SMA SC 500HE-20 Maintenance Manual

EN

Central Inverter

SUNNY CENTRAL 500HE-20/630HE-20/720HE-20/

760HE-20/800HE-20

Maintenance Manual

SC500-800HE20-WH-en-10 | 98-4110410 | Version 1.0

SMA Solar Technology AG Table of Contents

Table of Contents

1 Information on this Document. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Skills of Skilled Persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Personal Protective Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Maintenance Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Sunny Central HE-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Design of the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Maintenance when Voltage is Present. . . . . . . . . . . . . . . . . . . 14

5.1 Reading off Error Messages and Warnings . . . . . . . . . . . . . . . . . . . 14

5.2 Checking the DC Switch-Disconnector. . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Checking the External Fast-Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4 AC Circuit Breaker (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Maintenance Under Voltage-Free Conditions . . . . . . . . . . . . . 18

6.1 Disconnecting the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Disassembling the Panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Replacing Ventilation Grid Mats . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.4 Maintaining the Interior of the Switch Cabinet . . . . . . . . . . . . . . . . . 21

6.4.1 Disassembling the Protective Covers . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4.2 Checking the Interior of the Switch Cabinet. . . . . . . . . . . . . . . . . . . 21

6.4.3 Checking the Fuses/Disconnecting Blades . . . . . . . . . . . . . . . . . . . 21

6.4.4 Checking the Surge Arrester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4.5 Replacing the GFDI/Soft Grounding Relay . . . . . . . . . . . . . . . . . . . 23

6.4.6 Checking the Screw Connections of the Power Cabling . . . . . . . . . 24

6.4.7 Checking Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Maintenance Manual SC500-800HE20-WH-en-10 3

Table of Contents SMA Solar Technology AG

6.5 Checking the Switch Cabinet from the Outside. . . . . . . . . . . . . . . . . 27

6.5.1 Checking the Door Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.5.2 Checking the Locking Devices and Hinges . . . . . . . . . . . . . . . . . . . 28

6.5.3 Checking the Surface of the Switch Cabinet . . . . . . . . . . . . . . . . . . 28

6.5.4 Checking the Switch Cabinet for Corrosion. . . . . . . . . . . . . . . . . . . 29

6.6 Mounting the Protective Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.7 Mounting the Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.8 Maintenance after Connecting the Control Voltage . . . . . . . . . . . . . 31

6.8.1 Connecting the Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.8.2 Checking the Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.8.3 Checking the Heating Element and Hygrostat . . . . . . . . . . . . . . . . . 32

7 Maintaining the Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.1 Maintaining the Sunny String-Monitor. . . . . . . . . . . . . . . . . . . . . . . . 34

7.1.1 Disconnecting the Sunny String-Monitor . . . . . . . . . . . . . . . . . . . . . 34

7.1.2 Maintenance Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.1.3 Overview of the Main Components. . . . . . . . . . . . . . . . . . . . . . . . . 35

7.1.4 Checking the Mounting Location and Installation . . . . . . . . . . . . . . 38

7.1.5 Checking the Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.1.6 Checking the Enclosure Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.1.7 Checking the Base Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.1.8 Checking the Covers and Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.1.9 Checking the Fuses and Fuse Holders . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.10 Checking the Screw Connections and Clamp Connections. . . . . . . 43

7.1.11 Checking the Surge Arrester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1.12 Checking the Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1.13 Checking Shunt Release (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.1.14 Checking the Undervoltage Release (Optional) . . . . . . . . . . . . . . . 44

7.1.15 Checking the Earth Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.1.16 Checking the LEDs on the Measurement PCB . . . . . . . . . . . . . . . . . 45

4 SC500-800HE20-WH-en-10 Maintenance Manual

SMA Solar Technology AG Table of Contents

7.2 Maintaining the Sunny Main Box . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2.1 Disconnecting the Sunny Main Box . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2.2 Maintenance Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2.3 Overview of the Main Components. . . . . . . . . . . . . . . . . . . . . . . . . 46

7.2.4 Checking the Mounting Location and Installation . . . . . . . . . . . . . . 46

7.2.5 Checking the Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2.6 Checking the Enclosure Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2.7 Checking the Base Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2.8 Checking the Covers and Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2.9 Checking the Fuses and Fuse Holders . . . . . . . . . . . . . . . . . . . . . . . 50

7.2.10 Checking the Screw Connections and Clamp Connections. . . . . . . 50

7.3 Maintaining the SMA String-Combiner . . . . . . . . . . . . . . . . . . . . . . . 51

7.3.1 Disconnecting the SMA String-Combiner. . . . . . . . . . . . . . . . . . . . . 51

7.3.2 Maintenance Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.3.3 Checking the Mounting Location and Installation . . . . . . . . . . . . . . 52

7.3.4 Checking the Base Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.3.5 Checking the Enclosure and Enclosure Interior . . . . . . . . . . . . . . . . 52

7.3.6 Checking the String Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.3.7 Checking the Covers and Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.3.8 Checking the Fuses and Fuse Holders . . . . . . . . . . . . . . . . . . . . . . . 54

7.3.9 Checking the Screw Connections and Clamp Connections . . . . . . . 54

7.3.10 Checking the Surge Arrester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Maintenance Manual SC500-800HE20-WH-en-10 5

SMA Solar Technology AG

6 SC500-800HE20-WH-en-10 Maintenance Manual

SMA Solar Technology AG 1 Information on this Document

1 Information on this Document

Validity

This document applies to the following inverters and accessories:

• SC 500HE-20

• SC 630HE-20

• SC 720HE-20

• SC 760HE-20

• SC 800HE-20

•SSM

• SSM16-11

• SSM24-11

•SMB

•SMB-C

• SMA String-Combiner

Target group

This manual is intended for skilled persons. Only qualified personnel with the appropriate skills are

allowed to perform the tasks described in this manual (see Section2.2 "Skills of Skilled Persons",

page11).

Additional information

For more information on third-party components, contact the relevant manufacturers.

A maintenance report is enclosed with every inverter. The maintenance report describes the pending

maintenance work and the maintenance interval recommended by SMA Solar Technology AG.

Maintenance Manual SC500-800HE20-WH-en-10 7

1 Information on this Document SMA Solar Technology AG

%"/(&3

8"3/*/(

$"65*0/

/05*$&

Symbols

Symbol Explanation

Indicates a hazardous situation which, if not avoided, will result in death

or serious injury

Indicates a hazardous situation which, if not avoided, could result in death

or serious injury

Indicates a hazardous situation which, if not avoided, could result in minor

or moderate injury

Indicates a situation which, if not avoided, can result in property damage

Information that is important for a specific topic or objective, but is not

safety-relevant

☐ Indicates a requirement for meeting a specific goal

☑ Desired result

✖A problem that might occur

Nomenclature

The following nomenclature is used in this document:

Full designation Designation in this document

Sunny Central Inverter

Sunny Central Communication Controller SC-COM

Abbreviations

Abbreviation Designation Explanation

AC Alternating Current ‒

DC Direct Current ‒

ESD Electrostatic Discharge ‒

GFDI Ground-Fault Detection Interruption ‒

MSL Mean Sea Level ‒

PE Protective Earth Protective conductor

PV Photovoltaics ‒

8 SC500-800HE20-WH-en-10 Maintenance Manual

SMA Solar Technology AG 2 Safety

2 Safety

2.1 Safety Precautions

Electric shock

High voltages that can cause fatal electric shocks are present in the live components of the inverter.

• All work must be carried out as described in this manual. Observe all safety precautions.

Observe all safety precautions in this document and the inverter installation manual.

• Do not touch any live components in the inverter or the medium-voltage grid. Comply with all

applicable safety regulations for handling medium-voltage grids.

In the event of an earth fault, remember that plant components which are presumed earthed may still

be live.

• Ensure that no voltage is present before touching any part of the plant.

Hazardous voltages may still be present in the inverter even if the AC and DC main switches are

switched off.

• Wait at least 12 minutes after switching off the inverter. This allows the capacitors to perform

an electric discharge.

The insulation monitoring device with GFDI or remote GFDI does not provide protection from injury

when GFDI is activated. PV modules that are earthed by GFDI discharge voltage to earth. Entering

the PV field can lead to lethal electric shocks.

• Before entering the PV field, switch the PV modules to insulated operation.

• Ensure that the insulation resistance of the PV field is greater than 1 k Ω .

Operating a damaged inverter can lead to serious injuries from electric shock.

• Only use the inverter when it is working safely and properly and check for visible damage on

a regular basis.

• Ensure that all external safety equipment is freely accessible at all times and that regular checks

are carried out to ensure that it is fully functional.

Escape routes

Opening the doors of 2 inverters located opposite each other blocks the escape route.

• Only open 1 inverter door at any given time. Maintain the minimum passage width between the

open door of the inverter and the next fixed obstacle. The minimum passage width must comply

with national standards. In Germany, the minimum passage width is 500 mm.

Maintenance Manual SC500-800HE20-WH-en-10 9

2 Safety SMA Solar Technology AG

Electrostatic discharge

By touching electronic components, you can damage or even destroy the inverter through electrostatic

discharge (ESD).

• W hen wo rki ng o n th e in ver ter or h andli ng a sse mbl ies , ob ser ve t he e lectrost ati c disc har ge s afe ty

regulations and wear protective gloves.

• Discharge the electrostatic charge by touching uncoated, earthed enclosure parts (e.g. at the

protective conductor connection on the doors). This makes it safe to touch electronic

components.

Environmental influences

Moisture and dust penetration will damage the inverter.

• Do not open the inverter when it is raining or if humidity is over 95%.

• Only perform maintenance in a dry and dust-free environment.

Observing torque

Adhere to the torque specifications listed in the circuit diagram and installation manual.

• Contact the SMA Service Line if torque specifications are not given.

Storing documentation

This documentation must be accessible to all service and maintenance personnel at all times.

• Safely store this documentation within the immediate area of the inverter.

Warning signs

Warning signs must be clearly legible at all times.

• Replace warning signs if damaged.

10 SC500-800HE20-WH-en-10 Maintenance Manual

SMA Solar Technology AG 2 Safety

2.2 Skills of Skilled Persons

The work described in this document must be performed by skilled persons only. Skilled persons must

have the following skills:

• Knowledge of how an inverter works and is operated

• Training in how to deal with dangers and risks associated with operating and maintaining

electrical devices and plants

• Vocational training in the maintenance of electrical devices and plants

• Knowledge of all applicable standards and directives

• Knowledge of and adherence to this document and all safety precautions

2.3 Personal Protective Equipment

After the control voltage has been switched on, personal protective equipment is required for all work

performed. The protective equipment must conform with Directive 89/686/EEC. Any protective

equipment that is stipulated by law or otherwise required must also be used.

Maintenance Manual SC500-800HE20-WH-en-10 11

3 Maintenance Intervals SMA Solar Technology AG

3 Maintenance Intervals

Observing maintenance intervals ensures trouble-free operation of the Sunny Central. Maintenance

intervals depend on ambient and operating conditions. Under especially harsh ambient conditions,

certain maintenance tasks must be performed more frequently. These maintenance tasks are listed in

the maintenance report. SMA Solar Technology AG recommends an optical inspection every month

to determine maintenance needs. Under normal ambient and operating conditions, the Sunny Central

must be fully serviced at the following intervals:

Maintenance under normal ambient and operating conditions:

Description Interval

Routine maintenance Every 24 months

Preventative replacement intervals:

Description Interval

Replacing the 24 V power supply units*

Replacing the fans of the inverter bridge* Every 13 years

Ventilation grid mats Every 24 months

GFDI/soft grounding relay 100 trippings due to short circuit

Surge arrester If tripped

* Contact the SMA Service Line.

Every 10 years

Maintenance intervals

Plant size, location and ambient conditions influence the maintenance intervals.

• If the inverter is subject to adverse ambient conditions, SMA Solar Technology AG

recommends shortening the maintenance intervals.

Spare parts

Spare parts can be identified by their reference designation (ref. des.) and the circuit diagram. The

spare parts list includes the item number of each spare part. For information on a specific item number,

please contact the SMA Service Line.

12 SC500-800HE20-WH-en-10 Maintenance Manual

SMA Solar Technology AG 4 Sunny Central HE-20

4 Sunny Central HE-20

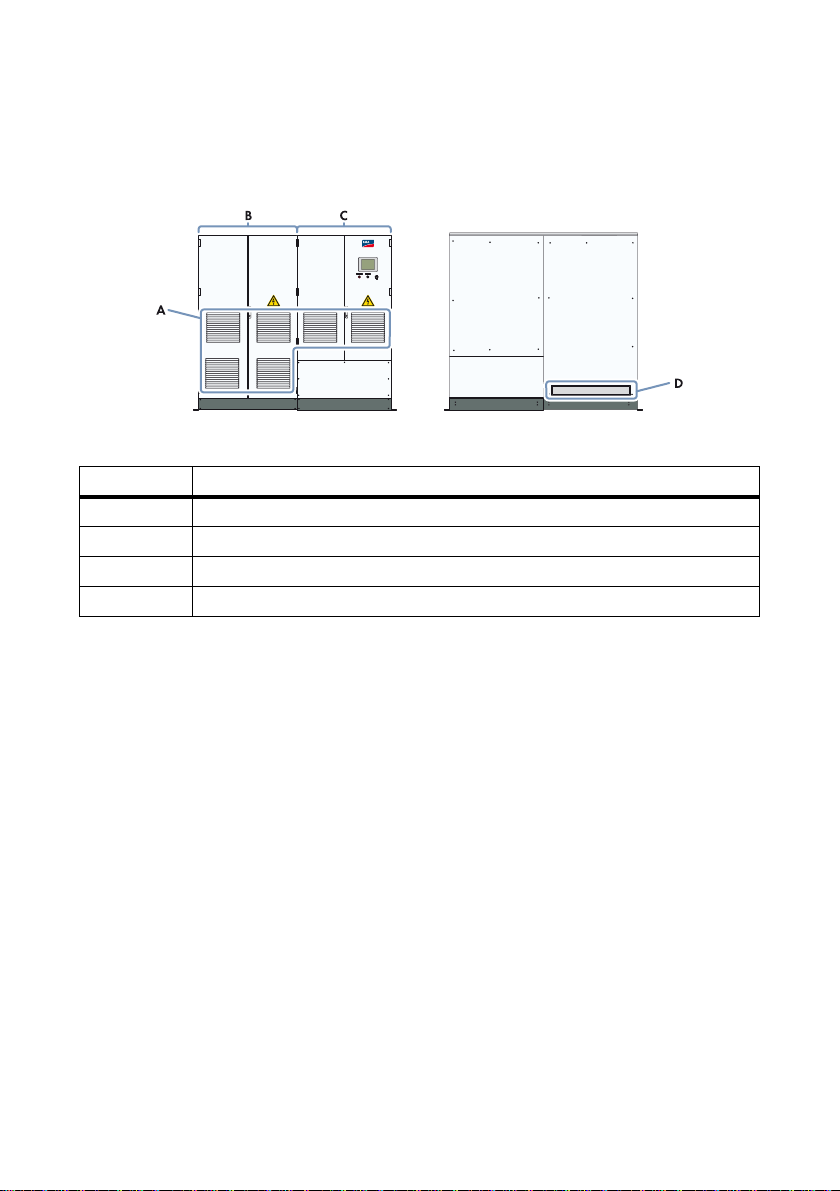

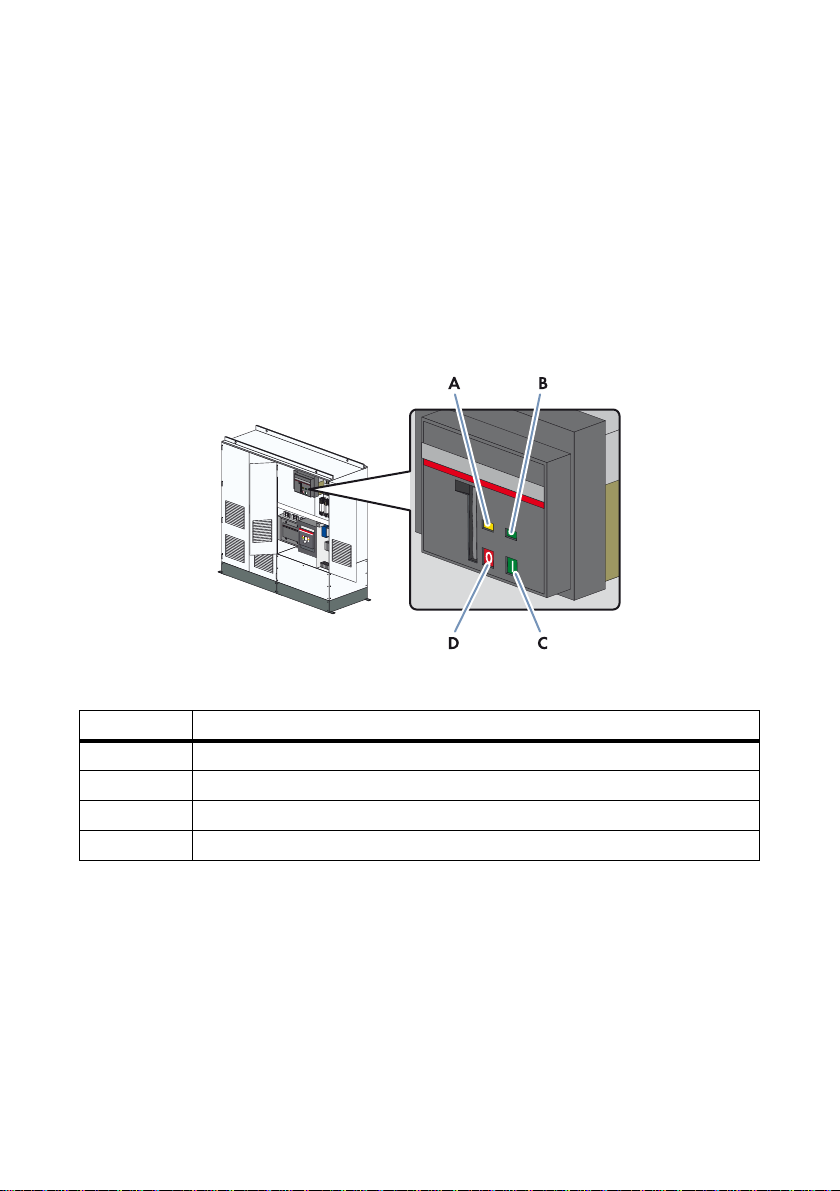

4.1 Design of the Inverter

Figure1: Design of the inverter

Item Description

AVentilation grid

B Inverter cabinet

C Interface cabinet

DExhaust vent

4.2 Type Label

You can identify the inverter by its type label. The type label is located in the interface and inverter

cabinet of the inverter. The serial number is also located at the front of the inverter.

Maintenance Manual SC500-800HE20-WH-en-10 13

5 Maintenance when Voltage is Present SMA Solar Technology AG

5 Maintenance when Voltage is Present

5.1 Reading off Error Messages and Warnings

You can connect a PC via the service interface on the outside of the interface cabinet

(see the Sunny Central installation manual).

• If an error occurs, view the error message on the display or SC-COM interface and respond

accordingly (see the Sunny Central user manual).

5.2 Checking the DC Switch-Disconnector

Figure2: Design of the DC switch-disconnector

Item Description

A Spring status indicator

B Position indicator

CON button

D OFF button

Requirements:

☐ Control voltage is present.

☐ DC voltage is connected.

14 SC500-800HE20-WH-en-10 Maintenance Manual

SMA Solar Technology AG 5 Maintenance when Voltage is Present

1. Move the key switch to "Stop".

2. Open the doors of the interface cabinet.

3. Check that the DC switch-disconnector is turned off and indicates the "Off" position.

If the DC switch-disconnector is not turned off and does not indicate the "Off" position, contact

the SMA Service Line.

4. Close the doors of the interface cabinet.

5. Switch the inverter to "Start".

6. Open the doors of the interface cabinet.

7. Check that the DC switch-disconnector is turned on and indicates the "On" position.

If the DC switch-disconnector is not turned on and does not indicate the "On" position, contact

the SMA Service Line.

8. Close the doors of the interface cabinet.

9. Move the key switch to "Stop".

10. Test the switching operation 3 times.

Maintenance Manual SC500-800HE20-WH-en-10 15

5 Maintenance when Voltage is Present SMA Solar Technology AG

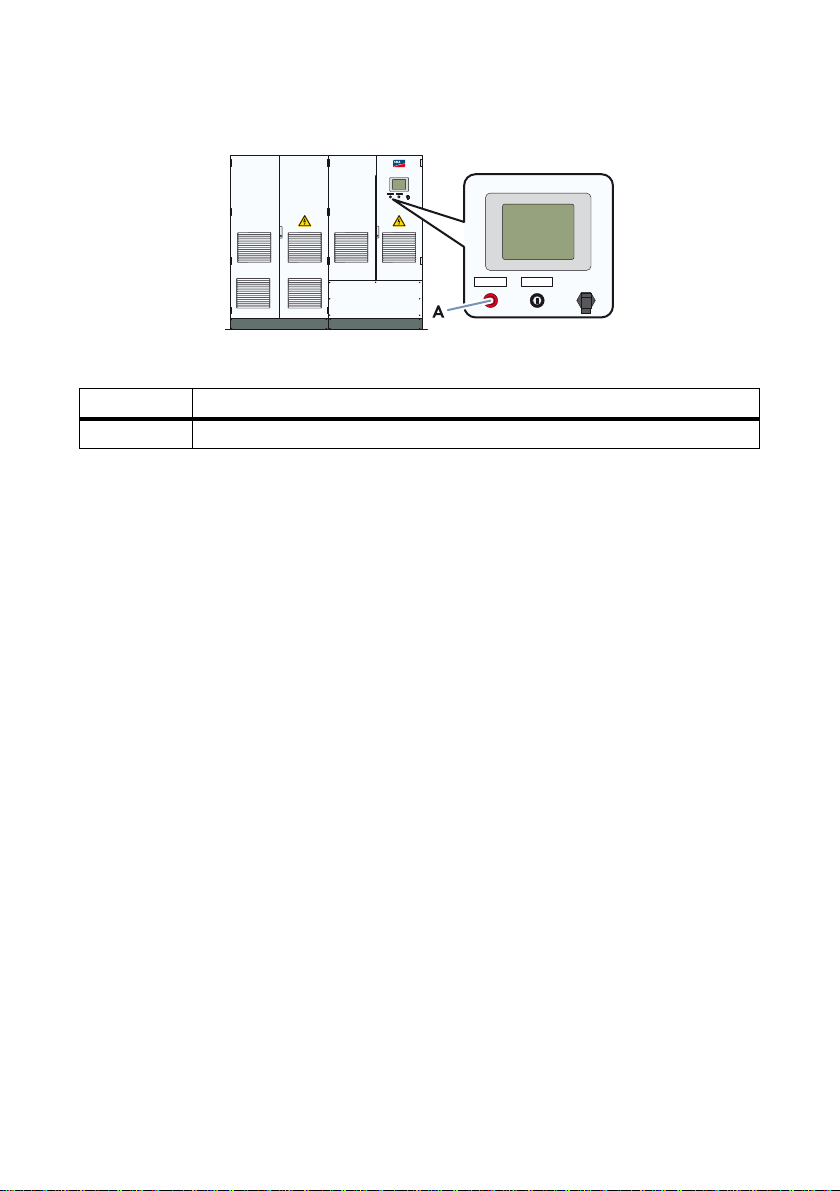

5.3 Checking the External Fast-Stop

Figure3: Position of the fast-stop

Item Description

A Fast-stop

Requirements:

☐ Control voltage is present.

☐ DC voltage is connected.

1. Check whether the DC switch-disconnector and the AC contactor audibly switch off when the

fast-stop is actuated.

If no switching noises can be heard, contact the SMA Service Line.

2. For inverters with display: check whether the inverter display shows the error message 9009.

If the display does not show the error message 9009, contact the SMA Service Line.

3. For inverters with light repeaters: check whether the red light repeater is illuminated.

If the red light repeater is not illuminated, contact the SMA Service Line.

4. Open the doors of the interface cabinet.

5. Check whether the DC switch-disconnector turns off and indicates the "Off" position.

If the DC switch-disconnector does not turn off and does not indicate the "Off" position, contact

the SMA Service Line.

6. Close the doors of the interface cabinet.

7. Unlock the fast-stop again.

8. Switch the inverter to "Start".

9. Test the switching operation 3 times.

16 SC500-800HE20-WH-en-10 Maintenance Manual

SMA Solar Technology AG 5 Maintenance when Voltage is Present

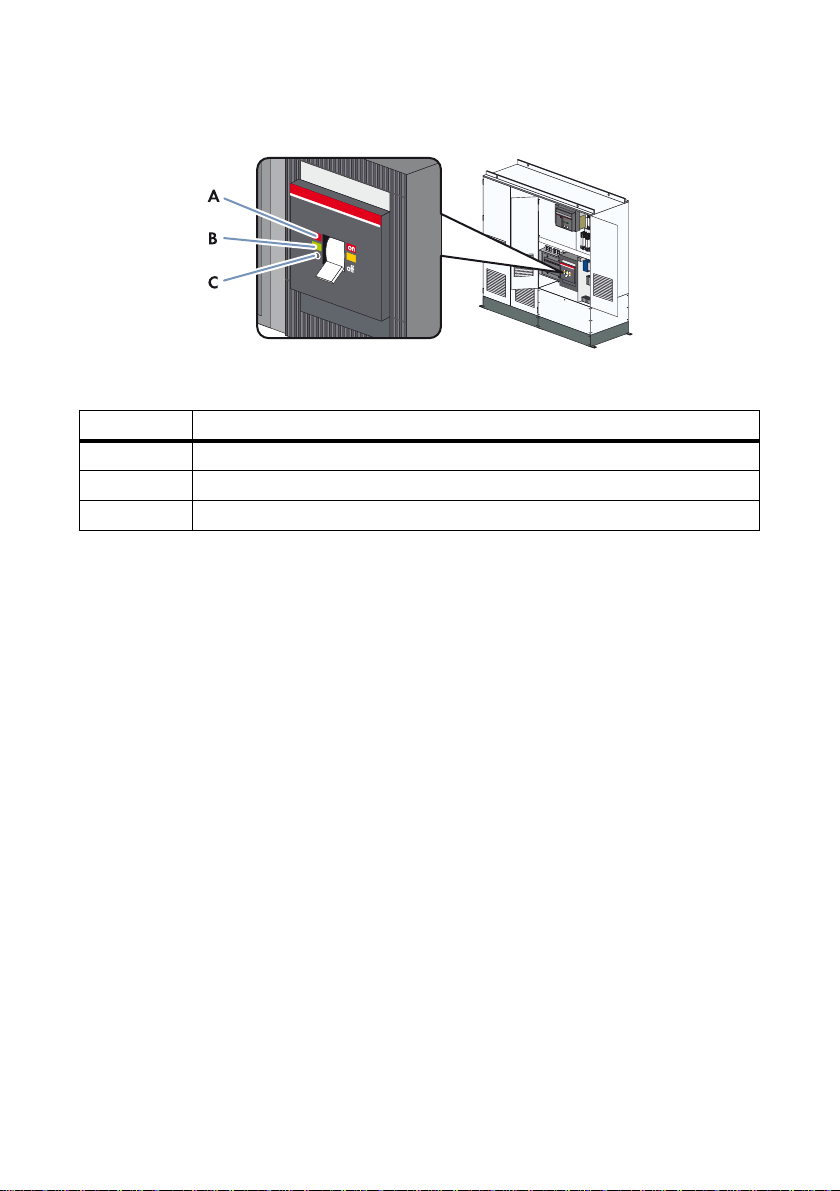

5.4 AC Circuit Breaker (Optional)

Figure4: Design of the AC circuit breaker

Item Description

A"On" position

B "Tripped" position

C "Off" position

Additional maintenance material that is required but not included in the scope of delivery:

☐ A testing device approved by the manufacturer of the AC circuit breaker (e.g. TT1 from ABB).

• Use the testing device to check whether the AC circuit breaker is ready for operation

(instructions are included in the testing device documentation).

• If an error is detected, contact the SMA Service Line.

Maintenance Manual SC500-800HE20-WH-en-10 17

6 Maintenance Under Voltage-Free Conditions SMA Solar Technology AG

%"/(&3

6 Maintenance Under Voltage-Free Conditions

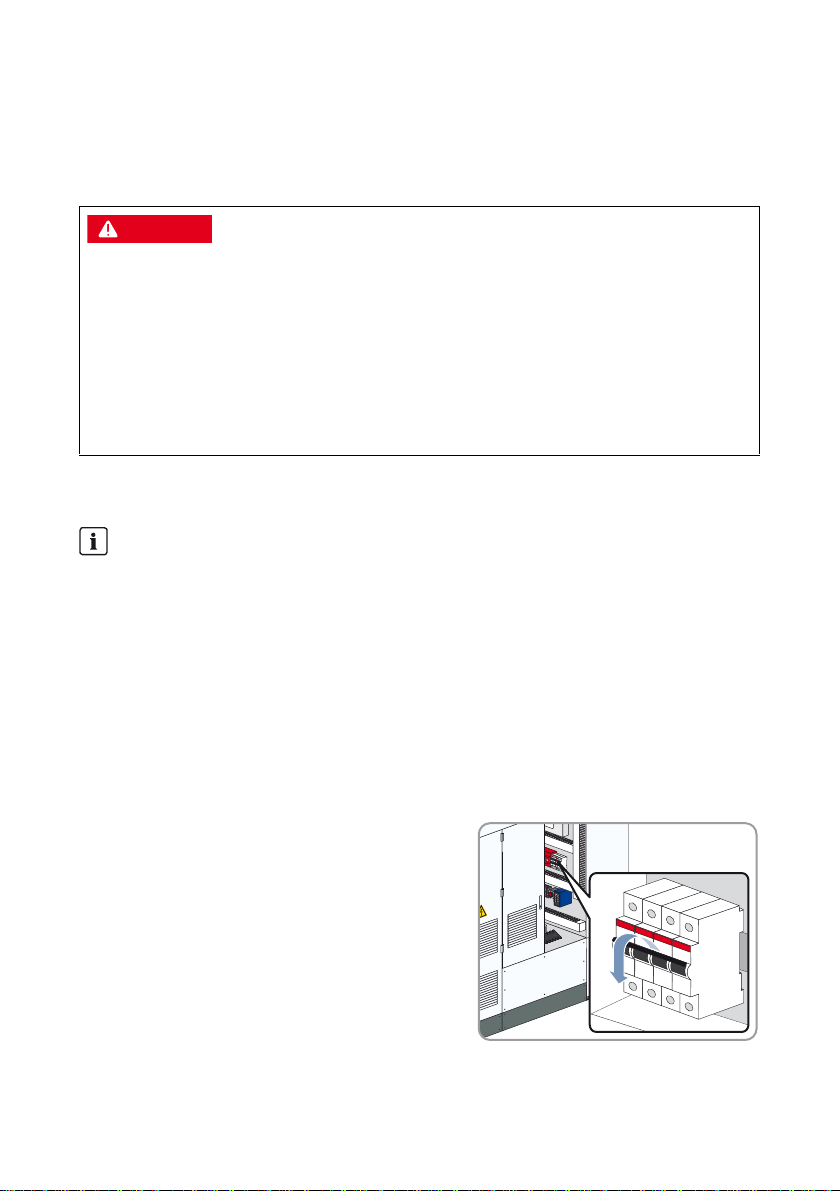

6.1 Disconnecting the Inverter

Electric shock due to live voltage.

The components of the Sunny Central are energised. Touching components of the Sunny Central

may result in death or severe injuries.

• Before performing any work on the Sunny Central, disconnect the inverter and ensure that it

cannot be reconnected.

• After disconnecting the inverter, wait at least 15 minutes until the inverter capacitors have

discharged completely.

•Ensure that no voltage is present.

Before doing any maintenance work, disconnect the inverter from all voltage sources as described in

this section.

Person authorised to operate the medium-voltage transformer

Only a duly authorised person may connect or disconnect the AC voltage of the

medium-voltage transformer.

1. Switch the inverter to "Stop".

2. Disconnect the AC voltage of the medium-voltage transformer externally.

3. Disconnect the DC voltage in the main distributor (e.g. Sunny Main Box) or the sub-distributor

(e.g. Sunny String-Monitor).

4. Switch off the AC circuit breaker.

5. Disconnect the external voltage supply externally.

6. Disconnect any additional external voltage.

7. Switch off the miniature circuit-breaker of the

external voltage supply and if necessary,

disconnect the internal power supply transformer.

18 SC500-800HE20-WH-en-10 Maintenance Manual

Loading...

Loading...