Page 1

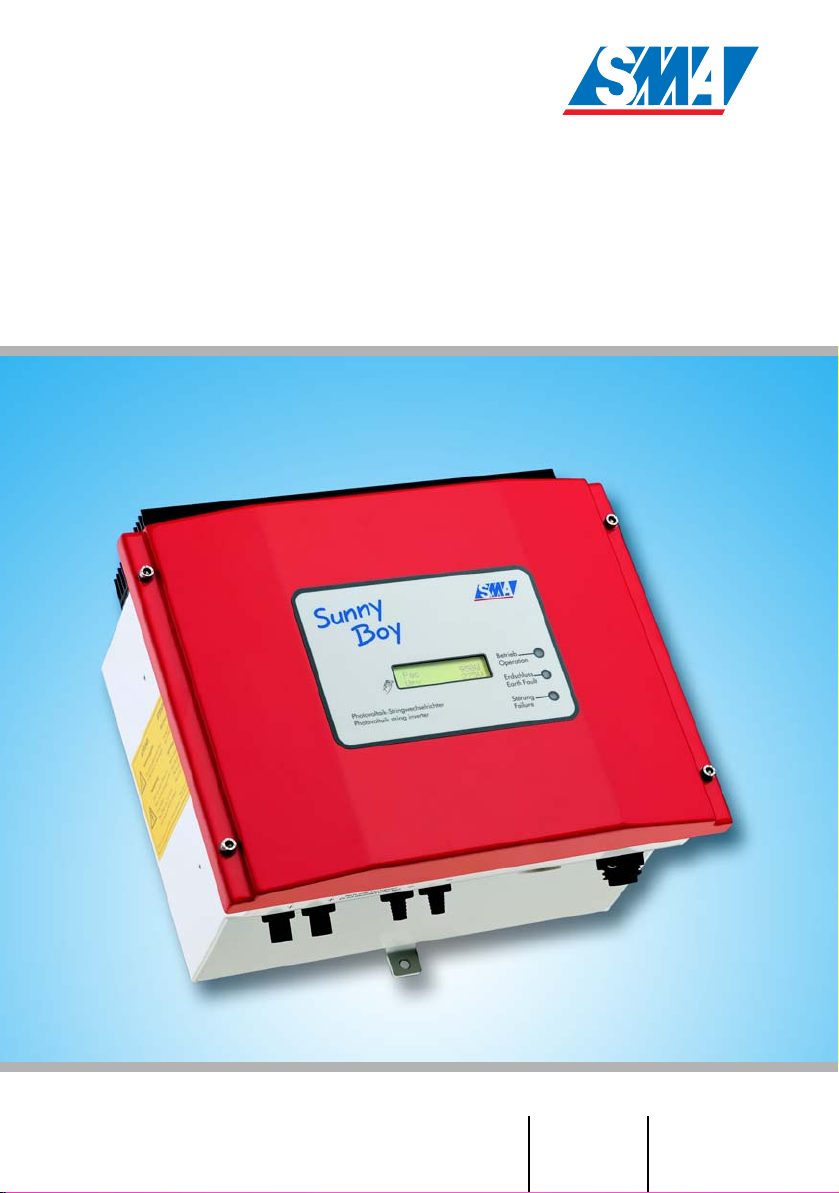

Sunny Boy 700

String Inverter Sunny Boy 700

Installation Guide Version 1.1 SB700-11:SA2006

Page 2

Page 3

SMA Technologie AG Explanation of Symbols used in this Document

Explanation of Symbols used in this Document

This symbol indicates information that is essential for a trouble-free

and safe operation of the product. Please read these sections carefully in order to avoid any damages of the equipment and for optimal personal protection.

This symbol indicates information that is required for the optimal operation of

the product. Read these sections carefully in order to ensure an optimal operation of the product and all its features.

This symbol indicates an example.

Installation Guide SB700-11:SA2006 Page 3

Page 4

Legal Restrictions SMA Technologie AG

Liability exclusion

The information contained in this documentation are the property of SMA Technologie AG. No part of this

documentation may be published without written permission from SMA Technologie AG. A reproduction for

internal purposes for the evaluation of the product or an appropriate application is permitted and does not

require authorization.

All information are based on our "General Terms and Conditions of Delivery of SMA Technologie AG”.

The content of this documentation is reviewed continuously and adjusted, if necessary. SMA Technologie

AG provides this documentation without exclusion of deviations and without warranty of completeness. You

will find the current version on the Internet at www.SMA.de or can obtain it via the usual sales channels.

Warranty or liability claims for all kinds are excluded in case of damages due to:

• Inappropriate use of the product

• Operation of the product in an improper environment

• Operation of the product without considering the relevant safety regulations

• Non-fulfillment of the warnings or safety instructions described in the documentation for the product

• Operation of the product under faulty conditions concerning security and protection

• Arbitrary changing of the product or the provided software

• Failure of the product due to interference of connected or contiguous devices out of legal limit values

• Disasters and force majeure

Software Licensing

The use of the provided software by SMA Technologie AG is subject to the following conditions:

The software may be reproduced for internal purposes and installed on any number of computers. Provided

source codes can be changed and adjusted on the company’s own authority according to the internal

purpose. Driver may be ported to other operating systems as well. No part of the source codes may be

published without written permission of SMA Technologie AG. Sublicensing of the software is not

acceptable.

Liability limitation: SMA Technologie AG disclaims liability for any direct or indirect consequential damages

arising from the use of the software produced by SMA Technologie AG. The same applies for the provision

and/or non-provision of support.

Provided software not produced by SMA Technologie AG is subject to the respective licensing and liability

agreements of the manufacturer.

Trademarks

All brand and product names used herein are trademarks or registered trademarks of their respective

holders, although they may not be specifically designated as such.

SMA Technologie AG

Hannoversche Strasse 1-5

34266 Niestetal

Germany

Tel. (+49) 5 61 95 22 – 0

Fax (+49) 5 61 95 22 – 100

www.SMA.de

E-Mail: info@SMA.de

© 2005 SMA Technologie AG. All rights reserved.

Page 4 SB700-11:SA2006 Installation Guide

Page 5

SMA Technologie AG Table of Contents

Table of Contents

1 Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Unit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2 External dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4 Installation requirements . . . . . . . . . . . . . . . . . . . . . 13

4.1 Installation site requirements . . . . . . . . . . . . . . . . . . . . . . . . .13

4.2 PV generator requirements. . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.3 Low voltage grid 230 V (AC). . . . . . . . . . . . . . . . . . . . . . . . .15

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Mounting the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.2 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.3 Setting the input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5.4 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6 Opening and closing the Sunny Boy . . . . . . . . . . . . 33

6.1 Opening the Sunny Boy. . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.2 Closing the Sunny Boy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.1 Input voltage range 119 ... 250 V DC . . . . . . . . . . . . . . . . . .35

7.1.1 PV generator connection data . . . . . . . . . . . . . . . . . . . . .35

7.1.2 Grid connection data . . . . . . . . . . . . . . . . . . . . . . . . . . .35

7.2 Input voltage range 96 ... 200 V DC . . . . . . . . . . . . . . . . . . .36

7.2.1 PV generator connection data . . . . . . . . . . . . . . . . . . . . .36

7.2.2 Grid connection data . . . . . . . . . . . . . . . . . . . . . . . . . . .36

7.3 Input voltage range 73 ... 150 V DC . . . . . . . . . . . . . . . . . . .37

7.3.1 PV generator connection data . . . . . . . . . . . . . . . . . . . . .37

7.3.2 Grid connection data . . . . . . . . . . . . . . . . . . . . . . . . . . .37

7.4 Device description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

7.5 Operating parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

8 Replacing the varistors. . . . . . . . . . . . . . . . . . . . . . . 41

9 Rating for a line circuit breaker. . . . . . . . . . . . . . . . . 45

10 Contact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Installation Guide SB700-11:SA2006 Page 5

Page 6

Table of Contents SMA Technologie AG

Page 6 SB700-11:SA2006 Installation Guide

Page 7

SMA Technologie AG Foreword

1 Foreword

The installation of the Sunny Boy may only be done by qualified

technicians. The installer must be approved by the utility company.

Please read the installation guide carefully before you begin with

the installation. The installation of utility interactive power sources

must be compliant with all applicable regulations of the utility

company and with all applicable regulations and standards.

The Sunny Boy 700 is equipped with the SMA grid guard. This is a type of

independent disconnection device. It ensures that the Sunny Boy 700 complies

with the VDEW (Verband der Elektrizitätswirtschaft – German Electricity

Industry Association) regulations for the connection and parallel operation of

electrical power units to the low-voltage grid of the electricity supply company

and with DIN VDE 0126 (4.99) which is a part of these regulations.

This installation manual is intended solely for qualified electricians. Its aim is to help

install and set up SMA Sunny Boy SB 700 inverters quickly and correctly.

For detailed information on troubleshooting and on how to use the Sunny Boy 700,

including information about the different communication options, please see the

operating instructions.

The „Sunny Design“ tool will help to dimension and check the size of your strings with

respect to the inverter you intend to use. Further information about „Sunny Design“

is available at www.SMA.de.

If your Sunny Boy is equipped with a communication interface, you will find detailed

instructions for installation in the description of the communication interfaces (PiggyBacks), which has been delivered with the device.

If you require further information, please call the Sunny Boy hotline on the following

number:

+49 (0)561 95 22-499

Installation Guide SB700-11:SA2006 Page 7

Page 8

Foreword SMA Technologie AG

Page 8 SB700-11:SA2006 Installation Guide

Page 9

SMA Technologie AG Safety information

2 Safety information

Check your plant configuration and the

string sizing with „Sunny Design“

(available at www.SMA.de) or with the

Sunny Boy Hotline before you start with

the installation. Exceeding the

specifications with the input voltage will

destroy the Sunny Boy. Overvoltage on

Betrieb

Photovoltaik-Stringwechselrichter

Operation

Photovoltaicstringinverter

Erdschluss

Earth

F

ault

Störung

Failure

Work on the Sunny Boy with the lid removed must be carried out

by a qualified electrician. Hazardous and even lethal voltages can

be encountered within the enclosure. Before working on the Sunny

Boy with the lid removed, the AC and DC voltages MUST be

disconnected from the Sunny Boy and it must be sure that all

capacitors are discharged.

The Sunny Boy must be disconnected from the mains and

precautions must be taken to prevent the grid being reconnected.

In addition, the connections to the PV generator must be

disconnected.

the DC side can even cause dangerous

explosions of the Sunny Boys input

capacitors and explosions of the

electrolytes coming from the exploded

capacitors.

After isolating the AC and DC voltage you must wait approx. 30

minutes for the capacitors in the Sunny Boy to discharge. Only then

is it safe to open the unit by removing the lid. You must also make

sure that no voltage is present in the device.

The electronics inside your Sunny Boy 700 is vulnerable in terms of

electrostatic discharge. Be sure to be connected to ground (e.g. the

enclosure of the Sunny Boy) before handling anything within the

enclosure of the Sunny Boy.

This appliance is not intended for use by young children or infirm

persons unless they have been adequately supervised by a

responsible person to ensure that they can use the appliance

safely.

Young children should be supervised to ensure that they do not

play with the appliance.

Installation Guide SB700-11:SA2006 Page 9

Page 10

Safety information SMA Technologie AG

Page 10 SB700-11:SA2006 Installation Guide

Page 11

SMA Technologie AG Overview

Vari

k

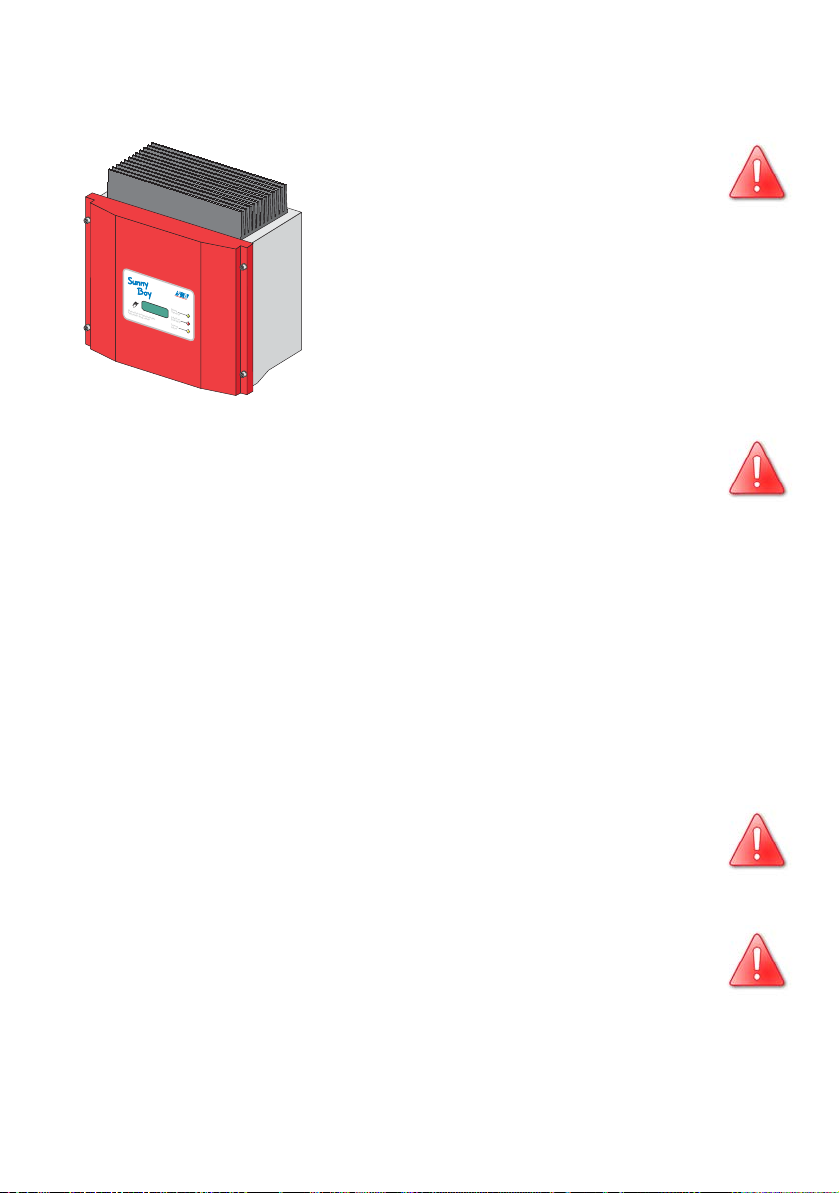

3 Overview

3.1 Unit description

The following diagram gives a schematic overview of the various components and

connection points inside the Sunny Boy 700 with the lid removed:

stors

page 41

PV input plug

(DC) page 26

et for communication

Soc

(RS232, RS485, NLM PiggyBack, Radio)

PE

PE (protective

earth) connecting

cable for lid

Socket for

display unit

Terminal block for

setting the input

voltage range

Slots for setting the

input voltage range

Operating status

LEDs

Communications

N

L

connector

Connection plug

(AC) page 21

Installation Guide SB700-11:SA2006 Page 11

Page 12

Overview SMA Technologie AG

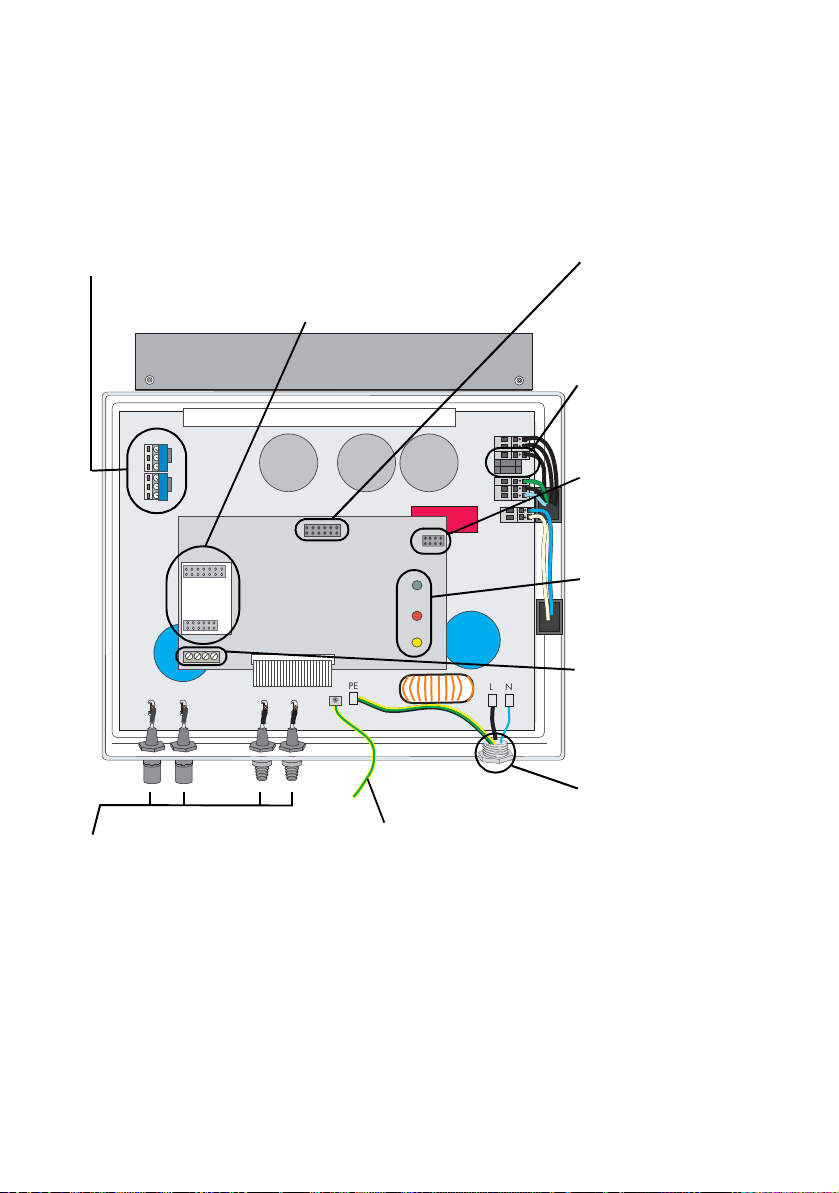

3.2 External dimensions

180 mm

Betrieb

Operation

Erdschluss

Photovoltaik-Stringwechselrichter

Photovoltaic

EarthFault

Störung

s

tring

i

nverter

Failure

322 mm

290 mm

Page 12 SB700-11:SA2006 Installation Guide

Page 13

SMA Technologie AG Installation requirements

4 Installation requirements

Please check that all of the conditions listed below are met before installing and

setting up the Sunny Boy.

4.1 Installation site requirements

The Sunny Boy 700 weighs 16 kg. Please take this weight into

account when choosing the installation site and method of

installation.

The ambient temperature must be within -25 °C to +60 °C.

The Sunny Boy 700 should be installed in a place where it is not

exposed to direct sunlight. An increased ambient temperature can

16 kg

The Sunny Boy is designed to be mounted on a vertical wall. For an optimum energy

yield and the most convenient operation, vertical installation at eye-level is

preferable. In case it is absolutely necessary to tilt the Sunny Boy to the back the

maximum angle is 45 °. If installing the unit outdoors, make sure that it is not slanting

forwards.

reduce the yield of the PV system.

It is not recommended to install the Sunny Boy lying on the back side with the lid

facing upwards.

min. 45°

Mount the Sunny Boy in a vertical position or

with a slight angle to the back.

Installation Guide SB700-11:SA2006 Page 13

Do not mount the Sunny Boy with an

angle to the front or on the back.

Page 14

Installation requirements SMA Technologie AG

When choosing the installation site, be sure to note the

following:

Unintentionally pulling out the DC plug connector under load can

damage the plug and result in bodily injury or death! Install the

Sunny Boy in such a way that it is not possible (e.g. for children) to

unplug the DC plug connector unintentionally.

Individual components in the Sunny Boy can reach a temperature

of more than 60 °C.

Do not install the Sunny Boy on flammable construction materials,

in areas where highly inflammable materials are stored or in

potentially explosive environments!

When choosing the installation site, ensure there is enough space for heat to

dissipate. Under normal conditions, the following guidelines should be applied for

the space to be kept clear around the Sunny Boy 700:

Minimum clearance

Sides 20 cm

20

cm

Top 20 cm

Underneath 20 cm

In front 5 cm

20 cm

Photovoltaik-Stringwechselrichter

Photovoltaic

Betrieb

Operation

Erdschluss

Earth

F

ault

Störung

5

s

tring

i

nverter

Failure

cm

20

cm

20 cm

In domestic installations, the unit should not be

mounted on plasterboard walls or similar as otherwise

audible vibrations are likely to result.

We recommend securing the unit to a solid surface.

The Sunny Boy 700 will emit a slight noise during

operation. This noise can be annoying when the Sunny

Boy is installed within a living area.

Page 14 SB700-11:SA2006 Installation Guide

Page 15

SMA Technologie AG Installation requirements

4.2 PV generator requirements

The Sunny Boy 700 is designed to be connected to up to two strings (PV modules

wired in series) having a homogenous structure (modules of the same type, identical

orientation, tilt and number).

The „Sunny Design“ tool will help to dimension and check the size of your string with

respect to the inverter you intend to use. Information about the „Sunny Design“ tool

is available at www.SMA.de.

The unit has four DC plug connectors (two for each string) for connecting the PV

generators. The connecting cables from the PV generators must also be fitted with this

type of plug connector. A pre-assembled set for connecting the free cable ends from

a string is available as an optional accessory. The SMA order codes for the various

connectors are as follows:

• Multi-contact 3 mm: "SWR-MC"

• Multi-contact 4 mm: "MC-SET"

• Tyco: "TYCO-SET"

Limit values for DC input

Max. voltage 250 V (DC)

Max. input current 10 A (DC)

4.3 Low voltage grid 230 V (AC)

The Sunny Boy must have a three-conductor connection to the mains (live (L), neutral

(N), protective earth (PE)).

The grid connection terminals on the AC connection

socket included in the accessories kit can take wires

with a cross-section of up to 2.5 mm². The accessories

Cable

diameter

o

11 ... 25 mm

Wire

cross-section

max. 2,5 mm²

kit also contains a PG13.5 AC connection socket for

connecting cables with a diameter between 9 mm and

13.5 mm, while the PG16 connection socket is used for

cables with a diameter up to a maximum of 17 mm. For detailed instructions, see

sections "Connecting the AC output with PG13.5" (page 22) and "Connecting the

AC plug with PG16" (page 24).

Installation Guide SB700-11:SA2006 Page 15

Page 16

Installation requirements SMA Technologie AG

We recommend using a 16 A line circuit

breaker to protect the power circuit. No

loads should be connected to this power

circuit.

Photovoltaik-Stringwechselrichter

Photovoltaic

Betrieb

Operation

Erdschluss

Earth

F

ault

Störung

stringi

nverter

Failure

16A

Rating for a line circuit breaker in a photovoltaic electrical

power unit operated in parallel with the low-voltage grid

Various factors should be taken into account when selecting line circuit breakers.

These include, for example:

• The type of cable used (conductor material and insulation)

• Ambient temperatures affect the cables (higher temperatures result in a reduced

maximum current load)

• Method of routing the cable (reduces the ampacity of the conductor)

• Bundling cables together (reduces the ampacity of the conductor)

• Loop impedance [Z] (in the event of a body contact this limits the current that can

flow and therefore determines the response behaviour of the circuit breaker)

• Adequate clearance between the circuit breakers in order to avoid excessive

heating (automatic circuit breakers trip earlier when they are warmer)

• Selectivity

• Protection class of the connected load (VDE 0100, part 410), Protection against

electric shock

Please have a look at chapter 9 "Rating for a line circuit breaker" (page 45).

1

The following standards

should be followed in all cases:

• DIN VDE 0298-4 (Cable routing and current-carrying capacity)

• DIN VDE 0100; part 430 (Protective measures; protection of cable and

cords against overcurrent)

• DIN VDE 0100; part 410 (Protective measures; protection against electric

shock)

1. The standards mentioned above are to be only used as a guideline for your

installation. They apply for installations in Germany. Please note that other

standards will apply for different countries throughout the world.

Page 16 SB700-11:SA2006 Installation Guide

Page 17

SMA Technologie AG Installation requirements

The system impedance at the installation site of the Sunny Boy 700 must be less than

1 Ohms for the islanding detection and the fuses to work porperly. In addition, we

recommend dimensioning the cable cross-section so that line losses do not exceed 1%

at the nominal power. Line losses depending on the cable length and cross-section

are shown in the graph below. It shows a multi-conduit cable with all conduits made

of copper.

1,4%

1,2%

1,0%

0,8%

0,6%

Loss

0,4%

0,2%

0,0%

0 m

Do not use cables where the losses will exceed 1.0 %.

1,5 mm²

5 m

10 m 15 m 20 m 25 m 30 m 35 m 40 m 45 m 50 m

2,5 mm²

Cable length

The maximum cable lengths for the different cable cross-sections are as follows:

Cable cross-section 1.5 mm² 2.5 mm²

Max. length 33 m 55 m

Installation Guide SB700-11:SA2006 Page 17

Page 18

Installation requirements SMA Technologie AG

The Sunny Boy 700 is designed for operation on 230 V grids and works at grid

voltages of 198 V to 260 V at 49.8 Hz to 50.2 Hz.

Limit values for AC output

Voltage range 198 V ... 260 V

Frequency range 49.8 Hz ... 50.2 Hz

Voltage range

(without MSD)

Frequency range

(without MSD)

180 V ... 260 V

45.5 Hz ... 54.5 Hz

The Sunny Boy 700 is equipped with an automatic 50 Hz / 60 Hz utility frequency

detection. It can therefore be connected to a 50 Hz or 60 Hz utility without any

further configuration changes. Pay attention to the local utility regulations in any

case.

Page 18 SB700-11:SA2006 Installation Guide

Page 19

SMA Technologie AG Installation

5 Installation

5.1 Mounting the unit

To make the job easier, we recommend you use the

supplied wall bracket to mount the Sunny Boy 700. For

vertical installation on solid concrete or block walls, for

example, you can fit the bracket using 8 mm x 50 mm

hexagon bolts to DIN 571 standard, stainless steel

type, and with wall plugs type SX8.

Betrieb

Photovoltaik-

Operation

Photovoltaic

Stringwechselrichter

s

Erdschluss

tring

i

nverter

E

arth

F

ault

Störun

g

Failure

When selecting the mounting materials, be sure to take

into account the weight of the Sunny Boy 700 (16 kg).

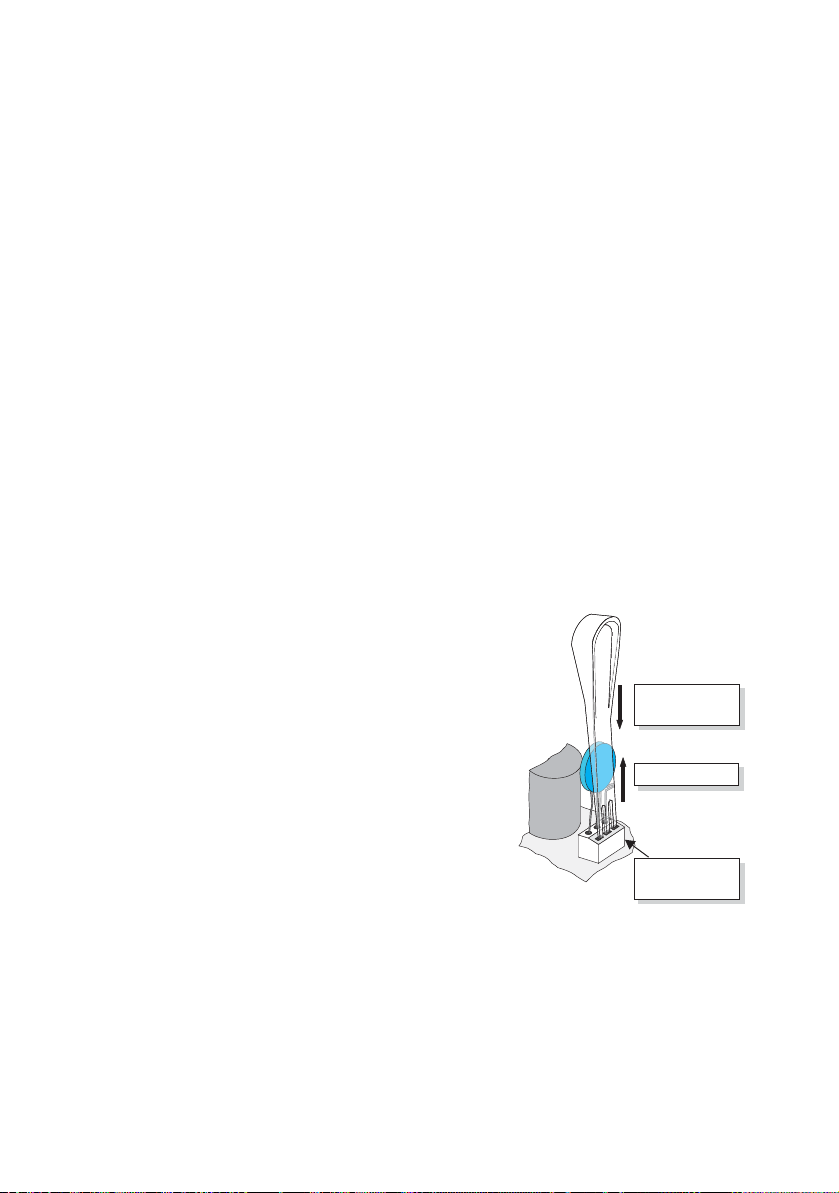

1. Fit the wall bracket (1). To mark the positions to

drill the holes, you can use the wall bracket as a

drilling template.

2. Now hook the Sunny Boy 700 onto the wall

bracket (2) at its upper mounting plate so that it

cannot be moved sideways.

3. Fix the Sunny Boy 700 onto its bracket by

screwing the supplied M6x10 bolt into the central

threaded hole at the bottom of the bracket (3).

4. Make sure the Sunny Boy 700 is positioned

securely on the bracket.

2

1

3

Installation Guide SB700-11:SA2006 Page 19

Page 20

Installation SMA Technologie AG

5.2 Electrical installation

Check the correct polarity before you connect the PV strings!

The complete wiring for a Sunny Boy 700 is shown schematically in the following

diagram:

16A

B

max. 2.5 mm²

Communication

String 1

String 2

Page 20 SB700-11:SA2006 Installation Guide

Page 21

SMA Technologie AG Installation

Connecting the AC output

Before you connect the mains cable to the AC connection socket,

make sure that no voltage is present at the cable.

A round plug connector system is used, which allows various cable diameters to be

used in the cable outlet. For this reason, the accessories kit includes a PG13.5

pressure screw and a PG16 pressure screw. Check which screw fitting is the right one

for your AC cable.

To connect up the AC output, follow these steps:

1. Check the grid voltage. If this is higher than

260 V, the Sunny Boy 700 will not be fully

operational. In this case, contact the local grid

operator for assistance.

The maximum grid voltage for feeding

Max. 260 V!

electricity into the grid is 260 V!

2. Isolate the grid connection (switch the line circuit

breaker to its "off" position), make sure it cannot

be switched back on, and test to make sure no

voltage is present.

Off!

1. 2. 3.

You must make sure that no voltage is

present at the AC output before opening

the Sunny Boy.

3. Now take the AC connection socket parts included in delivery of your Sunny Boy

700 and connect up the cable, with shielding and insulation stripped, as

described on the following pages:

Pressure screw

Sealing ring

for PG13.5

Threaded sleeve

Socket element

Installation Guide SB700-11:SA2006 Page 21

Cord grip

for PG13.5

for PG13.5

Pressure screw

version PG16

for large cable cross-

sections

Page 22

Installation SMA Technologie AG

Connecting the AC output with PG13.5

To connect a cable with a maximum diameter of 13.5 mm, proceed as follows.

1. Press the sealing ring into the cord grip.

Cord grip

Sealing ring

2. Now slide the pressure screw over the cable first of all, followed by the cord

grip with the sealing ring in it. Now slide the threaded sleeve over the cable.

Cord grip with

sealing ring

Threaded sleeve

Pressure screw

3. Now connect the individual conductors to the socket element in sequence.

- Protective earth PE (green/yellow) to the screw terminal

with the earth sign. It is required that the PE wire is

slightly longer than the L and N wires.

1

- Neutral conductor N (blue) to screw terminal 1.

2

- Live L (brown or black) to screw terminal 2.

3

- Terminal 3 remains unused.

Terminals in the socket

element

4. Make sure the wires are securely connected.

Connected wires

Pressure screw

Socket element

Threaded sleeve

Cord grip with

sealing ring

Page 22 SB700-11:SA2006 Installation Guide

Page 23

SMA Technologie AG Installation

5. Now screw the threaded sleeve onto the socket element and tighten it.

Threaded sleeve

screwed

onto socket element

Pressure screw

Cord grip with

sealing ring

6. Now screw the pressure screw into the

threaded sleeve and tighten it. The cord grip

with the sealing ring is pressed into the

threaded sleeve and can no longer be seen.

The AC connecting socket is now fully assembled.

Pressure screw

If you are not going to connect up the Sunny Boy immediately, close off the socket

element using the cap supplied in the accessories kit.

If the Sunny Boy is already installed, you can now connect up the fully assembled AC

connection socket to the flange plug on the Sunny Boy. To do this, remove the

protective cap from the flange plug on the Sunny Boy. Firmly tighten the threaded

ring on the AC connecting socket to the flange plug to seal the connection and secure

it.

Do not switch the line circuit breaker on yet! The Sunny Boy 700

may only be connected to the AC grid once the PV strings are

connected and the device is securely closed.

Installation Guide SB700-11:SA2006 Page 23

Page 24

Installation SMA Technologie AG

Connecting the AC plug with PG16

To connect a cable with a diamter between 13.5 mm and 16 mm, proceed as follows.

1. First of all, slide the pressure screw with the PG16 screw fitting onto the cable.

Now slide the threaded sleeve over the cable.

Pressure screw with

PG16 screw fitting

Threaded sleeve

2. Now connect the individual conductors to the socket element in sequence.

- Protective earth PE (green/yellow) to the screw terminal

with the earth sign. It is required that the PE wire is

slightly longer than the L and N wires.

- Neutral conductor N (blue) to screw terminal 1.

- Live L (brown or black) to screw terminal 2.

- Terminal 3 remains unused.

Terminals in the socket

3. Make sure the wires are securely connected.

3

element

1

2

Connected wires

Pressure screw with

Threaded sleeve

Socket element

PG16 screw fitting

4. Now screw the threaded sleeve onto the socket element and tighten it.

Threaded sleeve

screwed

onto socket element

Pressure screw with

PG16 screw fitting

Page 24 SB700-11:SA2006 Installation Guide

Page 25

SMA Technologie AG Installation

5. Now screw the pressure screw into into

the threaded sleeve and tighten it.

6. Firmly tighten the screw fitting against

the seal and in order to fasten the cable.

Pressure screw

PG16 screw fitting

The AC connecting socket is now fully assembled.

If you are not going to connect up the Sunny Boy immediately, close off the socket

element using the cap supplied in the accessory kit.

If the Sunny Boy is already installed, you can now connect up the fully assembled AC

connection socket to the flange plug on the Sunny Boy. To do this, remove the

protective cap from the flange plug on the Sunny Boy. Firmly tighten the threaded

ring on the AC connecting socket to the flange plug to seal the connection and secure

it.

Do not switch the line circuit breaker on yet! The Sunny Boy 700

may only be connected to the AC grid once the PV strings are

connected and the device is securely closed.

Installation Guide SB700-11:SA2006 Page 25

Page 26

Installation SMA Technologie AG

PV string (DC) connection

To connect up the input, follow these steps:

1. Check that the PV generator connectors have

the right polarity and do not exceed the

maximum string voltage of 250 V (DC). See also

section 4.2 "PV generator requirements"

(page 15).

Caution! Dangerous high voltages may be present. Danger of

death!

2. Taking one DC plug connector at a time,

measure the direct current voltage between one

DC plug connector of a string and earth

potential.

3. If the measured voltages are constant and if

their total is roughly the same as the open circuit

voltage of the string then there is a earth fault in

this string. Its approximate location can be

deduced from the relationships between the

voltages.

PE

Do not connect strings to the Sunny Boy 700 that contain a earth

fault until you have fixed the earth fault in the PV generator.

4. Repeat points 2 and 3 for each string.

5. Connect up the faultless PV generator strings to

the inverter.

6. Close off the unneeded DC input sockets using

the protective caps supplied in the accessories

kit.

Page 26 SB700-11:SA2006 Installation Guide

String 1

String 2

Page 27

SMA Technologie AG Installation

5.3 Setting the input voltage

The Sunny Boy 700 was developed for a nominal output power of 700 W. This

corresponds to a PV input voltage range of 119 ... 250 V DC at the nominal output

voltage.

For solar generators having an input voltage range of 96 ... 200 V DC or 73 ... 150

V DC it is possible to adjust the Sunny Boy 700's input voltage range accordingly. In

other words, it is also possible to connect smaller PV generators to the Sunny Boy

700.

Input voltage range Nominal output power

119 ... 250 V DC 700 W

96 ... 200 V DC 600 W

73 ... 150 V DC 460 W

For small PV systems please note:

The Sunny Boy 700 must be adjusted for the number of PV modules so that it

works in the optimum range.

Installation Guide SB700-11:SA2006 Page 27

Page 28

Installation SMA Technologie AG

The Sunny Boy 700 is factory set for the highest input voltage. To be able to use it

for smaller PV systems, you need to make some minor modifications to the unit. Inside

the Sunny Boy 700 at the top right there are a number of terminal blocks. The top

double terminal is not relevant for adjusting the input voltage range. Below the

double terminal there is a single terminal. This terminal is used to adjust the input

voltage. Below this terminal there are two free slots. You can see the input voltage

ranges associated with the slots from the drawing below.

Terminal in the slot

for

119 ... 250 V DC

Slot for

96 ... 200 V DC

Slot for

73 ... 150 V DC

The slots for the jumpers are

mounted on the Sunny Boy 700's

controller board. When supplied

from the factory, no jumper is fitted.

A jumper only needs to be used if

you want to operate the Sunny Boy

700 with a lower input voltage, i.e.

at 96 ... 200 V DC or at

73 ... 150 V DC.

Jumper slot for

96 ... 200 V DC

ENS2

200V

ENS1

150V

PE

L

Jumper slot for

73 ... 150 V DC

PE

N

N

L

Page 28 SB700-11:SA2006 Installation Guide

Page 29

SMA Technologie AG Installation

To adjust the input voltage, follow these steps:

1. Open the Sunny Boy 700 as described in section 6.1.

2. Pull the terminal upwards out of the terminal block and plug it into the

appropriate slot.

3. Plug the jumper provided in the accessories kit into the corresponding slot on the

controller board. If you want to use the Sunny Boy 700 with the maximum input

voltage range, then do not use the jumper.

4. Once the jumper is in place and the terminal plugged into the correct slot, close

the Sunny Boy 700 as described in section 6.2.

There is a schematic view of the connectors in the table below.

Voltage range Terminal block Jumper

Terminal in

slot 1

No jumper used

119 ... 250 V DC

(factory setting)

ENS2

ENS1

150V

200V

Terminal in

96 ... 200 V DC

slot 2

Terminal in

slot 3

Jumper fitted to

"200 V" position

Jumper fitted to

"150 V" position

ENS1

ENS2

200V

150V

73 ... 150 V DC

ENS2

ENS1

150V

200V

Installation Guide SB700-11:SA2006 Page 29

Page 30

Installation SMA Technologie AG

5.4 Startup

You can start up the Sunny Boy 700 when

• the lid is securely screwed on the enclosure,

• the AC (mains) cable is connected correctly,

• the DC cables (PV strings) are fully connected and the unused DC plug connectors

on the bottom of the enclosure are closed using the protective caps.

How to start up the inverter

1. First of all, switch the line circuit breaker to the

"on" position.

2. Check whether the LEDs indicate trouble-free

operation of the Sunny Boy 700 based on the

table on the next page. In that case, startup has

been successfully completed.

Photovoltaik-Stringwechselrichter

Photovoltaic

s

If the bottom yellow LED flashes four times at intervals of one

second, the grid voltage and the PV generator must be

disconnected from the Sunny Boy 700 immediately! There is a risk

of damage to the inverter resulting from excessive DC input

voltage.

On!

Off

Betrieb

Operation

Erdschluss

Earth

F

ault

Störung

tring

i

nverter

Failure

Check the string voltages again to make sure they are within the limits stated in

section 4.2 "PV generator requirements" (page 15). If the string voltages are too

high, the PV generator's planner / installer should be called upon for assistance.

If despite checking the string voltages the LED signal occurs again when the PV

generator is connected to the Sunny Boy 700, disconnect the PV generator from the

Sunny Boy again and contact SMA Technologie AG (see section 10 "Contact"

(page 49)).

Page 30 SB700-11:SA2006 Installation Guide

Page 31

SMA Technologie AG Installation

Green Red Yellow Status

off off OK (feeding grid)

on

blinking quickly

(3 x per second)

on / blinkingy

(1 x per second)

on / blinking

(shortly off 1 x

per second)

off

on

off off OK (stop)

on off failure

off off

on off failure

off off OK (derating)

on off failure

off

on

off failure

on OK (initialization)

OK (waiting, grid

monitoring)

off OK (night standby)

on / blinking failure

off failure

on / blinking failure

For a detailed description of the fault messages and their causes, see the operating

instructions.

Installation Guide SB700-11:SA2006 Page 31

Page 32

Installation SMA Technologie AG

Page 32 SB700-11:SA2006 Installation Guide

Page 33

SMA Technologie AG Opening and closing the Sunny Boy

6 Opening and closing the Sunny Boy

If you need to open the device for whatever reason, please

pay attention to section 2 "Safety information" (page 9).

6.1 Opening the Sunny Boy

Caution: Follow the sequence below under all circumstances.

1. Switch the line circuit breaker to the "off" position.

2. Disconnect the PV generator from the Sunny Boy 700.

3. Wait 30 minutes!

4. Remove the four screws from the lid and pull the lid off the enclosure. Unlock

the green-yellow PE connection and remove it from the lid and take the lid off.

6.2 Closing the Sunny Boy

Caution: Follow the sequence below under all circumstances.

1. Reconnect the earth wire (PE) to the lid. Now secure the lid to the Sunny Boy

700 by tightening the four screws evenly.

2. Connect the PV generator.

3. Switch the line circuit breaker to the "on" position.

4. Now check whether the LED display on the Sunny Boy 700 indicates that the

device is functioning correctly.

Installation Guide SB700-11:SA2006 Page 33

Page 34

Opening and closing the Sunny Boy SMA Technologie AG

Page 34 SB700-11:SA2006 Installation Guide

Page 35

SMA Technologie AG Technical data

7 Technical data

7.1 Input voltage range 119 ... 250 V DC

7.1.1 PV generator connection data

Max. input open circuit voltage U

PV 0

250 V

(based on -10 °C cell temperature)

Input voltage, MPP range U

Max. input current I

Max. input power P

PV max

PV

DC

119 V ... 250 V

7 A

780 W

Recommended generator power 900 Wp

All-pole isolator on the DC input side

DC plug connector

Overvoltage protection Thermally monitored varistors

Voltage ripple U

< 10 % of the input voltage

pp

Insulation protection Ground fault monitoring

(Riso > 1 MΩ)

Operating consumption < 4 W (standby)

Reverse polarity protection Short circuit diode

7.1.2 Grid connection data

Nominal output power P

Peak output power P

Nominal output current I

Harmonic distortion of output current

(at K

< 2 %, PAC > 0.5 P

Ugrid

AC nom

AC nom

K

)

Short-circuit strength Grid-side via current regulation

Operating range, grid voltage U

Operating range, grid frequency f

AC

All-pole isolation on grid side Independent disconnection device

Phase shift angle (based on the

current's fundamental frequency) cos phi 1

Overvoltage category III

Test voltage (50 Hz) 1.3 kV (1 s routine testing / 5 s type

Test surge voltage 4 kV (serial interface: 6 kV)

Own consumption in night mode 0.1 W

700 W

AC nom

700 W

ACm ax

3 A

< 3 %

IAC

198 ... 260 V AC

AC

49.8 ... 50.2 Hz

(MSD), redundant design

testing)

Installation Guide SB700-11:SA2006 Page 35

Page 36

Technical data SMA Technologie AG

7.2 Input voltage range 96 ... 200 V DC

7.2.1 PV generator connection data

Max. input open circuit voltage U

250 V (based on -10 °C cell

PV 0

temperature)

Input voltage, MPP range U

Max. input current I

Max. input power P

PV max

PV

DC

96 V ... 200 V

7 A

670 W

Recommended generator power 750 Wp

All-pole isolator on the DC input side

DC plug connector

Overvoltage protection Thermally monitored varistors

Voltage ripple U

< 10 % of the input voltage

pp

Insulation protection Ground fault monitoring

(Riso > 1 MΩ)

Operating consumption < 4 W (standby)

Reverse polarity protection Short circuit diode

7.2.2 Grid connection data

Nominal output power P

Peak output power P

Nominal output current I

Harmonic distortion of output current

(at K

< 2 %, PAC > 0.5 P

Ugrid

AC nom

ACnom

K

)

Short-circuit strength Grid-side via current regulation

Operating range, grid voltage U

Operating range, grid frequency f

AC

All-pole isolation on grid side Independent disconnection device

Phase shift angle (based on the

current's fundamental frequency) cos phi 1

Overvoltage category III

Test voltage (50 Hz) 1.3 kV (1 s routine testing / 5 s type

Test surge voltage 4 kV (serial interface: 6 kV)

Own consumption in night mode 0.1 W

600 W

AC nom

600 W

ACm ax

2.6 A

< 3 %

IAC

198 ... 260 V AC

AC

49.8 ... 50.2 Hz

(MSD), redundant design

testing)

Page 36 SB700-11:SA2006 Installation Guide

Page 37

SMA Technologie AG Technical data

7.3 Input voltage range 73 ... 150 V DC

7.3.1 PV generator connection data

Max. input open circuit voltage U

250 V (based on -10 °C cell

PV 0

temperature)

Input voltage, MPP range U

Max. input current I

Max. input power P

PV max

PV

DC

73 V ... 150 V

7 A

510 W

Recommended generator power 600 Wp

All-pole isolator on the DC input side

DC plug connector

Overvoltage protection Thermally monitored varistors

Voltage ripple U

< 10 % of the input voltage

pp

Insulation protection Ground fault monitoring

(Riso > 1 MΩ)

Operating consumption < 4 W (standby)

Reverse polarity protection Short circuit diode

7.3.2 Grid connection data

Nominal output power P

Peak output power P

Nominal output current I

Harmonic distortion of output current

(at K

< 2 %, PAC > 0.5 P

Ugrid

AC nom

ACnom

K

)

Short-circuit strength Grid-side via current regulation

Operating range, grid voltage U

Operating range, grid frequency f

AC

All-pole isolation on grid side Independent disconnection device

Phase shift angle (based on the current's

fundamental frequency) cos ϕ 1

Overvoltage category III

Test voltage (50 Hz) 1.3 kV (1 s routine testing / 5 s type

Test surge voltage 4 kV (serial interface: 6 kV)

Own consumption in night mode 0.1 W

460 W

AC nom

460 W

ACm ax

2 A

< 3 %

IAC

198 ... 260 V AC

AC

49.8 ... 50.2 Hz

(MSD), redundant design

testing)

Installation Guide SB700-11:SA2006 Page 37

Page 38

Technical data SMA Technologie AG

7.4 Device description

For a detailed description of the device, see the operating instructions.

General data

Protection category per DIN EN 60529 IP65

Dimensions (w x h x d)

Weight 16 kg (approx.)

External interfaces

Data transmission over mains power line Optional

Data transmission over separate data cable Optional,

Wireless data transmission Optional

Efficiency

Max. efficiency η

European standard efficiency η

The efficiency of the Sunny Boy 700 depends mainly on the input voltage of the

connected PV strings. The lower the input voltage, the higher is the efficiency of the

Sunny Boy 700.

max

euro

322 mm x 290 mm x 180 mm

(approx.)

RS232 / RS485, electrically separated

93.4 %

92 %

100

90

80

70

Overall efficiency [%]

60

50

Sunny Boy 700

40

01020304050 7060 80 90 100

Output power [%]

Page 38 SB700-11:SA2006 Installation Guide

Page 39

SMA Technologie AG Technical data

7.5 Operating parameters

Unauthorised changes to the operating parameters may result

in:

• Injury or accidents as a result of changing the internal

safety routines in the Sunny Boy

• Voiding the Sunny Boy's operating approval certificate

• Voiding the Sunny Boy's guarantee

Never change the parameters of your Sunny Boy without

express authorization and instructions.

The parameters with a grey background are only visible when in installer mode.

Name Unit Value range Factory setting

Betriebsart /

Operating mode

Default GER/ENS

dFac-Max Hz/s 0.005 ... 4.0 0.5

dZac-Max mOhm 0 ... 20000 350

E_Total kWh 0 ... 200000

Fac-Delta- Hz 0 ... 4.5 0.19

Fac-Delta+ Hz 0 ... 4.5 0.19

h_Total h 0 ... 200000

I-NiTest /

Testcurrent Zac

Speicherfunktion /

Memory function

Speicher/Storage Permanent, volatile Permanent

T-Start s 5 ... 300 10

T-Stop s 1 ... 3600 2

Uac-Min / Vac-Min V 180 ... 300 198

Uac-Max / Vac-Max V 180 ... 300 260

Upv-Start /

Vpv-Start

Usoll-Konst /

Vconst-Setpoint

mA 0 ... 6000 4500/

V 125 ... 250/

V 125 ... 330/

MPP, IKonst, UKonst, Stopp, Turbine

Mode, Insel Mode

Default Parameter, Reset Betriebsdaten,

Reset Fehler

100 ... 200/

75 ... 150

100 ... 330/

75 ... 330

MPP

4000/

3500

none

150/

125/

95

275/

275/

275

Installation Guide SB700-11:SA2006 Page 39

Page 40

Technical data SMA Technologie AG

The following parameters are displayed in the parameter list but cannot be changed:

Name Unit Value range Description

Plimit W 700/

600/

460

SMA-SN Serial number of the Sunny Boy

Software-BFR /

Firmware BFR

Software-SRR /

Firmware SRR

Upper limit for AC output power

Firmware version of the operation control unit (BFR)

Firmware version of the current control unit (SRR)

Page 40 SB700-11:SA2006 Installation Guide

Page 41

SMA Technologie AG Replacing the varistors

8 Replacing the varistors

The Sunny Boy 700 is a complex high-technology device. As a result, the possibilities

for fixing faults on site are limited to just a few items. Please don't try to carry out

repairs other than those described here. Use the SMA Technologie AG 24-hour

exchange service and repair service instead.

If the red LED on the status display glows continuously during operation, you should

first of all make sure that there is no earth fault in the PV generator.

1. Disconnect the Sunny Boy 700 from the low

voltage grid (pull out the AC plug or switch the

line circuit breaker to its "off" position). Make

sure the grid cannot be inadvertently

reconnected.

2. Disconnect the DC plug connectors for all

strings. Make sure you note the order of the

individual inverter inputs so you can put them

back in the right place later!

3. Taking one DC plug connector at a time,

measure the voltages between one DC plug

connector of a string and earth potential. Pay

attention to the safety warnings!

Off!

1. 2. 3.

You must make sure that no voltage is

present at the AC output before opening

String 1

String 2

Disconnect the PV generators from the

the Sunny Boy.

Sunny Boy.

PE

Measure the voltage between DC plug

connectors and earth potential.

Caution! Dangerous high voltages may be present. Danger of

death!

4. If the measured voltages are constant and if their total is roughly the same as

the open circuit voltage of the string then there is a earth fault in this string. Its

approximate location can be deduced from the relationships between the

voltages.

Installation Guide SB700-11:SA2006 Page 41

Page 42

Replacing the varistors SMA Technologie AG

5. Repeat points 3 and 4 for each string.

If you found a earth fault, it is probably not necessary to replace the varistors.

Instead, make sure the ground fault is fixed. Generally the PV generator's

installation engineer should be hired for this job. In this case continue as

described under point 10, but without reconnecting the faulty string. Instead of

reconnecting the string, protect its DC plug against accidental touch contact

(e.g. by fitting the protective caps or using sufficient high-voltage insulating

tape).

If you did not find any earth fault in the PV generators, it is likely that one of the

thermally monitored varistors has lost its protective function. These components

are wearing parts. Their functioning diminishes with age or following repeated

responses as a result of overvoltages. You can now check these varistors in the

following way, paying attention to the safety information in section 2 "Safety

information" (page 9):

6. Remove the screws that secure the lid and remove the lid from the Sunny Boy

700. Disconnect the PE connection from the lid. Make sure that no voltage is

present.

7. Using a continuity tester, check all the varistors to see if there is a conducting

connection between connectors 2 and 3. If there isn't, then that varistor is not

working. The positions of the varistors in the Sunny Boy 700 can be seen in

section 3.1 "Unit description" (page 11).

8. Replace the varistor concerned with a new one

as shown in the drawing to the right. Ensure the

varistor is installed the right way round! If you

do not receive a special tool for operating the

terminal clamps with your replacement

Insert the special tool to open

the terminal clamp.

varistors, please contact SMA. As an

alternative, the terminal contacts can be

operated using a suitable screwdriver. Since the

Remove the varistor.

failure of one varistor is generally due to factors

that affect all varistors in a similar way

(temperature, age, inductive overvoltages), it is

highly recommended that you replace both

varistors, not just the one that is obviously

defective. The varistors were specially

3 21

The pole with the small loop

(crimp) must be fitted to

terminal 1 when replacing the

varistor.

manufactured for use in the Sunny Boy 700 and

are not commercially available. They must be

ordered directly from SMA Technologie AG

(SMA order code: SB-TV1).

Page 42 SB700-11:SA2006 Installation Guide

Page 43

SMA Technologie AG Replacing the varistors

In case there are no spare varistors available the Sunny Boy 700

still can feed electricity into the grid. The input is not protected

against overvoltages in this case. Replacement varistors should be

obtained as soon as possible. In systems with a high risk of

overvoltages, the Sunny Boy 700 should not be operated with

defective varistors.

9. Reconnect the PE connection on the lid and close the Sunny Boy 700.

10. Connect up the faultless PV generator strings to

the inverter.

11. Close off the unneeded DC input sockets using

the protective caps supplied in the accessories

kit.

String 1

String 2

12. Switch the line circuit breaker to the "on"

position.

On!

13. Now check whether the LED display on the

Sunny Boy 700 indicates that the device is

functioning correctly.

Off

If no earth fault and no defective varistor were found, there is probably a fault in the

Sunny Boy. In this case, contact the SMA hotline to discuss what to do next.

Installation Guide SB700-11:SA2006 Page 43

Page 44

Replacing the varistors SMA Technologie AG

Page 44 SB700-11:SA2006 Installation Guide

Page 45

SMA Technologie AG Rating for a line circuit breaker

9 Rating for a line circuit breaker

Example for the thermal rating for a line circuit breaker in a photovoltaic

electrical power unit operated in parallel with the low-voltage grid

We assume a PV system with 9 Sunny Boy 700 inverters, with three inverters

per phase.

SB1100

Be

t

rie

P

h

b

otovolta

Operation

Ph

i

o

k

-

tovo

S

t

ring

l

taic

w

ech

s

trin

s

Erd

el

g

r

ichter

s

i

n

chlu

v

erter

ss

E

a

r

t

h

F

a

u

lt

S

t

öru

ng

Fail

u

re

L1

L2

L3

SB1100

Betr

Ph

i

eb

otov

Operation

o

lta

Ph

i

otov

k-St

ri

ol

ngwech

ta

i

c

s

t

ri

s

Er

n

el

g

d

ri

sc

i

ch

nv

hlu

t

ert

er

ss

E

er

a

rth

F

a

u

l

t

S

t

ör

ung

Fail

u

re

SB1100

Be

t

rie

P

ho

b

t

o

Opera

vo

l

Pho

t

a

ik-

t

ion

tov

S

tri

o

n

l

t

gwe

a

i

c

c

s

tr

hselri

i

Erd

ng

s

i

c

nv

chlu

hter

ert

ss

Ear

er

t

h

F

ault

S

t

öru

ng

Failure

...

SB1100

Be

t

r

Pho

i

e

b

t

o

Op

v

ol

e

Photovol

ta

r

a

i

k

t

-Strin

i

o

n

t

g

aic

w

ech

s

t

r

s

ing

Er

el

dschluss

ri

i

ch

nv

t

e

er

rter

Ea

rt

h

F

ault

S

t

örung

F

a

il

u

r

e

SB1100

Be

t

rie

P

h

b

o

t

ov

Ope

olt

Pho

aik-

r

ati

t

o

o

Stri

n

v

ol

n

ta

g

wec

i

c

s

tr

hse

i

Erd

ng

l

ri

s

i

c

nv

chlu

hte

ert

r

ss

Eart

er

h

F

a

u

l

t

Störun

g

Fa

il

u

r

e

SB1100

Be

t

r

Pho

i

e

b

t

o

Op

v

ol

e

Photovoltaic

t

ai

rat

k

-Strin

i

o

n

g

w

ech

s

tring

selric

E

rds

i

nverter

c

h

hluss

t

er

Ea

rt

h

F

ault

S

t

örung

F

a

il

u

r

e

N

Required technical information for the inverters used:

• Maximum output current = 3.5 A

• Maximum permissible fuse protection for the inverter = 16 A

The choice of cable together with the way it is routed, ambient temperatures and

other underlying conditions limit the maximum fuse protection for the cable.

• In our example we assume that the chosen cable (2.5 mm²) is ideally routed and

can take a nominal current of 11 A.

Selecting a line circuit breaker:

• The maximum possible nominal current for the cable used and the maximum

possible fuse protection for the inverter now limit the maximum possible nominal

current for the line circuit breaker.

• In our example, 10 A is possible.

However, the thermal suitability of the line circuit breaker still needs to be checked.

Installation Guide SB700-11:SA2006 Page 45

Page 46

Rating for a line circuit breaker SMA Technologie AG

When selecting line circuit breakers, a number of load factors need to be taken into

account. These can be found in the respective data sheets.

Example for the thermal selection of a 10 A line circuit breaker with B sensitivity

with no gap between the circuit breakers:

For example, one manufacturer's circuit breaker may be designed for an ambient

temperature of 50 °C.

Load factors according to data sheet specifications:

• Reduction through permanent load >1h = 0.9

• Reduction when 9 circuit breakers are arranged side-by-side without

gaps = 0.77

• Increase in nominal current as a result of ambient temperatures of 40 °C in the

circuit breaker panel = 1.07

2

3

1

Result:

The nominal load current for the line circuit breaker is calculated as:

Ibn = 10 A x 0.9 x 0.77 x 1.07 = 7.4 A

1. Permanent loads of longer than 1 hour are possible in photovoltaics.

2. When only one circuit breaker is used, this factor = 1

3. Because the circuit breakers are rated for 50 °C

Page 46 SB700-11:SA2006 Installation Guide

Page 47

SMA Technologie AG Rating for a line circuit breaker

Summary:

The selected line circuit breaker can be used in our example case since the maximum

current-carrying capacity for fault-free operation is higher than the maximum output

current of the inverter used. It will trip under rated operating conditions!

If the calculated current-carrying capacity of the circuit breaker had been lower than

the maximum output current from the inverter, the following solution might have been

used:

By spacing the circuit breakers at an interval of 8 mm, the reduction factor would be

0.98 instead of 0.77. As a result, the maximum current-carrying capacity would

increase to 9.4 A.

As well as the thermal rating of the circuit breakers and all other factors as specified

in section "Rating for a line circuit breaker in a photovoltaic electrical power unit

operated in parallel with the low-voltage grid" (page 16), of course the applicable

DIN VDE standards

here are:

• DIN VDE 0100; part 410

• DIN VDE 0100; part 430

• DIN VDE 0298; part 4

In special applications the relevant standards must be followed.

1

also need to be taken into account. The main ones that apply

1. The standards mentioned above are to be only used as a guideline for your

installation. They apply for installations in Germany. Please note that other

standards will apply for different countries throughout the world.

Installation Guide SB700-11:SA2006 Page 47

Page 48

Rating for a line circuit breaker SMA Technologie AG

Page 48 SB700-11:SA2006 Installation Guide

Page 49

SMA Technologie AG Contact

10 Contact

If you have any questions or technical problems concerning the Sunny Boy 700,

please contact our hotline. Please have the following information available when you

contact SMA:

• Inverter type

• Type and number of connected modules

• Communication method

• Serial number of the Sunny Boy

Address:

SMA Technologie AG

Hannoversche Strasse 1 - 5

34266 Niestetal

Germany

Tel.:+49 (0)561 95 22 - 499

Fax:+49 (0)561 95 22 - 4699

hotline@SMA.de

www.SMA.de

Installation Guide SB700-11:SA2006 Page 49

Page 50

Contact SMA Technologie AG

Page 50 SB700-11:SA2006 Installation Guide

Page 51

Page 52

www.SMA.de

SM

A

Technologie AG

5

l

G

y

0

e

a

ld

hil

t

a

5

i

4

ll

A

M

m

k

f

k

V

n

lano

ly

b

l

7

a

S

n

3

Hannoversche Straße 1–

34266 Niesteta

erman

Tel. +49 561 9522

info@SMA.d

SMA Technologie AG

SMA Solartechnology Chin

International Metro Center,

ing A, City Square No. Jia 3,

Bui

ipu Road, Changyang Distric

S

100025 Beijing, PR. Chin

Tel. +86 10 65 58 78 1

www.SMA-CHINA.com

SMA Amer

12

Grass Va

Tel. +1 530 273 4895

www.S

ca, Inc.

38 Loma Rica Drive, Unit C

ey, CA 95945, US

A-AMERICA.co

ertrieb SMA Italie

Via Lorenzo Valla, 16

20141 Mi

Ita

Tel. +39 02 847421

SMA Spanien

Vertrie

mes, 29

Ba

08006 Barcelon

pai

Tel. +34 639 40368

Innovation in Systemtechni

Page 52 SB700-11:SA2006 Installation Guide

ür den Erfolg der Photovoltai

Loading...

Loading...