Page 1

INSTRUCTION MANUAL

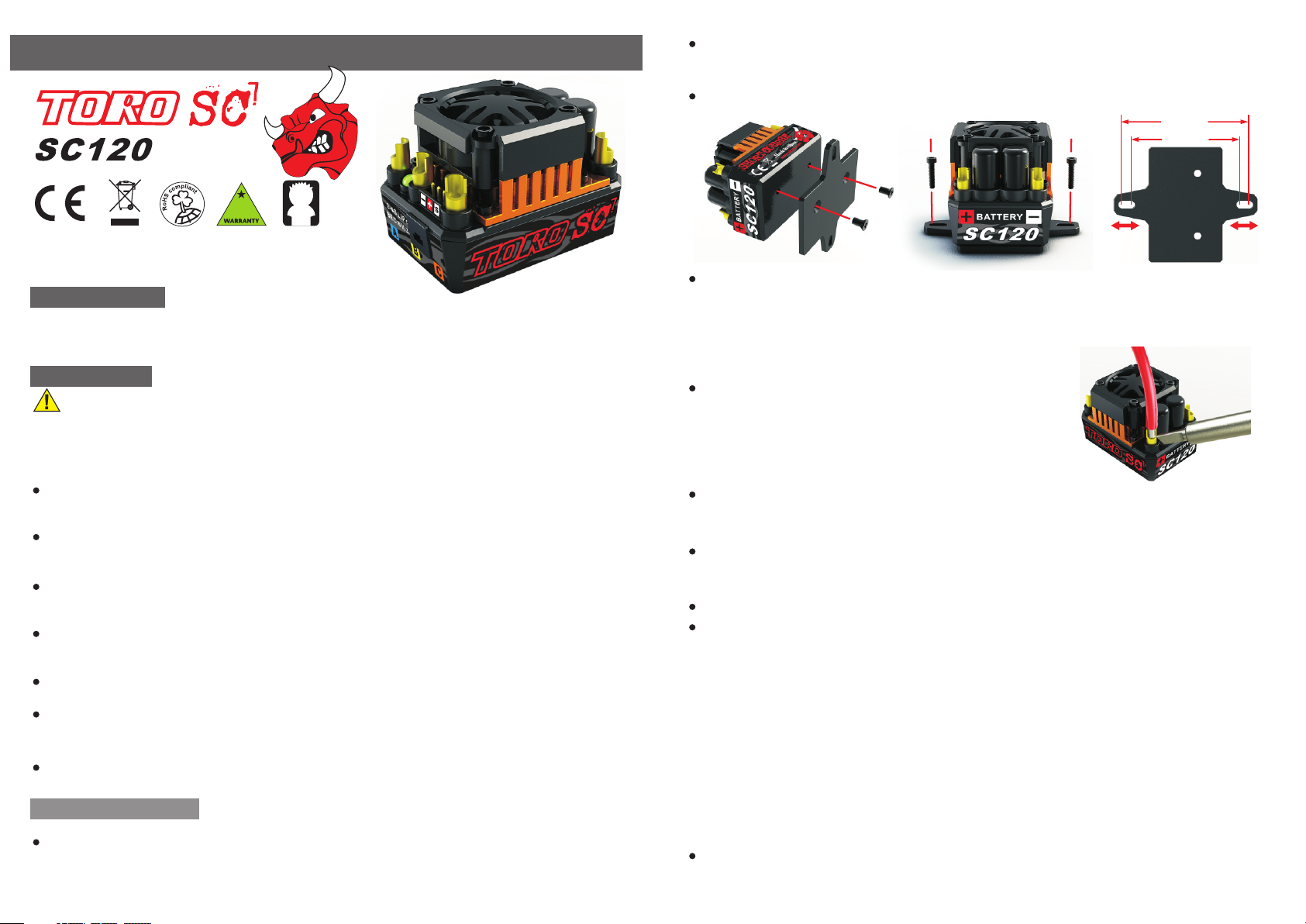

For best results clean the bottom of the speed control and chassis. Peel off the cover on one

side of the doubled-sided tape, and stick to the bottom of the speed control. Peel off other

side and stick the ESC to the chassis.

You may use the mounting plate(included) to fix the ESC to the chassis.

53mm

45.4mm

120

DAY S

14

+Yr

BRUSHLESS ESC FOR SHORT COURSE

INTRODUCTION

Congratulations and thank you for purchasing TORO, Short Course(SC), high performance

brushless motor electronic speed control. The TORO SC,brushless ESC represents a latest

technologies, providing all the features and robust design qualities.

SAFETY NOTE

WARNING: This is an extremely powerful brushless motor system. We strongly

recommend removing your pinion gear for your own safety and the safety of those around you

before performing calibration and programming functions with this system. Please keep your

hands, hair, cloth, clear from the gear train and wheels of an armed high performance system.

WATER & ELECTRONICS DON'T MIX!

Never allow water, moisture, or other foreign materials to get inside ESC, motor, or on the

PC Boards. Water damage will void the warranty!

NO REVERSE VOLTAGE!

Reverse battery polarity can damage ESC & void warranty. Disconnect battery immediately

if a reverse connection occurs.

DISCONNECT BATTERIES WHEN NOT IN USE

Always disconnect the battery pack from the speed control when not in use to avoid short

circuits and possible fire hazard.

2 - 4 LI-PO CELLS ONLY

Never use fewer than 2 or more than 4 LIPO cells in the vehicle's main battery pack. The

TORO SC handles up to 4S LIPO input (16.8 Volts MAX).

TRANSMITTER ON FIRST

Turn on the transmitter first THEN turn on the speed control.

INSULATE WIRES

Always insulate exposed wiring with heat shrink tubing or electrical tape to prevent short

circuits, which can damage ESC.

SHORT COURSE OR SMALLER

The TORO SC is intended for4x4 Short Course or Smaller.

BEFORE YOU BEGIN

1)Plan Speed Control Placement

Choose a location for the speed control that is protected from debris. To prevent radio

interference place the speed control as far away from the radio receiver as possible

and keep the power wires as short as possible.

1/ 8 2/ 8

Ver. 1.1 Ver. 1.1

Use a small piece of double-sided tape on the ON/OFF switch.

2)Solde ring

TIPS & TRICKS: Place the speed control upright and use double sided tape to secure it

to the bench. Doing so provides a stable work area and allows easy access to the solder

posts.

Attaching Wires to the Spe ed Cont rol:

Red wires are usually used to connect the speed control to

the positive battery terminal.

Black wire is typically used for the battery negative terminal.

Inspect the housing on the speed control next to each post

or refer to the diagrams to determine which color wire to

attach to each post.

Strip back the insulation of the wire by about 2.4mm to 3.2mm (3/32 to 1/8 and "pre-tin"

the wire by heating the end and applying solder until it is thoroughly covered.

CAUTION: Be very careful not to splash yourself with hot solder.

Place the tip of the iron in the notch on top of the post and apply a small amount of solder to

the post. When the solder has flowed, remove the soldering iron, wipe the tip clean and

apply a small amount of fresh solder to it.

Pre-Heat both the wire and the post.

Hold the wire so the tinned end is in contact with the notch of the post. Now touch the iron

tip to the wire and the post. Wait about 4 seconds for the solder to flow, and then remove the

iron while still holding the wire. You may let go of the wire after a second or two when the

solder sets.

Same techniques described in the preceding section may be used to solder the wires to the

battery or to battery connectors.

IMPORTANT: Take precautions if removing factory battery connectors. Connecting the

battery backwards will cause damage, and will void warranty. When soldering connectors to

a battery pack, cut only one wire of the battery pack at a time to ensure that the exposed

wires cannot short together.

HINT: If you are using connectors for both the battery and the motor, make sure that they

are not the same or that you have a male and a female attached to the speed control wires.

That way, you cannot accidentally connect the battery to the motor wires or vice versa.

Make sure that the connector ends will be mated together correctly, male to female, and that

the wire colors match red to red and black to black.

" ")

Page 2

Prolonged/excessive heating of solder post (motor or ESC) will damage PCB.

Note: Make sure no wire strands have strayed to an adjacent solder post, this will result in

short-circuiting & severe ESC damage, which will void the warranty.

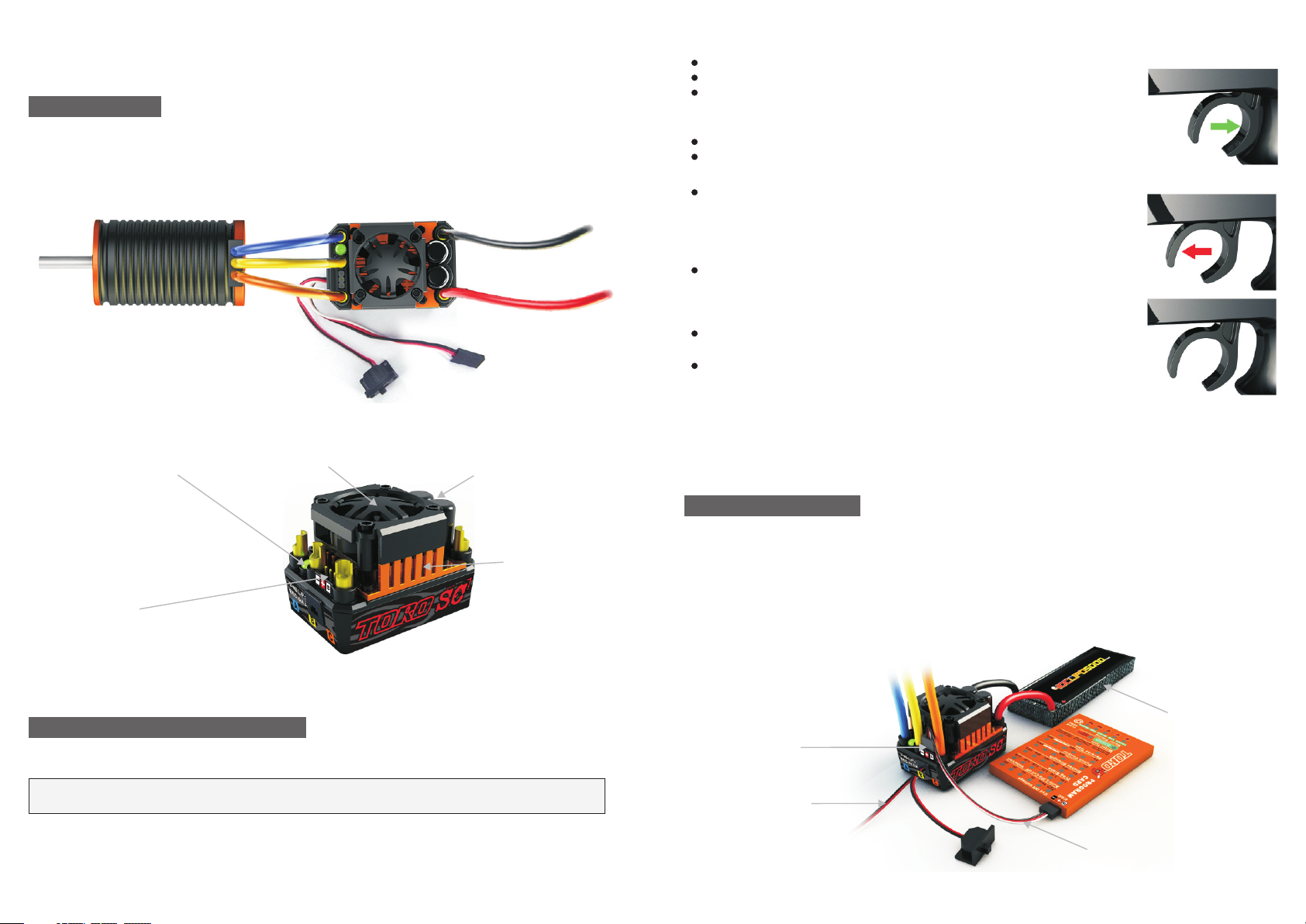

CONNECTIONS

Brushless Motor Wiring

Connect the blue, yellow and orange motor wires to the motor. There is no polarity on the

three ESC-to-motor wires, so do not worry about how you connect them initially. You may find

it necessary to swap two wires if the motor runs in reverse.

To Batt -

To Batt +

How to Calibra te ESC

ESC switch OFF.

Tur n on the Tra nsmitter.

Hold full thro ttle on your transm itter a nd turn the ESC's swi tch ON.

Keep holding f ull throttle on the t ransm itter. The ESC will flash es

LED and ring the i nitialization tones.

Wai t 2 secon ds

Green LED blin ks rapidly and the motor wil l rings 1 second indi cating

full throttl e measured.

Red LED blinks w hiles beeping, indicat ing it's time to push f ull

brake. Move th rottle trigger to f ull bra ke and wait few secon ds,

the ESC will bli nk red LED and rings 1 second in dicating full bra ke

measure.

Orange LED bli nks whiles beeping, indi cating it's time fo r neutral.

Relax trigge r to neutral (cente r). The ESC fl ash the orange LED

rapidly to acc ept the neutral pos ition .

ESC rings 1 seco nd indicating neutral po sition measure.

Status LED(Multi Color)

Forward: Green

Reverse: Red

Stand By: Orange

Fan / Program

Connector

Switch

On/Off

Fan

To Receiver

Channel 2 (Throttle)

Power Capacitor

Heat Sink

ESC/TRANSMITER CALIBRATION

IMPORTANT NOTE : Calibration is ne cessa ry for the first use of t he ESC, or whenever

used with a new/ differen t transmitter.

For users with a F utaba Transmitte r, you mus t reverse the throt tle channel signa l on

your transmi tter. Please refer t o your Fu taba instructio ns.

Individual t ransmitter's si gnals f or full throttle, f ull brake and neutr al vary. You must

calibrate yo ur ESC so that it will op erate m ore effectively with y ou tran smitter.

3/ 8 4/ 8

Ver. 1.1 Ver. 1.1

After calibr ation ESC will ring s 1 secon d indicating that i t is armed.

From this point on, when you connect batteries and turn on the switch, the ESC will give the

initialization tone and flash, and the arming tone will ring second or two later. If the ESC is

programmed for the Auto-Lipo setting, it will beep the number of cells in you Lipo pack

between the initialization tones and the arming tones. After the arming tone plays, the ESC

will ACTIVE and will respond to the throttle application.

ESC PROGRAMMING

1)Programming Card(Optional Part)

Programming Card allows you to modify the most commonly used settings in your TORO SC

controller all at the touch of a single button. No computer needed. Simply disconnect the Fan

lead from ESC and connect program lead form program card to ESC’s program connector.

Power the programming card as described below. Press and release button to move

between settings. Press and hold button to change the value for that setting. All the settings

will show on the programming card at once. Can't get any easier!

Battery

Fan / Program

Connector

To Receiver

Channel 2 (Throttle)

Program Lead

(Servo wire)

Page 3

2)Manual Prog ramming

Manual Progr amming TORO SC is a s simple as answering a few qu estions. T he

TORO SC asks q uesting by beepin g a setting number, fo llowe d by the possible

setting valu es. There ar e nine settings tha t can be programmed i n the TORO SC.

Programmable Features

Question (Setting)

1)Reverse Lockout(D)*

2)50%(D)*

2)50%(D)*

5)Disable(D)*

1)Disable(D)*

1)Large

2)Normal(D)*

3)Small

4)Very Small

5)Smallest

2)Normal(D)*

Motor Direction 1) Normal(D)*

2)Reverse

Note: Factory Defaults are indicated by asterisk (D)*

You must answer yes or no to the setting values as they are presented by TORO SC.

" " " "

This is default motor rotation direction

Opposite default motor rotation direction

When you enter programming mode the ESC will emit a sequence of beeps and LED flashes

that tell you which programming step you are in. There are two parts to the beep sequence.

The first set of beeps indicates the 'Setting Number (Question), e.g. Brake/Reverse Type, and

the second set of beeps indicates a Setting Value, e.g. Reverse Lockout. Answering "No" to a

Setting value will cause the ESC to ask for the next value in that section. After a "Yes" answer

is accepted, the ESC knows you aren't interested in any other option in that section, so it

skips to the first option in the next section.

Note: If you answer "no" to all Setting Values for a particular Setting Number, the ESC will

keep whatever value had been previously programmed. Only by answering "Yes" to a Setting

Value will the ESC store/change that value.

How to Enter Programming Mode

Plug Battery into the TORO SC

Hold full throttle on your transmitter

Turn the ESC switch ON

TORO SC flashes LED and rings once

Wait few seconds.

TORO SC flashes LED and rings 1 second indicating that it is ready for CALIBRATION mode

Continue to hold full throttle

TORO SC flashes LED while beeping

Wait another few seconds

TORO SC flashes LED and rings 1 second

TORO SC flashes LED while beeping indication that you are in PROGRAMMING mode

Let trigger go neutral (Centre)

2)Auto-Lipo(D)*

At this point the TORO SC will be flashing/beeping the following sequence:

Beep-Pause-Beep... and then repeats

This indicates that you are at Question 1 and it is asking to accept/reject value 1.

5/ 8 6/ 8

Ver. 1.1 Ver. 1.1

Page 4

When answering a question, you will need to move the trigger to yes (full throttle) position or

the no (full brake) position and keep it there for about 3 seconds. When the ESC has

accepted your answer it will confirm your reply by flashing the LED and emitting a beeping

tone. Release the trigger allowing it to go to Neutral to confirm that you are ready for ESC to

ask you next question. You are not required to continue through all nine programming options.

For example, if you wish only to change the Brake/Reverse Type (Option 1) then after

programming that setting you can disconnect power from the ESC and you're ready to run.

Disconnecting the controller in the middle of programming simply retains the values for the

remaining programming options that were previously set up.

FAN REPLACEMENT

The TORO SC comes with a 30mm x 30mm x 10mm 5V Brushless fan.

Should the fan need replacement, simply unplug the fans power wire

from the TORO SC, remove the 4 screws that secure the fan and

remove the fan cover.

SP EED CO NTROL SP ECIFI CATIO N

Controls, TORO SC

Motor Limits,TORO SC

Brushless ≤ 6000 KV

Brushless KV ≤ 4000

Brushless KV 3000≤

On Resistance,Brushless

Continuous /Burst Current

Switching BEC

Status LED

Thermal Overload Protection

Dimensions(LxWxH)

Weight (Without wires)

Rev/Brk/Brk or Fwd/Fwd

Input Power (Cells)

Up to 2S(8.4Volt), ideal for 1/10 short course

Up to 3S(12.6Volt), for 1/10 buggies and short course

Up to 4S(16.8Volt), ideal for 1/8 buggies

0.0004 Ohms per phase at 25℃(77℉)Trans.Temp

120Amp / 760Amp

6V 5Amp

1 with 3 color (Red, Green & Orange)

Yes

55x37.6x38.4mm (2.17x1.47x1.51in)

87g (3.07oz)

TROUBLE SHOOTING

Problem: My TORO ES C may or ma y not arm, but it will no t calibrate to my tra nsmitter

Solution: Mo st calibration is sues ca n be solved by changi ng settings on the tr ansmi tter.

Make sure you ha ve both your thrott le and brake endpoints (ca lled EPA or

ATV on your radio ) on the throttle cha nnel ou t to between 100 to 120 %. Make

sure if you have a F utaba or Futaba mad e transmitter to have the th rottle

channel set to t he reversed posit ion.

Problem: My ES C calibrates for th e full th rottle and full bra ke positions but wo n't

calibrate to t he neutral thrott le position. (Orange LED k eeps flashing)

7/ 8 8/ 8

Ver. 1.1 Ver. 1.1

Solution: Try moving the thro ttle trim one way, then the other (u sually towards the

throttle side is best). If your tra nsmitter has a 50/50 and 70/30 setting for the

throttle, set it for 50/50 and retr y cal ibration. Also, if you have changed the

dead band to a narrower band you may want to try going back t o the "nor mal"

setting.

Problem: My vehicl e acts like it has turbo lag (poor acceleration/pun ch fo r the first

few feet or yards)

Solution: Mak e sur e you're using high quality batterie s and a batt ery connector capable

of high amp flow (40-100 amps). This behavior is very typi cal of a bat tery pack

that is having difficulty providin g the p ower your vehicle/system requires for

top performance. Use co pper bars to connect cells rather than welded tabs.

Copper bars have a much lower resis tance.

Problem: My batter y pack is pl ugged into the ESC and nothing is working

Solution: Mak e sur e the E SC's receiver plug is plugged into channe l 2 on the rec eiver,

and that it's plugged in with the correc t orientation. Double check you r sol der

connections on the batt ery plug, and make sure the battery is showing good

voltage.

" "

PRODUCT WARRANTY

The TORO SC Brushless ESC is guaranteed to be free from defects in materials or

workmanship for a period of 120 days from the original date of purchase (verified by dated,

itemized sales receipt). Warranty does not cover incorrect installation, components worn by

use, damage to case or exposed circuit boards, damage due to timing, damage from using

more than 4S Li-Po cells input voltage, cross-connection of battery/motor power wires,

overheating solder tabs, reverse voltage application, improper use or installation of external

BEC, damage resulting from thermal overload or short-circuiting motor, damage from incorrect

installation of FET servo or receiver battery pack, tampering with internal electronics, allowing

water, moisture, or any other foreign material to enter ESC or get onto the PC board, incorrect

installation/wiring of input plug plastic, allowing exposed wiring or solder tabs to short-circuit,

or any damage caused by a crash, flooding or natural disaster. Because SKYRC has no

control over the connection & use of the speed control or other related electronics, no liability

may be assumed nor will be accepted for any damage resulting from the use of this product.

Every SKYRC speed control & motor is thoroughly tested & cycled before leaving our facility

and is, therefore, considered operational. By the act of connecting/operating speed control,

user accepts all resulting liability. In no case shall our liability exceed the product's original

cost. We reserve the right to modify warranty provisions without notice. This product is not

intended for use by children under 14 years of age without the strict supervision of an adult.

Use of this product in an uncontrolled manner may result in physical damage or injurise take

extra care when operating any remote control vehicle.

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Manufactured by

SKYRC TECHNOLOGY CO., LTD.

www.skyrc.com

2011 SkyRC Technology Co., Ltd. All Rights Reserved.

7504-0215-01

Loading...

Loading...