Page 1

Central inverter

SUNNY CENTRAL 100LV - 560HE

Installation Guide

SC125_560HE-IEN083220 | 98-4004820 | Version 2.0

EN

Page 2

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Notes on this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Storage of the Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Appropriate Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.1 Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.3 Special Hazards of Photovoltaic Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.4 Electrical Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.5 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.6 Disconnecting the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.7 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1 Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.1 Transport Possibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Identifying the Sunny Central . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.1 Checking for Transport Damages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Mounting the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 Installation Site Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.1 Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.2 Distance to the wall. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.3 Inverter Protection Rating / EMC / Sound Levels . . . . . . . . . . . . . . . . . . . . . 20

4.1.4 Electrical Operating Room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1.5 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installation Guide SC125_560HE-IEN083220 3

Page 4

Table of Contents SMA Solar Technology AG

4.2 On-Site Inverter Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.1 Remove transport locks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.2 Mechanical coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.3 Anchorage to the ground or wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.1 Internal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.1.1 Power cabling between sine filter and transformer . . . . . . . . . . . . . . . . . . . . 30

5.1.2 HE version: Power cable connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.1.3 PE connection between AC cabinet and DC / inverter cabinet . . . . . . . . . . 36

5.1.4 Control lines at the transfer terminal strip . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1.5 Connecting Sunny Central Control to power unit . . . . . . . . . . . . . . . . . . . . . 38

5.1.6 Internal control lines of the power unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.1.7 Communication for insulation monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.1.8 Installing internal temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1.9 Team cabling (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.1.10 EVR Cabling (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.1.11 Sunny Central for installation near the sea (optional). . . . . . . . . . . . . . . . . . 46

5.2 External Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2.1 AC grid-connection standard devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2.2 AC grid connection of HE versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.2.3 AC grid connection with MV stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.2.4 Connection PE rail with HE version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.2.5 AC control voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.2.6 Handling the Connection Terminals Control voltage. . . . . . . . . . . . . . . . . . . 59

5.2.7 DC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.2.8 Team Power Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.2.9 External messages and signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.2.10 Sensors and digital outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.2.11 Shield Contact Handling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.2.12 Serial Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.2.13 Emergency-stop cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.2.14 Surge protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4 SC125_560HE-IEN083220 Installation Guide

Page 5

SMA Solar Technology AG Table of Contents

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.1 Requirements for commissioning . . . . . . . . . . . . . . . . . . . . . . . . 73

6.2 Cabling Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.2.1 Cabling Check AC Grid Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.2.2 Cabling Check DC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.2.3 Cabling Check Serial Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.2.4 Emergency-stop cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.2.5 Settings for thermostats and hygrostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.3 Switch On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7 Appendix A: Transport instructions . . . . . . . . . . . . . . . . . 76

7.1 Overview of transport possibilities. . . . . . . . . . . . . . . . . . 77

8 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

9 Appendix A - Mechanical data . . . . . . . . . . . . . . . . . . . . . 81

9.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9.2 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10 Appendix B - Minimum Clearance . . . . . . . . . . . . . . . . . . 83

11 Appendix C - Air volume . . . . . . . . . . . . . . . . . . . . . . . . . . 85

12 Appendix D - Cable cross section and Torque. . . . . . . . . 86

12.1 DC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

12.2 AC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Installation Guide SC125_560HE-IEN083220 5

Page 6

Table of Contents SMA Solar Technology AG

6 SC125_560HE-IEN083220 Installation Guide

Page 7

SMA Solar Technology AG Notes on this Manual

1 Notes on this Manual

1.1 Validity

This manual describes the transport, the installation and the commissioning of SMA central inverters

of the following types:

• Sunny Central 100LV (SC 100LV)

• Sunny Central 125LV (SC 125LV)

• Sunny Central 150 (SC 150)

• Sunny Central 200 / 200HE (SC 200 / SC 200HE)

• Sunny Central 250 / 250HE (SC 250 / SC 250HE)

• Sunny Central 350 / 350HE (SC 350 / SC 350HE)

• Sunny Central 500HE (SC 500HE)

• Sunny Central 560HE (SC 560HE)

1.2 Target Group

This manual is addressed to the installer and the operator of a PV system equipped with Sunny

Centrals.

1.3 Storage of the Manuals

All manuals for the Sunny Central as well as for the installed components must be stored together with

the installation documentation and must be accessible at all times. The documents listed below are

included in the delivery of your Sunny Central. The following information is contained in these

documents.

• Installation guide: Mounting and Installation of the Sunny Central

• User manual: Operation of the Sunny Central and the Sunny Central Control

• Circuit diagrams: Variant circuit diagram of the Sunny Central

• Commissioning report: Checklist for commissioning. After successful commissioning, the

commissioning report has to be sent to SMA Solar Technology AG.

• Documentation of

accessories:

Installation Guide SC125_560HE-IEN083220 7

You will find documentation for optional accessories or optional

equipment for the Sunny Central (e.g. installation near the sea) at

www.SMA.de.

Page 8

Notes on this Manual SMA Solar Technology AG

1.4 Symbols Used

The following types of safety warnings as well as general information appear in this document:

DANGER!

"DANGER" indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING!

"WARNING" indicates a hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION!

"CAUTION" indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

ATTENTION!

"Attention!" indicates a situation that can result in property damage if not avoided.

Information

Information provides tips that are valuable for the optimal installation and operation of

your product.

8 SC125_560HE-IEN083220 Installation Guide

Page 9

SMA Solar Technology AG Safety

2 Safety

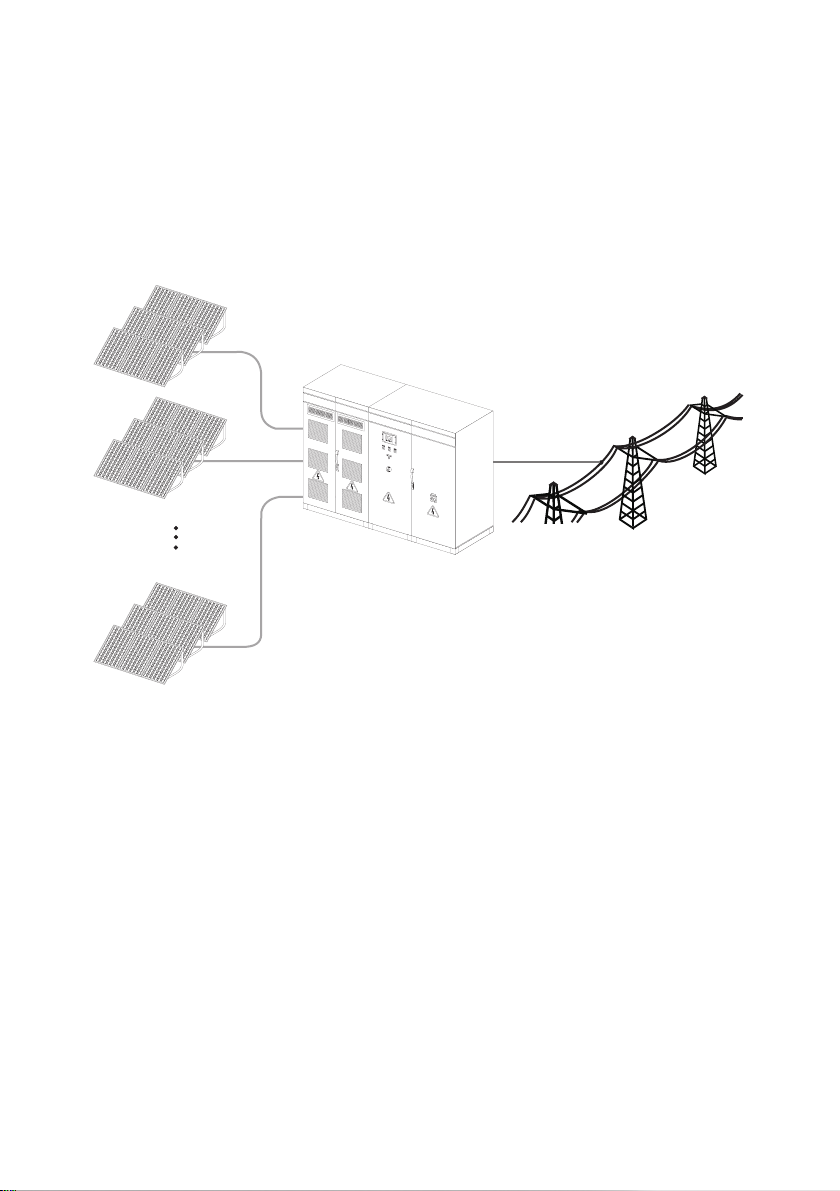

2.1 Appropriate Usage

The Sunny Central is a solar inverter. It is used to feed solar energy converted by solar modules using

photovoltaics into a low- or medium-voltage grid.

Principle of a grid-connected solar power system with a Sunny Central

Sunny Central

The standard Sunny Central is equipped with a low-voltage transform er a nd f eed s in to the l ow- vol tag e

grid.

Sunny Central LV

The Sunny Central LV feeds into the low-voltage grid. It is suitable for the connection of modules with

low voltage.

Sunny Central HE

The Sunny Central HE is a high efficiency photovoltaic inverter. It is not equipped with a low-voltage

transformer. The Sunny Central HE requires a suitable external medium-voltage transformer through

which it can feed into the grid.

Sunny Central MV

The MV stations are medium-voltage stations. In an MV station, two Sunny Central HEs feed into a

shared medium-voltage transformer. The Sunny Central MV feeds into the medium-voltage grid.

Installation Guide SC125_560HE-IEN083220 9

Page 10

Safety SMA Solar Technology AG

2.2 Safety Instructions

Faults which affect the safety of the device must be immediately rectified. Unauthorized modifications

and the use of spare parts not recommended by SMA Solar Technology may cause fire, material

damage and electrical shocks. Unauthorized personnel must not have access to the equipment.

Warning signs must always be clearly readable and immediately replaced if damaged.

2.2.1 Personnel

Only qualified technical personnel may perform any and all work on the Sunny Central. "Qualified"

means that the personnel must possess training relevant to the activity performed.

For commissioning and operation of the Sunny Central, the personnel must be familiar with the content

of the Sunny Central installation guide and user manual. In particular, the safety instructions must be

followed.

2.2.2 Installation

The mounting requirements described in the installation guide must be observed. The installation has

to be carried out in an electrical operating room to guarantee optimal noise and fire protection.

The Sunny Central product line has been type-tested and approved for installation in an industrial

environment in accordance with the industry-standard EMC limits (EMC = Electro Magnetic

Compatibility). Devices for installation in households are available upon request.

For the installation, the following points have to be taken into consideration:

• Separate airflow of the supply and exhaust air of the Sunny Central from other ventilation

systems to avoid the spread of smoke in the event of fire.

• An appropriate escape route must be ensured.

• An appropriate sound insulation (see Technical Data) must be ensured.

• The EMC specifications must be observed (see Technical data)

WARNING!

Smoke in electrical areas of operation

We recommend the installation of a smoke detector inside the electrical operating room

which con trols the external emergency- stop s witch of the devic e and sw itche s off the Sunny

Central in the event of smoke.

10 SC125_560HE-IEN083220 Installation Guide

Page 11

SMA Solar Technology AG Safety

2.2.3 Special Hazards of Photovoltaic Systems

Photovoltaic systems have special characteristics representing special hazards that are described

here:

• An active power source is connected. Depending on the operating mode there may be voltage

present, either from the photovoltaic generator and/or the Sunny Central. This is especially

important to note when disconnecting parts of the system

• Very high DC voltages are present (no zero-cros sing) that, in the case of a fault or inappropriate

use of fuses or plugs, may lead to arcing.

• The short-circuit current of the photovoltaic generator is only slightly more than the maximum

operating current and is also dependent on the level of solar irradiation. If a short-circuit occurs

in the system, the available fuses are not guaranteed to switch off.

• The grid structure of the PV generator is usually an IT grid, i.e. a non-grounded grid that could

become unintentionally grounded if a ground fault occurs.

• A highly branched generator may be difficult to disconnect if a fault develops (e.g. short-circuit).

In add iti on, we r eco mmen d th e us e of ext ern al D C cir cui t br eak ers fo r di sco nne cti ng t he i nve rte r

and/or the DC main cables / Sunny String monitors (DC circuit breakers are optionally

available). At every DC input, an easily accessible DC circuit breaker should be installed

(for further information see pre-standard VDE 0100, part 712 and VDI guidelines 6012).

2.2.4 Electrical Connection

The electrical connection must be carried out according to the installation guide, the relevant circuit

diagram and the technical data of the device.

Ensure the grid connection cable for grid feeding is fused at the nominal current indicated on the type

plate. If the specified nominal current differs from the nominal current of the fuse plug, the fuse plug

having the next highest nominal current may be used.

Grid connection cable

The grid connection cable for the internal power supply must be fused with the line circuit

breakers specified in the technical data.

Lightning protection

The devices are equipped with an internal overvoltage protection on the AC and DC sides. The

desired protection level can only be achieved, if a lightning protection area concept exists for the

installation building according to DIN VDE 0185-4, which means that at the building's entrance

(transfer lightning protection area LPZ 1), lightning conductors or combined surge and lightning

conductors are available among others which are not included in the delivery.

The combined surge and lightning protection for the signal inputs can be optionally ordered.

Installation Guide SC125_560HE-IEN083220 11

Page 12

Safety SMA Solar Technology AG

Emergency-stop

In installations with more than one device or with additional external emergency-stop switches, the

emergency shut-off circuits have to be connected and tested for correct functionality, as described in

the installation guide. The emergency shut-off circuit may only be supplied with voltage from a device.

Emergency shut-off circuit

• The emergency shut-off circuit may only be supplied with power from a single Sunny

Central.

• Set the bridges at the emergency-stop terminal strip of the device into correct position.

2.2.5 Power Supplies

WARNING!

Risk of lethal electric shock!

High voltages are present in the device.

• The protective ground connection must be made before the external voltage is

switched on.

• At the AC grid connection terminal, the nominal voltage, frequency and the righthand rotary field have to be maintained.

• Before inserting the DC input fuses (internal or external), the correct polarity and

earth fault protection of the inputs must be ensured. The fuses may only be inserted

or removed under load-free conditions and when using the appropriate personal

protective equipment and fuse carriers.

• In the case of inserted DC fuses (internal or external), reverse voltage is applied to

all externally connected DC main distributors and DC sub-distributors (Sunny String

Box) as well as the team device via the bus bar in the Sunny Central.

• The doors must remain closed when connecting the supplies!

Requirements for switching on the external power supplies

• All connections have been carried out according to the installation guide and the circuit

diagram.

• The protective ground connection for grid feed-in and for internal power supply has been made.

• The device has been switched off. The key switch is in the "stop" position and the main switches

are switched off.

• The DC input fuses (internal and external) are pulled and the protection against accidental

contact (Plexiglas covers) is installed. For team operation on both devices.

• The nominal voltage, frequencies and the right-hand rotary field are maintained (see device

technical data).

• The polarity of the DC voltage at the inputs/fuse inputs (device dependent) has been checked.

12 SC125_560HE-IEN083220 Installation Guide

Page 13

SMA Solar Technology AG Safety

• The polarity of the DC voltage at the inverter input/team input (device dependent) has been

checked.

• The photovoltaic generator has been checked with an insulation test to ensure that there is no

ground fault.

Sequence for switching on the external power supplies

• Grid voltage for the grid feed-in

• Grid voltage for internal power supply

• DC voltage from the photovoltaic generator

• DC voltage for team operation (optional)

2.2.6 Disconnecting the device

External disconnection of the device must always occur under load-free conditions. The device must

be switched off in order to do this, the key switch must be in the “Stop” position.

DANGER!

Risk of lethal electric shock!

Work on the Sunny Central may only be performed after switching off the power to the

unit. The VDE regulations must be followed.

• Disconnection (also team device)

• Secure against re-connection

• Verify that the installation is free of voltage

• Ground and short the unit if necessary (not on the DC side)

• If necessary, cover or protect against accidental contact with any neighboring

voltage carrying components

The following power supplies must be disconnected:

• Grid voltage for the grid feed-in

• Grid voltage for internal power supply (optional)

• DC voltage from the photovoltaic generator

• DC voltage for team operation (optional)

• If necessary, additional external voltages (e.g. emergency-stop)

Simply switching off the main AC and DC switches is not sufficient to ensure proper disconnection of

the device. The main switches only separate the power circuit from the grid and the photovoltaic

generator.

Installation Guide SC125_560HE-IEN083220 13

Page 14

Safety SMA Solar Technology AG

DANGER!

Risk of lethal electric shock!

Dangerous accidental-contact voltages can be present in the Sunny Central even when the

main AC and DC switches are switched off!

• After switching off the Sunny Central, wait a minimum of 5 minutes.

The disconnection of the DC voltage is carried out by the internal or external DC input fuses or, if

available, external circuit breakers. The disconnection with the DC input fuses has to be carried out

under load-free conditions.

The device contains capacitors on the DC and AC sides that discharge when the device is

disconnected. After switching off, there are dangerous accidental-contact voltages present within the

device for several minutes. If there is a fault in the device, these voltages may also remain present for

a longer period of time. For these reasons, wait a minimum of 5 minutes after switching off before

opening the device.

WARNING!

Risk of lethal electric shock!

• To avoid arcing, the load-free status must be checked with a current probe (using a

clamp-on ammeter) before removing the DC input fuses. The fuses may only be

pulled/inserted using the personal protective equipment and fuse carriers.

• In the case of inserted DC fuses (internal or external), reverse voltage is applied to

all externally connected DC main distributors and sub-distributors (Sunny String

Monitor) as well as the team device via the the bus bar in the Sunny Central.

• In the event of a failure, the DC contactors may carry a life-threatening DC voltage!

• The discharge time of the capacitors is longer than 5 minutes.

The Plexiglas cover must be removed in order to pull the fuses. The cover must never be removed from

both poles at the same time. After the cover has been removed from one pole, and the fuse has been

pulled, the cover must be immediately re-installed before removing the cover from the second pole.

The covers must always remain in place when fuses are not to be pulled.

Disconnection of system components without risk

In addition, we recommend the use of external DC circuit breakers for disconnecting the

inverter and/or the DC main cables / Sunny String monitors (DC circuit breakers are

optionally available). Even in the case of faults or fire, this allows system components to be

safely disconnected.

14 SC125_560HE-IEN083220 Installation Guide

Page 15

SMA Solar Technology AG Safety

Team devices

WARNING!

Risk of lethal electric shock!

Before working on a team device, both devices must be disconnected.

If two devices in the team are connected, all necessary measures have to be taken to disconnect both

devices. This especially applies to the DC inputs. The team contactor is not a reliable disconnection

unit between the devices.

2.2.7 General Information

Hearing Protection

The device fans and the power unit create significant levels of operating noise. In addition to this, a

fault in the device can lead to very high noise levels. For these reasons, we recommend the use of ear

protection when in the vicinity of the device.

High noise levels in electrical operating rooms

We rec omm end the use of e ar p rot ect ion whe n in the vic ini ty o f the Sunny Central electrical

operating room for extended periods.

Burns

Immediately after disconnecting the device, certain components can be very hot (e.g. fuses,

transformer core, sine filter, heat sinks etc.) - depending on the operating conditions.

Safety gloves should always be worn when working near components that can be expected to be

very hot.

High temperature of device components

We recommend wearing safety gloves during all work on the device.

Installation Guide SC125_560HE-IEN083220 15

Page 16

Delivery SMA Solar Technology AG

3 Delivery

3.1 Transport

Only the transport methods described in the installation guide are permissible, follow the transport

requirements in Appendix A.

The inverters consist of two switch cabinet units, the DC / inverter cabinet and the AC cabinet which

are separately transported and installed on site.

The inverters and/or inverter units are delivered on pallets. Under standard delivery conditions, a

forklift must be available. When unloading, the heavy-load markings mus t be g ive n du e co nsi der ati on.

3.1.1 Transport Possibilities

WARNING!

Heavy weight of switch cabinet units!

Danger of tipping during transport!

• The cabinet units must always be transported in an upright position.

• The center of gravity of the Sunny Central is indicated on the outside of the

packaging.

Transport using a pallet truck or forklift

For the transport of the respective switch cabinet with pallet trucks or forklifts, the plinth panel can be

unscrewed and in this way the fork of the pallet truck or lift can be put under the cabinet.

Both screws per plinth panel can be loosened with a TX30 torque key.

ATTENTION!

Damage to the Sunny Central through missing plinth panels

The plinth panels are essential for stable positioning of the switch cabinet. In the case of

transport on a pallet, it is necessary to install the plinth panels. Otherwise there is the risk

that the base will collapse under the weight of the switch cabinet.

Transport using a crane

Du e to the hea vy w eig ht o f th e sw itc h ca bin ets , th e trans por t with crane eyelets is only permitted under

certain conditions. The inverters are therefore delivered without crane eyelets. Otherwise there is the

risk of damaging the cabinet. Use an appropriate crane fork instead which can be put below the

switch cabinet when the plinth panels are unscrewed.

16 SC125_560HE-IEN083220 Installation Guide

Page 17

SMA Solar Technology AG Delivery

Transport using crane eyelets

The transport of the switch cabinets with crane eyelets is not permitted as a standard means

of transport!

In exc ept ion al c ase s, t he tran spo rt w ith cra ne e yel ets is p erm itt ed. In c ase of t ran spo rt u sin g

a crane, the following points have to be observed:

• Asymmetric weight distribution

•Heavy load.

• Most of the switch cabinet's weight is located in the rear area.

3.2 Identifying the Sunny Central

You can identify the Sunny Central using the type plate (see figure below). The type plate can be

found on the inside of the door of the Sunny Central.

A

B

C

A Type description of the Sunny Central with option key

B Version of the Sunny Central. "s" stands for "special version".

C Sunny Central Serial number

Installation Guide SC125_560HE-IEN083220 17

Page 18

Delivery SMA Solar Technology AG

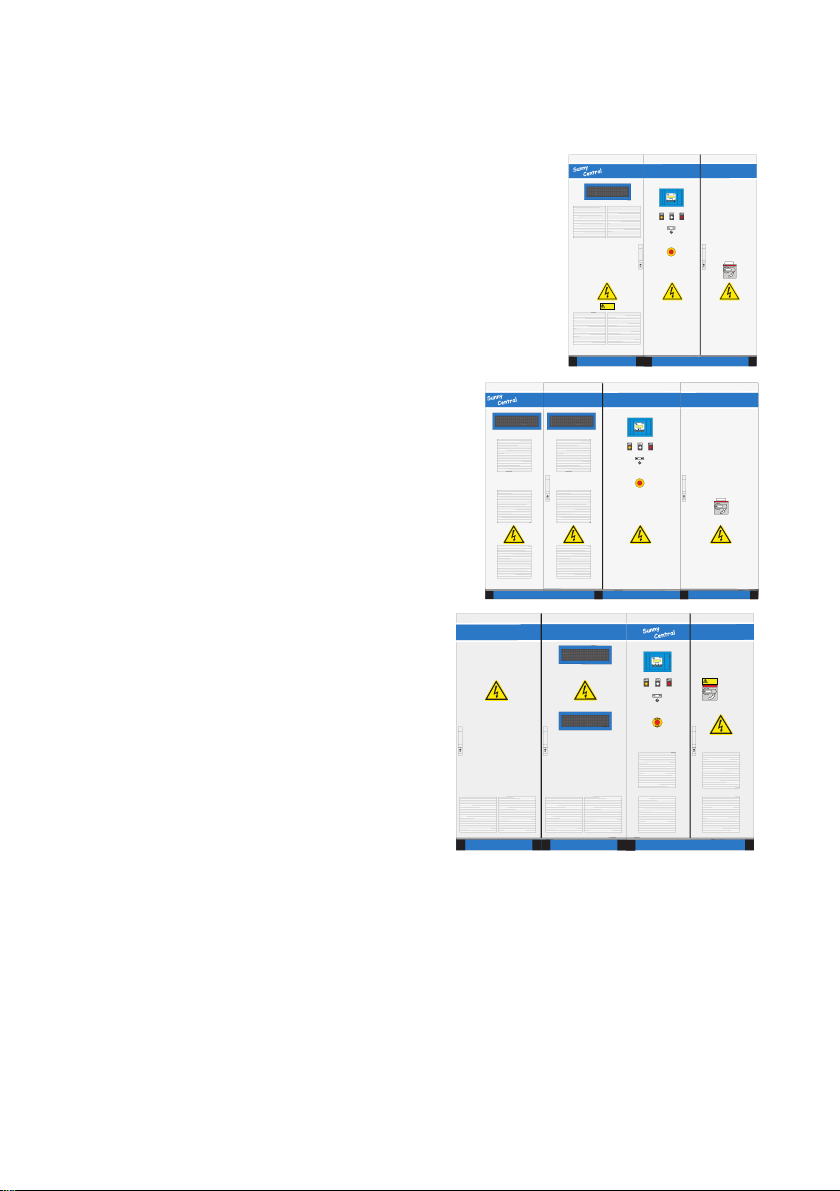

Switch cabinet view of Sunny Central inverter cabinets

Switch cabinet view Sunny Central 150

Achtung!

Bei ausgeschaltetem

Hauptschalter

unter Spannung

Switch cabinet view

Sunny Central 250 / 250HE

Switch cabinet view

Sunny Central 350 / 350HE

Achtung!

Bei ausgeschaltetem

Hauptschalter

unter Spannung

18 SC125_560HE-IEN083220 Installation Guide

Page 19

SMA Solar Technology AG Delivery

Switch cabinet view

Sunny Central 500 / 560HE

with EVR option (A)

Sunny Central MV station view

A

!

3.2.1 Checking for Transport Damages

Check the packaging and the device for any possible damage and compare the contents of the

de liv ery wit h the de liv ery doc ume nta tio n. I n th e case o f da mag e to the device and/or unclear delivery

contents, immediately contact SMA Solar Technology.

Transport security

The devices are delivered in part units which do not reflect the protection class specified in

the technical data. The packaging offers an appropriate protection against humidity and

damage.

3.2.2 Storage

Storage information

The equipment may only be stored in rooms protected from dust and moisture.

Installation Guide SC125_560HE-IEN083220 19

Page 20

Mounting the Device SMA Solar Technology AG

4 Mounting the Device

Sunny Central Installation requirements

Every Sunny Central has different individual installation requirements. These can be

ordered at any time from SMA Solar Technology and have to be observed for project

planning and for the preparation of the installation site.

4.1 Installation Site Requirements

4.1.1 Foundation

The foundation must guarantee solid and safe positioning of the inverter. T he fou ndation must p rovid e

the load-carrying capacity necessary to cope with the weight of the inverter. The inverter cabinet must

be ins tal led on a lev el surf ace . Any existing unevenness, depress ions or s lopes m ust be c orr ect ed p rio r

to installation.

4.1.2 Distance to the wall

When installing the inverter, appropriate distance to the wall for minimum passageways, escape

routes and ventilation have to be observed. Corresponding information about the inverter type in

question are included in the "Sunny Central Installation requirements" (separate document).

4.1.3 Inverter Protection Rating / EMC / Sound Levels

The Sunny Central is suitable for installation in a station located in a dry, dust-reduced environment

according to protection rating IP20. With regard to the EMC emissions and the noise level, the Sunny

Central inverter is designed for installation in an industrial environment.

Sunny Central installation location

The Sunny Central inverter has to be installed in an electrical operating room.

20 SC125_560HE-IEN083220 Installation Guide

Page 21

SMA Solar Technology AG Mounting the Device

4.1.4 Electrical Operating Room

For the installation and connection of the Sunny Central central inverters, observe DIN VDE 0100,

part 729, part 731. The requirements for the electrical operating room for the installation of high

voltage systems up to 1000 V as well as the requirements for passageways and escape routes are

included here.

Minimum passageway in electrical operating rooms

Observe the following points for a minimum passageway:

• With fully opened cabinet doors, a minimum passage width of 500 mm

(escape route) must be maintained, see DIN VDE 0100 part 729, part 731.

• To maintain the minimum passageway requirements, the cabinet doors in an inverter

sy ste m wi th two r ows of o ppo sin g ca bin ets (e.g. i nst all ati on i n a st ati on b uil din g) m ay

only be opened on one side at a time.

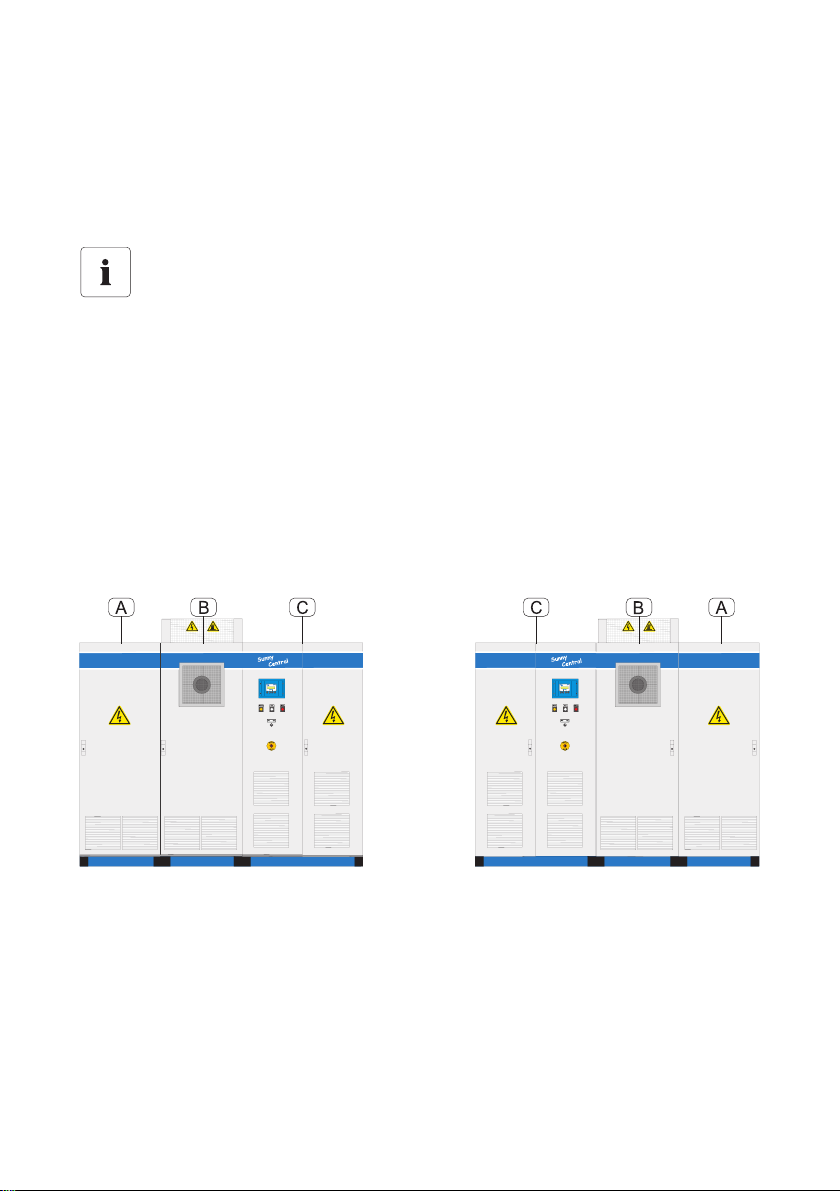

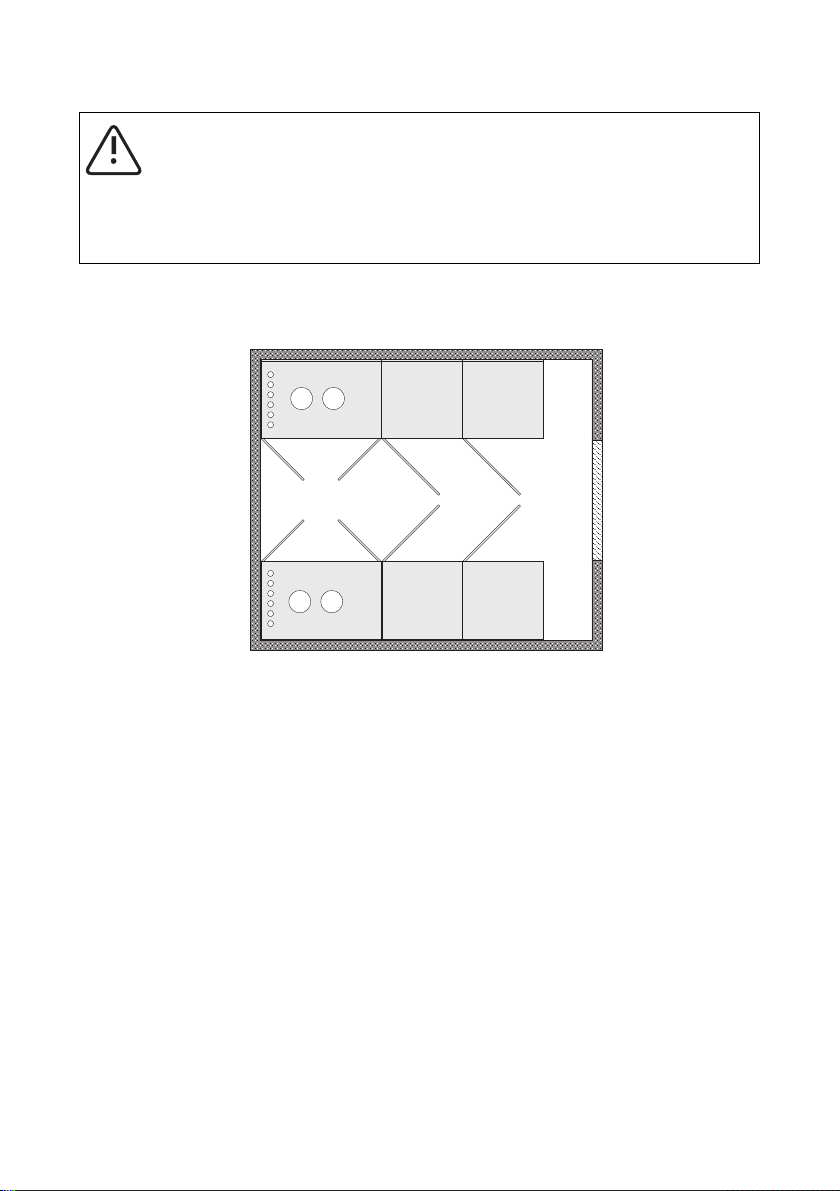

MV Stations

The inverters of the HE series are usually installed in a concrete compact station, generally opposite

as a "left" system and "right system". The installation has to be carried out in accordance with the VDE

guidelines for a closed electrical operating room. In the figure below, a left-hand and right-hand

system is shown.

Left system Right system

ADC cabinet

B Inverter cabinet

CAC cabinet

The AC cabinets should in any case be located at the partition wall to the transformer room in order

to implement the AC power cabling to the transformer with short cable routes.

Installation Guide SC125_560HE-IEN083220 21

Page 22

Mounting the Device SMA Solar Technology AG

WARNING!

Smoke in electrical areas of operation

We recommend the installation of a smoke detector inside the operating room which

controls the external emergency-stop connection of the device and which switches off the

Sunny Central in the event of smoke.

In the following a schematic top view of the Sunny Boys located in a station is shown. The installation

of the inverters is realized as a "right-hand system" (above) and "left-hand system" (below).

AC cabinet

Inverter cabinet

DC cabinet

Exit

Partition wall to the transformer room

AC cabinet

Inverter

DC cabinet

cabinet

4.1.5 Ventilation

For cooling the inverter, an appropriate air supply is necessary. To guarantee secure operation and

the maximum of feed-in power, the allowable ambient temperature has to be observed.

The required air is drawn through the switch cabinet doors and is blown out via the roof or the back

wall of the cabinet unit depending on the Sunny Central model Thus the devices can be installed

directly adjacent to each other. The air needed as well as the appropriate distance to the wall can be

found in the "Sunny Central Installation requirements" (separate document). Filters which clean the

absorbed air are installed at the air inlet openings.

Should the required amount of air at the installation site of the Sunny Central be too low, a larger

amount of air has to be made available (supply air bars, fan etc.) through construction measures.

The inlet air must satisfy the requirements of classification 3S2 (see table). The operation of the inverter

is suited to a relative humidity of 15 … 95 %.

22 SC125_560HE-IEN083220 Installation Guide

Page 23

SMA Solar Technology AG Mounting the Device

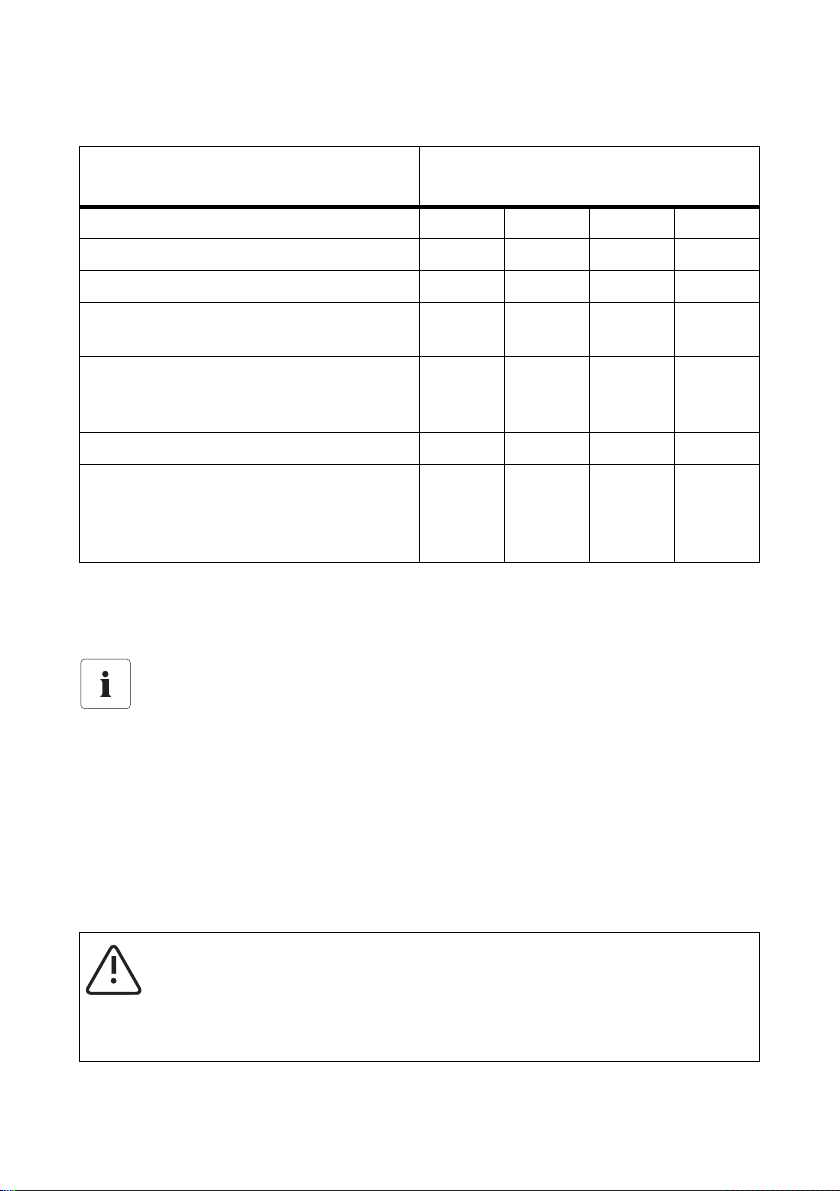

Air Quality Classification

Environmental requirements for fixed site use Class

3S1 3S2 3S3 3S4

a) Sand in the air [mg/m³] - 30 300 3000

b) Dust (suspended matter) [mg/m³] 0.01 0.2 0.4 4.0

c) Dust (fallout) [mg/m³] 0.4 1.5 15 40

Sites where dust fallout is kept to a minimum

through appropriate measures.

Si tes whe re no sp ecial m eas ures ha ve been taken

to reduce the sand or dust levels and which are

far from sand and dust sources

Sites near to sand and dust sources x x

Sites in production halls where sand or dust is

present, or sites in geographical locations in

which the air can contain high quantities of sand

and dust

Should the required air quality at the installation site of the Sunny Central not be available,

corresponding requirements have to be made available (e.g. additional filters in the building supply

air bar) through construction measures.

Ambient Conditions

The following points for environmental conditions have to be observed:

• amount of fresh air

• required air quality,

• relative humidity

• Allowable ambient temperatures

xxxx

xxx

x

The waste heat (exhaust air) produced by the inverter has to be led away from the device to observe

the maximum allowable ambient temperature and to ensure that the installation room is not

unnecessarily heated up by the warm exhaust air. This takes place through the installation of an

exhaust airflow (e.g. air channel).

CAUTION!

Risk of crushing and bruising by metal parts.

Remove the finger protection from the fan openings of the Sunny Central before installing

the exhaust airflow.

Installation Guide SC125_560HE-IEN083220 23

Page 24

Mounting the Device SMA Solar Technology AG

According to the Sunny Central type, the exhaust air is lead out of the inverter through either the top

or the rear. The Sunny Central types 350, 350HE, 500HE and 560HE have a combined exhaust

airflow from the top and through the rear of the cabinet units. The method of exhaust is described in

the "Sunny Central Installation requirements". With the exhaust airflow to the "rear" it is possible to

lead the exhaust air directly out of the building through a weather protection bar installed inside the

bu ild ing wal l. The i nve rte r ca n be ins tal led wit h the re ar t o the ope n buildi ng wall . To do t his , di sma ntl e

the finger protection from the fan openings and provide a seal or a frame-like air scoop with a seal.

Attach the air scoop to the building wall.

ATTENTION!

Operational reduction of the Sunny Central through overtemperature!

For an appropriate cooling of the inverter, the following points have to be observed:

• Obey the indicated amount of air.

• Clean the ventilation openings (filter pads) and the exhaust air bars at regular

intervals.

• Expel the exhaust air separately out of the individual cabinet components in order to

avoid thermal short circuit breaks.

Inverter specific details

The inverter-specific models of the ventilation system are described in the Sunny Central

Installation requirements (separate document).

24 SC125_560HE-IEN083220 Installation Guide

Page 25

SMA Solar Technology AG Mounting the Device

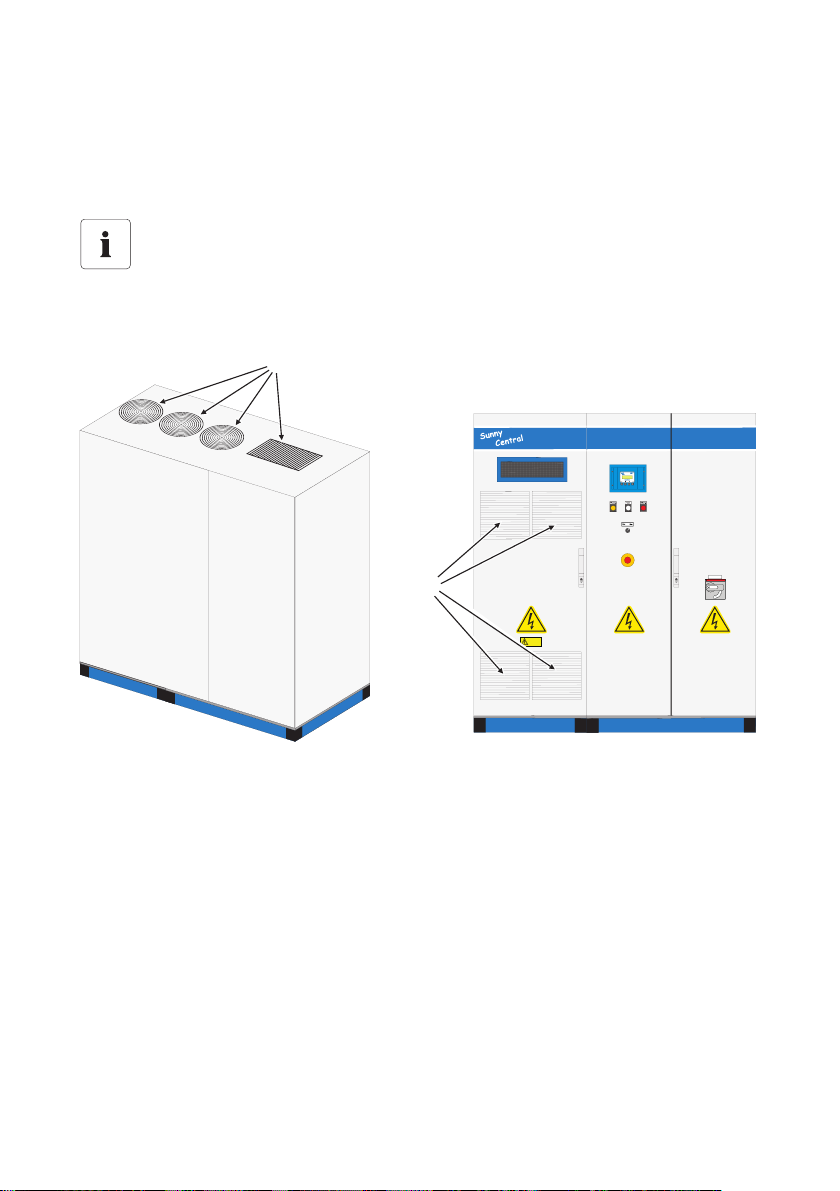

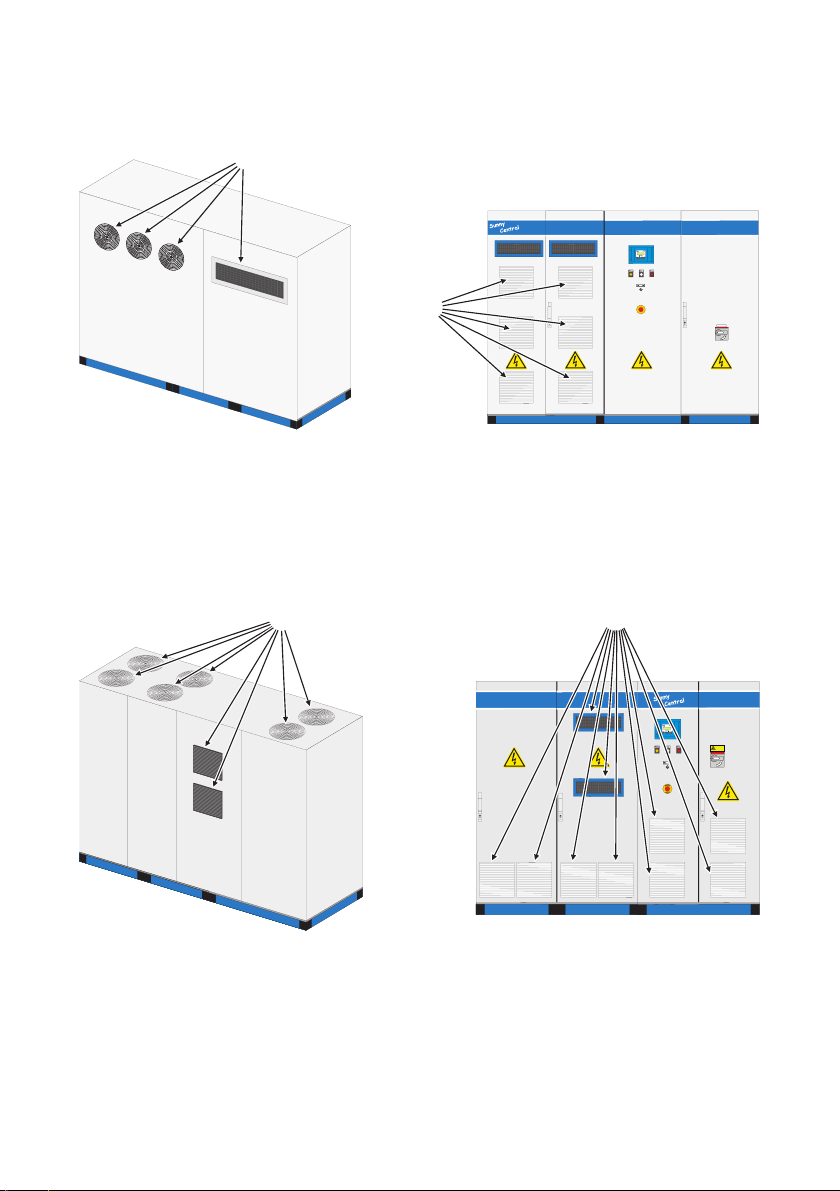

Overview of the ventilation openings

The exact position and size of the single air grills as well as for the supply air on the front side and

the exhaust air on the roof or at the rear side of the switch c abinets, are displayed with some example

cabinets.

The figures in this chapter show a "left system". Find more details about left and right

systems in chapter 4.1.4 „Electrical Operating Room“ (21).

Sunny Central 100LV / Sunny Central 150 / Sunny Central 125LV / Sunny

Central 200

A

B

Achtung!

Bei ausgeschaltetem

Hauptschalter

unter Spannung

AExhaust air BSupply air

Sunny Central 200HE

See figure above. The AC cabinet of the Sunny Central 200HE has 2 exhaust air openings; instead

of 3 as shown in the figure above.

Installation Guide SC125_560HE-IEN083220 25

Page 26

Mounting the Device SMA Solar Technology AG

Sunny Central 250

A

B

AExhaust air BSupply air

Sunny Central 250HE

See figure above. The AC cabinet of the Sunny Central 250HE has 2 exhaust air openings; instead

of 3 as shown in the figure above.

Sunny Central 350

A

B

Achtung!

Achtung!

Bei ausgeschaltetem

Bei ausgeschaltetem

Hauptschalter

Hauptschalter

unter Spannung

unter Spannung

AExhaust air BSupply air

Sunny Central 350HE

See figure above. The AC cabinet of the Sunny Central 350HE has 2 exhaust air openings; instead

of 4 as shown in the figure above and 2 supply air openings instead of 4 as shown in the figure

above.

26 SC125_560HE-IEN083220 Installation Guide

Page 27

SMA Solar Technology AG Mounting the Device

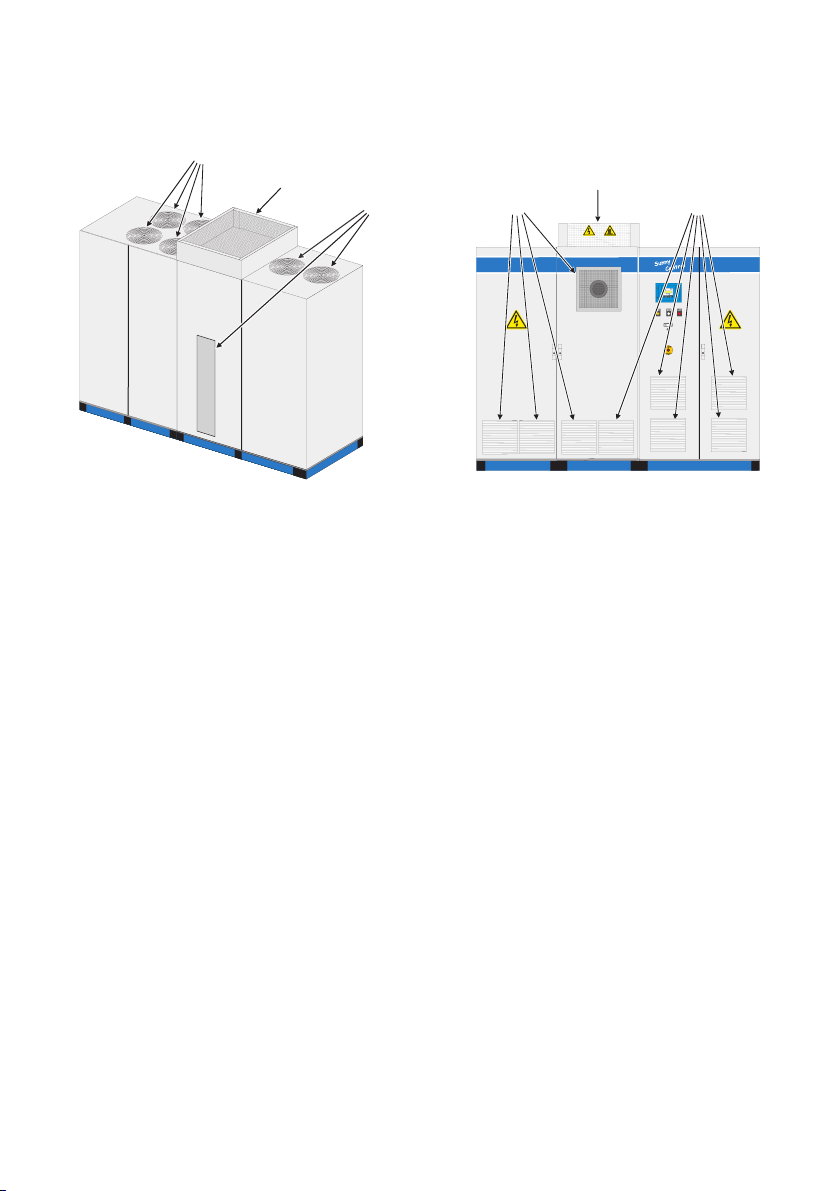

Sunny Central 500HE / Sunny Central 560HE

A

C

A

B B

AExhaust air BSupply air

CEVR option

C

Installation Guide SC125_560HE-IEN083220 27

Page 28

Mounting the Device SMA Solar Technology AG

4.2 On-Site Inverter Installation

The Sunny Centrals consist of two switch cabinet units, which are electrically and

mechanically connected on site. Make sure that both switch cabinets have the same serial

number. You will find the serial number on the type plate or on the transport packaging of

the Sunny Central switch cabinet.

After both switch cabinets have been installed next to each other, the transport locks of the transformer

have to be removed, the seals have to be inserted and the individual cabinets have to be mechanically

and electrically connected for the final mounting in the electrical operating room. All necessary

materials required for the connection of the switch cabinets are included in the delivery.

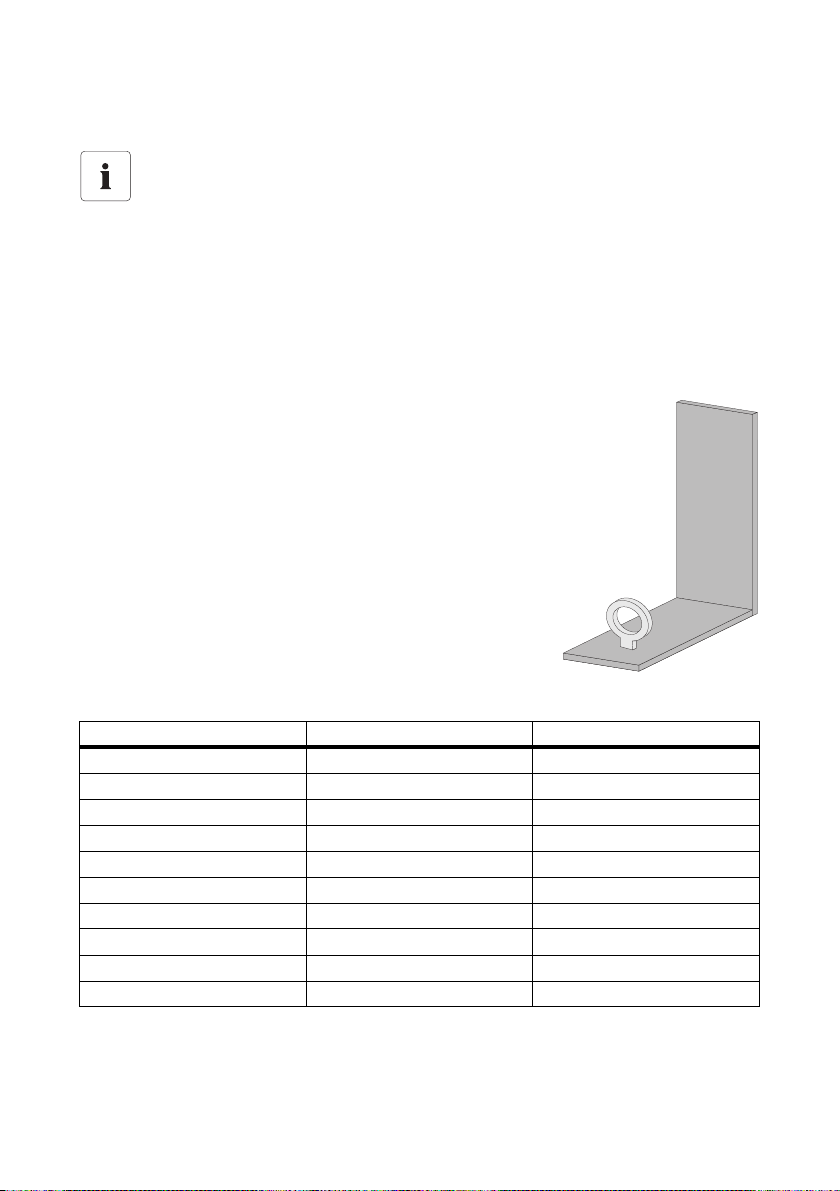

4.2.1 Remove transport locks

Remove the transport locks.

In some Sunny Centrals, the transfomers and the sine filter are

secured with transport locks on the cabinet. The transport lock is a

metal angle which is fixed at the switch cabinet side.

The following table shows which type is delivered with transport locks.

Sunny Central Transport lock Transformer Transport lock Sine filter

100LV yes no

125LV yes no

200 yes no

200HE no no

250 yes no

250HE no no

350 yes no

350HE no no

500HE no yes

560HE no yes

28 SC125_560HE-IEN083220 Installation Guide

Page 29

SMA Solar Technology AG Mounting the Device

4.2.2 Mechanical coupling

ATTENTION!

Humidity through missing seal!

Be for e both switc h ca bin ets are con nec ted wit h each o the r, t he delivered seal must be stuck

into the interface of the cabinets - if not already carried out ex-works.

The mechanical coupling of both switch cabinets is made through clamp joi nts . They c ons ist of t ermina l

clamps and brackets with which the cabinets can be screwed together in several places. In order to

do this, both cabinets have to be at the same level.

In the enclosed Rittal manual you will find information about how to mount the seals and the clamp

joints.

4.2.3 Anchorage to the ground or wall

The Sunny Centrals are so heavy that an additional anchorage to the ground or the wall is not

necessary.

Anchoring in a MV station

Su nny Cen tra ls w hic h ar e ho use d an d tr ans por ted in a MV s tat ion are ancho red to t he w all

and to the ground of the station to avoid moving and damage during transport.

Installation Guide SC125_560HE-IEN083220 29

Page 30

Electrical Connection SMA Solar Technology AG

5 Electrical Connection

After both switch cabinets have been installed next to each other and have been mechanically

connected, the individual cabinets must be electrically connected with each other. Afterwards, the

external electrical connections are established.

Realization of the electrical connection

For establishing the electrical connections and terminals, it is obligatory to follow the circuit

diagram included in the delivery.

All internal connections have to be made in order to prepare the inverter for the external

AC and DC connections.

5.1 Internal Connections

For the internal electric connection of the two cabinets, the following internal connections have to be

made:

• Power cabling between sine filter and transformer (not for the HE version)

• HE version: Power cabling between sine filter and power unit

• Sunny Central 250HE: Power cabling between sine filter and EMV filter

• Grounding connection between AC cabinet and DC / inverter cabinet

• Control line at the transfer terminal strip

• Communication between Sunny Central Control and power unit in DC / inverter cabinet

• Communication between Sunny Central and insulation monitoring

• Mounting of temperature sensor

• Power cabling Team concept (optional)

• Team communication RS485 (optional)

• Team control (optional)

• EVR resistor (optional)

Mounting the internal connections

The internal connections are to a great extent pre-mounted and must finally be inserted or

screwed into the cabinets when putting together.

5.1.1 Power cabling between sine filter and transformer

At the sine filter choke in the DC / inverter cabinet, three power cables (U1, V1, W1) are connected;

in the AC cabinet, they have to be connected to the appropriately marked terminal clamps

(U1, V1, W1) of the transformer. The cables have already been equipped with cable lugs and cut in

a way that the connection to the contact tip is clear. The sine filter is located in the Sunny Centrals of

the types 100LV, 125LV, 150, 200 and 250 behind the fuses of the DC / inverter cabinet.

30 SC125_560HE-IEN083220 Installation Guide

Page 31

SMA Solar Technology AG Electrical Connection

L+

L-

L-

L-

L+

L-

L+

L-

The transformer is located in these Sunny Central behind the front mounting plate of the AC cabinet.

In the Sunny Central 350, the sine filter is located under the power units in the DC / inverter cabinet

and the transformer is located in the lower area of the AC cabinet.

ATTENTION!

Operational reduction of the Sunny Central through faulty connection!

When connecting the power cables, be absolutely sure that the sensor cables are

connected to the respective connection tips.

The following connection order has to be observed:

1. Connection tip transformer with inserted screws

2. Cable lug power cable

3. Cable lug measurement cable

4. Detent edged ring

5. Nut

Connection points U, V, W for power cable in the Sunny Central 350

H1-02

L1

L1

L2

L2

L3

L3

L-

L-

L+

L+

A

B BB

A Terminal lugs Sine filter choke (DC / inverter cabinet)

B Terminal lugs Transformer (AC cabinet)

Installation Guide SC125_560HE-IEN083220 31

Page 32

Electrical Connection SMA Solar Technology AG

L+

L-

L+

L-

Connection points U, V, W for power cable in the Sunny Central 150

A A A BBB

A Terminal lugs Sine filter choke (DC / inverter cabinet)

B Terminal lugs Transformer (AC cabinet)

32 SC125_560HE-IEN083220 Installation Guide

Page 33

SMA Solar Technology AG Electrical Connection

L+

L-

L-

L-

L+

L-

L+

L-

5.1.2 HE version: Power cable connection

Sunny Central 200HE / Sunny Central 250HE / Sunny Central 350HE

At the inverter bridge in the DC / inverter cabinet, three power cables (U1, V1, W1) per power unit

are connected; in the AC cabinet, they have to be connected to the corresponding marked terminal

clamps (U1, V1, W1) of the sine filter choke. The cables have already been equipped with cable lugs

and cut in a way that the connection to the contact tip is clear.

Connection Sine filter choke in the AC cabinet Sunny Central 350HE

H1-02

L1

L1

L2

L2

L3

L3

L-

L-

L+

L+

A B BB

A Terminal lugs Power unit

B Terminal lugs Sine filter

Installation Guide SC125_560HE-IEN083220 33

Page 34

Electrical Connection SMA Solar Technology AG

Sunny Central 500HE / Sunny Central 560HE

The power cable connection of the power units in the inverter cabinet to the sine filter choke in the AC

cabinet is to be carried out using the delivered Radox cables (W131 to W139).

The delivered Radox cables have different lengths for the left-hand and right-hand systems.

With the help of the circuit diagram for the appropriate Sunny Central, attach the cables.

According to the provided circuit diagram, one power unit per phase is connected to the sine filter

choke with 3 x 1 x 185 mm². The appropriate connection screws are to be found at the connection

points.

ATTENTION!

Operational reduction of the Sunny Central through faulty connection!

When connecting the power cables, the following connection order has to be observed

(viewed from the front):

1. Screw

2. Washer

3. Cable lug

4. Connection point sine filter or power unit

5. Cable lug

6. Washer

7. Detent edged ring

8. Nut

34 SC125_560HE-IEN083220 Installation Guide

Page 35

SMA Solar Technology AG Electrical Connection

L-

L+

L-

L+

L-

L+

L+

L-

L+

L-

M3-810

M3-810

L+

L-

L+

L-

Procedure for power cabling:

1. The lower power unit has to be connected first, then the middle one and finally the top one.

2. The power cables with the delivered cable clamps have to be clamped into the corresponding

cable clamp rail.

3. Feed the cables through the opened side wall above the cabinet bottom plates, reinsert them in

the area of the AC cabinet and connect to the sine filter choke.

The following figure shows the terminal lugs at the three power units in the DC / inverter cabinet and

the connection of the power cables to the sine filter in the AC cabinet of the Sunny Central 500HE /

Sunny Central 560HE.

H1-02 H1-02

L+

L-

L+L-L+

L-

A Terminal lugs Sine filter choke

B Terminal lugs Power unit

Installation Guide SC125_560HE-IEN083220 35

Page 36

Electrical Connection SMA Solar Technology AG

L-

L+

L-

L+

L-

L+

L+

L-

L+

L-

M3-810

M3-810

L+

L-

L+

L-

5.1.3 PE connection between AC cabinet and DC / inverter cabinet

The PE rails for the individual switch cabinets are located at the bottom of the side areas. The two PE

rails with the prefabricated PE bridge which is already connected in a switch cabinet must be

connected together when putting together both inverters.

Example PE connection between the switch cabinets of the Sunny Central 500HE

H1-02 H1-02

L+

M3-810

L-

L+L-L+

L-

PE

Checking the grounding connection

When connecting the grounding connection, make sure that the screws are securely

positioned.

Position of the PE rail

Depending on the construction, the exact position of the PE rail in some switch cabinets is

located behind the fuse strip in the DC cabinet or behind the transformer in the AC cabinet.

With the help of the equipment identifier and the provided circuit diagram, the exact

position of the PE rail can be determined.

36 SC125_560HE-IEN083220 Installation Guide

Page 37

SMA Solar Technology AG Electrical Connection

L-

L+

L-

L+

L-

L+

L+

L-

L+

L-

M3-810

M3-810

L+

L-

L+

L-

5.1.4 Control lines at the transfer terminal strip

Checking of the cabling

When connecting the control lines, the correct sequence and the appropriate colors of the

wires have to be observed. The plugs are numbered consecutively.

Most control lines, which have to be connected between the swit ch cabinets, are simply connected to

the transfer terminal strips via plugs. The transfer terminal strips are located in the AC cabinet on the

mounting plate facing the DC / inverter cabinet. The cable bundles to be connected are marked with

target descriptions.

Example transfer terminal strip between the switch cabinets of the Sunny Central 500HE

H1-02 H1-02

L+

M3-810

M3-810

L-

L+L-L+

L-

Position of the transfer terminal strips

With the help of the equipment identifier and the provided circuit diagram, the exact

position of the transfer terminal strips can be determined.

Installation Guide SC125_560HE-IEN083220 37

Page 38

Electrical Connection SMA Solar Technology AG

L-

L+

L-

L+

L-

L+

L+

L-

L+

L-

M3-810

M3-810

L+

L-

L+

L-

5.1.5 Connecting Sunny Central Control to power unit

Attention!

Damage to the cabling through faulty installation

• The cabl es mus t neither be laid in th e cabl e channel, nor parallel to the power cables

(EMV).

• In the switch cabinet, the cables have to be laid freely.

• Connect he plug-in contact carefully to the board.

Connect the data line of the Sunny Central Control to the system control board at the power unit. For

this, the cable has a 4-pole white plug-in contact which has to be plugged into the system control

board. In most switch cabinets, the system control board and the control board (ADAPBFS) are

positioned below the power units, hanging upside down. In the switch cabinets of the

Sunny Centrals 500HE and 560HE, they are located on the top power unit.

The system control board communicates with the control board via a ribbon cable. The slot for the

plug of the data line is located on the right side of the board directly at the communication interface

(Piggy-Back).

Connection terminal for data line Sunny Central 500HE / Sunny Central 560HE

H1-02 H1-02

L+

L-

L+L-L+

L-

38 SC125_560HE-IEN083220 Installation Guide

Page 39

SMA Solar Technology AG Electrical Connection

L+

L-

L-

L-

L+

L-

L+

L-

Connection terminal for data line Sunny Central 350HE

H1-02

L1

L1

L2

L2

L3

L3

L-

L-

L+

L+

Position of connection terminal of data line

With the help of the equipment identifier and the provided circuit diagram, the exact

position of the connection terminal can be determined.

Installation Guide SC125_560HE-IEN083220 39

Page 40

Electrical Connection SMA Solar Technology AG

L-

L+

L-

L+

L-

L+

L+

L-

L+

L-

M3-810

M3-810

L+

L-

L+

L-

L+

L-

L-

L-

L+

L-

L+

L-

5.1.6 Internal control lines of the power unit

The X8 and X9 control lines coming from the AC cabinet are connected to the control board at the

power unit. The control board is also located hanging upside down at the power unit. In the switch

cabinets of the Sunny Centrals 500HE and 560HE, they are located on the top power unit. Both

2-pole green X8 and X9 plug-in contacts have to be fixed to the correspondingly marked sockets.

Connection of the internal control line with Sunny Central 500HE

H1-02 H1-02

L+

M3-810

Connection of the internal control line with Sunny Central 350HE

H1-02

L1

L1

L2

L2

L3

L3

L-

L-

L+

L+

L-

L-

L+L-L+

L-

Position of the connection terminals in the control line

With the help of the equipment identifier and the provided circuit diagram, the exact

position of the connection terminals can be determined.

40 SC125_560HE-IEN083220 Installation Guide

Page 41

SMA Solar Technology AG Electrical Connection

5.1.7 Communication for insulation monitoring

Attention!

Damage to the cabling through faulty installation.

• Lay the connection cables in the cable channel.

The insulation monitoring is located in the DC cabinet. A 2-wire data line connects the Sunny Central

Control with the insulation monitoring and has to be connected as follows:

• Connection: M (+) clamp insulation monitoring: brown wire

• Connection: M (-) clamp insulation monitoring: white wire

Insulation monitoring with connected data line (A) with Sunny Central 500HE and

Sunny Central 560HE

Position of the connection terminal of the insulation monitoring

With the help of the equipment identifier and the provided circuit diagram, the exact

position of the insulation monitoring can be determined.

Installation Guide SC125_560HE-IEN083220 41

Page 42

Electrical Connection SMA Solar Technology AG

L2

L3

L1

L2

L3

L1

L+

L-

L+

L-

5.1.8 Installing internal temperature sensor

The measurement of the inside temperature of the switch cabinet is carried out by a temperature

sensor. In the switch cabinets of the Sunny Central 350, Sunny Central 350HE, Sunny Central 500HE

and Sunny Central 560HE, the temperature sensor is pre-mounted. In all other switch cabinets, the

temperature sensor is located in the DC cabinet upon delivery of the inverters and has to be moved

to and fixed into the AC cabinet when assembling the two switch cabinets.

The temperature sensor has to be fixed in the middle of the inverter. Appropriate retaining screws and

a cable clamp are pre-mounted at the marked installation site.

Fixing the sensor:

1. Open the housing of the temperature sensor.

2. The lower part has to be screwed slightly onto the inside construction.

3. Close the cover of the temperature sensor.

Mo unt ing the tem per atu re s ens or i n th e DC cabi net of t he S unn y Central 150. The temperature sensor

has to be fixed to the right side panel in the DC cabinet.

L1 L2 L3

PE

N

PE

L1 L2 L3

N

42 SC125_560HE-IEN083220 Installation Guide

Page 43

SMA Solar Technology AG Electrical Connection

L-

L+

L-

L+

L-

L+

L+

L-

L+

L-

M3-810

M3-810

L+

L-

L+

L-

Position of the temperature sensor in the AC cabinet of the Sunny Central 500HE and

Sunny Central 560HE

H1-02 H1-02

L+

M3-810

L-

L+L-L+

L-

Installation Guide SC125_560HE-IEN083220 43

Page 44

Electrical Connection SMA Solar Technology AG

L1

L2

L3

L1

L2

L3

L+

L-

L-

L+

L-

L+

L+

L-

L+

L-

L+

L-

L2

L3

L1

L2

L3

L1

5.1.9 Team cabling (optional)

Optionally, two Sunny Centrals can be interconnected in one concrete station or in another electrical

operating room and together feed their power into the grid by means of a medium-voltage

transformer.

When using the team concept, the internal DC power connection of the team configuration has to be

connected between the two cabinet components.

With the inverters Sunny Central 350HE, Sunny Central 500HE and Sunny Central 560HE this is

already installed ex-works. The terminals of the team chief and the team member are different.

Team cabling of the team chief

With the team chief, two DC cables coming from the DC bus bar of the DC cabinet have to be

connected to the input of the team clamps in the AC cabinet.

Team clamp for team cabling with team chief with Sunny Central 250HE

A

B

A Connection points for internal team cabling

B Connection points for external team cabling

44 SC125_560HE-IEN083220 Installation Guide

Page 45

SMA Solar Technology AG Electrical Connection

L2

L3

L1

L1

L2

L3

L+

L-

L-

L-

L+

L-

L+

L-

L+

L-

L+

L-

L+

L-

Team cabling of the team member

ATTENTION!

Damage to the Sunny Central through incorrect cabling

• When connecting the team cables at the team contactor, the labeling of the cables

has to be observed.

• Check polarity of DC cables.

With the team member, the two DC cables for the internal team cabling coming from the DC bus bar

of the DC cabinet are to be led to the connection points (Shunt and NH fuses) at the team contactor.

The team contactor is located in the AC cabinet at the front mounting plate.

Checking of the cabling

When connecting the power cables, make sure that the screws are securely positioned.

Team contactor for team cabling with team member for Sunny Central 250HE

A

BB

A Connection points for internal team cabling

B Connection points for external team cabling

External team connection

The external team cabling is described in chapter 5.2.8?„Team Power Cabling“ (64).

Position of the connection terminals of the team contacts

Installation Guide SC125_560HE-IEN083220 45

With the help of the equipment identifier and the provided circuit diagram, the exact

position of the internal and external team contacts can be determined.

Page 46

Electrical Connection SMA Solar Technology AG

5.1.10 EVR Cabling (optional)

With the Sunny Centrals 350 and 500, the EVR resistor has to be mounted on top of the Sunny

Central. Proceed as follows:

1. The EVR resistor between the rails has to be pushed onto the roof of the Sunny Central.

2. 9 screws at the protective bar of the EVR resistor have to be removed.

3. Protective bar has to be taken off to the front.

4. Connect the grounding cables in EVR resistor to the left side of the bolt (torque 21 Nm).

5. Fix the EVR resistor with both screws on the left and right side of the EVR resistor onto the rails.

6. Connect the power cables using the provided circuit diagram (torque 21 Nm).

7. Fix the protective bar with 9 screws onto the EVR resistor (torque 2.6 Nm).

☑ The EVR resistor is installed.

5.1.11 Sunny Central for installation near the sea (optional)

Optional package for Sunny Centrals in the case of installation near the sea. With this optional

package, the Sunny Centrals are protected against salt mist and comply to the requirements of

DIN EN 60721-3-3, class 3C2 "Environmental Conditions for Fixed Use,. Weather-protected". You

can find further information in the separate documentation.

46 SC125_560HE-IEN083220 Installation Guide

Page 47

SMA Solar Technology AG Electrical Connection

5.2 External Connections

ATTENTION!

Yield loss due to poor electrical conductivity!

The connection points for the external terminals are either copper or aluminum. If copper

and aluminum are connected with each other at the connection point, the electrical

conductivity decreases.

• Check which material is used at the connection point.

• When combining both materials, use either a copper-aluminum washer or copperaluminum cable lugs.

For external electrical connection of the Sunny Centrals, the following connections have to be made:

• AC grid connection

• Connection PE rail with HE version

• AC control voltage

•DC connection

• Power cabling Team concept (optional)

• External messages and signals

• Sensors and digital outputs

• Communications connection

• Emergency-stop cabling

• Lightning / Surge protection

Making the external connections

Make the external connections with the help of the provided circuit diagram.

Dimensioning the connections

How to carry out the AC grid-connection point as well as the maximum inverter-specific

connection cross-section and cable lugs are included in the installation requirements of the

relevant Sunny Central.

5.2.1 AC grid-connection standard devices

WARNING!

Risk of death due to burns and electric shock when live parts of the low-voltage

grid are touched!

• Do not touch the live components of the Sunny Central or low-voltage grid.

• All safety precaution measures regarding the low voltage grid must be observed.

• Only work on this device when it is switched off and under voltage-free conditions.

Installation Guide SC125_560HE-IEN083220 47

Page 48

Electrical Connection SMA Solar Technology AG

The AC grid connection of the Sunny Central (except Sunny Central type HE) is 3-phased.

The Sunny Centrals are configured for the connection to a TN-C grid as standard.

Connection to TN-S or TT grid: Remove bridge between N and PE at the grid connection

(see circuit diagram).

Connection to IT grid: An IT grid can be project-specifically realized. Contact the Sunny

Central Service Line

The connection terminals are to be located in the AC switch cabinet in the lower area of the front

mounting plate. The cable must be routed into the inverter from below, the connection of the AC

cables are made using cable lugs.

En sur e th e gr id c onn ect ion cab le i s fu sed at t he n omi nal cur rent i ndi cat ed o n th e ty pe p lat e.

If the specified nominal current differs from the nominal current of the fuse plug, the fuse

plug having the next highest nominal current may be used.

The cables are fed through the socket and the base of the cabinet.

1. Open the base plates (slideable plate) in the front of the cabinet and pull the cable into the

inside of the cabinet.

2. For strain relief of the cables, fix the cable clamp rail with cable clips. The cable clips are

included in the delivery.

The connection terminals of the Sunny Central 350 are located in the upper area of the side panel of

the AC switch cabinet. The cable must be routed through cable bolting in the roof of the AC switch

cabinet, the AC cables are connected using cable lugs.

ATTENTION!

Damage to the Sunny Central due to faulty bolted connection at the AC

connection.

• For strain relief of the AC connection, only use aluminum cable clips.

• Screw the AC cables at the connection point with the appropriate torque

(see appendix).

48 SC125_560HE-IEN083220 Installation Guide

Page 49

SMA Solar Technology AG Electrical Connection

L1

L2

L3

L1

L2

L3

N

PE

N

PE

L+

L-

L-

L+

L-

L+

L+

L-

L+

L-

L+

L-

L2

L3

L1

L2

L3

L1

View of the AC connection of the Sunny Central 250

View of the AC connection of the Sunny Central 350

N

PE

L1

L2

L3

L3

L2L1

N

PE

Achtung!

Achtung!

Bei ausgeschaltetem

Bei ausgeschaltetem

Hauptschalter

Hauptschalter

unter Spannung

unter Spannung

Sealing the cable ports

To seal the slideable plates and the installed cables, install the seals included in the

delivery.

Installation Guide SC125_560HE-IEN083220 49

Correct installation of the rotary field

The grid connection must be installed in such a way that a right-hand rotary field lies at the

input of the cabinet. In case of incorrect connection, the Sunny Central issues a fault

message.

Page 50

Electrical Connection SMA Solar Technology AG

Position of the AC connection terminals

Due to construction, the AC connection can vary. With the help of the equipment identifier

and the provided circuit diagram, the exact position of the AC connection terminals can be

determined.

5.2.2 AC grid connection of HE versions

WARNING!

Risk of death due to burns and electric shock when live parts are touched!

• Do not touch the live components of the Sunny Central or the public grid.

• All safety precaution measures regarding the public grid must be observed.

• Only work on this device when it is switched off and under voltage-free conditions.

The Sunny Central HE series is designed for grid connection through a medium-voltage transformer.

The medium-voltage transformer is realized depending on the project. The form of grid connection of

the inverter is IT grid. That means: the grid between the inverters and the medium-voltage transformer

is not grounded. The connection is 3-phased with the following operating voltage:

V: nominal voltage between the external conductor: depending on the device type 270 V

(315 V with Sunny Central 560)

Vo: Nominal voltage between external conductor and ground: 1000 V (depending on the current

operation of the device)

ATTENTION!

High voltages in the IT grid.

Due to the IT grid, during inverter operation there are nominal voltages of up to 1000 V

between the external conductor and ground.

• When choosing the AC cables, take into account the increased demands on the

nominal voltage Vo against grounding.

The connection of one fuse load break switch in the AC cabinet of the inverter to the low voltage

winding of a medium-voltage transformers is 3-phase.

ATTENTION!

Damage to the Sunny Central through faulty AC connection.

Dimensioning of the AC cables which have to be connected

• Lay the AC cables with a voltage resistance of minimum 1000 V.

• Lay the AC cables ground- and short-circuit proof.

• Only use aluminum cable clips (included in the delivery) for the cable clips of the AC

connection.

50 SC125_560HE-IEN083220 Installation Guide

Page 51

SMA Solar Technology AG Electrical Connection

L2

L3

L1

L1

L2

L3

L+

L-

L-

L-

L+

L-

L+

L-

L+

L-

L+

L-

L+

L-

AC gri d co nne cti on f or I T gr id a t th e fu se s wit ch d isconn ect or in the AC cabinet Sunny Central 250HE,

the cable must be routed into the inverter from below.

AC grid connection for IT grid to copper bus bar via fuse switch disconnector in the AC cabinet of the

Sunny Central 350HE. Cables must be routed into the inverter from the top.

L1

L2

L3

Achtung!

Bei ausgeschaltetem

Hauptschalter

unter Spannung

AC grid connection for IT grid to EriFlex bus bars outside the AC cabinet of the Sunny Central 500HE

and 560HE

Installation Guide SC125_560HE-IEN083220 51

Page 52

Electrical Connection SMA Solar Technology AG

ATTENTION!

Operational reduction of the Sunny Central through faulty connection!

When connecting the power cables, the following connection order has to be observed

(viewed from the front):

1. Screw

2. Washer

3. Cable lug

4. Connection EriFlex

5. Cable lug

6. Washer

7. Detent edged ring

8. Nut

52 SC125_560HE-IEN083220 Installation Guide

Page 53

SMA Solar Technology AG Electrical Connection

L2

L3

L1

L2

L3

L1

1. EriFlex bus bars (included in the delivery) have to be inserted into the AC cabinet from the top.

2. Connect the EriFlex bus bars to the fuse switch disconnector in the AC cabinet.

3. Connect the AC cables from outside to the EriFlex bus bars.

AAA

L3

L2

L1

B

B

B

A EriFlex bus bars in the Sunny Central

B Openings in the switch cabinet roof for the EriFlex bus bars

AC connection Sunny Central 500HE / Sunny Central 560HE

The AC connection of the Sunny Central of the types 500HE and 560HE must be made

using the EriFlex bus bars that are included in the delivery.

Installation Guide SC125_560HE-IEN083220 53

Page 54

Electrical Connection SMA Solar Technology AG

5.2.3 AC grid connection with MV stations

WARNING!

Risk of death due to burns and electric shock when live parts of the public grid

are touched!

• Do not touch the live components of the Sunny Central or the public grid.

• All safety precaution measures regarding the public grid must be observed.

• Only work on this device when it is switched off and under voltage-free conditions.

The connection concept for two Sunny Central HE inverters is factory provided in the Sunny Central

MV sta tio n. I n th e Su nny Centra l MV sta tio n, t he A C co nne cti on is 3-phase to the high-voltage winding

of a three winding power converter medium voltage transformer. The connection is made with male

taper plug-in contacts not included in the delivery.

Grounding and short-circuiting of the MS transformer high-voltage side

• Grounding and short-circuiting of the MS transformer high-voltage side is made in the customer

side upstream MS switching station.

• Grounding and short-circuiting of the MS transformer under-voltage side is made in the Sunny

Central HE inverter on the AC fuse switch disconnector. The corresponding grounding and shortcircuiting set can be ordered at SMA.

• This is connected to the grounding cable, then put into the fuse switch disconnector and closed.

• The grounding cable is located in the marked cable channel of the AC cabinet.

Optional grounding and short-circuiting set

The grounding and short-circuiting set can be ordered at SMA.

WARNING!

Risk of death due to burns and electric shock when live parts of the medium

voltage are touched!

For service and maintenance work on the Sunny Central, disconnect the medium voltage

transformer from the grid.

54 SC125_560HE-IEN083220 Installation Guide

Page 55

SMA Solar Technology AG Electrical Connection

L-

L+

L-

L+

L-

L+

L+

L-

L+

L-

M3-810

M3-810

L+

L-

L+

L-

5.2.4 Connection PE rail with HE version

WARNING!

Risk of death due to burns and electric shock when live parts are touched!

• Do not touch the live components of the Sunny Central, the public grid or the lowvoltage grid.

• All applicable safety regulations must be observed.

• Only work on this device when it is switched off and under voltage-free conditions.

In the Sunny Central 200HE, Sunny Central 250HE and Sunny Central 350HE, the PE rail in the AC

cabinet has to be connected to the equipotential bonding of the installation site or the electrical

operating room. In the Sunny Central 500HE and Sunny Central 560HE, connect both PE rails in the

DC cabinet and in the inverter cabinet separately to the equipotential bonding or grounding.

Terminal for equipotential bonding in Sunny Central 500HE

H1-02 H1-02

L+

M3-810

M3-810

L-

L+L-L+

L-

PE

Cable dimensioning of the PE connection

The PE connection for the equipotential bonding has to be carried out with at least

1 x 50 mm².

Position of the PE rail

Depending on the construction, the exact position of the PE rail in some switch cabinets is

located behind the fuse strip in the DC cabinet or behind the transformer in the AC cabinet.

With the help of the equipment identifier and the provided circuit diagram, the exact

position of the PE rail can be determined.

Installation Guide SC125_560HE-IEN083220 55

Page 56

Electrical Connection SMA Solar Technology AG

L2

L3

L1

L2

L3

L1

L+

L-

L+

L-

5.2.5 AC control voltage

WARNING!

Risk of death due to burns and electric shock when live parts are touched!

• Only work on this device when it is switched off and under voltage-free conditions.

The energy required for driving the Sunny Central is provided by an external control voltage supply

source. As standard, The form of grid connection of the control voltage supply source is TN-S grid.

The connection in the Sunny Central inverters of the type 100LV, 125LV, 150, 200 and 200HE is

single-phase. For all other Sunny Centrals it is three phase. The connection is made via a separate

cable.

Realization of the external control voltage

When connecting the external control voltage, it is obligatory to follow the circuit diagram

included in the delivery.

As an option, the power required for driving the internal circuits of the Sunny Central 230 / 400 V

(except HE version) can be taken internally from the grid-feed-in line of the inverter. This reduces the

feed-in energy yields by the amount of power required by the inverter itself (fans, heating etc.). To

realize this, the connection terminals of the AC control voltage have to be bridged according to the

circuit diagram.

Connection terminal for control voltage in the Sunny Central 150

L1 L2 L3

L1 L2 L3

PE

N

PE

N

56 SC125_560HE-IEN083220 Installation Guide

Page 57