Slant/Fin 3000-190 User Manual

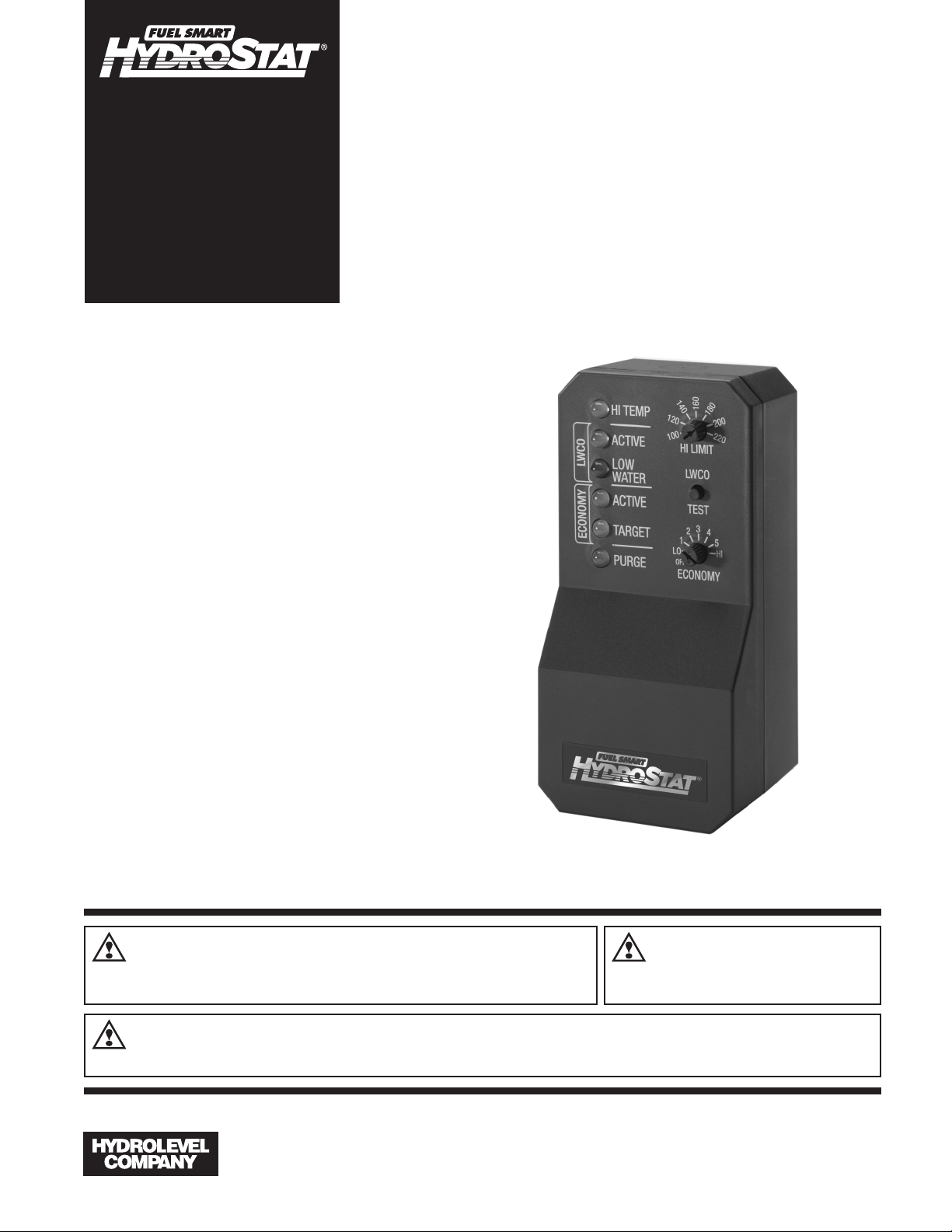

MODEL 3000

220°F (104°C) Max High Limit

MODEL 3000-190

190°F (88°C) Max High Limit

High Temp Limit / LWCO Control

with Thermal Targeting

for Gas Water Boilers

24 VAC Operating Voltage

PATENT NO. 7,891,572

™

Three

Function

Design

Temperature Limit Control

Provides high limit functionality for

cold start boilers.

INSTALLATION INSTRUCTIONS

and OPERATING MANUAL

• Saves Fuel – Features Thermal Targeting™ technology and

Thermal Pre-Purge capability

• Universal Design – Replaces common High Temp Aquastats*

• Easy to Install – Industry standard wiring, dial-type settings,

no external sensors necessary

• Operating Indicators – LEDs and Test Button provide continual and

on-demand status checks

• Prioritizes Hot Water – Gives priority to calls from indirect water heater

*Aquastat is a registered trademark of Honeywell International, Inc.

•

Low Water Cut-Off

Provides protection against potentially

dangerous low water conditions

when installed with the Hydrolevel

Electro-Well™ (see page 2 for details).

Boiler Reset Control

Utilizes

technology to conserve fuel by

monitoring heating demand and

establishing target boiler temperatures

below the high limit setting

(see page 5 for details).

WARNING

installing or servicing control. Only qualified personnel may install or service this control in

accordance with local codes and ordinances. Read instructions completely before proceeding.

Thermal Targeting

Electrical shock hazard. To prevent electrical shock, death or

equipment damage, disconnect power supply before

™

Model 3000

CAUTION

should be thoroughly cooled before installing or

servicing control.

To prevent serious

burns, boiler

Frozen pipes/water damage. Central heating systems are prone to shut down as a result of power or fuel outages,

WARNING

is recommended for unattended dwellings in climates subject to sustain below-freezing temperatures.

safety related fault conditions or equipment failure. Installation of freeze protection monitoring or other precautions

83 Water Street • New Haven, CT 06511 • Phone (203) 776-0473 • FAX (203) 773-1019 • www.hydrolevel.com

1

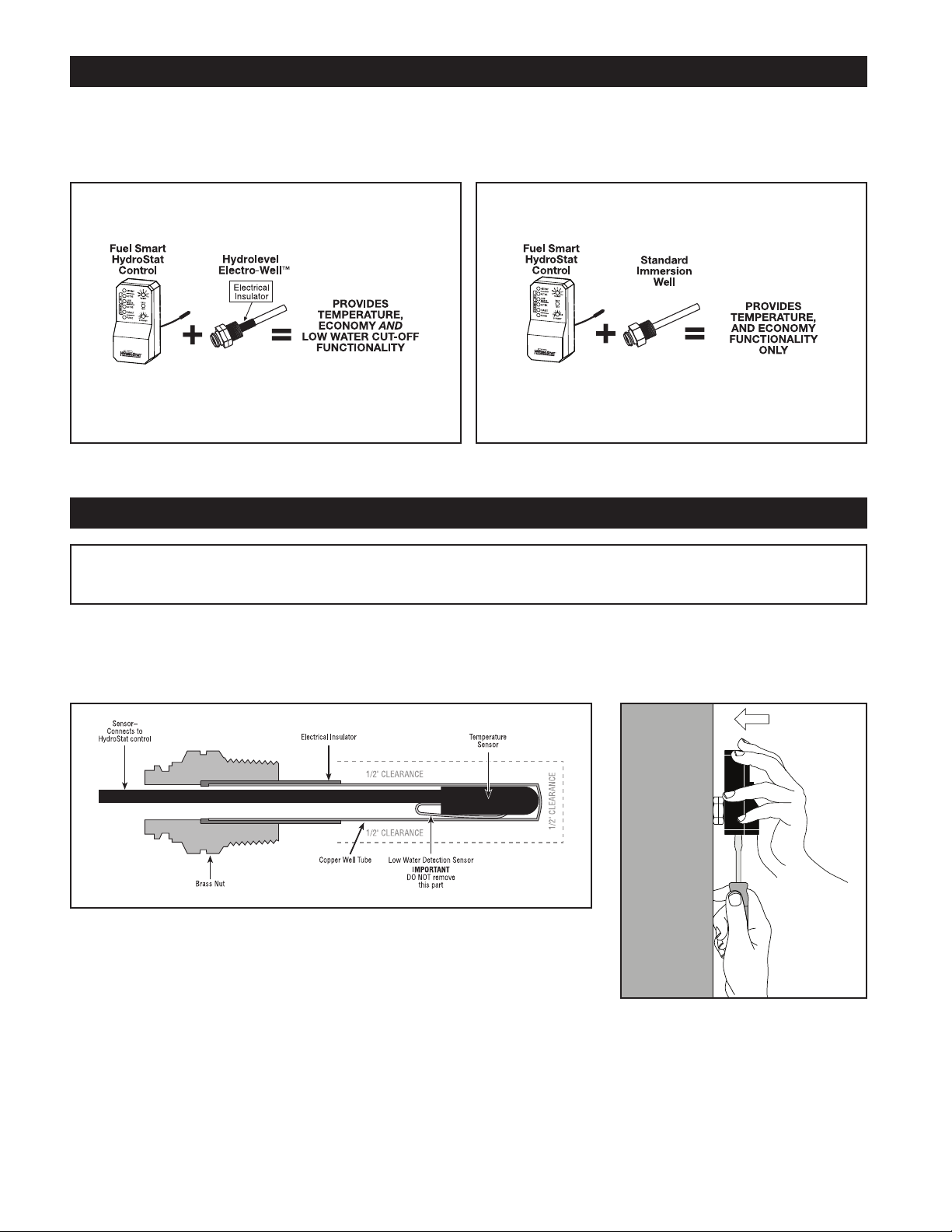

IMMERSION WELLS

Fuel Smart HydroStat can be installed on an existing immersion well already in the boiler or on a Hydrolevel Electro-Well™

(sold separately). The low water cut-off function is automatically activated when installed on an Electro-Well™.

IMPORTANT: The control will not provide low water cut-off protection when installed on a standard immersion well.

NOTE: Do not use heat-conducting grease.

Fuel Smart HydroStat installed

with Hydrolevel Electro-Well™

IMPORTANT: For proper operation of the low water cut-off function, there

must be a minimum of ½" clearance between the copper well tube and any

surface within the boiler.

See Electro-Well models on page 8.

NOTE: When installed on a standard immersion well, the “LWCO Active”

LED will not illuminate.

Fuel Smart HydroStat installed

with standard immersion well

MOUNTING THE CONTROL

IMPORTANT Make sure that the immersion well or Electro-Well™ is installed in the boiler manufacturer’s designated

temperature limit control tapping.

NNOOTTEE::

If installing an Electro-Well, pipe sealing compound should be used. Teflon tape is not recommended.

STEP 2 Place control on the well.

While holding box against well nut,

STEP 1

Insert sensor ALL THE WAY into well. (Fig. 1)

tighten well clamp screw. (Fig. 2)

FIG. 1

FIG. 2

NOTE: In the case of space restrictions,

the Fuel Smart HydroStat control may

be mounted in a horizontal orientation

without any loss of function.

2

lectrical shock hazard. To prevent electrical shock, death or equipment damage, disconnect power supply before

YGW

CR

YGW

CR

YGW

CR

E

WARNING

installing or servicing this control.

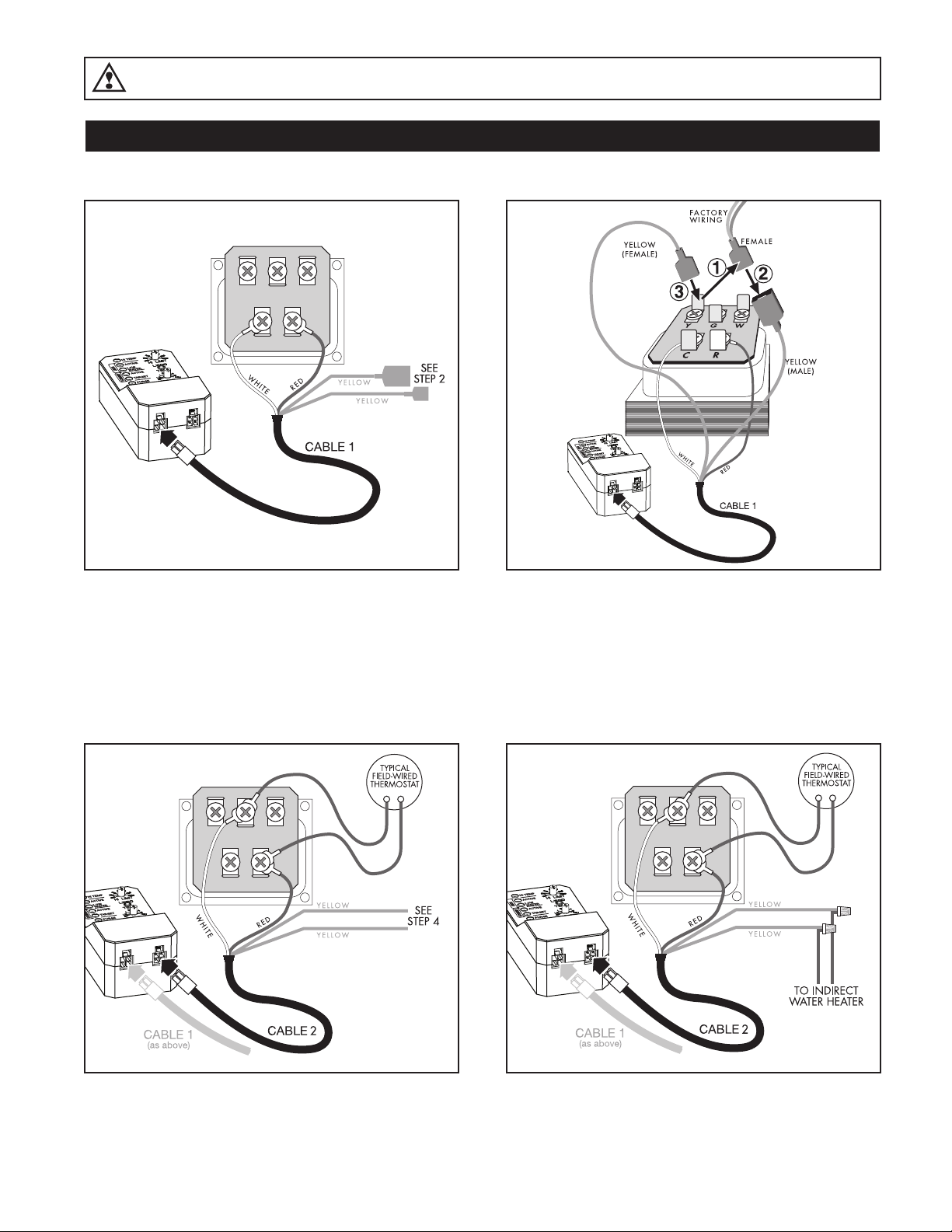

WIRING TO CONTROL CENTER

USE CABLE 1 – For boilers equipped with a Honeywell R8285 Control Center or equivalent.

Step Step

Connect the WHITE wire to C and the RED wire to R

using the screw terminals on the control center.

Unplug the factory-wired quick connect from terminal Y and plug into YELLOW wire with

nector. Plug YELLOW wire from cable with

male

con-

female

connector into terminal Y.

USE CABLE 2 – For Thermal Targeting and is optional. If Cable 2 is not used, turn Economy OFF.

IMPORTANT:

high limit setting to heat the indirect tank. The indirect signal must be separate from all heating zone signals. If you choose not to separate the indirect signal from

the heating zones, the Economy Feature should be turned OFF to insure that the boiler supplies adequate temperature to heat the indirect tank (see page 5).

When installing with an indirect water heater, the indirect wiring cable will bypass the Thermal Targeting feature and allow the boiler to fire to the

Step Step

Connect the WHITE wire to G and the RED wire to R

using the screw terminals on the control center. The

RED and WHITE wires must be connected in parallel

with the heating thermostat.

Connect the two YELLOW wires to the end switch

from the indirect water heater relay. NOTE: If you are

not connecting to an indirect water heater, the bare

ends of the YELLOW wires must be capped off separately with wire nuts.

3

Loading...

Loading...