Skyshark R/C

FANTASY

The Skyshark Fantasy was designed for both

beginning low wing pilots and serious sport flyers. It’s excellent slow flight abilities and gentle

stalls make the Fantasy one of the best low wing

trainer kits available today. Heavy duty wing

spars and fuselage make for an aircraft that can

withstand the mishaps that normally occur with a

begining pilot. Laser cutting and hand selected

balsa allows us to keep the weight and building

Wingspan . . . . . . . . . . . . . . . . . 60 inches

Wing Area . . . . . . . . . . . . . . . . 593 sq. inches

Overall Length . . . . . . . . . . . . . 52 inches

Flying Weight . . . . . . . . . . . . . . 5.5 - 6.5 lbs

Engine . . . . . . . . . . . . . . . . . . . .45 - .61 2-stroke

.56 - .91 4-stroke

Radio . . . . . . . . . . . . . . . . . . . . 4 Channel Min.

Building Experience Required . . .Basic

Flying Experience Required . . . Trainer

Average Build Time . . . . . . . . . . 30 hours

time to a minimum. If you are an experienced

builder, the Fantasy can be built and ready to fly

in the same amount of time as many ARFs. For

the sport flyer, the Fantasy features, a larger

rudder for better aerobatics, swept wing design

for speed and a simple, no hassle, engine

mounting setup. Engine choices also vary from a

simple .46 to a high perfomance .61. You can

even add a tuned pipe for real excitement!

Skyshark R/C Corporation

75 Mid Cape Ter, Ste 7

Cape Coral, FL 33991

Phone: (239) 800-1941

Website: www.skysharkrc.com

email: custserv@skysharkrc.com

Thank you for purchasing the Fantasy from Skyshark R/C.

Our goal, through computer technology and state-of-theart production techniques, is to offer aircraft that are fast

and easy to assemble with minimal sanding and shaping.

tle as 20 - 30 hours.

Occasionally hints will be included at certain building

steps. These are not required for completion, rather they

are tips intended to ease a particular process.

Your airplane has many unique features in its

design:

CAD Design

CAD design allows strength to be built into the airplane

without sacrificing weight. Accurate parts design and

placement ensures a perfect fit.

CAD Drawn Plans

The plans in this kit are not copied from a master set! They

are originals drawn directly from the CAD program where

the airplane was designed. We do this because it allows us

to use color, which helps you better visualize the various

components of the airplane, and we can use better quality

paper, which greatly reduces the possibility of shrinkage.

Since you’re going to build directly on the plans, they

ought to be the proper size! Also, parts placement is guaranteed to be accurate, so you can build a better, straighter

model.

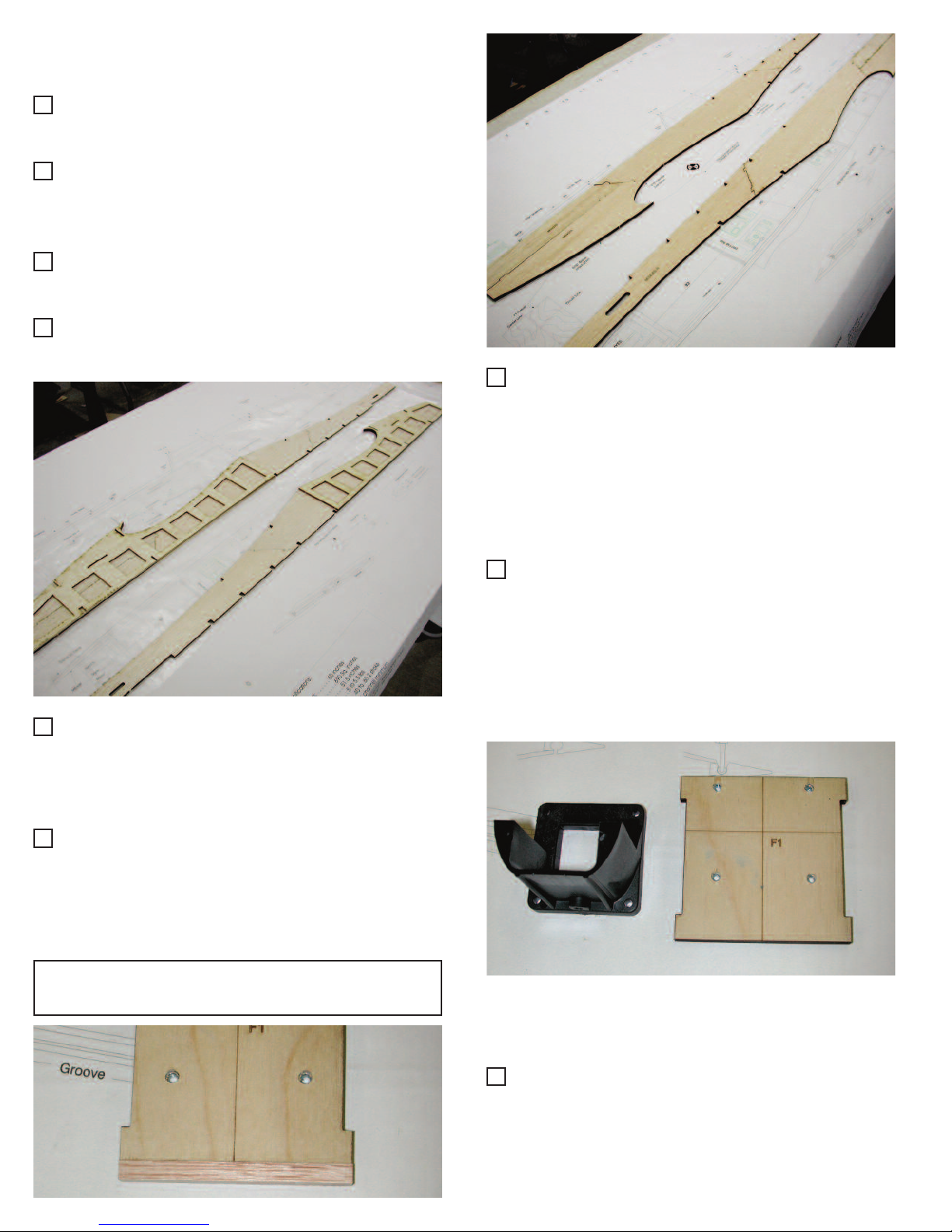

Laser Cut Parts

The same program that generates the design and plans

also drives the laser, so every part is reproduced exactly as

it was designed. Laser cutting also allows us to fit more

parts on each sheet of wood, reducing the waste, and lowering the cost to you. Since laser cutting does not have the

same limitations that mechanical cutters do, small and

hard-to-produce parts are simply a computer file away, so

you get a more accurate airplane.

The laser does not cut through the wood, it burns its way

through. As a result of this, occasionally there will be

scorching on the surface of the wood. This is normal, and

is only a surface discoloration, and does not affect the

wood in any other way. Similarly, the laser settings are optimized for wood density averages, so occasionally, due to

variations even in individual sheets, some areas might not

cut through completely. This is apparent mainly with the

plywood. Simply use care in removing the parts from the

sheets; most of the time, the parts will literally fall out of the

sheets!

Some hardware including a motor mount is not included in

the kit. There are so many choices for quality hardware that

these choices are left to the individual preferences of the

builder, rather than include something in the kit that you’ll

probably throw away anyway.

Decals

The decals provided are made from fuel-proof vinyl so

there is no need to clearcoat them. To apply, clean the surface with alcohol and wipe dry. Put a drop or two of soap

in a spray bottle filled with water. Shake the mixture and

spray onto the surface that you will be applying the decal

to. Peel the backing from the decal and apply to the surface

without pressing.Using a credit card or other flat item rub

the decals onto the surface from the center moving out to

the edges. This will force any water from under the decal.

Wipe with a clean dry cloth and remove the masking from

the decal. If the decal lifts while removing the masking,

allow the decal to dry before attempting to remove the

masking.

Engine Options

Engine choices range from .46 to .61 2-strokes, or .56 to

.91 4-strokes. The firewall is a limited size so make sure

you check you engine mount fit before deciding on a larger engine.

Retract Options

Retract installation is left up to the builder.

Dual Aileron Servos

Dual servos can be added to the wing instead of a single

servo torque rod setup without affecting performance. We

also leave this up to the builder

General Building Information

The Fantasy can be assembled by a person with little or no

building experience. This manual is written for the beginning builder. An advanced builder can build this kit in as lit-

This aircraft is not a toy. It must be flown in a responsible

manner according to the rules set forth by the Academy of

Model Aeronautics. The builder assumes the responsibility

for the proper assembly and operation of this product.

Skyshark R/C shall have no liability whatsoever, implied or

expressed, arising out of the intentional or unintentional

neglect, consequential damage, misuse, abuse, or abnormal usage of this product. Skyshark R/C shall have no liability whatsoever arising from the improper or wrongful

assembly of the product nor shall it have any liability due to

the improper or wrongful use of the assembled product.

Skyshark R/C shall have no liability for any and all additions, alterations, and modifications of this product.

Having said that mouthful, turn the page and start building

the best sport plane on the market!

2

Kit contents:

Needed to complete kit:

Fuselage Side Plan Sheet

Wing Plan Sheet

Laser Cut Wood Pack

1/4” x 3” x 24” Balsa (1)

3/32” x 4” x 36” Sheeting (5)

3/32” x 4” x 24” Sheeting (3)

1/4” sq. x 36” Balsa Sticks (4)

3/16” sq. x 24” Balsa Sticks (5)

1/4” x 1” x 36” Leading Edge (2)

3/8” x 1/2” Wing Spars (4)

3/8” x 1” x 36” T.E. and Aileron Stock (2)

5/8” x 1” x 5-7/8” Balsa (2)

Clear Canopy

Main Landing Gear

Dubro Nose Wheel Gear

Nose Wheel Gear Horn w/5/32” Collar

2-3/4” Dubro Wheels (3)

Dubro Aileron Torque Rods (2)

Sullivan Gold-N-Rods 36” (2)

Sullivan Gold-N-Rods 12” (2)

Sullivan Clevis Adapters (4)

Sullivan Clevises (4)

2-56 Pushrods (4)

Landing Gear Blocks (2)

Gear Anchor Blocks (2)

Wing Mounting Blocks (2)

F-1 Firewall

1/4” Wing Dowel

2 oz. Fiberglass Wing Joining Material

Elevator Connector Wire

Landing Gear Straps (4)

5/32” Wheel Collars (4)

CA Hinges (18)

Dubro Control Horns (1 pk.)

Dubro Easy Connectors (2)

1/4” Nylon Wing Mounting Bolts (2)

Thin CA Glue

Medium CA Glue

Thick CA Glue

(We use Balsa USA Gold on our prototypes)

RC56 Canopy Glue

5 Minute Epoxy

30 Minute Epoxy

Epoxy Brushes

2 rolls of film or fabric covering 72” x 26” each

8 -14 oz fuel tank (Du-Bro)

Silicon fuel tubing

Engine Mount (with nose wheel attachment)

(We recommend Hayes)

Engine and Mounting Hardware

4 Standard Servos

(Cutouts are sized for Hitec)

4 Channel Radio

Battery

6” Servo Extension

2-1/2” Spinner

Propeller

80, 120 and 240 grit sandpaper

Sanding block or bar

1/4-20 Tap & Drill Set

Balsa Filler

Masking Tape

Taildragger Version Only:

Tail gear

1” Tail wheel

3

Occasionally we will make reference to the plan in order to clarify the instructions. We have letters down the side and numbers across the bottom of the plans. In brackets [ ] we will give you the coordinates like a road map to locate the item

referred to. Find the letter and number and where they cross will be the location to look.

When working over the plan, waxed paper should be used to protect the plan and eliminate other frustrations caused by

parts sticking to the paper and the additional sanding involved.

If you plan on building the Taildragger version, please follow the taildragger add-ons listed under the appropriate sections.

Our prototype Tri-gear version required 4 oz. of tail weight with the battery moved to the back of the fuselage servo

tray. The plane was setup with a .46 engine and standard muffler. Be sure to account for this when building. The

Taildragger version should not require any additional tail weight.

Tail Surfaces

1. Find vertical fin (MS401, MS404), elevators

(MS403), horizontal stab (MS405) and rudder (MS402) parts.

2. Over the plans, join MS405 to the 1/4” x 3”

x 24” balsa sheet with thin or medium CA.

4. Remove above pieces from the plan and

mark a center line on the leading edge of

both elevators (MS403) and rudder

(MS402). Do the same on the trailing edge

of the fin and stab assembly.

5. Place a mark on these center lines indicating where the hinges and elevator joiner

wire are to be located. See plan [B24 &P24].

6. With a 3/32” drill bit, drill a hole in each elevator (MS403) half approximately 3/4” deep

to accept the elevator joiner rod. Cut a

groove from these holes on the front edge to

the inner end of each elevator half to allow

the joiner rod to fit flush with the elevators.

Put a few drops of thin CA in the drilled hole

and re-drill with the 3/32” bit once dry. This

will strengthen the hole.

3. Join MS401 to MS404 so they align with

the plans. Use thin or medium CA.

4

7. Where you have marked for the hinge locations on all tail group pieces, carefully cut

hinge slots with a #11 blade.

8. Bevel the front only of two MS403 [J24] and

MS402 [O24].

9. To provide clearance for the elevator joiner

wire, cut a 1/4” half round in the leading

edge of MS402. See photo.

10. Pin two MS403 down on the plan and trial

fit the elevator joiner wire. It should slip in

easily. Apply 5 minute epoxy to the joiner

holes and groove and slide the joiner wire

in place. Let cure and remove from board.

11. Trial fit all hinges to assure proper alignment. Do no glue hinges at this time.

12. Bevel leading dege of all control surfaces

so they move at the proper deflections.

Sand to marked line and round all outside

edges of the tail group. Do not sand areas

that will be inside the fuse and rudder tail

blocks.

Wing Assembly

13. Start the wing assembly by removing the

balsa ribs and 1/8” ply doublers (3 & 4)

from the laser sheets.

Taildragger Only:

Use ply doublers 3T and 4T

14. Glue the appropriate ply doublers to both

sides of R3 and R4. Align these carefully

as these set the angle of and re-enforce

your landing gear

5

15. The wing is sheeted from the leading edge

to the middle of the spar. These sheets

should be made up now while your work

area is clear. Locate (4) 3/32” x 4” x 36”

Balsa sheets and cut them to 30”. With

sand paper or 36” steel rule and a hobby

knife, true on 30” long edge of each sheet.

Over waxed paper, lay 2 sheets, trued

edges together and adjust until there is no

gap between the sheets. When you have a

good match, pin them down. Wick thin CA

along the joint. Unpin when dry and join

the other 2 sheets the same way. Lightly

block sand both sides of the joined sheets

in order to smooth out the glue line.

16. Take the two 8” wide sheets from previous

step and trim each sheet to 5-3/4” wide.

Make a mark 1-3/4” down from the upper

left corner and 1-3/4” up from the bottom

right corner. With a 36” steel rule, carefully

join the two marks and cut along the line.

Set these sheets aside for use later.

17. Start with the right panel. Align and pin the

3/8” x 1/2” x 36” main spar over the plan.

18. Locate two R1 ribs and glue on R1A balsa

wing dowel block on the outboard side of

each R1 rib as shown on the plan. Make

sure you have a right and left.

6

19. Using thin CA, reinforce the thin area of the

tabs on the front of ribs R10 and R11. This

will insure the tabs will stay on the ribs

while you are building the wing.

20. Lay R1 thru R11 over the spar in their proper location on the plan. Place the 1/4” sq.

trailing edge stick against the back of the

ribs in the slot provided. Starting with R1

and working thru R11, lay a small triangle

next to the rib to stand them 90 degrees to

the building surface and verify proper location over the plan. When satisfied, glue to

the main spar and trailing edge with CA.

Be sure to glue only the back of the ribs to

the 1/4” trailing edge. the tab will be

removed later.

Note: An easy way to insure the ribs are aligned

and evenly spaces is to check them with SW1

thru SW10 shear webs. DO NOT glue the shear

webs at this time.

21. Carefully fit the top spar into all rib slots

and glue. Make sure that all ribs remain at

90 degrees from the building surface.

22. Place the 1/4” x 1” x 36” leading edge

piece in the slots provide on the front of

each rib and glue. Glue the leading edge to

the front of each rib only. The tabs will be

broken off and discarded later.

7

23. Locate and glue shear webs SW1 thru

SW10 in place on the rear of the main spar

as show on the plan. Sand the shear webs

as needed to fit. Insure that the grain is

running vertical.

24. Break off the rear tab that holds the 1/4” sq.

trailing edge piece and sand the trailing

edge to match the taper of the ribs. Make

sure to leave the bottom part of the tab

attached to rib. This sets the correct

washout for the wing.

25. Using thick CA glue a 3/32” x 1” x 30”

sheet to the trailing edge of the wing flush

with the 1/4” sq. trailing edge.

26. Locate grooved landing gear blocks (1/2” x

7/8” x 3-7/8”) and drill a 5/32” hole at 90

degrees in the bottom of the landing gear

block groove 3/8” from the end.

8

27. Fit the grooved landing gear block into the

notches in R3 and R4. It should have a 1/2”

overhang on the end with the hole. Insure

this block fits flush with the top edge of the

ribs. When satisfied, remove block and use

30 minute epoxy to glue in place along with

the 1/2” x 7/8” x 1” vertical gear block as

shown in photo.

Taildragger Version:

The gear blocks will be forward of the main

spar.

28. Using the 3/32” tapered leading edge

sheets made previously in step 15, bevel

the angle to match where the ribs meet the

leading edge. Check for proper fit - there

should be no gaps between the sheeting

and the leading edge. Sand if necessary.

31. Using the 3/32” x 4” x 24” sheet provided,

cut two pieces 9-1/2” long. Glue these in

place over R1 thru R4, keeping one end

flush with R1. Cut and fit a piece to fill into

the gap left between the center section

sheeting and the trailing edge sheeting.

Glue in place.

29. Pin or weight the trailing edge of the wing

to the building surface. The wing must

remain flat when sheeting the front portion.

30. Apply thick CA to the tops of all ribs.

Working quickly, align the front of the

sheeting to the rear of the leading edge

piece and glue with thin CA. Once dry, roll

the sheeting to the rear down on top of the

spars and add weight to hold flat against

the ribs. Glue the rear edge of the sheeting

to the top spar using thin CA.

Option: If desired for looks, the rounded corners

shown on plan can be cut from scrap 3/32” sheet

and added.

9

32. Using scrap 3/32” sheeting, cut 1/4” wide

cap strips to fit the remaining seven ribs

left exposed. Glue these on ribs R5 thru

R10 centered on rib.

35. Remove the wing from your building surface. Check all glue joints and re-glue as

necessary. Pay particular attention to the

shear webs.

33. Glue cap strip to R11 flush with the outside

of the rib. You will be adding a wingtip to

this rib later.

36. Run a 5/32” drill thru the vertical gear block

and sheeting. This will allow you to locate

the landing gear groove later.

37. Break off the tabs on the front and back of

R1 thru R11. Lightly sand any imperfections left in those areas.

38. Turn wing upside down. Place a 1” tall

block under the trailing edge at R1 and a

1/2” block under the trailing edge at R11.

this will maintain the correct washout. You

can also cut a block to fit under R6 to

insure the trailing edge doesn’t flex while

sheeting the wing. Pin the wing to these

blocks and to the building surface.

39. Taper the 1/4” sq. trailing edge piece to

match the wing taper and glue a 3/32” x 1”

x 30” sheet in place as was done in step

25.

40. Fit and glue tapered LE sheet in place as

was done in steps 28, 29 and 30.

41. Sheet the center section from R1 thru R4

as was done in step 31.

42. Cap strip as was done in step 32.

Repeat steps 17 thru 42 to construct

left wing panel.

10

43. On both wing panels, trim and sand flush

the root, tip and trailing edge. On the top of

the center sheeting, mark the location of

the aileron servo cutout.

44. On both wing panels, carve and sand the

leading edge to blend with the contour of

the LE sheeting, then sand the front edge

round. See cross section [R2] and [R10] on

the plan.

Note: Do not sand the leading edge to a sharp or

pointed shape. The blunt contour is what allows

the Fantasy to perform well at very low speeds.

45. Find the two pieces of 3/8” x 1” x 36”

tapered aileron stock. Cut each in three

pieces to the length shown on the plan for

inner and outer trailing edge and aileron.

46. Take the two 2-5/8” pieces and groove the

fronts. Also groove the wing trailing edge to

accept the tubing on the aileron torque rod.

47. Lay the two 2-5/8” pieces end to end and

measure 1/2” from the center line in each

direction. At these points cut a groove in

each 2-5/8” piece and the trailing edge for

the vertical arm to move back and forth.

48. Cut a slot in the trailing edge of the wing

2-1/2” from the inboard end of the wing for

the torque rod hinge. Check everything for

fit and use epoxy to glue hinge into the

slot.

11

49. Draw a center line on each aileron and lay

out location of the hinges and aft facing

torque rod end. Drill a 3/32” hole and cut a

groove for the torque rod as was done on

the elevator halves. Cut the slots for

hinges in the ailerons and wing trailing

edge. Install aileron hinges and aileron. Do

not glue hinges or torque rod until covering

is completed.

50. Using medium CA, glue 2-5/8” blocks to

the inboard end of the trailing edge as

shown on plan. Insure you don’t get any

glue on the torque rod assembly.

Note: You can use a light coat of oil on the torque

rod assembly to keep any excess CA from sticking.

51. Glue two 1” tapered trailing edge pieces to

the outboard end of the wing trailing edge

with medium CA.

52. Block sand aileron and trailing edge pieces

to blend smoothly with wing sheeting.

Note: To make sanding the aileron easier, tack it

to the wing TE with a couple drops of thin CA.

53. Remove ailerons and bevel aileron leading

edge as shown on plan.

54. Align and glue WT wingtip blocks in place

flat against R11 using medium CA.

12

55. Sand WT to match the airfoil of the wing.

58. Sand a flat (2-7/8” long) area on the front

center of the wing leading edge. This

should be parallel to the trailing edge and

vertical when viewed from the side. Glue

LE1 dowel plate to this flat area. Sand to

blend with the contour of the wing.

56. The wing will be joined with its top side flat

against the building surface, laying on the

spar. Check the fit of ribs R1 without gluing. If necessary sand for a good fit top to

bottom and leading edge to trailing edge.

57. Over waxed paper, apply 30 minute epoxy

to both R1 ribs and join the wing halves.

Top surface down, align the airfoil shape of

each panel. When satisfied with alignment,

hold together with tape and pins until

cured.

59. Starting at the top trailing edge and working forward, secure one end of the fiberglass tape to the wing center section. Wrap

it tightly around the wing providing openings for the aileron torque rods. Brush with

30 minute epoxy, insuring that all parts of

the cloth are saturated. You can also attach

the cloth with thin CA.

Note: If you use epoxy, you can use a small

amount of denatured alcohol to thin it and make it

easier to spread.

60. When epoxy or CA is cured, place SP on

the marks that you made previously for the

servo cutout. Trace around the inside and

cut a hole for the servo in the wing sheeting. Use medium CA to glue SP to the wing

61. Locate the holes in the bottom sheeting for

the landing gear. Carefully cut the sheeting

toward the wing tip exposing the groove in

the landing gear block. Open this area to

provide a 5/32” x 3-1/4” slot. Mark areas

for the landing gear straps and remove the

sheeting under the straps so they sit flush

with the hardwood gear blocks.

Set wing aside for now. The wing dowel hole

will be cut later.

13

Fuselage Assembly

1. Locate MS406B-L, MS406B-R, MS406A(2

ea.), and MS407(2ea.).

2. Align and pin MS406B-R, one MS406A and

one MS407 over plan. Glue with thin CA.

This will be your right side.

3. Repeat for the left side using the other

MS406A, MS407 and MS406B-L.

4. Sand both side smooth.

5. Locate 2 ea. FD1 ply fuse doublers. Align

with the fuse sides made in the previous

steps. The front, top and wing saddles

should line up perfectly.

Note: Make sure you have a right and left side.

The ply doublers face inward when the sides are

standing vertical.

7. Locate F1 Firewall and align your engine

mount with the scribed lines on firewall. Drill

holes and install motor mount as instructed

by the mount manufacturer.

8. Using the steering arm as a guide, mark the

location of the steering cable exit. Drill two

holes for the fuel line and one hole for the

engine throttle. If you have a long drill bit,

you can also drill these holes later.

Taildragger Version:

Don’t drill any holes for the steering cable.

6. Remove the doublers and apply a thin layer

of 30 minute epoxy to each FD1. Re-align

with the fuse sides and allow to cure. Make

sure you wipe any excess epoxy from the

slots in FD1. You will use these slots for

alignment of the bulkheads later.

9. Add a piece of 1/4” sq. balsa to the bottom

of F1 and sand even with all sides. This will

allow you to contour the firewall to the bottom of the fuselage easier.

14

10. Locate B1B and B1A. Glue B1A to B1B

with thick CA or 5 minute epoxy. Use a 1/4”

dowel to insure the holes in each piece

align.

11. Locate B2, B3, and C1. Take left side on

fuselage and insert F1 and B1A/B assembly into the tabs as shown on the plan.

Next, insert B3 into the appropriate slot.

Make sure the wide end is butting up

against B1B and resting below B1A.

Remember the fuselage is built upside

down, so make sure the firewall is facing

the correct way.

13. Align the right fuselage side with F1, B1B,

B2, B3 and C1. Once everything is square

with C1 and the plan, clamp and glue all

joints from F1 to B2 with medium CA or 5

minute epoxy.

12. Place C1 on the plan and pin in place with

the scribed lines facing down. Align the left

fuselage assembly with C1 and place B2 in

the location shown on the plan.

Note: If you are using the supplied flexible

pushrods, insure the 2 round holes in B2 are closest to C1. If you are making control rods from

dowels, turn B2 so the rectangle cutout is closest

to C1.

15

14. Carefully align wing in saddle. Using 1/4”

dowel hole in B1A/B as a guide, drill a 1/4”

hole into the front of the wing. Remove

wing and epoxy the dowel into the wing

leaving 5/8” protruding. Set wing aside.

15. At the back of B2, score the balsa sides

about half way through on the inside. This

will allow you to bend the fuselage easier.

16. Wet the outside and bring the fuse side

into alignment with the plan. Glue with

medium CA at the tail.

17. Locate and glue with 5 min epoxy PW so

that it fits flush with the top of the cut-out for

the horizontal stab. This can be done while

the fuselage is pinned to the building surface or you can unpin the fuselage and turn

it over as show in the photo.

18. Using the 1/4” sq. x 36” balsa sticks, cut

and sand fuselage cross pieces to match

the plans for the top and bottom of the

fuselage sides.

16

19. Insert the 1/4” sq. pieces into the slots on

the fuselage sides and align so they are

flush. Glue with thin CA. Glue rear 1/4”

piece as shown on plans and in the inset

photo.

Note: If you removed the fuselage from the building surface during step 17. Make sure it is pinned

down and aligned with the plans for step 19.

20. Cut and fit 1/4” sq. vertical pieces and glue

to B2 and fuselage sides.

21. Using 3/32” balsa sheet pieces, sheet the

fuse bottom from B2 back to the tail. Insure

the grain is running crossways.

Taildragger Version:

Using scrap 1/8” ply, place on the bottom of the

fuselage at the very rear, mark shape and sand

to fit. Glue in place for tail wheel mount.

22. Once all pieces are glued and trimmed,

sand flush with sides. Remove fuse from

building surface.

23. Locate the two 7/8” x 1/2” x 1-5/8” wing

hold down blocks. Bevel each block so it

will fit flush with B2 and parallel with wing

saddle.

24. When satisfied with fit, use 5 minute epoxy

to glue blocks in place 1/32” below wing

saddle and flush with B2. Let dry.

17

25. Place wing onto fuselage. The wing dowel

will align the front and the wing joint should

align with the center of the fuselage. To be

very sure, you can use the method shown

in figure 1.

26. Once you have the wing centered, mark

where shown on the plan and drill two wing

bolt holes. Use a #7 numbered or 13/64”

fractional drill bit. If you do not have these

drill sizes you can use a 3/16”, but you will

have to be careful tapping the smaller hole.

27. Remove the wing and drill the wing only to

1/4”.

28. Using a 1/4-20 tap, tap the wing blocks.

Note: After tapping, clean the treads and apply

thin CA. Allow plenty of time to cure and re-tap.

This will give you good, strong threads.

32. Locate C3 (2 ea.) servo mounting backup

plates and glue with medium CA to each

side of the servo mounting holes in C1.

You can glue them to either side of C1.

Figure 1

29. Sand the balsa filler on the bottom of F1 so

it is flush with the fuselage sides.

30. Sheet the bottom of the fuselage from the

wing saddle to F1 as shown in photo.

31. Locate CS1 balsa strips and cap strip the

bottom of each fuselage side in front of F1

so they become flush with the bottom

sheeting.

18

33. Run the flexible control rods from the holes

in the rear of the fuselage to the holes in

B2. Glue in place with medium CA.

34. Locate turtle formers 1A and 1B. Place 1B

on top of 1A. Using 3/16” balsa stringers

as spacers center both pieces. Mark location and glue.

35. Bevel bottom of 1A/1B assembly. Center

and glue TG backrest flush with bottom.

37. Remove turtle formers 2,3,4,5,6, 7A & 7B

from 1/8” ply sheet. Glue 7A and 7B together so they align with each other.

36. Align the front of TG to the scribed line in

C2. Adjust the length of TG to fit around

C3. Glue in place with medium CA.

19

38. Glue formers 2 thru 7 in place (see plan).

Make sure they are centered with the

stringers and the fuselage sides. Also

insure that they stand at 90 degrees from

the fuselage side.

39. Locate five 3/16” sq. stringers. Cut and

sand to fit in the notches of turtles 1 thru 7.

40. Starting with the top stringer, use thin CA

to glue each stringer in place. Use 5 min

epoxy to reinforce the stringers to turtle 7.

Note: For a more finished look and increased

strength, you can also sheet the turtledeck with

1/16” balsa.

41. Install the flexible pushrods for the steering

and throttle cable at this time.

42. Now you are ready to install the fuel tank.

Assemble fuel tank and set tank into the

tank compartment. Determine necessary

foam padding to hold tank in the center so

that it will be even with the engine carburetor. Run fuel lines through the firewall.

Note: The fuel tank should have foam on the bottom and sides to prevent fuel foaming and a poor

running engine.

20

43. Locate two B6 cowl formers. Align and glue

them to each other as shown.

44. Align B4 with the scribed line on C1 and

sand the bottom of B4 so it will match the

angle shown on the plan [8L]. Glue B4 to

C1 aligning it with the scribed line. Test fit

B5 4” back from F1 and glue in place. You

may need to cut part of B5 so the fuel tank

will fit. Align and glue the B6 assembly on

top of F1.

45. Locate a 1/4” sq. x 36” stringer and cut to

fit between B4 and B6. Align and sand so

the stringers are flush with the top edge of

B4. Glue stringers to B4, B5 and B6 with

medium CA.

46. Sand stringers flush with the curve in B4

thru B6.

47. Cut 3/32” sheeting to fit over the cowl

stringers and flush with the fuselage sides.

Bevel the edges of the 3/32” sheeting so

they will fit flat on the fuselage sides.

Apply medium CA to the stringers and

fuselage sides and press the sheeting in

place.

Note: You may need to use water or window

cleaner on the outside of the sheeting so that it

will curve around the formers.

21

48. Sand sheeting flush with B4 and B6.

49. You can use the 1/4” B7 pieces to taper the

front of the cowl if you desire.

50. Glue two pieces of (one on each side) 1/4”

sq. x 5-1/2” on the top ends of C1 between

B4 and turtle 1 to form the cockpit sides.

51. Re-mount the wing on the fuse. Place the

horizontal stab on the fuse. Sight from the

rear and make certain the horizontal stab is

parallel with the top of the wing. This is

important for straight flight. Carefully sand

the stab saddle so the horizontal stab sits

level.

52. Remove horizontal stab and align TS2 (90

degrees) on TS1 along the scribed line so

they form a T shape.

53. Place the spacer assembly on the stab

saddle and center it at the front and rear of

the saddle. When perfectly centered, pin

the rear and front ends to the fuse.

22

54. Locate the two faring blocks (5/8” x 1” x 57/8”). Place them on both sides of the

spacer and flush with the back of turtle 7.

Glue the blocks to turtle 7 ONLY. Sand to

match the contour of turtle 7 and the angle

of the stringers. These blocks will hold your

vertical and horizontal stab in place.

55. Once the blocks are sanded to shape,

remove and discard the spacer. The blocks

should now have a taper that matches the

stringer angle as shown in photo. Sand the

rear of the blocks to match the fuselage

length.

56. Remove the 1/8” ply triangles and servo

plate from the laser cut sheet. Assemble

them as shown in the photo (use medium

CA). This assembly can be glued to the

fuselage side and used to mount your

throttle servo.

23

Finishing and final assembly

1. Sand the entire model to a smooth surface. Carefully

remove all sanding dust to allow proper adhesion of

your covering material.

12. Install the rudder and elevator pushrods and clevises. Make sure the control surfaces and servos are

in a neutral position when the radio is turned on.

13. Install the throttle cable and nose gear cable.

2. Cover your Fantasy with your choice of covering.

Follow the manufacturer’s instructions for the covering used.

3. In order to fuel proof the engine compartment, it is

easier to use a painted or epoxy finish rather than

applying film. You can use a coat of 30 minute epoxy

thinned with denatured alcohol or any fuel-proof paint

to seal the wood.

4. Remove the covering on top and bottom of the stab

and bottom of the fin where they are to be glued to

the fuse. Note: Be very careful not to score the wood

as it may cause failure of that surface in flight.

5. Use 30 minute epoxy to glue stab and fin in their

proper location. Before the epoxy cures, sight across

the rear of the stab to insure it is parallel with the

wing. Verify the fin is 90 degrees to the stab. Use

masking tape to hold the stab and fin in place.

6. Install rudder and elevator control horns where shown

on plan.

7. Hinge the elevator first using the provided hinges.

With a hobby knife, slit the film covering where each

hinge slot is located. Install one hinge in each slot of

the stab (halfway). Slide the elevator into position.

When fully seated, deflect the elevator to the maximum throw you will be using and put 3 or 4 drops of

thin CA on each hinge. Hold the elevator in the

deflected position until dry. Next turn aircraft upside

down and deflect the elevator in the opposite direction. Add 3 or 4 more drops of thin CA to that side of

the hinge and allow to dry.

8. Install the rudder using the same process as in step

7.

14. Install the aileron pushrods as described in the manufacturer’s instructions.

15. Cut out the canopy and fit it over the cockpit area.

Trim as necessary for a good fit. Use a few small

pieces of masking tape to hold the canopy tight to

the fuselage and go around the canopy edge with

RC-56 glue. Keep an eye out for drips until the glue

has thickened. Once the glue has dried completely,

you can use trim tape around the edge of the

canopy for a finished look.

16. Install landing gear wires, using landing gear straps

for mains and wheel collar/steering arm for nose

gear. Attach wheels.

17. Install engine, balanced prop and spinner.

18. Set the deflection of your control surfaces to the

measurements shown on the fuselage plan.

19. Balance the aircraft. The plane should be turned

upside down at balanced where the fuselage meets

the wings 7-1/2” in front of the trailing edge (5” back

from the leading edge). Do not attempt to fly a plane

that is not balanced withing the points shown on the

plans.

We hope that you enjoyed building your lasercut Fantasy because the best is yet to come!

Your input on the instruction, plans and flight is

very valuable to us and would be greatly

appreciated.

9. Install the ailerons using the same method used in

step 7. In addition, put a small amount of epoxy in the

aileron torque rod hole in order to secure it and keep

it from wearing the balsa on the aileron.

10. Install radio equipment where shown on the plan. Be

sure to follow the radio manufacturer’s instructions.

Wrap the receiver and battery in 1/4” or 1/2” foam

rubber to protect them from vibration. We use Hitec

475BB standard ball bearing servos and standard

Hitec 8 channel receiver in our prototype. There is

no need to use hi-torque servos in this aircraft.

11. Cut a hole in the side of the fuselage opposite the

exhaust for the on/off switch and charger jack.

24

Loading...

Loading...