Page 1

SkyRC Technology Co., Ltd. 2015

Version 1.0

D200D200

Soldering Station

AC/DC Dual Balance Charger

Page 2

TABLE OF CONTENTS

INTRODUCTION

SPECIAL FEATURES

WARNING AND SAFETY NOTES

PROGRAM FLOW CHART

OPERATION

OPERATING PROGRAM

CHARGING PROGRAM

BATTERY MEMORY SET AND CALL OUT

SYSTEM SETTING

BATTERY METER

BATTERY RESISTANCE METER

SOLDERING IRON

WARNING AND ERROR MESSAGE

USING THE CHARGE CONTROL SOFTWARE “CHARGE MASTER”

SPECIFICATION

CONFORMITY DECLARATION

COMMONLY USED TERMS

WARRANTY AND SERVICE

01

03

06

09

10

11

15

16

18

20

21

22

24

25

26

27

28

29

Page 3

Congratulations on your choice of SKYRC D200 AC/DC Dual Balance

Charger/Discharger. This unit is simple to use, but the operation of a

sophisticated automatic charger such as SKYRC D200 does require some

knowledge on the part of the user. These operating instructions are designed to

ensure that you quickly become familiar with its functions. It is therefore

important that you read right through the Operating Instructions, Warning and

Safety Notes before you attempt to use your new charger for the first time. We

hope you have many years of pleasure and success with your new battery

charger.

SKYRC D200 is a twin-channel charger with two independent circuits which

can charge two different kinds of batteries simultaneously. It also supports

power distribution in AC mode to make full use of the power when charging a

small battery in one channel and allocate all remaining power to charge another

big battery pack. What’s more, users could set the terminal voltage by

themselves and connect it to PC for PC control and firmware upgrade. Besides

that, users could also use it as Lithium Battery Meter and Battery Internal

Resistance Meter. There are Automatic Charging Current Limit, Capacity Limit,

Temperature Threshold and Processing Time Limit which makes the charger

safe to use.

SKYRC D200 is a high-performance, micro processor control charge/discharge

station with battery management suitable for use with all current battery types,

with integral equalizer for six-cell Lithium-Polymer (LiPo), Lithium iron

phosphate(LiFe) and Lithium-Ion (LiIon) batteries; maximum 20A charge

current and maximum 200W charge power. The additional LiHV mode is able to

charge the new generation of LiPo batteries with an end of charge voltage

4.35V.

Additionally, it has a built in soldering iron that can heat up to 450℃. With heavy

duty 60W, the temperature is adjustable from 200-450℃.

Please BE SURE to read these INSTRUCTIONS, WARNING and SAFETY

NOTES before you use the charger for the first time.

It can be dangerous to mis-handle batteries and battery chargers, as there is

always a risk of batteries catching fire and exploding.

INTRODUCTION

01 ·

D200

Page 4

INTRODUCTION

· 02

D200

Please read this entire operating manual completely and attentively

before using this product, as it covers a wide range of information on

operating and safety. Or please do use this product in company with a

specialist!

LCD Display

Output Socket

4mm Banana Plug

Balance Lead Socket

Cooling Fan

Balance Lead Socket

USB Port

Micro USB Port for

PC Link / WiFi Module

Connection

Temperature Sensor Port

Soldering Iron

Cord Receptacle

AC Input

100-240V

Cooling Fan

DC Input

11-20V

Resume or Start Charge

Processes

Alter Values

See the Status of Individual

Cells in Balance Charge Mode

Scroll Through the Main Menu

Stop Any Charge Processes

Switch from

Channel A to B or

Channel B to A

Temperature Sensor Port

Page 5

03 ·

D200

Twin-channel Charger

SKYRC D200 allows you to plug 2 batteries into one charger simultaneously, and it will

intelligently and automatically charge 2 battries at once to their maximum capacity. To top

of it, the batteries being charged do not even need to have the same configuration. You

can connect different chemistry(NiMH/NiCd/LiPo/LiFe/Lilon/LiHV/Pb)batteries into any of

the charging channels.

Dual Input and Power Distribution

The input of SKYRC D200 is AC 100-240V and DC 11-20V. In DC mode, the power of

channel A is 200W and channel B is 100W. Total power is 300W.

In AC mode, it supports power distribution, for example, Channel A is 150W, then

Channel B is 50W, the total power is 200W.

Optimized Operating Software

SKYRC D200 features the so-called AUTO function that set the feeding current during the

process of charging or discharging. Especially for lithium batteries, it can prevent the

overcharging which may lead to an explosion due to the user's fault. It can disconnect the

circuit automatically and alarm once detecting any malfunction. All the programs of this

product were controlled through two way linkage and communication, to achieve the

maximum safety and minimize the trouble. All the settings can be configured by users!

SPECIAL FEATURES

Page 6

SPECIAL FEATURES

· 04

D200

Internal Independent Lithium Battery Balancer

SKYRC D200 employs an individual-cell-voltage balancer. It isn't necessary to connect an

external balancer for balance charging.

Balancing Individual Cells Battery Discharging

During the process of discharging, SKYRC D200 can monitor and balance each cell of

the battery individually. Error message will be indicated and the process will be ended

automatically if the voltage of any single one cell is abnormal.

Adaptable to Various Type of Lithium Battery

SKYRC D200 is adaptable to various types of lithium batteries, such as LiPo, LiIon and

the new LiFe series of batteries.

LiHV Mode Available

The additional LiHV mode is able to charge the new generation of LiPo batteries with an

end of charge voltage 4.35 V.

Smart Phone Control via Wi-Fi Module (both iOS and Android)

Finally, your charger gets its own apps. This charger can be controlled and operated by

smart phones via Wi-Fi module(option part SK-600075).

Battery Memory (Data Store/Load)

The charger can store up to 20 different charge/discharge profiles for each channel. You

can keep the data pertaining to program setting of the battery of continuous charging or

discharging. Users can call out these data at any time without any special program

setting.

Terminal Voltage Control(TVC)

The charger allows user to change the end voltage. (for expert user only)

PC Control Software “Charge Master”

The free “Charge Master” software gives you unparalleled ability to operate the charger

through the computer. You can monitor pack voltage, cell voltage and other data during

the charging, view charge date in real-time graphs. And you can initiate, control charging

and update firmware from “Charge Master”.

With “Charger Master” and one computer, you could operate and update two channels

simultaneously.

Soldering Iron

Digital display shows temperature range from 200°C-450°C(392°F-842°F). Two soldering

tips, pencil tip and chisel tip are included. Power rate up to 60 watts.

Page 7

Automatic Charging Current Limit

You can set up the upper limit of the charging current when charging your NiMH or NiCd

battery, it is useful for the NiMH battery of low impedance and capacity in the 'AUTO'

charging mode.

Capacity Limit

The charging capacity is always calculated as the charging current multiplied by time. If

the charging capacity exceeds the limit, the process will be terminated automatically

when you set the maximum value.

Temperature Threshold*

The battery's internal chemical reaction will cause the temperature of the battery to rise.

If the temperature limit is reached, the process will be terminated.

This function is available by connecting optional temperature probe, which is not included in the package.

*

Processing Time Limit:

You can also limit the maximum process time to avoid any possible defect.

Battery Internal Resistance Meter

The user can check battery's total internal resistance and each cell's internal resistance.

LiPo Battery Meter

The user can check battery's total voltage, the highest voltage, the lowest voltage and

each cell's voltage.

SPECIAL FEATURES

05 ·

D200

Re-Peak Mode of NiMH/NiCd Battery

In re-peak charge mode, the charger can peak charge the battery once, twice or three

times in a row automatically. This is good for making certain the battery is fully charged.

Delta-peak Sensitivity for NiMH/NiCd

Delta-peak sensitivity for NiMH/NiCd battery: The automatic charge termination program

based on the principle of the Delta-peak voltage detection. When the battery's voltage

exceeds the threshold, the process will be terminated automatically.

Cyclic Charging/Discharging

1 to 5 cyclic and continuous process of charge > discharge or discharge > charge is

operable for battery refreshing and balancing to stimulate the battery's activity.

Fast and Storage Mode of Lithium Battery

Purposes to charge lithium battery varies, 'fast' charge reduce the duration of charging,

whereas 'store' state can control the final voltage of your battery, so as to store for a long

time and protect useful time of the battery.

Page 8

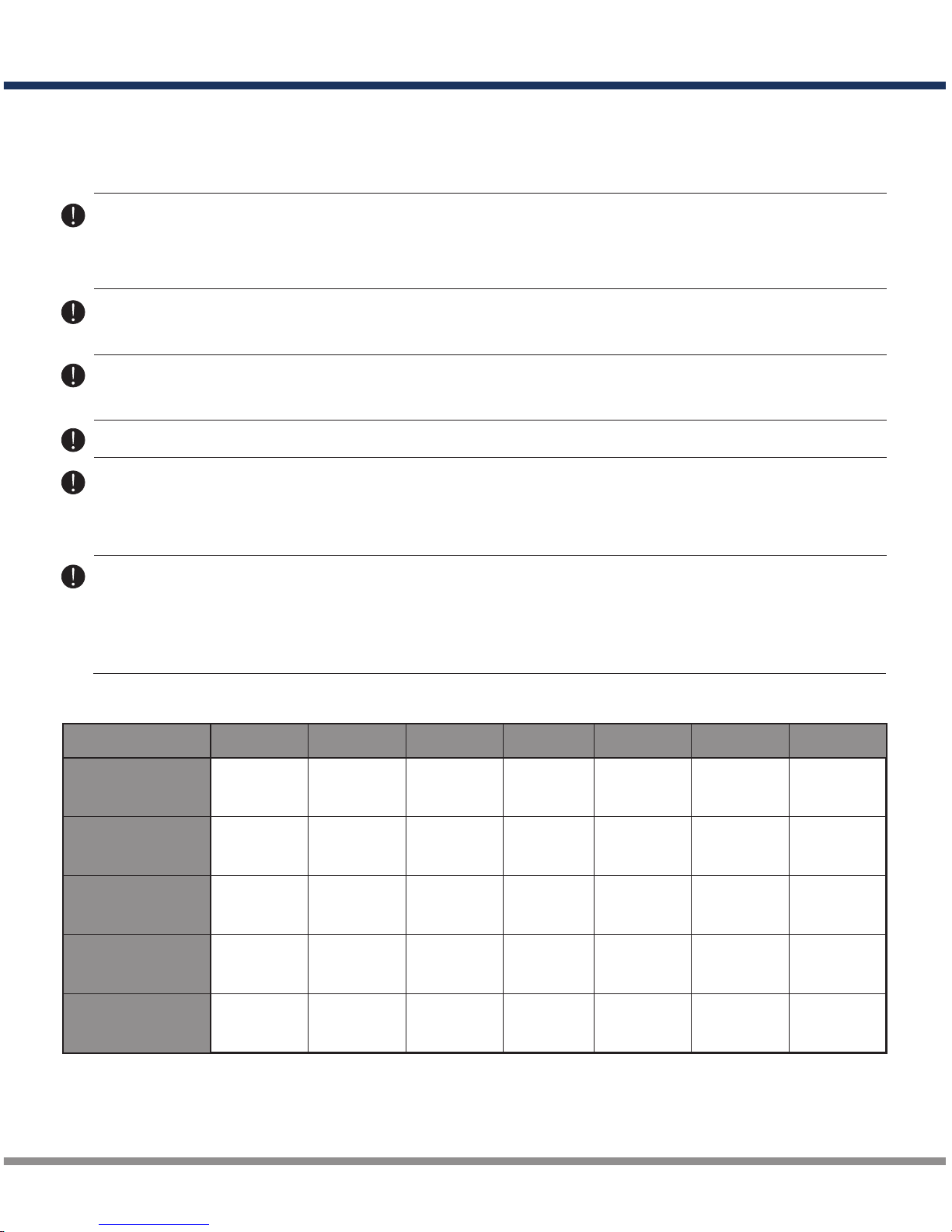

These warnings and safety notes are particularly important. Please follow the

instructions for maximum safety; otherwise the charger and the battery can be

damaged or at worst it can cause a fire.

Never leave the charger unattended when it is connected to its power supply. If any

malfunction is found, TERMINATE THE PROCESS AT ONCE and refer to the

operation manual.

Keep the charger well away from dust, damp, rain, heat, direct sunshine and vibration.

Never drop it.

The allowable DC input voltage is 11~20V DC, and charge power 200W for Channel A

and 100W for Channel B.

This charger and the battery should be put on a heat-resistant, noninflammable and

nonconductive surface. Never place them on a car seat, carpet or similar. Keep all

the inflammable volatile materials away from operating area.

Make sure you know the specifications of the battery to be charged or discharged to

ensure it meets the requirements of this charger. If the program is set up incorrectly,

the battery and charger may be damaged .It can cause fire or explosion due to

overcharging.

Be very careful to choose the correct voltage for different types of battery otherwise you

may cause damage to the batteries. Incorrect settings could cause the cells to fire or

explode.

WARNING AND SAFETY NOTES

The allowable AC input voltage is 100~240V AC, and charge power 200W for 2 channels.

· 06

D200

Standard Battery Parameters

3.7V/cell

Nominal

Voltage

Min. Discharge

Voltage

Max Charge

Voltage

Storage

Voltage

Allowable

Fast Charge

3.7V/cell

4.2V/cell

3.8V/cell

≦1C

LiPo

LiIon

3.6V/cell

4.1V/cell

≦1C

3.3V/cell

3.6V/cell

3.3V/cell

≦4C

LiFe

3.0-3.3V/cell 2.9-3.2V/cell

2.6-2.9V/cell

1.2V/cell

1.5V/cell

n/a

1C-2C

NiCd

1.2V/cell

1.5V/cell

n/a

1C-2C

MiMH

2.0V/cell

2.46V/cell

n/a

≦0.4C

Pb

0.1-1.1V/cell 0.1-1.1V/cell

1.8V/cell

LiHV

3.7V/cell

4.35V/cell

3.85V/cell

≦1C

3.1-3.4V/cell

Page 9

A battery pack which consists of different types of cells (including different

manufacturers)

A battery that is already fully charged or just slightly discharged.

Non-rechargeable batteries (Explosion hazard).

Batteries that require a different charge technique from NiCd, NiMh, LiPo or Gel cell

(Pb, Lead acid).

A faulty or damaged battery.

A battery fitted with an integral charge circuit or a protection circuit.

Batteries installed in a device or which are electrically linked to other components.

Batteries that are not expressly stated by the manufacturer to be suitable for the

currents the charger delivers during the charge process.

Please bear in mind the following points before commencing charging:

Did you select the appropriate program suitable for the type of battery you are

charging?

Did you set up adequate current for charging or discharging?

Have you checked the battery voltage? Lithium battery packs can be wired in parallel

and in series, i.e. a 2 cell pack can be 3.7V (in parallel) or 7.4V (in series).

Have you checked that all connections are firm and secure?

Make sure there are no intermittent contacts at any point in the circuit.

Charging

During charge process, a specific quantity of electrical energy is fed into the battery.

The charge quantity is calculated by multiplying charge current by charge time. The

maximum permissible charge current varies depending on the battery type or its

performance, and can be found in the information by the battery manufacturer. Only

batteries that are expressly stated to be capable of quick-charge are allowed to be

charged at rates higher than the standard charge current.

Connect the battery to the terminal of the charger: red is positive and black is

negative. Due to the difference between resistance of cable and connector, the

charger can not detect resistance of the battery pack, the essential requirement

for the charger to work properly is that the charge lead should be of adequate

conductor cross-section, and high quality connectors which are normally goldplated should be fitted to both ends.

Always refer to the manual by battery manufacturer about charging methods,

recommended charging current and charging time. Especially, the lithium battery

should be charged according the charging instruction provided by the manufacturer

strictly.

Never attempt to charge or discharge the following types of batteries.

WARNING AND SAFETY NOTES

07 ·

D200

Page 10

Discharging

The main purpose of discharging is to clean residual capacity of the battery, or to

reduce the battery voltage to a defined level. The same attention should be paid to

the discharging process as charging. The final discharge voltage should be set up

correctly to avoid deep-discharging. Lithium battery can not be discharged to lower

than the minimum voltage, or it will cause a rapid loss of capacity or a total failure.

Generally, lithium battery doesn't need to be discharged. Please pay attention to the

minimum voltage of lithium battery to protect the battery.

Some rechargeable batteries have a memory effect. If they are partly used and

recharged before the whole charge is accomplished, they remember this and will only

use that part of their capacity next time. This is a memory effect. It is said that NiCd

and NiMH batteries are suffering from memory effect. NiCd has more memory effect

than NiMH.

Attention should be paid to the connection of lithium battery especially.

Do not attempt to disassemble the battery pack arbitrarily.

Please get highlighted that lithium battery packs can be wired in parallel and in series.

In the parallel connection, the battery s capacity is calculated by multiplying single

battery capacity by the number of cells with total voltage stay the same. The voltages

imbalance may cause fire or explosion .Lithium battery is recommended to charge in

series.

WARNING AND SAFETY NOTES

· 08

D200

Page 11

PROGRAM FLOW CHART

BATT/PROGRAM

Pb BATT

ENTER

START

Pb CHARGE

2.0A 2.0V (1P)

DEC

INC

Pb DISCHARGE

0.1A 2.0V (1P)

BATT/PROGRAM

NiCd BATT

NiCd CHARGE

CURRENT 2.0A

ENTER

START

DEC

INC

NiCd DISCHARGE

0.1A CUT: 1.0V

DEC

INC

NiCd CYCLE

CHG>DCHG 1

BATT/PROGRAM

NiMH BATT

ENTER

START

NiMH CHARGE

CURRENT 2.0A

DEC

INC

NiMH DISCHARGE

0.1A CUT: 1.0V

NiMH CYCLE

CHG>DCHG 1

DEC

INC

BATT/PROGRAM

LiPo BATT

LiPo BALANCE CHG

2.0A 7.4V (2S)

LiPo CHARGE

2.0A 7.4V (2S)

LiPo FAST CHARGE

2.0A 7.4V (2S)

LiPo STORAGE

2.0A 7.4V (2S)

LiPo DISCHARGE

2.0A 7.4V (2S)

ENTER

START

DEC

INC

DEC

INC

DEC

INC

DEC

INC

DECINC

DECINC

BATT/PROGRAM

LiFe BATT

Lilo BALANCE CHG

2.0A 7.2V (2S)

Lilo CHARGE

2.0A 7.2V (2S)

Lilo FAST CHARGE

2.0A 7.2V (2S)

Lilo STORAGE

2.0A 7.2V (2S)

Lilo DISCHARGE

2.0A 7.2V (2S)

ENTER

START

DEC

INC

DEC

INC

DEC

INC

DEC

INC

BATT/PROGRAM

LiIo BATT

LiFe BALANCE CHG

2.0A 6.6V (2S)

LiFe CHARGE

2.0A 6.6V (2S)

LiFe FAST CHARGE

2.0A 6.6V (2S)

LiFe STORAGE

2.0A 6.6V (2S)

LiFe DISCHARGE

2.0A 6.6V (2S)

ENTER

START

DEC

INC

DEC

INC

DEC

INC

DEC

INC

DECINC

BATT/PROGRAM

BATT METER

4.20 4.19 4.19 V

0.00 0.00 0.00 V

MAIN 0.00V

H0.000V L0.000V

DEC

INC

DECINC

DECINC

DEC

INC

NiCd RE-PEAK

1

DEC

INC

NiMH RE-PEAK

1

DEC

INC

NiMH Auto CHARGE

CURRENT 2.0A

DEC

INC

NiCd Auto CHARGE

CURRENT 2.0A

DECINC

DECINC

DECINC

LiHV BALANCE CHG

2.0A 7.6V (2S)

LiHV CHARGE

2.0A 7.6V (2S)

LiHV FAST CHARGE

2.0A 7.6V (2S)

LiHV STORAGE

2.0A 7.6V (2S)

LiHV DISCHARGE

2.0A 7.6V (2S)

BATT/PROGRAM

LiHV BATT

ENTER

START

DEC

INC

DEC

INC

DEC

INC

DEC

INC

DECINC

Note: The flow chart is taking one channel for example as the flow chart for the two channels (Channel A and

Channel B) are identical.

BATT/PROGRAM

BATT MEMORY

ENTER

START

[ BATT MEMORY 1 ]

ENTER SET->

ENTER

START

BATT TYPE

LiPo

DEC

INC

BATT VOLTS

7.4V ( 2S )

DEC

INC

CHARGE CURRENT

4.9A

DEC

INC

DSCH CURRENT

2.2A

DSCH VOLTAGE

3.0V/CELL

TVC=YOUR RISK

4.20V

DEC

INC

ENTER

START

ENTER

START

BATT/PROGRAM

SYSTEM SETTING->

ENTER

START

Stop

Batt Type

DECINC

SAVE PROGRAM

ENTER

SAVE PROGRAM

SAVE….

[ BATT MEMORY 1 ]

LiPo 7.4V (2S )

[ BATT MEMORY 1 ]

C:4.9A D:2.2A

ENTER CHARGER

LOAD……

LiPo BALANCE CHG

4.9A 7.4V(2S)

LiPo CHARGE

4.9A 7.4V(2S)

DEC

INC

LiPo FAST CHARGE

4.9A 7.4V(2S)

DEC

INC

LiPo STORAGE

4.9A 7.4V(2S)

LiPo DISCHARGE

2.2A 7.4V(2S)

DEC

INC

DEC

INC

BATT TYPE

MiMH

DEC

INC

BATT VOLTS

2.4V (2S)

ENTER

START

CHARGE CURRENT

3.3A

DEC

INC

DEC

INC

TRICKLE

100mA

DEC

INC

PEAK DELAY

1Min

DECINC

DSCH CURRENT

2.2A

DEC

INC

DSCH VOLTAGE

1.1V/CELL

SAVE PROGRAM

ENTER

ENTER

START

BATT TYPE

Pb

BATT VOLTS

4.0V (2P)

DEC

INC

CHARGE CURRENT

3.3A

DEC

INC

DSCH CURRENT

1.5A

DEC

INC

DSCH VOLTAGE

1.7V/CELL

DEC

INC

SAVE PROGRAM

ENTER

DECINC

DEC

INC

DEC

INC

DECINC

BATT/PROGRAM

BATT RESISTANCE

DECINC

ENTER

START

005 003 003 mΩ

005 mΩ

DEC

INC

TATAL: 16mΩ

H: 5mΩ L: 3mΩ

ENTER

START

STARG/ENTER>3Seconds

SAVE PROGRAM

SAVE….

ENTER

START

[ BATT MEMORY 2 ]

NiMH 2.4V (2S )

[ BATT MEMORY 2 ]

C:1.0A D:1.0A

STARG/ENTER>3s

ENTER CHARGER

LOAD……

NiMH CHARGE

CURRENT 1.0A

NiMH Auto CHARGE

CURRENT 1.2A

DEC

INC

DEC

INC

DEC

INC

DEC

INC

NiMH DISCHARGE

1.0A CUT: 2.0V

NiMH RE-PEAK

2

NiMH CYCLE

DCHG>CHG 1

[ BATT MEMORY 2 ]

ENTER SET->

[ BATT MEMORY 3 ]

ENTER SET->

SAVE PROGRAM

SAVE….

ENTER

START

[ BATT MEMORY 3 ]

Pb 4.0V (2S )

[ BATT MEMORY 3 ]

C:3.3A D:1.5A

ENTER CHARGER

LOAD……

Pb CHARGE

3.3A 4.0V(2P)

Pb DISCHARGE

1.5A 4.0V(2P)

Rest Time

CHG>DCHG 10Min

DEC

INC

Safety Timer

ON 120Min

DEC

INC

Capacity Cut-Off

ON 5000mAH

DEC

INC

DECINC

DEC

INC

Temp Cut-Off

ON 50°C 122°F

NiMH Sensitivity

D.Peak Default

DEC

INC

NiCd Sensitivity

D.Peak Default

Key Beep ON

Buzzer ON

DEC

INC

DEC

INC

Version

HW:1.00 FW: 1.10

Load Factory Set

Enter

DEC

INC

DC Input Low

CUT-OFF 11.0V

ACMax Power Set

50W

DEC

INC

Temperature Unit

Celsius

DEC

INC

ENTER

START

09 ·

D200

START

ENTER > 3s

BATT/PROGRAM

ELECTRIC IRON

DECINC

ENTER

START

Soldering Iron

450℃ 450℃

SET REAL

Page 12

OPERATION

When you are willing to alter the parameter value in the program, press the

START/ENTER button to make it blink then change the value by pressing DEC and INC

button. The value will be stored by re-pressing the START/ENTER button. If there is

another parameter can be altered in the same screen, when you confirm the first

parameter value, the next parameter value will start to blink which means it is ready to

alert.

When you are willing to start the process, press and hold the START/ENTER button for 3

seconds. When you are willing to stop the progress or go back to previous step/screen,

press the BATT PROG/STOP button once.

When you power on the charger, it will enter LiPo Battery balance program directly. You

could change the mode (balance mode, normal charge mode, fast charge mode, store

mode or discharge mode), enter the desired charging/discharging mode, set the referred

parameter and start the progress.

If you have no request for LiPo Battery program, please press the BATT PROG/STOP

button to enter BATT PROGRAM screen.

CH A/CH B

It is used to switch from Channel A to B or Channel B to A.

BATT PROG / STOP Button:

It is used to stop the progress or go back to previous step/screen

DEC Button:

It is used to go through the menus and decrease the parameter value

INC Button:

It is used to go through the menus and increase the parameter value

ENTER / START Button:

It is used to enter parameter or store parameter on screen.

· 10

D200

Page 13

OPERATING PROGRAM

Here is the detailed procedure to make the charger work. All the screens and operations

will take Li-Po BALANCE CHARGE program for example,

Note: We will explain one channel as the operating procedure

of Channel A and Channel B is identical.

1. Connection

Connecting to power source

There are two kinds of inputs for SKYRC D200, DC 11-20V and AC 100-240V.

A. Operating in AC mode

SKYRC D200 comes with built in switching power supply. You can connect the AC

power cord directly to the main AC socket. (100-240V AC).

Note: The charging power in AC mode is 200W totally for Channel A and Channel B.

In AC mode, it supports Power Distribution. The total power for Channel A and

Channel B is 200W. You could set the AC Max Power for one channel (Take

Channel A for example)as following,

And the other channel (Channel B) will take the rest power automatically (For example, if

you set channel A as AC 150W, the channel B will be AC 50W).

If Channel A and Channel B are both charging, you can’t change the AC power.

If Channel A is charging, you can change AC power of Channel B and Channel

A will take the rest power automatically.

B. Operating in DC mode

Please connect SKYRC D200 with AC/DC power supply by supplied DC input cable. Also

you could use terminal clips with DC connectors, for attaching directly to 12V car

batteries. It is critically important that you use either a fully charged 13.8V car battery or a

high quality AC/DC power supply in the range of 11-20V DC output with minimum power

360W or higher to insure reliable performance.

Note: The charging power in DC mode is 200W for Channel A and 100W for Channel B.

Total power of D200 is 300W.

1).

BATT/PROGRAM

SYSTEM SETTING->

LIPO BALANCE

5.1A 22.2V(6S)

A

B

AC Max Power Set

150W

LIPO BALANCE

5.1A 22.2V(6S)

A

B

AC Max Power Set

150W

A

B

AC Max Power Set

50W

Safety Timer

ON 120Min

LIPO BALANCE

5.1A 22.2V(6S)

A

B

11 ·

D200

NOTE1:

NOTE2:

Page 14

Failure to connect as shown in this diagram will damage this charger.

To avoid short circuit between the charge lead always connect the charge cable to the

charger first, then connect the battery. Reverse the sequence when disconnecting.

WARNING:

Connecting the battery

Important!!! Before connecting a battery it is absolutely essential to check one last

time that you have set the parameters correctly. If the settings are incorrect, the

battery may be damaged, and could even burst into flames or explode. To avoid

short circuits between the banana plugs, always connect the charge leads to the

charger first, and only then to the battery. Reverse the sequence when

disconnecting the pack.

Balance Socket

The balance wire attached to the battery must be connected to the charger with the

black wire aligned with the negative marking. Take care to maintain correct polarity!

(See the wiring diagram below.)

This diagram shows the correct way to connect your battery to the SKYRC D200

while charging.

2).

3).

OPERATING PROGRAM

· 12

D200

For safety issue, the default setting for charging Lithium(LiPo, Lilo, LiFe and LiHV)

battery is using balance adaptor to connect battery and charger in Charge, Fast

Charge, Balance Charge and Storage modes. But if the battery comes no balance

wire, you could disable this function in system settingasfollowing,

B A T T / P R O G R A M

S Y S T E M S E T T IN G

B A L . C o n n e c t i o n

N O

Page 15

OPERATING PROGRAM

Locate the flowcharts show the entire programming menu. It is highly recommended to

have these flowcharts handy while learning to operate this charger.

There are two main ways in which to set the charger.

A memory profile is available for setting and storing pertinent information for up to

20 different batteries, each channel can store 10 sets. Once a battery's information

is stored into a memory it will be retained until changed again manually. Recalling a

battery's memory number makes the charger instantly ready to go!

If you do not wish to use the battery memories, this charger can be manually set

before each use.

2. Getting started

(1)

(2)

For following step, all are basing on manually set

3. BATT/PROGRAM Select

B A T T / P R O G R A M

L i P o B A T T

4. Mode Select

6. Program Start

L i P o B A L A N C E C H G

2 . 0 A 1 1 . 1 V ( 3 S)

Press INC and DEC to go through all the programs and press

START/ENTER to enter LiPo BATT Program.

5. Battery Setting

L i P o B A L A N C E C H G

2 . 0 A 1 1 . 1 V ( 3 S)

Press INC and DEC to go through all the modes and press

START/ENTER to enter LiPo Balance Charge Mode.

Press START/ENTER, the current value will start to blink, press

INC and DEC to change the value and press START/ENTER to

confirm your setting.

At the same time, the battery cells number will start to blink,

press INC and DEC to change the value and press

START/ENTER to confirm your setting.

L i P o B A L A N C E C H G

2 . 0 A 1 1 . 1 V ( 3 S)

B A T T E R Y C H E C K

W A I T . . .

L i P o B A L A N C E C H G

2 . 0 A 1 1 . 1 V ( 3 S)

Press and hold START/ENTER for 3 seconds to start the

program.

The charger is detecting the battery cell.

R shows the number of cells detected by the charger and S is

the number of cells set by you at the previous screen. If both

numbers are not identical, press STOP to go back to previous

screen to recheck the number of cells of the battery pack before

going ahead.

R : 3 S E R S : 3 S E R

C A N C E L ( S T O P )

START/ ENTER

START/ ENTER

START/ ENTER

START/ ENTER

START/ ENTER

> 3 Se cond s

13 ·

D200

Page 16

OPERATING PROGRAM

R : 3 S E R S : 3 S E R

C O N F I R M ( E N T E R )

L P 4 s 1 . 5 A 1 2 . 1 4 V

B A L 0 0 0 : 5 0 0 0 0 2 2

7. Charging Status Monitor

R shows the number of cells detected by the charger and S is the

number of cells set by you at the previous screen. If both numbers

are identical, press START/ENTER to start charging process.

During charge process, real-time status will be showed as left screen.

VARIOUS INFORMATION DURING THE PROCESS

Press INC or DEC during charging or discharging process, you can inquire various

information on LCD screen .

L P 4 s 1 . 5 A 1 2 . 1 4 V

B A L 0 0 0 : 5 0 0 0 0 2 2

4 . 0 7 4 . 0 6 4 . 1 1 V

0 . 0 0 0 . 0 0 0 . 0 0 V

F u e l = 9 0 %

C e l l = 4 . 1 0 V

IN C

IN C

L P 4 s 1 . 5 A 1 2 . 1 4 V

B A L 0 0 0 : 5 0 0 0 0 2 2

Ex t. Te mp -- -In t. Te mp 37 C

DE C

Te mp Cu t-O ff

50 C

DE C

Final voltage when the program ends.

Input voltage.

Safety timer ON and duration of time in minutes.

Capacity cut-off ON and the setting value of capacity.

Voltage of each cell in the battery pack when the battery is

connected with balance lead.

Internal temperature.

Temperature probe is needed to show external temperature.

Charged capacity percentage and average cell voltage of the

battery pack.

Real-time status: battery type, battery cell, charge current, battery

voltage, elapsed time and charged capacity

Cut off temperature

START/ ENTER

DE C

DE C

DE C

DE C

· 14

D200

Page 17

OPERATING PROGRAM

8. Program Stop

9. Program Complete

During the charging process, press STOP to stop the charging process.

When the charging process finishes, an audible sound will be heard.

NiMH

NiCd

RE-PEAK

CYCLE

Pb

Batt

Type

Operation

Program

Description

This charging mode is for charging LiPo/LiFe/LiIon/LiHV battery in normal mode.

This program is for charging or discharging LiPo/LiFe/LiIon/LiHV

battery which will not be used for long time.

The charging capacity may be less than normal charging but the

process time will be reduced.

This mode is for balancing the voltage of LiPo/LiFe/LiIon/LiHV battery

cells while charging.

The charger will charge NiMH and NiCd batteries using the

charge current set by the user.

In this program the charger detects the condition of the battery

which is connected to the output and automatically charges the

battery.

Note: you should set up the upper limit of the charge

current to avoid damage by excessive feeding current.

Some batteries of low resistance and capacity can lead to

higher current.

In re-peak charge mode, the charger can peak charge the

battery once, twice or three times in a row automatically. This is

good for confirming the battery is fully charged, and for checking

how well the battery receives fast charges.

1 to 5 cyclic and continuous process of charge>discharge or

discharge>charge is operable for battery refreshing and

balancing to stimulate the battery's activity.

LiPo

Lilon

LiFe

LiHV

CHARGE

DISCHARGE

STORAGE

FAST CHG

BAL CHARGE

CHARGE

AUTO CHG

DISCHARGE

CHARGE

DISCHARGE

Charging Program

Depends on different battery types, the operation programs are different.

This mode is for discharging LiPo/LiFe/LiIon/LiHV battery.

This mode is for discharging NiMH/NiCd battery.

This mode is for charging Pb battery.

This mode is for discharging Pb battery.

15 ·

D200

Page 18

BATTERY MEMORY SET AND CALL OUT

[ B A T T ME M OR Y 1 ]

E N T ER S E T- >

B A T T TY P E

L i P o

B A T T VO L TS

7 . 4 V ( 2S )

C H A RG E C UR R EN T

4 . 9 A

D S C H CU R RE N T

2 . 0 A

D S C H VO L TA G E

3 . 0 V/ C EL L

T V C =Y O UR R I SK

4 . 2 0V

S A V E PR O GR A M

E N T ER

The charger can store up to 20 different charge/discharge profiles(each channel 10 sets)

for your convenience, and the stored profiles can be recalled quickly without having to go

through the setup process.

When you are willing to alter the parameter value in the program, press START/ENTER to

make it blink then change the value with INC or DEC. The value will be stored by

pressing START/ENTER once.

Note: All following screen are taking 2S(7.4V) LiPo battery for example.

Enter the battery memory program.

(10 different charge/discharge profiles can be stored in each channel).

Set the battery type(LiPo/LiFe/LiIon/LiHV/NiMH/NiCd/Pb).

Set the voltage and number of cells(1S-6S).

Set the charge current(CH A 0.1-20.0A / CH B 0.1-10.0A).

Set the discharge current (0.1A-5.0A).

Set the discharge voltage(3.0-3.3V/Cell).

Set the terminal voltage(4.18-4.25V).

Press ENTER to save program.

1. Battery Memory Set

· 16

D200

START/ENTER

DE C INC

DE C INC

DE C INC

DE C INC

DE C INC

DE C INC

START/ENTER

Page 19

BATTERY MEMORY SET AND CALL OUT

E N T E R C H A R G E R

L O A D

L i P o B A L A N C E C H G

4 . 9 A 7 . 4 V ( 2 S)

S A V E P R O G R A M

S A V E .

[ B A T T M E M O R Y 1 ]

L i P o 7 . 4 V ( 2 S )

[ B A T T M E M O R Y 1 ]

C : 4 . 9 A D : 2 . 2A

Indicate the battery type and battery cell of the saved profile.

Indicate the charge and discharge current of the saved profile.

Press the START/ENTER for 3 seconds to call out the memory.

2. Battery Memory Call Out

Load the memory set

Press START/ENTER for 3 seconds to start the process.

17 ·

D200

START/ENTER

>3 Seconds

Page 20

SYSTEM SETTING

S a f e t y T i m e r

O N 1 2 0 M i n

R e s t T i m e

C H G > D C H G 1 0 M i n

C a p a c i t y C u t - O ff

O N 5 0 0 0 m A H

T e m p e r a t u r e U n it

C e l s i u s

T e m p C u t - O f f

O N 5 0 C 1 2 2 F

This program sets the maximum charge

capacity that will be supplied to the battery

during charge. If the delta peak voltage is

not detected nor the safety timer expired by

any reason, this feature will automatically

stop the process at the selected capacity

value.

When you start a charge process, the

integral safety timer automatically starts

running at the same time. This is

programmed to prevent overcharge the

battery if it proves to be faulty, or if the

termination circuit cannot detect the battery

full. The value for the safety timer should be

generous enough to allow a full charge of

the battery.

The battery's internal chemical reaction will

cause the temperature of the battery to

rise. If the temperature limit is reached, the

process will be terminated.

OFF/

ON

(100-50000 mAh)

It will be operated with the default value of the essential user settings when it is powered

on for the first time.The screen displays the following information in sequence and the

user can change the value of parameter on each screen.

When you are willing to alter the parameter value in the program, press START/ENTER to

make it blink then change the value with INC or DEC. The value will be stored by

pressing START/ENTER once.

ITEM

SELECTION DESCRIPTION

OFF/

ON

(1-720 Min)

OFF/

ON

(20 C/68 F 80 C/176 F)

Celsius

Fahrenheit

1-60Min

A rest time allowing the battery to cool

down between charging/discharging cycle.

You can choose the temperature displayed

by Celsius or Fahrenheit as you like.

· 18

D200

Page 21

ITEM

SELECTION DESCRIPTION

SYSTEM SETTING

N i M HS e n s i t i v i ty

D . P e a k D e f a u l t

N i C dS e n s i t i v i ty

D . P e a k D e f a u l t

Default: 4mV/Cell

5-15mV/Cell

K e y B e e p O N

B u z z e r O N

OFF/ON

The beep sounds at every time touching

the buttons to confirm your action. The

beep or melody sounded at various times

during operation to alert different mode

changes.

I n p u t . P o w e r L o w

C u t - O f f 1 1 . 0V

10.0-11.0V

This program monitors the voltage of input

battery. If the voltage drops below the value

you set the operation forcibly terminated to

protect the input battery.

This program is for NiMH/NiCd battery only.

When the charger detects the delta peak

value reaches the value you set, the

charger will say the battery is fully charged.

L o a d F a c t o r y S e t

E n t e r

V e r s i o n

H W : 1 . 0 0 F W : 1 . 1 0

Press ENTER to load factory default setting.

It indicates the hardware and firmware

version.

19 ·

D200

A C M a x P o w e r S e t

2 0 0 W

0-200W

It is to set the max AC power of the present

channel. Once you set it, the another

channel will take the rest.

Max Charge Power for CH A 200W

Max Charge Power for CH B 100W

Page 22

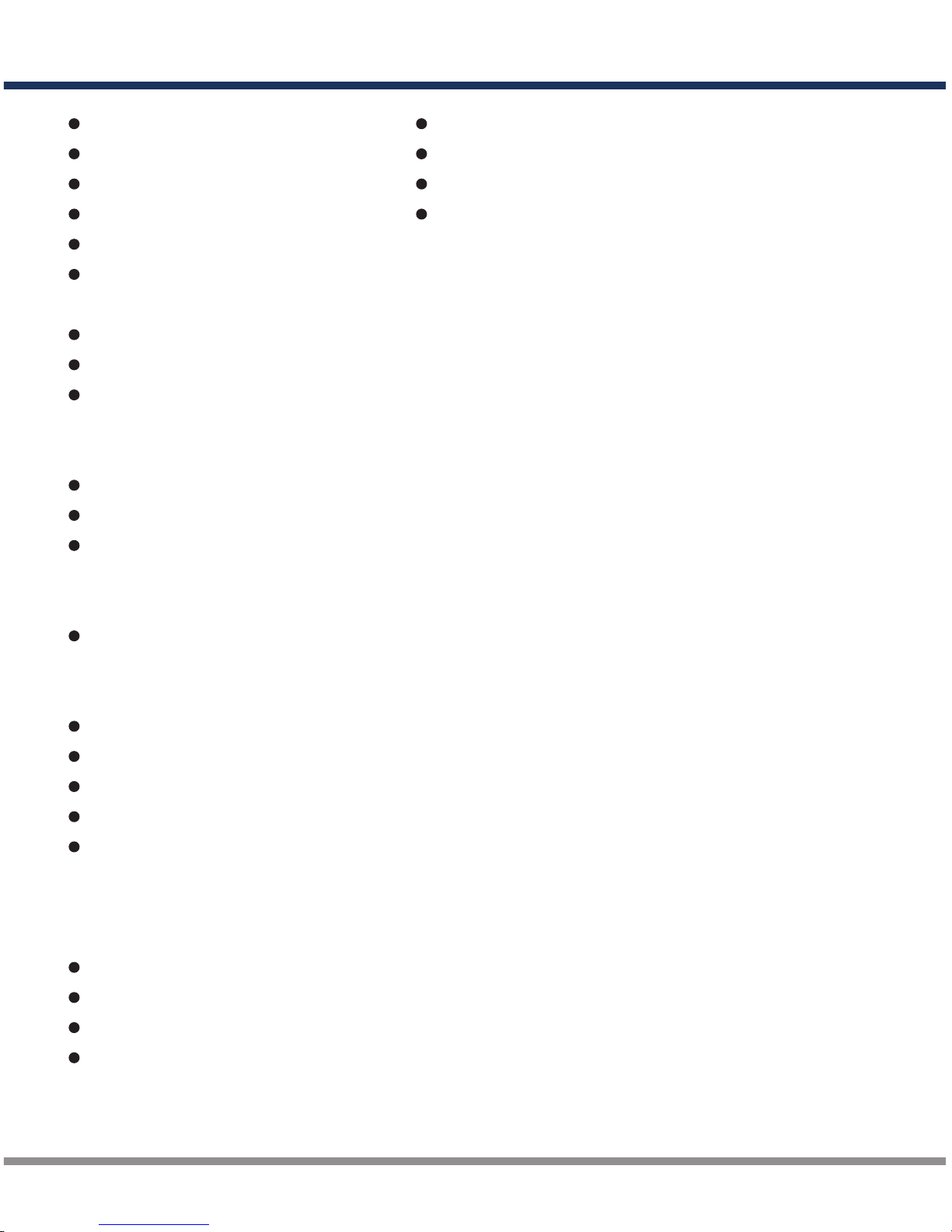

BATTERY METER

The user can check battery's total voltage, the highest voltage, the lowest voltage and

each cell's voltage.

Please connect the battery to the charger main battery lead to battery socket and balance

wires to balance socket.

B A T T / P R O G R A M

B A T T M E T E R

4 . 2 0 4 . 1 9 4 . 1 9 V

4 . 1 8 4 . 1 8 4 . 1 9 V

M A I N 2 5 . 1 3 V

H 4 . 2 0 0 V L 4 . 1 8 2 V

Press the START/ENTER to enter the Lithium

Battery Meter program.

The screen indicate each cell's voltage.

The screen indicate the total voltage, the highest

voltage and the lowest voltage.

START

ENTE R

· 20

D200

DE C

Battery

Pack

Battery

Pack

This diagram shows the

correct way to connect

your battery to check

the voltage.

IN C

4.19 4.15 4.18V

4.15 4.19 4.18V

A

B

4.19 4.15 4.18V

4.15 4.19 4.18V

Page 23

BATTERY RESISTANCE METER

The user can check battery's total resistance, the highest resistance, the lowest

resistance and each cell's resistance.

Please connect the battery to the charger main battery lead to battery socket and balance

wires to balance socket.

Press the START/ENTER to enter the Lithium

Battery Resistance program.

The screen indicate each cell's resistance.

The screen indicate the total resistance, the highest

resistance and the lowest resistance.

Star t

Ente r

B A T T / P R O G R A M

B A T T R E S I S T A N C E

0 1 2 0 0 5 0 0 5 mΩ

0 0 6 mΩ

T A T AL :2 8mΩ

H :1 2 mΩ L:5 mΩ

21 ·

D200

DE C

Battery

Pack

Battery

Pack

This diagram shows the

correct way to connect

your battery to check

the resistance.

IN C

A

B

005 003 003 mΩ

005 003 003 mΩ

005 003 003 mΩ

005 003 003 mΩ

Page 24

SOLDERING IRON

· 22

D200

1) Connect the soldering iron cord to the receptacle securely.

1. Setup and Connection

2) Choose desired soldering tip and install it

3) Saturate cleaning sponge with water and place it into the stand,

4) Put the iron on the stand and do not touch any metallic parts while operating.

Insert

Rotating clock-wise

2. Operation and Setting Temperature

CAUTION: When the soldering station in operation, the tip temperature is

between 200°C-450°C(392°F-842°F).

Any mishandling may lead to burns or fire. Do not use the soldering iron near

flammable items such as Nitro Gas, LiPo Battery, and etc.

For safety reason, DO NOT charge battery and soldering items at same time.

B A T T / P R O G R A M

L i P o B A T T

Power on the charger, select channel A,

and press DEC or INC button.

A

B A T T / P R O G R A M

E L E C T R I C I R ON

Press the START/ENTER to enter the

electric iron program.

START

ENTE R

Soldering Iron

350℃ 260℃

SET REAL

Press INC or DEC button to set the desired temperature.

And the temperature will adjust automatically.

The screen indicates the set and real temperature.

Press STOP/PROG button to stop this function.

INC/ DEC

A

Page 25

SOLDERING IRON

3. Replacing the Tip

Power off, unplug the cord, and allow the iron to cool down.

Hold the tip and put it out

Insert the new tip

4. Parameter Change

B A T T / P R O G R A M

S Y S T E M S E T T I N G ->

A

START

ENTE R

T e m p e r a t u r e U n it

C e l s i u s

A

T e m p e r a t u r e U n it

F a h r e n h e i t

A

Press ENTER button to enter SYSTEM SETTING.

press INC or DEC button to enter temperature unit set.

Press ENTER button and the temperature unit will start

to blink, press INC or DEC to change the unit.

Press ENTER button again to confirm the selection.

INC/ DEC

Replacement Parts

Pencil Tip (SK-600090-01)

Chisel Tip (SK-600090-02)

D200

23 ·

Page 26

WARNING AND ERROR MESSAGE

In case of an error the screen will display the cause of error and emit an audible sound.

Incorrect polarity connected.

The battery is interrupted.

C O N N E C T E R R O R

C H E C K M A I N P O R T

Thebattery connection is wrong.

The cell number is wrong.

C E L L N U M B E R

I N C O R R E C T

Voltage of one cell in the battery pack is too high.

C E L L E R R O R

H I G H V O L T A G E

Voltage of one cell in the battery pack is too low.

C E L L E R R O R

L O W V O L T A G E

The internal temperature of the unit goes too high.

I N T . T E M P . T O O H I

D C I N T O O L O W

Input voltage less than 11V.

Input voltage higher than 20V.

D C I N T O O H I G H

B A T T E R Y W A S F U L L

The battery voltage is higher than the maximum voltage

which the user sets when charging in balance mode.

C E L L E R R O R

V O L T A G E - I N V A L I D

Voltage of one cell in the battery pack is invalid.

The external temperature of the battery goes too high.

E X T . T E M P . T O O H I

O V E R C H A R G E

C A P A C I T Y L I M I T

The battery capacity is more than the maximum capacity

which the user sets.

O V E R T I M E L I M I T

The charging time is longer than the maximum charging

time which the user sets.

B A L A N C E C O N N E C T

E R R O R

Thebalanceconnectiswrong.

· 24

D200

Page 27

The free “Charge Master” software gives you unparalleled ability to operate the charger

through the computer. You can monitor pack voltage, cell voltage and other data during

the charging, view charge date in real-time graphs. And you can initiate, control charging

and update firmware from “Charge Master”.

In order to connect the charger to the computer and use the “Charge Master”, you are

required to use a USB cable which is not included in this package. The cable must be

terminated on one end with “A” plug and the opposite end is terminated with “micro-B”

plug which can connect to charger directly.

You can control, monitor, operate and upgrade two channels with one computer.

The “Charge Master” can be download from www.skyrc.com.

USING THE CHARGE CONTROL SOFTWARE

“CHARGE MASTER”

THESETCONTAINS

1

2

3

4

5

6

7

8

9

10

1. SKYRC D200 Charger

2. XH Adaptor X 2

3. Power Cord

4. Charging Cable X 2

5. Banana Connectors with XT60 Connector Charging Cable X 2

6. Soldering Iron Handle

7. Soldering Tip (Pencil Tip)

8. Soldering Tip (Chisel Tip)

9. Soldering Iron Stand

10. Cleaning Sponge

25 ·

D200

Page 28

SPECIFICATION

DC Input Voltage : 11-20V AC Input Voltage: 100-240V

Display Type: 128x64 LCD Display Backlight: Cool White

Case Material: Plastic Controls: Five Buttons

Case Size: 197x182x71mm Weight: 1260g

PC Communications: USB Port for PC Control & Firmware Upgrade

External Port: 2-6S Balance Socket-XH, Temperature Probe Socket,

Iron Socket, Battery Socket, DC Input, Micro USB Port for PC.

Delta Peak Detection for NiMH/NiCd: 3-15mV/cell / Default: 4mV/cell

Charge Cutoff Temperature: 20ºC/68ºF-80ºC/176ºF(adjustable)

Charge Voltage: NiMH/NiCd: Delta peak detection

LiPo: 4.18-4.25V/cell LiIon: 4.08-4.2V/cell

LiFe: 3.58-3.7V/cell LiHV: 4.25-4.35V/cell

Balance Current: 300mA/cell

Reading Voltage Range: 0.1-26.1V/cell

Battery Types/Cells: LiPo/LiIon/LiFe/LiHV: 1-6cells

NiMH/NiCd: 1-15cells

Pb: 2-20V

Battery Capacity Range: NiMH/NiCd: 100-50000mAh

LiPo/LiIon/LiFe/LiHV: 100-50000mAh

Pb: 100-50000mAh

Charge Current: Channel A: 0.1-20A; Channel B: 0.1-10A

Safety Timer: 1-720minutes off

Charge Wattage: AC 200W DC 200W+100W

Discharge Current: (0.1A-5.0A) x2

Discharge Cut-off Voltage: NiMH/NiCd: 0.1-1.1V/cell

LiPo: 3.0-3.3V/cell LiIon: 2.9—3.2V/cell

LiFe: 2.6-2.9V/cell LiHV: 3.1-3.4V/cell

Pb: 1.8V

Discharge Wattage: 10Wx2

Balance Cells: 2-6 cells

Memory: 10x2 Different Charge/Discharge Profiles

Charge Method: CC/CV for Lithium Types and Lead (Pb) Batteries

Delta-peak Sensitivity for NiMH/NiCd.

· 26

D200

Page 29

CONFORMITY DECLARATION

This symbol means that you must dispose of electrical from the General household

waste when it reaches the end of its useful life. Take your charger to your local

waste collection point or recycling centre. This applies to all countries of the

European Union, and to other European countries with a separate waste collection

system.

D200 satisfy all relevant and mandatory CE directives and FCC Part 15 Subpart B: 2014.

For EC directives:

The product has been tested to meet the following technical standards:

EN 55014-1:2006+

A1:2009+A2:2011

EN 55014-2:1997+

A1:2001+A2:2008

EN 61000-3-2:2006+

A1:2009+A2:2009

EN 61000-3-3:2013

EN 55014-1: Electromagnetic Compatibility Requirements for household appliances, electric tools

and similar apparatus -a Part 1: Emission

EN 55014-2: Electromagnetic Compatibility Requirements for household appliances, electric tools

and similar apparaturs - Part 2: Immunity product family

standard

EN 61000-3-2: Electromagnetic Compatibility (EMS)

Part 3-2: Limits for harmonic current

emissions(Equipment input current up to and including

16A per phase)

Electromagnetic Compatibility (EMS) - Part 3-3: Limits Limitation of voltage changes, voltage fluctuations and

flicker in public low-voltage supply systems, for

equipment with rated current≤16A per phase and not

subject to conditional connection.

EN 60335-1:2012+

A11:2014

EN 60335-2-29:2004

+A2:2010

Part 1: General requirements

Part 2-29: Particular requirements for battery chargers

Measurement methods for electromagnetic fields of

household appliances and similar apparatus with regard

to human exposure

27 ·

D200

Page 30

Commonly used terms

Final charge voltage: the voltage at which the battery's charge limit (capacity limit) is

reached. The charge process switches from a high current to a low maintenance rate

(trickle charge) at this point. From this point on further high current charging would cause

overheating and eventual terminal damage to the pack.

Final discharge voltage: the voltage at which the battery's discharge limit is reached. The

chemical composition of the batteries determines the level of this voltage. Below this

voltage the battery enters the deep discharge zone. Individual cells within the pack may

become reverse polarized in this condition, and this can cause permanent damage.

A, mA: unit of measurement relating to charge or discharge current.1000 mA = 1 A

(A=Ampere,mA=Milliampere)

Ah, mAh: unit of measurement for the capacity of a battery (Amperes x time unit; h = hour).

If a pack is charged for one hour at a current of 2 A, it has been fed 2 Ah of energy. It

receives the same quantity of charge (2 Ah) if it is charged for 4 hours at 0.5 A, or 15

minutes (=1/4 h) at 8 A.

'C'-rating: Capacity is also referred to as the 'C' rating. Some battery suppliers recommend

charge and discharge currents based on the battery 'C' rating. A battery's '1C' current is the

same number as the battery's rated capacity number, but noted in mA or amps. A 600mAh

battery has a 1C current value of 600mA, and a 3C current value of (3 x 600mA) 1800mA or

1.8A. The 1C current value for a 3200mAh battery would be 3200mA (3.2A).

Nominal voltage(V): The nominal voltage of the battery pack can be determined as follows;

-.NiCd or NiMH: multiply the total number of cells in the pack by 1.2. A 8-cell pack will have a

nominal voltage of 9.6 volts (8x1.2).

-.LiPo: multiply the total number of cells in the pack by 3.7. A 3-cell LiPo wired in series will

have a nominal voltage of 11.1 volts (3x3.7).

-.LiIo: multiply the total number of cells in the pack by 3.6. A 2-cell LiIo wired in series will have

a nominal voltage of 7.2 volts (2x3.6).

-.LiFe: multiply the total number of cells in the pack by 3.3. A 4-cell LiIo wired in series will have

a nominal voltage of 13.2 volts (4x3.3).

-.LiHV: multiply the total number of cells in the pack by 3.7V. A 4-cell LiHV wired in series will

have a nominal voltage of 14.8 volts (4x3.7).

If the nominal voltage of the battery is not printed on the battery's label, consult your battery

manufacturer or supplier. Do not guess the rated voltage of battery.

COMMONLY USED TERMS

· 28

D200

Page 31

WARRANTY AND SERVICE

This charger is designed and approved exclusively for use with the types of battery stated

in this Instruction Manual. SkyRC accepts no liability of any kind if the charger is used for

any purpose other than that stated.

We are unable to ensure that you follow the instructions supplied with the charger, and

we have no control over the methods you employ for using, operating and maintaining the

device. For this reason we are obliged to deny all liability for loss, damage or costs which

are incurred due to the incompetent or incorrect use and operation of our products, or

which are connected with such operation in any way.Unless otherwise prescribed by law,

our obligation to pay compensation, regardless of the legal argument employed, is limited

to the invoice value of those SkyRC products which were immediately and directly

involved in the event in which the damage occurred.

Liability exclusion

Warranty and service

We guarantee this product to be free of manufacturing and assembly defects for a period of

one year from the time of purchase. The warranty only applies to material or operational

defects, which are present at the time of purchase. During that period, we will repair or

replace free of service charge for products deemed defective due to those causes.

This warranty is not valid for any damage or subsequent damage arising as a result of misuse,

modification or as a result of failure to observe the procedures outlined in this manual.

The warranty service is valid in China only.

If you need warranty service overseas, please contact your dealer in the first

instance, who is responsible for processing guarantee claims overseas. Due

to high shipping cost, complicated custom clearance procedures to send

back to China. Please understand SkyRC can't provide warranty service to

overseas end user directly.

If you have any questions which are not mentioned in the manual, please

feel free to send email to info@skyrc.cn

Note:

1.

2.

3.

29 ·

D200

Page 32

Printed in China 2015.02

All specifications and figures are subject to change without notice.

Manufactured by

SKYRC TECHNOLOGY CO., LTD.

www.skyrc.com

7504-0601-01

Loading...

Loading...