Slugger JCM312U, JCM312auto Instruction Manual

®

© C. & E. FEIN GmbH. Printed in Germany. Figure not obligatory. Subject to technical changes. 3 41 01 169 21 0 BY 2011.09.

®

JCM312U

7 270 38

JCM312auto

7 270 39

2

English _____________ Instruction manual___________________

Español _____________ Instrucciones de uso _________________

3

25

3 41 01 169 21 0.book Seite 2 Mittwoch, 7. September 2011 3:32 15

3

en

For your safety.

Read all safety warnings and all

instructions. Failure to follow

the warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

Do not use this power tool before you

have thoroughly read and completely

understood this Instruction Manual, including

the figures, specifications, safety regulations

and the signs indicating DANGER, WARNING and CAUTION.

Only carry out such operations with this

power tool as intended for by the manufacturer. Only use cutting tools and accessories

that have been approved by the manufacturer.

Please also observe the relevant national

industrial safety regulations.

Non-observance of the safety instructions in

the said documentation can lead to electric

shock, burns and/or severe injuries.

This Instruction Manual should be kept for

later use and enclosed with the power tool,

should it be passed on or sold.

SAVE THESE INSTRUCTIONS.

The term “power tool” in the warnings refers

to your mains-operated (corded) power tool

or battery operated (cordless) power tool.

General Safety Rules.

1) Work area safety

a) Keep work area clean and well lit. Clut-

tered or dark areas invite accidents.

b)Do not operate power tools in explosive at-

mospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

electric shock.

b)Avoid body contact with earthed or

grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an in-

creased risk of electric shock if your body

is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

d)Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device (RCD) protected supply. Use of an

RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol or medication. A moment of inatten-

tion while operating power tools may result in serious personal injury.

b)Use safety equipment. Always wear eye

protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

WARNING

3 41 01 169 21 0.book Seite 3 Mittwoch, 7. September 2011 3:32 15

4

en

c) Avoid accidental starting. Ensure the switch

is in the off-position before plugging in.

Carrying power tools with your finger on

the switch or plugging in power tools that

have the switch on invites accidents.

d)Remove any adjusting key or wrench before

turning the power tool on. A wrench or a

key left attached to a rotating part of the

power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better

control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose clothing

or jewelery. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelery or long hair can be

caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure these are connected and properly

used. Use of these devices can reduce

dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The cor-

rect power tool will do the job better and

safer at the rate for which it was designed.

b)Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the

risk of starting the power tool accidentally.

d)Store idle power tools out of the reach of

children and do not allow persons unfamiliar with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalign-

ment or binding of moving parts, breakage

of parts and any other condition that may

affect the power tools operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean. Prop-

erly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and tool

bits etc., in accordance with these instructions and in the manner intended for the

particular type of power tool, taking into

account the working conditions and the

work to be performed. Use of the power

tool for operations different from those

intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a quali-

fied repair person using only identical replacement parts. This will ensure that the

safety of the power tool is maintained.

3 41 01 169 21 0.book Seite 4 Mittwoch, 7. September 2011 3:32 15

5

en

Special safety instructions.

Wear personal protective equipment. Depending on the application, use a face shield,

safety goggles or safety glasses. Wear ear protection. The safety glasses must be capable of

protecting against flying particles generated

by the various operations. Prolonged exposure to high intensity noise may cause loss of

hearing.

Secure the power tool with the safety strap

supplied if there is danger of it falling, especially for work carried out at elevated heights,

when drilling horizontally or above the head. If

there is a power loss, or the power plug is

pulled out, the magnetic holding power is not

maintained.

When working overhead or on vertical surfaces, the coolant container must not be used.

Use Slugger Cutting Paste instead. Liquids

penetrating your electric power tool may

cause electric shock.

Avoid touching the drilled core that is automatically ejected by the pilot pin when the working

procedure is finished. Contact with the core

when it is hot, or if it falls, can cause personal

injuries.

Operate the power tool only from grounded

contact sockets that comply with the specifications. Do not use any connection cables that are

damaged; use extension cables with a grounded contact that are checked at regular intervals. A grounded conductor without

continuity can cause an electric shock.

Do not machine any material containing asbestos. Asbestos is carcinogenic.

To prevent injuries, always keep your hands,

clothing, etc. away from rotating swarf. The

swarf can cause injuries. Always use the chipping protector.

Do not attempt to remove the cutting tool if it

does not turn. This can lead to serious injuries.

Do not rivet or screw any name-plates or signs

onto the power tool. If the insulation is dama-

ged, protection against an electric shock will

be ineffective. Adhesive labels are recommended.

Do not use accessories which are not specifically designed and recommended by the power

tool manufacturer. Safe operation is not ensu-

red merely because an accessory fits your

power tool.

Clean the ventilation openings on the power

tool at regular intervals using non-metal tools.

The blower of the motor draws dust into the

housing. An excessive accumulation of metallic dust can cause an electrical hazard.

Hold power tool by insulated gripping surfaces

when performing an operation where the cutting accessory may contact hidden wiring or its

own cord. Cutting accessory contacting a

“live” wire will make exposed metal parts of

the power tool “live” and shock the operator.

Before putting into operation, check the power

connection and the power plug for damage.

Handling hazardous dusts

When working with power

tools, such as when grinding,

sanding, polishing, sawing or for other work

procedures where material is removed, dusts

develop that are both hazardous to one’s health

and can spontaneously combust or be explosive.

Contact with or inhaling some dust types can

trigger allergic reactions to the operator or

bystanders and/or lead to respiratory infections, cancer, birth defects or other reproductive harm.

Examples of such materials which contain

chemicals that can produce hazardous dusts,

are:

– Asbestos and materials containing asbestos

– Lead-containing coatings, some wood types

such as beech and oak

– Minerals and metal

– Silicate particles from bricks, concrete and

other materials containing stone

– Solvent from solvent-containing paint/var-

nish

– Arsenic, chromium and other wood pre-

servatives

WARNING

3 41 01 169 21 0.book Seite 5 Mittwoch, 7. September 2011 3:32 15

6

en

– Materials for pesticide treatment on boat

and ship hulls.

To minimize the unwanted intake of these

materials:

– Use dust extraction matched appropriately

for the developing dust.

– Use personal protective equipment, such as

a P2 filter-class dust protection mask.

– Provide for good ventilation of the work-

place.

The risk from inhaling dusts depends on the

frequency how often these materials are

worked. Materials containing asbestos may

only be worked by specialists.

Wood and light-metal dust can

cause spontaneous combustion

or explosions.

Hot mixtures of sanding dust and paint/varnish residuals or other chemical materials in

the filter bag or the vac filter can self-ignite

under unfavourable conditions, such as sparking from sanding metal, continuous sunlight

or high ambient temperatures. To prevent

this:

– Avoid overheating the material being

sanded and the power tool.

– Empty the dust collector/container in time.

– Observe the material manufacturer’s work-

ing instructions.

Observe the relevant regulations for the

materials being worked.

Emission values for sound (Two-figure – specifications as per ISO 4871)

CAUTION

Sound emission JCM312U JCM312auto

A-weighted emission pressure power level

measured at the workplace LpA (re 20 µPa), in

decibels 84 84

Measuring uncertainty KpA, in decibels 3 3

Measured A-weighted sound power level LwA

(re 1 pW), in decibels 95 95

Measuring uncertainty KwA, in decibels 3 3

Measured C-weighted peak sound pressure

level L

pCpeak

, in decibels 101 101

Measuring uncertainty K

pCpeak

, in decibels 3 3

REMARK: The sum of the measured emission value and respective measuring inaccuracy represents the upper limit of the values that can occur during measuring.

Wear ear protection!

Measured values determined in accordance with the corresponding product standard.

3 41 01 169 21 0.book Seite 6 Mittwoch, 7. September 2011 3:32 15

7

en

Extension cord

If the use of an extension cord

is required, its length and conductor cross-section must be adequate for the

application in order to prevent a voltage drop in

the extension cord, power loss and overheating

of the power tool. Otherwise, the extension

cable and power tool are prone to electrical

danger, and the working efficiency is

decreased.

Recommended dimensions of extension cords

at an operating voltage of 120 V – single-phase

a. c., with only one power tool

JCM312U/JCM312auto connected:

Intended use of the power tool.

Magnetic base drill for drilling with annular

tools and twist drill bits, reaming, countersinking and tapping on materials with surfaces

suitable for magnets in weather-protected

environments using the cutting tools and

accessories recommended by the manufacturer.

Operation of the power tool off power generators.

Operate the power tool only off

a.c. generators with sufficient power

output that do not have any distortion of the

voltage curve.

Operating the power tool off

power generators whose noload speed exceeds the voltage value on the

type plate of the power tool is prohibited.

Max. cable length, ft Max. cable length, m

≤ 100 100

–200

≤ 30 30

– 60

Min. conductor size

(A.W.G.)

Min. conductor

cross-section, mm

2

14 12 2.5 4

CAUTION

WARNING

3 41 01 169 21 0.book Seite 7 Mittwoch, 7. September 2011 3:32 15

8

en

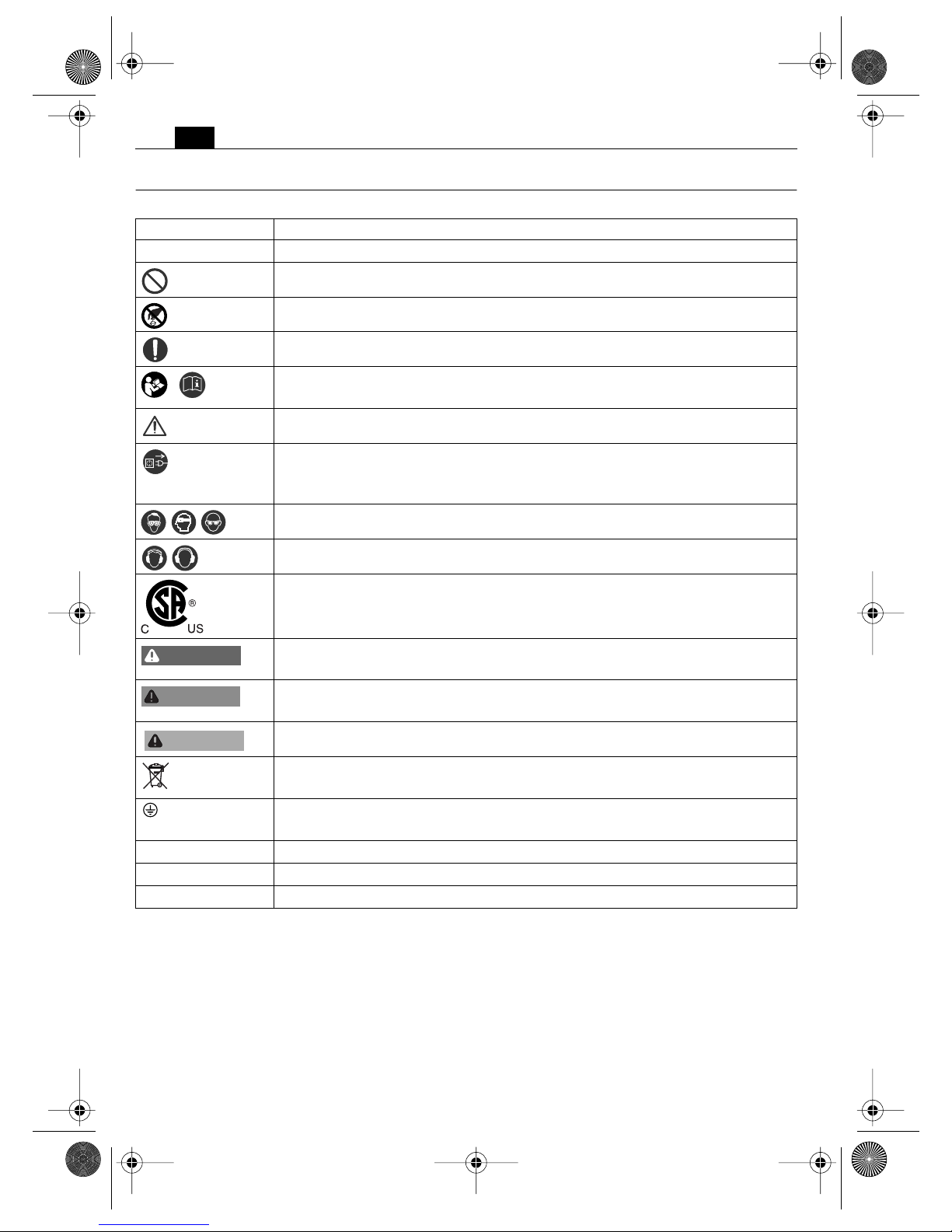

Symbols.

Symbol Explanation

➤

Action to be taken by the user

General prohibition sign. This action is forbidden!

Do not touch the rotating parts of the power tool.

Follow the instructions in the adjacent text!

Be absolutely sure to read the enclosed documentation such as the

Instruction Manual and the General Safety Instructions.

Observe the information in the adjacent text or graphic!

Before commencing this working step, pull the power plug out of the

socket. Otherwise there will be danger of injury if the power tool should

start unintentionally.

Use eye protection during operation.

Use ear protection during operation.

This symbol confirms the certification of this product for the USA and

Canada.

This sign warns of a directly imminent, dangerous situation. A false reaction can cause a severe or fatal injury.

This sign indicates a possible dangerous situation that could cause severe

or fatal injury.

This sign warns of a possible dangerous situation that could cause injury.

Worn out power tools and other electrotechnical and electrical products

should be sorted separately for environmentally-friendly recycling.

Product with basic insulation and exposed, conductive parts additionally

connected to the ground conductor.

~ or a. c. Alternating current

1 ~ Alternating current single-phase

Ø Diameter of a round part

DANGER

WARNING

CAUTION

3 41 01 169 21 0.book Seite 8 Mittwoch, 7. September 2011 3:32 15

9

en

Character Unit of measure, national Explanation

n

o

rpm Revolution speed at no-load

P W Electric output

Hz Frequency

f V Electric voltage

I A Electric current intensity

° Angle width

m lbs Mass

l ft, in Length, height, depth, diameter and tapping

m, s, kg, A, mm, V, W,

Hz, N, °C, dB, rpm, m/s

2

Basic and derived units of measure from the international system of units SI.

3 41 01 169 21 0.book Seite 9 Mittwoch, 7. September 2011 3:32 15

10

en

Technical description and specifications.

Before mounting or replacing cutting tool or accessories, pull the power plug. This

preventive safety measure rules out the danger of injuries through accidental

starting of the power tool.

All accessories described or shown in this instruction manual will not be included with your

power tool.

WARNING

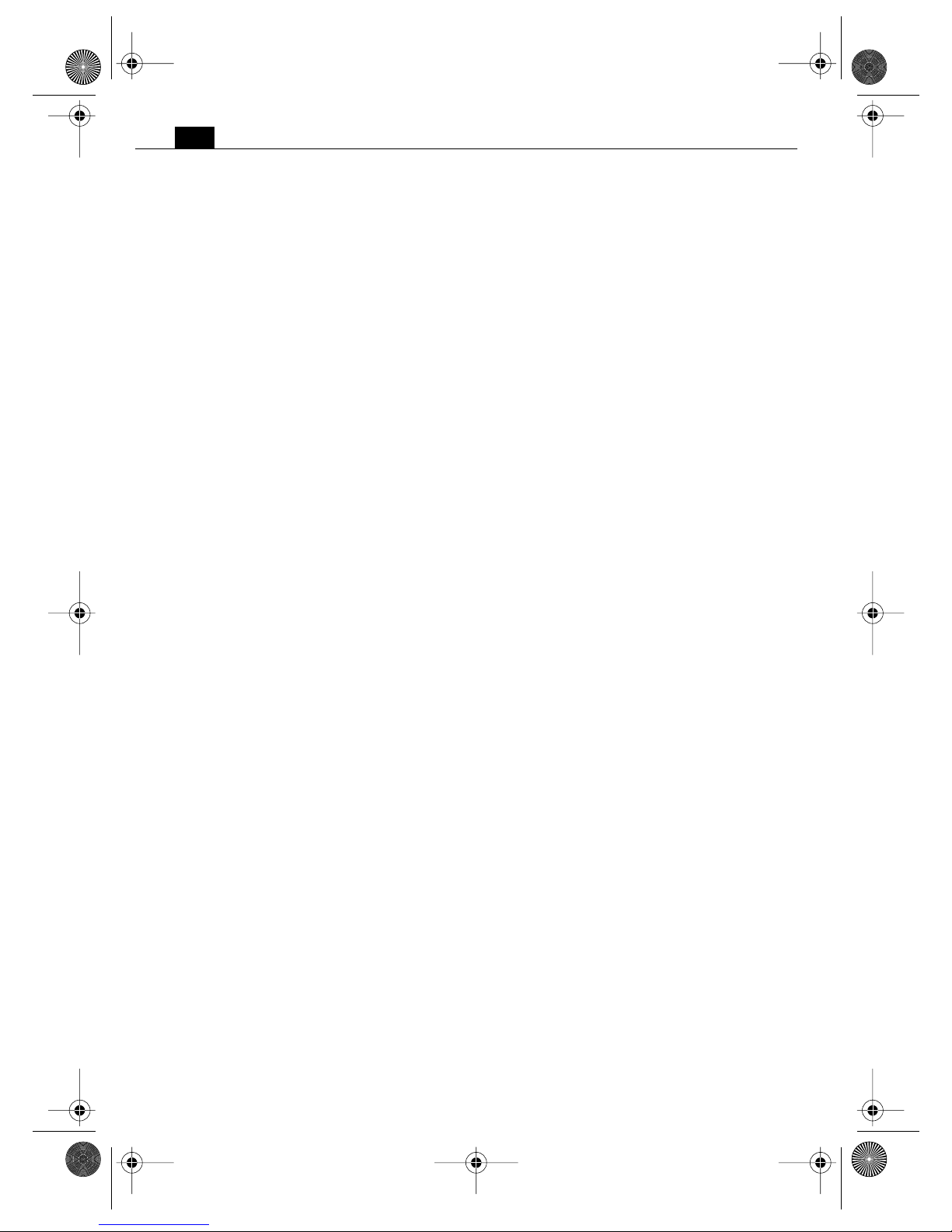

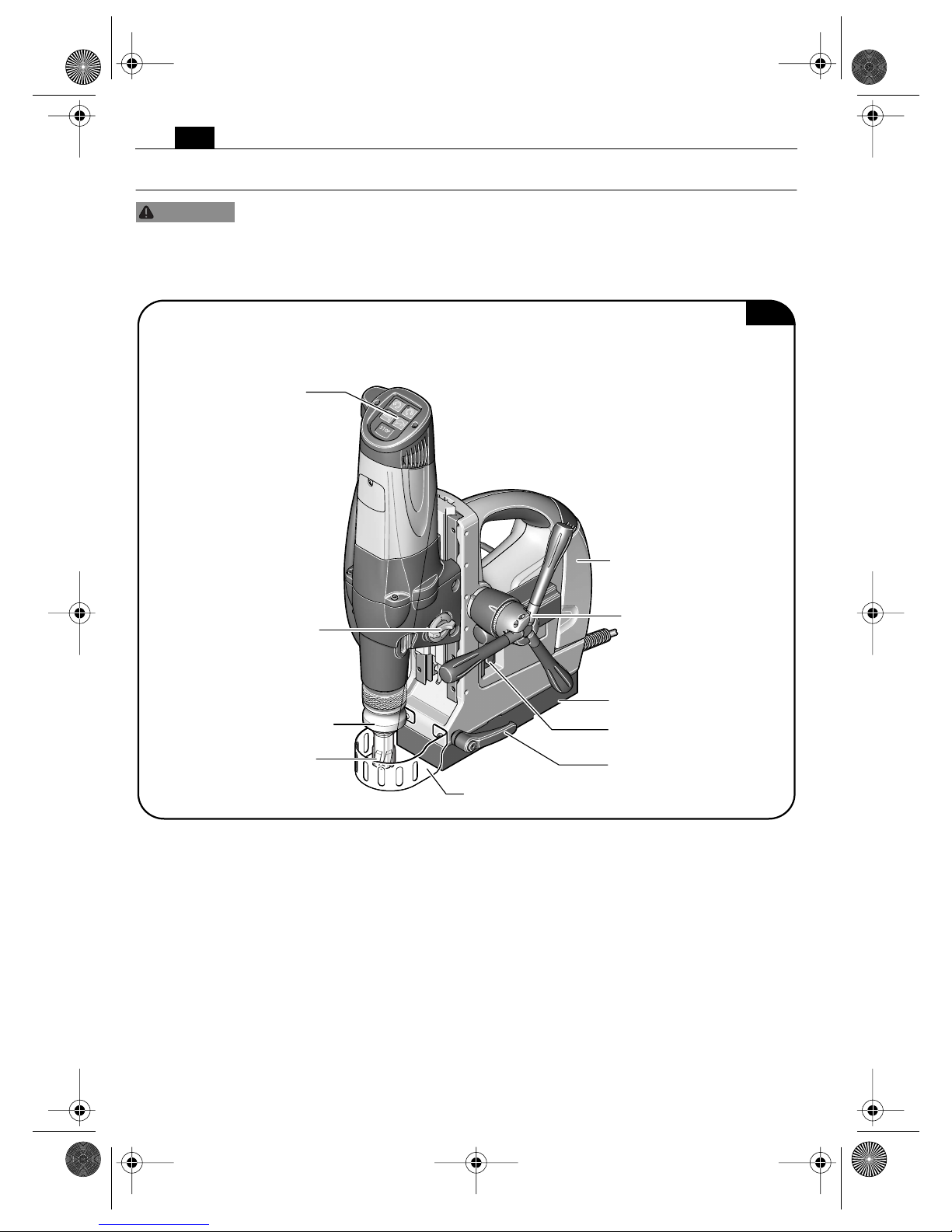

Fig. 1

JCM312auto

Coolant container

Spoke handle

with feed motor

Magnetic base

Magnet ON/OFF switch

Clamping lever

Chip guard

QuickIN Max

tool holder

Gear switch

Cutting tool

Viseo Touch Pad

3 41 01 169 21 0.book Seite 10 Mittwoch, 7. September 2011 3:32 15

11

en

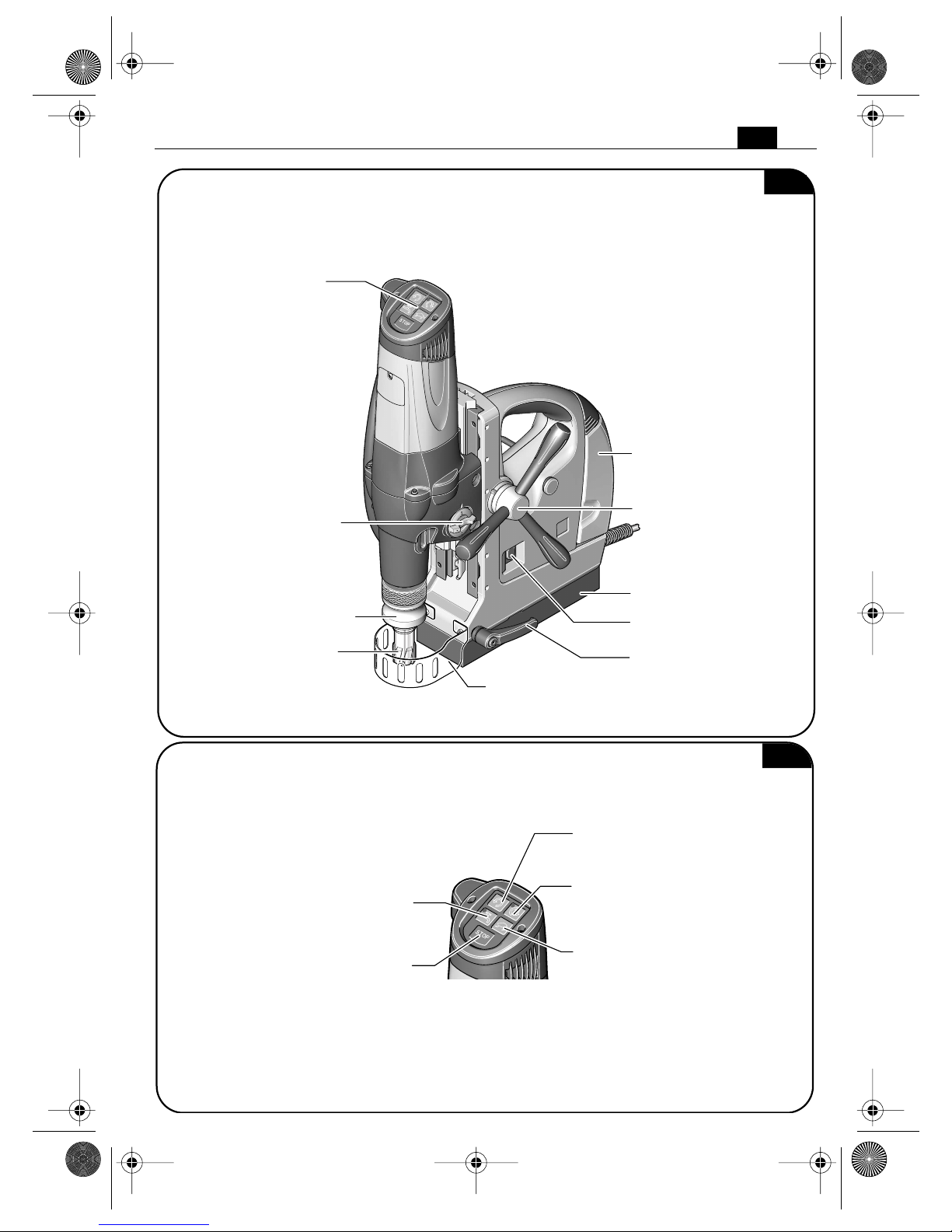

Viseo Touch Pad

Fig. 2

JCM312U

Coolant container

Spoke handle

Magnetic base

Magnet ON/OFF switch

Clamping lever

Chip guard

QuickIN Max

tool holder

Gear switch

Cutting tool

Button for cooling lubricant

supply

Button for speed reduction

Stop motor button

Button for starting the drill

motor in clockwise direction

Button for starting the drill

motor in counterclockwise

direction (tip operation)

Fig. 3

3 41 01 169 21 0.book Seite 11 Mittwoch, 7. September 2011 3:32 15

12

en

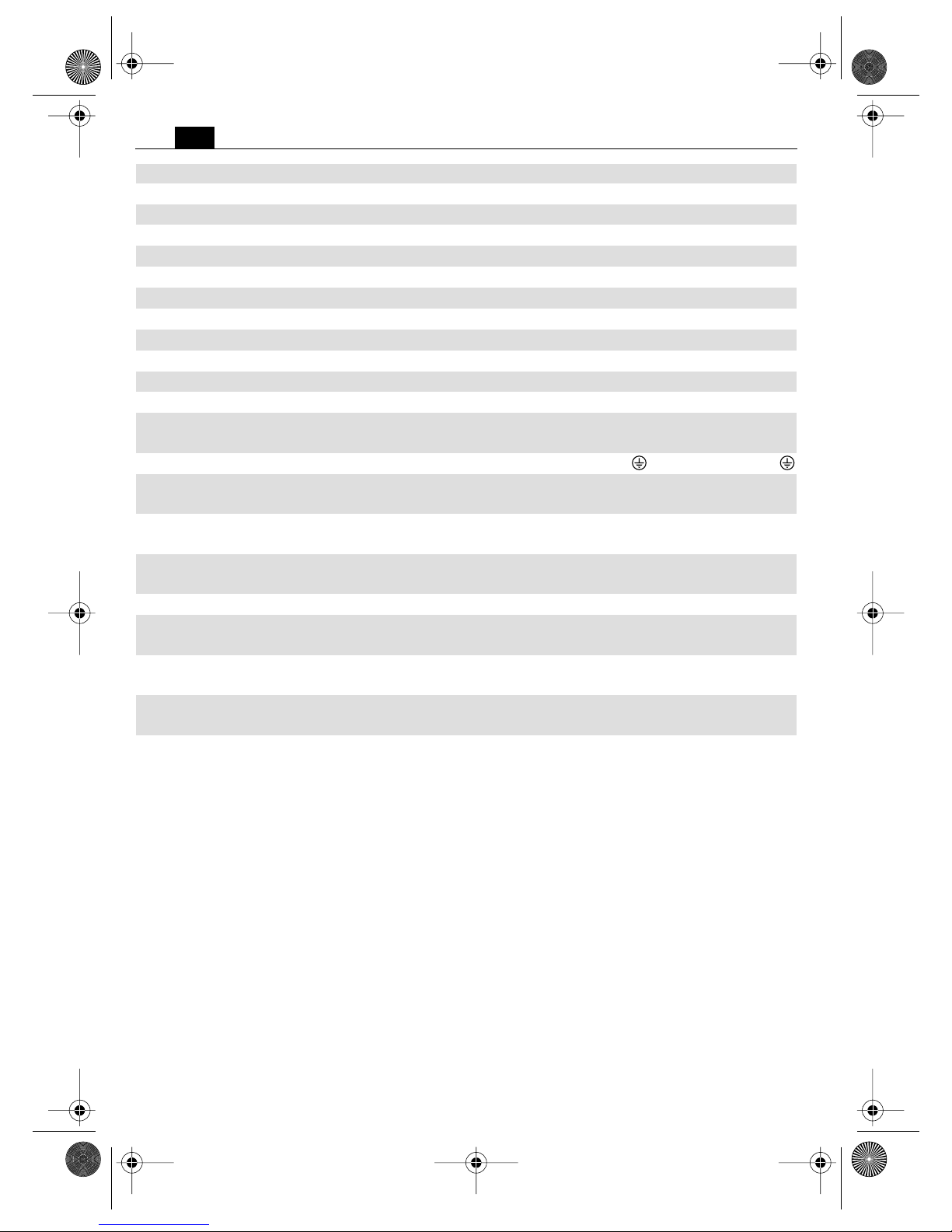

Type JCM312U JCM312auto

Reference number 7 270 38 7 270 39

Current consumption 15 A 15 A

Power supply type 1 ~ 1 ~

No-load speed (Clockwise)

1st gear 180 rpm 180 rpm

2nd gear 260 rpm 260 rpm

3rd gear 580 rpm 580 rpm

No-load speed (Counterclockwise)

1st gear 180 rpm 180 rpm

2nd gear 260 rpm 260 rpm

3rd gear 580 rpm 580 rpm

Weight according to EPTA-Procedure 01/2003 25.4 kg

55.9 lbs

26.4 kg

58 lbs

Class of protection I I

Core drilling capacity in steel - TCT (carbide tipped

cutter)

12 – 80 mm

7

/16 in–3 1/8 in

12 – 80 mm

7

/16 in–3 1/8 in

Core drilling capacity in steel – HSS (high speed

steel)

12 – 65 mm

7

/16 in–2 9/16 in

12 – 65 mm

7

/16 in–2 9/16 in

Drilling capacity in steel – HSS twist drill bit 32 mm

1 1/4 in

32 mm

1 1/4 in

Bolt hole diameter max. M27, 1 1/8 in M27, 1 1/8 in

Max. twist drill diameter with the supplied chuck 13 mm

1

/2 in

13 mm

1

/2 in

Reamer diameter 31 mm

1 3/16 in

31 mm

1 3/16 in

Counterboring diameter 50 mm

2 in

50 mm

2 in

3 41 01 169 21 0.book Seite 12 Mittwoch, 7. September 2011 3:32 15

13

en

Assembly instructions.

Filling coolant tank.

Before mounting or replacing cutting tools or accessories, pull the power plug.

This preventive safety measure rules out the danger of injuries through accidental starting of the power tool.

Prevent the flow of liquid along the cable into the socket or into the core drill,

as this can lead to electric shock. Tie a bow in the cord near the plug so that

any liquid can drip off.

Only use water soluble cutting fluid that is capable of being pumped like Slugger Cutting Fluid.

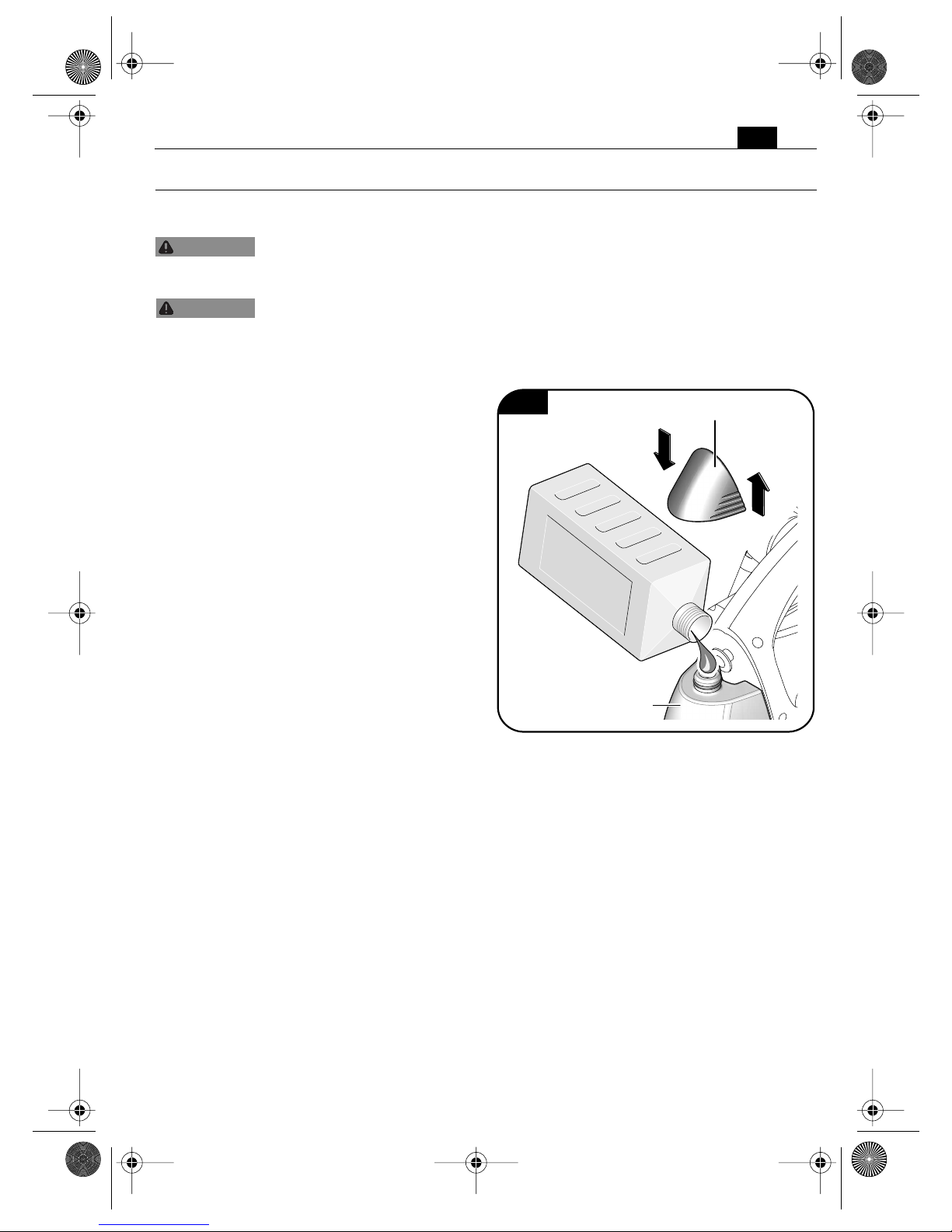

Filling the mounted coolant tank (Fig. 4).

➤ Pull off the upper closing cap of the

coolant tank.

➤ Fill in pump-feedable water soluble

Slugger Cutting Fluid. Do not use oil!

➤ Mount the upper closing cap firmly

onto the coolant tank.

WARNING

WARNING

Fig. 4

Coolant container

Upper closing cap

3 41 01 169 21 0.book Seite 13 Mittwoch, 7. September 2011 3:32 15

14

en

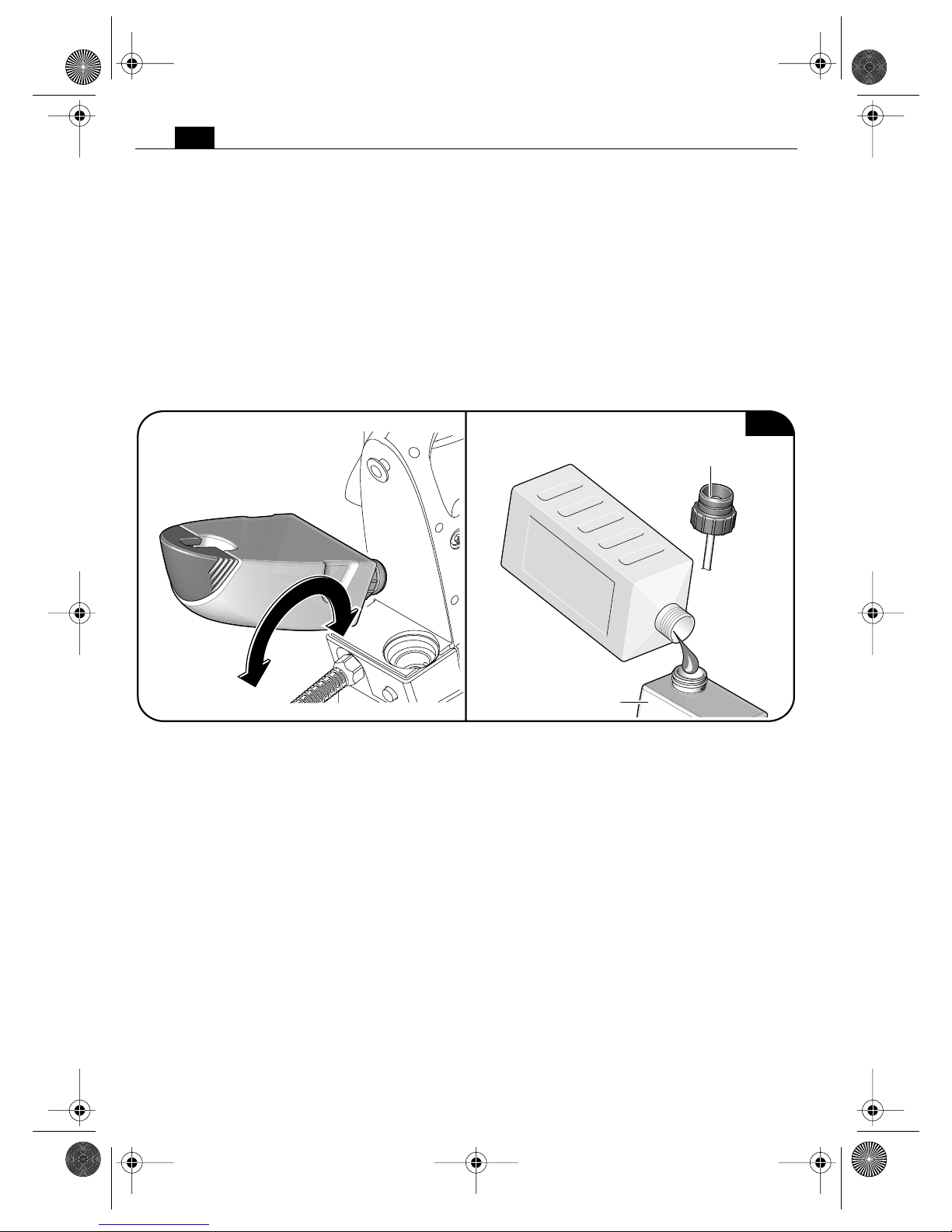

Filling the removed coolant tank. (Fig. 5).

➤ Pull the empty coolant tank out of drill

stand housing of the magnetic base drill.

➤ Unscrew the bottom closing cap from

the coolant tank.

➤ Fill in pump-feedable water soluble

Slugger Cutting Fluid. Do not use oil!

➤ Firmly screw the bottom closing cap

back on to the coolant tank.

➤ Insert the filled coolant tank into the

holder on the drill stand housing intended for this purpose.

Fig. 5

Coolant container

Bottom closing cap

3 41 01 169 21 0.book Seite 14 Mittwoch, 7. September 2011 3:32 15

15

en

Changing the tool.

Secure the power tool with the safety strap supplied at all times, especially for

work carried out at elevated heights, when drilling horizontally or above the head.

If there is a power loss, or the power plug is pulled out, the magnetic holding power is not

maintained.

Before mounting or replacing cutting tools or accessories, pull the power plug.

This preventive safety measure rules out the danger of injuries through accidental starting of the power tool.

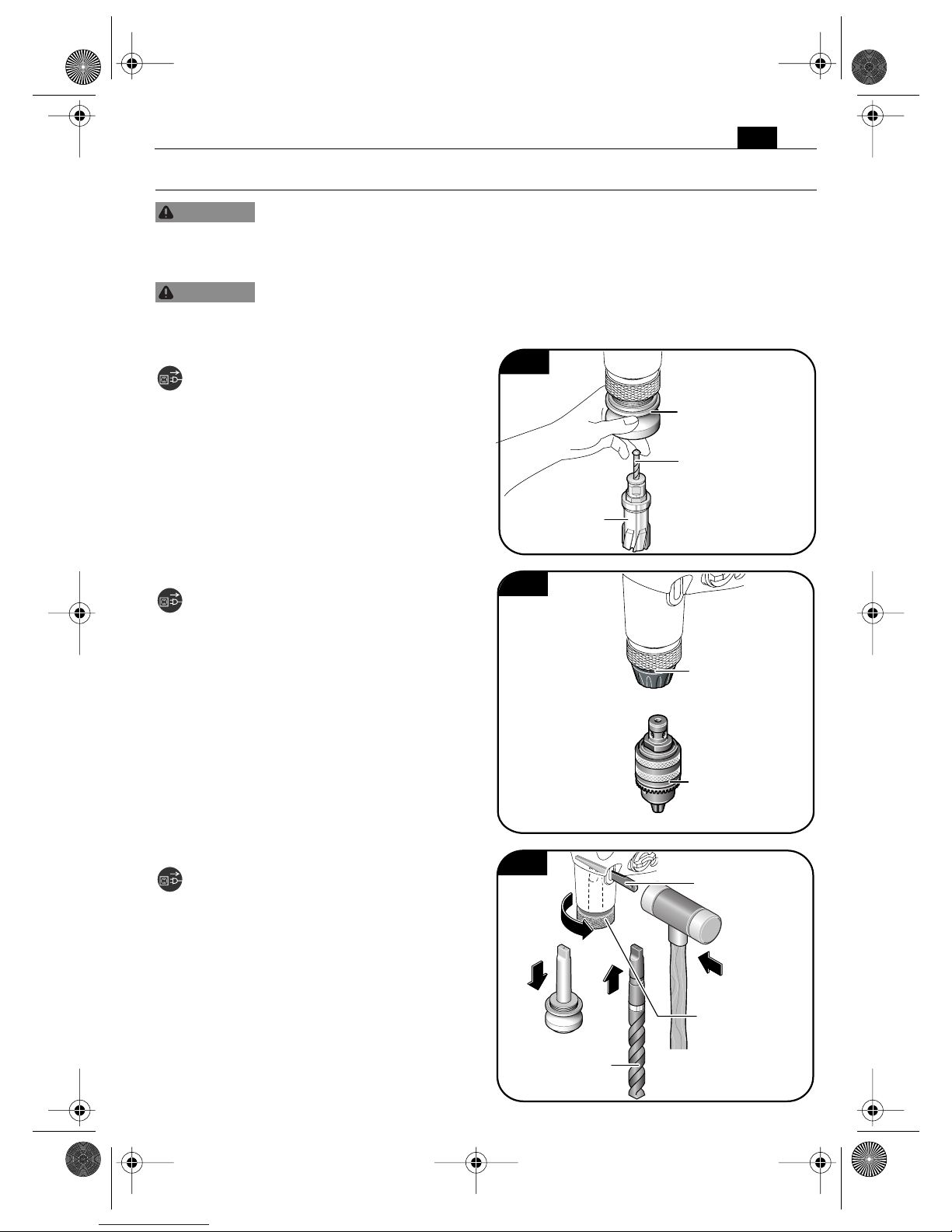

Carbide tipped cutter (Fig. 6).

➤ Insert the pilot pin into the carbide tip-

ped cutter.

➤ Pull the QuickIN Max clamping sleeve

of the tool holder downward. Insert the

carbide tipped cutter with the pilot pin.

Do not touch the sharp edges of the carbide tipped cutter.

Key-type drill chuck (Fig. 7).

➤ Turn the QuickIN clamping sleeve of

the tool holder leftward and insert the

geared drill chuck.

Twist drill bit (Fig. 8).

➤ Turn the knurled nut until it spins

through.

➤ Place the drift in position and apply a

hammer blow to remove the tool holder.

➤ Clean the inside cone of the output

shaft and insert the twist drill bit.

WARNING

WARNING

Fig. 6

QuickIN Max.

tool holder

Pilot pin

Carbide tipped cutter

Fig. 7

QuickIN

tool holder

Key-type drill

chuck

1.

2.

3.

4.

Fig 8

Twist drill bit

Drift

Knurled nut

3 41 01 169 21 0.book Seite 15 Mittwoch, 7. September 2011 3:32 15

Loading...

Loading...