Universally known as perhaps the most effective

dive bomber ever flown, the Stuka (a contraction

of the word “Sturzkampfflugzeug” or diving battle

aircraft) was born of a generation of aircraft rendered obsolete before the advent of WWII.

Design work began in 1933, and the prototype

first flew in 1935. Tested in combat first in the

Spanish Civil War, the Stuka proved its worth.

The -B model grew out of shortcomings defined

in this conflict, and cemented the profile of the

Stuka that would terrorize a continent only a few

years later. The Stuka flew in all theaters in

WWII, enjoying great success in the early battles

in Poland Scandinavia, and Russia. Only the

Battle of Britain would humble the mighty Stuka,

showing that it couldn’t succeed against determined fighter opposition.

The Stuka has a wingspan of 45 feet 3 inches, a

length of 36 feet 3 inches, a maximum weight of

almost 9,500 pounds, and could carry a variety

of bombs to a maximum of 2,200 pounds. The

Stuka is powered by a water-cooled, 12 cylinder

iverted-vee Junkers Jumo 211engine producing

1,200 horsepower. Crew consisted of the pilot

and a gunner firing a 7.92 mm MG 15 machine

gun. Forward firepower included two 7.92 mm

MG 17 machine guns mounted in the wings.

Later models were outfitted as tank destroyers,

firing 40 mm cannons mounted in pods under

the wings.

Skyshark R/C Corporation

75 Mid Cape Terrace, Ste 7

Cape Coral, FL 33991, U.S.A.

Website: www.skysharkrc.com

email: cservice@skysharkrc.com

Thank you for purchasing the JU-87 Stuka from Skyshark

R/C Corporation. For the first time, R/C enthusiasts have a

choice in scale aircraft designs. Our goal, through computer technology and state-of-the-art production techniques, is

to offer aircraft which in the past have not been modeled

simply because they weren’t popular enough to justify mass

production. Our production techniques allow us to produce

aircraft which, though not as popular and well known as P51s and P-47s, still offer historical significance (good or

bad!), Good looks and flying characteristics, and a uniqueness that is sure to turn heads wherever you take your airplane!

Your airplane has many unique features

in its design:

parts on each sheet of wood, reducing the waste, and lowering the cost to you. Since laser cutting does not have the

same limitations that mechanical cutters do, small and

hard-to-produce parts are simply a computer file away, so

you get a more accurate airplane.

Plastic and Fiberglass

The cowl is accurately reproduced in high quality fiberglass.

The canopy is accurately reproduced in clear plastic, and

the wheel pants are reproduced in heavy duty styrene plastic.

A Word About the Building Options

Engine Options

Many parts of the country (and the world) sit at higher elevations. At 7200 feet, a .40 size airplane will barely fly with

a .40 engine. The engine size range of .45 to .61 for this kit

is designed to compensate for engine performance loss

due to elevation. Below 3500 feet in elevation, a good .45

will fly the Stuka with authority. Above 3500 feet, a larger

engine will help return the airplane to sea level performance.

Electric Options

CAD Design

CAD design allows strength to be built into the airplane

without sacrificing weight. Accurate parts design and placement ensures a perfect fit.

CAD Drawn Plans

The plans in this kit are not copied from a master set! They

are originals drawn directly from the CAD program where

the airplane was designed. We do this because it allows us

to use color, which helps you better visualize the various

components of the airplane, and we can use better quality

paper, which greatly reduces the possibility of shrinkage.

Since you’re going to build directly on the plans, they ought

to be the proper size! Also, parts placement is guaranteed

to be accurate, so you can build a better, straighter model.

Laser Cut Parts

The same program that generates the design and plans

also drives the laser, so every part is reproduced exactly as

it was designed. Laser cutting also allows us to fit more

Electric conversion on a kit this size is very easy and

straightforward. You will simply need to plan for a battery

hatch in order to save having to remove the wing for bat-

tery changes.

Retract Options

Right!

Flaps

The flaps can be made functional. A linkage arrangement

is shown on the plans, explained in this manual, and some

required parts are provided. The scale offset hinging system

makes functional flaps as easy as adding a servo! Some

adjustment of the flaps will be required whether the flaps

are functional or not; remember, the surfaces are airfoils,

and need to be set for optimum flight performance.

1

General Building Information

Accessories needed to finish the Stuka:

The Stuka can be built by a person with average building

skills. It is designed for someone who has built a trainer or

low wing sport plane. No unusual building techniques are

required, although more difficult areas are explained in

detail where necessary. Certain steps in the building

process must be followed as depicted, or you might find

yourself digging back into the structure to redo something.

These areas are outlined when necessary.

Occasionally hints will be included at certain building steps.

These are not required for completion, rather they are tips

intended to ease a particular process.

The laser does not cut through the wood, it burns its way

through. As a result of this, occasionally there will be

scorching on the surface of the wood. This is normal, and is

only a surface discoloration, and does not affect the wood

in any other way. Similarly, the laser settings are optimized

for wood density averages, so occasionally, due to variations even in individual sheets, some areas might not cut

through completely. This is apparent mainly with the plywood. Simply use care in removing the parts from the

sheets; most of the time, the parts will literally fall out of the

sheets!

Hardware and a motor mount are not included in the kit.

There are so many choices for quality hardware that these

choices are left to the individual preferences of the builder,

rather than include something in the kit that you’ll probably

throw away anyway. A vibration-dampening motor mount is

recommended for use regardless of engine choice, so

select a mount suited to your particular engine.

Sullivan Gold-N-Rods, 48" (Part no. 504) or other appropriate pushrods

Sullivan RST-10 or -12 Fuel Tank or other 10 - 12 ounce

fuel tank

Motor mount for appropriate engine

2-3/4” Stuka Spinner

3-1/2" Main Wheels (Robart #135)

1-1/2" Tailwheel (Dubro 150TW)

Hinges - We normally use CA hinges for ease.

Control Horns, Clevises, Bolts, Nuts, Screws, etc. (consult

our website)

1/9th Scale Pilot Bust Figures (2)

Engine, Muffler, Radio, Covering, Paint, etc.

Electric Conversion:

Brushless Outrunner Motor 400-600Kv

Cobra 4120-16 or E-flite Power 52

ESC: OS70, Cobra 80 or E-flite 80

Battery: Ulti-Power 5 cell 3300 - 5200mAh

This aircraft is not a toy. It must be flown in a responsible

manner according to the rules set forth by the Academy of

Model Aeronautics. The builder assumes the responsibility

for the proper assembly and operation of this product.

Skyshark R/C Corporation shall have no liability whatsoever, implied or expressed, arising out of the intentional or

unintentional neglect, misuse, abuse, or abnormal usage of

this product. Skyshark R/C Corporation shall have no liability whatsoever arising from the improper or wrongful

assembly of the product nor shall it have any liability due to

the improper or wrongful use of the assembled product.

Skyshark R/C Corporation shall have no liability for any and

all additions, alterations, and modifications of this product.

Having said that mouthful, turn the page and start building

the best airplane on the market!

Rare Earth Magnets for battery hatch.

Notes:

2

Horizontal Stabilizer Assembly

1. Pin S1 to the board. Cut the stab leading edge from

3/8 x ¼ balsa stock and pin in place. Cut the stab

trailing edge from ¼ x ¼ balsa stock and pin in place.

Glue all the pieces.

3. Sheet both sides of the vertical stab. So not sheet

the tab on S2.

4. Sand the leading edge to shape. Sand all the edges

smooth.

2. Cut the stab stringers from ¼ x ¼ balsa stock and

glue in place.

3. Sheet the top of the horizontal stabilizer using a

piece cut from 1/16 x 4 x 36 balsa sheet.

4. Cut a slot in the sheeting to match the slot in S1. This

will align the vertical stab during assembly.

5. Sheet the bottom of the horizontal stab.

6. Sand the leading edge to shape and sand all the

edges smooth.

Elevator Assembly

1. Glue E2 into the slot in E1. Guides for the rib are

etched into E1 for reference.

2. Repeat for E3, E4, E5, E6 and E7. See Figure 5.

3. Bevel the trailing edge of E1 to match the taper of

the ribs.

4. Fill the inboard space between ribs E2 and E3 with

scrap balsa and sand even with the ribs. This will

provide strength for the elevator joiner wire and control horn mount.

Vertical Stabilizer Assembly

1. Pin S2 and S3 to the board. Cut the stab trailing

edge from ¼ x ¼ balsa stock and pin in place. Glue

all the pieces.

2. Cut the stringer and top support from ¼ x ¼ balsa

stock, pin in place, and glue.

5. Note that all E1s are marked for location. Glue the

respective E1 to the previous assembly, aligning all

the ribs into the slots.

6. Cut the elevator leading edge from ¼ x ¼ balsa

stock and glue into the channel in the elevator

assembly. Make sure the edges of E1 attach firmly to

the leading edge. Sand all edge smooth.

7. Glue the elevator horn to the end of the elevator

assembly.

3

8. Repeat for the remaining elevator.

Rudder Assembly

1. Glue R2 into the slot in R1. Repeat for R3, R4, R5,

and R6.

2. Bevel the edge of R1 to match the contour of the

ribs.

3. Fill the open bay between R2 and R3 with scrap

balsa. Sand to match the ribs.

Center Wing Section

1. Epoxy W2A to W2. Make a right and left side (be

careful here; it’s easy to make two left sides!)

2. Epoxy W4B to W4. Make a right and left side.

Repeat the “be careful” part.

4. Glue the remaining R1 to the assembly.

5. Glue two R8s together, then glue to the bottom of the

rudder assembly.

6. Cut the rudder leading edge from 3/8 x ¼ balsa

stock, and glue in place. Note that the leading edge

extends to the bottom of R8s and the upper edge of

the built-up portion of the rudder assembly.

Note: The first part of assembling the center wing

section should be accomplished by interlocking

the pieces only. Do not glue them until the instructions say.

3. Slide W1 into the slot in W14. (There is an extra W1

in the pre-cut sheets; discard this piece.)

4. Slide W2 (with W2A facing outward) into its slot in

W14. Slide W13 under W14 and insert the tab into

the slot in W2.

7. Glue two R7s together, and glue to the top of the rudder assembly. The rudder horn may be re-inforced

by soaking it with thin CA. Sand R7 and R8 to match

the taper of the rudder.

5. Slide the other W2 into the slot in W13 and insert the

tab on W14 into W2. Align this assembly to the board

and pin in place.

4

6. Slide W22 Ply Servo Tray into the slots in W1 and

W2. Slide W3s in place and pin to the board.

7. Slide W4s (with W4Bs facing inward) in place and

pin to the board.

13. Unpin the assembly from the board and turn it over.

Cut the bottom balsa spars from ¼ x ¼ stock and

glue in place.

8. Glue all the pieces at this time. Add tri-stock to the

corners of W13 and W14 and W2 and W4.

9. Glue W15 to the trailing edges of W1 and W2.

10. Glue W16 to the trailing edges of W3 and W4,

11. Cut the balsa spars from ¼ x ¼ stock, and

glue in place. Add ¼ x ¼ spacers to W22

for the servos to mount to. Add the mounts

for the flaps on top of W22, and the

mounts for the ailerons on the bottom of

W22.

14. Cut the Maple Gear Blocks to size and epoxy into

the slots in W2, W3 and W4. Relieve the slots as

necessary to allow the gear block to fit flush.

15. Epoxy the Maple Gear Block Anchors to the gear

blocks and W2A.

16. Add tri-stock to the sides of the gear blocks for support.

Note: The spar in this case is not for structural strength, it’s

for attachment of other pieces.

12. Cut the leading edge pieces from 3/8 x 1

x 18 balsa stock, and glue in place. Glue

the center piece first, followed by the

outer pieces. Leave at least 1/16” overlap

of the leading edge with the ribs for the

sheeting to but against.

17. If you plan to add functional flaps, drill a hole in

W19 at the “+” and slide W19 into the slots in W3

and W4. Align flush with the edge of W4.

18. Install bellcranks to W19 (on the bottom), with the

“L” facing outward. Add the pushrods for the servo

5

linkage.

19. Glue W21 Dowel Guides to the top and bottom

spars as indicated on the plans. Install so that the

arrow faces up and inward. This will properly align

the hole for the dowel.

20. Slide F23 onto W1. This will provide a guide for

drilling the holes in the leading edge for the dowels.

Mark the holes, and drill or bore ¼” holes in the

leading edge. Remove F23.

25. Trim and sand the sheeting, and carefully trim the

sheeting flush with the inside edge of W2.

26. Cut three 3 1/2” pieces from 1/16 x 4 x 36 balsa

sheet, and one 3 1/2” piece from 1/16 x 3 x 36 balsa

sheet. Edge glue these sheets. Sand the edges

until the sheet lays in the slot between the other

sheets.

27. Cut short pieces from 1/8 x ¼ balsa stock. Glue

these pieces to W2, aligning them with the edge of

the rib. These pieces will form an edge for the

sheeting to lay on.

21. Cut the dowels to size (approximately 5/8 to ¾”

should extend from the leading edge) and slide

them into the wing. Slide F23 onto the ends of the

dowels to align them. Epoxy the dowels in place

(DO NOT epoxy F23 in place! You’ll need it later)

Remove F23 and set it aside.

22. Sand the top of the center section smooth. Bevel

W2A to match the angle of the ribs.

28. Sheet the center of the wing section.

29. Remove the wing from the board. Remove the tabs

on the ribs.

30. The trailing edge extends ½” past W15 and W16.

Mark this location and trim the trailing edge sheeting. Bevel the sheeting to match the lower rib camber.

23. Cut three 5” section from sheets of 1/16 x 4 x 36

balsa, and cut one 5” section from 1/16 x 3 x 36

balsa. Edge glue these sheets.

24. Trim the sheet to fit the outer panel of the center

section. Trim the leading edge to fit, but allow a

slight overlap on the edges; this will be trimmed

later. Allow for at least 1/2” overlap of the trailing

edge. Sheet the angled section. Repeat for the

other side.

31. If you are building the fixed flap option, add a 3/8”

maple block to W4 in the location shown on the

plans. Glue it flush with the bottom of W4, and sand

to the angle of the ribs.

32. Mark the locations of the flap pushrod exits.

6

33. Cut slots in W1 and W2s for locating W23 Ply

Holddown Plate. The location for W23 is shown on

the plans. Glue W23 in place. Drill a small pilot hole

through W23, W1 and the top sheeting to locate the

holddown bolt postion.

37. Add 1/8 x ¼ spacers to W2 to support the bottom

center sheeting, just as you did with the top.

34. If you use the Gold-N-Rod pushrod option, do the

following: Cut the red 48” housing into two 17”

lengths. Cut the yellow pushrod into two 19”

lengths. Assemble the pushrods and the Dubro

Aileron Ball-Link Connector into one continuous

pushrod. Slide the pushrod through the holes in the

ribs and center in the wing. Slide the housings over

the pushrod until 1/8” extends past W2. Glue the

housings to the ribs, but leave the housings at W2

free to “float”.

38. Cut three 3 ½” sections from 1/16 x 4 x 36 balsa

sheet, and a 3 1/2” section 1” long from spare 1/16”

sheeting. Edge glue these pieces.

39. Sand the edges of this sheet to fit snugly in the center section. Glue the sheet in place.

40. Trim and sand the sheets at the trailing edge, W4,

and the joined edges.

41. Cut both the top and bottom sheets as shown to

allow for servo fit.

42. Cut out the slots for the flap linkage.

43. Cut out the slots for the wire gear legs.

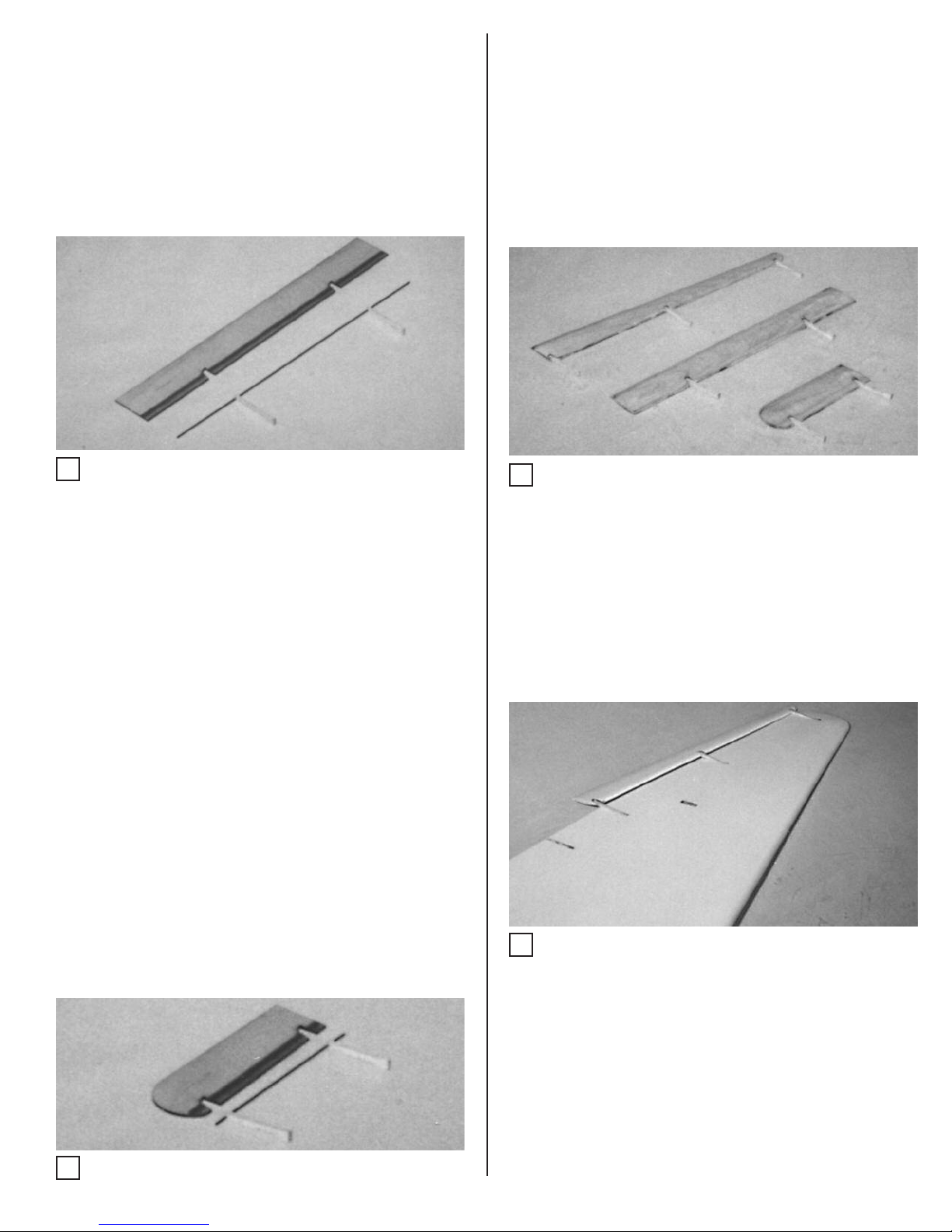

Right Wing Panel Assembly

35. Using the same technique as the top sheeting, cut

5” sections of 1/16 x 4 x 36 balsa sheets and 5”

sections of 1/16 x 3 x 36 balsa sheets and edge

glue. Sheet the outer sections of the center section.

36. Trim the sheeting flush with W2, and trim and sand

the trailing edge even with the top sheeting.

1. Slide W4A into the slot in the Ply Spar and align with

W4 (they’re the same size). Glue in place. For the

fixed flap option, glue a maple block to W4A as

shown on the plans.

2. Cut two 24” lengths from 1/4” x 1/4” balsa sticks.

Glue one of these spars to the Ply spar, aligning it

with the bottom edge, and fitting it into the slot in

7

W4A.

3. Thin the outer 4” of the balsa spar to allow the fit of

the last two ribs. Thin to 1/8”.

4. Slide W5, W6, W7, and W8 onto the Ply Spar, align,

and glue.

5. Glue W17 to the trailing edges of the ribs.

6. Drill a hole in W20 and assemble the bellcrank to it.

7. Slide W20 into the slot in W8 (the bellcrank will be on

the bottom of W20) and cut the pushrod housing and

pushrod to size. Attach a clevis to the pushrod and

the bellcrank and align the assembly.

12. Select two 1/16” x 4” x 24” sheets. Cut a 1/16 x 3 x

36 balsa sheet in half. Edge glue the two 4” sheets

and one 3” sheet to form the top sheeting.

13. Trim the leading edge to fit, and sand the inner

edge to match the center section sheeting. Sheet

the top surface of the right wing panel.

14. Mark a point 9/16” perpendicular to W17 at W8.

Mark another point 11/16” perpendicular to W18 at

W12. Connect these points and the trailing edge of

the center section. Trim the top sheeting to match

these lines.

8. Slide W9 in place, slide W20 into the slot in W9, and

glue all the pieces.

9. Glue W10, W11, and W12 in place.

10. Glue W18 against W17 and to the trailing edges of

W9 thru W12. Glue the remaining ¼ x ¼ x 24 balsa

spar in place. Thin the outer 4” to 1/8” to fit in W11

and W12.

11. Cut the 3/8 x 1 x 36 balsa leading edge to length,

and glue in place. Cut scrap 1/16” balsa for shear

webs and glue in place (see plans for location).

15. Remove the tabs on the rib bottoms, and bevel the

top sheeting trailing edge to match the bottom rib

camber.

16. Mark the location of the exit point of the aileron linkage so the slot can be cut after sheeting.

17. Select two 1/16” x 4” x 24” balsa sheets. Edge glue

these two pieces and the remaining 3 x 18 sheet to

form the bottom sheeting.

18. Trim the sheeting to fit the leading edge, and sand

the inner edge to match the center section sheet-

8

ing. Sheet the bottom of the wing panel.

19. Trim the trailing edge to match the top sheeting

and the center section sheeting.

20. Glue on the wingtip. Sand to shape.

Note: the slots in the trailing edge in the picture will be cut

later.

6. Drill a hole in W20 and assemble the bellcrank to it.

Left Wing Panel Assembly

1. Slide W4A into the slot in the Ply Spar and align with

W4 (they’re the same size). Glue in place. For the

fixed flap option, glue a maple block to W4A as

shown on the plans.

2. Cut two 24” lengths from 1/4” x 1/4” balsa sticks.

Glue one of these spars to the Ply spar, aligning it

with the bottom edge, and fitting it into the slot in

W4A.

7. Slide W20 into the slot in W8 (the bellcrank will be

on the bottom of W20) and cut the pushrod housing

and pushrod to size. Attach a clevis to the pushrod

and the bellcrank and align the assembly.

8. Slide W9 in place, slide W20 into the slot in W9, and

glue all the pieces.

9. Glue W10, W11, and W12 in place.

10. Glue W18 against W17 and to the trailing edges of

W9 thru W12. Glue the remaining ¼ x ¼ x 24 balsa

spar in place. Thin the outer 4” to 1/8” to fit in W11

and W12.

3. Thin the outer 4” of the balsa spar to allow the fit of

the last two ribs. Thin to 1/8”.

4. Slide W5, W6, W7, and W8 onto the Ply Spar, align,

and glue.

5. Glue W17 to the trailing edges of the ribs.

11. Cut the 3/8 x 1 x 36 balsa leading edge to length,

and glue in place. Cut scrap 1/16” balsa for shear

webs and glue in place (see plans for location).

12. Select two 1/16” x 4” x 24” balsa sheets. Cut a 1/16

x 3 x 36 balsa sheet in half. Edge glue the two 4”

sheets and one 3” sheet to form the top sheeting.

13. Trim the leading edge to fit, and sand the inner

edge to match the center section sheeting. Sheet

9

the top surface of the right wing panel.

14. Mark a point 9/16” perpendicular to W17 at W8.

Mark another point 11/16” perpendicular to W18 at

W12. Connect these points and the trailing edge of

the center section. Trim the top sheeting to match

these lines.

15. Remove the tabs on the rib bottoms, and bevel the

top sheeting trailing edge to match the bottom rib

camber.

Fuselage Assembly

1. Pin two ¼ x ¼ x 36 balsa spars to the fuselage top

view as shown. Cut a ¼ x ¼ balsa stock for a fin post.

Glue in place. Bevel the ends of the spars to fit at the

fin post.

2. Bevel the top edge of F2A to match the angle of

F1A. Glue F2A in place.

16. Mark the location of the exit point of the aileron linkage so the slot can be cut after sheeting.

17. Select two 1/16” x 4” x 24” balsa sheets. Edge

glue these two pieces and the remaining 3 x 18 sheet

to form the bottom sheeting.

18. Trim the sheeting to fit the leading edge, and sand

the inner edge to match the center section sheeting.

Sheet the bottom of the wing panel.

3. Using the fuselage angle gauge provided, set F1A

in place and set the angle. F1A will rest against F2A.

Glue in place.

4. Glue the bulkheads F3A through F10 in place.

5. Add ¼ x ¼ balsa keels between F1A and F3A, and

between F5A and F8A.

6. Glue F12 in the slots in F8A and F9A.

7. Align F11 with F9A and the fin post, resting on F10.

The top edge of F11 will align with the bottom of the

notch in F9A. Glue in place.

19. Trim the trailing edge to match the top sheeting

and the center section sheeting.

20. Glue on the wingtip. Sand to shape.

Note: the slots in the trailing edge in the picture will be

cut later.

The remainder of wing construction will be accomplished after fuselage assembly.

10

8. Add 1/8 x ¼ balsa stringers to the fuselage, starting

with the bottom row first. Add the stringers simultaneously to each side; this will help keep the fuse

straight. Bevel the stringers that attach to the fin

post.

9. After the bottom row is in, add F21 and F22 Cockpit

Floors. Note that F22 buts against F5A.

10. Continue adding stringers, noting that the third row

stops at F10. This row will also twist as you lay it in

the grooves. Also note that this row does not extend

between F3A and F5A.

11. Add a stringer between F3A and F5A, fitting in the

slot in F4A. This stringer is for locating the sheeting

only. Attach it level with the other stringers, butting

against F3A and F5A.

12. Sand F11 to match the contours of F9A and F10

and the fin post. Sand any high spots from the fuselage structure.

13. Pin short pieces of 1/8” balsa scrap to the edges of

the fuse at the ¼ x ¼ spars. This will elevate the

sheeting by 1/8” to allow the bottom sheeting to

attach.

14. Using 1/16 x 4 x 36 balsa sheets, sheet the fuse-

lage. Pick matched density sheets to prevent warping, and sheet both sides of the fuse at the same

time.

16. Add the pushrods by feeding the housings through

the holes in the bulkheads. A slight amount of the

stringer near F9A will have to be relieved to allow

the housing to pass through. Cut a hole in the

sheeting between F9A and F10 to allow the

pushrod to pass through.

17. Glue the housings in place. The pushrods may be

added later during control surface installation.

This will keep the fuse from warping. Work slowly, starting

at the center, moving fore and aft, side to side. Glue the

sheeting one stringer section at a time, working up. After

gluing to the second row of stringers, cut the balsa away

from the cockpit area (you don’t have to be precise, this just

relieves the stress in the sheets). Wetting the sheets with

water or a water/ammonia mix will help the sheeting conform to the fuse. Trim the sheeting as you get to the top, to

butt the sheets together. Trim away the sheeting at the aft

end as you finish sheeting around the fin post, F10, F9A,

and F8A. This area is difficult, and the sheeting may crack

as it tries to conform to this area. Glue the cracked areas

and continue. This area will be smoothed with lightweight

filler later.

15. Trim the sheeting at the cockpit area by placing the

canopy in position and marking its edges. Try to

leave at least 1/8” of the sheeting overlapping. Trim

and sand the sheeting flush with F1A and the fin

post/F11 area.

11

18. Slide F14 into the fuselage and locate the tab into

the slot in F3A.

19. Slide F2B onto F14; concurrently, slide F1B onto

F14. Lock the tabs and slots into each other and

glue all the pieces.

20. Glue F3B, F4B, F5B, F8B, F7B, and F8B in place.

21. Glue F13 into place against F5B, F2B, and the

balsa spar.

22. Add ¼ x ¼ balsa keel pieces to the slots in F1B and

F2B, and the slots in F5B though F8B.

23. Add 1/8 x ¼ balsa stringers to the lower fuse half.

Add short segments to F1B and F2B. Add the

stringers from the spar to the keel, simultaneously

to prevent fuse twisting. The stringers but against

F9B.

24. Trim and sand the stringers even with F9B, F5B,

F2B, and F1B.

30. Align the trailing edge of the wing with the fuselage

and mark it’s location. Drill a hole through the wing

center section (corresponding with the pilot hole

you drilled earlier) and through F24. Tap the hole in

F24 for your wing holddown bolt. Remove the wing

from the fuselage.

31. Slide F15 into position, inserting the tabs on F1A

and F2A into the slots. Epoxy in place.

32. Trim F16 to clear F23 and the dowels and epoxy to

F2B and F1B.

33. Bevel the edges of F17 to fit into the slots in F14

and F15. Epoxy both pieces in place.

34. Bevel the edges of F18 to fit into the slots in F14

and F16. Epoxy both pieces in place.

25. Slide F24 Ply Holddown Plate into the slots in F13

and epoxy in place.

26. Using 1/16 x 4 x 36 balsa sheets, and using the

same techniques as with the top sheeting, sheet

the bottom half of the fuselage.

27. Trim and sand the sheeting at F9B and F1B. Trim

and sand the wing saddle area flush with F13, F5B,

and F2B.

28. Place the wing in the wing saddle and center and

align the leading edge with the fuselage (the dowel

holes in F2B are cut oversize to allow adjustment).

When centered, mark the location.

29. Working through the open area in the front of the

fuse, slide F23 onto the dowels and epoxy to F2B

(NOT the dowels!). Hold the wing in it’s aligned

position while the glue sets.

12

35. Epoxy the firewall in place.

36. Slide the tabs on F19 into the slots in F15 and F1A

and glue in place.

37. Slide the tabs on F20s into the slots in F16 and F1B

and glue in place.

38. Center and align the horizontal stab onto F11. Align

the stab with the fuselage, check for level, and

epoxy in place.

39. Slide the tab on the vertical stab into the slot in the

horizontal stab and epoxy in place.

40. Using the elevator assemblies as a guide, glue the

stab horns onto the ends of the horizontal stabilizer.

41. Fill the aft fuselage area with lightweight filler to fill

any gaps and smooth the surfaces.

42. Glue the balsa tail block to the aft lower fuselage

and sand to shape. Fill any gaps with lightweight

filler and sand smooth.

48. Cut an access hole in the belly pan for servo

access. Cut a hatch cover (plastic cover provided;

cut to size) for the hole.

49. Locate the screw holes for the cover. Glue hardwood screw supports behind the skin and mount

the hatch cover.

43. Mount the wing to the fuselage. Glue F2C to the

leading edge, aligning it with F2B.

44. Glue F5C to the trailing edge, aligning it with F5B.

45. Cut a ¼ x ¼ balsa keel to size and glue to F2C and

F5C.

46. Slide F3C and F4C under the keel until they’re snug

with the wing and the keel. Do not bow the keel, it

should be straight.

47. Glue the pre-cut 1/16” belly pan panels in place,

one side at a time, and work the panel along the

stringers and glue to the wing sheeting. Trim and

sand the ends. Cut a hole to allow access to the

wing holddown bolt.

Flaps & Ailerons

The flaps and ailerons are built up with a hinging system

that closely approximates the full-size airplane’s offsett control surfaces. Building these assemblies is not difficult; however, care should be used to prevent getting the parts

mixed up, crossed, or backward during assembly. Once an

assembly is glued together, it’s permanent. A method that

works is to work only with the parts needed for a particular

control surface at one time; that way, you won’t have 50

pieces laying on your work bench at once.

1. Remove two AH-1 hinges from the parts tree.

Carefully sand the edges smooth and scuff the sides

with sandpaper. Epoxy the hinges together, making

sure they’re aligned. Repeat this procedure with two

AH-2s, and again with two AH-3s.

3. Note that the aileron halves are marked top and bottom and side to side. Start with the left bottom

aileron half. Cut a piece from the 1/16” wire provided to fit in the channel in the aileron.

13

4. Slide the hinges onto the wire with the slots facing

up.

4. The hinges will set at an angle, so carefully, using a

1/16” drill bit, drill the hole in the hinges to an angle

(it helps to hand drill this). Work until the angle

matches the slots in the aileron.

5. Center the hinges with the slots in the aileron (AH-3

at the tip, AH-2 in the center, AH-1 at the base)and

with the slots in the hinges facing up (it helps to have

the wing handy for reference).

13. Same hinge assembly techniques, glue two FHs

together, and make two hinges. Cut the 1/16” wire

to fit, and slide the hinges onto the wire.

14. Epoxy the “top left” half to the bottom, trapping the

wire/hinge assembly.

15. Repeat for the right side flap section.

6. Lay the hinge/wire assembly into the channel in the

aileron, and epoxy the “top left” aileron half to the

bottom, trapping the wire. Clean the epoxy from the

hinge slots, and place the aileron on a flat surface (it

helps to add weight for pressure to the assembly)

and let the epoxy cure.

7. Repeat the procedure for the right aileron, starting

with the bottom right half. If you always start with the

bottom half, the slot in the hinges always faces up.

8. Build the outer flap section the same as the ailerons,

starting with the bottom left half.

9. Epoxy two FHs (flap hinge) together. All the flap

hinges are the same, and use the same assembly

techniques as with the aileron hinges. Make two

hinges.

10. Angle drill the hinges to match the slots in the flap,

and cut the 1/16” wire to fit. Slide the hinges onto

the wire, and epoxy the “top left” half to the bottom.

Remember, start with the bottom half and the hinge

slots face up!

16. Trim and sand the edges of the control surfaces to

remove excess epoxy. Carefully remove any

excess epoxy buildup in the hinge slots.

17. Sand the aileron and flap sections to an airfoil

shape (shown on the plans). You don’t have to be

exact here, we even tested an airplane with square

control surfaces, but I don’t recommend that; it’s a

scale airplane, after all!

11. Repeat the procedure for the right side flap section.

12. Same techniques again for the inner flap section,

start with the bottom left half.

14

18. Since mounting the control surfaces can be considered a final assembly item, I recommend covering

the wing and control surfaces before attaching

them to the wing. Here we go:

19. Locate and cut slots through the wing sheeting

(CAREFULLY! That’s my favorite word!) Flush with

the respective ribs. See plans for hinge/rib relationships. Trim the slots and test fit the aileron/hinge

until the hinges slide into the slots and lock into

W18 (for the ailerons, W17/W16 for the flaps). Trim

the slots in the hinges to allow for the angle. Note

that the ailerons and flap sections cannot be

reversed; each is specific.

Test fit each control surface, and trim until, with the hinges

locked in place, the control surface pivots freely and doesn’t interfere with the wing.

20. Starting with the ailerons, epoxy the hinges in

place. Don’t go overboard, but don’t skimp with the

glue.

25. Locate the position of the maple blocks either side

of W4. Mount the control horns on each flap section

and gauge the angle to the block. Drill the block at

that angle, and install pushrods into the blocks.

Connect with clevises to the control horns. We will

adjust them in a moment.

Functional flaps:

Mount the control horn for the inner flap section. Connect

the bellcrank and control horn for the inner flap section with

a pushrod and clevis. Mount a control horn to the outer flap

section at an angle pointing slightly aft of the bellcrank linkage. Attach a clevis and pushrod to the control horn and

bend the pushrod until it is parallel to the inner flap pushrod.

Mark this location, remove both pushrods, and solder them

together. (Scuff the puhsrods with sandpaper; find a piece

of old automotive wire, and peel off the insulation and save

a few strands of the wire. Wrap the pushrods with the wire

and then solder; the joint will outlast the airplane!)

Now let’s adjust everything: using the W4 (flap) and W8

(aileron & flap) incidence gauges provided, start with the

ailerons. Connect the pushrod and servo and center the

servo. Mount the W8 Incidence Gauge to the wing (top) at

the inner end of the aileron and adjust the aileron to match

the guage (if your aileron doesn’t quite match the contours

of the gauge, that’s OK. Eyeball it, because this is preliminary) repeat for the other aileron. Connect and center the

flap servo. Use the W4 Incidence Gauge to set the outer

flap section. The flap and aileron should be even with both

centered. Adjust the inner flap section to match the outer.

21. Bevel the edges of the outer and inner flap sections

to allow a flush seam, and epoxy the outer flap section in place. Verify that the flap and aileron ends

are even.

22. The inner flap section hinges do not attach to ribs.

Locate the slots by test fitting and comparing with

the outer flap. Maintain the same distance with the

wing trailing edge, and epoxy in place.

23. Mount the control horn for the aileron directly aft of

the linkage, and mount the horn on the aileron so

that the screws do not interfere with the wire

trapped inside. Connect the aileron linkages and

adjust.

24. Each flap section uses it’s own control horn. Do the

following for fixed flaps:

15

Final Assembly

1. Glue F25 Cockpit Bulkhead to the top of F4A and

angle it to match the rear of the forward sliding

canopy.

2. Finish the interior as you wish. An instrument panel

is provided on the 3-view drawings; cut it out, and

glue it to the back of the pre-cut balsa panel, and

glue in place. Add pilot figures, etc., to suit. A rear

machine gun may be added. Note that a portion of

the rear cockpit floor is relieved to allow the servos

to fit. You may build up this area with scrap balsa if

you desire.

3. Glue the canopy in place.

4. The wheel pants may be mounted either as a permanent installation or removable for flight. To mount

them permanently, do the following:

5. Mount the gear leg into the slot in the wing. Slide F27

onto the wire. Slide the wheel onto the wire and position the inside half of the wheel pant to the wire.

Mark the position where the wire meets the plastic.

Check for wheel clearance. Bolt the wheel pant to

the gear leg using a gear strap. Epoxy F27 to the

wheel pant. Place the outside half against the inner

half and check for clearance. When satisfied, permanently mount the wheel, and glue the wheel pant

halves together. Paint to match your color scheme.

The down side to permanently mounting the wheel

pants is that access to the wheels is impossible.

Removable wheel pants can be accomplished by adding

blocks to the inside edges of the wheel pants. Drill through

the blocks and screw the wheel pants together. Add the

gear strap to mount one half to the gear leg, and cut F27 in

half and glue to each wheel pant half to locate to the gear

leg. Paint to match your color scheme, and remove for

flight.

Servo and Receiver installation

3/8” maple blocks are provided for servo rails. Mount

these as shown on the plans and mount the servos.

Mount the receiver and connect the components. The battery may be mounted in a location that will aid in balancing the airplane.

Covering

Cover the airplane with the covering of your choice. The

covering choices are too numerous to mention, but the

airplane shown in the photos was covered with film, painted, and clear-coated. It is recommended that the airplane

and control surfaces be covered separately.

Control Surfaces

Locate the control arm positions, and install the control

arms. Final sand the control surfaces. Locate the hinge

points (hinges and other hardware are not provided int he

kit because everyone has his own preferences. Rather

than put in stuff that most of you will throw away, we left it

out to keep the kit price down) and install the hinges and

control surfaces. Use at least three hinges per control surface for best results. Connect and adjust the pushrods.

Fuel Tank and Throttle Cable

After deciding which direction the engine will point (up,

down, or sideways) drill holes for and install the throttle

cable. Mount the fuel tank of your choice, and connect the

lines.

Center of Gravity:

The CG is measured with the aircraft UPSIDE DOWN 37/16” back for the wing leading edge, where the wing

meets the fuselage.

6. Locate the cowl to the fuse and mark the screw locations. Gluing a piece of carbon fiber or aluminum to

the cowl at the screw hole will add strength to this

area and will prevent cracking.

The remainder of the construction consists of attaching

the rest of the components to the airplane. Most of this is

builder’s choice, and individual tastes, styles, and component selection, so any detailed descriptions would be

impossible. The remainder of assembly is described in

general terms only.

Engine installation

Measure and mark the center horizontally and vertically of

the firewall; this will be the centerpoint for motor mount

installation. Install the motor mount and engine of your

choice. The photos of the airplane are shown with a .61

installed inverted, completely enclosed. Inverted engine

installation causes it’s own set of problems, so the flat firewall allows the engine to be installed pointing any direction that suits you (side mounted with a Pitts-style muffler

will hide most of the engine/muffler and exhaust system).

Control Throws:

Ailerons: 7/16” up & down

Elevator: 7/16” up & 3/8” down

Flaps: 1” down

Rudder: 3/4” left & right

Flying

The Stuka is a very stable flyer, but approach the first few

flights with caution; it will take several flights to “dial in” the

flap and aileron incidences, so as you make changes,

make them gradual and incremental. Large adjustments

may create the opposite effect you were intending!

The rest is up to you! Fly and enjoy!

16

1. After painting the laser-cut cockpit parts, cut

the clear plastic gauge inserts to size. Be sure

to cut away any areas where stringers will

attach or notches where levers will be inserted.

2. Using a small amount of medium CA, attach

the clear gauge insert to the back of the panel

so the protruding lenses fit into the laser cut

holes.

3. Color any necessary parts of the paper gauge

panel and apply glue to the front of the paper.

DO NOT USE CA for this step (the fumes from

the CA will cloud the gauges). We use a

Scotch glue stick for our prototypes.

4. Apply the paper to the back of the panel so the

gauges line up with the laser-cut holes and

allow to dry.

Skyshark R/C

Gauge Face Assembly Instructions

Paper gauge faces are located on the 3-view drawing that are included with the instruction manual.

Loading...

Loading...