Page 1

UserManual

SUNNYCENTRAL500CPXT/ 630CPXT/ 720CPXT/

760CPXT/ 800CPXT/ 850CPXT/ 900CPXT

SCCPXT-BA-E4-en-54 | 98-100500.04 | Version 5.4

ENGLISH

Page 2

Legal Provisions

SMA Solar Technology AG

Legal Provisions

The information contained in these documents is property of SMA Solar Technology AG. Any publication, whether in

whole or in part, requires prior written approval by SMA Solar Technology AG. Internal reproduction used solely for

the purpose of product evaluation or other proper use is allowed and does not require prior approval.

SMA Warranty

You can download the current warranty conditions from the Internet at www.SMA-Solar.com.

Trademarks

All trademarks are recognized, even if not explicitly identified as such. A lack of identification does not mean that a

product or symbol is not trademarked.

The BLUETOOTH® word mark and logos are registered trademarks of BluetoothSIG,Inc. and any use of these marks

by SMASolarTechnologyAG is under license.

Modbus® is a registered trademark of Schneider Electric and is licensed by the Modbus Organization, Inc.

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

Phillips® and Pozidriv® are registered trademarks of Phillips Screw Company.

Torx® is a registered trademark of Acument Global Technologies, Inc.

SMASolarTechnologyAG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

E-mail: info@SMA.de

© 2004 to 2015SMASolarTechnologyAG. All rights reserved.

User ManualSCCPXT-BA-E4-en-542

Page 3

SMA Solar Technology AG

Table of Contents

Table of Contents

1 Information on this Document ..................................................................................................... 9

1.1 Validity .............................................................................................................................................................. 9

1.2 Target Group .................................................................................................................................................... 9

1.3 Additional Information...................................................................................................................................... 9

1.4 Symbols............................................................................................................................................................. 9

1.5 Typographies.................................................................................................................................................... 10

1.6 Nomenclature................................................................................................................................................... 10

2 Safety............................................................................................................................................. 11

2.1 Intended Use..................................................................................................................................................... 11

2.2 Safety Information ............................................................................................................................................ 12

2.3 Personal Protective Equipment......................................................................................................................... 14

3 Product Overview......................................................................................................................... 16

3.1 Design of the inverter ....................................................................................................................................... 16

3.2 Devices of the Inverter...................................................................................................................................... 16

3.3 Operating and Display Elements..................................................................................................................... 17

3.3.1 Function of the Switches................................................................................................................................... 17

3.3.1.1 Key Switch........................................................................................................................................................ 17

3.3.1.2 AC Disconnection Unit .................................................................................................................................... 18

3.3.1.3 DC Switchgear................................................................................................................................................. 18

3.3.2 Touch Display................................................................................................................................................... 19

3.3.2.1 Design............................................................................................................................................................... 19

3.3.2.2 Explanation of Symbols................................................................................................................................... 19

3.3.3 LEDs of the SC-COM ....................................................................................................................................... 23

3.3.3.1 LEDs on the Enclosure...................................................................................................................................... 23

3.3.3.2 LEDs on the Network Port................................................................................................................................ 24

3.3.3.3 LEDs on the Optical Fiber Terminals ............................................................................................................... 25

3.3.4 User Interface ................................................................................................................................................... 26

3.3.4.1 Design of the User Interface............................................................................................................................ 26

3.3.4.2 Tree View and Device View ............................................................................................................................ 26

3.3.4.3 Status Symbols ................................................................................................................................................. 27

3.4 Symbols on the Product.................................................................................................................................... 27

4 Commissioning.............................................................................................................................. 28

4.1 Safety during Commissioning .......................................................................................................................... 28

4.2 Requirements for Commissioning..................................................................................................................... 28

4.3 Visual Inspection and Mechanical Test........................................................................................................... 29

4.3.1 Sequence for Visual Inspection and Mechanical Test ................................................................................... 29

4.3.2 Checking the Connections of the Cables for Communication, Control Supply Voltage and Monitoring.. 29

4.3.3 Checking the High-Current Contacts Made at the Installation Site .............................................................. 30

4.3.4 Checking the High-Current Contacts Made at the Factory ........................................................................... 30

4.3.5 Checking the Settings of the Switching Units.................................................................................................. 30

4.3.6 Checking the Connectors................................................................................................................................. 31

4.4 Connection and Measurement ....................................................................................................................... 31

4.4.1 Sequence for Connection and Measurement ................................................................................................ 31

4.4.2 Checking the Output Voltage of the Inverter.................................................................................................. 31

4.4.3 Checking the DC Voltage................................................................................................................................ 32

4.4.4 Switching On the Supply Voltage and the AC Disconnection Unit .............................................................. 32

4.5 Function Test...................................................................................................................................................... 33

User Manual 3SCCPXT-BA-E4-en-54

Page 4

Table of Contents

SMA Solar Technology AG

4.5.1 Checking the Fans............................................................................................................................................ 33

4.5.2 Checking the Heating Elements and Hygrostat.............................................................................................. 34

4.6 Configuration.................................................................................................................................................... 35

4.6.1 Configuring the Network Settings on the Computer...................................................................................... 35

4.6.2 Information on Integrating the Inverter into a Local Network ....................................................................... 35

4.6.3 Configuring the Inverter for a Static Network ................................................................................................ 36

4.6.4 Adjusting Network Ports .................................................................................................................................. 36

4.6.5 Detecting New Devices ................................................................................................................................... 37

4.6.6 Setting the Power Limitation............................................................................................................................. 37

4.6.6.1 Setting the Active Power Ramp-Up ................................................................................................................. 37

4.6.6.2 Setting the Frequency-Dependent Active Power Limitation ........................................................................... 37

4.6.6.3 Setting the Frequency-Independent Active Power Limitation......................................................................... 38

4.6.6.4 Setting Reactive Power Control....................................................................................................................... 38

4.6.6.5 Setting Q at Night ........................................................................................................................................... 39

4.6.7 Setting Grid Monitoring and Grid Limits......................................................................................................... 40

4.6.7.1 Setting Grid Voltage Monitoring .................................................................................................................... 40

4.6.7.2 Setting Power Frequency Monitoring ............................................................................................................. 40

4.6.7.3 Activating the Manual Resume Mode ............................................................................................................ 40

4.6.8 Setting the Grid Support.................................................................................................................................. 41

4.6.8.1 Setting Full and Limited Dynamic Grid Support (FRT) ................................................................................... 41

4.6.8.2 Setting Enable Islanding Detection ................................................................................................................. 41

4.6.8.3 Setting the Medium Voltage ........................................................................................................................... 41

4.6.9 Setting Project-Specific Parameters ................................................................................................................. 42

4.6.9.1 Setting the Remote Shutdown ......................................................................................................................... 42

4.6.9.2 Deactivating the "Fully Hermetic" Transformer Protection ............................................................................. 42

4.6.10 Setting the String Current Monitoring ............................................................................................................ 42

4.6.10.1 Detecting the Sunny Central String-Monitor Controller and the Inverter...................................................... 42

4.6.10.2 Setting the Date and Time of the Sunny Central String-Monitor Controller ................................................. 42

4.6.10.3 Detecting the Sunny String-Monitors via the Sunny Central String-Monitor Controller............................... 42

4.6.10.4 Redetecting the Sunny String-Monitors via the Sunny Central String-Monitor Controller ........................... 43

4.6.10.5 Detecting the Sunny String-Monitors via the Communication Unit ............................................................... 43

4.6.10.6 Adjusting the Identification of the Sunny String-Monitors.............................................................................. 43

4.6.10.7 Changing the Communication Period ............................................................................................................ 43

4.6.10.8 Changing the Monitoring Period.................................................................................................................... 44

4.6.10.9 Assigning Strings to Different Measuring Channels ...................................................................................... 44

4.6.10.10 Assigning Strings to Different Groups............................................................................................................. 44

4.6.10.11 Setting the Tripping Time................................................................................................................................. 45

4.6.10.12 Setting the Tolerance....................................................................................................................................... 45

4.6.11 Configuring the Zone Monitoring ................................................................................................................... 45

4.6.12 Changing System Settings via Touch Display ................................................................................................ 46

4.6.12.1 Selecting the Language................................................................................................................................... 46

4.6.12.2 Setting the Date, Time and Time Zone ........................................................................................................... 46

4.6.12.3 Selecting the Display Format........................................................................................................................... 46

4.6.12.4 Setting the Brightness....................................................................................................................................... 46

4.6.13 Changing the System Settings via the User Interface .................................................................................... 46

4.6.13.1 Selecting the Language................................................................................................................................... 46

4.6.13.2 Setting the Date, Time and Time Zone ........................................................................................................... 47

4.6.13.3 Entering the Operator Name.......................................................................................................................... 47

4.6.13.4 Changing the Password for the User Groups................................................................................................ 47

4.6.14 Configuring System Settings via XML File....................................................................................................... 48

4.6.14.1 Uploading the File custom.xml........................................................................................................................ 48

4.6.14.2 Downloading the File custom.xml................................................................................................................... 48

4.6.14.3 Deleting the File custom.xml............................................................................................................................ 49

User ManualSCCPXT-BA-E4-en-544

Page 5

SMA Solar Technology AG

Table of Contents

4.6.15 Resetting the Communication Unit................................................................................................................... 49

4.7 Switching the Inverter On................................................................................................................................. 49

5 Disconnecting and Reconnecting................................................................................................. 51

5.1 Safety When Disconnecting and Reconnecting Voltage Sources................................................................. 51

5.2 Disconnecting the Inverter................................................................................................................................ 51

5.2.1 Switching off the Inverter ................................................................................................................................. 51

5.2.2 Disconnecting the DC Side.............................................................................................................................. 51

5.2.3 Disconnecting the AC Side.............................................................................................................................. 52

5.2.4 Disconnecting the Supply Voltage and External Voltages ............................................................................ 52

5.3 Reconnecting the Inverter................................................................................................................................. 53

5.3.1 Reconnecting the Supply Voltage and External Voltages ............................................................................. 53

5.3.2 Reconnecting the AC Side............................................................................................................................... 54

5.3.3 Reconnecting the DC Side............................................................................................................................... 54

5.3.4 Restarting the Inverter ...................................................................................................................................... 54

6 Operation...................................................................................................................................... 55

6.1 Safety during Operation.................................................................................................................................. 55

6.2 Displaying Operating Data ............................................................................................................................. 55

6.2.1 Displaying Operating Data via the User Interface ........................................................................................ 55

6.2.2 Displaying the Operation Data via Sunny Portal........................................................................................... 55

6.2.2.1 Registering the Inverter in Sunny Portal .......................................................................................................... 55

6.2.2.2 Adjusting the PV System Identifier for Sunny Portal ....................................................................................... 56

6.2.2.3 Deleting the Sunny Portal Buffer ..................................................................................................................... 56

6.3 Saving Operating Data.................................................................................................................................... 56

6.3.1 Reducing Storage Capacity by Averaging .................................................................................................... 56

6.3.2 Setting the Data Transmission Frequency ....................................................................................................... 57

6.3.3 Downloading Operating Data Using the FTP Server..................................................................................... 57

6.3.3.1 Defining Read and Write Access Rights......................................................................................................... 57

6.3.3.2 Accessing the FTP Server via the Web Browser ............................................................................................ 57

6.3.3.3 Activating Automatic Data Transmission via FTP Push ................................................................................... 58

6.3.4 Downloading Operating Data via HTTP Download...................................................................................... 58

6.3.4.1 Downloading Data in XML Format ................................................................................................................. 58

6.3.4.2 Downloading Data in CSV Format ................................................................................................................. 59

6.3.5 Saving Operating Data on a Memory Card.................................................................................................. 60

6.3.5.1 Information on Saving Data on a Memory Card .......................................................................................... 60

6.3.5.2 Inserting the Memory Card ............................................................................................................................. 60

6.3.5.3 Enabling Data Storage on the Memory Card ............................................................................................... 60

6.3.5.4 Displaying the Memory Capacity Available on the Memory Card ............................................................. 61

6.4 Updating the Firmware .................................................................................................................................... 61

6.4.1 Automatic Update............................................................................................................................................ 61

6.4.2 Update via User Interface ............................................................................................................................... 61

6.5 Changing the Insulation Monitoring................................................................................................................ 62

6.5.1 Insulation Monitoring with GFDI and Insulation Monitoring Device ........................................................... 62

6.5.1.1 Safety during Insulation Monitoring of the PV Power Plant with GFDI and Insulation Monitoring Device 62

6.5.1.2 Switching to Insulated Operation ................................................................................................................... 62

6.5.1.3 Switching to Grounded Operation................................................................................................................. 63

6.5.2 Insulation Monitoring with Remote GFDI and Insulation Monitoring Device............................................... 63

6.5.2.1 Information on Insulating PV Modules with Remote GFDI and Insulation Monitoring Device ................... 63

6.5.2.2 Switching to Insulated Operation ................................................................................................................... 63

6.5.2.3 Switching to Grounded Operation................................................................................................................. 63

6.6 Deleting the Device Description....................................................................................................................... 63

User Manual 5SCCPXT-BA-E4-en-54

Page 6

Table of Contents

SMA Solar Technology AG

6.7 Sending a ZIP File with Service Information ................................................................................................... 63

7 Troubleshooting ............................................................................................................................ 65

7.1 Safety during Troubleshooting......................................................................................................................... 65

7.2 Activating Alert in the Event of a Fault ............................................................................................................ 65

7.3 Reading Off Disturbance Messages ............................................................................................................... 66

7.3.1 Reading Off Error Messages via Touch Display............................................................................................ 66

7.3.2 Reading Off Disturbance Messages via the User Interface .......................................................................... 66

7.3.3 Displaying the Event Report............................................................................................................................. 66

7.3.3.1 Enabling Automatic Read-Out of Events......................................................................................................... 66

7.3.3.2 Displaying and Downloading the Event Report............................................................................................. 66

7.4 Acknowledging Disturbance Messages.......................................................................................................... 67

7.4.1 Acknowledging Disturbance Messages via the Key Switch.......................................................................... 67

7.4.2 Acknowledging Disturbance Messages via the User Interface..................................................................... 67

7.5 Remedial Action in Case of Disturbances....................................................................................................... 67

7.5.1 Inverter Behavior in Case of Disturbances...................................................................................................... 67

7.5.2 Explanation of the Error Tables....................................................................................................................... 69

7.5.3 Error Numbers 01xx to 13xx - Disturbance on the Utility Grid .................................................................... 69

7.5.4 Error Numbers 34xx to 40xx - Disturbance on the PV Array........................................................................ 70

7.5.5 Error Numbers 6xx to 9xx - Disturbance on the Inverter............................................................................... 72

7.5.6 Displaying Disturbance Messages for Active Power Limitation..................................................................... 75

7.5.7 Displaying Disturbance Messages for the Reactive Power Setpoint............................................................. 76

8 Disposal ......................................................................................................................................... 78

9 Periodic Actions............................................................................................................................. 79

9.1 Mounting and Disassembly Work................................................................................................................... 79

9.1.1 Disassembling and Mounting the Panels........................................................................................................ 79

9.1.2 Disassembling and Mounting the Protective Covers...................................................................................... 80

9.2 Entering the Password via the Touch Display ................................................................................................. 81

9.3 Parameter Overview......................................................................................................................................... 81

9.3.1 Accessing the Parameter Overview ................................................................................................................ 81

9.3.2 Saving Parameter Changes............................................................................................................................. 81

9.4 User Interface.................................................................................................................................................... 81

9.4.1 Logging Into the User Interface ....................................................................................................................... 81

9.4.2 Logging Out of the User Interface................................................................................................................... 82

10 Function Description ..................................................................................................................... 83

10.1 Operating States .............................................................................................................................................. 83

10.1.1 Overview of the Operating States .................................................................................................................. 83

10.1.2 Stop................................................................................................................................................................... 84

10.1.3 Grid Monitoring .............................................................................................................................................. 84

10.1.3.1 Monitoring the Grid Voltage........................................................................................................................... 84

10.1.3.2 Monitoring the Power Frequency ................................................................................................................... 85

10.1.4 Grid Monitoring Time Reached....................................................................................................................... 85

10.1.5 Startup............................................................................................................................................................... 86

10.1.5.1 In Normal Operation: Active Power Ramp-Up .............................................................................................. 86

10.1.5.2 After Grid Fault: Decoupling Protection Ramp............................................................................................... 86

10.1.6 Load Operation................................................................................................................................................ 86

10.1.6.1 MPP .................................................................................................................................................................. 86

10.1.6.2 Q at Night........................................................................................................................................................ 86

10.1.7 Shutdown.......................................................................................................................................................... 87

User ManualSCCPXT-BA-E4-en-546

Page 7

SMA Solar Technology AG

Table of Contents

10.1.8 Disturbance....................................................................................................................................................... 87

10.2 Safety Functions................................................................................................................................................ 87

10.2.1 Manual Shutdown Functions........................................................................................................................... 87

10.2.1.1 External Fast Stop ............................................................................................................................................ 87

10.2.1.2 Remote Shutdown............................................................................................................................................ 88

10.2.2 Automatic Shutdown Functions ....................................................................................................................... 88

10.2.2.1 Grid Management Shutdown......................................................................................................................... 88

10.2.2.2 Transformer Protection..................................................................................................................................... 88

10.2.2.3 Active Islanding Detection............................................................................................................................... 88

10.2.2.4 Passive Islanding Detection............................................................................................................................. 89

10.2.3 Grounding and Insulation Monitoring............................................................................................................ 89

10.2.3.1 Mode of Operation......................................................................................................................................... 89

10.2.3.2 GFDI ................................................................................................................................................................. 89

10.2.3.3 Remote GFDI.................................................................................................................................................... 90

10.2.3.4 Insulation Monitoring Device .......................................................................................................................... 91

10.2.3.5 GFDI and Insulation Monitoring Device......................................................................................................... 92

10.2.3.6 Remote GFDI and Insulation Monitoring Device........................................................................................... 93

10.2.4 Low-Temperature Option ................................................................................................................................. 94

10.3 Power Control................................................................................................................................................... 94

10.3.1 Frequency-Dependent Active Power Limitation .............................................................................................. 94

10.3.2 Frequency-Independent Active Power Limitation............................................................................................ 95

10.3.2.1 No Active Power Limitation: Off Mode.......................................................................................................... 95

10.3.2.2 Active Power Limitation with Setpoint Command via Modbus Protocol: WCtlCom Mode ........................ 95

10.3.2.3 Active Power Limitation with Absolute Value: WCnst Mode ........................................................................ 95

10.3.2.4 Active Power Limitation as a Percentage of Nominal Power: WCnstNom Mode ...................................... 96

10.3.2.5 Active Power Limitation via Standard Signal: WCnstNomAnIn Mode ........................................................ 96

10.3.3 Reactive Power Control ................................................................................................................................... 96

10.3.3.1 No Reactive Power Control: Off Mode ......................................................................................................... 96

10.3.3.2 Reactive Power Control with Setpoint Command via Modbus Protocol: VArCtlCom Mode...................... 96

10.3.3.3 Reactive Power Control with Setpoint Command via Modbus Protocol: PFCtlCom Mode........................ 96

10.3.3.4 Reactive Power Control with Absolute Value: VArCnst Mode...................................................................... 96

10.3.3.5 Reactive Power Control as a Percentage of the Nominal Power: VArCnstNom Mode ............................. 96

10.3.3.6 Reactive Power Setpoint via Standard Signal: VArCnstNomAnIn Mode .................................................... 97

10.3.3.7 Reactive Power Setpoint via Displacement Power Factor cos φ: PFCnst Mode .......................................... 97

10.3.3.8 Displacement Power Factor cos φ via Standard Signal: PFCnstAnIn Mode................................................ 98

10.3.3.9 Displacement Power Factor cos φ as a Function of Feed-In Power: PFCtlW Mode.................................... 99

10.3.3.10 Reactive Power as a Function of the Grid Voltage: VArCtlVol Mode.......................................................... 99

10.3.3.11 Measures for Voltage Support through Parameterization of Reactive Power/Voltage Characteristic

Curve: VArCtlVolHystDb Mode...................................................................................................................... 100

10.3.3.12 Measures for Voltage Support through Parameterization of Reactive Power/Voltage Characteristic

Curve: VArCtlVolHystDbA Mode ................................................................................................................... 103

10.3.4 Q at Night ........................................................................................................................................................104

10.3.4.1 No Q at Night: Off Mode.............................................................................................................................. 104

10.3.4.2 Q at Night with Operation Command via Modbus Protocol: VArCtlCom Mode....................................... 104

10.3.4.3 Q at Night with Absolute Value: VArCnst Mode .......................................................................................... 104

10.3.4.4 Q at Night as a Percentage of the Nominal Power: VArCnstNom Mode .................................................. 104

10.3.4.5 Q at Night via Standard Signal: VArCnstNomAnIn Mode .......................................................................... 104

10.3.4.6 Q at Night Depending on the Grid Voltage: VArCtlVol Mode.................................................................... 105

10.3.4.7 Measures for Voltage Support through Parameterization of Reactive Power/Voltage Characteristic

Curve: VArCtlVolHystDb Mode...................................................................................................................... 106

10.3.4.8 Measures for Voltage Support through Parameterization of Reactive Power/Voltage Characteristic

Curve: VArCtlVolHystDbA Mode ................................................................................................................... 109

10.3.5 Behavior in the Absence of Active and Reactive Power Setpoints................................................................110

10.4 Structure of the Communication Network.......................................................................................................110

User Manual 7SCCPXT-BA-E4-en-54

Page 8

Table of Contents

SMA Solar Technology AG

10.5 Grid Management Services.............................................................................................................................112

10.5.1 Requirements for Grid Management Services ...............................................................................................112

10.5.2 Dynamic Grid Support (FRT) ...........................................................................................................................112

10.5.2.1 Full and Limited Dynamic Grid Support (FRT)................................................................................................ 112

10.5.2.2 Grid Support in Case of Untervoltage (LVRT)................................................................................................ 113

10.5.2.3 Dynamic Undervoltage Detection................................................................................................................... 114

10.5.2.4 Grid Support in the Event of Overvoltage (HVRT)......................................................................................... 115

10.6 Zone Monitoring...............................................................................................................................................115

11 Operating Data and Parameters ................................................................................................117

11.1 Operating Data ................................................................................................................................................117

11.1.1 Inverter..............................................................................................................................................................117

11.1.1.1 Power Limitation............................................................................................................................................... 117

11.1.1.2 Error Channels ................................................................................................................................................. 119

11.1.1.3 Measured Values............................................................................................................................................. 119

11.1.1.4 Internal Device Values..................................................................................................................................... 119

11.1.1.5 Internal Meters................................................................................................................................................. 120

11.1.1.6 Service-Relevant Displays................................................................................................................................ 120

11.1.2 Sunny Central String-Monitor Controller ........................................................................................................121

11.1.2.1 Instantaneous Values....................................................................................................................................... 121

11.1.2.2 Internal Device Values..................................................................................................................................... 121

11.1.2.3 Status Values.................................................................................................................................................... 121

11.1.3 Sunny String-Monitor .......................................................................................................................................121

11.1.3.1 Instantaneous Values....................................................................................................................................... 121

11.1.3.2 Internal Device Values..................................................................................................................................... 121

11.1.3.3 Status Values.................................................................................................................................................... 122

11.1.4 Zone Monitoring ..............................................................................................................................................122

11.1.4.1 Instantaneous Values....................................................................................................................................... 122

11.1.4.2 Status Values.................................................................................................................................................... 122

11.2 Parameters .......................................................................................................................................................123

11.2.1 Inverter..............................................................................................................................................................123

11.2.1.1 Power Limitation............................................................................................................................................... 123

11.2.1.2 Grid Monitoring and Grid Limits..................................................................................................................... 134

11.2.1.3 Grid Support .................................................................................................................................................... 137

11.2.1.4 Insulation monitoring ....................................................................................................................................... 138

11.2.1.5 Project-Specific Parameters ............................................................................................................................. 139

11.2.2 Sunny Central String-Monitor Controller ........................................................................................................141

11.2.3 Sunny String-Monitor .......................................................................................................................................143

11.2.4 Zone Monitoring ..............................................................................................................................................144

12 Appendix.......................................................................................................................................146

12.1 Information for Installation ...............................................................................................................................146

12.1.1 Minimum Clearances.......................................................................................................................................146

12.1.1.1 Minimum Clearances for Outdoor Installation .............................................................................................. 146

12.1.1.2 Minimum Clearances in Electrical Equipment Rooms.................................................................................... 148

12.2 Type Label.........................................................................................................................................................150

12.3 XML File custom.xml .........................................................................................................................................150

12.3.1 Structure of the XML File custom.xml...............................................................................................................150

12.3.2 Parameters and Values for the File custom.xml..............................................................................................151

13 Contact...........................................................................................................................................154

14 Revision History ............................................................................................................................156

User ManualSCCPXT-BA-E4-en-548

Page 9

SMA Solar Technology AG

1 Information on this Document

1.1 Validity

This document is valid for the following device types:

1 Information on this Document

Device type Production version OCU firmware

version

SC500CP‑10 (SunnyCentral500CPXT) E4 01.70.20.R 01.70.62.R

SC630CP‑10 (SunnyCentral630CPXT)

SC720CP‑10 (SunnyCentral720CPXT)

SC760CP‑10 (SunnyCentral760CPXT)

SC800CP‑10 (SunnyCentral800CPXT)

SC850CP‑10 (SunnyCentral850CPXT)

SC900CP‑10 (SunnyCentral900CPXT)

The production version is indicated on the type label.

The firmware version can be read off from the user interface.

Illustrations in this document are reduced to the essential and may deviate from the real product.

DSP firmware

version

1.2 Target Group

The tasks described in this document must only be performed by qualified persons. Qualified persons must have the

following skills:

• Knowledge of how the product works and is operated

• Training in how to deal with the dangers and risks associated with installing and using electrical devices and

systems

• Training in the installation and commissioning of electrical devices and systems

• Knowledge of all applicable standards and directives

• Knowledge of and adherence to this manual and all safety precautions

1.3 Additional Information

Links to additional information can be found at www.SMA-Solar.com.

1.4 Symbols

Symbol Explanation

Indicates a hazardous situation which, if not avoided, will result in death or serious injury

Indicates a hazardous situation which, if not avoided, can result in death or serious injury

Indicates a hazardous situation which, if not avoided, can result in minor or moderate injury

Indicates a situation which, if not avoided, can result in property damage

Information that is important for a specific topic or goal, but is not safety-relevant

User Manual 9SCCPXT-BA-E4-en-54

Page 10

1 Information on this Document

Symbol Explanation

Indicates a requirement for meeting a specific goal

Desired result

A problem that might occur

1.5 Typographies

Typographies Use Example

SMA Solar Technology AG

bold

>

[Button/Key]

• Display messages

• Elements on a user interface

• Terminals

• Slots

• Elements to be selected

• Elements to be entered

• Connects several elements to be

selected

• Button or key to be selected or

pressed

• Set parameter WGra to 0.2.

• Select PV system > Detect.

• Select [Start detection].

1.6 Nomenclature

Complete designation Designation in this document

SunnyCentral Inverter

SunnyCentralCommunicationController SC-COM or communication unit

User ManualSCCPXT-BA-E4-en-5410

Page 11

SMA Solar Technology AG

2 Safety

2 Safety

2.1 Intended Use

The SunnyCentral is a PV inverter which converts the direct current generated in the PV modules into grid-compliant

alternating current. An external MV transformer fitted downstream feeds the generated alternating current into the

utility grid.

The product is suitable for indoor and outdoor use.

The enclosure complies with degree of protection IP54. The inverter is classified under Class4C2 as per

EN60721-3-4 and is suitable for operation in a chemically active environment.

The maximum permissible DC input voltage of the inverter must not be exceeded.

The inverter must only be operated in conjunction with a suitable MV transformer.

• The MV transformer must be designed for voltages that arise during pulsed mode of the inverter.

• For the SunnyCentral 500CPXT/ 630CPXT/ 720CPXT/ 760CPXT/ 800CPXT the maximum voltage to

ground is: ±1,450V

• For the SunnyCentral 850CPXT/900CPXT the maximum voltage to ground is: ±1,600V

• Do not connect more than one inverter to one winding of the MVtransformer.

• The neutral conductor on the low-voltage side of the MV transformer must not be grounded.

You can find further information on suitable transformers in the Technical Information "Requirements for MediumVoltage Transformers and Transformers for Internal Power Supply for the SunnyCentral series CPXT and CP-JP and for

SunnyCentralStorage".

Do not deactivate or modify settings that affect grid management services without first obtaining approval from the grid

operator.

Use this product only in accordance with the information provided in the enclosed documentation and with the locally

applicable standards and directives. Any other application may cause personal injury or property damage.

Alterations to the product, e.g. changes or modifications, are only permitted with the express written permission of

SMA Solar Technology AG. Unauthorized alterations will void guarantee and warranty claims and usually void the

operation permit. SMA Solar Technology AG shall not be held liable for any damage caused by such changes.

Any use of the product other than that described in the Intended Use section does not qualify as appropriate.

The enclosed documentation is an integral part of this product. Keep the documentation in a convenient place for

future reference and observe all instructions contained therein.

All work on the product must only be performed using appropriate tools and in compliance with the ESD protection

regulations.

Suitable personal protective equipment is to be worn by all persons working on or with the product.

Unauthorized persons must not operate the product and must be kept at a safe distance from the product.

The product must not be operated with open covers or doors.

The product must not be opened when it is raining or when humidity exceeds 95%.

The product must not be operated with any technical defects.

The type label must remain permanently attached to the product.

User Manual 11SCCPXT-BA-E4-en-54

Page 12

2 Safety

SMA Solar Technology AG

2.2 Safety Information

This section contains safety information that must be observed at all times when working on or with the product. To

prevent personal injury and property damage and to ensure long-term operation of the product, read this section

carefully and observe all safety information at all times.

Danger to life from electric shock due to live voltage

High voltages are present in the live components of the product. Touching live components results in death or serious

injury due to electric shock.

• Wear suitable personal protective equipment for all work on the product.

• Do not touch any live components.

• Observe all warning messages on the product and in the documentation.

• Observe all safety information of the module manufacturer.

• After switching off the inverter, wait at least 15minutes before opening it to allow the capacitors to discharge

completely (see Section5.2, page51).

Danger to life from electric shock due to live DC cables

DC cables connected to PV modules that are exposed to sunlight carry live voltage. Touching live cables results in

death or serious injury due to electric shock.

• Prior to connecting the DC cables, ensure that the DC cables are voltage-free.

• Wear suitable personal protective equipment for all work on the device.

Danger to life from electric shock due to ground fault

If a ground fault has occurred, parts of the PV power plant that are supposedly grounded may in fact be live.

Touching incorrectly grounded parts of the PV power plant results in death or serious injuries from electric shock.

• Before working on the PV power plant, ensure that no ground fault is present.

• Wear suitable personal protective equipment for all work on the device.

Danger to life from electric shock due to damaged product

Operating a damaged product can lead to hazardous situations that result in death or serious injuries due to electric

shock.

• Only operate the product when it is in a flawless technical condition and safe to operate.

• Check the product regularly for visible damage.

• Make sure that all external safety equipment is freely accessible at all times.

• Make sure that all safety equipment is in good working order.

• Wear suitable personal protective equipment for all work on the product.

User ManualSCCPXT-BA-E4-en-5412

Page 13

SMA Solar Technology AG

Danger to life from electric shock even if the inverter is disconnected on the AC and DC sides

The precharge unit of the order option "QatNight" will carry live voltage even if the AC disconnection unit and the

DC switchgear are open. Touching live components results in death or serious injury due to electric shock.

• Do not touch any live components.

• Switch off the inverter.

• After switching off the inverter, wait at least 15minutes before opening it to allow the capacitors to discharge

completely.

• Ensure that no voltage is present.

• Do not remove protective covers.

• Observe the warning messages.

• Wear suitable personal protective equipment for all work on the product.

Danger to life from electric shock when entering the PV field

2 Safety

Ground-fault monitoring does not provide protection from personal injury. PV modules which are grounded with

ground-fault monitoring discharge voltage to ground. Entering the PV field can result in lethal electric shocks.

• Ensure that the insulation resistance of the PV field exceeds the minimum value. The minimum value of the

insulation resistance is: 1 kΩ.

• Before entering the PV field, switch the PV modules to insulated operation.

• Configure the PV power plant as a closed electrical operating area.

Danger to life from electric shock if the product is not locked

If the product is not locked, unauthorized persons will have access to live components carrying lethal voltages.

Touching live components can result in death or serious injury due to electric shock.

• Always close and lock the product.

• Remove the keys.

• Store the keys in a safe place.

• Ensure that no unauthorized persons have access to the closed electrical operating area.

Danger to life due to blocked escape routes

In hazardous situations, blocked escape routes can lead to death or serious injury. Opening the doors of two

products located opposite each other can block the escape route. It is imperative that the escape route is freely

accessible at all times.

• An escape route must be available at all times. Make sure the minimum passage width of the escape route

meets local standards.

• Do not place any objects in the escape route area.

• Remove all tripping hazards from escape routes.

User Manual 13SCCPXT-BA-E4-en-54

Page 14

2 Safety

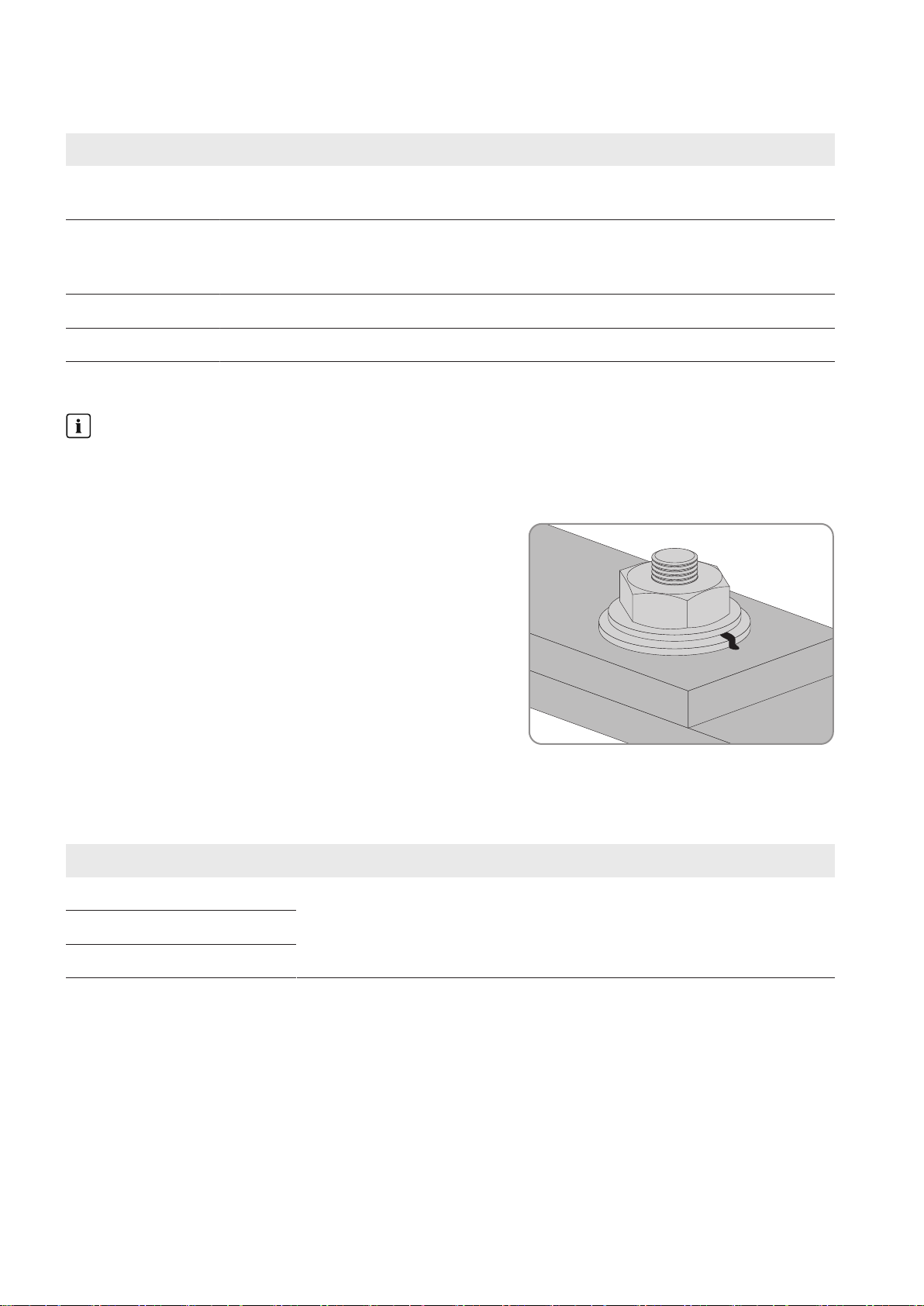

Risk of fire due to failure to observe torque specifications on live bolted connections

Failure to follow the specified torques reduces the ampacity of live bolted connections so that the contact resistances

increase. This can cause components to overheat and catch fire.

• Ensure that live bolted connections are always tightened with the exact torque specified in this document.

• When working on the device, use suitable tools only.

• Avoid repeated tightening of live bolted connections as this may result in inadmissibly high torques.

Risk of burns due to hot components

Some components of the product can get very hot during operation. Touching these components can cause burns.

• Observe the warnings on all components.

• During operation, do not touch any components marked with such warnings.

• Wear suitable personal protective equipment for all work on the product.

SMA Solar Technology AG

Property damage due to dust intrusion and moisture penetration

Dust or moisture intrusion can damage the product and impair its functionality.

• Do not open the enclosure during rainfall or when humidity exceeds the specified thresholds. The humidity

thresholds are: 15%…95%.

• Only perform maintenance work when the environment is dry and free of dust.

• Operation of the product is only permitted when it is closed.

• Connect the external supply voltage after mounting and installing the product.

• If the installation or commissioning process is interrupted, mount all panels.

• Close and lock the enclosure.

• The product must always be closed for storage.

• Store the product in a dry and covered location.

• Temperature at the storage location must be in the specified range. The temperature range is: −25°Cto+70°C

.

Damage to electronic components due to electrostatic discharge

Electrostatic discharge can damage or destroy electronic components.

• Observe the ESD safety regulations when working on the product.

• Wear suitable personal protective equipment for all work on the product.

• Discharge electrostatic charge by touching grounded enclosure parts or other grounded elements. Only then is

it safe to touch electronic components.

2.3 Personal Protective Equipment

Always wear suitable protective equipment

When working on the product, always wear the appropriate personal protective equipment for the specific job.

The following personal protective equipment is regarded to be the minimum requirement:

User ManualSCCPXT-BA-E4-en-5414

Page 15

SMA Solar Technology AG

☐ In a dry environment, safety shoes of categoryS3 with perforation-proof soles and steel toe caps

☐ During precipitation or on moist ground, safety boots of categoryS5 with perforation-proof soles and steel toe

caps

☐ Tight-fitting work clothes made of 100%cotton

☐ Suitable work pants

☐ Individually fitted hearing protection

☐ Safety gloves

Any other prescribed protective equipment must also be used.

2 Safety

User Manual 15SCCPXT-BA-E4-en-54

Page 16

3 Product Overview

3 Product Overview

3.1 Design of the inverter

SMA Solar Technology AG

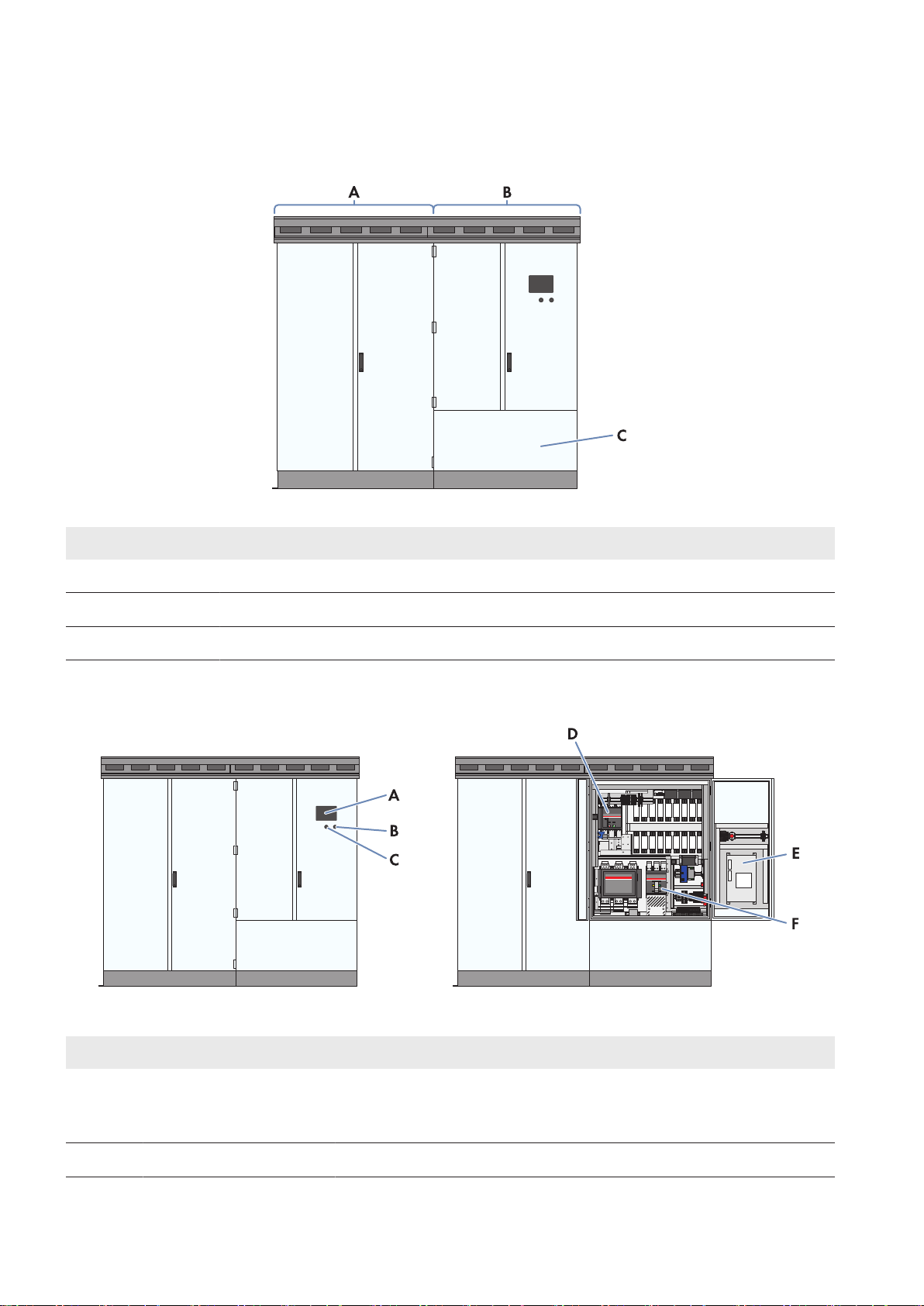

Figure 1: Design of the Inverter

Position Designation

A Inverter cabinet

B Interface cabinet

C Connection area

3.2 Devices of the Inverter

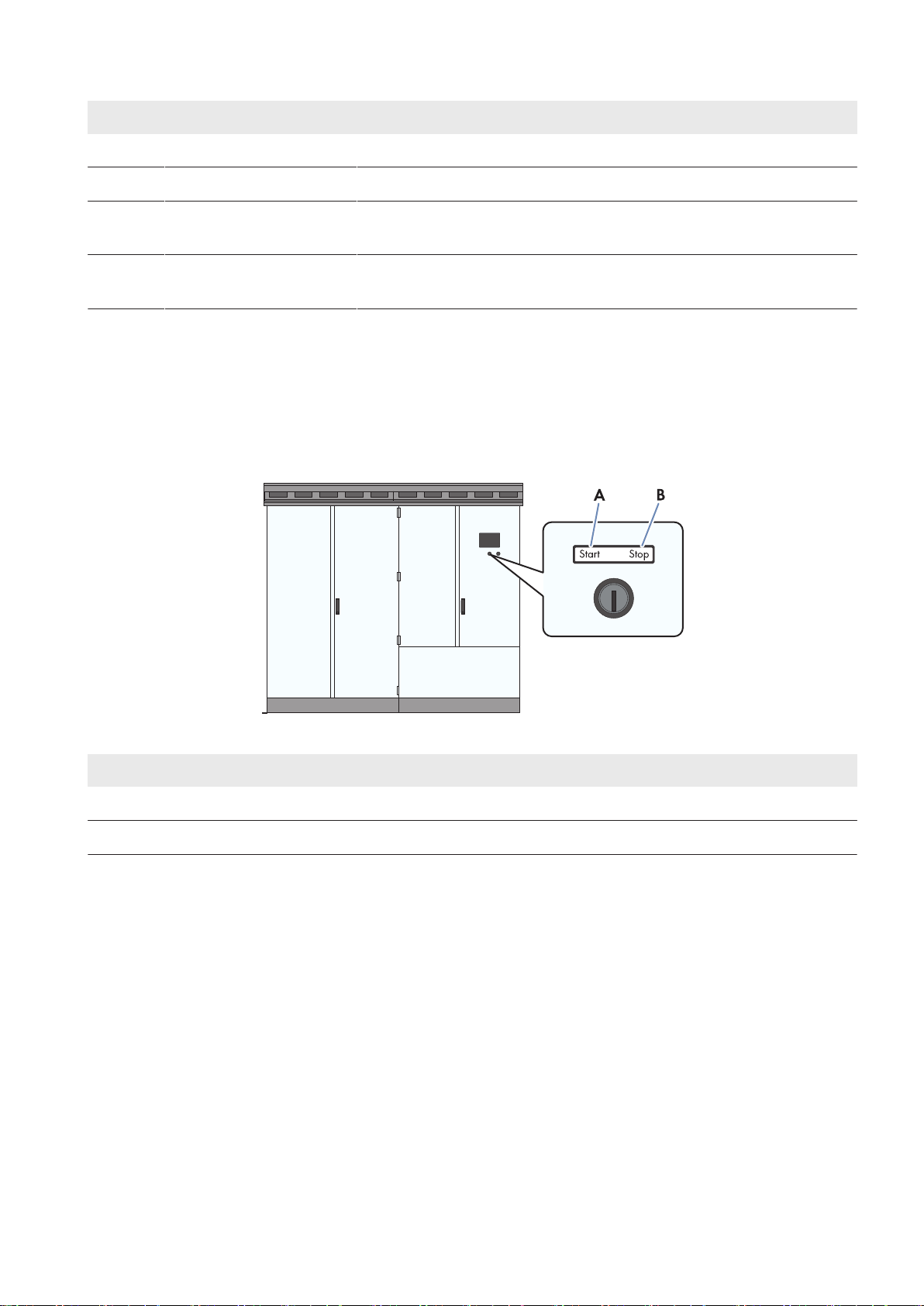

Figure 2: Devices of the inverter

Position Device Description

A Touch display Different kinds of inverter data can be viewed on the touch display. The

touch display is only used to view data. The display screen is activated by

touching the touch display.

B Service interface The service interface allows access to the user interface.

User ManualSCCPXT-BA-E4-en-5416

Page 17

SMA Solar Technology AG

Position Device Description

C Key switch The key switch is used to switch the inverter on and off.

D DC switchgear The DC switchgear disconnects the inverter from the PV array.

E SC-COM The SC-COM is the communication unit of the inverter. The SC-COM estab-

lishes the connection between the inverter and the system operator.

F AC disconnection unit The AC disconnection unit disconnects the inverter from the MVtrans-

former.

3 Product Overview

3.3 Operating and Display Elements

3.3.1 Function of the Switches

3.3.1.1 Key Switch

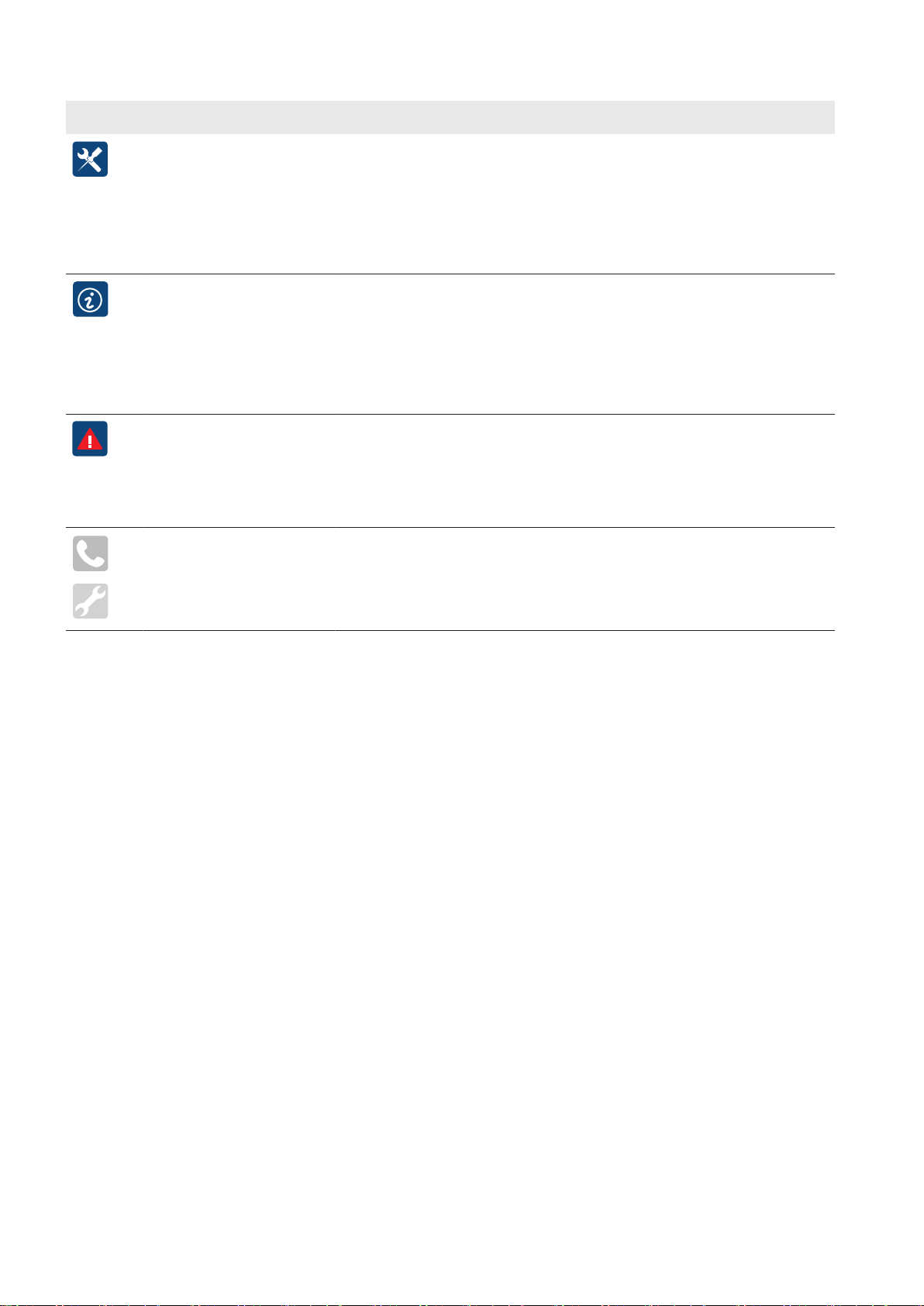

The key switch is used to switch the inverter on and off.

Figure 3: Switch positions of the key switch

Position Designation

A

B

Switch position Start

Switch position Stop

Switch position "Start"

If the key switch is turned to Start, a motor drive switches the DC switchgear on and the inverter switches from the

operating state "Stop" to the operating state "Grid monitoring". Provided that there is sufficient irradiation and a valid

utility grid connection, the inverter switches to feed-in operation. If there is insufficient irradiation and the input voltage

is therefore too low, the inverter remains in the operating state "Grid monitoring".

Switch position "Stop"

If the key switch is turned to Stop while the inverter is in the operating state "Grid monitoring", a motor drive switches

the DC switchgear off. The inverter switches to the operating state "Stop". If the key switch is turned to Stop while the

inverter is in the operating state "MPP load operation", the inverter switches to the operating state "Shutdown". Once

shutdown is complete, the AC disconnection unit and the DC switchgear are opened automatically and the inverter

switches to the operating state "Stop".

User Manual 17SCCPXT-BA-E4-en-54

Page 18

3 Product Overview

3.3.1.2 AC Disconnection Unit

The AC disconnection unit disconnects the inverter from the MV transformer.

Figure 4: Switch positions of the AC disconnection unit from ABB

SMA Solar Technology AG

Position Designation Explanation

A

B Central switch position The AC disconnection unit was tripped and is open.

C

Switch position on

Switch position off

The AC disconnection unit is closed.

The AC disconnection unit is open.

3.3.1.3 DC Switchgear

The DC switchgear disconnects the inverter from the PV power plant.

Figure 5: Indicators on the DC load-break switch

Position Designation

A Spring status indicator

B Position indicator

User ManualSCCPXT-BA-E4-en-5418

Page 19

SMA Solar Technology AG

Position Designation

C ON button

D OFF button

3 Product Overview

3.3.2 Touch Display

3.3.2.1 Design

The touch display is used to display instantaneous values and parameter settings. Tapping the symbols on the touch

display activates the corresponding functions. If the touch display has not been touched for five minutes, it will switch

off and the logged in user will be logged out. The touch display is divided into three areas.

Figure 6: Design of the touch display

Position Designation Explanation

A Status info line Number of the active menu, login status and time

B Information field Area of the main menu

C Navigation line Navigation area

3.3.2.2 Explanation of Symbols

Information field

You can access the following sub-menus and screens from the information field:

Symbol Designation Explanation

E-today line graph Diagram 103: Representation of energy fed in during the current day in

kWh.

Bar chart Diagram 104: Representation of energy fed in during the last 14days in

kWh.

User Manual 19SCCPXT-BA-E4-en-54

Page 20

3 Product Overview

Symbol Designation Explanation

DC side Representation of the instantaneous value

• PV power in W

• Insulation resistance in Ω

• PV current in A

• PV voltage in V

• Diagram of string-current monitoring

– Diagram 132 and 133: Group currents of the individual Sunny

String‑Monitors

– Diagram 140 to 146: String currents of the individual Sunny

String‑Monitors

SMA Solar Technology AG

String-current monitoring of

the DC side

Switch on DC or AC side

closed

Switch on DC or AC side

open

Status of switches on DC or

AC side unknown

Inverter data Representation of the following inverter data:

Representation of the instantaneous values of the string-current monitoring

of the individual Sunny String-Monitors

If you see this symbol between the "DC side" symbol and the "Inverter

data" symbol, the DC switchgear is closed.

If you see this symbol between the symbol "Inverter data" and the symbol

"AC side", the AC disconnection unit is closed.

If you see this symbol between the "DC side" symbol and the "Inverter

data" symbol, the DC switchgear is open.

If you see this symbol between the symbol "Inverter data" and the symbol

"AC side", the AC disconnection unit is open.

If you see this symbol between the "DC side" symbol and the "Inverter

data" symbol, the switch status of the DC switchgear is not known.

If you see this symbol between the symbol "Inverter data" and the symbol

"AC side", the switch status of the AC disconnection unit is unknown.

• Device type

• Operating state

• Symbol for utility grid menu

• Symbol for temperature display

• Symbol for fan display

User ManualSCCPXT-BA-E4-en-5420

Page 21

SMA Solar Technology AG

Symbol Designation Explanation

AC side Representation of the following instantaneous values:

• Active power in W

• Reactive power in VAr

• Power frequency in Hz

• AC current in A

• AC voltage in V

Utility grid First menu page:

• Active mode of active power limitation

• Target active power in kW

• Actual active power in kW

Second menu page

• Active mode of reactive power setpoint

• Target reactive power in VAr

3 Product Overview

• Target displacement power factor cos φ

• Target excitation type of the displacement power factor

• Actual reactive power in VAr

• Actual displacement power factor cos φ

• Actual excitation type of the displacement power factor

Settings menu

Symbol Designation Explanation

Language selection Select this symbol to open the language selection menu.

Brightness setting Select this symbol to open the brightness setting menu.

Time setting Select this symbol to open the time setting menu.

Format selection Select this symbol to open the format selection menu.

Password entry Select this symbol to open the password entry menu.

Navigation line

Symbol Designation Explanation

Back Select this symbol to go back to the previous page.

Homepage Select this symbol to go to the homepage.

User Manual 21SCCPXT-BA-E4-en-54

Page 22

3 Product Overview

Symbol Designation Explanation

Settings • Language selection

• Brightness setting

• Time setting

• Format selection

• Password entry

Information • OS: version of the operating system

• App.: version of the application software

• SC-COM version: SC-COM software version

• Ser.No.: inverter serial number

• Hardware: hardware version and serial number of the SC-COM

Error • ErrNo: error number

• TmsRmg: time until reconnection

• Msg: error message

SMA Solar Technology AG

• Dsc: corrective measure

Service • Telephone receiver: Contact Service.

• Tool: Contact your installer.

User ManualSCCPXT-BA-E4-en-5422

Page 23

SMA Solar Technology AG

3.3.3 LEDs of the SC-COM

3.3.3.1 LEDs on the Enclosure

3 Product Overview

Figure 7: LEDs on the enclosure

LED designation Status Explanation

POWER glowing green The SC-COM is supplied with voltage.

off The SC-COM is not supplied with voltage.

SD1 flashing green Read or write access to system drive

SD2 flashing green Read or write access to internal data drive

CF flashing green Read or write access to external SD memory card

H1 flashing green The SC-COM is transmitting data to Sunny Portal/FTP server.

glowing green The most recent data transmission to Sunny Portal/FTP server was

successful.

glowing red The most recent data transmission to Sunny Portal/FTP server has

failed.

off Data transmission to Sunny Portal/FTP server is deactivated.

User Manual 23SCCPXT-BA-E4-en-54

Page 24

3 Product Overview

LED designation Status Explanation

H2 flashing green The SC-COM is communicating with the devices connected within the

system.

glowing green Internal communication has taken place in the last five minutes.

glowing red An error has occurred in the internal communication.

off No internal communication for more than five minutes.

H3 flashing red The SC-COM is starting up.

glowing red An error has occurred in the SC-COM.

glowing green The SC-COM is ready for use.

H4 glowing green An internal memory card exists and less than 92% of its storage ca-

pacity is used.

glowing red The internal memory card is full and the oldest saved data is being

overwritten.

SMA Solar Technology AG

flashing red 92% of the storage capacity of the internal memory card is used.

H5 glowing green An external memory card exists and less than 92% of its storage ca-

pacity is used.

glowing red The external memory card is full.

flashing red 92% of the storage capacity of the external memory card is used.

off There is no external memory card.

H6 - Not assigned

H7 - Not assigned

H8 flashing green Application is running.

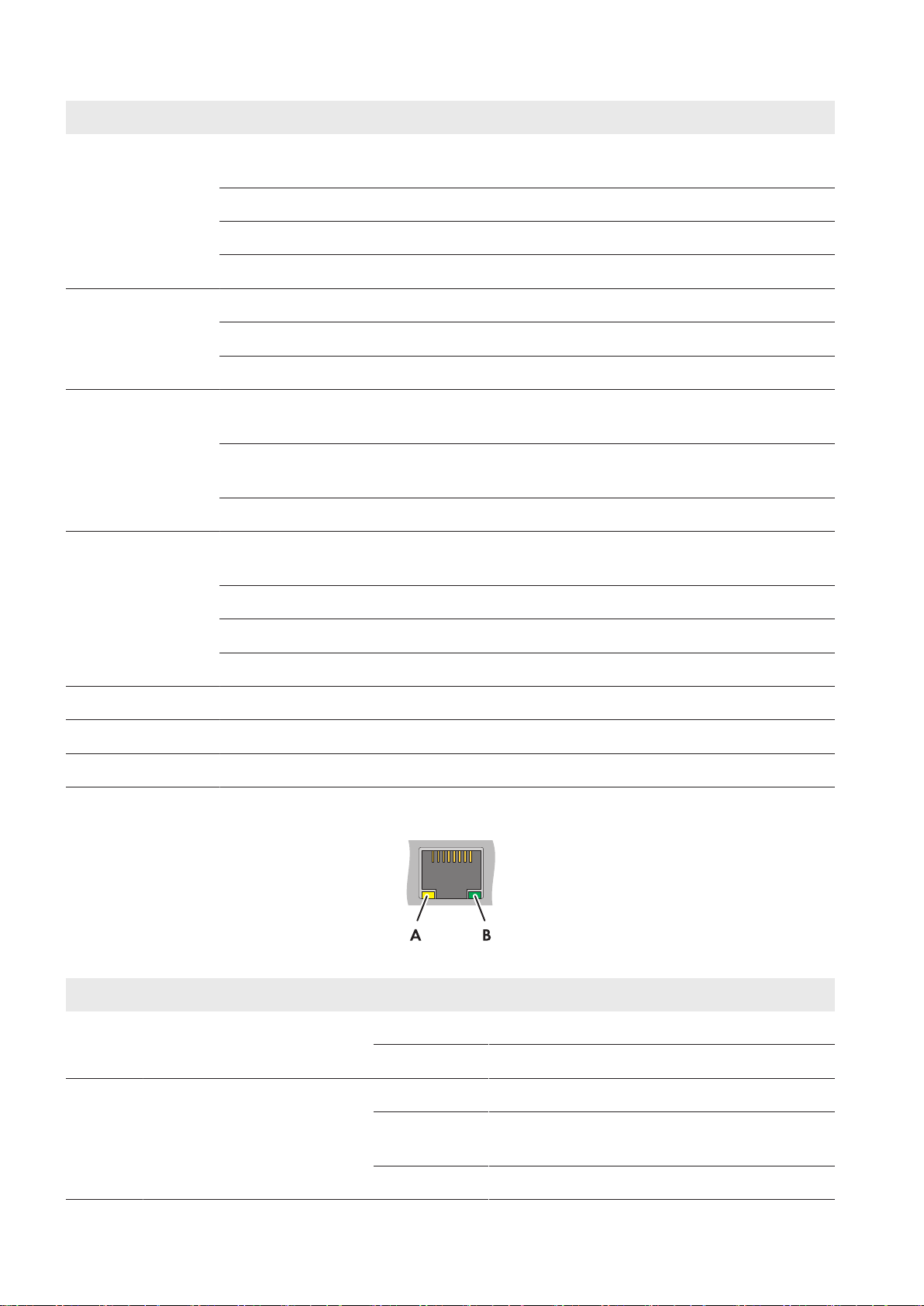

3.3.3.2 LEDs on the Network Port

Figure 8: LEDs on the network port

Position LED Color Status Explanation

A Speed yellow on 100 MBit data transfer rate

off 10 MBit data transfer rate

B Link/Activity green on Connection (Link) established.

flashing The SC-COM is transmitting or receiving data (Ac-

tivity).

off No connection established.

User ManualSCCPXT-BA-E4-en-5424

Page 25

SMA Solar Technology AG

3 Product Overview

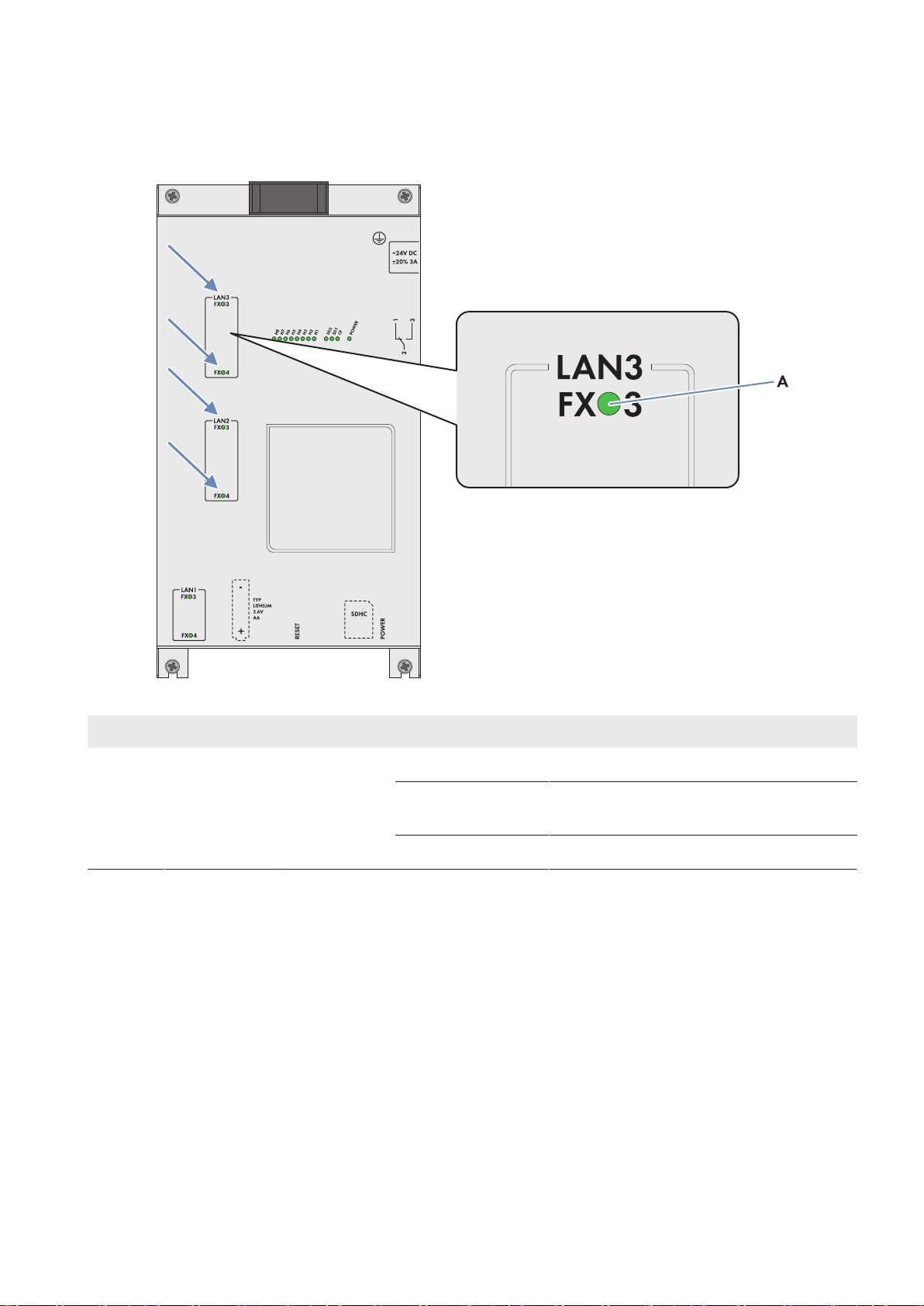

3.3.3.3 LEDs on the Optical Fiber Terminals

The SC-COM is also available with pre-wired optical fiber connections. If the optical fibers are connected to the splice

box of the inverter, the status of the connection will be indicated by the LEDs of the SC-COM.

Figure 9: LEDs for the status of the optical fiber connection

Position LED Color Status Explanation

A Link / Activity green on Connection (Link) established.

flashing The SC-COM is transmitting or receiving data

(Activity).

off No connection established.

User Manual 25SCCPXT-BA-E4-en-54

Page 26

A

B

C

D

E

3 Product Overview

SMA Solar Technology AG

3.3.4 User Interface

3.3.4.1 Design of the User Interface

Via the user interface, you can set the communication of the devices of your PV power plant, configure the inverter

parameters and read off error messages and operating data.

Figure 10: Design of the user interface (example)

Position Designation

A Tree view or device view

B Status bar

C Logout button

D Navigation bar

E Content area

3.3.4.2 Tree View and Device View

You can call up data of the individual devices of your PV power plant in the tree view or the device view. Depending

on which view you have selected, the devices are sorted differently.

Symbol Designation Explanation

Tree view In the tree view, the user interface shows the devices in the or-

der in which they are connected to the data bus.

Device view In the device view, the user interface shows all devices sorted

by device type. The number shown in parentheses indicates the

number of devices of a device type.

User ManualSCCPXT-BA-E4-en-5426

Page 27

SMA Solar Technology AG

3 Product Overview

3.3.4.3 Status Symbols

Depending on the status of the device communication, the device symbols are displayed in the tree or device view with

various status symbols.

Symbol Explanation

The inverter is ready for operation.

There is an error in the inverter.

An error has occurred in the communication with the inverter.

3.4 Symbols on the Product

The following gives an explanation of all the symbols found on the inverter and on the type label.

Symbol Designation Explanation

CE marking The product complies with the requirements of the applicable EU di-

rectives.

Protection classI All electrical equipment is connected to the grounding conductor sys-

tem of the product.

Degree of protectionIP54 The product is protected against interior dust deposits and splashing

water from all angles.

Beware of a danger zone This warning symbol indicates a danger zone. Be particularly vigilant

and cautious when working on the product.

Beware of dangerous voltage

Beware of hot surface The product can get hot during operation. Avoid contact during oper-

Use hearing protection. The product generates loud noises. When working on the product,

Observe the documentation.

The product operates at high voltages. All work on the product must

be carried out by qualified persons only.