Page 1

EN

Central inverter

SUNNY CENTRAL

500HE/630HE/720HE/760HE/800HE

Installation Manual

SCxxxHE-20-IA-IEN111210 | 98-40005110 | Version 1.0

Page 2

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Information on this Manual. . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Skilled Workers Qualification. . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Sunny Central . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.1 Design and Function of the Sunny Central . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.2 Serial Number and Device Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1.3 Symbols on the Sunny Central . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1.4 Touch Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

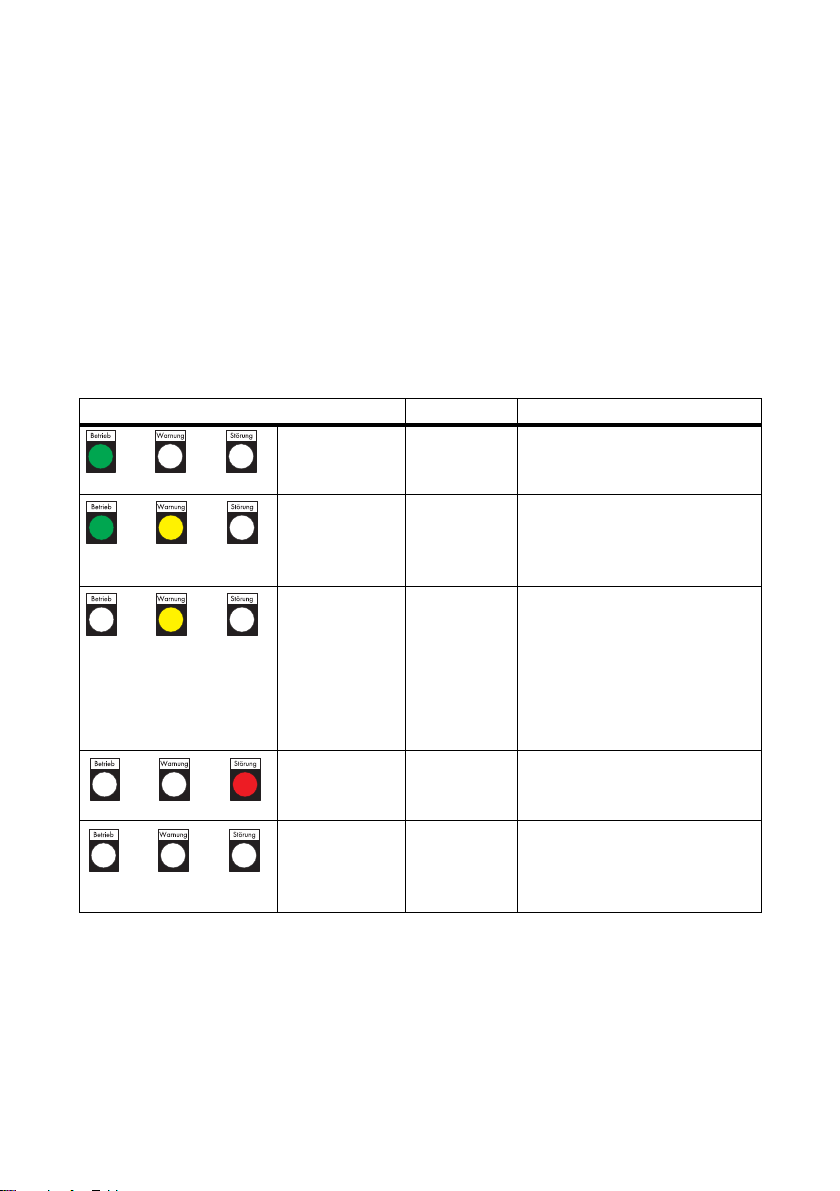

3.1.5 Indicator lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.6 Quick-Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1.7 Key Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Sunny Central Communication Controller. . . . . . . . . . . . . . . . . 18

4 Delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Check for Transport Damage . . . . . . . . . . . . . . . . . . . . . . . . . . 19

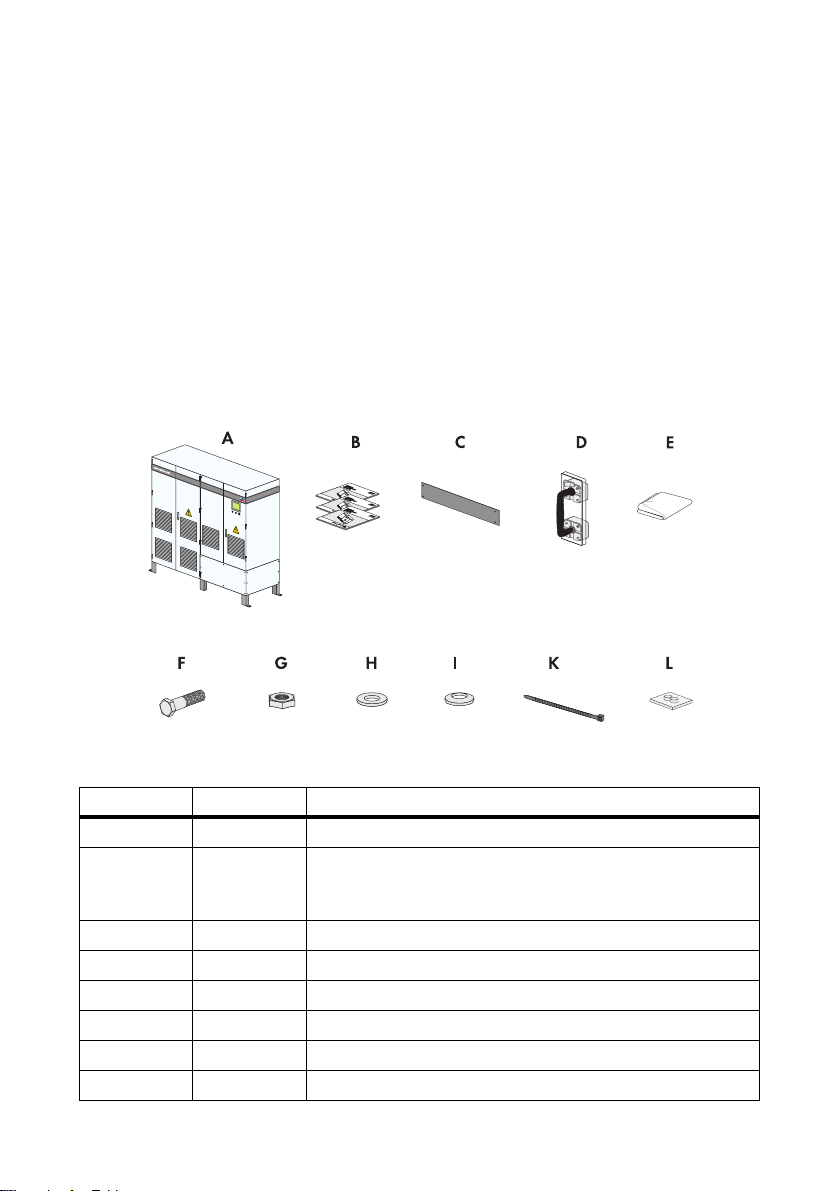

4.2 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Preparation for Installation . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1 Installation Site Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 22

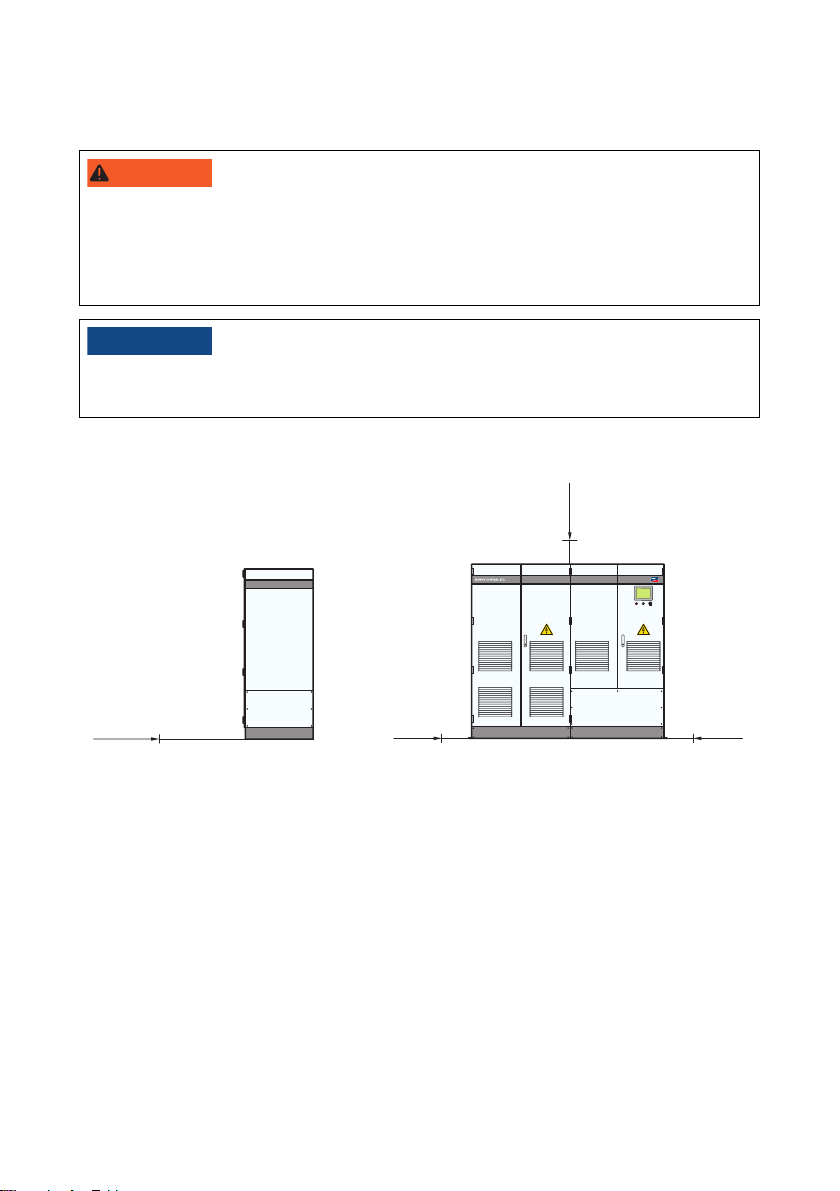

6.1.1 Dimensions of the Sunny Central. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1.2 Ambient Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1.3 Minimum Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1.4 Requirements for Cable Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1.5 Requirements for cable routing between inverter and transformer . . . . . . . . 27

Installation Manual SCxxxHE-20-IA-IEN111210 3

Page 4

Table of Contents SMA Solar Technology AG

6.2 Preparing the Station Floor for Installation . . . . . . . . . . . . . . . . 28

6.2.1 Position of the mounting holes for the Sunny Central . . . . . . . . . . . . . . . . . . 28

6.2.2 Drilling mounting holes in the station floor . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7 Transporting the Sunny Central . . . . . . . . . . . . . . . . . . . . 29

7.1 Center of gravity of the inverter . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2 Transporting the Sunny Central with a Forklift . . . . . . . . . . . . . 30

7.3 Mounting the kick plates at the rear of the inverter. . . . . . . . . . 30

7.4 Transporting the Sunny Central with a Pallet Truck. . . . . . . . . . 31

7.5 Transporting the Sunny Central with a Crane . . . . . . . . . . . . . . 32

8 Installation of the Sunny Central. . . . . . . . . . . . . . . . . . . . 34

8.1 Sealing the exhaust air zone . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.2 Fastening the Inverter on the Foundation . . . . . . . . . . . . . . . . . 34

8.3 Disassembling the Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.4 Removing the Transport Lock from the Inverter Cabinet . . . . . . 35

9 AC and DC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.1 Safety during Cable Connection . . . . . . . . . . . . . . . . . . . . . . . 36

9.2 Connection Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.3 Connection area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.3.1 DC Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.3.2 DC Busbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.4 Cable Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.4.1 Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.4.2 Cleaning the contact surfaces of terminal lugs and

connection lugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.4.3 Connecting cables with 1 terminal lug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.4.4 Connecting cables with 2 terminal lugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.5 Connecting the PE cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 5

SMA Solar Technology AG Table of Contents

9.6 Connecting the DC cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.6.1 Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.6.2 Connecting the SMB Connection Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.6.3 Connecting the DC Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.7 Connecting the AC Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.8 Mounting the kick plates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10 Cable Connection in the Connection Cabinet . . . . . . . . . 45

10.1 Connection area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.2 Preparing the Cable Connection . . . . . . . . . . . . . . . . . . . . . . . 46

10.3 Leading the Cables into the Connection Cabinet . . . . . . . . . . . 47

10.4 Connecting the Cables in the Connection Cabinet. . . . . . . . . . 48

10.4.1 Connecting the cables to the customer terminal block . . . . . . . . . . . . . . . . . 48

10.4.2 Important Measures for Non-utilized Options. . . . . . . . . . . . . . . . . . . . . . . . 48

10.4.3 Connecting the Sunny String-Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.4.4 Connecting the Remote Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.4.5 Connecting the External Target Value Specification . . . . . . . . . . . . . . . . . . . 50

10.4.6 Connecting the Transformer Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.4.7 Connecting the External Voltage Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.4.8 Connecting the External Quick-Stop Cabling . . . . . . . . . . . . . . . . . . . . . . . . 52

11 Connection of the Communication Devices . . . . . . . . . . . 54

11.1 Structure of a Plant Network. . . . . . . . . . . . . . . . . . . . . . . . . . . 54

11.2 Position of the communication ports . . . . . . . . . . . . . . . . . . . . . 55

11.3 Building a Plant Network with Copper Cables. . . . . . . . . . . . . 56

11.4 Building a Plant network with Optical Fibers . . . . . . . . . . . . . . 56

12 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

12.1 Commissioning the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

12.2 Checking the Cabling on the Inverter . . . . . . . . . . . . . . . . . . . . 58

Installation Manual SCxxxHE-20-IA-IEN111210 5

Page 6

Table of Contents SMA Solar Technology AG

12.3 Checking the Inverter Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . 59

12.3.1 Checking the DC Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

12.3.2 Checking the AC Grid Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

12.3.3 Checking the External Voltage Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

12.4 Mounting the Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

12.5 Inserting Fuses or Disconnecting Blades . . . . . . . . . . . . . . . . . . 62

12.6 Switching on the Voltage Supply . . . . . . . . . . . . . . . . . . . . . . . 63

12.7 Switching on the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

13 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

14 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

14.1 Sunny Central 500HE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

14.2 Sunny Central 630HE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

14.3 Sunny Central 720HE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

14.4 Sunny Central 760HE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

14.5 Sunny Central 800HE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

15 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 7

SMA Solar Technology AG 1 Information on this Manual

1 Information on this Manual

Validity

It is valid for the following device types with firmware version 01.14.12.R or higher:

• Sunny Central 500HE (SC 500HE-20)

• Sunny Central 630HE (SC 630HE-20)

• Sunny Central 720HE (SC 720HE-20)

• Sunny Central 760HE (SC 760HE-20)

• Sunny Central 800HE (SC 800HE-20)

Target Group

This manual is intended for skilled workers. Only qualified personnel are allowed to perform the tasks

set forth in this manual (see section 2.3"Skilled Workers Qualification",page12).

Additional Information

Additional information is available at www.SMA.de/en:

Information Document type

Installation requirements for Sunny Central 500HE/630HE/

720HE/760HE/800HE

Medium-voltage Transformers − Important requirements for

medium-voltage transformers for Sunny Central of the HE and

CP range.

COM-B − Communication distributor for large-scale plants with

Sunny Central, Sunny Mini Central or Sunny Tripower

Sunny Main Box ‒ Connecting the DC cabling for PV inverters Technical information

Technical information

Technical information

Technical information

Installation Manual SCxxxHE-20-IA-IEN111210 7

Page 8

1 Information on this Manual SMA Solar Technology AG

%"/(&3

8"3/*/(

$"65*0/

/05*$&

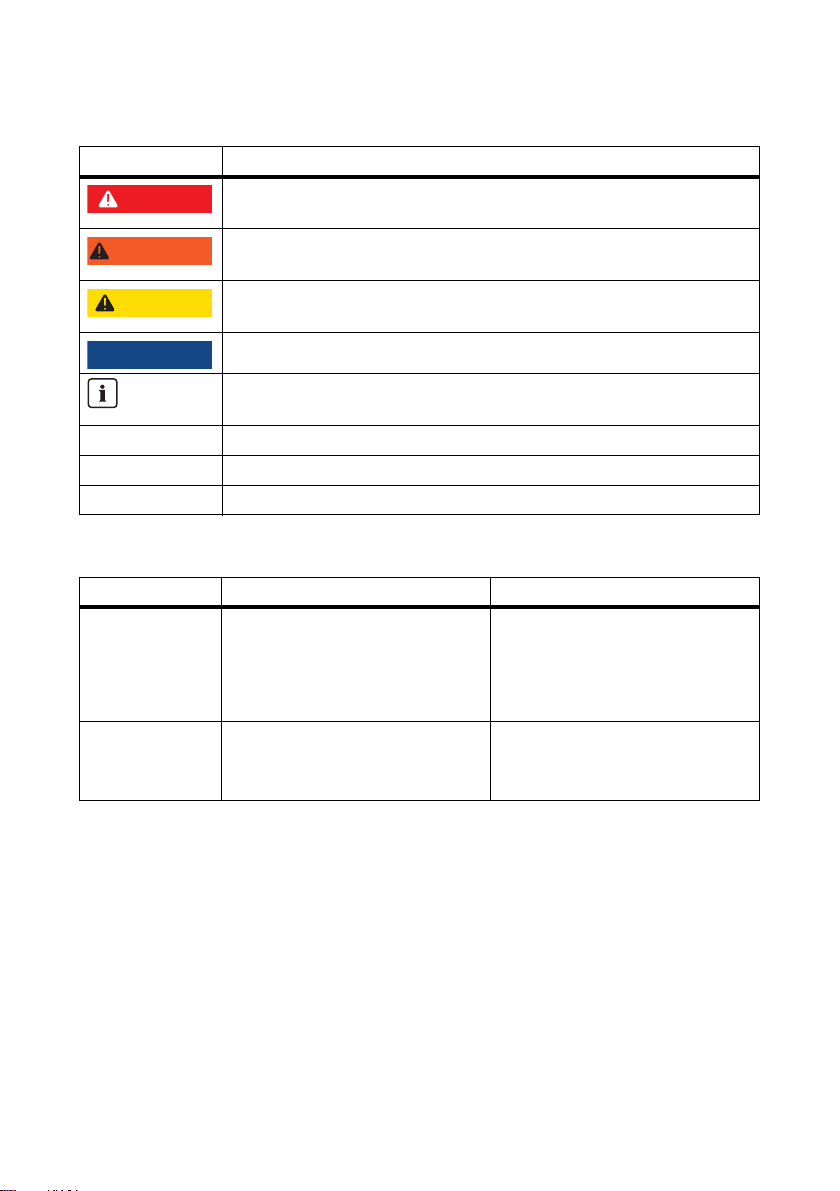

Symbols

Symbol Explanation

Indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Indicates a situation that can result in property damage if not avoided.

Indicates information that is important for a specific topic or objective, but is

not safety-relevant.

☐ Indicates a requirement for meeting a specific goal.

☑ Desired result.

✖ Undesired result. Followed by a solution on how to achieve the desired result.

Typography

Typography Usage Example

"light" • Display messages

• Parameters

• Terminals

•Sockets

bold • Elements which you should

select

• Elements which you should enter

• The inverter switches into the

"Waiting" operating state.

• Set parameter "FanTest" to 1.

Nomenclature

In this manual, the Sunny Central of the HE series is referred to as Sunny Central or inverter.

In this manual, the Sunny Central Communication Controller is also referred to as SC-COM.

8 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 9

SMA Solar Technology AG 2 Security

A

B

C

D

E

S

M

A

S

M

A

H

E

2Security

2.1 Intended Use

The Sunny Central is a central inverter which converts the direct current from PV modules into

alternating current. Here, the maximum permissible DC input voltage must not be exceeded.

The Sunny Central is suitable for indoor installation, providing that the specified safety distances are

complied with. The enclosure complies with the IP21 protection class. IP21 means that the closed

inverter is protected against vertically falling dripping water. The inverter is classified under

Class 3 C1L according to EN 60721-3-3.

Inverters of the HE series may only be operated in connection with a suitable transformer.

The transformer must be designed for the voltages that arise during pulsed operation of the inverter.

The voltages can reach a magnitude of maximum ±1 450 V to ground. (see Technical Information

"Medium-voltage Transformer" at www.SMA.de/en).

Do not switch off or change s ettings th at affe ct gri d management without first obtaining approval from

the distribution grid operator.

Figure1: Principle of a grid-tie PV plant with an inverter

Position Description

APV modules

B Sunny String-Monitor

C Sunny Central

D Medium-voltage Transformers

E Power distribution grid

Installation Manual SCxxxHE-20-IA-IEN111210 9

Page 10

2 Security SMA Solar Technology AG

2.2 Safety Instructions

Electrical Risk

Risk of electric shock when touching conductive parts

High voltages that can cause electrical shocks are present in the inverter. Work on the inverter is only

allowed if the power is disconnected and in compliance with the guidelines that apply at the

installation location.

• Disconnect the following components:

– Grid voltage for grid feeding

– Internal supply

–DC voltage from the PV array

– Additional external voltages (e.g., control signals of a control room)

• Ensure that the device cannot be reconnected.

•Ensure that no voltage is present.

• Ground and short-circuit.

• Cover or safeguard any adjacent live components.

Electric shock through capacitors not fully discharged

Hazardous voltages may still be present in the inverter even if the AC and DC main switches are

switched off.

• Wait at least 12 minutes after switching off the inverter.

Electric shock caused by damage on the inverter

The operation of a damaged inverter can lead to serious or lethal injuries through electric shock.

• Operate the inverter only in technically proper and operationally safe status.

• Check the inverter regularly for visible damage.

• Ensure that all safety features are freely accessible at all times.

• Regularly check for correct functioning.

Electric shock caused by ground fault

In case of a ground fault, assume that grounded plant components are still live.

• Ensure that no voltage is present before touching.

Electric shock when entering the PV field

The insulation monitoring device with GFDI or Remote GFDI does not provide protection from injury

when GFDI is activated. PV modules grounded by means of GFDI disperse voltage to ground.

When entering the PV field, lethal electric shocks may occur.

• Before entering the PV field, switch the PV modules to insulated operation.

• Ensure that the insulation resistance of the PV field is greater than 1 k Ω .

10 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 11

SMA Solar Technology AG 2 Security

Electric shock resulting from a failure to comply with safety requirements

Failure to follow this manual, the general instructions or safety instructions may lead to severe injury

due to electric shock.

• Only perform work as described in this manual. Observe all safety instructions.

• Establish all electrical connections according to the circuit diagram.

• Safely store the documentation within the immediate area of the inverter. It must be accessible

to service and maintenance personnel at all times.

Electrostatic discharge can damage electronic components

Electrostatic discharge can destroy component parts.

• During work on the inverter and handling of the components, observe the ESD protection

regulations and wear protective gloves.

• Discharge electrostatic charges through contact with unvarnished, grounded enclosure parts

(e.g., on the PE connection of the doors). Only then is it safe to touch any electronic components.

Burn Hazard

Some components, such as fuses, can become hot during operation.

• Wear safety gloves when working on the inverter.

Inverter Damage

Tampering with the device may result in plant damage.

• Do not operate the inverter while the door is open.

If the key remains in the door lock, the inverter can be opened by unauthorized persons.

• Remove the key from the door locks and from the key switch.

• Keep the keys in a safe place.

Penetrating moisture can damage the inverter.

• Do not open the inverter when it is raining or in case of humidity > 95%.

Electrostatic discharge can destroy components.

• During work on the inverter and handling of the components, observe the ESD protection

regulations and wear protective gloves.

• Discharge electrostatic charges through contact with unvarnished, grounded enclosure parts

(e.g., on the PE connection of the doors). Only then it is safe to touch any electronic components.

Warning signs must be easily readable at all times and must be replaced in the event of damage.

Hazard due to blocked escape route

Opening of the doors of 2 opposing inverters blocks the escape route. It is imperative that the escape

route is freely accessible at all times. Make sure the minimum passage width of the route meets local

standards. In Germany, the minimum passage width is 500 mm.

• Only the door of one inverter may be open at any given time.

Installation Manual SCxxxHE-20-IA-IEN111210 11

Page 12

2 Security SMA Solar Technology AG

2.3 Skilled Workers Qualification

All work on the inverter may only be carried out by qualified technical personnel. Qualified means

that the personnel has the relevant training for the tasks.

For commissioning and operating the inverter, the personnel must be familiar with the installation

manual and the user manual. Observe safety instructions.

12 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 13

SMA Solar Technology AG 3 Product Description

3 Product Description

3.1 Sunny Central

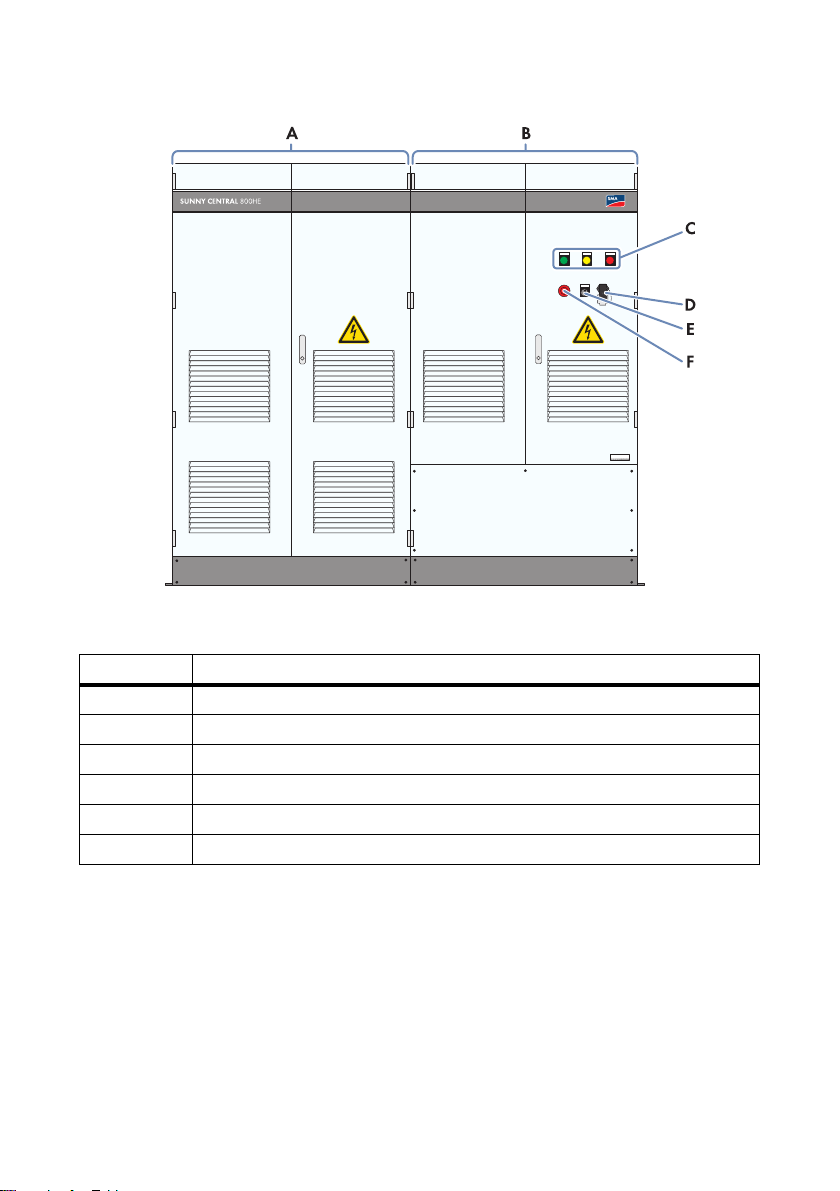

3.1.1 Design and Function of the Sunny Central

The Sunny Central is a PV inverter that converts the direct current from the PV array into alternating

current for the grid.

Figure2: Sunny Central, using the example of a Sunny Central 800HE with touch display

Position Description

A Inverter cabinet

B Connection cabinet

CTouch display

D Service interface

EKey Switch

FQuick-Stop

Installation Manual SCxxxHE-20-IA-IEN111210 13

Page 14

3 Product Description SMA Solar Technology AG

Figure3: Sunny Central, using the example of a Sunny Central 800HE with indicator lights

Position Description

A Inverter cabinet

B Connection cabinet

C Indicator lights

D Service interface

EKey Switch

FQuick-Stop

The Sunny Central can implement the requirements of the distribution grid operator with the aid of the

Power Reducer Box or the Sunny Central Communication Controller.

14 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 15

SMA Solar Technology AG 3 Product Description

3.1.2 Serial Number and Device Type

The serial number (Serial No.) and device type (Type) of the Sunny Central are listed on the type

label. The type label is located on the inside of the right door on both the inverter cabinet and the

connection cabinet.

Reading off the serial number

You can identify the serial number without opening the inverter. The serial number is located at

the bottom right on the outside of the switch cabinet door. You can also read off the serial

number from the display.

Reading off the firmware

You can read off the version number of the firmware from the inverter and the display via the

user interface of the Sunny Central Communication Controllers or from the display.

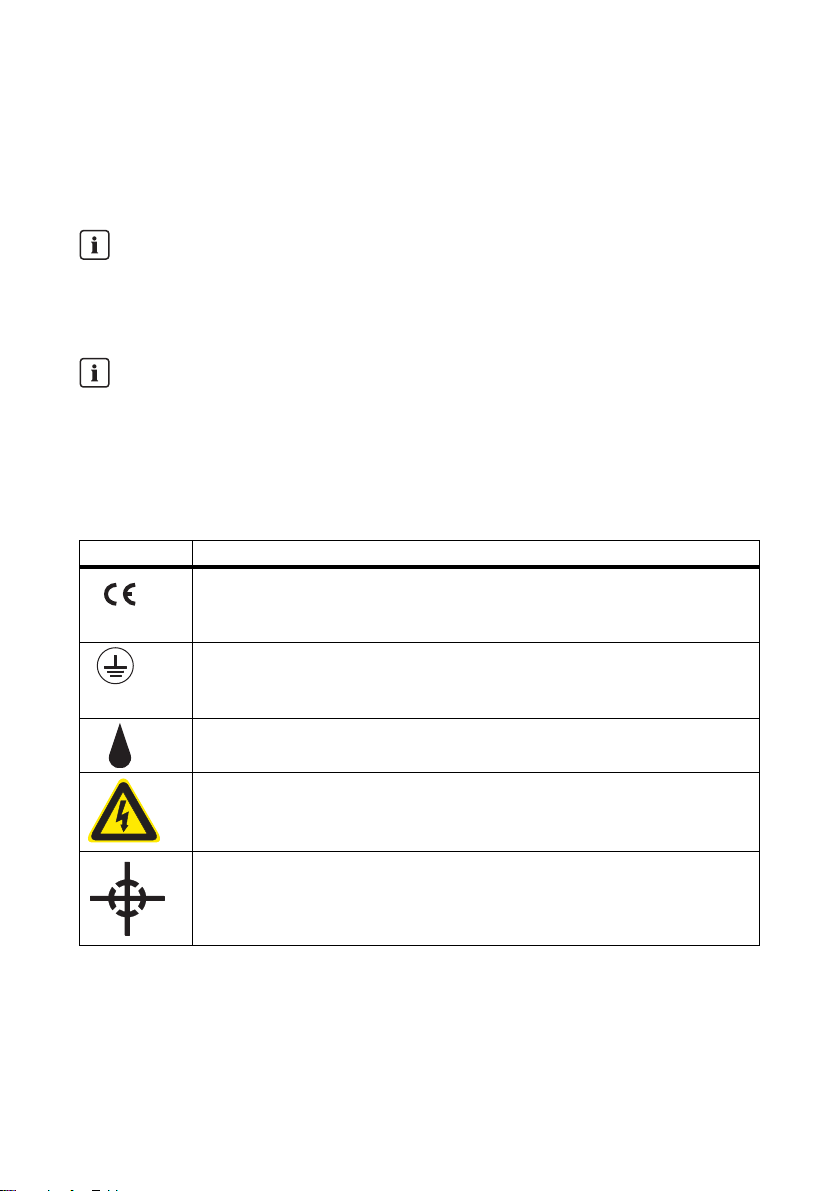

3.1.3 Symbols on the Sunny Central

All the symbols on the Sunny Central and the type label are explained below.

Symbol Description

CE mark.

The Sunny Central complies with the relevant provisions of the European

Community.

Protection class I.

All operating facilities are connected to the protective conductor system of the

Sunny Central.

Degree of protection IP 21.

The Sunny Central is protected against dripping water.

Beware of dangerous electrical voltage.

The Sunny Central operates at high voltages. All installation work on the

Sunny Central must be performed by electrically skilled persons only.

Center of gravity of the inverter.

Installation Manual SCxxxHE-20-IA-IEN111210 15

Page 16

3 Product Description SMA Solar Technology AG

3.1.4 Touch Display

Depending on which option is ordered, the Sunny Central may be equipped with a touch display.

Different kinds of inverter data can be viewed on the touch display. The touch display is only used as

a means for viewing data. The display switches off if it is inactive for more than 5 minutes. It switches

on when it is touched.

3.1.5 Indicator lights

Depen ding on whi ch options are ord ered, the Sunny Cen tral may be equipped with 3 indi cator lights.

The indicator lights show the status of the inverter.

The functions of each status are described below.

Condition Description Function

Green indicator

light glows

continuously

Yellow and green

indicator lights

glow

continuously

Yellow indicator

light glows

continuously

Red indicator

light glows

continuously

All indicator lights

are off

Feed-in

operation

Limited

operation

Warning The Sunny Central is currently not

Fault The Sunny Central has detected a

No feed-in

operation

The Sunny Central is feeding into

the power distribution grid.

The Sunny Central has detected a

warning. The warning currently

does not affect the operation of the

Sunny Central.

feeding power into the grid and

has detected a warning. It is

automatically reset as soon as the

warning is no longer present.

This status is used, for instance,

when the level of irradiation is low.

fault and is now switched off.

The Sunny Central is not feeding

into the grid, the supply voltage is

disconnected, or the key switch is

set to "Stop".

16 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 17

SMA Solar Technology AG 3 Product Description

3.1.6 Quick-Stop

In case of emergency, this switch enables disconnection of the inverter from the PV array and the

medium-voltage grid within 500 ms.

Tripping the quick-stop function

The quick-stop function may only be tripped if there is imminent danger.

Pressing the quick-stop button does not trip rapid discharge of the capacitor.

Pressing the quick-stop button opens the DC contactor, switches off the inverter bridge and

disconnects the inverter from the AC grid.

3.1.7 Key Switch

The key switch is used to switch the Sunny Central on and off.

Switch position "Start"

After turning the switch to the "Start" position, the Sunny Central switches from "Stop" mode to

"Grid monitoring" mode. If there is sufficient irradiation and a valid grid connection, the Sunny Central

switches to feed-in operation. If there is insufficient irradiation, the input voltage is too low for startup,

and the Sunny Central remains in the "Grid monitoring" state.

Switch position "Stop"

If the key switch is turned to "Stop" when the Sunny Central is in the "Grid monitoring" mode, a motor

drive automatically shuts off the DC main switch. The Sunny Central goes into the "Stop" mode.

If the key switch is turned to "Stop" when the Sunny Central is in "MPP load operation", the

Sunny Central switches to the operating state "Shutdown". Once shutdown is complete, the AC

contactor and the DC main switch tur n off aut oma tic all y and the Sunny C entral goe s into "Sto p" mode.

Installation Manual SCxxxHE-20-IA-IEN111210 17

Page 18

3 Product Description SMA Solar Technology AG

HE

SUNNY CENTRAL

STRING MONITOR CONTROLLER

3.2 Sunny Central Communication Controller

The SC-COM is the central communication interface of the inverter. The SC-COM establishes the

connection between the inverter and the plant operator.

Figure4: SC-COM

The SC-COM collects all data from the connected devices. The SC-COM enables monitoring,

parameterization and remote diagnosis of the inverter via computer, as well as power regulation by

the grid operator.

These various tasks performed by the SC-COM can be organized in 2 separate networks:

• Monitoring network: takes care of the monitoring, parameterization and remote diagnosis

functions.

• Regulation network: here, the specifications issued by the distribution grid operator for grid

stability management are transmitted. Since the regulation network is used exclusively for

transmitting the data of the distribution grid operator, the specifications are made available in

the requisite time.

If there is only a low level of data flow in the monitoring network, the grid operator specifications can

also be transmitted via the monitoring network. In this case, there is no need for 2 networks.

The operator can access all data stored in the SC-COM via an Ethernet connection.

You can set the parameters of the inverter via the SC-COM.

The networks are realized on the basis of copper cables or optical fibers.

PV Plant Communication Type

The interface of the SC-COM is set by default to "COM 3". The default setting of the baud rate

for the following options is:

• Option 11/0 without hub: baud rate 115 200

• Options 11/1 and 11/2 with hub: baud rate 19 200

Do not modify these settings.

18 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 19

SMA Solar Technology AG 4 Delivery

4Delivery

4.1 Check for Transport Damage

Every inverter has been thoroughly checked by SMA Solar Technology AG before leaving our

factory. Despite the robust packaging, damage can occur during shipping and transport. Carry out a

visual inspection of the inverter before installation. Should you find any visible damage, contact your

retailer and the transport company responsible for the delivery of the inverter.

4.2 Scope of Delivery

Check the delivery for completeness and any visible external damage. Contact your retailer or the

SMA Serviceline if the delivery is incomplete or damaged.

Figure5: Delivery components

Position Quantity Description

A 1 Sunny Central

B1SMA documentation set:

installation manual, user manual, circuit diagram,

commissioning report

C6Kick plate

D1LV/HRC fuse handle

E 1 Non-woven abrasive

F34Screw

G34Nut

H 68 Fender washer

Installation Manual SCxxxHE-20-IA-IEN111210 19

Page 20

4 Delivery SMA Solar Technology AG

Position Quantity Description

I68Spring washer

K 80 Cable tie

L 3 Rubber seal (9.5 mm … 17 mm)

Position of the LV/HRC fuse handle

For order option DC fuse, the LV/HRC fuse handle is to be found on the inner side of the right

door of the connection cabinet.

20 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 21

SMA Solar Technology AG 5 Storage

/05*$&

/05*$&

5Storage

If you need to store the inverter prior to final installation, note the following points:

Penetrating moisture can damage the inverter.

• Only store the inverter in a closed state.

• Storage permissible in dry, covered locations only. Observe the conditions for degree of

protection IP 21.

• Temperature at the storage location between ‒20°C … +50°C.

An uneven foundation may damage the frame construction.

• The foundation must be suitable for the weight of the inverter of 1 670 kg.

• Unevenness of the foundation max. 0.25%.

Storage in cold conditions and high humidity

If when storing the Sunny Central you connect the external voltage supply and switch on the

miniature circuit-breaker of the external voltage supply, the heater is activated automatically in

the event of high humidity. The connection of the external voltage supply is described in section

10.4.7"Connecting the External Voltage Supply",page51.

Installation Manual SCxxxHE-20-IA-IEN111210 21

Page 22

6 Preparation for Installation SMA Solar Technology AG

HE

906 mm

1 202 mm

100 mm

1 202 mm

2 404 mm

2 093 mm

6 Preparation for Installation

6.1 Installation Site Requirements

6.1.1 Dimensions of the Sunny Central

Figure6: Dimensions

Height Width Depth

2 093 mm 2 404 mm 906 mm

6.1.2 Ambient Conditions

☐ The required amount of supply air is available. If the required amount of air cannot be

guaranteed, install an extra ventilation, e.g., external fans.

☐ The installation site must be accessible at all times.

☐ The altitude of the installation site must be below the maximum installation altitude

(see section 14"Technical Data",page66).

☐ The ambient temperature must be within the operating temperature range

(see section 14"Technical Data",page66).

☐ The installation site is compliant with the requirements on ambient conditions

(see "Installation Conditions for Sunny Central 500HE/630HE/720HE/760/HE/800HE”).

22 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 23

SMA Solar Technology AG 6 Preparation for Installation

8"3/*/(

/05*$&

HE

300 mm

220 mm

300 mm

1 200 mm

6.1.3 Minimum Clearances

Danger of fire due to overheating of cables.

Differing cable lengths result in excessive heating of the cables.

• All line conductors from the inverter to the transformer must be of the same length.

• The cable length between the connection points must not exceed a maximum of 15 m.

Damage to the inverter and transformer due to discharged air being sucked in.

• Install the plant so that the inverter cannot suck in any exhaust air.

Minimum clearance for 1 inverter

Figure7: Minimum clearances of the inverter

The exhaust air vent is located at the rear of the inverter.

For the optimum operation of the inverter, observe the following points:

Installation Manual SCxxxHE-20-IA-IEN111210 23

• Do not block or close the exhaust air vent.

• Ensure that the station is equipped with a suitable exhaust air vent.

• In order to prevent thermal short circuits in the inverter, ensure that there are exhaust air ducts

in closed rooms.

• The exhaust air vents must be accessible for cleaning at all times.

Page 24

6 Preparation for Installation SMA Solar Technology AG

A

B

Figure8: Minimum clearance for 1 inverter in an electrical equipment room

Position Description

A Minimum passage width

Maint ain the min imum pa ssage widt h between t he open door of the Sunny Cen tral

an d th e next fi xed obs tac le. The mini mum pas sag e wi dth must com ply with national

standards. In Germany, the minimum passage width is 500 mm.

BInverter

24 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 25

SMA Solar Technology AG 6 Preparation for Installation

8"3/*/(

Minimum clearances for 2 inverters

Figure9: Minimum clearances for 2 inverters in an electrical equipment room

Position Description

A Minimum passage width

Maint ain the min imum pa ssage widt h between t he open door of the Sunny Cen tral

an d th e next fi xed obs tac le. The mini mum pas sag e wi dth must com ply with national

standards. In Germany, the minimum passage width is 500 mm.

BInverter

In order to comply with the escape route regulations, only one inverter may be open at a time.

Danger due to blocked escape route

Opening of the doors of 2 opposing inverters blocks the escape route. It is imperative that the

escape route is freely accessible at all times. Make sure the minimum passage width of the route

meets local standards. In Germany, the minimum passage width is 500 mm.

• Only the door of one inverter may be open at any given time.

• Observe the minimum passage width.

Installation Manual SCxxxHE-20-IA-IEN111210 25

Page 26

6 Preparation for Installation SMA Solar Technology AG

6.1.4 Requirements for Cable Routing

Laying the cables

This document does not specify at what time the cables are to be laid in the foundation.

The time for laying the cables must be decided individually for the particular plant.

☐ Cable entries are located in the connection cabinet.

☐ Empty tubes for the cable routing have been laid

under the foundation.

☐ The communication cables are separated from

the AC and DC cables.

☐ An appropriate number of cable entries

is provided:

– AC cables: 3

– DC cables: according to the number of

DC cables

–PE cables: 1

– Communication cables: 1

Figure10: Cable entries for 9 DC inputs (example)

Position Description

AEntry for AC cable

BEntry for DC cable

CEntry for PE cable

D Entry for communication cable

26 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 27

SMA Solar Technology AG 6 Preparation for Installation

L2

L1

L3

L2

L1

L3

L2

L1

L3

1d

>2d

--

>2d

--

6.1.5 Requirements for cable routing between inverter and transformer

☐ The AC cables are 3-phase cables.

☐ Between the transformer and the inverter, there are 3 separate cable routes, e.g., cable

channels, for the AC cables.

☐ The spacing between the cable routes must be at least twice the diameter of an AC cable.

Figure11: Arrangement of AC cables with three cables per line conductor (example).

Observe cable clearances

Lay an L1, L2 and L3 line conductor in each cable route. The spacing between the cable pairs

must be at least twice the diameter of a cable. This prevents current imbalances.

Installation Manual SCxxxHE-20-IA-IEN111210 27

Page 28

6 Preparation for Installation SMA Solar Technology AG

2 404 mm

16 mm

906 mm

773 mm

A

A

A

A

2 470 mm

2 510 mm

6.2 Preparing the Station Floor for Installation

6.2.1 Position of the mounting holes for the Sunny Central

Before installing the inverter, prepare the mounting fixtures in the floor.

There are 4 mounting brackets in the base area of the inverter for anchoring in the foundation.

Figure12: Position of the mounting brackets on the inverter

Position Description

A Mounting brackets

6.2.2 Drilling mounting holes in the station floor

1. Mark the positions of the mounting holes on the foundation corresponding to the mounting

brackets.

2. Drill mounting holes at the marked places in the foundation.

28 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 29

SMA Solar Technology AG 7 Transporting the Sunny Central

7 Transporting the Sunny Central

7.1 Center of gravity of the inverter

The center of gravity of the inverter is marked on the packaging and on the enclosure with the

appropriate symbol.

Center of gravity of the inverter

The center of gravity is not in the middle of the Sunny Central. Keep this in mind during

transportation of the Sunny Central.

Installation Manual SCxxxHE-20-IA-IEN111210 29

Page 30

7 Transporting the Sunny Central SMA Solar Technology AG

8"3/*/(

/05*$&

7.2 Transporting the Sunny Central with a Forklift

Danger of crushing if the raised Sunny Central tips over or falls during lifting.

If the inverter is raised and transported without due care or too quickly, it may tip over or fall.

• Transport the Sunny Central as close to the ground as possible at all times.

• Use all suspension points for transportation.

• Avoid fast or jerky movements with the forklift.

• Keep a safe distance from the Sunny Central at all times during transport.

• All means of transport used must be designed for the weight of th e Sunny Central of 1 670 kg.

Damage to the inverter due to inappropriate transport.

• Never place the inverter on an unstable, uneven surface, not even for a short period of time.

• Do not transport the inverter with mounted kick plates.

1. Move the forklift under the inverter from the front or

the rear. Use the fork bracket. This will prevent the

Sunny Central from slipping during transport.

2. Secure the inverter, e.g., with retaining straps, to prevent it tipping over.

3. Raise the inverter slightly.

4. Transport the inverter to the installation site.

7.3 Mounting the kick plates at the rear of the inverter

Prior to aligning the inverter on the foundation, the kick plates must be fastened in place at the rear of

the inverter.

1. Mount the kick plates at the rear of the inverter in the prescribed position.

2. Attach the kick plates to the inverter using a Torx screwdriver.

30 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 31

SMA Solar Technology AG 7 Transporting the Sunny Central

8"3/*/(

/05*$&

7.4 Transporting the Sunny Central with a Pallet Truck

Danger of crushing if raised Sunny Central tips over, falls or sways during lifting.

If the inverter is raised and transported without due care or too quickly, it may tip over or fall.

• Always approach the inverter with the pallet truck from the side.

• Transport the Sunny Central as close to the ground as possible at all times.

• Use all suspension points for transportation.

• Avoid fast or jerky movements with the pallet truck.

• Keep a safe distance from the Sunny Central at all times during transport.

• All means of transport used must be designed for the weight of th e Sunny Central of 1 670 kg.

Damage to the inverter due to inappropriate transport.

• Only place the inverter on firm, level surfaces.

• Do not transport the inverter with mounted kick plate.

1. Approach the inverter with the pallet truck from the

side. This will prevent the inverter from tipping over.

2. Raise the inverter slightly.

3. Transport the inverter to the installation site.

Installation Manual SCxxxHE-20-IA-IEN111210 31

Page 32

7 Transporting the Sunny Central SMA Solar Technology AG

8"3/*/(

/05*$&

H

E

7.5 Transporting the Sunny Central with a Crane

Danger of crushing if raised Sunny Central tips over, falls or sways during lifting.

If the inverter is raised and transported without due care or too quickly, it may tip over or fall.

• Transport the Sunny Central as close to the ground as possible at all times.

• Use all suspension points for transportation.

• Use steel cables or chains with lifting hooks and shackles.

• Avoid fast or jerky movements with the crane.

• Keep a safe distance from the Sunny Central at all times during transport.

• All means of transport used must be designed for the weight of th e Sunny Central of 1 670 kg.

Damage to the inverter due to inappropriate transport.

• Put the inverter down on firm, level surfaces only.

1. Attach hooks of the steel cables/chains or lifting hook shackles to all 4 crane eyes on the

Sunny Central.

2. If the inverter is transported with the crane fork,

it must approach the inverter from the front.

32 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 33

SMA Solar Technology AG 7 Transporting the Sunny Central

3. Raise the crane hook slowly until the steel cables or

chains are tensioned.

4. Ensure that all steel cables and load hooks or load beams and shackles are attached correctly.

5. Raise the inverter slightly.

6. Transport the inverter to the installation site.

Installation Manual SCxxxHE-20-IA-IEN111210 33

Page 34

8 Installation of the Sunny Central SMA Solar Technology AG

/05*$&

/05*$&

8 Installation of the Sunny Central

8.1 Sealing the exhaust air zone

When the inverter is installed in the station, the exhaust air vent of the inverter must be connected to

the exhaust air of the station. The connections between the openings must be sealed tight. This will

ensure that all the warm air exhausted from the inverter is ducted out.

Damage to the inverter due to overheating.

Non-existent or inadequate sealing between the exhaust air vent of the inverter and the exhaust air

zone of the station may result in overheating of the inverter.

• Make sure that the warm exhaust air from the inverter is ducted out. When selecting the

sealing material make sure it is suited for air temperatures of up to +70°C.

8.2 Fastening the Inverter on the Foundation

Once the inverter has been aligned on the foundation, you can fasten it in place with concrete screw

anchors.

Additional mounting material (not included in the scope of delivery):

☐ 4 suitable concrete screw anchors must be provided.

• Insert the screw anchors through the brackets on the inverter into the foundation. The exact

procedure depends on the type of screw anchors used.

8.3 Disassembling the Panels

Damage due to PE cables being ripped out.

The panels are connected to the inverter via PE cables.

• When dismantling the panels, take care not to damage the PE cables.

The panels are located in the lower section of the connection cabinet.

1. Remove the panel screws using a Torx screwdriver (T30).

2. Carefully remove the front panel of the connection area. First, pull the panel forwards by

80 mm … 100 mm.

3. Detach PE cable from the rear side of the panel.

34 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 35

SMA Solar Technology AG 8 Installation of the Sunny Central

4. Remove the panels.

5. Remove the screws from the Plexiglas cover and remove the cover from the inverter.

8.4 Removing the Transport Lock from the Inverter Cabinet

Subject to the production version, the inverter power units are secured during transport with ESDprotected bubble wrap.

1. Open the inverter cabinet.

2. Remove the bubble wrap from each of the

3 inverter bridges. Observe the safety measures for

ESD protection.

3. Close the inverter cabinet.

Installation Manual SCxxxHE-20-IA-IEN111210 35

Page 36

9 AC and DC Connection SMA Solar Technology AG

9 AC and DC Connection

9.1 Safety during Cable Connection

Risk of fire

Too low ampacity of the connection cables leads to strong heating.

The connection cables must have sufficient ampacity. The ampacity depends on the following

conditions:

•Cable cross-section

•Cable type

•Routing method

•Ambient conditions

• Only use aluminum cables or copper cables.

Inadequate connections and oxidized contact surfaces cause excessive heating.

Tin-plated copper rails are standardly provided in the inverter for the connection of copper or

aluminum cables.

• Only use the nuts, screws and washers provided in the scope of delivery for the connection.

• Only use tin-plated crimp-type terminal lugs.

• Always connect 2-hole terminal lugs with 2 screws.

• Before connecting the cables, clean the contact surfaces (see section 9.4.2).

• Do not touch the contact surfaces after cleaning.

Non-observed torques cause strong heating.

To ensure the required ampacity at the connection points, all torques specified in this document must

be observed.

• For connections of tin-plated aluminum terminal lugs, observe a torque of 37 Nm.

• For connections of tin-plated copper terminal lugs, observe a torque of 60 Nm.

9.2 Connection Options

DC Fuses or DC Busbar

Depending on the order option, the inverter will be equipped with either DC fuses or DC busbars.

Each terminal lug can be assigned with 1 or 2 cables.

You can connect 1-hole or 2-hole terminal lugs to the DC fuses.

You can only connect 1-hole terminal lugs to the DC busbar.

36 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 37

SMA Solar Technology AG 9 AC and DC Connection

Grounding the PV modules

Depending on the configuration option, you can connect positive or negative grounded PV modules,

or ungrounded PV modules, to the Sunny Central.

9.3 Connection area

9.3.1 DC Fuses

Figure13: Connection area (example)

Position Description

A Connection lug PE cable

B Connection lugs DC‒ cables

C Connection lugs DC+ cables

D Connection lug AC cable - line conductor L

E Connection lug AC cable - line conductor L

F Connection lug AC cable - line conductor L

Installation Manual SCxxxHE-20-IA-IEN111210 37

3

2

1

Page 38

9 AC and DC Connection SMA Solar Technology AG

A

B

C

D

E

F

34 mm

90 mm

80 mm

80 mm

14 mm

14 mm

330.8 mm

329.5 mm

487.5 mm

179 mm

274 mm

476 mm

648 mm

9.3.2 DC Busbar

Figure14: Dimensions of the DC busbar

Position Description

A Connection lug PE cable

B Connection lug DC‒ cable

C Connection lug DC+ cable

D Connection lug AC cable - line conductor L

E Connection lug AC cable - line conductor L

F Connection lug AC cable - line conductor L

38 SCxxxHE-20-IA-IEN111210 Installation Manual

3

2

1

Page 39

SMA Solar Technology AG 9 AC and DC Connection

9.4 Cable Connection

9.4.1 Requirements

Cable

• Only use copper or aluminum cables.

• AC cables are designed to carry maximum voltages of 1 450 V to ground and an effective

value of 800 V.

• Connect a maximum of 2 DC cables to each fuse input.

Terminal lugs

• Only use tin-plated crimp-type terminal lugs.

• The width of the terminal lugs must exceed the washer diameter (32 mm). This will ensure that

the defined torques are effective over the whole surface.

9.4.2 Cleaning the contact surfaces of terminal lugs and connection lugs

1. Clean the contact surfaces with a clean cloth and ethanol cleaner.

2. Clean the contact surfaces with the non-woven abrasive included in the delivery until they have

a slight metallic shine. Avoid damage to the coated contact surfaces.

3. Remove metal dust with a clean cloth and ethanol cleaner.

4. Do not touch the contact surfaces again after cleaning.

Installation Manual SCxxxHE-20-IA-IEN111210 39

Page 40

9 AC and DC Connection SMA Solar Technology AG

E2

D

A

B

C

B

F

A

B

C

C

B

F

C

A

B

C

C

B

F

E1

D

A

B

C

C

B

F

9.4.3 Connecting cables with 1 terminal lug

Only use the screws and nuts included in the scope of delivery for fastening terminal lugs and

connection lugs.

Figure15: Assembly of the connection for 1 terminal lug

Position Description

AScrew M12

BSpring washer

C Fender washer

D Copper busbar

E1 Tin-plated 1-hole terminal lug

E2 Tin-plated 2-hole terminal lug

FNut

• Always connect terminal lugs to connection lugs in the order specified above.

40 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 41

SMA Solar Technology AG 9 AC and DC Connection

D2

E

D2

B

C

B

C

A

F

A

B

C

B

F

C

B

C

B

C

A

F

D1

E

D1

B

C

B

C

A

F

9.4.4 Connecting cables with 2 terminal lugs

Only use the screws and nuts included in the scope of delivery for fastening terminal lugs and

connection lugs.

Figure16: Assembly of the connection for 2 terminal lugs

Position Description

AScrew M12

BSpring washer

C Fender washer

D1 Tin-plated 1-hole terminal lug

D2 Tin-plated 2-hole terminal lug

E Copper busbar

FNut

• Always connect terminal lugs to connection lugs in the order specified above.

Installation Manual SCxxxHE-20-IA-IEN111210 41

Page 42

9 AC and DC Connection SMA Solar Technology AG

%"/(&3

9.5 Connecting the PE cables

Equipotential Bonding

Ground the inverter according to the applicable regulations.

1. Lead the PE cables into the connection cabinet.

2. Strip the PE cable insulation.

3. Fit terminal lugs to the PE cables.

4. Connect the PE cables to PE connection rail according to circuit diagram and the instructions in

section 9.4.

9.6 Connecting the DC cables

9.6.1 Requirements

Cables from the PV modules

• Only use copper or aluminum cables.

• A maximum of 2 DC cables can be connected to each fuse input.

9.6.2 Connecting the SMB Connection Kit

Risk of lethal electric shock. Voltage is present in PV modules exposed to light.

Even after disconnection, high voltages will still be present at the DC input of the inverter if the DC

main distribution and DC sub-distribution have not been disconnected.

• If DC main distributions are installed, disconnect the fuses in the main distributions and ensure

that the device cannot be accidentally reconnected.

• I f DC sub-dis tri but ion s are ins tal led , discon nec t th e fuses i n th e sub-di str ibu tio ns a nd ensur e th at

the device cannot be accidentally reconnected.

• Observe all safety precautions of the module manufacturer.

To connect the Sunny Main Box to the inverter, you need the SMB Connection Kit. You can only

connect the SMB Connection Kit to an inverter with DC fuses. The busbar of the SMB Connection Kit

links 3 inverter DC terminals and enables the connection of up to 4 DC cables.

42 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 43

SMA Solar Technology AG 9 AC and DC Connection

%"/(&3

1. Position and screw the busbar firmly over

3 DC terminals.

2. Pull the fuses out of the 3 DC terminal lugs. To do this, use a LV/HRC fuse handle.

9.6.3 Connecting the DC Cables

Risk of lethal electric shock. Voltage is present in PV modules exposed to light.

• If DC main distributions are installed, disconnect the fuses in the main distributions and ensure

that the device cannot be accidentally reconnected.

• I f DC sub-dis tri but ion s are ins tal led , discon nec t th e fuses i n th e sub-di str ibu tio ns a nd ensur e th at

the device cannot be accidentally reconnected.

• Observe all safety precautions of the module manufacturer.

Disconnection on the DC Side

The DC main and sub-distribution boxes should be equipped with circuit breakers. Circuit

breakers enable trouble-free DC side disconnection of the inverter.

1. Lead the DC cable into the connection cabinet.

2. Strip the DC cable insulation.

3. Fit terminal lugs to the DC cables.

4. Connect the DC cables to the DC terminal lugs or DC busbar according to the circuit diagram

and the instructions in section 9.4.

Installation Manual SCxxxHE-20-IA-IEN111210 43

Page 44

9 AC and DC Connection SMA Solar Technology AG

%"/(&3

8"3/*/(

9.7 Connecting the AC Cables

Risk of lethal electric shock. High voltages are present on the voltage carrying

components of the low-voltage and medium-voltage grids.

• Observe all safety regulations for working with the low-voltage grid and medium-voltage grid.

• Disconnect the miniature circuit breakers and ensure that they cannot be accidentally

reconnected.

• Disconnect the inverter from the DC sub-distribution and DC main distribution.

•Ensure that no voltage is present.

Risk of fire. Differing cable lengths lead to overheating of the cables.

• All cables of the line conductors must be of the same length.

1. Insert the AC cables through the base into the connection cabinet.

2. Strip the AC cable insulation.

3. Fit the AC cables with terminal lugs.

4. Connect the AC cables to the AC busbar according to the circuit diagram and the instructions

in section 9.4.

9.8 Mounting the kick plates

1. Mount the kick plates at the front of the inverter in the prescribed position.

2. Attach the kick plates to the inverter using a Torx screwdriver.

44 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 45

SMA Solar Technology AG 10 Cable Connection in the Connection Cabinet

10 Cable Connection in the Connection Cabinet

10.1 Connection area

Figure17: Terminals in the connection cabinet

Position Description

A Test and disconnect terminals

B Miniature circuit-breaker of the grid monitoring

C Miniature circuit-breaker of the external voltage supply

D Customer connection terminals

E Gasket plate with rubber seals (6 mm … 7 mm)

F Cable anchoring rail

Installation Manual SCxxxHE-20-IA-IEN111210 45

Page 46

10 Cable Connection in the Connection Cabinet SMA Solar Technology AG

10.2 Preparing the Cable Connection

1. Switch off the miniature circuit-breaker of the

external voltage supply.

2. Switch off the miniature circuit-breaker of the grid

monitoring.

3. Open the test and disconnect terminals.

4. Unscrew and remove the Plexiglas in front of the fuses.

46 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 47

SMA Solar Technology AG 10 Cable Connection in the Connection Cabinet

H

E

5. Remove all fuses and disconnecting blades from all

fuse holders. To do this, use a LV/HRC fuse handle.

10.3 Leading the Cables into the Connection Cabinet

1. Remove the 4 screws at the top of the gasket plate.

2. Remove the gasket plate.

3. Loosen the 3 screws on the side of the gasket plate.

4. Remove the required number of rubber seals from the gasket plate. Make sure that the diameter

of the rubber seals corresponds to the diameter to the cables to be inserted. Use the additional

rubber seals included in the scope of delivery, if necessary.

5. Remove the sealing plugs from the seals.

6. Lead the cables through the rubber seals.

7. Insert the rubber seals into the gasket plate without deformation. This will ensure a tight seal.

8. Tighten the screws on the side of the gasket plate.

9. Screw the gasket plate to the floor of the connection cabinet.

Installation Manual SCxxxHE-20-IA-IEN111210 47

Page 48

10 Cable Connection in the Connection Cabinet SMA Solar Technology AG

/05*$&

60 mm

15 mm 40 mm

5 mm

10.4 Connecting the Cables in the Connection Cabinet

10.4.1 Connecting the cables to the customer terminal block

1. Strip cable jacket to approx. 60 mm.

2. Strip conductor insulation to 5 mm.

3. Attach the bootlace ferrule to the conductors and crimp gas-tight.

4. Connect the cable in accordance with the circuit diagram.

– Insert a screwdriver into the square hole next to the terminal and open the terminal lock by

pressing it.

– Connect the cables to the terminals using bootlace ferrules.

– Remove the screwdriver from the terminal.

10.4.2 Important Measures for Non-utilized Options

Non-utilized External Quick-Stop

Damage to the Sunny Central caused by faulty installation of the external quick-stop.

If an external quick-stop is installed incorrectly, this may damage the Sunny Central and restrict the

function of the quick-stop.

• If no external quick-stop is installed, the terminals must be bridged according to the circuit

diagram.

Non-utilized Remote Shutdown

• If you are not using the remote shutdown option, set the parameter "ExtStrStpEna" to Off after

commissioning (see operating manual included in the delivery).

Non-utilized Transformer Protection

• If you are not using the transformer protection option, set the parameter "ExtTrfErrEna" to Off

after commissioning (see operating manual included in the delivery).

48 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 49

SMA Solar Technology AG 10 Cable Connection in the Connection Cabinet

1

2

1

2

10.4.3 Connecting the Sunny String-Monitor

Sunny String-Monitor

You will find further information in the technical description of the Sunny String-Monitor.

1. Lead the Sunny String-Monitor cable into the connection cabinet (see section 10.3).

2. Connect the cable according to the circuit diagram (see section 10.4.1).

3. Remove the shield clamp from the busbar.

4. Press the shield clamp onto the cable until it clicks

into place, and fasten hand-tight.

5. Fasten the cable to the cable anchoring rail using a cable tie. This secures the cable from being

pulled off.

10.4.4 Connecting the Remote Shutdown

With the remote shutdown unit you can deactivate the Sunny Central e.g. from a control room.

The remote shutdown is similar to the stop function of the key switch.

1. Lead the remote shutdown cable into the connection cabinet (see section 10.3).

2. Connect the cable according to the circuit diagram (see section 10.4.1).

3. Remove the shield clamp from the busbar.

4. Attach the shield clamp until it clicks into place, and

fasten hand-tight.

5. Fasten the cable to the cable anchoring rail using a cable tie. This secures the cable from being

pulled off.

Installation Manual SCxxxHE-20-IA-IEN111210 49

Page 50

10 Cable Connection in the Connection Cabinet SMA Solar Technology AG

1

2

10.4.5 Connecting the External Target Value Specification

Signal Transmission

External target values for reactive and active power are normally specified by the distribution

grid operator, and e.g. distributed via a radio ripple control receiver. The Power Reducer Box

receives the target values from the radio ripple control receiver and sends these to the inverter

via the SC-COM. The inverter then implements the distribution grid operator specification and

feeds, for example, a specified reactive power into the power distribution grid. Ask your

distribution grid operator which signal transmission is used.

If these target values are not transmitted via the SC-COM and Power Reducer Box, there are

terminals located in the inverter for connecting the external target value specifications.

The inverter processes standard signals from 4 mA ... 20 mA.

How the external target value specification works

You will find further information on how the external target value specification works in the

inverter's operating manual.

1. Lead the external target value specification cable into the connection cabinet (see section

10.3).

2. Connect the cable according to the circuit diagram (see section 10.4.1).

3. Remove the shield clamp from the busbar.

4. Attach the shield clamp until it clicks into place,

and fasten hand-tight.

5. Fasten the cable to the cable anchoring rail using a cable tie. This secures the cable from being

pulled off.

50 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 51

SMA Solar Technology AG 10 Cable Connection in the Connection Cabinet

/05*$&

1

2

10.4.6 Connecting the Transformer Protection

The inverter is equipped with a connection terminal for the transformer monitoring system of the

medium-voltage transformer. This will shut down the inverter immediately in the event of a fault. To use

the transformer monitoring, an external voltage supply of 230 V/50 Hz must be provided.

1. Lead the transformer protection cable into the connection cabinet (see section 10.3).

2. Connect the cable according to the circuit diagram (see section 10.4.1).

3. Remove the shield clamp from the busbar.

4. Press the shield clamp down until it clicks into place,

and fasten hand-tight.

5. Fasten the cable to the cable anchoring rail using a cable tie. This secures the cable from being

pulled off.

10.4.7 Connecting the External Voltage Supply

The in verter draws el ectricity for its inter nal power supply from the grid via the ext ernal voltage s upply.

Requirements for the external voltage supply:

Damage to the inverter due to incorrect power supply connection

• Connect the neutral conductor 'N'.

• Ground the star point of the transformer for internal power supply.

• External, three-phase auxiliary supply voltage of 230 V (3/N/PE) each

Miniature circuit-breaker between the external voltage supply and the inverter

A type B miniature circuit-breaker with a nominal current of 16 A is installed in the inverter.

• Provide for a selective miniature circuit-breaker for insulating the cable to the inverter.

Installation Manual SCxxxHE-20-IA-IEN111210 51

Page 52

10 Cable Connection in the Connection Cabinet SMA Solar Technology AG

/05*$&

Required Material:

• Cable with a maximum conductor cross-section of 4 mm²

1. Lead the external voltage supply cable into the connection cabinet (see section 10.3).

2. Connect the cable according to the circuit diagram (see section 10.4.1).

3. Fasten the cable to the cable anchoring rail using a cable tie. This secures the cable from being

pulled off.

10.4.8 Connecting the External Quick-Stop Cabling

The Sunny Central is equipped by default with a quick-stop button. If the external quick-stop function

is required, it can be connected according to the circuit diagram.

Damage to the Sunny Central caused by faulty installation of the external quick-stop.

If an external quick-stop is installed incorrectly, this may damage the Sunny Central and restrict the

function of the quick-stop.

• When connecting the external quick-stop cabling, it is obligatory to follow the circuit diagram

included in the delivery. The connection is made at the terminals.

• If no external quick-stop is installed, the terminals must be bridged according to the circuit

diagram.

Routing of the quick-stop cable

The cable entry is the floor of the cabinet.

1. Lead the external quick-stop cable into the connection cabinet (see section 10.3).

2. Connect the cable according to the circuit diagram (see section 10.4.1).

3. Fasten the cable to the cable anchoring rail using a cable tie. This secures the cable from being

pulled off.

52 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 53

SMA Solar Technology AG 10 Cable Connection in the Connection Cabinet

/05*$&

Quick-stop function for several Sunny Centrals in one plant

Damage to the Sunny Central due to missing quick-stop function.

• In plants with more than one inverter, the quick-stop circuits of the installed devices must be

linked with each other and tested for correct functioning.

• The quick-stop string may only be supplied with voltage from one Sunny Central.

If several Sunny Centrals are in operation in one plant, they must all be switched off when the

quick-stop button is pressed on one inverter (creation of a quick-stop stop string). To achieve this, the

quick-stop buttons of all Sunny Centrals are switched in series.

The necessary 24 V supply voltage for the quick-stop string can be tapped internally by up to two

Sunny Centrals installed in one station. If more than two Sunny Centrals are installed in one station or

th e di sta nce bet wee n th e tw o Su nny Cen tra ls i s gr eat er t han 5 m, the voltage supply must be provided

externally.

Installation Manual SCxxxHE-20-IA-IEN111210 53

Page 54

11 Connection of the Communication Devices SMA Solar Technology AG

11 Connection of the Communication Devices

11.1 Structure of a Plant Network

Before you can connect the inverter to a computer via the service interface or the Internet, the

SC-COM must be set up in the plant network.

Figure18: Basic structure of large-scale plant networks

54 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 55

SMA Solar Technology AG 11 Connection of the Communication Devices

11.2 Position of the communication ports

Figure19: Position of the communication ports

Position Description

ASplice box*

B Network terminal RJ45 socket and surge arrester

*Optional

Installation Manual SCxxxHE-20-IA-IEN111210 55

Page 56

11 Connection of the Communication Devices SMA Solar Technology AG

11.3 Building a Plant Network with Copper Cables

You can integrate the SC-COM into the plant network using a copper cable. If you integrate the

SC-COM permanently into a network with Internet access, it will be able to transmit plant data to

Sunny Portal automatically.

Requirement for the communication cable:

☐ Stripped, shielded twisted pair cable of category 5 (CAT 5) or higher.

• Plug the communication cable into the RJ45 socket in the connection cabinet.

11.4 Building a Plant network with Optical Fibers

Depending on the order option, you can integrate the SC-COM into the plant network using optical

fibers. If you integrate the SC-COM permanently into a network with Internet access, it will be able to

transmit the plant data to Sunny Portal automatically.

The optical fiber is connected in the splice box. The splice box is equipped with an SC-P plug.

You can connect the optical fiber to the SC-P plug in two ways:

• Connection of optical fiber using SC connector

• Connection of optical fiber via pigtail

Connection of optical fiber using SC connector

1. Mount SC connector on optical fiber.

2. Plug the SC connector into the SC-P plug in the splice box.

Connection of optical fiber via pigtail

Requirement for the pigtail:

☐ The cable is equipped with a 50 μm multi-mode fiber.

☐ The cable has an SC connector.

1. Splice the optical fiber with the pigtail in the splice box.

2. Plug SC connector into the SC-P plug in the splice box.

56 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 57

SMA Solar Technology AG 12 Commissioning

8"3/*/(

12 Commissioning

12.1 Commissioning the Inverter

Danger of fire if the connection is faulty.

• Switch off all switch elements before the test:

– Switch the inverter to Stop.

–Pull out the fuses.

– Switch off the internal main switches and the miniature circuit-breaker.

Warranty or Guarantee Claims

Warranty or guarantee claims can only be made valid if the initial start-up was carried out by

SMA Solar Technology AG or if the fully completed and signed "Commissioning Report for

Sunny Central Plants" is completed and available at SMA Solar Technology AG.

1. Check the cabling on the inverter (see section 12.2).

2. Commission the DC sub-distribution, e.g. Sunny String-Monitor

(see DC sub-distribution documentation).

3. Commission the DC main distribution, e.g. Sunny Main Box

(see DC main distribution documentation).

4. Check the DC voltages (see section 12.3.1).

5. Insert fuses or disconnecting blades (see section 12.5).

6.

7. Check the AC grid voltage (see section 12.3.2).

8. Check the AC self-consumption voltage (see section 12.3.3).

9. Switch on the voltage supply (see section 12.6).

Installation Manual SCxxxHE-20-IA-IEN111210 57

Only a duly authorized person trained in electrical safety can connect the

AC voltage of the medium-voltage transformer.

Switch on the AC voltage of the medium-voltage transformer.

☑ The electronic components of the inverter switch on.

☑ The fans switch on and start taking air in through the air intake vents.

✖ The fans have not come on?

• Contact the SMA Serviceline.

Page 58

12 Commissioning SMA Solar Technology AG

10. Switch the AC switch on.

11. Mount the panels (see section 12.4).

12. Close the doors.

13. Providing there is no error showing on the indicator lights or the display, switch the inverter on

(see section 12.7).

☑ The DC switch switches on with an audible click.

☑ Under conditions of sufficient irradiation, the inverter starts feeding into the grid.

✖ Are the display or indicator lamps showing an fault?

• Follow the operating manual for troubleshooting.

12.2 Checking the Cabling on the Inverter

1. Ensure that all connections are executed in accordance with the circuit diagram.

2. Ensure that all AC, DC and PE connections are securely in place.

3. Ensure that equipotential bonding of the inverter to the installation site has been carried out.

4. Ensure that all connections in the connection cabinet are securely in place.

58 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 59

SMA Solar Technology AG 12 Commissioning

8"3/*/(

/05*$&

12.3 Checking the Inverter Voltage

12.3.1 Checking the DC Voltages

Danger of electric arcs if the measuring device is not properly connected.

• Ensure that the measuring device is connected correctly.

• Select the appropriate measuring range.

Damage to the inverter due to excessive DC voltages.

The DC voltage of the PV array must not exceed the maximum voltage of the inverter.

•V

= 1 000 V / 1 100 V

PV

1. Measure the DC voltage for each input and record in the Commissioning Report. To do this, use

the DC+ and DC— terminal lugs in the connection area as measuring points.

2. Compare the DC voltages.

☑ The voltages are approximately the same and do not exceed the maximum DC voltage of

the inverter.

✖ The voltages deviate from each other and exceed the maximum DC voltage of the inverter.

• Ensure that the cabling has been executed in accordance with the circuit diagram.

3. Check that the polarity of each input is correct.

4. Measure the DC voltage for each plus pole to ground and record in the Commissioning Report.

To do this, use the DC+ terminal lugs and PE connection busbar as measuring points.

☑ There is a measurable voltage drop.

✖ There is no measurable voltage drop?

A ground fault has occurred.

• Eliminate the ground fault.

Installation Manual SCxxxHE-20-IA-IEN111210 59

Page 60

12 Commissioning SMA Solar Technology AG

12.3.2 Checking the AC Grid Voltage

1. Measure the rotating magnetic field at the the AC terminal lugs using a rotating-field instrument.

☑ The detected rotating magnetic field is right-rotating.

✖ Is the detected rotating magnetic field left-rotating?

2 line conductors are incorrectly connected.

• Swap over the connections of the two of the three line conductors.

2. Measure the AC voltage at the AC terminal lugs between the following terminals and record in

the Commissioning Report:

–L

- L

1

2

–L1 - L

3

–L2 - L

3

–L1 - PE

–L

- PE

2

–L

- PE

3

☑ AC voltage is approximately the same as the nominal voltage of the inverter.

✖ Does the AC voltage strongly deviate from the nominal voltage of the inverter?

• Have the transmission ratio of the medium-voltage transformer ad jus ted by a n au tho riz ed

person.

60 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 61

SMA Solar Technology AG 12 Commissioning

12.3.3 Checking the External Voltage Supply

1. Using a rotating-field instrument, measure the rotating magnetic field at the miniature circuitbreaker of the external voltage supply. To do this, use the measuring points on the miniature

circuit-breaker of the external voltage supply.

☑ The detected rotating magnetic field is right-rotating.

✖ Is the detected rotating magnetic field left-rotating?

2 line conductors are incorrectly connected.

• Swap over the connections of the two of the three line conductors and repeat the

measurement.

2. Mea sur e th e AC vol tages at the min iat ure circ uit -br eak er of the external voltage supply between

the following terminals and record in the Commissioning Report: To do this, use the measuring

points on the miniature circuit-breaker of the external voltage supply.

–L

- L

1

2

–L1 - L

3

–L2 - L

3

–L1 - N

–L

- N

2

–L

- N

3

–L1 - PE

–L

- PE

2

–L

- PE

3

–N

- PE

☑ The voltage between the line conductors is within the range of 360 V ... 440 V. The voltage

between line conductor and neutral conductor or PE conductor is within the range of

207 V … 243 V. The voltage between PE conductor and neutral conductor is 0 V.

Installation Manual SCxxxHE-20-IA-IEN111210 61

Page 62

12 Commissioning SMA Solar Technology AG

%"/(&3

H

E

12.4 Mounting the Panels

Risk of death due to electric shock when live parts of the inverter are touched.

• Do not touch live components in the central inverter.

1. Fix all cables to the cable anchoring rail using cable ties.

2. Fasten the PE cables to the panels of the connection cabinet.

3. Check that the PE cables are securely fixed.

4. Screw on the Plexiglas cover over the AC terminal lugs.

5. Screw on the panels.

12.5 Inserting Fuses or Disconnecting Blades

1. If you are not using an SMB connection kit, insert fuses. To do this, use a LV/HRC fuse handle.

2. If you are using an SMB connection kit, insert

disconnecting blades. To do this, use a LV/HRC

fuse handle.

3. Screw the Plexiglas cover back on over the fuses.

62 SCxxxHE-20-IA-IEN111210 Installation Manual

Page 63

SMA Solar Technology AG 12 Commissioning

12.6 Switching on the Voltage Supply

1. Close the test and disconnect terminals.

2. Switch on the miniature circuit-breaker of the grid

monitoring.

3. Switch on the miniature circuit-breaker of the

external voltage supply.

Installation Manual SCxxxHE-20-IA-IEN111210 63

Page 64

12 Commissioning SMA Solar Technology AG

%"/(&3

4. Check the 3 indicator lamps on the 3 printed circuit

boards of the power units in the inverter cabinet.

☑ Indicator lights glow green.

✖ Are indicator lights not glowing green?

• Contact the SMA Serviceline.

12.7 Switching on the Inverter

Danger to life through electric shock in the event of improper use or unauthorized

opening of the inverter.

High voltages are present in the inverter during operation.

• Do not operate the inverter while the door is open.

• Remove the keys from the door locks on the inverter station.

• Keep the keys in a safe place.

Requirements:

☐ All electrical connections made on site are correctly executed and firmly in place.

☐ The entire electrical system including the PV plant has been tested by the plant installer in