© C. & E. Fein GmbH. Printed in USA. Figure not obligatory. Subject to technical changes. 3 41 01 246 21 0 BY 2018.04.

by FEIN

by FEIN

USA

FEIN Power Tools, Inc.

1000 Omega Drive

Suite 1180

Pittsburgh, PA 15205

Phone: 800-441-9878

www.feinus.com

Canada

FEIN Canadian Power Tool

Company

323 Traders Boulevard East

Mississauga, Ontario L4Z 2E5

Telephone: (905) 8901390

Phone: 1-800-265-2581

www.fein.com

FEIN Service USA

FEIN Power Tools, Inc.

2735 Hickory Grove Road

Davenport, IA 52804

Phone: 800-441-9878

magdrillrepair@feinus.com

Headquarter

C. & E. Fein GmbH

Hans-Fein-Straße 81

D-73529 Schwäbisch Gmünd-Bargau

www.fein.com

JMU 137 QW (**) 7 270 ...

JMU 137 MQW (**) 7 270 ...

JMU 137-2 QW (**) 7 270 ...

OBJ_DOKU-0000006757-003.fm Page 1 Wednesday, April 4, 2018 9:31 AM

2

Instruction Manual

Mode d’emploi

Instrucciones de uso

en

3

fr29es

55

OBJ_BUCH-0000000261-003.book Page 2 Thursday, January 11, 2018 5:30 PM

3

en

en

For your safety.

Read all safety warnings and

all instructions. Failure to fol-

low the warnings and instructions may result

in electric shock, fire and/or serious injury.

Save all warnings and instructions for futurereference.

Do not use this power tool before you

have thoroughly read and completely

understood this Instruction Manual, including

the figures, specifications, safety regulations

and the signs indicating DANGER, WARNING and CAUTION.

Only carry out such operations with this

power tool as intended for by the manufacturer. Only use cutting tools and accessories

that have been approved by the manufacturer.

Please also observe the relevant national

industrial safety regulations.

Non-observance of the safety instructions in

the said documentation can lead to an electric

shock, burns and/or severe injuries.

This Instruction Manual should be kept for

later use and enclosed with the power tool,

should it be passed on or sold.

SAVE THESE INSTRUCTIONS.

The term “power tool” in the warnings refers

to your mains-operated (corded) power tool

or battery operated (cordless) power tool.

General safety rules.

1) Work area safety

a)Keep work area clean and well lit. Clut-

tered or dark areas invite accidents.

b)Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away

while operating a power tool. Distrac-

tion can cause you to lose control.

2) Electrical safety

a)Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools. Unmodified

plugs and matching outlets will reduce

risk of electric shock.

b)Avoid body contact with earthed or

grounded surfaces such as pipes, radiators, ranges and refrigerators. There is

an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power

tool will increase the risk of electric

shock.

d)Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase

the risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor use. Use of a cord suitable for out-

door use reduces the risk of electric

shock.

f) If operating a power tool in a damp loca-

tion is unavoidable, use a ground fault

circuit interrupter (GFCI) protected supply. Use of an GFCI reduces the risk of

electric shock.

3) Personal safety

a)Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating

power tools may result in serious personal injury.

b)Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your

finger on the switch or energising

power tools that have the switch on

invites accidents.

WARNING

OBJ_BUCH-0000000261-003.book Page 3 Thursday, January 11, 2018 5:30 PM

4

en

d)Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose cloth-

ing or jewelery. Keep your hair, clothing

and gloves away from moving parts.

Loose clothes, jewelry or long hair can

be caught in moving parts.

g)If devices are provided for the connec-

tion of dust extraction and collection

facilities, ensure these are connected

and properly used. Use of dust collec-

tion can reduce dust-related hazards.

4) Power tool use and care

a)Do not force the power tool. Use the cor-

rect power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was

designed.

b)Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the

switch is dangerous and must be

repaired.

c) Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

e) Maintain power tools. Check for mis-

alignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power

tool repaired before use. Many accidents

are caused by poorly maintained power

tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

g) Use the power tool, accessories and tool

bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations different from those

intended could result in a hazardous situation.

5) Service

a)Have your power tool serviced by a qual-

ified repair person using only identical

replacement parts. This will ensure that

the safety of the power tool is maintained.

Special safety instructions.

Wear protective equipment. Depending on the

application, wear face shield or safety goggles. Wear hearing protection. The safety

glasses/goggles must be suitable to protect

against the particles emitted from different

operations. Continuous high exposure to

noise can lead to loss of hearing.

Do not touch the sharp edges of the core drill

bit. Danger of injury.

Replace the protective cable bushing immediately when damaged. A defective protective

cable bushing can lead to overheating of the

machine and to an emergency stop.

Before putting into operation: Mount the chip

guard to the machine.

Always secure the power tool with with the

supplied clamping strap. In case of a power

failure or when the power plug is pulled, the

magnetic holding power is not maintained.

When carrying out such work, beware of falling objects, such as cores or chips.

OBJ_BUCH-0000000261-003.book Page 4 Thursday, January 11, 2018 5:30 PM

5

en

When working overhead or on vertical surfaces, the coolant container must not be used.

Use Slugger Cutting Paste instead. Liquids

penetrating your electric power tool maycause electric shock.

Avoid touching the drilled core that is automatically ejected by the pilot pin when the

working procedure is finished. Contact with

the core when it is hot, or if it falls, can cause

personal injuries.

Operate the power tool only from grounded

contact sockets that comply with the specifications. Do not use any connection cables

that are damaged; use extension cables with

a grounded contact that are checked at regular intervals. A ground conductor without

continuity can cause an electric shock.

To prevent injuries, always keep your hands,

clothing, etc. away from rotating chips. The

chips can cause injuries. Always use the chip

guard.

Do not attempt to remove the cutting tool if it

still turns. This can lead to serious injuries.

Hold power tool by insulated gripping surfaces when performing an operation where

the cutting accessory may contact hidden

wiring or its own cord. Cutting accessory con-

tacting a “live” wire will make exposed metal

parts of the power tool “live” and shock the

operator.

Beware of any concealed electric cables, gas

or water conduits. Check the working area

before commencing work, e. g. with a metal

detector.

Do not work materials containing magnesium.

Danger of fire.

Do not work CFP (carbon-fiber-reinforced

polymer) and materials containing asbestos.

These materials are considered carcinogenic.

Do not rivet or screw any name-plates or

signs onto the power tool. If the insulation is

damaged, protection against an electric shock

will be ineffective. Adhesive labels are recommended.

Do not overload the power tool or the storage

case and do not use it as a ladder or stand.

Overloading or standing on the power tool or

the storage case can lead to the upward shifting of the center of gravity of the power tool

or the storage case, and its tipping over.

Do not use accessories which are not specifically designed and recommended by the

power tool manufacturer. Safe operation is

not ensured merely because an accessory fits

your power tool.

Clean the ventilation openings on the power

tool at regular intervals using non-metal

tools. The blower of the motor draws dust

into the housing. An excessive accumulation

of metallic dust can cause an electrical hazard.

Before putting into operation, check the

power connection and the power plug for

damage.

Recommendation: The tool should always be

supplied with power via a ground fault circuit

interrupter (GFCI) with a rated current of

30 mA or less.

OBJ_BUCH-0000000261-003.book Page 5 Thursday, January 11, 2018 5:30 PM

6

en

Handling hazardous dusts.

When working with power

tools, such as when grinding,

sanding, polishing, sawing or for other work

procedures where material is removed, dusts

develop that are both hazardous to one’s

health and can spontaneously combust or be

explosive.

Contact with or inhaling some dust types can

trigger allergic reactions to the operator or

bystanders and/or lead to respiratory infections, cancer, birth defects or other reproductive harm.

Examples of such materials which contain

chemicals that can produce hazardous dusts,

are:

– Asbestos and materials containing asbes-

tos;

– Lead-containing coatings, some wood

types such as beech and oak;

– Minerals and metal;

– Silicate particles from bricks, concrete and

other materials containing stone;

– Solvent from solvent-containing paint/

varnish;

– Arsenic, chromium and other wood pre-

servatives;

– Materials for pesticide treatment on boat

and ship hulls;

– Stainless steel dust, metal dust and non-

ferrous metal dust;

To minimize the unwanted intake of these

materials:

– Use dust extraction matched appropriately

for the developing dust.

– Use personal protective equipment, such

as a P2 filter-class dust protection mask.

– Provide for good ventilation of the work-

place.

The risk from inhaling dusts depends on how

often these materials are worked. Materials

containing asbestos may only be worked on

by specialists.

Wood and light-metal dust can

cause spontaneous combustion or explosions.

Hot mixtures of sanding dust and paint/varnish residuals or other chemical materials in

the filter bag or the vac filter can self-ignite

under unfavourable conditions, such as sparking from sanding metal, continuous sunlight

or high ambient temperatures. To prevent

this:

– Avoid overheating the material being

sanded and the power tool.

– Empty the dust collector/container rou-

tinely.

– Observe the material manufacturer’s

working instructions.

– Observe the relevant regulations for the

materials being worked.

WARNING

CAUTION

OBJ_BUCH-0000000261-003.book Page 6 Thursday, January 11, 2018 5:30 PM

7

en

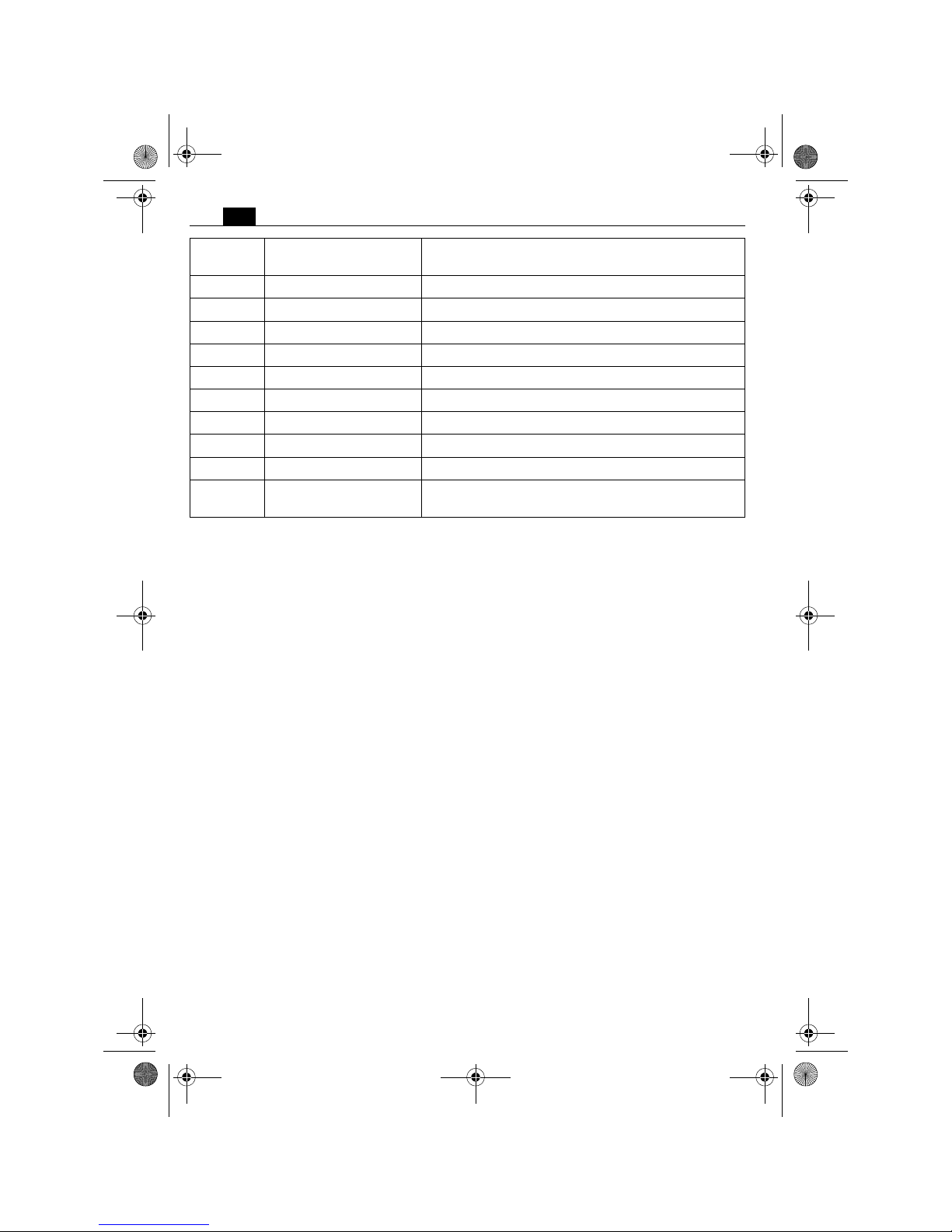

Emission values for sound (Two-figure – specifications as per ISO 4871)

Extension cable.

If the use of an extension cord

is required, its length and conductor cross-section must be adequate for the

application in order to prevent a voltage drop

in the extension cord, power loss and overheating of the power tool. Otherwise, the

extension cable and power tool are prone to

electrical danger, and the working efficiency is

decreased.

Sound emission JMU 137 QW (**) JMU 137 MQW (**) JMU 137-2 QW (**)

A-weighted emission

pressure power level measured at the workplace

L

pA

(re 20 μPa), in deci-

bels 86.7 86.7 85.6

Measuring uncertainty

K

pA

, in decibels 3 3 3

Measured A-weighted

sound power level

L

wA

(re 1 pW), in decibels 97.7 97.7 96.6

Measuring uncertainty

K

wA

, in decibels 3 3 3

C-weighted peak sound

pressure level measured at

the workplace

L

pCpeak

, in

decibels 101.2 101.2 98.9

Measuring uncertainty

K

pCpeak

, in decibels 3 3 3

Mean vibrational value

(core drilling)

– m/s

2

– ft/s

2

< 2.5

8.3

< 2.5

8.3

< 2.5

8.3

Measuring uncertainty

K

,

in

– m/s

2

– ft/s

2

1.5

4.9

1.5

4.9

1.5

4.9

REMARK: The sum of the measured emission value and respective measuring inaccuracy

represents the upper limit of the values that can occur during measuring.

Wear hearing protection!

Measured values determined in accordance with the corresponding product standard.

WARNING

OBJ_BUCH-0000000261-003.book Page 7 Thursday, January 11, 2018 5:30 PM

8

en

Intended use of the power tool:

Magnetic core drill unit for drilling with core

drill bits and solid drill bits, reaming, countersinking and tapping on materials with surfaces

suitable for magnets in weather-protected

environments using the application tools and

accessories recommended by Slugger.

Operation of the power tool off power generators.

This power tool is also suitable for use

with AC generators with sufficient power

output that correspond to the Standard

ISO 8528, design type G2. This Standard is

particularly not complied with when the socalled distortion factor exceeds 10 %. When

in doubt, please refer to the generator

instruction/specification guide.

Operating the power tool off

power generators whose noload speed exceeds the voltage value on the

type plate of the power tool is prohibited.

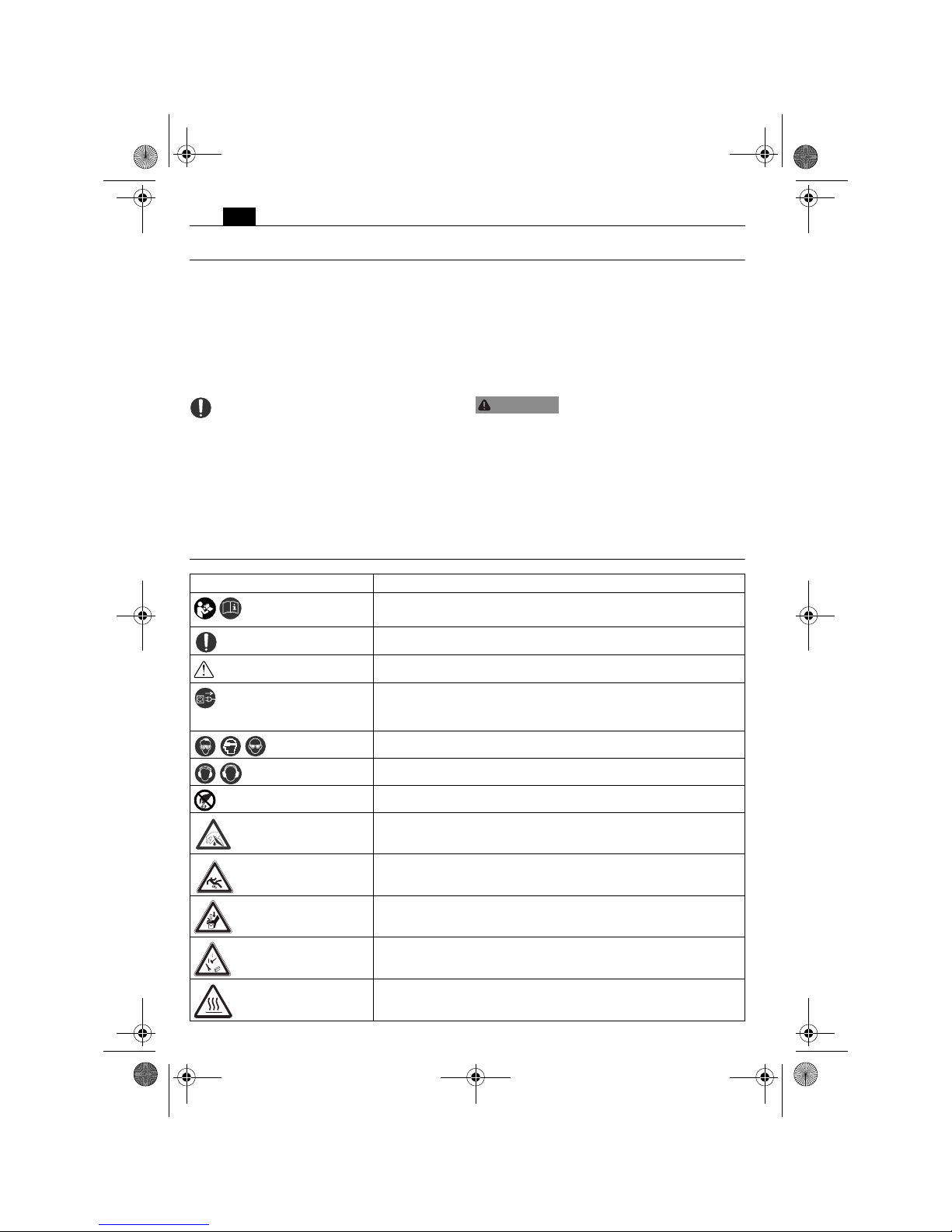

Symbols.

WARNING

Symbol, character Explanation

Make sure to read the enclosed documents such as the

Instruction Manual and the General Safety Instructions.

Observe the instructions in the text or graphic opposite!

Observe the instructions in the text or graphic opposite!

Before commencing this working step, pull the power plug

out of the socket. Otherwise there will be danger of injury if

the power tool should start unintentionally.

Use eye protection during operation.

Use ear protection during operation.

Do not touch the rotating parts of the power tool.

Warning against sharp edges of application tools, such as the

cutting edges of the cutter blades.

Danger of slipping!

Danger of crushes or contusions!

Caution! Falling objects!

Hot surface!

OBJ_BUCH-0000000261-003.book Page 8 Thursday, January 11, 2018 5:30 PM

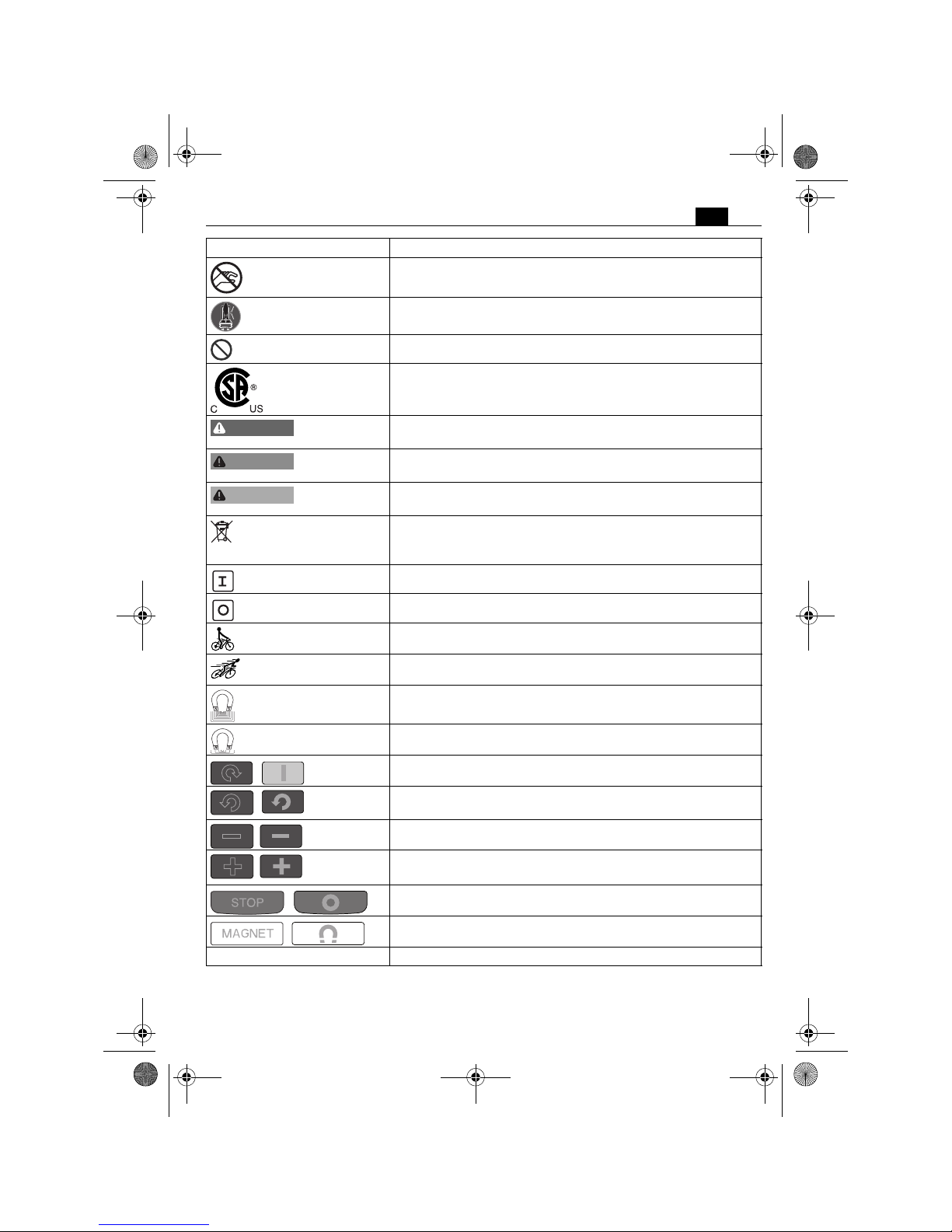

9

en

Do not reach in!

Fasten strap!

General prohibition sign. This action is prohibited.

This symbol confirms the certification of this product for the

USA and Canada.

This sign warns of a directly imminent, dangerous situation. A

false reaction can cause a severe or fatal injury.

This sign indicates a possible dangerous situation that could

cause severe or fatal injury.

This sign warns of a possible dangerous situation that could

cause injury.

Worn out power tools and other electrotechnical and electrical products should be sorted separately for environmentallyfriendly recycling.

Start drill motor. Rotation direction: clockwise

Stop motor

Low speed

High speed

Magnetic holding power, sufficient

Magnetic holding power, insufficient

Start drill motor. Rotation direction: clockwise

Start drill motor in inch mode. Rotation direction: counterclockwise

Speed reduction in steps

Speed increase in steps

Stop motor

Switches the magnet On/Off

(**) may contain numbers and letters

Symbol, character Explanation

DANGER

WARNING

CAUTION

OBJ_BUCH-0000000261-003.book Page 9 Thursday, January 11, 2018 5:30 PM

10

en

Character Unit of measurement,

national

Explanation

n

0

rpm; /min; min-1; r/min No-load speed

P

W Electrical power

°Angle width

U V Electric voltage

f Hz Frequency

I

A Electric current intensity

m

lbs Mass

l ft, in Length, width, height, depth, diameter or thread

Ø ft, in Diameter of a round part

m, s, kg, A, mm, V, W,

Hz, N, °C, dB, min, m/s

2

Basic and derived units of measurement from the

international system of units SI.

OBJ_BUCH-0000000261-003.book Page 10 Thursday, January 11, 2018 5:30 PM

11

en

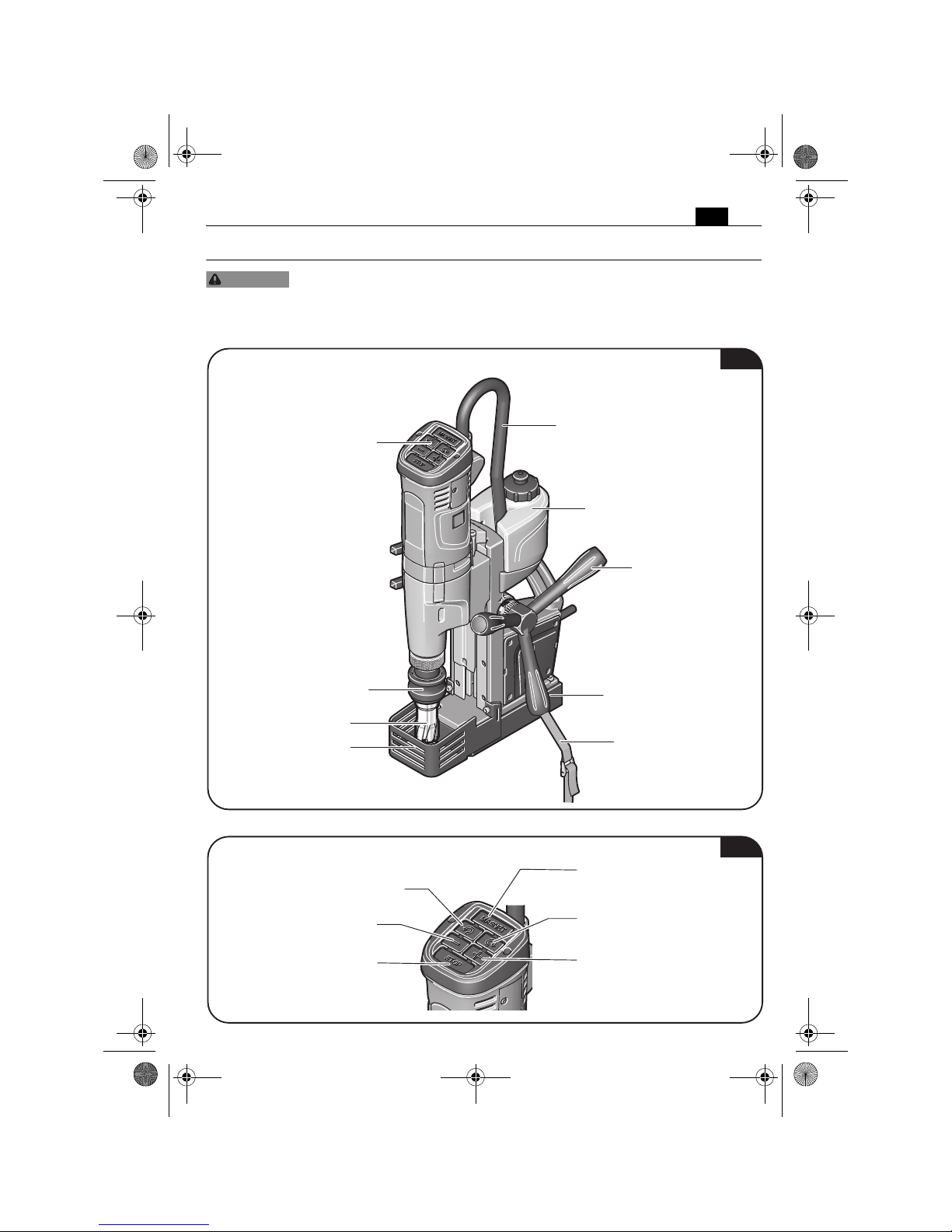

Technical description and specifications.

Before mounting or replacing cutting tool or accessories, pull the power plug.

This preventive safety measure rules out the danger of injuries through accidental starting of the power tool.

Not all accessories described or shown in this instruction manual will be included with yourpower tool.

WARNING

Application tool

Chip guard

Tool holder

Viseo Touch Pad

Drill-motor cable

Coolant container

Spoke handle

Magnetic foot

Clamping strap

Fig. 1

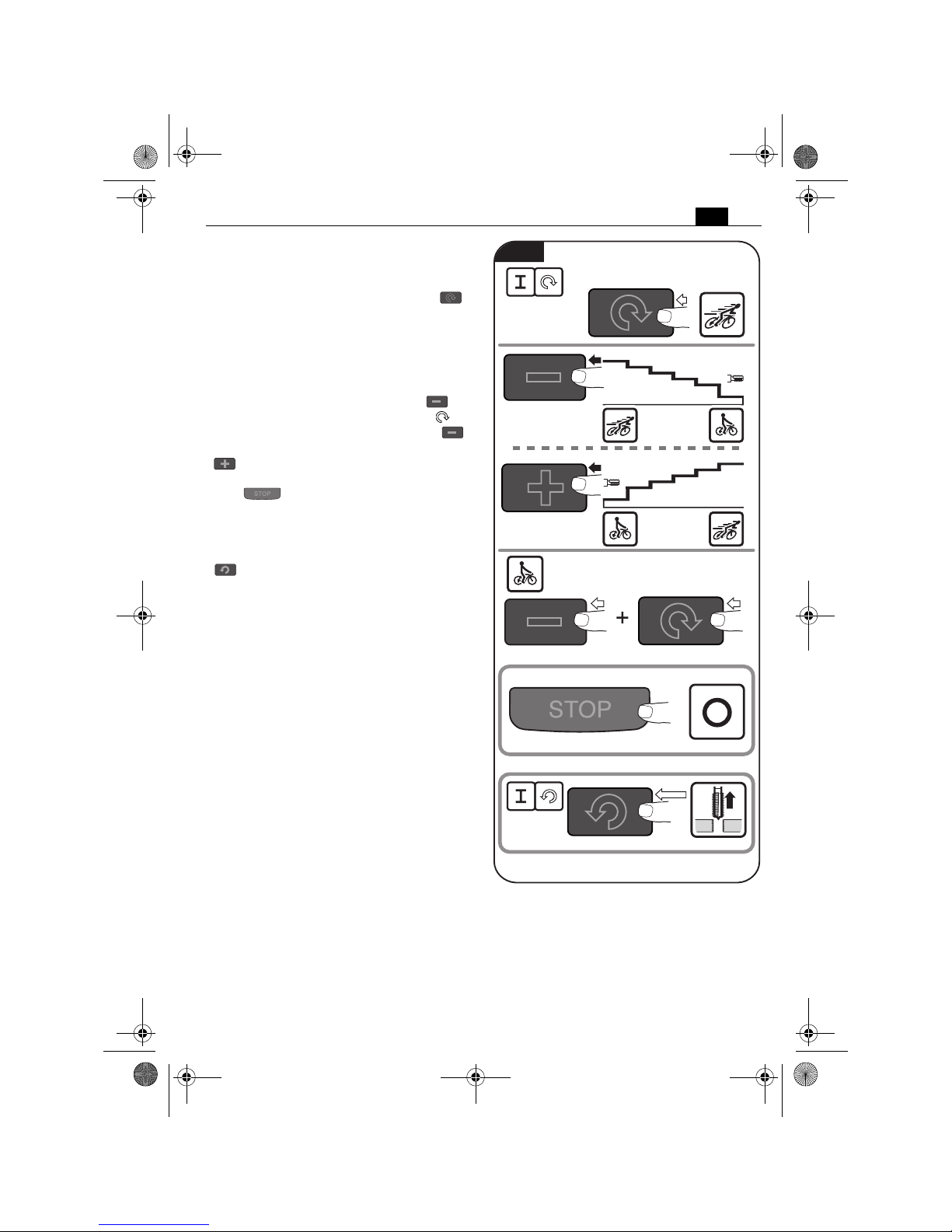

Switches the magnet On/Off

Starts the drill motor

Rotation direction: clockwise

Speed reduction in steps

Starts the drill motor in inch mode

Rotation direction: anticlockwise

Stops the drill motor

Speed increase in steps

Fig. 2

OBJ_BUCH-0000000261-003.book Page 11 Thursday, January 11, 2018 5:30 PM

12

en

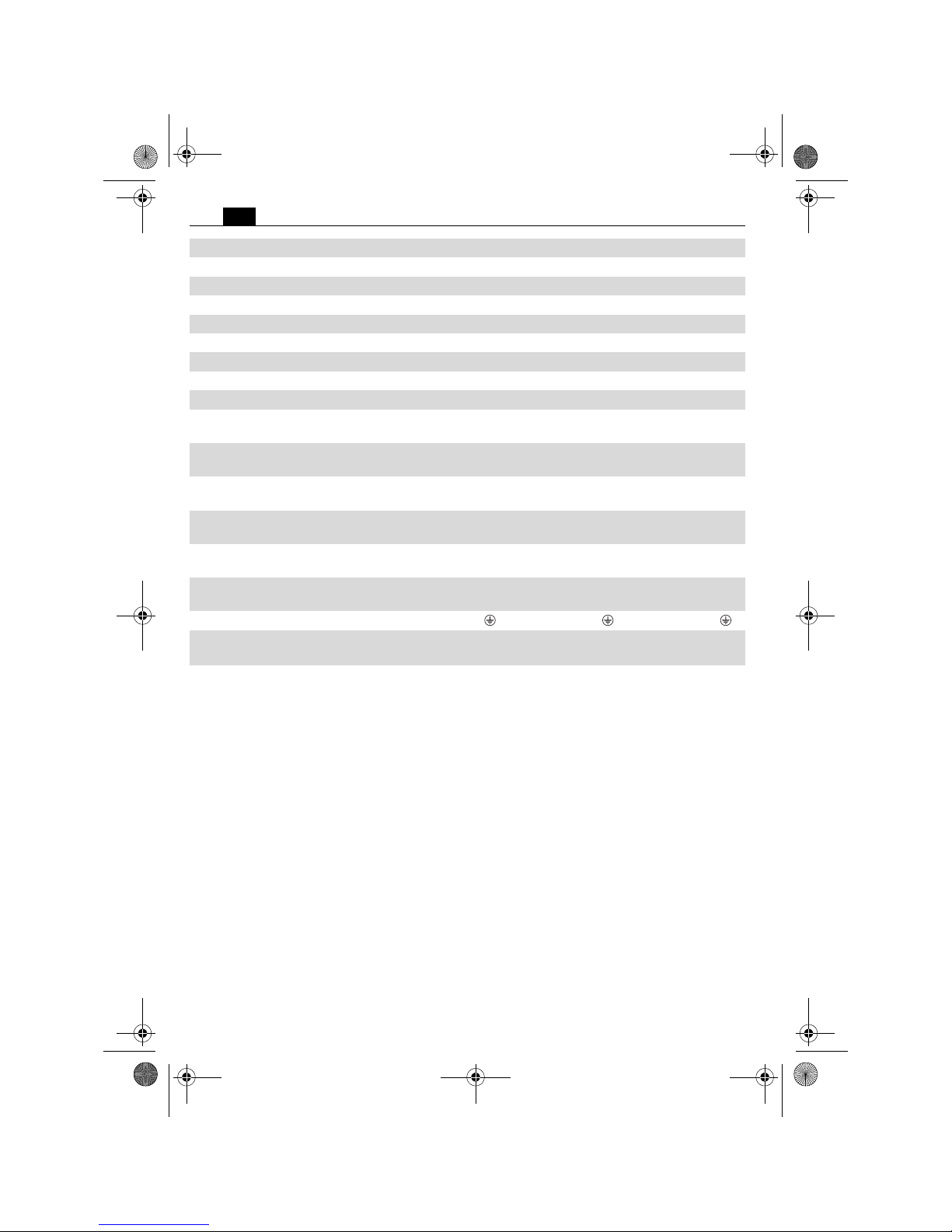

Type JMU 137 QW (**) JMU 137 MQW (**) JMU 137-2 QW (**)

Order number 7 270 ... 7 270 ... 7 270 ...

Current consumption 9.2 A 9.2 A 9.2 A

No-load speed (right rotation)

1. Gear 550 /min 550 /min 550 /min

2. Gear – – 1700 /min

No-load speed (left rotation)

1. Gear 370 /min 370 /min 370 /min

2. Gear – – 1140 /min

Drilling capacity in steel - TCT/

high speed steel (core drill bits)

7/16 in – 1 3/8 in

11 mm – 35 mm

7/16 in – 1 3/8 in

11 mm – 35 mm

7/16 in – 1 3/8 in

11 mm – 35 mm

Drilling capacity in steel - high

speed steel (HSS) (twist drill bit)

5/8 in

16 mm

11/16 in

18 mm

5/8 in

16 mm

Tapped hole 9 16/4 in

M14

9 16/4 in

M14

9 16/4 in

M14

Reamer diameter 5/8 in

16 mm

11/16 in

18 mm

5/8 in

16 mm

Counterboring diameter 1 1/4 in

32 mm

1 1/4 in

32 mm

1 1/4 in

32 mm

Weight according to

EPTA-Procedure 01

23.4 lbs

(10.6 kg)

24.25 lbs

(11.0 kg)

24.25 lbs

(11.0 kg)

Class of protection /I /I /I

Allowable ambient temperature 23°F ... 104°F

–5°C ... +40° C

23°F ... 104°F

–5°C ... +40°C

23°F ... 104°F

–5°C ... +40°C

OBJ_BUCH-0000000261-003.book Page 12 Thursday, January 11, 2018 5:30 PM

13

en

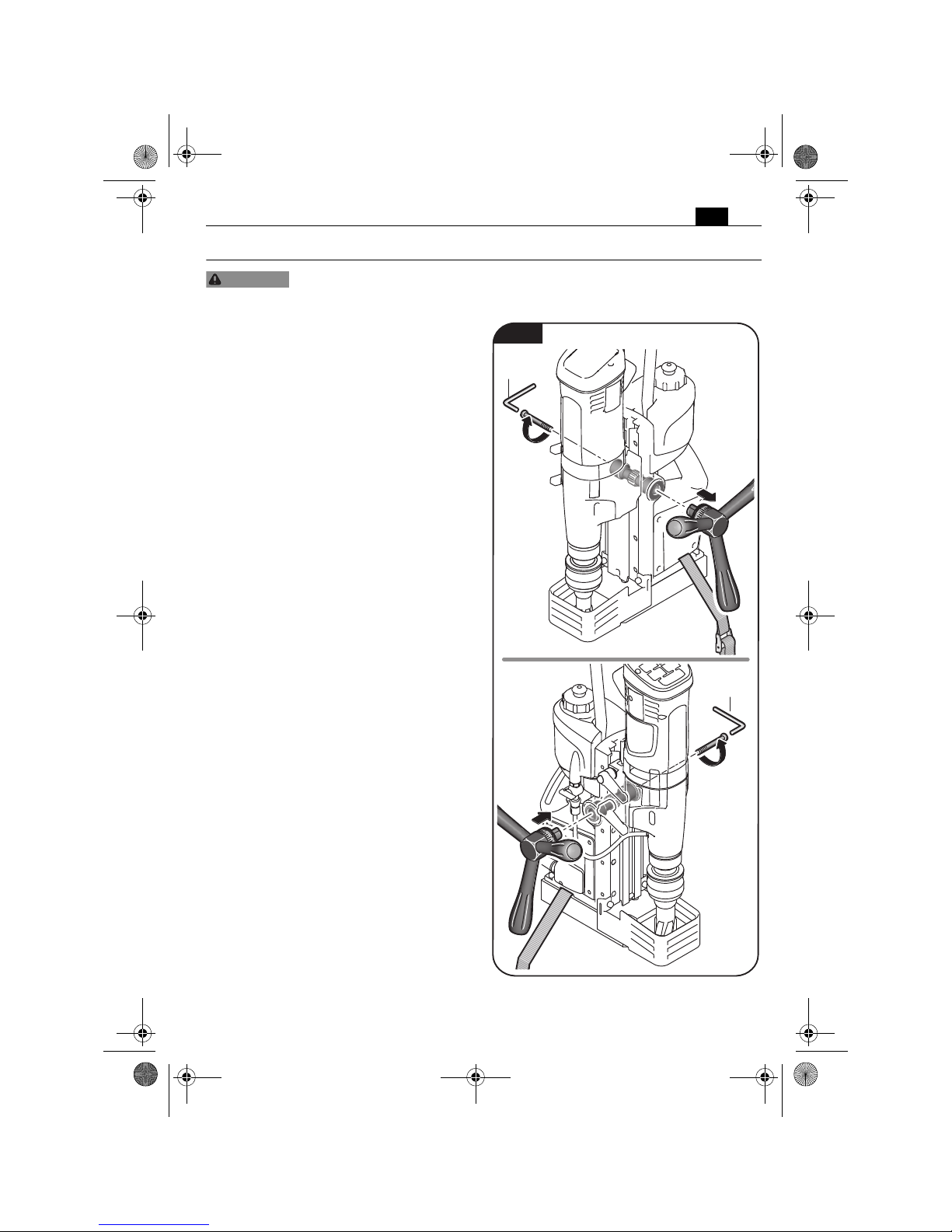

Assembly instructions.

Before mounting or replacing cutting tool or accessories, pull the power plug.

This preventive safety measure rules out the danger of injuries through accidental starting of the power tool.

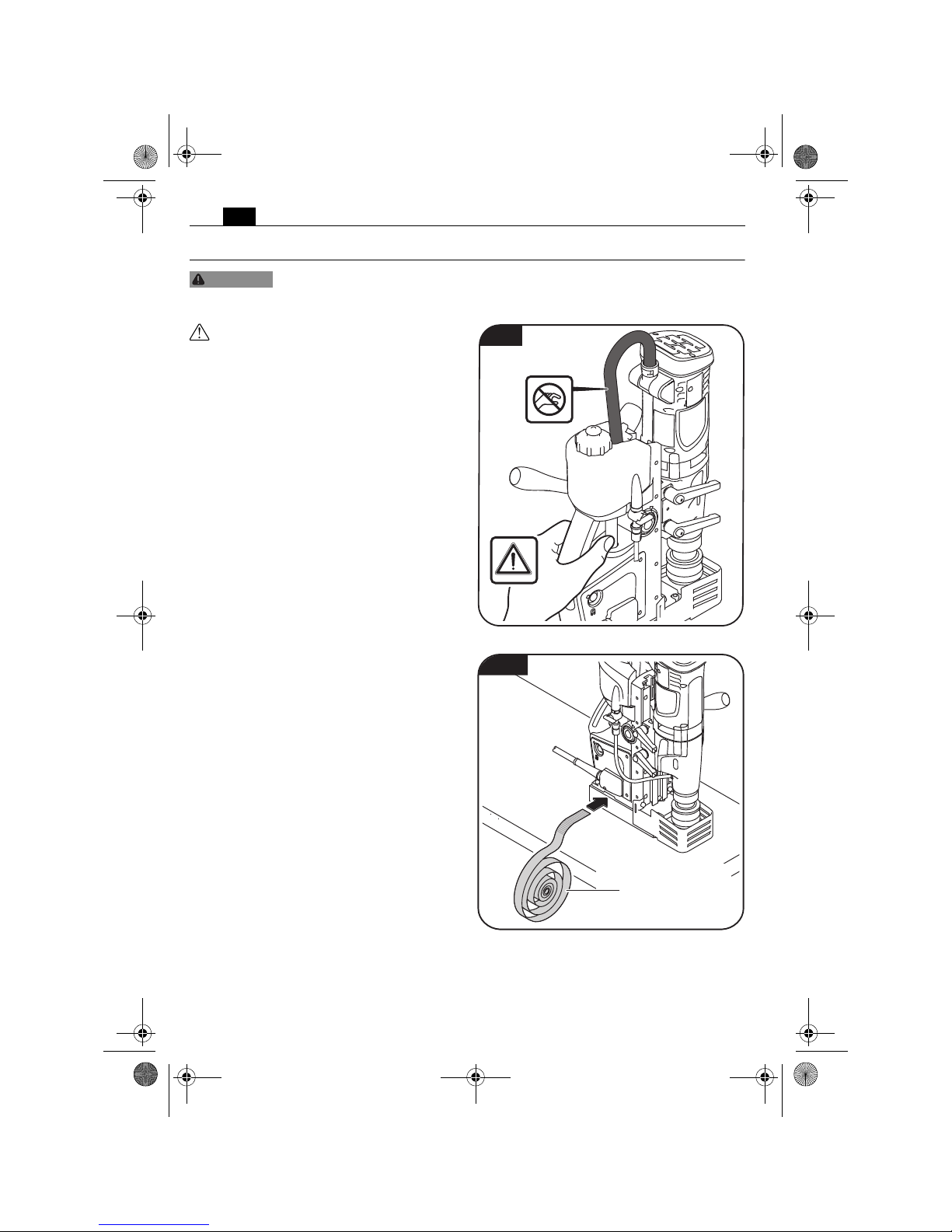

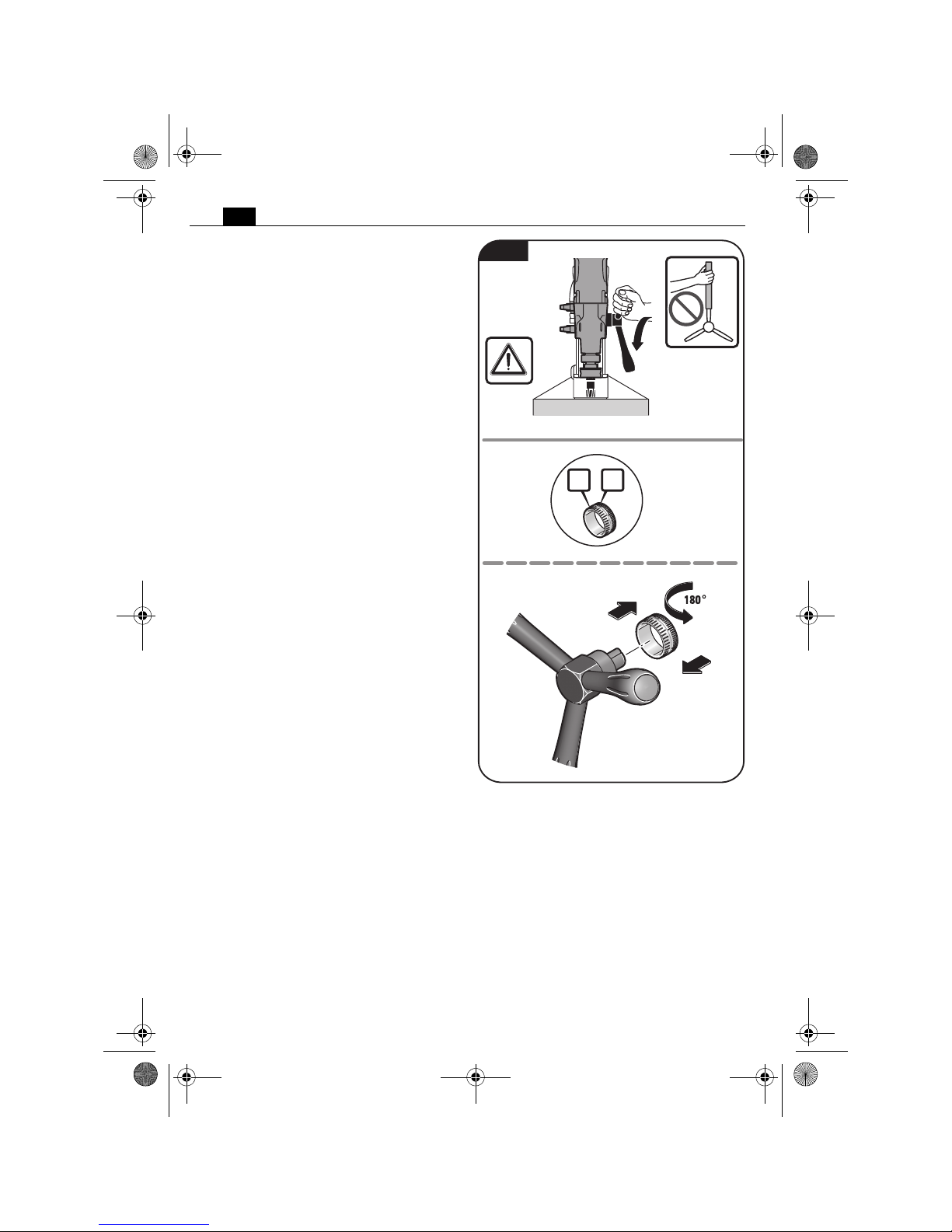

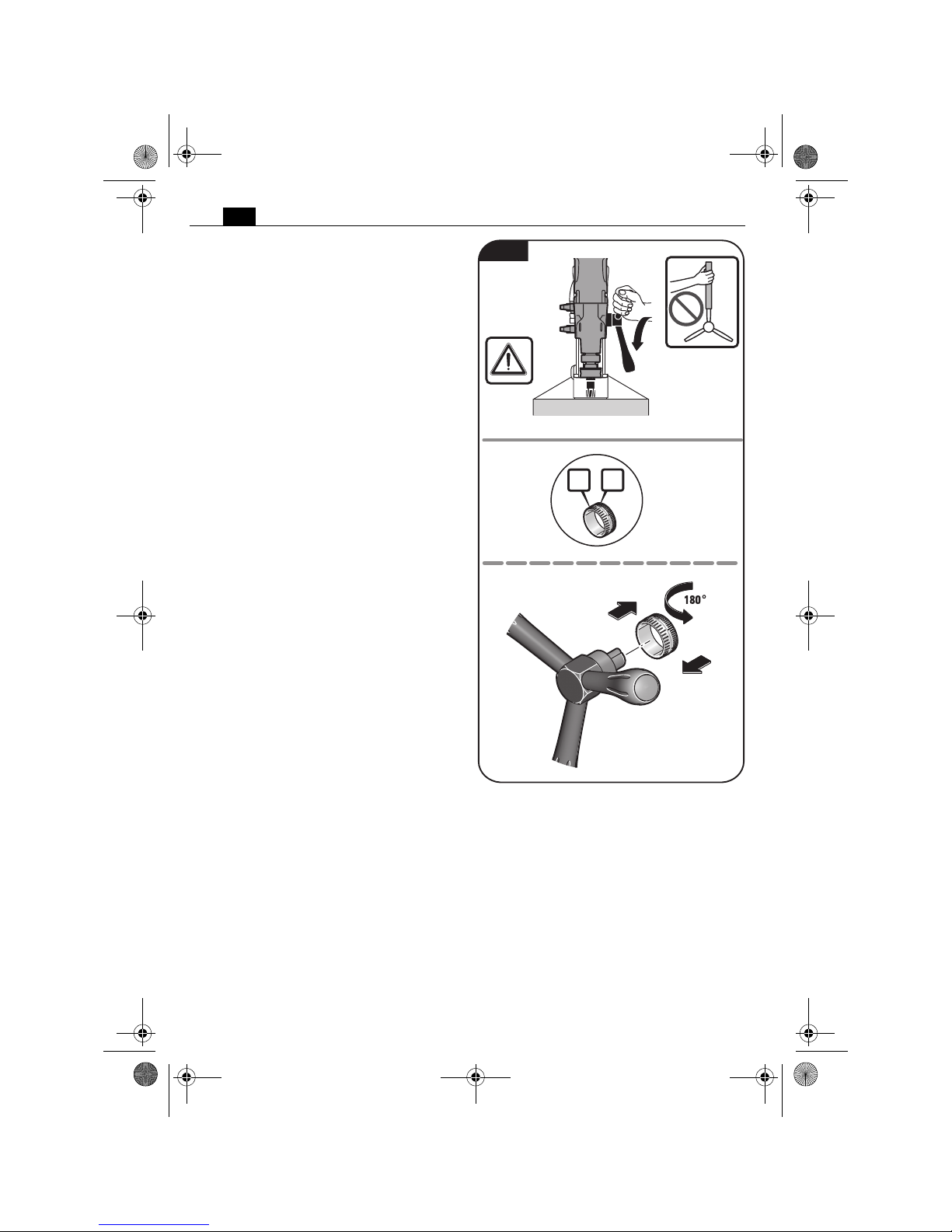

Mounting the spoke handle

(figure 3).

The hub assembly can be mounted on either

side.

Loosen the screw using a hex key.

Remove the spoke handle.

Mount the spoke handle on the other side

and tighten the screw using a hex key.

WARNING

1.

2.

3.

4.

5 mm /

3/16 in

5 mm /

3/16 in

Fig. 3

OBJ_BUCH-0000000261-003.book Page 13 Thursday, January 11, 2018 5:30 PM

14

en

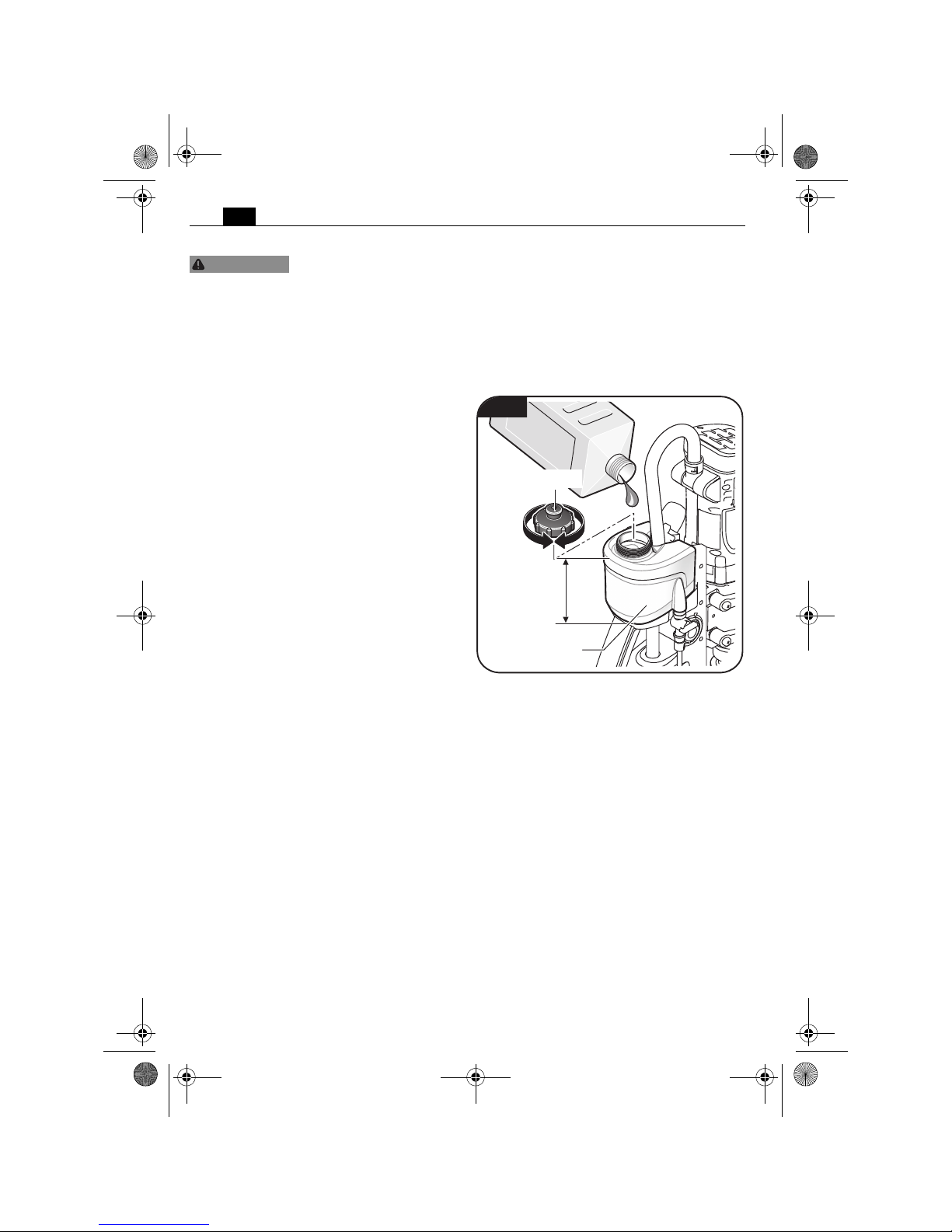

Filling the coolant container.

Prevent the flow of liquid along the cable into the socket outlet or into the core

drill unit, as this can lead to electric shock. Tie a bow in the cable near the plug,

so that any liquid can drip off.

Do not use the magnetic core drill unit when the cooling-lubricant system is defective. Each

time before operating, check for tightness against leaks and for cracks in the hoses. Prevent liquids from entering or penetrating electrical components.

Only use a coolant-lubricant emulsion (oil in water) as the cooling agent.

Observe the manufacturer's instructions on coolant.

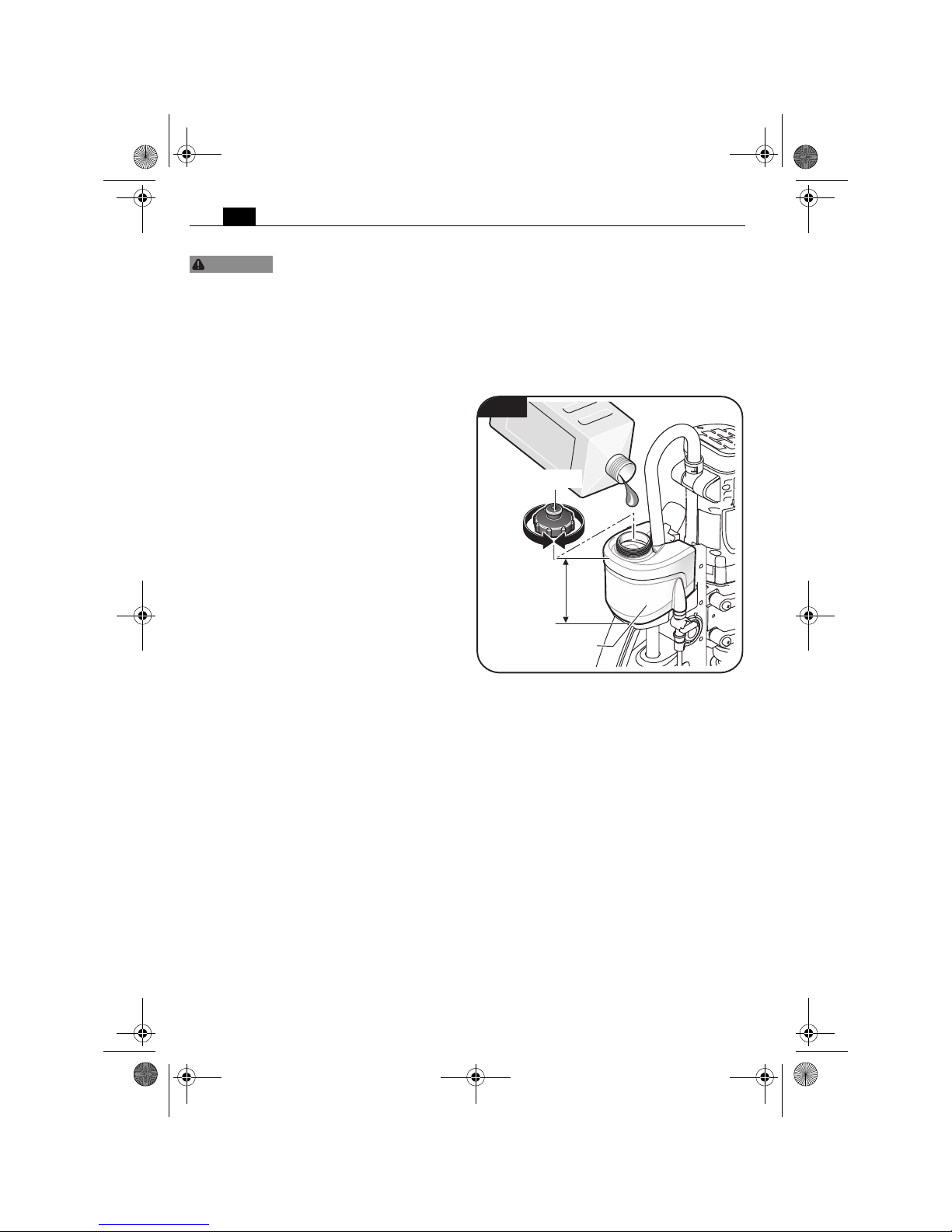

Filling the mounted coolant container

(figure 4)

Unscrew the cap from the coolant container.

Fill in pump-feedable cooling lubricant,

e.g. Slugger cutting oil.

Screw the cap onto the coolant container

again.

WARNING

3.

1.

2.

Coolant container

Upper closing cap

max. 500 ml

max. 17 fl. OZ.

Fig. 4

OBJ_BUCH-0000000261-003.book Page 14 Thursday, January 11, 2018 5:30 PM

15

en

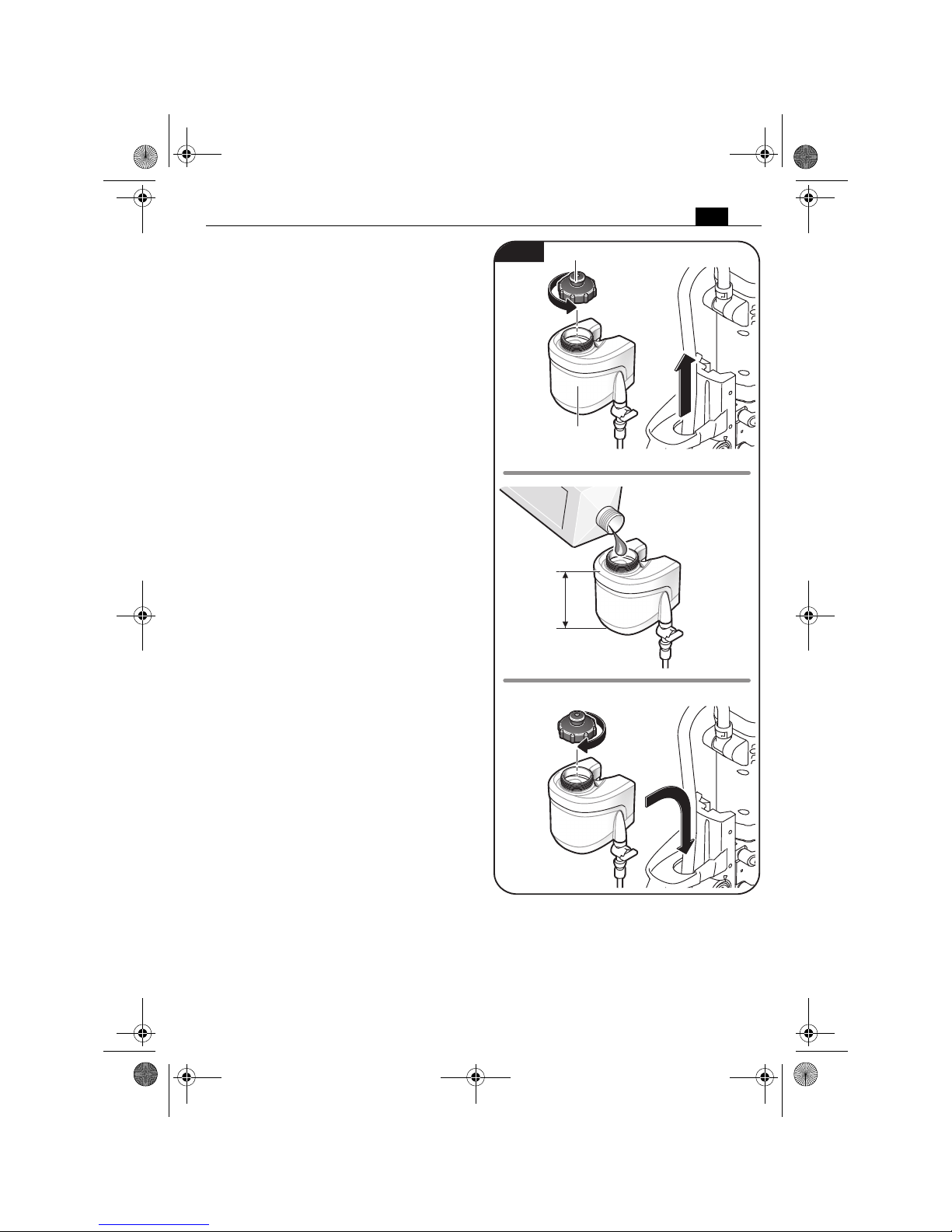

Filling the dismounted coolant container

(figure 5)

Pull the empty coolant container out of the

drill stand housing of the magnetic core drill.

Unscrew the cap from the coolant container.

Fill in pump-feedable cooling lubricant,

e.g. Slugger cutting oil.

Screw the cap onto the coolant container

again.

Insert the filled coolant container into the

holder on the drill stand housing intended for

this purpose.

1.

3.

2.

5.

4.

Coolant container

Upper closing cap

max. 500 ml

max. 17 fl. OZ.

Fig. 5

OBJ_BUCH-0000000261-003.book Page 15 Thursday, January 11, 2018 5:30 PM

16

en

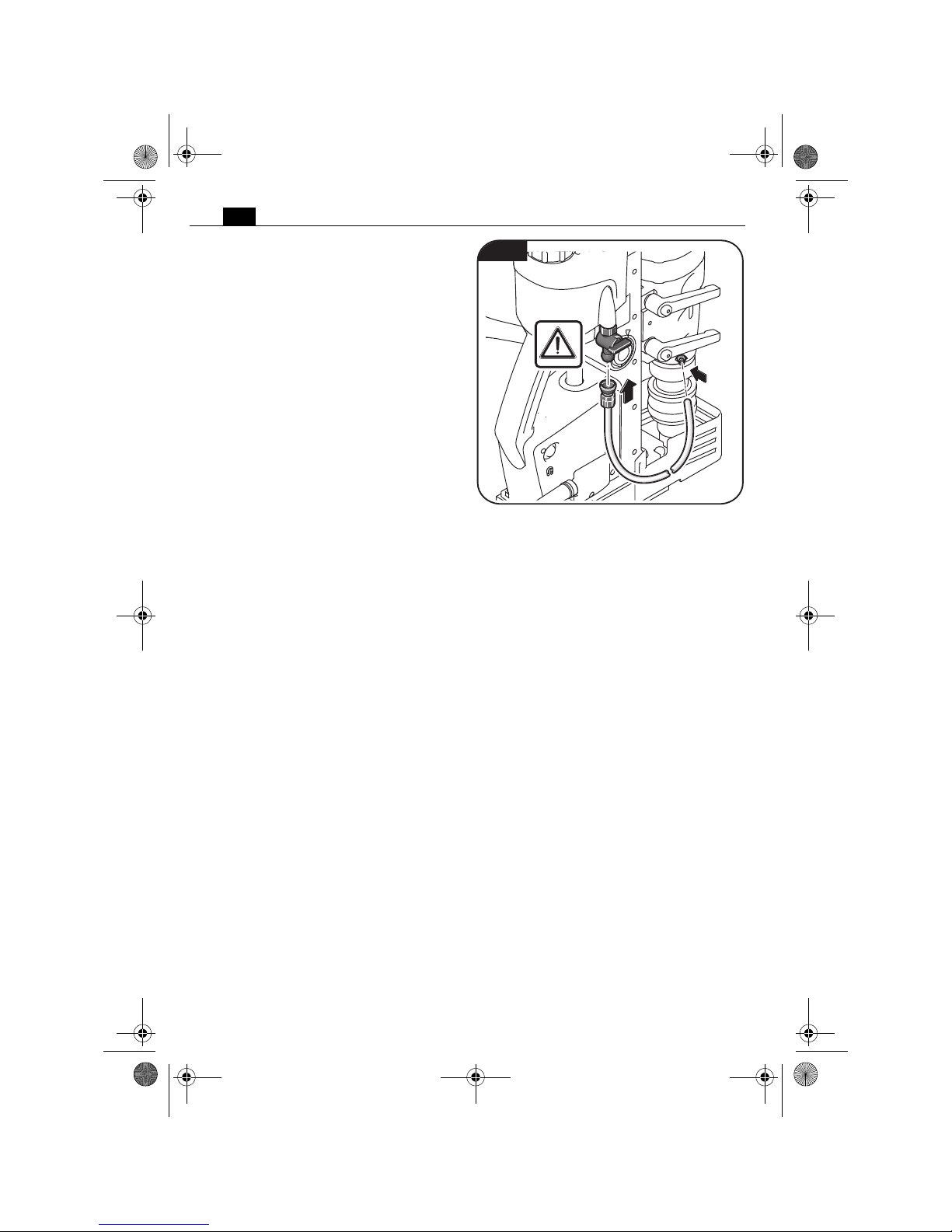

Mounting the coolant hose (figure 6).

Connect the coolant hose.

Fig. 6

OBJ_BUCH-0000000261-003.book Page 16 Thursday, January 11, 2018 5:30 PM

17

en

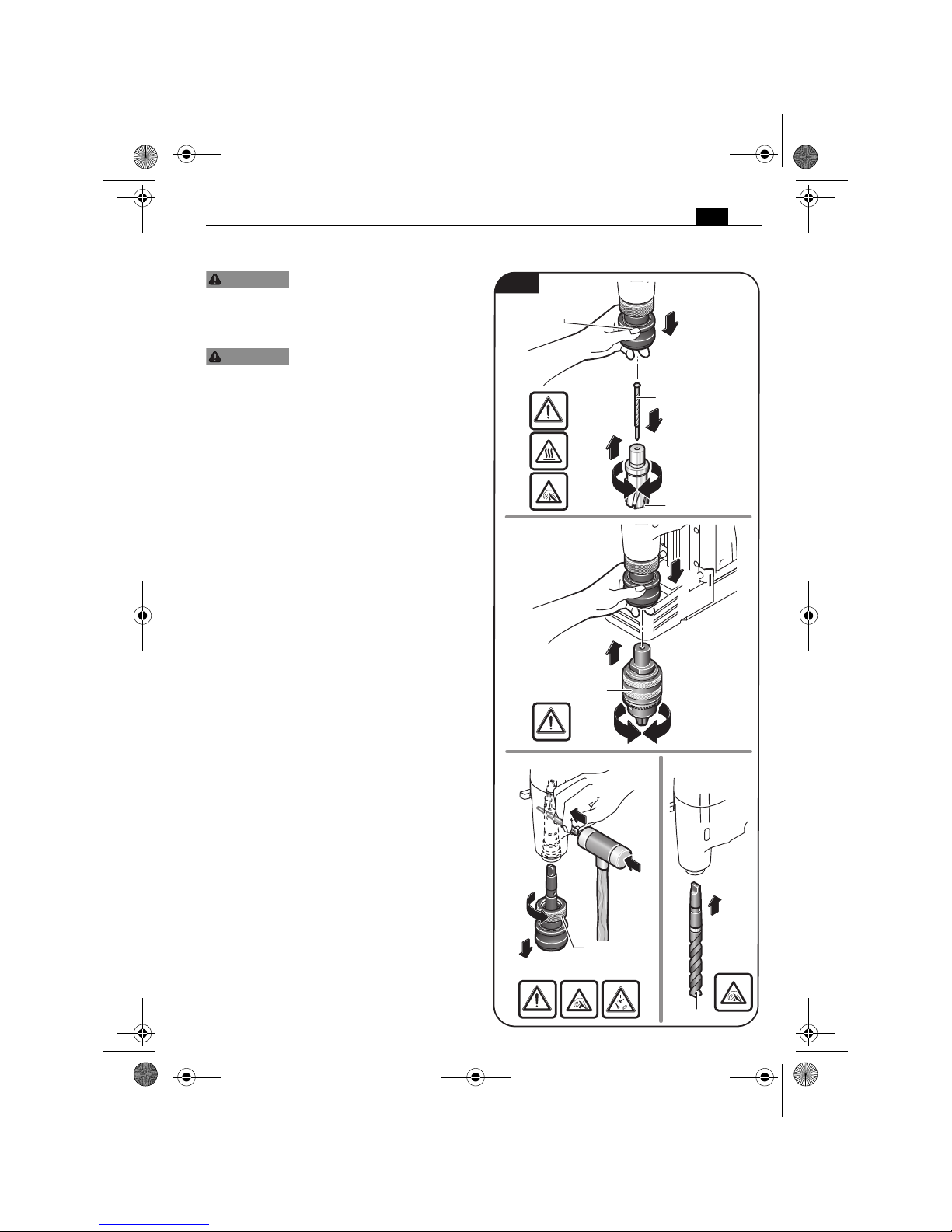

Tool changing (figure 7).

Always secure the power tool

with the supplied clamping

strap. In case of a power failure or when the

power plug is pulled, the magnetic holding

power is not maintained.

Switch the machine off and

pull the power plug before

mounting or replacing application tools and

accessories (not overhead!). This preventive

safety measure rules out the danger of injuries

through accidental starting of the power tool.

Core drill bit

Insert the pilot pin into the cutter.

Pull the clamping sleeve of the tool holder

down and insert the core drill bit with the

centering pin into the tool holder.

Do not touch the sharp edges of the core drill

bit. Danger of injury.

Drill chuck

Pull the clamping sleeve of the tool holder

down and insert the drill chuck.

Drill bit

The knurled nut has a left-hand thread; turn

clockwise to release!

Loosen the knurled nut and remove the tool

holder by applying a hammer blow to the

positioned drift.

Clean the inside cone of the output shaft and

insert the drill bit.

WARNING

WARNING

1.

2.

3.

2.

3.

4.

1.

Drill chuck

Clamping sleeve

Centering pin

Core drill bit

JMU 137 MQW

1.

3.

2.

4.

5.

MK 2

MT 2

CM 2

Drill bit

Knurled nut

Fig. 7

OBJ_BUCH-0000000261-003.book Page 17 Thursday, January 11, 2018 5:30 PM

18

en

Working instructions.

Always secure the power tool with the supplied clamping strap. In case of a

power failure or when the power plug is pulled, the magnetic holding power is

not maintained.

Always carry the power tool by its handle, not by the drill-motor cable.

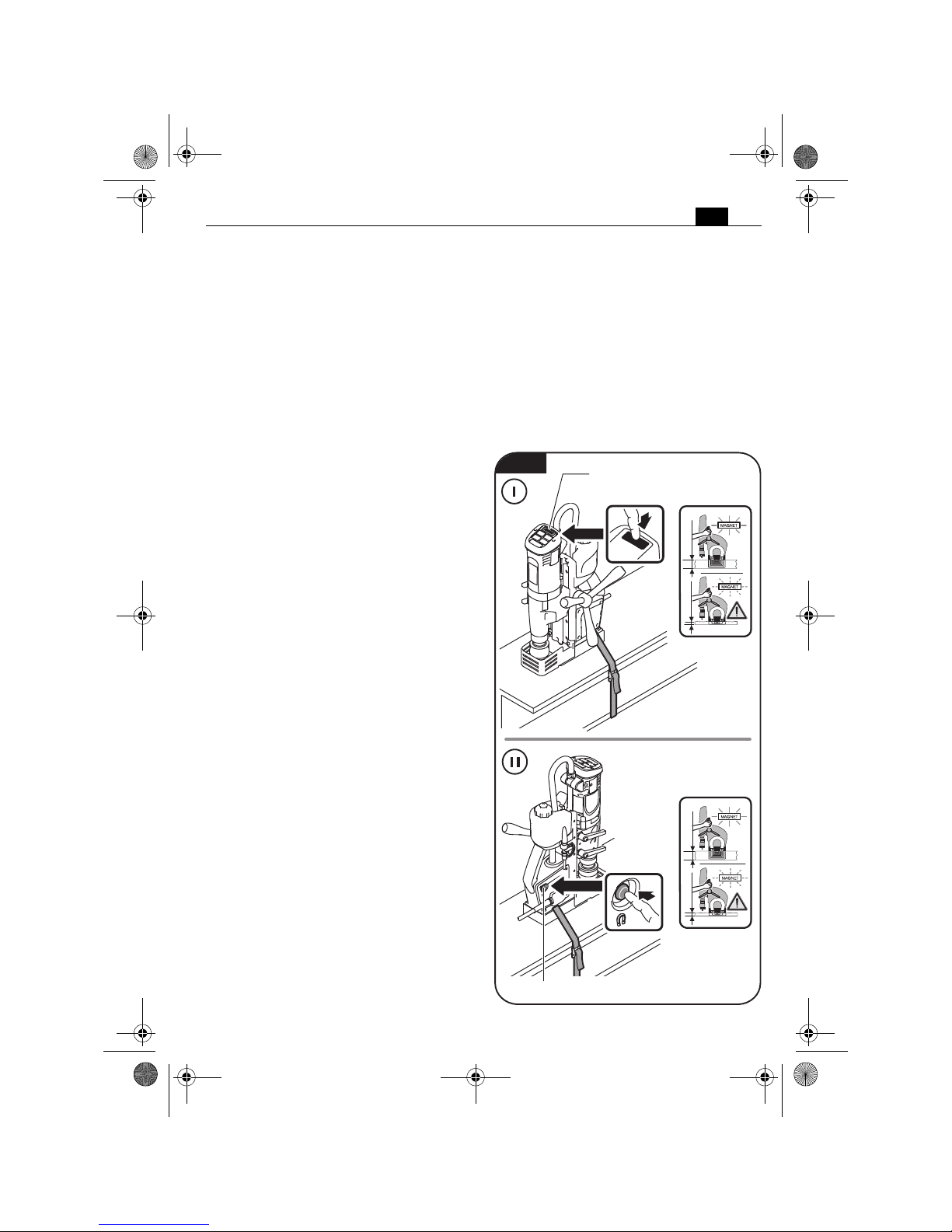

Fastening the safety strap (figure 9).

Always secure the power tool to the workpiece with the supplied clamping strap.

WARNING

Fig. 8

Clamping strap

Fig. 9

OBJ_BUCH-0000000261-003.book Page 18 Thursday, January 11, 2018 5:30 PM

19

en

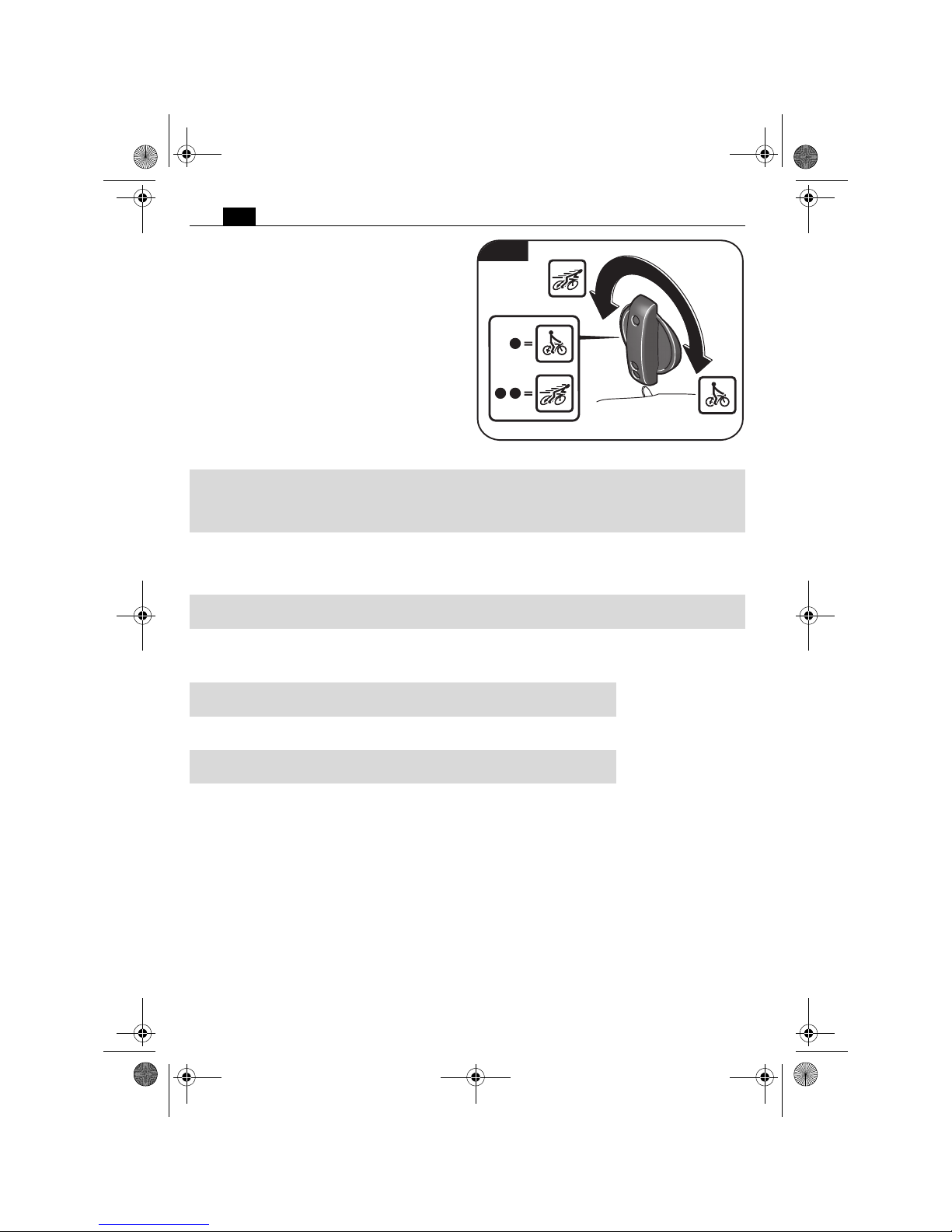

For switching the magnet ON

(figure 10).

Pay attention that the set-up surface for the

magnetic foot is flat, clean, rust-free and icefree. Remove varnish, putty/filler layers and

other materials. Prevent an air gap between

the magnetic foot and the set-up surface. The

air gap reduces the magnetic holding power.

When working, always use the magnetic foot;

pay attention that the magnetic holding

power is sufficient:

– When the green button on the control

panel lights up permanently, the magnetic

holding power is sufficient and the machine

can be operated with normal feed.

– When the Magnet button on the control

panel flashes, the magnetic holding power

possibly is insufficient and the machine

must be operated with reduced feed.

When working on materials that are non-ferrous, suitable fixation devices obtainable as

accessories from the manufacturer, e. g. suction plates, vacuum plates or pipe-drilling

devices must be used.

When working on steel materials with a

material thickness of less than 12 mm /

1

/2in,

the workpiece must be reinforced with an

additional steel plate in order to guarantee the

magnetic holding power.

Work only with the absolutely required

amount of feed. Excessive feed can lead to

breakage of the application tool and loss of

the magnetic holding power.

The magnetic foot is monitored by means of

a power sensor. If the magnetic foot is defective, the motor will not start.

When the power supply is disconnected

while the motor is running, a protective circuit prevents automatic restarting of the

motor. Restart the motor again. Adjust the

gear setting only when the machine is at a

complete stop or when the motor is running

down. Do not stop the drill motor during the

drilling procedure. Remove the core drill bit

from the drill hole only while the drill motor

is running. If the core drill bit gets jammed/

stuck in the material, stop the drill motor and

carefully rotate out the core drill bit turning in

counterclockwise direction. After each drilling run, remove the chips and the drilled out

core. Do not touch the chips with your bare

hands. Always use a chip hook. Danger of

burning! The surface of the magnet can reach

high temperatures. Do not touch the magnet

with your bare hands. When changing a drill

bit, pay attention not to damage the cutting

edges. When core-drilling layered material,

remove the core and the chips after having

drilled through each layer. Do not use the

magnetic core drill unit when the coolinglubricant system is defective. Check for tightness against leaks and for cracks in the hoses.

Prevent liquids from entering or penetrating

electrical components. The core drill units do

not have overload protection. In case of

improper use, the motor can become damaged.

=

Switches the magnet On/Off

=

Switches the magnet On/Off

Fig. 10

> 12 mm

< 12 mm

> 12 mm

< 12 mm

OBJ_BUCH-0000000261-003.book Page 19 Thursday, January 11, 2018 5:30 PM

20

en

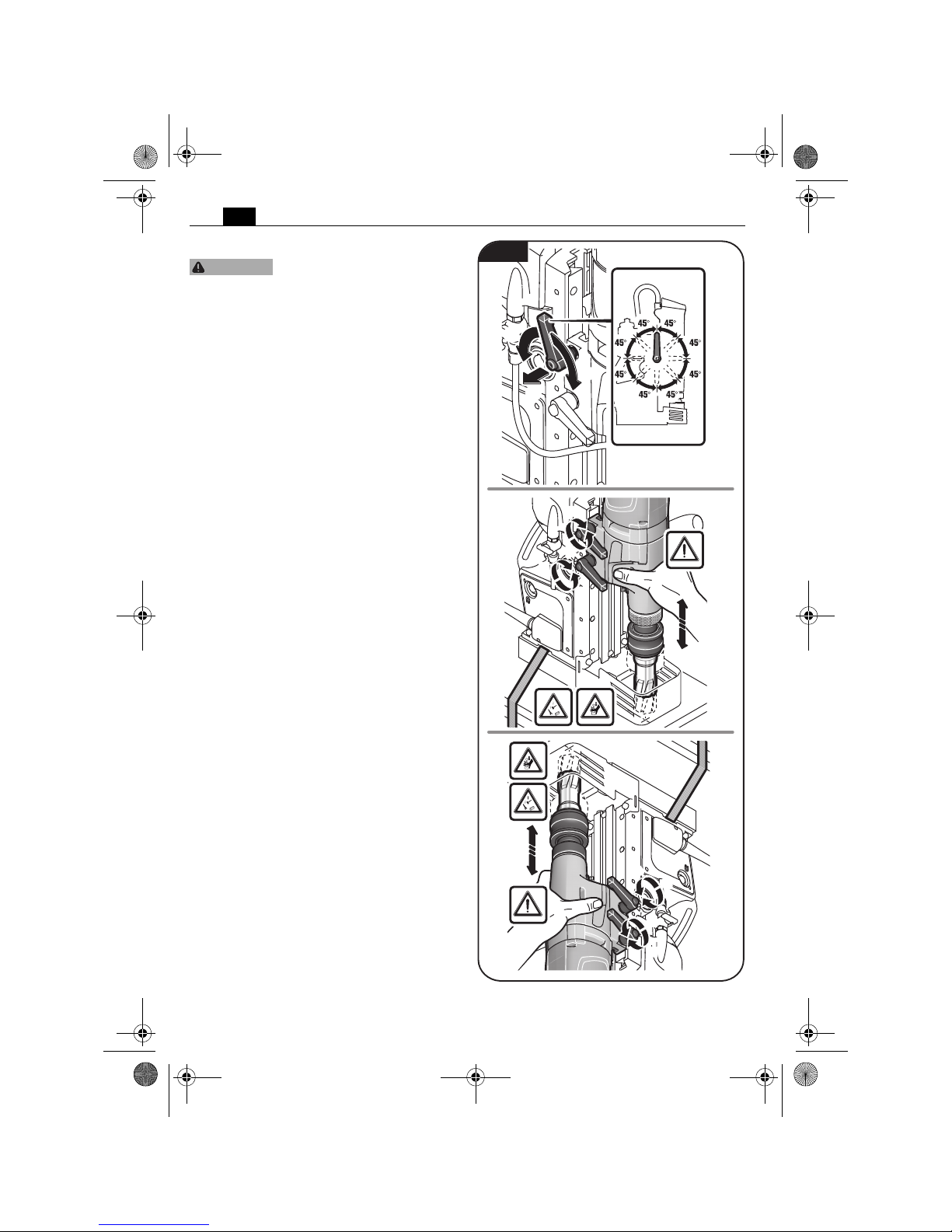

Adjusting the stroke range (figure 11).

Hold the power tool firmly

with one hand when releasing

the two fastening levers.

To move the fastening levers over each other,

pull a fastening lever outward and then turn

the fastening lever in 45° steps.

Loosen both fastening levers with the other

hand.

Adjust the desired stroke range.

Tighten both fastening levers again.

CAUTION

1.

2.

2.

3.

1.

4.

4.

2.

2.

1.

3.

4.

4.

2.

2.

Fig. 11

OBJ_BUCH-0000000261-003.book Page 20 Thursday, January 11, 2018 5:30 PM

21

en

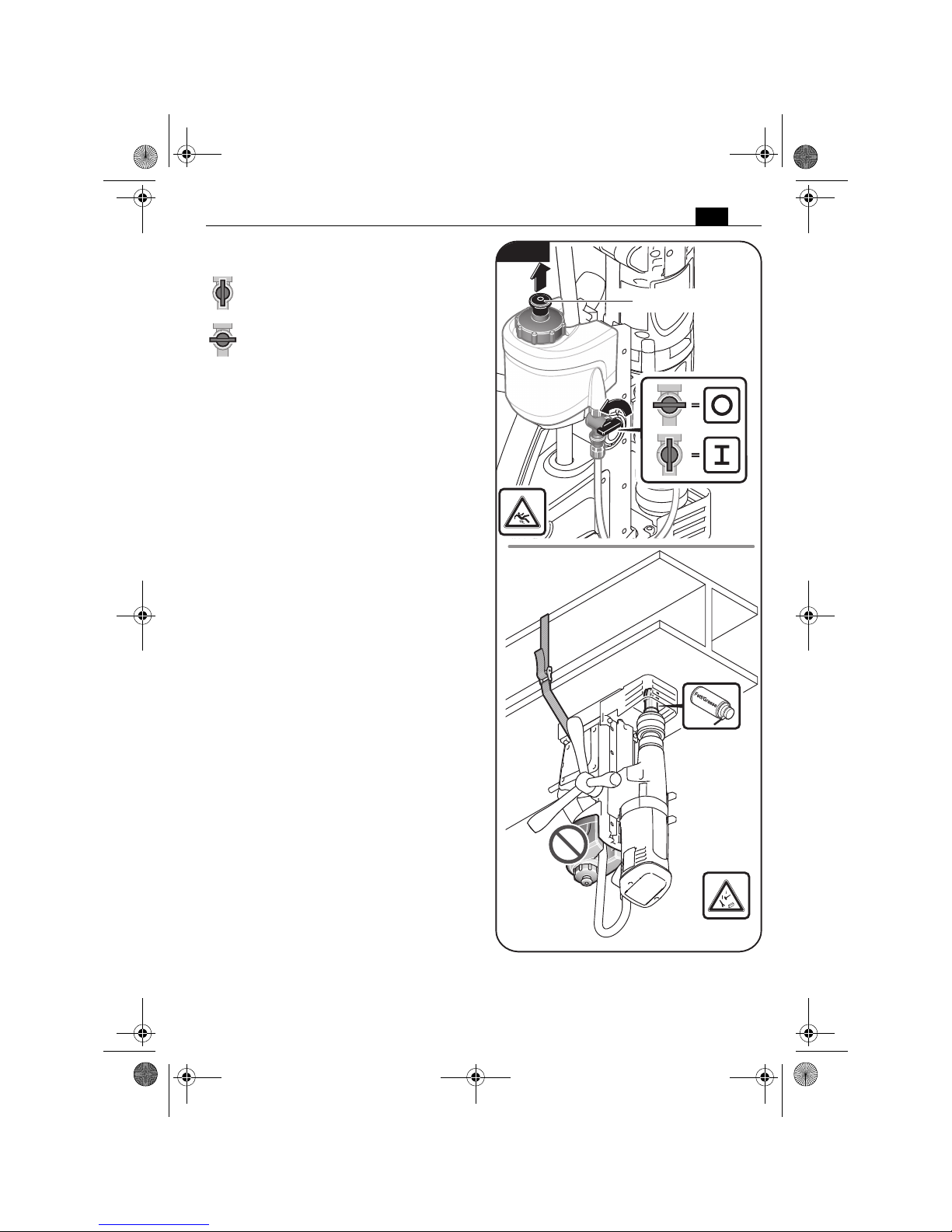

Activating and deactivating the coolant-lubricant flow (figure 12).

To activate the cooling-lubricant flow,

open the ventilation first and then turn

the flow valve to the position shown.

For switching off or when working

overhead, deactivate the cooling-lubricant flow. Shut the ventilation and turn

the flow valve to the position shown.

When working overhead, use a cooling-lubricant paste from Slugger.

1.

2.

Ventilation

Fig. 12

OBJ_BUCH-0000000261-003.book Page 21 Thursday, January 11, 2018 5:30 PM

22

en

Switching the gear setting (figure 13).

With the gear switch, you can select the

speed and thus the torque.

Adjust the gear setting only when the

machine is at a complete stop or when the

motor is running down.

Set the switch to gear 1 to work at low speed

with high torque. This setting is suitable for

drilling with large drill bit diameters and for

tapping.

Set the switch to gear 2 to work a t high speed

with low torque. This setting is suitable for

drilling with small drill bit diameters.

Fig. 13

Drilling capacity

in steel - TCT/

high speed steel

(core drill bits)

Drilling capacity

in steel - high speed

steel (HSS)

(twist drill bit)

Tapped hole

JMU 137 QW

(**),

JMU 137-2 QW

(**)

1. Gear 7/16 in – 1 3/8 in

11 mm – 35 mm

1/4 in – 5 8/8 in

6 mm – 16 mm

3/8 in – 9/16 in

M5 – M14

JMU 137 MQW

(**)

1. Gear 7/16 in – 1 3/8 in

11 mm – 35 mm

3/8 in – 11 16/8 in

10 mm – 18 mm

3/8 in – 9/16 in

M5 – M14

JMU 137-2QW

(**)

2. Gear

–

1/16 in – 3 8/8 in

1.5 mm – 9 mm

-

Max. diameter

for reaming

Max. diameter for

counterboring

JMU 137 MQW

(**)

1. Gear ≤ 5/8 in

≤ 16 mm

≤ 1 1/4 in

≤ 32 mm

JMU 137 MQW

(**)

1. Gear ≤ 11/16 in

≤ 18 mm

≤ 1 1/4 in

≤ 32 mm

JMU 137-2QW

(**)

1. Gear ≤ 5/8 in

≤ 16 mm

≤ 1 1/4 in

≤ 32 mm

OBJ_BUCH-0000000261-003.book Page 22 Thursday, January 11, 2018 5:30 PM

23

en

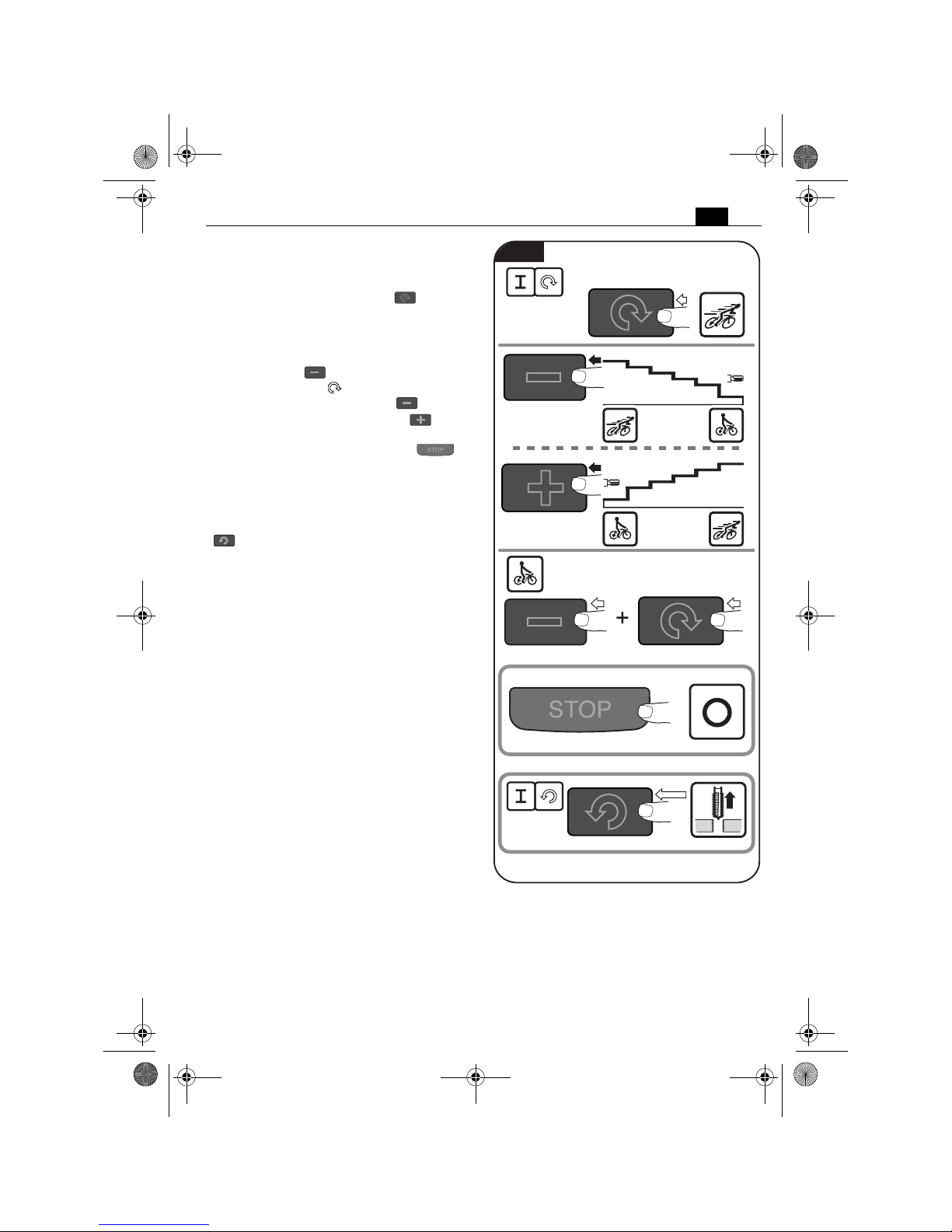

Starting and stopping the drill motor

(figure 14).

To start the drill motor with clockwise rotation, press the button with the „ “ symbol.

The drill motor starts with the highest speed.

The last set speed is automatically stored

(Memory Function). To start the power tool

with the last set speed, press and hold the

button with the symbol, and then press

the button with the symbol.

To lower the speed, press the „ “ symbol.

To increase the speed, press the „ “ symbol.

To stop the drill motor, press the „ “

symbol.

Do not stop the drill motor during the drilling

procedure.

To start the drill motor with counterclockwise rotation, press the button with the

„ “ symbol. The drill motor will run as

long as the button is pressed.

When the power supply is disconnected

while the drill motor is running (e.g. removal

of the battery), a protective circuit prevents

automatic restarting of the drill motor. Restart

the drill motor again.

In case of overload, the drill motor automatically stops and must be restarted again.

100l%

85

l%

75

l%

60

l%

50

l%

25

l%

100

l%

85

l%

75

l%

60

l%

50

l%

25

l%

Memory Function

Fig. 14

OBJ_BUCH-0000000261-003.book Page 23 Thursday, January 11, 2018 5:30 PM

24

en

Feed (figure 15).

Work only with the absolutely required

amount of feed. Excessive feed can lead to

breakage of the application tool and loss of

the magnetic holding power.

To generate feed, turn the spoke handle manually while the drill motor is switched on.

The scale can be used with “inch” or with

“cm” graduation.

cm

inch

1.

inch

cm

3.

2.

Fig. 15

OBJ_BUCH-0000000261-003.book Page 24 Thursday, January 11, 2018 5:30 PM

25

en

Instructions for core drilling.

Only remove the cutting tool from the hole

while the motor is running.

If the carbide tipped cutter should remain

stuck in the material, stop the drill motor and

carefully turn the carbide tipped cutter out

counterclockwise.

After each drilling operation, remove the

chips and the slug.

Do not touch the chips with your bare

hand. Always use a chip hook.

Danger of burns! The surface

of the magnet can reach high

temperatures. Do not touch the magnet with

your bare hands.

For core drilling in layered material, use a suitable Slugger ID cutter.

When changing a cutting tool, pay attention

not to damage the cutting edges.

When core drilling layered material, remove

the core and the chips after having drilled

through each layer.

CAUTION

Error message/

Response of magnet

button

Meaning Corrective action

Indicator lights up

green

Magnetic holding power is

sufficient.

Indicator flashes

green

Magnetic holding power

possibly insufficient.

Even when working on steel materials where the material thickness is

below 12 mm, the workpiece must

be made thicker with an additional

steel plate in order to ensure the

magnetic holding power.

Indicator lights up red

for 1 second

– Motion sensor has actuated

– Overload shut-off has

actuated

– Incorrect mains voltage

After malfunction correction, the

power tool can be switched on again.

Indicator flashes red

3 x

No speed signal If the error occurs frequently, send

the machine to your Slugger customer service agent.

Indicator lights up red

continuously

– Incorrect mains voltage/

mains frequency

– Drill stand is overheated

– Button is blocked when

switching on

After malfunction correction, the

power tool can be switched on again.

If the error occurs frequently, send

the machine to your Slugger customer service agent.

Indicator flashes red

continuously

Power tool is defective. Send the machine to your Slugger

customer service agent

OBJ_BUCH-0000000261-003.book Page 25 Thursday, January 11, 2018 5:30 PM

26

en

Repair and customer service.

Before mounting or replacing cutting tool or accessories, pull the power plug.

This preventive safety measure rules out the danger of injuries through accidental starting of the power tool.

Exchangeable parts

If required, you can change the following

parts yourself:

application tools, coolant container

Drill-motor guide (figure 16).

After several hours of operation, the play in the drill-motor guide can increase. As a consequence, the drill motor can glide alongside the drill-motor guide by itself. Malfunctions are possible in machine operation. In this case, retighten all fastening screws of the drill-motor guide

correspondingly so that the drill motor can easily be moved manually, yet does not glide by

itself.

WARNING

2,5 mm /

3/32 in

2,5 mm /

3/32 in

2,5 mm /

3/32 in

Fig. 16

OBJ_BUCH-0000000261-003.book Page 26 Thursday, January 11, 2018 5:30 PM

27

en

Service.

Have maintenance carried out

only through qualified personnel. Incorrectly mounted cables and components can cause serious injuries. Have the

required service carried out only through an

authorized Slugger repair facility.

When replacing the power

tool's protective cable bushing

or cord between the drill stand and drill

motor is required, this must be carried out by

Slugger or by an authorized Slugger Service

Agent, in order to avoid hazardous situations.

Use only original spare parts.

The current spare parts list for this power

tool can be found in the Internet at

www.fein.com.

Cleaning.

Prior to any cleaning or main-

tenance, disconnect the power

tool from the power supply in order to avoid

accidents.

When using in environments

with conductive dust in the air,

such as when working metals, this dust can

settle in the interior of the power tool. This

can impair the total insulation of the power

tool. Therefore, regularly blow out the interior

of the power tool from outside via the ventilation openings with dry, oil-free compressed

air; always wear eye protection when doing

this. For additional protection, connect a

residual current device (RCD) on the line side.

Do not attempt to clean

clogged or dirty ventilation

openings of the power tool with pointed

metal objects; use nonmetal tools or objects

if necessary.

Do not use cleaning agents

and solvents that can cause

damage to plastic parts. These include: Gas-

oline, carbon tetrachloride, chloric solvents,

ammonia and domestic cleaning agents that

contain ammonia.

Cooling-lubricant system.

Flush the cooling-lubricant system with

water, clean and drain it completely when not

using the machine for periods longer than

two weeks.

Warranty and liability.

The warranty for the product is valid in accordance with the legal regulations in the country

where it is marketed.

Environmental protection, disposal.

Sort scrapped power tools and accessories for environmental-friendly recycling. For further

information, please contact your specialist shop.

WARNING

CAUTION

WARNING

WARNING

CAUTION

CAUTION

OBJ_BUCH-0000000261-003.book Page 27 Thursday, January 11, 2018 5:30 PM

28

en

Provided accessories (figure 17).

Drift

Power tool carrying case

Chip hook

Centering pin

Clamping strap

Chip guard

Tool holder

105 mm

JMU 137 MQW (**)

JMU 137 MQW (**)

Fig. 17

OBJ_BUCH-0000000261-003.book Page 28 Thursday, January 11, 2018 5:30 PM

29

fr

fr

Pour votre sécurité.

Lire tous les avertissements de sécurité et

toutes les instructions. Ne pas suivre les aver-

tissements et instructions peut donner lieu à

une électrocution, un incendie et/ou une

blessure sérieuse.

Conservez tous les avertissements et toutes

les instructions pour pouvoir vous y reporter

ultérieurement.

Ne pas utiliser cet outil électrique avant

d’avoir soigneusement lu et parfaitement

compris cette notice d’utilisation y compris

les figures, les spécifications, les consignes de

sécurité ainsi que les indications marquées par

DANGER, AVERTISSEMENT et ATTENTION.

N’utiliser cet outil électrique que pour les travaux pour lesquels il a été conçu par le fabricant. N’utiliser que des outils de travail et

accessoires autorisés par le fabricant.

De même, respecter les dispositions concernant la prévention des accidents du travail en

vigueur dans le pays en question.

Le non-respect des instructions de sécurité se

trouvant dans la documentation mentionnée

peut entraîner un choc électrique, un incendie

et / ou de graves blessures.

Bien garder cette notice d’utilisation en vue

d’une utilisation ultérieure ; elle doit être

jointe à l’appareil en cas de transmission ou de

vente à une tierce personne.

GARDER SOIGNEUSEMENT CES INSTRUCTIONS DE SECURITE.

Le terme « outil électrique » dans les consignes de sécurité fait référence à votre outil

électrique alimenté par le secteur (avec cordon d’alimentation) ou votre outil fonctionnant sur batterie (sans cordon

d’alimentation).

Instructions générales de

sécurité.

1) Portée

a)Maintenir la zone de travail propre et

bien éclairée. Les zones en désordre ou

sombres sont propices aux accidents.

b)Ne pas faire fonctionner les outils élec-

trique en atmosphère explosive, par

exemple en présence de liquides inflammables, de gaz ou de poussières. Les

outils électroportatifs produisent des

étincelles qui peuvent enflammer les

poussières ou les fumées.

c) Maintenir les enfants et les personnes

présentes à l’écart pendant l’utilisation

de l’outil. Les distractions peuvent vous

faire perdre le contrôle de l’outil.

2) Sécurité électrique

a) Il faut que les fiches de l’outil électrique

soient adaptées au socle. Ne jamais

modifier la fiche de quelque façon que

ce soit. Ne pas utiliser d’adaptateurs

avec des outils à branchement de terre.

Des fiches non modifiées et des socles

adaptés réduiront le risque de choc

électrique.

b)Éviter tout contact du corps avec des

surfaces reliées à la terre telles que

tuyaux, radiateurs, cuisinières et réfrigérateurs. Il existe un risque accru de

choc électrique si votre corps est relié à

la terre.

c) Ne pas exposer les outils à la pluie ou à

des conditions humides. La pénétration

d’eau à l’intérieur d’un outil augmentera

le risque de choc électrique.

d)Veiller à ne pas endommager le cordon.

Ne jamais utiliser le cordon pour porter,

tirer ou débrancher l’outil. Maintenir le

cordon à l’écart de toute source de chaleur, de lubrifiant, d’arêtes ou de parties

en mouvement. Des cordons endomma-

gés ou emmêlés augmentent le risque

de choc électrique.

e) Lors qu’on utilise un outil à l’extérieur,

utiliser un prolongateur adapté à l’utilisation extérieure. L’utilisation d’un cor-

don adapté à un usage à l’extérieur

réduit le risque de choc électrique.

f) Si l’usage d’un outil dans un emplace-

ment humide est inévitable, utilisez une

alimentation protégée par un dispositif

à courant différentiel résiduel (RCD).

L’usage d’un RCD réduit le risque de

choc électrique.

AVERTISSEMENT

OBJ_BUCH-0000000261-003.book Page 29 Thursday, January 11, 2018 5:30 PM

30

fr

3) Sécurité des personnes

a)Rester vigilant, regarder ce que vous

êtes en train de faire. Faire preuve de

bon sens lors de l’utilisation de l’outil.

Ne pas utiliser un outil lorsque vous êtes

fatigué ou sous l’emprise de drogues,

d’alcool ou de médicaments. Un

moment d’inattention en cours d’utilisation d’un outil peut entraîner des graves

blessures.

b)Utiliser un équipement de sécurité. Tou-

jours porter une protection pour les

yeux. Les équipements de sécurité tels

que les masques contre les poussières,

les chaussures de sécurité antidérapantes, les casques ou les protections

acoustiques utilisés pour les conditions

appropriées réduiront les blessures de

personnes.

c) Eviter tout démarrage intempestif.

S’assurer que l’interrupteur est en position arrêt avant de retirer la fiche de la

prise de courant. Porter les outils en

ayant le doigt sur l’interrupteur ou brancher des outils dont l’interrupteur est en

position marche est source d’accidents.

d)Retirer toute clé de réglage avant de

mettre l’outil en marche. Une clé laissée

fixée sur une partie tournante de l’outil

peut provoquer des blessures.

e) Ne pas se précipiter. Garder une posi-

tion et un équilibre adaptés à tout

moment. Cela permet un meilleur

contrôle de l’outil dans des situations

inattendues.

f) S’habiller de manière adaptée. Ne pas

porter de vêtements amples ou de

bijoux. Garder les cheveux, les vêtements et les gants à distance des parties en mouvement. Des vêtements

amples, des bijoux ou les cheveux longs

peuvent être pris dans des parties en

mouvement.

g)Si des dispositifs sont fournis pour le

raccordement d’équipements pour

l’extraction et la récupération des poussières, s’assurer qu’ils sont connectés

et correctement utilisés. Utiliser des

collecteurs de poussière peut réduire

les risques dus aux poussières.

4) Utilisation et entretien de l’outil

a)Ne pas forcer l’outil. Utiliser l’outil

adapté à votre application. L’outil adap-

té réalisera mieux le travail et de manière plus sûre au régime pour lequel il a

été construit.

b)Ne pas utiliser l’outil si l’interrupteur ne

permet pas de passer de l’état de marche à l’état d’arrêt et vice versa. Tout

outil qui ne peut pas être commandé par

l’interrupteur est dangereux et il faut le

réparer.

c) Débrancher la fiche de la source d’ali-

mentation en courant et/ou le bloc de

batteries de l’outil avant tout réglage,

changement d’accessoires ou avant de

ranger l’outil. De telles mesures de

sécurité préventives réduisent le risque

de démarrage accidentel de l’outil.

d)Conserver les outils à l’arrêt hors de la

portée des enfants et ne pas permettre

à des personnes ne connaissant pas

l’outil ou les présentes instructions de le

faire fonctionner. Les outils sont dange-

reux entre les mains d’utilisateurs novices.

e) Veiller à la maintenance de l’outil.

S’assurer qu’il n’y a pas de mauvais alignement ou de blocage des parties

mobiles, des pièces cassées ou toute

autre condition pouvant affecter le fonctionnement de l’outil. En cas de dommages, faire réparer l’outil avant de

l’utiliser. De nombreux accidents sont

dus à des outils mal entretenus.

f) Garder affûtés et propres les outils per-

mettant de couper. Des outils destinés à

couper correctement entretenus avec

des pièces coupantes tranchantes sont

moins susceptibles de bloquer et sont

plus faciles à contrôler.

g)Utiliser l’outil, les accessoires et les

lames etc., conformément à ces instructions et aux prescriptions en vigueur

pour ce type d’appareil. Tenir compte

également des conditions de travail et

du travail à réaliser. L’utilisation de

l’outil pour des opérations différentes

de celles prévues pourrait donner lieu à

des situations dangereuses.

OBJ_BUCH-0000000261-003.book Page 30 Thursday, January 11, 2018 5:30 PM

31

fr

5) Maintenance et entretien

a)Faites entretenir l’outil par un répara-

teur qualifié utilisant uniquement des

pièces de rechange identiques. Cela

assurera que la sécurité de l’outil soit

maintenue.

Instructions particulières de sécurité.

Toujours porter un équipement de protection.

En fonction de l’application, porter un écran

facial ou des lunettes de sécurité. Utiliser une

protection auditive. Les lunettes de sécurité

doivent pouvoir protéger les yeux contre les

particules projetées lors de toutes sortes de

travaux. Une exposition permanente au bruit

intense peut provoquer une perte de l’audition.

Ne pas toucher les bords aigus de la fraise à

carotter. Danger de blessure.

Remplacer immédiatement une gaine de protection endommagée. Une gaine de protec-

tion défectueuse peut entraîner une

surchauffe de la machine et avoir un arrêt

d’urgence pour conséquence.

Avant la première mise en service : Monter le

protège-mains sur la machine.

Sécuriser l’outil électrique uniquement avec

la sangle livrée avec. La force d’attraction

magnétique n’est plus active lors d’une panne

de courant ou lorsque l’appareil est débranché. Lors des travaux, veiller à toujours se

protéger contre les objets tombants tels que

carottes et copeaux.

Effectuez les travaux sur les éléments de

construction verticaux ou au-dessus de la tête

sans utiliser le réservoir du liquide de refroidissement. Utilisez un spray refroidissant. Les

liquides qui entreraient dans l’outil électrique

peuvent causer un choc électrique.

Évitez de toucher la carotte qui est automatiquement éjectée par la goupille de centrage

quand le travail est terminé. Le contact avec

la carotte brûlante ou qui tombe peut entraîner des blessures.

N’utilisez l’outil électrique qu’avec des prises

de courant de sécurité conformes à la législation. N’utilisez que des câbles de raccordement en parfait état et des rallonges

régulièrement contrôlées. Un conducteur de

protection discontinu peut entraîner un choc

électrique.

Maintenir vos mains, vêtements etc. toujours

loin des copeaux en rotation pour éviter de

vous blesser. Les copeaux peuvent causer des

blessures. Toujours utiliser le protège-mains.

N’essayez pas d’enlever l’outil de travail tant

qu’il est en rotation. Ceci peut causer de gra-

ves blessures.

Tenir l’outil par les surfaces de préhension

isolées, lors de la réalisation d’une opération

au cours de laquelle l’organe de coupe peut

entrer en contact avec un câblage non apparent ou son propre cordon d’alimentation. Le

contact avec un fil « sous tension » peut également mettre « sous tension » les parties

métalliques exposées de l’outil électrique et

provoquer un choc électrique sur l’opérateur.

Faites attention aux câbles électriques,

conduites de gaz et d’eau éventuellement

cachés. Avant de commencer le travail,

contrôlez la zone de travail à l’aide d’un

détecteur de métaux par exemple.

Ne pas travailler de matériaux contenant du

magnésium. Il y a risque d’incendie.

Ne pas travailler du PRFC (plastique à renfort

fibre de carbone) et pas de matériaux contentant de l’amiante. Ils sont considérés cancéri-

gènes.

Il est interdit de visser ou de riveter des plaques ou des repères sur l’outil électrique.

Une isolation endommagée ne présente

aucune protection contre une électrocution.

Utilisez des autocollants.

OBJ_BUCH-0000000261-003.book Page 31 Thursday, January 11, 2018 5:30 PM

32

fr

Ne pas surcharger l’outil électrique ou le coffret de rangement et ne pas l’utiliser en tant

qu’échelle ou échafaudage. Surcharger ou se

placer sur l’outil électrique ou le coffret de

rangement peut causer le déplacement du

centre de gravité de l’outil électrique ou du

coffret de rangement vers le haut provoquant

ainsi le renversement de ce dernier.

N’utilisez pas des accessoires qui n’ont pas

été spécialement conçus ou autorisés par le

fabricant de l’outil électrique. Le seul fait

qu’un accessoire puisse être monté sur votre

outil électrique ne garantit pas une utilisation

sans risque.

Nettoyez régulièrement les ouïes de ventilation de l’outil électrique avec des outils nonmétalliques. La ventilation du moteur aspire

la poussière à l’intérieur du carter. Une trop

grande quantité de poussière de métal accumulée peut provoquer des incidents électriques.

Avant la mise en service, s’assurer que le

câble de raccordement et la fiche sont en parfait état.

Recommandation : Faites toujours fonctionner l’outil électrique sur un réseau électrique

équipé d’un disjoncteur différentiel 30 mA

max.

Maniement de poussières nocives.

Lors du travail avec des

outils, par ex. lors du

ponçage, polissage, sciage ou d’autres opérations enlevant du matériau, des poussières

sont générées qui peuvent être nocives pour

la santé, auto-inflammables ou explosives.

Toucher ou aspirer certaines poussières peut

causer des réactions allergiques et/ou des

maladies respiratoires, un cancer, des malformations à la naissance ou autres anomalies de

reproduction auprès de l’utilisateur ou de

personnes se trouvant à proximité.

Quelques exemples de tels matériaux et de

produits chimiques qu’ils contiennent dont

l’usinage génère des poussières nocives :

– l’amiante et les matériaux contenant de

l’amiante ;

– peintures contenant du plomb, certains

bois tels que le bois de chêne et de hêtre ;

– minéraux et métal ;

– les particules de silicate contenues dans les

briques, le béton et autres matériaux

contenant de la roche ;

– les solvants contenus dans les vernis et

peintures ;

– l’arsenic, le chrome et d’autres lasures ;

– produits pour la lutte contre les vermines

sur la coque de bateaux et de bâtiments ;

– poussières d’aciers fins, poussières de

métaux et poussières de métaux non-ferreux.

Pour minimiser la résorption indésirable de

ces matériaux :

– Utilisez une aspiration adaptée à la pous-

sière générée.

– Utilisez des équipements personnels de

protection tels que par exemple un masque anti-poussière de la classe filtre P2.

– Veiller à bien aérer la zone de travail.

Le risque causé par le fait d’aspirer des pous-

sières dans les poumons dépend de la fréquence à laquelle ces matériaux sont

travaillés. Les matériaux contenant de

l’amiante ne doivent être travaillés que par

des personnes qualifiées.

Les poussières de bois et les

poussières de métaux légers

peuvent causer une auto-inflammation ou une

explosion.

Des mélanges chauds de poussières de ponçage contenant des résidus de vernis, de polyuréthane ou de produits chimiques dans le sac

à poussières ou dans le filtre de l’aspirateur

peuvent s’enflammer dans certaines conditions telles que projection d’étincelles lors du

ponçage de métaux, rayonnement solaire

direct permanent ou température ambiante

élevée. Pour prévenir ces conditions :

– Evitez la surchauffe des matériaux travaillés

et de l’outil électrique.

– Videz à temps le bac de récupération des

poussières.

– Respectez les indications de travail du

fabricant du matériau.

– Respectez les règlements en vigueur aux

matériaux à traiter.

AVERTISSEMENT

ATTENTION

OBJ_BUCH-0000000261-003.book Page 32 Thursday, January 11, 2018 5:30 PM

33

fr

Valeurs d’émission du niveau sonore (Indication à deux chiffres conformément

à la norme ISO 4871)

Câble de rallonge.

Au cas où une rallonge

serait nécessaire, la longueur ainsi que la section du conducteur de

celle-ci doivent être appropriées à l’utilisation

afin d’éviter une baisse de tension dans la rallonge, une perte de puissance et une surchauffe de l’outil électrique. Sinon la rallonge

et l’outil électrique présentent des dangers

électriques et l’efficacité du travail est entravée.

Émission acoustique JMU 137 QW (**) JMU 137 MQW (**) JMU 137-2 QW (**)

Mesure réelle (A) du niveau

de pression acoustique sur

le lieu de travail

L

pA

(re 20 μPa), en décibel 86.7 86.7 85.6

Incertitude

K

pA

, en décibel 3 3 3

Mesure réelle (A) du niveau

d’intensité acoustique pondéré

L

wA

(re 1 pW),

en décibel 97.7 97.7 96.6

Incertitude

K

wA

, en décibel 3 3 3

Mesure réelle (C) du niveau

max. de pression acoustique sur le lieu de travail

L

pCpeak

, en décibel 101.2 101.2 98.9

Incertitude

K

pCpeak

,

en décibel 3 3 3

valeur de vibration

moyenne (carottage)

– m/s

2

– ft/s

2

< 2.5

8.3

< 2.5

8.3

< 2.5

8.3

Incertitude

K

, en

– m/s

2

– ft/s

2

1.5

4.9

1.5

4.9

1.5

4.9

REMARQUE : La somme de la valeur d’émission mesurée et de l’incertitude constitue la

limite supérieure des valeurs qui peuvent apparaître pendant des mesurages.

Porter une protection acoustique !

Valeurs de mesure mesurées conformément à la norme correspondante du produit.

AVERTISSEMENT

OBJ_BUCH-0000000261-003.book Page 33 Thursday, January 11, 2018 5:30 PM

34

fr

Conception de l’outil électrique :

Unité de perçage conçue pour le perçage avec

fraises à carotter et forets hélicoïdaux, l’alésage, le lamage et le taraudage de matériaux

magnétiques, dans un environnement à l’abri

des intempéries avec utilisation des outils de

travail et des accessoires autorisés par Slugger.

Fonctionnement de l’outil électrique

avec des générateurs de courant.

Cet outil électrique est également conçu

pour fonctionner sur des groupes électrogènes d’une puissance suffisante correspondant à la norme ISO 8528, classe de

modèle G2. Cette norme n’est pas respectée

si le facteur de distorsion harmonique dépasse 10 %. En cas de doute, s’informer sur le

groupe électrogène utilisé.

Il est interdit de faire

fonctionner l’outil électrique sur des générateurs de courant dont la

tension à vide dépasse la valeur de tension

indiquée sur la plaque signalétique de l’outil

électrique.

Symboles.

AVERTISSEMENT

Symbole, signe Explication

Lire impérativement les documents ci-joints tels que la notice

d’utilisation et les instructions générales de sécurité.

Suivre les indications données dans le texte ou la représentation graphique ci-contre !

Suivre les indications données dans le texte ou la représentation graphique ci-contre !

Avant d’effectuer ce travail, retirer la fiche de la prise de courant. Sinon, il y a risque de blessures dû à un démarrage non

intentionné de l’outil électrique.

Lors des travaux, porter une protection oculaire.

Lors des travaux, porter une protection acoustique.

Ne pas toucher les éléments en rotation de l’outil électrique.

Attention aux bords tranchants des outils de travail tels que

les lames des couteaux.

Danger de glisser !

Danger d’écrasement !

Attention aux objets qui pourraient tomber !

OBJ_BUCH-0000000261-003.book Page 34 Thursday, January 11, 2018 5:30 PM

35

fr

Surface chaude !

Ne pas mettre les mains dedans !

Attacher la ceinture !

Signal général d’interdiction. Cette action est interdite !

Ce symbole confirme la certification de ce produit aux EtatsUnis et au Canada.

Cette indication met en garde contre une situation dangereuse imminente. Une mauvaise manipulation peut entraîner

de graves blessures ou la mort.

Cette indication indique une situation éventuellement dangereuse pouvant entraîner de graves blessures ou la mort.

Cette indication met en garde contre une situation potentiellement dangereuse qui peut entraîner des blessures.

Trier les outils électriques ainsi que tout autre produit électrotechnique et électrique et les déposer à un centre de recyclage respectant les directives relatives à la protection de

l’environnement.

Démarrer le moteur de carottage. Sens de rotation vers la

droite

Arrêter le moteur

Vitesse de rotation faible

Vitesse de rotation élevée

Force magnétique suffisante

Force magnétique insuffisante

Démarrer le moteur de carottage. Sens de rotation vers la

droite

Démarrer le moteur de carottage en mode de palpage. Sens

de rotation vers la gauche

Réduction de la vitesse par étapes

Augmentation de la vitesse par étapes

Arrêter le moteur

Activer / désactiver l’aimant

(**) peut contenir des chiffres ou des lettres

Symbole, signe Explication

DANGER

AVERTISSEMENT

ATTENTION

OBJ_BUCH-0000000261-003.book Page 35 Thursday, January 11, 2018 5:30 PM

36

fr

Signe Unité nationale Explication

n

0

rpm ; /min ; min-1;

r/min

Vitesse à vide

P

W Unité de mesure pour la puissance électrique

° Unité de mesure pour la largeur d’angle

U V Unité de mesure pour la tension électrique

f Hz Unité de mesure pour la fréquence

I.

A Unité de mesure pour l’intensité du courant

électrique

m

lbs Unité de mesure pour la masse

l ft, in Unité de mesure pour longueur, largeur, hauteur,

profondeur, diamètre ou filetage

Ø ft, in Diamètre d’un élément

m, s, kg, A, mm, V, W,

Hz, N, °C, dB, min, m/s

2

Unités de base et unités dérivées du système

international SI.

OBJ_BUCH-0000000261-003.book Page 36 Thursday, January 11, 2018 5:30 PM

37

fr

Description technique et spécification.

Avant de commencer les travaux de montage ou avant de changer les

outils de travail et les accessoires, retirer la fiche de secteur. Cette

mesure de sécurité préventive exclut un danger de blessure causé par un démarrage non intentionné de l’outil électrique.

Il se peut que seule une partie des accessoires décrits ou représentés dans cette notice d’utilisation soit fournie avec l’outil électrique.

AVERTISSEMENT

Outil de travail

Dispositif anti-copeaux

Porte-outil

Viseo Touch Pad

Câble de moteur de carottage

Réservoir du produit

de refroidissement

Croisillon

Embase électromagnétique

Sangle de serrage

Fig. 1

Activer/désactiver l’aimant

Démarrer le moteur de carottage.

Sens de rotation vers la droite

Réduire la vitesse de

rotation par étapes

Démarrer le moteur de carottage

en mode de palpage.

Sens de rotation vers la gauche

Arrêter le moteur

de carottage

Augmenter la vitesse de

rotation par étapes

Fig. 2

OBJ_BUCH-0000000261-003.book Page 37 Thursday, January 11, 2018 5:30 PM

38

fr

Type JMU 137 QW (**) JMU 137 MQW (**) JMU 137-2 QW (**)

Référence 7 270 ... 7 270 ... 7 270 ...

Courant absorbé 9.2 A 9.2 A 9.2 A

Vitesse à vide (rotation vers la

droite)

1ère vitesse 550 tr/min 550 tr/min 550 tr/min

2ème vitesse – – 1700 tr/min

Vitesse à vide (rotation vers la

gauche)

1ère vitesse 370 tr/min 370 tr/min 370 tr/min

2ème vitesse – – 1140 tr/min

Diamètre de perçage acier -

carbure/

acier rapide (carotteur)

7/16 in – 1 3/8 in

11 mm – 35 mm

7/16 in – 1 3/8 in

11 mm – 35 mm

7/16 in – 1 3/8 in

11 mm – 35 mm

Diamètre de perçage acier acier rapide (foret hélicoïdal)

5/8 in

16 mm

11/16 in

18 mm

5/8 in

16 mm

Alésage 9/16 in

M14

9/16 in

M14

9/16 in

M14

Diamètre alésoir 5/8 in

16 mm

11/16 in

18 mm

5/8 in

16 mm

Diamètre lamage 1 1/4 in

32 mm

1 1/4 in

32 mm

1 1/4 in

32 mm

Poids suivant

EPTA-Procedure 01

23.4 lbs

(10.6 kg)

24.25 lbs

(11.0 kg)

24.25 lbs

(11.0 kg)

Classe de protection /I /I /I

Température ambiante

admissible

23°F ... 104°F

–5°C ... +40° C

23°F ... 104°F

–5°C ... +40°C

23°F ... 104°F

–5°C ... +40°C

OBJ_BUCH-0000000261-003.book Page 38 Thursday, January 11, 2018 5:30 PM

39

fr

Indications de montage.

Avant de commencer les travaux de montage ou avant de changer les

outils de travail et les accessoires, retirer la fiche de secteur. Cette

mesure de sécurité préventive exclut un danger de blessure causé par un démarrage non intentionné de l’outil électrique.

Montage du croisillon (figure 3).

Le croisillon peut être monté des deux côtés.

Desserrez la vis à l’aide d’une clé mâle pour

vis à six pans creux.

Retirez le croisillon.

Introduisez le croisillon de l’autre côté et serrezh la vis à l’aide d’une clé pour vis à six pans

creux.

AVERTISSEMENT

1.

2.

3.

4.

5 mm /

3/16 in

5 mm /

3/16 in

Fig. 3

OBJ_BUCH-0000000261-003.book Page 39 Thursday, January 11, 2018 5:30 PM

40

fr

Remplissage du réservoir du liquide de refroidissement.

Evitez l’écoulement du liquide de refroidissement le long du câble dans la

prise ou dans l’unité de perçage ; ceci peut causer un choc électrique. Fai-

tes une boucle avec le câble devant la prise pour permettre au liquide de s’égoutter.

Ne pas utiliser la carottière si le système de refroidissement est défectueux. Avant chaque uti-

lisation, contrôler l’étanchéité et si les tuyaux flexibles présentent des fissures. Éviter la pénétration de liquide dans les éléments électriques.

N’utilisez comme réfrigérant qu’une émulsion de lubrifiant-réfrigérant (mélange huile/eau).

Tenez compte des instructions du fabricant du produit.

Remplissage du réservoir du liquide de refroidissement monté (figure 4)

Dévissez le capuchon du réservoir du liquide

de refroidissement.

Remplissez d’un liquide de refroidissement

pouvant être pompé, par ex. huile de coupe

Slugger.

Revissez le capuchon du réservoir du liquide

de refroidissement.

AVERTISSEMENT

3.

1.

2.

Réservoir du produit

de refroidissement

Capuchon supérieur

max. 500 ml

max. 17 fl. OZ.

Fig. 4

OBJ_BUCH-0000000261-003.book Page 40 Thursday, January 11, 2018 5:30 PM

41

fr

Remplissage du réservoir du liquide de refroidissement démonté (figure 5)

Retirez le réservoir du liquide de refroidissement du carter de support de l’unité de perçage.

Dévissez le capuchon du réservoir du liquide

de refroidissement.

Remplissez d’un liquide de refroidissement

pouvant être pompé, par ex. huile de coupe

Slugger.

Revissez le capuchon du réservoir du liquide

de refroidissement.

Montez le réservoir du liquide de refroidissement rempli dans le support prévu du support de perçage.

1.

3.

2.

5.

4.

Réservoir du

produit de refroidissement

Capuchon supérieur

max. 500 ml

max. 17 fl. OZ.

Fig. 5

OBJ_BUCH-0000000261-003.book Page 41 Thursday, January 11, 2018 5:30 PM

42

fr

Montage du tuyau du liquide de

refroidissement (figure 6).

Connectez le tuyau du liquide de refroidissement.

Fig. 6

OBJ_BUCH-0000000261-003.book Page 42 Thursday, January 11, 2018 5:30 PM

43

fr

Changement d’outil (figure 7).

Sécuriser l’outil électrique uniquement avec la

sangle livrée avec. La force d’attraction

magnétique n’est plus active lors d’une panne

de courant ou lorsque l’appareil est débranché.

Arrêtez la machine et

retirez la fiche de secteur (pas au-dessus de la tête !) avant tout

montage ou remplacement d’accessoires.

Cette mesure de sécurité préventive exclut

un danger de blessure causé par un démarrage

non intentionné de l’outil électrique.

Fraise à carotter

Faites passer la tige de centrage à travers la

fraise à carotter.

Tirez la douille de serrage du porte-outil vers

le bas et introduisez la fraise à carotter avec la

tige de centrage dans le porte-outil.

Ne pas toucher les bords aigus de la fraise à

carotter. Danger de blessure.

Mandrin de perçage

Tirez la douille de serrage du porte-outil vers

le bas et introduisez le mandrin de perçage.

Foret hélicoïdal

L’écrou de blocage a un filet à gauche, tourner

vers la droite pour le desserrer !

Desserrez l’écrou de blocage et faites sortir le

porte-outil à l’aide d’un chasse-cône.

Nettoyer le cône intérieur de l’arbre de sortie

et monter le foret hélicoïdal.

AVERTISSEMENT

AVERTISSEMENT

1.

2.

3.

2.

3.

4.

1.

Mandrin de perçage

Douille de serrage

Goupille de

centrage, longue

Carotteur

JMU 137 MQW

1.

3.

2.

4.

5.

MK 2

MT 2

CM 2

Barre de

perçage

Ecrou moleté

Fig. 7

OBJ_BUCH-0000000261-003.book Page 43 Thursday, January 11, 2018 5:30 PM

44

fr

Indications pour le travail.

Sécuriser l’outil électrique uniquement avec la sangle livrée avec. La

force d’attraction magnétique n’est plus active lors d’une panne de courant ou lorsque l’appareil est débranché.

Porter l’outil par la poignée et ne pas par

le câble du moteur de carottage.

Montage de la sangle de serrage

(figure 9).

Bloquez la machine sur la pièce à l’aide de la

sangle de serrage.

AVERTISSEMENT

Fig. 8

Sangle de serrage

Fig. 9

OBJ_BUCH-0000000261-003.book Page 44 Thursday, January 11, 2018 5:30 PM

45

fr

Mise en marche de l’aimant

(figure 10).

Veiller à ce que la surface sur laquelle est

posée l’embase électromagnétique soit plane,

propre et exempte de rouille et de glace.

Enlever les couches de vernis et de mastic et

autres matériaux. Éviter un entrefer entre

l’embase électromagnétique et la surface de

montage. L’entrefer réduit la force d’attraction magnétique.

Utilisez toujours l’embase magnétique lors du

travail et veillez à ce que la force magnétique

soit suffisante.

– Si le voyant vert du panneau de commande

reste allumé en permanence, c’est que la

force magnétique est suffisante et la

machine peut être utilisée avec avance

normale.

– Si la touche aimant du panneau de com-

mande clignote, c’est que la force magnétique n’est éventuellement pas suffisante et

la machine doit être utilisée avec force

d’avance réduite.

Pour les travaux sur les matériaux non ferreux, utilisez des dispositifs de fixation appropriés du fabricant, disponibles comme

accessoires, tels que par ex. plaque à vide ou

dispositif de perçage pour tuyaux.

Afin de garantir la force d’attraction magnétique également avec des matériaux en acier

d’une épaisseur inférieure à 12 mm, renforcer

la pièce à travailler par une plaque supplémentaire en acier.

N’appliquez que la force d’avance absolument

nécessaire. Les forces d’avance trop élevées

peuvent entraîner une rupture de l’accessoire

et une perte de la force d'attraction magnétique.

L’embase magnétique est surveillée par un capteur de courant électrique. Au cas où l’embase

magnétique serait défectueuse, le moteur ne

démarre pas.

Lorsque l’alimentation en courant électrique

est interrompue alors que le moteur est en

marche, un dispositif de rupture de protection

empêche un redémarrage du moteur. Redémarrez le moteur. Réglez la vitesse de rotation

au ralenti ou à l’arrêt du moteur. Ne pas arrêter le moteur de carottage durant le processus

de perçage. Ne sortir le carotteur du trou que

lorsque le moteur tourne encore. Au cas où le

carotteur resterait coincé dans le matériau,

arrêter le moteur de carottage et sortir pru-

demment le carotteur en le tournant dans le

sens inverse des aiguilles d’une montre. Après

chaque opération de perçage, enlever les

copeaux et la carotte. Ne pas toucher les

copeaux à la main. Toujours utiliser un crochet

à copeaux. Risque de brûlures ! La surface de

l’aimant peut atteindre des températures élevées. Ne pas toucher l’aimant avec les mains

nues. Lors du remplacement du carotteur, ne

pas endommager les lames. Lors du carottage

de matériaux stratifiés, enlever la carotte et les

copeaux après chaque couche percée. Ne pas

utiliser la carottière si le système de refroidissement est défectueux. Contrôlez l’étanchéité

et si les tuyaux flexibles présentent des fissures. Éviter la pénétration de liquide dans les

éléments électriques. Les carotteuses ne sont

pas équipées d’une protection contre la surcharge. En cas d’utilisation non conforme, le

moteur peut être endommagé.

=

Activer/désactiver l’aimant

=

Activer/désactiver l’aimant

Fig. 10

> 12 mm

< 12 mm

> 12 mm

< 12 mm

OBJ_BUCH-0000000261-003.book Page 45 Thursday, January 11, 2018 5:30 PM

46

fr

Réglage de la plage de course

(figure 11).

Tenez l’outil électrique ferme-

ment d’une main par le

moteur de carottage lorsque vous desserrez

les deux leviers de fixation.

Pour pouvoir bouger les leviers de fixation

superposés, tirer le levier de fixation vers

l’avant et le tourner en pas de 45°.

Desserrez les deux leviers de fixation de

l’autre main.

Réglez la plage de course souhaitée.

Resserrez les deux leviers de fixation.

ATTENTION

1.

2.

2.

3.

1.

4.

4.

2.

2.

1.

3.

4.

4.

2.

2.

Fig. 11

OBJ_BUCH-0000000261-003.book Page 46 Thursday, January 11, 2018 5:30 PM

47

fr

Mise en marche ou arrêt du débit du

produit de refroidissement

(figure 12).

Pour activer le débit du liquide de

refroidissement, ouvrez la purge d’air

et tournez la soupape de traversée

dans la position indiquée sur la figure.

Pour arrêter ou pour les travaux effectués au-dessus de la tête, arrêtez le

débit du liquide de refroidissement.

Fermez la purge d’air et tournez la

soupape de traversée dans la position

indiquée sur la figure.

Pour les travaux effectués au-dessus de la

tête, utilisez une pâte de refroidissement de

Slugger.

1.

2.

Aération

Fig. 12

OBJ_BUCH-0000000261-003.book Page 47 Thursday, January 11, 2018 5:30 PM

48

fr

Commutation de la vitesse de rotation

(figure 13).

Le commutateur de vitesse permet de sélectionner la vitesse de rotation et ainsi le couple.

Réglez la vitesse de rotation au ralenti ou à