Page 1

INSTRUCTION MANUAL

DOBSONIAN SYNSCAN - 8” 10” 12” 14” 16”

ENTER

SETUP

ESC

UTILITY

3

RATE

2

TOUR

1

M IC

6

NGC

5

USER

4

PLANET

9

OBJECT

8

7

ID

0

240412V1

180610V6-3.08

Page 2

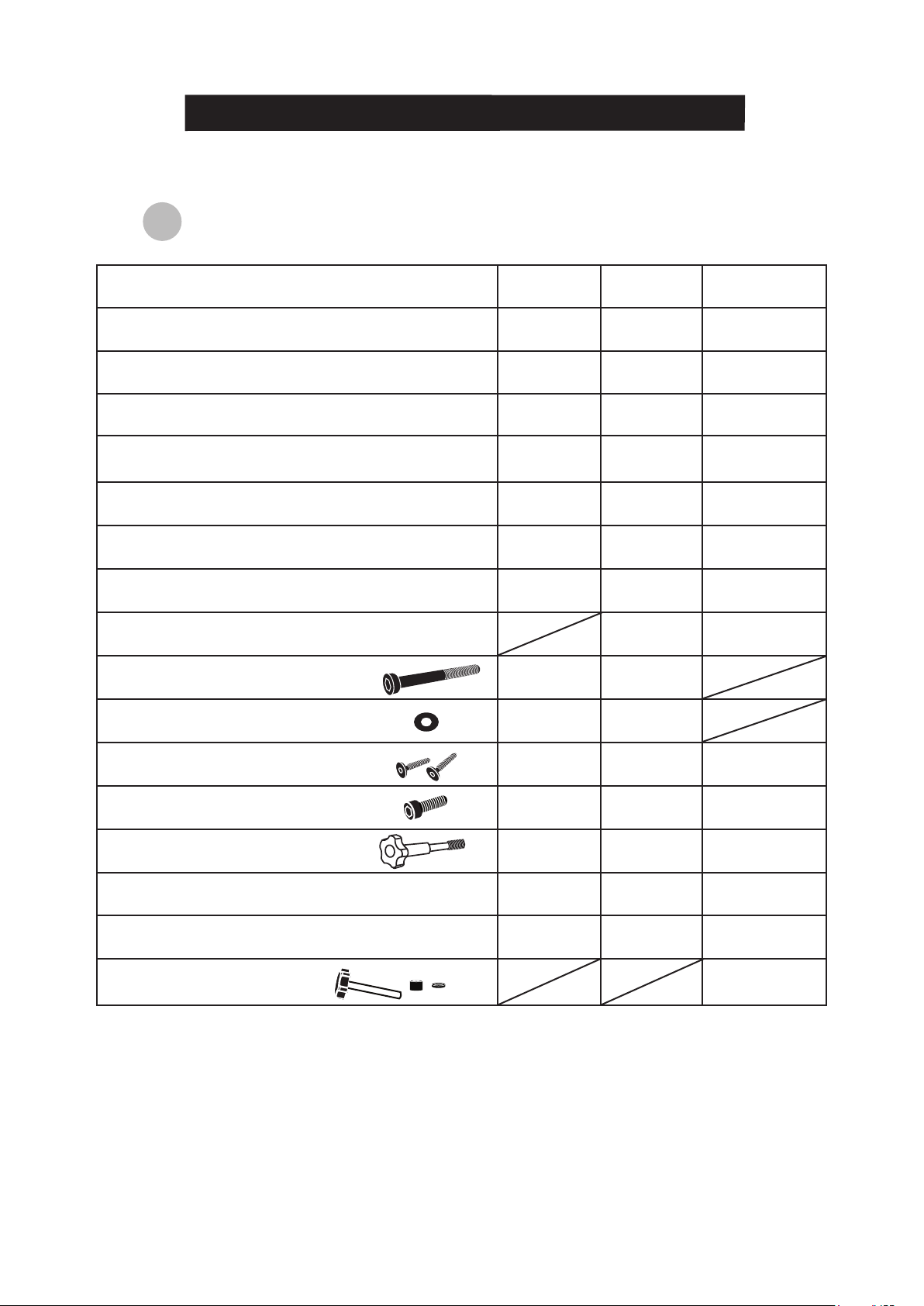

TABLE OF CONTENTS

DOBSONIAN BASE ASSEMBLY

DOBSONIAN BASE ASSEMBLY – – – – – – – – – – – – – – – – – – – – – – – – – – 3

TELESCOPE SETUP

PRIMARY MIRROR INSTALLATION – – – – – – – – – – – – – – – – – – – – – – – – 7

ALIGNING THE FINDERSCOPE

TELESCOPE SETUP – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – 10

FOCUSING

ALIGNING THE FINDERSCOPE – – – – – – – – – – – – – – – – – – – – – – 10

POWER REQUIREMENTS

FOCUSING – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – 10

POWERING THE DOBSONIAN SYNSCAN

POWER REQUIREMENTS – – – – – – – – – – – – – – – – – – – – – – – – – 10

THE SYNSCAN AZ

POWERING THE DOBSONIAN SYNSCAN – – – – – – – – – – – – – – – – 10

INTRODUCTION TO THE SYNSCAN AZ

THE SYNSCAN AZ – – – – – – – – – – – – – – – – – – – – – – – – – – – – – 11

SYNSCAN AZ HAND CONTROL

INTRODUCTION TO THE SYNSCAN AZ – – – – – – – – – – – – – – – – – 11

AUTOTRACKING OPERATION

SYNSCAN AZ HAND CONTROL – – – – – – – – – – – – – – – – – – – – – 11

INITIAL SETUP

AUTOTRACKING OPERATION – – – – – – – – – – – – – – – – – – – – – – – – – – 13

AUTOMATIC TRACKING

INITAL SETUP – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – 13

AZ GOTO OPERATION

AUTOMATIC TRACKING – – – – – – – – – – – – – – – – – – – – – – – – – – 13

INITIAL SETUP

AZ GOTO OPERATION – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – 14

STAR ALIGNMENT

INITIAL SETUP – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – 14

POINTING ACCURACY ENHANCEMENT (PAE)

STAR ALIGNMENT – – – – – – – – – – – – – – – – – – – – – – – – – – – – – 14

OBJECT DATABASE IN THE SYNSCAN AZ

POINTING ACCURACY ENHANCEMENT (PAE) – – – – – – – – – – – – – 16

SELECTING AN OBJECT

OBJECT DATABASE IN THE SYNSCAN AZ – – – – – – – – – – – – – – – – 18

SELECTING AN OBJECT – – – – – – – – – – – – – – – – – – – – – – – – – 18

UTILITY FUNCTIONS

UTILITY FUNCTIONS – – – – – – – – – – – – – – – – – – – – – – – – – – – 19

SETUP FUNCTIONS

SETUP FUNCTIONS – – – – – – – – – – – – – – – – – – – – – – – – – – – – 19

USING THE USER DEFINED DATABASE

USING THE USER DEFINED DATABASE – – – – – – – – – – – – – – – – – 20

IDENTIFYING AN UNKNOWN OBJECT

IDENTIFYING AN UNKNOWN OBJECT – – – – – – – – – – – – – – – – – – 21

LINKING WITH A COMPUTER

LINKING WITH A COMPUTER – – – – – – – – – – – – – – – – – – – – – – – 21

UPDATING THE SYNSCAN AZ FIRMWARE

UPDATING THE SYNSCAN AZ FIRMWARE – – – – – – – – – – – – – – – – 22

SYNSCAN AZ MENU TREE

SYNSCAN AZ MENU TREE – – – – – – – – – – – – – – – – – – – – – – – – – – – – 24

TECHNICAL SPECIFICATIONS

TECHNICAL SPECIFICATIONS – – – – – – – – – – – – – – – – – – – – – – – – – – 25

APPENDIX A - RS-232 CONNECTION

APPENDIX A - RS-232 CONNECTION – – – – – – – – – – – – – – – – – – – – – – – – I

APPENDIX B - STANDARD TIME ZONES OF THE WORLD

APPENDIX B - STANDARD TIME ZONES OF THE WORLD – – – – – – – – – – – – III

3

7

8

8

8

8

9

9

9

11

11

11

12

12

12

14

16

16

17

17

18

19

19

20

22

23

I

III

BEFORE YOU BEGIN

This instruction manual is applicable to all the models listed on the cover. Follow the

instructions for your specific model in the manual. Read the entire instructions

carefully before beginning. Your telescope should be assembled during daylight

hours. Choose a large, open area to work to allow room for all parts to be unpacked.

While every effort has been made to ensure that the information contained in this

instruction manual is accurate and complete, no liability can be accepted for any

errors or omissions. Sky-Watcher Telescope reserves the right to change the

specifications of the hardware and software described herein at any time without

prior notice. Please always check our web site to obtain the latest information:

http://www.skywatchertelescope.net

Page 3

arts List

P

DOBSONIAN BASE ASSEMBLY

PARTS

Round base assembly

Right side panel assembly

Left side panel assembly

Front panel

Eyepiece holder / Countersunk head Phillips screws

Countersunk head Phillips screws (silver)

Feet /

Handle

Reinforce board

Hex socket head cap screw M5x60

Large washer for M5 screw

8” and 10”

1pc

1pc

1pc

1pc

1pc / 3pcs

3pcs / 3pcs

3pcs

8pcs

8pcs

12”

1pc

1pc

1pc

1pc

1pc / 3pcs

3pcs / 3pcs

3pcs

2pcs

8pcs

8pcs

14” and 16”

1pc

1pc

1pc

1pc

1pc / 3pcs

3pcs / 3pcs

2pcs

2pcs

Hex socket flat head screw 7x50

Hex socket head cap screw M8x25

Optical tube locking screw

Allen Wrenches (2mm, 4mm, 6mm)

Phillips screw driver

Fastening bolts and washers

6pcs

6pcs

1pc

1pc each

1pc

12pcs

6pcs

1pc

1pc each

1pc

6pcs

4pcs

1pc

1pc each

1pc

12pcs each

3

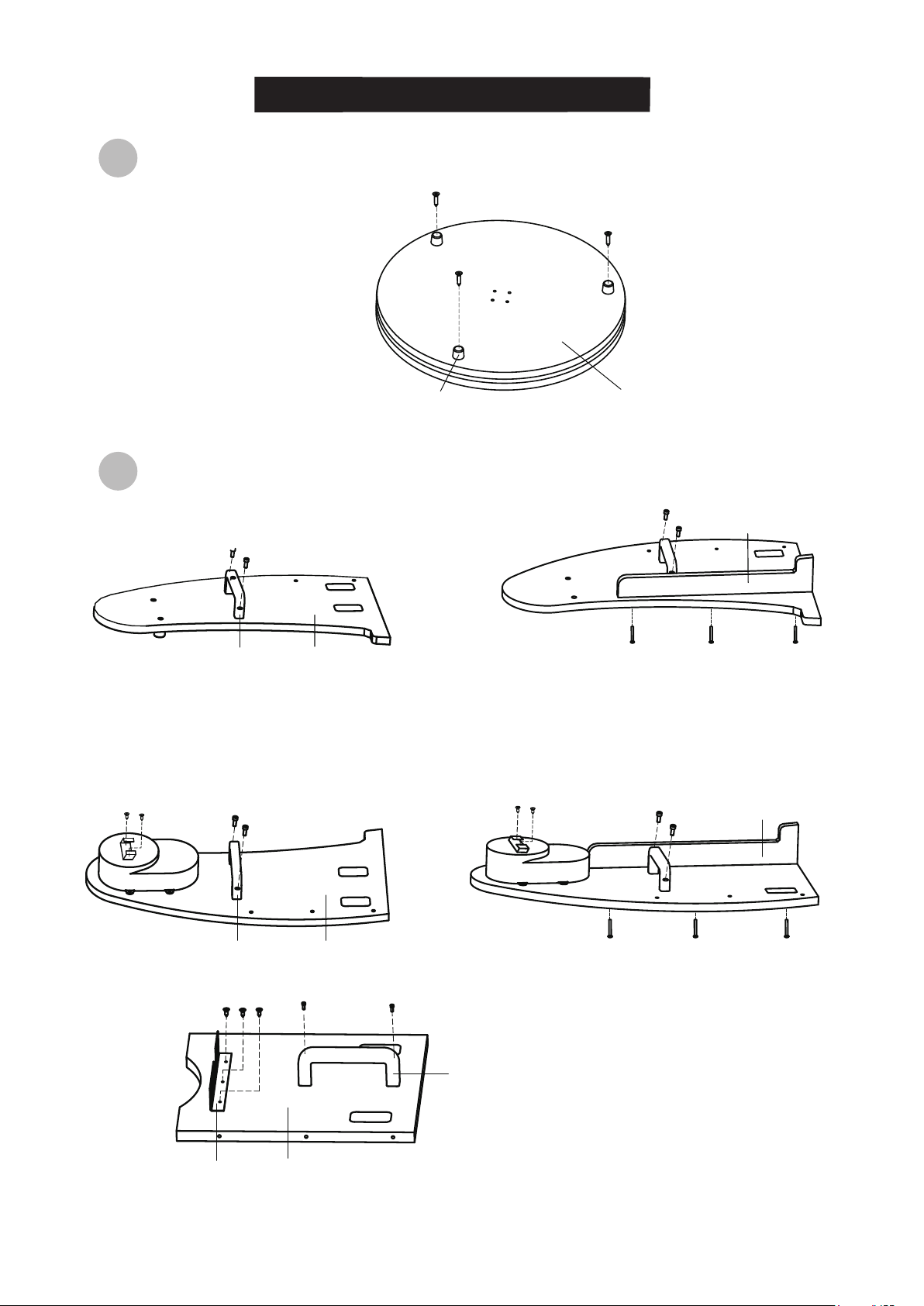

Page 4

ound base assembly setup

R

Flip the round base assembly over.

Attach the feet onto the assembly

using the Countersunk head

Phillips screws provided.

ide and front panel setup

S

8”, 10”, and 12”

Round base assembly (the bottom side)Foot

Right side panel

Left side panel

(8” and 10”)

Using the two screws provided, attach the holder

to the latitude motor box.

Locate the hand control holder.

Handle

Handle

(8” and 10”)

Right side panel assembly

Right side panel assembly

(12”)

Hex socket flat head screw 7x50

(12”)

Locate the hand control holder. Using the

two screws provided, attach the holder to the

latitude motor box.

Hex socket flat head screw 7x50

Reinforce board

Reinforce board

Front panel

Eyepiece holder Front panel

Handle

4

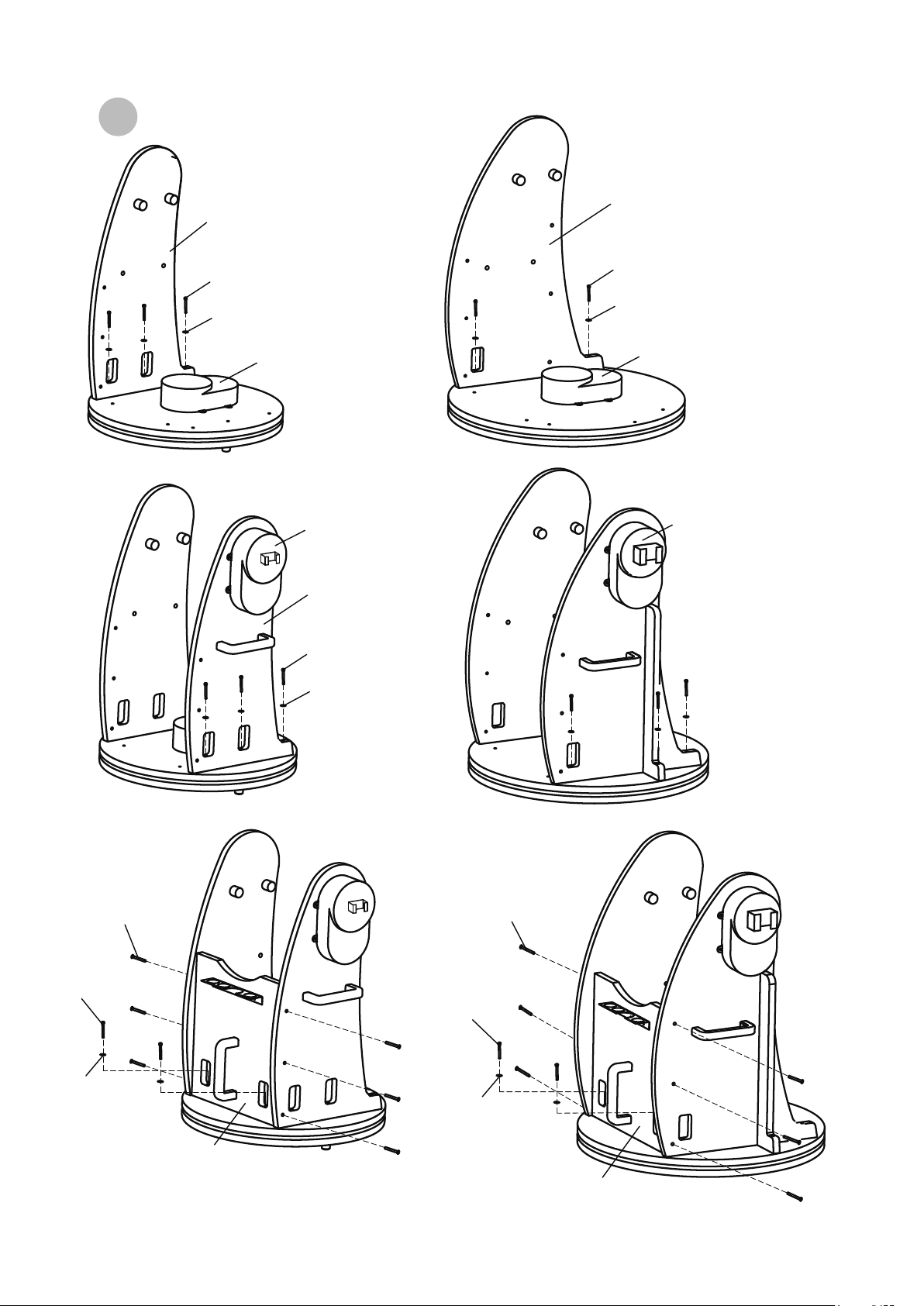

Page 5

ount setup

M

(8” and 10”)

Right side panel assembly

Hex socket head cap

screw M5x60

Large washer for

M5 screw

Azimuth Motor box

(8” and 10”)

Altitude Motor box

Left side panel

assembly

(12”)

Right side panel assembly

Hex socket head cap

screw M5x60

Large washer for

M5 screw

Azimuth Motor box

(12”)

Altitude Motor box

Left side panel

assembly

(8” and 10”)

Hex socket flat

head screw 7x50

Hex socket

head cap

screw M5x60

Hex socket head

cap screw M5x60

Large washer

for M5 screw

Hex socket head

cap screw M5x60

Large washer

for M5 screw

(12”)

Hex socket flat

head screw 7x50

Hex socket

head cap

screw M5x60

Hex socket

flat head

screw 7x50

Large washer

for M5 screw

Front panel

Hex socket flat

head screw 7x50

Large washer

for M5 screw

Front panel

5

Page 6

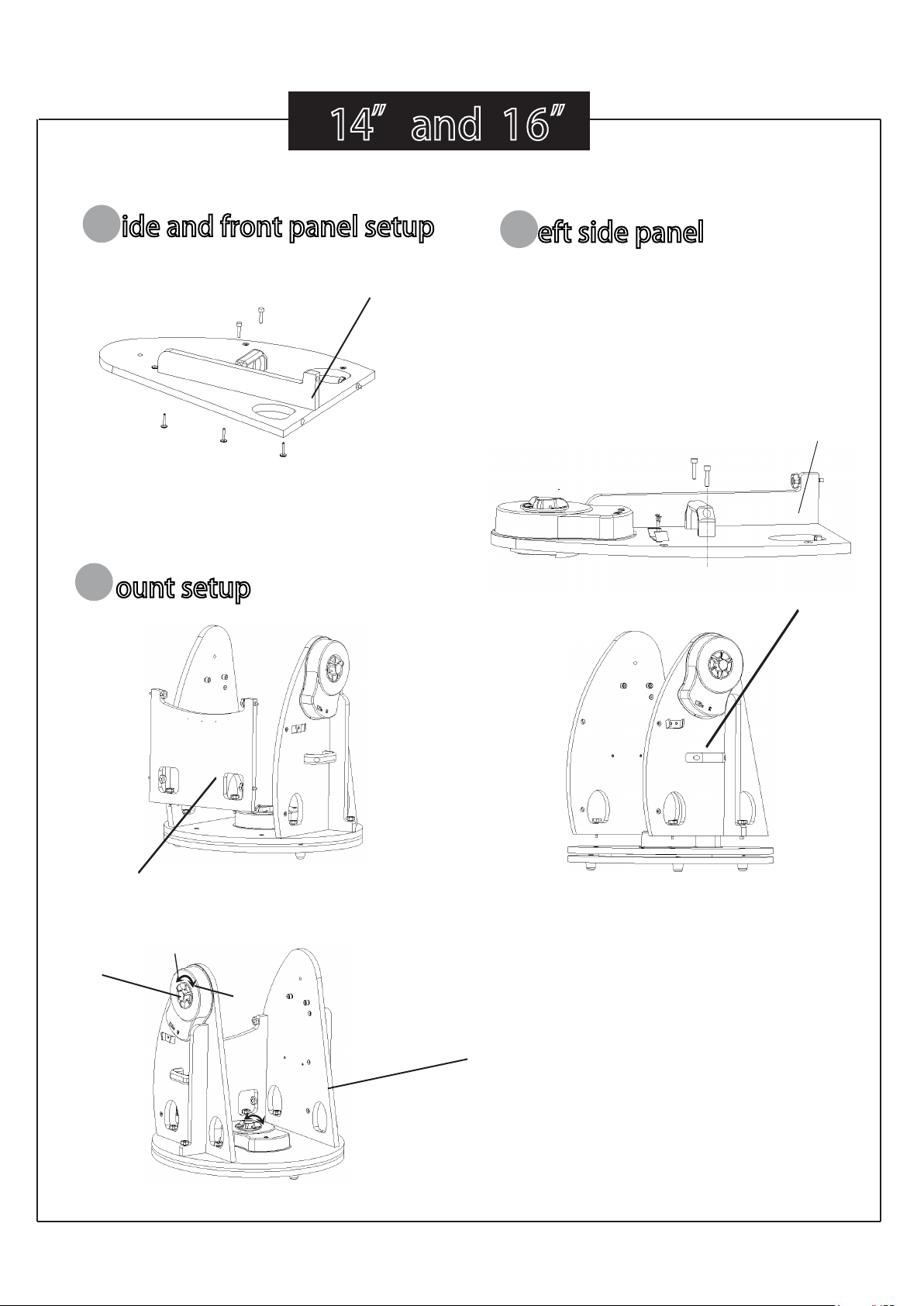

14”and 16”

ide and front panel setup

S

L eft side panel

Right side panel

Hex socket flat head screw 7X50

ount setup

M

Reinforce board

Locate the hand control holder.

Using the two screws provided ,

attach the holder to the Left side

panel assembly

Reinforce board

Left side panel

assembly

Front panel

handwheel

loose

lock

When using GoTo and tracking

function , please tighten the

handwheel

6

Page 7

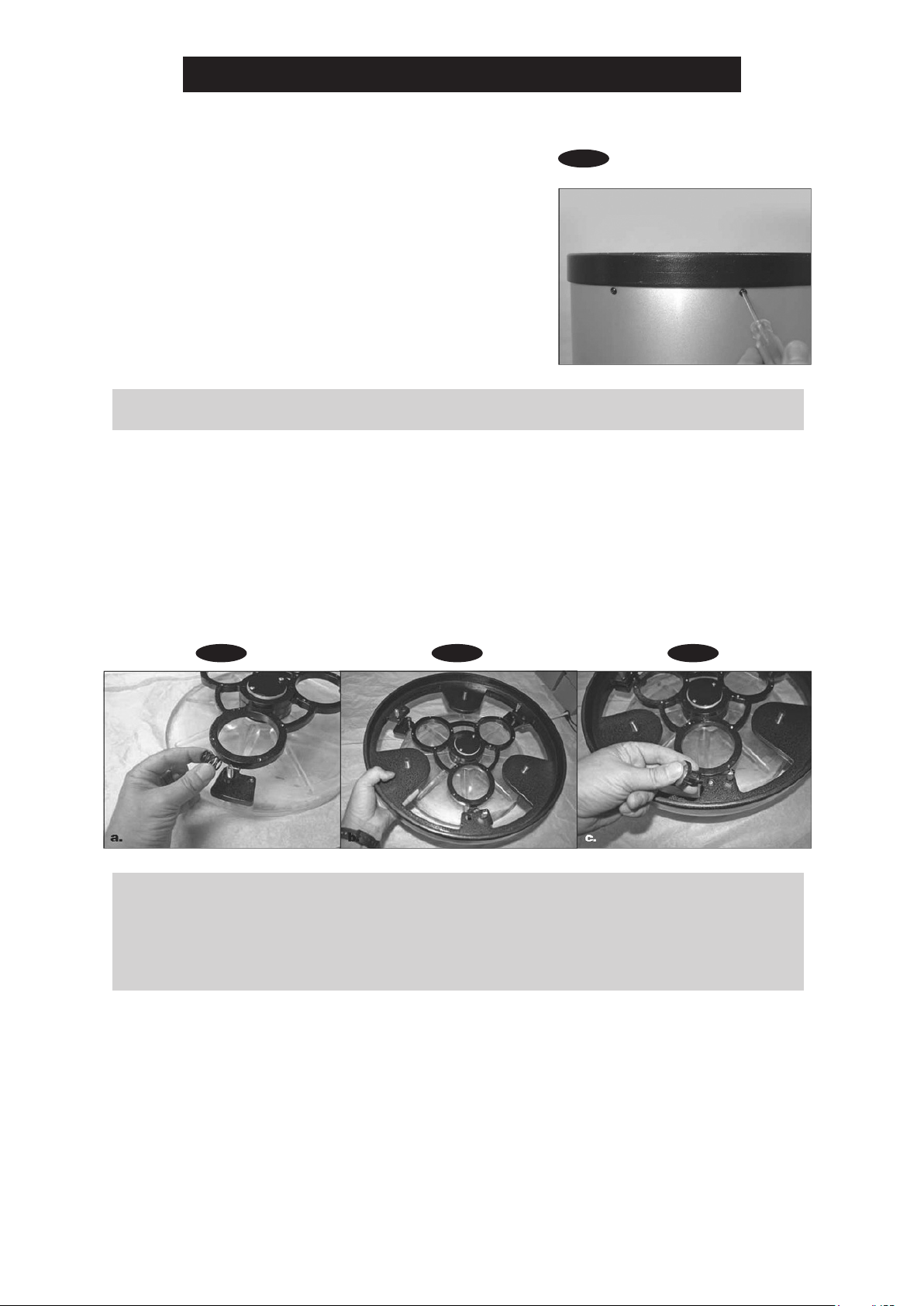

PRIMARY MIRROR INSTALLATION

1. When installing the mirror into the optical tube, you

must rst remove the rear end ring attached to the lower

section of the optical tube. Simply unthread and remove

the eight Phillips-head screws that connect the end ring

to the tube (Figure 1), and then pull the end ring off of

the tube.

Caution: The raw edge of the tube itself will be exposed

after the rear end ring is removed from the tube. Be

careful not to cut or injure yourself on the tube’s edge.

Please also be careful not to pinch your ngers when

attaching the assembled mirror cell onto the tube.

Fig.1

Figure 1. To remove the rear end ring, unthread the eight screws on the tube.

2. Before beginning to assemble the rear end ring to the mirror support cell, nd a clean, at surface

and place a clean cloth or towel on it. Turn the mirror cell over so that the mirror is facing downward

and then put it down on the cloth. Place the three springs onto the three exposed threaded shafts

(see Figure 2a). Lower the end ring onto the mirror cell so that the threaded shafts pass through it,

and the end ring rests on the springs (Figure 2b). Add a nylon washer to each collimation knob and

thread the collimation knobs through the end ring and onto the threaded shafts (Figure 2c). Conrm

that the knobs have at least three full turns of engagement on the shafts. The mirror and end ring

assembly is now all set to be installed onto the lower tube section.

Fig.2a Fig.2b Fig.2c

Figure 2. (a) Place the three springs on the exposed threaded shafts of the mirror cell (b) Lower

the rear end ring onto the mirror cell so that the threaded shafts of the mirror cell pass through

the end ring, and the end ring rests on the springs (c) Thread the collimation knobs, with nylon

washers attached, through the rear end ring and onto the threaded shafts. Check that the knobs

have at least three full turns of engagement on the shafts.

7

Page 8

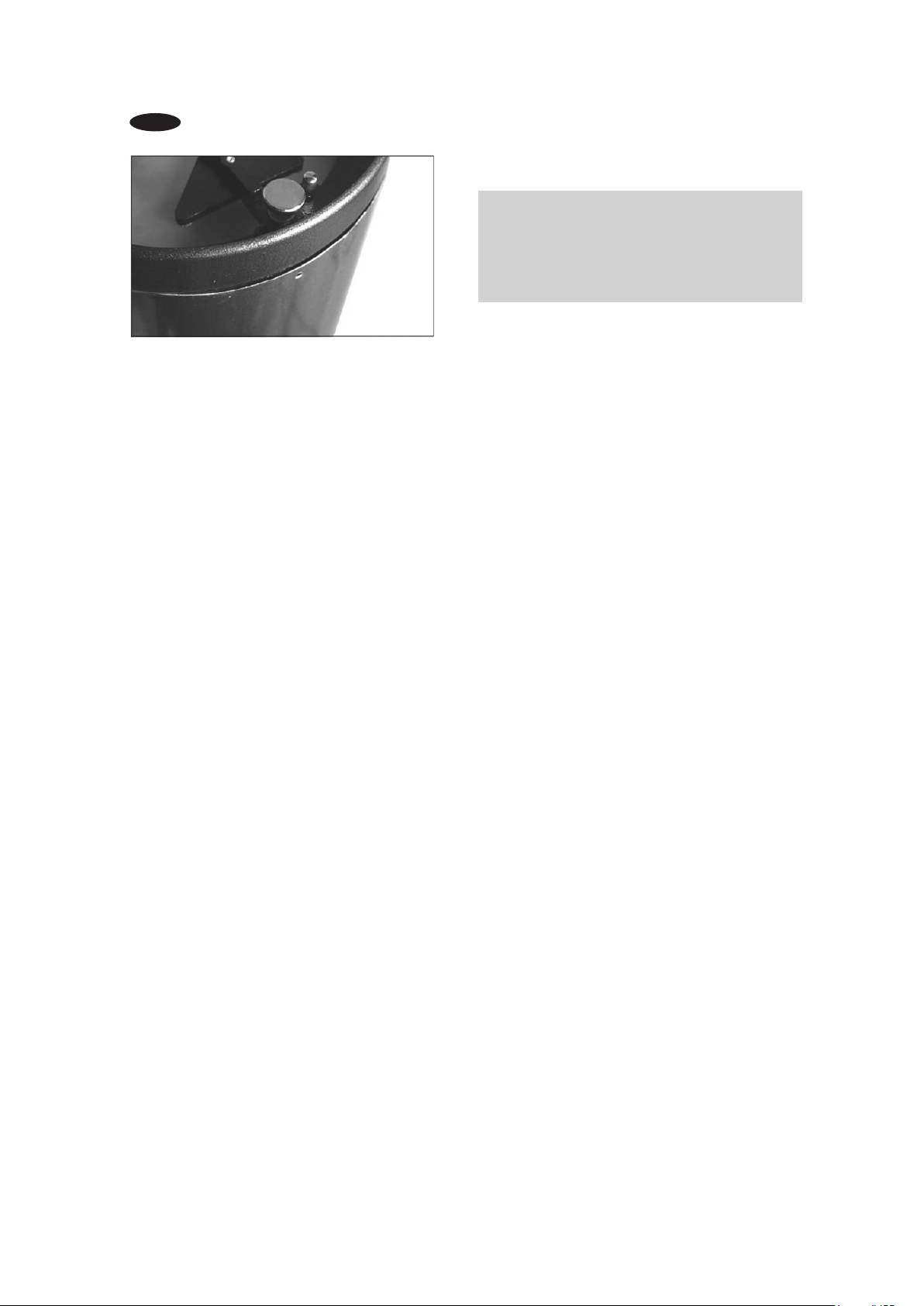

Fig.3

Figure 3. Find the area of tube that is bulging out and obstructing it from seating in

the end ring. Press on the bulge to force

the tube into the end ring.

3. It can be a tricky task when assembling the end ring (and mirror cell) back onto the tube.

The complication is that the large diameter and thin metal of the tube will cause the tube to

become somewhat out of round once the end ring is removed. To assemble the rear end ring

(with mirror and mirror cell now connected) to the tube, position the lower section of the tube

up vertically so that the raw edge of the tube is up. Line up the threaded holes in the edge of

the end ring with the holes in the end of the tube. Then, lower the entire assembly onto the

tube. (Be careful to avoid nger pinching during this step.) There may be a bulge in the

perimeter of the tube that obstructs the end ring from fully seating onto the tube (Figure 3).

Simply press the bulge down and the entire mirror cell assembly should seat onto the tube.

Now, replace the eight Phillips screws that connect the rear end ring to the tube.

8

Page 9

TELESCOPE SETUP

Place the mount on the ground. Place a bubble level on

1.

the top of the round base to ensure the mount is set on a

leveled plane. Better leveling will yield better tracking

performance.

To extend the telescope tube, loosen the three slider lock

2.

screws and pull the top part of the telescope assembly

out until it clicks in place Tighten the slider lock screws.

Do not over-tighten.

Remove the dust cap and the protective cover in the front

3.

of the tube.

Loosen these screws

Grab the telescope tube with both hands at the positions indicated in the diagram below.

4.

Hold the telescope tube directly above the mount. Align the side bearings of the tube to the

5.

mounting platforms on the inner side of the side boards. Lower the telescope tube and

carefully place it on the base.

Tighten the locking screw to secure the tube in place.

6.

Mounting platform. Make sure that

the side bearing aligns with this

when placing the tube on the mount.

Lift up the telescope tube by holding here

Optical Tube

Locking screw

Locate the finderscope bracket

7.

and carefully remove the

rubber-o-ring from it. Position

the o-ring into groove on the

finderscope tube.

Slide the finderscope bracket

8.

into the mounting slot and

tighten the screw to hold the

bracket in place.

Loosen the two adjusting screws

9.

on the bracket. Pull back the

spring-loaded screw and position

the finderscope into its bracket by

sliding it backwards until the rubber

o-ring seats.

(Straight through finderscope

shown here)

9

Page 10

onnecting the cables

C

Power supply cable: The Dobsonian SynScan requires

12-Volts DC Nominal power. The power cable from the

battery pack or other power supply goes into the jack labeled

Power on the altitude motor box. (Fig.a).

To avoid tangling of the power cable, the battery pack or

power tank can be placed on the round base, behind the

front panel. Pass the cable through the first hole on the

left side panel to plug into the power jack.

AZ motor cable: This is the flat cable with 8-pin RJ-45 plug on

both end. Insert one end into the jack labeled "Az Motor" on

the altitude motor box and the other end into the azimuth

motor box on the round base.

Hand control cable: This is the coil cable with a 8-pin RJ-45

plug on one end and a 6-pin RJ-12 plug on the other. Plug the

RJ-45 end into the hand control (Fig.e) and the other end into

the outlet on the altitude motor box (Fig.a).

Fig.a

Hand control

holder

Hand control

cable goes here

Altitude motor box

AZ motor cable

goes here

Power switch

Power cable

goes here

ligning the Finderscope

A

Fig.b

(Straight through finderscope

shown here)

Fig.c

ocusing

F

Slowly turn the focus knobs (Fig.c), one way or the other, until the

image in the eyepiece is sharp. The image usually has to be

finely refocused over time, due to small variations caused by

temperature changes, flexures, etc. This often happens with short

focal ratio telescopes, particularly when they haven't yet reached

outside temperature. Refocusing is almost always necessary

when you change an eyepiece or add or remove a Barlow lens.

These fixed magnification scopes mounted on the optical tube are very useful

accessories. When they are correctly aligned with the telescope, objects can

be quickly located and brought to the centre of the field. Alignment is best

done outdoors in day light when it's easier to locate objects. If it is necessary

to refocus your finderscope, sight on an object that is at least 500 yards

(metres) away. Loosen the locking ring by unscrewing it back towards the

bracket. The front lens holder can now be turned in and out to focus. When

focus is reached, lock it in position with the locking ring (Fig.b).

1.

Choose a distant object that is at least 500 yards away and

point the main telescope at it. Adjust the telescope so that

the object is in the centre of the view in your eyepiece.

2.

Check the finderscope to see if the object centred in the

main telescope view is centred on the crosshairs.

3.

Use the two small alignment screws to centre the

finderscope crosshairs on the object. The screws work in

opposition to a spring-loaded knob (Fig.c).

Fig.c

10

Page 11

AZ

TM

ntroduction to the SynScan

I

The SynScanTM AZ is a precision-engineered instrument that provides two different operation modes:

AUTO-TRACKING MODE

The Sky-Watcher Dobsonian SynScan telescope has a patented dual encoder design incorporated to

record the position of the telescope. Under the Auto-Tracking Mode, you may choose to manually, or

electronically, move the telescope to any position without deactivating the tracking mode first. After

moving to a new object, the telescope will automatically begin to track the new object accurately. No

re-setup is required in one observing session.

If you are familiar with the night sky, or if you wish to quickly set up the telescope for tracking the

object, AUTO-TRACKING MODE will allow you to operate the telescope in the traditional way with

added bonus of automatic tracking and digital setting circle.

AZ GOTO MODE

The AZ GOTO MODE provides extensive computerized GO-TO functions to assist you in finding and

enjoying the night sky treasures, such as planets, nebulea, star clusters, galaxies and much more.

The hand control allows you to point your telescope to a specific object or even tour the skies at the

touch of a button. The user friendly menu system allows automatic slewing to over 42,900 objects.

Even an inexperienced astronomer can master its variety of features in a few observing sessions.

AZ

TM

ynScan

S

On the bottom of the hand control, the middle port is used for RS-232 communications between the

SynScan

power port allows independent use of the SynScanTM AZ hand control for users who wish to browse

the database or update the firmware without connecting to the telescope (Fig.e).

TM

AZ and a computer or other devices. (See “Linking with a Computer” for details.) The DC

AZ Hand Control

Fig.e

RJ-45

RJ-12 DC power port

The DC power port on the hand control is for hand control stand-alone applications only. For

telescope applications, use the 12V DC outlet on the mount.

To connect the SynScan AZ to a PC, use only the RS-232 cable provided with the mount.

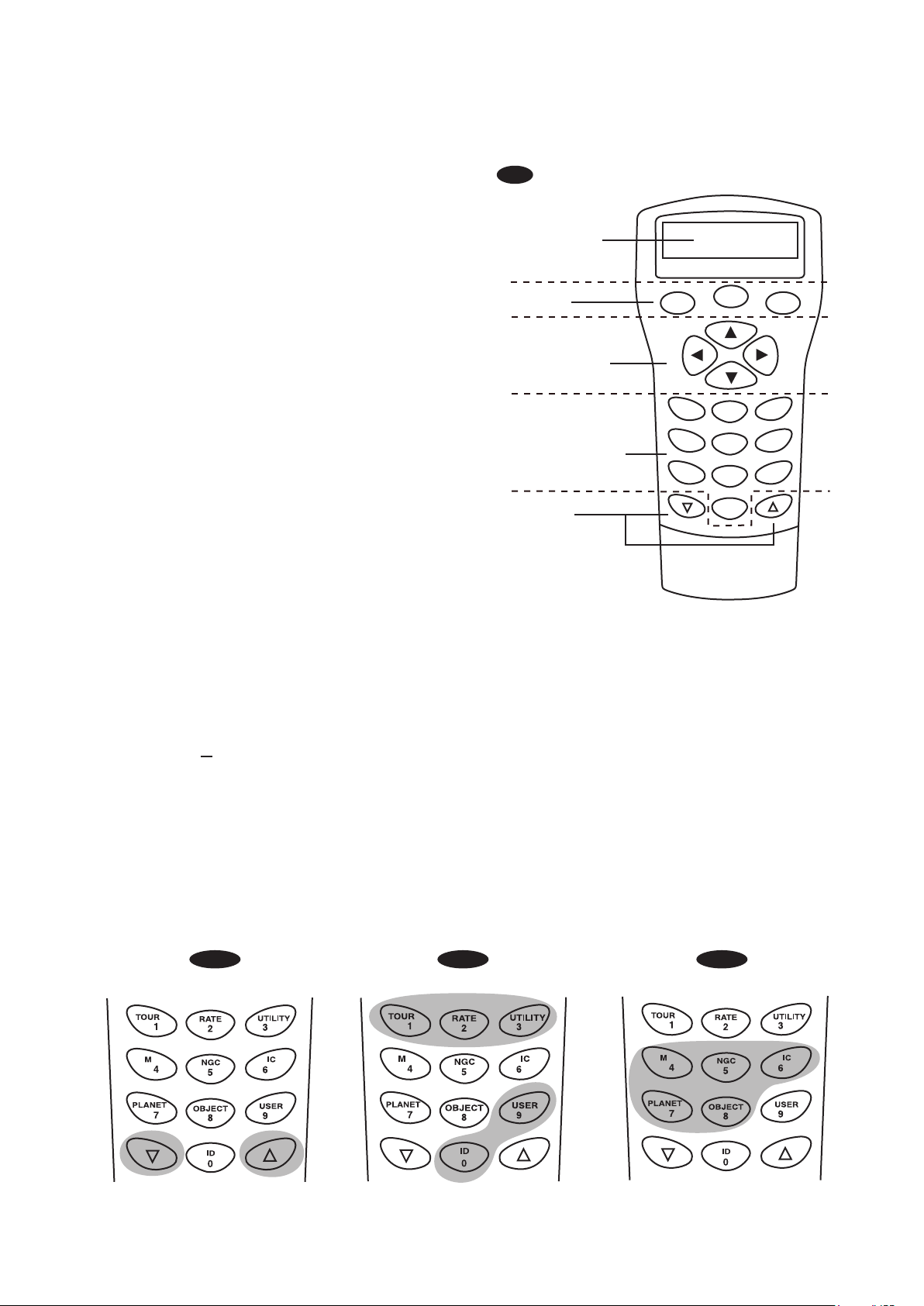

The SynScanTM AZ Hand Control allows direct access to all the motion controls of the telescope and a

database with a range of preset objects. The Hand Control comes with a dual-line, 16 character

display screen that is backlit for comfortable viewing of the telescope information and scrolling text. To

explore the many functions that the SynScanTM AZ has to offer, there are 4 main categories of control

on the Hand Control (Fig.f):

11

Page 12

Mode keys

The mode keys are located near the top, close

to the LCD display. They include the ESC,

ENTER, and SETUP keys:

ESC key is used to escape from a certain

command or to go back a level in the menu tree.

SETUP key is a quick hot key that takes you to

the Setup submenu.

ENTER key is used to select the functions and

submenus in the menu tree, and to confirm

certain functional operations.

Directional keys

The directional keys allow complete control of

the telescope at almost any step in the

SynScan's operation. These controls are

locked out when the telescope is slewing to an

object. They are normally used to initially align,

center objects in the eyepiece, and manual

guiding. The left and right directional keys can

also be used to move the text cursor when

entering data to the hand control.

Fig.f

Display screen

Mode keys

Directional keys

Dual purpose keys

Scroll keys

ESC

SETUP

TOUR

PLANET

RATE

1

2

M IC

NGC

4

5

OBJECT

7

8

ID

0

ENTER

UTILITY

3

6

USER

9

Scroll Keys

(Fig.g-1)

The up and down scroll keys allow you to scroll up and down within the menu tree or selections.

Dual Purpose keys

These keys range from the middle to the bottom of the hand control. They serve two distinct

purposes data entry and quick reference hot keys.

TOUR key (Fig.g-2) takes you on a preset tour across the sky you are currently under.

RATE key (Fig.g-2) changes the speed rate of the motors when the direction keys are pressed.

There are 10 speeds to choose from: 0 (slowest) to 9 (fastest).

UTILITY key (Fig.g-2) shows functions such as Show Position, Display Time...etc.

USER key (Fig.g-2) gives access to up to 25 user-defined coordinates.

ID key (Fig.g-2) identifies the object the telescope is currently pointing to.

NGC, IC, M, PLANET, and OBJECT keys (Fig.g-3) allow direct access to SynScan

over 42,900 objects.

Fig.g-1 Fig.g-2 Fig.g-3

TM

database of

12

Page 13

AUTOTRACKING OPERATION

nitial Setup

I

Make sure that the telescope is set on a level

1.

ground. Point the telescope to the North.

Locate the altitude scale on the inside of the left side

2.

board. Lower the telescope tube in altitude until it

reads 0. (Fig.h).

Connect the hand control to the mount with the provided cable. Plug

3.

the DC 12

The initial screen displayed on the hand control is the Version Screen.

Press ENTER to proceed. The hand control will display a warning

4.

concerning pointing the telescope at the sun without proper equipment.

If you have read the message already, pressing ENTER will bypass the

message and skip to the next step.

volt power into the outlet of the mount. Turn on the power.

Fig.h

NORTH

The hand control's red light will become dimmer and the backlight of the key pads will turn off

if idle for 30 seconds. Pressing any key turns it back on.

5.

Enter the telescope's current latitudinal and longitudinal coordinates using the numeric keypad. First

enter the longitudinal coordinate, followed by the latitudinal coordinate. Use the scroll keys to choose

between W or E, and N or S. Pressing the left or right directional keys will move the cursor to the

previous or next number. Press ENTER to confirm. The format you enter should look like this: 123 04’ W

6.

49 09’N.

Enter your current time zone in hours and minutes (see Appendix C), using the scroll keys and numeric

key pad (+ for East, - for West). Press ENTER to confirm. The format you enter should look like this if

7.

you are in Pacific Standard Time (PST): -08:00.

8.

Enter the date in the following format mm/dd/yyyy using the numeric keypad. Press ENTER to confirm.

Enter your current local time using the 24 hr time mode (e.g. 2:00PM=14:00). Press ENTER to view the

time you just entered. If it is incorrect, press ESC to go back to the previous screen. If correct, press

ENTER again to confirm. After entering the current time, the SynScanTM AZ will prompt "DAYLIGHT

SAVING?". Use the scroll keys to make the selection and press ENTER to confirm. After setting the

daylight saving, SynScan

TM

will display "Begin alignment?". Press "2" to bypass the alignment procedure.

If a mistake was entered into the SynScanTM AZ hand control, press the ESC key to go back to the

previous menu, and press

ENTER to start again.

The accuracy of the coordinate readings is dependent on the correctness of the setup. For best

result, make sure that the telescope is leveled and pointed to the North in the initial position. The

data entered into the hand control must be as accurate as possible.

9.

Press SETUP and then use the scroll keys to browse to the “Auto Tracking >” sub-menu. Press

ENTER to enter the Auto-tracking mode.

utomatic tracking

A

The telescope is now ready to point to any object and start tracking at the sidereal rate. The hand control

will display the coordinates of the direction the telescope is pointed. Press the scroll keys to switch

between the following three coordinate formats: Celestial, Terrestrial, and Telescope mount coordinates.

You may press ESC to exit from the Autotracking mode at any time during tracking to browse or choose

other functions provided by the SynScanTM AZ hand control. To return to the Autotracking mode, choose

“Auto-Tracking” under SETUP menu and press ENTER.

When the power is on, you may choose to adjust the telescope electronically by using the hand

control or manually by pushing the tube. The telescope will calculate the coordinates

accordingly and display the information correctly on the hand control.

13

Page 14

AZ GOTO OPERATION

nitial Setup

I

Make sure the mount is level to the ground.

1.

Point the telescope roughly to the brightest star in the sky to your naked eyes.

2.

Connect the hand control to the mount with the provided cable. Plug the DC 12 volt power into the

3.

outlet of the mount to turn on the power. Flip the power switch to the “on” position.

The initial screen displayed on the hand control is the Version Screen. Press ENTER to proceed.

4.

The hand control will display a warning concerning pointing the telescope at the sun without

5.

proper equipment. If you have read the message already, pressing ENTER will bypass the

message and skip to the next step.

The hand control's red light will become dimmer and the backlight of the key pads will turn

off if idle for 30 seconds. Pressing any key turns it back on.

6.

Enter the telescope's current latitudinal and longitudinal position using the numeric keypad.

First enter the longitudinal coordinate, followed by the latitudinal coordinate. Use the scroll

keys to choose between W or E, and N or S. Pressing the left or right directional keys will

move the cursor to the previous or next number. Press ENTER to confirm. The format you

enter should look like this: 123 04’ W 49 09’N.

7.

Enter your current time zone in hours and minutes (see Appendix C), using the scroll keys

and numeric key pad (+ for East, - for West). Press ENTER to confirm. The format you enter

should look like this if you are in Pacific Standard Time (PST): -08:00.

8.

Enter the date in the following format mm/dd/yyyy using the numeric keypad. Press ENTER

to confirm.

9.

Enter your current local time using the 24 hr time mode (e.g. 2:00PM=14:00). Press ENTER

to view the time you just entered. If it is incorrect, press ESC to go back to the previous

screen. If correct, press ENTER again to proceed to the daylight saving setting.

If a mistake was entered into the SynScanTM AZ hand control, press the ESC key to go back to

the previous menu, and press ENTER to start again.

After setting the daylight saving, SynScan

10.

the alignment procedure.

tar Alignment

S

In order for the SynScanTM AZ to correctly point to objects in the sky, it must first be aligned to two to three

known positions (stars) in the sky. As the Earth rotates on its axis every 24 hours, astronomical objects

appear to move through the sky following an arc. With the supplied information, the telescope can

replicate a model of the sky and the movements of astronomical objects. Star alignment can be done

anytime during the observing session by choosing Alignment under Setup Mode, in the Main Menu.

There are two ways to align the SynScanTM AZ Brightest Star alignment and 2-Star alignment. If

you are using the SynScanTM AZ for the first time, and you are not familiar with the celestial object in

the sky, we recommend that you begin with the Brightest Alignment. The Brightest Star alignment will

prompt and help you find the brightest star of a specific direction in the sky at your current site. It is

convenient for user to identify the brightest star in the sky. Before performing the alignment method,

make sure that your finderscope is well aligned with the telescope tube. See the next page for tips on

how to choose the alignment stars. Below describes a step-by-step procedure on how to perform the

Brightest Star Alignment:

TM

will display "Begin alignment?". Press "1" to start

14

Page 15

Brightest Star Alignment

This alignment method is the most suitable if you are unfamiliar with the night sky, or are unsure of the name

of the brighter stars.

Find a visible single bright star that is far apart from any object in the sky. Point the telescope roughly

1.

to the star.

In the alignment screen, select Brightest-Star Align using the scroll keys. Press ENTER to confirm. The

2.

hand control will prompt "Select Region:" for you to select one of the eight directional divisions in

azimuth angle from the north, northeast, east, southeast to northwest etc. Select the region where the

chosen star is located and press ENTER.

Each division covers 90-degree span in azimuth. The table below explains the range of the eight

directional divisions.

Directional division Span range in azimuth

The northern sky 315 ° ~ 45 °

The northeast sky 0 ° ~ 90 °

The eastern sky 45 ° ~ 135 °

The southeast sky 90 ° ~ 180 °

The slewing speed can be

adjusted by pressing on the

RATE button. Then choose a

number between 0 (slowest) - 9

(fastest).

The southern sky 135 ° ~ 225 °

The southwest sky 180 ° ~ 270 °

The western sky 225 ° ~ 315 °

The northwest sky 270 ° ~ 360 °

Once the directional division has been selected, the hand control will generate a list of the stars located

3.

within this region that are brighter than 1.5 in magnitudes, starting from the brightest to the dimmest.

The stars and planets below 10 degrees, higher than 75 degrees in elevation or fainter than 1.4 in

magnitudes will be filtered out.

The name and magnitude of the alignment star will be displayed on the first line of the LCD. The

4.

approximate position will be prompted on the second line. For example, if Arcturus is prompt as

alignment star, its magnitude is 0.0 and location is at 88.1 degree east and 24.1 degree above the

horizon. You will see the LCD display as shown in Fig.i.

For the first alignment star, the mount will not slew to the star auto-

5.

matically. Use the directional buttons to manually slew the telescope

Fig.i

to point to the object in the finder and then center it in the eyepiece.

You may change the slewing speed by pressing the RATE button,

and then choose a number between 0 (slowest) - 9 (fastest). You will

1. Arc turu s 0 .0

E 8 8 .1° 2 4.1 °

find that Rate 4 may be best suited for centering the object in the

finderscope and Rate 3 or less for centering in the eyepiece view.

Once the star has been centered in the eyepiece, if it is a planet the hand control will prompt you to rese-

6.

lect a star from the list as the first alignment star. Otherwise the hand control will prompt a list of objects

for you to choose as the second alignment star. Select an object from the list. The hand control will command the mount to slew the telescope to point to the star. If you see multiple objects in the eyepiece

view, the chosen star should be the brightest among all. Center the star in the eyepiece again. If both

alignment stars are properly aligned, "Alignment Successful" will display on the LCD. Otherwise, the

warning "Alignment Failed" will show and the alignment will have to be done again. You may exit the

alignment procedure by pressing the ESC key anytime during the procedure.

To ensure the accuracy of the star

alignment, make sure to end the

movement with the UP or RIGHT

directional key when centering the

object in the eyepiece view.

SynScan

TM

AZ will beep once when it has

finished slewing to an object. Do not try to

adjust the telescope before you hear the beep.

SynScan

TM

AZ will only respond to the

key while slewing.

15

ESC

Page 16

Two-Star Alignment

The two star alignment procedure is similar to the Brightest Star alignment, except that the hand control

will not prompt for you to select a directional region for a bright star. Below describes a step-by-step

procedure on how to perform the Two-Star Alignment:

1.

In the alignment screen, select 2-Star Align using the scroll keys. Press ENTER to confirm.

2.

The SynScan

first alignment star. Using the scroll keys, choose a star you are most familiar with and press

ENTER. The telescope will not automatically slew to the first selected alignment star. Use the

directional buttons to manually slew the telescope to point to the object. Now look through the

eyepiece and adjust the telescope so that the object is centered in the field of view of the

eyepiece. Press ENTER to confirm. You will find that Rate 4 may be best suited for centering the

object in the finderscope and Rate 3 or less for centering in the eyepiece view.

3.

SynScanTM AZ will now provide a list of objects for the second alignment star. Choose a star using

the scroll keys and press ENTER. The telescope will start slewing towards the chosen object.

When the slewing stops, adjust the telescope with the directional keys until the star is centered on

the crosshairs in the finder scope. Repeat the centering procedure to center the object in the field

of the eyepiece and press ENTER to confirm.

4.

If both alignment stars are properly aligned, "Alignment Successful" will display on the LCD.

Otherwise, the warning "Alignment Failed" will show and the alignment will have to be done again.

Following is some pointers on how to choose appropriate alignment stars:

Select two stars that are at least 60 degrees apart in Azimuth. The more distance between the two alignment stars, the better accuracy the alignment will produce. Choosing two stars with similar altitude will

also create a better result.

TM

AZ will provide a list of stars available in your current sky for you to choose as the

The result of the star alignments is stored in the hand control even after the power has been shut off.

You will only need to perform the star alignment once as long as these two criteria are met: 1. The

telescope has been properly parked to one of the three Park Scope positions before turning off the

power. 2. The telescope setup, including the mount, has not been moved. Accessory change is

acceptable as long as it is done with great caution. When the hand control is turned on for the next

time, make sure to choose YES when prompt whether to start from the park position. The time

entered during initial setup should be based on the same source as last time. For example, if you

enter the time on your watch during this observing session, the time you enter next time should also

be read from your watch.

ointing Accuracy Enhancement (PAE)

P

After the star alignment, select an object in the object list and slew the telescope to the object in the sky.

If you notice pointing error after slewing the telescope to the object, you may use the Pointing Accuracy

Enhancement (PAE) to further improve the accuracy in the specific area where the object is located. The

PAE function will only correct the pointing error in the 5-degree spanned area of the chosen star. Other

regions of the sky will not be affected.

The PAE function also makes it easier to find deep-sky objects that are too dim to spot. This can be

done by selecting a bright object nearby to perform the PAE. Once the pointing accuracy of the specific

area is enhanced the telescope will be able to accurately place the dim deep-sky object near the center

of the eyepiece view.

Other than bright named stars, you may also choose planets or objects in the Messier, NGC, or IC

catalog as the PAE object.

Follow these steps to perform the PAE:

1.

From a sky chart or a planetarium software, choose a bright object in the same area that you would

like to perform the PAE in. This object should be a known object that is easy to identify.

2.

Find this PAE object in the SynScan hand control database and go-to the object. If your mount is

under the control of a planetarium software, click on the object to slew to it.

16

Page 17

3.

After slewing to the object, press ESC to exit from the object catalog. Press the Utility button to enter

to the Utility menu. Choose PAE under the utility menu and press ENTER.

The SynScan hand control provides a short cut to quickly activate the PAE function. After exiting from

the object catalog, instead of using the Utility menu, press and hold down the ESC key for 2 seconds.

4.

The hand control will display “Re-centering obj” and the name of the PAE object will appear in a

blinking mode (3 times). If the PAE object is selected from a planetarium software the hand control will

display “Last goto object” instead of the name.

Use the directional keys to adjust the telescope so that the PAE object is in the center of the eyepiece.

5.

Press ENTER to record the result or press ESC to abort the operation if you do not wish to keep the

result. Upon pressing the ENTER key, the SynScan

automatically compensate the pointing error for this particular region in the sky.

TM

will record the amount of displacement and

The result for PAE is stored in the hand control even after the power has been shut off. You will

only need to perform the star alignment once as long as these two criteria are met: 1. The telescope

is moved to its home position (Park the telescope) before turning off the power. 2. The telescope

setup, including the mount, has not been moved. Accessory change is acceptable as long as it is

done with great caution. When the hand control is turned on for the next time, make sure to choose

YES when prompt whether to start from the park position. The time entered during initial setup

should be based on the same source as last time. For example, if you enter the time on your watch

during this observing session, the time you enter next time should also be read from your watch.

17

Page 18

TM

bject database in the SynScan

O

TM

The SynScan

AZ comes with a vast database with over 42,900 objects coordinates and

AZ

information all available in the palm of your hand. The database contains the following catalogs:

Solar System - The other 8 planets of our solar system, plus the Moon.

Named Star - A list of 212 best known stars from the SynScanTM AZ database.

*NGC - 7,840 of the brightest deep sky objects from the Revised New General Catalog.

IC - 5,386 of standard stars and deep sky objects from the Indexed Catalog.

Messier - Complete list of 110 Messier objects.

Caldwell - Complete list of 109 Caldwell objects.

Double Stars - Includes 55 well-known double stars.

Variable Stars - Includes 20 will-known variable stars.

SAO - Includes 29,523 stars.

electing an Object

S

Once the telescope has been aligned. You can now access and view the 42,900 different objects

in the SynScan

TM

database. There are three methods of selecting a celestial object to view:

TOUR - Takes you on a preset tour across your current sky. It

Fig.j-1

(Fig.j-1)(Fig.j-1)

will automatically choose from the database the brightest and

most beautiful deep-sky objects for your viewing pleasure. Use

the scroll keys to view through the deep sky objects. Choose the

desired object by pressing ENTER. It will show the coordinate of

the chosen object. Use the scroll keys to view other information

such as magnitude, size and constellation. Pressing ENTER

once more will cause the telescope to slew to the object.

M, NGC, IC - These shortcut keys give you access to the most

popular celestial catalogues to date. Each Catalog has a set

number of objects to choose from. Use the numeric keys to

select an object by entering its number. Pressing ENTER will

display its coordinate. Primary information such as size,

magnitude, and constellation are obtained by pressing the scroll

Fig.j-2

keys. Pressing ENTER once more will cause the telescope to

slew to the object.

PLANET - This shortcut key takes you straight to the Planets

sub menu in the database. Use the scroll keys to scroll through

the list of planets in our solar system. Press ENTER to view its

coordinates, and ENTER once more to slew to the planet.

USER - This will take you to the database that you have defined

for yourself. You can enter a new location or recall the objects

that have been previously saved (see Using the User Defined

Database).

Fig.j-3

The OBJECT key takes you to the Objects Catalogue, where

you have complete access to over 42,900 celestial objects in the

(Fig.j-2)(Fig.j-2)

database. (See Object database in the SynScan

menu tree.)

TM

AZ and the

OBJECT CATALOG

In the Main Menu, scroll down to OBJECT CATALOG and press

ENTER. Similar to the OBJECT key, this gives you the complete

(Fig.j-3)(Fig.j-3)

*NGC 2000.0 database, edited by Roger W. Sinnott, copyright by Sky Publishing Corporation. Used with permission.

access to all 42,900 celestial objects in the database. (See

Object database in the SynScan

TM

AZ and the menu tree.)

18

Page 19

tility Functions

U

Utility Functions are useful tools that provide simple, one-step processes to your SynScanTM AZ.

Show Position - This displays the coordinates of the location where the telescope is

currently pointed. The coordinates can be displayed in Dec and RA, Alt and Azm, or Ax1 (the

angular reading of the elevation) and Ax2 (the azimuth axes of the mount). Use the scroll

keys to choose your desired reading.

Show Information - Under this submenu, you may check local time, local sidereal time,

hardware, firmware and database version of the SynScan hand control. If the hand control is

connected to the mount, this menu will also display the firmware of motor control board.

Time - This displays the local time and the local sidereal time.

Version - This displays the hardware, firmware and database version of the SynScan

hand control. This menu also displays the firmware version of the motor control board, if

the hand control is connected to the mount. Use the scroll keys to scroll up or down to

view the version numbers.

Temperature – This displays the temperature detected from the thermal sensor in the

hand control in both Celsius and Fahrenheit.

Power Voltage – This displays the power voltage detected from hand control in Volts.

Park Scope - The Park Scope function is useful when you prefer to have the telescope

start from a certain position for your next observing session. No star alignment will be

required in your next observing session as long as the telescope has not been moved.

There are three options to park your telescope:

HOME position - This is the position where both Ax1 and Ax2 reads 0. If you have done

the star alignment for GoTo operation or followed the initial setup for autotracking

operation, the HOME position of your telescope should be North facing and the tube

parallel to the ground.

CURRENT position - This is the position where the telescope is currently pointed.

CUSTOM position - This is the position where the telescope was previously parked

before the power was last turned off. This option is useful when you prefer to always start

the telescope from a certain position other than the HOME position.

PAE - Pointing Accuracy Enhancement. See page 13 for information.

Clear PAE data – This function clears all PAE data stored in the hand control.

GPS – This allows you to obtain information from the optional SynScan

PC Direct Mode – The PC Direct Mode is used for updating the firmware of the motor

control board. It allows direct communication between the computer and the motor control

board of the mount.

TM

GPS receiver.

TM

AZ

etup Functions

S

The Setup functions allow you to change any system variable or information regarding location,

time, date, and alignment configurations. To access the Setup Functions, either press SETUP key

on the key pad or scroll to SETUP under menu option using the scroll keys. Below lists the

different types of functions available to you, and their purposes.

Date - Allows you to change the date entered at the initial setup.

Time - Allows you to change the current time.

Observing site - Allows you to change the current location.

Daylight Savings - Allows you to change the Daylight Savings option.

Alignment - Allows you to perform the star alignment.

Alignment Stars -

Auto Select - When this option is chosen, the hand control will filter out the star not

suitable for star alignment.

Sort by - This allows the hand control to generate a list of alignment stars and display

them alphabetically or by their magnitude.

Backlash - This feature allows you to insert a value for each axis to compensate for its backlash.

For better pointing accuracy, it is important that the backlash value is set to be equal or greater than

the real amount of backlash between the gears. The default setting of the backlash is 0 d 00' 00" (0

degree, 0 arcmin. and 0 arcsec.). Use the numeric keys to enter the desired value and press the

19

Page 20

RIGHT directional key to move the cursor to the next digit. First set the value for R.A. Press

ENTER to proceed to Dec.

Tracking

Auto Tracking - Allows the telescope to automatically track a celestial object without star

alignment. The hand control will display the coordinates of the direction the telescope is pointed at.

You may press the scroll keys to switch the coordinate to a different mode.

Set Slew Limits - Allows you to set the slewing limits of the mount on altitude axis. Setting the slew

limit prevents the optical tube from colliding with mount. To set the slew angular limitations in

altitude, use the numeric keys to enter the degrees and the RIGHT or LEFT keys to move the

cursor. The slew limit range is dependent on the mount and the optical tube installed on the mount.

Sid. Rate: This activates tracking in Sidereal rate (Dual Axes Tracking).

Lunar Rate: This activates tracking in Lunar rate (Dual Axes Tracking).

Solar Rate: This activates tracking in Solar rate (Dual Axes Tracking).

Stop Tracking: This stops the tracking instantly.

The slew limit can be set any time but it will come into effect only until the star alignment has

been performed.

Re-align Encoder - There are two encoders built in each axis of the Sky-Watcher Dobsonian Pro

mount. One encoder is coupled to the axis shaft and the other coupled to the motor shaft. This dual

encoder design (US Patent #: 7,228,253) allows you to manually move the telescope by hand any

time without losing the count on the axis encoder as long as the power is on. This enables the

Dobsonian to perform the Go-To and Autotracking functions to a certain degree of accuracy.

However, since the encoder at the axis shaft has lower resolution than the encoder coupled on the

motor shaft, you may need to calibrate the encoders from time to time to secure Go-To accuracy.

Following these steps to re-align the encoders:

The accuracy of the SynScan system depends heavily on the initial set up and star alignment. If you

notice inaccuracy in the Go-To performance, make sure that the initial set up and star alignment are

done correctly before considering re-aligning the encoders.

1.

Choose Re-align Encoder under SETUP menu. Press ENTER to start.

2.

The hand control will prompt you the two alignment starts chosen during the previous

star-alignment procedure. Use the scroll keys to select one of them and press ENTER to confirm.

3.

The telescope will slew to the selected reference star. Use the directional keys to put the star in

the center of the eyepiece field. Press ENTER to confirm.

4.

The hand control will prompt “Re-align Encoder completed.” on the LCD screen. Press ENTER to

confirm and finish the Re-align Encoder procedure.

Handset Setting - This submenu allows adjustments of the brightness of the LCD backlit, the

darkness of the LCD lettering, the brightness of the LED backlit and the beeper volume. Press the

RIGHT or LEFT directional key to increase or decrease the value.

Factory Setting - This submenu allows you to reset the hand control to its default setting.

sing the User Defined Database

U

SynScanTM AZ allows you to save up to 25 objects in the user defined database.

Fig.k

Saving an object to the database

Find the User Objects under the Object Catalog. Press ENTER.

1.

The User Defined menu can also be accessed by pressing the quick

reference hot key “USER” (Fig.k).

Choose Edit Object by using the scroll keys. Press ENTER.

1.

The SynScan™ AZ hand control stores the user-defined objects in two

2.

formats - RA-Dec and AzAlt. Choose your desire format by pressing 1

for RA-Dec or 2 for Alt-Azimuth.

20

Page 21

The SynScan™ AZ hand control will display the coordinates where the

1.

telescope is currently pointed at in your desired format. See Fig.l for an

example of the RA-Dec readout. If this is the location you would like to

save, simply press ENTER to record the coordinates. You may also

change the coordinates using the numeric keypad to enter numbers and

the scroll keys to choose between “+” and “-”. The RIGHT or LEFT

directional keys will move the cursor to the next or previous digit. Press

ENTER to save once you have entered the new coordinates.

Fig.l

Ent e r RA- D E C :

22h 4 6 . 1m + 9 0 0 0

Fig.m

If the coordinates entered do not exist, the AZ SynScan hand control will not

respond when the ENTER key is pressed. Check the entry for mistake and

enter the correct coordinates.

After the coordinates have been saved, the hand control will display an

2.

User Object number as shown in Fig.m. Use the scroll keys to change to

the number you wish to represent the coordinates and press ENTER.

The SynScan

3.

number you just entered. Press ENTER to go to the object or ESC to

return to the Input Coordinate menu.

TM

AZ will display "View Object?" and the User Object

Sav e ? < ENT E R >

Use r o bj. # 0 3

The User Object number displayed may not be a vacant one. If you are unsure which numbers are

vacant, it is recommended that you first check for the available numbers by recalling the saved

user objects.

Recalling an user defined object

1.

Find the User Objects under the Recall Object. Press ENTER.

2.

Use the scroll keys to browse through the User Object number until the number representing the

object you wish to view is present. Press ENTER to view its coordinate. Press ENTER again if

you wish to view the object. The telescope will start to slew to the object upon confirmation. The

hand control will not respond if a vacant User Object number is selected. Use the scroll keys to

choose another number and try again.

If the recalled object is below horizon, the SynScanTM AZ hand control will display "Below

Horizon !!" and automatically return to the Recall Object menu.

dentifying an Unknown Object

I

SynScanTM AZ has the ability to identify the unknown object the telescope is

currently pointing at. To do so, simply:

1.

Press the ID key (Fig.n) or scroll down to IDENTIFY in the main menu

and press ENTER to identify the object.

2.

The hand control will display a list containing the closest known object in

each M, IC, NGC, and Named Star catalogs and its distance to the

exact location where the telescope is pointed. Use the scroll keys to

view these objects.

3.

Press ESC to exit from this function.

Fig.n

inking with A Computer

L

Another feature of SynScanTM AZ is the ability to connect to a computer via a serial

communication cable. Many commercially available planetarium softwares can

be used to control SynScanTM AZ. SynScanTM AZ Version 3.00 and later is

compatible with Celestron 5i/8i and NexStar GPS command protocol.

Make sure that the telescope has been aligned.

1.

Connect the RS-232 cable to the RJ-12 connector on the hand control

2.

and to the COM-port of your computer (Fig.o).

21

Fig.o

Hand Control

RJ- 12

Page 22

Do not use RS-232 cable other than the one provided to connect

between the hand control and your computer. It may damage your

computer or the hand control. If you are making your own cable based

on the information provided in Appendix B, make sure that only pin 2, 3

and 5 connect to the com connector on your computer.

3.

In the planetarium software of your choice, choose "Sky-Watcher

RJ-11 Pin-outs

6 5 4 32 1

1= EXPD+

2= TD

3= GND

4= EXPD5= RD

6= +12V

Mount, Celestron NexStar 5i/8i" or "Celestron NexStar 8/9/11" in

the driver setup menu and follow the instructions provided by

your program to establish the connection to the telescope. The

SynScanTM AZ should be under the full control of your computer

once the connection is successfully established.

4.

When you are finished, follow the instructions provided by your

See Appendix C for

more information on

RS-232 connection.

software to close the connection to the telescope.

Do not disengage the SynScan AZ unit before you disengage the program. Doing so may cause

some programs to freeze.

TM

pdating the SynScan

U

From version 3.0 onward, the SynScanTM AZ firmware is user upgradable. Users can download the latest

version of the SynScanTM AZ firmware from the Sky-Watcher web site and easily update their hand controls.

System requirements

SynScan

TM

AZ Hand Control of version 3.0.or later.

Windows95 or later

An available RS-232C communication port on the PC.

PC link cable that comes with the SynScanTM AZ hand control.

DC power supply with 7.5~15V/100mA (min.) output. Power plug should be 2.1mm diameter, tip

positive.

Preparing your PC for the update

Create a folder for all SynScan

1.

Visit the Firmware Download Support Page of the Sky-Watcher website at:

2.

http://www.SkywatcherTelescope.net.

Download and save the SynScanTM Firmware Loader to the SynScan folder on your computer. You

3.

may create a shortcut on the desktop for quick access in the future. You will only need to download

this software once. Once it is saved on your computer, only the firmware data file is needed for

future updates.

Download and save the firmware data file named SynScanVXXXXAZ.ssf to the SynScan folder.

4.

(The XXXX indicates the version number of the firmware.)

Firmware

TM

AZ related files on your computer and name it SynScan.

Visit the Sky-Watcher website frequently to check for the latest firmware.

Updating the SynScan

Plug the RJ-11 end of the PC link cable into the jack in the middle socket on

1.

the hand control (Fig.e). Push the connector into the hand control until it clicks

into place. Plug the other end of the cable, the DB9 connector, to the RS-232

port on your PC.

Press and hold down the key "0" and "8" simultaneously, then plug the power

2.

cord into the hand control, as shown in Fig.p.

The hand control will give a beep, indicating a successful start up. The

3.

SynScanTM AZ will display: "SynScanTM Update Ver. x.x" on the LCD screen, as

seen in Fig.q. This indicates the version of the SynScan Bootloader.

Run the SynScanFirmwareLoader software on your PC. Once the program is

4.

launched, you should see a window as Fig.p. The "HC.Version" button

provides the version number of the hardware, firmware and database of your

hand control. It is for your reference only. You will not need it for the update.

TM

AZ Hand Control

22

Fig.p

SETUP

ESC

TOUR

RATE

1

2

M IC

NGC

4

5

PLANET

OBJECT

7

8

ID

0

ENTER

UTILITY

3

6

USER

9

Page 23

Fig.q

Fig.r

SynScan Firmware Loader

SynScan Firmware Loader

SynScan

ESC

5.

Click "Browse" to select the SynScanVXXXXAZ.ssf file in the SynScan folder. Click

Ver. 1.7

SETUP

Update

ENTER

Firmware File:

Enforce database update

Auto-detect COM Port COM Port

Update

Update

Ver. 3.0

COM 1

HC. Version

"Update" to start downloading the new firmware into your SynScanTM AZ hand control. You

will see the status of the update below the "Update" and "HC. Version" buttons (Fig.s).

Browse

Fig.s

SynScan Firmware Loader

SynScan Firmware Loader

Ver. 3.0

Firmware File:

Enforce database update

Auto-detect COM Port COM Port

Update

Update

78%

6.

When the download is complete, the status will show "Update Complete". The SynScanTM

COM 1

HC. Version

Browse

hand control is now updated to the newest firmware. Generally it takes about 30 seconds

to update the firmware. It may take longer if you are using an USB to Serial adapter

(USB-to-RS232 converter).

If the error message "Can not connect to a SynScan hand control" is shown, check the cable connection

and the PC link cable itself. Make sure it is all in good working condition. Close all applications that

may be occupying the RS-232 port and try again.

If you receive the error message "Firmware update failed…", reset the hand control by removing the

power plug and then re-connecting it. Repeat the update procedure.

By default, the data communication rate between SynScanTM hand control and the PC is set to be 115kbps.

The RS-232C port on some PCs may not support such high rate. If the update process fails after a few

tries, you can reduce the rate by pressing the "SETUP" key on the hand control after the power supply is

plugged in. This will reduce the data rate to 38.4 kbps (mid-rate)* or 9.6 kbps (low-rate). The LCD screen

will show the word "Mi" or "Lo" in the lower right hand corner to indicate that it is now in medium or

low communication rate. The steps for updating the firmware remain the same except that now it takes

longer to complete.

*Available in SynScan Bootloader version 1.6 or later.

23

Page 24

AZ

MAIN MENU

SETUP MODE

Date

Time

Observ. Site

Daylight Saving

Alignment

Brightest Star

Align.

2-Star Align

Alignment Stars

Auto Select

Sort By

Backlash

Tracking

Sidereal Rate

Lunar Rate

Solar Rate

Stop Tracking

Auto-Tracking

Set Slew Limits

Re-align Encoder

Handset Setting

UTILITY FUNC. IDENTIFY

Show Position

Show Information

Time

Version

Temperature

Power Voltage

Park Scope

PAE

Clear PAE Data

GPS

PC Direct Mode

TOUR

OBJECT CATALOG

Named Star

Solar System

Mercury

Venus

Mars

Jupiter

Saturn

Uranus

Neptune

Pluto

Moon

NGC Catalogue

IC Catalog

Messier Catalog

Caldwell Catalog

SAO Catalogue

Double Star

Variable Star

User Objects

Recall Object

Edit Object

Factory Setting

24

Page 25

SynScanTM AZ SPECIFICATIONS

Power Supply:

Motor type:

Slew speeds:

Tracking Rates:

Tracking Mode:

Alignment Method:

Database:

Go-To Pointing Accuracy:

Resolution:

10 to 15 V DC 1Amp, 2.1mm Plug (Center positive)

DC Servo Motors

Rate 0 = 1.0X

Rate 1 = 2.0X

Rate 2 = 8X

Rate 3 = 16X

Rate 4 = 32X

Rate 5 = 200X

Rate 6 = 400X

Rate 7 = 600X

Rate 8 = 800X

Rate 9 = 1000X

Sidereal, Lunar, Solar

Dual Axes Tracking

Brightest-Star Alignment, Two-Star Alignment

25 user defined objects. Complete M, NGC and IC catalog, partial

SAO catalogues, total 42,900 objects

Up to 5 arc min

Motor encoder: 1,620,000 counts per revolution,

Main axis encoder: 11,748 counts per revolution

25

Page 26

The SynScanTM AZ telescopes are designed to receive control commands sent from a computer

Hand Control

via the RS-232 port and RS-232 cable. Once connected, the SynScanTM AZ can be controlled by

most popular planetarium software program. The SynScanTM AZ will communicate with the

personal computer at 9600 bits/sec, no parity and stop bit. All angles are communicated with 16

bit angle and communicated using ASCII hexadecimal.

Description PC Command ASCII

Echo Kx X#

Goto Azm-Alt B12AB, 4000 # 10 characters sent.

Goto Ra-Dec R34B, 12CE # Scope must be aligned. If

Get Azm-Alt Z 12AB, 4000# 10 characters returned,

Get RA-Dec E 34AB, 12CE# Scope must be aligned.

Cancel Goto M #

Is Goto in Progress L 0# or 1# 0=No, 1=Yes: “0” is ASCII

Is Alignment Complete J 0# or 1# 0=No, 1=Yes

HC version V 22 Two bytes representing V2.2

Stop/Start Tracking Tx

32-bit goto RA-Dec r34AB0500,12CE0500 #

32-bit get RA-Dec e 34AB0500,

32-bit goto Azm-Alt b34AB0500,12CE0500 #

32-bit get Azm-Alt z 34AB0500,

x= 0 (Tracking off)

x= 1 (Alt-Az on)

x= 2 (EQ-N)

x= 3 (EQ-S)

Response

Useful to check

communication

B=Command, 12AB=Azm,

comma, 4000=Alt. If

command conflicts with slew

limits, there will be no action.

command conflicts with slew

limits, there will be no action.

12AB=Azm, comma,

4000=Alt, #

character zero

# Alt-Az tracking requires

alignment

The last two characters will

12CE0500#

12CE0500#

always be zero.

The last two characters will

always be zero.

Notes

26

I

Page 27

Physical Connection Diagram

RJ-11 Connector

1

2

3

4

5

6

1= NC

2= RD

3= GND

4= NC

5= TD

6= NC

RD = 2

GND = 5

TD = 3

1 2

3 5

The Back of the DB9 Pinout

dditional RS232 Commands

A

Sending a track rate through RS232 to the hand control

1.

Multiply the desired tracking rate (arc seconds /second) by 4. For example: if the

desired track rate is 120 arc seconds/second (proximately 8 times of sidereal rate),

then the TRACKRATE = 480.

2.

Separate TRACKRATE into two bytes, such that (TRACKRATE =

3.

TrackRateHighByte*256 + TrackRateLowByte). For example TRACKRATE = 480,

then TrackRateHighByte = 1, TrackRateLowByte = 224.

To send a tracking rate, send the following 8 bytes:

a. Positive Azm tracking: 80, 3, 16, 6, TrackRateHighByte, TrackRateLowByte, 0, 0

b. Negative Azm tracking: 80, 3, 16, 7, TrackRateHighByte, TrackRateLowByte, 0, 0

c. Positive Alt tracking: 80, 3, 17, 6, TrackRateHighByte, TrackRateLowByte, 0, 0

d. Negative Alt tracking: 80, 3, 17, 7, TrackRateHighByte, TrackRateLowByte, 0, 0

The number 35 is returned from the hand control.

4.

Sending a slow-Goto command through RS232 to the hand control

1.

Convert the angle position to a 24bit number. Example: if the desired position is 220?,

then POSITION_24BIT = (220/360)*224 = 10,252,743

2.

Separate POSITION_24BIT into three bytes such that (POSITION_24BIT =

PosHighByte * 65536 + PosMedByte * 256 + PosLowByte). Example: PosHighByte =

156, PosMedByte = 113, PosLowByte = 199

3.

Send the following 8 bytes:

a. Azm Slow Goto: 80, 4, 16, 23, PosHighByte, PosMedByte, PosLowByte, 0

b. Alt Slow Goto: 80, 4, 17, 23, PosHighByte, PosMedByte, PosLowByte, 0

The number 35 is returned from the hand control.

4.

6

9

Resetting the position of Az or Alt

1.

Convert the angle position to a 24bit number, same as Slow-Goto example.\

2.

Send the following 8 bytes:

a. Azm Set Position: 80, 4, 16, 4, PosHighByte, PosMedByte, PosLowByte, 0

b. Alt Set Position: 80, 4, 17, 4, PosHighByte, PosMedByte, PosLowByte, 0

The number 35 is returned from the hand control.

3.

27

II

Page 28

III

28

Page 29

aution!

C

NEVER USE YOUR TELESCOPE TO LOOK DIRECTLY AT THE SUN. PERMANENT EYE

DAMAGE WILL RESULT. USE A PROPER SOLAR FILTER FOR VIEWING THE SUN. WHEN

OBSERVING THE SUN, PLACE A DUST CAP OVER YOUR FINDERSCOPE TO PROTECT IT

FROM EXPOSURE. NEVER USE AN EYEPIECE-TYPE SOLAR FILTER AND NEVER USE

YOUR TELESCOPE TO PROJECT SUNLIGHT ONTO ANOTHER SURFACE, THE INTERNAL

HEAT BUILD-UP WILL DAMAGE THE TELESCOPE OPTICAL ELEMENTS.

Loading...

Loading...