Page 1

EN

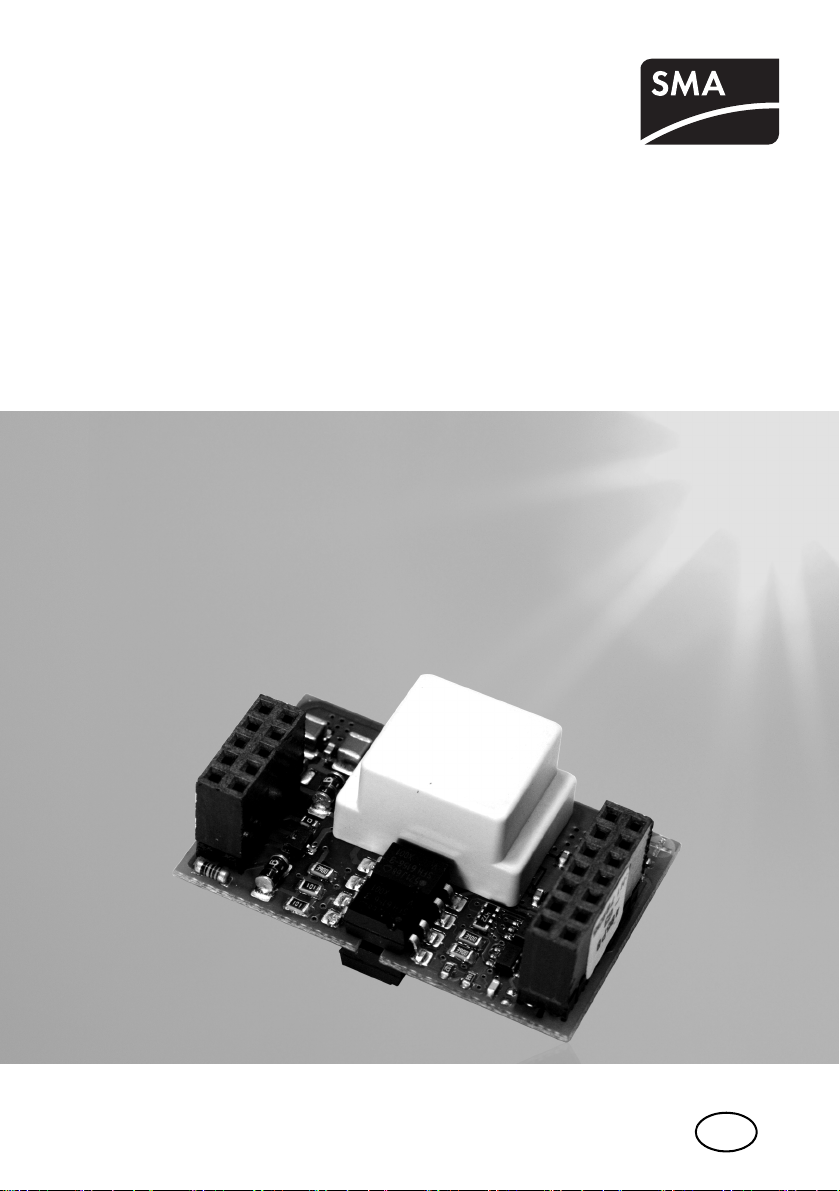

System Monitoring

485PB-NR, 485PB-MS-NR

Installation Guide

485PB-SB-NR-IEN101311 | 98-00012611 | Version 1.1

Page 2

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Notes on this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Appropriate Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Packing List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Overview of Interface Port and Cable Route . . . . . . . . . . . . . . . 8

4.2 Installing the Communication Interface . . . . . . . . . . . . . . . . . . . 10

4.3 Connecting the Communication Interface. . . . . . . . . . . . . . . . . 11

4.3.1 Preparing the Enclosure Opening on the Inverter . . . . . . . . . . . . . . . . . . . . . 11

4.3.2 Installing the Cable in the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3.3 Connecting the Cable to the Communication Interface . . . . . . . . . . . . . . . . 14

4.4 Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installation Guide 485PB-SB-NR-IEN101311 3

Page 4

Notes on this Manual SMA Solar Technology AG

1 Notes on this Manual

1.1 Validity

This manual applies to the 485PB-NR and 485PB-MS-NR communication interfaces.

1.2 Target Group

This manual is intended for the installer.

1.3 Symbols Used

The following types of safety instructions and general information appear in this document as

described below:

DANGER!

"DANGER" indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING!

"WARNING" indicates a hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION!

"CAUTION" indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE!

"NOTICE" indicates a situation that can result in property damage if not avoided.

Information

Information provides tips that are valuable for the optimal installation and operation of

your product.

4 485PB-SB-NR-IEN101311 Installation Guide

Page 5

SMA Solar Technology AG Safety

2 Safety

2.1 Appropriate Usage

The RS485PB-NR and RS485PB-MS-NR communication interfaces make it possible to establish wired

RS485 communication. With these communication interfaces you can configure inverter parameters

with a communication product and view momentary values of the inverter. The following inverter

models are supported by the communication interfaces:

• 485PB-NR suppor ts t he f oll owi ng i nverter mod els : SB /SW R/W B 70 0, S B/SWR/WB 1100(E)

(LV), SB/SWR/WB 1700 (E), SWR 2000, SB 2100TL, SB/SWR/WB 2500, SB/WB 2800i,

SB/SWR/WB 3000, SB/WB 3300, SB/WB 3800.

• 485PB-MS-NR supports the following inverter models: SB 3300TL (HC), SB 4200TL (HC), SB

5000TL (HC) (W).

The communication interfaces (485PB-NR and 485PB-MS-NR) comply with the following standard:

• TIA/EIA-485-A, 1998

The interfaces are provided as an add-on kit or are pre-installed in the inverter.

Installation Guide 485PB-SB-NR-IEN101311 5

Page 6

Safety SMA Solar Technology AG

2.2 Safety Precautions

DANGER!

Risk of lethal electric shock when opening the inverter.

• All work on the inverter must be carried out exclusively by qualified personnel.

• Disconnect the inverter on the AC and DC sides as described in the inverter manual.

WARNING!

Danger to life through high voltage if the communication cable is not installed

properly.

Install the communication cable separately from the grid connection (AC cable) and also

separately from the signaling contact, if necessary.

NOTICE!

Electrostatic discharges can damage the communication interface.

• Avoid coming into contact with components' connections and plug contacts.

• Ground yourself before touching the communication interface by touching the

protective conductor (PE) or a non-coated part of the inverter housing.

NOTICE!

Metal or cable scraps in the housing can damage the inverter.

• Make sure that no metal scraps of the cable shield or the cable fall into the open

inverter when working on the cable.

• Remove any metal or cable scraps, if necessary.

6 485PB-SB-NR-IEN101311 Installation Guide

Page 7

SMA Solar Technology AG Unpacking

3 Unpacking

3.1 Packing List

Position Number Description

A 1 RS485 Piggy-Back: 485PB-G3

B1 Jumper

C 1 Shield clamp

D 1 Screw for fastening the shield clamp

E1 Contact disk

F2 Insulating tubes

G 2 Conductive bonding sheets

H 1 Cable tie

I 1 Flat cable connector

K 2 Cable glands (with single seal insert)

L 1 Cable gland (with double seal insert)

M 2 Counter nuts for the cable glands

N 1 Installation guide with RS485 cabling plan poster

*

Is only required for SB/WB 3300 and SB/WB 3800 inverter models.

*

*

*

*

3.2 Identification

You can identify the communication interface by the type label. The type label is located on one of

the socket connectors of the communication interface.

Installation Guide 485PB-SB-NR-IEN101311 7

Page 8

Electrical Connection SMA Solar Technology AG

D F E D F E

A

B

C

4 Electrical Connection

This section describes the installation and connection of the RS485 Piggy-Back communication

interface. It is assumed that the inverter is situated in the middle of the RS485 communication bus. If

the inverter is situated at the end of the RS485 communication bus, carry out the following steps for

one cable only and connect the termination (see Page 15).

If the communication interface is preinstalled, you can skip Section 4.2 "Installing the

Communication Interface" (Page 10).

4.1 Overview of Interface Port and Cable Route

For an inverter of type SB/WB

SB/WB 700

SB/WB 1100

8 485PB-SB-NR-IEN101311 Installation Guide

SB/WB 1100, SB/WB 1100 (E) (LV), SB/WB 1700 (E), SB 2100TL,

SB/WB 2500, SB/WB 2800i, SB/WB 3000

Page 9

SMA Solar Technology AG Electrical Connection

D E F D E F

A

B

C

D F E D F E

A

B

C

SB/WB 3300, SB/WB 3800 SB 3300TL(HC), SB 4200TL(HC), SB 5000TL(HC)(W)

For an inverter of type SWR

SWR 700 SWR 1100 (E) (LV), SWR 1700 (E),

SWR 2000, SWR 2500, SWR 3000

Position Description

AInterface port

B Screw terminals for connection of the communication cabling

CJumper slot

D Cable route (gray surface)

E Enclosure openings at the bottom of the inverter

F Connector tab for PE

Installation Guide 485PB-SB-NR-IEN101311 9

Page 10

Electrical Connection SMA Solar Technology AG

A

4.2 Installing the Communication Interface

In order to install the communication interface for the SB, WB and SWR inverters mentioned above

proceed as follows:

1. Open the inverter as described in the inverter documentation.

2. In inverters of the SWR type, resistors with a black

ring must be removed before installation. Carefully

cut off the resistors with a black ring using diagonal

cutting pliers.

3. Plug the communication interface (A) to the left of

the interface port. The 2 pins on the right of the short

pin row below stay free.

☑ The communication interface is installed.

10 485PB-SB-NR-IEN101311 Installation Guide

Page 11

SMA Solar Technology AG Electrical Connection

4.3 Connecting the Communication Interface

4.3.1 Preparing the Enclosure Opening on the Inverter

Perform the following steps, depending on the inverter model:

• For inverter models with one enclosure opening see Section "Inverter Models with One

Enclosure Opening" (Page 11)

• For inverter models with two enclosure openings see Section "Inverter Models with Two

Enclosure Openings" (Page 11)

Inverter Models with One Enclosure Opening

1. Open the inverter as described in the inverter documentation.

2. Push the filler plug out of the enclosure opening

which is located at the bottom of the inverter.

3. Insert the cable gland with the double seal insert

in to the e ncl osu re open ing of the i nve rter and fasten

it from inside with a nut.

4. Unscrew the nut of the cable gland and push out

the seal insert.

5. Push out the filler plug in the seal insert with a screwdriver depending on the number of cables

to be led through.

☑ The enclosure opening on the inverter is prepared.

Inverter Models with Two Enclosure Openings

1. Open the inverter as described in the inverter documentation.

2. Push out the filler plug at the bottom of the inverter

depending on the number of cables to be led

through.

Installation Guide 485PB-SB-NR-IEN101311 11

Page 12

Electrical Connection SMA Solar Technology AG

3. Place the cable gland with single seal insert into the

prepared enclosure opening of the inverter and

fasten it with a nut from inside the enclosure.

4. Loosen the nut of the cable gland so that the cable

can be inserted.

☑ The cable opening on the inverter is prepared.

4.3.2 Installing the Cable in the Inverter

The instructions for preparing and installing the shield clamp only apply for SB/WB 3300

and SB/WB 3800 inverter models.

1. If you are using a shield clamp, proceed as follows:

– Measure 4 cm plus the length of one insulating

tube f rom the end of the c able an d strip app rox.

1.5 cm of the cable sleeve down to the shield.

– Apply a conductive bonding sheet around the

stripped area of the cable.

☑ The cable is prepared for the shield clamp.

– Insert the cable into the inverter through the

cable gland.

– Use the screw and the contact disk to fasten the

shield clamp to the screwing device for the

shield clamp on the inverter.

– P ush the s tri pped par t of the cabl e in to the sh iel d

clamp.

☑ The shield clamp is installed.

12 485PB-SB-NR-IEN101311 Installation Guide

Page 13

SMA Solar Technology AG Electrical Connection

B

A

C

D

2. If you are not using a shield clamp, proceed as follows:

– Insert the cable into the enclosure through the cable gland.

– Strip the cable sleeve to match the length of the

cable route (A). The length of the cable route

depends on the inverter model (see images in

Section 4.1 "Overview of Interface Port and

Cable Route" on Page 8).

– Shorten the unused insulated conductors down

to the cable sleeve (C).

– Shorten the cable shield to reach the PE

co nne ctor (co nne cto r ta b) ( B) in the inv ert er a nd

twist it. The length to the PE connector depends

on the inverter model (see images in Section 4.1

"Overview of Interface Port and Cable Route"

on Page 8).

– Connect the flat cable connector to the cable

shield.

– Connect the flat cable connector with the PE

connector tab.

– Strip 6 mm off the insulated conductors (D).

3. Tighten the nut of the cable gland to secure the cable.

4. Installing the insulating tube:

DANGER!

Danger to life through high voltage if there is a fault with the communication

cable.

• Pull an insulating tube over the wires of the used cables that

reaches up to the inverter enclosure opening. The insulating

tube must completely cover the wires inside the enclosure.

• If necessary, cut the insulating tube back to the required

length.

5. For simplification the two cables can be bound together with a cable tie.

6. Install the cable with an insulating tube along the cable route to the screw terminals.

☑ The cable is installed in the inverter.

Installation Guide 485PB-SB-NR-IEN101311 13

Page 14

Electrical Connection SMA Solar Technology AG

4.3.3 Connecting the Cable to the Communication Interface

Cabling plan for an RS485 communication bus

See the RS485 cabling plan poster for the cabling, wiring, and termination of an RS485

communication bus.

Cabling plan for SB/WB and SWR inverter models

The cabling plan for SB/WB and SWR inverter models is identical.

NOTICE!

Damage to the terminal block if wire sleeves are used.

Wire sleeves deform when tightening the screw terminals and can no longer be removed

from the terminal block afterwards.

• Do not use wire sleeves when connecting the communication cable.

1. Connect the wires to the screw terminals (2, 5, 7)

below the interface port (torque: 0.23 Nm).

Write down the colors of each wire:

2 ____________________________

5 ____________________________

7 ____________________________

2. Set the termination where necessary (see Page 15).

3. Close the inverter as described in the inverter

documentation.

☑ The communication interface is connected.

14 485PB-SB-NR-IEN101311 Installation Guide

Page 15

SMA Solar Technology AG Electrical Connection

4.4 Termination

Connect the termination only if the inverter is positioned at the end of the RS485 communication bus.

Termination is done through a jumper on the jumper slot. Refer to the RS485 cabling plan poster for

the termination of an RS485 communication bus.

Carry out the following steps to terminate the RS485 communication bus.

1. Open the inverter as described in the inverter documentation.

2. Plug the jumper onto the jumper slot A in the

inverter.

3. Close the inverter as described in the inverter

documentation.

☑ The RS485 communication bus is terminated.

Installation Guide 485PB-SB-NR-IEN101311 15

Page 16

Decommissioning SMA Solar Technology AG

5 Decommissioning

5.1 Disassembly

1. Remove the RS485 Piggy-Back communication interface.

2. Disconnect the wires from the screw terminals.

3. Remove the jumper, if applicable.

4. Remove the cable tie, if applicable.

5. If you are using a shield clamp:

– Pull the cable out of the shield clamp.

– Unscrew the shield clamp.

6. If you are not using a shield clamp:

– Remove the cable shield from the PE connector.

7. Remove the insulating tube.

8. Loosen the nut of the cable gland.

9. Pull the cable out of the device.

10. Remove the cable gland from the enclosure.

11. Plug the enclosure opening at the bottom of the inverter with a filler plug.

12. Close the inverter as described in the inverter documentation.

☑ The communication interface has been decommissioned.

5.2 Disposal

At the end of its service life, dispose of the communication interface in accordance with the currently

applicable disposal regulations for electronic waste at the installation site, or send it back at your

expense to SMA Solar Technology AG labeled "ZUR ENTSORGUNG" ("for disposal").

16 485PB-SB-NR-IEN101311 Installation Guide

Page 17

SMA Solar Technology AG Technical Data

6 Technical Data

Mechanical Data

Width x Height x Depth 28 mm x 42 mm x 16 mm

Weight 14 g

Mounting location in the inverter

Interfaces

Communication bus in the inverter

Communication

Communication interface RS485

Max. communication range of RS485 1,200 m

Ambient Conditions

Ambient temperature (operation) –25 °C … +85 °C

Relative humidity 5 % … 95 %, non condensing

Installation Guide 485PB-SB-NR-IEN101311 17

Page 18

Contact SMA Solar Technology AG

7 Contact

If you have technical problems concerning our products, contact the SMA Serviceline . We re quire t he

following information in order to provide you with the necessary assistance:

• Type and serial number of the inverter

• Serial number of the communication interface

•Communication type

• Blink code or display of the inverter

SMA Solar Technology AG

Sonnenallee 1

34266 Niestetal, Germany

www.SMA.de

SMA Serviceline

Inverters: +49 561 9522 1499

Communication: +49 561 9522 2499

Fax: +49 561 9522 4699

E-Mail: Serviceline@SMA.de

18 485PB-SB-NR-IEN101311 Installation Guide

Page 19

SMA Solar Technology AG Legal Restrictions

The information contained in this document is the property of SMA Solar Technology AG. Publishing its content, either partially or

in full, requires the written permission of SMA Solar Technology AG. Any internal company copying of the document for the

purposes of evaluating the product or its correct implementation is allowed and does not require permission.

Exclusion of liability

The general terms and conditions of delivery of SMA Solar Technology AG shall apply.

The content of these documents is continually checked and amended, where necessary. However, discrepancies cannot be

excluded. No guarantee is made for the com pleteness of these documents. The latest version is available online at www.SMA.de

or from the usual sales channels.

Guarantee or liability claims for damages of any kind are excluded if they are caused by one or more of the following:

• Damages during transportation

• Improper or inappropriate use of the product

• Operating the product in an unintended environment

• Operating the product whilst ignoring relevant, statutory safety regulations in the deployment location

• Ignoring safety warnings and instructions contained in all documents relevant to the product

• Operating the product under incorrect safety or protection conditions

• Altering the product or supplied software without authority

• The product malfunctions due to operating attached or neighboring devices beyond statutory limit values

• In case of unforeseen calamity or force majeure

The use of supplied software produced by SMA Solar Technology AG is subject to the following conditions:

• SMA Solar Technology AG rejects any liability for direct or indirect damages arising from the use of software developed by

SMA Solar Technology AG. This also applies to the provision or non-provision of support activities.

• Supplied software not developed by SMA Solar Technology AG is subject to the respective licensing and liability agreements

of the manufacturer.

SMA Factory Warranty

The current guarantee conditions come enclosed with your device. These are also available online at www.SMA.de and can be

downloaded or are available on paper from the usual sales channels if required.

Trademarks

All trademarks are recognized even if these are not marked separately. Missing designations do not mean that a product or brand

is not a registered trademark.

The Bluetooth

Solar Technology AG is under license.

SMA Solar Technology AG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

E-Mail: info@SMA.de

© 2004 to 2010 SMA Solar Technology AG. All rights reserved

®

wor d mark an d logos are registere d trademarks owned by Bl uetooth SI G, Inc. and an y use of s uch marks b y SMA

Installation Guide 485PB-SB-NR-IEN101311 19

Page 20

4."4PMBS5FDIOPMPHZ"(

XXX4."EF

Loading...

Loading...