

c. Resulting from the sizing of the circuit breakers for ambient temperatures of

50 °C.

Page 52 SMC50_60-11:SE2006 Installation Guide

Page 53

SMA Technologie AG Sizing of a Circuit Breaker

Result:

The nominal current of the circuit breaker is

Inr = 32 A x 0.9 x 0.77 x 1.07 = 23.7 A

The circuit breaker selected for this installation is not suitable due to the fact that the

maximum tolerable current of the circuit breaker is below the maximum current of the

used inverter. It will trip in normal operation.

A solution for this plant would be the installation of the circuit breakers with an 8 mm

gap between each unit. This would result in a reduction coefficient of 0.98 instead of

0.77. This would result in a maximum current of 30 A.

A further solution could be the installation of circuit breakers with a rating of 40 A.

In this case all different aspects have to be evaluated again with respect to this

change. An installation of the circuit breakers in the distribution box without gap between the units would result in a nominal current of Inr = 40 A x 0.9 x 0.77 x 1.07

= 29.6 A.

SMA recommends the installation described above with a gap between the circuit

breakers.

As well as the thermal rating of the circuit breakers and all other factors as specified

in section „Sizing of a circuit breaker for the AC line of a photovoltaic inverter for

utility interaction” (page 19), of course the applicable DIN VDE standards

need to be taken into account. The main ones that apply here are:

• DIN VDE 0100 Part 410 and/or the international standard IEC 60364-4-41:1992

• DIN VDE 0100 Part 430 and/or the international standard IEC 364-4-43:1977

and IEC 364-4-473:1977

• DIN VDE 0298 Part 4

a

also

a. The standards listed here are standards that apply in Germany. Please note that

other standards apply in other countries. Beside the standards above other standards may be applicable in special installations.

Installation Guide SMC50_60-11:SE2006 Page 53

Page 54

Sizing of a Circuit Breaker SMA Technologie AG

Page 54 SMC50_60-11:SE2006 Installation Guide

Page 55

SMA Technologie AG Contact

11 Contact

If you have any questions or technical problems with the Sunny Mini Central 5000/

6000 our hotline will be glad to help you. Please keep the following data ready when

calling SMA:

• Type of inverter used

• Number and type of connected modules

• Communication

• Serial number of Sunny Mini Central 5000/6000

Address: SMA Technologie AG

Hannoversche Strasse 1 - 5

34266 Niestetal

Germany

Tel.:+49 (561) 95 22 - 499

Fax:+49 (561) 95 22 - 4699

hotline@SMA.de

www.SMA.de

Installation Guide SMC50_60-11:SE2006 Page 55

Page 56

Contact SMA Technologie AG

Page 56 SMC50_60-11:SE2006 Installation Guide

Page 57

Page 58

SMATechnologie AG

www.SMA.de

Hannoversche Straße 1–5

34266 Niestetal

Germany

Tel. +49 561 9522 - 0

Fax +49 561 9522 - 100

www.SMA.de

SMA Technologie AG

SMA America, Inc.

12438 Loma Rica Drive, Unit C

Grass Valley, CA 95945

USA

Tel. +1 530 273 4895

Fax +1 530 2747 271

www.SMA-AMERICA.com

SMA Solartechnology China

Room 20F, InternationalMetro Center,

Building A , City Square No. Jia 3,

Shilipu Road, Changyang District

100025 Beijing, PR. China

Tel. +86 10 65 58 78 15

Fax +86 10 65 58 78 13

www.SMA-CHINA.com

Page 58 SMC50_60-11:SE2006 Installation Guide

Loading...

Loading...