Page 1

CA

US

Central Inverter

SUNNY CENTRAL 500HE-US/500HE-CA

Operating Manual

SC500HEUS-eng-BE-BUS120320 | 98-4104420 | Version 2.0

Page 2

Page 3

SMA America, LLC Legal Restrictions

Copyright © 2012 SMA America,LLC. All rights reserved.

No part of this document may be reproduced, stored in a retrieval system, or transmitted, in any form

or by any means, electronic, mechanical, photographic, magnetic or otherwise, without the prior

written permission of SMA America,LLC.

Neither SMA America,LLC nor SMA Solar Technology Canada Inc. makes representations, express

or implied, with respect to this documentation or any of the equipment and/or software it may

describe, including (with no limitation) any implied warranties of utility, merchantability, or fitness for

any particular purpose. All such warranties are expressly disclaimed. Neither SMA America,LLC nor

its distributors or dealers nor SMA Solar Technology Canada Inc. nor its distributors or dealers shall

be liable for any indirect, incidental, or consequential damages under any circumstances.

(The exclusion of implied warranties may not apply in all cases under some statutes, and thus the

above exclusion may not apply.)

Specifications are subject to change without notice. Every attempt has been made to make this

document complete, accurate and up-to-date. Readers are cautioned, however, that

SMAAmerica,LLC and SMA Solar Technology Canada Inc. reserve the right to make changes

without notice and shall not be responsible for any damages, including indirect, incidental or

consequential damages, caused by reliance on the material presented, including, but not limited to,

omissions, typographical errors, arithmetical errors or listing errors in the content material.

All trademarks are recognized even if these are not marked separately. Missing designations do not

mean that a product or brand is not a registered trademark.

The Bluetooth

®

word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and

any use of such marks by SMA America,LLC and SMA Solar Technology Canada Inc. is under

license.

SMA America, LLC

3801 N. Havana Street

Denver, CO 80239 U.S.A.

SMA Solar Technology Canada Inc.

2425 Matheson Blvd. E

8th Floor

Mississauga, ON L4W 5K5

Canada

Operating Manual SC500HEUS-eng-BE-BUS120320 3

Page 4

Important Safety Instructions SMA America, LLC

%"/(&3

8"3/*/(

$"65*0/

/05*$&

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions for the following products:

• Sunny Central 500HE-US

• Sunny Central 500HE-CA

This manual must be followed during installation and maintenance.

The product is designed and tested according to international safety requirements, but as with all

electrical and electronic equipment, certain precautions must be observed when installing and/or

operating the product. To reduce the risk of personal injury and to ensure the safe installation and

operation of the product, you must carefully read and follow all instructions, cautions and warnings

in this manual.

Warnings in this document

A warning describes a hazard to equipment or personnel. It calls attention to a procedure or practice,

which, if not correctly performed or adhered to, could result in damage to or destruction of part or all

of the SMA equipment and/or other equipment connected to the SMA equipment or personal injury.

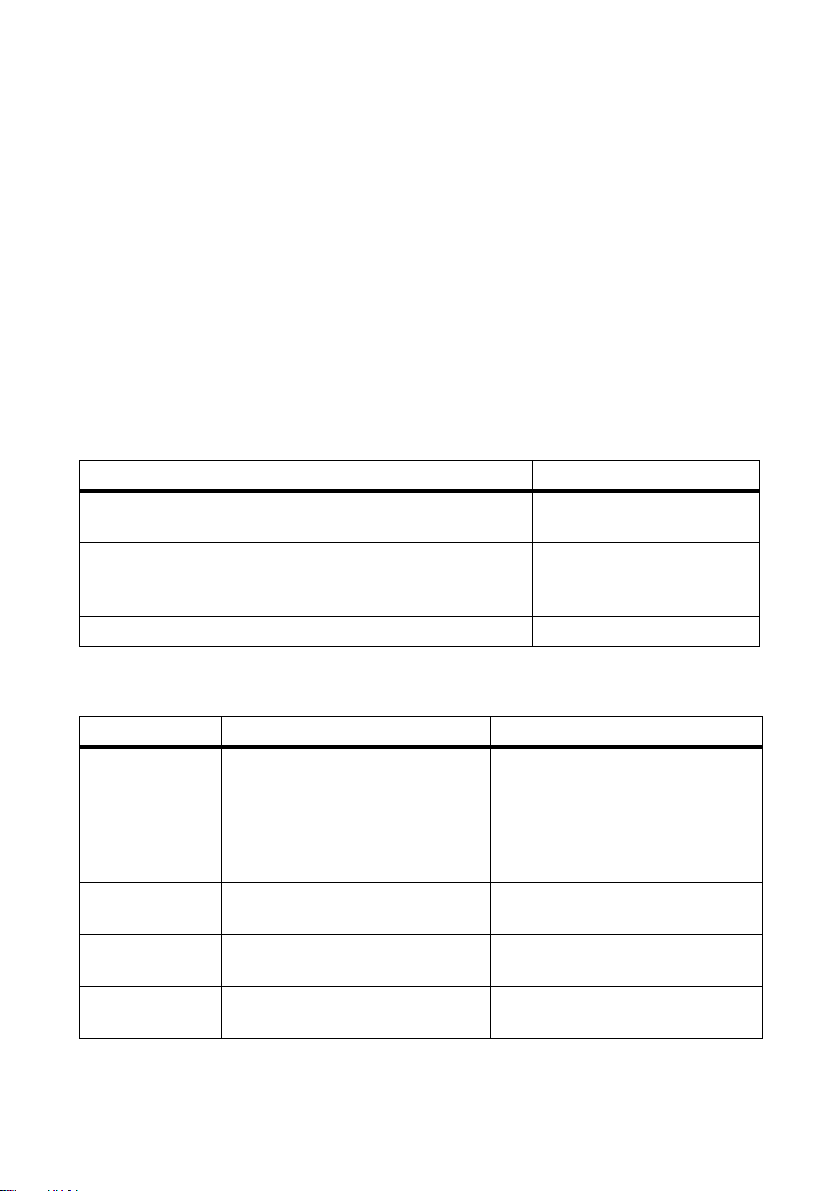

Symbol Description

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

4 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 5

SMA America, LLC Important Safety Instructions

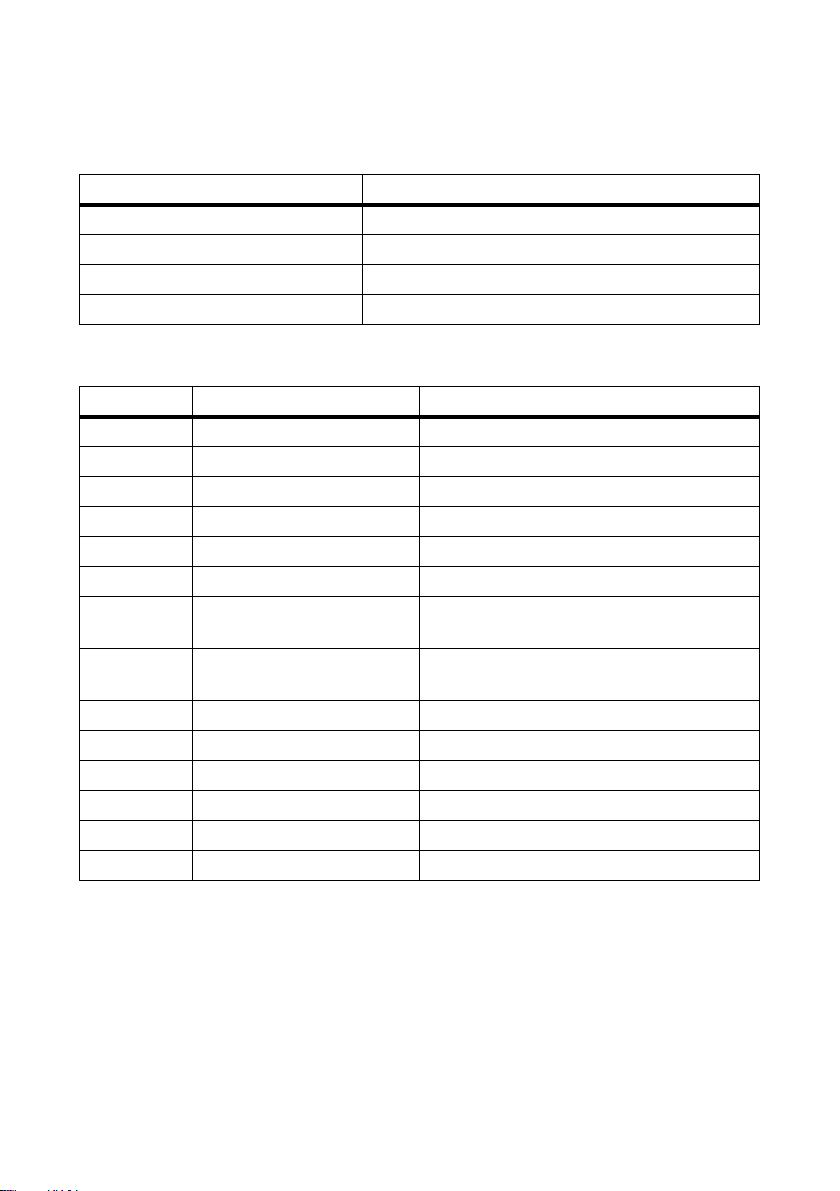

Other Symbols in this document

In addition to the safety and hazard symbols described on the previous pages, the following symbol

is also used in this manual:

Symbole Description

Indicates information that is important for a specific topic or objective, but is not

safety-relevant.

☐ Indicates a requirement for meeting a specific goal.

☑ Desired result

✖ A problem that could occur

Markings on this product

The following symbols are used as product markings with the following meanings.

Symbol Description

Warning regarding dangerous voltage

The product works with high voltages. All work on the product must only be

performed as described in the documentation of the product.

Electric arc hazards

The product has large electrical potential differences between its conductors. Arc

flashes can occur through air when high-voltage current flows. Do not work on the

product during operation.

If access during operation cannot be avoided, please regard all safety

regulations stated within NFPA 70E.

Beware of hot surface

The product can become hot during operation. Do not touch the product during

operation.

Observe the operating instructions

Read the documentation of the product before working on it. Follow all safety

precautions and instructions as described in the documentation.

Evaluated to the requirements of the Underwriters Laboratories Standard for

Safety for Inverters, Converters, Controllers and Interconnection System

Equipment for Use With Distributed Energy Resources, UL 1741.

The inverter has been additionally evaluated by Underwriters Laboratories to

CAN/CSA C22.2 No. 107.1-1, "General Use Power Supplies".

Operating Manual SC500HEUS-eng-BE-BUS120320 5

Page 6

General Warnings SMA America, LLC

8"3/*/(

General Warnings

General Warnings

All electri cal installations m ust be done in accordance with the local and NationalElectrical Code

ANSI/NFPA 70 or the Canadian Electrical Code® CSAC22.1. This document does not and is not

intended to replace any local, state, provincial, federal or national laws, regulation or codes

applicable to the installation and use of the product, including without limitation applicable

electrical safety codes. All installations must conform with the laws, regulations, codes and

standards applicable in the jurisdiction of installation. SMA assumes no responsibility for the

compliance or noncompliance with such laws or codes in connection with the installation of the

product.

The product contains no user-serviceable parts except for the fans on the bottom of the enclosure

and the filters behind the fans as well as the handle covers on the sides of the unit. For all repair and

maintenance, always return the unit to an authorized SMA Service Center.

Before installing or using the product, read all of the instructions, cautions, and warnings in this

manual.

Before connecting the product to the electrical utility grid, contact the local utility company. This

connection must be made only by qualified personnel.

Wiring of the product must be made by qualified personnel only.

®

6 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 7

SMA America, LLC Table of Contents

Table of Contents

1 Information on this Manual. . . . . . . . . . . . . . . . . . . . . . . . 11

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1 Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 Qualification of Skilled Workers. . . . . . . . . . . . . . . . . . . . . . . . 13

2.3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Sunny Central . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4 Stop/Start Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5 Sunny WebBox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.6 Sunny Central String-Monitor Controller. . . . . . . . . . . . . . . . . . 23

3.7 Insulation Monitoring Via GFDI . . . . . . . . . . . . . . . . . . . . . . . . 24

3.8 Grid Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.8.1 Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.8.2 Active Power Limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.8.3 Reactive Power Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.9 Active Island Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4 Operating the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1 Display Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2 Switching Diagram Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3 Navigating the Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4 Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.5 Changing the Time Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.6 Changing the Date Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.7 Displaying the Firmware Version . . . . . . . . . . . . . . . . . . . . . . . 31

Operating Manual SC500HEUS-eng-BE-BUS120320 7

Page 8

Table of Contents SMA America, LLC

5 Configuring the Network Settings . . . . . . . . . . . . . . . . . . 32

6 Communication with the Sunny WebBox . . . . . . . . . . . . 34

6.1 Displaying the Instantaneous Values. . . . . . . . . . . . . . . . . . . . . 34

6.2 Changing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7 Active Power Limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.1 Power Frequency-Dependent Active Power Limitation . . . . . . . 35

7.2 Power Frequency-Independent Active Power Limitation . . . . . . 36

7.2.1 Selecting the Procedure using the Parameter "P-WMod" . . . . . . . . . . . . . . . 36

7.2.2 "Off" Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2.3 "WCtlCom" Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2.4 "WCnst" Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2.5 "WCnstNom" Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.2.6 "WCnstNomAnIn" Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.3 Displaying the Active Power Limitation Status . . . . . . . . . . . . . . 38

7.4 Displaying Error Messages and Warnings for Active Power

Limitation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8 Reactive Power Regulation . . . . . . . . . . . . . . . . . . . . . . . . 40

8.1 Procedure for Reactive Power Regulation. . . . . . . . . . . . . . . . . 40

8.1.1 Selecting the Procedure using the Parameter "Q-VArMod". . . . . . . . . . . . . . 40

8.1.2 "Off" Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.1.3 "VArCtlCom" Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.1.4 "PFCtlCom" Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.1.5 "VArCnst" Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.1.6 "VArCnstNom" Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.1.7 "VArCnstNomAnIn" Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.1.8 "PFCnst" Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.1.9 "PFCnstAnIn" Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.1.10 "PFCtlW" Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.1.11 "VArCtlVol" Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.1.12 "VArCtlVolHystDb" Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 9

SMA America, LLC Table of Contents

8.2 Error Messages and Warnings for the Reactive Power

Setpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9 Grid Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.1 How Grid Monitoring Works . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.2 Monitoring the Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.3 Monitoring the Power Frequency . . . . . . . . . . . . . . . . . . . . . . . 52

9.4 Connecting to Grid After Rectifying a Fault . . . . . . . . . . . . . . . 54

10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10.1 Reading Off Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10.2 Rectifying the Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.2.1 Error Types and Waiting Times for Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.2.2 Errors 01-13 - Power Distribution Grid Errors . . . . . . . . . . . . . . . . . . . . . . . . 57

10.2.3 Errors 34-38 - PV Array Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.2.4 Errors 60-87 - Sunny Central Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.2.5 Communication Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.3 Confirming the Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

11 Instantaneous Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

11.1 Overview of all Instantaneous Values. . . . . . . . . . . . . . . . . . . . 62

11.2 Instantaneous Values by Topic . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.2.1 Instantaneous Values for Active and Reactive Power . . . . . . . . . . . . . . . . . . 63

11.2.2 Error Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.2.3 Measured Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.2.4 Device-Internal Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.2.5 Internal Counters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Operating Manual SC500HEUS-eng-BE-BUS120320 9

Page 10

Table of Contents SMA America, LLC

12 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

12.1 Overview of all Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

12.2 Parameters by Topic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

12.2.1 Parameters for Active Power Limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

12.2.2 Parameters for Reactive Power Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . 77

12.2.3 Parameters for Grid Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

12.2.4 Parameters for Grid Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

12.2.5 Device-Internal Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

13 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

10 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 11

SMA America, LLC 1 Information on this Manual

1 Information on this Manual

Validity

This manual applies to the following device types:

• SC 500HE-US from firmware version 1.070

• SC 500HE-CA from firmware version 1.070

Target group

This manual is intended for skilled workers. Only skilled workers are allowed to perform the tasks set

forth in this manual (see section 2.2 "Qualification of Skilled Workers", page 13).

Additional information

Additional information is available at www.SMA-America.com:

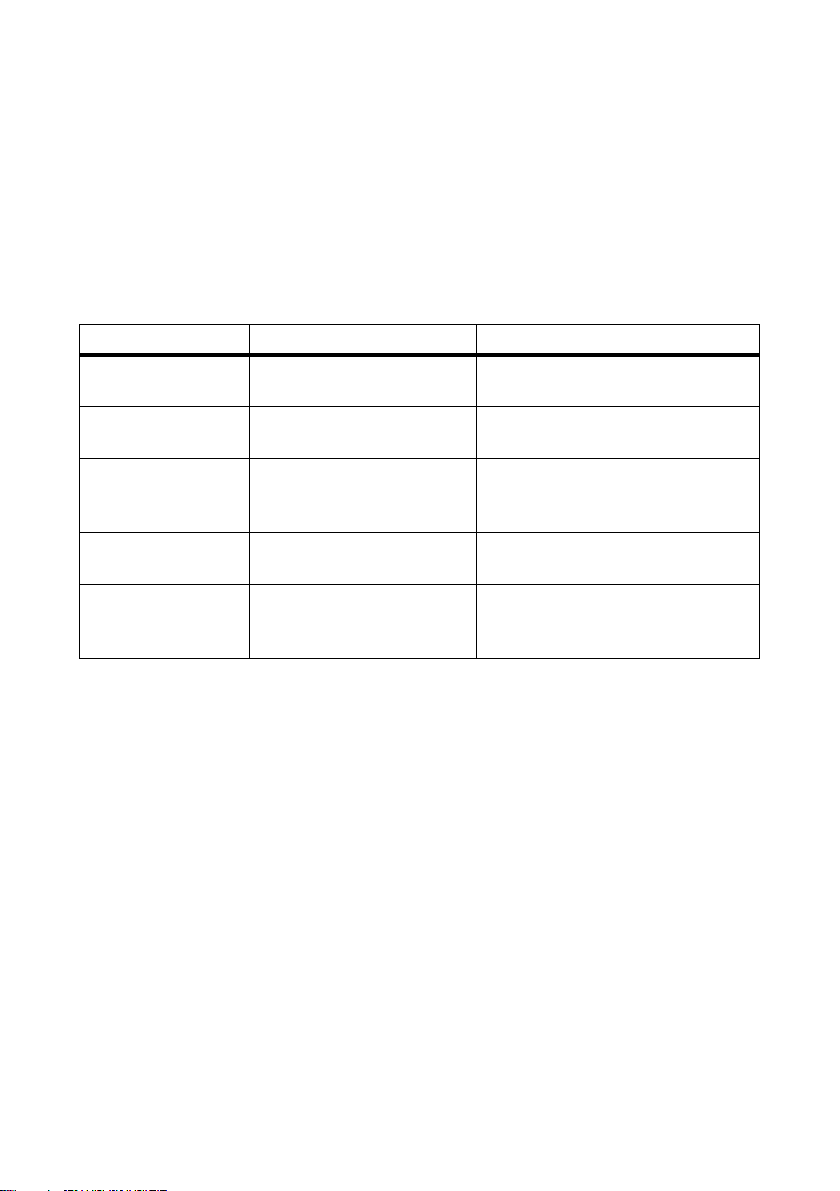

Document title Document type

Installation requirements for SUNNY CENTRAL 500HE-US/

SUNNY CENTRAL 500HE-CA

Transformer Requirements - requirements of medium-voltage and

auxiliary transformers for SUNNY CENTRAL 500HE-US /

SUNNY CENTRAL 500HE-CA

Plant Communication in large-scale PV Plants Technical information

Technical information

Technical information

Typography

Typography Usage Example:

"light" • Display messages

• Parameters

• Instantaneous Values

• Elements of a graphic user

interface

bold • Elements to be entered • Enter 192.168.0.100 in the

> • Several elements that are to be

selected

[Button/key] • Button or key to be selected or

pressed

Operating Manual SC500HEUS-eng-BE-BUS120320 11

• The parameter "P-W" defines the

active power to be fed in.

"IP address" field.

•Select Plant > Devices.

•Select [OK].

Page 12

1 Information on this Manual SMA America, LLC

Nomenclature

The following nomenclature is used in this manual:

Complete designation Designation in this manual

SMA America, LLC SMA

SMA Solar Technology Canada Inc. SMA

Sunny Central 500HE-US Sunny Central or inverter

Sunny Central 500HE-CA Sunny Central or inverter

Abbreviations

Abbreviation Designation Explanation

AC Alternating Current ‒

OCU Operational Control Unit ‒

OCS Operational Control System ‒

DC Direct Current ‒

DSP Digital Signal Processor ‒

ESD Electrostatic Discharge ‒

GFDI Ground-Fault Detection

Interruption

GSM Global System for Mobile

Communication

IP Internet Protocol ‒

LAN Local Area Network ‒

LCD Liquid Crystal Display ‒

MPP Maximum Power Point ‒

PE Protective Earth ‒

PV Photovoltaic ‒

‒

‒

12 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 13

SMA America, LLC 2 Safety

2Safety

2.1 Intended Use

The Sunny Central is a central inverter that converts direct current generated by the PV modules into

alternating current when the DC input voltage is in the 330 V to 600 V range, and when the

permissible ambient conditions are adhered to. The alternating current that is generated is fed into the

power distribution grid by a transformer that is connected in series.

The inverter may be used both indoors and outdoors. The inverter may only be operated with a

suitable transformer, taking into consideration the maximum permissible DC input voltage and the

permissible ambient temperatures (see Technical information "Transformer Requirements requirements of medium-voltage and auxiliary transformers for SUNNY CENTRAL 500HE-US /

SUNNY CENTRAL 500HE-CA" and the installation manual of the inverter). The transformer must be

designed for the voltages that arise during pulsed mode of the inverter.

The inverter corresponds to the protection class NEMA 3R and can also be operated in rain, sleet,

and snow.

Only persons meeting all of the skills standards for the target group may work on or with the

Sunny Central.

For intended use, please also read the product documentation and observe all safety precautions.

All work on the Sunny Central must be performed with the appropriate tools.

Suitable personal protective equipment according to specifications from NFPA 70E is to be worn by

all persons working on or with the Sunny Central.

Unauthorized persons may not operate the Sunny Central and must keep at a distance from the

Sunny Central.

For safety reasons, it is forbidden to modify the product or install components that are not explicitly

recommended or distributed by SMA for this product.

The Sunny Central may not be operated with its doors open.

The Sunny Central may not be opened when it is raining or when humidity exceeds 95%.

The Sunny Central may not be operated if there are any technical defects.

Any use of the Sunny Central other than that described in the Intended Use section is not regarded as

intended use. Unauthorized installations and modifications compromise operational safety and void

the operation permission as well as all warranty claims.

2.2 Qualification of Skilled Workers

Qualified skilled workers have been adequately trained and have demonstrated the ability and

knowledge to fit, operate, and perform maintenance on the device.

Qualified skilled workers have been trained in how to deal with the dangers and risks associated with

fitting electrical installations and have all the necessary knowledge for averting danger.

Operating Manual SC500HEUS-eng-BE-BUS120320 13

Page 14

2 Safety SMA America, LLC

%"/(&3

2.3 Safety Precautions

Electrical hazards

Electric shock from live voltage

High voltages are present at the inverter and its components. Some maintenance work must be done

when voltage is present. Failure to adhere to the safety messages may lead to severe or lethal

injuries due to electric shock.

• Wear class 2 personal protective equipment.

• Always perform work in compliance with the regulations specified in 29 CFR, Chapter XVII,

Part 1910 (OSHA), NEC, and NFPA 70E.

• Do not touch any live components of the inverter or the medium-voltage grid.

• Follow instructions precisely.

• Observe safety messages.

• Before performing any work on the inverter, always disconnect the inverter if voltage is not

absolutely necessary.

• After disconnecting the inverter, wait at least 10 minutes until the inverter's capacitors have

discharged completely.

• Before performing work on the inverter, ensure that no voltage is present.

Electric shock caused by ground fault

In a ground fault, plant sections that are supposedly grounded may in fact be live. Failure to adhere

to the safety messages may lead to severe or lethal injuries due to electric shock.

• Ensure that no voltage is present before touching any components.

• Wear class 2 personal protective equipment.

Electric shock due to damaged inverter

Operating a damaged inverter can lead to hazardous situations that may result in serious or lethal

injuries caused by electric shock.

• Only operate the inverter if it is in safe and technically faultless working order.

• Only operate the inverter if there is no visible damage.

• Regularly check for visible damage.

• Make sure that all external safety equipment is freely accessible at all times.

• Make sure that all safety equipment is in good working order.

14 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 15

SMA America, LLC 2 Safety

/05*$&

8"3/*/(

/05*$&

8"3/*/(

Damage to electronic components due to electrostatic discharge

Electrostatic discharge can damage or destroy electronic components.

• Observe the ESD safety regulations when working on the unit.

• Wear personal protective equipment.

• Neutralize any electrostatic charge before touching electronic components, for example by

touching the PE connection of the doors.

Environmental hazards

Danger to life due to blocked escape routes

In hazardous situations, blocked escape routes can lead to serious injury or death.

• An escape route of at least 3 ft. (915 mm) wide must be available at all times.

• Do not place any objects in the escape route area.

• Remove all tripping hazards from the escape routes.

Damage to the inverter caused by dust or moisture penetration

Dust intrusion or moisture penetration can damage the inverter and impair the functionality of the

inverter.

• Do not open the inverter when it is raining or when humidity exceeds 95%.

• Perform maintenance on the Sunny Central only when the environment is dry and free of dust.

Hazards due to human error

Danger to life due to electric shock when the inverter is unlocked

Unlocked inverters can be opened by unauthorized persons. This means that unauthorized persons

have access to components on which lethal voltages are present.

• Ensure that unauthorized persons have no access to the inverter.

• Always lock the inverter.

Operating Manual SC500HEUS-eng-BE-BUS120320 15

Page 16

2 Safety SMA America, LLC

8"3/*/(

$"65*0/

Mechanical hazards

Risk of fire due to failure to observe torque specifications

Failure to follow the torque specifications indicated in the installation manual reduces the ampacity

of the screw connections. This can cause components to overheat and catch fire.

• Always use the torques specified in the installation manual.

• Regularly check that mounted components have always been set at the torque specified in the

installation manual.

Danger from illegible or missing warning signs

Warning signs on the Sunny Central warn operators about hazardous areas and must always be

present and legible.

• Regularly check and make sure that all warning signs are present and undamaged.

• Immediately replace missing, faded, or damaged warning signs.

Thermal hazards

Risk of burns due to hot components.

The components of the Sunny Central can become very hot. Touching these components can lead

to burn injuries.

• Do not touch hot components.

• Wait until hot components have sufficiently cooled down.

• Observe safety messages in the inverter.

• Wear class 2 personal protective equipment.

16 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 17

SMA America, LLC 3 Product Description

3 Product Description

3.1 Sunny Central

The Sunny Central is a PV inverter that converts the direct current from the PV array into alternating

current for the power distribution grid.

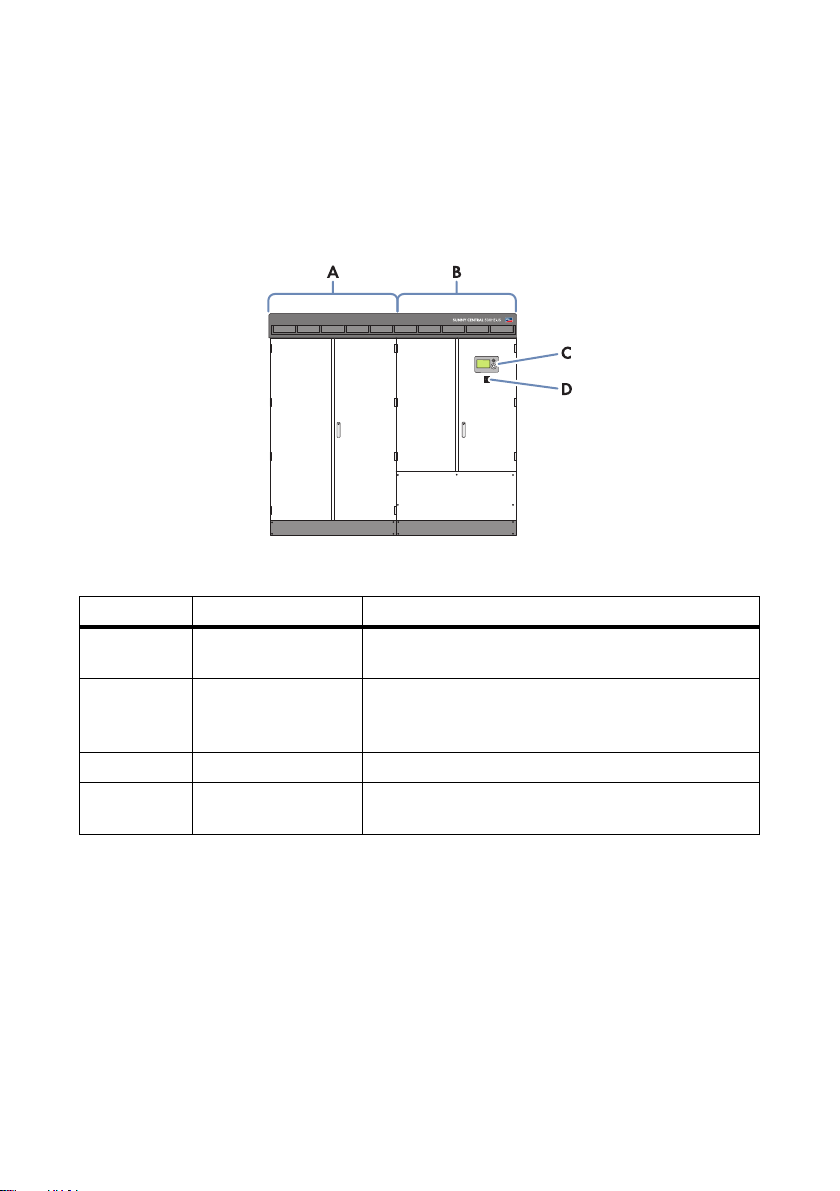

Figure 1: Sunny Central 500HE-US

Position Designation Explanation

A Inverter Cabinet The inverter cabinet contains the inverter bridge for

converting direct current to alternating current.

B Interface Cabinet All AC, DC, and data cables can be connected to the

interface cabinet. This cabinet contains the system control

and optional communication devices.

C Display Read the yield values and error messages off the display.

D Stop/Start Switch Use the stop/start switch to switch the Sunny Central on

or off.

The Sunny Central can be controlled via the Power Reducer Box and the Sunny WebBox, and

therefore can meet the requirements of the grid operator.

Operating Manual SC500HEUS-eng-BE-BUS120320 17

Page 18

3 Product Description SMA America, LLC

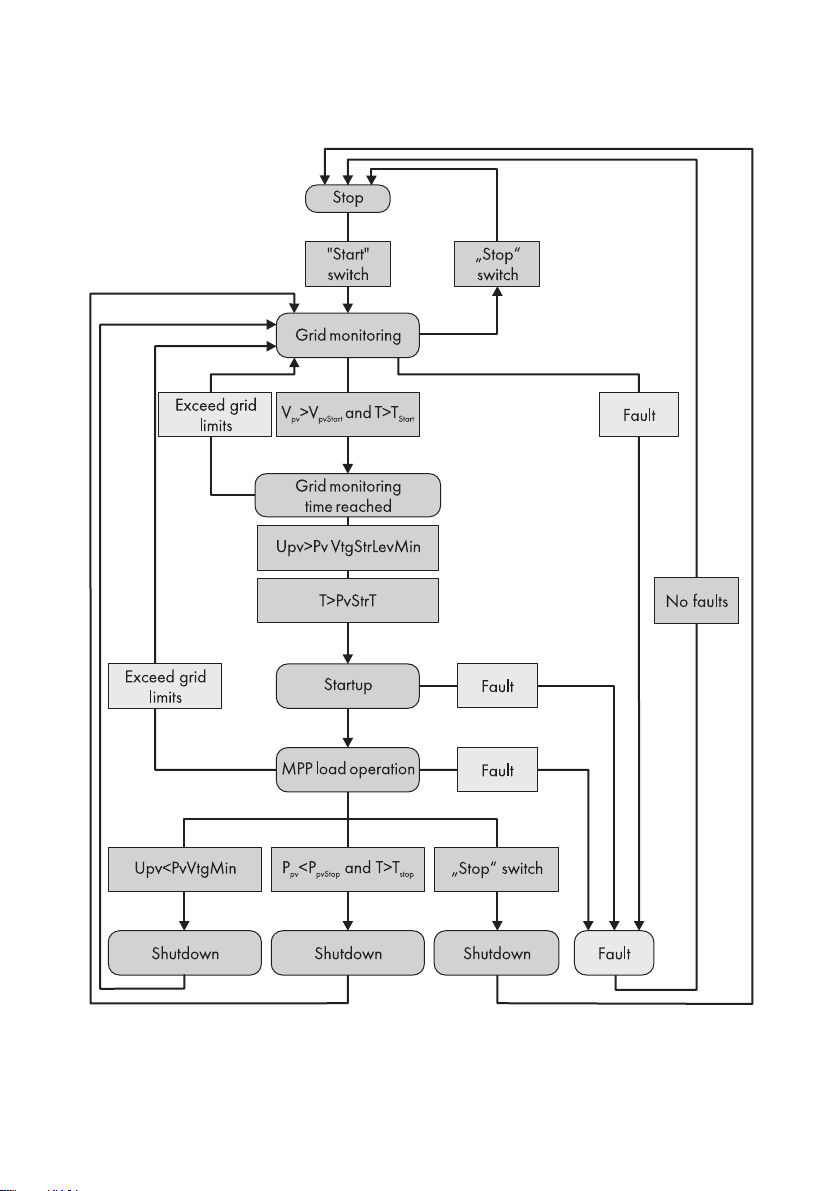

The inverter cycles through various states during operation:

Figure 2: Principle overview of the operating states of the Sunny Central

18 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 19

SMA America, LLC 3 Product Description

Stop

The Sunny Central is switched off. If the stop/start switch is set to "Start", the Sunny Central switches

to the operating state "Grid monitoring".

Grid Monitoring

The Sunny Central is in the operating state "Grid monitoring". The grid limits will now be monitored

continuously. If the grid limits are exceeded during the monitoring time, the Sunny Central will restart

"Grid monitoring".

If a grid fault does not occur during the grid monitoring time, the AC contactor closes and the

Sunny Central switches to the operating state "Grid monitoring time reached".

Grid monitoring time reached

The Sunny Central is in the operating state "Grid monitoring time reached". If the input voltage V

PV

exceeds the value of the parameter "PvVtgStrLevMin", the Sunny Central waits until the time specified

in the "PvStrT" parameter elapses. If the input voltage VPV does not fall below the value of the

parameter "PvVtgStrLevMin" during this time, the Sunny Central checks whether the power distribution

grid is connected. If a valid power distribution grid is available, the Sunny Central switches to the

operating state "Startup".

The value of the parameter "PvVtgStrLevMin" must be adjusted to conform to the PV array connected

to the Sunny Central.

Startup

The Sunny Central is in the operating state "Startup". The Sunny Central moves to its initial operating

point and begins the feed-in process.

MPP load operation

In the MPP range, the Sunny Central feeds into the power distribution grid and permanently works at

the maximum power point (MPP). If the measured power during the time int erva l "PvPwrMinT" is below

the value of the parameter "PvPwrMin" or the stop/start switch is set to "Stop", the Sunny Central

switches to the operating state "Shutdown".

Shutdown

The Sunny Central is in the operating state "Shutdown". If the stop/start switch is set to "Stop", the

Sunny Central switches to the operating state "Stop". The AC contactor and the DC contactor open

automatically.

If the Sunny Central shuts down because the feed-in conditions have not been met, the Sunny Central

switches to the operating state "Grid monitoring".

Fault

If a fault occurs during operation, the Sunny Central switches off and the fault is shown on the display

(see section 10 "Troubleshooting", page 55).

Operating Manual SC500HEUS-eng-BE-BUS120320 19

Page 20

3 Product Description SMA America, LLC

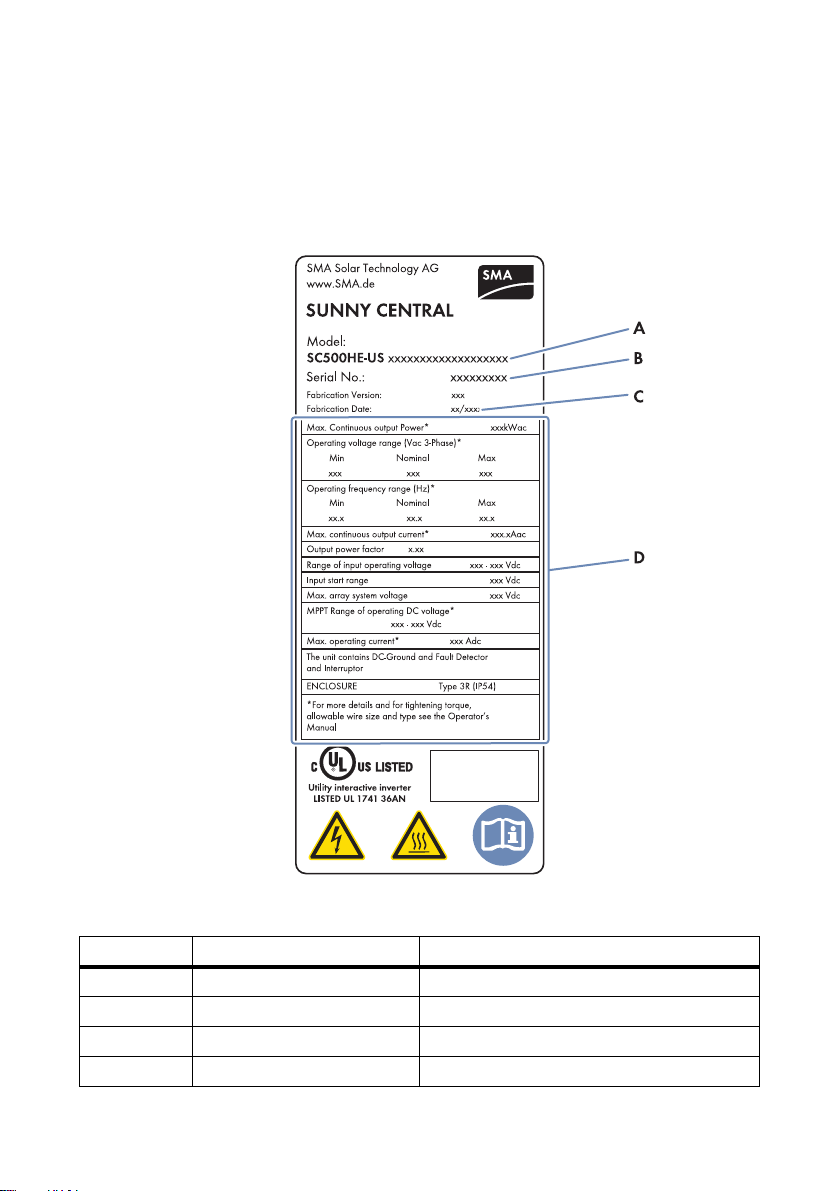

3.2 Type Label

The type label provides a clear identification of the Sunny Central. Two type labels are attached to

the Sunny Central. The type labels can be found on both the top left side in the connection cabinet

and on the right side in the inverter cabinet.

Additionally, the serial number can be found on the roof of the inverter at the top left.

Figure 3: Layout of the type label

Position Designation Explanation

AModel Device type

B Serial no. Inverter serial number

C Fabrication date Date of manufacture

D ‒ Device-specific characteristics

20 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 21

SMA America, LLC 3 Product Description

3.3 Display

Read the yield values of the inverter and error messages off the display. If there is an error, the button

glows red.

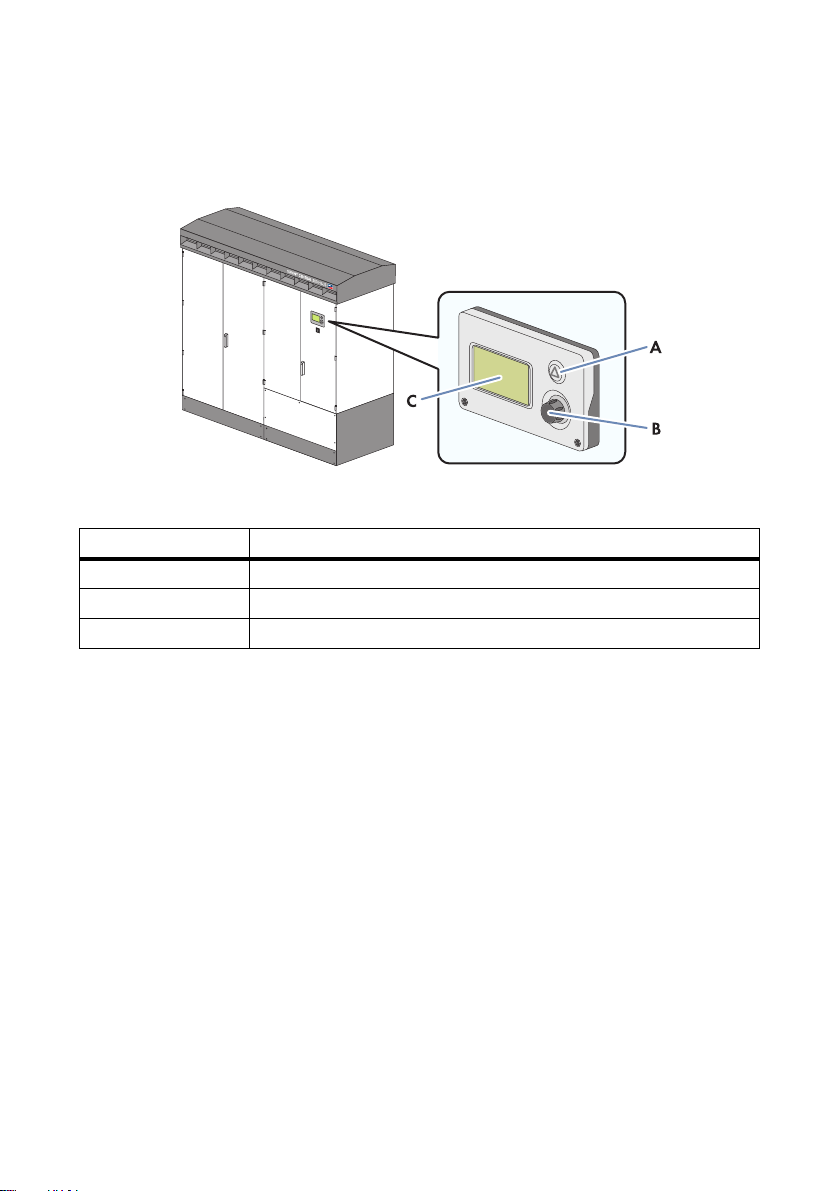

Figure 4: Display and control elements

Position Designation

AButton

BSwitch

CDisplay

The display can be operated by pushing and pulling the switch and by using the button

(see section 4 "Operating the Display", page 27). By pushing the switch, you can switch on the

backlight of the display.

3.4 Stop/Start Switch

Use the stop/start switch to switch the Sunny Central on or off.

Switch position "Start"

After turning the stop/start switch to "Start", a motor drive closes the DC contactor and the

Sunny Central goes from the operating state "Stop" to the operating state "Grid monitoring". If there

is sufficient irradiation and a valid power distribution grid connection, the Sunny Central switches to

feed-in operation. If there is insufficient irradiation and, in turn, the input voltage is too low, the

Sunny Central remains in the operating state "Grid monitoring".

Operating Manual SC500HEUS-eng-BE-BUS120320 21

Page 22

3 Product Description SMA America, LLC

Switch position "Stop"

If the stop/start switch is turned to "Stop" while the Sunny Central is in the operating state

"Grid monitoring", a motor drive opens the DC contactor. The Sunny Central switches to the operating

state "Stop".

If the stop/start switch is turned to "Stop" while the Sunny Central is in the operating state

"MPP load operation", the Sunny Central switches to the operating state "Shutdown". Once shutdown

is complete, the AC contactor and the DC contactor open automatically and the Sunny Central

switches to the operating state "Stop".

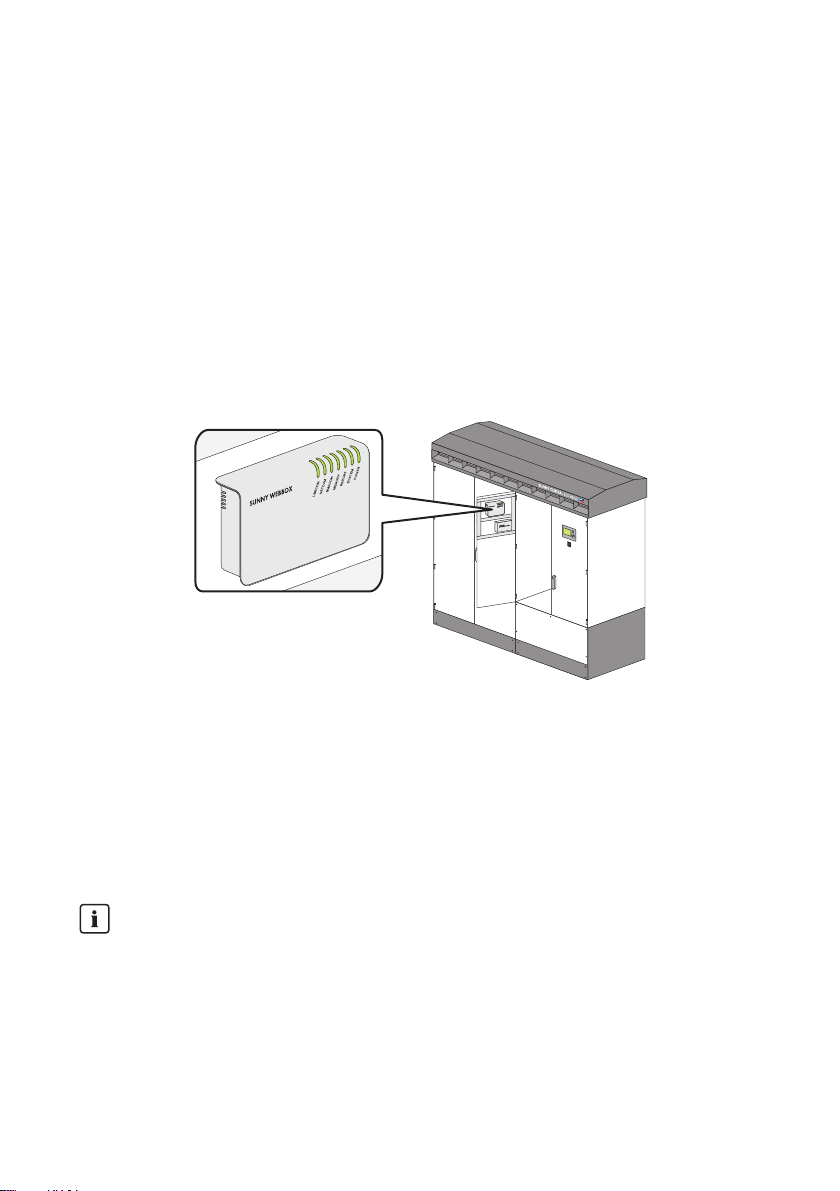

3.5 Sunny WebBox

The Sunny WebBox is a device that monitors and controls the inverter. The Sunny WebBox

establishes the connection between the PV plant and its operator.

Figure 5: Sunny WebBox in the Sunny Central

The Sunny WebBox collects all the data from connected devices. Using the Sunny WebBox, the

monitoring, parameterization, and remote diagnosis of the Sunny Central can be performed via a

computer. The operator can access all data stored in the Sunny WebBox via an Internet connection

or a GSM modem.

You can configure the settings of the Sunny WebBox in the web browser by entering the IP address

of the Sunny WebBox.

Communication type of the PV plant

The interface of the Sunny WebBox is set by default to "SMA-COM" and a 19 200 baud rate.

Do not modify these settings.

22 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 23

SMA America, LLC 3 Product Description

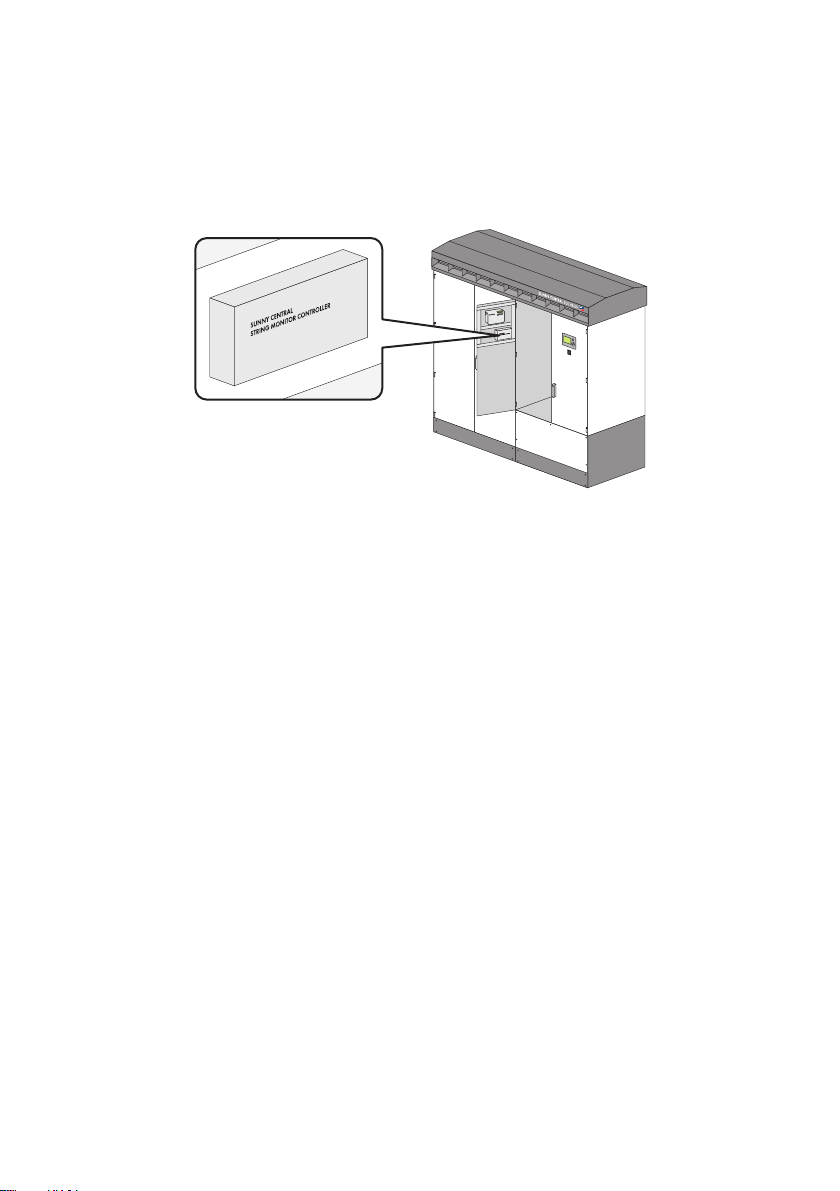

3.6 Sunny Central String-Monitor Controller

Depending on which options are ordered, the Sunny Central may be equipped with a Sunny Central

String-Monitor Controller for stringcurrent monitoring. The Sunny Central String-Monitor Controller

allows communication between the Sunny Central String-Monitors and the Sunny Central.

Figure 6: Sunny Central String-Monitor Controller

The Sunny Central String-Monitors measure the string currents via an integrated measuring circuit

board and continuously calculate the average value of the string currents. The measuring circuit board

compares the string currents with the average values. If a string current exceeds or falls below a

specified tolerance for the average value, a warning or fault is generated and displayed via the

Sunny WebBox user interface.

Operating Manual SC500HEUS-eng-BE-BUS120320 23

Page 24

3 Product Description SMA America, LLC

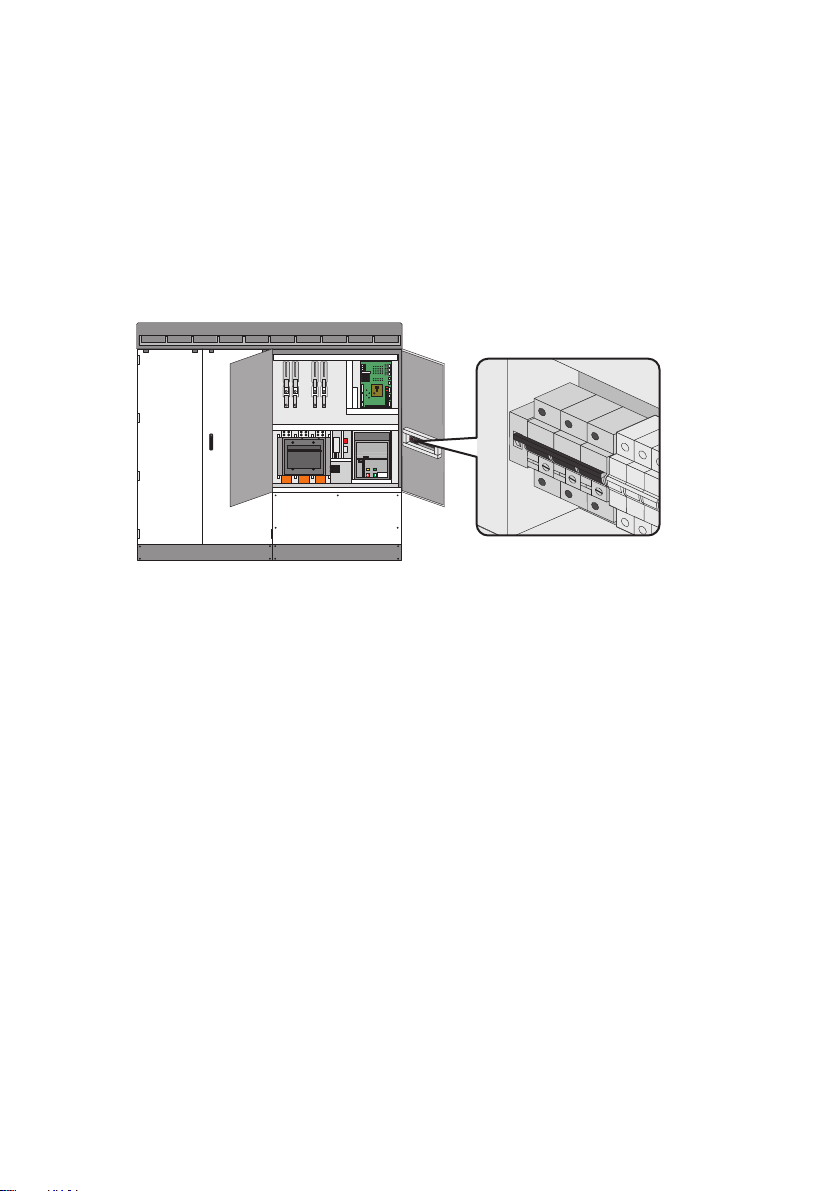

3.7 Insulation Monitoring Via GFDI

The insulation monitoring in the Sunny Central is performed via Ground Fault Detection Interruption

(GFDI).

GFDI is performed via a high-performance k-type miniature circuit-breaker with adjustable operating

current. The miniature circuit-breaker is integrated in the inverter and connected between a positively

or negatively grounded input busbar and the grounding busbar.

Figure 7: GFDI in the Sunny Central

3.8 Grid Management

3.8.1 Requirements

PV plants must participate in feed-in management in accordance with IEEE 1547. Most importantly

the grid operator must be able to limit the power of the PV plant by remote control and temporarily

reduce it to zero in critical cases. The relevant control commands of the grid operator must therefore

be transmitted to the Sunny Central quickly and reliably for implementation.

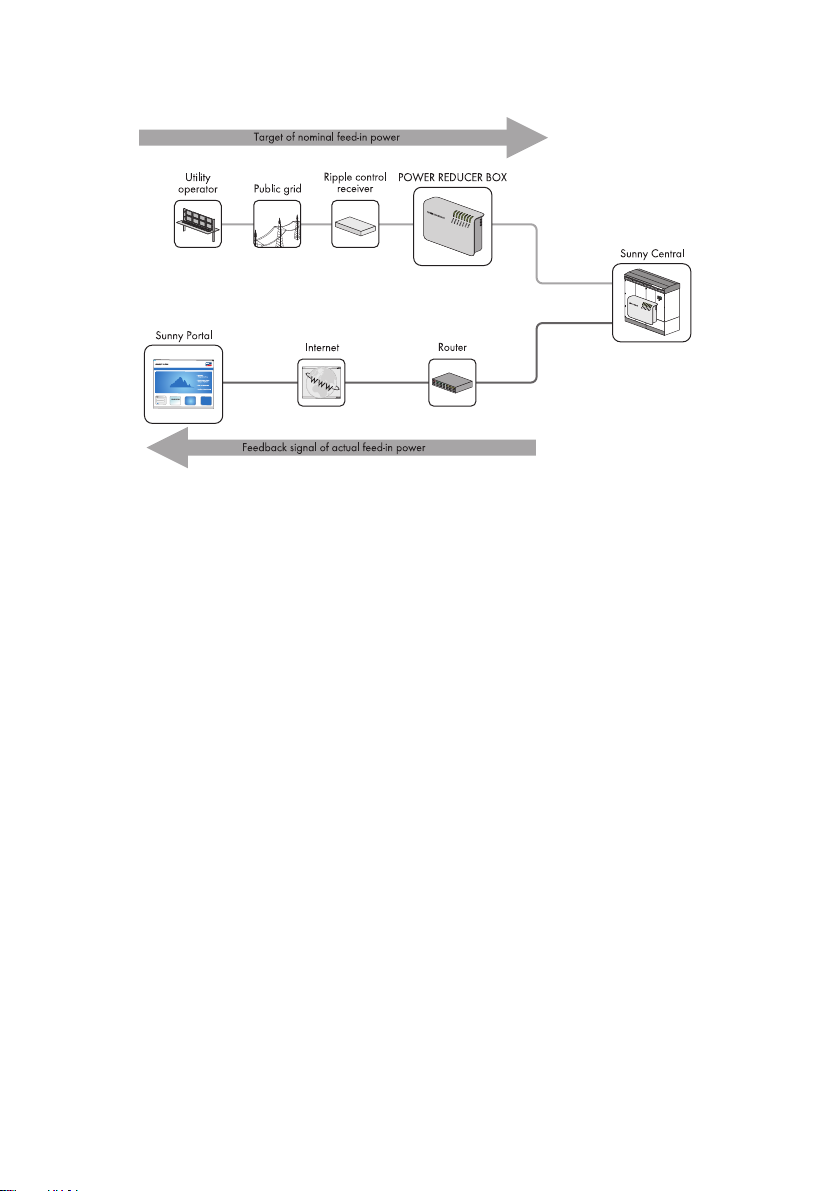

The following figure shows how the specifications of the grid operator are implemented. The

Power Reducer Box sends the specifications of the grid operator to the inverters.

24 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 25

SMA America, LLC 3 Product Description

Figure 8: Principle of grid integration

Besides the Power Reducer Box, there are two other options for meeting the requirement of the grid

operator:

• Receiving the signals via two analog inputs on the Sunny Central

• Manual specification adjustment via parameters

3.8.2 Active Power Limitation

There are five methods for limiting the active power independent o f th e po wer fre que ncy . Th e limit ca n

be defined using a parameter and supplied by the grid operator via an external signal.

At the same time, the active power can be limited depending on the power frequency (for information

on active power limitation parameterization, see section 7 "Active Power Limitation", page 35).

3.8.3 Reactive Power Regulation

The Sunny Central can provide reactive power. There are eleven methods for specifying the reactive

power target value. They include entering a fixed parameter, processing an external signal from the

grid operator or specifying the reactive power using characteristic curve parameters (for information

on reactive power regulation, see section 8 "Reactive Power Regulation", page 40).

Operating Manual SC500HEUS-eng-BE-BUS120320 25

Page 26

3 Product Description SMA America, LLC

3.9 Active Island Detection

The Active Island Detection function detects the formation of stand-alone grids during a grid failure

and disconnects the Sunny Central from the power distribution grid.

Loss of UL certification

The Active Island Detection function is standardized by IEEE 1547. Deactivation of the

islanding detection results in the loss of the UL certification of the inverter and SMA is not liable

for any resulting damage.

Stand-alone grids form when the following conditions occur simultaniously:

• The medium-voltage grid fails.

• The Sunny Central feeds in an amount x of power.

• There is a consumer on the same branch of the grid with a load equal to the amount x of power.

26 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 27

SMA America, LLC 4 Operating the Display

4 Operating the Display

4.1 Display Symbols

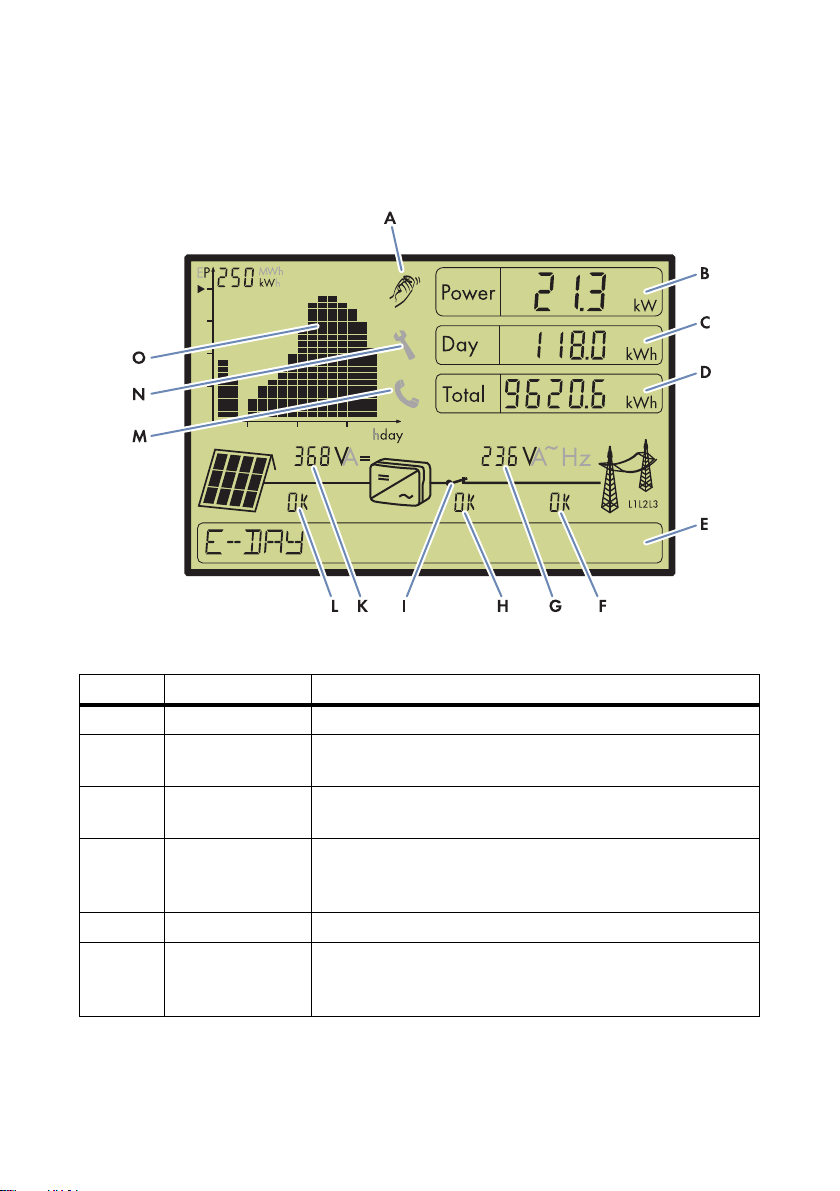

Figure 9: Display layout (example)

Position Designation Explanation

A Tapping Tapping on the enclosure switches on the backlight.

B Power Power that the Sunny Central is feeding into the power

distribution grid. The display is updated every 5 seconds.

C Day Energy that the Sunny Central has fed into the grid today.

The display is updated every 5 seconds.

D Total Energy that the Sunny Central has fed into the power distribution

grid during its operating time. The display is updated every

5 seconds.

E Text line The text line shows the menu or an error description.

F Power distribution

grid error number

Operating Manual SC500HEUS-eng-BE-BUS120320 27

If there is an error in the power distribution grid, an error number

will be shown in this position (see section

10 "Troubleshooting", page 55)

Page 28

4 Operating the Display SMA America, LLC

Position Designation Explanation

G Grid values In this position, the display shows the following values of the

power distribution grid:

•Voltage

•Frequency

• Average value of the current for all 3 line conductors

The display switches between the values every 2 seconds.

H Sunny Central error

number

If there is an error in the Sunny Central, an error number will be

shown in this position (see section

10 "Troubleshooting", page 55).

I Grid relay Grid relay open: The Sunny Central is not feeding into the powe r

distribution grid, e.g. at night.

Grid relay closed: The Sunny Central is feeding into the power

distribution grid.

K PV array values In this position, the display shows the following values of the

PV array:

•Voltage

•Current

The display switches between the values every 2 seconds.

L PV array error

number

If there is an error in the PV array, an error number will be shown

in this position (see section 10 "Troubleshooting", page 55).

M Telephone receiver If this symbol is lit, there is an error in the Sunny Central that

cannot be rectified on site. Contact the SMA Service Line

(see section 13 "Contact", page 87)

N Wrench If this symbol is lit, there is an error that can be rectified on site

(see section 10 "Troubleshooting", page 55).

O Diagram The power fed in by the Sunny Central is represented in a

diagram on the display. View the diagram in day mode

"E-HISTORY" or in hour mode "E-DAY" (see section

4.2 "Switching Diagram Modes", page 29). The diagram

updates every 5 seconds.

28 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 29

SMA America, LLC 4 Operating the Display

4.2 Switching Diagram Modes

View the power fed in by the Sunny Central as a diagram in the display. The diagram can be shown

in day mode or hour mode.

Figure 10: Diagram in hour mode and day mode (examples)

Position Designation

A Diagram in hour mode

B Diagram in day mode

C Energy fed in during the current day

D Power fed in during the current hour

ENo power is fed in

The diagram is shown in day mode by default. The diagram displays a total of 16 hours or 16 days

as bars. The current hour or the current day is the bar furthest to the right in the diagram (C and D).

With every new hour or new day, the diagram scrolls further to the left, out of the screen.

• To change to the day mode diagram view, turn the switch next to the display to the left.

• To change to the hour mode diagram view, turn the switch to the right.

4.3 Navigating the Menu

Using the switch next to the display, you can navigate the menu and select and configure values.

• To access the menu, press and hold the switch and the button for 2 seconds.

• To change the category, turn the switch (see section 4.4 "Menu Structure", page 30).

• To select a category tap the switch once.

• To go back, turn the switch until "BACK" shows on the display, tap the switch.

• To confirm an entry, tap the switch once.

• To increase or reduce values, turn the switch to the right or to the left.

Operating Manual SC500HEUS-eng-BE-BUS120320 29

Page 30

4 Operating the Display SMA America, LLC

4.4 Menu Structure

Access the menu in the text line. The menu has the following menu structure.

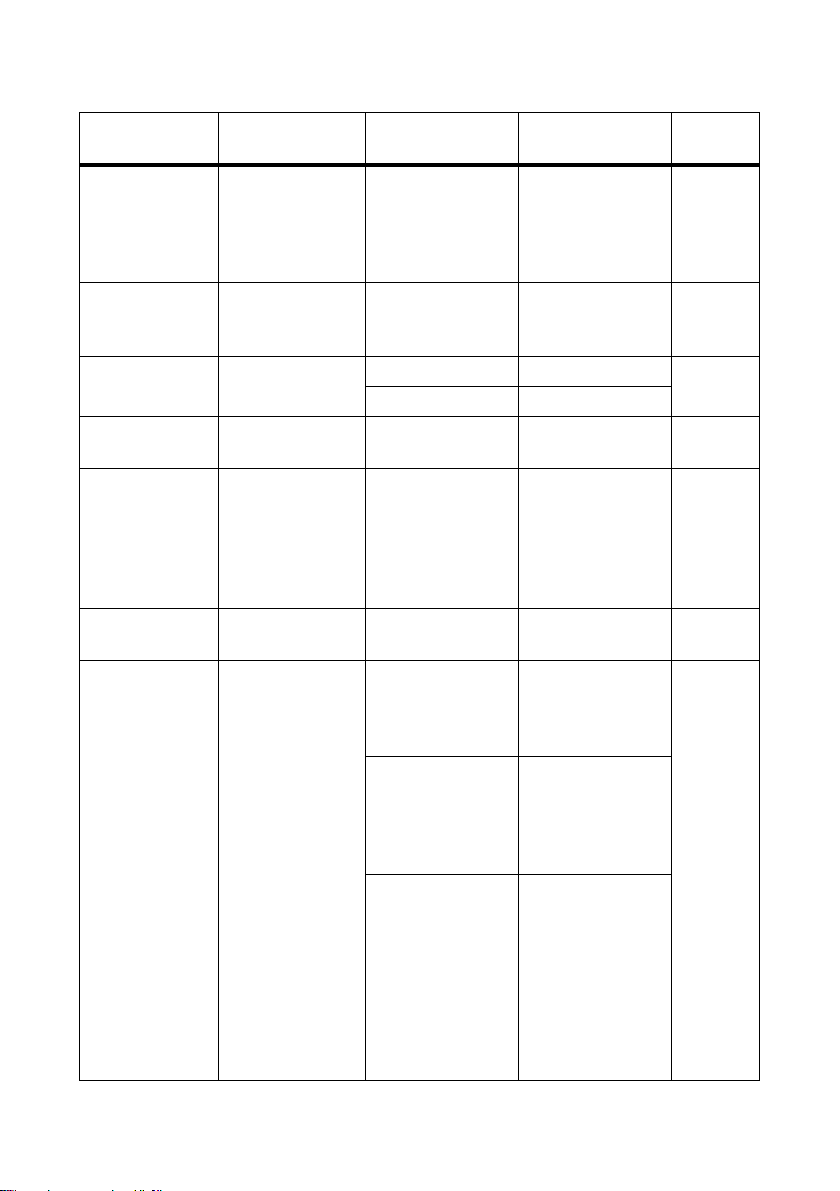

Menu level 1 Menu level 2 Menu level 3 Menu level 4

SETTINGS CURRENT TIME

TIME SETTINGS SET CURRENT TIME HOUR

MIN

BACK

SET CURRENT DATE YEAR

MONTH

DAY

BACK

BACK

BACK

INFO VERSION BFR

VERSION DSP

VERSION DISPLAY

VERSION LCD

BACK

BACK

Category Explanation

SETTINGS Set the date and time and read off the current time.

CURRENT TIME This category shows the current time.

TIME SETTINGS Change time and date (see section 4.5 "Changing the Time

Setting", page 31 and section 4.6 "Changing the Date Setting", page 31)

INFO This category shows the firmware version of the display and the

Sunny Central.

VERSION BFR This category shows the firmware version of the Sunny Central operation

control unit.

VERSION DSP This category shows the firmware version of the Sunny Central digital

signal processor.

VERSION DISPLAY This category shows the firmware version of the display.

VERSION LCD This category shows the firmware version of the LCD display.

30 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 31

SMA America, LLC 4 Operating the Display

4.5 Changing the Time Setting

1. Press the switch and the button for 2 seconds.

☑ The text line reads "SETTINGS".

2. Select TIME SETTINGS > SET CURRENT TIME > HOUR.

3. Use the switch to select the desired hour and confirm by tapping the switch.

4. Select MIN.

5. Use the switch to select the desired minute and confirm by tapping the switch.

4.6 Changing the Date Setting

1. Press the switch and the button for 2 seconds.

☑ The text line reads "SETTINGS".

2. Select TIME SETTINGS > SET CURRENT DATE > YEAR.

3. Use the switch to select the desired year and confirm by tapping the switch.

4. Select MONTH.

5. Use the switch to select the desired month and confirm by tapping the switch.

6. Select DAY.

7. Use the switch to select the desired day and confirm by tapping the switch.

4.7 Displaying the Firmware Version

1. Press the switch and the button for 2 seconds.

☑ The text line reads "SETTINGS".

2. Select INFO.

3. Use the switch to select the desired firmware version (see section 4.4 "Menu Structure", page 30).

4. Tap the switch.

5. Read off the desired firmware version.

Operating Manual SC500HEUS-eng-BE-BUS120320 31

Page 32

5 Configuring the Network Settings SMA America, LLC

5 Configuring the Network Settings

In order to access the inverter via the Internet, the Sunny WebBox must be set up in a plant network

(for information on the Sunny WebBox, see the SunnyWebBox user manual. In order for multiple

Sunny Centrals to operate in the same network, the Sunny WebBox must receive a unique network

address from every Sunny Central (for information on the network concept in a PV plant,

see technical information "Plant Communication in large-scale PV plants" at www.SMA-America.com).

Settings:

• Set the IP address on the computer

• Set the IP address of the Sunny WebBox

Setting the IP address on the computer

1. In Windows, select Start > Run.

2. Enter ncpa.cpl in the box and press [OK].

☑The "Network Connections" window opens.

3. Double-click on the LAN connection via which the Sunny Central is connected.

4. Select [Properties].

☑The "Local Area Connection Properties" window opens.

5. Mark "Internet Protocol (TCP/IP)" and select [Properties].

☑The "Internet Protocol (TCP/IP) Properties" window opens.

6. Note down the existing network settings so that you can restore the settings in your computer

after commissioning the Sunny Central.

7. In the "Internet Protocol (TCP/IP) Properties" window, enter the following properties:

•Enter 192.168.0.100 in the "IP address" field.

•Enter 255.255.255.0 in the "Subnet mask" field.

8. Select [OK].

9. In the "Local Area Connection Properties" window, select [OK].

☑ The computer is set according to the network settings of the Sunny Central.

32 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 33

SMA America, LLC 5 Configuring the Network Settings

Setting the IP address of the Sunny WebBox

1. Co nne ct a lap top to t he S unn y We bBo x us ing a pa tch cab le. For this purp ose , us e th e cr oss ove r

cable.

2. Enter 192.168.0.168 in the address bar of the web browser.

☑ The user interface of the Sunny WebBox appears.

3. Enter the installer password in the appropriate field on the homepage.

4. Select [Login].

5. Select WebBox > Settings > Network.

6. In the "IP address" field, enter the static IP address under which the Sunny WebBox is to be

accessed in the local network.

7. Enter the subnet mask of your network in the "Subnet mask" field.

8. Enter the gateway IP address of your network in the "Gateway address" field. Usually,

the IP address of the router has to be entered here.

9. Enter the IP address of the DNS server (Domain Name System) in the "DNS server address"

field. Usually, the IP address of the router has to be entered here.

10. Select [Save] and [Confirm].

Operating Manual SC500HEUS-eng-BE-BUS120320 33

Page 34

6 Communication with the Sunny WebBox SMA America, LLC

6 Communication with the Sunny WebBox

6.1 Displaying the Instantaneous Values

1. Start the Sunny WebBox user interface (see the SunnyWebBox user manual).

2. Enter the installer password in the appropriate field on the homepage and confirm with [Login].

3. Select Plant > Devices.

4. Select the desired device from the list.

5. Select the Instantaneous values tab.

☑ The instantaneous values of the desired device are displayed.

6.2 Changing Parameters

1. Start the SunnyWebBox user interface ((see the SunnyWebBox user manual).

2. Enter the installer password in the appropriate field on the homepage and confirm with [Login].

3. Select Plant > Devices.

4. Select the desired device from the list.

5. Select the Parameter tab.

6. Change the value of the respective parameter via the "Value" field.

7. Select [Save].

34 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 35

SMA America, LLC 7 Active Power Limitation

7 Active Power Limitation

The Sunny Central can limit its active power if requested by the grid operator. The limitation of the

active power can be performed both dependent on the power frequency and independent of the grid

frequency. The frequency-dependent active power limitation is regulated in accordance with the

specifications of IEEE 1547 and cannot be changed. This section describes the function and

parameterization of both types of active power limitation.

7.1 Power Frequency-Dependent Active Power Limitation

During active power limitation dependent on the power frequency, the Sunny Central constantly

checks the connected power frequency.

Figure 11: Behavior of the Sunny Central when exceeding the "P-HzStr" frequency limit

If the power frequency exceeds a limiting value defined in the parameter "P-HzStr", sho wn u nde r po int

A, the Sunny Central will save the current feed-in capacity P

. The reduced feed-in capacity is

mom

calculated based on this saved value. The reduction of the feed-in capacity is defined by the

parameter "P-WGra". T his parameter ind icates the percentage of the saved power P

by which the

mom

power per Hz will be reduced if the power frequency continues to rise.

If the power frequency decreases again as shown in point B, the last reached feed-in capacity will

remain valid. Only if the power falls below the limiting value defined in the parameter "P-HzStop",

shown here in point C, can the fed-in power be increased again. The saved value P

mom

will be

rendered invalid.

If the power frequency exceeds the grid limit, the Sunny Central will shut down and switch over to the

operating state "Grid monitoring". The Sunny Central will remain in the "Grid monitoring" operating

state until all feed-in conditions are fulfilled again.

Operating Manual SC500HEUS-eng-BE-BUS120320 35

Page 36

7 Active Power Limitation SMA America, LLC

Calculating the active power limit

Formula: P

Grenz

= P

mom

– ( (f

– P-HzStr) * P-WGra * P

Netz

mom

)

P

Grenz

P

mom

Power frequency

f

Netz

Power limit

Current power

P-HzStr Selected frequency limit at which the active power will be reduced

P-WGra Gradient of the active power limitation

Example: Calculating the active power limit

A Sunny Central with 500 kW feeds in 350 kW (P

) into the power distribution grid.

mom

The frequency will reach up to 51.2 Hz.

The difference between the current power frequency and "P-HzStr" (51.2 Hz - 50.2 Hz) multiplied

by the gradient "P-WGra" (40%/Hz) results in an active power reduction of 40% of the last

available power P

(350 kW). This results in an active power limitation of 140 kW and a

mom

maximum active power of 210 kW.

Calculation:

210 kW = 350 kW – ( (51.2 Hz – 50.2 Hz) * 40 %/Hz * 350 kW )

7.2 Power Frequency-Independent Active Power Limitation

7.2.1 Selecting the Procedure using the Parameter "P-WMod"

Use the "P-WMod" parameter to set the procedure for the frequency-independent active power

li mit ati on. Use the par ame ter to c onf igu re h ow t he p ara met ers of the grid operator should be received

and implemented. The default value for this parameter is "WCnst".

There are five different procedures for power frequency-independent active power limitation:

Procedure Description

Off The active power is limited to the nominal device power "Pmax".

WCtlCom The active power limitation is received by the Sunny WebBox via

the Power Reducer Box and then forwarded to the Sunny Central.

WCnst The active power limitation is entered as an absolute value via the

parameter "P-W".

WCnstNom The active power limitation is entered as a percentage value via

the parameter "P-WNom".

WCnstNomAnIn Active power limitation is set at the input terminals using an analog

signal for specifying the target value.

36 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 37

SMA America, LLC 7 Active Power Limitation

Parameter blocking

The parameter "P-WMod" may only be changed when the device is in the operating state

"Stop". The entry will not be accepted in other operating states.

1. Ensure that the inverter is in the operating state "Stop".

2. Launch the Sunny WebBox user interface.

3. Enter the installer password in the appropriate field on the homepage and confirm with [Login].

4. Change the parameter "P-WMod" in the Sunny WebBox user interface

(see section 6.2 "Changing Parameters", page 34).

5. Change the parameters belonging to the selected procedure.

6. Confirm the parameter entry with [Save].

7.2.2 "Off" Procedure

The feed-in capacity is limited by the parameter "Pmax".

The parameter "Pmax" defines the nominal power of the inverter and is set to the local conditions

during commissioning. Before the parameter "Pmax" can be changed, the device must be in the

operating state "Stop" and the installer password must be entered.

Parameter used Pmax

7.2.3 "WCtlCom" Procedure

The target value for active power limitation is received by the Sunny WebBox via the

Power Reducer Box and then forwarded to the Sunny Central. If the Sunny Central has received no

signal for 5 minutes, the error message "P-WModFailStt" will be displayed (see section

7.4 "Displaying Error Messages and Warnings for Active Power Limitation", page 39).

Parameters used None

7.2.4 "WCnst" Procedure

The active power limitation is entered as an absolute value via the parameter "P-W".

The parameter "P-W" defines the active power to be fed in. The parameter "P-W" can be changed

during feed-in operation. The value of the parameter "P-W" may be as large as the value of the

parameter "Pmax" at maximum.

Parameter used P-W

Operating Manual SC500HEUS-eng-BE-BUS120320 37

Page 38

7 Active Power Limitation SMA America, LLC

7.2.5 "WCnstNom" Procedure

Th e ac tiv e powe r li mit ati on is s et a s a per cen tag e vi a the p ara meter "P-WNom". The percentage value

refers to the parameter "Pmax".

The parameter "P-WNom" indicates the percentage of maximum possible power to be fed in. The

parameter "P-WNom" can be changed during feed-in operation.

Parameter used P-WNom

7.2.6 "WCnstNomAnIn" Procedure

The active power limitation is set at the input terminals using an analog signal for specifying the target

value (see the inverter installation manual). This is usually implemented by a ripple control receiver.

The electrical current strength of the connected signal determines the rated active power.

The analog measured values must be between 4 mA and 19 mA. If the analog signal is less than

2 mA, the error message will be displayed in the instantaneous value "P-WModFailStt"

(see section 7.4 "Displaying Error Messages and Warnings for Active Power Limitation", page 39).

Signal Power limit Description

< 2 mA Last valid value and/or "Pmax"

after restart

2mA…4mA 0 kW No power is fed into the grid.

4 mA … 19 mA 0 kW … Pmax Fed-in energy is determined using a

> 19 mA Pmax Fed-in energy is equal to the value of the

Signal is in the invalid range.

characteristic curve

parameter "Pmax".

The analog value is converted to a target value for active power limitation. Here, the parameter

"Pmax" is the end point of the linear characteristic curve.

Parameters used None

7.3 Displaying the Active Power Limitation Status

The instantaneous value "P-WModStt" displays the status of the active power limitation.

• Display the instantaneous value

(see section 6.1 "Displaying the Instantaneous Values", page 34).

38 SC500HEUS-eng-BE-BUS120320 Operating Manual

"P-WModStt" on the SunnyWebBox user interface

Page 39

SMA America, LLC 7 Active Power Limitation

Display Explanation

"Off" No procedure for active power limitation has been selected..

"WMax" Active power is limited by the specified maximum limit. Here, the limit is based on

the value of the parameter "Pmax".

"Hz" Active power is limited by a frequency increase.

"Tmp" Active power is limited due to temperature derating.

"AmpPv" Active power is limited via PV power limitation.

7.4 Displaying Error Messages and Warnings for Active Power Limitation

The instantaneous value "P-WModFailStt" displays the error messages or warnings associated with

active power limitation.

• Display the instantaneous value

section 6.1 "Displaying the Instantaneous Values", page 34).

Display Cause and corrective measures

"Off" No procedure for active power limitation has been selected.

"Ok" A procedure for active power limitation has been selected and there are no errors.

"ComFail" The procedure "WCtlCom" has been selected and the expected signal with a valid

active power limitation has been absent for 5 minutes.

Corrective measures:

• E nsu re t hat the Sunny W ebB ox a nd t he Pow er R edu cer Box can be a ccessed

via the Internet.

• Ensure that the Sunny WebBox and the Power Reducer Box are connected

correctly.

• Ensure that the cabling between the Sunny WebBox and the inverter is OK.

"AnInFail" The procedure "WCnstNomAnIn" has been selected and the value measured at the

analog input is less than 2 mA.

Corrective measures:

• Ensure that the signal cable is correctly connected to the analog input.

"P-WModFailStt" on the SunnyWebBox user interface (see

Operating Manual SC500HEUS-eng-BE-BUS120320 39

Page 40

8 Reactive Power Regulation SMA America, LLC

8 Reactive Power Regulation

The Sunny Central can supply reactive power if required by the grid operator. The grid operator

defines the procedures and target values used for this.

8.1 Procedure for Reactive Power Regulation

8.1.1 Selecting the Procedure using the Parameter "Q-VArMod"

The parameter "Q-VArMod" is used to select the procedure for reactive power regulation. Use the

parameter to configure how the specifications of the grid operator are to be received and

implemented.

There are eleven different procedures for reactive power regulation. The default value for this

parameter is "Off".

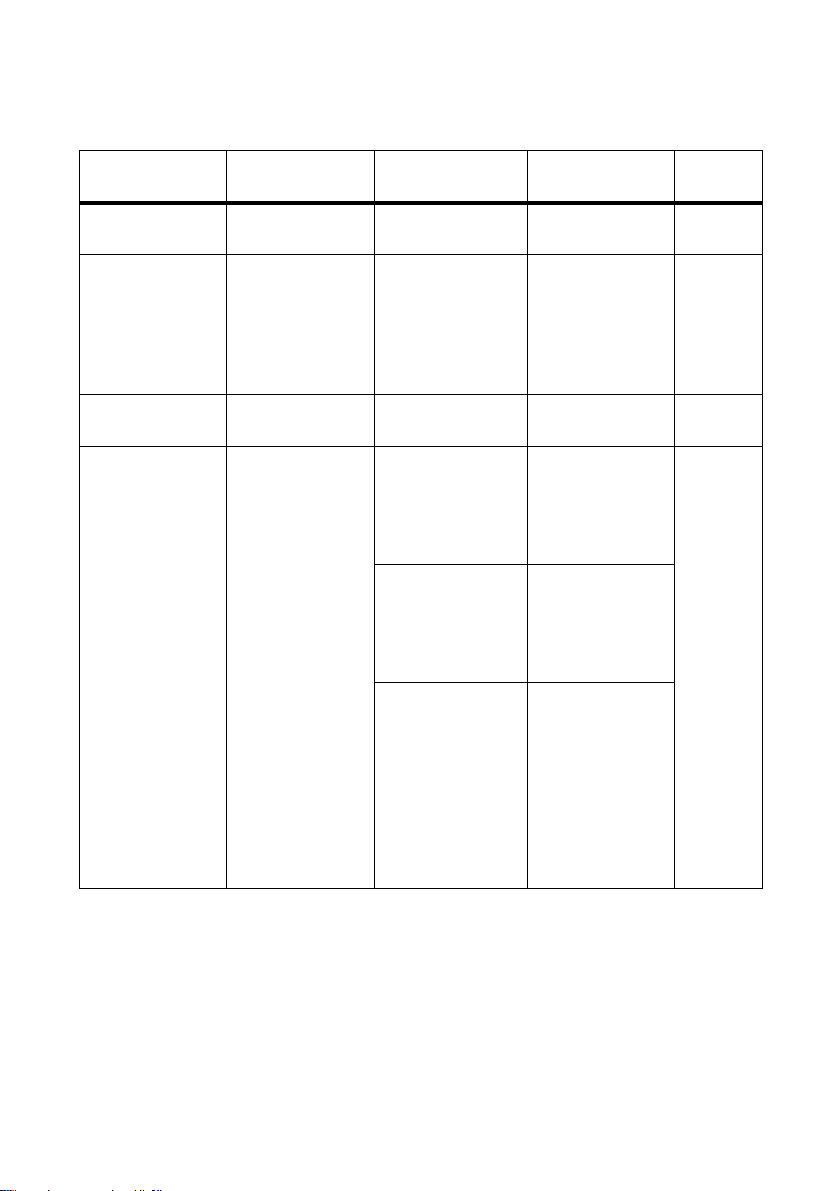

Procedure Description

"Off" The reactive power target value is limited to 0 kVAr.

"VArCtlCom" The reactive power target value is received by the Sunny WebBox via the

Power Reducer Box and forwarded to the Sunny Central. The target value

is transmitted as a percentage and converted to kVAr inside the inverter.

"PFCtlCom" The reactive power target value is received by the Sunny WebBox via the

Power Reducer Box and forwarded to the Sunny Central. A displacement

power factor cos φ is transmitted as a target value.

"VArCnst" The parameter "Q-VAr" is used to set the reactive power target value in

kVAr.

"VArCnstNom" The parameter "Q-VArNom" is used to set the reactive power target value

as a percentage based on "Pmax".

"VArCnstNomAnIn" The reactive power target value is imported through an analog input. The

analog value is converted into a reactive power target value.

"PFCnst" The reactive power target value is set using a displacement power factor

cos φ.

"PFCnstAnIn" The reactive power target value is imported through the analog input for

specifying target values. The analog value is converted into a

displacement power factor cos φ.

"PFCtlW" The displacement power factor cos φ is set depending on the feed-in

capacity. The dependency is depicted by a parameterizable curve.

"VArCtlVol" Reactive power is set depending on the line voltage. The parameterization

of this function depends on the medium voltage.

40 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 41

SMA America, LLC 8 Reactive Power Regulation

Procedure Description

"VArCtlVolHystDb" The supply of reactive power helps perform voltage-stabilizing measures

in the event of over- or undervoltage. The parameterization is performed

using a reactive power/voltage characteristic curve.

Parameter blocking

The parameter "Q-VArMod" may only be changed when the device is in the operating state

"Stop". The entry will not be accepted in other operating states.

1. Ensure that the inverter is in the operating state "Stop".

2. Start the Sunny WebBox user interface.

3. Enter the password in the appropriate field on the homepage and confirm with [Login].

4. Change the parameter "Q-VArMod" (see section 6.2 "Changing Parameters", page 34).

5. Change the parameters belonging to the selected procedure.

6. Confirm the parameter entry with [Save].

8.1.2 "Off" Procedure

The reactive power target value is limited to 0 kVAr. This target value cannot be influenced.

Parameters used None

8.1.3 "VArCtlCom" Procedure

The reactive power target value is received by the Sunny WebBox via the Power Reducer Box and

forwarded to the Sunny Central. The target value is transmitted as a percentage and converted to

kVAr inside the inverter.

If the Sunny Central has received no signal for 5 minutes, the "Q-VArModFailStt" error message will

be displayed.

Parameters used None

8.1.4 "PFCtlCom" Procedure

The reactive power target value is received by the Sunny WebBox via the Power Reducer Box and

forwarded to the Sunny Central. A displacement power factor cos φ is transmitted as a target value.

If the Sunny Central has received no signal for 5 minutes, the error message will be displayed in the

instantaneous value "Q-VArModFailStt".

Parameters used None

Operating Manual SC500HEUS-eng-BE-BUS120320 41

Page 42

8 Reactive Power Regulation SMA America, LLC

8.1.5 "VArCnst" Procedure

The parameter "Q-VAr" is used to set the reactive power target value in kVAr. For this purpose, the

parameter "Q-VAr" must be in the range of "‒Qmax" to "+Qmax".

Parameter used Q-VAr

8.1.6 "VArCnstNom" Procedure

The parameter "Q-VArNom" is used to set the reactive power target value in percent. The parameter

"Q-VArNom" refers to "Pmax". If the calculated amount of reactive power exceeds the predefined

value "Qmax", the power will be limited to "Qmax". If the calculated amount of reactive power falls

below the predefined value "‒Qmax", the power will be limited to "‒Qmax".

Parameter used Q-VArNom

8.1.7 "VArCnstNomAnIn" Procedure

The reactive power target value is set at the input terminals using an analog signal for specifying the

target value (see the the inverter installation manual). This is usually implemented by a ripple control

receiver.

The analog value is converted into a reactive power target value. The electrical current strength of the

connected signal determines the target value.

The analog measured values must be between 4 mA and 19 mA. If the analog signal is less than

2 mA, the error message will be displayed in the instantaneous value "Q-VArModFailStt".

Signal Power limit Explanation

< 2 mA Last valid value or 0 kVAr after

restart

2mA…4mA −Pmax The maximum amount of negatively

4 mA − Pmax Starting point of the curve

11.5 mA 0 kVAr Zero-crossing of the curve

> 19 mA +Pmax End point of the curve

42 SC500HEUS-eng-BE-BUS120320 Operating Manual

Signal is in the invalid range.

excited reactive power is fed in.

Maximum amount of negatively excited

reactive power is fed in.

No reactive power is fed in.

Maximum amount of positively excited

reactive power is fed in.

Page 43

SMA America, LLC 8 Reactive Power Regulation

11,5

Q [VAr]

1942

- Q

max

- P

max

0

I [mA]

Q

max

P

max

The analog value is converted to a target value for power limitation. Here, the parameter "Pmax" is

the end point of the linear characteristic curve.

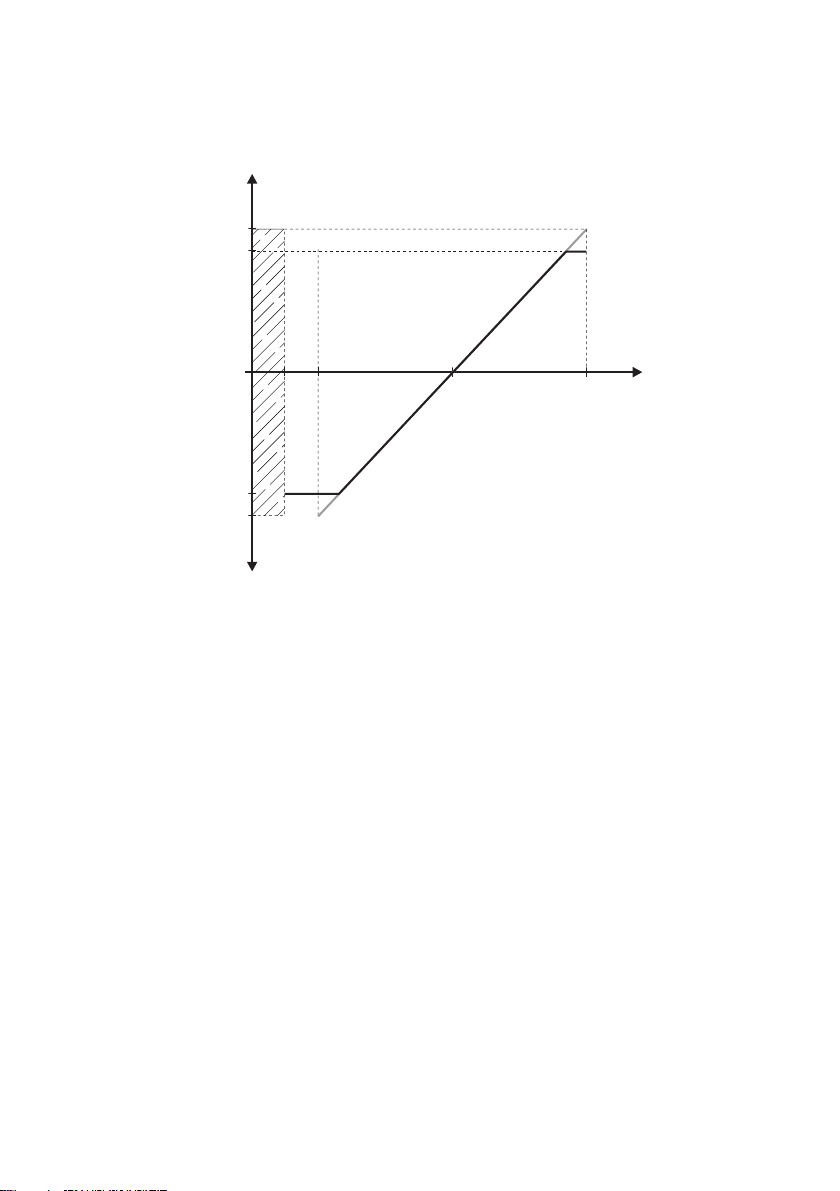

Figure 12: Limiting the parameter "Pmax" to the parameter "Qmax"

If the value of "Pmax" exceeds the value of "Qmax", the characteristic curve of the value Q

limited to "Qmax" and the reactive power value in the range from +Q

max

to +P

will constantly

max

max

will be

remain at "Qmax".

If the value of "‒Pmax" falls below the value of "‒Qmax", the characteristic curve of the value ‒Q

will be limited to "‒Qmax" and the reactive power value in the range from ‒Q

max

to ‒P

max

max

will

constantly remain at "‒Qmax".

Parameters used None

8.1.8 "PFCnst" Procedure

The reactive power setpoint is set using the parameters "PF-PF" and "PF-PFExt". The parameter "PF-PF"

indicates the displacement power factor cos φ and the parameter "PF-PFExt" indicates the degree of

overexcitation or underexcitation. The parameter "PFAbsMin" is the start and end point of the linear

characteristic curve.

Parameters used PF-PF

PF-PFExt

Operating Manual SC500HEUS-eng-BE-BUS120320 43

Page 44

8 Reactive Power Regulation SMA America, LLC

8.1.9 "PFCnstAnIn" Procedure

The reactive power target value is set at the input terminals using an analog signal for specifying the

target value (see the inverter installation manual). This is usually implemented by a ripple control

receiver.

The analog value is converted into a displacement power factor cos φ. The electrical current strength

of the connected signal determines the target value.

The analog measured values must be between 4 mA and 19 mA. If the analog signal is less than

2 mA, the error message will be displayed in the instantaneous value "Q-VArModFailStt".

Signal Power limit Description

< 2 mA Last valid value,

or 1 after restart

2mA…4mA "PFAbsMin"/underexcited The maximum amount of negatively

4 mA "PFAbsMin"/underexcited Starting point of the curve

11.5 mA 1 Zero-crossing of the curve

>19mA "PFAbsMin"/overexcited End point of the curve

Signal is in the invalid range.

excited reactive power is fed in.

Maximum amount of negatively excited

reactive power is fed in.

No reactive power is fed in.

Maximum amount of positively excited

reactive power is fed in.

The analog value is converted into a target value for the displacement power factor cos φ. Here, the

parameter "PFAbsMin" is the start and end point of the linear characteristic curve.

Parameter used "PFAbsMin"

44 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 45

SMA America, LLC 8 Reactive Power Regulation

1

PF-PFStop /

PF-PFExtStop

PF-PFStr /

PF-PFExtStr

PF-WStr

PF-WStop

leading

Current active power

lagging

8.1.10 "PFCtlW" Procedure

For the procedure "PFCtlW", the displacement power factor cos φ is set depending on the feed-in

capacity. The dependency is depicted by a parameterizable curve. The parameters of the curve may

be set to either make it rise or fall. The start and end points of the characteristic curve can be set via

parameters.

Figure 13: Characteristic curve for reducing reactive power depending on active power

On the basis of a linear characteristic curve with an upper and lower limit, a displacement power

factor cos φ can be regulated dependent on the active power fed in at the time. The start and end

points of the characteristic curve can be set via parameters. The course of the characteristic curve is

determined by the setting of the start and end points.

Parameters used "PF-PFStr"

"PF-PFExtStr"

"PF-PFStop"

Operating Manual SC500HEUS-eng-BE-BUS120320 45

"PF-PFExtStop"

"PF-WStr"

"PF-WStop"

Page 46

8 Reactive Power Regulation SMA America, LLC

8.1.11 "VArCtlVol" Procedure

Contact the SMA Service Line before changing any parameters

Contact the SMA Service Line before selecting or configuring the "VArCtlVol" procedure.

The reactive power is set depending on the line voltage. The reactive power target value is adjusted

in stages.

Figure 14: Characteristic curve for reducing reactive power depending on line voltage

If the line voltage changes by the parameterizable voltage difference "Q-VDif" for the configurable

duration of "Q-VDifTm", the reactive power target value is adapted by the value "Q-VArGr".

The parameterization of this function depends on the medium voltage.

Parameters used "Q-VDif"

"Q-VArGra"

"Q-VDifTm"

"Q-VRtgOfsNom"

46 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 47

SMA America, LLC 8 Reactive Power Regulation

8.1.12 "VArCtlVolHystDb" Procedure

Contact the SMA Service Line before changing any parameters

The procedure "VArCtlVolHystDb" may only be selected and configured after consultation with

the SMA Service Line.

By supplying reactive power, the inverter helps perform voltage-stabilizing measures in the event of

overvoltage or undervoltage. The parameters are configured using a reactive power/voltage

characteristic curve. The characteristic curve can be flexibly configured by parameterizing the slope,

a type of deadband through 2 voltage points, and a hysteresis.

Figure 15: Characteristic curve for reducing reactive power without deadband and without hysteresis

Operating Manual SC500HEUS-eng-BE-BUS120320 47

Page 48

8 Reactive Power Regulation SMA America, LLC

VolNomP1 = VolNomP2

VArGraNom

VolWidNom

Q

[VAr]

max

Q

max

line voltage

Figure 16: Characteristic curve for reducing reactive power with deadband

Figure 17: Characteristic curve for reducing reactive power with hysteresis

48 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 49

SMA America, LLC 8 Reactive Power Regulation

Figure 18: Characteristic curve for reducing reactive power with deadband and hysteresis

The parameter "Q-VArTmsSpnt" determines the delay time after which the calculated reactive power

target value is actively used.

In order to prevent several systems with the function from influencing each other, the parameter

"Q-VArTmsVtg" can be used to set a delay time. This delay time indicates for how long a voltage

change must be pending before a change in the reactive power supply will result. This allows several

systems to alternately regulate the line voltage at the grid connection joint.

You can activate and deactivate the delay time using the parameter "Q-EnaTmsVtg".

Parameters used "Q-VolWidNom"

"Q-VolNomP1"

"Q-VolNomP2"

"Q-VArGraNom"

"Q-VArTmsSpnt"

"Q-VArTmsVtg"

"Q-EnaTmsVtg"

Operating Manual SC500HEUS-eng-BE-BUS120320 49

Page 50

8 Reactive Power Regulation SMA America, LLC

8.2 Error Messages and Warnings for the Reactive Power Setpoint

The instantaneous value "Q-VArModFailStt" displays errors or warnings relating to the reactive power

setpoint.

• Display the instantaneous value

"Q-VArModFailStt" on the Sunny WebBox user interface (see

section 6.1 "Displaying the Instantaneous Values", page 34).

Display Cause and corrective measures

"Off" No procedure for specifying the reactive power setpoint has been selected.

"Ok" A procedure for specifying the reactive power setpoint has been sel ect ed and the re

are no errors.

"ComFail" The procedure "VArCtlCom" or "PFCtlCom" has been selected and the expected

signal with a valid reactive power setpoint has been absent for at least 5 minutes.

Corrective measures:

• E nsu re t hat the Sunny W ebB ox a nd t he Pow er R edu cer Box can be a ccessed

via the Internet.

• Ensure that the Sunny WebBox is connected correctly.

• Ensure that the cabling between the Sunny WebBox and the inverter is OK.

"AnInFail" The procedure "VArCnstNomAnIn" or "PFCnstNomAnIn" has been selected and the

value measured at the analog input is less than 2mA.

Corrective measures:

• Ensure that the signal cable is correctly connected to the analog input.

50 SC500HEUS-eng-BE-BUS120320 Operating Manual

Page 51

SMA America, LLC 9 Grid Monitoring

9 Grid Monitoring

9.1 How Grid Monitoring Works

The Sunny Central has an integrated grid monitoring function. This means that the Sunny Central

monitors the power distribution grid to ensure that it remains within a definable range of limiting

values. If the configured limiting values for the line voltage or the power frequency are exceeded or

are not met for a specific time, the Sunny Central disconnects from the power distribution grid.

Loss of UL certification

The limiting values for the line voltage and the power frequency are configured in accordance

with IEEE 1547. Changes to the factory-configured limiting values result in the loss of UL

certification.

• If the UL certification is the deciding factor for the operation permission of the inverter, do

not make any changes to the factory-configured limiting values for the grid monitoring

parameters.

9.2 Monitoring the Line Voltage

For the line voltage monitoring, two limiting values in percent are defined for the minimum and the

maximum line voltage respectively, in accordance with IEEE 1547. The percentage is based on the

nominal voltage of the inverter.

If the line voltage falls below the value defined in the parameter "VCtllLim" or "VCtlllLim", the

Sunny Central waits for the period defined in the parameter "VCtllLimTm" or "VCtlllLimTm" and

disconnects from the power distribution grid.

If the line voltage increases above the value defined in the parameter "VCtlhLim" or "VCtlhhLim", the

Sunny Central waits for the period defined in the parameter "VCtlhLimTm" or "VCtlhhLimTm" and

disconnects from the power distribution grid.

Example: Behavior of the inverter in the event of undervoltage

The first limiting value for the undervoltage is defined in the parameter "VCtllLim" and is 88% of the

nominal voltage of the inverter. The associated period is set to 2 000 ms in the parameter

"VCtllLimTm". The second limiting value for the undervoltage is defined in the parameter "VCtlllLim"

and is 50% of the nominal voltage of the inverter. The associated period is set to 160 ms in the

parameter "VCtlllLimTm".

The line voltage falls to 85% of the nominal voltage and has therefore fallen below the first limiting

value of the undervoltage. The inverter waits 2 000 ms. If the line voltage does not increase above

the first limiting value within this period, the inverter disconnects from the power distribution grid. If

the line voltage falls below the second limiting value, the Sunny Central switches off after 160 ms.

Operating Manual SC500HEUS-eng-BE-BUS120320 51

Page 52

9 Grid Monitoring SMA America, LLC

Figure 19: Parameters for monitoring the line voltage

Parameters Explanation Default value

"VCtlllLim" The second limiting value for the undervoltage 50%

"VCtlllLimTm"

Time period for the second limiting value of the undervoltage

160 ms

"VCtllLim" The first limiting value of the undervoltage 88%

"VCtllLimTm" Time period for the first limiting value of the undervoltage 2 000 ms

"VCtlhLim" The first limiting value for the overvoltage 110%

"VCtlhLimTm" Time period for the first limiting value for the overvoltage 1 000 ms

"VCtlhhLim" The second limiting value for the overvoltage 120%

"VCtlhhLimTm"