Skyware Type 960 .96 Meter Class I and II Antenna System,Type 123 1.2 Meter Class I and II Antenna System Assembly Instructions Manual

Assembly Instructions

Type 960 .96 Meter Class I and II Antenna System

Type 123 1.2 Meter Class I and II Antenna System

with Factory Assembled Az/El Cap Mount

8000842-01

Skyware Global

1315 Industrial Park Drive

Smith eld, NC 27577 USA

Telephone: +1-919-934-9711

Internet: www.skywareglobal.com

Printed in U.S.A.

04/11 8000842-01 Rev G EC-01063

™

1

Skyware Global

VERY SMALL APERTURE TERMINAL (VSAT) PRODUCTS

TWELVE (12) MONTH LIMITED WARRANTY

Se ll er wa rr ant s t ha t a ll S k yw ar e Gl ob al ma nu fa ct ure d V SAT pr odu c ts are transferred rightfully and with go od title; that they are free from

any lawful security interest or other lien or encumbrance unknown to Buyer. Seller also warrants that for a period of twelve (12) months

from the date of shipm ent from Seller’s factor y, all its VSAT produ cts s hall b e fre e from de fects in mate rial a nd workmanship which arise

under proper and normal use and service. Buyer’s exclusive remedy hereunder is limited to Seller’s correction (either at its plant or at

such other place as may be agreed upon between Seller and Buyer) of any such defects by repair or replacement at no cost to Buyer,

except for the costs of any transportation in connection with the return of the defective VSAT products to be replaced or repaired, and

the costs to remove and/or reinstall the products, which shall be borne by Buyer. The limited warranty period shall not be extended

beyond its original term with respect to any part or parts repaired or replaced by seller hereunder.

This warranty shall not apply to VSAT products which (i) have been repaired or altered in any way so as to a ect stability or

durability, (ii) have been subject to misuse, negligence or accident, (iii) have been damaged by severe weather conditions such as

excessive wind, ice, storms, lightning, or other natural occurrences beyond Seller’s control; (iv) have presented damages, defects or

nonconformances caused by improper shipping, handling or storage, and (v) have not been installed, operated or maintained in

accordance with Seller’s instructions.

Buyer shall present any claims along with the defective VSAT product(s) to Seller immediately upon failure Non-compliance with any

part of this warranty procedure may invalidate this warranty in whole or in part.

SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, OTHER THAN AS SPECIFICALLY STATED ABOVE. EXPRESSLY EXCLUDED

ARE ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THE FOREGOING SHALL

CONSTITUTE ALL OF SELLER’S LIABILITY (EXCEPT AS TO PATENT INFRINGEMENT) WITH RESPECT TO THE VSAT PRODUCTS. IN

NO EVENT SHALL SELLER BE LIABLE FOR ANY LOSS OF PROFITS OR REVENUE, LOSS OF USE, INTERRUPTION OF BUSINESS, OR

INDIRECT, SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES OF ANY KIND AS A RESULT OF THE USE OF THE

PRODUCTS MANUFACTURED BY SELLER, WHETHER USED IN ACCORDANCE WITH THE INSTRUCTIONS OR NOT. UNDER

NO CIRCUMSTANCES SHALL SELLER’S LIABILITY TO BUYER EXCEED THE ACTUAL SALES PRICE OF THE VSAT PRODUCTS

HEREUNDER.

In some jurisdictions, Buyer may have other rights under certain statutes that may imply non-excludable warranties. No representative is

authorized to assume for Seller any other liability in connection with the VSAT products.

DATE DESCRIPTION REVISION

08/06 ECN 9007484 Rev B

11/07 5075515 Rev C

05/08 5078314 Rev D

09/08 5075934 Rev E

01/10 654 Rev F

04/11 EC-01063 Rev G

MANUAL REVISION HISTORY

WARRANTY

DO NOT DISCARD CONTENTS

The product in this packaging was placed in the market after August 13, 2005. Its components must not be discarded with

normal municipal or household waste.

Contact your local waste disposal agency for recovery, recycling, or disposal instructions.

LAW: Installation and installer must meet local codes and ordinances regarding safety! Installation of this product should be performed only

by a professional installer and is not recommended for consumer Do-It-Yourself installations.

DANGER: WATCH FOR WIRES! Installation of this product near power lines is extremely dangerous and must never be attempted. Installa-

tion of this product near power lines can result in death or serious injury! For your own safety, you must follow these important safety rules.

Failure to follow these rules could result in death or serious injury.

1. Perform as many functions as possible on the ground.

2. Watch out for overhead power lines. Check the distance to the power lines before starting installation. Stay at least 6 meters (20 feet)

away from all power lines.

3. Do not install antenna or mast assembly on a windy day.

4. If you start to drop antenna or mast assembly, move away from it and let it fall.

5. If any part of the antenna or mast assembly comes in contact with a power line, call your local power company. DO NOT TRY TO

REMOVE IT YOURSELF! They will remove it safely.

6. Make sure that the mast assembly is properly grounded.

WARNING: Assembling dish antennas on windy days is extremely dangerous and must never be attempted. Due to the surface area of the

re ector, even slight winds create strong forces. For example, this antenna facing a wind of 32 km/h (20 mph) can undergo forces of

269 N (60 lb). BE PREPARED TO SAFELY HANDLE THESE FORCES AT UNEXPECTED MOMENTS. ATTEMPTING TO ASSEMBLE, MOVE OR

MOUNT A DISH ON WINDY DAYS COULD RESULT IN DEATH OR SERIOUS INJURY. Skyware Global is not responsible or liable for damage

or injury resulting from antenna installations.

WARNING: Antennas improperly installed or installed to an inadequate structure are very susceptible to wind damage. This damage can

be very serious or even life threatening. The owner and installer assumes full responsibility that the installation is structurally sound to support

all loads (weight, wind and ice) and properly sealed against leaks. Skyware Global will not accept liability for any damage caused by a

satellite system due to the many unknown variable applications.

WARNINGS

2

PRE INSTALLATION CONSIDERATIONS

TOOLS REQUIRED:

Compass 13 mm Deep Socket (3/8” Drive) 10 mm Nut Driver Torque Wrench

Clinometer #1 or #2 Phillips Screwdriver 10 mm Socket (3/8” Drive) 9” Magnetic Level

3/8” Drive Ratchet Wrench 13 mm Combination Wrench 10 mm Combination Wrench (2) 17 mm Open End Wrenches

ADDITIONAL INSTALLATION MATERIALS (Not Included with Antenna)

Installation Mount (Ground Pole, King Post, Wall Mount or Roof Mount)

Grounding Rod, Clamp & Grounding Block - As required by National Electric Code or local codes.

Ground Wire - #10 solid copper or #8 aluminum as required by National Electric Code or local codes (length as required).

RG-6 Coaxial Cables from antenna to indoor units.

Concrete: See “Ground Pole” section for quantity

M10 or #3 Rebar: See “Ground Pole” section for quantity. Deformed steel per ASTM A615, Grade 40 or 60.

SITE SELECTION

The rst and most important consideration when choosing a prospective antenna site is whether or not the area can provide an acceptable “look angle” at the satellites. A site with a clear, unobstructed view is preferred. Also consider obstruction that may occur in the future

such as the growth of trees. Your antenna site must be selected in advance so that you will be able to receive the strongest signal available.

To avoid obstructions, etc., conduct an on-site survey with a portable antenna. The satellite antenna can be installed on a ground pole,

wall/roof mount, or non-penetrating roof mount with 2-7/8” or 3” outside diameter mast. The chosen mount type should be assembled and

in place before installing the antenna. Refer to instructions packed with mount for its proper installation. The mast pipe must be vertical and

plumb to insure ease of alignment.

As with any other type of construction, a local building permit may be required before installing an antenna. It is the property owner’s

responsibility to obtain any and all permits.

Before any digging is done, information regarding the possibility of underground telephone lines, power lines, storm drains, etc., in the

excavation area should be obtained from the appropriate agency.

Because soils vary widely in composition and load capacity, consult a local professional engineer to determine the appropriate foundation

design and installation procedure. A suggested foundation design with conditions noted is included in this manual for reference purposes

only.

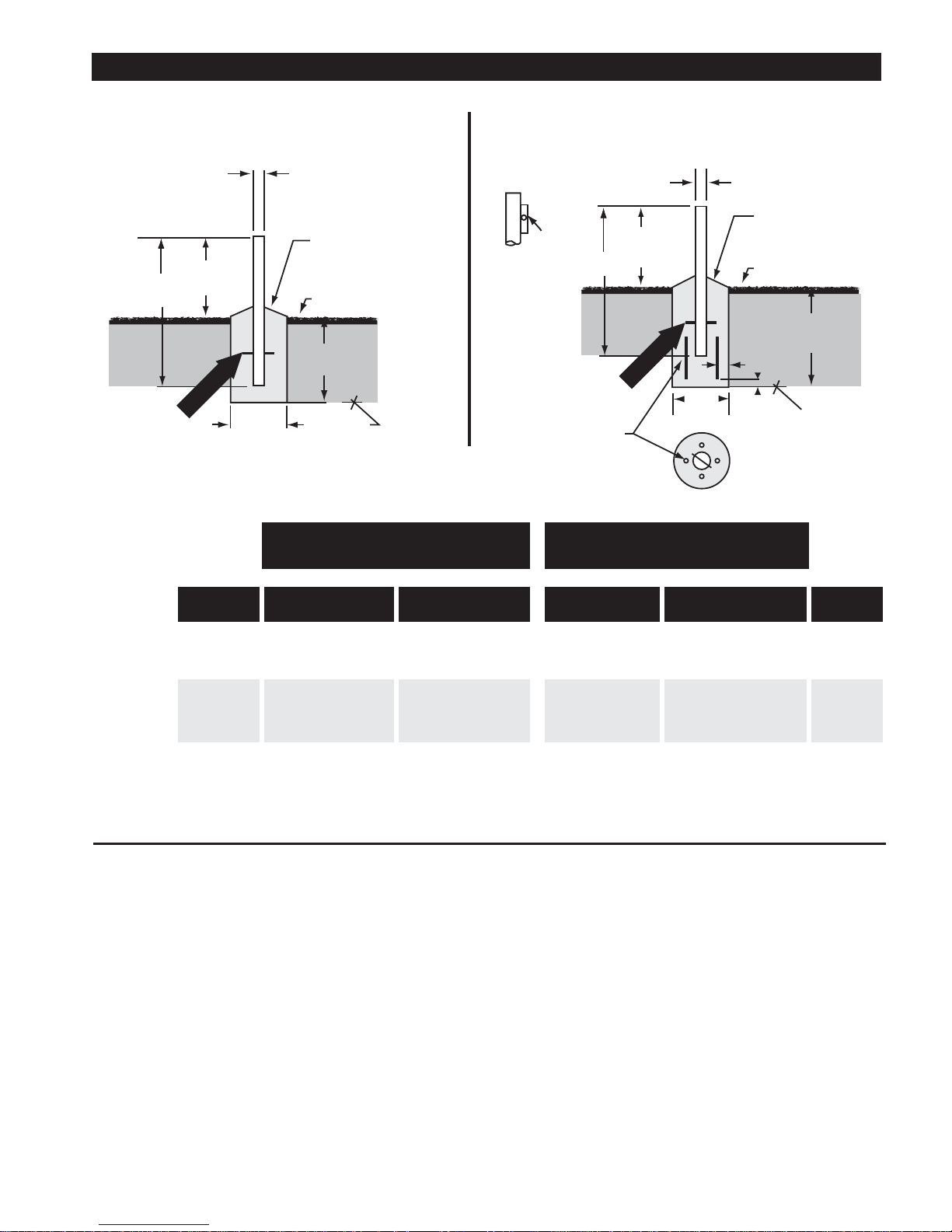

1.2 m

Antenna

3

7.3 cm or 7.6 cm

(2.88” or 3 .00” O.D.)

91.4 cm max.

(36”)

182. 9 cm

(72”)

102 cm

(40” )

#3 reba r

x diameter

of pier. Inser t through

hole in tube a nd center.

#3 Reba r

D

Minimum

Diameter

25 mm

to 51 mm

(1” to 2”) slope

for water run -o

Grade

Below

Frost L ine

182. 9 cm

(72”)

25 mm to 51 mm (1” to 2”)

slope for wa ter run-o

Grade

7.3 cm or 7.6 cm

(2.88” or 3 .00” O.D.)

D

Minimum

Diameter

Below

Frost L ine

Approx.

51 mm

(2”)

127 c m

(50”) (See Note)

#3 rebar x .46 m (18”)

Insert through

hole in tube a nd center.

#3 Reba r

#3 rebar x .6 m (24”)

at 60˚ apar t (S ee note)

51 mm

(2”)

Bubble

Level

Ground Pole Must Be

Vertical in All Directions

at Top

NOTE:

127 cm (50”) may

be increase d to frost

line. Concrete a nd

length of re bar will

increase

accordingly.

Bottom View

NOTE:

1. Poles are not supplied (purchase locally to above speci cations) and must be eld drilled 5/8” diameter

for M10 #3 rebar, 5.5 mm for self tapping grounding screw and (.218”) for 1/4-20 self tapping grounding screw. Poles and screws must

be galvanized or painted for protection.

2. Pole and foundation design based on the following criteria:

a. Uniform building code Exposure B or C wind loading.

b. Vertical soil pressure of 13790 kPa (2000 pounds per square foot).

c. Lateral soil pressure of 2758 kPa (400 pounds per square foot).

d. Concrete compressive strength of 17.2 MPa (2500 pounds per square inch) in 28 days.

3. See page 6 for grounding recommendations.

CAUTION: The foundation design shown does not represent an appropriate design for any speci c locality. Soil conditions vary and may

not meet design criteria given in Note 2. Consult a local professional engineer to determine your soil conditions and appropriate foundation.

GROUND POLE INSTALLATION

Pier Foundations Deep Frost Line Foundations

WIND VEL DIM D CO NC VOL DIM D CONC VOL DIM D CONC VOL DIM D CONC VOL GROUN D

km/h (mph) cm (in) m3 (ft3) cm (in) m3 (ft3) cm (in) m3 (ft3) cm (in) m3 (ft3) POLE

161 (100) 25 (10) 0.05 (1. 8) 38 (15) 0.12 (4.1) 18 (7) 0.03 (1.1) 25 (10) 0.06 (2.2) A, B or C

201 (125) 36 (14) 0.10 (3.7) 51 (20) 0.21 (7.4) 2 3 (9) 0.05 (1.9) 36 (14) 0.13 (4.6) A, B or C

161 (100) 30 (12) 0.07 (2.5) 46 (18) 0.17 (6.0) 20 (8) 0.04 (1.4) 33 (13) 0.11 (3.8) A ,B or C

201 (12 5) 43 (17) 0.15 (5.2) 61 (24) 0.30 (10.5) 30 (12) 0.09 (3.2) 48 (19) 0.23 (8.1) A or C

EXPOSURE B

96 cm

Antenna

EXPOSURE C

EXPOSURE B

EXPOSURE C

POLE SPECIFICATIONS:

Ground Pole “A” 2-1/2 Schedule 40 Steel ASTM A53 Pipe (73 mm x 5 mm Wall/2.88” OD x .203” Wall)

Ground Pole “B” 3.0” OD x 9 Gauge (.148” Wall) Steel ASTM A501 Pipe (76 mm OD x 3.8 mm Wall)

Ground Pole “C” 2-1/2 Schedule 80 Steel ASTM A53 Pipe (73 mm x 7 mm Wall/2.88” OD x .276” Wall)

91.4 cm max.

(36”)

Pier Foundations Deep Frost Line Foundations

The Az/El mount is factory con gured to achieve elevation angles from 8° to 54°. For higher angles, the elevation adjustment screw

setting must be modi ed. (See table for elevation ranges). Before proceeding with antenna installation, determine the elevation angle for

the site (refer to main installation instructions). If the elevation setting for the site is greater than ~ 52º, follow these steps:

Antenna Model Range As Shipped Range At High Angle Setting

1.2 m Type 123 8˚ to 54˚ 42˚ to 85˚

96 cm Type 960 8˚ to 54˚ 34˚ to 85˚

Adjustment procedure:

1 Loosen two elevation clamp nuts (in curved

slots), and loosen elevation pivot bolts

2 Swing the housing up against the

underside of the elevation adjustment

screw head

3 Set the az/el mount on the side closer to

the elevation adjustment bolt

4 Loosen the bottom nut on the elevation

adjustment screw. (Use two open-end

wrenches to release the double nuts)

5 Run the top nut up tight against the

az/el housing and elevation screw head,

then back o nut half a turn

6 Run bottom nut along the elevation screw

against top nut

7 While holding the top nut in place with a

wrench rmly tighten the bottom nut

against it to lock them both in that

position.

8 The az/el is now con gured for high

elevation angles. Proceed with the

installation as instructed in the installation

manual.

Bottom Nut Top Nut

High Elevation Angle SettingFactory Setting of Elevation Screw

Clamp Nut

(2 Places)

Elevation

Pivot Bolts

(2 Places)

Note new

position of top

and bottom nut.

Elevation

Pivot Bolts

(2 Places)

Top Bracket

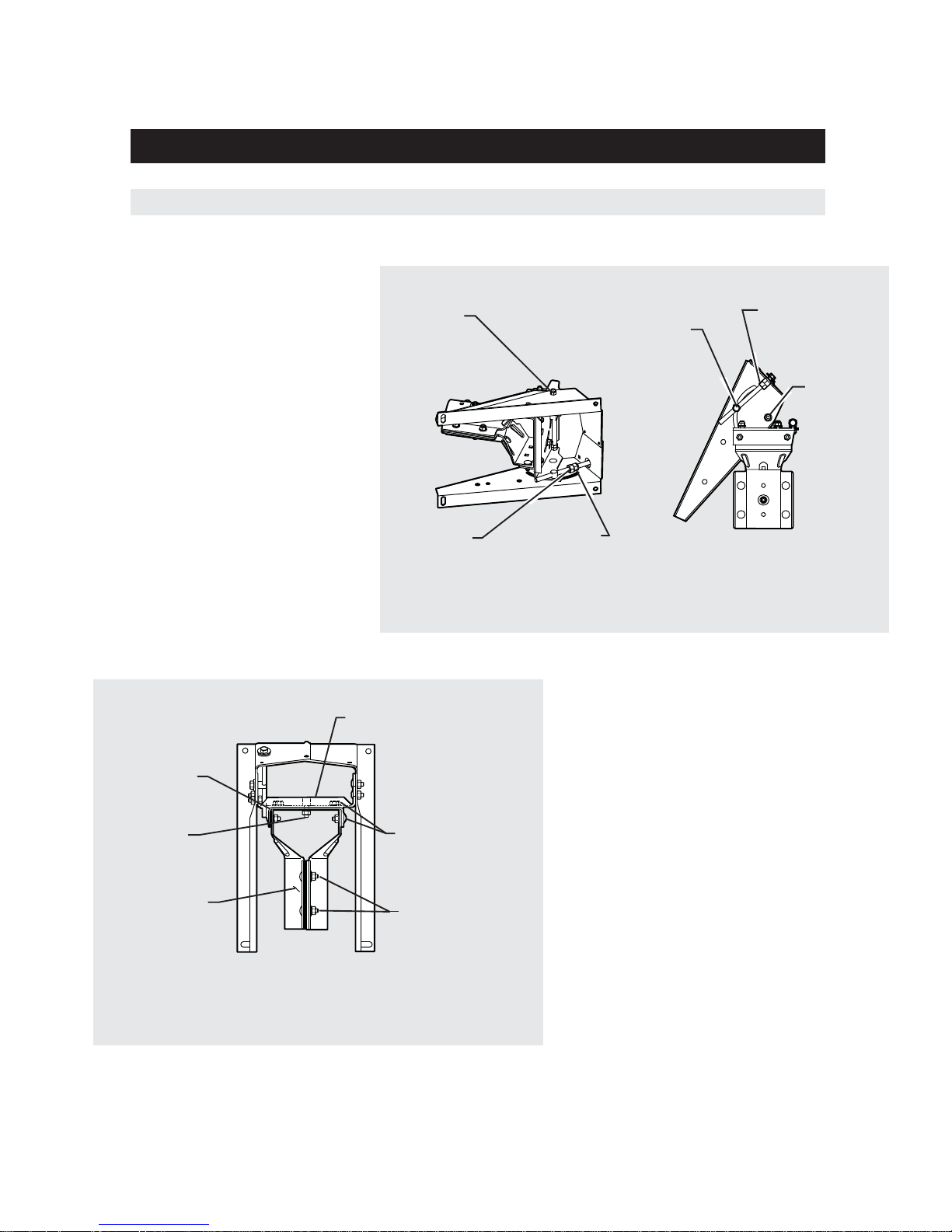

U Bracket

Carriage Bolt

and Hex Nut

(4 Places)

Half Clamp

(2 Places)

Clamp Bolts

(Carriage Bolt

and Hex Nut)

(4 Places)

Hex Nut

Swivel Nut

Loosen (4) carriage bolts and nuts securing the

“U” bracket to the top bracket. Loosen (4)

carriage bolts and nuts securing “U” Bracket to

(2) half clamps. Loosen swivel nut and hex nut.

Install AZ/EL cap mount onto ground pole. Equally

tighten (4) clamp bolts so that cap is held stationary on ground pole, but can be swiveled with

slight pressure (approximately 2.7 N-m (2 ft-lb).

Retighten and torque (4) carriage bolts and nuts

securing “U” bracket to half clamps to 24.4 Nm

(18 ft-lb). Leave loose (4) carriage bolts, swivel nut

and hex nuts, for ne tune option.

4

ASSEMBLY AND INSTALLATION

Assembling Re ector Onto Az/El Cap Mount

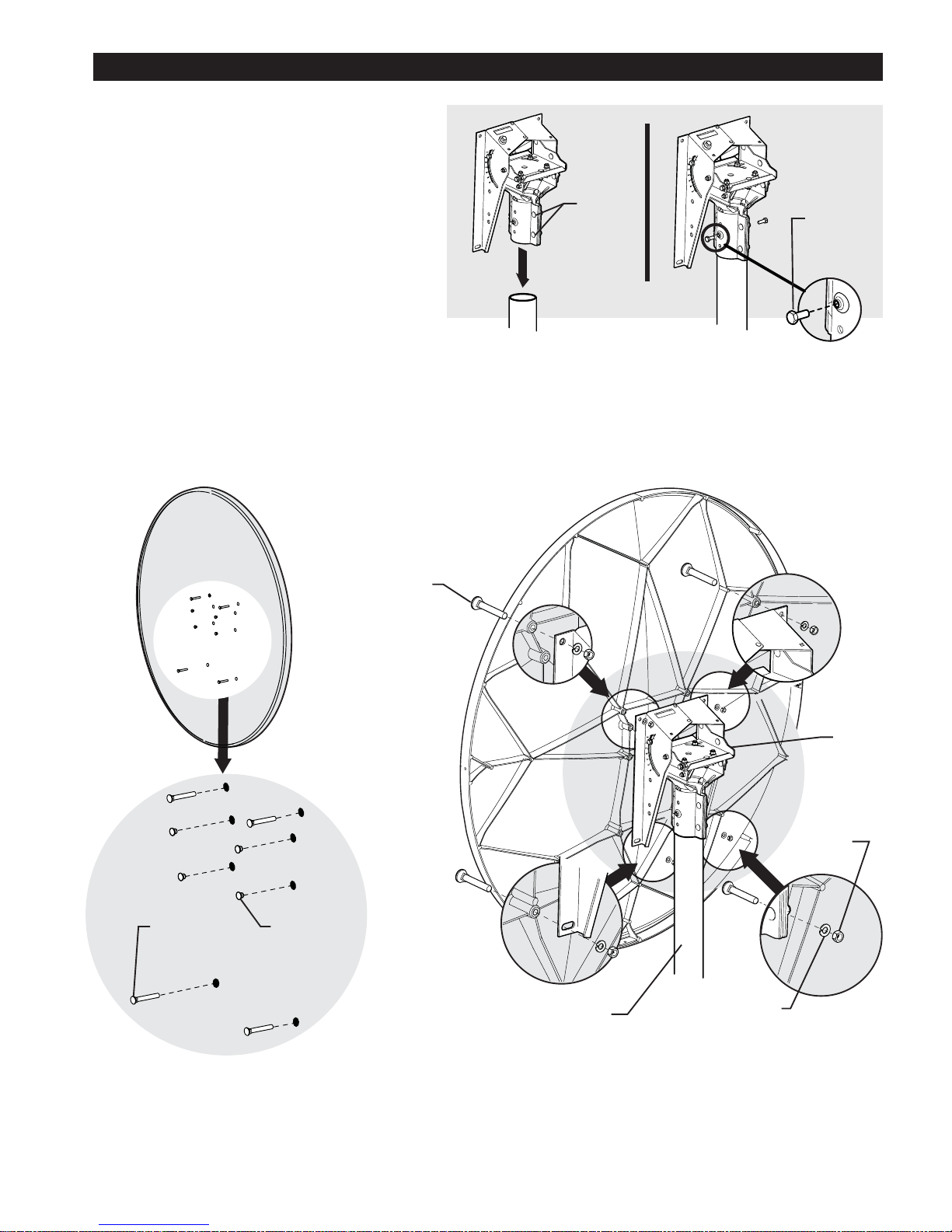

Install four M8 x 60 mm plow bolts into holes in re ector face. Lift re ector and insert exposed portion of bolt into holes in az/el mounting

ange. Secure re ector to az/el mount with 4 lock washers and hex nuts onto plow bolts. Tighten and torque to 15 N-m (11 ft-lb). Press t

hole plugs in remaining four unused holes of the re ector.

IMPORTANT: Note orientation of feed leg mounting holes in re ector rim. Top of re ector does NOT have feed leg mounting hole.

Az/El

Cap

Mount

Installation Pole

M8 x 60 mm

Plow Bolts

(4 Places)

Hex Nut

(4 Places)

Lock Washer

(4 Places)

M8 x 60 mm

Plow Bolts

(4 Places)

Hole Plugs

(4 Places)

Front View of Re ector Rear View of Re ector

5

Installing Az/El Cap Mount Onto Pole

Before installing az/el cap onto pole, installation mount

should be in place. Loosen (4) hex nuts on pipe clamp. Install

az/el cap onto pole. Equally tighten (4) clamp bolts so that

cap is held stationary on pole, but can be swiveled with

slight pressure. Tighten approximately 2.7 N-m (2 ft-lb ).

Insert (2) M8 set screws into threaded inserts in pipe clamp.

Do not tighten.

Back View

M8 Set

Screws

(2 Places)

Clamp

Bolts

(4 Places)

Loading...

Loading...