Page 1

Central Inverter

SUNNY CENTRAL 200 / 250 / 250HE / 350

Installation Guide

SC20_25_35-IEN094521 | 98-4004821 | Version 2.1

EN

Page 2

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Notes on this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Scope of Validity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Appropriate Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2.2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.3 Special Hazards of Photovoltaic Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.4 Working on the Sunny Central . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.5 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Scope of Delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Standard Scope of Delivery

Sunny Central 200 / 250 / 250HE . . . . . . . . . . . . . . . . . . . . 13

3.2 Standard Scope of Delivery Sunny Central 350 . . . . . . . . . . . 15

3.3 Identifying the Sunny Central . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.1 Check for transport damage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Installation site requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Electrical Service Room. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.1 Minimum Passage Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.2 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Transport Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installation Guide SC20_25_35-IEN094521 3

Page 4

Table of Contents SMA Solar Technology AG

4.4.1 Transporting the Sunny Central using a Lifting Cart or Forklift . . . . . . . . . . . 25

4.4.2 Transporting the Sunny Central using a Crane . . . . . . . . . . . . . . . . . . . . . . . 26

4.5 Assembly at the Installation Site . . . . . . . . . . . . . . . . . . . . . . . . 27

4.5.1 Connecting Switch Cabinets to one Another . . . . . . . . . . . . . . . . . . . . . . . . 27

4.5.2 Removing the Transport Locks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 Internal Electrical Connections . . . . . . . . . . . . . . . . . . . . . 30

5.1 Preparatory Work for the Sunny Central 200 / 250 with

the "Protection against Chemically Active Substances" Option 30

5.2 Connecting the Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2.1 Sunny Central 200 / 250 / 250HE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2.2 Sunny Central 350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.2.3 Sunny Central 200 / 250 with the "Protection against chemically active

substances" option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.3 Connecting the PE Connection . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3.1 Sunny Central 200 / 250 / 250HE and 350 . . . . . . . . . . . . . . . . . . . . . . . 40

5.3.2 Sunny Central 200 / 250 with the "Protection against chemically active

substances" option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.4 Connecting the Control Lines on the Transfer Terminal Strip. . . 42

5.5 Connecting the Sunny Central Control to the Power Unit. . . . . 43

5.6 Connecting the Internal Control Lines . . . . . . . . . . . . . . . . . . . . 44

5.7 Connecting Insulation Monitoring (optional) . . . . . . . . . . . . . . 45

5.8 Installing the Internal Temperature Sensor . . . . . . . . . . . . . . . . 46

5.9 Sunny Central in Team Connection (optional) . . . . . . . . . . . . . 47

5.9.1 Connecting the Team Cable to

Sunny Central 200 / 250 / 250HE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.9.2 Connecting Team Cables for Sunny Central 200 / 250 with the

"Protection against Chemically Active Substances" Option . . . . . . . . . . . . . 48

5.9.3 Team Cables for Sunny Central 350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.10 Connecting the EVR Resistor (optional). . . . . . . . . . . . . . . . . . . 50

6 External Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4 SC20_25_35-IEN094521 Installation Guide

Page 5

SMA Solar Technology AG Table of Contents

6.1 Removing the Sliding Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.2 Connecting the AC Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2.1 Connecting the AC Cable to the Sunny Central 200 / 250 . . . . . . . . . . . . 53

6.2.2 Connecting the AC Cable to the Sunny Central 350 . . . . . . . . . . . . . . . . . . 54

6.2.3 Connecting the AC Cable to the Sunny Central 250HE. . . . . . . . . . . . . . . . 55

6.3 Connecting the External PE Connection

(Sunny Central 250HE only) . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.4 Connecting the Internal AC Power Supply . . . . . . . . . . . . . . . . 58

6.4.1 Connecting the External Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.4.2 Connecting the Internal Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.5 Connecting the DC Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.5.1 Sunny Central 200 / 250 / 250HE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.5.2 Sunny Central 350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.6 Connecting the Team Cable (optional). . . . . . . . . . . . . . . . . . . 64

6.7 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.7.1 Analog Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.7.2 External Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.7.3 Overview of the Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.7.4 Handling Notes for Shielded Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.8 Remote Deactivation Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.9 Connecting the Communication . . . . . . . . . . . . . . . . . . . . . . . . 68

6.9.1 NET Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.9.2 RS485 data line for communication with Sunny String- Monitors. . . . . . . . . 69

6.9.3 Serial Interfaces for Team Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.10 Connecting the Emergency Shut-off . . . . . . . . . . . . . . . . . . . . . 71

6.11 Fitting the Sliding Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.1 Checking the Sunny Central Cabling . . . . . . . . . . . . . . . . . . . . 74

7.1.1 Checking the Connection of the Serial Interfaces . . . . . . . . . . . . . . . . . . . . . 75

7.1.2 Checking the Emergency Shut-Off Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . 75

Installation Guide SC20_25_35-IEN094521 5

Page 6

Table of Contents SMA Solar Technology AG

7.1.3 Checking the Thermostat and Hygrostat Settings . . . . . . . . . . . . . . . . . . . . . 76

7.2 Checking the Voltages on the Sunny Central . . . . . . . . . . . . . . 76

7.3 Preparation for Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . 78

7.4 Switching On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.1 Sunny Central 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.2 Sunny Central 250 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.3 Sunny Central 250HE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.4 Sunny Central 350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6 SC20_25_35-IEN094521 Installation Guide

Page 7

SMA Solar Technology AG Notes on this Manual

1 Notes on this Manual

1.1 Scope of Validity

This manual describes the transport, installation and commissioning of SMA central inverters of the

following types:

• Sunny Central 200 (SC 200)

• Sunny Central 250 (SC 250) with the "Protection against chemically active substances" option

• Sunny Central 250 (SC 250)

• Sunny Central 250 (SC 250) with the "Protection against chemically active substances" option

• Sunny Central 250HE (SC 250HE) with the "High Efficiency" option

• Sunny Central 350 (SC 350)

1.2 Target Group

This manual is intended for installers and operators of photovoltaic systems equipped with Sunny

Centrals.

1.3 Additional Information

Keep all manuals for the Sunny Central and for the installed components together with the system

documentation. They must be accessible at all times.

You will find further information on the Sunny Central in the download area of www.SMA.de/en.

Among other things, the download area contains the following items:

• Sunny Central Installation Requirements

• Sunny Central Certificates

• Additional information on other options (e.g. GFDI)

Installation Guide SC20_25_35-IEN094521 7

Page 8

Notes on this Manual SMA Solar Technology AG

1.4 Symbols Used

The following types of safety instructions and general information appear in this document as

described below:

DANGER!

DANGER indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING!

WARNING indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION!

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE!

NOTICE indicates a situation that can result in property damage, if not avoided.

Information

Information provides tips that are valuable for the optimal installation and operation of

your product.

8 SC20_25_35-IEN094521 Installation Guide

Page 9

SMA Solar Technology AG Safety

2 Safety

2.1 Appropriate Usage

Sunny Central is a central inverter. It feeds solar energy converted via photovoltaics from solar

modules into a low- or medium-voltage grid.

Principle of a grid-connected solar power system with a Sunny Central

A Photovoltaic generator B Sunny Central C Low voltage or medium

voltage grid

Sunny Central 200 / 250 / 350

Sunny Central 200 / 250 / 350 contains a low voltage transformer and feeds i nto low volt age grids.

Sunny Central 250HE

Sunny Central 250HE is a high-efficiency central inverter without its own low-voltage transformer. The

Sunny Central 250HE feed into the medium-voltage grid via a shared medium-voltage transformer.

2.2 Safety Instructions

Faults that affect or limit the safety of the device must be rectified immediately. Unauthorized

modifications and spare parts not recommended by SMA Solar Technology may cause fire, material

damage and electrical shock. Unauthorized personnel must not have access to the devices.

Si gns mus t al way s be att ach ed i n pr omi nen t po siti ons . Da mag ed s igns mus t be rep lace d im med iat ely .

2.2.1 Personnel

Only qualified personnel may work on the Sunny Central. “Qualified” means that the personnel must

have been trained for the activity performed.

The personnel must be familiar with the content of the installation guide and user manual in order to

commission and / or operate the Sunny Central. In particular, the safety ins tructions must be followed.

Installation Guide SC20_25_35-IEN094521 9

Page 10

Safety SMA Solar Technology AG

2.2.2 Installation

Observe the installation conditions for the Sunny Central (separate document). The describe what you

must bear in mind when installing the Sunny Central.

An electrical service room is ideal for installation of the Sunny Central, to achieve optimal noise and

fire protection.

The Sunny Central was designed for use in industrial environments in terms of the EMC thresholds

(EMC = Electromagnetic Compatibility).

Note the following points when installing the Sunny Central:

• The inlet and exhaust ventilation systems for the Sunny Central must be separate to any other

ventilation, in order to minimize smoke distribution in case of fire.

• A sufficient escape route must be guaranteed.

• The EMC specifications must be observed (see technical data).

Smoke detector

We recommend that you install smoke detectors in the service room to deactivate the

Sunny Central if smoke develops. Incorporate the smoke detector in the Emergency Stop

circuit.

2.2.3 Special Hazards of Photovoltaic Systems

Photovoltaic systems in particular have some special hazards. They are described below:

• An active power source is connected. Depending on the operating mode, there may be voltage

present from the photovoltaic generator and the Sunny Central. This is especially important to

note when disconnecting particular parts of the system

• As a result of the very high DC voltages, arcing may occur if fuses and plugs are used

incorrectly.

• The short circuit current of the photovoltaic generator is only slightly higher than the maximum

operating current and also depends on irradiation conditions. If a short-circuit occurs in the

system, the available fuses are not guaranteed to switch off.

• A highly complex generator array may be difficult to disconnect if a fault develops (e.g. short

circuit). We recommend additional external DC circuit breakers, which disconnect the inverter,

the main DC lines and the Sunny String-Monitors (DC switches are available as an option).

2.2.4 Working on the Sunny Central

Work may only be performed on the Sunny Central when it is disconnected. Observe the following

safety rules when working on the Sunny Central:

1. Disconnect

2. Ensure that the device cannot be reconnected

3. Ensure that no voltage is present in the system

4. Ground and short-circuit if necessary

10 SC20_25_35-IEN094521 Installation Guide

Page 11

SMA Solar Technology AG Safety

5. If necessary cover or protect against accidental contact with any voltage-carrying components.

The individual safety rules are listed in greater detail below:

Disconnection (in the event of team connection: both team members must be

disconnected)

If the Sunny Central is running with team connection, disconnect both the team leader and the team

device. The following list shows which sources of voltage must be be disconnected:

1. Grid voltage for grid feeding (AC main switch)

2. Gri d vo lta ge fo r th e su ppl y the sys tem 's p owe r su pply (if the system draws its power supply from

external sources)

3. DC voltage from the photovoltaic generator

– Unplug the DC fuses to disconnect the photovoltaic generator. The DC fuses of the two poles

are behind the protective covers. Remove the protective covers to pull the DC fuses. Never

remove both covers simultaneously. After removing the fuses on one pole, attach the covers

again.

– Pull the DC input fuses only when the load is off to prevent dangerous arcing. Use a clip-on

ammeter to measure whether the DC input is off-load. The DC input fuses may only be

re mov ed w ith per son al s afe ty e qui pme nt a nd a fus e gr ip. The re a re t hre e wa ys t o di sco nne ct

the DC voltage from the photovoltaic generator:

– Pull the internal DC input fuse

– Pull the external DC input fuse (if a Sunny Main Box is used)

– Via an external circuit breaker (if available)

4. DC voltage for team connection (if team connection is used)

5. Additional external voltage (e.g. emergency shut-off)

Even deactivated Sunny Central units may contain voltages which are dangerous to the touch. After

deactivating the Sunny Central, wait at least 5 minutes until all capacitors are discharged before

starting to work on the Sunny Central.

When the DC fuses are inserted in the Sunny Central (on both team members if team connection is

used), there is a reverse voltage on the DC main and sub-distributors.

Disconnecting system parts without danger

We recommend additional DC circuit breakers for the Sunny Central, the main DC lines

and Sunny String-Monitors. DC circuit breakers allow system parts to be disconnected

without danger.

Ensure that the device cannot be reconnected

Ensure that the Sunny Central cannot be reactivated.

Ensure that no voltage is present in the system

Ensure that all internal and external sources of voltage are disconnected.

Installation Guide SC20_25_35-IEN094521 11

Page 12

Safety SMA Solar Technology AG

Ground and short-circuit the unit if necessary (not on the DC side)

Ground and short-circuit the AC side. The DC side does not have to be grounded.

If necessary, cover or shield any adjacent live components

Cover or shield all adjacent live parts to prevent accidental contact.

2.2.5 General Information

Overvoltage and lightning protection

The devices have internal overvoltage protection on the AC and DC sides. However, the desired

protection level can only be achieved if a lightning protection area concept exists for the installation

building as per DIN VDE 0185-4, i.e. lightning conductors or combined surge and lightning

conductors (not included in delivery) are available at, among other locations, the building’s entrance

(transfer lightning protection area LPZ 1).

The combined overvoltage and lightning protection for the analog inputs can be ordered as an

option.

Emergency Shut-off

In photovoltaic systems with more than one Sunny Central, or additional external emergency shut-off

switches, the emergency-shut off circuits must be connected to one another. Only one Sunny Central

may supply the emergency shut-off circuit with voltage. For further information on connecting external

emergency shut-off switches, see section 6.10”Connecting the Emergency Shut-off” (page71).

Ear Protection

The device fans and the power unit create elevated levels of operating noise. In addition to this, a

fault in the device can lead to very high sound levels. While in the service room, we recommend that

you wear ear protection.

Burns

Immediately after disconnecting the Sunny Central, depending on the operating conditions, certain

components can be very hot (e.g. fuses, transformer core, sine wave filter, heatsinks etc.).

When working on hot components, we recommend that you wear gloves.

Torque

The circuit diagram contains a torque list. It provides details on all relevant torques. Observe these

torques when tightening the individual threaded connections. You can also ask Sunny Central Service

what the respective torques are.

Fuse Grip

A fuse grip is supplied with the Sunny Central for removing and inserting the fuses when the power

supply is disconnected. Additional safety equipment is required if fuses are not removed or inserted

when the power supply is disconnected.

12 SC20_25_35-IEN094521 Installation Guide

Page 13

SMA Solar Technology AG Scope of Delivery

3 Scope of Delivery

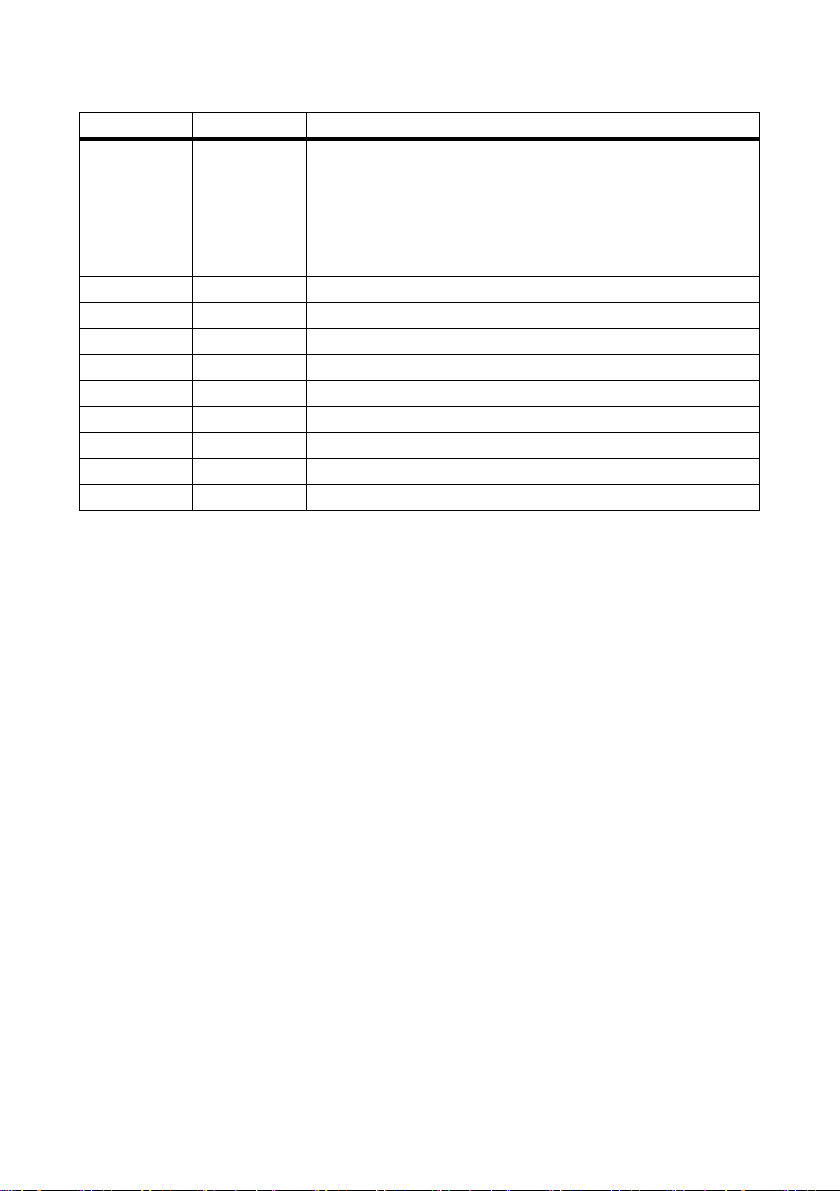

3.1 Standard Scope of Delivery Sunny Central 200 / 250 / 250HE

Position Number Name

A 1 DC- / inverter cabinet

B 1 AC cabinet

C1Document set

• Installation guide

• User manual

• Variant circuit diagram

• Commissioning report

D 1 Documentation of the optional insulation monitoring (Bender)

E1Fuse grip

F 2 Terminal profile 3 m

Installation Guide SC20_25_35-IEN094521 13

Page 14

Scope of Delivery SMA Solar Technology AG

Position Number Name

G 1 Switch cabinet installation set

• Vertical baying clamp

• Baying bracket TS corner

• Horizontal baying clamp

• Baying quick connector

H1 18 OBO cable clamp 16 – 22 mm

H2 1 OBO cable clamp 58 – 64 mm

H3 8 OBO cable clamp 28 – 34 mm

H4 16 OBO cable clamp 22 – 28 mm

I1 18 OBO clamping saddle

I2 1 OBO clamping saddle

I3 8 OBO clamping saddle

I4 16 OBO clamping saddle

K 10 Shield clamp 0-8mm

14 SC20_25_35-IEN094521 Installation Guide

Page 15

SMA Solar Technology AG Scope of Delivery

3.2 Standard Scope of Delivery Sunny Central 350

Position Number Name

A 1 DC- / inverter cabinet

B 1 AC cabinet

C1Document set

• Installation guide

• User manual

• Variant circuit diagram

• Commissioning report

D 1 Documentation of the optional insulation monitoring (Bender)

E1Fuse grip

F 2 Terminal profile 3 m

G 1 Switch cabinet installation set

• Vertical baying clamp

• Angle bracket TS corner

• Horizontal baying clamp

• Baying quick connector

H1 6 OBO cable clamp 16 – 22 mm

H2 12 OBO cable clamp 28 – 34 mm

H3 24 OBO cable clamp 22 – 28 mm

I1 6 OBO clamping saddle

Installation Guide SC20_25_35-IEN094521 15

Page 16

Scope of Delivery SMA Solar Technology AG

Position Number Name

I2 12 OBO clamping saddle

I3 24 OBO clamping saddle

K1 5 Shield clamp 0-8mm

K2 4 Shield clamp 19 mm

3.3 Identifying the Sunny Central

You can identify the Sunny Central using the type label. The type label is located on the inside of the

door of the Sunny Central.

The serial number (A) is printed on the type label and on the front side of the Sunny Central.

3.3.1 Check for transport damage

Ch eck the dev ice pac kag ing and t he S unn y Ce ntr al f or a ny po ssi ble damage and compare the scope

of delivery with the delivery documentation. In the case of damage to the device or unclear delivery

contents, immediately contact SMA Solar Technology.

16 SC20_25_35-IEN094521 Installation Guide

Page 17

SMA Solar Technology AG Scope of Delivery

3.3.2 Storage

The transport packaging provides sufficient protection against moisture and damage when

transporting the Sunny Central.

Notice!

Penetrating moisture can damage the Sunny Central.

• The storage condition requirements are the same as the conditions for operating the

Sunny Central.

• Storing the Sunny Mini Central in packaging.

• Avoid extended storage.

• If stored for an extended period, remove moisture and soiling.

• Before commissioning, contact Sunny Central Service if the storage period is longer

than one year.

Installation Guide SC20_25_35-IEN094521 17

Page 18

Installation SMA Solar Technology AG

4 Installation

This section describes the transport options for the Sunny Central and the requirements of the

installation site.

Different transport and installation conditions apply to each Sunny Central. They are available in the

SMA Solar Technology download area.

Identifying cabinet units

The Sunny Central consists of 2 switch cabinets. If multiple Sunny Central units are

delivered, only install switch cabinets with the same serial number together.

4.1 Installation site requirements

Floor

The floor must guarantee solid and safe positioning of the Sunny Central. The floor must provide the

load-carrying capacity necessary to cope with the weight of the Sunny Central. Do not install the

Sunny Central on a slope. Level any unevenness in the floor.

Wall Clearances

When installing the Sunny Central, comply with the corresponding wall clearances for minimum

passages, escape routes and ventilation. The "Sunny Central Installation Requirements" (separate

document) contain the respective minimum clearances.

Inverter Protection Rating / EMC / Sound Levels

The Sunny Central is suitable for installation in dry areas with low dust levels. The Sunny Central was

designed for use in industrial environments in terms of the EMC thresholds (EMC = Electromagnetic

Compatibility) and sound levels.

4.2 Electrical Service Room

When installing and connecting the Sunny Central central inverter, observe the requirements for

electrical operating rooms, installing high-voltage current plants up to 1000 V, and the requirements

for passage widths and escape routes.

4.2.1 Minimum Passage Width

Note the following points for the escape routes in electrical service rooms:

• When the switch cabinet door is opened as far as possible, a minimum passage of 500 mm

(escape route) must remain.

• I n or der to c omp ly w ith the m ini mum pas sag e wi dth , if two swit ch cabinets are installed opposite

one another (e.g. in a station building), only one of the switch cabinets may be opened.

18 SC20_25_35-IEN094521 Installation Guide

Page 19

SMA Solar Technology AG Installation

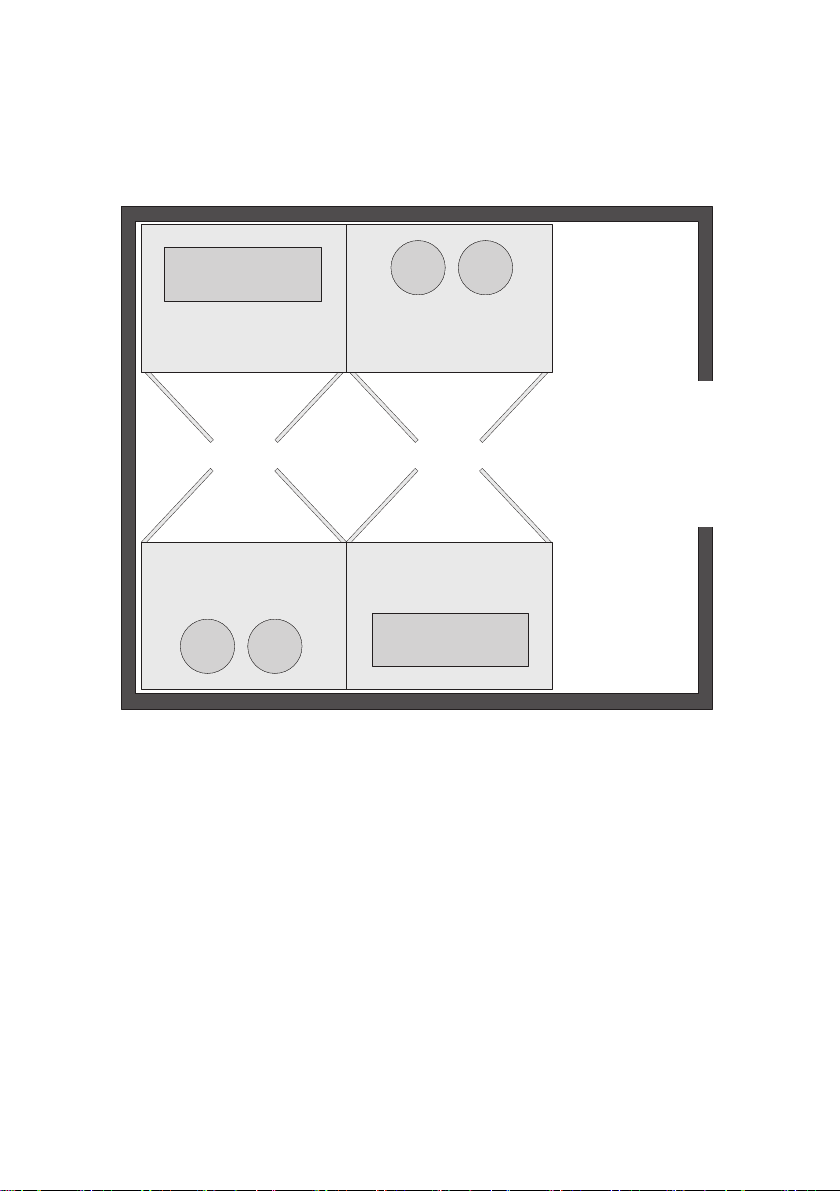

4.2.2 Design

The following illustration is a schematic of the layout of an electrical service room with a

Sunny Central 250HE.

4.3 Ventilation

An incoming air supply is required to cool the Sunny Central. In order to guarantee safe operation

and the maximum of feed-in power, the permitted ambient temperature must be observed.

The required air is drawn through the switch cabinet doors and is blown out via the top or the rear

wall of the cabinet unit depending on the Sunny Central model. This means that the devices can be

installed right next to one another. See the "Sunny Central Installation Requirements" (separate

document) for the air requirements as well as appropriate wall clearances. Filters are installed at the

air inlet openings. They clean the inlet air.

If the volu me of air at the installat ion sit e of the Sun ny Cent ral is insufficient, then on-site measures must

be taken to provide greater quantities of air (ventilation grilles, blowers, fans, etc.).

The inlet air must satisfy the requirements of classification 3S2. If a Sunny Central is used in a

chemically-active environment, the inlet air must satisfy the requirements of classification 3C1.

The central inverter can be operated in relative humidity from 15 ... 95 %.

Installation Guide SC20_25_35-IEN094521 19

Page 20

Installation SMA Solar Technology AG

The heat generated by the Sunny Central (exhaust air) must be dissipated to comply with the

maximum permitted ambient temperature. We recommend routing the exhau st air ( air duc t) out o f the

electrical service room.

Overview of the Air Inlets and Outlets

The positions of the air outlets differ depending on the Sunny Central model selected. During

installation, ensure that the air inlets and outlets are not covered.

Air Routing for the "EVR" Option

If the "EVR" option was selected, the exhaust air cannot be routed through the top of the

Sunny Central.

NOTICE!

Overheating impairs the operation of the Sunny Central.

Ensure that the Sunny Central is sufficiently cooled:

• Provide the required air volume for the Sunny Central.

• Clean the ventilation openings (filter pads) and the exhaust air bars at regular

intervals. See the Sunny Central maintenance manual for the exact cleaning intervals.

• Route the exhaust air separately from the individual cabinet units (air outlets of the

power units and the switch cabinet) to prevent thermal short circuits.

If routing the exhaust air through the rear wall of the Sunny Central, the exhaust air can be routed

directly out of the building via a weatherproof grille installed on-site in the building wall. The Sunny

Central can then be set up with the rear of the cabinet directly against the opening in the building

wall. Remove the finger guard from the fan openings and secure a seal or frame-like air hood to the

building wall.

DANGER!

Loss of limbs!

If the exhaust air is routed directly out of the building, the rotor blades of the fan are not

protected against contact.

• When cleaning the ventilation duct, switch off the Sunny Central.

• Do not start to clean the ventilation duct until the rotor blades of the fan have come

to a stop.

20 SC20_25_35-IEN094521 Installation Guide

Page 21

SMA Solar Technology AG Installation

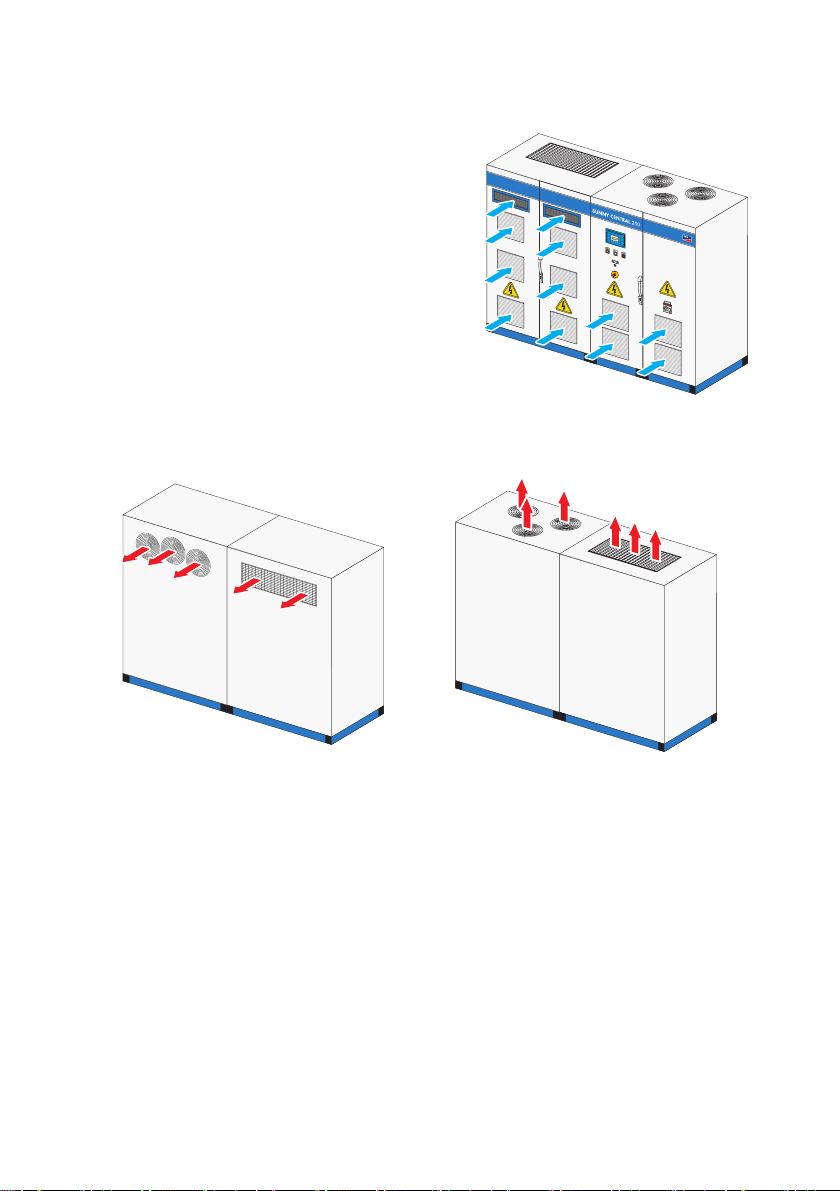

The following illustrations show examples of where the individual air inlets and outlets are located.

Sunny Central 200 air inlets

Sunny Central 200 air outlets

The position of the air outlets of the Sunny Central 200 depends on the variant. Depending on the

variant, the air outlets are on the rear or in the top of the Sunny Central.

Air outlets on the rear Air outlets in the top

Installation Guide SC20_25_35-IEN094521 21

Page 22

Installation SMA Solar Technology AG

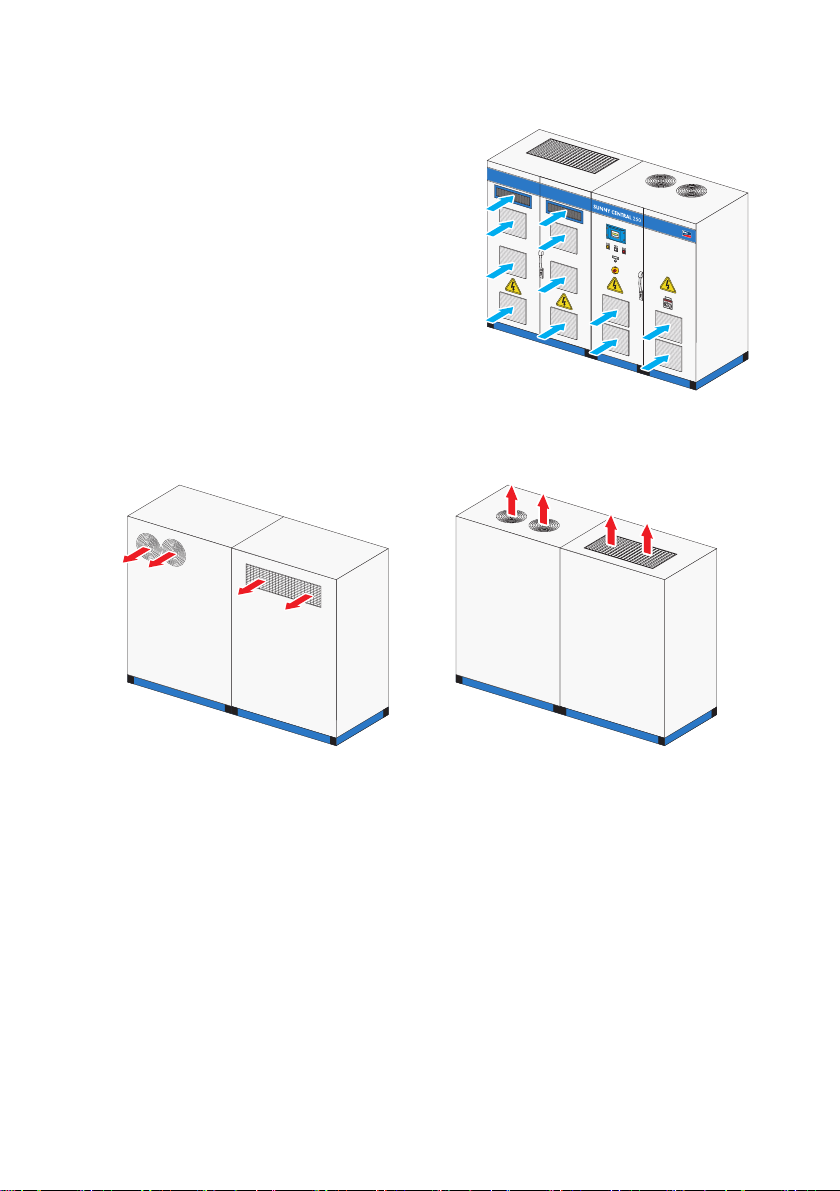

Sunny Central 250 air inlets

Sunny Central 250 air outlets

The position of the air outlets of the Sunny Central 250 depends on the variant. Depending on the

variant, the air outlets are on the rear or in the top of the Sunny Central.

Air outlets on the rear Air outlets in the top

22 SC20_25_35-IEN094521 Installation Guide

Page 23

SMA Solar Technology AG Installation

Sunny Central 250HE air inlets

Sunny Central 250HE air outlets

The position of the air outlets of the Sunny Central 250HE depends on the variant. Depending on the

variant, the air outlets are on the rear or in the top of the Sunny Central.

Air outlets on the rear Air outlets in the top

Installation Guide SC20_25_35-IEN094521 23

Page 24

Installation SMA Solar Technology AG

Sunny Central 350 air inlets and outlets

Supply air Exhaust air

4.4 Transport Options

Sunny Centrals can be transported with a forklift, lifting cart or a crane fork. They consist of two switch

cabinet units, the DC- / inverter cabinet and the AC cabinet.

WARNING!

Danger of crushing if the switch cabinet unit tips over!

The Sunny Central can tip over during

transport if the center of gravity is not in the

middle.

• Only transport switch cabinet units

upright.

• The center of gravity is indicated on the

packaging and on the Sunny Central.

24 SC20_25_35-IEN094521 Installation Guide

Page 25

SMA Solar Technology AG Installation

4.4.1 Transporting the Sunny Central using a Lifting Cart or Forklift

1. Use a TX30 torque wrench to remove the front and

rear base covers.

2. Pick up the switch cabinet unit with the lifting cart or

forklift.

3. Transport the switch cabinet unit to the installation

site.

4. Reattach the front and rear base covers.

Installation Guide SC20_25_35-IEN094521 25

Page 26

Installation SMA Solar Technology AG

4.4.2 Transporting the Sunny Central using a Crane

1. Use a TX30 torque wrench to remove the front and

rear base covers.

2. Pick up the switch cabinet unit with the crane fork.

3. Transport the switch cabinet unit to the installation

site.

4. Reattach the front and rear base covers.

26 SC20_25_35-IEN094521 Installation Guide

Page 27

SMA Solar Technology AG Installation

4.5 Assembly at the Installation Site

The Sunny Centrals have a high dead weight. Additional anchoring in the floor or in the wall is

unnecessary.

4.5.1 Connecting Switch Cabinets to one Another

Enclosed documentation of the switch cabinet manufacturer

Follow the instructions in the enclosed documentation of the switch cabinet manufacturer to

connect the two switch cabinets to one another. The assembly procedure is described

there.

If you are using a Sunny Central 200 / 250 with the "Protection ag ain st c hem ica lly act ive sub sta nce s"

option, the switch cabinets must be connected to one another as described below.

1. Attach the included sealing material all around the cabinet frame of the AC cabinet.

A Seal material

2. Install the switch units at the installation site.

Installation Guide SC20_25_35-IEN094521 27

Page 28

Installation SMA Solar Technology AG

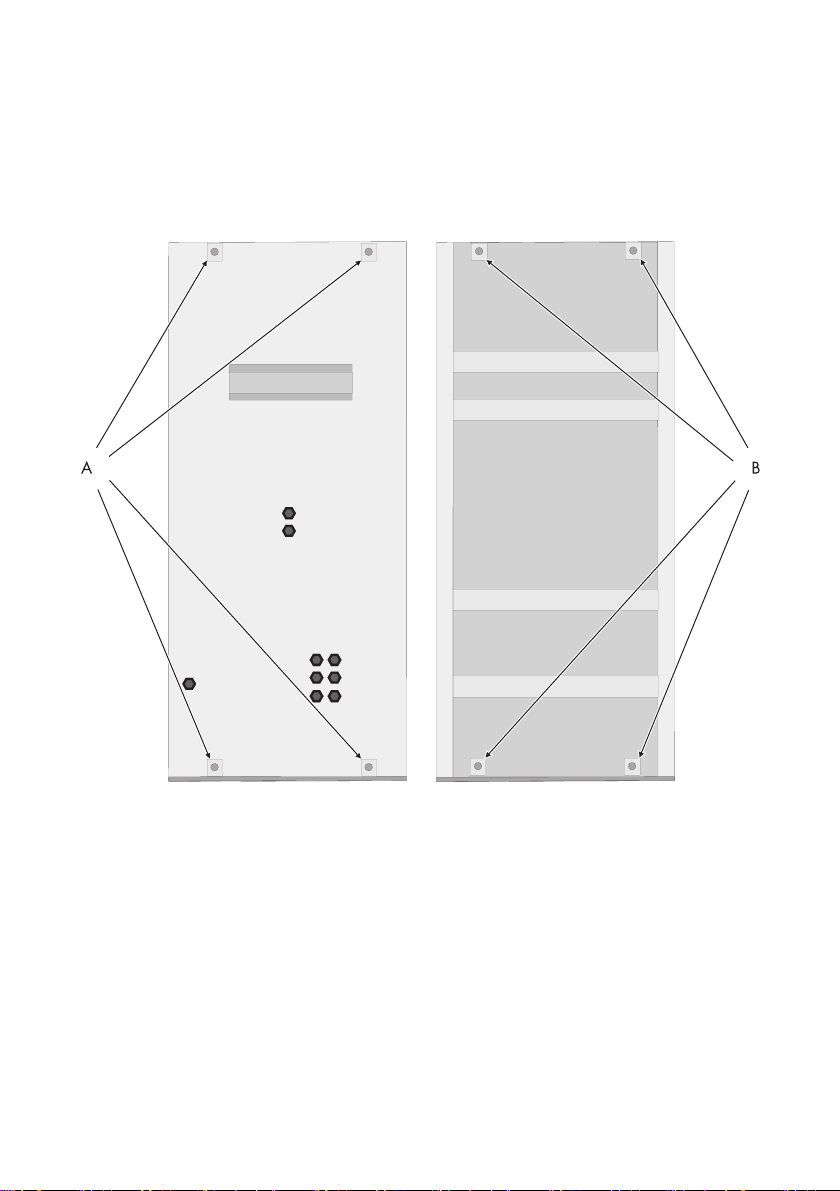

3. Connect the switch cabinet units at positions A and B with the provided bolts, washers, locking

washers and brackets. Follow the instructions in the enclosed Rittal documentation. The diagram

below shows Sunny Central 250 with the "Protection against chemically active substances"

option.

☑ The switch cabinet units are connected to each other.

28 SC20_25_35-IEN094521 Installation Guide

Page 29

SMA Solar Technology AG Installation

4.5.2 Removing the Transport Locks

In some Sunny Centrals, the transformer is fitted with transport locks. They connect the transformer to

the switch cabinet. The following table shows the Sunny Centrals are fitted with a transport lock for

the transformers.

Sunny Central Transformer transport lock

Sunny Central 200 yes

Sunny Central 250 yes

Sunny Central 250HE no

Sunny Central 350 yes

1. Remove the transport lock bolts (A, B and C).

2. Remove the transport locks.

☑ The transport locks have been removed.

Installation Guide SC20_25_35-IEN094521 29

Page 30

Internal Electrical Connections SMA Solar Technology AG

5 Internal Electrical Connections

Circuit diagram and equipment identifier

The exact position of the individual connection points can be determined with the help of

the equipment identifier and the provided circuit diagram. In the front part of the circuit

diagram, you will find an overview with data on the cable number and the respective

connection point.

Electrical connections

For all electrical connections it is imperative that you comply with the supplied circuit

diagram.

The following steps must be taken to make the internal electrical connection:

• Connect the power cables

• Connect the PE connection

• Connect the control cables to the power unit

• Connect the Sunny Central Control to the power unit

• Connect the internal control cables

• Connect the insulation monitoring (optional)

• Fit the internal temperature sensor

• Connect the team cable (optional)

• Connect the EVR resistor (optional)

5.1 Preparatory Work for the Sunny Central 200 / 250 with the "Protection against Chemically Active Substances" Option

The Sunny Central 200 / 250 units with the "Protection against chemically active substances" option

have an encapsulated design. The two switch cabinet units are separated by a side wall. There are

two sliding plates with a clamping felt in the side wall. The data and control lines are routed through

the sliding plates which connect the DC cabinet to the AC cabinet. The procedure is described below.

The following figures show the Sunny Central 250 with the "Protection against chemically active

substances" option as an example.

30 SC20_25_35-IEN094521 Installation Guide

Page 31

SMA Solar Technology AG Internal Electrical Connections

1. Open the knurled nuts on the sliding plates (A).

2. Move the sliding plates up or down.

3. Route the following wires through the clamping felt into the AC cabinet.

–Control lines

(see section 5.4”Connecting the Control Lines on the Transfer Terminal Strip” (page42)).

–Data lines

(see section 5.5”Connecting the Sunny Central Control to the Power Unit” (page43)).

– Internal control lines X8 and X9

(see section 5.6”Connecting the Internal Control Lines” (page44)).

– Insulation monitoring cable (optional)

(see section 5.7”Connecting Insulation Monitoring (optional)” (page45)).

– Temperature sensor

(see section 5.8”Installing the Internal Temperature Sensor” (page46)).

☑ The individual lines are routed through the clamping felt into the AC cabinet. They are

required in the following steps.

Notice!

Air permeable cable ducts cause corrosion in the Sunny Central.

• Press the sliding plates together with sufficient force.

• Tighten the knurled nuts on the sliding plates.

4. Connect the control cables to the transfer terminal strip.

☑ The control cables are connected.

Installation Guide SC20_25_35-IEN094521 31

Page 32

Internal Electrical Connections SMA Solar Technology AG

5.2 Connecting the Power Cables

5.2.1 Sunny Central 200 / 250 / 250HE

The power cables connect the power units in the DC / inverter cabinet with the sine wave filter in the

AC cabinet.

The power cables (U1, V1, W1) are already connected to the sine wave filter and cut to length, so

that the allocations on the power units are clear.

The following diagram shows the connection points of the power cables on the power unit of the

Sunny Central 250.

A Power unit connection lugs

Procedure for power cabling:

1. Unscrew the protective cover of the power unit.

☑ The protective cover has been removed. The connections on the power unit are now

accessible.

2. Route the cables through the open side wall above the cabinet base plates into the DC- cabinet.

3. Use cable ties to bind the cables in the base of the switch cabinet.

4. Connect the left power unit first. Hold the bolts when tightening the nuts.

32 SC20_25_35-IEN094521 Installation Guide

Page 33

SMA Solar Technology AG Internal Electrical Connections

DANGER!

Danger of fire.

Incorrect connection of the power units can cause fires.

• Observe the sequence when connecting the power units.

ABolt

BLocking washer

CWasher

DPower cable lugs

E Connection guide

FWasher

GLocking washer

HNut

5. Bind the power cable with cable ties. If you do not do so, pointed or sharp metal edges could

damage the insulation of the cable.

☑ Power cabling is complete.

6. Reattach the protective cover to the power unit.

☑ The protective cover has been fitted.

Installation Guide SC20_25_35-IEN094521 33

Page 34

Internal Electrical Connections SMA Solar Technology AG

5.2.2 Sunny Central 350

The power cables connect the sine wave filter in the DC- / inverter cabinet with the transformer in the

AC cabinet.

The power cables (U1, V1, W1) are already connected to the sine wave filter and cut to length, so

that the allocations on the transformer are clear.

The following diagram shows the connection points of the power cables on the transformer of the

Sunny Central 350.

A Sine wave filter connection lugs

Procedure for power cabling:

1. Route the cables through the open side wall above the cabinet base plates into the DC- cabinet.

2. Use cable ties to bind the cables in the base of the switch cabinet.

3. Connect the power cables. Hold the bolts when tightening the nuts.

DANGER!

Danger of fire.

Incorrect connection of the power units can cause fires.

• Observe the sequence when connecting the power units.

34 SC20_25_35-IEN094521 Installation Guide

Page 35

SMA Solar Technology AG Internal Electrical Connections

ABolt

BWasher

C Measurement line cable lug

DPower cable lug

E Connection guide

FWasher

GLocking washer

HNut

4. Bind the power cable with cable ties. If you do not do so, pointed or sharp metal edges could

damage the insulation of the cable.

☑ Power cabling is complete.

5. Reattach the protective cover to the power unit.

☑ The protective cover has been fitted.

Installation Guide SC20_25_35-IEN094521 35

Page 36

Internal Electrical Connections SMA Solar Technology AG

5.2.3 Sunny Central 200 / 250 with the "Protection against chemically active substances" option

The power cables connect the power units in the DC / inverter cabinet with the sine wave filters in the

AC cabinet. For the Sunny Central 200, 3 power cables must be connected and 6 are required for

the Sunny Central 250.

The power cables (U1, V1, W1) are already connected to the sine wave filter and cut to length, so

that the allocations on the power units are clear.

The following diagram shows the connection points of the power cables on the power unit of the

Sunny Central 250.

A Power unit connection lugs

Procedure for power cabling:

1. Unscrew the protective cover of the power unit.

☑ The protective cover has been removed. The connections on the power unit are now

accessible.

36 SC20_25_35-IEN094521 Installation Guide

Page 37

SMA Solar Technology AG Internal Electrical Connections

2. Route cables 2W1, 2V1 and 2U1 through the cable gland (B) into the DC cabinet.

3. Connect cables 2W1, 2V1 and 2U1 to the left power unit.

Installation Guide SC20_25_35-IEN094521 37

Page 38

Internal Electrical Connections SMA Solar Technology AG

DANGER!

Danger of fire.

Incorrect connection of the power units can cause fires.

• Observe the sequence when connecting the power units.

ABolt

BLocking washer

CWasher

D Connection guide

EPower cable lug

FWasher

GLocking washer

HNut

4. Route cables 2W2, 2V2 and 2U2 through the cable gland (C) into the DC cabinet.

5. Connect cables 2W2, 2V2 and 2U2 to the right power unit.

38 SC20_25_35-IEN094521 Installation Guide

Page 39

SMA Solar Technology AG Internal Electrical Connections

DANGER!

Danger of fire.

Incorrect connection of the power units can cause fires.

• Observe the sequence when connecting the power units.

ABolt

BLocking washer

CWasher

D Connection guide

EPower cable lug

FWasher

GLocking washer

HNut

6. Tighten cable glands B and C (see figure page 37).

Notice!

Air permeable cable glands cause corrosion in the Sunny Central.

• Tighten the cable gland sufficiently.

7. Bind the power cable with cable ties. If you do not do so, pointed or sharp metal edges could

damage the insulation of the cable.

☑ Power cabling is complete.

8. Reattach the protective cover to the power unit.

☑ The protective cover has been fitted.

Installation Guide SC20_25_35-IEN094521 39

Page 40

Internal Electrical Connections SMA Solar Technology AG

5.3 Connecting the PE Connection

5.3.1 Sunny Central 200 / 250 / 250HE and 350

The PE rails of the two switch cabinets must be connected to one another. They are in the lower area

of the side walls. The required cables are included. The following diagram shows the connection point

of the PE connection of the Sunny Central 250 as an example.

Position of the PE rail

The exact position of the PE rail differs depending on the model. The exact position of the

PE rail can be determined with the help of the equipment identifier and the circuit diagram

enclosed.

1. Connect the PE cables to the marked PE rails.

2. Ensure that the PE connection is correct and secure.

☑ The PE cable is connected.

40 SC20_25_35-IEN094521 Installation Guide

Page 41

SMA Solar Technology AG Internal Electrical Connections

5.3.2 Sunny Central 200 / 250 with the "Protection against chemically active substances" option

The PE rails for each cabinet are located in the lower region of the sides. The required cables are

included. The following diagram shows the connection point of the PE connection of the Sunny

Central 250.

Position of the PE rail

The exact position of the PE rail differs depending on the model. The exact position of the

PE rail can be determined with the help of the equipment identifier and the circuit diagram

enclosed.

1. Route the PE cable through the cable gland (A).

Installation Guide SC20_25_35-IEN094521 41

Page 42

Internal Electrical Connections SMA Solar Technology AG

2. Connect the PE cable to the marked grounding bar.

3. Tighten the cable gland (A).

Notice!

Air permeable cable glands cause corrosion in the Sunny Central.

• Tighten the cable gland sufficiently.

4. Ensure that the PE connection is correct and secure.

☑ The PE cable is connected.

5.4 Connecting the Control Lines on the Transfer Terminal Strip

The control lines are located in the transfer cable duct of the inverter cabinet The control lines are

marked with target designations. The following diagram shows the exact position of the transfer

terminal strip of the Sunny Central 250.

A Transfer terminal strip

Position of the transfer terminal strip

The exact position of the transfer terminal strip differs depending on the model. The exact

position of the individual terminals can be determined with the help of the equipment

identifier and the circuit diagram enclosed.

Allocation of the control lines

The terminal designation is used for unique allocation of the control lines

1. Connect the control lines on the transfer terminal strip.

☑ The control lines are connected.

42 SC20_25_35-IEN094521 Installation Guide

Page 43

SMA Solar Technology AG Internal Electrical Connections

5.5 Connecting the Sunny Central Control to the Power Unit

The data lines connect the Sunny Central Control to the controller board at the power unit. The data

line is fitted with a 4-pin plug-in contact.

The following diagram shows the plug-in contact on the controller board of the Sunny Central 250 as

an example.

A Controller board plug-in contact

Laying data lines

In order to guarantee interference-free signal transfer on the data line, it may not be laid

parallel to the power cables or in the cable duct. Instead, lay the data line freely in the

switch cabinet.

1. Connect the data line of the Sunny Central Control to the controller board at the power unit.

☑ The data line is connected.

Installation Guide SC20_25_35-IEN094521 43

Page 44

Internal Electrical Connections SMA Solar Technology AG

5.6 Connecting the Internal Control Lines

The internal control lines X8 and X9 are located in the transfer cable duct of the inverter cabinet. They

connect the AC cabinet to the controller board. The controller board is located on the power unit.

The following diagram shows the plug-in contact on the controller board of the Sunny Central 250 as

an example.

A Plug-in contact for internal control lines X8 and X9

Position of the connection terminals of the control lines

The exact position of the plug-in contact differs depending on the mod el. The exa ct po sit ion

of the conn ection termina ls can b e dete rmined with the he lp of the equipment identifier and

the circuit diagram enclosed.

1. Connect control lines X8 and X9 to the controller board.

☑ The control lines are connected.

44 SC20_25_35-IEN094521 Installation Guide

Page 45

SMA Solar Technology AG Internal Electrical Connections

5.7 Connecting Insulation Monitoring (optional)

The 2-core connection line of the insulation monitoring system is located in the transfer duct. It connects

the DC cabinet to the insulation monitoring system. The insulation monitoring system is located in the

DC cabinet.

The following diagram shows the position of the insulation monitoring system in the Sunny

Central 250 as an example.

Position of the insulation monitoring system

The exact position of the insulation monitoring system differs depending on the model. The

exact position of the insulation monitoring system can be determined with the help of the

equipment identifier and the circuit diagram enclosed.

1. Connect the insulation monitoring system.

☑ The insulation monitoring system is connected.

Installation Guide SC20_25_35-IEN094521 45

Page 46

Internal Electrical Connections SMA Solar Technology AG

5.8 Installing the Internal Temperature Sensor

Temperature sensor in the Sunny Central 350

The temperature sensor in the Sunny Central 350 is pre-installed ex works. Continue with

section 5.9”Sunny Central in Team Connection (optional)” (page47).

The internal temperature sensor records the temperature in the switch cabinet. It is located in the

transfer cable duct. The internal temperature sensor is fitted to the inside of the switch cabinet. A

corresponding top hat rail is pre-mounted at the marked installation location.

The following diagram shows the position of the internal temperature sensor in the Sunny Central 250

as an example.

Position of the internal temperature sensor

The exact position of the internal temperature sensor differs depending on the model. The

exact position of the internal temperature sensor can be determined with the help of the

equipment identifier and the circuit diagram enclosed.

1. Click the temperature sensors into place in the top hat rail.

☑ The temperature sensor is installed.

46 SC20_25_35-IEN094521 Installation Guide

Page 47

SMA Solar Technology AG Internal Electrical Connections

5.9 Sunny Central in Team Connection (optional)

2 Sunny Centrals can also be connected to one another as an option. If team connection is used, the

internal team cabling of both switch cabinet units must be connected.

5.9.1 Connecting the Team Cable to Sunny Central 200 / 250 / 250HE

Team cabling must be implemented for the team leader and the team device.

Te am c abl ing is p re- ins tal led in t he A C cabine t. T he t eam cab les a re i n th e AC cab ine t. T he c onn ect ion

terminals for team cabling are in the DC cabinet.

The following diagram shows the position of the connection terminals for team cabling in the

Sunny Central 250.

A Team cable connection point

Position of the connection terminals for team cabling

The exact position of the connection terminals for team cabling can be determined with the

help of the equipment identifier and the circuit diagram enclosed.

1. Connect the team cable (L+) to L+ on the busbar.

2. Connect the team cable (L-) to L- on the busbar.

☑ The team cables are connected.

Installation Guide SC20_25_35-IEN094521 47

Page 48

Internal Electrical Connections SMA Solar Technology AG

5.9.2 Connecting Team Cables for Sunny Central 200 / 250 with the "Protection against Chemically Active Substances" Option

Team cabling must be implemented for the team leader and the team device.

Te am c abl ing is p re- ins tal led in t he A C cabine t. T he t eam cab les a re i n th e AC cab ine t. T he c onn ect ion

terminals for team cabling are in the DC cabinet.

The following diagram shows the position of the connection terminals for team cabling in the

Sunny Central 250.

A Team cable connection point

Position of the connection terminals for team cabling

The exact position of the connection terminals for team cabling can be determined with the

help of the equipment identifier and the circuit diagram enclosed.

48 SC20_25_35-IEN094521 Installation Guide

Page 49

SMA Solar Technology AG Internal Electrical Connections

1. Route the team cables through the cable glands

(A).

2. Tighten the cable gland (A).

Notice!

Air permeable cable ducts cause corrosion in the Sunny Central.

• Tighten the cable gland sufficiently.

3. Connect the team cable (L+) to L+ on the busbar.

4. Connect the team cable (L-) to L- on the busbar.

☑ The team cables are connected.

5.9.3 Team Cables for Sunny Central 350

Internal team cabling in the Sunny Central 350 is already completely connected when it leaves the

plant.

Installation Guide SC20_25_35-IEN094521 49

Page 50

Internal Electrical Connections SMA Solar Technology AG

5.10 Connecting the EVR Resistor (optional)

The EVR resistor increases the maximum permissible DC voltage which may be present at the device's

connection when idle to 1000 V DC. The EVR resistor is mounted on the top of the Sunny Central If

the EVR resistor is used, the exhaust air cannot be routed through the top of the Sunny Central. The

exhaust air is routed through the rear wall.

The following diagram shows the position of the EVR

resistor (A) using the Sunny Central 250 as an example.

Position of the connection terminals of the EVR resistor.

The exact position of the EVR resistor be determined with the help of the equipment

identifier and the circuit diagram enclosed.

1. Slide the EVR resistor between the rails onto the top of the Sunny Central.

2. Remove the 9 bolts on the protective grille of the EVR resistor.

3. Remove the protective grille forwards.

4. Connect the PE cable in the EVR resistor to the bolt on the left side.

5. Secure the EVR resistor to the rails using the two bolts on the left and right in the EVR resistor.

6. Connect the power cables (included) as shown in the circuit diagram provided.

7. Secure the protective grille to the EVR resistor using the 9 bolts.

☑ The EVR resistor is connected.

50 SC20_25_35-IEN094521 Installation Guide

Page 51

SMA Solar Technology AG External Connections

6 External Connections

WARNING!

Risk of death due electric shock when live parts of the low-voltage grid are

touched!

• Only work on the Sunny Central when it is switched off and voltage-free.

• All applicable safety requirements regarding the low-voltage grid must be observed.

WARNING!

Danger of fire in the event of direct contact of copper and aluminum.

If copper and aluminum come into contact, the contact surface between the cable lug and

the connection guide can oxidize. This causes the contact point to heat up. In turn, this can

cause a fire.

• Use a cupal washer or a copper-aluminum cable lug.

Connection Sizing

The installation conditions (separate document) contain the maximum connection cross

sections of the lines and cable lugs. You can download the installation conditions in the

Download area of www.SMA.de/en.

Electrical connections

For all electrical connections, it is imperative that you use the supplied circuit diagram.

The following steps, explained in the next sections, are required for the external electrical connection.

•Connect the AC grid

• Connect the PE connection to the equipotential bonding (Sunny Central 250HE only)

• Connect the internal AC power supply

•Connect the DC cable

• Connect the team cable (optional)

• Connect the analog inputs

• Connect the communication

• Connect the emergency shut-off

• Connect the overvoltage protection

Installation Guide SC20_25_35-IEN094521 51

Page 52

External Connections SMA Solar Technology AG

6.1 Removing the Sliding Plates

The external cables are fed in via the base of the Sunny Central. To do so, sliding plates in the base

must be removed. The following diagram shows the position of the sliding plates in the DC- / inverter

cabinet and in the AC cabinet.

1. Remove the sliding plates (A) in the front area of the DC- / inverter cabinet and the AC cabinet.

2. Keep the sliding plates in a safe place. After completing the installation work, the sliding plates

must be reinstalled. (See section 6.11”Fitting the Sliding Plates” (page72)).

NOTICE!

Soiling in the Sunny Central adversely affects operation.

• I f no wor k is perf orm ed o n th e Su nny Cen tra l (e .g. at ni ght ), re-insert the sliding plates

to protect the Sunny Central against soiling.

52 SC20_25_35-IEN094521 Installation Guide

Page 53

SMA Solar Technology AG External Connections

6.2 Connecting the AC Grid

6.2.1 Connecting the AC Cable to the Sunny Central 200 / 250

Grid Structure

Sunny Centrals are configured for a TN-C grid connection. They can also be connected to

TN-S or TT grids. To do so, remove the jumper between N and PE on the grid connection.

An IT grid can be implemented specifically for each project. Contact the Sunny Central

Service Line.

Fuse Links

The grid con nection ca ble mus t be fus ed at th e nominal current indicated on the type plate.

If the specified nominal current differs from the nominal current of the fus e plug, use the fu se

plug with the next highest nominal current.

The AC grid connection points are at the bottom left of the AC cabinet.

The following illustration shows the connection points for the AC grid in the Sunny Central 250 as an

example.

Position of the AC grid connection points

The exact position of the AC grid connection points differs depending on the model. The

exact position of the AC grid connection points can be determined with the help of the

equipment identifier and the circuit diagram enclosed.

1. Route the cable through the base opening into the AC cabinet.

2. Fit cable lugs to the cable.

3. Connect the cable.

4. Fit the strain relief of the AC grid connection lines. Use the enclosed cable clamps to secure the

strain relief to the cable rail.

Installation Guide SC20_25_35-IEN094521 53

Page 54

External Connections SMA Solar Technology AG

Observe the field of rotation.

The field of rotation at the grid connection points must be right. If the field of rotation is not

right, the Sunny Central will output an error message.

☑ The AC cables are now connected.

6.2.2 Connecting the AC Cable to the Sunny Central 350

Grid Structure

Sunny Centrals are configured for a TN-C grid connection. They can also be connected to

TN-S or TT grids. To do so, remove the jumper between N and PE on the grid connection.

An IT grid can be implemented specifically for each project. Contact the Sunny Central

Service Line.

Fuse Links

Fuse the grid connection cable at the nominal current indicated on the type plate. If the

specified nominal current differs from the nominal current of the fuse plug, use the fuse plug

with the next highest nominal current.

The AC grid connection points are at the top of the AC cabinet.

The following illustration shows the connection points for the AC grid in the Sunny Central 350 as an

example.

Position of the AC grid connection points

The exact position of the AC grid connection points differs depending on the model. The

exact position of the AC grid connection points can be determined with the help of the

equipment identifier and the circuit diagram enclosed.

54 SC20_25_35-IEN094521 Installation Guide

Page 55

SMA Solar Technology AG External Connections

1. Route the cable through the cable glands in the top into the interior of the switch cabinet.

2. Fit cable lugs to the cable.

3. Connect the cable.

4. Tighten the cable gland.

Observe the field of rotation.

The field of rotation at the grid connection points must be right. If the field of rotation is not

right, the Sunny Central will output an error message.

☑ The AC cables are now connected.

6.2.3 Connecting the AC Cable to the Sunny Central 250HE

The Sunny Central 250HE is designed for connection to a medium voltage transformer. The grid

connection form of the Sunny Central is an IT grid. In an IT grid, only the housings of the equipment

are grounded. An insulation fault between the external line and the ground grounds the external line

and causes increased voltage in the intact external line. The AC connection is 3-phase. The nominal

voltage (U) between the external lines is 270 V, the nominal voltage between the external line and

the ground is (U

)1000 V (depending on the current operating status of the Sunny Central).

0

DANGER!

Danger of fire.

During operation, there are nominal voltages of up to 1000 V to the ground in an IT grid.

If unsuitable AC cables are used, a fire could break out.

• Use only AC cables suitable for nominal voltages of up to 1000 V.

• Use only AC cables which are resistant to grounding and short circuits.

The connection to the fuse switch in the AC cabinet is 3-phase.

Installation Guide SC20_25_35-IEN094521 55

Page 56

External Connections SMA Solar Technology AG

The following diagram shows the connection points for the AC grid of the Sunny Central 250HE as

an example.

Position of the AC grid connection points

The exact position of the AC grid connection points differs depending on the model. The

exact position of the AC grid connection points can be determined with the help of the

equipment identifier and the circuit diagram enclosed.

1. Route the cable through the base opening into the AC cabinet.

2. Fit cable lugs to the cable.

3. Connect the cable.

4. Fit the strain relief of the AC grid connection lines. Use the enclosed cable clamps to secure the

strain relief to the cable rail.

Observe the field of rotation.

The field of rotation at the grid connection points must be right. If the field of rotation is not

right, the Sunny Central outputs an error message.

☑ The AC cables are now connected.

56 SC20_25_35-IEN094521 Installation Guide

Page 57

SMA Solar Technology AG External Connections

6.3 Connecting the External PE Connection (Sunny Central 250HE only)

The grid connection form of the Sunny Central is an IT grid. The PE rail in the AC cabinet must be

incorporated in the equipotential bonding to ground the Sunny Central 250HE housing.

PE cable sizing

Use PE cables with a line cross section of at least 1 x 50 mm2.

The following diagram shows the connection point of the external PE connection.

Position of the PE rail

The exact position of the PE rail can be determined with the help of the equipment identifier

and the circuit diagram enclosed.

1. Route the cable through the base opening into the AC cabinet.

2. Connect the PE cable in the AC cabinet.

☑ The PE cable is connected.

Installation Guide SC20_25_35-IEN094521 57

Page 58

External Connections SMA Solar Technology AG

6.4 Connecting the Internal AC Power Supply

The power required to operate the Sunny Central 200, Sunny Central 250 and Sunny Central 350

is either supplied via an external power supply or tapped internally. If the power is tapped internally,

the energy yield decreases by the system's own power requirements (fan, heater) of the Sunny

Central.

In the Sunny Central 250HE, an internal supply transformer can be connected in addition to the

ex ter nal pow er s upp ly. For det ail ed i nfo rma tio n on conn ect ing the internal supply transformer, see the

Technical Information "Sunny Central - Important Information on Internal Supply Transformers). The

standard grid connection structure for the internal power supply is a TN-S grid.

The Sunny Central 200 requires a single phase internal supply, the Sunny Central 250,

Sunny Central 250HE and Sunny Central 350 require a three-phase internal supply.

Circuit breaker for Internal Supply

Protect the grid connection line with a circuit breaker. See the Technical Data (see

section 8”Technical Data” (page81)) for notes on dimensioning the line circuit breaker.

The following diagram shows the connection terminals for the internal AC power supply in the

Sunny Central 250.

58 SC20_25_35-IEN094521 Installation Guide

Page 59

SMA Solar Technology AG External Connections

The following diagram shows the connection terminals for the internal AC power supply in the

Sunny Central 350.

Position of the AC grid connection terminals

The exact position of the AC grid connection terminals differs depending on the model. The

exact position of the AC grid connection terminals can be determined with the help of the

equipment identifier and the circuit diagram enclosed.

6.4.1 Connecting the External Power Supply

1. Route the cable through the base opening into the AC cabinet.

2. Compress the AC grid connection terminals with a screwdriver.

3. Insert the cable into the terminal clamp.

4. Remove the screwdriver.

☑ The internal AC power supply is connected.

6.4.2 Connecting the Internal Power Supply

1. Bridge the terminal clamps in accordance with the circuit diagram.

2. Compress the AC grid connection terminals with a screwdriver.

3. Insert the cable into the terminal clamp in accordance with the circuit diagram.

4. Remove the screwdriver.

☑ The internal AC power supply is connected.

Installation Guide SC20_25_35-IEN094521 59

Page 60

External Connections SMA Solar Technology AG

6.5 Connecting the DC Cable

The DC- / inverter cabinet contains optional high and low voltage fuses. They allow the string

distribution boxes (e.g. Sunny Main Box) to be connected. All Sunny Centrals are equipped with one

busbar per potential as standard.

Protected inputs on the Sunny Central

The Sunny Central has protected inpu ts o n the DC s ide . The num ber depends on the device

type. The number of DC inputs in the various Sunny Centrals is specified in the Technical

Data.

NOTICE!

Insufficient voltage resistance of the DC connection cable can cause short circuits

which damage the Sunny Central.

• Use only DC cables which are sufficiently voltage-resistant.

60 SC20_25_35-IEN094521 Installation Guide

Page 61

SMA Solar Technology AG External Connections

6.5.1 Sunny Central 200 / 250 / 250HE

The following diagram shows the connections of the DC inputs in the Sunny Central 250 as an

example.

A DC cable connection point

Position of the DC inputs

The exact position of the DC inputs differs depending on the model. The exact position of

the DC inputs can be determined with the help of the equipment identifier and the circuit

diagram enclosed.

1. Route the cable through the base opening into the DC cabinet.

2. Fit cable lugs to the cable.

3. Connect the cable.

4. Fit the strain relief of the AC grid connection lines. Use the enclosed cable clamps to secure the

strain relief to the cable rail.

☑ The DC cables are now connected.

Installation Guide SC20_25_35-IEN094521 61

Page 62

External Connections SMA Solar Technology AG

6.5.2 Sunny Central 350

The following diagram shows the connections of the DC inputs in the Sunny Central 350 as an

example.

A DC cable connection point

Position of the DC inputs

The exact position of the PE rail differs depending on the model. The exact position of the

DC inputs can be determined with the help of the equipment identifier and the circuit

diagram enclosed.

The DC fuses are arranged in 2 rows. The cables are initially connected to the DC fuses of the rear

mounting plate. The front DC cables cannot be connected to the fuses until the rear DC cables have

been connected.

62 SC20_25_35-IEN094521 Installation Guide

Page 63

SMA Solar Technology AG External Connections

1. Remove the front mounting plate with the DC fuse units.

2. Route the cable through the base opening into the DC cabinet.

3. Fit cable lugs to the cable.

4. Connect the cables to the DC fuses of the rear mounting plate.

5. Fit the strain relief of the DC cables. The cable clamps required are included. Secure the cable

clamps to the cable rail.

6. Reattach the front mounting plate.

☑ The cables are connected to the DC fuses of the rear mounting plate.

7. Route the cable through the opening into the DC cabinet.

8. Fit cable lugs to the cable.

9. Connect the cable to the DC fuses of the front mounting plate.

10. Fit the strain relief of the AC grid connection lines. Use the enclosed cable clamps to secure the

strain relief to the cable rail.

☑ The DC cables are now connected.

Installation Guide SC20_25_35-IEN094521 63

Page 64

External Connections SMA Solar Technology AG

6.6 Connecting the Team Cable (optional)

The power cables in team connection connect the team leader to the team device. The cables required

(standard length 5 m) are included. If the cable length is insufficient, another cable can be used. This

cable must have a DC voltage resistance of 1000 V and be designed for the expected DC team

cu rre nt a t a n omi nal out put of 1 00 % . Se e th e fo llo win g ta ble for t he r equ ire d in for mat ion on D C te am

current.

Sunny Central Maximum DC current input Maximum DC team current

Sunny Central 200 472 A 236 A

Sunny Central 250 591 A 296 A

Sunny Central 350 800 A 400 A

Th e co nnection ter min als for t eam con nec tio n are loc ate d in the cab ine t. T he f oll owi ng diagr am s how s

the position of the connection terminals in the Sunny Central 250.

A Team cable connection point

Position of the connection terminals for the team connection.

The precise position of the connection terminals for the team connection differs depending

on the model. The exact position of the connection terminals can be determined with the

help of the equipment identifier and the circuit diagram enclosed.

1. Route the cable through the base opening into the DC cabinet.

2. Fit cable lugs to the cable.

3. Connect the cable.

64 SC20_25_35-IEN094521 Installation Guide

Page 65

SMA Solar Technology AG External Connections

4. Fit the strain relief. Use the enclosed cable clamps to secure the strain relief to the cable rail.

☑ The team cables are connected.

6.7 Analog Inputs

Connecting the Overvoltage Protection (optional)

The combined overvoltage and lightning protection for the signal inputs is available as an option.

Position of the overvoltage protection.

The exact position of the overvoltage protection can be determined with the help of the

equipment identifier and the circuit diagram enclosed.

6.7.1 Analog Sensors

The Sunny Central allows a PT 100 temperature sensor and two additional sensors (pre-configured

as ExtSollrr and ExtGlolrr) on the Sunny Central Control panel via the customer’s terminal strip. See

the table below for the respective connection options available for the customer. These sensors can

be configured by the customer.

Connecting the Sensors

The procedure for connecting the sensors to the terminal strip in the Sunny Central Control

is described in the documentation included.

Configuring the Sensors

Please refer to the Sunny Central operating instructions for detailed information.

6.7.2 External Signals

Other than the analog sensors, three further signal transducers can be connected (preconfigured as

ExtAlarm, ExtSolP and ExtSolQ). These signals have a direct effect on the operation of the Sunny

Central.

The external alarm input (ExtAlarm) can be used to monitor the function of the medium voltage

transformer, for example. Note that sensors often require a 24 VDC power supply. It can be tapped

internally in the Sunny Central, or provided by an external source of power. The circuit diagram

provided must be followed when connecting external signal transducers.

The other analog inputs (ExtSolP, ExtSolQ) help to regulate the effective and reactive power of the

Sunny Central. These sensors are also connected to the customer’s terminal strip.

Installation Guide SC20_25_35-IEN094521 65

Page 66

External Connections SMA Solar Technology AG

6.7.3 Overview of the Analog Inputs

Assignment of the analog inputs on the Sunny Central Control

When connecting the analog inputs and for the digital signals, it is obligatory to follow the

included circuit diagram.

The connection is made at the connection terminals. Here, the connections for fourconductor and two-conductor sensors should be noted and any required measuring

converters should be made available.

Analog Inputs Ain Name Meaning

Customer Ain 1 ExtSolP External default nominal value for active power

Customer Ain 3 ExtSollrr External radiation sensor

Customer Ain 4 ExtGlolrr Pyranometer (measurement of global solar

irradiation)

Customer Ain 5 ExtAlarm External alarm input, e.g. for monitoring the

functioning of the medium-voltage transformer

Customer Ain 6 ExtSolQ External default nominal value for reactive power

Customer Ain 8 TmpExt C External temperature sensor / PT 100

6.7.4 Handling Notes for Shielded Contacts

Always use a shielded product for external signal and bus lines. Contact the shield on the shield rail

with the shield clamps over a large area. Use the shield clamps provided for the connection.

The connection terminals of the signal and bus lines are in the AC cabinet. The following diagram

shows the position of the connection terminals in the Sunny Central 250.

A Connection point for shielded contact rail

66 SC20_25_35-IEN094521 Installation Guide

Page 67

SMA Solar Technology AG External Connections

The following diagram shows the position of the connection terminals in the Sunny Central 350.

A Connection point for shielded contact rail

Position of the connection terminals for signal and bus lines.

The exact position of the connection terminals for signal and bus lines can be determined

with the help of the equipment identifier and the circuit diagram enclosed.

NOTICE!

Damage to the shield clamps.

• Only tighten the shield clamps hand-tight.

• Tightening the shield clamps using a screwdriver can damage the insulation.

1. Remove the line insulation.

2. Attach the shield clamp.

☑ The shield clamp snaps into place.

3. Tighten the shield clamps hand-tight. Tightening

using a screwdriver is not necessary.

Installation Guide SC20_25_35-IEN094521 67

Page 68

External Connections SMA Solar Technology AG

6.8 Remote Deactivation Unit

In addition to the key switch, another deactivation device can be implemented It is installed on the

terminals in the Sunny Central. For this purpose, a 230 V power supply must be connected with the

internal terminal.

Remote deactivation unit

For special project-specific requirements, the Sunny Central can be fitted with a remote

deactivation unit combined with monitoring of the activation condition. This switching

option allows the Sunny Central to be controlled from a control center without activating

the key switch on the Sunny Central.

When connecting the remote deactivation unit, the circuit diagram included must be

observed.

6.9 Connecting the Communication

6.9.1 NET Interface