Page 1

his manual must be left with owner and should be

T

ung on or adjacent to the boiler for reference.

BOBCAT

h

DIRECT-VENT SEALED COMBUSTION CONDENSING BOILER

HOT WATER MODELS B-120A and B-200A

GAS-FIRED BOILERS FOR NATURAL AND L.P. PROPANE GASES

INSTALLATION AND OPERATING INSTRUCTIONS

TABLE OF CONTENTS

Dimensions, Rating and Orifice Sizes ........................................2

Identification of Parts..................................................................3

Installation Requirements ...........................................................4

Contamination Prevention...........................................................5

Mounting the boiler on a wall......................................................6

Venting Application .....................................................................6

Boiler Room Air Supply and Ventilation......................................6

Non-Direct Vent Installation ........................................................6

Flue Gas Venting Requirements.................................................7

Additional Installation Requirements for Massachusetts............7

Vent and Air Intake Material .......................................................8

PVC/CPVC Pipe General Assembly Method..............................8

Vent and Air Intake Restrictions .................................................8

Sidewall Venting, Non-Direct Vent ............................................10

Vent Termination Location and Clearance ................................10

Non-Direct Vent Vertical Venting...............................................10

Direct Vent Installation ..............................................................10

Sidewall Venting, Direct Vent ....................................................10

Vent/Air Intake Termination Installation.....................................16

Direct Vent, Venting and Air Intake through a Roof ..................17

Venting and Air Intake Regular Inspection ...............................18

Condensate Removal System..................................................18

Gas Piping ................................................................................18

Electrical Wiring........................................................................19

Wiring Diagram.........................................................................20

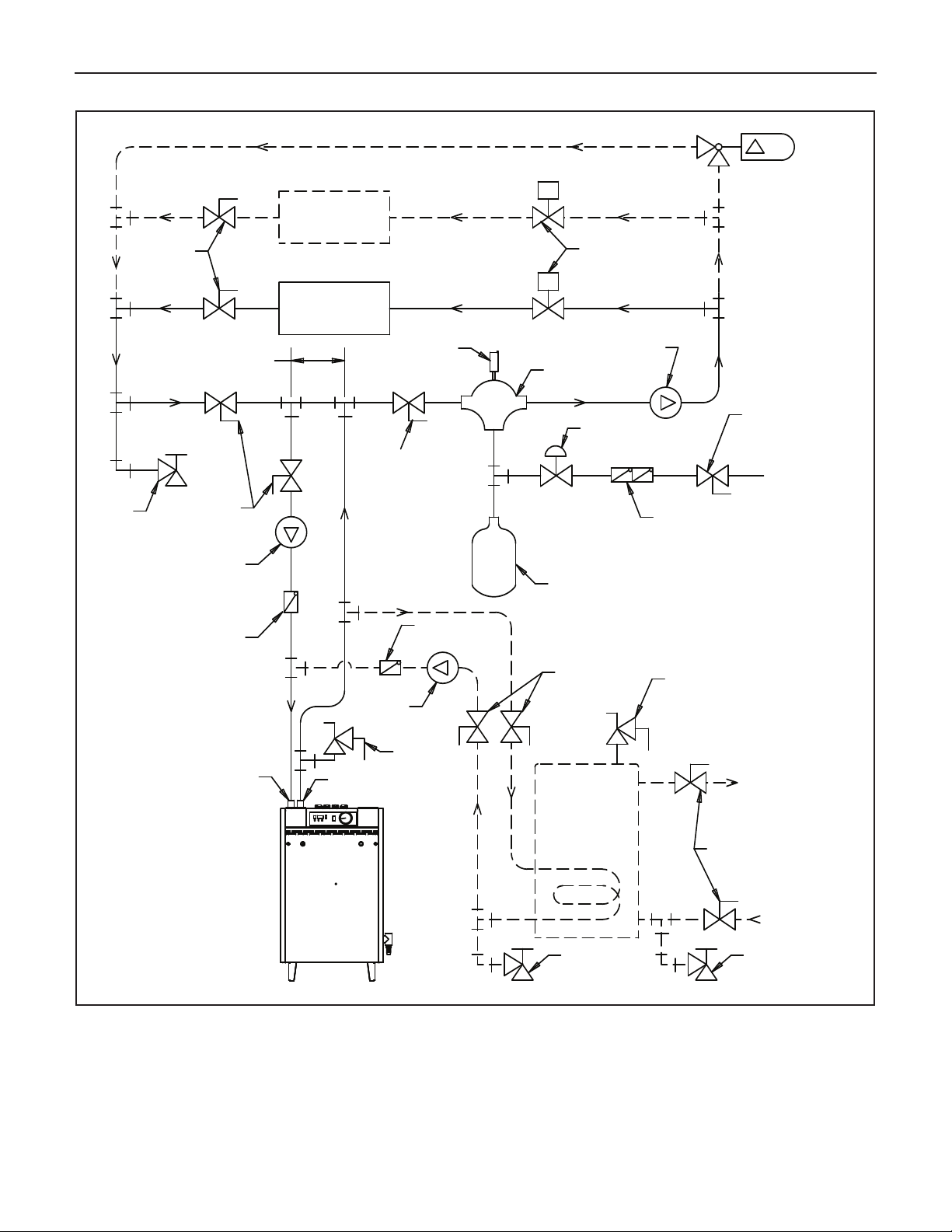

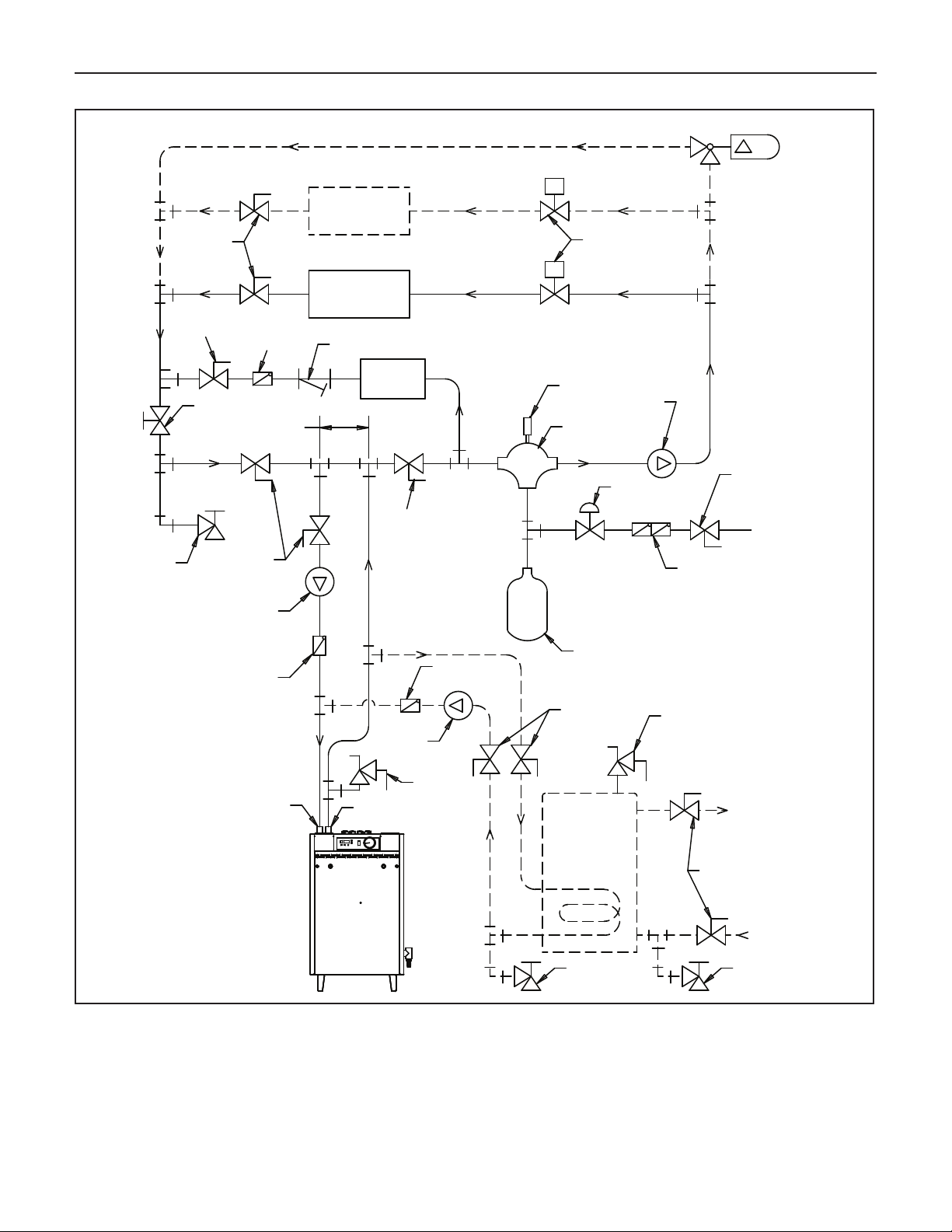

Single and Multi Zoning............................................................22

Water Piping .............................................................................24

Operating Instructions...............................................................30

Boiler Control Display...............................................................30

Boiler Control

Sequence of Operation

Gas Input Rate Adjustment ......................................................37

Safety Check ...........................................................................38

Care and Maintenance .............................................................41

General Troubleshooting Guide ................................................42

version to Propane.............................................................43

Con

............................................................................30

.............................................................36

READ ALL OF THE FOLLOWING

WARNINGS AND STATEMENTS

INSTALLATION INSTRUCTIONS

Installation location ONLY as permitted in paragraph

entitled "LIQUEFIED PETROLEUM (L.P.) PROPANE

GAS-FIRED BOILER LOCATION" on page 5 of this

instruction book.

The above warning does not apply to

gas fired boilers.

The installation must conform to the requirements of

the authority having jurisdiction or, in the absence of

such requirements, to the National Fuel Gas Code,

ANSI Z223.1-latest edition. The installation must also

conform to the additional requirements in this Slant/Fin

Instruction Book.

In addition where required by the authority having jurisdiction, the installation must conform to American

Society of Mechanical Engineers Safety Code for

Controls and Safety Devices for Automatically Fired

Boilers, No. CSD-1.

IMPORTANT

BEFORE READING THE

WARNING

LIQUEFIED PETROLEUM (L.P.)

PROPANE GAS-FIRED BOILERS

NATURAL

WARNING

The venting system of this boiler is under positive pressure.

Leakage from this system can be hazardous and if not avoided

can result in death or serious injury. In addition to the recommendations within this manual and the User’

venting system, from the flue collector to the outdoor discharge,

must be carefully checked annually by a qualified service agency.

Heating Contractor

Address

Phone Number

Printed in U.S.A. 808 Part No. 86-5756000 Publication No. BA-40

s Information Manual, the

This boiler

installed, connected, serviced and repaired by a

ained, e

tr

precautions required f

licensed or otherwise qualified, in compliance with the

authority having jurisdiction.

, gas piping and accessories must be

ienced service technician, f

xper

Boiler Model Number

Boiler Serial Number

Installation Date

WARNING

amiliar with all

or gas-fired equipment and

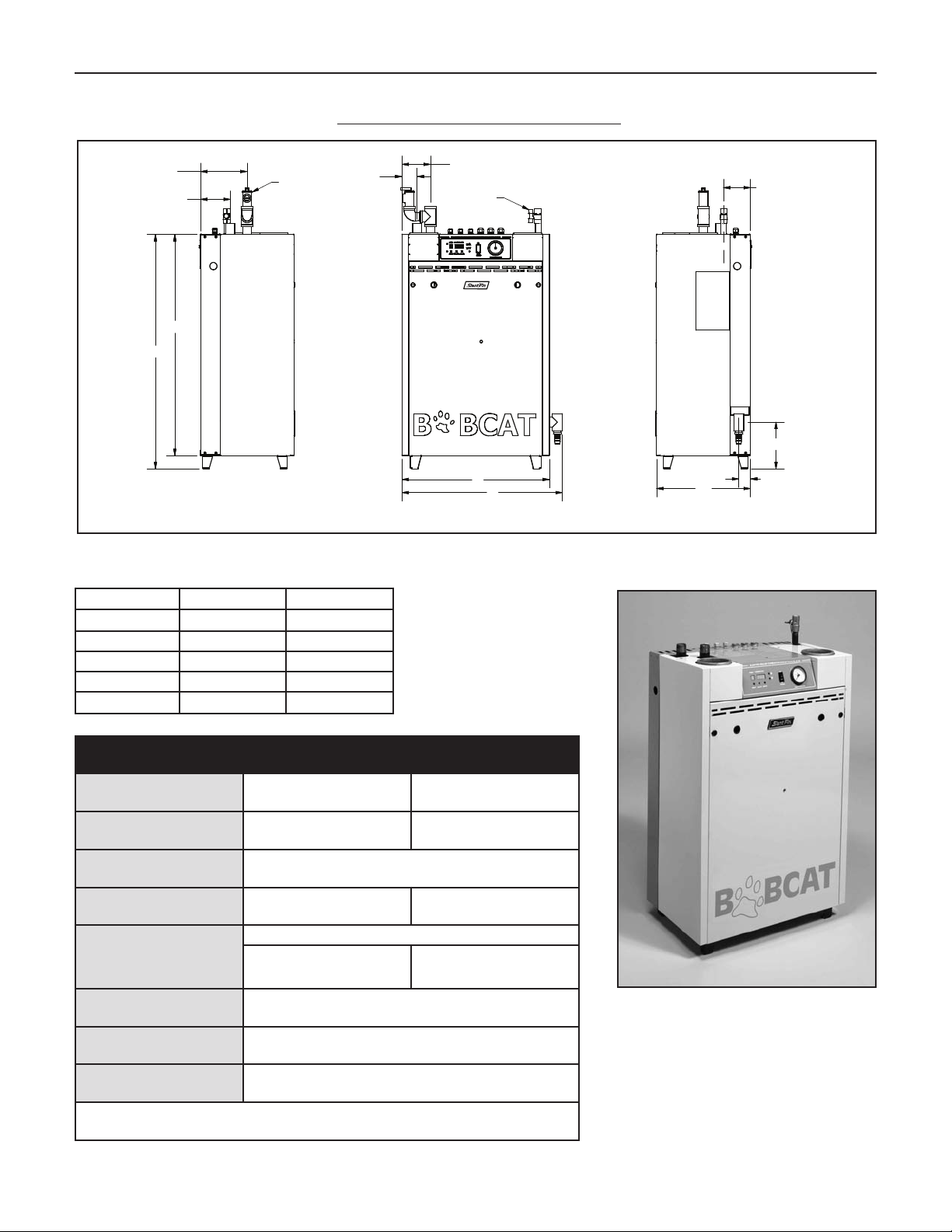

Page 2

FRONT

LEFT SIDE

RIGHT SIDE

7

41/2

D

C

21/4

4

1/4

B

A

1

4

13/4

E

4

GAS

SHUTOFF

VALVE

PRESSURE

RELIEF

VALVE

2

Bobcat Models B-120A and B-200A

RATINGS AND DIMENSIONS

Figure 1. Dimensions data

Dimension B-120A B-200A

A 22 30

B 23 7/8 31 7/8

C 33 38

D 35 40

E 7 10

SPECIFICATIONS:

Fuel Rate Input:

Boiler Water Volume:

Water Piping

Connections:

Weight of Boiler

(uncrated):

Gas orifice siz

Gas Piping Connection:

Vent Connection:

B-120A Boiler B-200A Boiler

120,000 BTUH max

30,000 BTUH min

1.0 gallon (8.3 lbs) 1.4 gallon (11.07 lbs)

145 lbs. 200 lbs.

1” NPT (male)

Natural Gas - No or

e:

Propane - .2025” inside

diameter

**

1/2” NPT (female)

pipe (PVC

nominal I.D

3”

.

200,000 BTUH max

50,000 BTUH min

ifice used*

Propane - .2600” inside

diameter

**

, CPVC or stainless steel)

Bobcat Boiler

Air Intake Connection:

No or

*Note:

**See page 42 f

3” nominal I.D. pipe (PVC, CPVC or stainless steel)

ifice changes are required f

or conversion procedure to propane.

or high altitude installations

.

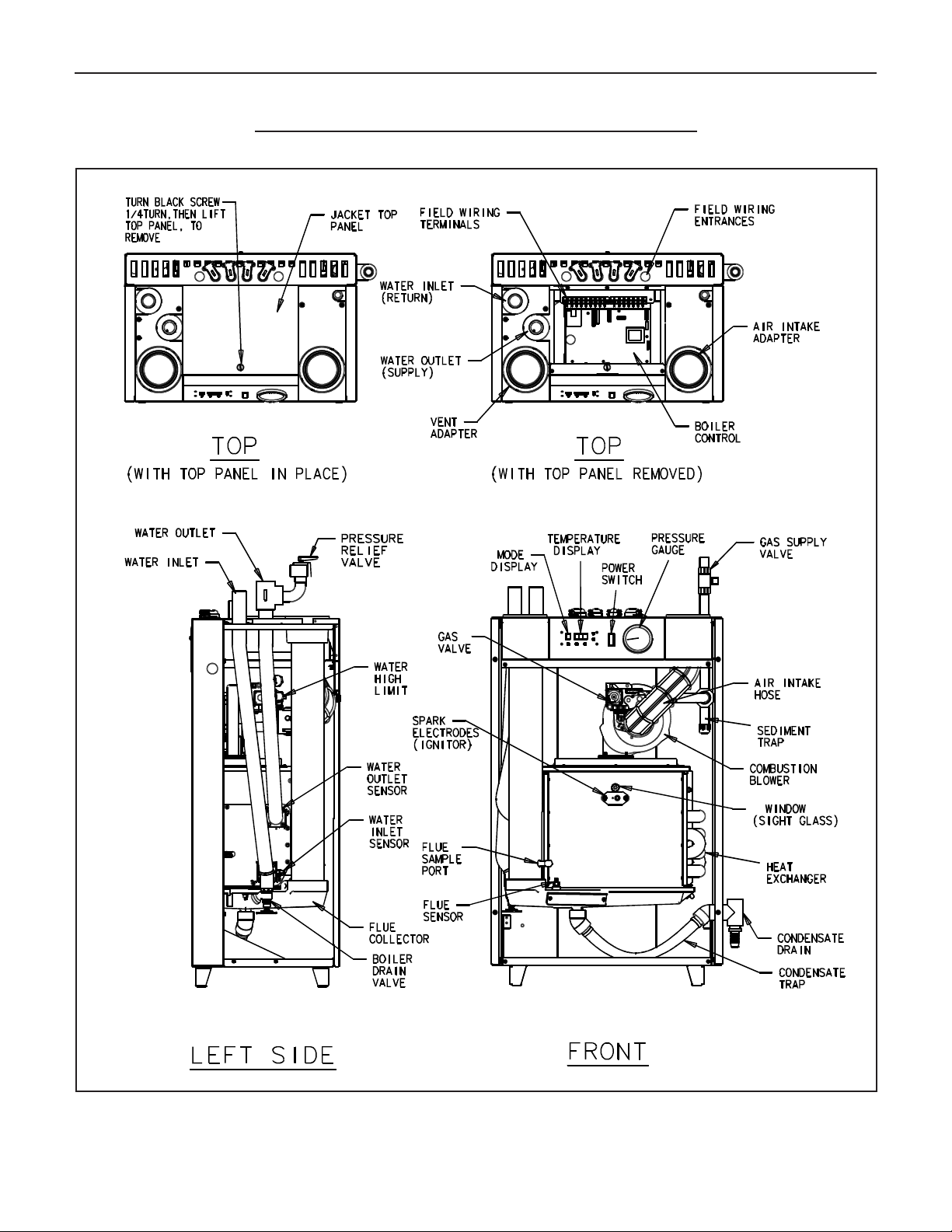

Page 3

Bobcat Models B-120A and B-200A

LOCATION AND IDENTIFICATION OF PARTS

3

Figure 2.

Location and identification of parts (model B-120A is shown)

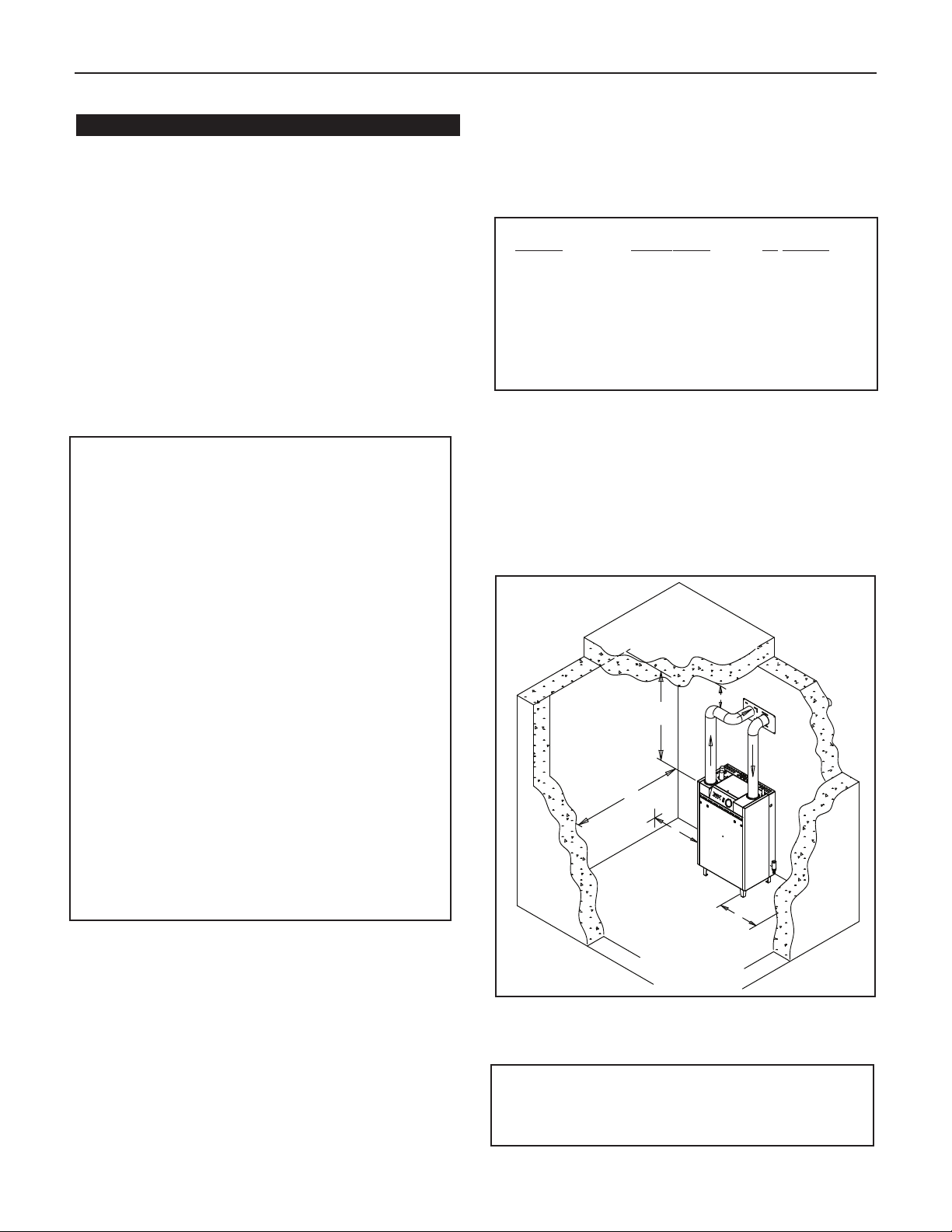

Page 4

4

: 2" FOR ENCLOSED

*

1"

3"

6"

*

2"

2"

Bobcat Models B-120A and B-200A

INSTALLATION REQUIREMENTS

The installation must conform to the requirements of the

authority having jurisdiction or, in the absence of such

requirements, to the National Fuel Gas Code, ANSI Z223.1latest edition.

This installation must also conform to the additional require-

ents in this Slant/Fin Instruction Book.

m

BOILER LOCATION

Provide a level, solid foundation or vertical wall for the boiler.

Location should be as near as possible to chimney or outside

wall so that the flue pipe from boiler is short and direct. (See

paragraph heading “Vent Termination Location and Clearance” on page 9.) The location should also be such that all

boiler components are protected from water (dripping, spraying, rain, etc.) during appliance operation and service (circulator replacement, control replacement, etc.).

WARNING

LIQUEFIED PETROLEUM (L.P.) PROPANE GAS-FIRED

BOILER LOCATION

REQUIRES SPECIAL ATTENTION

Liquefied Petroleum (L.P.) propane gas is

Therefore, propane boilers, piping, valves should NOT be

installed in locations where propane leaking from defective

equipment and piping will "pool" in a basement or other

space below the leak.

A spark or flame from the boiler or other source may ignite

the accumulated propane gas causing an explosion or fire.

Provide a level, solid foundation for the boiler. Location

should be as near the chimney as possible so that the flue

pipe from boiler to chimney is short and direct.

The UNIFORM MECHANICAL CODE may be in effect in

your geographic area.

The following precautions are cited by the 1994 UNIFORM

MECHANICAL CODE, section 304.6:

"LPG Appliances. Liquefied petroleum gas-burning

appliances shall not be installed in a pit, basement or

similar location where heavier-than-air-gas might collect.

Appliances so fueled shall not be installed in an abo

grade under-floor space or basement unless such location is pro

unbur

Consult Chapter 5 of the 1994 UNIFORM MECHANICAL

CODE f

remov

BOILER FOUNDA

A. Provide a solid, level foundation or vertical wall capable of

suppor

xtending at least 2" past the jac

e

dimensions of boilers, page 2. See also figure 4a & 4b for

mounting the boiler on the wall.

Boiler can be installed on both comb

.

B

non-comb

above carpeting.

C. If boiler is to be located over buried conduit containing

electric wires or telephone cables, consult local codes or

the National Board of Fire Underwr

requirements.

vided with an approv

ned gas."

or design criter

al of unbur

ned gas

ting the w

le floors, but must NOT be installed on or

ustib

ia of the "approv

.

TION

eight of the boiler filled with w

ed means for remo

heavier than air.

val of

le and

or

ater

, and

ed" means f

ket on all sides. See

ustib

or specific

iters f

ve-

MINIMUM CLEARANCES FROM COMBUSTIBLE

CONSTRUCTIONS

. Minimum clearances to the exterior surfaces of the boiler

A

shall be as follows:

INIMUM ALCOVE AND CLOSET CLEARANCE

M

or Combustible Recommended

F

Surf

ace Construction for Service

ront 6" 18"

F

Rear 0" 0"

Left Side 2" 8"

Right Side 2" 8"

op 3" 18"

T

Flue Connector:

Enclosed — 2" 6"

Uninclosed — 1" 6"

B. Provide accessibility clearance of 8" on sides requiring

servicing and 18" on sides used for passage.

C. All minimum clearances shown above must be met. This

may result in increased values of some minimum clearances in order to maintain the minimum clearances of

others.

D. Clearance from hot water pipes shall be 1 inch**.

t points where hot water pipes emerge from a floor,

** A

the clearance at the opening through the finished floor boards or wall

or ceiling boards may be not less than 1/2 inch. Each such opening

shall be covered with a plate of uncombustible material.

Figure 3. Bobcat boiler min. clearances for combustible

construction.

SAFETY

THE BOILER AREA CLEAR AND FREE FR

KEEP

COMBUSTIBLE MATERIALS, GASOLINE AND OTHER

FLAMMABLE VAPORS AND LIQUIDS.

wall or ceiling,

OM

Page 5

Bobcat Models B-120A and B-200A

CONTAMINATION PREVENTION

The combustion air supply must not be susceptible to contamination sources, whether the combustion air comes from the

interior or exterior of the building. Contaminated air can cause

orrosion or other damage to the heat exchanger and compo-

c

nents of the boiler, causing failure of these parts or unsafe

operation.

Below is a list of products and areas which may cause

contaminated combustion air:

PRODUCTS TO AVOID

• Spray cans containing chloro/fluorocarbons

• Permanent wave solutions

• Chlorinated waxes/cleaners

• Chlorine-based swimming pool chemicals

• Calcium chloride used for thawing

• Sodium chloride used for water softening

• Refrigerant leaks

• Paint or varnish removers

• Hydrochloric acid/muriatic acid

• Cements and glues

• Antistatic fabric softeners used in clothes dryers

• Chlorine-type bleaches, detergents, and cleaning

solvents found in household laundry rooms

• Adhesives used to fasten building products and other

similar products

5

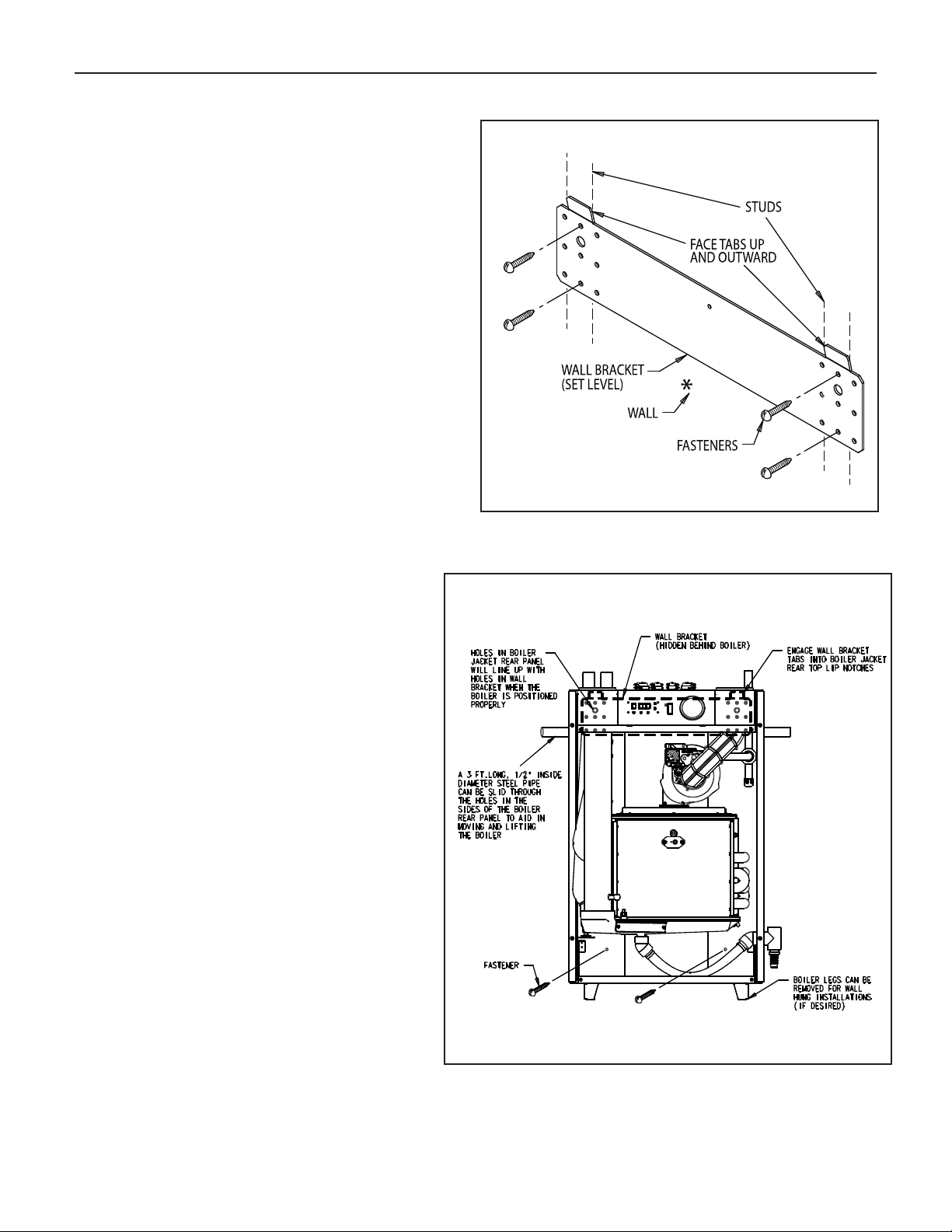

Figure 4a. Wall bracket securement

AREAS LIKELY TO HAVE CONTAMINANTS

• Dry cleaning/laundry areas and establishments

• Swimming pools

• Metal fabrication plants

• Beauty shops

• Refrigeration repair shops

• Photo processing plants

• Auto body shops

• Plastic manufacturing plants

• Furniture refinishing areas and establishments

• New building construction

• Remodeling areas

• Garages with workshops

Figure 4b. Mounting boiler on the wall

Page 6

6

MOUNTING THE BOILER ON A WALL

Be sure that the wall is vertically plumb and capable of carrying

the weight of the boiler and the system piping, when full of

water. See page 2 for the boiler weight.

e sure that there are studs available in the proper locations,

B

for securing the boiler wall bracket and back panel.

(See Figures 4a and 4b).

For wood stud walls, use lag screws or wood screws with a

coarse thread and a minimum of 3” in length.

For metal stud walls, use toggle-style bolts that are specifically

esigned for such and maximum capacity exceeds the weight

d

of the boiler and the system piping when full of water.

DO NOT use anchors driven into sheetrock to hold the boiler

up on the wall. If mounting the boiler on a cement wall, use

anchors that are specifically designed for such, and maximum

capacity exceeds the weight of the boiler and the system

piping, when full of water.

A. INSTALL THE WALL BRACKET. SEE FIGURE 4a.

1. Remove the wall bracket from the boiler jacket rear panel,

by unfastening the single screw that holds it in place, for

shipping purposes only.

2. Select the location on the wall where the boiler will be

mounted. The upward facing tabs of the wall bracket will

align with the top surface of the boiler jacket, and 3 feet of

open wall space will be needed to accommodate the boiler

jacket rear panel below this.

Bobcat Models B-120A and B-200A

. Lift the boiler up against the wall, with the top edge of the

4

acket slightly above the wall bracket tabs. There are 2

j

holes in the upper corners of the jacket rear panel, that

can visually be aligned with the 2 larger diameter holes in

the wall bracket, to ensure that the wall bracket tabs line

up and engage with the boiler jacket near top lip notches

properly.

. There are 2 fastener holes in the lower area of the boiler

5

ear panel, just below the flue collector, for insuring the

r

oiler does not move off the wall bracket. Mark these 2

b

holes, with the boiler in place, then lift the boiler off the wall

bracket.

6. Determine which fastener type will best engage with the

wall construction at the location of the 2 market holes. Drill

out the appropriate diameter and depth holes for the

fasteners, where marked.

7. Lift the boiler up onto the wall bracket again, as described

in Step 4. Secure the boiler to the wall, with the 2 fasteners

in the lower rear panel area.

8. If able to, the 1/2” diameter lifting pipe should be removed

from the boiler rear panel.

9. The 4 boiler legs may be removed at this time, if desired. 2

screws hold each leg in place, from inside the jacket

panel.

10. The boiler side panels can be replaced at this time, but the

front panel should be left off, for the startup procedure

later in the installation.

3. For sheetrock and stud construction, locate the studs and

determine which set of holes in the wall bracket best align

with the center of the studs. For cement walls, determine

a location for the wall bracket to mount where the anchors

will be secure, devoid of seams or cracks.

4. Place the bracket in the selected location, with the 2 tabs

positioned up and facing outward, level it out, and mark

the holes to be used. A minimum of 4 of these holes must

be utilized, regardless of w

5. Drill the appropriate diameter and depth holes for the

fasteners used in the wall, where marked.

6. Fasten the wall bracket to the wall, being sure that the

tabs face upward and outward, and the fasteners have

engaged the w

B. INSTALL THE BOILER ON THE WALL. SEE FIGURE 4b.

1. Remove the boiler jacket front cover, by turning the 2 black

screws 1/4 turn to the open position, then lifting off.

2. Remove both the boiler jacket side panels, by removing

the 2 sheetmetal screws in the top and bottom front edge,

then lift off.

3. To aid in lifting the boiler, a 3 foot long, 1/2” inside diameter

steel pipe can be slid through the holes in the sides of the

boiler rear panel. Let the pipe extend out each side of the

jacket evenly, for hand-holds, and pick up the boiler without

letting it tilt, for safety.

all proper

all material.

ly.

VENTING APPLICATION

The Bobcat B-120 and B-200 are sealed combustion type

boilers, they may be installed and vented either as a direct vent

boiler which all air for combustion is obtained directly from outside or as a non-direct vent boiler which air for combustion is

taken from inside the boiler room.

The Bobcat B-120 and B-200 boilers must be vented by 3"

diameter PVC/CPVC schedule 40 pipe, or the proper 3” diameter stainless steel venting system (see “vent material” on page

7) through the roof or sidewall.

BOILER ROOM AIR SUPPLY AND VENTILATION

An ample supply of air is required for combustion and ventilation. When buildings are insulated, caulked and weatherstripped, now or later on, direct openings to outside may be

required and should be provided. If the boiler is not near an

outside wall, air may be ducted to it from outside wall openings.

Provisions for combustion and ventilation air must be made in

accordance with section 5.3, Air for Combustion and Ventilation, of the National Fuel Gas Code, ANSI Z223.1-latest edi

tion, or applicable provisions of the local building codes. The

following recommendation applies to buildings of energy-saving

construction, fully caulked and weatherstripped.

INSTALLATION IN ENCLOSED BOILER ROOM REQUIRES

O UNOBSTRUCTED OPENINGS FOR PASSAGE OF AIR

TW

INTO THE BOILER ROOM:

-

Page 7

Bobcat Models B-120A and B-200A

7

A. NON-DIRECT VENT INSTALLATION

1. Air drawn horizontally from outdoors DIRECTLY through

n outside wall;

a

ne louvered opening near the floor and

o

one louvered opening near the ceiling, each opening with a

minimum FREE air passage area of

1 square inch per 4000

Btuh of total appliances’ input.

2.

Air drawn horizontally through HORIZONTAL DUCTS;

ne opening near the floor and one opening near the ceiling,

o

each opening with a minimum FREE air passage area of

1

square inch per 2000 Btuh of total appliances’ input.

Air drawn VERTICALLY from outdoors; one opening at the

3.

floor and one opening at the ceiling, each opening with a

inimum FREE air passage area of

m

square inchper 4000

1

Btuh of total appliances’ input.

4.

Air drawn from inside the building; one opening near the

floor and one opening near the ceiling, each opening with a

minimum FREE air passage area of

1 square inch per 1000

Btuh of total appliances’ input.

IF BOILERS ARE INSTALLED ADJACENT TO OTHER FUEL

BURNING EQUIPMENT, THE AREA OF FREE OPENINGS

MUST BE APPROPRIATELY INCREASED TO ACCOMMODATE

THE ADDITIONAL LOAD.

B. DIRECT VENT INSTALLATION

Adequate air supply should be provided to prevent overheating of

the boiler controls and boiler room. Openings for passage of air

into the boiler room for direct-vent installation must be at least

1

⁄2

of the openings required for the non-direct vent as

mentioned above.

If additional non-direct vent appliances are installed in the same

space and adequate air openings are provided for them, there

are no additional air openings required for the Bobcat

B-120 and B-200 boilers.

For both direct and non-direct installation, the following must be

considered:

- Openings must never be reduced or closed. If doors or

windows are used for air supply, they must be locked

open.

- Protect against closure of openings by snow and debris.

Inspect frequently.

No mechanical draft exhaust or supply fans are to be

-

used in or near the boiler area.

- Boiler area must never be under negative pressure.The

w of combustion and v

flo

entilating air to the boiler m

ust

not be obstructed.

FLUE GAS VENTING REQUIREMENTS

The Bobcat B-120 and B-200 series boilers are high efficiency,

mechanically f

enting arrangements than natural draft, lower efficiency boilers.

v

THE FOLLO

READ AND FOLLO

orced draft boilers and, theref

WING INSTR

UCTIONS MUST BE CAREFULL

WED IN ORDER T

ore, require different

VOID ANY HAZ-

O A

Y

ARDOUS CONDITIONS DUE TO IMPROPER INSTALLATION

OF THE AIR INTAKE AND FLUE GAS VENTING SYSTEM.

The vent piping installation MUST be in accordance with these

uctions and with ANSI Z223.1-latest edition NA

instr

TIONAL

FUEL GAS CODE, Part 7, Venting of Equipment. Other local

codes may also apply and must be followed. Where there is a

conflict betw

shall apply

boiler ser

.

ies.

een these requirements

The use of a v

ent damper is NOT permitted on this

, the more str

ingent case

ADDITIONAL REQUIREMENTS FOR THE COMMONWEALTH

OF MASSACHUSETTS

When the Bobcat is installed and used in the Commonwealth of Massachusetts, the following additional requirements pursuant to Massachusetts

code 248 CMR MUST be met:

(1). Exisiting chimneys shall be permitted to have their use continued

when a gas conversion burner is installed, and shall be equipped with a

manual reset device that will automatically shut off gas to the burner in the

event of a sustained back-draft.

(2)(a). For all side wall horizontally vented gas fueld equipment installed in

every dwelling, building or structure used in whole or part for residential

purposes, including those owned or operated by the Commonwealth and

where the side wall exhaust vent termination is less than seven (7) feet

above finsihed grade in the area of the venting, including but not limited to

decks and porches, the following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time

of installation of the side wall horizontal vented fueled equipment, the

installing plumber or gasfitter shall observe that a hard wired carbon

monoxide detector with an alarm and battery back-up is installed on the

floor level where the gas equipment is to be installed. In addition, the

installing plumber or gasfitter shall observe that a battery operated or hard

wired carbon monoxide detector with an alarm is installed on each additional level of the dwelling, building or structure served by the side wall

horizontal vented gas fueled equipment. It shall be the responsibility of the

property owner to secure the services of qualified licensed professionals

for the installation of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented gas fueld equipment

is installed in a crawl space or an attic, the hard wired carbon monoxide

k up may be installed on the next adja-

detector with alarm and batter

cent floor le

b. In th event that the requirements of this subdivision can not be met at

the time of completion of installation, the o

ty (30) days to comply with the above requirements; provided, however,

that dur

detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon

monoxide detector as required in accordance with the above provisions

shall comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3.

mounted to the exterior of the building at a minimum height of eight (8)

feet above grade directly in line with the exhaust vent terminal for the hori-

ontally v

z

read, in print size no less that one-half (1/2) inch in size,

DIRECTLY BELOW, KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the installation unless,

upon inspection, the inspector obser

signage installed in accordance with the provisions of 248 CMR

5.08(2)(a)1 through 4.

(b) EXEMPTIONS. The following equipment is exempt from 248 CMR

5.08(2)(a)1 through 4:

1.

Required TO Be Vented” in the most current edition of NFPA 54 as

adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or str

ing or structure used in whole or part for residential purposes.

vel.

ing said thir

SIGNA

ented gas fueled heating appliance or equipment. The sign shall

The equipment listed in Chapter 10 entitled

ty (30) day period, a battery operated carbon monoxide

A metal or plastic identification plate shall be per

GE.

y bac

es carbon mono

v

ucture separ

wner shall have a period of thir-

manently

“GAS VENT

xide detectors and

“Equipment Not

ate from the dw

elling, build-

Page 8

8

Bobcat Models B-120A and B-200A

ENT AND AIR INTAKE MATERIALS

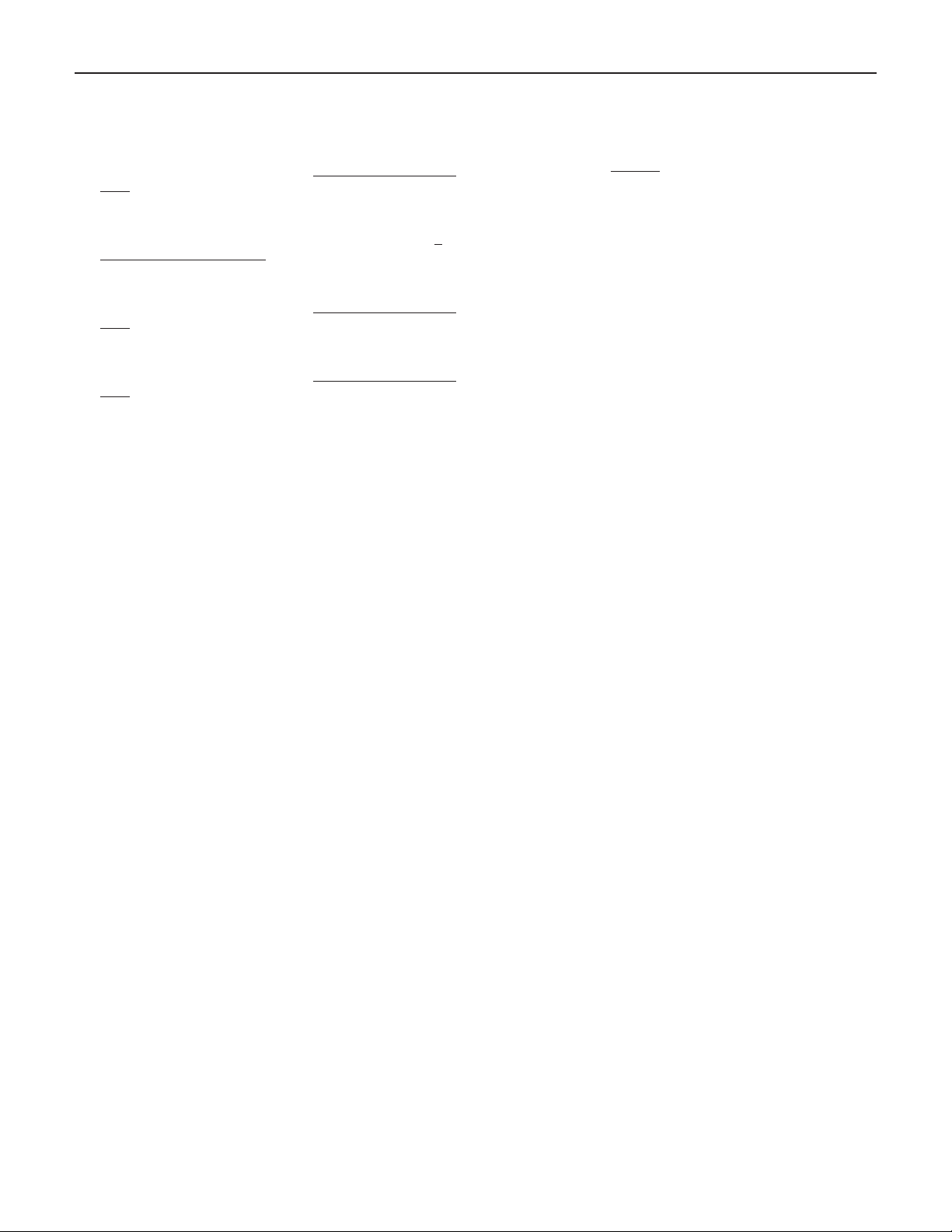

V

The vent and air intake system for direct or non-direct vent

installation must be 3” diameter PVC/CPVC schedule. 40 pipe,

or UL listed single wall 3” diameter AL29-4C* stainless steel

aterial. The following manufacturers’ systems are approved

m

for use within a specified minimum and maximum equivalent

vent length in this manual.

Manufacturer

Heat-Fab. Inc. Saf-T Vent Not Required

ProTech System, FasNSeal Not Required

Inc.

Flex-L StaR-34 GE-IS806

International, Inc.

Z-Flex, Inc. Z-Vent GE, RTV 106

N/A PVC pipe, PVC primer

N/A CPVC pipe, CPVC primer

*AL29-4C is a registered Trademark of Allegheny Ludlum Corp

Type/System

EZ Seal

Schedule 40 and cement

Schedule 40 and cement

Sealant

When joining the various components of the listed stainless

steel vent systems, the manufacturers’ instructions should be

closely followed to insure proper sealing. Use sealant specified

by vent system manufacturer for sealing of pipe and fittings, if

required. When joining the PVC/CPVC pipe and fittings, follow

the instructions provided in this manual. All connections must

be liquid and pressure tight. DO NOT use galvanized flue pipe

or any plastic-type materials other than PVC/CPVC Schedule

40.

The integral adapters on the boiler are designed to accommodate either PVC/CPVC Schedule 40 pipe or the listed stainless

steel vent systems.These adapters have built-in sealing rings,

so no additional sealant is required. Make sure the pipes are

round and burr-free, and push down into the appropriate step

of the adapter, until sn

ug. (See Figure 5).

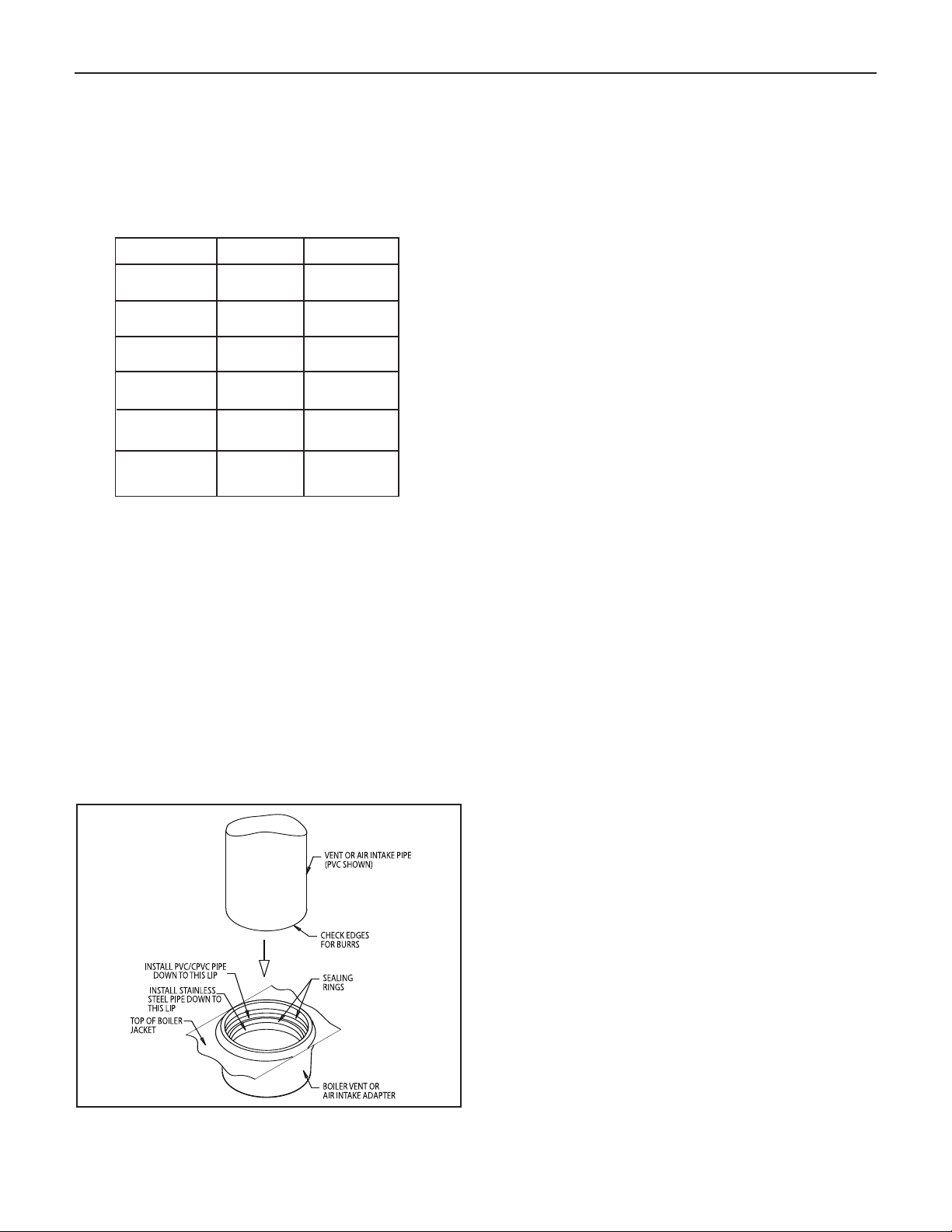

PVC/CPVC PIPE GENERAL ASSEMBLY METHOD

The following are the recommended methods for cutting,

cleaning and connecting PVC and CPVC pipe, for both the

vent and air intake piping system:

1. When laying out the piping system, work from the boiler

vent and air intake adapter to the point of outside

ermination.

t

2. Cut the PVC/CPVC pipe to the required lengths, and

pre-assemble the entire system, before sealing.

Disassembly after sealing, to make any corrections, will not

e possible.

b

3. Once the pre-assembled PVC/CPVC pipe vent and air

intake system is verified to be of the proper length pipe and

fitting orientation, begin disassembling and preparing the

pipes and fittings for the sealing process.This can be done

section by section, or the complete vent and air intake

system can be disassembled. It is recommended to mark

the various parts, before complete disassembly, to

eliminate the possibility of errors during re-assembly.

4. De-burr the inside and outside of every PVC/CPVC pipe, to

ensure that they engage fully into the fittings, and flow is

not compromised. A small chamfer on the outside of each

pipe can particularly aid in the final assembly process.

5. Wipe or knock out any debris from inside the PVC or

CPVC pipe, which may have accumulated there from the

cutting process or storage. Debris can cause operational

problems with the boiler combustion components.

6. Thoroughly clean the outside ends of each pipe, and the

inside of each fitting. The surfaces must be dry for the

sealing agents to work properly. Handle the prepared pipe

lengths away from the cleaned ends, and handle the

cleaned fittings, from the outside, to avoid contamination.

7. Re-assembly of the PVC or CPVC pipe should be done in

sections, to avoid the primer and cement drying before the

parts are engaged.

8. For each joint, first apply a coat of primer to the outside

sealing surface of the pipe and the inside sealing surface of

each fitting. Use only the primer type that is specified for

either the PVC or CPVC pipe that is bing utilized.

9. Before the primer dries, apply a coat of cement over it. A

second coat of cement can be applied, if necessary, but

must be done quickly and in a manner that avoids

unnecessar

uild-up that w

y b

ould cause obstr

the system. Use only the cement type that is specified f

either the PVC or CPVC pipe that is being utiliz

uction inside

or

ed.

10. Before the cement dries, insert the pipe into the fitting. A

slight twisting motion while pushing the pipe into the fitting

will aid in distrib

par

ts fully engage.

uting the cement evenly and ensuring the

11. Quickly wipe the excess cement from the outside areas of

the joint.

Discard an

ags used to a

y r

void later getting the

cement on hands, clothes and equipment.

Figure 5.

Adapter

Vent and Air Intake Pipe installation into Boiler

.

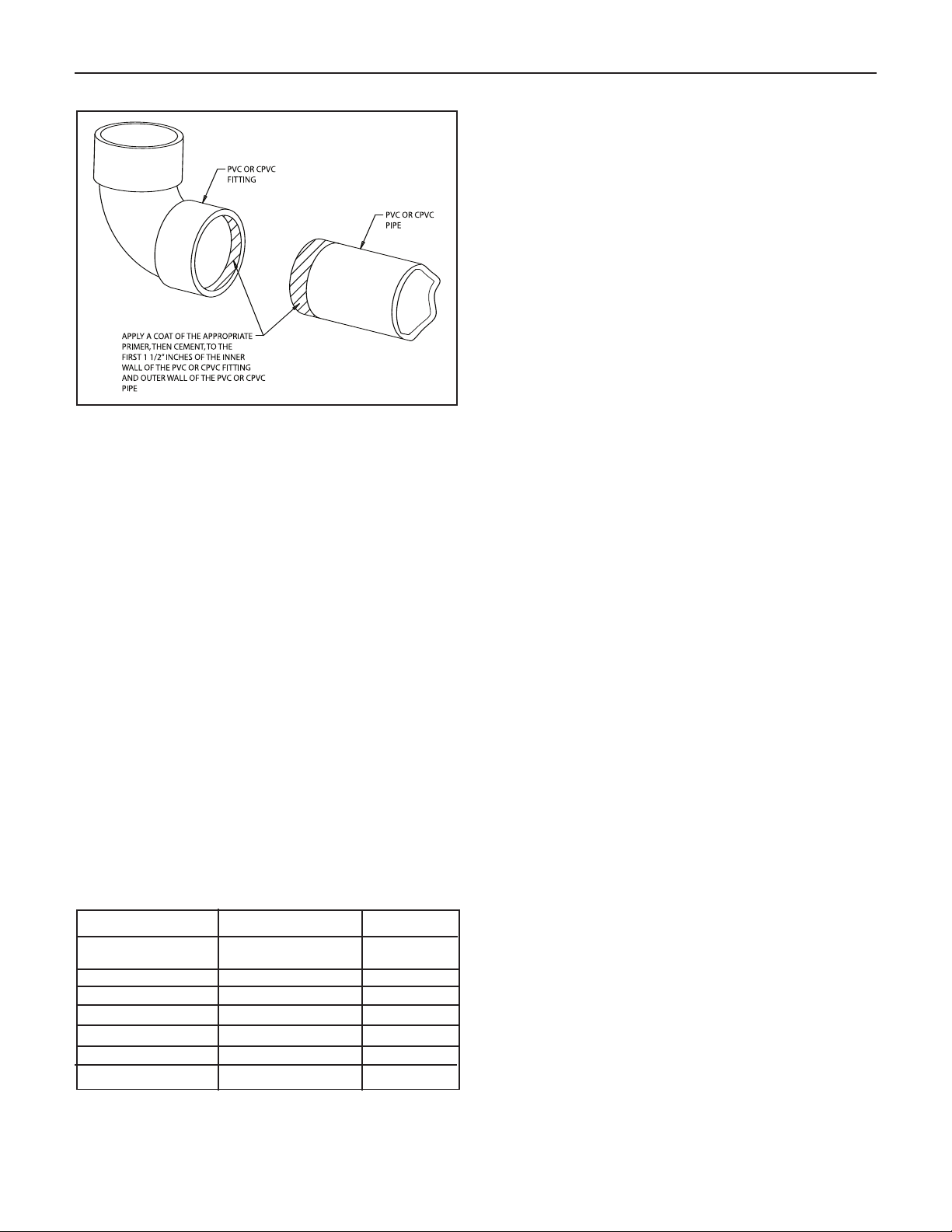

VENT AND AIR INTAKE RESTRICTIONS

1. Maximum allowed equivalent vent and air intake length for

all of the approved vent and air intake materials is 100 feet

for B-120 and 50 feet for B-200.

2. Equivalent of vent or air intake length is sum of the

straight pipe lengths and equivalent length of elbows as

wn in the tab

sho

le on this page.

Page 9

Bobcat Models B-120A and B-200A

Figure 6.

3. The vent termination is in addition to the allowed

equivalent lengths.

4. Minimum vent length is 2 feet of straight pipe, plus the one

90˚ elbow that is required.

5. Vent length restriction is for both direct and non-direct

vent installations.

9

. The B-120 and B-200 boilers are equipped with a built-in

6

ondensation drain and trap.The trap must be filled with

c

water. DO NOT operate the boiler without filling the trap with

water to prevent flue gas discharge into space. The drain

must dispose of possibly large quantities of condensate,

which may require a neutralizing system. Refer to the

“Condensate Drainage” section of this manual. No additional

condensation drain and trap is required on the vent piping

system itself.

. The horizontal vent pipe must be sloped upward from the

7

boiler at a pitch of at least 1/4” per 1 foot of run, so that

the condensate from the vent system runs to the boiler

vent adapter pipe, then out the built-in condensation drain

and trap.

8. The horizontal vent and air intake pipes must be supported

with pipe straps, at intervals no greater than 5 feet, when

PVC/CPVC pipe is utilized. This support spacing applies

also to stainless steel vent pipe, unless the manufacturer’s

instructions permit otherwise. The vertical vent and air

intake pipes also must be supported, wherever the building

construction provides allowance for it, such as ceiling or

roof passage openings where a firestop and support or

braces can be affixed.

9. Minimum clearances of vent pipes from combustible

constructions must be maintained (see Page 4). No

clearance is required between the vent and air intake pipes

of this boiler.

EXAMPLE: Boiler model B-120 is to be installed. The

combustion air is provided by air intake piping directly to the

boiler (direct-vent installation). The vent piping will be PVC

and installation location will require the use of 4 elbows for

the vent to run the termination. The air intake piping will also

be PVC, and also will require the use of 4 elbows.

In this case, the maximum straight pipe vent length that can

be utilized with the 4 elbows would be: 100’ - (4’ x 5’) = 80’.

Since the air intake pipe also is PVC and requires the use of

4 elbows, the maximum straight pipe air intake length that

can be utilized is also 80 feet.

If the air for combustion were taken from the boiler room

(non-direct vent installation), still the maximum straight vent

length would be 80 feet.

Equivalent Length of Various 90-Degree Elbows

Manufacturer

, Inc. Saf-T Standard 3

ab

Heat-F

Heat-Fab, Inc. Saf-T, tight radius elbow 6

ech System, Inc.

ProT

Flex-L International, Inc. StaR-34 6

Z-Flex, Inc. Z-Vent 6

N/A PVC, Schedule 40 5

N/A

ype/System

T

elbow

asNseal

F

, Schedule 40

CPVC

Equivalent

Length (Feet)

6

5

10. Common venting with other appliances or another Bobcat

boiler is not allowed.

11. DO NOT install a vent damper or similar devices in vent

system or on the boiler.

12. DO NOT insulate venting system.

Page 10

10

Bobcat Models B-120A and B-200A

VENTING INSTALLATION

Only PVC/CPVC and approved stainless steel materials listed

on page 8 may be used for the venting system installation. If

stainless steel vent systems are used, follow the manufactur-

r’s instructions, in conjunction with these instructions.

e

I. Non-Direct Vent Installation

The air for combustion is taken from the ambient air

surrounding the boiler; therefore, ample supply of air is required

for combustion and ventilation (see page 7.)

DO NOT use this installation method if the surrounding of the

boiler is contaminated. See page 5 for the list of harmful

contaminants and their sources, to avoid.

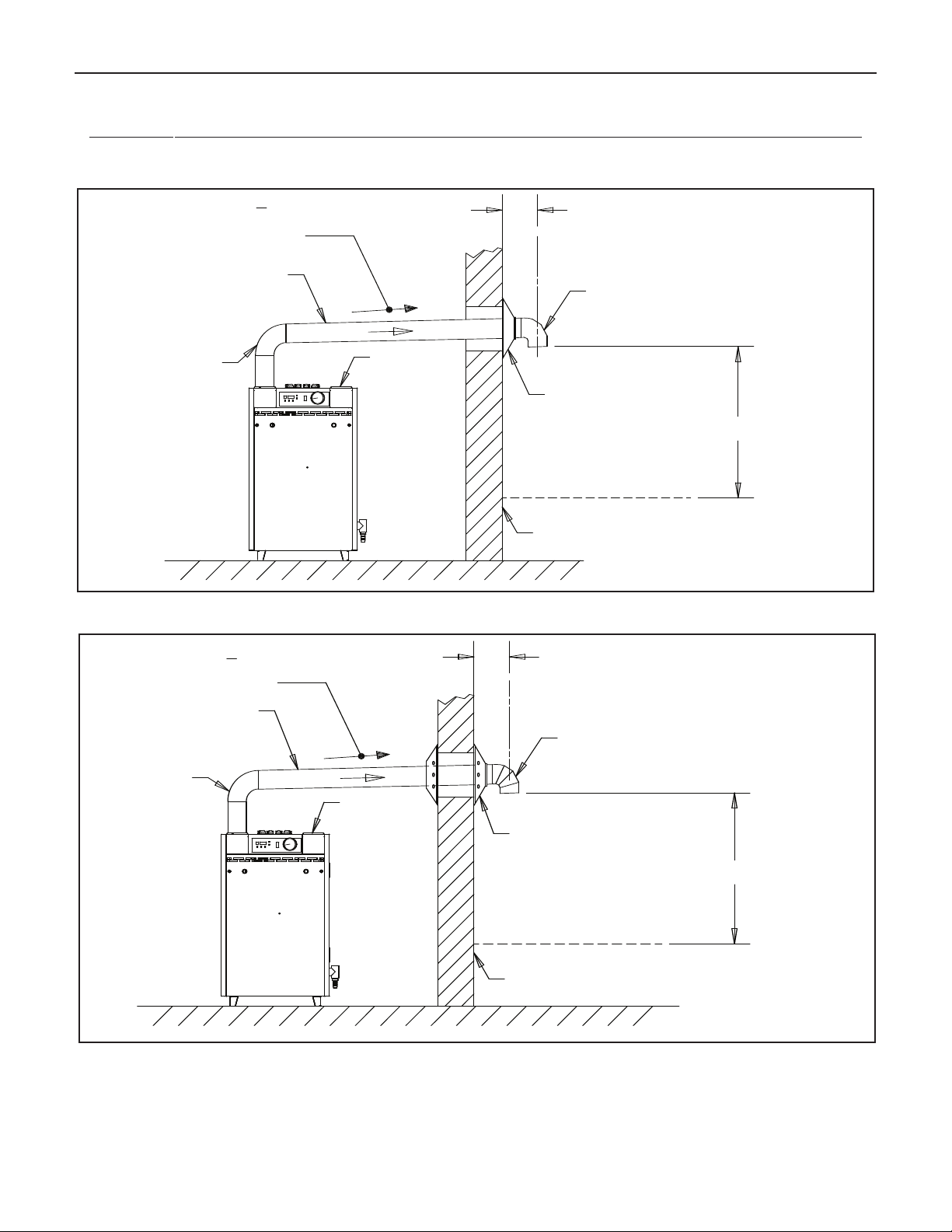

A. SIDEWALL VENTING - NON-DIRECT VENT

Figures 7 and 8 show typical horizontal sidewall venting. For

combustible wall passage of vent piping, a UL listed thimble

or flashing and sealing boot must be used, providing the wall

thickness from 3" minimum up to 12" maximum. The vent

piping must terminate with a screened tee or elbow termination

facing down.

CAUTION: Flue gasses exiting from the vent terminal will

condense. Building materials in the area of the vent terminal

should be protected from discoloration and degradation.

VENT TERMINATION LOCATION AND CLEARANCES

1. The venting system shall terminate at least 3 feet above

any forced air inlet located within 10 feet.

2. The venting system shall terminate at least 12 inches

below or 12 inches horizontally from any door, window

or gravity air inlet into any building.The bottom of the vent

terminal or air intake terminal shall be at least 12 inches

above grade or the normal snow level whichever is

greater.

3. Through the wall vents shall not terminate over public

walkways or over areas where condensate or vapor could

create a nuisance or hazard or could be detrimental to

the operation of regulators, relief valves or other equipment. Minimum clearance of 4 feet horizontal distance is

maintained, from electric meters, gas meters, regulators

and relief equipment.

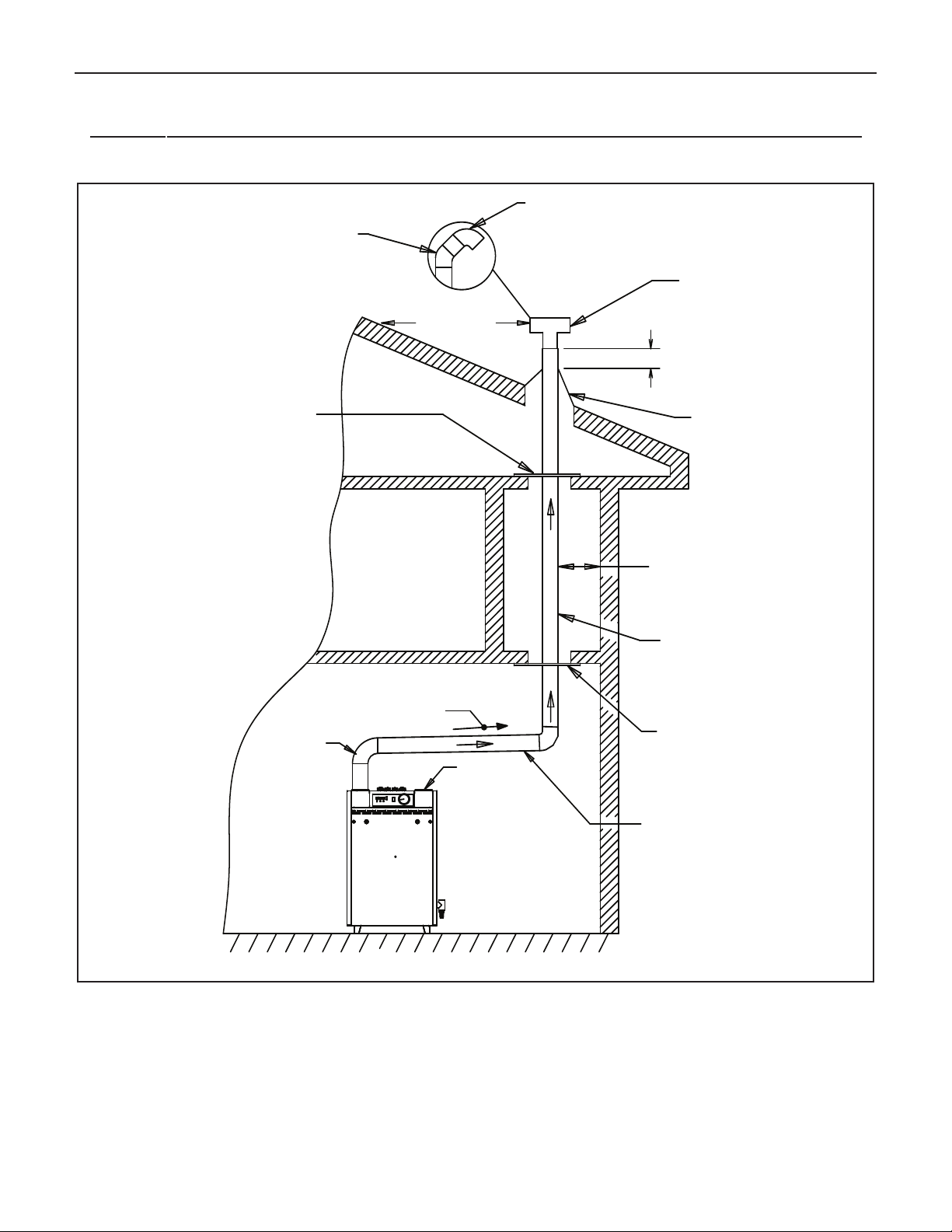

B. NON-DIRECT VENT - VERTICAL VENTING

Figure 9 shows typical venting through the roof.The vent pipe

must pass through the ceiling, floor and the roof vertically

hrough a 6" minimum diameter cutout. A fire stop is required

t

or each ceiling and floor penetration. For roof passage, an

f

appropriate UL listed roof flashing must be used.

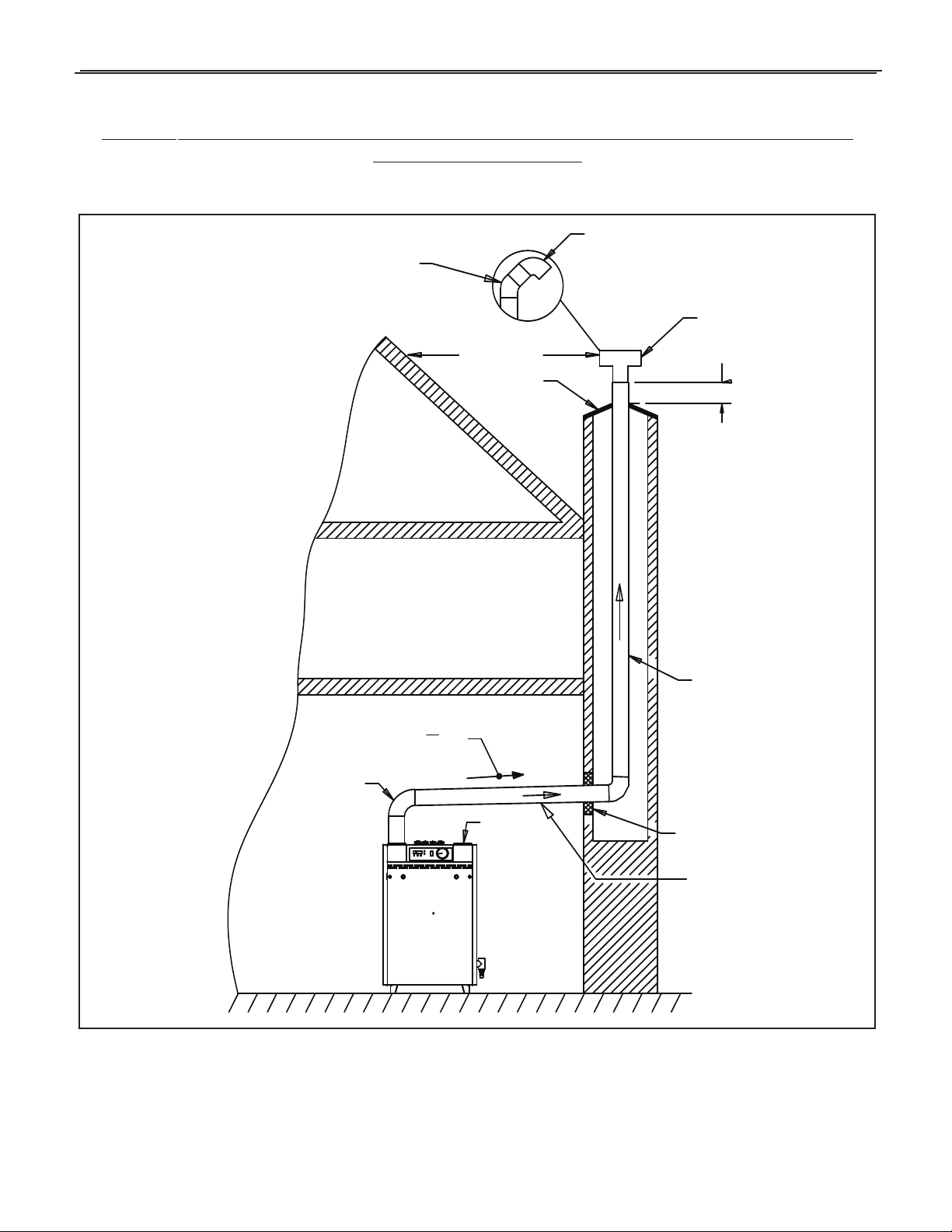

An existing chimney (see Figure 10) may be used as a chase

for vertical venting. Other appliances CANNOT be vented into

the same chimney or vent pipe within the chimney.

The vertical vent piping must terminate with a screened tee,

ombination of 45˚ elbow and a 90˚ screened elbow termina-

c

tion or a rain cap termination.

II. Direct Vent Installation

Air intake piping from outside to the boiler air intake adapter

provides the air for combustion.The boiler surrounding may be

contaminated (See page 5). Piping the air intake to the outside

can prevent contaminants from the boiler surrounding from

entering the combustion air supply.

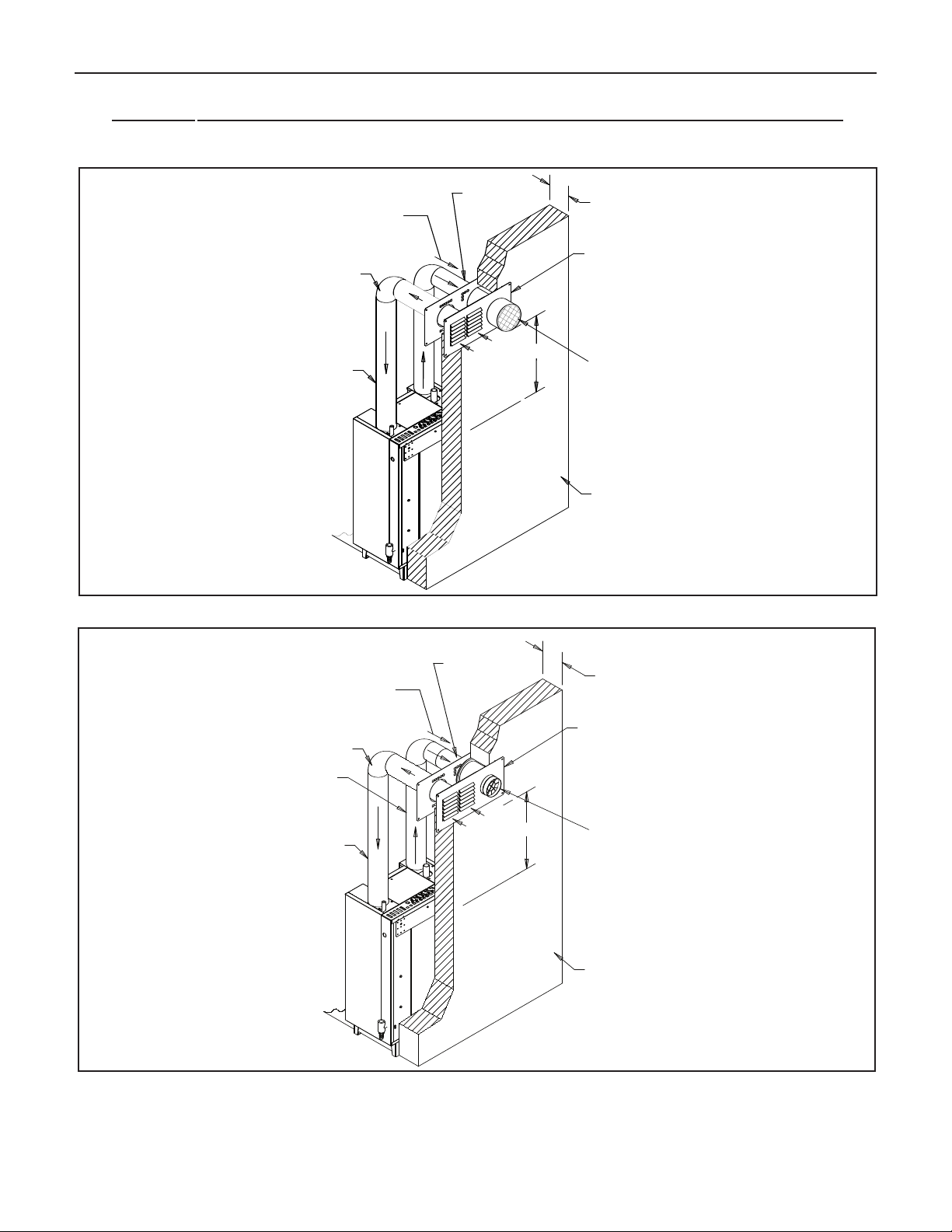

A. SIDEWALL DIRECT VENTING

Figures 11 and 12 show typical sidewall direct venting, using a

Slant/Fin vent/air intake termination. There are 2 different models of vent/air intake termination available. One is designed

specifically for PVC/CPVC venting, and the other is designed

specifically for stainless steel venting systems. Only these 2

models of vent/air intake termination are approved for this

method of installation. Refer to the Slant/Fin Bobcat B-120 and

B-200 boilers Parts List (publication number B-10PL) for the

appropriate model for the vent material to be used.

CAUTION: Flue gasses existing from the vent terminal will condense. Building materials in the area of the terminal should be

protected from discoloration and degradation, in addition to the

requirements of the vent termination location and clearances

stated in this manual.

4. Vent termination must not be located in any confined

space (i.e.

any overhang or deck.Vent termination should not allow

flue gas discharge towards neighbor’s windows or where

personal injury or property damages can occur.

window w

ells

es, narrow alleys) or under

v

, alco

Page 11

Bobcat Models B-120A and B-200A

9 IN. MAX.

6

IN. MIN.

A

IR INTAKE

(DO NOT BL0CK)

O

UTSIDE WALL

SLOPE UP 1/4 IN.

PER FOOT MIN.

F

ROM BOILER TO

V

ENT TERMINATION

12" MIN

SNOW LINE

(

SEE DEFINITION)

T

ERMINATION 90˚ ELBOW

WITH SCREEN

90˚ ELBOW

S/FP/N 440695 (ADJUSTABLE

3 IN. DIA.

PVC/CVPC

P

IPE FOR

V

ENT

A U/L LISTED FLASHING

AND SEALING BOOT MUST

B

E USED ON COMBUSTIBLE

WALLS.

9 IN. MAX.

6 IN. MIN.

AIR INTAKE

(DO NOT BL0CK)

OUTSIDE WALL

SLOPE UP 1/4 IN.

PER FOOT MIN.

FROM BOILER TO

VENT TERMINATI ON

12" MIN

SNOW LINE

(SEE DEFINITION)

OUTSIDE VENT TERMINATION

90˚ ELBOW WITH SCREEN

STAN DARD

90˚ ELBOW

S/FP/N 440695 (ADJUSTABLE

3 INCH. DIA.

STAINLESS

STEEL VENTING

MATE RIAL FOR

VENT

A U/L LISTED WALL THIMBLE

MUST BE USED ON COMBUSTIBLE

WALLS. S/F P/N 440695

(ADJUSTABLE 5 IN.TO 8 IN.)

MAY BE USED. ABOVE THIMBLE

MUST BE USED WITH HEAT-FAB

SLIP JOINT CONNECTOR

BOBCAT MODELS B-120 and B-200 NON-DIRECT VENT, SIDEWALL VENTING

All joints must be liquid and pressure tight. Use 3” dia. PVC/CPVC schedule 40 pipe or U/L listed single wall 3" dia.

AL29-4C S.S.*. venting materials (See page 7).

11

Figure 7. Non-direct vent, side wall venting - utilizing PVC/CPVC pipe for venting.

Figure 8.

** Definition of Sno

Non-direct vent, side wall venting - utilizing stainless steel vent materials for venting.

wledge of local conditions will re

Kno

w Line:

The height should be used as the SNOW LINE.

AL 29-4C IS A REGISTERED

*

TRADEMARK OF ALLEGHENY LUDLUM CORP

eal the maxim

v

.

um height that repeated sno

alls accumulate to.

wf

Page 12

12

1 FT MIN.

SLOPE UP 1/4 IN.

PER FOOT MIN.

2" MIN

3 IN. DIA. PVC/CPVC

PIPE OR STAINLESS STEEL

VENTING MATERIAL FOR VENT

1

0 FT. MIN

RAIN CAP TERMINATION MAY BE USED

AIR INTAKE

(DO NOT BLOCK)

3 IN. DIA. PVC/CPVC

PIPE OR STAINLESS STEEL

VENTING MATERIAL FOR VENT

90˚ ELBOW

FIRESTOP AND

SUPPORT

F

LASHING AND

STORM COLLAR

VENT TERMINATI ON

TEE WITH SCREEN

90˚ TERMINATION

ELBOW WITH SCREEN

FIRESTOP AND

SUPPORT

ALTERNATE VERTICAL TERMINATION

45˚ ELBOW

*

*

Bobcat Models B-120A and B-200A

BOBCAT MODELS B-120 and B-200 NON-DIRECT VENT, VENTING THROUGH A ROOF

All joints must be liquid and pressure tight. Use 3” dia. PVC/CPVC schedule 40 pipe or U/L listed single wall 3" dia.

AL29-4C S.S.*. venting materials (See page 7).

Figure 9. Bobcat models B-120 and B-200 - non-direct vent, venting through the roof

AL 29-4C IS A REGISTERED TRADEMARK OF ALLEGHENY LUDLUM CORP

*

.

Page 13

Bobcat Models B-120A and B-200A

SEAL CHIMNEY OPENING

WITH MORTAR OR COVER PLATE

1 FT MIN.

SLOPE UP 1/4 IN.

PER FOOT MIN.

AIR INTAKE

(DO NOT BLO CK)

3 INCH DIA. PVC/CPVC

PIPE OR STAINLESS STEEL

VENTING MATERIAL FOR

VENT

10FT.MIN.

CHIMNEY

TOP PLATE

RAIN CAP TERMINATION MAY BE USED

VENT TERMINATI ON

TEE WITH SCREEN

90˚ TERMINATION

ELBOW WITH SCREEN

ALTERNATE VERTICAL TERMINATION

45˚ ELBOW

3 INCH DIA. PVC/CPVC

PIPE OR STAINLESS STEEL

VENTING MATERIAL FOR

VENT

90˚ ELBOW

*

*

BOBCAT MODELS B-120 and B-200 NON - DIRECT VENT, UTILIZING AN EXISTING

CHIMNEY AS A CHASE

All joints must be liquid and pressure tight. Use 3” dia. PVC/CPVC schedule 40 pipe or U/L listed single wall 3" dia.

AL29-4C S.S.*. venting materials (See page 7).

13

Figure 10. Bobcat models B-120 and B-200 - non-direct vent, utilizing an existing chimney as a chase.

AL 29-4C IS A REGISTERED

*

TRADEMARK OF ALLEGHENY LUDLUM CORP

.

Page 14

14

SLOPE UP 1/4"

PER FOOT MIN.

FROM BOILER TO

VENT TERMINATION

90˚ ELBOW

3" DIA.

PVC/CPVC

PIPE FOR

AIR INTAKE

SNOW

LIN

E**

(SEE

DEF

INIT

ION

)

AIR

INT

AKE

LOU

VER

S

12"MIN

O

UTSIDE

W

ALL

3

"

D

IA. PVC/CPVC

C

OUPLING WITH SCREEN

SLANT/FIN

VENT/AIR INTAKE

TERMINATION UNIT

PART # 860802

3"

– 16

"

THICK

WALL

3"

DIA.

PVC/CPVC

PIPE FOR

VENT

SLOPE UP 1/4”

PER FOOT MIN.

FROM BOILER TO

VENT TERMINATION

90˚ ELBOW

3" DIA.

STAINLESS

STEEL VENTING

MATERIAL FOR

VENT

3" DIA.

PVC/CPVC

PIPE FOR

AIR INTAK E

AIR

IN

TAK

E

LOU

VER

S

SNO

W L

INE

**

(SEE

DE

FIN

ITIO

N)

12"MIN

OUTSIDE

WALL

STRAIGHT SCREENED

VENT TERMINATI ON

SLANT/FIN

VENT/AIR INTAKE

TERMINATION UNIT

PART # 451138

3-12"

THICK

WALL

3

"

DIA.

HEAT-FAB SLIP

JOINT CONNECTOR

Bobcat Models B-120A and B-200A

BOBCAT MODELS B-120 and B-200 - DIRECT VENT, SIDEWALL VENTING

All joints must be liquid and pressure tight. Use 3” dia. PVC/CPVC schedule 40 pipe or U/L listed single wall 3" dia.

AL29-4C S.S.*. venting materials (See page 7).

Figure 11. Direct vent, sidewall venting illustration; utilizing PVC/CPVC pipe for venting

wall venting illustration;

w Line:

side

wledge of local conditions will reveal the maximum height that repeated snowfalls accumulate to.

Kno

Figure 12.

Direct vent,

** Definition of Sno

The height should be used as the SNOW LINE.

AL 29-4C IS A REGISTERED

*

TRADEMARK OF ALLEGHENY LUDLUM CORP

utilizing stainless steel vent materials f

.

or venting.

Page 15

Bobcat Models B-120A and B-200A

WALL

(

3"-18" THICK)

S

CREW

3" DIA.

P

VC/CPVC

PIPE FOR

A

IR INTAKE

S

TOP

FOR AIR/VENT

OUTSIDE TERMINAL

3" DIA.

PVC/CPVC

P

IPE FOR

VENT

F

LUE

GASES

W

ALL

(3"-12" THICK)

OUTSIDE

TERMINATION

PLATE

COMBUSTION

AIR

SEAL

H

ERE

O

UTSIDE

T

ERMINATION

PLATE

I

NSIDE

T

ERMINATION

P

LATE

I

NSIDE

T

ERMINATION

PLATE

3

" DIA.

PVC/CPVC

COUPLING

W

ITH SCREEN

L

OUVERS

3" DIA.

P

VC/CPVC

PIPE FOR

A

IR INTAKE

3" DIA.

PVC/CPVC

P

IPE FOR VENT

SCREW

3

" DIA.

PVC/CPVC

C

OUPLING

WITH SCREEN

WALL

(3"-12" THICK)

SCREW

3" DIA.

PVC/CPVC

PIPE FOR

AIR INTAKE

STOP

FOR AIR/VENT

OUTSIDE TERMINAL

4" GALV. PIPE

(WALL THIMBLE

FOR COMBUSTIBLE

WALLS ONLY)

3" DIA. AL29-4C

S.S.VENT PIPE

(SLIP JOINT CONNECTOR)

FLUE

GASES

WALL

(3"-12" THICK)

OUTSIDE

TERMINATION

PLATE

COMBUSTION

AIR

SEAL

HERE

DO NOT

SEAL HERE

OUTSIDE

TERMINATION

PLATE

INSIDE

T

ERMINATION

PLATE

INSIDE

TERMINATION

PLATE

STRAIGHT

SCREENED

TERMINATION

STRAIGHT

SCREENED

TERMINATION

LOUVERS

4" GALV. PIPE

(WALL THIMBLE)

3" DIA.

PVC/CPVC

P

IPE FOR

AIR INTAKE

3" DIA. AL29-4C

S.S.VENT PIPE

(SLIP JOINT

CONNECTOR)

SCREW

15

Figure 13a. Vent/Air intake termination; utilizing PVC/CPVC pipe for venting.

Figure 13b. Vent/Air intake termination; utilizing stainless steel venting materials.

Page 16

16

Bobcat Models B-120A and B-200A

ENT/AIR INTAKE TERMINATION FOR PVC/CPVC

V

ENTING INSTALLATION

V

This termination is designed specifically for 3” diameter PVC or

CPVC Schedule 40 pipe to be used as the vent and air intake

piping material, only. It can be used on a combustible wall,

provided the 1” minimum clearance of the vent pipe to any

combustible surface is maintained.

. Termination must be installed horizontally.

1

. Refer to Figure 13a for installation details.

2

3. Wall thickness should be 3” to 12” thick.

4. Follow instruction for “vent termination location and

clearances” explained on page 9.

5. Cut a rectangular opening with the following dimensions in

the wall.

Height: 5

Width: 12

1

⁄4”

3

⁄4”

6. From outside of the wall, install outside termination plate

using 4 screws. Make sure the louvers are at left side. Seal

the plate perimeter with silicon.

7. Apply a bead of silicon around the outer surface of the out

side termination plate air intake collar, about 1/2” from the

edge. This will seal the air intake pipe to the air intake

collar, in step #9.

8. From inside, install the inside termination plate, using 4

screws. Make sure that the holes for the vent and air intake

pipe visually line up with the vent passage hole and air

intake collar on the outside termination plate.

9. Cut the PVC or CPVC air intake pipe to the proper

dimension to fit onto the air intake collar of the terminal.

Slide the air intake pipe through the inside termination

plate and onto the air intake collar, where the sealant was

pre-applied in Step #7.

Cut the PVC or CPVC vent pipe so that it will extend out

10.

past the outer surface of the outside termination plate by

2”.

11. Cement a 3” diameter PVC or CPVC coupling onto the

PVC or CPVC vent pipe, and install a stainless steel

screen into the coupling.

ENT/AIR INTAKE TERMINATION FOR STAINLESS STEEL

V

ENTING INSTALLATION

V

This termination is designed specifically for Heat-Fab Saf-T

vent 3” diameter stainless steel venting system to be used as

the vent, and 3” diameter PVC or CPVC schedule 40 pipe to

be used as the air intake piping material, only. It can be used

on a combustible wall, provided a length of 4” diameter galvanized pipe is installed as a thimble around the vent pipe, for the

all passage.

w

. Termination must be installed horizontally.

1

2. Refer to Figure 13b for installation details.

3. Wall thickness should be 3” to 12” thick.

4. Follow instruction for “vent termination location and

clearances” explained on this page.

5. Cut a rectangular opening with the following dimensions in

the wall.

Height: 5

Width: 12

1

⁄4”

3

⁄4”

6. From outside of the wall, install outside termination plate

using 4 scre

ws. Make sure the louvers are at left side. Seal

the plate perimeter with silicon.

7. Apply a bead of silicon around the outer surface of the

outside termination plate air intake collar, about 1/2” from

the edge. This will seal the air intake pipe to the air intake

collar, in step #11.

8. For combustible wall a 4” galvanized pipe must be used as

a wall thimble.The length of the 4” galvanized pipe should

be approximately 1” shorter than the wall thickness.

9. From inside the building, fit galvanized pipe over 4” collar of

the outside plate.

10. From inside, install inside termination plate using 4 screws.

Make sure the 4” collar on the plate, penetrated into the

anized pipe.

galv

Cut the PVC or CPVC air intak

11.

e pipe to the proper

dimension to fit onto the air intake collar of the terminal.

Slide the air intake pipe through the inside termination

plate and onto the air intake collar, where the sealant was

pre-applied in Step #7.

12. From outside the wall, insert the bare end of the PVC or

CPVC vent pipe through the outside and inside terminal

plates, until the coupling is flush with the outside wall plate.

13. From inside, proceed with the air intake and vent pipe

installation. Follow the proper PVC/CPVC assembly

actices specified on page 8, and v

pr

enting system

restrictions specified on page 8 of this manual.

12. Assemble and seal straight screened termination to the slip

joint connector.

rom outside of the building, insert vent pipe (slip joint

F

13.

connector and termination assembly) through the 3” holes

of the outside and inside termination plate.

14. From inside, proceed with air intake and vent pipe

installation. Follow vent manufacturer’s instructions and

restrictions specified on page 8 of this manual.

Page 17

Bobcat Models B-120A and B-200A

SNO

W L

INE

1 FT.MIN.

1 FT.MIN.

STRAIGHT TERMINATI ON

WITH SCREEN

10 FT. MIN

FIRESTOP AND

SUPPORT

2" MIN.

SLOPE UP 1/4 IN.

PER FOOT MIN.

3

"

DIA. PVC/CPVC

OR STAINLESS

STEEL VENTING

MATERIAL FOR

VENT

3

"

DIA. PVC/CPVC

OR STAINLESS

STEEL PIPE FOR

AIR INTAKE

FIRESTOP AND

SUPPORT

PIPE

SUPPORT

FLASHING AND

STORM COLLAR

AIR INTAKE

180˚ ELBOW

WITH SCREEN

or PVC/CPVC pipe, follow the proper assembly practices

B. DIRECT VENT - VENTING AND AIR INTAKE

THROUGH A ROOF

F

pecified on page 8, and venting system restrictions specified

s

on page 8 of this manual. For stainless steel venting systems,

igure 14 shows typical vertical venting. The vent pipe must

F

ass through the ceiling, floor and the roof vertically through a

p

follow the vent manufacturer’s instructions and the restrictions

specified on page 8 of this manual

6” minimum diameter cutout. A fire stop is required for each

ceiling and floor penetration. For roof passage an appropriate

UL listed roof flashing must be used.

The vertical vent piping must terminate with a screened

straight termination. The air intake termination should be a

screened 180˚ elbow facing down.The air intake opening must

e at least 1 foot below the vent opening.

b

BOBCAT MODELS B-120 and B-200 - DIRECT VENT, VENTING AND AIR INTAKE

THROUGH A ROOF

All joints must be liquid and pressure tight. Use 3” dia. PVC/CPVC schedule 40 pipe or U/L listed single wall 3" dia.

AL29-4C S.S.*. venting materials (See page 7).

17

Figure 14. Direct vent, venting and air intake through a roof.

** Definition of Snow Line: Knowledge of local conditions will reveal the maximum height that repeated snowfalls accumulate to.

The height should be used as the SNOW LINE.

AL 29-4C IS A REGISTERED TRADEMARK OF ALLEGHENY LUDLUM CORP

*

.

Page 18

18

CONDENSATE TRAP,

FILLED WITH

WATER

DRAIN VACUUM

BREAKER, LEAVE

OPEN

PLASTIC

TUBING

NEUTRALIZING

UNIT

(IF REQUIRED)

CONDENSATE

PUMP

(IF REQUIRED)

DRAIN

INSIDE

BUILDING

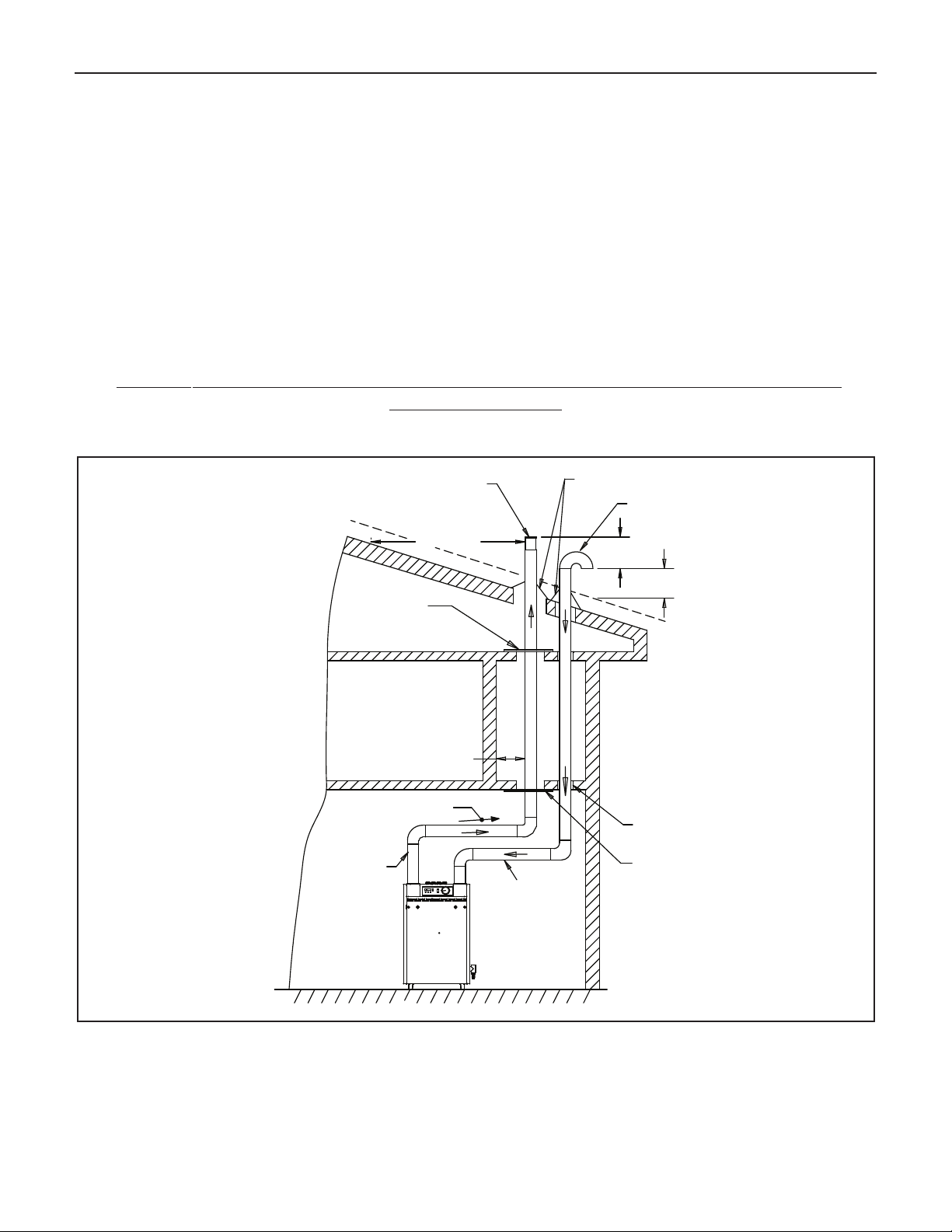

VENTING AND AIR INTAKE SYSTEM REGULAR INSPECTION

A. Inspect the system regularly for condensation, corrosion,

agging and/or physical damage. A qualified professional

s

should service the boiler annually and include such an

inspection at that time. The homeowner should look over the

system monthly for damage, water stains, any signs of rust,

other corrosions or separation of the vent and air intake piping

(if direct-vent).

B. Should an inspection turn up signs of condensation, corrosion,

sagging or damage, the boiler should be shut down immediately and the condition should be corrected by a qualified

professional.

CONDENSATE REMOVAL SYSTEM

The Bobcat B-120 and B-200 boilers are equipped with a built-in

condensation drain and trap.The trap must be filled with water. DO

NOT operate the boiler without filling the trap with water to prevent

flue gas discharge into space. Periodic inspection should be made

of this assembly for deterioration of the tubing and to insure that

the trap is not plugged. If it is plugged or appears to have excessive sediment in it, it should be removed from the drain assembly,

straightened out to clear the obstruction, reformed, filled with water

and reinstalled as before.

A 3/4”

PVC tee, located on the right side of the boiler jacket, is

provided to run the condensate liquid from the boiler. Connect the

plastic tubing that will be run to the drain to the bottom take-off of

the tee. Leave the top take-off of the tee open, to act as a vacuum

breaker. If the building drain is above the bottom portion of the tee,

a condensate removal pump will be required.This pump must

have an overflow switch, and be compatible with the acidic condensate liquid, as must all fittings and the tubing used in this condensate removal system. (See Figure 15).

No part of the condensate removal system can be exposed to

freezing temperatures, or any other conditions that could cause

blockage. DO NOT run drain tubing to the outside of the building.

In addition, certain jurisdictions or drain pipe materials may require

a neutralization unit to be installed in the condensate removal system. Any piping other than plastic types will be subject to corrosion

ioration from the acidic condensate

or deter

vel as low as 3.0. A condensate filter containing lime, marble, or

le

phosphate chips can neutralize the condensate to a pH level

, which may have a pH

Bobcat Models B-120A and B-200A

bove 6.5, which is safe for all drain piping materials. (See Figure

a

5). The neutralizing filter medium will require periodic changing,

1

to ensure it’s affectiveness. Replacing the medium on an annual

basis is recommended, or refer to the manufacturer’s instructions

for systems that are available for neutralizing condensate.

COMMONWEALTH OF MASSACHUSETTS SPECIAL

REQUIREMENT

When the Bobcat B-120A and B-200A are installed and used in

the Commonwealth of Massachusetts, a neutralization unit MUST

be installed in the condensate removal system.

GAS PIPING

A. Local installation codes apply. The pipe joint compound used

on threads must be resistant to the action of liquefied petroleum gases.

B. The gas supply line to the boiler should run directly from the

meter for natural gas or from the fuel tank for L.P. propane gas.

A manual gas supply shut-off valve is provided on the boiler’s

gas supply pipe. (See Figure 2, on page 3). Local codes may

specify a manual main gas supply shut-off valve to be 5’ above

the floor, and a disconnection union at the gas piping entrance

to the boiler. In this case, unless the boiler is wall mounted at

the right height, the gas supply shut-off valve must be relocated

to the specified location. If the gas supply pipe must be upsized

for flow considerations, then the same size main gas supply

shut-off valve must be used.

Selecting pipe size for natural gas:

1. Measure or estimate the length of piping from the meter to

the installation site.

2. Consult gas supplier for heating value of gas (Btu/cu. ft.).

3. Divide boiler rated input by heating value to find gas flow in

piping (cu. ft. per hour).

4. Use table below to select proper pipe size.

EXAMPLE: Boiler model B-120 is to be installed. Distance from

gas meter to the boilers is 30ft. Heating value of natural gas is

1020 Btu/cu. Ft. Select proper pipe size.

Gas flow = 120,000 Btu/hour

1020 Btu/cu. ft.

= 118 cu. ft. per hour

Figure 15. Condensate disposal system

Page 19

Bobcat Models B-120A and B-200A

19

t 30 ft. length of pipe, match required capacity from table on

A

his page (choose higher capacity, in this case is 152 cu. ft. per

t

hour). Required pipe size is

mproper gas pipe sizing will result in flame outages, insuffi-

I

3

⁄4".

cient heat and other installation difficulties. For more information and also if other appliances are to be attached to the

piping system, see Appendix C of National Fuel Gas Code

ANSI Z223.1-latest edition.

C. The boiler and its gas connection must be leak tested

before replacing the boiler in operation. Use liquid soap

solution for all gas leak testing. DO NOT use open flame.

This boiler and it’s individual shutoff valve must be

disconnected from the gas supply piping system during and

pressure testing of that system at test pressures in excess

1

of

⁄2 PSIG. This boiler must be isolated from the gas supply

piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping system

at test pressures equal to or less than

1

⁄2 PSIG.

D. All gas piping used should be inspected thoroughly for

cleanliness before makeup. A sediment trap is integrally

provided, as illustrated on page 3.

E. The minimum and maximum gas supply pressure (at the

inlet of gas valve) are shown on the boiler rating plate for

the type of gas used. Gas supply pressure should never be

less than minimum or more than maximum pressure when

the boiler or any other appliance is turned on or off.

Length

of pipe

in Feet

Gas Flow In piping -- cu. ft. per hr.

Iron Pipe Size (IPS) — inches

1/2

3

/4 11

1

/4

11/2

10 132 278 520 1050 1600

20 92 190 350 730 1100

30 73 152 285 590 890

40 63 130 245 500 760

50 56 115 215 440 670

60 50 105 195 400 610

70 46 96 180 370 560

80 43 90 170 350 530

90 40 84 160 320 490

100 38 79 150 305 460

vity = 0.6.

At pressure drop of 0.3 in. w

, specific gr

ater

a

oiler must be electrically grounded in accordance with the

B

equirements of the authority having jurisdiction, or, in the

r

absence of such requirements, with the National Electrical

Code, ANSI/NFPA 70-latest edition.

Proper polarity is critical for the power supply connections.

Reversed polarity will cause system lockout. Proper grounding is critical for boiler operation, connect the ground wire to

the green ground screw next to the line voltage terminal

trip.

s

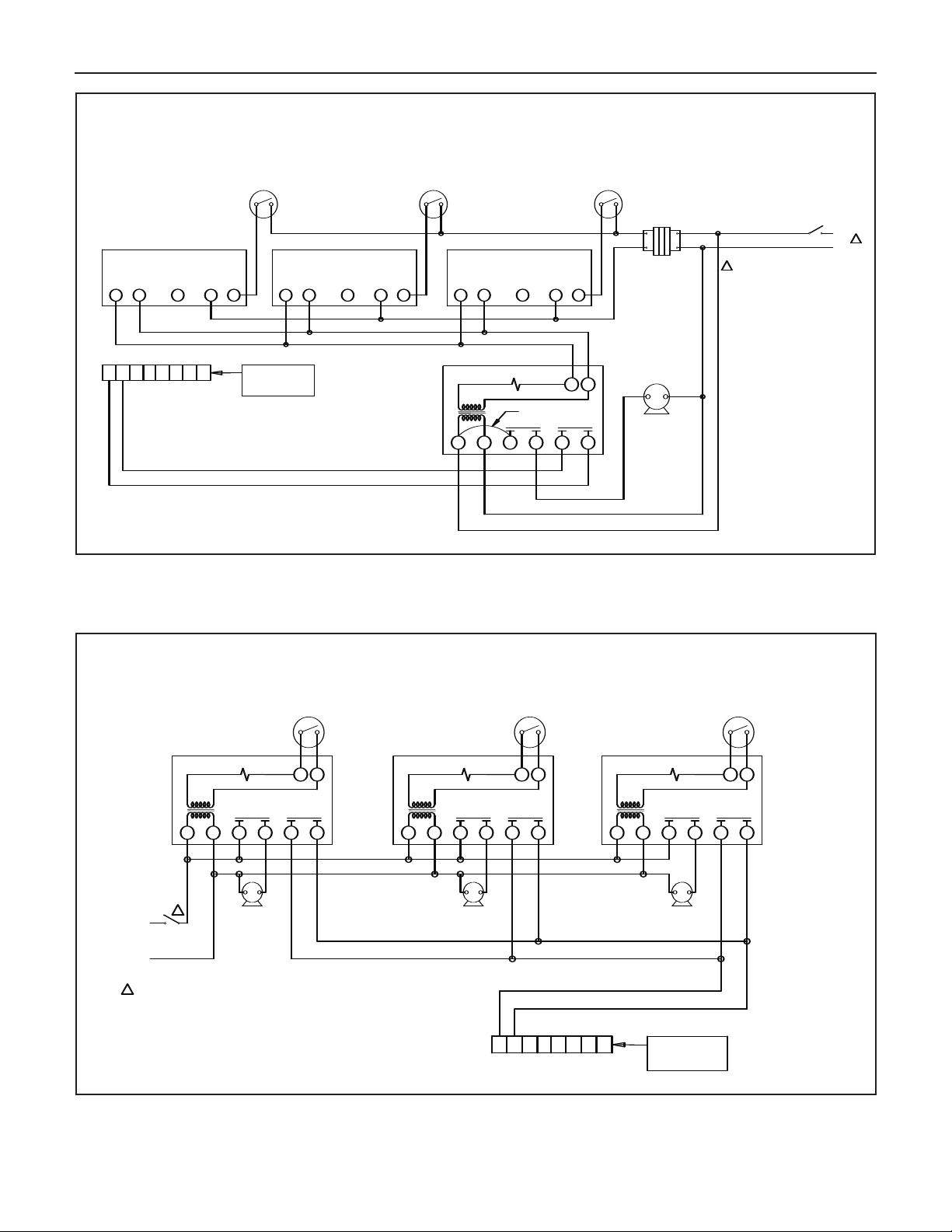

2. Circulator(s)

A set of terminals are provided for the boiler (primary loop)

circulator. Only wire this circulator to these terminals,

additional (secondary loop) circulators for space heating

require the use of relays and a separate power source.

For multiple zoning, either zone valves or circulators maybe

used.

For zone valve system (See Figure 17a).

For pump zoning system (See Figure 17b and 17c).

DO NOT use boiler transformer to power external

accessories like zone valve and relays, overload and/or

burned out transformer and boiler malfunction can result.

Use separate transformer to power such components.

A second set of terminals are provided for the domestic hot

water tank circulator (if used). The primary loop circulator is

always de-energized when the DHW tank circulator is

energized, for priority.

3. SPACE HEATING THERMOSTAT(S)

Install thermostat on an inside wall and away from any heat

sources, sunshine and drafts. A set of terminals are provided for connection of 24 volt style thermostats, relays or zone

valve end switches (isolated contacts). (See wiring diagram

Figure 16a).

Thermostat heat anticipator: For a non-zoned system set

thermostat heat anticipator to 0.1 Amps, for zoned system

set to match power requirements of zone valves or relays.

Refer to man

see instr

uctions with ther

ufacturer’

s instructions and specifications. Also

mostat.

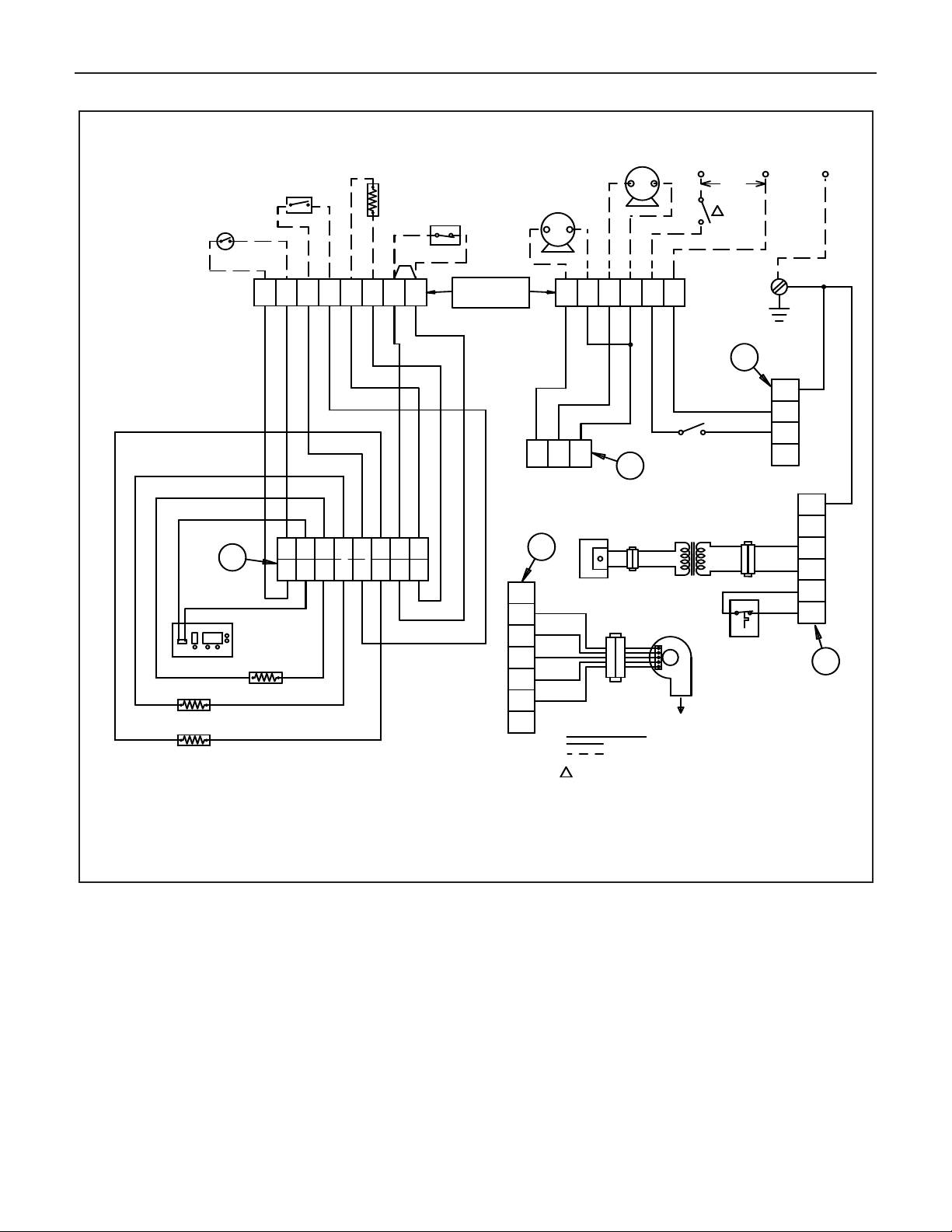

ELECTRICAL WIRING

All field wiring to the boiler is connected to the 2 sets of

minal str

ter

ips, located under the jacket top panel.

(See Figure 2, on page 3)

DANGER: Before wiring always turn off electric power supply.

Otherwise, shock or death can result.

1. Power Supply

A separately fused circuit is recommended. Use standard

15 Amp. fuse or breaker and 14 gage conductors in BX

le or conduit.

cab

Provide disconnect means and overload protection as

am (Figure 16a) boiler

required.

See boiler wir

ing diag

r

control (Figure16b) and ladder diagram (Figure 16c).

4. DOMESTIC HOT WATER TANK THERMOSTAT

A set of terminals are provided for connection of the DHW

tank thermostat (if used). (See wiring diagram Figure 16a).

5. OUTDOOR AIR SENSOR

A set of terminals are provided for connection of an outdoor

air sensor (if this method is used). (See wir

ing diagr

am

Figure 16a).

Mount on

The outdoor air sensor m

ust be a 12k ohm type

.

an outside wall, shielded from direct sunlight or flow of heat

or cooling form other sources. See instructions provided

with sensor.

6. LOW WATER CUTOFF

or connection of a LWCO. If

A set of ter

this de

minals are pro

vice is used, remove the factory installed jumper from

vided f

these terminals. (See wiring diagram Figure 16a).

Page 20

20

WIRE LEGEND:

1

M

CAUTION:

1

2

3

4

5

6

7

8

9

10

11 12

13 14 15

16

12

3

4

5

6

78

HN

H

N

HN

1

2

3

4

5

6

1

J5

J2

J6

J13

2

3

1

2

3

4

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS.

PROPER OPERATION AFTER SERVICING".

WW

BL

R

BL

GY

DISPLAY

GY

W

G

BK

G

M

BK

G

W

G

ROUND

R

Y

PR

PK

B

R

GY

PR

BK

W

M

1

2

3

4

5

6

7

J9

BK

R

G

W

BL

1

W

W

W

BK

GY

GY

G

Y

G

Y

GY

FACTORY WIRED

FIELD WIRED, FIELD SUPPLIED

PROVIDE DISCONNECT MEANS & OVERLOAD PR OTECTION AS

REQUIRED.

IF ANY OF THE ORIGINAL WIRE AS SUPPLIEDWITH THE

APPLIIANCE MUST BE REPLACED, IT MUST BE REPLACED

WITH TYPE 105˚C OR ITS EQUIVALENT.

24V ROOM

T

HERMOSTAT

WIRING ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION.

"VERIFY

FIELD WIRING

TERMINALS

120V/24V

TRANSFORMER

DHW

C

IRCULATO R

(

IF USED)

DHW TANK

THERMOSTAT

(IF USED)

2

PIN

C

ONNECTOR

G

AS VALVE

HONEYWELL

VK8115

3 PIN

CONNECTOR

W

ATER HIGH

LIMIT

(WHITE CONNECTOR)

SUPPLY WATER SENSOR

(RED CONNECTOR)

R

ETURN WATER SENSOR

(BLUE CONNECTOR)

FLUE GAS SENSOR

(CLEAR CONNECTOR)

POWER

ON/OFF

S

WITCH

BOILER

CIRCULATO R

L

2

NEUTRAL

L1

HOT

120V

60HZ

1

2 K ohm

OUTDOOR

S

ENSER

(IF USED)

LOW WATER

C

UT OFF

(IF USED,REMOVE

7

-8 JUMPER)

5 PIN

C

ONNECTOR

COMBUSTION

B

LOWER

Bobcat Models B-120A and B-200A

Figure 16a. Schematic wiring diagram.

Page 21

Bobcat Models B-120A and B-200A

ARGUS CONTROL PHC794-S1

J5

J2

J

6

J9

FUSE

GROUND

S

PARK

CABLE

SPARK IGNITOR

J13

J12

T2

GND

NEUTRAL

HOT

L2

L1

120V/60HZ

120V

10V

120V

24V

M

M

DISPLAY

M

CHASSIS

GND

DISCONNECT

SWITCH

SPARK

ELECRODE

DHW CIRCULATO R

(IF USED)

BOILER

CIRCULATO R

COMBUSTION

BLOWER

BOILER ON/OFF

SWITCH

GAS

VALVE

SUPPLY WATER

SENSOR

RETURN WATER

SENSOR

FLUE GAS

SENSOR

OUTDOOR SENSER

(IF USED)

MICRO PROCESSOR

ON CONTROL BOARD

120V SECTION OF

CONTROL BOARD

LOW WATER CUT OFF

(IF USED) OR JUMPER

DHW THERMOSTAT

(IF USED) OR SENSOR

ROOM

THERMOSTAT

WATE R HIGH

LIMIT

21

Figure 16b. Boiler Control.

Figure 16c. Ladder wiring diagram.

Page 22

22

1

END

SWITCH

T

H-TR

MOTOR

2

T

TT T TT TT TT TT T TT

T

T

3

456

S

PAC E

HEATING

S

YSTEM

CIRCULATOR

END

S

WITCH

TH-TR

MOTOR

Z

ONE 2

THERMOSTAT

V8043E/F

END

S

WITCH

T

H-TR

MOTOR

ZONE 3

THERMOSTAT

V8043E/F

1 2 3 4 5 6 7 8

FIELD WIRING

T

ERMINALS

O

N BOILER

JUMPER

R

845A

R

ELAY

LI

L2

1

ZONE 1

THERMOSTAT

120V/24V

T

RANSFORMER

1

POWER SUPPLY, P ROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

MULTIZONING OF "BOBCAT" BOILER;

ZONE VALVE SYSTEM USING V8043E/F ZONE VALVES AND R845A RELAY

DISCONNECT

SWITCH

V8043E/F

1 2 3 4 5 6 7 8

FIELD WIRING

TERMINALS

ON BOILER

1

2

TT

3456

TT TT

LI

L2

DISCONNECT

SWITCH

1

R845A

RELAY ZONE 3

CIRC.

ZONE 3

R845A

RELAY ZONE 2

CIRC.

ZONE 2

R845A

RELAY ZONE 1

CIRC.

ZONE 1

ZONE 3

THERMOSTAT

ZONE 2

THERMOSTAT

ZONE 1

THERMOSTAT

1

POWER SUPPLY, PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

MULTIZONING OF "BOBCAT" BOILER;

PUMP ZONING SYSTEM USING R845A RELAY

1

23456

1

23456

Bobcat Models B-120A and B-200A

Figure 17a. Multizoning of Bobcat boiler; zone valve system.

Figure 17b.

Multizoning of Bobcat boiler;

pump zoning system using R845A rela

y

.

Page 23

Bobcat Models B-120A and B-200A

LI

L2

1

DISCONNECT

SWITCH

120V/24V

T

RANSFORMER

FIELD WIRING

TERMINALS

ON BOILER

C

IRC.

ZONE 3

ZONE 3

THERMOSTAT

1

P

OWER SUPPLY, PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

MULTIZONING OF "BOBCAT" BOILER;

PUMP ZONING SYSTEM USING R882A/B RELAYS

C

IRC.

ZONE 2

R882A/B

R882A/B

ZONE 2

THERMOSTAT

C

IRC.

ZONE 1

R882A/B

ZONE 1

T

HERMOSTAT

120V/60HZ

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1

2

TT

3

4

56

LI

L2

1

1

POWER SUPPLY, PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

DISCONNECT

SWITCH

R845A

RELAY

THERMOSTAT

CIRCULATOR

FIELD WIRING

TERMINALS

ON BOILER

LI

L2

1

1

1 2 3 4 5 6 7 8

POWER SUPPLY, PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

DISCONNECT

SWITCH

THERMOSTAT

CIRCULATOR

R 882A/B

RELAY

120 V / 24 V

TRANSFORMER

FIELD WIRING

TERMINALS

ON BOILER

23

Figure 17c. Multizoning of Bobcat boiler; pump zoning system using R882A/B relays.

Figure 17d. Single zoning of Bobcat boiler; pump

zoning system using R845A relay.

Figure 17e. Single zoning of Bobcat boiler; pump zoning system using R882A/B relay.

Page 24

24

Bobcat Models B-120A and B-200A

WATER PIPING

1. Connection of system to boiler:

rimary/secondary piping of the system is recommended, to

P

nsure the proper flow through the boiler. (See Figures 20

e

through 22). The boiler loop piping must be the same

diameter as the water outlet (supply) and inlet (return) piping

connections provided on the boiler, particularly on longer

loops. See page 2 for piping connection size.

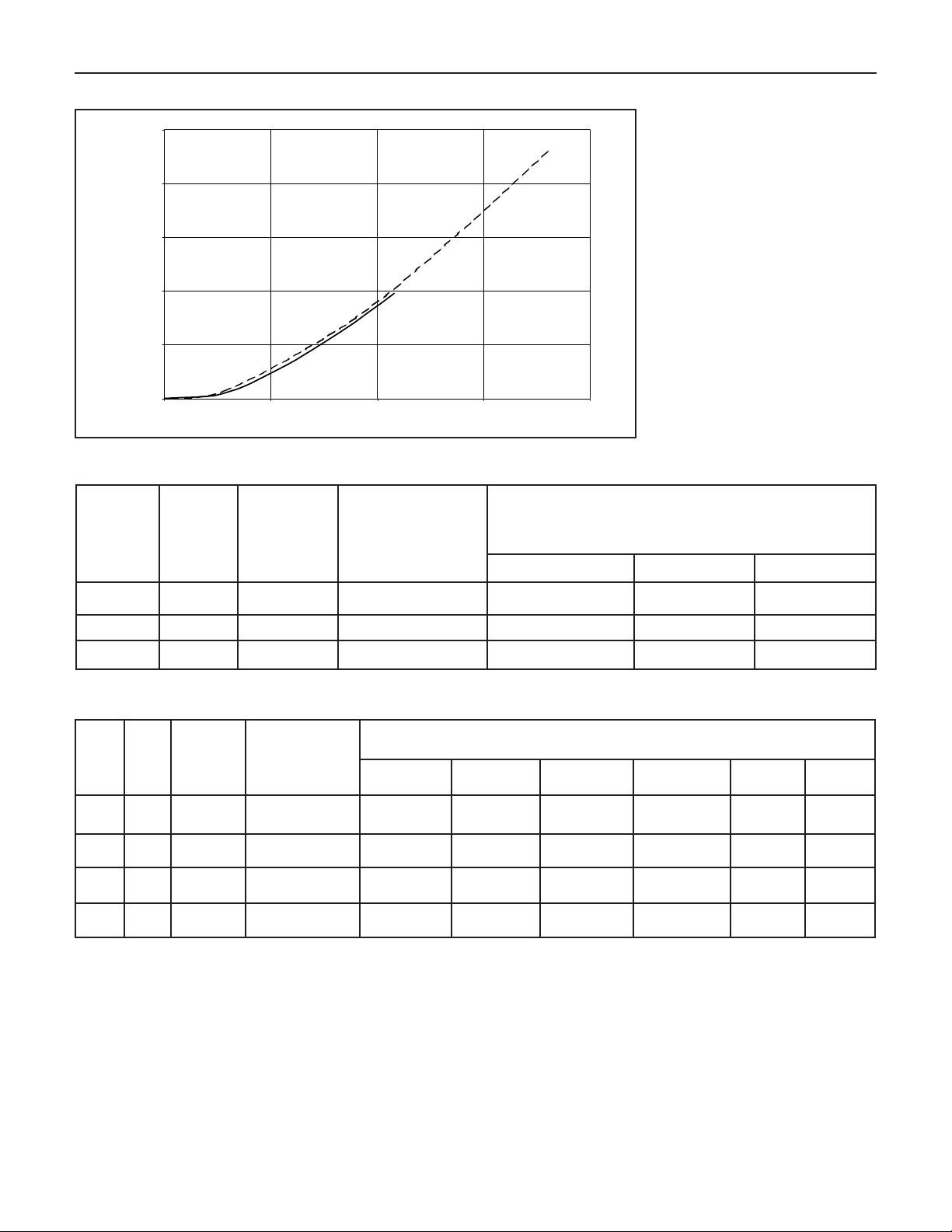

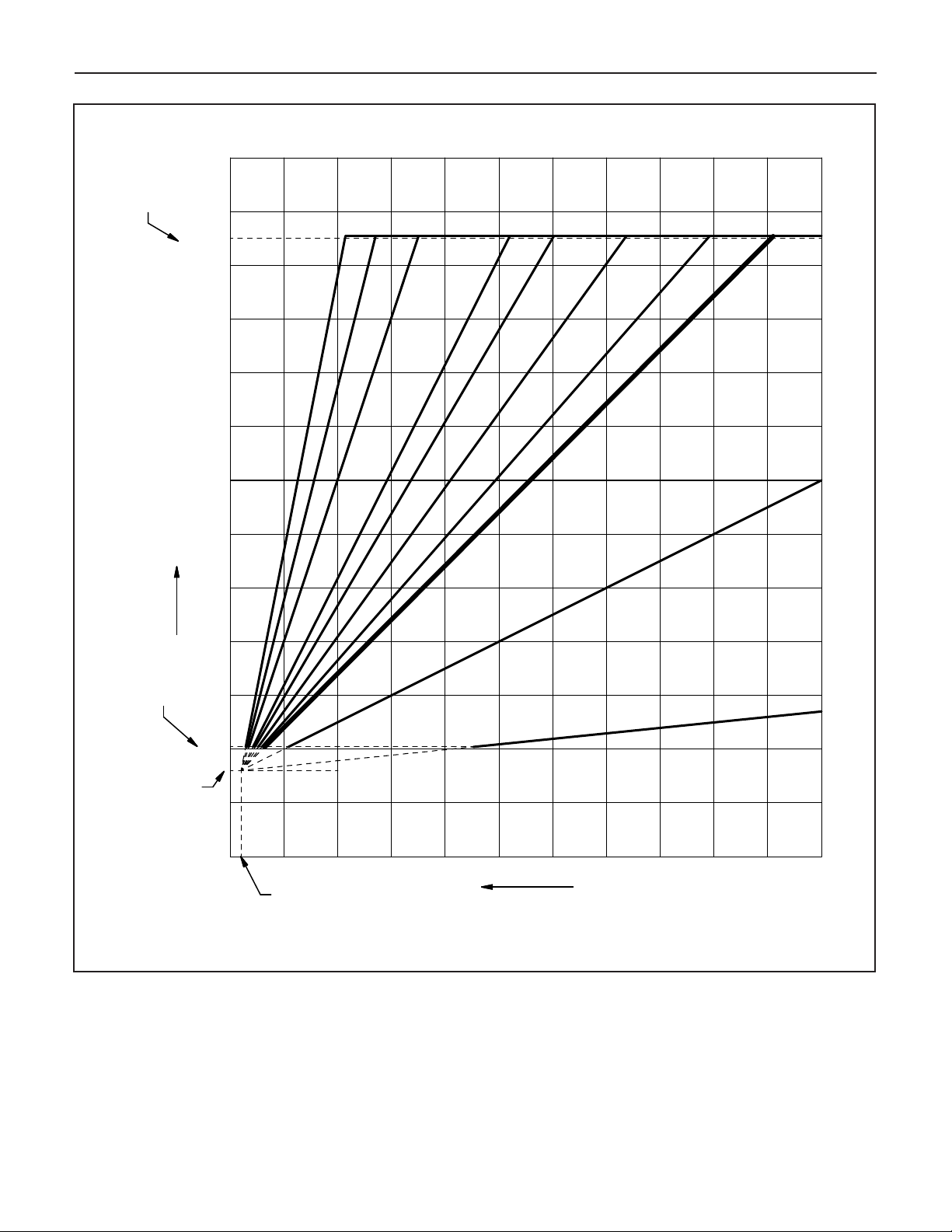

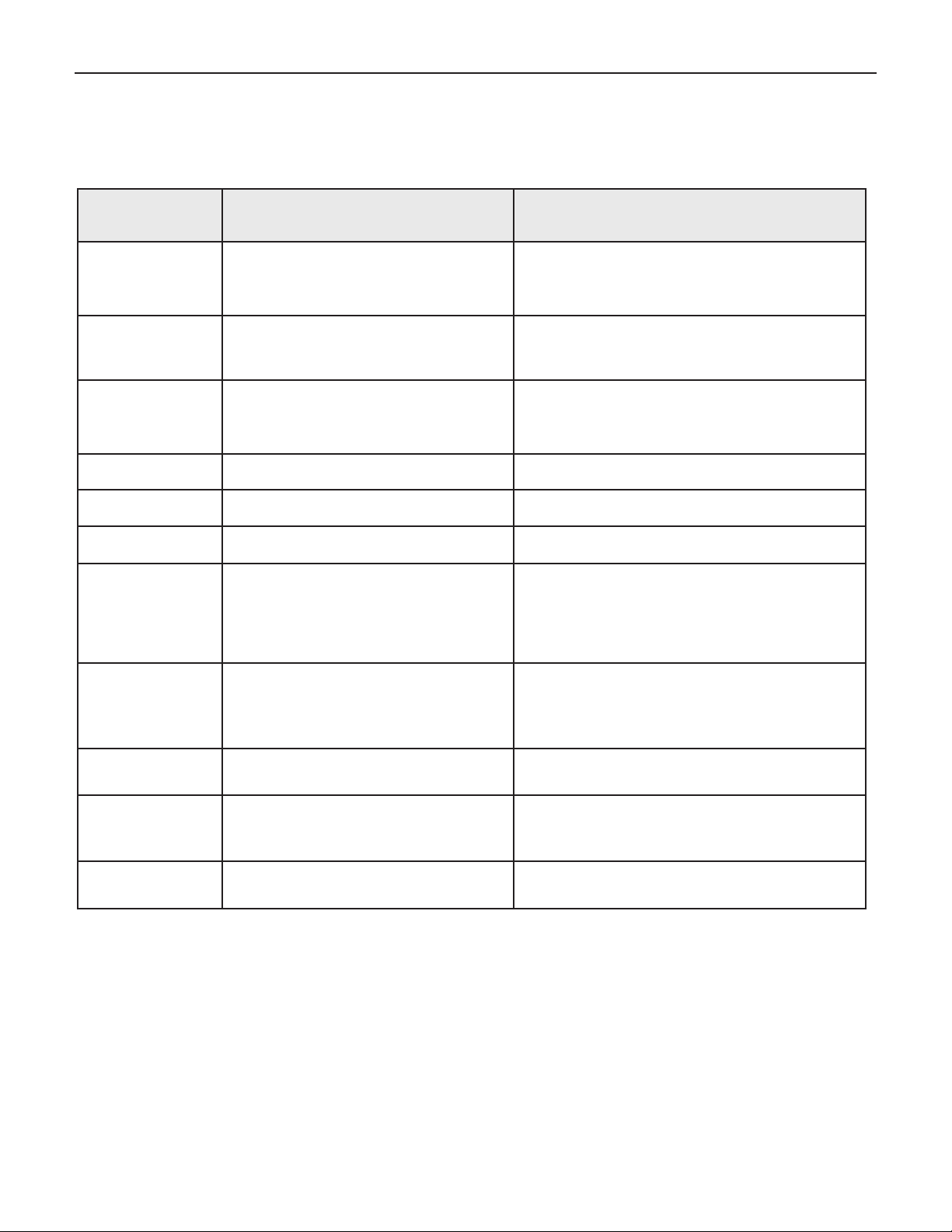

2. Circulator Pumps:

The boiler loop piping must utilize the Taco 0011 circulator for

-120 and 0013 for B-200 that is supplied with the boiler, to

B

nsure the proper flow through the boiler. Refer to Figure 19

e

for the boiler water side pressure drop and Table 2a and 2b

for the recommended pump models for the domestic hot

water system. Install the pumps in the orientation shown in

Figures 20 through 22.

3. Relief Valve(supplied with boiler):

Tee the relief valve into the boiler water outlet (supply) piping

as close to the water outlet (supply) connection as possible.

(See Figure 18). The relief valve’s discharge piping must be

the same size or larger than the relief valve’s outlet, and must

terminate 6” minimum from floor with a plain (no threads) end.

Place a bucket under pressure relief valve discharge. Make

sure discharge is always visible. DO NOT hard-pipe to drain

piping, or any place where freezing could occur. No shut-off

valve is permitted between the relief valve and boiler, or in the

discharge line.

4. Air Control System:

An appropriately sized diaphragm-type expansion tank must

be used to control the system pressure. See boiler volume

data on page 2, and the recommended location in Figures 20

through 22. An air vent is recommended to be installed on an

air separator in close proximity to the expansion tank.

5. Cold Water Fill:

A pressure reducing (fill) valve, with a shut-off valve upstream

of it, should be installed in close proximity of the expansion

tank. (See Figures 20 through 22). Use a back flow check

valve in the cold water supply as required by local codes.

w Water Cutoff:

6. Lo

On a hot water boiler installed above radiation level, the boiler

must be provided with a low water cutoff device at the time of

installation by the installer (see Figure 18 for piping

arrangement).

7. Water Treatment and Freeze Protection:

A good water treatment program will not only extend the

useful life of this boiler but it will also save much of the time

nd expense of repairs made necessary by preventable

a

ccurrences. A reputable water treatment company should be

o

consulted to evaluate and determine the best overall

treatment program for your boiler equipment.

The heat exchanger is made of aluminum, so the system

water must be maintained between 7.0 and 8.5 PH level.

horoughly flush the system, before connecting the boiler, to

T

emove any sediment or glycol.

r

Anti-freeze is sometimes used in hydronic systems to

protect against freez-up in the event of power failure or

boiler shut down in the cold winter.

(Propyleneglycol with Pro-Tek 922 inhibitor) by Rhomar

Water Management, Inc.

instructions for proper application and proper mixture for

um ambient temperature.

minim

other than that supplied by Slant-Fin or specifically

approved and/or recommended for use by Slant-Fin

will void this warranty.

Never use Ethylene Glycol as it is toxic to humans.