Slugger USA101 Operator's Manual

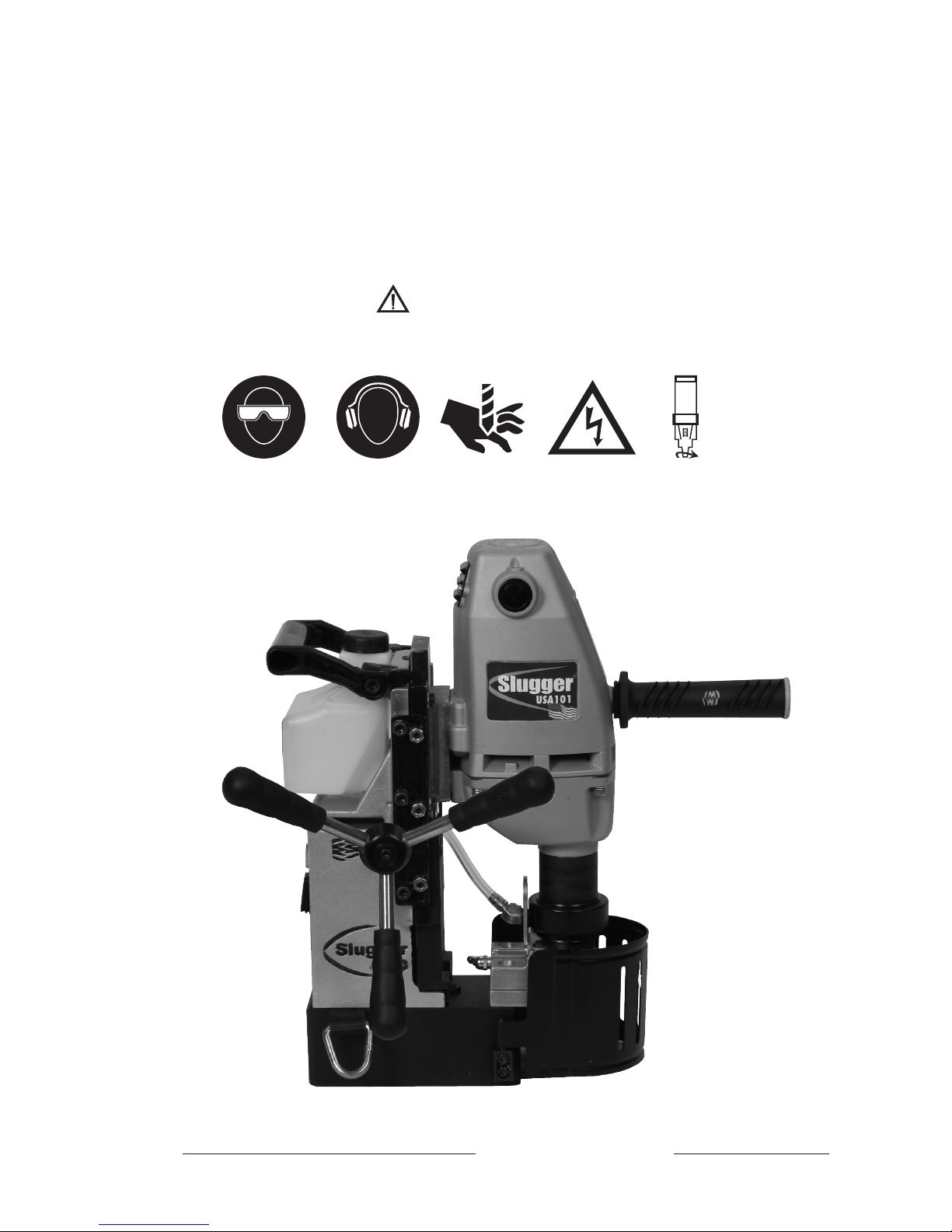

Slugger® USA101

Slugger Portable Magnetic Drilling Machine

OPERATOR’S MANUAL

EYE PROTECTIO N

REQUIRED

HEARING PROTE CTION

REQUIRED

MODEL #USA101 (120V) OR #USA101-2 (240V)

Serial # Date of Purchase

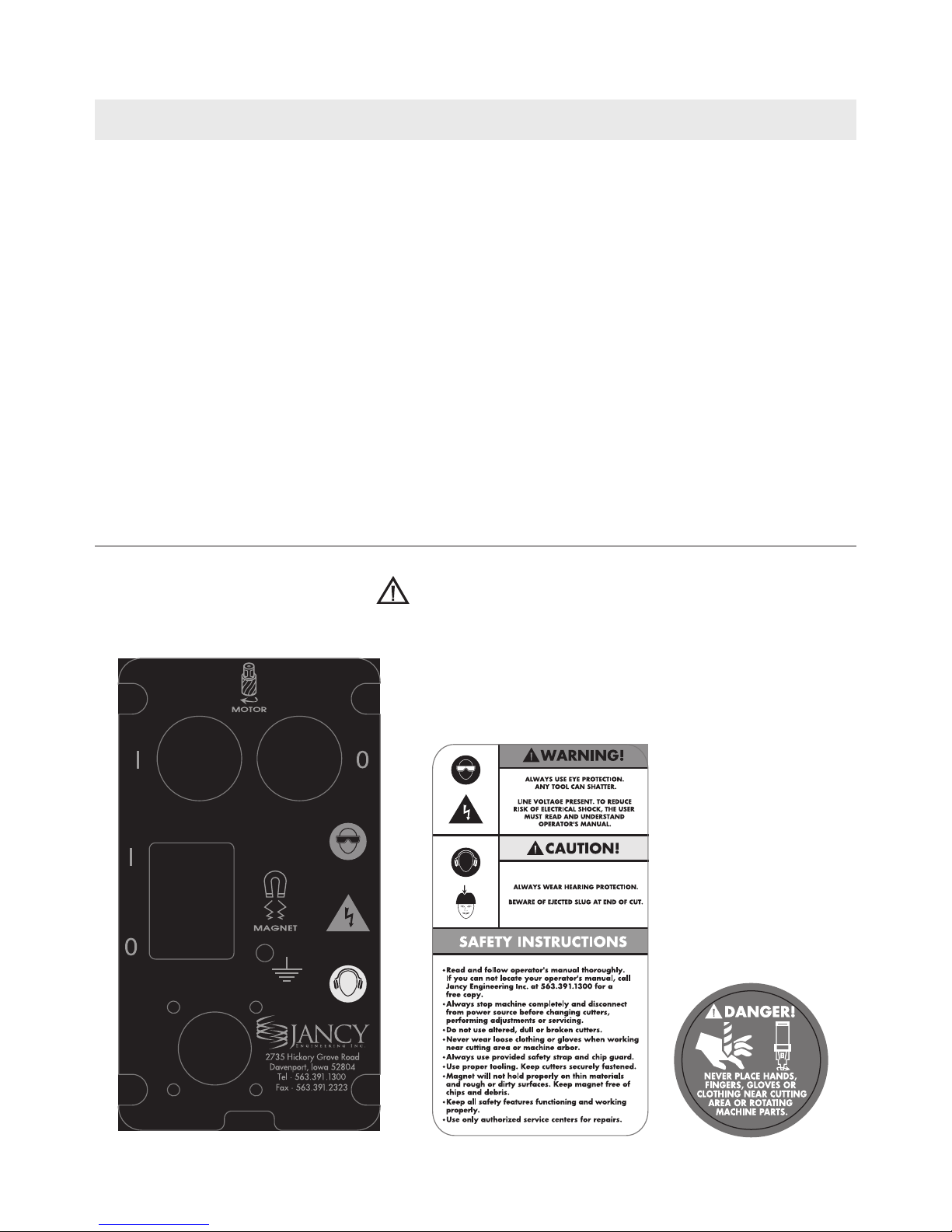

WARNING!

before use, be sure everyone using this machine reads and understands

all safety and operating instructions in this manual.

NEVER PLACE

FINGERS NEAR

CUTTING AREA OR

MACHINE ARBOR

LINE VOLTAGE

PRESENT

BEWARE OF

ROTATING

MACHINE PARTS

United States Patent #5,415.503

Slugger Portable Magnetic Drilling Machine

Congratulations on your purchase of a Slugger portable magnetic drilling machine. Slugger drilling machines are

designed to deliver fast, efficient hole drilling performance in portable applications. Please take a moment to complete

and mail your product warranty registration card. Doing so will validate your machine’s warranty period and ensure

prompt service if needed. Thank you for selecting a Slugger product from Jancy Engineering Inc.

table of contents

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Special Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Grounding Instructions and Extension Cords . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating Instructions & Contents of Package . . . . . . . . . . . . . . . . . . . . . . . 7

Getting Started & Before You Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Before The Cut, Ready To Cut & After The Cut . . . . . . . . . . . . . . . . . . . . . . 8

Basic Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Regular Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Machine Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Machine Parts List, Motor Slide Breakdown & Parts List . . . . . . . . . . . . . . . . 13

Motor Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Motor Parts List, Panel Breakdown & Parts List . . . . . . . . . . . . . . . . . . . . . 15

Arbor Breakdown & Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Frame Breakdown & Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-18

JANCY ENGINEERING RESERVES THE RIGHT TO MAKE

IMPROVEMENTS AND MODIFICATIONS TO DESIGN WITHOUT PRIOR NOTICE.

limited warranty

Jancy Engineering Inc. will, within one (1) year from the original date of purchase, repair or replace any goods found to

be defective in materials or workmanship, provided the product warranty registration card has been returned to Jancy

Engineering Inc. within thirty (30) days of purchase date. This warranty is void if the item has been damaged by accident, neglect, improper service or other causes not arising out of defects in materials or workmanship. This warranty does

not apply to machines and/or components which have been altered, changed, or modified in any way, or subjected to

use beyond recommended capacities and specifications. Electrical components are subject to respective manufacturers’

warranties. All goods returned defective shall be returned prepaid freight to Jancy, which shall be the buyer’s sole and

exclusive remedy for defective goods. In no event shall Jancy Engineering be liable for loss or damage resulting directly or

indirectly from the use of merchandise or from any other cause. Jancy Engineering is not liable for any costs incurred on

such goods or consequential damages. No officer, employee or agent of Jancy is authorized to make oral representations

of fitness or to waive any of the foregoing terms of sale and none shall be binding on Jancy.

™

2

important safety instructions

WARNING!

when using electric tools, basic safety precautions should always be followed

to reduce risk of fire, electric shock and personal injury.

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE REFERENCE.

1. Keep Work Area Clean

•Cluttered areas and benches invite injuries.

2. Consider Work Area Environment

•Do not expose power tools to rain.

•Do not use power tools in damp or wet locations.

•Keep work area well lit.

•Do not use tool in presence of flammable liquids or gases.

3. Guard Against Electric Shock

•Prevent body contact with grounded surfaces. For example: pipes, radiators, ranges and refrigerator enclosures.

4. Keep Children Away

•Do not let visitors contact tool or extension cord.

•All visitors should be kept away from work area.

5. Store Idle Tools

•When not in use, tools should be stored in a dry, high and locked-up place, out of reach of children.

6. Do Not Force Tool

•It will do the job better and safer at the rate for which it was intended.

7. Use Right Tool

•Do not force a small tool or attachment to do the job of a heavy-duty tool.

•Do not use tool for unintended purpose. For example: Do not use a circular saw for cutting tree limbs or logs.

8. Dress Properly

•Do Not Wear Gloves While Operating A Drill.

•Do not wear loose clothing or jewelry. They can be caught in moving parts.

•Non-skid footwear is recommended when working outdoors.

•Wear protective hair covering to contain long hair.

9. Use Safety Glasses

•Also use face or dust mask if cutting operation is dusty.

10. Do Not Abuse Electrical Cord

•Never carry tool by cord or yank it to disconnect from receptacle.

•Keep cord from heat, oil and sharp edges.

11. Secure Work

•Use clamps or a vise to hold work. It’s safer than using your hand and it frees both hands to operate tool.

12. Do Not Overreach

•Keep proper footing and balance at all times.

3

13. Maintain Tools With Care

•Keep tools sharp and clean for better and safer performance.

•Follow instructions for lubricating and changing accessories.

•Inspect tool cords periodically and if damaged, have repaired by authorized service facility.

•Inspect extension cords periodically and replace if damaged.

•Keep handles dry, clean, and free from oil and grease.

14. Disconnect Tools

•Unplug when not in use, before servicing, and when changing accessories, such as bits and cutters.

15. Remove Adjusting Keys And Wrenches

•Form habit of checking to see that keys and adjusting wrenches are removed from tool before turning it on.

16. Avoid Unintentional Starting

•Do not carry a plugged-in tool. Always disconnect from power source before moving.

•Be sure switches are off before connecting to a power source.

17. Outdoor Use Extension Cords

•When tool is used outdoors, use only extension cords intended for use outdoors and so marked.

18. Stay Alert

•Watch what you are doing. Use common sense. Do not operate tool when you are tired.

•Do not use when taking medications that may cause drowsiness.

19. Check Damaged Parts

•Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine

that it will operate properly and perform its intended function.

•Check alignment of moving parts, binding of parts, breakage of parts, mounting, and any other conditions

that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced

by an authorized service center.

•Do not use this tool if switches do not turn it on and off. Have defective switches replaced by authorized

service center.

important safety instructions

4

WARNING!

do not operate machine if warning and /or instruction labels are missing or damaged.

contact jancy engineering for replacement labels.

1. If you require an additional manual, please contact Jancy Engineering at (563) 391-1300 for a FREE copy.

2. Never place hands, fingers, gloves or clothing near cutting area or rotating machine parts.

3. Always disconnect machine from power source before changing cutters, clearing chips, refilling lubricant or

performing adjustments.

4. Keep all safety features functioning and working properly.

5. Never wear loose clothing, gloves or jewelry when working near cutting area or rotating machine parts.

6. Always use eye and hearing protection.

7. Always use safety strap and chip guard provided with machine.

8. Always use proper tooling. Keep cutters securely fastened.

9. Do not use dull or broken cutters.

10. Do not use Slugger drilling machines on surfaces or materials being welded. Doing so can damage the

machine’s electrical components.

11. Beware of slugs ejected at end of cut. They become HOT during the cut.

12. Magnet will not hold properly on thin materials or rough and dirty surfaces.

13. Keep bottom of magnet burr free and clear of chips and debris.

14. To reduce the risk of electrical shock, do not use machine in wet or damp areas.

15. Do not remove or alter electrical panels. Use only authorized service centers for repairs.

special instructions

SMART MAGNET CIRCUITRY.

TM

Made in USA

Patent # 5,415,503

5

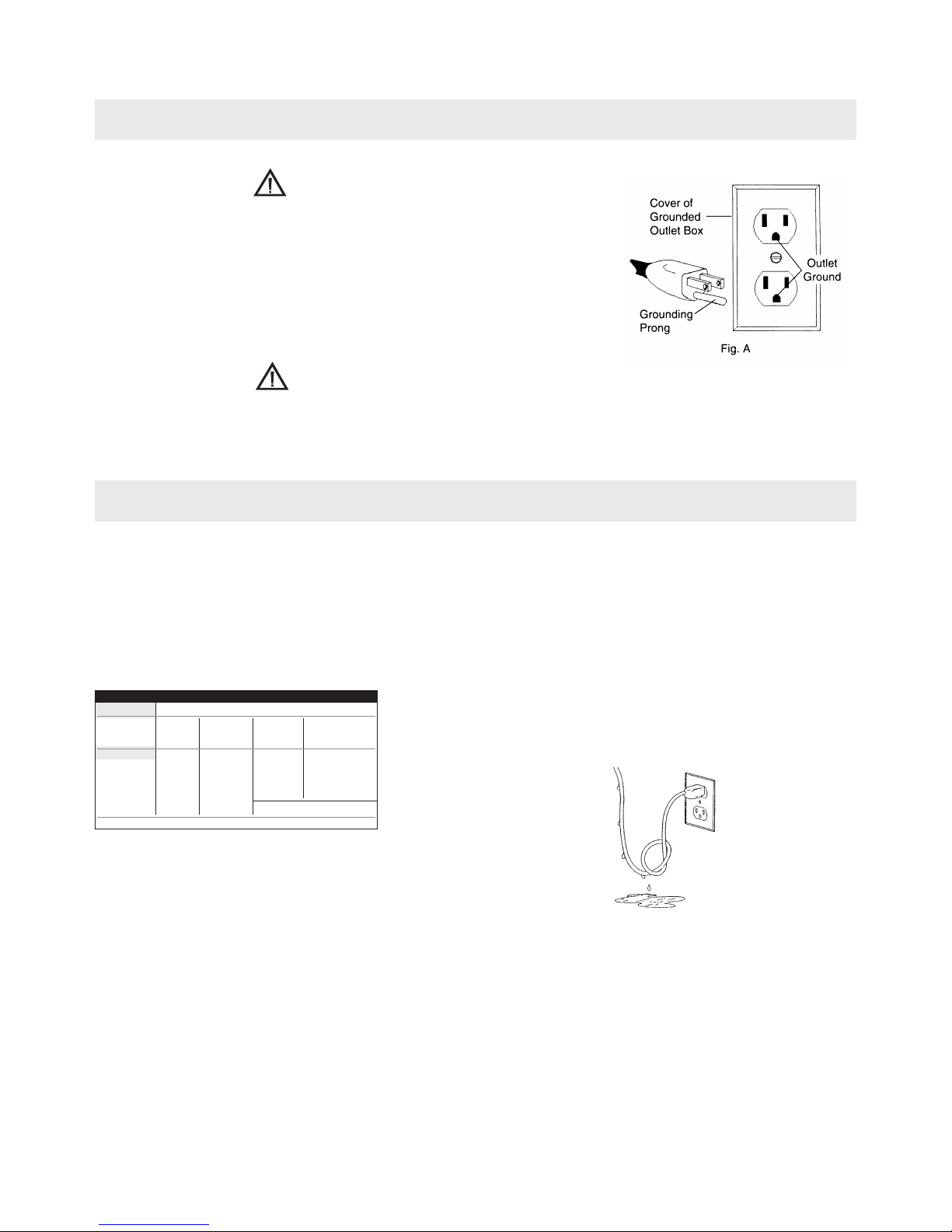

WARNING!

Improperly connecting the grounding wire can result in the risk of electrical shock.

Check with a qualified electrician if you are in doubt as to whether the outlet is

properly grounded. Do not modify the plug provided with tool. Never remove the

grounding prong from the plug. If the cord or plug is damaged, have it repaired

before using. If the plug will not fit the outlet, have a proper outlet installed by a

qualified electrician. The USA101 must be plugged into an appropriate outlet,

properly installed and grounded in accordance with all codes and ordinances.

The plug and outlet should look like those in Figure A.

WARNING!

do not use slugger drilling machines on surfaces or materials being

welded. doing so can result in personal injury and/or damage to the

slugger drilling machine.

grounding instructions

DRIP LOOP: To help prevent cutting fluids from traveling

along power cord and contacting power source, tie a drip

loop in power cord as shown in Figure B.

Fig. B

Use only 3-wire extension cords that have 3-prong grounding-type plugs and 3-pole receptacles that accept the tool’s

plug. Replace or repair damaged cords. Make sure your extension cord is in good condition. When using an extension

cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop

in line voltage resulting in loss of power and overheating. Jancy recommends using a minimum 12 gauge extension cord

not to exceed 100 feet. The table below is supplied only as a guide to minimum gauge for extension cords, where the

smaller the gauge number, the heavier the cord.

extension cords

minimum gauge for extension co rds

volts total length of cord in feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

amperage

0-6 18 16 16 14

6-10 18 16 14 12

10-12 16 16 14 12

12-16 14 12

not recommended

recommended

wire gauge

*

jancy recommends using a minimum 12 gauge extension

cord not to exceed 100 feet.

6

Loading...

Loading...