Instructions – MEV

OPERATING

INSTRUCTIONS

INS2000GB

2011-12-11

Cryostat

MEV

1

Instructions – MEV

2

Instructions – MEV

3

CONTENTS

1.

INTENDED USE

............................................................

4

2.

SYMBOLS

............................................................

4

3.

SAFETY NO

TES

............................................................

4

4.

COMPONENTS

............................................................

8

5.

SPECIFICATIONS

............................................................

9

6.

UNPACKING AND INSTALLA

TION

............................................................

10

7.

INITIAL OPERATION

............................................................

1

3

8.

OPERATION OF MICROTOME

............................................................

1

9

9. OPE

RATION OF CRYOSTAT

............................................................

28

10

.

CLEANING AND

MAINTENANCE

............................................................

3

2

11

.

SERVICE

............................................................

3

4

12

.

OPTIONAL ACCESSORIES

............................................................

3

5

13

.

WARRANTY

............................................................

3

6

14

.

DISPOSAL

............................................................

3

6

Instructions – MEV

4

1. INTENDED USE

The floor standing open top cryostat MEV is intended for rapid freezing and cutting thin

sections of frozen specimens for professional use in routine and research laboratories in

the fields of biology, medicine and industry.

The system of knife advance operates very reliable from 0.5 to 100 µm with trimming

function up to 300 µm. The quality of cutting of this microtome is increased by the

automatic retraction during the upstroke of the specimen, which avoids rubbing on the

disposable blades or microtome knives. This stops rapid deterioration of the disposable

blade or microtome knife.

2. SYMBOLS

Dangers, warnings and cautions are marked by this symbol

i

Special instructions regarding the operation of the

instrument are marked by this symbol

3. SAFETY NOTES

The SLEE Medical open top cryostat MEV is provided with the following safety features:

MEV

Hand wheel stop

••••

Finger protection for Knife- and blade-holder

••••

The institution which owns the unit and the persons working with the unit, servicing or

repairing it have the responsibility for a hazard-free use.

Instructions – MEV

5

3.1 Hand wheel stop

Always use the finger protection

with the knife-/blade holder and put

hand wheel in stop position

• before working with the

knife or specimen

• before changing the

specimen

• during break time

Hand wheel stop released. Movement.

Hand wheel stop activated. No movement.

The

hand wheel

can be stopped in

any position. For this purpose move

the stop lever towards the centre.

For releasing the stop please turn

the lever towards the outside again.

Instructions – MEV

6

3.2 FINGER PROTECTION

Use the finger protection always

• Before you start any work with

the knife or specimen

• Before changing the specimen

• During work break

Finger protection released.

Finger protection activated.

Instructions – MEV

7

3.3 ELECTRICAL POWER CONNECTION

Do not use any extension lead.

Make sure that electric power is constant:

• This should be examined during installation of the unit by a

competent person

• Use a dedicated fuse for the unit

• Do not connect another unit to the same power circuit.

• Before turning on the instrument, check if the voltage of the mains

supply is identical with the name plate of the unit

3.4 WORKING WITH KNIVES AND DISPOSABLE BLADES

Microtome knives and disposable blades have extremely sharp edges and this can lead

to injuries.

Please be extremely careful when handling microtome knives and disposable blades.

Do not place microtome knives or disposable blades at unsecured areas.

Never position microtome knives or dis

posable blades with the sharp edge

pointing upwards.

Store blades in a covered container. Use a container that has guides to

hold the blades rigid.

Never try to catch a falling microtome knife.

Always insert the specimen first and then the microtome kn

ife or

disposable blade.

To avoid compression or knife marks, ensure that the blade is clean.

Instructions – MEV

8

4. COMPONENTS

The SLEE open top cryostat MEV is provided with the following standard components:

MEV

Basic unit with refrigeration system

••••

Semi-automatic rotary microtome

••••

Operation manual

••••

2x Specimen holder

(1x Ø 22mm; 1x Ø 35 mm)

••••

clear-cut

Brush

••••

Anti-roll plate

Ready to use

••••

1x Bottle cryostat low temperature oil

••••

4x 100 ml CryoGlue embedding medium

••••

1 Box of disposable blades (50 pcs.) or 1

steel knife (16 cm C-profile)

••••

Set of Allen keys

••••

Instructions – MEV

9

5. SPECIFICATIONS

Operating temperature range

+10 °C to +

25 °C

Section thickness setting range

0.5 -

100 µm

Section thickness selection

MEV

0 - 2 µm in 0.5-µm steps

2 - 20 µm in 1-µm steps

20 - 50 µm in 2-µm steps

50 – 100 µm in 5 µm steps

Horizontal specimen advance

28 mm

Vertical specimen stroke

57 mm

Specimen retraction on return stroke

0 – 200 µm; selectable

Dimensions and weight

[width x depth x height]

600 mm

x

680 mm x

1130

mm

Weight

without accessories

110 kg

Specimen orientation, horizontal

8°

Specimen orientation, vertical

8°

Specimen orientation,

z-axis

360°

Trimming thickness

0 – 300

µm, freely programmable

Instructions – MEV

10

6. UNPACKING AND INSTALLATION

6.1 UNPACKING THE INSTRUMENT

In standard design you will receive the unit in a wooden box standing on a wooden

pallet. It is equipped with four rollers and two feet, adjustable in height in the front.

Remove the screws from the wooden box with the head screws screwdriver or battery

screwdriver with insert for head screws.

Option 1

If the unit is near the installation site, remove the front cover of the cooling unit (see

section simple service work) and lift the unit slightly with one hand at the outer edge

and the other hand at the rear edge of the cover, move approx. halfway off the pallet

and lower the front to the ground. After this the unit is lifted at the rear, the pallet is

removed and the rear part lowered to the ground.

Option 2

If the unit has to be transported further the wheelbarrow is useful. Push the

wheelbarrow from the rear under the unit and lift it carefully off the pallet.

Extend the two front feet to stabilize the cryostat in its position by turning the

supporting screws counter clockwise.

For repacking use the original cases. Keep the packing material.

Instructions – MEV

11

6.2 INSTALLATION SITE REQUIREMENTS

The site for installation should meet the following requirements:

• A maximum ambient temperature of 25

°C

• No direct sunlight into the coolin

g chamber

• A minimum distance between wall and rear of the instrument of 10

-

20 cm

should be guaranteed

• A free ventilation of fresh air from underneath the instrument should be

guaranteed

6.2 INSTALLATION

For opening the chamber push the window to the top.

Remove the transport security underneath the specimen holder and position the waste

tray.

After installation, wait at least 4 hours before switching the instrument

on. Failure to comply may result in severe damage to the instrument.

Instructions – MEV

12

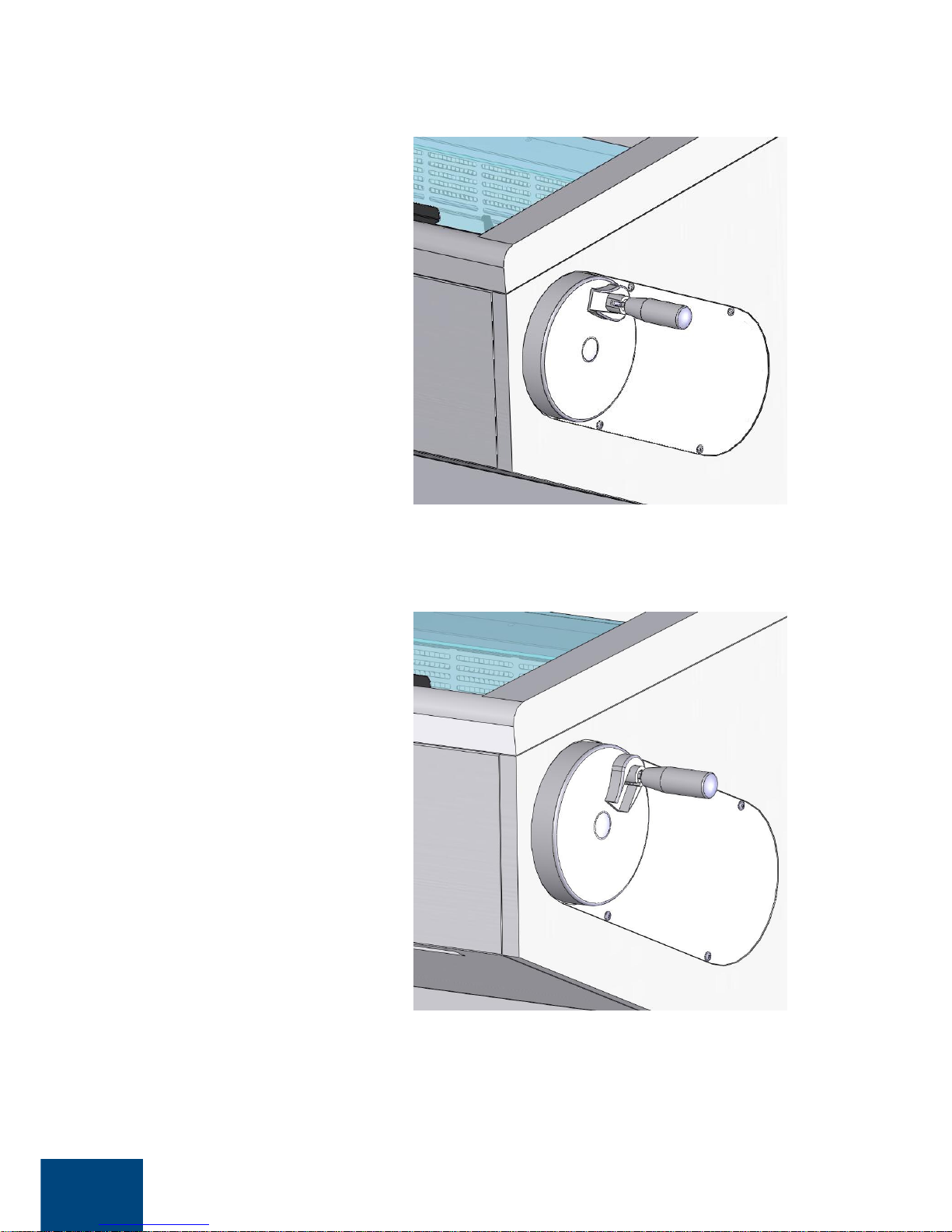

6.3 COLLAPSIBLE HANDWHEEL LEVER

The instrument is delivered with a

ready to use hand wheel lever that

is folded away for transport

reasons.

• Before you start any work

unfold the hand wheel lever

by simply pulling the lever

into a horizontal position.

• For folding the lever back,

pull the horizontally

orientated lever and fold it

away.

Hand wheel lever in folded position.

Hand wheel lever unfolded.

Instructions – MEV

13

7. INITIAL OPERATION

7.1 MAIN DISPLAY

The main display will show the day and time, the

cutting thickness, the trimming thickness, the current

chamber temperature, the target chamber temperature,

the status of the quick-freeze unit (optional) and the

total electronic status of the instrument and a cutting

counter (optional).

TUE 13:05:05

CUT: 7 µm

Trim: 19µm

Cha: -20 °C (-22)

QF: 0

Status:OK 0000

7.2 CONTROL PANEL

Software settings and motor operation can be

operated with the control panel on the left to side of

the instrument.

MEV Control Panel.

Instructions – MEV

14

7.3 SOFTWARE SETTINGS

Press to open the Settings menu.

>

Chamber temp -20 °C

Quickfreeze Off

UV disinfection

Light Auto

To move further down in the main menu list,

press .

Retraction 5 µm

Start defrost

Contrast

>

TIME TUE 13:05:05

To

move further up in the main menu list,

Press .

>

Light Auto

Light duration 10 m

Chamber incr -15 °C

Retraction 5 µm

To change values, select a setting.

Press to open the setting.

Change entries by pressing or .

Store new settings by pressing .

Light duration 10 m

>

Chamber incr -15 °C

Retraction 5 µm

Start defrost

Press to return to the main menu.

TUE 13:05:05

CUT: 7 µm

Trim: 19µm

Cha: 22 °C (25)

QF: 0

Status:OK 0000

Instructions – MEV

15

7.4 AUTOMATIC DEFROST, DISINFECTION AND POWER SAVING SETTINGS

Press to open the Settings menu.

>

Chamber temp -20 °C

Quickfreeze Off

UV disinfection

Light Auto

Select Program settings and press to open the

menu for setting automatic defrost and power saving

times.

TIME TUE 13:05:05

Language English

Display version

>

Program settings 5 µm

Enter PIN Code.

PIN Code is usually restricted to service technicians or

instrument administrators

Enter PIN

0000

Se

lect defrosting programs 1 to 3 and set a time for the

automatic defrosting programme.

(e.g. each day at 12:00 h and at 23:00 h in this

example)

>

Defr. Start 1 12:00

Defr. Start 2 23:00

Defr. Start 3 __:__

Disinf. Req. __:__

Select

temperature increase start and set a starting

time for the automatic power saving mode.

(e.g. start at 21:00 h in this example)

Disinf. delay 10 h

>

Incr. start 21:00

Incr. end 04:00

Incr. days ____56_

Select temperature increase end

and set a ending time

for the automatic power saving mode.

(e.g. end at 04:00 h in this example)

Disinf. delay 10 h

Incr. start 21:00

>

Incr. end 04:00

Incr. days ____56_

Instructions – MEV

16

Select temperature increase days and set the days at

that the automatic power saving mode will be active

for 24 hours.

(e.g. Fridays and Saturdays in this example)

Disinf. delay 12___

Incr. start 21:00

Incr. end 04:00

>

Incr. days ____56_

1-Monday 2-Tuesday 3-Wednesday 4-Thursday 5-Friday 6-Saturday 7-Sunday

Settings for disinfection parameters:

The disinfection cycle works in a semi-automated way.

First select a time when the system will ask for a

disinfection cycle.

(e.g. at 12:00 h the instrument will ask for a

disinfection cycle).

>

Disinfec. Req. 12:00

Disin. Days 12____

Disin. Delay 10 h

Select the days in which a disinfection cycle can be

activated.

(e.g. Monday and Tuesday in this example)

Disinfec. Req. 12:00

>

Disin. Days 12____

Disin. Delay 10 h

1-Monday 2-Tuesday 3-Wednesday 4-Thursday 5-Friday 6-Saturday 7-Sunday

Select the delay time at which the disinfection cycle will

be activated.

(e.g. 10 hours)

After confirmation the disinfection cycle will start at 10

p.m.

Disinfec. Req. 12:00

Disin. Days 12____

>

Disin. Delay 10 h

Instructions – MEV

17

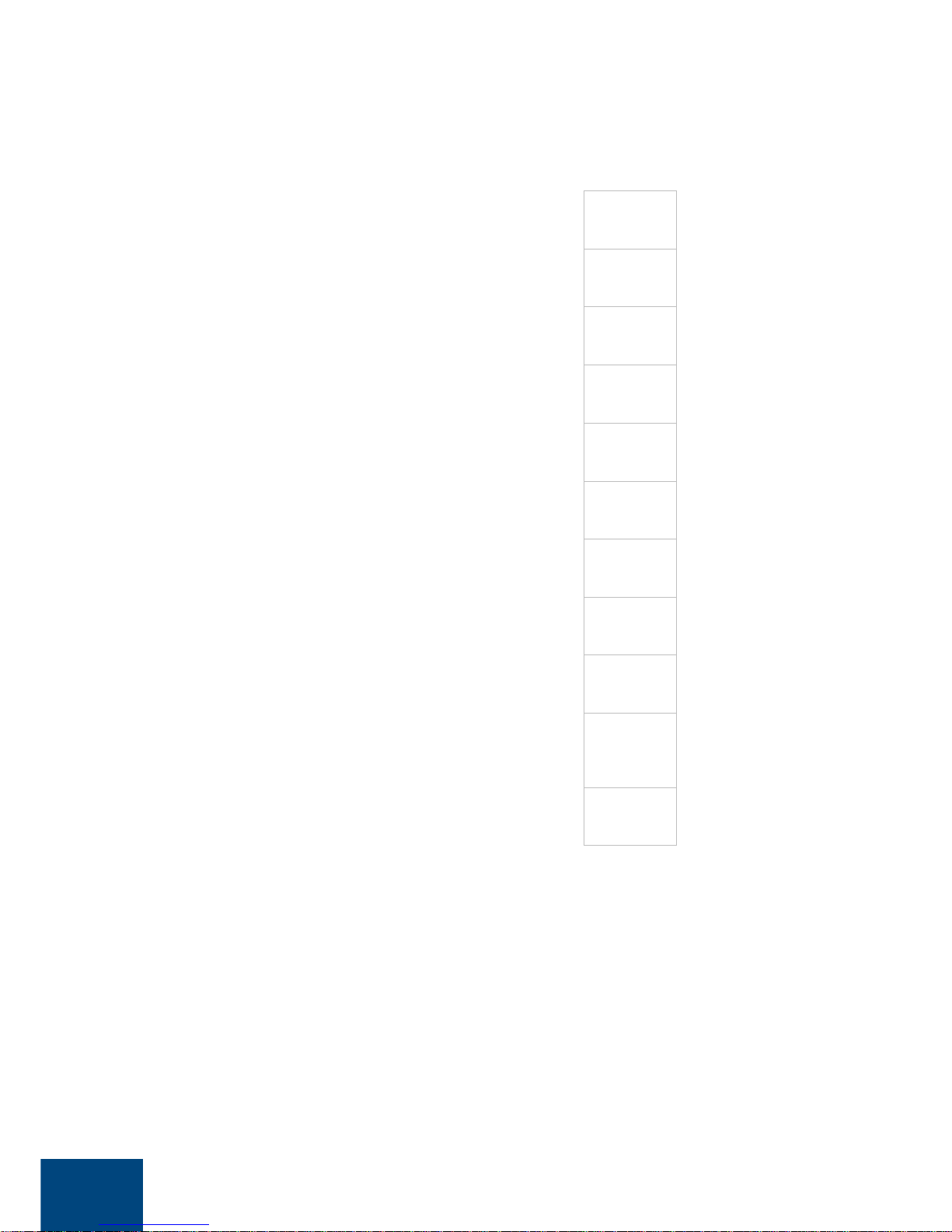

7.5 List of available software settings

Chamber temperature

-35 °C to

ambient

The recommended working temperature is -15 °C to -25 °C

Object cooling

(optional)

ON / OFF

If the instrument is equipped with the optional

object cooling system, its function can be activated

or deactivated.

Object temperature

(optional)

-

50 °C to 0 °C

If the instrument is equipped with the optional

object cooling system, its function can be activated

or deactivated.

Quick

-

freeze

(optional)

ON / OFF

If the instrument is equipped with the optional fast

cooling peltier system, its function can be activated

or deactivated.

The default setting for automatic deactivation of the

quick freeze is set to 30 minutes. The timer for

automatic deactivation can be set by an authorized

service technician.

UV disinfection

(optional)

ON /OFF

If the instrument is equipped with the optional UVC disinfection system, its function can be activated

or deactivated.

The default setting for automatic deactivation is set

to 30 minutes. The timer can be set by an

authorized service technician.

Light

ON / OFF / AUTO

The light can be set on or off. If AUTO has been

selected, the light will switch off after the time

being set under Light duration.

Light duration

0 - 99 minutes

Instructions – MEV

18

Chamber Increase

For power saving, a higher temperature can be set

for defined times and/or days.

The selected temperature should be below 0 °C to avoid

damage to the microtome by freezing moisture.

Retraction

0 -

200 µm

Start defrost

Activate

A manual defrost procedure is activated.

Trim latching

ON/OFF

If Trim latching mode is activated, trimming function

is activated and deactivated by pressing once.

If Trim latching mode is deactivated, trimming

function is activated by continuously pressing .

Contrast

Display contrast

Time

Day and Time

Language

A language can be selected out of a list of available

languages.

Display version

Display of software version.

Program setting

s Upon selecting Program settings the

automatic

defrost and power saving settings can be changed.

Instructions – MEV

19

8. OPERATION OF MICROTOME

8.1 INSERTION AND ORIENTATION OF KNIFE

Activate hand wheel lock.

Loosen the knife fixation by turning

two screws in the front of the knife

holder counter clockwise

Remove/Insert knife

Adjust knife height by turning the

wheels on the left and right side of

the knife holder base.

Tighten the knife fixation by turning

the two screws in the front of the

knife holder clockwise.

Release hand wheel lock for cutting.

Loosening of knife fixation and insertion of new knife.

Fixation and height adjustment of knife.

Instructions – MEV

20

8.2 INSERTION AND ORIENTATION OF DISPOSABLE BLADE

Activate hand wheel lock.

Remove finger protection.

Loosen the blade fixation by turning

the right lever counter clockwise.

Remove/Insert blade from one side.

Tighten the blade fixation by

turning the right lever clockwise.

Loosening of blade fixation and insertion of new blade.

Fixation of blade.

Instructions – MEV

21

For adjusting the cutting angle of

the blade, loosen the blade holder

fixation by turning the right lever on

the blade holder base counter

clockwise.

Set new angle for cutting by turning

the knob in the front of the blade

holder or by manual tilting the

blade holder. A tilt towards the

object holder increases the cutting

angle (clockwise turn of the knob),

a tilt away from the object holder

decreases the cutting angle (counter

clockwise turn of the knob).

Tighten the blade holder fixation by

turning the right lever on the blade

holder base clockwise.

Release hand wheel lock for cutting.

Loosening of blade holder fixation and adjusting new

cutting angle (increased cutting angle).

Fixation of blade holder with increased cutting angle.

Instructions – MEV

22

8.3 SPECIMEN MOUNTING

The instrument is equipped with 24

freezing positions. The temperature

is approx. 10 °C lower than the

actual cryochamber temperature.

In order to prepare a specimen for

sectioning, place the specimen

holder on a freeze point, add some

drops of embedding medium

(e.g.GSV1) on the holder and

carefully press the object on top.

Wait until the object is frozen (mat

surface or pressure).

8.4 INSERTION OF OBJECT HOLDER

Turn hand wheel to its highest

position and activate the hand

wheel stop.

Release the object holder fixation by

turning the fixation lever counter

clockwise.

Remove/Insert object holder.

Tighten the object holder by turning

the fixation lever clockwise.

Release of object holder fixation; removal and/or insertion

of object holder.

Instructions – MEV

23

8.5 SPECIMEN ORIENTATION ADJUSTMENT

Turn hand wheel to its highest position

and activate the hand wheel stop.

For orientation of the specimen, open the

fixing lever.

For upward and downward orientation

use the upper orientation wheel.

For orientation to the left and right use

the left orientation wheel.

Close the orientation fixing lever.

Release hand wheel lock for cutting.

Opening of orientation fixation lever and

orientation of object holder upwards and

downwards.

Orientation of object holder to the left and right.

Fastening of orientation fixation.

Instructions – MEV

24

8.6 FAST APPROACH TO SPECIMEN

Press to move the knife holder base towards the sample.

Press to move the knife holder away from the sample.

8.7 SLOW APPROACH TO SPECIMEN

Press to move the knife holder base slowly towards the sample.

8.8 THICKNESS ADJUSTMENT FOR TRIMMING

To change the trimming settings, press continuously and press or to increase

or decrease the value.

8.9 THICKNESS ADJUSTMENT FOR CUT

To change the cutting thickness, press or to increase or decrease the value.

8.10 TRIMMING OF SPECIMEN

Insert object holder.

Orientate specimen as desired.

Deactivate the hand wheel stop.

Release finger protection.

If Trim latching mode is activated, trimming function is

activated and deactivated by pressing once.

Activation of trimming function is displayed as

illustrated.

TUE 13:05:05

--

TRIM

-- Trim: 19µm

Cha: -20 °C (-22)

QF: 0

Status:OK 0000

If Trim latching mode is deactivated, trimming function is activated by continuously

pressing .

Activation of trimming function is displayed as illustrated above.

Turn hand wheel evenly clockwise

Instructions – MEV

25

8.11 MANUAL CUTTING

Deactivate the hand wheel stop.

Release the finger protection.

Turn hand wheel evenly clockwise.

A counter clockwise movement will also result in cutting and incremental advance of the specimen.

Approach specimen either by trimming or slow approach.

Set the required section thickness. Change entries by

pressing or . The selected section thickness is

indicated in the display.(e.g. 7 µm in this example)

TUE 13:05:05

CUT: 7 µm

Trim: 19µm

Cha: -20 °C (-22)

QF: 0

Status:OK 0000

Turn hand wheel until some even sections have been obtained.

Clean the microtome knife or disposable blade (always away from the cutting edge)

with a cold brush.

Position anti-roll plate onto the microtome knife or disposable blade and cut. If

necessary readjust the height of the guide plate.

Leave hand wheel with handle at its lowest point (specimen holder underneath the

microtome knife or disposable blade).

Transfer the section onto a slide.

i

Leave brush always in the chamber to keep it cold.

Instructions – MEV

26

8.12 ANTI-ROLL PLATE

Each instrument is equipped with

an anti-roll plate.

To adjust the height of the anti-roll

plate turn the wheel to the left or

right.

For pick up of the samples turn the

anti-roll plate side wards with the

help of the knob.

Height adjustment of anti-roll plate.

i

For height adjustment of the anti-roll-plate it is recommended to

adjust the correct height during cutting.

Instructions – MEV

27

8.13 TIPS AND TRICKS

It is common knowledge that the temperature of the cryostat plays an important role in

the quality of the tissue sections obtained. Each type of tissue needs a different

temperature as shown in the following list. The temperature ranges indicated in the

table below are approximate values and may require adjustments for individual tissues.

Type of Tissue

Recommended temperature range at

the knife or blade edge [°C]

Bone marrow -16 to -25

Brain -7 to -10

Breast with fat -25 to -30

i

For tissue, which has to

be cut considerably

below normal chamber

temperature (e.g. fatty

tissues) and in order to

avoid cooling artefacts,

an additional bench top

CO2 freezer is available.

Exceptionally freezing

spray can be used.

Breast without fat -16 to -20

Cartilage -13 to -20

Fat -30 to -40

Heart -20 to -25

Intestinal -13 to -20

Kidney -13 to -20

Larynx -13 to -16

Lip -10 to -20

Liver -7 to -13

Lung -13 to -20

Lymph-Node -13 to -20

Lymphatic -13 to -20

Lymphoid -13 to -20

Muscle -13 to -20

Nose -13 to -20

Rectal -13 to -20

Scrapings -16 to -25

Skin with fat -16 to -25

Skin without fat -10 to -16

Spleen -7 to -10

Testicle -10 to -13

Tongue -13 to -20

Uterine-Curettings -7 to -10

Instructions – MEV

28

9. OPERATION OF CRYOSTAT

9.1 UVC DISINFECTION

[only applicable to instruments equipped with this feature]

UV-C radiation at 254 nm has an intense germicidal effect. Microorganisms, such as

viruses, bacteria, fungi and yeasts are effectively destroyed in the area accessible to UV

light without the addition of chemicals.

The cryostat MEV can be equipped with an UVC light source that can either request

activation in defined periods (see section 7.3) or is manually activated.

The default setting for the UVC light duration and the automatic deactivation is set to

30 minutes. The timer can be set by an authorized service technician.

i

For safety reasons UVC lig

ht will be deactivated upon opening of the

lid of the cryochamber. The UVC disinfection will be aborted and has

to be activated again for surface disinfection.

The default setting for automatic deactivation is set to 30 minutes.

The timer can be set by an authorized service technician.

9.2 QUICK FREEZE POSITION

[only applicable to instruments equipped with this feature]

For convenience of the user, the cryostat MEV can be equipped with a quick freeze shelf

with two positions located in the object freezing shelf. Upon activation the installed

peltier element will cool down the two quick freeze position to approximately -55 °C.

The quick freeze shelf can be activated as described in section 7.2.

i

The default setting for automatic deactivation of the quick freeze is

set to 30 minutes. The timer for automatic deactivation can be set by

an authorized service technician.

Instructions – MEV

29

9.3 HEAT EXTRACTOR

[only applicable to instruments equipped with this feature]

For a more rapid freezing process with

improved structural preservation of tissues

and a flattened block surface, the

instrument can optionally be equipped

with an heat extractor.

Apply the heat extractor on top of the

specimen during the freezing process.

Heat extractor without quick freeze positions.

Heat extractor. With quick freeze positions.

i

Use of the heat extractor can lead to changed orientation of the

specimen in the frozen block, especially for smaller samples.

If precise orientation of the specimen is required, the freezing procedure

should be performed without the heat extractor.

Instructions – MEV

30

9.4 AUTOMATIC/MANUAL DEFROST

For optimum performance of the cooling unit a low thermal contact resistance at the

cooling lamella is required. Upon frequent use of the instrument moisture will

condensate and freeze on the surface of the cooling lamella and increase the thermal

contact resistance. To avoid further build-up of the ice film, automatic defrosting cycles

can be performed.

During an automatic defrost or an manual activated defrost hot gas from the cooling

system is pressed through the evaporator. All ice which has built up is melted, the water

drops into a heated tray below of the evaporator and from there it flows into a tray with

hot tubes and evaporates inside the instrument.

The defrost will last till the system reaches a temperature of +20°C on the evaporator.

The temperature inside the chamber is still below 0°C so that samples can be left on the

cooling bar.

i

The default setting for automatic defrost is set to 00:00 o’clock

(midnight) each day. For changing the settings, please refer to section

7.3.

Instructions – MEV

31

9.5 COMPLETE DEFROST OF THE INSTRUMENT

It is highly recommended to completely defrost the instrument at least every 6 months.

If the instrument is used regularly in warm tropical climate a more frequent complete

defrost might be necessary.

Turn hand wheel to its highest position and

activate the hand wheel stop.

Remove samples and tools from the

cryochamber.

Switch off the instrument

Place a container at the flexible outlet hose to

collect all the melt water.

Remove the rubber plug at the right backward

of the cryochamber.

Dry the inside of the cryochamber completely.

Switch on the instrument.

Flexible hose to drain out melt water.

Removal of rubber plug in cryochamber.

i

Before

starting a complete defrost of the instrument, assure that all

samples have been removed from the cryochamber.

Before switching on the instrument ensure that the instrument is

completely dry, otherwise ice built up can damage mechanical parts.

Instructions – MEV

32

10. CLEANING AND MAINTENANCE

10.1 CLEANING

The recommended frequency of cleaning of the cryostat chamber depends on how

frequently the instrument is used.

Wear protective clothing and disposable gloves according to Good

Laboratory Practices.

Please take note of the safety aspects of the instrument.

Do not use acetone or xylene for cleaning the unit. Only use alcoholic

media.

Never spray or use cleaning medium directly onto the touch panels.

10.2 DISINFECTION

Spray disinfection with alcohol-based disinfectants is applicable without removing the

microtome from the cryochamber. When disinfecting the instrument, take appropriate

protective measures (gloves, mask, protective clothing, etc.).

Wear protective clothing and disposable gloves according to Good

Laboratory Practices.

When using detergents and disinfectants please comply with the safety

precautions of the disinfectant manufacturer!

The integrated anti-roll plate of the blade holder can be cleaned with

alcohol.

Dispose of waste liquid according to the waste disposal regulations!

Do not turn the instrument on before the cryochamber and the

microtome are completely dry otherwise ice built up can damage

mechanical parts.

All components removed from the cryostat must be carefully dried before

returning them to the cryochamber!

Instructions – MEV

33

10.3 RECOMMENDED MAINTENANCE AND SERVICE SCHEDULE

Daily

Remove frozen section waste from the cryostat chamber after every day

of usage.

Disinfection if necessary.

Weekly

Cleaning of blade holder (see section 10.3).

Cleaning of window.

Monthly

Check of temperature sensor in cryocha

mber.

Cleaning of cryostat ventilation (see section 10.4).

Yearly

Complete Service

(performed by authorized SLEE service technician)

• check of all functions

• complete defrost

• removing of microtome

• oiling of movable parts

• check of cooling system

• check of driving system

• complete disinfection / cleaning / drying

10.4 CLEANING OF CRYOSTAT VENTILATION

During usage of the instrument dust will

deposit on the ventilation of the cooling

unit. This can negatively affect the cooling

performance of the instrument.

Remove dust from the ventilation grill on

the right and left side of the instrument

with a regular vacuum cleaner monthly.

Cleaning of cryostat ventilation with vacuum

cleaner.

Instructions – MEV

34

11. SERVICE

Internal components should only be serviced by technicians authorized by SLEE.

If technical service or spare parts are necessary, please contact your local SLEE Medical

distributor. Please have the following information available:

• Complete contact details

• Type of instrument and serial number

• Place of instrument and name of user

• Purpose of service call

• Delivery date of the unit

If it is necessary to return the instrument, it must be cleaned and disinfected before

delivery. It must be returned in its original packing.

If the instrument or parts thereof are sent back in a dirty or non-disinfected condition,

SLEE reserves the right to return the parts to the debit of the customer.

Instructions – MEV

35

12. OPTIONAL ACCESSORIES

Standard Knife Holder

#10156010

Disposable Blade Holder (low profile)

#10157005

Disposable Blade Holde

r (high profile)

#10158005

2x Quick freezing positions

# 10159000

UV disinfection

# 10169000

Cutting counter

#10090020

Heat extractor

#33000316

Object holder (Ø 22 mm)

#30000002

Object holder (Ø 35 mm)

#30000000

Object holder (Ø 50 mm)

#30000003

Cork plate (

100

pcs.; Ø 20 mm)

#30001001

CryoGlue e

mbedding medium (

4x 125 ml)

#30001100

clear-cut

Brush

#30001030

Anti

-

roll plate

(disposable blade holder)

#32001050

Anti

-

roll plate (standard knife holder)

#32001049

Disposable blade (low

profile; 50

pcs.)

#28407000

Disposable blade (high profile; 50

pcs.)

#28408000

Freezing spray (173 g)

#30001010

Cryostat low temperature oil (50 ml)

#30001011

Bench top CO

2

freezer

#10100002

Instructions – MEV

36

13. WARRANTY

SLEE Medical GmbH guarantees that the product delivered has been subjected to a

comprehensive quality control procedure, and that the product is faultless and complies

with all technical specifications and/or agreed characteristics warranted.

SLEE Medical GmbH guarantees that the instrument is manufactured under an ISO 9001

quality management system.

Unauthorized modification or repair by third party persons will void the warranty.

Only original SLEE spare parts must be used.

Guarantee claims can be put forward only if the instrument is used according to this

manual and for the purpose described.

Mistakes and errors which occur because of improper use cannot be accepted.

14. DISPOSAL

The instrument or parts of the instrument must be disposed of according to existing

local applicable regulations.

SLEE

medical GmbH

Carl-Zeiss-Str. 49

55129 Mainz / Germany

Tel. +(49) 61 31/9 58 71-0

Fax +(49) 61 31/9 58 71-722

mail@slee.de

http://www.slee.de

Loading...

Loading...