Page 1

CA

US

Central Inverter

SUNNY CENTRAL 500HE-US/CA

Installation Manual

SC500HEUS-IA-US_en-14 | 98-4017514 | Version 1.4

Page 2

Page 3

SMA America, LLC Legal Restrictions

Legal Restrictions

Copyright © 2013 SMA America,LLC. All rights reserved.

No part of this document may be reproduced, stored in a retrieval system, or transmitted, in any form

or by any means, electronic, mechanical, photographic, magnetic or otherwise, without the prior

written permission of SMA America,LLC.

Neither SMA America,LLC nor SMA Solar Technology Canada Inc. makes representations, express

or implied, with respect to this documentation or any of the equipment and/or software it may

describe, including (with no limitation) any implied warranties of utility, merchantability, or fitness for

any particular purpose. All such warranties are expressly disclaimed. Neither SMA America,LLC nor

its distributors or dealers nor SMA Solar Technology Canada Inc. nor its distributors or dealers shall

be liable for any indirect, incidental, or consequential damages under any circumstances.

(The exclusion of implied warranties may not apply in all cases under some statutes, and thus the

above exclusion may not apply.)

Specifications are subject to change without notice. Every attempt has been made to make this

document complete, accurate and up-to-date. Readers are cautioned, however, that

SMAAmerica,LLC and SMA Solar Technology Canada Inc. reserve the right to make changes

without notice and shall not be responsible for any damages, including indirect, incidental or

consequential damages, caused by reliance on the material presented, including, but not limited to,

omissions, typographical errors, arithmetical errors or listing errors in the content material.

All trademarks are recognized even if these are not marked separately. Missing designations do not

mean that a product or brand is not a registered trademark.

The Bluetooth

any use of such marks by SMA America,LLC and SMA Solar Technology Canada Inc. is under

license.

®

word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and

SMA America, LLC

3801 N. Havana Street

Denver, CO 80239 U.S.A.

SMA Solar Technology Canada Inc.

2425 Matheson Blvd. E

8th Floor

Mississauga, ON L4W 5K5

Canada

Installation Manual SC500HEUS-IA-US_en-14 3

Page 4

Important Safety Instructions SMA America, LLC

%"/(&3

8"3/*/(

$"65*0/

/05*$&

Important Safety Instructions

SAVE THESE INSTRUCTIONS

This manual contains important instructions for the following products:

• Sunny Central 500HE-US

This manual must be followed during installation and maintenance.

The product is designed and tested according to international safety requirements, but as with all

electrical and electronic equipment, certain precautions must be observed when installing and/or

operating the product. To reduce the risk of personal injury and to ensure the safe installation and

operation of the product, you must carefully read and follow all instructions, cautions and warnings

in this manual.

Warnings in this document

A warning describes a hazard to equipment or personnel. It calls attention to a procedure or practice,

which, if not correctly performed or adhered to, could result in damage to or destruction of part or all

of the SMA equipment and/or other equipment connected to the SMA equipment or personal injury.

Symbol Description

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

Warnings on this product

The following symbols are used as product markings with the following meanings.

Symbol Description

Warning regarding dangerous voltage

The product works with high voltages. All work on the product must only be

performed as described in the documentation of the product.

Beware of hot surface

The product can become hot during operation. Do not touch the product during

operation.

4 SC500HEUS-IA-US_en-14 Installation Manual

Page 5

SMA America, LLC

Symbol Description

Electric arc hazards

The product has large electrical potential differences between its conductors. Arc

flashes can occur through air when high-voltage current flows. Do not work on the

product during operation.

Risk of Fire

Improper installation of the product may cause a fire.

Observe the operating instructions

Read the documentation of the product before working on it. Follow all safety

precautions and instructions as described in the documentation.

Installation Manual SC500HEUS-IA-US_en-14 5

Page 6

SMA America, LLC

8"3/*/(

General Warnings

General Warnings

Al l el ect ric al ins tal lat ions m ust be m ade in acc ord anc e wi th the local and NationalElectrical Code

ANSI/NFPA 70 or the Canadian Electrical Code® CSAC22.1. This document does not and is not

intended to replace any local, state, provincial, federal or national laws, regulation or codes

applicable to the installation and use of the product, including without limitation applicable

electrical safety codes. All installations must conform with the laws, regulations, codes and

standards applicable in the jurisdiction of installation. SMA assumes no responsibility for the

compliance or noncompliance with such laws or codes in connection with the installation of the

product.

The product contains no user-serviceable parts.

For all repair and maintenance, always return the unit to an authorized SMA Service Center.

Before installing or using the product, read all of the instructions, cautions, and warnings in this

manual.

Before connecting the product to the electrical utility grid, contact the local utility company. This

connection must be made only by qualified personnel.

Wiring of the product must be made by qualified personnel only.

®

6 SC500HEUS-IA-US_en-14 Installation Manual

Page 7

SMA America, LLC Table of Contents

Table of Contents

1 Notes on this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 Target Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 Validity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Additional Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4 Structure of this Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1 Appropriate Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 The Sunny Central . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1 System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2 The Design of the Sunny Central . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3 Location of the Safety Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4 Identifying the Sunny Central. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5 Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1 Unpacking and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Transport and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Choosing the Installation Site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1.1 Dimensions and weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1.2 Ambient Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1.3 Minimum Clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1.4 Characteristics of the Base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2 Preparation of the Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2.1 Position of the Mounting Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2.2 Size of the Mounting Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2.3 Drilling Holes into the Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installation Manual SC500HEUS-IA-US_en-14 7

Page 8

Table of Contents SMA America, LLC

5.3 Transporting the Sunny Central . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3.1 Center of Gravity of the Sunny Central . . . . . . . . . . . . . . . . . . . . . . 28

5.3.2 Equipment for Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4 Transporting the Sunny Central with a Crane . . . . . . . . . . . . . . . . . . 30

5.4.1 Uninstalling the Roof of the Sunny Central. . . . . . . . . . . . . . . . . . . . 30

5.4.2 Moving the Sunny Central with a Crane . . . . . . . . . . . . . . . . . . . . . 32

5.4.3 Installing the Roof of the Sunny Central. . . . . . . . . . . . . . . . . . . . . . 32

5.5 Installing the Sunny Central . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.5.1 Removing the Kick Plates from the Sunny Central . . . . . . . . . . . . . . 34

5.5.2 Attach the Sunny Central to the base. . . . . . . . . . . . . . . . . . . . . . . . 35

5.5.3 Install Ventilation Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.5.4 Attaching the Kick Plates to the Sunny Central. . . . . . . . . . . . . . . . . 36

6 Attaching the Conduits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.1 Insert cables from the right into the Sunny Central . . . . . . . . . . . . . . 37

6.2 Insert cables from below into the Sunny Central . . . . . . . . . . . . . . . . 38

7 Connecting Optional Communication Devices . . . . . . . . . . . . 39

7.1 Position of the Communication Devices. . . . . . . . . . . . . . . . . . . . . . . 40

7.2 Connecting the Sunny SensorBox (optional). . . . . . . . . . . . . . . . . . . 41

7.2.1 Connecting the Data Cable of the Sunny SensorBox . . . . . . . . . . . 41

7.3 Sunny WebBox (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.3.1 Installing the WebBox in the Sunny Central. . . . . . . . . . . . . . . . . . . 45

7.3.2 Connecting the Sunny WebBox in the Sunny Central . . . . . . . . . . . 45

7.3.3 Connecting the Cable to the Sunny WebBox . . . . . . . . . . . . . . . . . 45

7.3.4 Termination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.2 Connection in Control and Interface Cabinet . . . . . . . . . . . . . . . . . . 48

8.2.1 Connection Area for Analog inputs and auxiliary power . . . . . . . . 48

8.2.2 Connection Area of the Low Temperature Option . . . . . . . . . . . . . . 49

8.2.3 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8 SC500HEUS-IA-US_en-14 Installation Manual

Page 9

SMA America, LLC Table of Contents

8.2.4 Optional External 3-phase voltage supply

(3AC, 208/120V, 60Hz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.2.5 Connecting the external 208 V power supply. . . . . . . . . . . . . . . . . 50

8.2.6 Connecting Analog input setting cables. . . . . . . . . . . . . . . . . . . . . . 53

8.2.7 Connecting Cables for the Low Temperature Option. . . . . . . . . . . . 54

8.3 Connection Area for AC, DC cables and ground . . . . . . . . . . . . . . . 55

8.4 Connection Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.4.1 DC Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.4.2 Grounding the PV modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.4.3 Cable connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.4.4 Cable requirements for DC, AC and PE connection . . . . . . . . . . . . 58

8.4.5 Additional cable requirements for DC connection . . . . . . . . . . . . . . 58

8.5 Connecting DC cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.5.1 Connecting DC cables with screw terminals . . . . . . . . . . . . . . . . . . 59

8.5.2 Connecting DC cables with cable lugs . . . . . . . . . . . . . . . . . . . . . . 60

8.6 Connection of the PV Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.6.1 PV Modules: DC − Connection at Negative Grounding and DC+

Connection at Positive Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.6.2 PV Modules: DC+ Connection at Negative Grounding and DC −

Connection at Positive Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.7 AC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.7.1 Additional cable requirements for AC connection . . . . . . . . . . . . . . 65

8.7.2 Arranging AC cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.7.3 Connecting AC cables to busbars . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.7.4 AC Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.8 Connecting protective earth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.8.1 Additional cable requirements for PE connection. . . . . . . . . . . . . . . 71

8.8.2 Connecting protective earth to Terminal Blocks . . . . . . . . . . . . . . . . 71

8.8.3 Connecting protective earth to busbar. . . . . . . . . . . . . . . . . . . . . . . 72

9 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.1 Visual Inspection of the Sunny Central . . . . . . . . . . . . . . . . . . . . . . . 73

9.2 Switching the Sunny Central On . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.2.1 Check the Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Installation Manual SC500HEUS-IA-US_en-14 9

Page 10

Table of Contents SMA America, LLC

10 Opening the Sunny Central. . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10.1 Opening the Control and Interface Cabinet . . . . . . . . . . . . . . . . . . . 80

10.2 Opening the Power Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

11 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11.1 Measurement Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

11.2 Torques and Cable Sizes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

12 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13 Appendix - Celsius to Fahrenheit conversion. . . . . . . . . . . . . . 87

10 SC500HEUS-IA-US_en-14 Installation Manual

Page 11

SMA America, LLC 1 Notes on this Manual

1 Notes on this Manual

This manual describes the installation and the commissioning of a Sunny Central 500HE-US and

Sunny Central 500HE-CA with up to 9 DC fuses. This manual does not cover any details concerning

PV modules. Information concerning the PV modules is available from the manufacturer of the PV

modules.

1.1 Target Group

This manual is for qualified personnel. Qualified personnel has received training and has

demonstrated skills and knowledge in the construction and operation of the device. Qualified

personnel is trained to deal with the dangers and hazards involved in installing electric devices.

1.2 Validity

This manual is valid for the Sunny Central 500HE-US and Sunny Central 500HE-CA. In this manual

the Sunny Central 500HE-US and Sunny Central 500HE-CA are referred to as "Sunny Central".

In this document, the manufacturer of the SMA inverters described herein, being SMA America, LLC

or SMA Solar Technology Canada Inc. as indicated on the type label of the inverter, is referred to as

SMA.

1.3 Additional Information

You can find further information on special subjects in the download area of www.sma-america.com

or www.sma-solar.com.

Among other things, the download area contains the following items:

• Installation guide "Sunny Central String-Monitor Controller"

• Installation guide "Sunny Central 485HUB"

• Installation guide "Sunny Sensor 485HUB"

1.4 Structure of this Documentation

The Sunny Central's installation comprises several steps. Here we will describe the contents you will

find in the sections of the installation instructions.

The instructions are divided into the following sections:

Section 2: Safety

In this section you will find general safety directions which you must observe throughout the entire

installation process. Pay special attention to this section, so as to avoid personal and material

damages.

Installation Manual SC500HEUS-IA-US_en-14 11

Page 12

1 Notes on this Manual SMA America, LLC

Section 3: The Sunny Central

In this section you will see how one can identify the Sunny Central. A short description of the Sunny

Central's design and functions is given here.

Section 4: Unpacking

This section describes what to look out for upon receiving your Sunny Central, and who to turn to if

your Sunny Central is damaged.

Section 5: Transport and Installation

This section shows you how to find the best installation site for your Sunny Central. It provides

step-by-step instructions on how to transport and install the Sunny Central and connect the cabinets

with each other electrically. Observe all safety precautions in this section to avoid material and

personal damages.

Section 6: Attaching the Conduits

In this section you will learn where to insert the cables in the Sunny Central and where to punch the

holes for the conduits.

Section 7: Connecting Optional Communication Devices

The Sunny Central can be equipped with different communication devices. This section explains how

the communication devices in the Sunny Central are connected.

Section 8: Electrical Connection

This section describes how the Sunny Central is connected to the grid and to the PV modules, and

what precautions must be observed in order to avoid material and personal damages. It provides

information on the necessary cable sizes and the magnitude of the torque for the cable connection.

Section 9: Commissioning

This section explains, step-by-step, how to put the Sunny Central into operation, and how you can

determine that the commissioning was successful.

Section 10: Opening the Sunny Central

Th is s ect ion de scr ibe s how t o open the Sun ny Cen tra l an d what precautions must be observed in order

to avoid personal damages.

Section 11: Parameter

This section provides an overview of the parameters of the Sunny Central and their respective

threshold values.

12 SC500HEUS-IA-US_en-14 Installation Manual

Page 13

SMA America, LLC 1 Notes on this Manual

Section 12: Technical Data

In this section you will find the technical data for the Sunny Central's operation, the norms to which it

conforms and the required cables and torques.

Installation Manual SC500HEUS-IA-US_en-14 13

Page 14

2 Safety SMA America, LLC

A

B

C

D

G

E F

2 Safety

In this section you will find general safety directions which you must observe throughout the entire

installation process. Pay special attention to this section, so as to avoid personal and material

damages.

2.1 Appropriate Usage

The Sunny Central is a MPPT (maximum power point tracker) PV inverter that converts the DC energy

from PV modules to AC energy. This energy is then fed into the public grid.

The SunnyCentral500HE‑US is designed for indoor and outdoor installation.

The Sunny Central HE-US is a high efficiency PV inverter and it does not include a transformer inside

its cabinets. You can connect up to 2 Sunny Centrals to one transformer.

External output transformer requirements

• The Sunny Central has been evaluated by UL for compliance with Underwriters Laboratory (UL)

1741 / IEEE 1547 requirements at the inverter terminals and with UL Recognized external

transformer Model 3UI380/310, Manufactured by J. Schneider. This transformer is rated for a

voltage of 200 V L-L on the inverter side and an impedance of less than 6%.

• If the Sunny Central is used with a different transformer other than the transformer used during

testing, the external transformer used must be a UL Listed type, with separate primary and

secondary windings rated 500 kVA minimum, and limited to a maximum impedance variance

of less than or equal to 6%. This external transformer is required to be located between the

output of the Sunny Central and the utility power connection.

The Authority Having Jurisdiction (AHJ) must consider the possible consequences of using a different

transformer other than the one used to evaluate the Sunny Central by UL. In addition, the AHJ must

consider the effects of using different UL Listed transformers with respect to electrical ratings,

impedance, and the resultant affect on the performance of the inverter, with respect to the ratings and

impedance specified in the installation manual.

Refer to the technical description "Transformer Requirements" for a detailed Transfomer information.

The description is available at www.sma-america.com and www.sma-solar.com

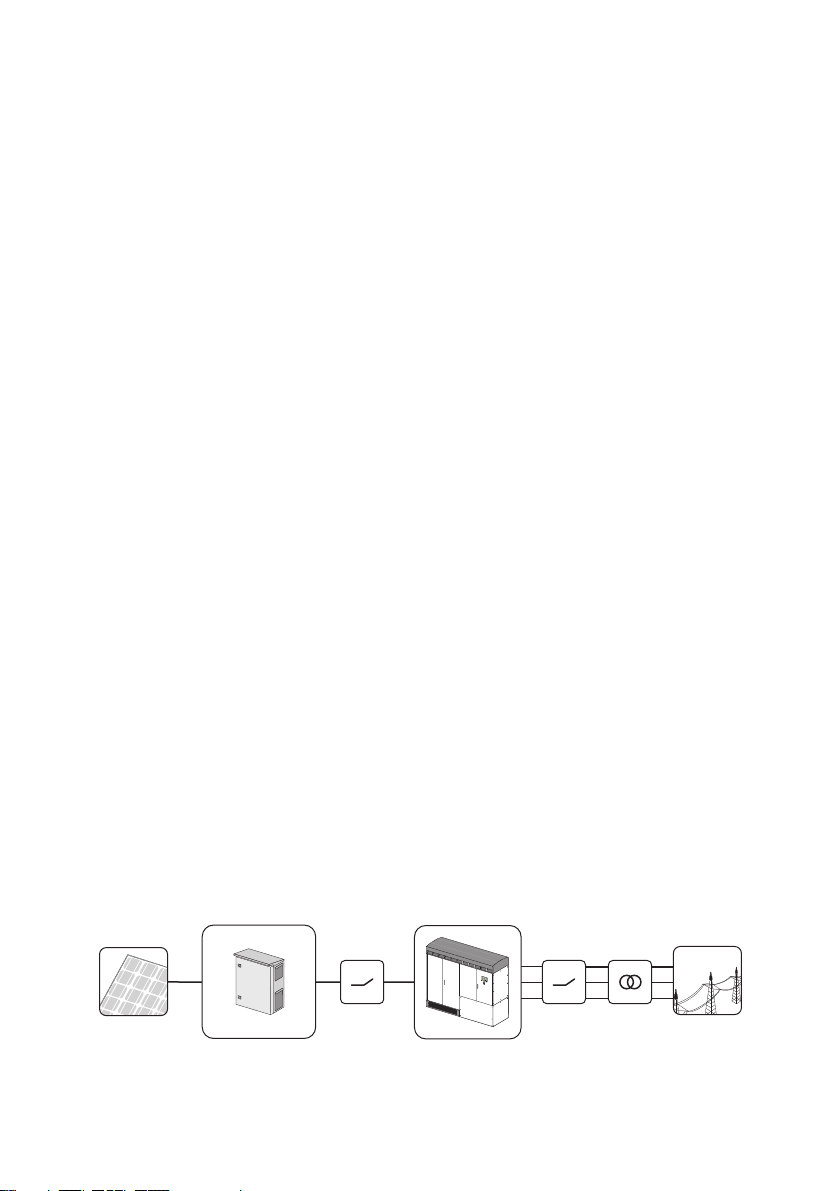

Principle of a PV Power System with a Sunny Central

14 SC500HEUS-IA-US_en-14 Installation Manual

Page 15

SMA America, LLC 2 Safety

Position Description

APV modules

B DC distribution with DC fuses (e.g., Sunny Central String-Monitor)

C e. g. SMA Disconnect Unit

D Sunny Central

E e. g. SMA Disconnect Unit

FTransformer

GPublic grid

Any other application of the Sunny Central or installation of components and modifications which are

not explicitly allowed endanger the safety and void the warranty as well as the operation permit.

PV and AC disconnect

As an option, the internal AC circuit breaker of the Sunny Central can be mounted externally either in

the Disconnect Unit made by SMA or in another cabinet provided by others.

Th e un it i s prov ide d wi th a UL l isted cir cui t br eak er on t he o utp ut r ate d 16 00 A fo r br anc h ci rcu it

protection. If the circuit breaker shall be located externally to secure the AC path, you have to

use the same type of circuit breaker (ABB Emax E2B-A with 42 kA rated short-circuit current,

ABB Emax E2N-A with 65 kA rated short-circuit current or ABB Emax E2H-A with 85 kA rated

short-circuit current and and 1600 A continuous current rating each) to ensure UL listing of the

whole system.

®

According to National Electrical Code

neccessary to install a PV and AC disconnect. Therefore, either the Disconnect Unit made by

SMA for PV as well as AC disconnection or a solution provided by others has to be used to

satisfy this requirement.

ANSI/NFPA 70 and Canadian Electrical Code it is

Disclaimer

• It is prohibited to use the Sunny Central for purposes other than those described here.

• It is prohibited to modify the Sunny Central or to install components that are not explicitly

recommended by SMA or sold by SMA for this purpose.

• It is prohibited to connect the Sunny Central without transformer to the grid. Operating the

Sunny Central without transformer causes a short-circuit and can destroy the Sunny Central.

Installation Manual SC500HEUS-IA-US_en-14 15

Page 16

2 Safety SMA America, LLC

%"/(&3

%"/(&3

%"/(&3

%"/(&3

2.2 Safety Instructions

High voltages are present in the live components of the low voltage grid.

Death resulting from burning and electric shock.

• Do not touch the live components of the Sunny Central or low-voltage grid.

• Pay close attention to all safety precaution measures regarding the low voltage grid.

During operation, high voltages are present in the Sunny Central.

Death resulting from electric shock.

• Do not operate the Sunny Central with doors open.

During operation, high voltages are present in the Sunny Central.

Death resulting from electric shock.

• Before commencing work on the Sunny Central:

• Disconnect completely

• Ensure that the device cannot be reconnected

•Ensure that no voltage is present.

• Ground and short-circuit

• Cover any nearby live parts

Normally grounded conductors may be ungrounded and energized when a ground-fault is

indicated.

Risk of electric shock.

•Test before touching.

• Work on the Sunny Central must be carried out by qualified personnel.

16 SC500HEUS-IA-US_en-14 Installation Manual

Page 17

SMA America, LLC 2 Safety

8"3/*/(

8"3/*/(

$"65*0/

/05*$&

Failure to follow the manual, the operating instructions and the safety precautions may lead to

severe injury from electric shock.

• All work on the Sunny Central shall only be done as described in this manual.

• Pay attention to all safety instructions.

• Follow all operating instructions.

• If problems occur when performing the work described here, contact SMA America.

Operating a damaged Sunny Central may cause severe injury from electric shock.

• The Sunny Central shall only be used when it is technically faultless and safe to operate.

• Operate the Sunny Central only if there are no visible damages.

• Regularly check the Sunny Central for visible damage.

• Ensure that all safety features are accessible at all times and that their correct operation is

tested regularly.

Cuts and scratches due to sharp edges inside the Sunny Central.

• When working on the Sunny Central wear protective gloves.

The components in the Sunny Central can be damaged by electrostatic discharge.

• When working on the Sunny Central and when handling the components observe all ESD

safety regulations.

• Discharge electrostatic charge by touching the grounded Sunny Central enclosure.

• Only then is it safe to touch any electronic components.

Storage of handbooks

Keep this documentation in the immediate vicinity of the Sunny Central. It must be accessible to

service and maintenance personnel at any time.

Do not store the documentation or any other papers in the Sunny Central.

Installation Manual SC500HEUS-IA-US_en-14 17

Page 18

3 The Sunny Central SMA America, LLC

3 The Sunny Central

In this section you will see how to identify the Sunny Central. A short descrip tion of the Sunny Cen tral's

design and functions are given here.

3.1 System Overview

The Sunny Central is an inverter for indoor and outdoor. The enclosure is made of stainless steel and

al umi num whi ch con for ms t o th e NE MA 3 R pr ote cti on rat ing . NE MA 3R means that the Sunny Central

is protected against dust and water when it is closed. The Sunny Central is protected from salt fog

pariculars, it can be operated in chemically aggressive environments.

Operating Principles

The PV modules convert a portion of sunlight into electrical energy (direct current). The Sunny Central

then converts the direct current into alternating current and feeds it into the public grid. This current

can be used directly, or it can be sold to your energy provider.

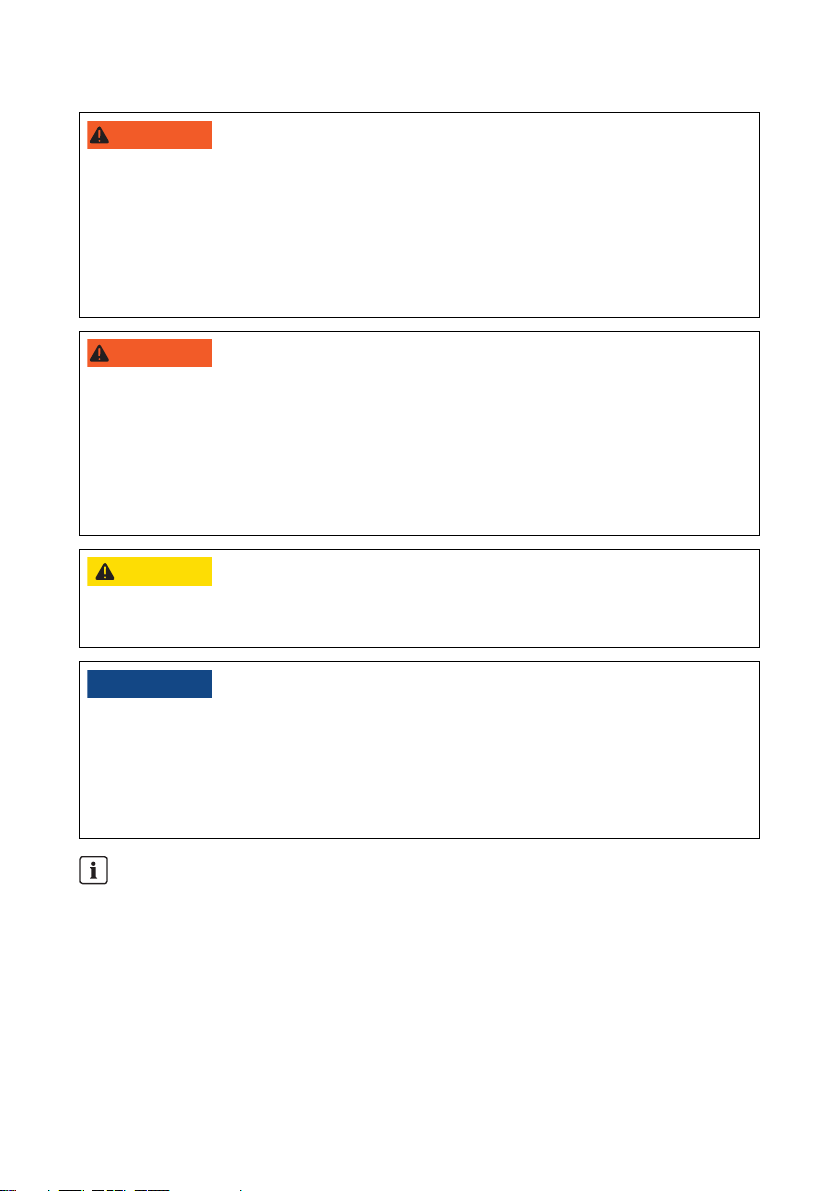

3.2 The Design of the Sunny Central

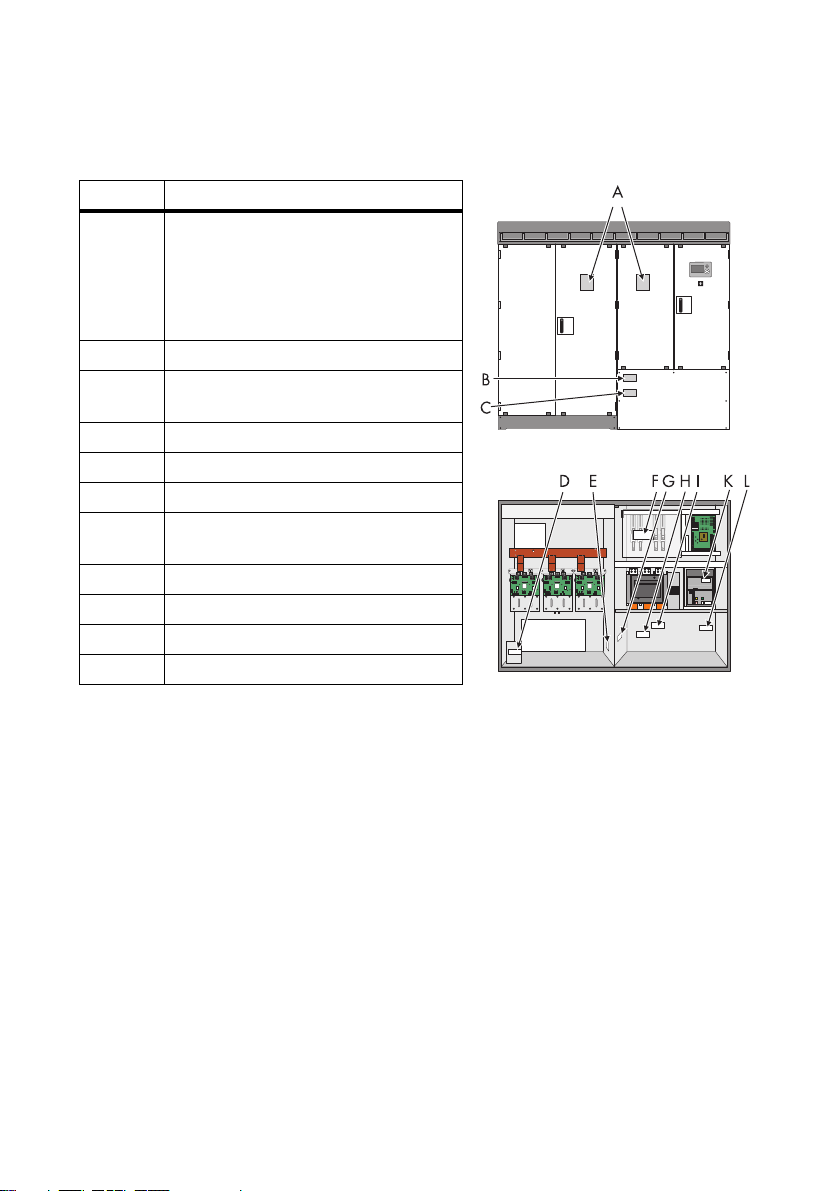

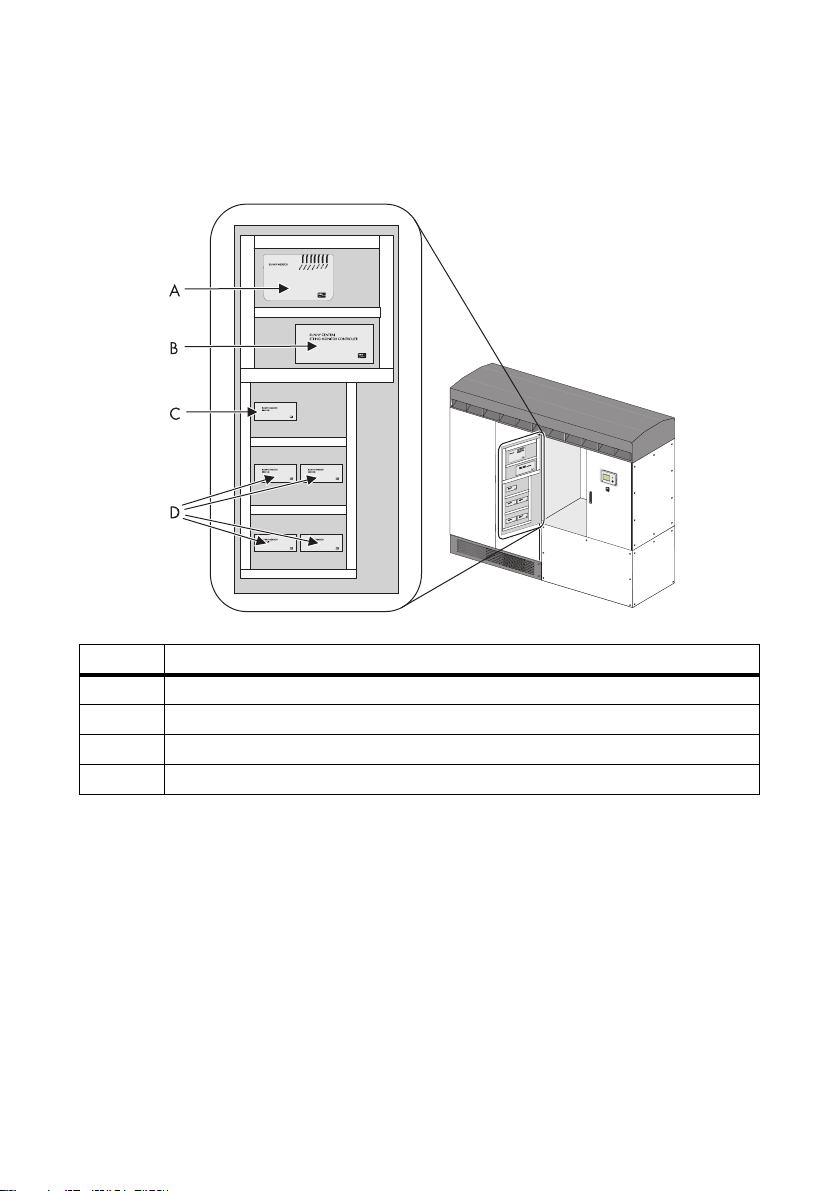

Position Cabinet Description

A Power Cabinet The power cabinet contains the power unit for converting direct

current to alternating current.

BControl and

Interface

Cabinet

18 SC500HEUS-IA-US_en-14 Installation Manual

All AC, DC and communication cables are connected in the control

and interface cabinet. The control and interface cabinet contains:

•system control

• Sunny Display

• stop/start switch

optional communication devices

Page 19

SMA America, LLC 3 The Sunny Central

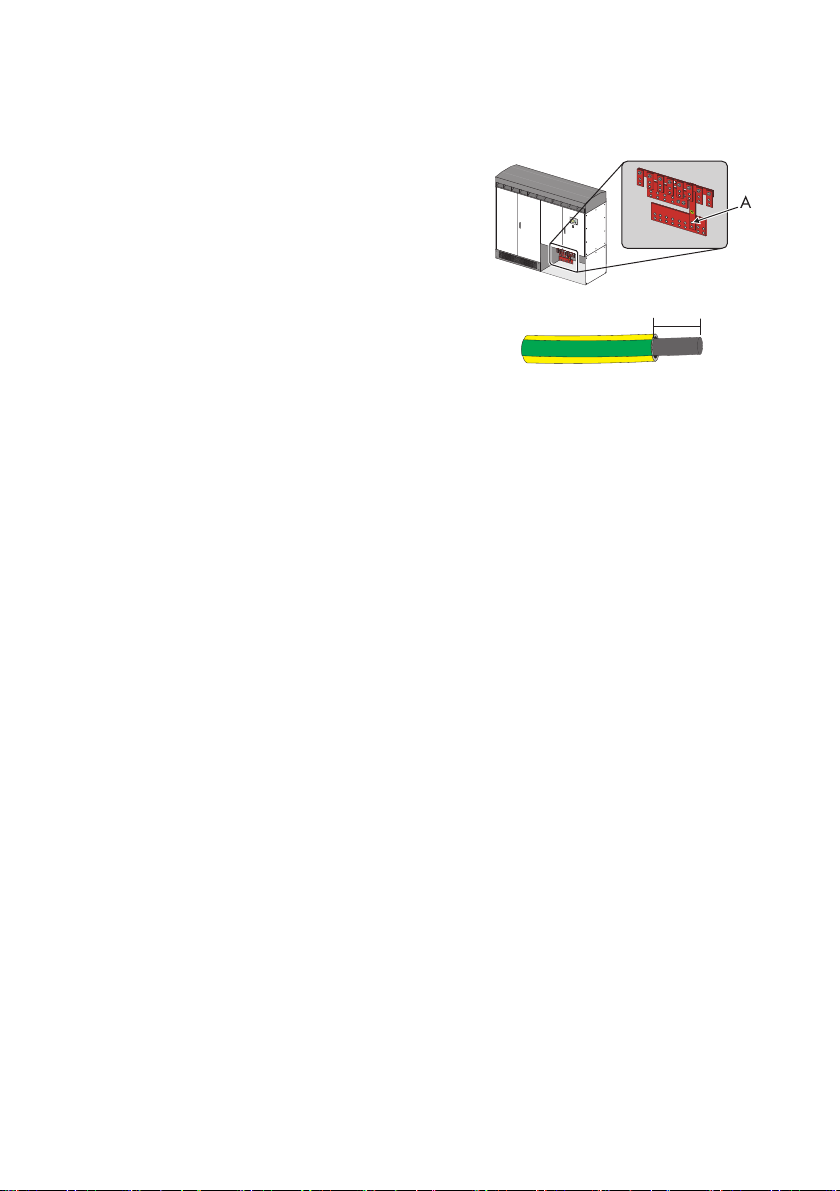

3.3 Location of the Safety Notices

The figure to the right shows the location of the safety notices on the Sunny Central.

Position Description

A Power Cabinet door and Control and

Interface Cabinet door

Warning regarding high voltages in the

Sunny Central.

B Warning regarding hazardous voltage.

C Notice regarding operation of the

Sunny Central without transformer.

D Warning regarding hazardous voltages.

E Warning regarding hot surface.

F Warning regarding hot surface.

G Information regarding negative

grounding.

H Information regarding positive grounding.

I Information regarding equipment ground

K Notice not to change settings

L Information regarding AC voltage.

Installation Manual SC500HEUS-IA-US_en-14 19

Page 20

3 The Sunny Central SMA America, LLC

SMA America

www.sma-america.com

SUNNY CENTRAL

Model:

xxxxxxxxxxxxxxxxxxxSC500HE-US

Serial No.: xxxxxxxxx

Fabrication Date:

Max. Continuous output Power*

Operating voltage range (Vac 3-Phase)*

Min

xxx

Operating frequency range (Hz)*

Max. continuous output current*

Range of input operating voltage

MPPT Range of operating DC voltage*

xxxkWac

Nominal Max

xxx xxx

Min

xx.x

Nominal Max

xx.x xx.x

xxx.xAac

Output power factor

x.xx

xxx - xxx Vdc

The unit contains DC-Ground and Fault Detector

and Interruptor

Max. operating current*

xxx - xxx Vdc

xxx Adc

ENCLOSURE

Type 3R (IP54)

*For more details and for tightening torque,

allowable wire size and type see the Operator’s

Manual

xx/xxxx

A

Fabrication Version: xxx

Utility interactive inverter

LISTED UL 1741 36AN

Range of input operating voltage

xxx - xxx Vdc

Range of input operating voltage

xxx - xxx Vdc

Engineered in Germany - Assembled in Denver/Colorado

US80

B

C

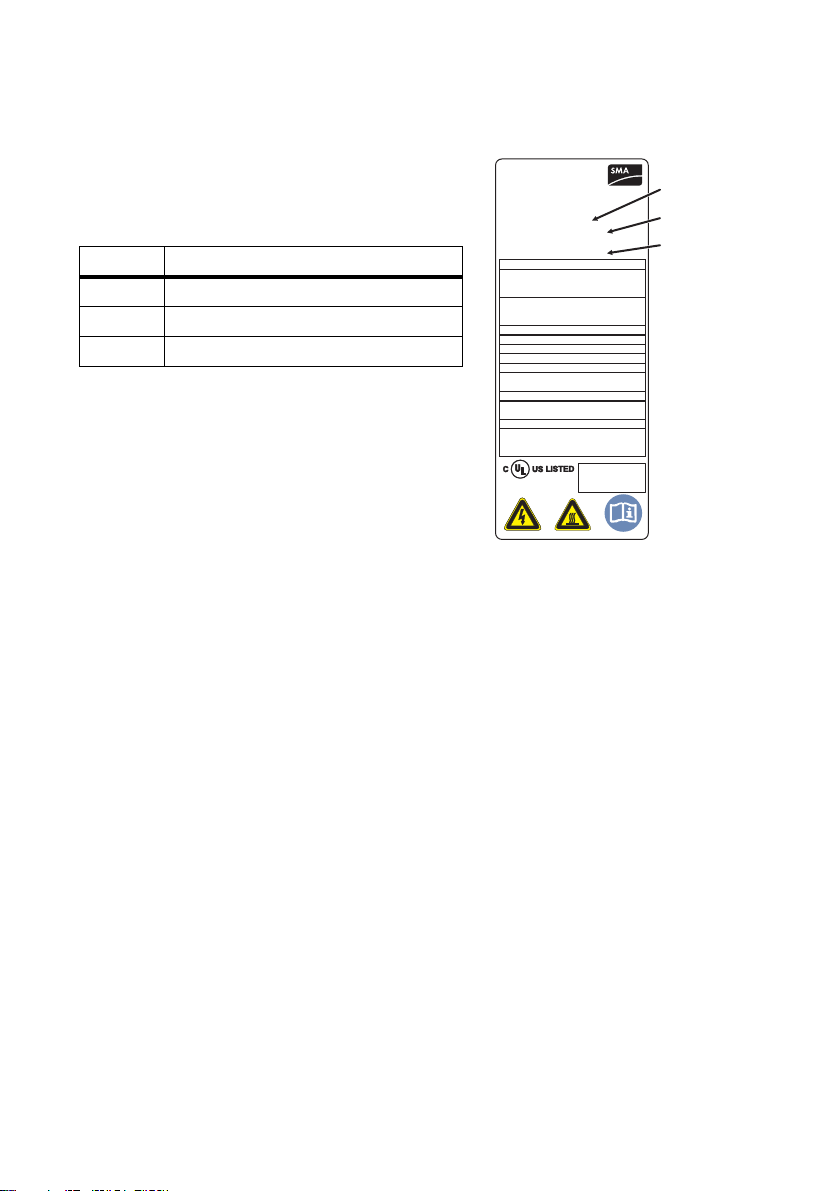

3.4 Identifying the Sunny Central

You can identify the Sunny Central using the type plate

(see figure at right). The type plate is on the inside of the

Control and Interface Cabinet on the upper left side and

in the Power Cabinet on the right side.

Position Description

A Type description of the Sunny Central

B Serial number of the Sunny Central

C Date of manufacture

3.5 Firmware

The Sunny Central's firmware, and that of the display, are shown on the display of the Sunny Central.

The Sunny Central’s user manual describes how to obtain the firmware version.

20 SC500HEUS-IA-US_en-14 Installation Manual

Page 21

SMA America, LLC 4 Unpacking

4 Unpacking

This section describes what to look out for upon receiving your Sunny Central, and who to turn to if

your Sunny Central is damaged.

Refer to the technical description "Unpacking the Sunny Central 500HE-US" for a detailed

step-by-step instruction. The description is fixed at the shipping container.

4.1 Unpacking and Inspection

All SMA Sunny Centrals are thoroughly checked before they are packaged and shipped. Although

they are shipped in sturdy packaging, damage can still occur during shipping and delivery. It is

important to carefully inspect the shipping container and contents prior to installation. If you detect

any external damage after unpacking, report the damage immediately to your SMA dealer and

shipping company that delivered the unit. If it becomes necessary to return the Sunny Central, use the

original packing material.

If you need assistance with a damaged Sunny Central, contact your SMA dealer or SMA America.

Contact information for SMA America is provided in chapter 12.

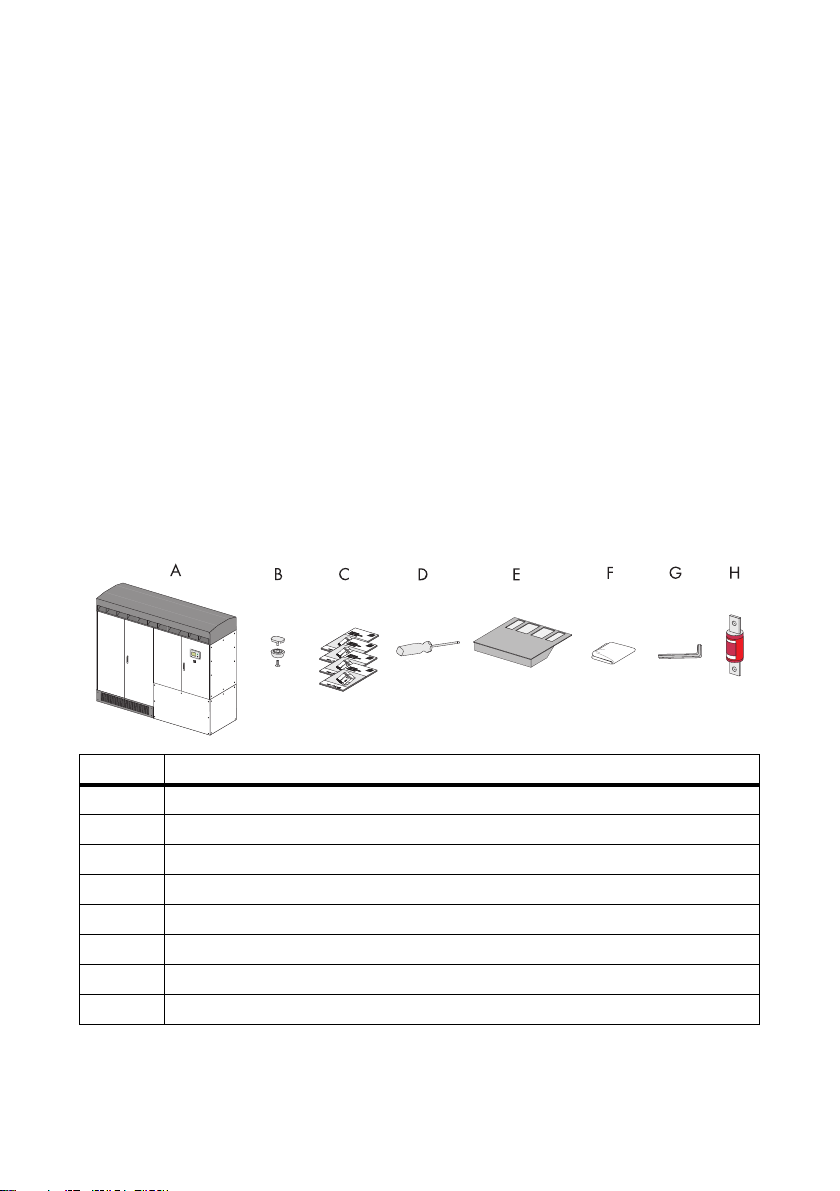

4.2 Scope of Delivery

Position Description

ASunny Central

B Condensate drain

C Installation Guide, User Manual, Circuit Diagram, Test Report

DTorx screwdriver

E Ventilation plate with air filters for installation in the base of the Sunny Central

F Non-woven abrasive

G Allen key

H Separate DC fuses*

*option

Installation Manual SC500HEUS-IA-US_en-14 21

Page 22

4 Unpacking SMA America, LLC

/05*$&

/05*$&

4.3 Storage

Improper storage can cause moisture to seep into the Sunny Central.

Damage to the Sunny Central.

• The Sunny Central must be closed during storage.

• If stored for 6 months or longer, make sure the storage area is dry.

• The storage temperature has to be between − 13°Fto140°F( − 25°Cto+60°C).

Uneven underground can damage the frame construction.

• The underground must be suitable for the weight of the inverter of 1,800 kg.

• The underground may only deviate from a level of 0.25%.

22 SC500HEUS-IA-US_en-14 Installation Manual

Page 23

SMA America, LLC 5 Transport and Installation

5 Transport and Installation

This section shows you how to find the best installation site for your Sunny Central. It provides

instructions on how to transport and install a single Sunny Central as well as two Sunny Centrals to

one transformer. Observe all safety precautions in this section to avoid material and personal

damages.

5.1 Choosing the Installation Site

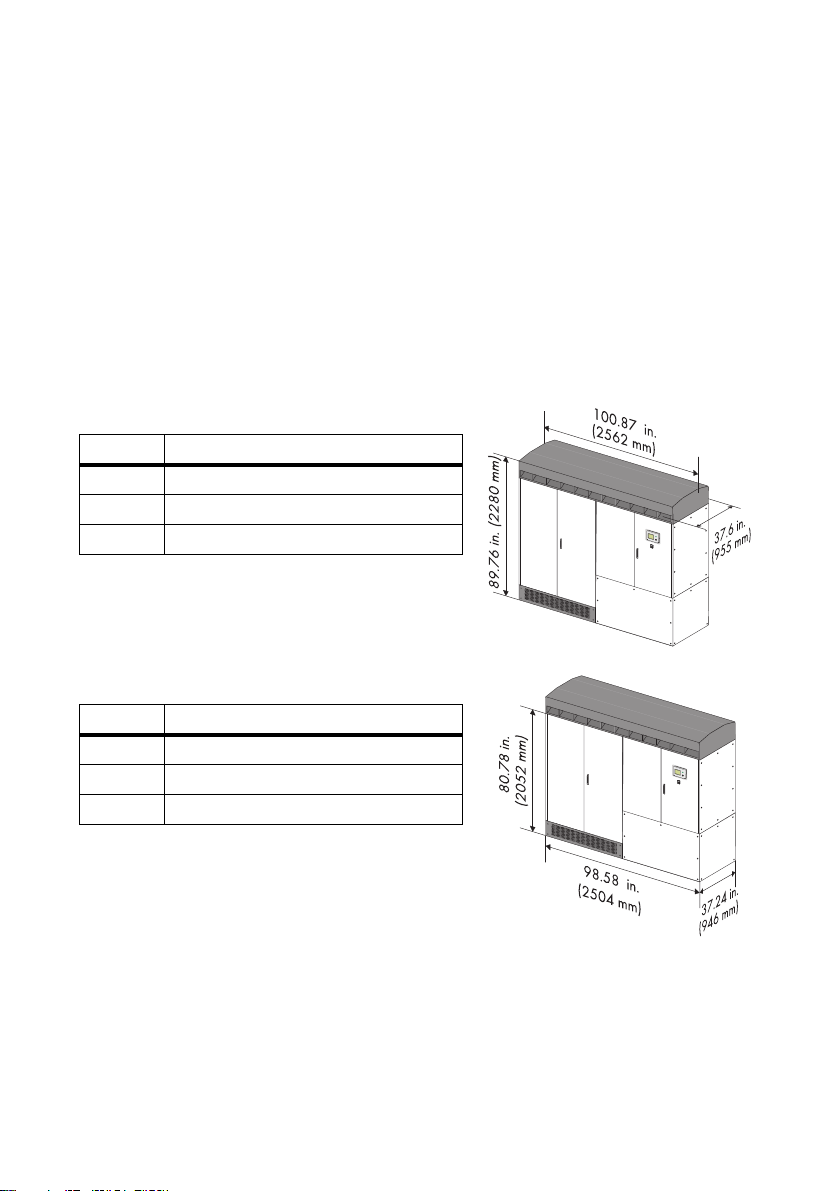

5.1.1 Dimensions and weight

The Sunny Central has a total weight of approx. 3,970 lbs (1,800 kg).

Dimensions with roof

Position Dimension

Height 89.76 in. (2,280 mm)

Width 100.87 in. (2,562 mm)

Depth 37.60 in. (955 mm)

Dimensions without roof

Position Dimension

Height 80.79 in. (2,052 mm)

Width 98.58 in. (2,504 mm)

Depth 37.24 in. (946 mm)

Installation Manual SC500HEUS-IA-US_en-14 23

Page 24

5 Transport and Installation SMA America, LLC

12 in.(300 mm)

6 in.

47 in.

6 in.(150 mm) A

16 in. (406 mm)

(150 mm)

(1200 mm)

47 in.

(1200 mm) B

5.1.2 Ambient Conditions

• The installation location must be accessible at all times.

• The ambient temperature must be between ‒13°F and +122°F (between –25°C and+50°C).

• Direct solar irradiation reduces the output power of the Sunny Central.

• Refer to the installation requirements for further information on indoor placement.

• For more information see section 11 and the "Installation requirements for Sunny Central

500HE-US" which can be downloaded at www.sma-america.com and www.SMA-Solar.com.

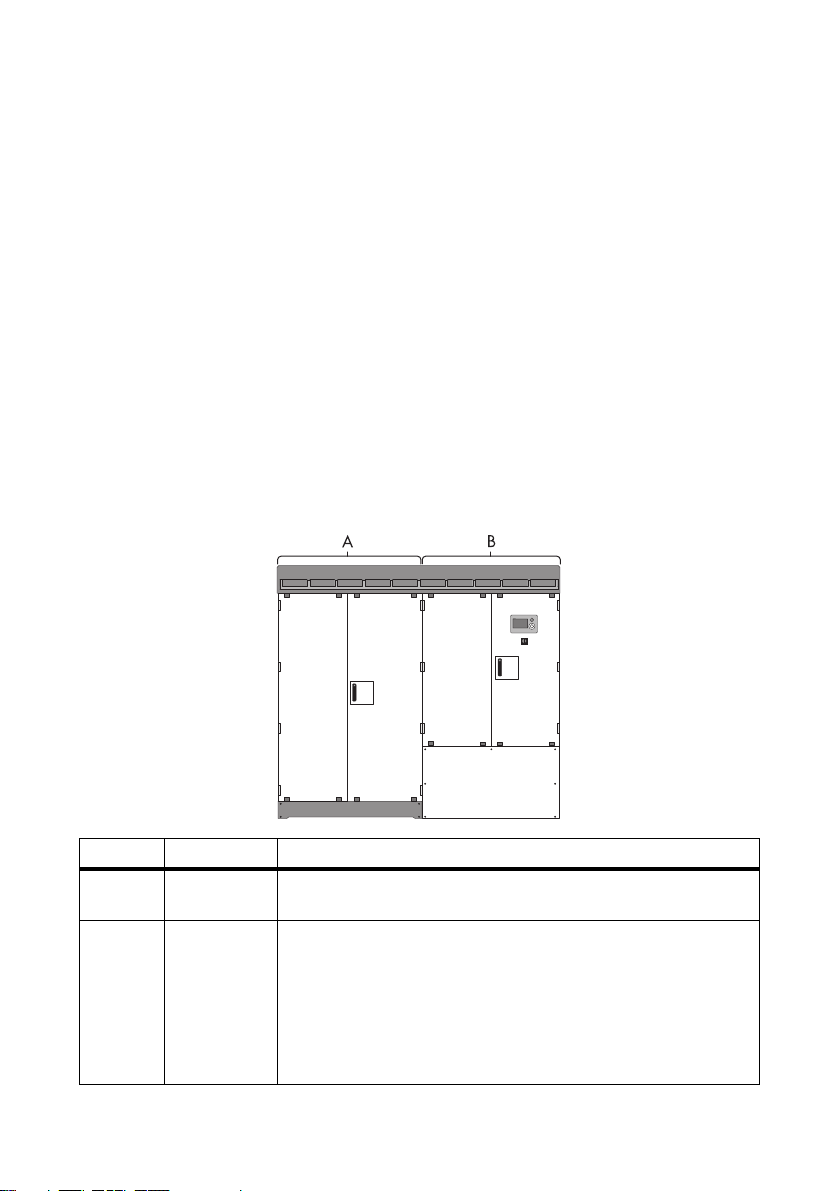

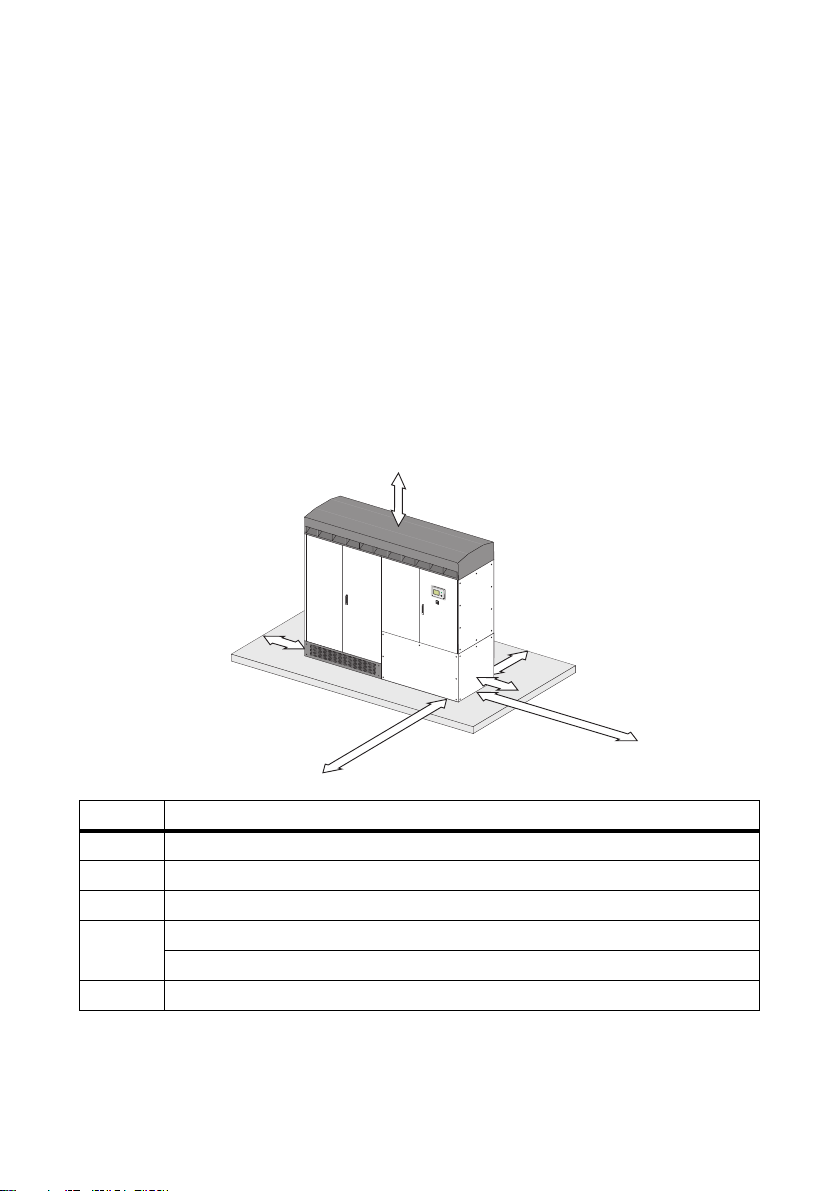

5.1.3 Minimum Clearance

Minimum Clearance 1 Sunny Central

Observe the specified minimum clearances for the cables, ventilation and for opening the doors. For

installing the Sunny Central in closed rooms an air supply of 1,766 CFM (3,000 m³/h) is needed.

Position Minimum Clearance

Front 47 in. (1,200 mm)

Left side 6 in. (150 mm)

Rear 12 in. (300 mm)

Right side A: Cables inserted from below 6 in. (150 mm)

B: Cables inserted from the side 47 in. (1,200 mm)

Top 16 in. (406 mm)

24 SC500HEUS-IA-US_en-14 Installation Manual

Page 25

SMA America, LLC 5 Transport and Installation

8"3/*/(

12 in.

(300 mm)

6 in.

48 in.

47 in.

A

B

D

D

(150 mm)

(1220 mm)

(1200 mm)

47 in.

(1200 mm)

12 in.

(300 mm)

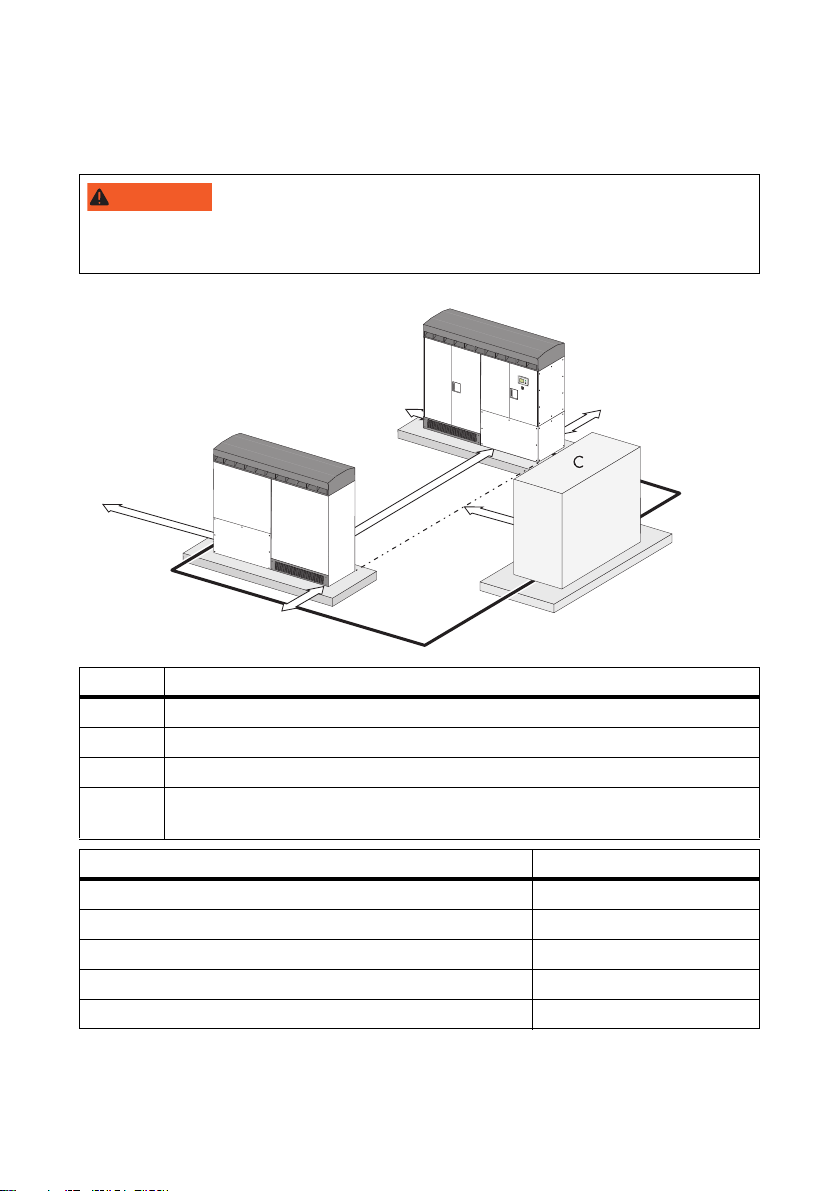

Minimum Clearance 2 Sunny Centrals with Transformer

Observe the specified minimum clearances for the cables, for ventilation and for opening the doors.

Opening the doors of two Sunny Central devices blocks the escape route.

• Only open the doors of one Sunny Central at the same time.

Position Description

A Sunny Central 1

B Sunny Central 2

C Medium voltage transformer

D Cable route between Sunny Central and transformer. The cables between the

Sunny Central and the transformer may not be longer then 49 ft. (15 m).

Position Dimensions

Sunny Central rear 12 in. (300 mm)

Distance between Sunny Central A an B 48 in. (1,800 mm)

Right side of Sunny Central A 47 in. (1,200 mm)

Left side of Sunny Central B 6 in. (150 mm)

Distance between transformer and Sunny Centrals 47 in. (1,200 mm)

Installation Manual SC500HEUS-IA-US_en-14 25

Page 26

5 Transport and Installation SMA America, LLC

min. 110 in.

min. 45. in.

(1150 mm)

(2800 mm)

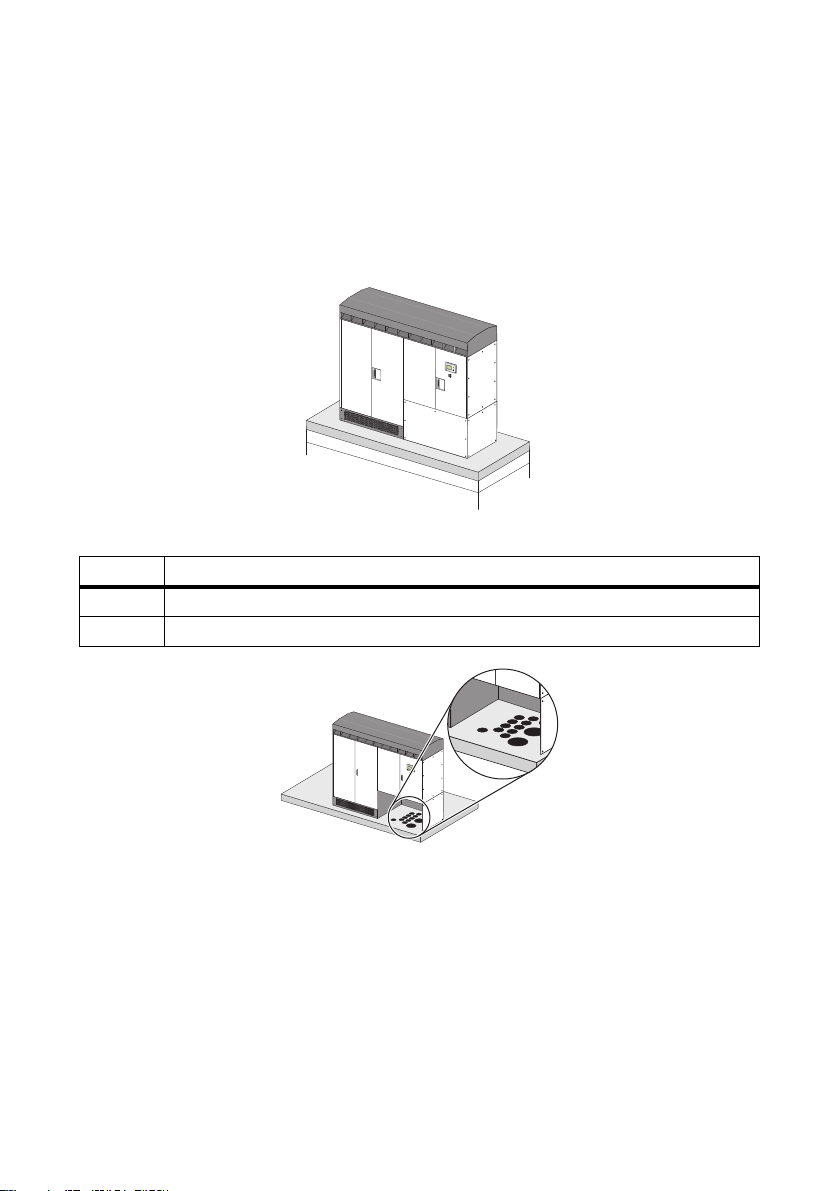

5.1.4 Characteristics of the Base

The foundation must be made of concrete or of a metal frame (skid).

• The mounting surface must be level and strong enough to support the weight of the inverter.

The evenness of the foundation must be better than 0.25%.

• The width and depth of the base must be at least the same size as the Sunny Central.

The recommended minimum sizing is shown in picture below.

Position Description

Width 110 in. (2,800 mm)

Depth 45 in. (1150 mm)

• To insert the cables from below, the cable conduits must be laid in the foundation

(see section 6.2).

26 SC500HEUS-IA-US_en-14 Installation Manual

Page 27

SMA America, LLC 5 Transport and Installation

5.2 Preparation of the Base

The inverter must be secured to the foundation per local building codes. At the bottom of the

Sunny Central there are 6 mounting holes for anchoring it to its base.

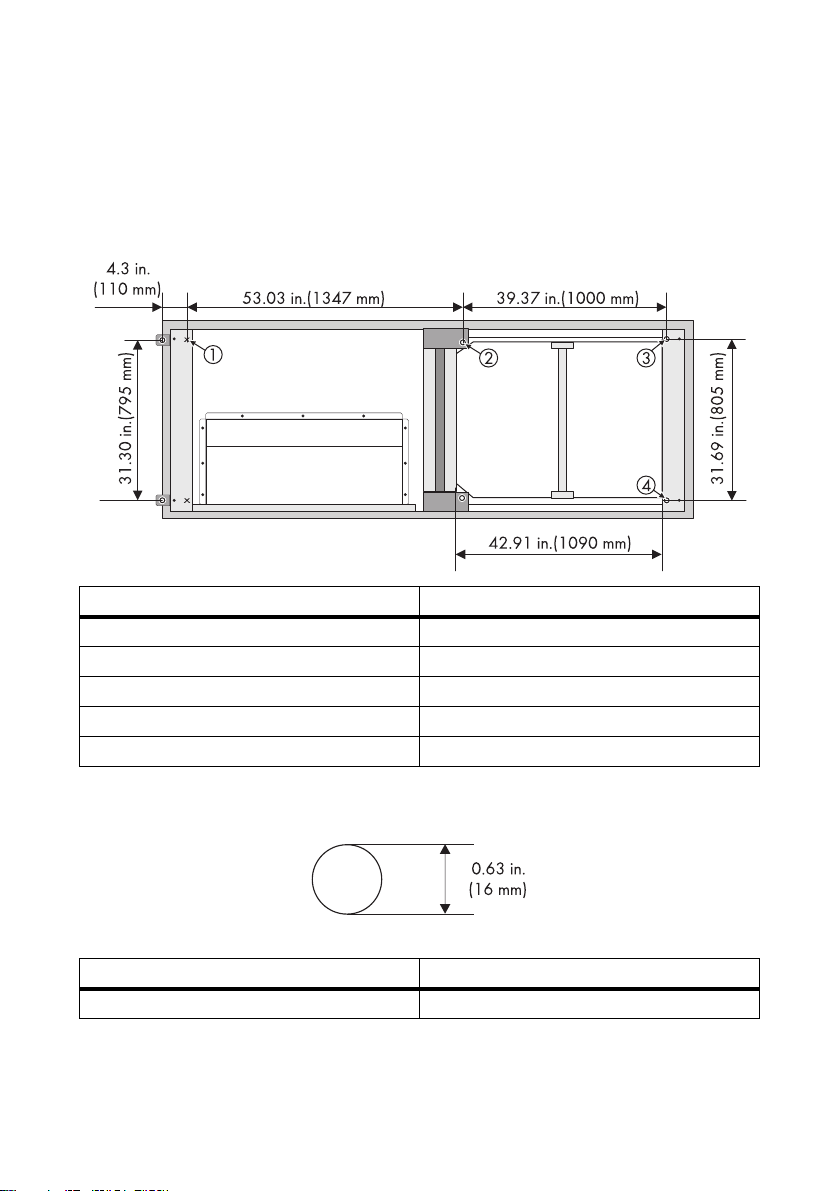

5.2.1 Position of the Mounting Holes

Position Dimension

Distance between hole 3 and 4 31.69 in. (805 mm)

Distance between hole 1 and 2 53.03 in. (1,347 mm)

Distance between hole 2 and 3 39.37 in. (1,000 mm)

Cable entry width 42.91 in. (1,090 mm)

Cable entry depth 31.69 in. (805 mm)

5.2.2 Size of the Mounting Holes

Position Dimension

Diameter 0.63 in. (16 mm)

Installation Manual SC500HEUS-IA-US_en-14 27

Page 28

5 Transport and Installation SMA America, LLC

%"/(&3

8"3/*/(

5.2.3 Drilling Holes into the Base

Drilling into live wires.

Death resulting from electric shock.

• Check the installation location for electric cables laid in the base.

1. Measure the distances for the holes.

2. Mark the positions of the holes.

3. Drill the holes into the base on marked positions.

4. Put dowels into the drill holes.

5.3 Transporting the Sunny Central

Remove the kick plates before transporting the Sunny Central (see section 5.5.1).

Sunny Central may tip over if improperly transported.

Bruises and fractures.

• Pay attention to the center of gravity of the Sunny Central (see section 5.3.1).

• Transport the Sunny Central only as described in this manual.

• Any equipment used for the transport of the Sunny Central must be suitable for the weight of

the Sunny Central.

• Do not tilt the Sunny Central during transport.

5.3.1 Center of Gravity of the Sunny Central

The center of gravity of the Sunny Central is marked on

the packaging with the symbol on the right.

The center of gravity is not in the middle of the

Sunny Central.

Position of Center of Gravity measured from left front

corner of inverter:

horizontal: 47.65 in

vertical: 23.62 in

depth: 18.50 in

28 SC500HEUS-IA-US_en-14 Installation Manual

Page 29

SMA America, LLC 5 Transport and Installation

5.3.2 Equipment for Transport

Any equipment used for the transport of the Sunny Central must be suitable for the weight of the

Sunny Central. The following equipment can be used for the transport of the Sunny Central:

• Crane with an according fork for the transport of the Sunny Central.

• Forklift or pallet truck.

• Crane and hoisting steele-wire rope hoisting hooks and steel loops.

Example of Transporting the Sunny Central Cabinet

Installation Manual SC500HEUS-IA-US_en-14 29

Page 30

5 Transport and Installation SMA America, LLC

A

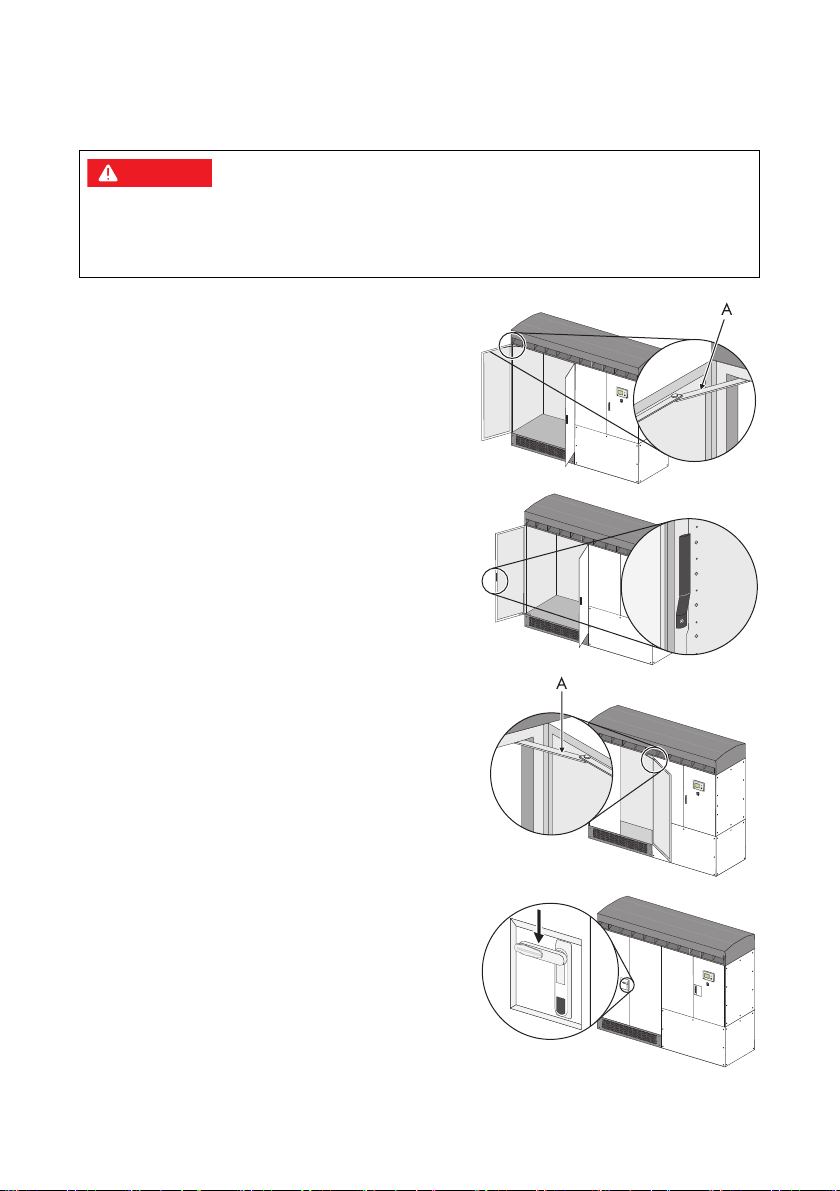

5.4 Transporting the Sunny Central with a Crane

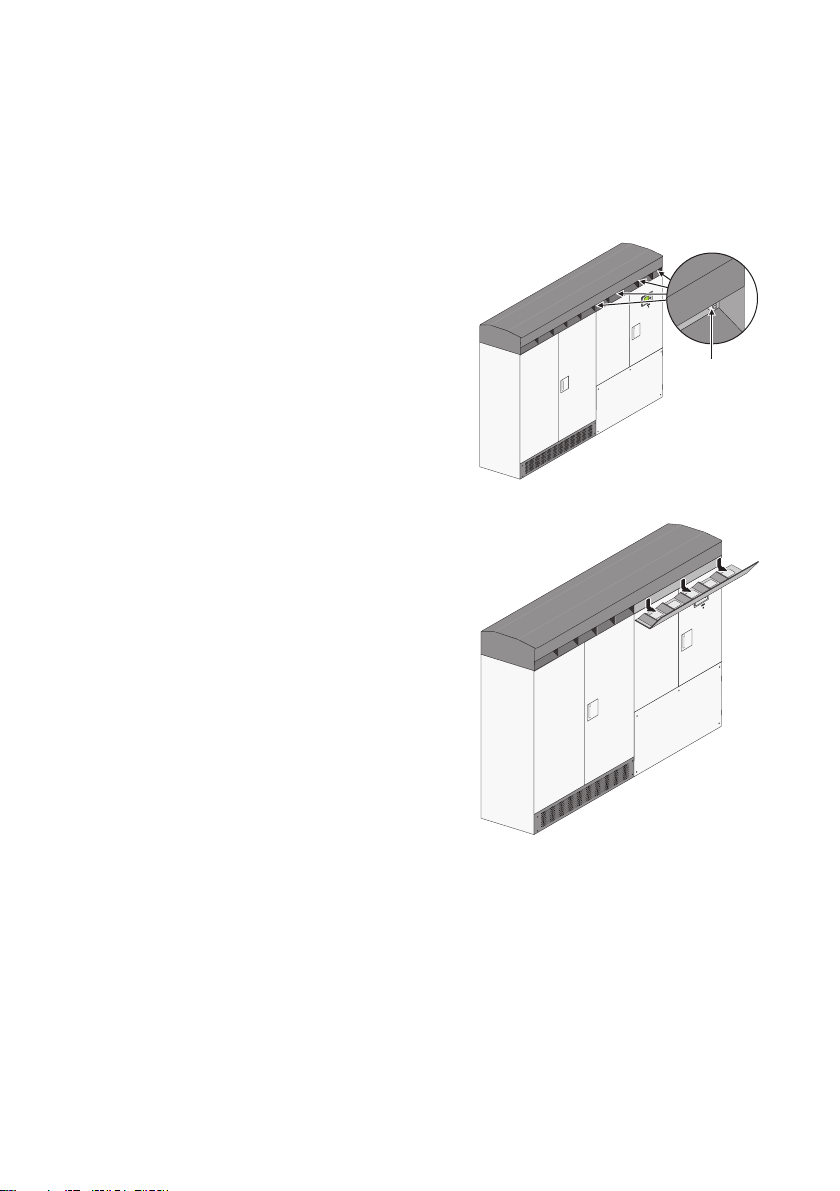

5.4.1 Uninstalling the Roof of the Sunny Central

To transport the Sunny Central with a crane you must remove the roof of the Sunny Central.

1. Loosen th e screws (A) of t he right air filte r and keep

them in a safe place.

2. Disassemble the right air filter by pulling its lower

side forward and up.

30 SC500HEUS-IA-US_en-14 Installation Manual

Page 31

SMA America, LLC 5 Transport and Installation

A

3. Loosen the screws of the left air filter (A) and keep

them in a safe place.

4. Dissassemble the left air filter by pulling its lower

side forward and up.

5. Move the front edge of the roof up and move the

roof slightly backwards to put it out off the guide

rail.

6. Unscrew the PE cable from the fixing point on top

of the Sunny Central.

7. Remove the roof of the Sunny Central.

Installation Manual SC500HEUS-IA-US_en-14 31

Page 32

5 Transport and Installation SMA America, LLC

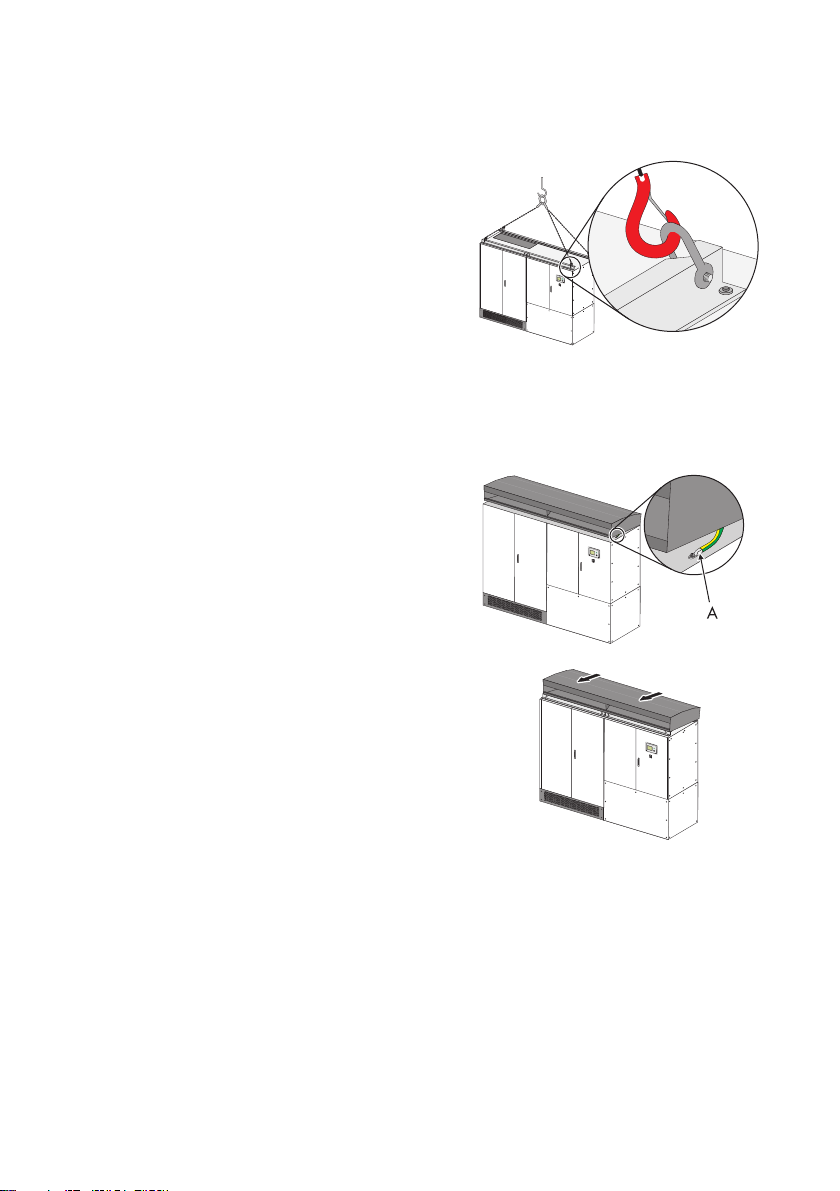

5.4.2 Moving the Sunny Central with a Crane

1. For transporting the Sunny Central with a crane use

suitable hoisting steel-wire ropes, hoisting hooks

and loops.

2. Anchor the loops at the intended openings in the

guide rails.

3. Take the heavy weight of the Sunny Central into

account.

5.4.3 Installing the Roof of the Sunny Central

After moving the Sunny Central by crane you must install the roof of the Sunny Central.

1. Apply the roof to the top of the Sunny Central. Keep the front edge of the roof up.

Fasten the PE cable to the fixing point on top of the

Sunny Central.

2. Move the roof forward to apply it to the guid rail.

Move the front edge of the roof down.

32 SC500HEUS-IA-US_en-14 Installation Manual

Page 33

SMA America, LLC 5 Transport and Installation

A

3. Assemble the left air filter by pushing its upper side

forward and up.

4. Tighten the screws (A) of the left air filter.

5. As sem ble th e righ t air fil ter by pushi ng its upper si de

forward and up.

Installation Manual SC500HEUS-IA-US_en-14 33

Page 34

5 Transport and Installation SMA America, LLC

A

A

B

6. Tighten the screws (A) of the right air filter.

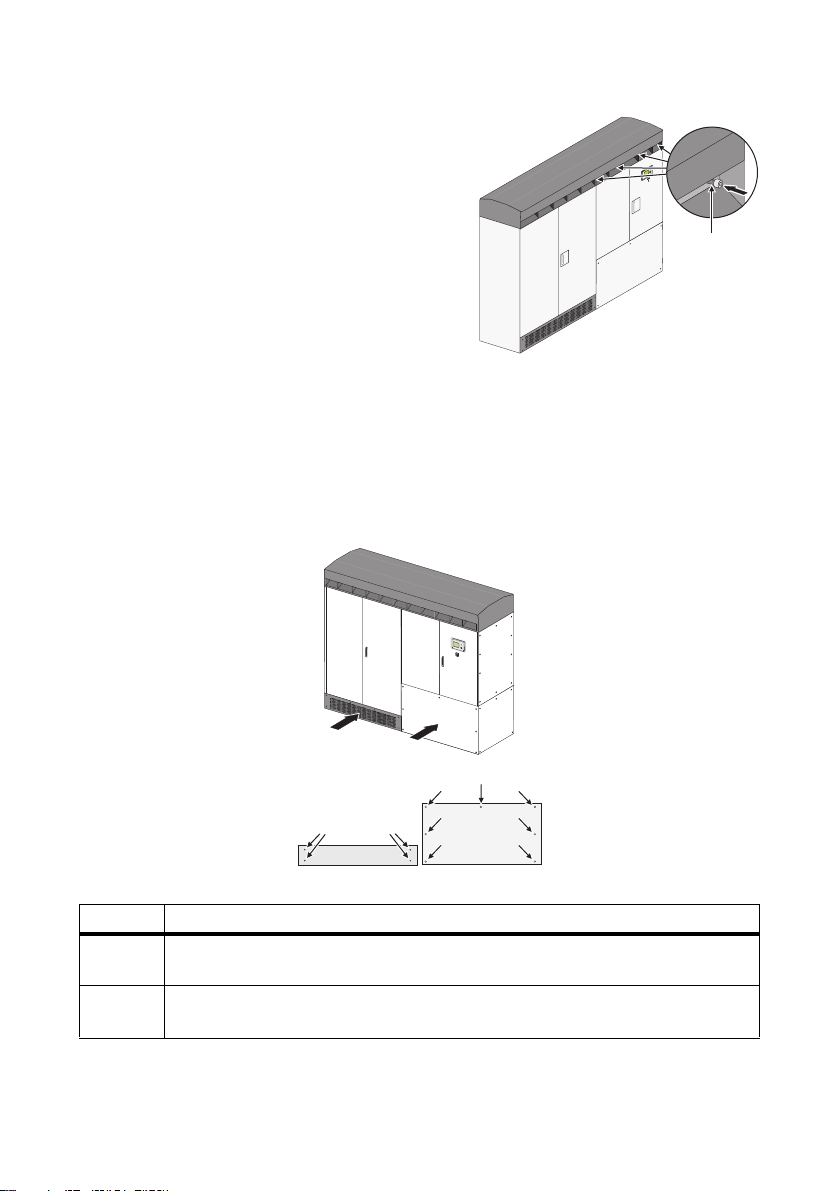

5.5 Installing the Sunny Central

5.5.1 Removing the Kick Plates from the Sunny Central

Kick plates are located on the front and back of the Sunny Central. The position of the kick plates is

shown in the figure below.The kick plates are mounted on the cabinets of the Sunny Central with

screws.

Position Description

A Power Cabinet front side and rear side. 4 screws in total. 2 screws on the right and

2 screws on the left.

B Control Cabinet front side and rear side. 7 screws in total. 3 screws on the right,

1 screw in the middle, 3 screws on the left.

1. Remove the screws of the kick plates on the front and on the rear of the Sunny Central using a

torx screwdriver.

34 SC500HEUS-IA-US_en-14 Installation Manual

Page 35

SMA America, LLC 5 Transport and Installation

2. Remove the kick plates of the Power Cabinet by

pulling them toward you (see figure on the right).

3. Remove the kick plates of the Control Cabinet

carefully by pulling it 3 to 4 in. toward you.

Pay attention not to tear the grounding-cable.

4. Remove the grounding-cables on the backside of

the kick plates.

5. Remove the kick plates of the Control Cabinet.

6. Load the cabinet on a forklift or a crane fork from

the front (see section 5.3.2).

7. Transport the cabinet to the installation site. During transport, be sure to follow all the instructions

provided in section 5.3).

5.5.2 Attach the Sunny Central to the base

The mounting holes (A) are located on the outside of the

Sunny Central's stands.

The holes for mounting the Sunny Central to the base

have a diameter of 0.63 in. (16 mm). Use appropriate

mounting material.

Figure to the right: Mounting hole in the front left stand of

the Power Cabinet.

1. Insert screws in all 6 mounting holes of the

Sunny Central (for the position of the mounting

holes, refer to section 5.2).

2. Tighten screws.

Installation Manual SC500HEUS-IA-US_en-14 35

Page 36

5 Transport and Installation SMA America, LLC

A

A

5.5.3 Install Ventilation Plates

Slides for installing the ventilation plate are located on the

stands of the Power Cabinet.

Figure to the right: slide in the front left stand (A) of the

Power Cabinet.

1. Place the ventilation plate (A) onto the slide in the

Power Cabinet and push into the Sunny Central.

The grille in the ventilation plate must be in the

back.

If properly installed, the ventilation plate should not

protrude from the cabinet.

Tip: If the ventilation plate gets stuck when pushing it into

the Sunny Central, hold it from the bottom and press the

middle area upwards while pushing it in.

5.5.4 Attaching the Kick Plates to the Sunny Central

1. Attach the kick plates to front and back of the

Power Cabinet and tighten the screws.

2. Install the Grounding-cables to the kick plates of the

Control Cabinet, attach the kick plates and tighten

the screws with a TX screwdriver.

36 SC500HEUS-IA-US_en-14 Installation Manual

Page 37

SMA America, LLC 6 Attaching the Conduits

/05*$&

AA A

C

BBBB

BBBBB

6 Attaching the Conduits

In this section you will learn where to insert the cables in the Sunny Central and where to punch the

holes for the conduits.

The DC cables, the AC cables and the communication cables can be routed into the Sunny Central's

Control and Interface Cabinet from the right or from below. The two options are described below.

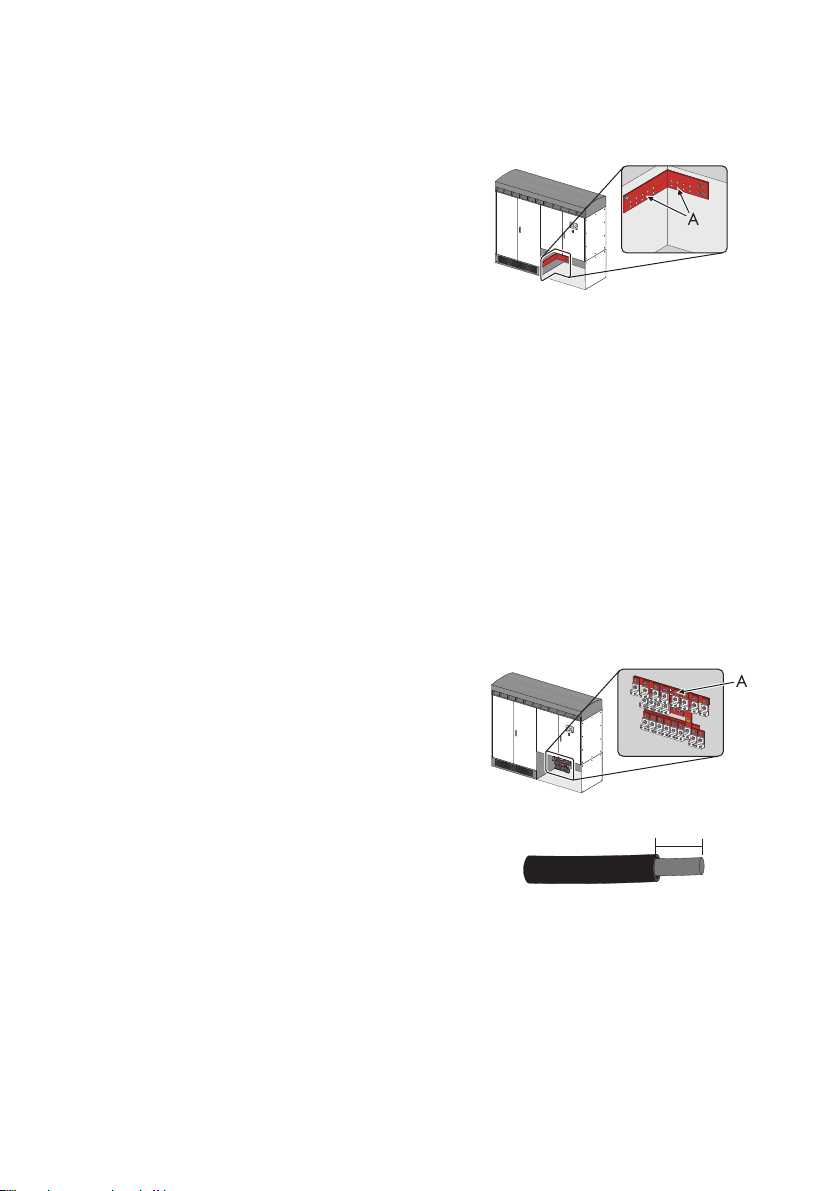

6.1 Insert cables from the right into the Sunny Central

Insert the DC cables, the AC cables and the data cables into the Sunny Central from the right. A metal

sheet is attached to the Sunny Central for this purpose.

Seeping moisture during installation of the Sunny Central.

Damage to the electronics of the Sunny Central.

• Do not open the Sunny Central when it is raining or when a high humidity is present (> 95%).

• For conduit hubs, use only UL Listed rainproof, or wet location hubs complying with UL 514B

for entry into the enclosure.

1. Remove the plate screws.

2. Put the screws and washers aside.

3. Remove the kick plate of the Control Cabinet

carefully by pulling it 3 to 4 in. toward you. Pay

attention not to tear the grounding-cable.

4. Remove the grounding-cable on the backside of the

kick plate of the Control Cabinet.

5. Remove the kick plate of the Control Cabinet.

6. Remove the braces (A).

7. Mark all the holes for the conduits.

Example for a plate prepared for the connection of

9 DC strings.

A: Conduit for AC cable

B: Conduit for DC cable

C: Conduit for communication cable

Do not lay the AC connection cables of one phase together in one cable duct. All

cables of one phase must have the same length.

Please refer to section 8.7.2 for information on arrangement of AC cabling.

Installation Manual SC500HEUS-IA-US_en-14 37

Page 38

6 Attaching the Conduits SMA America, LLC

8. Punch holes for the conduits.

9. Check the seal of the plate.

10. Attach the plate to the Sunny Central.

11. Attach the screws and washers and tighten with a torque of 31 in.-lbs.

12. Insert the conduits into the openings.

13. Attach the conduits with the appropriate hubs.

6.2 Insert cables from below into the Sunny Central

Insert the DC cables, the AC cables and the data cables

into the Sunny Central from the bottom through the

foundation.

38 SC500HEUS-IA-US_en-14 Installation Manual

Page 39

SMA America, LLC 7 Connecting Optional Communication Devices

/05*$&

/05*$&

7 Connecting Optional Communication Devices

The Sunny Central can be equipped with a Sunny WebBox and/or a Sunny SensorBox and

Sunny Central String-Monitoring communication equipment. For more details concerning the

Sunny Central String-Monitor US see the manual of the Sunny Central String-Monitor US.

This section explains how the Sunny WebBox and the Sunny SensorBox in the Sunny Central is

connected.

The components in the Sunny Central can be damaged by electrostatic discharge.

• When working on the Sunny Central and when handling the components observe all ESD

safety regulations.

• Discharge electrostatic charge by touching the grounded Sunny Central enclosure.

• Only then is it safe to touch any electronic components.

Seeping moisture during installation of the Sunny Central.

Damage to the electronics of the Sunny Central.

• Do not open the Sunny Central when it is raining or when a high humidity is present (> 95%).

• For conduit hubs, use only UL Listed rainproof, or wet location hubs complying with UL 514B

for entry into the enclosure.

Installation Manual SC500HEUS-IA-US_en-14 39

Page 40

7 Connecting Optional Communication Devices SMA America, LLC

7.1 Position of the Communication Devices

The Sunny WebBox is located on the inside of the Power Cabinet's door.

Position Description

A Sunny WebBox (see section 7.3)

B Sunny Central String Monitor Controller

C Sunny Sensor 485Hub (see section 7.2)

D 485Hub-SC

40 SC500HEUS-IA-US_en-14 Installation Manual

Page 41

SMA America, LLC 7 Connecting Optional Communication Devices

SUNNY SENSOR

485HUB

SSB

Communication

A

c

tiv

ity

A

c

tiv

ity

Powe

r

Powe

r

+12V

GND

D+

D–

A

7.2 Connecting the Sunny SensorBox (optional)

This section describes how to connect the Sunny SensorBox to the Sunny Sensor 485Hub in the

Sunny Central.

Data cable

The data cable for the connection of the Sunny SensorBox to the Sunny Sensor 485Hub must meet

the following requirements:

• The data cable must not be longer than 4,000 ft (1,200 m).

•Use:

– cables with a section of 2 x 2 x AWG 24 (2x0.25mm

– shielded twisted pair cables

Data Cable Recommendation

SMA also provides data cables. Please contact your electrician or wholesaler.

2

)

7.2.1 Connecting the Data Cable of the Sunny SensorBox

Connect the data cable to the socket (A) on the bottom of the Sunny Sensor 485Hub.

1. Open the Control and Interface Cabinet as

described in section 10.1.

2. Route the data cables separately from AC and DC

cables. Draw the data cable into the Sunny Central

(see section 6)).

3. Remove the insulation of the data cable by approx.

2.4 in. (60 mm) and uncover the shield.

4. Uncover the wires about 1.8 in. (45 mm).

5. Strip the wires about 0.2 in. (5 mm).

Installation Manual SC500HEUS-IA-US_en-14 41

Page 42

7 Connecting Optional Communication Devices SMA America, LLC

6. Connect the wires to the connector as shown in the

figure on the right.

Position Description

A Sunny Sensor 485Hub socket

BPlug

CSunny SensorBox

7. Note down the wire color:

+12 V ______________________________

GND ______________________________

D+ ______________________________

D − ______________________________

8. Insert the plugs into the socket on the bottom of the

Sunny Sensor 485Hub.

9. Close the Sunny Central.

The operating manual of the Sunny SensorBox shows you

how to connect the data cable in the SensorBox and

connect the sensors to the Sunny SensorBox.

7.3 Sunny WebBox (optional)

For more information on the Sunny WebBox (e.g., operation) see its technical description.

The technical description is included in the scope of delivery and is available for download at

www.SMA-America.com.

The commu nication between the Sunny We bBox and the PC or the network is conducted via Ethernet.

The Sunny WebBox is equipped with an integrated network connection, which enables it to be

connected to any Ethernet network. The connection supports Ethernet and Fast-Ethernet networks.

The speed adapts automatically to the connected switch, router or PC.

42 SC500HEUS-IA-US_en-14 Installation Manual

Page 43

SMA America, LLC 7 Connecting Optional Communication Devices

Sunny WebBox in a Network

The Sunny WebBox can be integrated into a network via a router or a switch. If the Sunny WebBox

is permanently integrated into a network with Internet access, it can automatically transmit the data of

your PV system to Sunny Portal.

Position Description

ASunny WebBox

B Switch or router

CComputer

D Laptop

Data cable

The data cable for the connection of the Sunny WebBox to a network must meet the following

requirements:

• The data cable must not be longer than 330 ft. (100 m).

•Use:

– High-quality, straight-through patch cables,

– shielded twisted pair cables,

– of category 5 (CAT 5) or higher.

Installation Manual SC500HEUS-IA-US_en-14 43

Page 44

7 Connecting Optional Communication Devices SMA America, LLC

Sunny WebBox Connected to a PC / Laptop

To read out the data, the Sunny WebBox can be connected to a PC or Laptop. This connection should

not be made long-term; it only serves the purpose of reading the data.

Position Description

ASunny WebBox

B Laptop

Cable

The cable for the connection of the Sunny WebBox to a PC / Laptop must meet the following

requirements:

• The cable must not be longer than 330 ft. (100 m).

•Use:

– High quality crossover cable,

– shielded twisted pair cables,

– of category 5 (CAT 5) or higher.

44 SC500HEUS-IA-US_en-14 Installation Manual

Page 45

SMA America, LLC 7 Connecting Optional Communication Devices

2

3

4

A B

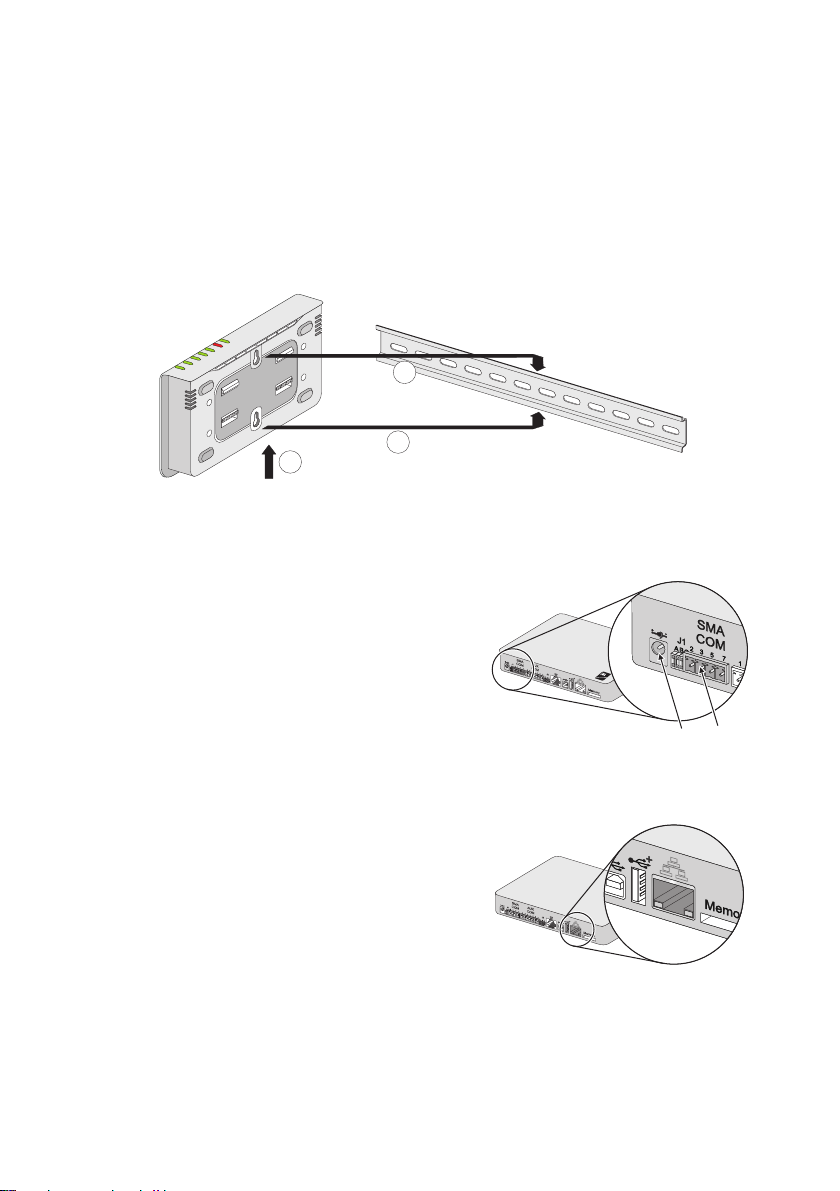

7.3.1 Installing the WebBox in the Sunny Central

1. Open the Control and Interface Cabinet as described in section 10.1.

2. Hook both lower brackets of the Sunny WebBox under the lower edge of the top-hat rail.

3. Press the Sunny WebBox upwards.

4. Snap the top edge of the top-hat rail into the top mounting brackets of the Sunny WebBox.

7.3.2 Connecting the Sunny WebBox in the Sunny Central

1. Plug the W215 connector into the SMA COM

socket (B) of the WebBox.

2. Insert the power supply plug into socket (A) of the

WebBox.

7.3.3 Connecting the Cable to the Sunny WebBox

The network connection on the Sunny WebBox is marked

as displayed on the adjacent graphic. The same marking

fo r th e ne two rk c onn ectio ns i s us ual ly t o be fou nd o n your

switch, router, PC or Laptop. If this is not the case, please

refer to the switch, router, PC or Laptop manual.

3. Route the cables separately from AC and DC

cables. Draw the cable into the Sunny Central

(see section 6).

4. Plug the cable into the Sunny WebBox's socket.

5. Plug the cable into the socket of the switch, router, PC or Laptop.

6. Close the Interface Cabinet of the Sunny Central.

Installation Manual SC500HEUS-IA-US_en-14 45

Page 46

7 Connecting Optional Communication Devices SMA America, LLC

A

7.3.4 Termination

To ensure sufficient signal quality of the RS485 data bus,

it must be terminated on both ends.

The Sunny WebBox is located at one of the end points of

the RS485 data bus.

• Mount jumper to J1A.

The jumper is mounted upon delivery.

Signal biasing (jumper J1B and jumper J1C)

To ensure sufficient signal quality of the RS485 communication bus, a bias must be connected to the

WebBox.

• Connect jumper to J1B and J1C.

Both jumpers are mounted upon delivery.

46 SC500HEUS-IA-US_en-14 Installation Manual

Page 47

SMA America, LLC 8 Electrical Connection

/05*$&

/05*$&

8 Electrical Connection

This section describes how the Sunny Central is connected to the grid and to the PV modules, and

what precautions must be observed in order to avoid material and personal damages. It provides

information on the necessary cable sizes and the magnitude of the torque for the cable connection.

8.1 Safety

The components in the Sunny Central can be damaged by electrostatic discharge.

• When working on the Sunny Central and when handling the components observe all ESD

safety regulations.

• Discharge electrostatic charge by touching the grounded Sunny Central enclosure.

• Only then is it safe to touch any electronic components.

Seeping moisture during installation of the Sunny Central.

Damage to the electronics of the Sunny Central.

• Do not open the Sunny Central when it is raining or when a high humidity is present (> 95%).

• For conduit hubs, use only UL Listed rainproof, or wet location hubs complying with UL 514B

for entry into the enclosure.

Installation Manual SC500HEUS-IA-US_en-14 47

Page 48

8 Electrical Connection SMA America, LLC

ABCD E

8.2 Connection in Control and Interface Cabinet

8.2.1 Connection Area for Analog inputs and auxiliary power

The illustration below shows the connecting area for analog inputs and auxiliary power.

Position Description

A Analog input limiting active power 4mAto20mA

B Analog input set point reactive power 4mAto20mA

C External start/stop

D Fault external transformer

E 208V external control voltage

48 SC500HEUS-IA-US_en-14 Installation Manual

Page 49

SMA America, LLC 8 Electrical Connection

8.2.2 Connection Area of the Low Temperature Option

For the low-temperature option, the supply voltage for the heating elements is provided by means of

the external terminals. If the ambient temperature is below –13°F (–25°C), the heating elements

switch on. This ensures that the temperature in the inverter cannot decrease any further.

Position Designation Wire size

AHeating ‒

B X481: 24 V signal. The 24 V signal

disconnects the auxiliary power supply

of the inverter.

C X483: The 24 V signal switches on/

disconnects the inverter externally.

D X482: 230 V supply voltage of the

heating.

E X220: 208 V control voltage. See section 8.2.3

AWG12

In accordance with National Electrical Code

ANSI/NFPA 70

AWG12

In accordance with National Electrical Code

ANSI/NFPA 70

AWG14

In accordance with National Electrical Code

ANSI/NFPA 70

®

®

®

Installation Manual SC500HEUS-IA-US_en-14 49

Page 50

8 Electrical Connection SMA America, LLC

/05*$&

8.2.3 Requirements

Cable Requirements

Cable Size Cable

2

12 AWG (4mm

14 AWG (4mm2) minimum 194°F (90°C) minimum, copper wire

) minimum 140°F (60°C) minimum, copper wire

Grid

For connecting the external voltage, a 208 V grid is required at the installation site.

8.2.4 Optional External 3-phase voltage supply (3AC, 208/120V, 60Hz)

It is possible to connect the Sunny Central to an external 208 V voltage supply. The Sunny Central

consumes up to 1,700 W in operation. It draws the energy from the PV field. At installation sites,

where the feed-in tariff per kWh does apply, it may be useful to connect the Sunny Central to an

ex ter nal vol tag e su ppl y. T he S unn y Ce ntr al t hen dra ws t he e lec tri cit y fo r its inte rna l po wer sup ply fro m

the grid via the external voltage supply.

Fuses between external power supply and Sunny Central

The installer is responsible for installing the fuses between the external power supply and the

Sunny Central. The Sunny Central has an internal fuse of 16 A.

8.2.5 Connecting the external 208 V power supply

Details for auxiliary power connection are shown in the circuit diagrams attached to the

Sunny Central.

1. Insert the cable through a separate cable duct into the Sunny Central (see section 6).

2. Loosen the 4 screws on top of the gasket plate in

the base of the Control Cabinet in a

counterclockwise direction and remove them.

50 SC500HEUS-IA-US_en-14 Installation Manual

Page 51

SMA America, LLC 8 Electrical Connection

3. Loosen the 3 screws on the side of the gasket plate

in a counterclockwise direction and remove them.

4. Remove a rubber gasket out from the gasket plate.

5. Place the rubber gaskets on the cable.

6. Install the rubber gasket on the cable in the opening

of the gasket plate.

7. Place the 3 screws on the side of the gasket plate and tighten them in a clockwise direction.

8. Place the 4 screws on top of the gasket plate and tighten them in a clockwise direction in the

base of the Control Cabinet.

9. Remove the insulation of the cable by

approx. 2.4 in. (60 mm).

10. Uncover the wires about 1.8 in. (45 mm).

11. Strip the wires about 0.2 in. (5 mm).

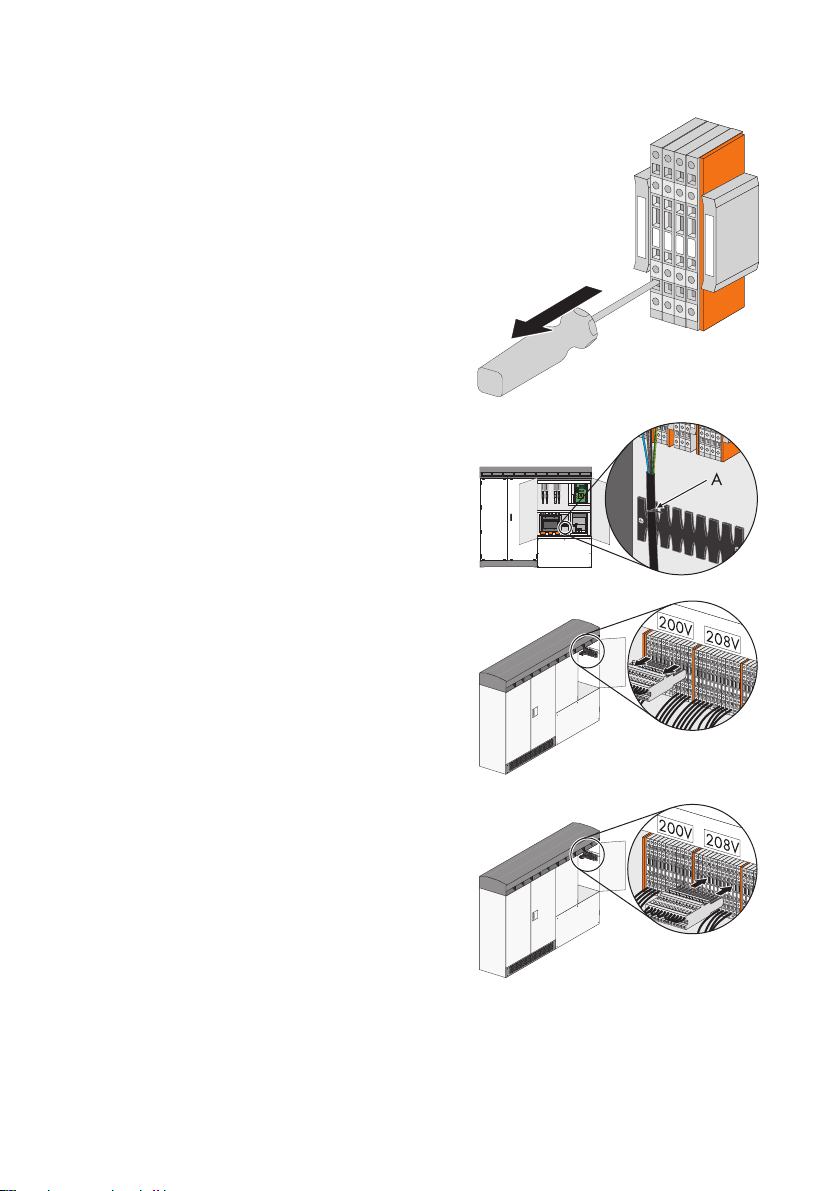

12. Insert the screwdriver into the rectangular opening

of the terminal and press it.

☑ The terminal is open.

13. Connect the AC wire line A to the terminal 1.

14. Connect the AC wire line B to the terminal 2.

15. Connect the AC wire line C to the terminal 3.

16. Connect the grounding cable to the terminal 4.

17. Pull the screwdriver out of the terminal.

Installation Manual SC500HEUS-IA-US_en-14 51

Page 52

8 Electrical Connection SMA America, LLC

18. Pull the insulated conductor to check that it is

securely in place.

☑ The insulated conductors of the external power

supply are connected.

19. Fasten the cable to the cable anchoring rail using a

cable tie.

☑ The cable is protected against pulling out.

20. Pull the plug out of the terminal block marked with

"200 V".

21. Insert the plug into the terminal block marked with

"208 V".

☑ The external 208 V power supply is connected.

52 SC500HEUS-IA-US_en-14 Installation Manual

Page 53

SMA America, LLC 8 Electrical Connection

8.2.6 Connecting Analog input setting cables

1. Remove the insulation of the cable by

approx. 2.4 in. (60 mm).

2. Uncover the wires about 1.8 in. (45 mm).

3. Strip the wires about 0.2 in. (5 mm).

4. Insert the screwdriver into the rectangular opening

of the terminal and press it.

5. The terminal is open.

6. Connect the positive wire of the active power to

terminal A.

7. Connect the negative wire of the active power to

terminal B.

8. Connect the ground wire of the active power to

terminal C.

9. Connect the positive wire of the reactive power to

terminal A.

10. Connect the negative wire of the reactive power to

terminal B.

11. Connect the ground wire of the reactive power to

terminal C.

Installation Manual SC500HEUS-IA-US_en-14 53

Page 54

8 Electrical Connection SMA America, LLC

12. Pull the screwdriver out of the terminal.

13. Pull the insulated conductor to check that it is securely

in place.

☑ The insulated conductors of the external power

supply are connected.

14. Fasten the cable to the cable anchoring rail using a

cable tie.

☑ The cable is protected against pulling out.

8.2.7 Connecting Cables for the Low Temperature Option

• Connect the cables to the terminals in accordance with the circuit diagram.

54 SC500HEUS-IA-US_en-14 Installation Manual

Page 55

SMA America, LLC 8 Electrical Connection

8.3 Connection Area for AC, DC cables and ground

The cables of the PV modules and the external transformer / switch gear are connected in the

Interface area.

Sunny Central for the Connection of 9 DC Strings with busbars (Standard)

Position Description

A DC − connection (neg. grounding), DC+ connection (pos. grounding)

B DC+ connection (neg. grounding), DC − connection (pos. grounding)

CAC connection

D Ground connection

Installation Manual SC500HEUS-IA-US_en-14 55

Page 56

8 Electrical Connection SMA America, LLC

Sunny Central for the Connection of 9 DC Strings with Terminal Blocks (Option)

Position Description

A DC − connection (neg. grounding), DC+ connection (pos. grounding)

B DC+ connection (neg. grounding), DC − connection (pos. grounding)

CAC connection

D Ground connection

56 SC500HEUS-IA-US_en-14 Installation Manual

Page 57

SMA America, LLC 8 Electrical Connection

/05*$&

8.4 Connection Options

There are various options for connecting the Sunny Central to the public grid and the PV modules.

When placing your order these options will enable you to adapt the Sunny Central connection area

to the characteristics of the PV modules and the grid. This section demonstrates the various connection

options.

8.4.1 DC Fuses

The Sunny Central must be equipped with 6 to 9 DC fuses. All other numbers of fuses contradict

UL listing of the inverter system. Every fuse has a separate rail to which 1 or 2 DC strings can be

connected.

The fuse characteristics have to match the following to ensure UL listing of the inverter system:

• Supplementary cartridge fuses suitable for branch circuit protection

• Type LDC, manufactured by Littelfuse

• Provided for branch circuit protection of DC field wiring

• Rated 600 Vac/Vdc

• Rated 130°C

• Maximum current rating of 450 A, no minimum limit

• Intermixing of different fuse ratings is possible

Such fuse types will be installed as defined in the option code upon order. The Sunny Central can be

delivered without fuses which are allowed to be provided in the end installation. Such fuses can be

ordered via SMA Service.

The DC fuse installation on site must be done by SMA Service only.

8.4.2 Grounding the PV modules

Depending on the configuration option, you can connect positive or negative grounded PV modules

to the Sunny Central.

8.4.3 Cable connection

You can connect all AC and DC cables to terminals or to busbars. Use cable lugs to connect the

cables to the busbars.

Installation Manual SC500HEUS-IA-US_en-14 57

Page 58

8 Electrical Connection SMA America, LLC

8.4.4 Cable requirements for DC, AC and PE connection

☐ Connect all cable using copper or aluminium conductors that are suitable for temperatures of

+194°F (+90°C) and in accordiance with National Electrical Code

☐ Use the screw terminal or the screws included in scope of delivery for mounting cable lugs only.

Cable lugs have to be UL listed compression lugs with two securement holes (

in diameter) and a distance between the holes of 13⁄4 in. (44mm). Both holes have to be

utilized in installation. The width of the lugs has to exceed the washer diameter of 1

(32mm) to ensure defined torque values listed below.

The screw terminals can be connected with 1 or 2 conductors each.

☐ Use the screw terminals or cable lugs to connect the DC cables.

☐For individual cable sizing refer to article National Electrical Code

Connection method Cable size Torque

Cable fixing in screw terminal 4AWGto600kcmil

(25mm²to304mm²)

Cable lug, aluminum on

copper busbar

Cable lug, copper on

copper busbar

4AWGto800kcmil

(25mm²to405mm²)

4AWGto800kcmil

(25mm²to405mm²)

Screw terminals are pre-mounted upon delivery. If they have to be fixed again on the copper busbar,

use a torque of 27.5ft.-lbs. (37 Nm).

®

ANSI/NFPA 70.

1

/2in. (13mm)

®

310.

41.5ft.-lbs. (56.5Nm)

27.5ft.-lbs. (37Nm)

44.5ft.-lbs. (60Nm)

1

⁄4in.

8.4.5 Additional cable requirements for DC connection

• Use the cable lugs to connect DC cables.

• Connect 2 conductors per input terminal maximum. Both conductors must have the same sizing.

• The DC inputs are isolated from the enclosure and the system grounding. If required by section

250 of the National Electrical Code

grounding.

Maximum number of DC inputs: 9xPV+, 9xPV − , 9xground

Maximum number of DC fuses: 9 (sized 450 A maximum)

DC input voltage: 330-600 V

Maximum DC current: 1600 A

58 SC500HEUS-IA-US_en-14 Installation Manual

®

, ANSI/NFPA 70, the installer is responsible for this

Page 59

SMA America, LLC 8 Electrical Connection

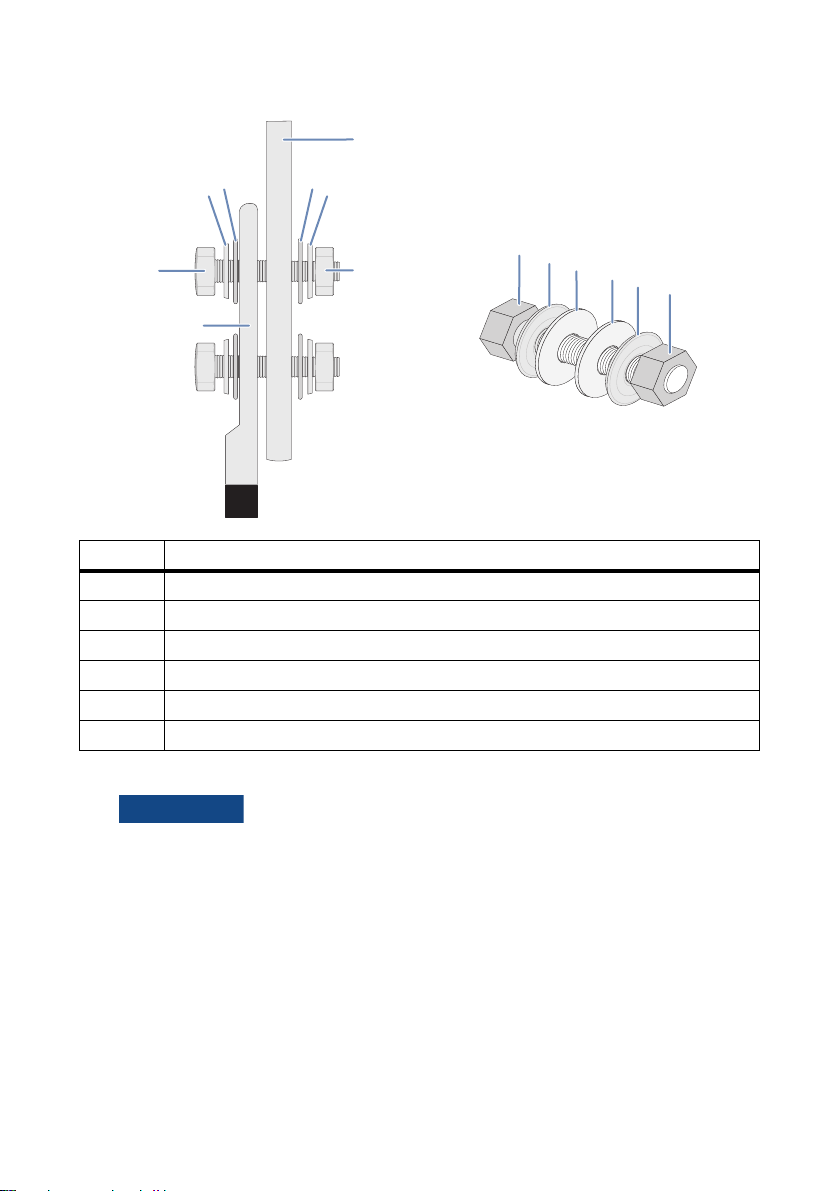

%"/(&3

%"/(&3

E

D

C

A

F

C

A

B

C

F

C

B B

B

8.5 Connecting DC cables

8.5.1 Connecting DC cables with screw terminals

Voltage is present in PV modules exposed to light.

Death resulting from electric shock.

•Cover the PV modules.

• Switch off the fuses in the DC distribution boxes (e.g. Sunny Central String-Monitor) and

secure them against reconnection.

• Follow all safety precautions of the module manufacturer.

Normally grounded conductors may be ungrounded and energized when a ground-fault is

indicated.

Risk of electric shock.

•Test before touching.

• Work on the Disconnect Unit must be carried out by qualified personnel.

Position Description

A Nut ‒ size: M 12

Installation Manual SC500HEUS-IA-US_en-14 59

Page 60

8 Electrical Connection SMA America, LLC

%"/(&3

%"/(&3

Position Description

B Spring washer

C Washer

D Cable lug

E Busbar

F Screw head ‒ size: M12

1. Strip the cable by about 11⁄5 in. (30 mm).

2. Open the set screw of the terminal completely.

3. Plug the copper or aluminum conductor of the cable into the screw terminal and tighten it with

the specified torque.

4. If necessary, tighten the screw terminal to the busbar again using a torque wrench with a torque

of 27ft.-lbs.(37Nm).

8.5.2 Connecting DC cables with cable lugs

Voltage is present in PV modules exposed to light.

Death resulting from electric shock.

•Cover the PV modules.

• Switch off the fuses in the DC distribution boxes (e.g. Sunny Central String-Monitor) and

secure them against reconnection.

• Follow all safety precautions of the module manufacturer.

Normally grounded conductors may be ungrounded and energized when a ground-fault is

indicated.

Risk of electric shock.

•Test before touching.

• Work on the Disconnect Unit must be carried out by qualified personnel.

60 SC500HEUS-IA-US_en-14 Installation Manual

Page 61

SMA America, LLC 8 Electrical Connection

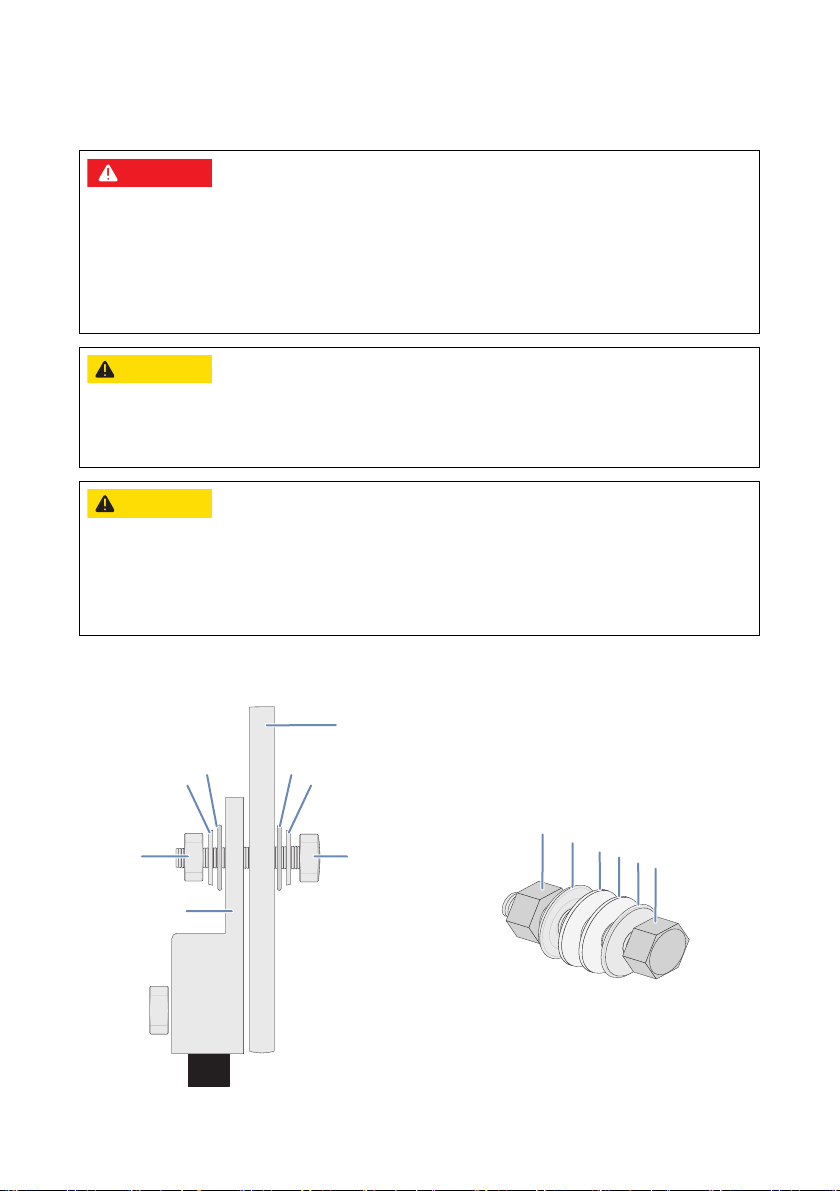

/05*$&

E

D

B

C

A

F

C

B

A

B

C

B

F

C

Position Description

A Screw head - size: M12

B Spring washer

C Washer

D Cable lug

E Busbar

F Nut - size: M12

Procedure of connecting

1.

Oxide layers on contact surfaces after transport and storing of the Disconnect Unit.

Yield loss resulting due to poor electrical conductivity.

• Before connecting the cables, clean the contact surfaces.

• Use only the non-woven abrasive delivered with the Sunny Central.

• Do not clean the surfaces with sandpaper.

• Do not damage the tin coating.

• Do not touch the contact surfaces after they have been cleaned.

2. Position the cable lug or lugs on the busbar.

3. Tighten the screw with a nut in a clockwise direction.

4. Connect all DC cables as illustrated above.

Installation Manual SC500HEUS-IA-US_en-14 61

Page 62

8 Electrical Connection SMA America, LLC

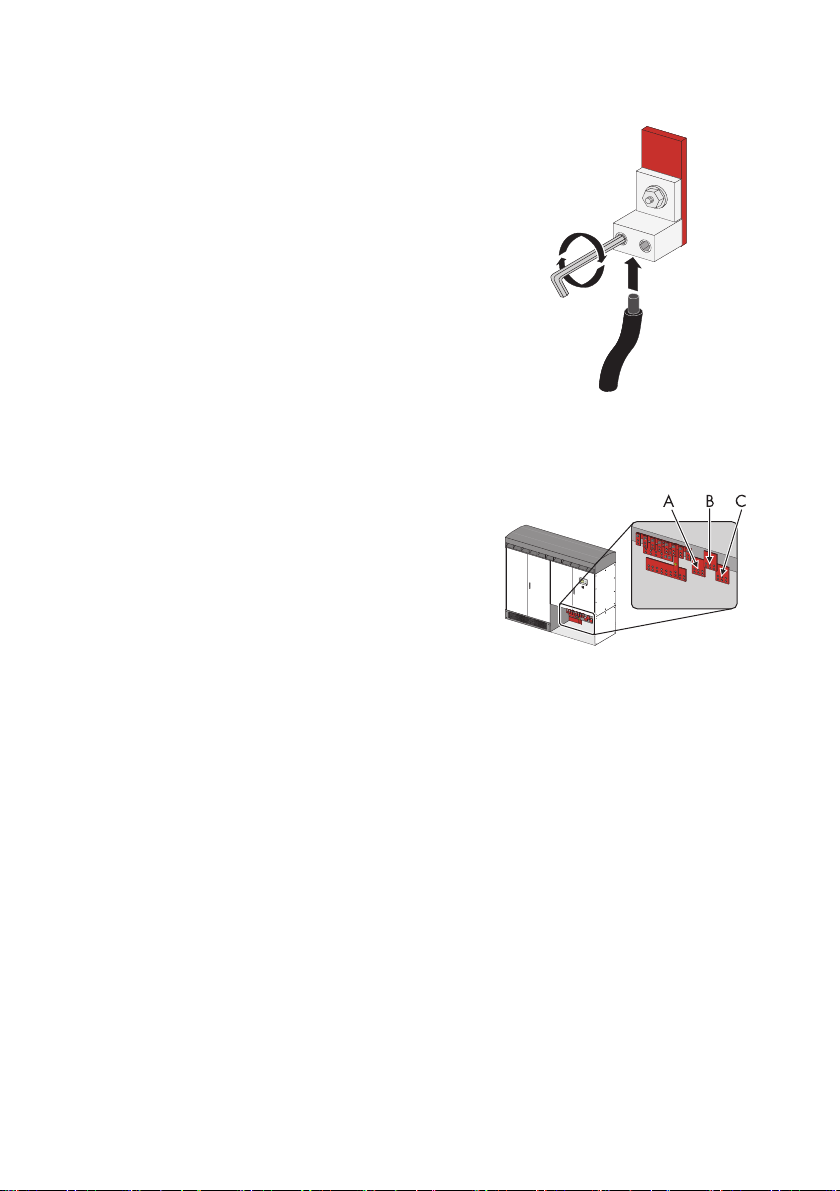

1.2 in.

8.6 Connection of the PV Modules

Do not connect the PV modules until the optional communication cables have been connected

(see section 7). DC distribution boxes (e.g. Sunny Central String-Monitor) must be installed between

the PV modules and the Sunny Central, where the PV module cables are gathered and led to the

Sunny Central.

The Photovoltaic System Grounding must be installed per the requirements of Sections 690.41

through 690.47 of the National Electrical Code, ANSI/NFPA 70 and is the responsibility of the

installer.

8.6.1 PV Modules: DC − Connection at Negative Grounding and DC+ Connection at Positive Grounding

Connection with Terminal Blocks

The illustration below shows a Sunny Central which is equipped for connection to 9 or 18 DC strings.

A Sc rew ter min als for the co nne cti on o f th e PV mo dul es'

grounded DC path cables.

1. Strip the cable by about 1.2 in. (30 mm).

2. Open the screw terminal completely.

3. Plug the copper inner conductor of the cable into

the screw terminal.

4. Tighten the screw terminal using a screwdriver.

The required torque is 315 in-lb.

5. Connect all grounded DC path cables of the PV

modules as described above.

62 SC500HEUS-IA-US_en-14 Installation Manual

Page 63

SMA America, LLC 8 Electrical Connection

1.2 in.

Connection to busbars

A Busbars for the connection of the PV modules'

grounded DC path cables.

1. Open the Sunny Central as described in section 10.1.

2. Position the cable lug or lugs on the busbar.

3. Insert the lock washers and screws into the holes.

4. Tighten the screw with a nut in a clockwise direction using a torque of 55 ft.-lbs.

5. Connect all grounding cables as described above.

6. The DC– cables are connected.

8.6.2 PV Modules: DC+ Connection at Negative Grounding and DC − Connection at Positive Grounding

Connection with Terminal Blocks

The illustration below shows a Sunny Central which is equipped for connection to 9 or 18 DC strings.

A Sc rew ter min als for the co nne cti on o f th e PV mo dul es'

ungrounded DC path cables.

Position: Interface Cabinet, right wall, middle.

1. Strip the cable by about 1.2 in. (30 mm).

2. Open the screw terminal completely.

Installation Manual SC500HEUS-IA-US_en-14 63

Page 64

8 Electrical Connection SMA America, LLC

3. Plug the copper inner conductor of the cable into

the screw terminal.

4. Tighten the screw terminal using a screwdriver.

The required torque is 315 in-lb.

5. Connect all ungrounded DC path cables of the PV

modules as described above.

Connection to busbars

A Busbar for the connection of the PV modules'

ungrounded DC path cables.

Position: Interface Cabinet, right wall, middle.

1. Open the Sunny Central as described in section 10.1.

2. Position the cable lug or lugs on the busbar.

3. Insert the lock washers and screws into the holes.

4. Tighten the screw with a nut in a clockwise direction using a torque of 55 ft.-lbs.

5. Connect all grounding cables as described above.