Page 1

EN

Central Inverter

SUNNY CENTRAL 400HE / 500HE / 630HE

Installation Guide

SCxxxHE-IEN104432 | 98-4007732 | Version 3.2

Page 2

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Notes on this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Appropriate Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.1 Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.3 Special Hazards of Photovoltaic Plants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.4 Electrical Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.5 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.6 Disconnecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.7 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1 Standard Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Scope of Delivery (depending on the model). . . . . . . . . . . . . . 18

3.3 Identifying your Sunny Central . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4 Check for Transport Damage . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.1 Installation Site Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2 Electrical Operating Room . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.1 MV Stations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.1 Exhaust Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installation Guide SCxxxHE-IEN104432 3

Page 4

Table of Contents SMA Solar Technology AG

4.4 Transport Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.4.1 Transport Using a Pallet Truck or Forklift . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4.2 Transport Using a Crane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.5 On-Site Inverter Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.5.1 Mechanical Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.5.2 Mechanical Coupling for the "Chemically Active" Option . . . . . . . . . . . . . . 35

4.5.3 Anchorage to the Ground or Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5 Internal Electrical Connections . . . . . . . . . . . . . . . . . . . . . 37

5.1 Connecting the Power Cable Connection. . . . . . . . . . . . . . . . . 37

5.1.1 Connecting the Power Cable for the "Chemically Active" Option. . . . . . . . . 41

5.2 Connecting the Internal PE Connection. . . . . . . . . . . . . . . . . . . 42

5.3 Connecting the Control Cables on the Transfer Terminal Strip . 44

5.3.1 Connecting the Control Cables to the Transfer Terminal Strip in the

AC Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.4 Connecting the Sunny Central Control to the Power Unit. . . . . 46

5.5 Connecting the Internal Control Cables of the Power Unit . . . . 47

5.6 Connecting the Communication Unit for Insulation

Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6 External Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.1 Connecting High-Current Contacts . . . . . . . . . . . . . . . . . . . . . . 50

6.2 Connecting the AC Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2.1 Mounting and Dismounting the Plexiglas Cover and Sliding Plate . . . . . . . . 55

6.2.2 Procedure for Models 13/0 and 13/4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.2.3 Procedure for Model 13/1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.2.4 Procedure for Model 13/2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2.5 Procedure for Model 13/3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2.6 Procedure for Model 13/5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.2.7 Connecting the AC Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.3 AC Grid Connection for MV Stations . . . . . . . . . . . . . . . . . . . . 69

6.4 Connecting the PE Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4 SCxxxHE-IEN104432 Installation Guide

Page 5

SMA Solar Technology AG Table of Contents

6.5 Connecting the Internal Power Supply . . . . . . . . . . . . . . . . . . . 72

6.5.1 Connecting the External Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.5.2 Connecting the Internal Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.6 Connecting the DC Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.6.1 Connecting the DC Cable to the Busbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.6.2 Connecting the DC Cable to the Low-Voltage HRC Fuses . . . . . . . . . . . . . . 78

6.6.3 Additional Connections of DC Main Distributors . . . . . . . . . . . . . . . . . . . . . 81

6.7 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.7.1 Analog Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.7.2 External Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.7.3 Overview of the Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.7.4 Handling the Shield Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.8 Remote Deactivation Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.9 Serial Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.10 Emergency Stop Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.11 Overvoltage Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.1 Removing the Transport Locks. . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.2 Checking the Sunny Central Cabling . . . . . . . . . . . . . . . . . . . . 91

7.2.1 Checking Internal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.2.2 Checking the AC Grid Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.2.3 Checking the Internal AC Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.2.4 Checking the DC Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.2.5 Checking the Connection of the Serial Interfaces . . . . . . . . . . . . . . . . . . . . . 92

7.2.6 Checking the Emergency Stop Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.2.7 Checking the Thermostat and Hygrostat Settings . . . . . . . . . . . . . . . . . . . . . 93

7.3 Checking the Voltages on the Sunny Central . . . . . . . . . . . . . . 93

7.4 Preparation for Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . 95

7.5 Switching On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Installation Guide SCxxxHE-IEN104432 5

Page 6

Table of Contents SMA Solar Technology AG

8 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8.1 Sunny Central 400HE-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8.2 Sunny Central 500HE-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.3 Sunny Central 630HE-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6 SCxxxHE-IEN104432 Installation Guide

Page 7

SMA Solar Technology AG Notes on this Manual

1 Notes on this Manual

1.1 Validity

This manual describes the transport, installation, and commissioning of SMA central inverters of the

following types:

• Sunny Central 400HE (SC 400HE-11)

• Sunny Central 500HE (SC 500HE-11)

• Sunny Central 630HE (SC 630HE-11)

1.2 Target Group

This manual is intended for installers and operators of PV plants equipped with Sunny Centrals.

1.3 Additional Information

All manuals for the Sunny Central as well as for the installed components must be stored together with

the plant documentation and must be accessible at all times. The documents listed below are included

in the scope of delivery for your Sunny Central. The following information is contained in these

documents.

• Installation guide: Setup and installation of the Sunny Central

• User manual: How to operate the Sunny Central and Sunny Central Control

• Circuit diagrams: Variant circuit diagram of the Sunny Central

• Maintenance manual Regular maintenance work on the Sunny Central

• Maintenance protocol List of the regular maintenance work and its intervals as well as the

preventive replacement intervals of individual components.

• Commissioning report Check list for commissioning. After successful commissioning, the

commissioning report has to be sent to SMA Solar Technology AG.

• Accessory documentation: The documentation for optional accessories or optional equipment

for the Sunny Central can be found at www.SMA.de/en.

Installation Guide SCxxxHE-IEN104432 7

Page 8

Notes on this Manual SMA Solar Technology AG

1.4 Symbols Used

The following types of safety instructions and general information appear in this document as

described below:

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING!

WARNING indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION!

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE!

NOTICE indicates a situation that can result in property damage if not avoided.

Information

Information provides tips that are valuable for the optimal installation and operation of

your product.

8 SCxxxHE-IEN104432 Installation Guide

Page 9

SMA Solar Technology AG Safety

2 Safety

2.1 Appropriate Usage

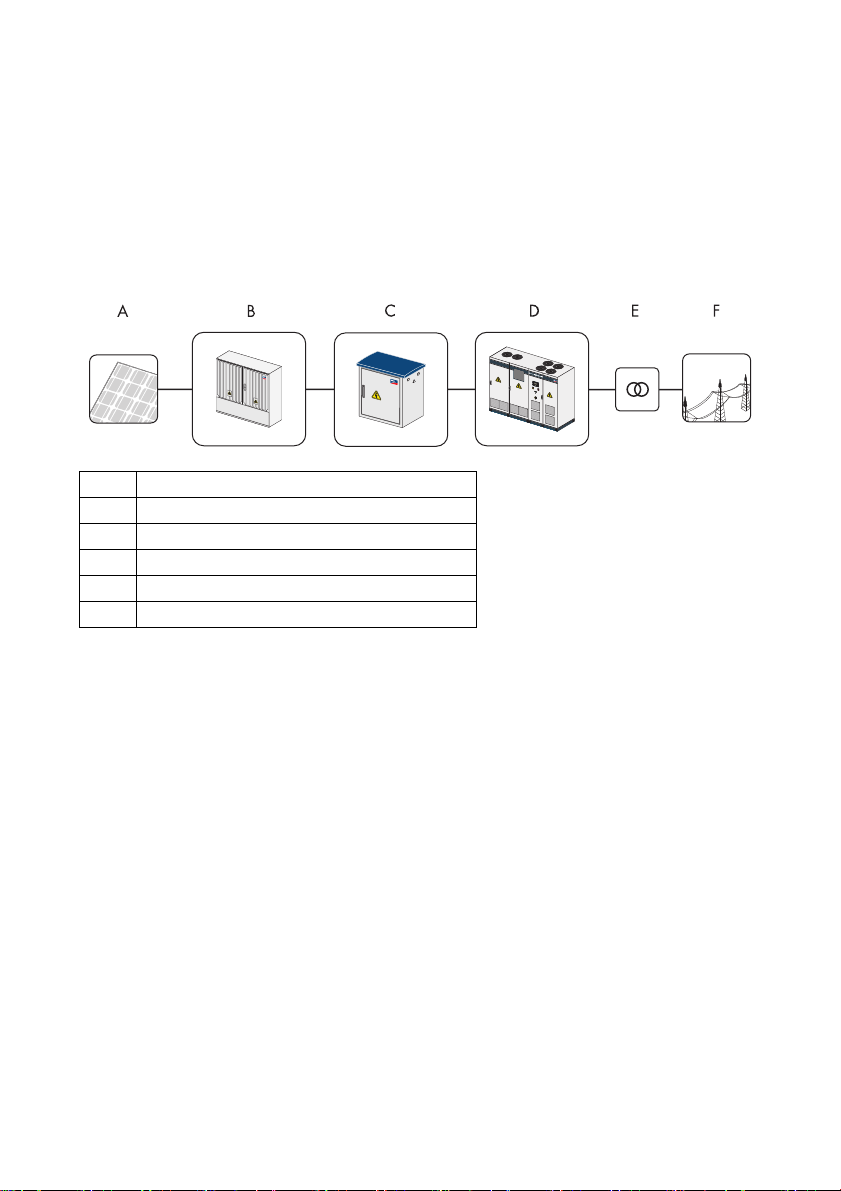

The Sunny Central is a PV inverter. It allows photovoltaic solar energy from solar modules to be

converted and fed into a medium-voltage grid.

Principle of a grid-tie PV plant with a Sunny Central

APV modules

B Sunny String-Monitor

C Sunny Main Box

D Sunny Central

E Medium-voltage transformer

F Electrical grid

Sunny Central HE

The Sunny Central HE is a high efficiency solar inverter. It does not have its own low-voltage

transformer. The Sunny Central HE requires an adapted external medium-voltage transformer via

which it can feed into the grid.

The following standards apply for all devices of this series:

EMC EN 61000-6-2, EN 61000-6-4

Grid monitoring As per BDEW regulations

CE conformity yes

Installation Guide SCxxxHE-IEN104432 9

Page 10

Safety SMA Solar Technology AG

2.2 Safety Precautions

Failures that affect or limit the safety of the device must be rectified immediately. Unauthorized

mo dif ica tio ns a nd t he u se o f sp are par ts n ot r eco mme nde d by SMA Solar Technology may cause fire,

material damage, and electrical shock. Unauthorized personnel must not have access to the devices.

Warning signs must always be clearly readable and immediately replaced if damaged.

2.2.1 Personnel

Any work on the Sunny Central may be executed by qualified technical personnel only. "Qualified"

means that the personnel must possess training relevant to the activity performed.

The personnel must be familiar with the content of the Sunny Central installation guide and user

manual in order to commission and / or operate the Sunny Central. Please observe all safety

information carefully.

2.2.2 Installation

The installation requirements described in the installation guide must be satisfied. Installation must

occur in an electrical operating room, in order to guarantee optimum noise and fire protection.

Wi th r ega rd t o the EMC lim it va lue s (E MC = ele ctr omag net ic c omp atibility), the Sunny Central device

range is type tested for installation in an industrial environment. Devices suitable for installation in

domestic areas are available on request.

The following points must be observed for the installation:

• The intake and exhaust ventilation systems for the Sunny Central must be separate to any other

ventilation systems so as to prevent smoke distribution in the event of a fire.

• A sufficient escape route must be guaranteed.

• Appropriate sound insulation must be provided.

• The EMC specifications must be observed (see technical data).

WARNING!

Smoke development in electrical operating rooms.

We recommend the installation of a smoke detector inside the operating room which

controls the external emergency stop switch of the device and switches off the Sunny

Central in the event of smoke.

10 SCxxxHE-IEN104432 Installation Guide

Page 11

SMA Solar Technology AG Safety

2.2.3 Special Hazards of Photovoltaic Plants

Photovoltaic plants have special characteristics representing special hazards that are described here:

• An active power source is connected. Depending on the operating mode, there may be voltage

present from the photovoltaic generator and/or the Sunny Central. This is especially important

to note when disconnecting particular parts of the plant.

• V ery hig h DC vol tag es ar e pr ese nt ( no z ero -cro ssi ng) tha t, i n the case of a fault or inappropriate

use of fuses or plugs, may lead to arcing.

• The short circuit current of the photovoltaic generator is only slightly higher than the maximum

operating current and also depends on the irradiation. If a short-circuit occurs in the plant, the

available fuses are not guaranteed to switch off.

• The grid structure of the PV generator is generally a non-grounded grid that could become

unintentionally grounded if a ground fault occurs.

• A highly branched generator array may be difficult to disconnect if a fault develops (e.g. short

circuit). We recommend the extra use of external DC circuit breakers for disconnecting the

inverter and / or the DC main cables / Sunny String-Monitors, DC circuit breakers optionally

available. At every DC input, an easily accessible DC circuit breaker should be installed. For

further information see pre-standard VDE 0100, part 712 and VDI guideline 6012.

2.2.4 Electrical Connection

The electrical connection must be performed according to this installation guide, the variant circuit

diagram and the technical data of the device.

Ensure the grid connection cable for grid feeding-in is fused at the nominal current indicated on the

type plate. If the specified nominal current differs from the nominal current of the fuse plug, the fuse

plug having the next highest nominal current may be used.

Grid connection cable

The grid connection cable for the in ter nal pow er s upp ly m ust be secured with the line circuit

breaker specified in the technical data.

Lightning Protection

The devices have type I internal lightning protection on the AC side and type II internal overvoltage

protection on the DC side and the internal power supply. However, the desired protection level can

only be achieved if a lightning protection area concept exists for the installation building as per

DIN VDE 0185-4, i.e. lightning conductors or combined overvoltage and lightning conductors

(n ot i ncl ude d in deli ver y) a re a vailabl e at loc ati ons includi ng t he b uil ding’s e ntr anc e (t ransfer l igh tning

protection area LPZ 1).

Combined overvoltage and lightning protection for the signal inputs can be optionally ordered.

Installation Guide SCxxxHE-IEN104432 11

Page 12

Safety SMA Solar Technology AG

Emergency Stop

In plants having more than one device, the respective emergency stop switches must be connected

to get her and checked f or c orr ect operati on a s de scr ibe d in thi s in sta lla tio n gu ide. The eme rge ncy sto p

circuit may only be supplied with voltage from a single device.

Emergency stop circuit

• The emergency stop circuit may only be supplied by a Sunny Central.

• Correctly mount the bridges on the device's emergency stop terminal strip.

2.2.5 Power Supplies

WARNING!

Risk of lethal electric shock.

High voltages are present in the device.

• The grounding conductor must be made before the external voltage is switched on.

• At the AC grid connection terminal, the nominal voltage, frequency and the

right‑hand rotary field have to be maintained.

• The correct polarity and ungroundedness must be ensured before inserting the DC

input fuses (internal or external). The fuses may only be inserted and / or removed

under load-free conditions and using the appropriate personal protective equipment

and fuse carriers.

• When the DC fuses (internal or external) have been inserted, reverse voltage exists,

via the Sunny Central busbars, on all externally connected DC main distribution

boxes and DC sub-distribution boxes (Sunny String Box).

• The doors must remain closed when connecting the supplies!

Requirements for the Use of External Power Supplies

• All connections have been made according to the installation guide and the circuit diagram.

• The grounding conductor for grid feed-in and for internal power supply has been made.

• The device is switched off. The key switch is in the “Stop” position and the main switches are off.

• The DC input fuses (internal or external) are connected and the protection against contact

(Plexiglas covers) is mounted.

• The nominal voltages, frequencies and the right-hand rotary field are maintained.

• The polarity of the DC voltage at the inputs / fuse inputs (device dependent) has been checked.

• The polarity of the DC voltages at the inverter input (device dependent) has been checked.

• The photovoltaic generator has been checked with an insulation test to ensure that there is no

ground fault.

12 SCxxxHE-IEN104432 Installation Guide

Page 13

SMA Solar Technology AG Safety

Sequence for Switching On the External Power Supplies

1. Grid voltage for grid feeding

2. Grid voltage for internal power supply

3. DC voltage from the photovoltaic generator

2.2.6 Disconnecting

External isolation of the device must always occur under load-free conditions. The device must be

switched off in order to do this, i.e. the key switch must be in the “Stop” position.

DANGER!

Risk of lethal electric shock.

Work on the Sunny Central may be performed only after switching off the power to the

unit. The VDE regulations must be followed:

•Disconnect

• Ensure that the device cannot be reconnected

• Ensure that no voltage is present

• Ground and short-circuit the unit if necessary (not on the DC side)

• If necessary, cover or shield any adjacent live components

The following power supplies must be isolated:

• Grid voltage for grid feeding

• Grid voltage for internal power supply (optional)

• DC voltage from the photovoltaic generator

• Additional external voltage if necessary (e.g. emergency stop)

Simply switching off the main AC and DC switches is not sufficient to ensure proper isolation of the

device. The main switches only separate the power circuit from the grid and the photovoltaic

generator.

DANGER!

Risk of lethal electric shock.

Dangerous accidental-contact voltages can be present in the Sunny Central even when the

main AC and DC switches are switched off!

• Wait at least 5 minutes after switching off the Sunny Central.

The DC voltage is isolated using the internal or external DC input fuses, or using an external circuit

breaker if present. Isolation by removing the DC input fuses must occur under load-free conditions.

Installation Guide SCxxxHE-IEN104432 13

Page 14

Safety SMA Solar Technology AG

Th e de vic e con tai ns c apa cit ors on th e AC and DC si des tha t mus t di scha rge onc e the dev ice has bee n

switched off. After switching off, dangerous accidental-contact voltages remain within the device for

several minutes. If there is a fault in the device, these voltages may also be present for a longer period

of time. Wait at least 5 minutes after switching off the device before opening the device.

WARNING!

Risk of lethal electric shock!

• To avoid arcing, the load-free status of the device must be checked with a current

probe (using a clamp-on ammeter) before removing the DC input fuses. The fuses

may only be inserted or removed using the appropriate personal protective

equipment and fuse carrier.

• When the DC fuses (internal or external) have been inserted, reverse voltage exists,

via the Sunny Central busbars, on all externally connected DC main distribution

boxes and DC sub-distribution boxes (Sunny String-Monitor).

• In the event of a failure, the DC contactor may carry a life-threatening DC voltage!

• The discharge time of the capacitors is longer than 5 minutes.

To extract the fuses, the Plexiglass cover must be removed. Immediately reinstall the cover after the

cover has been removed from one pole and the fuse has been extracted. The cover must always be

mounted unless a fuse is to be extracted.

Disconnecting plant parts without danger

We recommend the extra use of external DC circuit breakers for disconnecting the

Sunny Central, DC main cables and Sunny String-Monitor; DC circuit breakers are

optionally available. This allows system components to be safely isolated, even in the case

of faults or fire.

14 SCxxxHE-IEN104432 Installation Guide

Page 15

SMA Solar Technology AG Safety

2.2.7 General Information

Ear Protection

The device fans and the power module create significant levels of operating noise. In addition to this,

a fault in the device can lead to very high sound levels.

High noise levels in electrical operating rooms

We recommend the use of ear protection when in the vicinity of the Sunny Central

operating room for extended periods.

Burns

Immediately after isolating the device, depending on the operating conditions, certain components

can be very hot (e.g. fuses, transformer core, sinusoidal filter, heat sinks etc.).

Safety gloves should always be worn when working near components that can be expected to be

very hot.

High temperature on device parts

We recommend that safety gloves be worn during all work on the device.

Installation Guide SCxxxHE-IEN104432 15

Page 16

Delivery SMA Solar Technology AG

3 Delivery

3.1 Standard Scope of Delivery

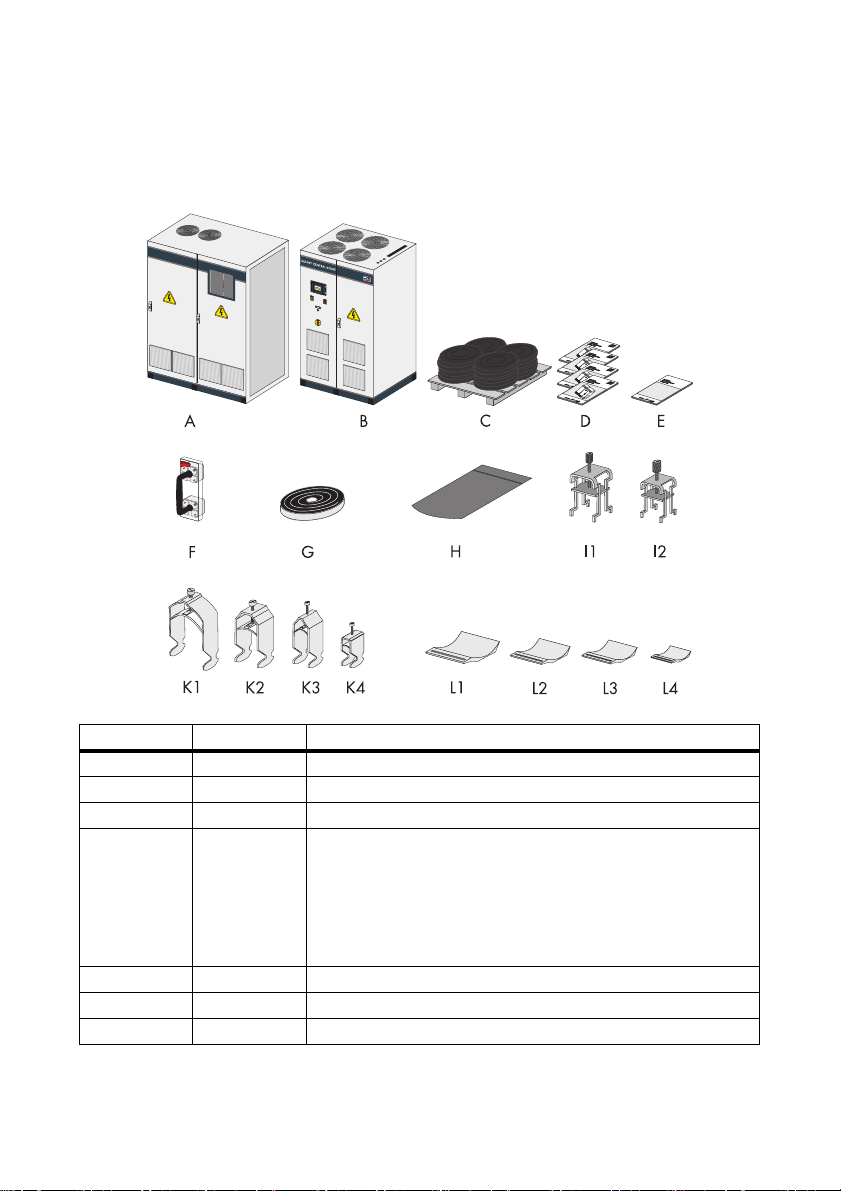

Position Quantity Designation

A 1 DC / inverter cabinet

B 1 AC cabinet

C1Power cabling

D 1 SMA document set

• Installation guide

• User manual

• Variant circuit diagram

• Commissioning report

E 1 Documentation of the optional insulation monitoring (Bender)

F 1 Low-voltage HRC fuse carrier, optional

G 2 Terminal profile, 3 m Rittal SZ 2573.000

16 SCxxxHE-IEN104432 Installation Guide

Page 17

SMA Solar Technology AG Delivery

Position Quantity Designation

H 1 Rittal assembly set

• Delivery pouch, 2-door TS8 1200 x 2000

• Angle bracket TS corner TS8800.430

• Quick angle connector TS TS8800.500

• Rittal angle plate PS 4582.500

• Sealing tape

I1 4 Shield clamping saddle 7 - 16mm Wago 790-116

I2 5 Shield clamping saddle 0 - 8mm Wago 790-108

K1 6 OBO cable clip 34 – 40 mm

K2 17 OBO cable clip 28 – 34 mm

K3 21 OBO cable clip 22 – 28 mm

K4 14 OBO cable clip 12 – 16 mm

L1 6 OBO opposite sleeve 1197169 2058 FW/40

L2 17 OBO opposite sleeve 1197282 2058 FW/34

L3 21 OBO opposite sleeve 1197347 2058 FW/28

L4 14 OBO opposite sleeve 1197401 2058 FW/16

Installation Guide SCxxxHE-IEN104432 17

Page 18

Delivery SMA Solar Technology AG

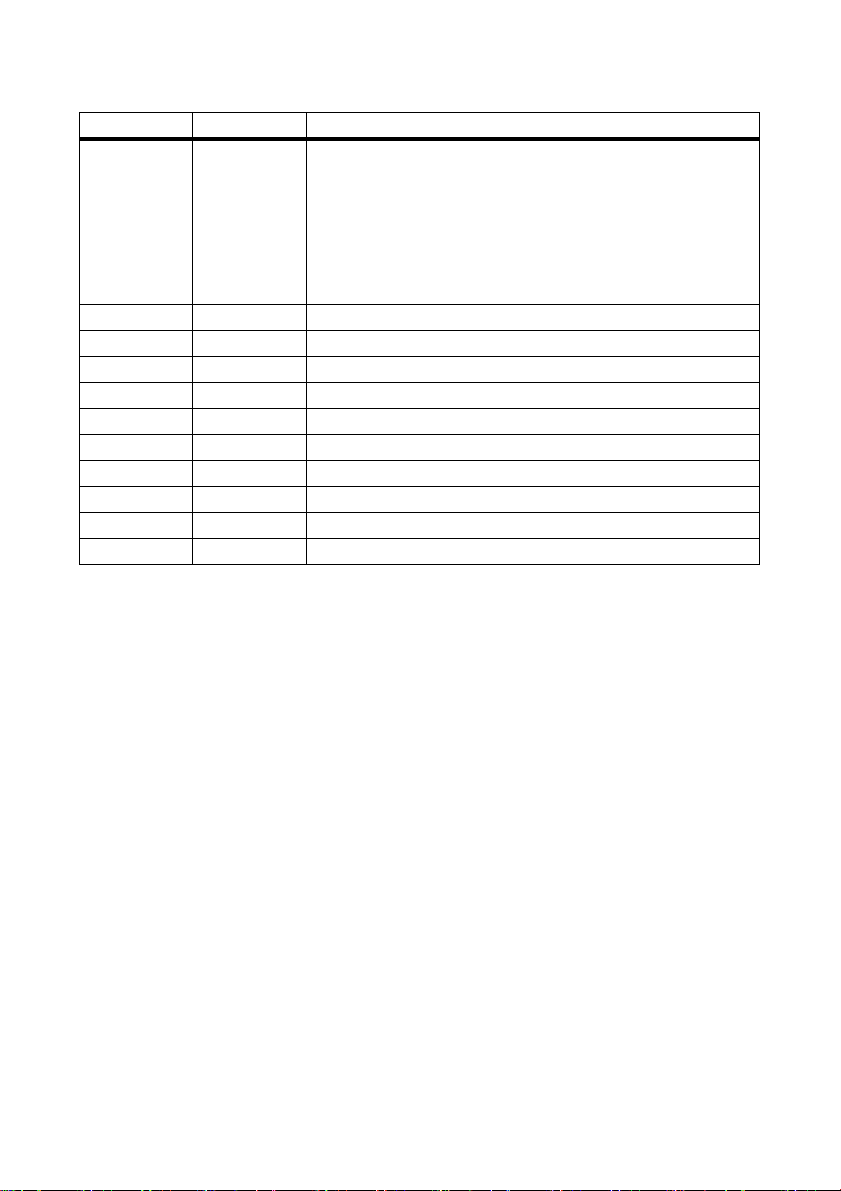

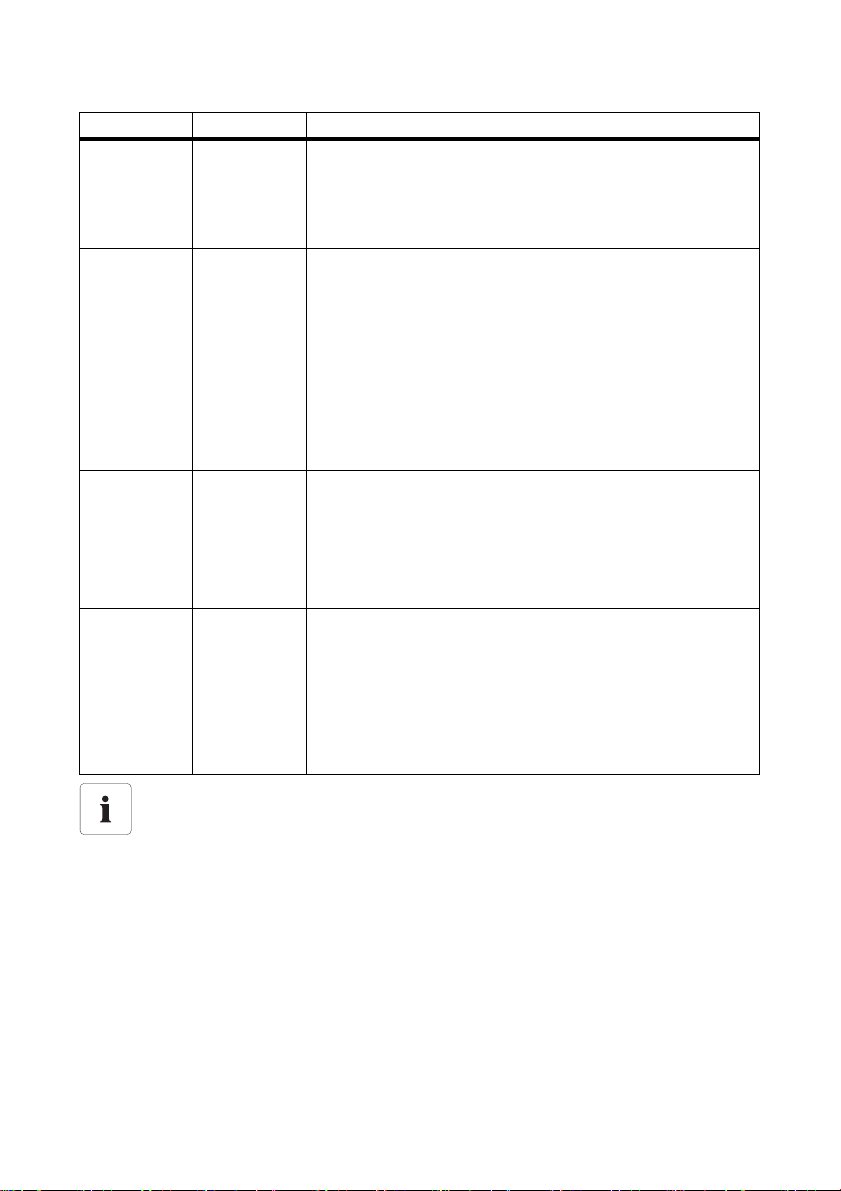

3.2 Scope of Delivery (depending on the model)

Position Quantity Designation

A 1 AC connection model 13/0:

• 3 x straight copper bar (same length)

• 3 x insulator

• 1 x retaining bracket

• 3 x insulator and setscrew

B 1 AC connection model 13/1:

• 3 x L-shaped copper bar

• 3 x insulator

• 1 x retaining bracket

• 3 x insulator and setscrew

18 SCxxxHE-IEN104432 Installation Guide

Page 19

SMA Solar Technology AG Delivery

Position Quantity Designation

C 1 AC connection model 13/2:

• 3 x U-formed copper bar

• 3 x insulator

• 3 x insulator and setscrew

D 1 AC connection model 13/3:

• 3 x U-formed copper bar

• 3 x support

• 1 x retaining bracket

• 3 x insulator and setscrew

• 18 x cable clip and opposite sleeve

• 3 x cable rail for side panels

• 6 x sliding nut

E 1 AC connection model 13/4:

• 3 x copper bar, varying angles

• 3 x insulator

• 1 x retaining bracket

• 3 x insulator and setscrew

F 1 AC connection model 13/5

• 3 x copper bar 2 x angled + separated

• 3 x insulator

• 1 x retaining bracket

• 3 x insulator and setscrew

• 6 x screw connector for the separated bars

Retaining brackets on the device

The retaining brackets are pre-installed on the device.

Installation Guide SCxxxHE-IEN104432 19

Page 20

Delivery SMA Solar Technology AG

A

SUNNY CENTRAL 630HE

AA

SMA

3.3 Identifying your Sunny Central

You can identify the Sunny Central using the type label. The type label is located on the inside of the

Sunny Central’s door.

In addition, the series number (A) is located on the front

side of the device.

Selecting switch cabinet units

Sunny Centrals are supplied as two switch cabinet units. If several Sunny Centrals are

delivered and installed together, switch cabinet units with the same serial number have to

be installed side by side.

3.4 Check for Transport Damage

Check the packaging and the device for any possible damage and compare the scope of delivery

with the delivery documentation. In the case of damage to the device and/or unclear delivery

contents, immediately contact SMA Solar Technology.

Transport safety

The inverters are delivered as two separate switch cabinet units. They do not satisfy the

protection class requirements as specified in the technical data. The transport packaging

provides sufficient protection against moisture and damage.

20 SCxxxHE-IEN104432 Installation Guide

Page 21

SMA Solar Technology AG Delivery

3.5 Storage

The switch cabinet units do not satisfy the protection class requirements as specified in the technical

data. The transport packaging provides sufficient protection against moisture and damage after

shipping. The switch cabinet units may not be stored outdoors.

Notice!

Improper storage may cause damage to the Sunny Central.

Improper storage can cause moisture or dust to seep into the Sunny Central.

• Only store the Sunny Central in areas where it is protected from dust and moisture.

• The conditions under which the Sunny Central is stored must correspond to the

intended operating conditions.

• Do not store the Sunny Central outdoors.

Installation Guide SCxxxHE-IEN104432 21

Page 22

Installation SMA Solar Technology AG

4 Installation

Sunny central installation requirements

Each Sunny Central has individual installation requirements. These can be ordered at any

time from SMA Solar Technology and have to be observed for project planning and

preparation of the installation site.

Selecting switch cabinet units

During installation and internal cabling, make sure the switch cabinet units have the same

series number.

4.1 Installation Site Requirements

Sunny central installation location

The Sunny Central should be installed in an electrical operating room.

Floor

The foundation must guarantee solid and safe positioning of the inverter. The foundation must provide

the load-carrying capacity necessary to cope with the weight of the inverter. The inverter cabinet must

be installed on a level surface. Any existing unevenness, depression or slope must be corrected prior

to installation.

Wall Clearances

When installing the inverter, appropriate distance to the wall for minimum passageways, escape

routes, and ventilation have to be observed. Appropriate specifications for each type of inverter are

contained in the Sunny Central Installation Requirements (separate document).

Inverter Protection Rating / EMC / Sound Levels

The Sunny Central is suitable for a dry, dust-reduced environment, according to IP20 protection rating.

With regard to the EMC emissions and the noise level, the Sunny Central inverter is conceived for

setup in an industrial environment.

4.2 Electrical Operating Room

For the installation and connection of the Sunny Central central inverters, observe DIN VDE 0100,

part 729, part 731. The requirements for the electrical operating room for the installation of highvoltage systems up to 1 000 V as well as the requirements for passageways and escape routes are

included therein.

22 SCxxxHE-IEN104432 Installation Guide

Page 23

SMA Solar Technology AG Installation

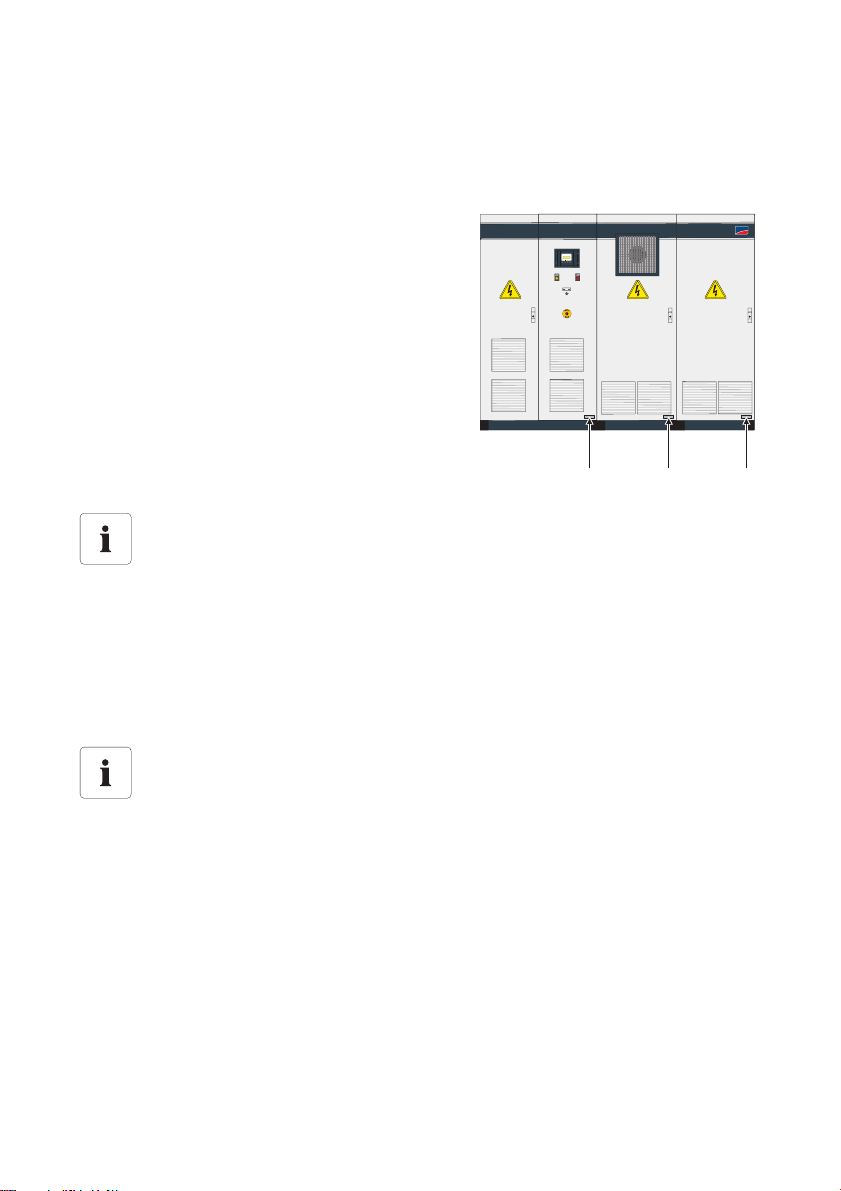

A

B

C C

B

A

SUNNY CENTRAL 630HESUNNY CENTRAL 630HE

SMA

SMA

Minimum passageway in electrical operating rooms

Observe the following points for a minimum passageway:

• With fully opened switch cabinet doors, a minimum passage width of 500 mm

(escape routes) must be maintained, see DIN VDE 0100 part 729, part 731.

• To maintain the minimum passageway requirements, the cabinet doors in an inverter

system with two rows of opposing cabinets (e.g. in a station building) may only be

opened on one side at a time.

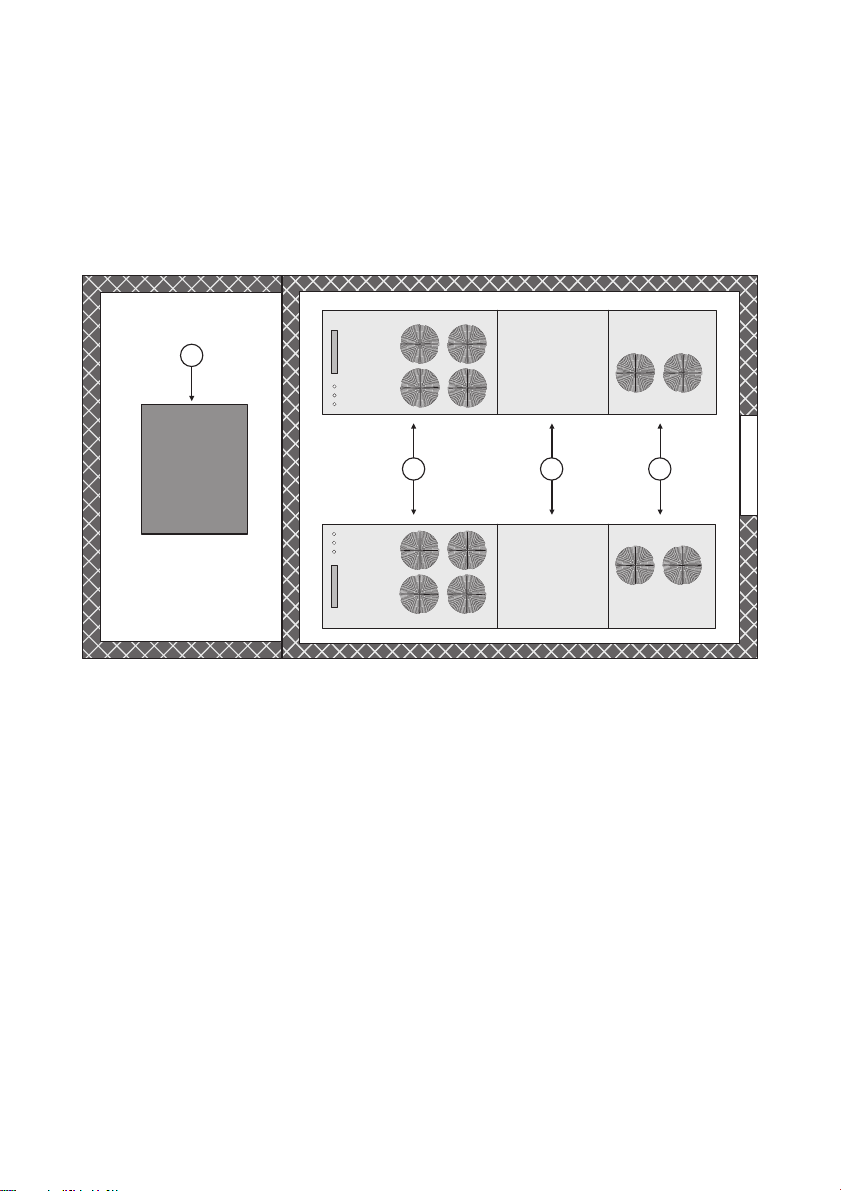

4.2.1 MV Stations

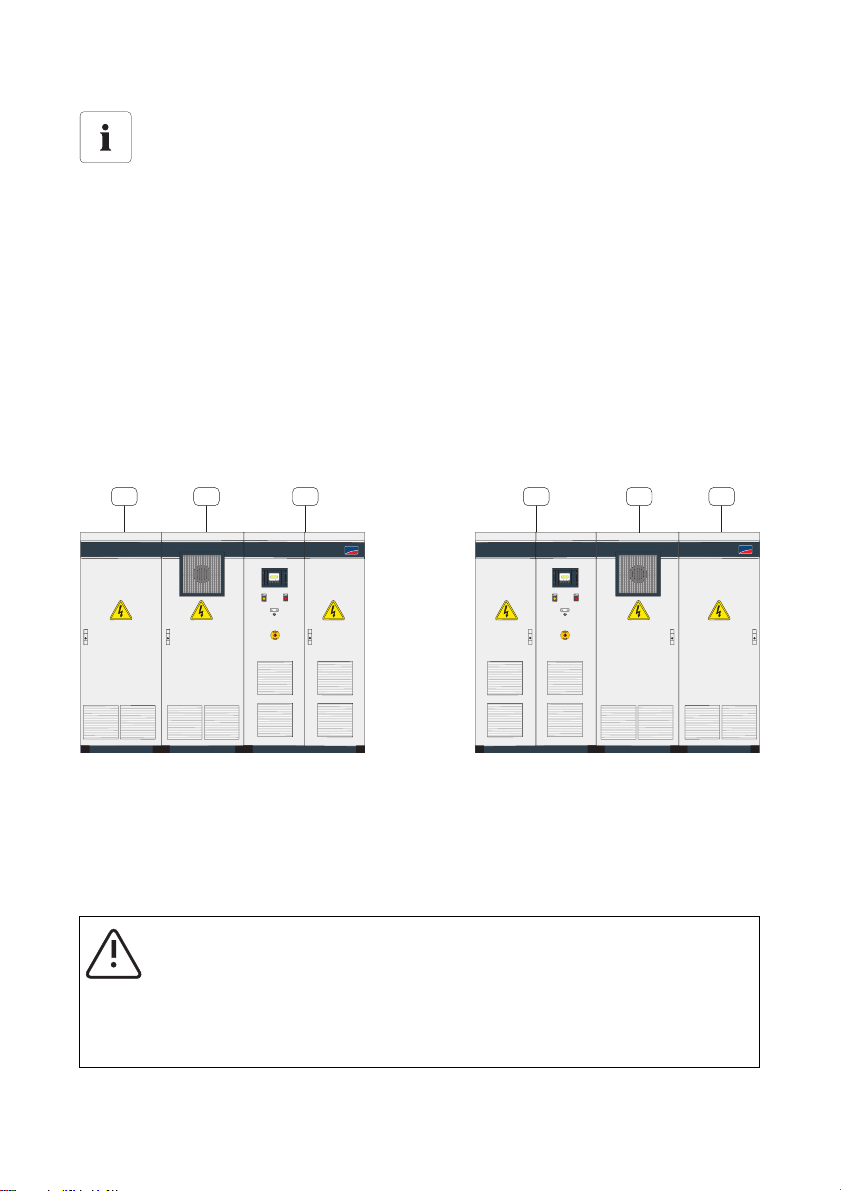

Inverters in the HE se ries ar e normally s et up in a compa ct concrete substation, opposite to each other

as a “left-hand system” and a “right-hand system”. The installation h as t o be car rie d ou t in accorda nce

with the VDE guidelines for a closed electrical operating room. The figure below depicts a left-hand

and a right-hand system.

Left system Right system

ADC cabinet

BInverter cabinet

CAC cabinet

The AC cabinets should always stand next to the dividing wall to the transformer room, to allow the

AC power cables to be connected to the transformer over the shortest possible route.

WARNING!

Smoke development in electrical operating rooms.

We recommend the installation of a smoke detector inside the operating room which

controls the external emergency stop connection of the device and which switches off the

Sunny Central in the event of smoke.

Installation Guide SCxxxHE-IEN104432 23

Page 24

Installation SMA Solar Technology AG

A B C

D

Sunny Centrals in a Station

A selection of schematic top views of a Sunny Central installed in a station and a transformer room

are included below. The inverter has bee n installed as a “ right -hand system” (above) and a “left-hand

system” (below). A station may also include only one Sunny Central. In addition to a transformer, the

option exists to also include a medium-voltage switchgear in a transformer room.

MV Station with two Sunny Centrals without Medium-Voltage Switchgear

A AC cabinet

B Inverter cabinet

C DC cabinet

DTransformer

24 SCxxxHE-IEN104432 Installation Guide

Page 25

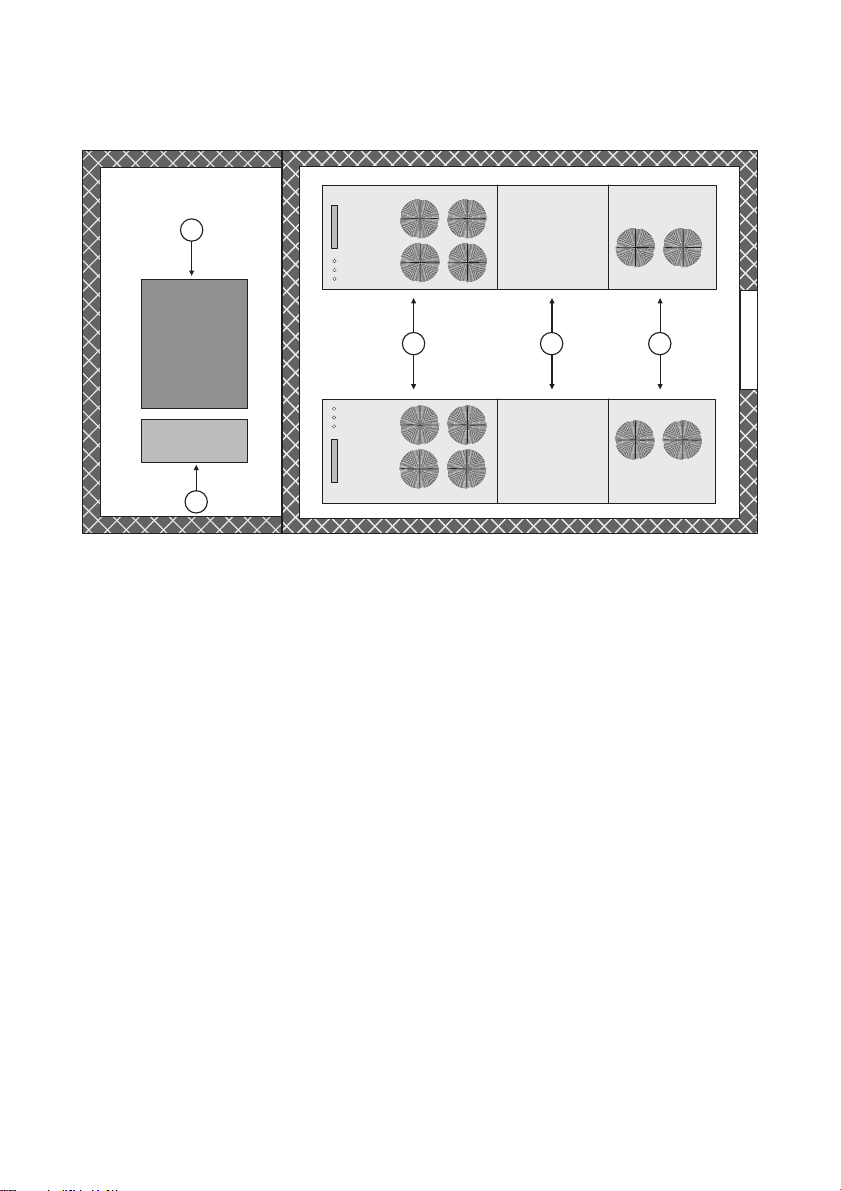

SMA Solar Technology AG Installation

A B C

D

E

MV Station with two Sunny Centrals and Medium-Voltage Switchgear

A AC cabinet

B Inverter cabinet

C DC cabinet

DTransformer

E Medium-voltage switchgear

Installation Guide SCxxxHE-IEN104432 25

Page 26

Installation SMA Solar Technology AG

A B C

D

A B C

D

E

MV Station with one Sunny Central without Medium-Voltage Switchgear

A AC cabinet

B Inverter cabinet

C DC cabinet

DTransformer

MV Station with one Sunny Central and Medium-Voltage Switchgear

A AC cabinet

B Inverter cabinet

C DC cabinet

DTransformer

E Medium-voltage switchgear

26 SCxxxHE-IEN104432 Installation Guide

Page 27

SMA Solar Technology AG Installation

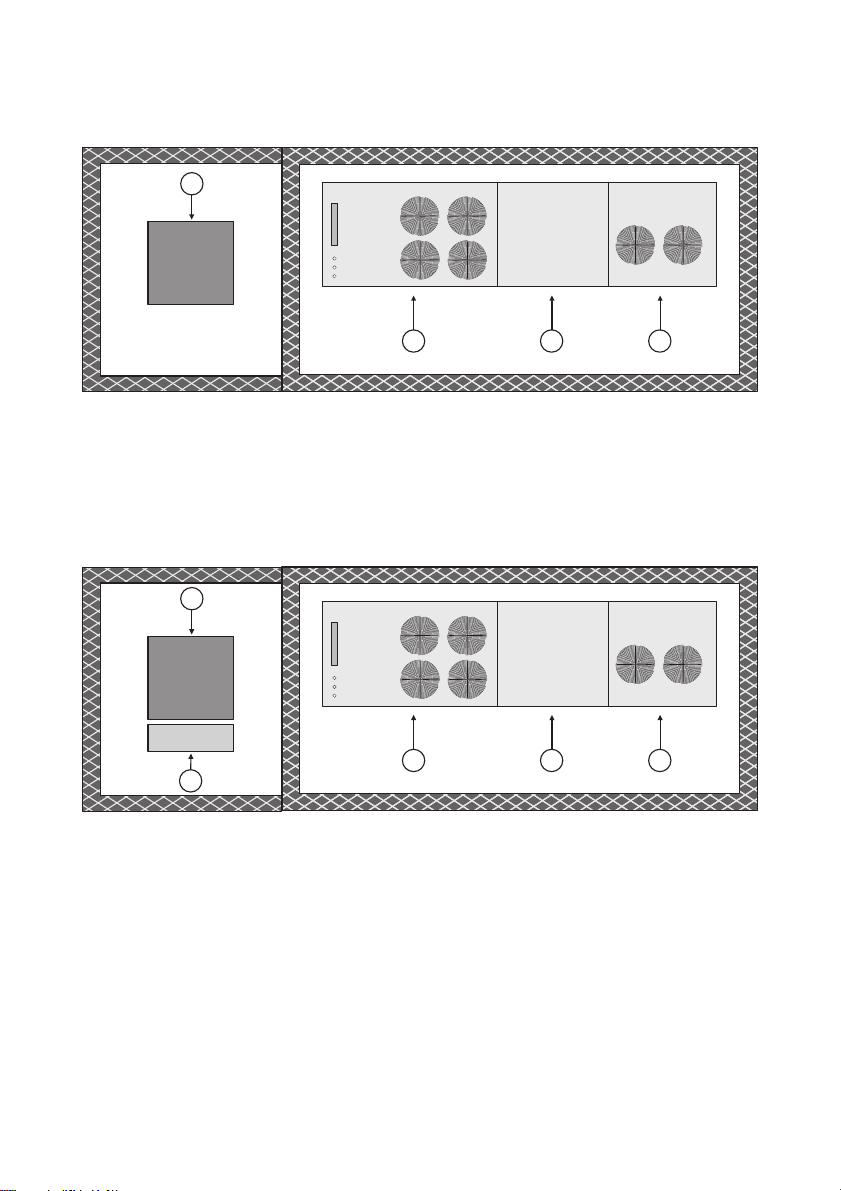

4.3 Ventilation

Appropriate inlet ventilation is required for cooling the inverter. In order to guarantee safe operation

and maximum feed-in power, the permissible ambient temperature must be observed.

The required air is drawn through the switch cabinet doors and is blown out via the roof or the rear

pa nel of t he c abi net uni t de pen din g on the Sun ny C ent ral model Thi s al low s th e de vic es t o be ins tal led

directly next to each other. See the Sunny Central Installation Requirements (separate document) for

the air requirements as well as appropriate wall clearances. Filters for cleaning the inlet air are

installed at the inlet vents.

If the required volume of air at the installation site of the Sunny Central is too small, then on-site

measures must be taken to provide greater quantities of air (ventilation grills, blowers, fans, etc.).

The inlet air must satisfy the requirements of classification 3S2 (see table). Classification 3C2 must be

met if installation is to occur in chemically aggressive environments, e.g. installation near the sea. The

operation of the inverter is suited to a relative humidity of 15 … 95 %.

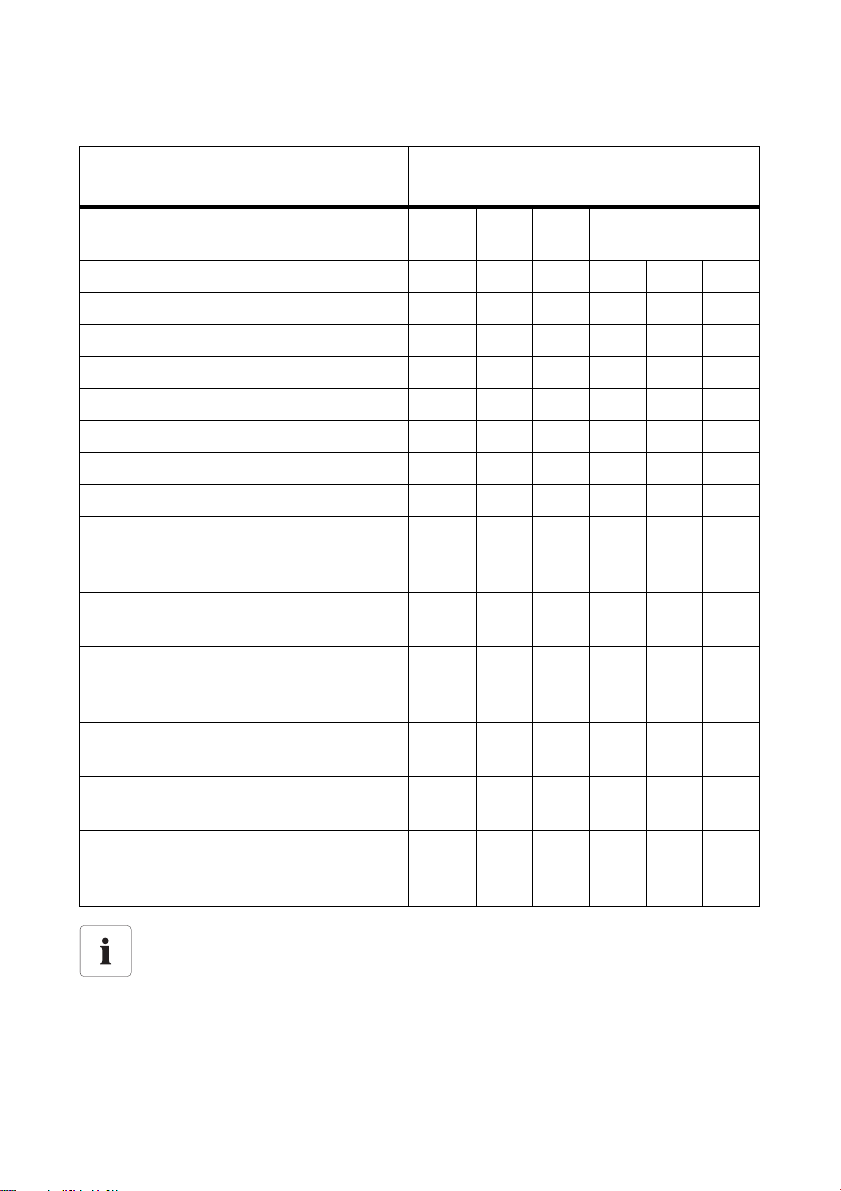

Air Quality Classification for Mechanically Active Substances

Environmental conditions for stationary

application

3S1 3S2 3S3 3S4

Class

a) Sand in the air [mg / m³] - 30 300 3 000

b) Dust (suspended matter) [mg / m³] 0.01 0.2 0.4 4.0

c) Dust (fallout) [mg / m³] 0.4 1.5 15 40

Sites where appropriate measures are taken to

xxxx

keep dust levels to a minimum.

Sites where no special measures have been taken

xxx

to reduce the sand or dust levels and which are

not located in the vicinity of sand or dust sources.

Sites near sand and dust sources x x

Sites in production halls where sand or dust is

x

present, or sites in geographical locations where

the air is prone to high levels of sand and dust.

Installation Guide SCxxxHE-IEN104432 27

Page 28

Installation SMA Solar Technology AG

Air Quality Classification for Chemically Active Substances

Environmental conditions for stationary

application

Class

3C1R 3C1L 3C1 3C2 3C3 3C4

a) Marine salt - - - Occurrence of marine

salt

b) Sulfur dioxide, mg / m³ 0.01 0.1 0.1 1.0 10 40

c) Hydrogen sulfide, mg / m³ 0.0015 0.01 0.01 0.5 10 70

c) Chlorine, mg / m³ 0.001 0.01 0.1 0.3 1.0 3.0

d) Hydrogen chloride, mg / m³ 0.001 0.01 0.1 0.5 5.0 5.0

e) Hydrogen fluoride, mg / m³ 0.001 0.003 0.003 0.03 2.0 2.0

f) Ammonia, mg / m³ 0.03 0.3 0.3 3.0 35 175

g) Ozone, mg / m³ 0.004 0.01 0.01 0.1 0.3 2.0

h) Nitrogen oxides, mg / m³ 0.01 0.1 0.1 1.0 9.0 20

Installation sites with carefully monitored and

x xxxxx

regulated atmospheres (category clean

spaces).

Installation sites with carefully regulated

xxxxx

atmospheres.

Installation sites in rural or densely populated

xxxx

areas with little industry and moderate traffic

volume.

Installation sites in densely populated areas

xxx

with industry and high traffic volume.

Installation sites directly neighboring industrial

xx

plants, with chemical emissions.

Installation sites directly inside of industrial

x

plants, with emission of high concentrations of

chemical pollutants.

Environmental Conditions

The following points must be observed in relation to environmental conditions:

• Required amount of fresh air

• Stipulated air quality

• Relative humidity

• Permissible ambient temperature

28 SCxxxHE-IEN104432 Installation Guide

Page 29

SMA Solar Technology AG Installation

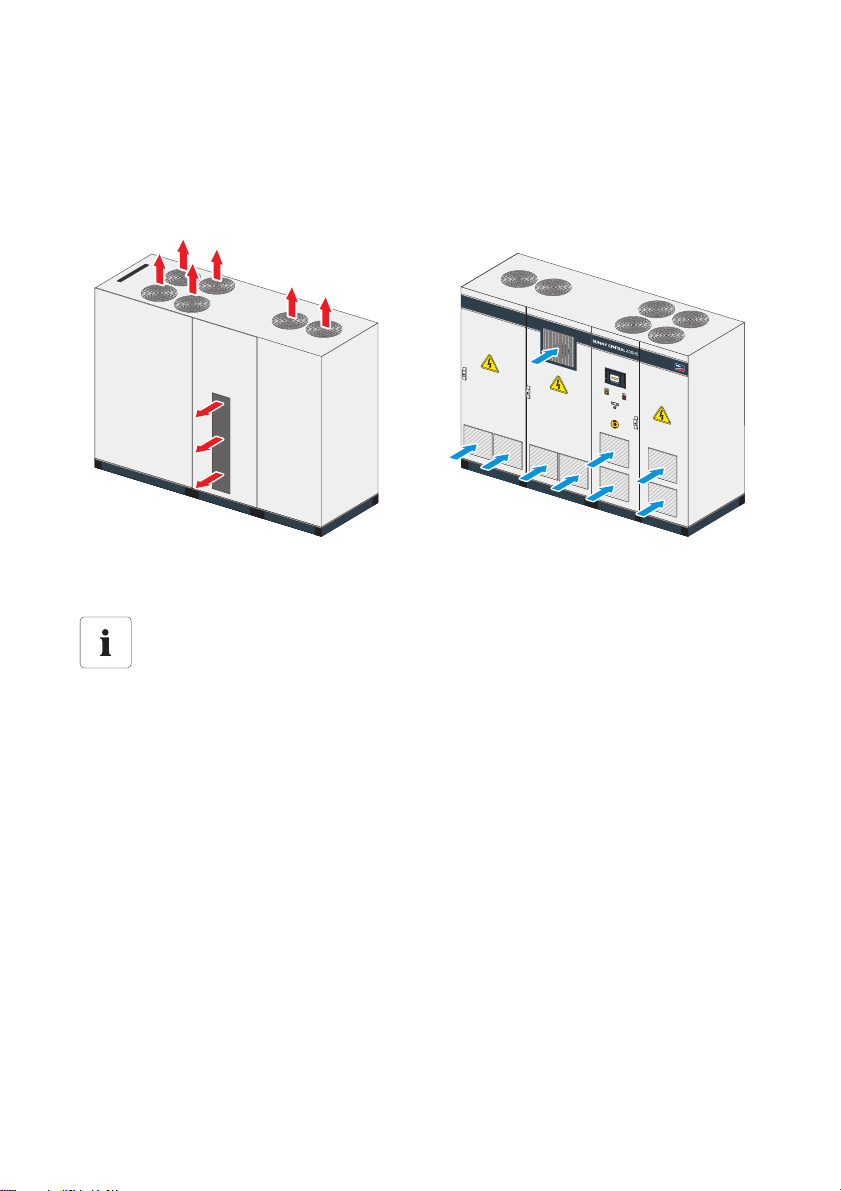

4.3.1 Exhaust Airflow

The heated exhaust air generated by the inverter must be ducted away from the device so that the

maximum permissible environmental temperature is not exceeded and / or the war m ex hau st ai r do es

not unnecessarily heat the installation room.

CAUTION!

Risk of crushing from metal parts.

• Remove the finger protection from the fan openings of the Sunny Central before

installing the exhaust airflow.

The exhaust airflow of the DC and AC cabinets occurs upward. This is achieved through the on-site

installation of an exhaust airflow (e.g. air conduit).

The exhaust airflow of the inverter cabinet occurs on the rear-side. The Sunny Central can be set up

with the rear panel directly against the opening in the building wall. An on-site sealing or a frame-like

air box with seals is to be installed for this purpose. The air box must be fastened onto the building

wall.

NOTICE!

Operational reduction of the Sunny Central through overtemperature!

For an appropriate cooling of the inverter, the following points have to be observed:

• Observe the indicated amount of air.

• Clean the ventilation openings (filter pads) and the exhaust grills at regular intervals.

• Expel the exhaust air separately out of the individual cabinet components in order to

avoid thermal short circuit breaks.

Information regarding the inverter

The specific configuration of the ventilation systems for each inverter is to be taken from the

Sunny Central Installation Requirements (separate document).

Installation Guide SCxxxHE-IEN104432 29

Page 30

Installation SMA Solar Technology AG

Overview of the Air Inlets and Outlets

Examples are used below to illustrate the exact position and size of the single air grills as well as for

the supply air on the front side (B) and the exhaust air on the roof or at the rear side (A) of the switch

cabinets.

AExhaust air BSupply air

Exact dimensions

For exact dimensions, please refer to the Installation Requirements of the relevant device.

The Installation Requirements are available at www.SMA.de/en.

30 SCxxxHE-IEN104432 Installation Guide

Page 31

SMA Solar Technology AG Installation

4.4 Transport Options

The inverter consists of two switch cabinet units, the DC / inverter cabinet and the AC cabinet, which

are separately transported and assembled together on site.

The inverters and switch cabinet units are delivered on pallets. A fork lift or a hoist is used to transport

the device to its final mounting location.

WARNING!

Heavy weight of the switch cabinet units!

Danger of tipping during transport!

• The cabinet units must always be transported in an upright position.

• When unloading, the heavy-load

markings must be given due

consideration.

– The center of gravity of the

Sunny Central is marked on the

outside of the packaging and on the

switch cabinet units.

– The labeling on the switch cabinet

units can be removed residue-free

following installation.

NOTICE!

Missing base panels could damage the Sunny Central.

• The base panels are essential for stable positioning of the switch cabinet.

• In the case of transport on a pallet, it is necessary to install the base panels.

Otherwise there is the danger that the base will collapse under the weight of the

switch cabinet.

Remove side base panels for cable routing

In the final installation location, one of the side base panels can be removed for cable

routing. The stability of the switch cabinet is still guaranteed.

Installation Guide SCxxxHE-IEN104432 31

Page 32

Installation SMA Solar Technology AG

SMA

SUNN

Y CENTRAL 630HE

S

U

N

N

Y

C

EN

TR

A

L 6

3

0

H

E

4.4.1 Transport Using a Pallet Truck or Forklift

1. Unscrew the base panels on the front and back base.

2. The two screws per base panel can be unscrewed

using a Torx TX30 screwdriver.

3. Insert the fork of a pallet truck or forklift under the

cabinet.

32 SCxxxHE-IEN104432 Installation Guide

Page 33

SMA Solar Technology AG Installation

4.4.2 Transport Using a Crane

NOTICE!

Inappropriate transport could cause damage to the Sunny Central.

In case of transport using a crane, the following points have to be observed:

• Asymmetric weight distribution

•Heavy duty

• The weight of the switch cabinet units is mainly distributed to the rear of the cabinet.

1. Unscrew the base panels on the front and back; see 4.4.1”Transport Using a Pallet Truck or

Forklift” (page32).

2. Insert the fork of a crane under the cabinet.

Transport using crane eyelets.

The heavy weight of the individual switch cabinet units means that transport using crane

eyelets is not permitted. A suitable crane fork should be used instead.

Installation Guide SCxxxHE-IEN104432 33

Page 34

Installation SMA Solar Technology AG

4.5 On-Site Inverter Installation

After both switch cabinet units have been installed next to each other, the transport locks of the

sinusoidal filter have to be removed, the seals have to be inserted and the individual cabinets have to

be mec han ica lly and elec tri cal ly c onn ect ed for th e fi nal mou nti ng in the operating room. All necessary

materials required for connecting the switch cabinets are included in the delivery.

4.5.1 Mechanical Coupling

NOTICE!

Moisture ingress due to lack of sealing!

• Before the two cabinets can be mechanically joined together, the seals provided must

be glued into the appropriate recesses in the cabinets, if this has not already been

done by default.

The mechanical connection of the two cabinets is done using baying clamps. They consist of terminal

clamps and brackets with which the cabinets can be screwed together in several places. In order to

do this, both cabinets have to be at the same level.

NOTICE!

Damage due to impurities!

• Do not carry out any machining work on or in the inverter.

• Remove impurities from the Sunny Central.

• Seal openings.

Observe the installation guide of the switch cabinet manufacturer.

The installation of the seals and baying clamps is described in the installation guide from

the Rittal company annexed to this document.

34 SCxxxHE-IEN104432 Installation Guide

Page 35

SMA Solar Technology AG Installation

A

A

4.5.2 Mechanical Coupling for the "Chemically Active" Option

If you are using a Sunny Central with the "Protection against chemically active substances" option,

the switch cabinets must be connected to one another as described below.

Mounting the Switch Cabinet Units

1. Attach the included sealing material all around the cabinet frame (A) of the AC cabinet.

2. Position the switch cabinet units near the installation location.

3. During mounting, insert the PE cable through the

cable gland (A).

4. Set up the switch cabinet units in the installation

location.

5. Connect the PE cable, see 5.2”Connecting the

Internal PE Connection” (page42).

☑ The switch cabinet units are mounted and can

now be screwed together.

Installation Guide SCxxxHE-IEN104432 35

Page 36

Installation SMA Solar Technology AG

A

B

DC/inverter cabinet side view AC cabinet side view

Screwing the Switch Cabinet Units Together

6. Open the AC cabinet.

7. Connect the switch cabinet units at positions A and B with the provided bolts (M8x45 mm),

washers, and brackets. Torque: 21 Nm.

8. The switch cabinet units are screwed together in the AC cabinet.

☑ The switch cabinet units are connected to each other.

4.5.3 Anchorage to the Ground or Wall

The weight of the Sunny Centrals is heavy, and for this reason additional anchorage to the ground or

wall is not necessary.

Anchorage in an MV station

Sunny Centrals that are housed and transported within an MV station are anchored to the

wall and floor of the station so that they do not slide and become damaged during

transport.

36 SCxxxHE-IEN104432 Installation Guide

Page 37

SMA Solar Technology AG Internal Electrical Connections

5 Internal Electrical Connections

Once both switch cabinet units have been installed alongside each other and are mechanically

connected, the individual cabinets must be electrically joined together.

Realizing the electrical connection

The circuit diagram provided must be used for establishing the electrical connections and

connectors.

To prepare the inverter for the external AC and DC connections, all internal connections

must be installed first.

For internal electrical connection of the two cabinets, the following connections must be established:

• Power cable connection between the sinusoidal filter and power unit

• Grounding connection between AC cabinet and DC / inverter cabinet

• Control cables on the transfer terminal strip

• Communication between the Sunny Central Control and the power unit in the inverter cabinet

• Communication between the Sunny Central Control and the insulation monitoring system

Installing the internal connections

For the most part, the internal connections are pre-assembled and must be plugged or

screwed in when joining the cabinets together.

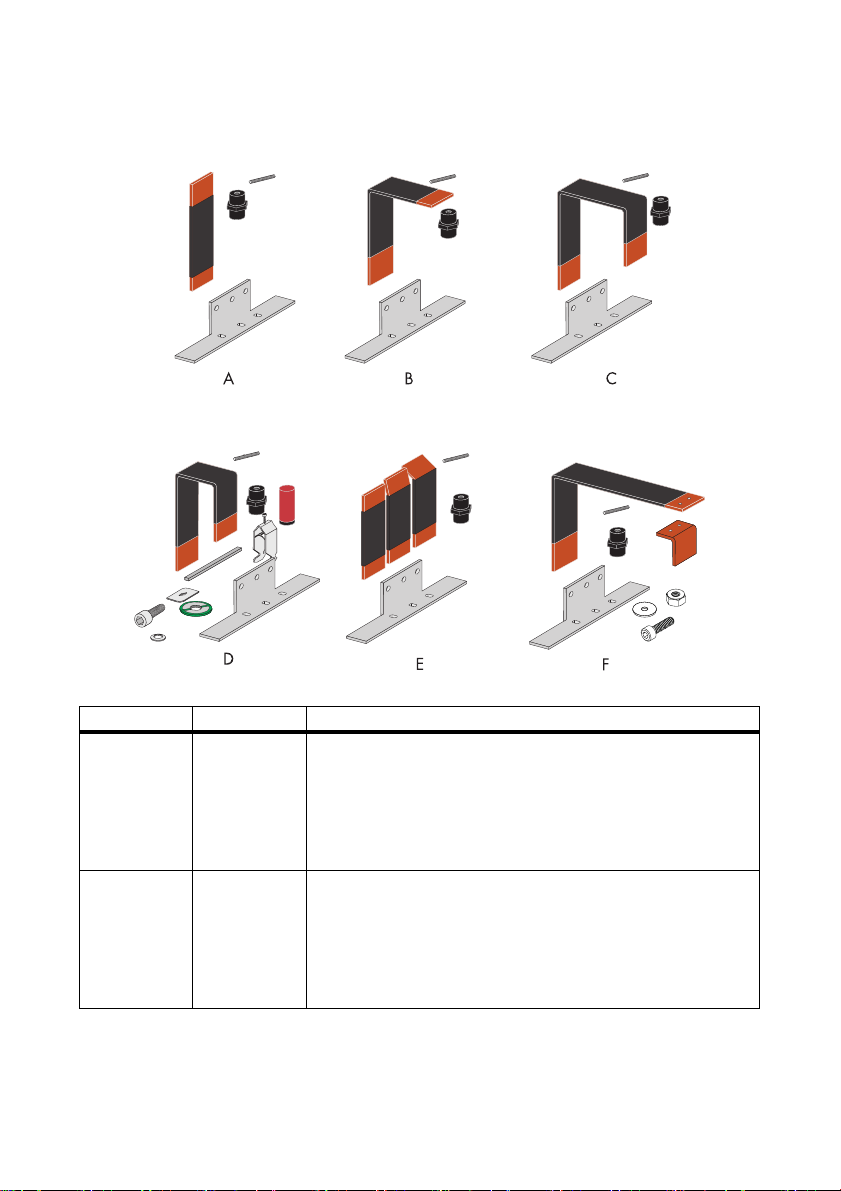

5.1 Connecting the Power Cable Connection

The power cable connection of the power units in the inverter cabinet to the sinusoidal filter choke in

the AC cabinet is to be carried out using the delivered Radox cables (W131 to W139).

Observe the cable length

The Radox cables included in the delivery have different lengths for left-hand and righthand systems. Arrange the cables according to the circuit diagram of the respective Sunny

Central.

According to the circuit diagram included in the delivery, one power unit per phase is connected to

the sinusoidal filter choke, each measuring 3 x 1 x 185 mm². The corresponding terminal screws are

located on the connection points.

Installation Guide SCxxxHE-IEN104432 37

Page 38

Internal Electrical Connections SMA Solar Technology AG

4

5

1

2

3

6

7

8

NOTICE!

Operational reduction of the Sunny Central due to faulty connection!

The following connection sequence must be observed when connecting the power cables

to the sinusoidal filter choke:

1. Screw

2. Spring washer

3. Washer

4. Terminal lug

– Only in the case of a middle power

cable; this will be installed on the

rear-side of the connection point.

5. Connection point sinusoidal filter or

power module

• Terminal lug

– Only in the case of the two exterior

power cables; these will be installed

on the front-side of the connection

point.

6. Washer

7. Spring washer

8. Nut

38 SCxxxHE-IEN104432 Installation Guide

Page 39

SMA Solar Technology AG Internal Electrical Connections

Procedure for power cabling:

1. First connect the lower power unit followed by the middle unit and then the upper unit.

NOTICE!

Warming of the Sunny Central due to cable routing near the internal fans.

• In the left cabinet system, lay the power cables to the left and right of the three

internal fans in order to avoid affecting their function.

2. Affix the 3 power cables of the respective external conductor to the stabilizer bars using cable

ties.

3. Feed the power cables through the opening in the side wall above the cabinet plate and feed

back in at the area of the AC cabinet.

4. Use cable ties to bind the power cables to the plates of the switch cabinet.

5. Connect the 3 power cables of the respective external conductor to the sine-wave filter.

Installation Guide SCxxxHE-IEN104432 39

Page 40

Internal Electrical Connections SMA Solar Technology AG

L-

L+

L-

L+

L-

L+

M3-810

M3-810

L+

L-

AAA B

The following figure shows the terminal lugs at the three power units in the inverter cabinet and the

connection of the power cables to the sinusoidal filter in the AC cabinet of the Sunny Central.

A Terminal lugs of the sinusoidal filter choke

B Terminal lugs of the power unit

40 SCxxxHE-IEN104432 Installation Guide

Page 41

SMA Solar Technology AG Internal Electrical Connections

A

B

5.1.1 Connecting the Power Cable for the "Chemically Active" Option

The power cables are included in the scope of delivery and must be connected to the power units in

the inverter cabinet and to the sinusoidal filter choke in the AC cabinet. Three cables are connected

per phase. The cable routing in the right and left system is different. The following figure shows the

position of the glands in the left system; the position of the glands in the right system are mirror-inverted.

Connecting the Power Cables in the Left System

1. Connect L3 at the lower power module in the inverter cabinet.

2. Insert L3 through the cable gland A.

3. Connect L3 at the sinusoidal filter in the AC cabinet according to the label,

4. Tighten the cable gland A.

5. Connect L1 at the middle power module in the inverter cabinet.

6. Insert L1 through the cable gland B.

7. Connect L1 at the sinusoidal filter in the AC cabinet according to the label.

8. Tighten the cable gland B.

9. Connect L2 at the upper power module in the inverter cabinet.

10. Insert L2 through the cable gland C.

11. Connect L2 at the sinusoidal filter in the AC cabinet according to the label.

12. Tighten the cable gland C.

Installation Guide SCxxxHE-IEN104432 41

Page 42

Internal Electrical Connections SMA Solar Technology AG

Connecting the Power Cables in the Right System

1. Connect L1 at the lower power module in the inverter cabinet.

2. Insert L1 through the cable gland A.

3. Connect L1 at the sinusoidal filter in the AC cabinet according to the label.

4. Tighten the cable gland A.

5. Connect L3 at the middle power module in the inverter cabinet.

6. Insert L3 through the cable gland B.

7. Connect L3 at the sinusoidal filter in the AC cabinet according to the label.

8. Tighten the cable gland B.

9. Connect L2 at the upper power module in the inverter cabinet.

10. Insert L2 through the cable gland C.

11. Connect L2 at the sinusoidal filter in the AC cabinet according to the label.

12. Tighten the cable gland C.

Laying cables

The power cables must be bundled in the inverter cabinet by using cable ties. This prevents

the cables from being damaged by pointed or sharp metal edges.

☑ The power cables are connected.

5.2 Connecting the Internal PE Connection

The individual switch cabinets are equipped with PE rails that must be connected together at the time

of installation. A pre-assembled PE cable can be found in the AC cabinet. The PE rails are located at

the bottom of the AC cabinet, behind the sinusoidal filter choke. A PE rai l is loc ate d in the DC / inver ter

cabinet at the bottom of the exterior wall of the DC cabinet, and an additional rail can be found in

the connecting point between the DC and inverter switch cabinet units.

1. Feed the cable behind the sinusoidal filter choke in the AC cabinet and the power units in the

inverter cabinet into the DC cabinet.

2. Connect the cable to the PE rail in the DC cabinet.

42 SCxxxHE-IEN104432 Installation Guide

Page 43

SMA Solar Technology AG Internal Electrical Connections

L-

L+

L-

L+

L-

L+

M3-810

M3-810M3-810

L+

L-

PE

Example PE connection between the switch cabinets of the Sunny Central

Check the grounding connection

When connecting the grounding connection, make sure that the screws are securely

positioned.

Position of the PE rail

Due to the design, the exact position of the PE rail is next to the fuse strip in the DC cabinet

and behind the sinusoidal filter in the AC cabinet. The exact position of the PE rail can be

determined with the help of the equipment identifier and the provided circuit diagram.

Installation Guide SCxxxHE-IEN104432 43

Page 44

Internal Electrical Connections SMA Solar Technology AG

5.3 Connecting the Control Cables on the Transfer Terminal Strip

Check the cabling

When connecting the control lines, the correct sequence and the appropriate colors of the

insulated conductors have to be observed. The plugs are sequentially numbered.

Most control cables that have to be connected between the switch cabinets are connected to the

transfer terminal strips via plugs. The transfer terminal strip is located in the AC cabinet on the

mounting plate that is oriented toward the inverter cabinet. The cable bundles to be plugged in are

labeled with their destination.

Example transfer terminal strip between the switch cabinets of the Sunny Central

Position of the transfer terminal strips

The exact position of the transfer terminal strips can be determined with the help of the

equipment identifier and the provided circuit diagram.

44 SCxxxHE-IEN104432 Installation Guide

Page 45

SMA Solar Technology AG Internal Electrical Connections

A

5.3.1 Connecting the Control Cables to the Transfer Terminal Strip in the AC Cabinet

The control cables (A) are routed to the outside of the

DC / inverter cabinet during factory production.

1. Insert the control cables into the sockets in the AC

cabinet as described in 5.3”Connecting the Control

Cables on the Transfer Terminal Strip” (page44).

Make sure the plugs are not swapped.

☑ The control cables are connected.

Installation Guide SCxxxHE-IEN104432 45

Page 46

Internal Electrical Connections SMA Solar Technology AG

L-

L+

L-

L+

L-

L+

A

5.4 Connecting the Sunny Central Control to the Power Unit

Notice!

Faulty installation could damage the cabling

• Do not lay the cables in the cable channel or parallel to the power cables (EMC).

• Place the cables freely in the switch cabinet.

• Connect the plug-in contact carefully to the board.

Co nne ct t he d ata lin e of the Sun ny C ent ral C ont rol to t he c ont rol ler b oar d at the pow er u nit . Th e ca ble

possesses a 4-pole white plug that is to be plugged into the controller board. The ADAPBFS

(controlboard) and controller board are located in the inverter cabinet on the topmost power unit.

The controller board communicates with the ADAPBFS board via a ribbon cable. The slot for the plug

of the data line is located on the right side of the board directly at the communication interface

(Piggy‑Back).

Connection terminal (A) for the data cable in the Sunny Central

46 SCxxxHE-IEN104432 Installation Guide

Page 47

SMA Solar Technology AG Internal Electrical Connections

L-

L+

L-

L+

L-

L+

A

5.5 Connecting the Internal Control Cables of the Power Unit

The control cable coming from the AC cabinet is already plugged in upon delivery. Plug in the

X31/32 control cable via the terminal strip.

Connection (A) of the internal control cable for the Sunny Central

Connecting the control cable

Adhere to the circuit diagram included in the delivery when connecting the internal control

cable.

Installation Guide SCxxxHE-IEN104432 47

Page 48

Internal Electrical Connections SMA Solar Technology AG

5.6 Connecting the Communication Unit for Insulation Monitoring

Insulation monitors from Bender

An insulation monitoring device from Bender can optionally be built into the Sunny Central.

A user manual is included with the device.

Notice!

A faulty installation could damage the cabling.

• Lay the connection cables in the cable channel.

The insulation monitoring system is located in the DC cabinet. A 2-conductor data cable connects the

Sunny Central Control to the insulation monitoring system and is delivered pre-cabled. The connection

is made via the transfer terminal strip.

Insulation monitor with connected data cable in the

Sunny Central.

Position of the connection terminal of the insulation monitoring

The exact position of the connection terminals of the insulation monitoring can be

determined with the help of the equipment identifier and the circuit diagram included in the

delivery.

48 SCxxxHE-IEN104432 Installation Guide

Page 49

SMA Solar Technology AG External Connections

6 External Connections

The following connections have to be made in order to connect the Sunny Central externally:

• AC grid connection

• PE rail connection

• AC control voltage

•DC connection

• External messages and signals

• Sensors and digital outputs

• Communication connector

• Emergency stop cabling

• Lightning and overvoltage protection

Installing the external connections

Adhere to the circuit diagram included in the delivery when realizing external connections.

Dimensioning the connections

The implementation of the AC grid connection point as well as the maximum inverterspecific connection cross-section and terminal lugs are included in the Installation

Requirements of the relevant Sunny Central.

Installation Guide SCxxxHE-IEN104432 49

Page 50

External Connections SMA Solar Technology AG

6.1 Connecting High-Current Contacts

The terminals in the DC and AC areas of the Sunny Central are made of copper, so there are no

special requirements for the connection of copper cables. No special measures are required to

connect the DC cable to the cage clamps. The connection of aluminum terminal lugs to the copper

bars of the AC connection or to the fuse holders of LV / HRC 3 fuses in the DC connection area

requires the use of copper-clad aluminum washers. The copper-clad aluminum washers neutralize the

co nta ct r esi stance b etw een the aluminum terminal lugs and the copper bars. See below for installation

of the copper-clad aluminum washers.

Keeping the contacts clean

Sweat and fatty acids from the fingers must not be transferred to the contacts. Use clean

gloves to connect the power cabling.

1. Remove any grease from the contacts with a clean cloth and ethanol cleaning solution. Clean

only the contacts used.

2. Clean the contacts with a cleaning felt. The contacts are clean if they have a slight metallic shine.

Using different cleaning cloths

The cleaning felt can only be used for one type of material. Never use a felt for aluminum

if it has been used on copper. Store and select the cleaning felt and cloth in a way that

ensures they cannot be mixed up, e.g. by using different colored cloths.

Tin-plated copper is to be treated like copper and tin-plated aluminum like aluminum.

3. Cleaning creates metal dust. Remove this with a clean cloth and ethanol cleaning solution.

Removing metal dust

Do not remove metal dust with the compressed air gun.

4. Clean copper-clad aluminum washers. Even when cleaning the copper-clad aluminum washers,

copper and aluminum must be strictly kept separate. Only touch the edges of the washers.

5. In ser t th e co ppe r-c lad alu minu m wa she r be twe en t he c opp er an d al umi num. For rai ls, adj ust thi s

copper-clad aluminum washer to the dimensions of the contact areas.

6. Observe the connection sequences and secure the terminal lug.

50 SCxxxHE-IEN104432 Installation Guide

Page 51

SMA Solar Technology AG External Connections

Connection Sequence for DC Connection

NOTICE!

Operational reduction of the Sunny Central due to faulty connection!

When connecting the power cables, the following connection seque nce must be o bser ved :

1. Screw

2. Spring washer

3. Washer

4. Connection point for copper bar

5. Copper-clad aluminum washer

• when using aluminum cables

6. Aluminum terminal lug

7. Washer

8. Spring washer

9. Nut

Installation Guide SCxxxHE-IEN104432 51

Page 52

External Connections SMA Solar Technology AG

Connection Sequence for AC Connection

NOTICE!

Operational reduction of the Sunny Central due to faulty connection!

When connecting the power cables, the following connection seque nce must be o bser ved :

1. Screw

2. Spring washer

3. Washer

4. Terminal lug

5. Copper-clad aluminum washer

6. Connection point for copper bar

• Copper-clad aluminum washer, if

required

• Terminal lug, if required

7. Washer

8. Spring washer

9. Nut

52 SCxxxHE-IEN104432 Installation Guide

Page 53

SMA Solar Technology AG External Connections

SM

A

SUNNY CENTRAL 630HE

6.2 Connecting the AC Grid

The AC connection is made on the copper bars located on the outside on top of the Sunny Central

roof.

The connection can be made in five different manners:

Model 13/0

In this case, the connection is made to three straight

copper bars.

Model 13/1

In this case, the connection is made to three L-shaped

copper bars.

Installation Guide SCxxxHE-IEN104432 53

Page 54

External Connections SMA Solar Technology AG

Model 13/2

In this case, the connection is made to three U-shaped

copper bars.

Model 13/3

In this case, the connection is made to three U-shaped

copper bars.

The particularity of this connection is the so-called side

ou tle t; h ere the AC c abl ing is f ed downw ard dir ect ly a lon g

the side of the Sunny Central.

Model 13/4

In this case, the connection is made to three copper bars,

ea ch o f wh ich is a ngl ed d iff erently . Se en f rom the fro nt, the

first will not be angled, and the second and third will be

angled at 15° and 30°, respectively.

These models are only offered for left-handed switch

cabinets.

Model 13/5

In this case, the connection is made to three U-shaped

copper bars.

The particularity of of this connection is the separated

copper bars.

Diverse installation models

Depending on the specific model, the different copper bars or insulators as well as other

add-on parts included in the accessories must be installed.

54 SCxxxHE-IEN104432 Installation Guide

Page 55

SMA Solar Technology AG External Connections

Damaged insulators

If an insulator becomes damaged, it must be replaced with an insulator of the same type

or model.

Observe the internal power supply connection

If the Sunny Central power supply is picked up internally at the AC connection, the internal

power supply must be connected prior to the installation of the AC copper bars (see

6.5.2”Connecting the Internal Power Supply” (page74)).

6.2.1 Mounting and Dismounting the Plexiglas Cover and Sliding Plate

Regardless of the type of AC grid connection, the Plexiglas cover over the fuse load disconnection

unit and the sliding plate in the roof of the Sunny Central must be removed in order to install the

relevant copper bars. These components are put back on once the copper bars have been installed.

Instructions for mounting and dismounting these parts are provided in this chapter.

WARNING!

Risk of death due to burns and electric shock when live parts are touched!

• Do not touch the live components of the Sunny Central, the power distribution grid or

the low-voltage grid.

• All safety precaution measures regarding the power distribution grid must be

observed.

• Only work on the device when it is switched off and voltage-free.

Installation Guide SCxxxHE-IEN104432 55

Page 56

External Connections SMA Solar Technology AG

A

B

Removing and Mounting the Plexiglas Cover

The Sunny Central is delivered with a Plexiglas cover mounted a bove the load disconnection unit. The

cover must be dismounted prior to the installation of the copper bars.

1. Unscrew the two knurled screws (A)

of the Plexiglas cover (B) located above the load

disconnection unit.

2. Remove the Plexiglas cover.

56 SCxxxHE-IEN104432 Installation Guide

Page 57

SMA Solar Technology AG External Connections

B

A

The Plexiglas cover must be put back on once the copper bars have been installed.

1. Mount the Plexiglas cover (B). For this purpose,

tightly screw in the two knurled screws.

Mounting and Dismounting the Sliding Plate

Sliding plates are included in the delivery of the Sunny Central. The front sliding plate must be

dismounted prior to the installation of the copper bars.

1. Remove the front s liding plate (A) from the roo f of the

Sunny Central. For this purpose, remove the three

screws on the underside.

Installation Guide SCxxxHE-IEN104432 57

Page 58

External Connections SMA Solar Technology AG

The sliding plate must be put back on once the copper bars have been installed.

1. Mount the front sliding plate into the roof of the

Sunny Central. For this purpose, tightly fasten the

three screws on the underside.

6.2.2 Procedure for Models 13/0 and 13/4

1. Remove the Plexiglas cover and sliding plate, see 6.2.1”Mounting and Dismounting the

Plexiglas Cover and Sliding Plate” (page55).

2. Mount the three insulators to the angle section. For

this purpose, tightly fasten the three insulators to the

press-fitted threaded bolts.

3. Feed the copper bars into the AC cabinet from

above.

58 SCxxxHE-IEN104432 Installation Guide

Page 59

SMA Solar Technology AG External Connections

E

4. Connect the copper bars to the fuse load

disconnection unit (E) in the AC cabinet.

5. Mount the copper bars to the insulators. For this

purpose, screw the setscrews included in the delivery

into the still unused insulators and fasten them to the

other insulators through the copper bars. In this

manner, the two insulators function like locknuts.

6. Mount the Plexiglas cover and front sliding plate, see 6.2.1”Mounting and Dismounting the

Plexiglas Cover and Sliding Plate” (page55).

7. Connect the AC cable to the copper bars from the outside.

6.2.3 Procedure for Model 13/1

1. Remove the Plexiglas cover and front sliding plate, see 6.2.1”Mounting and Dismounting the

Plexiglas Cover and Sliding Plate” (page55).

2. Mount the three insulators next to the opening in the

roof of the switch cabinet for the copper bars.

Installation Guide SCxxxHE-IEN104432 59

Page 60

External Connections SMA Solar Technology AG

E

3. Feed the copper bars into the AC cabinet from

above.

4. Connect the copper bars to the fuse load

disconnection unit (E) in the AC cabinet.

5. Mount the copper bars to the insulators. For this

purpose, screw the setscrews included in the delivery

into the still unused insulators and fasten them to the

other insulators through the copper bar. In this

manner, the two insulators function like locknuts.

6. Mount the Plexiglas cover and front sliding plate, see 6.2.1”Mounting and Dismounting the

Plexiglas Cover and Sliding Plate” (page55).

7. Connect the AC cable to the copper bars from the outside.

60 SCxxxHE-IEN104432 Installation Guide

Page 61

SMA Solar Technology AG External Connections

E

6.2.4 Procedure for Model 13/2

1. Remove the Plexiglas cover and front sliding plate, see 6.2.1”Mounting and Dismounting the

Plexiglas Cover and Sliding Plate” (page55).

2. Mount the three insulators next to the opening in the

roof of the switch cabinet for the copper bars.

3. Feed the copper bars into the AC cabinet from

above.

4. Connect the copper bars to the fuse load

disconnection unit (E) in the AC cabinet.

Installation Guide SCxxxHE-IEN104432 61

Page 62

External Connections SMA Solar Technology AG

5. Mount the copper bars to the insulators. For this

purpose, screw the setscrews included in the delivery

into the still unused insulators and fasten them to the

other insulators through the copper bars. In this

manner, the two insulators function like locknuts.

6. Mount the Plexiglas cover and front sliding plate, see 6.2.1”Mounting and Dismounting the

Plexiglas Cover and Sliding Plate” (page55).

7. Connect the AC cable to the copper bars from the outside.

6.2.5 Procedure for Model 13/3

1. Remove the Plexiglas cover and front sliding plate, see 6.2.1”Mounting and Dismounting the

Plexiglas Cover and Sliding Plate” (page55).

2. Mount the three supports to the angle bracket on the

side wall of the Sunny Central.

3. Feed the copper bars into the AC cabinet from

above.

62 SCxxxHE-IEN104432 Installation Guide

Page 63

SMA Solar Technology AG External Connections

E

4. Connect the copper bars to the fuse load

disconnection unit (E) in the AC cabinet.

5. Mount the copper bars to the insulators. For this

purpose, screw the setscrews included in the delivery

into the still unused insulators and fasten them to the

supports through the copper bars. In this manner, the

two insulators function like locknuts.

Installation Guide SCxxxHE-IEN104432 63

Page 64

External Connections SMA Solar Technology AG

6. Mount the cable rails to the pre-assembled rails on

the side wall of the Sunny Central. Use the sliding

nuts included in the delivery for this. These are

located in the middle of the rails on the side wall of

the Sunny Central.

7. Mount the Plexiglas cover and front sliding plate, see 6.2.1”Mounting and Dismounting the

Plexiglas Cover and Sliding Plate” (page55).

8. Connect the AC cable to the copper bars from the outside. Feed the cables down the rails

located on the side of the Sunny Central and fasten them with cable clips and opposite sleeves.

64 SCxxxHE-IEN104432 Installation Guide

Page 65

SMA Solar Technology AG External Connections

E

6.2.6 Procedure for Model 13/5

1. Remove the Plexiglas cover and front sliding plate, see 6.2.1”Mounting and Dismounting the

Plexiglas Cover and Sliding Plate” (page55).

2. Mount the three insulators next to the opening in the

roof of the switch cabinet for the copper bars.

3. Feed the copper bars into the AC cabinet from

above.

4. Connect the copper bars to the fuse load

disconnection unit (E) in the AC cabinet.

Installation Guide SCxxxHE-IEN104432 65

Page 66

External Connections SMA Solar Technology AG

5. Mount the copper bars to the insulators. For this

purpose, screw the setscrews included in the delivery

into the still unused insulators and fasten them to the

other insulators through the copper bars. In this

manner, the two insulators function like locknuts.

6. Screw the second part of the copper bar to the part

that is already mounted. Use the screw connections

included in the delivery for this.

7. Mount the Plexiglas cover and front sliding plate, see 6.2.1”Mounting and Dismounting the

Plexiglas Cover and Sliding Plate” (page55).

8. Connect the AC cable to the copper bars from the outside.

66 SCxxxHE-IEN104432 Installation Guide

Page 67

SMA Solar Technology AG External Connections

6.2.7 Connecting the AC Cable

Selection of the medium-voltage transformer.

Th e Su nny Cen tra ls o f th e HE seri es a re i nve rte rs w ith out a lo w-voltage transformer. Special

transformers are required for connecting the Sunny Central to the medium-voltage grid.

Connecting several Sunny Central inverters in parallel at one transformer coil is not

permitted. If requested, SMA Solar Technology offers support in specifying and selecting

a suitable medium-voltage transformer.

The connection must be 3-phase with the following operating voltages:

• U, nominal voltage between the external conductors

– for SC 400HE-11 = 270 V

– for SC 500HE-11 = 270 V

– for SC 630HE-11 = 315 V

• Uo, nominal voltage between external conductor and ground: 1 350 V (depending on the

current operating point of the device)

NOTICE!

High voltages in the grid.

Damage to the Sunny Central through faulty AC connection.

Due to the typology of the grid nominal voltages of up to 1 350 V are present between the

external conductor and ground. Pay attention to the dimensioning of the AC cables to be

connected.

• When choosing the AC cables, take into account the increased demands on the

nominal voltage Vo against grounding.

• Dimension the AC cables with a voltage resistance of at least 1 350 V.

• Lay the AC cables ground- and short-circuit proof.

• Only use aluminum cable clips for the cable inlet of the AC connection.

The connection of one fuse load disconnection unit in the AC cabinet of the inverter to the low-voltage

winding of a medium-voltage transformer is 3-phase.

AC power supply line for IT grid on the copper bars on the outside of the AC cabinet of the Sunny

Central.

Connection of aluminum terminal lug

If aluminum terminal lugs are used for connection to the copper bar, refer to notes in

chapter 6.1”Connecting High-Current Contacts” (page50).

Installation Guide SCxxxHE-IEN104432 67

Page 68

External Connections SMA Solar Technology AG

4

5

1

2

3

6