Page 1

Installation Manual

SUNNY ISLAND 3.0M / 4.4M / 6.0H / 8.0H

SI30M-44M-60H-80H-IA-en-30 | Version 3.0 ENGLISH

Page 2

Legal Provisions SMA Solar Technology AG

Legal Provisions

The information contained in this document is the property of SMA Solar Technology AG. Publishing its content, either

partially or in full, requires the written permission of SMA Solar Technology AG. Any internal company copying of the

document for the purposes of evaluating the product or its correct implementation is allowed and does not require

permission.

SMA Warranty

You can download the current warranty conditions from the Internet at www.SMA-Solar.com.

Trademarks

All trademarks are recognized, even if not explicitly identified as such. A lack of identification does not mean that a

product or symbol is not trademarked.

The BLUETOOTH

marks by SMA Solar Technology AG is under license.

®

Modbus

is a registered trademark of Schneider Electric and is licensed by the Modbus Organization, Inc.

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

®

Phillips

Torx

and Pozidriv® are registered trademarks of Phillips Screw Company.

®

is a registered trademark of Acument Global Technologies, Inc.

®

word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and any use of these

SMA Solar Technology AG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

E-mail: info@SMA.de

© 2004 to 2014 SMA Solar Technology AG. All rights reserved.

2 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Information on this Document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5 Typographies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.6 Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Information for Handling Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Scope of Delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Additional Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 Sunny Island . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Scope of Functions of Device Types SI3.0M-11 and SI4.4M-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3 Multifunction Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4 Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 Requirements for Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Mounting the Sunny Island. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1 Content and Structure of the Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2 Connection Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.3 Connecting the Grounding Conductor in Systems With Grounded Battery . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.4 Connecting the Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.4.1 Connecting the Fuse Switch-Disconnector BatFuse to the Sunny Island. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

7.4.2 Connecting the Utility Grid in the System for Increased Self-Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

7.4.3 Connecting an Automatic Transfer Switch in the Battery Backup System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.4.3.1 Automatic Transfer Switch Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.4.3.2 Connecting the AC Power Cables to the Automatic Transfer Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.4.3.3 Connecting the Control Cables to the Automatic Transfer Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.4.3.4 Connecting the Measuring Cables to the Automatic Transfer Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

7.4.4 Connecting the Stand-Alone Grid or Multicluster Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

7.4.5 Connecting the Generator in an Off-Grid System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7.4.6 Inserting Filler Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7.4.7 Communication Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7.4.7.1 Connecting the Sunny Remote Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7.4.7.2 Connecting the Data Cable of the Lithium-Ion Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.4.7.3 Connecting Speedwire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.4.7.4 Connecting the Data Cable for the Internal Communication of the Cluster . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

7.4.7.5 Connecting the Data Cable of the Sunny Island Charger 50 Charge Controller. . . . . . . . . . . . . . . . . . . . . . . . .35

7.4.7.6 Connecting the Data Cable of the Multicluster Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Installation Manual SI30M-44M-60H-80H-IA-en-30 3

Page 4

Table of Contents SMA Solar Technology AG

7.4.7.7 Connecting Control and Measuring Cables of the Multicluster Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.4.7.8 Connecting the Cable of the Multicluster Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.4.7.9 Connecting RS485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.4.8 Connecting the Battery Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

7.4.9 Connecting the Battery Current Sensor in the Off-Grid System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

7.4.10 Connecting the Control Cable for Autostart Generators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

7.4.11 Connecting a Signal Generator for Generators Without Autostart Function. . . . . . . . . . . . . . . . . . . . . . . . . . .42

7.4.12 Connecting Load-Shedding Contactors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7.4.13 Connecting the Time Control for External Processes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

7.4.14 Connecting Message Devices for Operating States and Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . .45

7.4.15 Connecting the Battery Room Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

7.4.16 Connecting the Electrolyte Pump for the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

7.4.17 Connecting the Control Cable for the Use of Excess Energy in an Off-Grid System. . . . . . . . . . . . . . . . . . . . .48

7.4.18 Connecting the Signal Cable of the External Generator Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

7.5 Connecting the Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.5.1 Connecting the DC Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

7.5.2 Connecting the AC Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

7.5.3 Connecting the Grounding Conductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

7.5.4 Connecting the Data Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

7.5.5 Connecting Relay 1 and Relay 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

7.5.6 Connecting BatVtgOut, DigIn, BatTMP, and BatCur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

7.5.7 Connecting ExtVtg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

7.6 Checking the Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.7 Sealing and Closing the Sunny Island . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.8 Inserting the Fuse Links in the Fuse Switch-Disconnector BatFuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

8.1 Basic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.1.1 Starting the Quick Configuration Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

8.1.2 Performing Basic Configuration of the Sunny Island . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

8.1.3 Setting Sunny Island Charger for Charge Controller/Sunny Island Charger in Off-Grid Systems . . . . . . . . . .64

8.1.4 Commissioning the Battery Current Sensor in Off-Grid Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

8.1.5 Setting the Functions of the Multifunction Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

8.2 Battery Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.2.1 Safety When Setting the Battery Management Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

8.2.2 Adjusting the Battery Management to the Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

8.2.3 Changing the Battery Usage Through Battery Backup Systems Without Increased Self-Consumption . . . . . . .68

8.2.4 Battery Usage Through Systems for Increased Self-Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

8.2.4.1 Seasonal Adjustment of the Battery Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.2.4.2 Changing the Battery Usage Through Systems for Increased Self-Consumption Without a

Battery Backup Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.2.4.3 Changing the Battery Usage Through Battery Backup Systems with Increased Self-Consumption . . . . . . . . . . . 72

8.2.5 Changing the Battery Protection Mode in Off-Grid Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

8.2.6 Configuring the Resistance of the Battery Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

8.2.7 Setting the Control of the Battery Room Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

8.3 Energy Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.3.1 Setting Load Shedding in a Multicluster System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

8.3.2 Setting One-Level Load Shedding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

4 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 5

SMA Solar Technology AG Table of Contents

8.3.3 Setting Two-Level Load Shedding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

8.3.4 Setting Time-Dependent One-Level Load Shedding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

8.3.5 Setting Time-Dependent Two-Level Load Shedding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

8.3.6 Setting Utilization of Excess Energy in Off-Grid Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

8.4 Generator Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.4.1 Configuration of the Thresholds for Generator Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

8.4.1.1 Changing the Current Thresholds for the Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

8.4.1.2 Changing the Voltage Thresholds for the Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

8.4.1.3 Changing the Frequency Thresholds of the Generator Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.4.1.4 Changing the Permitted Reverse Power in the Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

8.4.1.5 Configuring the Current Limit for the Generator Depending on the Frequency . . . . . . . . . . . . . . . . . . . . . . . . . .84

8.4.2 Changing the Type of the Generator Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

8.4.3 Configuring Generator Run Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

8.4.3.1 Changing the Warm-Up Time for the Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

8.4.3.2 Changing the Minimum Run Time for the Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

8.4.3.3 Changing the Power-Down Time for the Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

8.4.3.4 Changing the Minimum Stop Time for the Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

8.4.4 Configuring the Generator Request. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

8.4.4.1 Changing the Automatic Generator Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

8.4.4.2 Changing a State-Of-Charge-Dependent Generator Request. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

8.4.4.3 Setting a Time-Dependent Generator Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.4.4.4 Configuring the Load-Dependent Generator Request. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

8.4.4.5 Time-Controlled Generator Requesting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

8.4.4.6 Changing the Generator Request via the Charging Process of the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

8.4.4.7 Setting an External Generator Request. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

8.4.5 Configuring the Procedure in the Event of a Generator False Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

8.5 Setting the Time Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

8.6 Changing Thresholds for Systems for Increased Self-Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.7 Changing the Automatic Frequency Synchronization in Off-Grid Systems. . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.8 Completing Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9 Supplementary Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.1 Entering the SMA Grid Guard Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.2 Determining the Battery Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.3 Setting Time-Dependent Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.4 Setting Time-Controlled Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

10 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.1 AC1 Connection for Stand-Alone Grid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.2 AC2 Connection for Utility Grid and Generator (External Energy Source) . . . . . . . . . . . . . . . . . . . . . . . . . 95

10.3 DC Connection for Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

10.4 Efficiency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.5 Sunny Island 3.0M Efficiency Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.6 Sunny Island 4.4M Efficiency Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.7 Sunny Island 6.0H Efficiency Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.8 Sunny Island 8.0H Efficiency Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.9 Energy Consumption in No-Load Operation and Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.10 Noise Emission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Installation Manual SI30M-44M-60H-80H-IA-en-30 5

Page 6

Table of Contents SMA Solar Technology AG

10.11 Grid Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

10.12 Protective Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

10.13 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

10.14 DC Load Limitation Curve of the Multifunction Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.15 General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

11 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

12 Contact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 7

SMA Solar Technology AG 1 Information on this Document

1 Information on this Document

1.1 Validity

This document is valid for the following device types:

• SI3.0M-11 (Sunny Island 3.0M) from firmware version 3.2

• SI4.4M-11 (Sunny Island 4.4M) from firmware version 3.2

• SI6.0H-11 (Sunny Island 6.0H) from firmware version 3.1

• SI8.0H-11 (Sunny Island 8.0H) from firmware version 3.1

1.2 Target Group

The activities described in this document may only be performed by qualified persons. Qualified persons must have the

following skills:

• Training in how to deal with the dangers and risks associated with installing and using electrical devices and batteries

• Training in the installation and commissioning of electrical devices

• Knowledge of and adherence to the local standards and directives

• Knowledge of and compliance with this document and all safety information

1.3 Additional Information

Additional information is available at www.SMA-Solar.com:

Document title Document type

Mounting on Wood Base Technical Information

Battery Management in Off-Grid Systems Technology Brochure 6

Battery Management Technical Information

Grounding in Off-Grid Systems Technical Information

External Energy Sources Technical Information

PV Inverters Technical Information

SMA Flexible Storage System With Battery Backup

Function

SMA Smart Home Planning Guidelines

Planning Guidelines

Installation Manual SI30M-44M-60H-80H-IA-en-30 7

Page 8

1 Information on this Document SMA Solar Technology AG

'$1*(5

:$5 1,1*

&$87,21

/05*$&

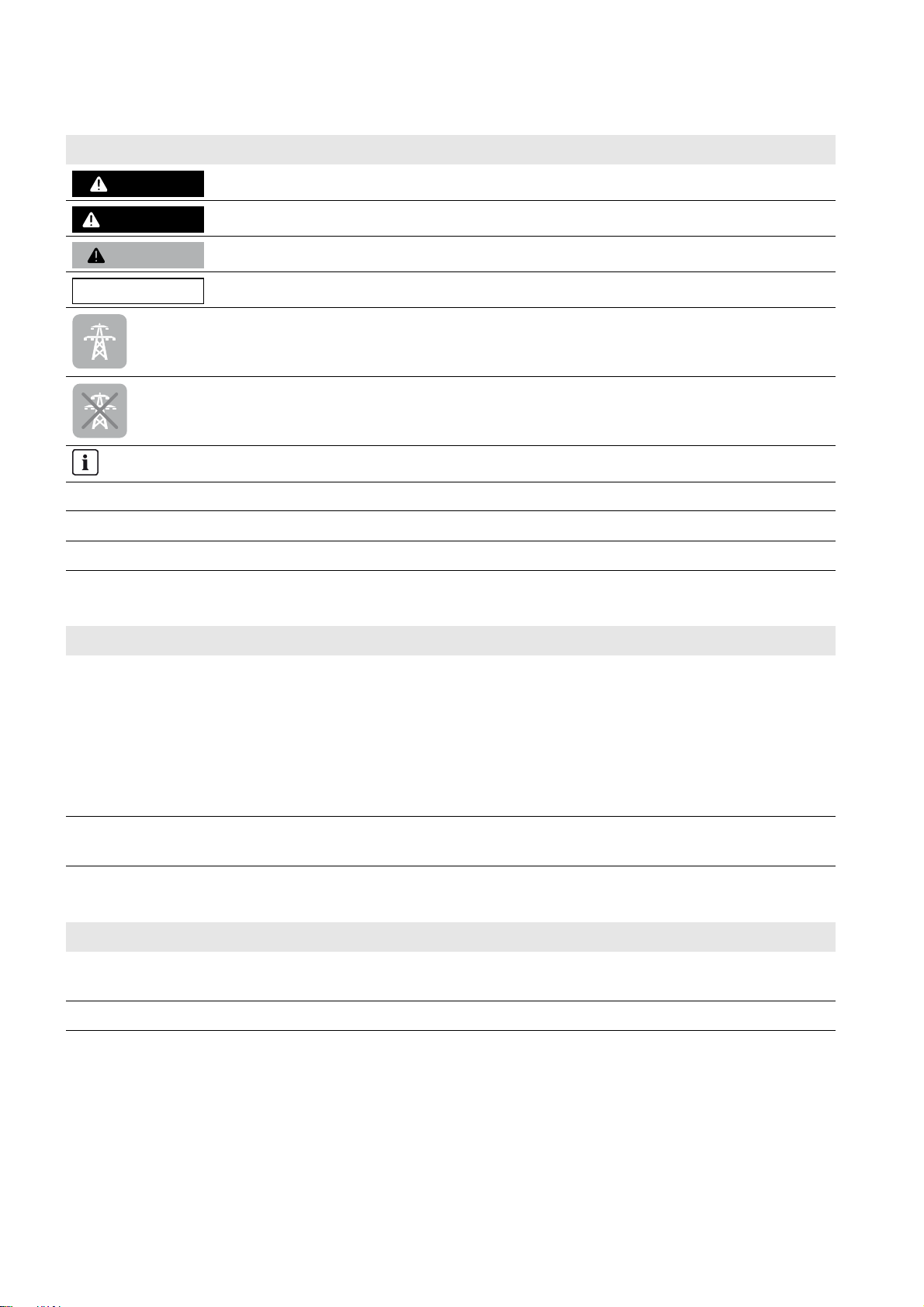

1.4 Symbols

Symbol Explanation

Indicates a hazardous situation which, if not avoided, will result in death or serious injury

Indicates a hazardous situation which, if not avoided, can result in death or serious injury

Indicates a hazardous situation which, if not avoided, can result in minor or moderate injury

Indicates a situation which, if not avoided, can result in property damage

Section that is relevant for SMA Flexible Storage Systems only

Section that is relevant for off-grid systems only

Information that is important for a specific topic or goal, but is not safety-relevant

☐ Indicates a requirement for meeting a specific goal

☑ Desired result

✖ A problem that might occur

1.5 Typographies

Typography Use Example

bold • Display messages

• Parameters

• Connections

•Fuse holders

• Elements to be selected

• Elements to be entered

> • Several elements that are to be

selected

• Connect the grounding conductor to

AC 2Gen/Grid.

• Select the parameter 235.01 GnAutoEna

and set to Off.

•Select 600# Direct Access > Select

Number.

1.6 Nomenclature

Complete designation Designation in this document

Off-grid system, battery backup system, system for

increased self-consumption

System

Sunny Boy, Sunny Mini Central, Sunny Tripower PV inverters

Menus are presented as follows: menu number, hash, and menu name (e.g. 150# Compact Meters).

Parameters are presented as follows: menu number, period, parameter number, and parameter name (e.g. 150.01

GdRmgTm). The term parameter includes parameters with configurable values as well as parameters for displaying

values.

8 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 9

SMA Solar Technology AG 2 Safety

2 Safety

2.1 Intended Use

The Sunny Island is a battery inverter which controls the electrical energy balance in an off-grid system, in a battery

backup system, or in a system for increased self-consumption. In a battery backup system, you can also use the

Sunny Island for increased self-consumption.

The Sunny Island is suitable for use indoors and in weather-protected outdoor areas.

The grid configuration of the generator or the utility grid must be a TN or TT system. Cables with copper wires must be

used for the installation.

Use this product only in accordance with the information provided in the enclosed documentation and with the locally

applicable standards and directives. Any other application may cause personal injury or property damage.

Device types SI3.0M-11 and SI4.4M-11 do not support all off-grid system variants. Only device types SI6.0H-11 and

SI8.0H-11 are suitable for single-phase single cluster systems and three-phase multicluster systems (see the Quick

Reference Guide "Off-Grid Systems").

The Sunny Island is not suitable for supplying life-sustaining medical devices. A power outage must not lead to personal

injury.

AC sources (such as PV inverters) can be used in off-grid systems and battery backup systems for energy supply. Too

much power from the AC sources in the stand-alone grid or with battery backup systems in a battery backup grid can

lead to system failures. The maximum output power of the AC sources must be observed in off-grid systems and battery

backup systems (see Section10 "Technical Data", page94). The powers of the individual Sunny Island inverters are

added to yield the total maximum power.

The Sunny Island uses batteries for the storage of energy. The nominal voltage of the battery must correspond to the input

voltage on the DC connection. A fuse switch-disconnector (e.g. BatFuse) must be installed between the battery and the

Sunny Island. The battery room must be ventilated in compliance with the requirements of the battery manufacturer and

with the locally applicable standards and directives (see documentation of the battery manufacturer). If connecting a

lithium-ion battery, the following must be observed:

• The lithium-ion battery must comply with the locally applicable standards and directives and be intrinsically safe.

• Battery management of the lithium-ion battery must be compatible with the Sunny Island (see "Safety Information" in

the quick reference guide for the relevant system).

In off-grid systems with lead-acid batteries only, a maximum of four Sunny Island Charger charge controllers can be

connected per cluster. The battery management must record the DC current when charging and discharging the battery.

A battery current sensor may be installed to allow precise measurement of the battery current. The Sunny Island is not

suitable for establishing a DC distribution grid.

The Sunny Island can control various devices in the system (e.g. load-shedding contactors) via two multifunction relays.

The multifunction relays are not suitable for controlling functions which may endanger persons in the event of a

malfunction of the multifunction relays – for example, if there is insufficient redundancy in the ventilation of the battery

room.

Alterations to the product, e.g. modifications or conversions, are permitted only with the express written permission of

SMA Solar Technology AG. Unauthorized alterations will void guarantee and warranty claims and usually void the

operation permit. SMA Solar Technology AG shall not be held liable for any damage caused by such changes.

Any use of the product other than that described in the Intended Use section does not qualify as appropriate.

The enclosed documentation is an integral part of this product. Keep the documentation in a convenient place for future

reference and observe all instructions contained therein.

The type label must remain permanently attached to the product.

Installation Manual SI30M-44M-60H-80H-IA-en-30 9

Page 10

2 Safety SMA Solar Technology AG

:$5 1,1*

&$87,21

2.2 Safety Information

This section contains safety information that must be observed at all times when working on or with the product. To prevent

personal injury and property damage and to ensure long-term operation of the product, read this section carefully and

observe all safety information at all times.

Danger to life from electric shocks due to connected voltage and risk of injury from short-circuit currents

High voltages are present inside the Sunny Island inverter. When the enclosure lid is removed, live components can be

touched which can result in death or serious injury due to electric shock. Short-circuit currents in the battery can cause

heat build-up and electric arcs. Burns or eye injuries due to flashes may result.

• When carrying out any work on the electrical installation, wear suitable personal protective equipment.

• Turn off or disconnect the following devices from voltage sources in the given order:

–Sunny Island

– The circuit breakers of the Sunny Island inverter on the distribution board and the control and measurement

voltages

– Load-break switch of the battery

• Ensure that the system cannot be reconnected.

• Open the enclosure lid on the Sunny Island inverter and ensure that no voltage is present.

• Ground and short-circuit the AC conductors outside the Sunny Island inverter.

• Cover or isolate any adjacent live components.

Danger to life from electric shock due to damaged Sunny Island

Operating a damaged Sunny Island can lead to hazardous situations that can result in death or serious injuries due to

electric shock.

• Only operate the Sunny Island when it is technically faultless and in an operationally safe state.

• Check the Sunny Island for visible damage.

• Make sure that all external safety equipment is freely accessible at all times.

• Make sure that all safety equipment is in good working order.

Risk of crushing injuries due to movable generator parts

Moving parts in the generator can crush or sever body parts. A generator can be started automatically by the

Sunny Island.

• Only operate the generator with the safety equipment.

• Install, maintain, and operate the generator according to the manufacturer's specifications.

Risk of burns due to short-circuit currents on the disconnected Sunny Island

The capacitors at the DC connection input area store energy. After the battery is disconnected from the Sunny Island,

battery voltage remains temporarily on the DC connection. A short circuit at the DC connection can lead to burns and

may damage the Sunny Island inverter.

• Wait 15 minutes before performing any work at the DC connection or on the DC cables. This allows the capacitors

to discharge.

10 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 11

SMA Solar Technology AG 2 Safety

&$87,21

/05*$&

:$5 1,1*

Risk of burns due to hot components

Some components on the Sunny Island inverter may heat up significantly during operation. Touching these components

can cause burns.

• Touch only the enclosure lid of the Sunny Island inverter during operation.

• When the Sunny Island is open, do not touch hot surfaces.

Destruction of the Sunny Island inverter due to electrostatic discharge (ESD)

Touching the electronic components within the Sunny Island inverter can lead to damage to or destruction of the

Sunny Island.

• Do not touch any electronic assemblies.

• Ground yourself before touching any connections.

2.3 Information for Handling Batteries

Danger to life due to explosive gases

Explosive gases may escape from the battery and cause an explosion. This can result in death or serious injury.

• Protect the battery environment from open flames, embers, or sparks.

• Install, operate, and maintain the battery in accordance with the manufacturer's specifications.

• Do not heat the battery above the temperature permitted or burn the battery.

• Ensure that the battery room is sufficiently ventilated.

Chemical burns and poisoning due to battery electrolyte

If handled inappropriately, battery electrolyte can cause irritation to the eyes, respiratory system, and skin and it can

be toxic. This may result in blindness and serious chemical burns.

• Protect the battery enclosure against destruction.

• Do not open or deform the battery.

• Whenever working on the battery, wear suitable personal protective equipment such as rubber gloves, apron,

rubber boots, and goggles.

• Rinse acid splashes thoroughly with clear water and consult a doctor.

• Install, operate, maintain, and dispose of the battery according to the manufacturer's specifications.

Risk of injury due to short-circuit currents

Short-circuit currents in the battery can cause heat build-up and electric arcs. Burns or eye injuries due to flashes may

result.

• Remove watches, rings, and other metal objects.

• Use insulated tools.

• Do not place tools or metal parts on the battery.

Installation Manual SI30M-44M-60H-80H-IA-en-30 11

Page 12

2 Safety SMA Solar Technology AG

&$87,21

/05*$&

Risk of burns due to hot battery components

Improper battery connection may result in excessively high transition resistances. Excessive transition resistances give

rise to localized heat build-up. Heat build-up can cause burns.

• Ensure that all pole connectors are connected with the connecting torque specified by the battery manufacturer.

• Ensure that all DC cables are connected with the connecting torque specified by the battery manufacturer.

Permanent damage to the battery due to improper handling

Improper storage, transport, set-up, and maintenance of the battery can cause it to become permanently damaged.

Logs can help to determine the cause.

• Comply with all requirements of the battery manufacturer with regard to storage, transport, and mounting location.

• Check and log the status of the battery before commissioning and before performing maintenance work:

• Check the battery for visible damage and log.

• Measure and log the fill level and acid density of FLA batteries.

• In the case of lead-acid batteries, measure and log the voltages of the individual cells.

• Perform and log the test routines required by the battery manufacturer.

Tip: Many battery manufacturers provide suitable logs.

Damage to the battery due to incorrect settings

Incorrect settings lead to premature aging of the battery. The parameter settings in the menu 220# Battery,

222# Chargemode, 262# BatUsage and 223# Protection impact the charging behavior of the Sunny Island

inverter (see Section8.2 "Battery Management", page67).

• Check whether initial battery charging with special settings is required.

If an initial charge is required, adjust the charging behavior of the Sunny Island inverter for one-off initial charging

(see Section8.2.2, page67).

• Ensure that the values for the battery as recommended by the battery manufacturer are set in the menus

222# Chargemode (see Section8.2.2, page67), 262# BatUsage (see Section 8.2.3, page 68 and Section

8.2.4, page 69), and 223# Protection (see Section8.2.5, page75) (for the technical data of the battery see

the documentation provided by the battery manufacturer). Note that the charging behavior names used by

SMA Solar Technology AG and the battery manufacturer may, in some cases, differ in meaning (for the charging

behavior of the Sunny Island inverter, see the Technical Information "Battery Management"). Tip: For questions

relating to the settings of the Sunny Island inverter, please contact the SMA Service Line.

Prior damage to batteries

Batteries may have suffered prior damage due to production defects. Logs can help to determine the cause.

• Check and log the status of the battery before commissioning and before performing maintenance work:

Performance impairment of batteries

Transition resistances can impair the performance of the batteries.

• Note the torques when connecting the battery.

12 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 13

SMA Solar Technology AG 3 Scope of Delivery

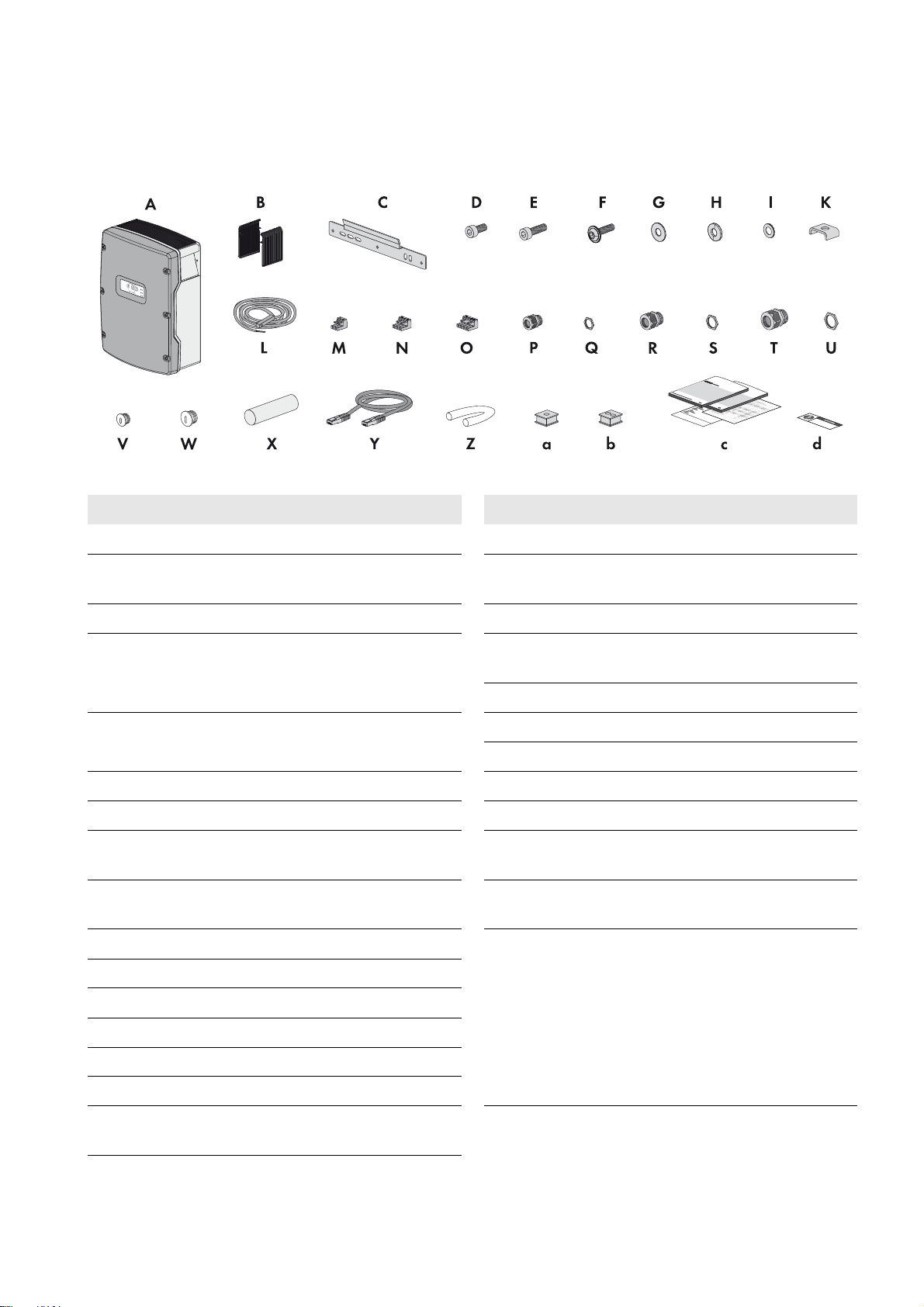

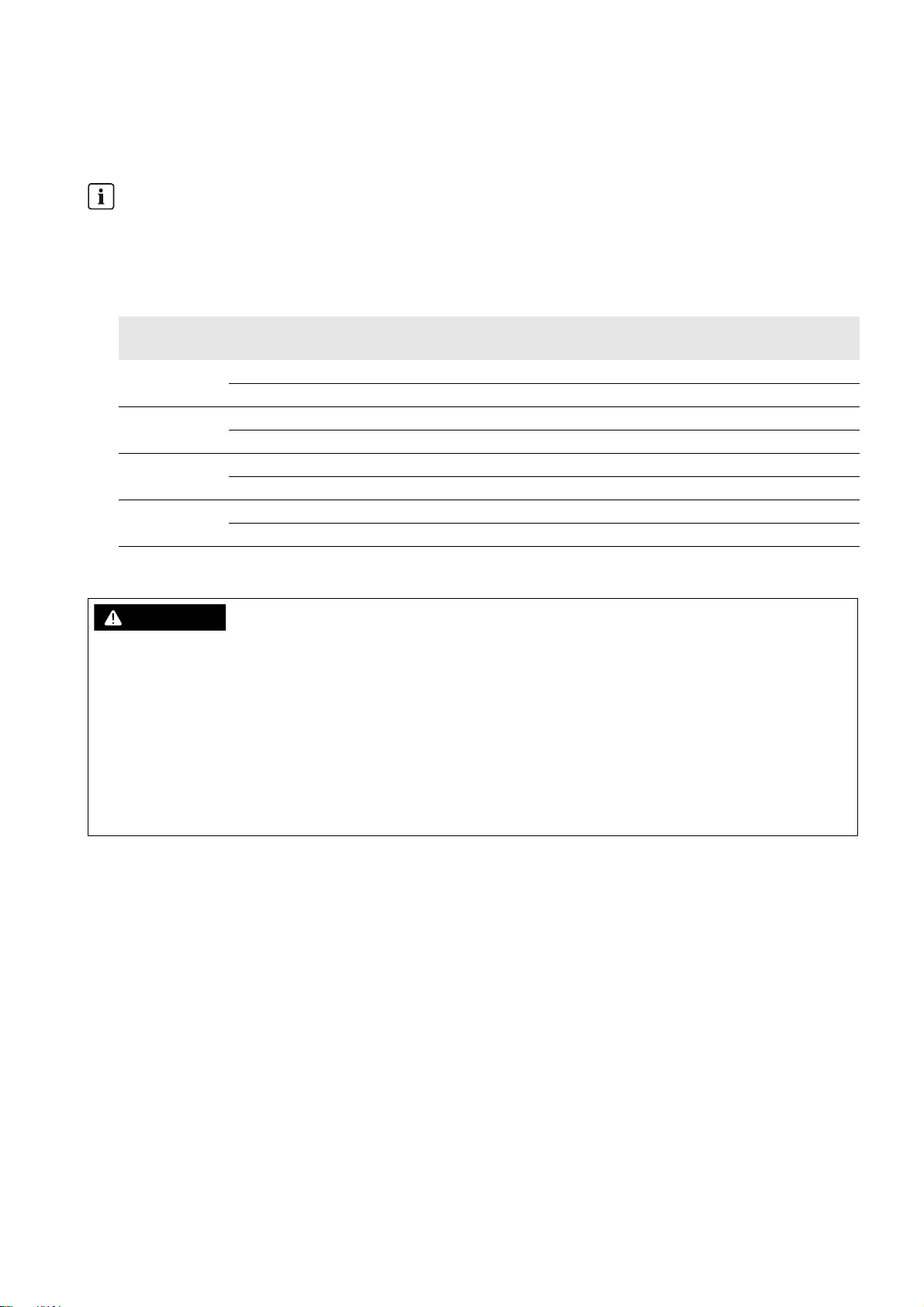

3 Scope of Delivery

Check the scope of delivery for completeness and any externally visible damage. Contact your distributor if the scope of

delivery is incomplete or damaged.

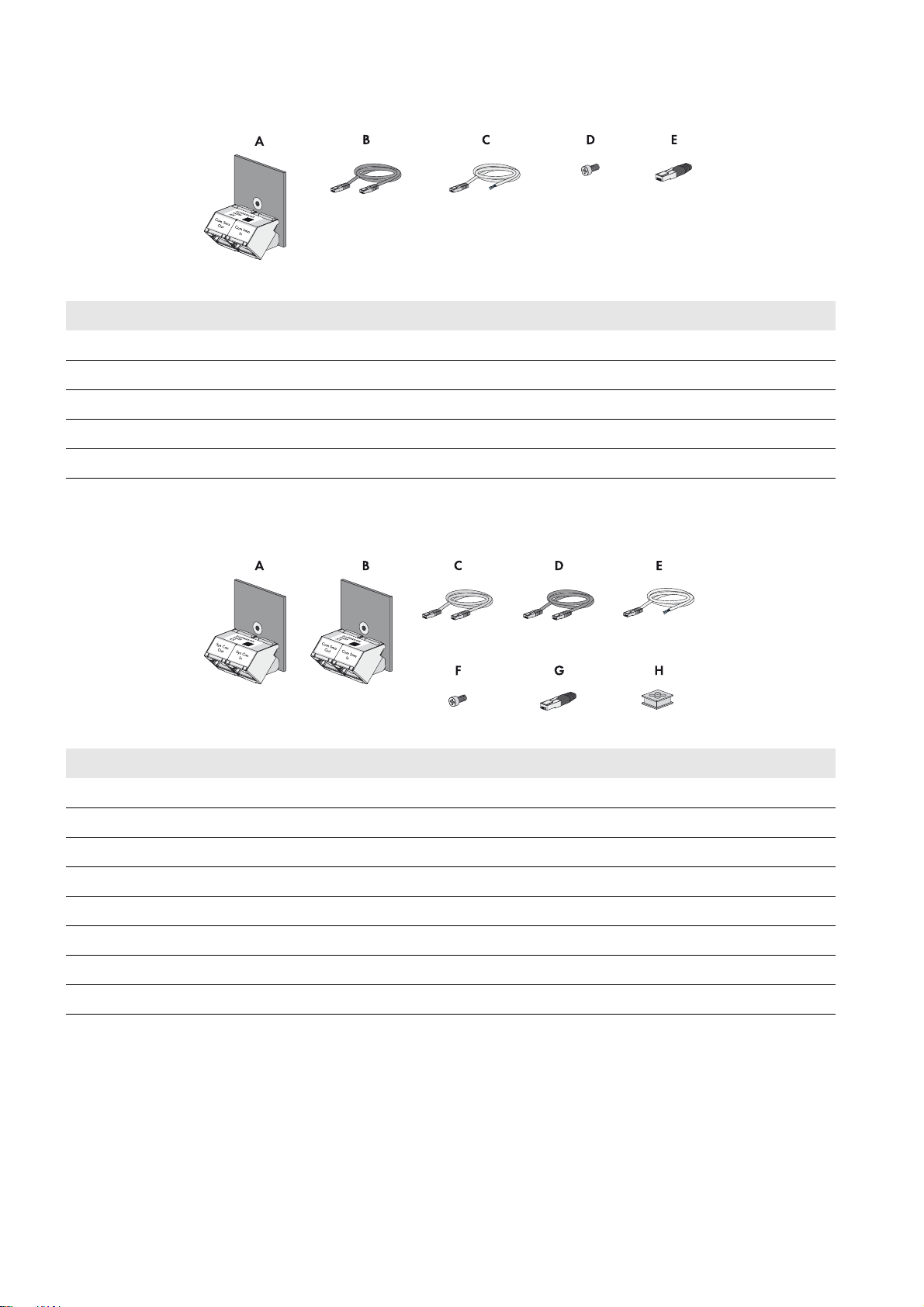

Figure1: Components included in the scope of delivery

Position Quantity Designation Position Quantity Designation

A 1 Sunny Island R 2 M25 cable gland

B 2 Ventilation grid S 2 Counter nut for M25 cable

gland

C 1 Wall mounting bracket T 2 M32 cable gland

D 2 Hexagon socket screw M6x10 U 2 Counter nut for M32 cable

gland

V 1 Filler plug M20

E 2 Hexagon socket

screw M6x16*

F 2 Hexagon socket screw M8x20 Y 1 Black data cable CAT5e, 2 m

G2 Fender washer M8 Z 2 Silicon tube 10 mm x 500 mm

H 2 Spring washer M8 a 1 Cable support sleeve for one

I 2 M6 conical spring washer*

K 1 Clamping bracket c 1 Installation manual, operating

L 1 Battery temperature sensor

M1 2-pole terminal

N2 3-pole terminal

O2 4-pole terminal

P 1 M20 cable gland

W 1 Filler plug M25

X 1 Putty in a separate accessory kit

cable

b 2 Cable support sleeve for two

cables

manual, three Quick Reference

Guides:

"SMA Flexible Storage System",

"SMA Flexible Storage System

with Battery Backup Function",

"Off-Grid Systems"

Q 1 Counter nut for M20 cable

gland

* 1 spare part for the enclosure lid included

Installation Manual SI30M-44M-60H-80H-IA-en-30 13

d 1 Warning label

Page 14

3 Scope of Delivery SMA Solar Technology AG

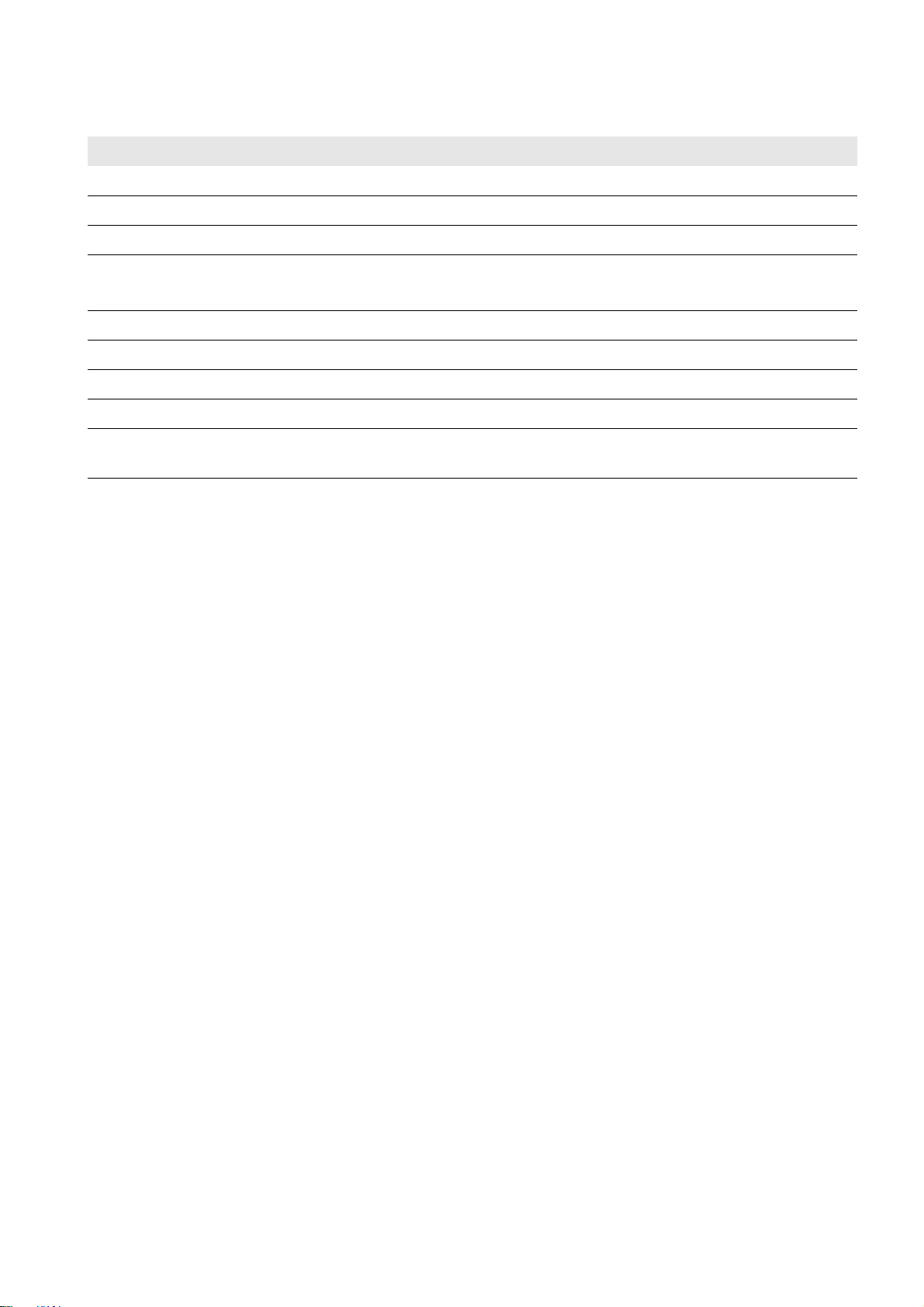

Communication for RS485 order option

Figure2: Components of the Communication for RS485 order option

Position Quantity Designation

A 1 SI-COMSMA.BGx, installed in the Sunny Island* ex works

B 1 Gray data cable CAT5e, 5 m

C 1 White data cable CAT5e with three wires with stripped insulation

D 1 Screw, installed in the Sunny Island ex works

E 1 Terminator, plugged into SI-COMSMA.BGx ex works

* In the case of a cluster system, the communication interface is only installed in the master.

Communication for multicluster system order option

Figure3: Components of the Communication for multicluster system order option

Position Quantity Designation

A 1 SI-SYSCAN.BGx* , installed in the master ex works

B 1 SI-COMSMA.BGx** , installed in the master ex works

C 1 Yellow data cable CAT5e, 5 m

D 1 Gray data cable CAT5e, 5 m

E 1 White data cable CAT5e with three wires with stripped insulation

F 2 Screw, installed in the Sunny Island ex works

G 2 Terminator, plugged into SI-SYSCAN.BGx and SI-COMSMA.BGx ex works

H 1 Cable support sleeve for 4 cables

* CAN communication interface

** RS485 communication interface

14 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 15

SMA Solar Technology AG 4 Additional Tools Required

4 Additional Tools Required

Tools Explanation

Drill ‒

Drill bit Mounting of the wall mounting bracket

Allen key, AF 5 ‒

Torque wrench Attachment: AF 5

Measurement range: 4 Nm to 12 Nm

Crimping pliers Crimping of the DC cable terminal lugs

Crimping tool Crimping of the bootlace ferrules

Flat-blade screwdriver Connection of the control and measuring cables to the terminals

Current clamp Measuring of the battery current

Measuring device for voltage

measurement

Measuring of the AC voltages in the system and measuring of the battery

voltage

Installation Manual SI30M-44M-60H-80H-IA-en-30 15

Page 16

5 Product Description SMA Solar Technology AG

5 Product Description

5.1 Sunny Island

The Sunny Island is a battery inverter which controls the electrical energy balance in an off-grid system, in a battery

backup system, or in a system for increased self-consumption. In a battery backup system, you can also use the

Sunny Island for increased self-consumption.

Figure4: Design of the Sunny Island inverter

Position Designation

A Ventilation grid

BType label

C Control panel

DEnclosure lid

The Sunny Island supplies AC loads in the system from a battery or charges the battery with the energy provided by AC

sources (e.g. PV inverter). AC sources supply loads and are used by the Sunny Island to recharge the battery. In order

to be able to increase the availability of the off-grid system and reduce the battery capacity, the Sunny Island can use

and control a generator as an energy reserve.

The loads may temporarily overload the Sunny Island. If there is a short circuit, the Sunny Island briefly feeds short-circuit

currents into the utility grid. As a result, the Sunny Island may trip certain circuit breakers (see Section10 "Technical Data",

page94).

Type label

The type label clearly identifies the product. The type label is located on the right-hand side of the enclosure (for a

description of the type label, see the Sunny Island inverter operating manual).

You will require the information on the type label to use the product safely and when seeking customer support from the

SMA Service Line.

5.2 Scope of Functions of Device Types SI3.0M-11 and SI4.4M-11

The following functional restrictions apply for device types SI3.0M-11 and SI4.4M-11:

• All Sunny Island inverters in a cluster must be of the same device type.

• Device types SI3.0M-11 and SI4.4M-11 do not support all off-grid system variants. Single-phase systems can

include a maximum of one Sunny Island SI3.0M-11 or SI4.4M-11. Three-phase systems can include a maximum of

three Sunny Island SI3.0M-11 or SI4.4M-11.

Only device types SI6.0H-11 and SI8.0H-11 are suitable for single-phase single cluster systems and three-phase

multicluster systems (see the Quick Reference Guide "Off-Grid Systems").

16 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 17

SMA Solar Technology AG 5 Product Description

5.3 Multifunction Relay

Using two multifunction relays, each Sunny Island can control various functions and can display operating states and

warning messages. In battery backup systems, master multifunction relays are set permanently to control the contactors

within the automatic transfer switch.

Possible function or

output

Controlling generators The multifunction relay activates if a generator request is received from the Sunny Island

Control of the tie switch

and of the contactors for

grounding

Control of load-shedding

contactors

Time control for external

processes

Display of operating

states and warning

messages

Control of a battery-room

fan

Explanation

inverter's generator management. With the multifunction relay, you can control generators

equipped with electrical remote-start function or connect a signal generator for generators

with no autostart function (see Section 7.4.10 and 7.4.11).

In battery backup systems, the multifunction relays control the contactors for grid coupling

and grounding.

The multifunction relay is activated depending on the state of charge of the battery.

Depending on the configuration, you can install a one-level load shedding with one

multifunction relay or a two-level load shedding with two multifunction relays. You can also

adjust the thresholds for the state of charge of the battery depending on the time of day

(see Section 7.4.12).

The multifunction relays can be time-controlled (see Section 7.4.13).

Each multifunction relay can display either one event or one warning message

(see Section 7.4.14).

The multifunction relay is activated when the charging current leads to the battery emitting

gasses. A connected battery room fan is switched on for at least one hour (see Section

7.4.15).

Control of an electrolyte

pump

Use of excess energy In off-grid systems during the constant voltage phase, a multifunction relay is activated and

Depending on the nominal energy throughput, the multifunction relay is activated at least

once a day (see Section 7.4.16).

thus controls additional loads that can put any excess energy to good use (see Section

7.4.17).

Installation Manual SI30M-44M-60H-80H-IA-en-30 17

Page 18

5 Product Description SMA Solar Technology AG

5.4 Communication

The Sunny Island is equipped with two interface slots for the connection of SMA communication interfaces.

Interface slot SICOMSMA

The interface slot SICOMSMA is for connecting the Speedwire data module SWDMSI-xx or the RS485 communication

interface SI-COMSMA.BGx.

The Speedwire data module SWDMSI-xx allows the Sunny Island inverter to be integrated into a Speedwire network.

Speedwire is a cable-based type of communication based on the Ethernet standard and the communication protocol

SMA Data2+. This enables inverter-optimized 10/100 Mbit data transmission between Speedwire devices, e.g.

between Sunny Island and Sunny Home Manager.

The SI-COMSMA.BGx communication interface allows the Sunny Island inverter to be integrated into an RS485

communication bus. You can connect the Sunny Island to the following products using RS485:

• SMA communication products (e.g. Sunny WebBox)

•PV inverters

• Wind power inverters

• Extension cluster masters

If the Sunny Island inverters are ordered with the RS485 communication interface SI-COMSMA.BGx or with the

Speedwire data module SWDMSI-xx, the Sunny Island inverters are delivered with premounted communication

interfaces.

Interface slot SISYSCAN

On Sunny Island device types SI6.0H-11 or SI8.0H-11, the interface slot SISYSCAN is for connecting the multicluster

data module SI-SYSCAN.BGx.

In a multicluster system, the masters of the clusters must communicate with each other via a separate CAN bus. An

SI-SYSCAN.BGx communication interface must be installed in each master for multicluster communication.

If the Sunny Island inverters are ordered with the communication interface SI-SYSCAN.BGx, the masters are delivered

with premounted communication interfaces.

18 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 19

SMA Solar Technology AG 6 Mounting

6 Mounting

6.1 Requirements for Mounting

Mounting location:

☐ A stable, non-flammable support surface must be used at the mounting location, e.g. concrete or masonry. In the

living area, ensure that the support surface is not made of drywall or similar. When in operation, the Sunny Island

makes noises which can be perceived as annoying.

☐ The mounting location must be suitable for the weight and dimensions of the Sunny Island inverter (see Section10

"Technical Data", page94).

☐ The mounting location must be clear and safely accessible at all times without the need for any auxiliary equipment

(e.g. scaffolding or lifting platforms). Non-fulfillment of these criteria may restrict servicing.

☐ The mounting location must not hinder access to disconnection devices.

☐ The mounting location must not be exposed to direct solar irradiation. Direct solar irradiation can cause the

Sunny Island to overheat.

☐ Climatic conditions must be met (see Section10 "Technical Data", page94).

☐ The mounting location must be less than 3,000 m above MSL. From altitudes of 2,000 m above MSL, the power

decreases by 0.5% every 100 m.

☐ The ambient temperature should be below 40°C. This will ensure the optimum operation of the Sunny Island inverter

(see Section10.9 "Energy Consumption in No-Load Operation and Standby", page98).

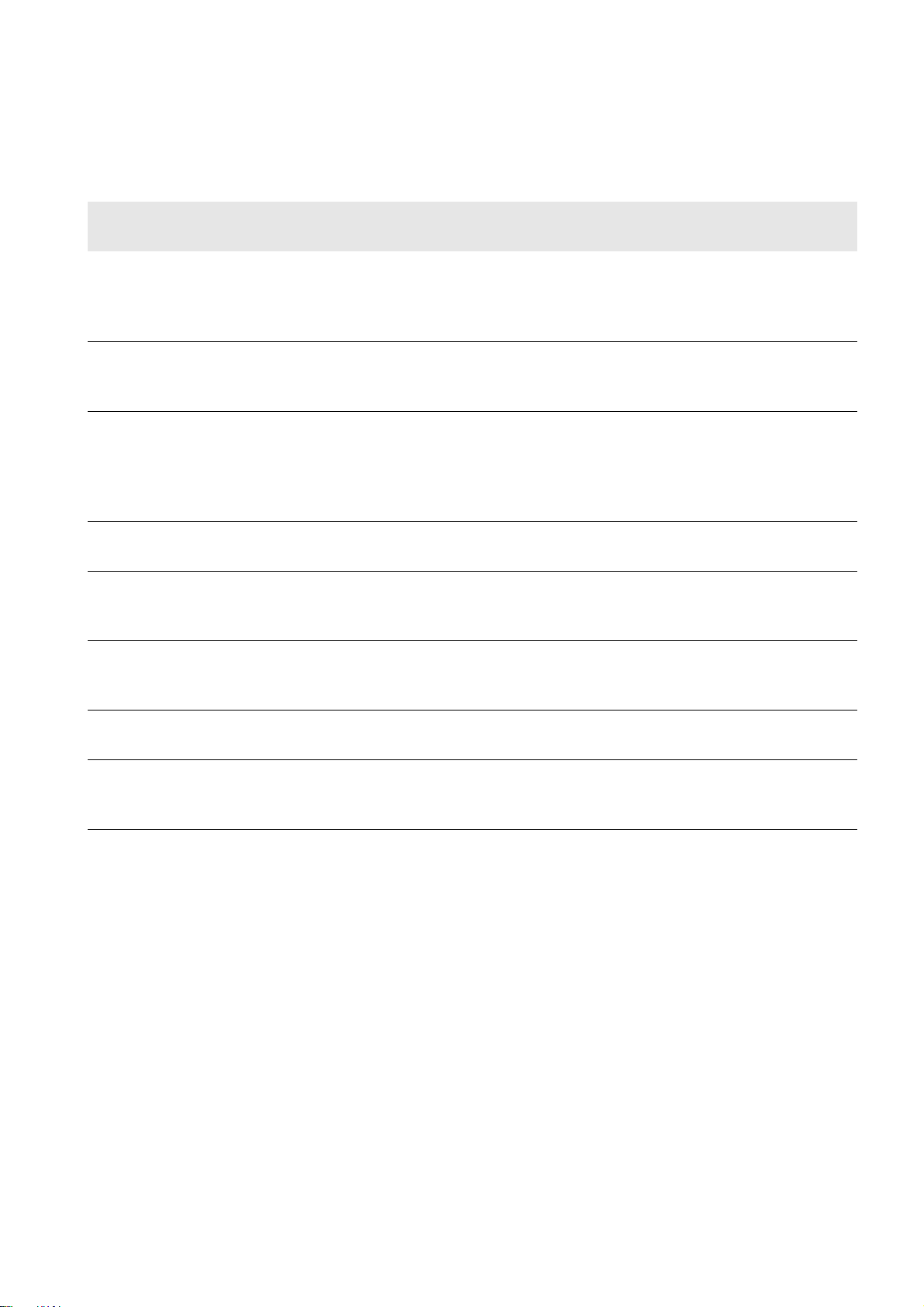

Mounting position:

Figure5: Permissible and impermissible mounting positions

☐ The mounting location must be suitable for a permitted mounting position. The control panel should be at eye level.

This will make it easier to operate the buttons and view the LED signals.

Installation Manual SI30M-44M-60H-80H-IA-en-30 19

Page 20

6 Mounting SMA Solar Technology AG

Clearances:

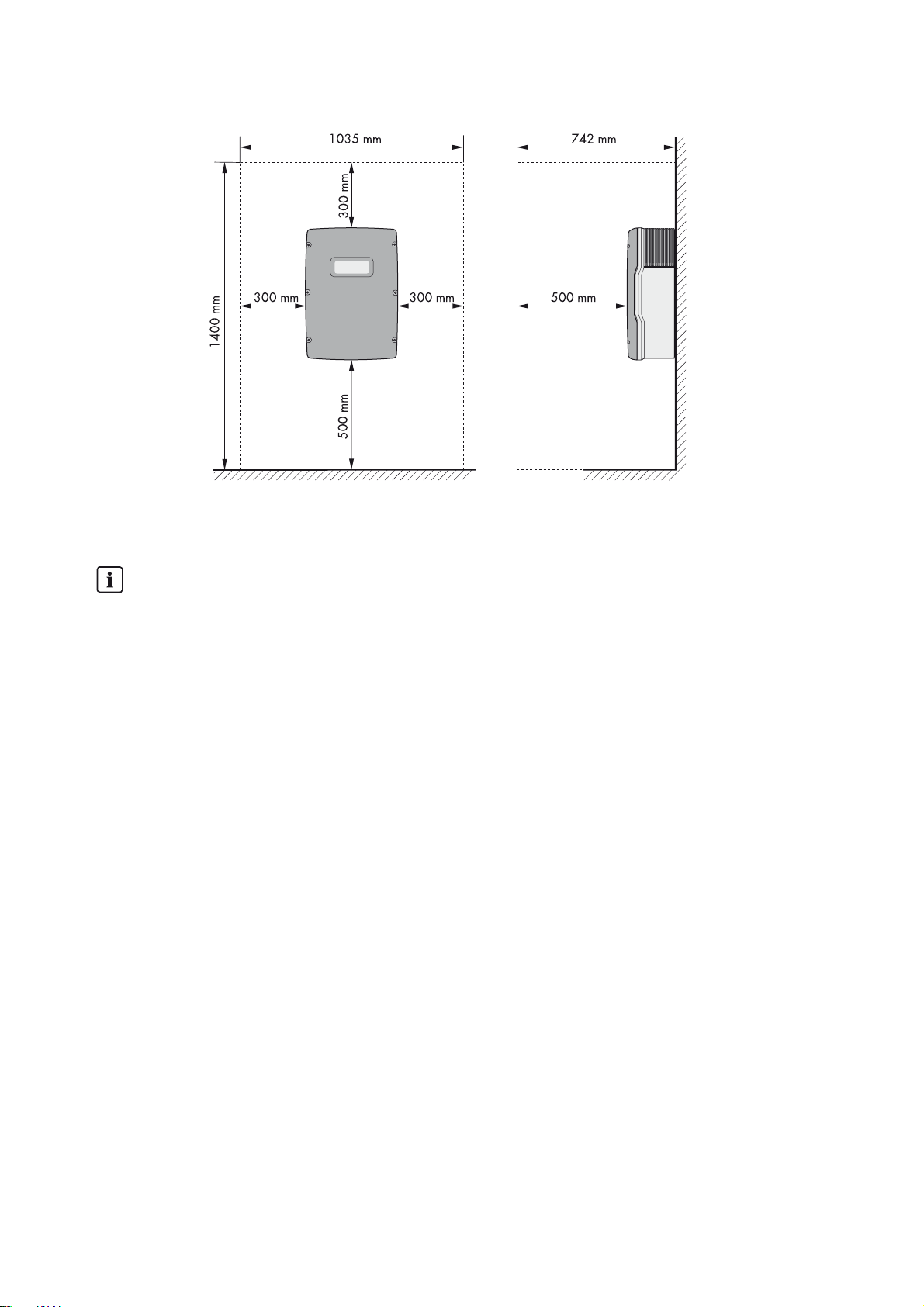

Figure6: Minimum clearances

☐ The mounting location must be suitable for mounting while observing minimum clearances to walls, other

Sunny Island units or other objects. This will allow for sufficient heat dissipation.

Multiple Sunny Island inverters installed in areas with high ambient temperatures

There must be sufficient clearance between the Sunny Island inverters to ensure that the cooling air of the

adjacent inverter is not drawn in.

• In order to guarantee sufficient cooling of the Sunny Island inverters, the clearances between the

Sunny Island units should be significantly greater than the minimum clearances.

• Ensure sufficient fresh-air supply.

20 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 21

SMA Solar Technology AG 6 Mounting

:$5 1,1*

6.2 Mounting the Sunny Island

Danger to life due to fire or explosion

Care taken during design does not preclude the possibility of a fire developing in electrical devices. Contact with

flammable materials allows the fire to spread. This can result in death or serious injury.

• Do not mount the Sunny Island on flammable construction materials.

• Do not mount the Sunny Island near highly flammable materials.

• Do not mount the Sunny Island in potentially explosive atmospheres.

• Ensure that the battery room is sufficiently ventilated and that all other requirements for the installation location of

the battery are complied with (see battery manufacturer documentation). This will prevent the build-up of explosive

and dangerous gases.

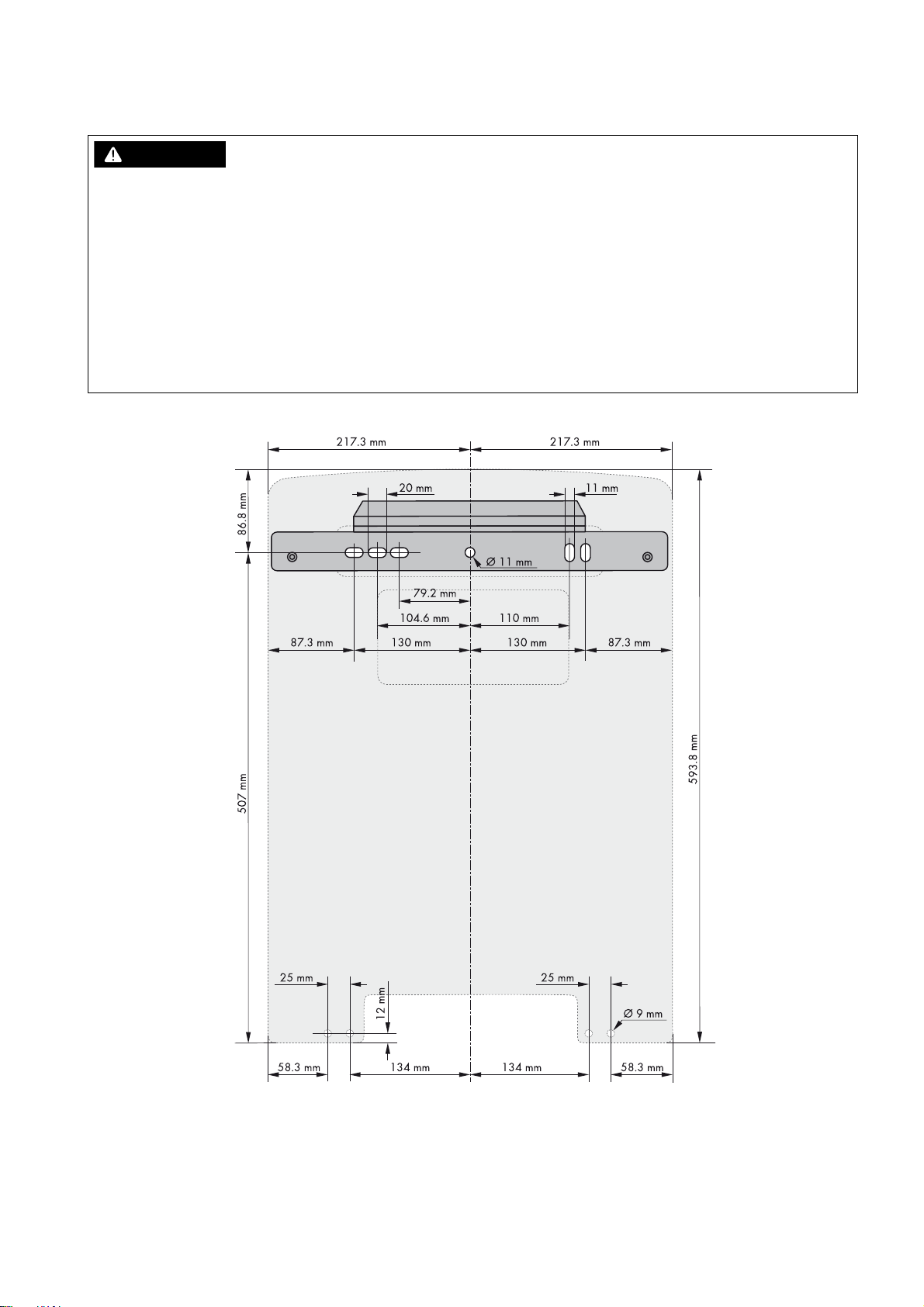

Dimensions for wall mounting:

Figure7: Dimensions of the wall mounting bracket and dimensions of the drill holes for the optional anti-theft device on the Sunny Island inverter

Installation Manual SI30M-44M-60H-80H-IA-en-30 21

enclosure

Page 22

6 Mounting SMA Solar Technology AG

&$87,21

Sunny Island with order options "Communication for RS485" or "Multicluster System"

Any ordered communication interfaces are installed in the master ex works. The master can be identified by the

labeling on the packaging.

• For single-cluster systems and multicluster systems, mount the Sunny Island units with integrated communication

interfaces at the planned mounting locations for masters.

Additionally required mounting material (not included in the scope of delivery):

☐ At least two screws that are suitable for the support surface.

☐ At least two washers suitable for the screws.

☐ At least two screw anchors suitable for the support surface and the screws.

☐ If the inverter is to be secured against theft, two security screws that can only be unscrewed with a special tool.

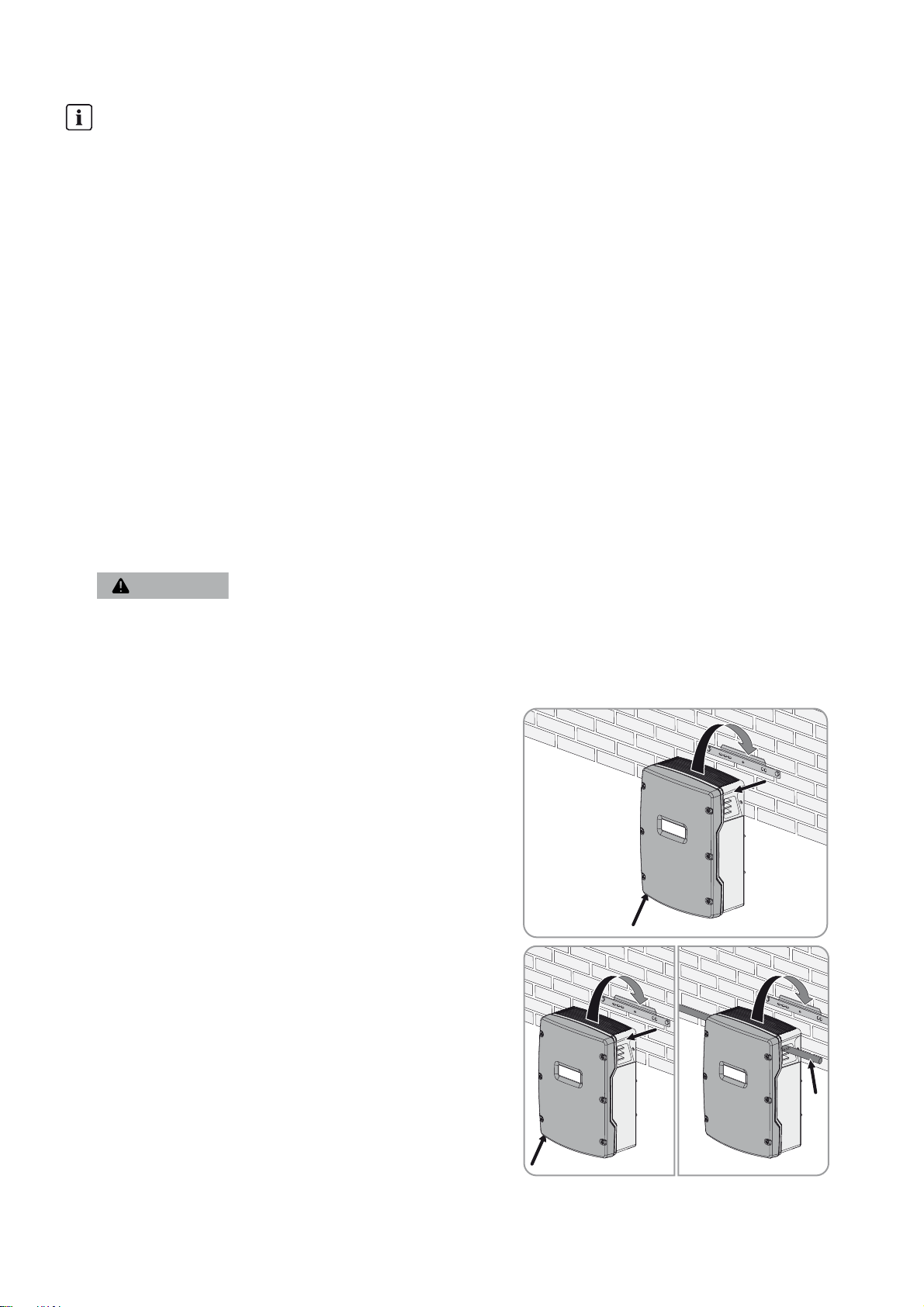

Procedure:

1. At the mounting location, mark the position of the drill holes using the wall mounting bracket. Use at least one hole

on the right side of the wall mounting bracket and one on the left.

2. Ensure that there are no electric lines or other supply lines in the wall behind the marked positions.

3. Drill the holes and insert the screw anchors.

4. Secure the wall mounting bracket horizontally to the wall using screws and washers.

5. If the Sunny Island is to be secured against theft, mark the drill holes for the anti-theft device. Use at least one hole

on the right and one on the left.

6.

Risk of injury due to the heavy weight of the Sunny Island inverter

Improper transport and mounting can result in the Sunny Island falling. Falling may lead to bruising and broken

bones.

• Keep in mind the weight of the Sunny Island inverter (see Section10 "Technical Data", page94).

• With the SI3.0M-11 and SI4.4M-11, the Sunny Island should

be mounted to the wall mounting bracket. For this, use the side

recess grips. Keep the Sunny Island in a horizontal position

during transport.

• With the SI6.0H-11 and SI8.0H-11, the Sunny Island should

be mounted to the wall mounting bracket. For this, use the

side recess grips or a steel rod (diameter: maximum 30 mm).

Keep the Sunny Island in a horizontal position during

transport.

22 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 23

SMA Solar Technology AG 6 Mounting

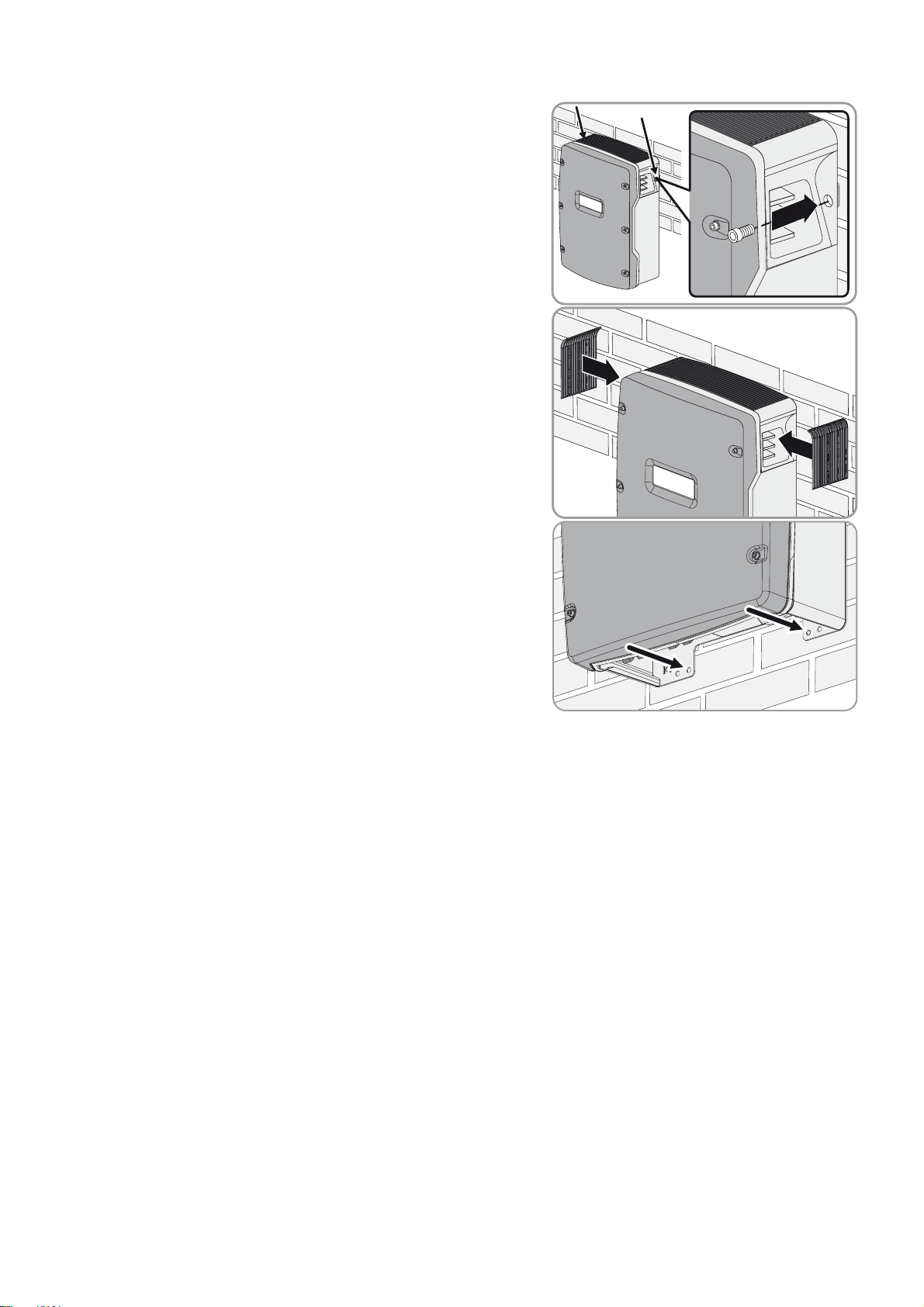

7. Use an Allen key (AF 5) to attach the Sunny Island to the wall

mounting bracket on both sides with the M6x10 screws provided

(torque: 4 Nm to 5.7 Nm). This will prevent the Sunny Island from

being lifted off the bracket.

8. Seal off the recess grips with the ventilation grids:

• Place the ventilation grid marked links/left on the left recess

grip.

• Place the ventilation grid marked rechts/right on the right

recess grip.

9. In order to protect the Sunny Island against theft, attach the bottom

side to the wall with two security screws.

10. Ensure that the Sunny Island is firmly attached.

Installation Manual SI30M-44M-60H-80H-IA-en-30 23

Page 24

7 Electrical Connection SMA Solar Technology AG

7 Electrical Connection

7.1 Content and Structure of the Section

The sub-sections differ in their structure. Some sub-sections refer to the correct connection of devices, others refer to basic

procedures.

An overview detailing which contents the sub-sections describe and which contents should be read and adhered to can

be found in the following table.

Section Explanation

7.2 Connection Area Graphic overview of the connection area

7.3 Connecting the Grounding Conductor

in Systems With Grounded Battery

7.4 Connecting the Devices Information on connection and circuitry of individual devices with

7.5 Connecting the Cables Correct connection of the cables to the respective connections

7.6 Checking the Wiring You must read and observe the section for the connections used.

7.7 Sealing and Closing the Sunny Island You must read and observe this section.

7.8 Inserting the Fuse Links in the Fuse

Switch-Disconnector BatFuse

For systems with grounded battery, this section must be read and

observed.

specification of connections on the Sunny Island

You must read and observe the sections for the connections used.

You must read and observe this section.

24 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 25

SMA Solar Technology AG 7 Electrical Connection

7.2 Connection Area

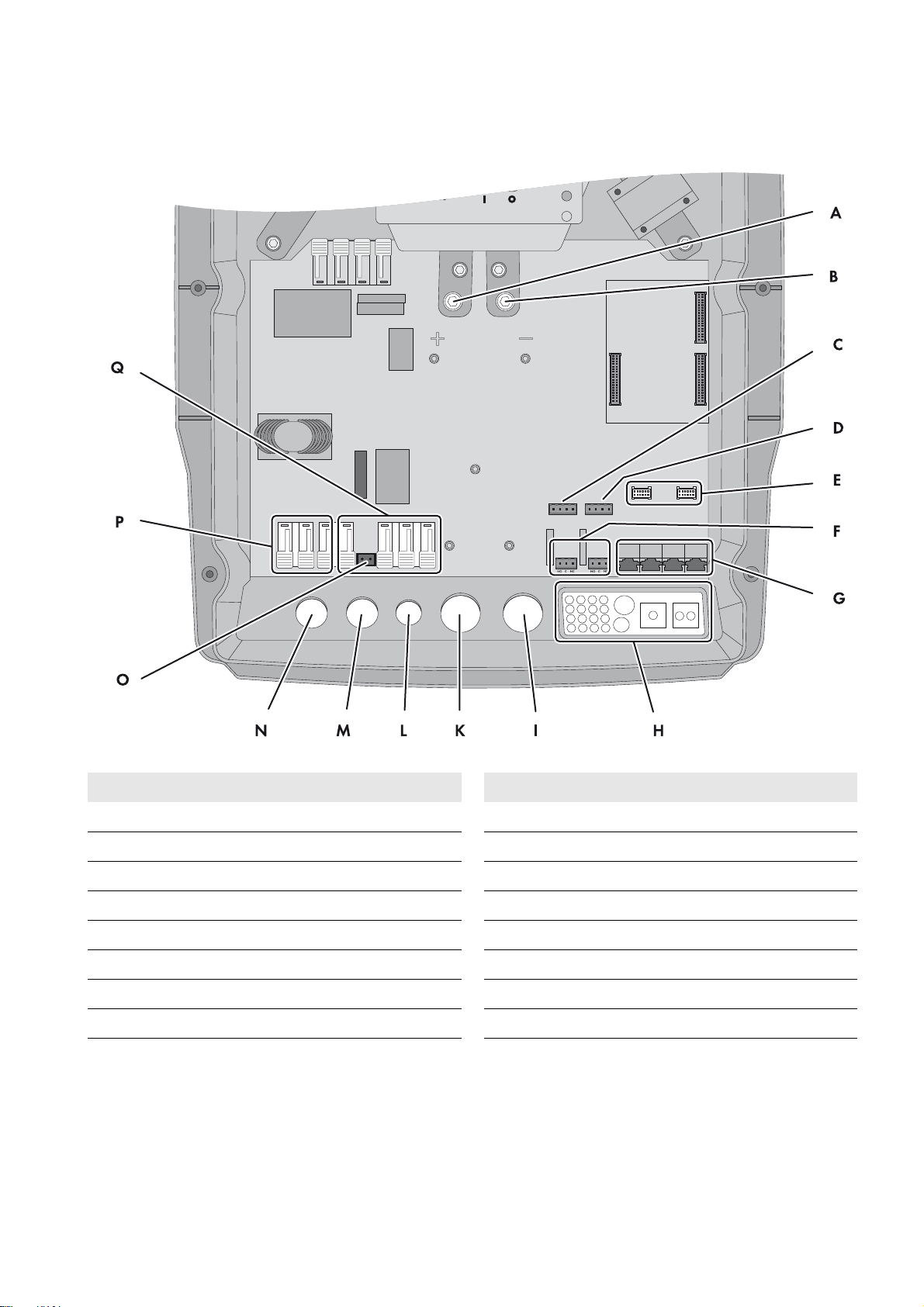

Figure8: Connection area of the Sunny Island inverter

Position Designation Position Designation

A DC+ connection I Enclosure opening for DC-

B DC- connection K Enclosure opening for DC+

C BatTmp and BatCur connections L Enclosure opening for PE/ExtVtg

D BatVtgOut and DigIn connections M Enclosure opening for AC2

E 2 interface slots N Enclosure opening for AC1

F Relay1 and Relay2 connections O ExtVtg connection

G Communication connection P AC1 connection

H Cable feed-through plate Q AC2 connection

7.3 Connecting the Grounding Conductor in Systems With Grounded Battery

If you ground the battery, you can ground it at the positive terminal or at the negative terminal with a grounding

conductor. SMA Solar Technology AG does not recommend grounding the battery. If the battery is grounded, the

enclosure of the Sunny Island must also be grounded. This additional grounding is no substitute for the grounding at

connections AC1 and AC2.

Installation Manual SI30M-44M-60H-80H-IA-en-30 25

Page 26

7 Electrical Connection SMA Solar Technology AG

Conductor cross-section:

You must determine the required conductor cross-section of the grounding conductor, taking into account the applicable

local standards and directives. The calculation of the grounding conductor cross-section depends on the type and size of

the connected battery, the external fuse in the BatFuse, and the material of the grounding conductor.

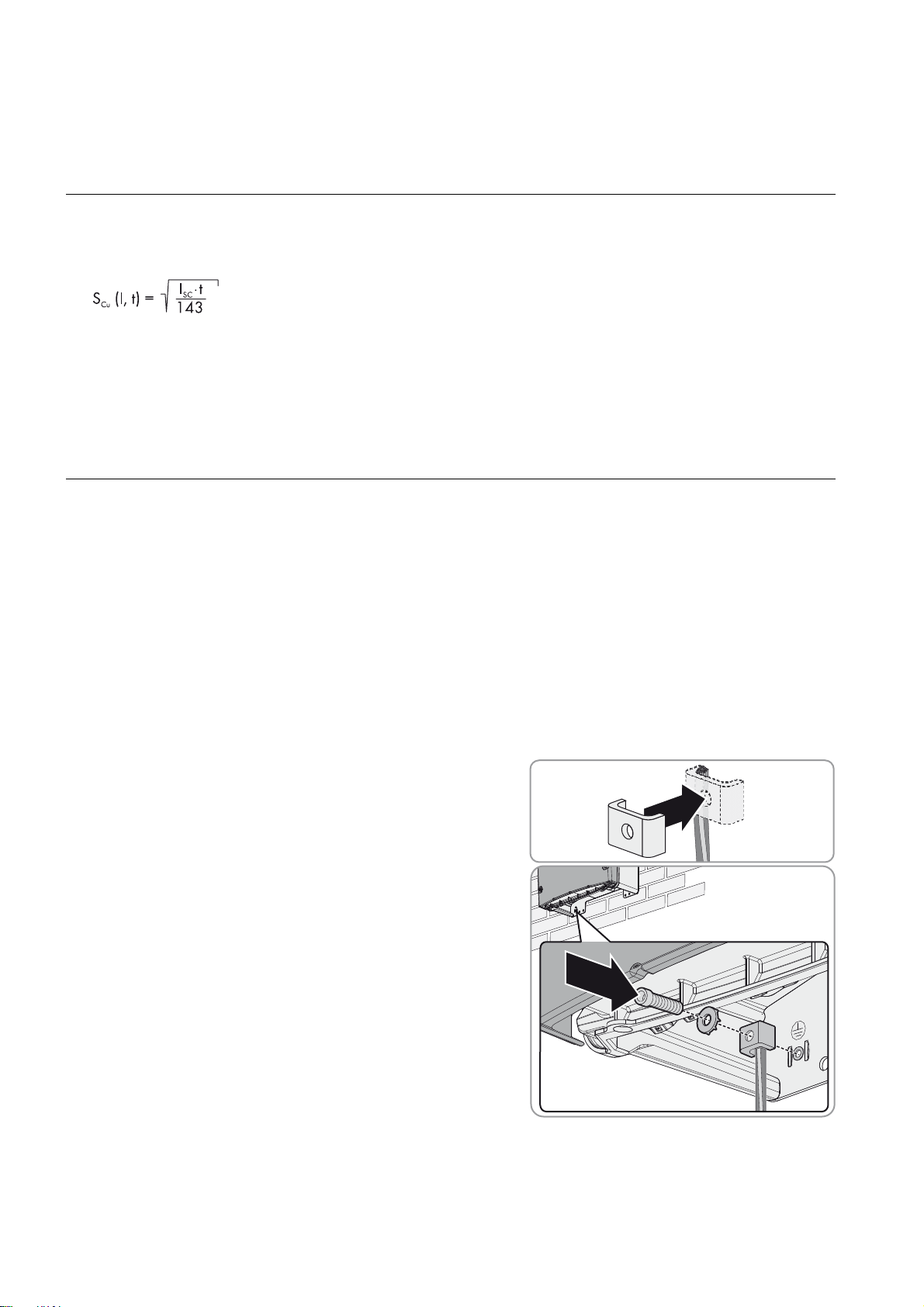

Example: Calculation of the grounding conductor cross-section

Grounding conductor made of copper. The required cross-section of the grounding conductor can be calculated using

the following formula:

SC

= conductor cross-section in mm²

u

= short-circuit current in A

I

SC

= interruption time in s

t

Typical tripping times for an LV/HRC fuse are around 25 ms for short-circuit currents between 2,000 A and 10,000 A.

Grounding with a cross-section of 16 mm² is sufficient for short-circuit currents up to 10,000 A.

Cable requirement:

☐ Copper wire

☐ Maximum conductor cross-section: 16 mm²

☐ The cross-sections of the battery grounding conductor and Sunny Island inverter grounding conductor must be the

same.

Procedure:

1. Calculate the cross-section of the grounding conductor.

2. Ground the battery at the positive terminal or negative terminal using a conductor with the calculated cross-section.

3. Also ground the Sunny Island enclosure using a conductor with the calculated cross-section, as follows:

• Strip the grounding conductor.

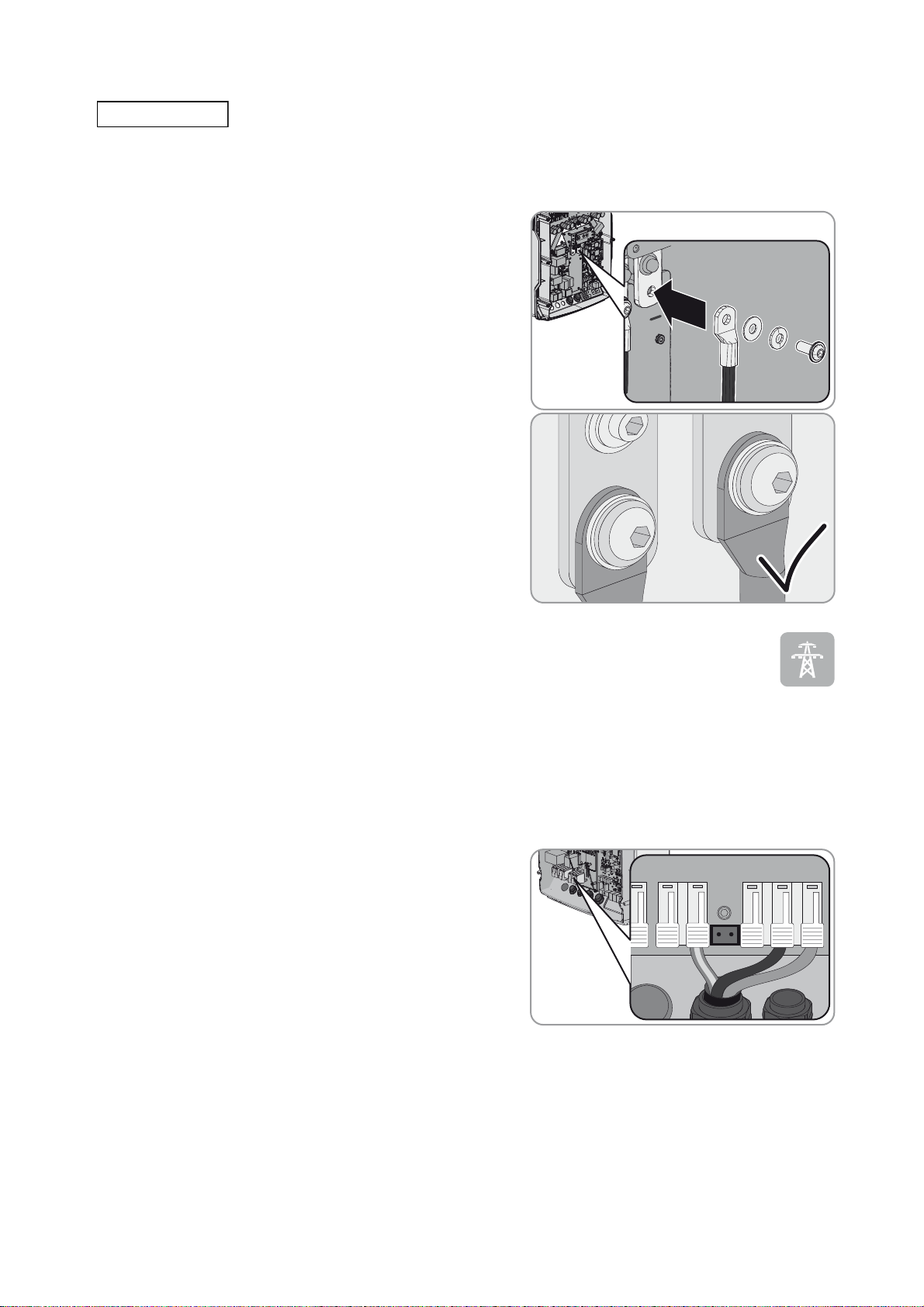

• Place the clamping bracket over the conductor. Position the

conductor on the left.

• Fasten the clamping bracket with the hexagon socket screw

M6x16 and a conical spring washer (AF 5, torque: 4 Nm to

5.7 Nm). The teeth of the conical spring washer must face the

clamping bracket.

26 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 27

SMA Solar Technology AG 7 Electrical Connection

:$5 1,1*

7.4 Connecting the Devices

7.4.1 Connecting the Fuse Switch-Disconnector BatFuse to the Sunny Island

Cables for DC connection

Long cables and insufficient conductor cross-sections reduce the efficiency of the system and the overload capacity

of the Sunny Island inverter. The maximum cable length from the battery to the Sunny Island via the fuse

switch-disconnector is 10 m. The recommended minimum conductor cross-section is dependent upon the battery

voltage, power, and cable length:

Sunny Island Cable length*

SI 8.0H ≤ 5 m 70 mm² 14 mm to 21 mm M8, 20 mm to 25 mm wide

>5 m 95 mm² 14 mm to 21 mm M8, 20 mm to 25 mm wide

SI 6.0H ≤ 5 m 50 mm² 14 mm to 21 mm M8, 20 mm to 25 mm wide

>5 m 70 mm² 14 mm to 21 mm M8, 20 mm to 25 mm wide

SI 4.4M ≤ 5 m 50 mm² 14 mm to 21 mm M8, 20 mm to 25 mm wide

>5 m 70 mm² 14 mm to 21 mm M8, 20 mm to 25 mm wide

SI 3.0M ≤ 5 m 50 mm² 14 mm to 21 mm M8, 20 mm to 25 mm wide

>5 m 70 mm² 14 mm to 21 mm M8, 20 mm to 25 mm wide

* Cable length from the battery to the Sunny Island via the fuse switch-disconnector

** Maximum cable diameter on the Sunny Island: 25 mm Maximum cable diameter on the BatFuse: 21 mm

Danger to life due to incompatible lithium-ion battery

An incompatible lithium-ion battery can lead to a fire or an explosion. With incompatible lithium-ion batteries, it is not

ensured that the battery management will protect the battery.

• Ensure that the battery complies with the locally applicable standards and directives and is intrinsically safe.

• Ensure that the lithium-ion batteries are approved for use with the Sunny Island.

The list of lithium-ion batteries approved for the Sunny Island is updated regularly (see the Technical Information

"List of Approved Lithium-Ion Batteries" at www.SMA-Solar.com).

• If no lithium-ion batteries approved for the Sunny Island can be used, use lead-acid batteries.

Conductor

cross-section

Cable diameter**

Terminal lug

Procedure:

1. Ensure that the load-break switch of the BatFuse is open and secured against reconnection.

2. On the Sunny Island, remove all screws of the lower enclosure lid using an Allen key (AF 5) and remove the

3. Clean the contact surfaces of the DC+ and DC- connections with ethanol, for example. This reduces the transition

Installation Manual SI30M-44M-60H-80H-IA-en-30 27

enclosure lid. Retain the screws and conical spring washers for later use.

resistance on the contact surfaces. A low transition resistance increases the system stability and minimizes the risk of

damage to the Sunny Island.

Page 28

7 Electrical Connection SMA Solar Technology AG

/05*$&

4.

Damage to Sunny Island inverter due to reverse polarity or incorrect terminal lug selection

If the DC cables are swapped, high currents will flow after the load-break switch has closed and these can damage

the Sunny Island.

• Fasten the DC power cables to the DC connection with

M8x20 screws, ensuring correct polarity (torque: 12 Nm). In

doing so, ensure that the cable is connected correctly (see

Section7.5.1 "Connecting the DC Power Cable", page50)

and adhere to the following screw assembly: screw head |

spring washer | fender washer | terminal lug | DC

connection.

☑ The contact surfaces of the fender washers have full

contact with the terminal lugs.

7.4.2 Connecting the Utility Grid in the System for Increased Self-Consumption

Requirements:

☐ The system is not a battery backup system

☐ For connection of the Sunny Island inverter to the utility grid, there must be a circuit breaker and a type A

residual-current device on the distribution board (for circuitry overview, see the Quick Reference Guide

"SMA Flexible Storage System").

Procedure:

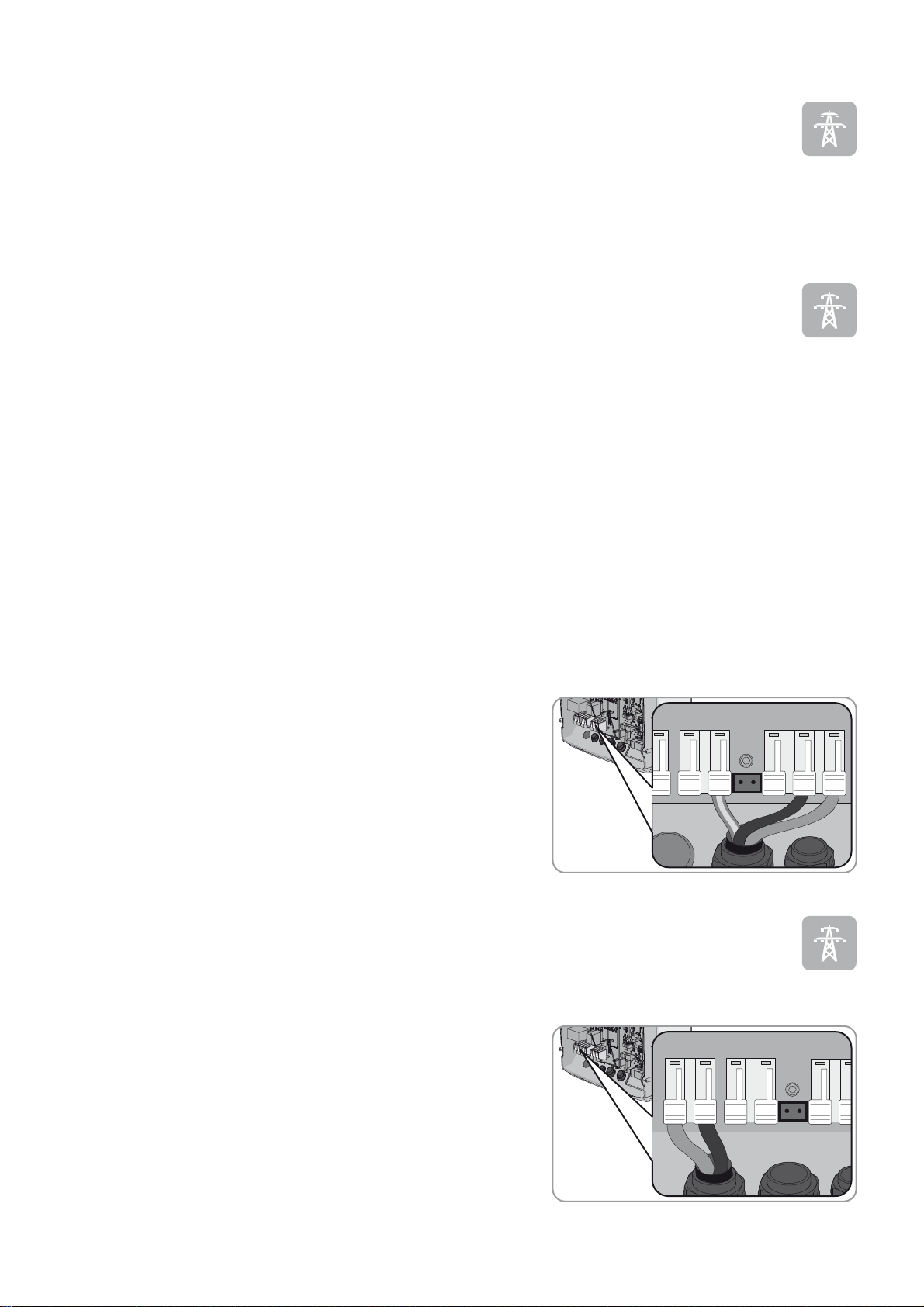

1. On the Sunny Island, connect the power cable to the terminals

AC2 Gen/Grid: Ensure that the cable is correctly connected (see

Section7.5.2 "Connecting the AC Power Cable", page52).

• Connect the line conductor to AC2 Gen/Grid L.

• Connect the neutral conductor to AC2 Gen/Grid N

• Connect the grounding conductor to AC2 Gen/Grid PE.

2. Connect an additional grounding conductor to the AC1 Loads/SunnyBoys PE terminal if the power cable

conductor cross-section is smaller than 10 mm² (see Section7.5.3 "Connecting the Grounding Conductor",

page53).

.

TT

28 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 29

SMA Solar Technology AG 7 Electrical Connection

7.4.3 Connecting an Automatic Transfer Switch in the Battery Backup System

7.4.3.1 Automatic Transfer Switch Function

The automatic transfer switch separates the utility grid from the battery backup grid in battery backup systems. The control

cable, measuring cable and power cable link the automatic transfer switch to the Sunny Island (for circuitry overview,

see the Quick Reference Guide "SMA Flexible Storage System with Battery Backup Function").

7.4.3.2 Connecting the AC Power Cables to the Automatic Transfer Switch

The AC power cables conduct the energy between the battery backup grid and the Sunny Island (for circuitry

overview, see the Quick Reference Guide "SMA Flexible Storage System with Battery Backup Function").

Requirements:

☐ For a three-phase battery backup system, L1 must be assigned to the master, L2 to slave 1, and L3 to slave 2.

This creates a right-hand rotating magnetic field.

☐ The power of the AC sources in the battery backup grid must not exceed the maximum connected power of the PV

inverters in the battery backup systems (see Section10.2 "AC2 Connection for Utility Grid and Generator (External

Energy Source)", page95). The powers of the individual Sunny Island inverters are added to yield the total

maximum power.

Cable requirements:

☐ Copper wire

☐ Number of conductors in the cable: 3

☐ Conductor cross-section: 10 mm² to 16 mm²

☐ Cable diameter: 9 mm to 18 mm

Procedure:

• On the Sunny Island, connect the power cable from X3 to terminal

AC2 Gen/Grid (for circuitry overview, see the Quick Reference

Guide

"SMA Flexible Storage System with Battery Backup Function").

Ensure that the cable is correctly connected (see Section7.5.2

"Connecting the AC Power Cable", page52).

• Connect the line conductor to AC2 Gen/Grid L.

• Connect the neutral conductor to AC2 Gen/Grid N

• Connect the grounding conductor to AC2 Gen/Grid PE.

.

TT

7.4.3.3 Connecting the Control Cables to the Automatic Transfer Switch

The control cables conduct the control signals of the multifunction relays to the contactors (for circuitry

overview, see the Quick Reference Guide "SMA Flexible Storage System with Battery Backup Function").

Procedure:

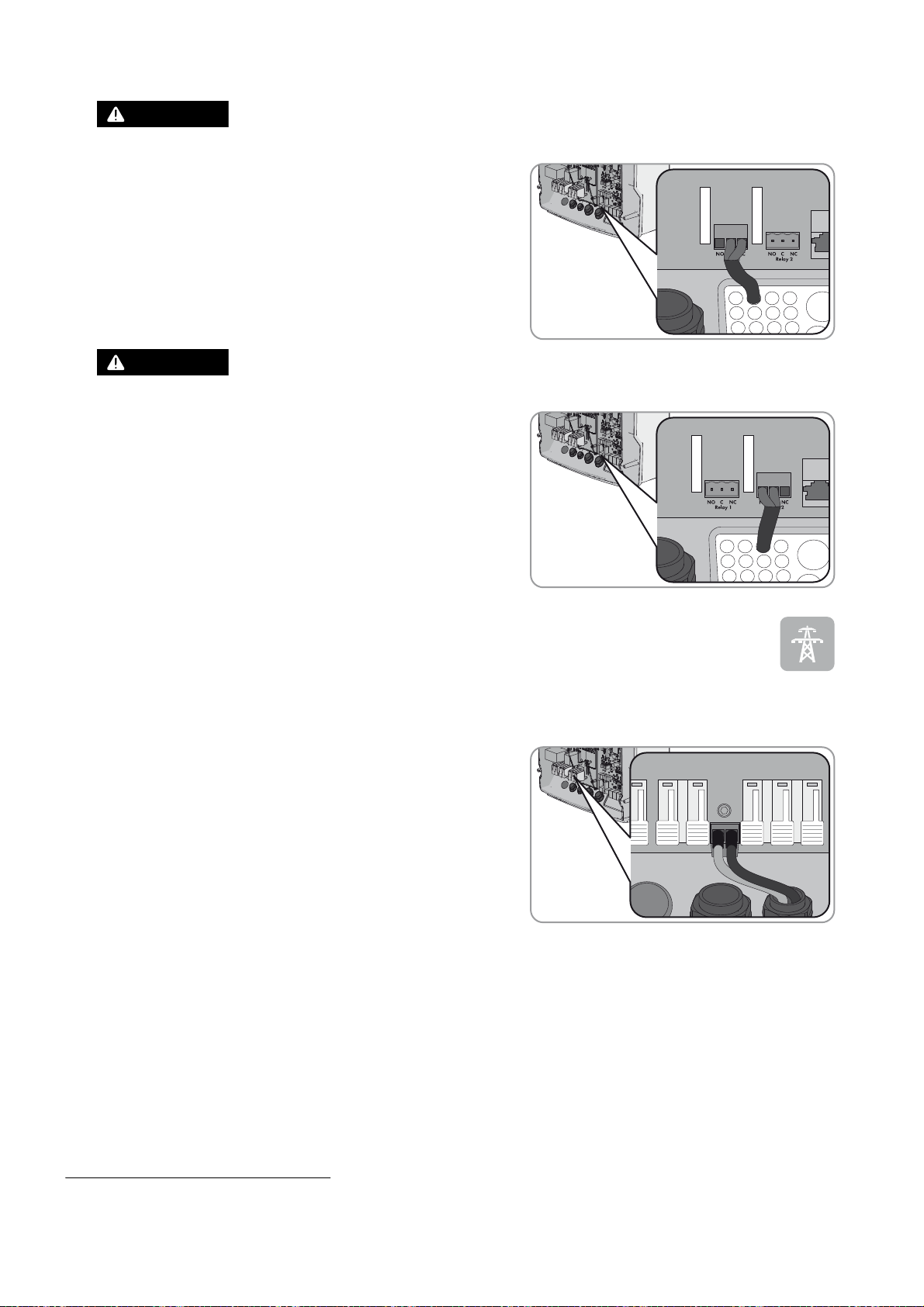

1. On the master, connect the cable from X5 L and X5 N (for the

control voltage) to terminal AC1 Loads/SunnyBoys. Ensure that

the cable is correctly connected (see Section7.5.2 "Connecting

the AC Power Cable", page52).

Installation Manual SI30M-44M-60H-80H-IA-en-30 29

Page 30

7 Electrical Connection SMA Solar Technology AG

:$5 1,1*

:$5 1,1*

2.

Danger to life from electric shock due to incorrect insulation

• Connect the control cable of X4 1 and X4 2 to the Relay1 C

and Relay1 NC terminals. Ensure that the cable is correctly

connected (see Section7.5.5 "Connecting Relay 1 and

Relay 2", page55).

3.

Danger to life from electric shock due to incorrect insulation

• Connect the control cable of X5 1 and X5 2 to the Relay2 C

and Relay2 NO terminals. Ensure that the cable is correctly

connected (see Section7.5.5 "Connecting Relay 1 and

Relay 2", page55).

7.4.3.4 Connecting the Measuring Cables to the Automatic Transfer Switch

The Sunny Island measures the voltages of the respective line conductors via one measuring cable. In addition,

the master also verifies whether the tie switch is activated or deactivated (for circuitry overview, see the Quick

Reference Guide "SMA Flexible Storage System with Battery Backup Function").

Procedure:

1. On the Sunny Island, connect the measuring cable X4 Ln * and

X4 N for voltage monitoring to the ExtVtg terminal. Ensure that

the cable is correctly connected (see Section7.5.7 "Connecting

ExtVtg", page57).

2. At the master, connect the tie switch monitoring. Ensure that the cable from X5 3 and X5 4 is correctly connected

(see Section7.5.6 "Connecting BatVtgOut, DigIn, BatTMP, and BatCur", page56).

• Connect BatVtgOut − with DigIn − within the master.

• Connect the insulated conductor from X5 3 to DigIn+.

• Connect the insulated conductor from X5 4 to BatVtgOut+.

* Ln = L1 to L3

30 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 31

SMA Solar Technology AG 7 Electrical Connection

:$5 1,1*

7.4.4 Connecting the Stand-Alone Grid or Multicluster Box

In the off-grid system, connect the AC loads and the grid-parallel AC sources (e.g. PV inverters) to connection

AC1 on the Sunny Island inverter via an AC distribution board. In the case of a multicluster system, the

Multicluster Box is the AC distribution board that is connected to connection AC1.

Requirements for connecting Sunny Island inverters in single-phase parallel single-cluster systems:

Figure9: Correct, symmetric connection and incorrect, asymmetric connection of the Sunny Island inverters

☐ For a single-phase parallel single-cluster system, the cable length and conductor cross-section from each

Sunny Island to the AC distribution board must be identical. This will allow for stable and symmetric operation.

Danger to life due to fire

In case of a short circuit, the short-circuit current driven by the generator flows over the unfused cable between the

Sunny Island and the AC distribution board. Short-circuit currents can cause fires.

• If the generator fuse is larger than the fuse on the AC distribution board, configure the cable for the generator fuse.

Procedure:

1. On the Sunny Island, connect the cable to the AC1 Loads/

SunnyBoys terminal. Ensure that the cable is correctly connected

(see Section7.5.2 "Connecting the AC Power Cable", page52).

2. If the conductor cross-section of the grounding conductor is less than 10 mm², make sure that an additional

grounding conductor is connected to terminal AC2 Loads/SunnyBoys PE (see Section7.5.3 "Connecting the

Grounding Conductor", page53).

Installation Manual SI30M-44M-60H-80H-IA-en-30 31

Page 32

7 Electrical Connection SMA Solar Technology AG

:$5 1,1*

7.4.5 Connecting the Generator in an Off-Grid System

In single systems and single cluster systems, connect a generator to connection AC2 of the Sunny Island

inverter. For a multicluster system, connect the generator directly to the Multicluster Box (see the Multicluster

Box documentation).

Danger to life from electric shock due to incorrect connection of the neutral conductor

Connecting the neutral conductor incorrectly can cause failure of the protective functions in the system. This can result

in death or serious injury.

• Connect the neutral conductor to terminal AC2 Gen/Grid N.

Requirements:

☐ A separate cable must be laid for each Sunny Island from the AC distribution board or directly from the generator.

☐ In single-phase parallel single cluster systems, the cable lengths and conductor cross-sections from each Sunny Island

to the AC distribution board or directly to the generator must be configured in the same way.

☐ In a three-phase system, L1 must be assigned to the master, L2 to slave 1, and L3 to slave 2.

Procedure:

• Connect the power cable to the AC2 Gen/Grid terminal on the

Sunny Island. Connect the neutral conductor to terminal N and

ensure that the cable is correctly connected (see Section7.5.2

"Connecting the AC Power Cable", page52).

7.4.6 Inserting Filler Plugs

• Seal unused enclosure openings of the Sunny Island with filler plugs. The enclosure openings will then comply with

degree of protection IP54.

7.4.7 Communication Connection

7.4.7.1 Connecting the Sunny Remote Control

A data cable is included with the Sunny Remote Control for connection purposes. If the data cable is not long enough,

you can replace it with a longer data cable.

Cable requirements:

☐ Cable length: maximum 20 m

☐ Classification: CAT5e

☐ Type of plug: RJ45

32 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 33

SMA Solar Technology AG 7 Electrical Connection

Procedure:

1. Insert the data cable in the pin connector Display on the

Sunny Island (see Section7.5.4 "Connecting the Data Cable",

page54).

2. Connect the other end of the data cable to the Sunny Remote Control.

7.4.7.2 Connecting the Data Cable of the Lithium-Ion Batteries

Requirement:

☐ The total length of the communication bus must not exceed 30 m. Keep in mind that the communication bus possibly

connects several nodes such as additional Sunny Island inverters.

Cable requirements:

☐ Classification: CAT5e

☐ Type of plug: RJ45

Procedure:

1. Plug the data cable into a free pin connector ComSync on the

Sunny Island. Ensure that the cable is correctly connected

(see Section7.5.4 "Connecting the Data Cable", page54).

2. Connect the other end of the data cable to the battery management of the lithium-ion battery (see battery

manufacturer documentation).

3. Ensure that the communication bus is closed at each end, e.g. with a terminator.

7.4.7.3 Connecting Speedwire

Requirement:

☐ A Speedwire data module for Sunny Island must be installed (see the installation manual of the

SMA Speedwire/Webconnect data module).

Cable requirements:

☐ Cable length between two nodes:

– maximum 50 m with patch cable

– maximum 100 m with extension cable

☐ Cross-section: minimum 2 x 2 x 0.22 mm² or minimum 2 x 2 x AWG 24

☐ Cable type: 100BaseTx, CAT5 with shielding S-UTP, F-UTP or higher

☐ Type of plug: RJ45

Installation Manual SI30M-44M-60H-80H-IA-en-30 33

Page 34

7 Electrical Connection SMA Solar Technology AG

Procedure:

1. On the Sunny Island, insert the data cable in the pin connector of

the Speedwire data module (for electrical connection, see the

installation manual of the Speedwire data module Sunny Island).

2. Connect the other end of the data cable to the router or network switch.

7.4.7.4 Connecting the Data Cable for the Internal Communication of the Cluster

In a cluster, the Sunny Island inverters communicate via a black data cable.

Figure10: Internal communication cabling

34 SI30M-44M-60H-80H-IA-en-30 Installation Manual

Page 35

SMA Solar Technology AG 7 Electrical Connection

Requirements:

☐ The total length of the communication bus must not exceed 30 m. Keep in mind that the communication bus possibly

connects several nodes such as other Sunny Island Chargers.

Procedure:

1. Plug the data cable into a free pin connector ComSync on the

Sunny Island. Ensure that the cable is correctly connected (see

Section7.5.4 "Connecting the Data Cable", page54).

2. Ensure that the communication bus is closed at each end, e.g. with a terminator.

7.4.7.5 Connecting the Data Cable of the Sunny Island Charger 50 Charge Controller

A maximum of four Sunny Island Charger 50 devices can be connected per cluster (see the Quick Reference

Guide "Off-Grid Systems").

Requirements:

☐ The total length of the communication bus must not exceed 30 m. Keep in mind that the communication bus possibly