SLS Blot Washer Operator's Manual

Operator’s Manual

For Automated Western Blot Processing

ii

Notice

The information contained in this document is subject to change without notice.

This document contains proprietary information which is protected by copyright. All rights are

reserved. No part of this document may be photocopied, reproduced, or translated to another

language without prior written consent of Stovall Life Science, Inc.

Stovall Life Science, Inc.

206-G South Westgate Drive • Greensboro, North Carolina USA

Phone: 800-852-0102

Fax: 336-852-3507

Email: info@slscience.net

www.slscience.com

iii

Chapter 1: System Familiarization

and Assembly

Placement in the Laboratory ...................... 1

Electrical Considerations ........................... 1

Current Requirements ............................ 2

Fuse Replacement .................................. 2

Connecting Power ..................................... 3

System Overview ....................................... 3

Hardware Familiarization ....................... 3

Software Familiarization ......................... 5

Tube Routing ............................................. 6

Color Coding ......................................... 6

Connecting the Waste Removal System . . 8

Connecting the Wash System ................. 8

Inserting Tubing Into the Solenoid Valves . 9

Checking for Leaks ............................... 10

Using a Second Delivery Container ...... 10

Cleaning the Blot Washer After Use ......... 12

Cleaning Tubing and Containers ........... 12

Discarding Waste and Replacing Wash

Buffer ................................................... 13

Cleaning the Exterior Surface ............... 13

Chapter 2: Creating and Running

Programs

Keys You Should Be Familiar With ........... 15

Powering On the Blot Washer .................. 15

Selecting the Program Number to Edit

or Run ..................................................... 16

Editing a Program .................................... 16

Starting a Program ................................... 22

Pausing a Program ................................... 23

Stopping a Program ................................. 23

Using the Quad Harness .......................... 23

Scaling Up or Back .............................. 26

Default Program Descriptions .................. 26

Chapter 3: Calibration

Keys You Should Be Familiar With ........... 29

Checking System Pressure ....................... 30

Calibrating Dispense Volume ................... 30

Setting the Aspiration Vacuum Factor ....... 31

Chapter 4: Appendices

Accessory Part Numbers .......................... 33

Specifications .......................................... 33

Declaration of Conformity ....................... 35

Table of Contents

1

Chapter 1: System Familiarization

and Assembly

Placement in the Laboratory

Place the instrument away from sinks or other sources of water

that pose a shock hazard. Do not locate the Blot Washer where

the power cord will be walked on or exposed to water or chemical

spills.

Warning: Do not operate around flammable liquids or gases.

Electrical Considerations

For personal safety the Blot Washer must be properly grounded.

The power cords have a three-prong, grounded plug that mates

with a standard three-prong, grounded wall receptacle to minimize

the possibility of electric shock. The user should have the wall

receptacle and circuit checked by a qualified electrician to be

assured that the receptacle is properly grounded. Where a twoprong receptacle is encountered, it is the responsibility of the user

to replace it with a properly grounded three-prong wall receptacle.

Warning: Do not under any circumstances, cut or remove the

third ground prong from the power cord. Do not use a two-prong

adapter plug.

2 CHAPTER 1

System Familiarization and Assembly

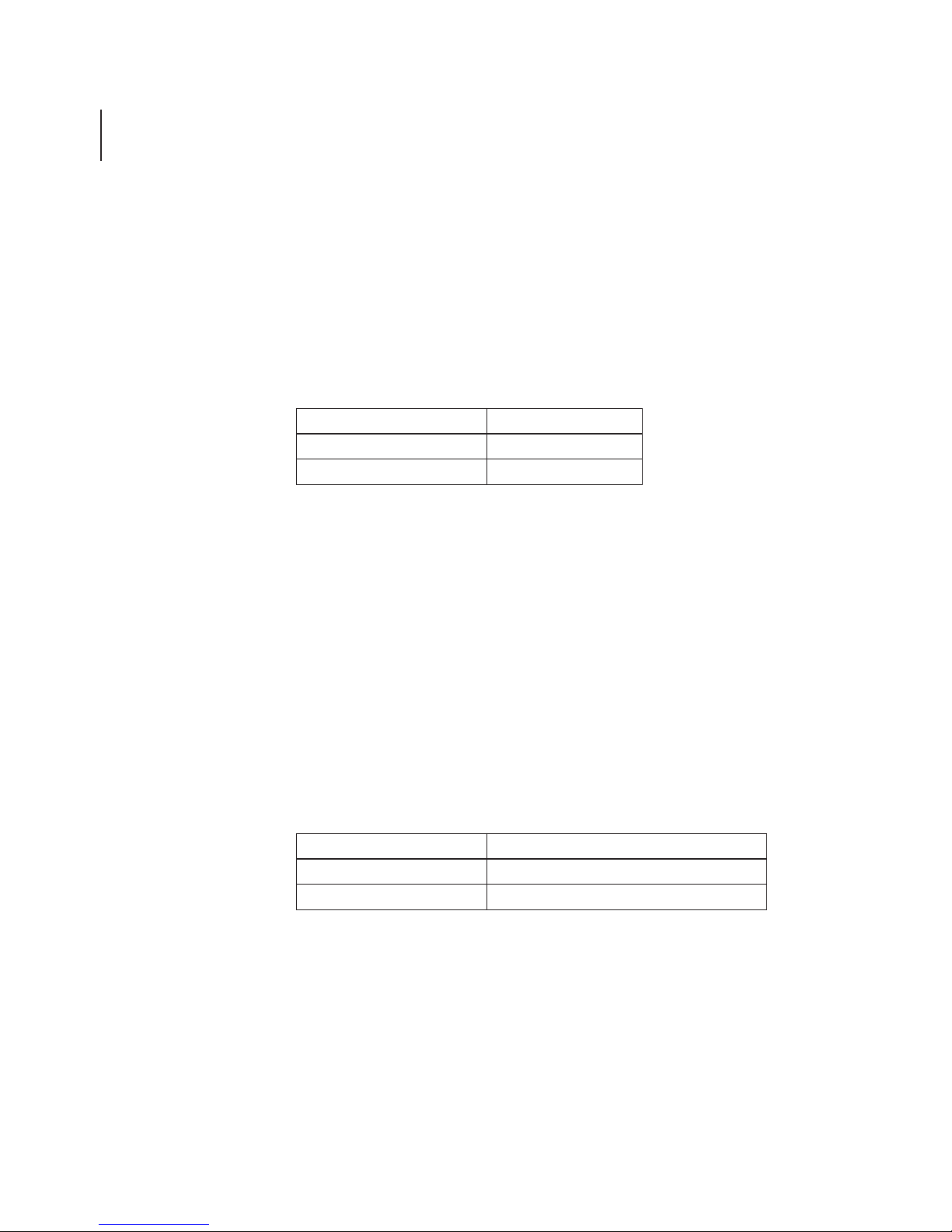

Current Requirements

Current demand for the Blot Washer is modest, but it should be

added to other current demand on the circuit to make sure total

current demand does not exceed the rating of the fuse or circuit

breaker in use. Current demand for the various Blot Washer models

are listed below.

Caution: Be sure the line voltage is of the same value specified on

the nameplate located on the back panel.

Fuse Replacement

Warning: Before replacing a blown fuse, turn all switches to the

OFF position and unplug the instrument.

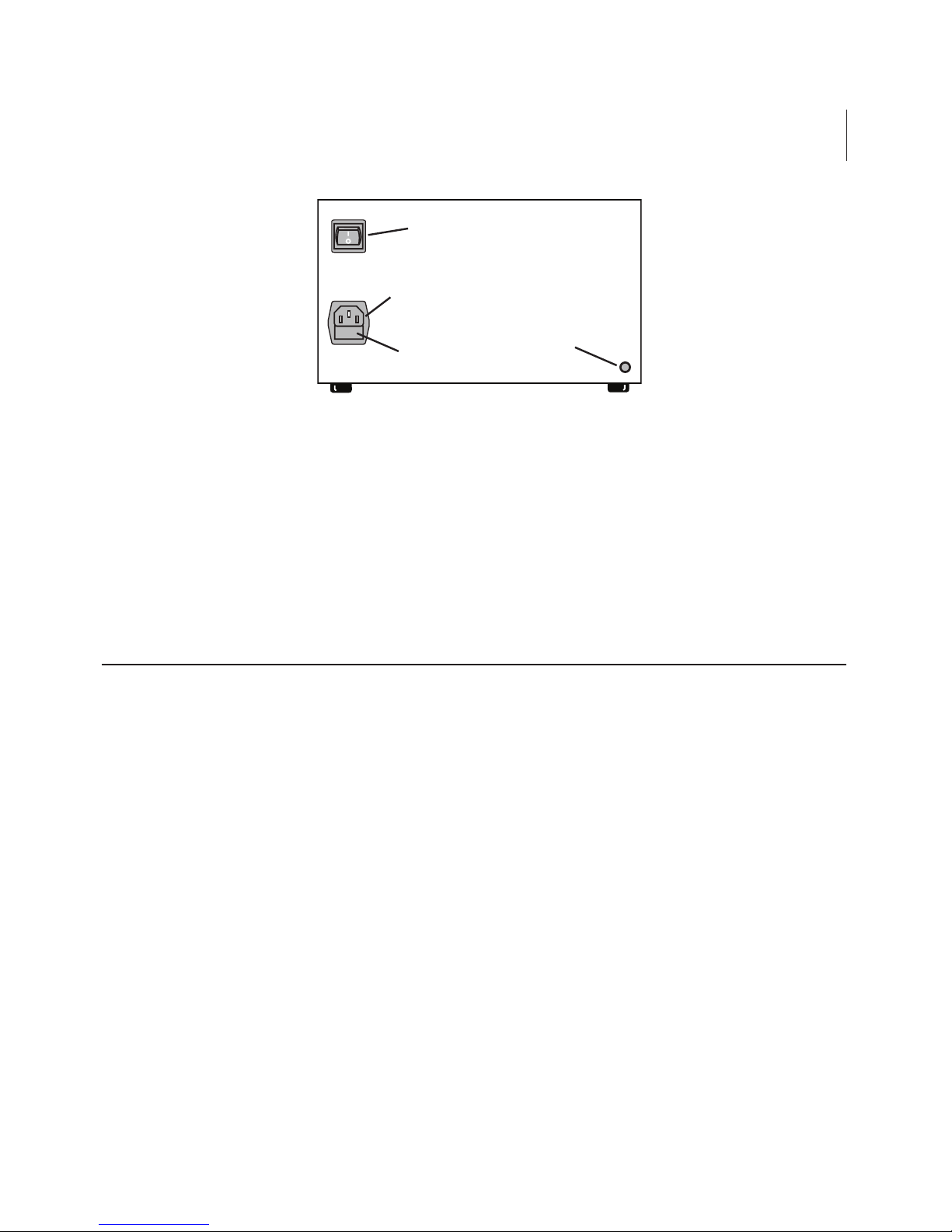

Figure 1 shows the location of the fuse in a small fuse drawer on

the back panel of the Blot Washer. A spare fuse is also located

in this drawer. Should the fuse blow, replace with a new fuse of

the same value. To remove a fuse, place the tip of a slot blade

screwdriver into the top of the fuse drawer and pry open.

Blot Washer Model Current Demand

115V < 0.5 Amps

230V < 0.25 Amps

Blot Washer Model Fuse Description

115V

5 mm x 20 mm, 500 mAmp

230V 5 mm x 20 mm, 250 mAmp

3

Power ON/OFF Switch

Fuse Drawer

Power Receptacle

Vacuum Inlet

Port

Blot Washer Back Panel

Connecting Power

Connect the power cord to the power receptacle on the Blot

Washer back panel and connect the power cord plug to a wall or

bench outlet.

System Overview

Hardware Familiarization

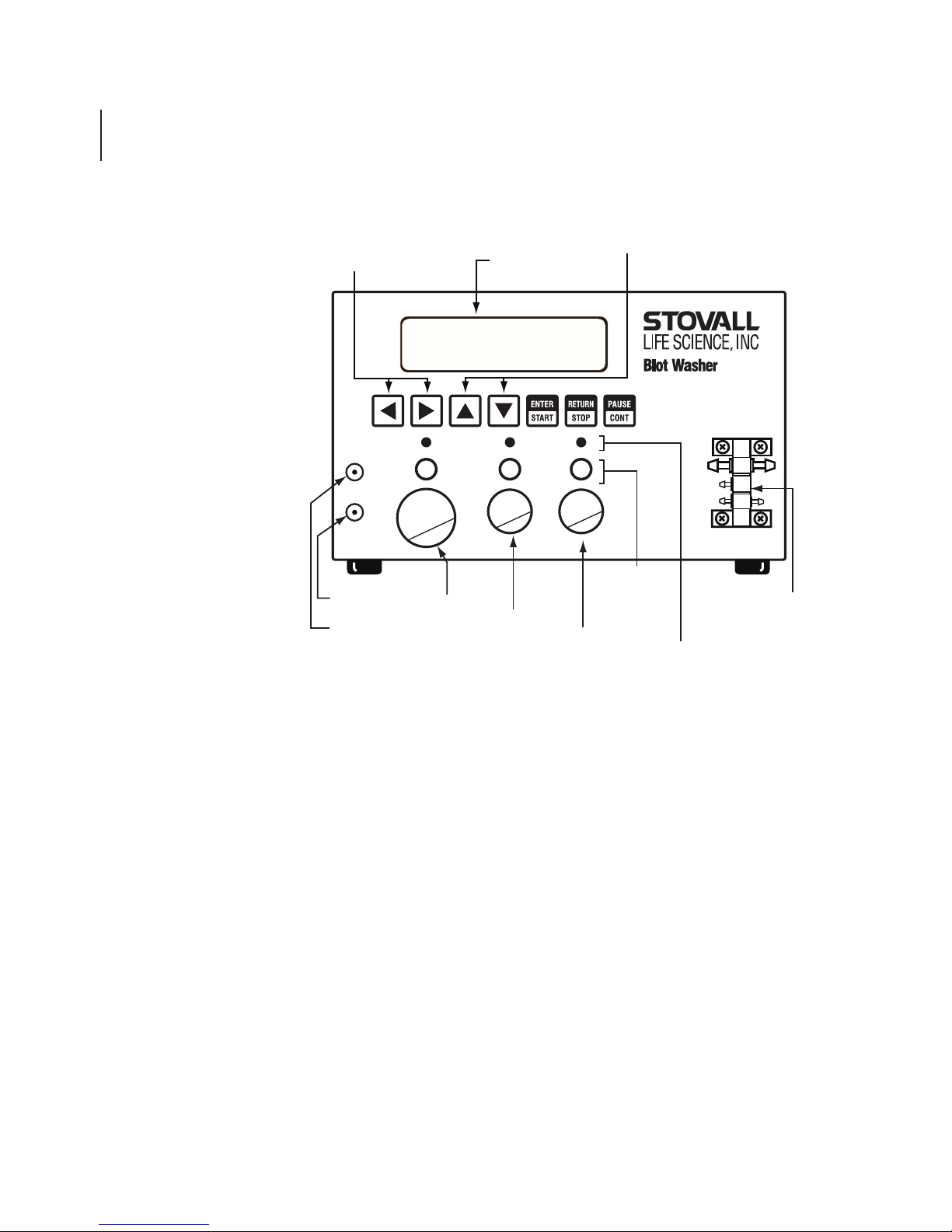

The Stovall Blot Washer is a straightforward liquid delivery and

aspiration instrument. An internal pump supplies positive pressure

for liquid delivery and house vacuum aspirates waste liquids from

blot containers. Air pressure from the internal pump is directed

through the blue pressure port located on the left side of the Blot

Washer (Figure 2). The vacuum inlet is located on the back panel

of the instrument (Figure 1) and the black vacuum outlet port is

beneath the blue air pressure port on the left side of the instrument

front panel.

Figure 1. Blot washer back panel showing location of the ON/OFF

power switch, power receptacle, fuse drawer, and vacuum port.

4

Vacuum Port

(black)

Pressure Port

(blue)

Aspiration

Valve

Dispense

Valve #1

Dispense

Valve #2

Manual

Valve

Control

Buttons

Manifold

Green Indicator

Lights Signaling

Valve Open

Scroll keys to select

program functions

(edit programs,

calibration, etc.)

LCD Display

Keys to increment/decrement

steps, dispense quantities, cyles,

timing, number of blots, etc.

Figure 2. Major components on the Blot Washer front panel.

CHAPTER 1

System Familiarization and Assembly

Software wash programs operate three solenoid valves to control

the flow of liquids. The normal condition of all valves is closed,

where by the flow of liquids is impeded by pinching the silicone

tubing closed. From left to right on the front panel (Figure 2) the

valves are:

• Aspiration Valve (larger) controls the aspiration of liquids to the

waste bottle.

• Dispense Valve #1 controls the delivery of wash buffer from the

large wash bottle.

• Dispense Valve #2 controls reagent delivery from the 140 ml

syringe or a second delivery reservoir.

5

During operation, the internal pump pressurizes the Wash Bottle

(Figure 3) through an air pressure line. When a new wash cycle

starts, Dispense Solenoid Valve #1 opens and the pressure in the

Wash Bottle dispenses wash buffer from the Wash Bottle to the blot

container.

The vacuum source is used to lower the air pressure in the

Waste Bottle. During a waste removal, the Aspiration Solenoid

Valve (Figure 2) opens and waste liquid is aspirated from the blot

container, and flows into the Waste Bottle.

When a wash program is configured, the user enters how many of

these dispense/aspiration cycles there are in a given wash step, how

much wash buffer is dispensed, and how long the liquid remains in

the blot container before aspiration.

Dispense Solenoid Valve #2 adds versatility by allowing a second

delivery container to be connected (Figure 5). Similar to the Wash

bottle, this second container is pressurized by the pump and liquid

is dispensed to the blot container when Dispense Solenoid Valve #2

is opened under program control. This second delivery container

can be used to dispense a second wash buffer or secondary

antibodies.

Each of the solenoid valves has a circular button above it. These

buttons manually open the solenoid valves and operate the valves

independently of programmed sequences. Manual control is most

commonly used when tubes are flushed during cleaning or during

calibration. When a solenoid valve is open, under program or

manual control, the indicator light above the manual control button

is illuminated.

Software Familiarization

Creating programs for a variety of wash sequences is described in

Chapter 2 and additional software functions for calibration are

discussed in Chapter 3. Before connecting tubing and filling

6 CHAPTER 1

System Familiarization and Assembly

reservoir bottles, remove all port plugs, turn on the power switch,

and use the instructions in Chapters 2 and 3 to familiarize yourself

with the keypad and general software operation.

The most important keys to learn are the and keys for

navigation through menus and programs, and the or keys for

choosing options or changing numbers. The key is especially

important for navigation when editing programs. The other

three keys on the keypad are used to start, stop and pause wash

programs.

Tube Routing

The Blot Washer, reservoir bottles, and blot containers can be placed

in many different configurations depending on available lab space.

Lengths of supplied tubing are initially generous enough to accommodate different configurations. Once an optimal configuration has

been determined for your lab, you may want to shorten excessively

long tubes for a more organized, orderly appearance.

Figure 3 shows tubing connections for a standard configuration that

can be used to wash blots in one blot container. Tube routing is

shown for the wash bottle, waste bottle and vacuum source, Blot

Washer, and a single blot container connected to the Blot Washer

using the single dispensing harness.

Color Coding

Connectors on the wash bottle, waste bottle, and Blot Washer are all

color coded to facilitate making the correct connections.

Connecting each end of a tube to the same color connector will

lead to correct connections in most cases. The color codes have the

following meanings:

Black: vacuum source Orange: liquid waste

Blue: air pressure source Green: liquid dispensing

7

Figure 3. Standard tubing configuration for one delivery (wash)

bottle and one blot container. Connector color codes are shown.

Air Pressure Tubing

(Blue Luer Lock)

Wash Delivery Tubing

(Green Luer Lock)

Vacuum Tubing

(Black Luer Lock)

Waste Tubing

(Orange Luer Lock)

Western Blot

Incubation Box

or Similar Blot

Container

Wash

Bottle

Waste

Bottle

Delivery

Tubing

Waste

Tubing

Blue

Black

Collet with Delivery and

Aspiration Bits clipped

to the Blot Container

Blot Washer Console

8 CHAPTER 1

System Familiarization and Assembly

Connecting the Waste Removal System

Thick-walled, 1/4” i.d. tubing has been supplied for connecting a

house vacuum source to the black vacuum port (Figure 1) on the

back panel of the Blot Washer. Alternatively, this tubing can be

used to connect the Accessory Vacuum Pump.

The vacuum passes though the console and is available at the black

connector on the lower left side of the Blot Washer front panel

(Figure 2). Connect the black front panel vacuum connector to the

matching black connector on the Waste Bottle. Use the orange

connector to connect waste tubing from the Waste Bottle to the top

connector on the left side of the manifold (Figure 3). The waste

tubing should also be passed through the large Aspiration Solenoid

Valve. Insertion of tubing in solenoid valves is described later in

this chapter. Finally, the waste line is completed by connecting one

end of the single dispensing harness waste tube to the right side

connector on the manifold, and the other end to the aspiration bit

attached to the blot container. Make sure the bottom of the

aspiration bit touches the bottom of the blot container and the

beveled side of the aspiration bit faces the wall of the container.

(The aspiration bit suctions up the blot itself if the beveled side

points to the middle of the blot container.)

Connecting the Wash System

For best performance, place the Wash Bottle above the blot

container. Begin by connecting air delivery tubing from the blue

luer lock on the left side of the Blot Washer front panel (Figure 2) to

the blue luer lock connector on top of the Wash Bottle. Next

connect a wash delivery tube (smaller than the air delivery tubing)

from the green luer lock on top of the Wash Bottle to the middle

connector on the left side of the manifold (Figure 2). The wash

delivery tubing should pass through the Dispense Valve #1. Insertion

of tubing in solenoid valves is described below. Finally, the wash

Loading...

Loading...