Page 1

INSTRUCTION MANUAL

K V = 4 0 8 4 U = 8 . 2 V

R P M= 3 3 4 9 0 I = 3 . 1 A

K V = 4 0 8 4 U = 8 . 2 V

R P M= 3 3 4 9 0 I = 3 . 1 A

BRUSHLESS MOTOR ANALYZER

SK-500020

FUNCTIONS

KV Measurement

RPM Measurement

Voltage Measurement

Ampere Measurement

Motor Timing Checking

1) Average Timing 2) Phase A, B, C Timing

Noise Level

Hall Effect Sensor Test

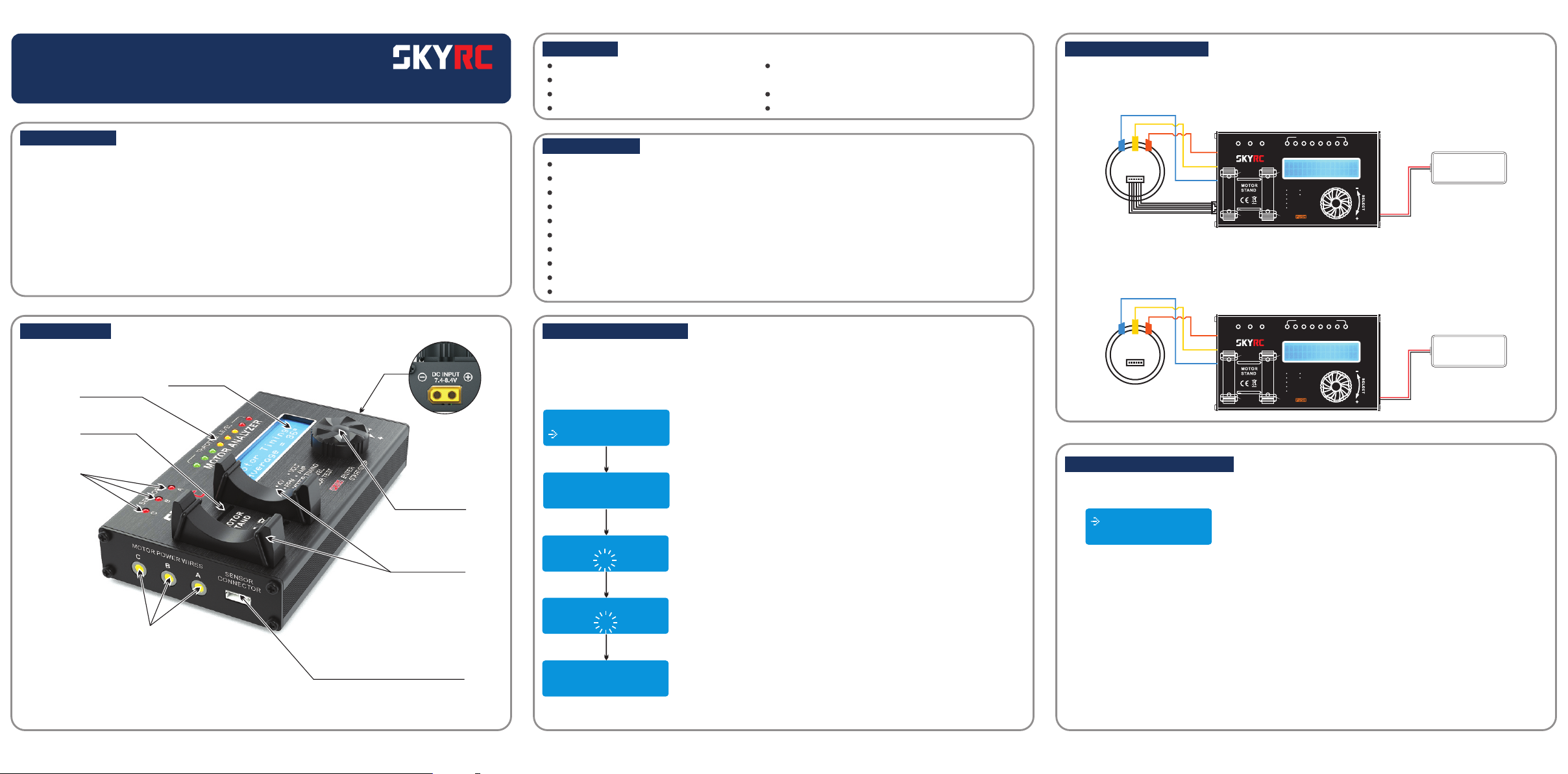

CONNECTION DIAGRAM

Brushless Motor with Sensor

(1) Connect Sensor Cable and Motor Power Wires A, B, C

(2) Connect to Power Source (Reverse Polarity Will Damage This Unit)

INTRODUCTION

Thank you for purchasing the Motor Analyzer BMA-01. We are confident you will find it to be an

indispensable tools you use to make your hobby more funs and enjoyable.

Brushless motors are the most popular motor choice now in the RC Car and model aircraft industry.

With their superior power to weight ratios, a large range of sizes, from under 5 grams to large motors

rated at thousands of watts, they have revolutionized the market for electric-powered model field.

The motor analyzer is a precision electronic device that is especially designed for measuring the KV

value, RMP, current drawn, motor timing, vibration noise level and checking the function of hall effect

sensors of a brushless motor. It comes with a 2X16 characters LCD that is able to display real time

measuring value of either sensor or sensor-less brushless motor.

ILLUSTRATION

Throttle Level

LED Indicators

Noise Sensor

Inside

Hall Effect

Sensors Indicator

Motor Power

Wires Connector

LCD Display

DC Input

7.4-8.4V

Rotary Dial

Motor Stand

Sensor Harness Connector

SPECIFICATION

Input Voltage 7.4-8.4V (Suggested to Use 2S LiPo Battery)

LCD Display Screen: Blue Backlight Background, White Text, 16 Characters X 2 Lines

KV Value Accuracy: +/- 3%

Motor Timing Accuracy: +/- 4%

Motor Timing Range: 0-70°

Noise Level Measurement Range : 60dB - 120dB

Dimension: 136.5mm x 80.6mm x 24.5mm

Net Weight: 282gram (Without Cabel)

Supported Motor: Sensor or Sensor-less Brushless Motor (2 Poles to 36 Poles)

Current Drawn Less Than 30A at 8.4V Without Loading

MOTOR MAGNET POLES

In order to measure the RPM and KV value correctly, you need to select the magnet poles number

according to the motor you are testing. The default values of this motor analyzer for car motor are 2

poles.

For magnet poles other than 2, you need do the setting as follow:

3 . N o i s e L e v e l

4 . P o l e o f M o t o r

Turn Rotary Dial

and press

P o l e o f M o t o r

0 2

Press Rotary Dial again

number of pole will blinking

P o l e o f M o t o r

0 2

Turn Rotary Dial to select

number of pole

P o l e o f M o t o r

1 4

Press again to confirmRotary Dial

number of pole

P o l e o f M o t o r

1 4

THROTTL E LEVEL

MOTOR ANALYZER

KV VOLT

RPM AMP

MOTOR TIMING

NOISE LEVEL

SENSOR TEST

ENTER

START/STOP

LiPo 2 Cells

Battery

A B

Motor

SENSO R

C B A

C

C

B

A

RC Car Brushless Motor without Sensor

(1) Connect Motor Power Wires A, B, C to Motor Analyzer A, B, C

(2) Connect to Power Source (Reverse Polarity Will Damage This Unit)

THROTTL E LEVEL

MOTOR ANALYZER

KV VOLT

RPM AMP

MOTOR TIMING

NOISE LEVEL

SENSOR TEST

ENTER

START/STOP

LiPo 2 Cells

Battery

A B

Motor

SENSO R

C B A

C

C

B

A

CONNECTION PROCEDURES

Connect Motor Analyzer to 7.4V-8.4V power source, the screen will be light up and display will

(1)

show functions selection.

1 . K V R P M U I

2 . M o t o r T i m i n g

For sensor type motor, connect A, B, C wire cable from Motor Analyzer to motor A, B, C connector.

(2)

Please make sure the wires should be connected properly before starting operation.

Wire A: Blue Color

Wire B: Yellow Color

Wire C: Orange Color

Connect sensor harness cable.

1

2

3

Page 2

APPLICATIONS

1. KV / VOLT / RPM / AMP

1 .K V R P M U I

2 .M o t o r Ti m i n g

KV(RPM per Volt) Show the rotor RPM/Volt at a certain throttle power level. The KV rating of

brushless motor is the constant relating the motors unloaded RPM to the peak voltage on the wires

connected to the coils (the "back-EMF"). For example, a 6,768 KV motor, supplied with 7.9 V, will run

at a nominal 53,468 rpm.

U(VOLT) Show the input voltage to motor checker.

RPM(Revolution Per Minutes) Show the rotor revolution at a certain throttle power level.

I(AMP) Show the current drawn by the motor at a certain throttle power level.

The above picture shows the throttle power level. In order to prevent from giving a max power to

the motor from the start up, the default power level is 0 for every time to start running the motor.

The maximum throttle power level is 8.

After you turn Rotary Dial and motor will start running. As the motor is running, the corresponding

parameters will be measured and shown on the display screen.

When the STOP key is pressed, the motor will stop running immediately and the last data measured by

motor analyzer will be recorded and kept on the display screen.

To freewheel the motor at high speed without loading may damage your motor. We suggest you to stop

the motor as soon as the throttle level is reach maximum.

P re s s a n d Tu r n

t o St a r t

Press Rotary Dial again Turn Rotary DialPress Rotary Dial

K V= 0 0 0 0 U =0 . 0 V

R PM = 0 0 00 0 I = 0 .0 A

K V = 6 7 6 8 U = 7 . 9 V

R P M = 5 3 4 6 8 I = 1 . 6 A

K V= 6 7 6 8 U =7 . 9 V

R PM = 5 3 46 8 I = 1 .6 A

Press Rotary Dial (STOP)

2. MOTOR TIMING

MOTOR TIMING: Physical endbell timing, usually between 0 and 70 degrees, requires tools to

rotate the sensor board.

Hall effect

sensor

Timing

0°

20

40

Rotor

Direction

Timing

30°

Hall effect

sensor

40

20

RotorRotor

Timing

45°

Hall effect

sensor

40

20

4 5 6

Average Motor Timing

2 .M o t o r Ti m i n g

3 .N o i s e Le v e l

Use Rotary Dial to

select Motor Timing

M ot o r T i mi n g

P re s s t o S ta r t

M ot o r T i mi n g

Press Rotary Dial Press Rotary Dial

Again and Wait

M ot o r T i mi n g

A ve r a g e = 30

3 seconds

Press Rotary Dial

to hold screen

P h. A P h . B Ph . C

3 0 29 31

Phase A, B and C

Sensor Timing

The performance of the motor is not only related to the endbell timing. It also depend on alignment and

quality of internal parts such as sensor board and rotor.

P h. A P h . B Ph . C

3 0 29 31

Above picture show the actual timing of three sensor elements. This feature shows and measures the

quality of your motor's sensor. Ideally, when the setting of timing on your is 30°, you want the three sensor

elements connected to A, B and C leads to shown exactly same number of degrees. However it is very

difficult to get the same reading in reality world. All manufacturers have variance in the production of

sensors. The values of each A, B and C sensor depends on production batch and how well the sensor chip

is aligned on the PCB. And the distance between sensor and rotor can affect the reading also.

Smaller difference between these values makes a good sensor board.

The Motor Analyzer may not show the same K/V value and Degree of Timing as the manufacturer claims.

The K/V value and Degree of Timing are dependent of many things related to the conditions under which

the motor is running. Motor Analyzer run all motors under the same working conditions and make it easier

to compare between brands and setups.

3. NOISE LEVEL

NOISE LEVEL: Poor assembly motor, inferior bearing and unbalanced rotor can generate a vibration.

Whenever a motor in air vibrates, it causes compression waves in the air. These waves move away from

the motor as sound or noise.

Vibration noise of motor is adverse the performance of motor. By measure the noise level of motors, you

can select the less noise motor.

The decibel (dB) is a logarithmic unit used to express noise level in this motor analyzer.

2 .M o t o r Ti m i n g

3 .N o i s e Le v e l

Use Rotary Dial to

select Noise Level

N oi s e L e ve l

P re s s a n d Tu r n

N oi s e L e ve l

0 40 d B P e ak : 0 4 5d B

Press Rotary Dial Turn Rotary Dial to

Increase Throttle Level

N oi s e L e ve l

0 65 d B P e ak : 0 6 9d B

Show current Noise Level

and Peak Noise Level

4. HALL EFFECT SENSOR TEST (BRUSHLESS MOTOR WITH SENSOR ONLY)

Sensored-type (motors with an extra six wires harness, connected to Hall Effect Sensors). Hall sensors

are commonly used to time the speed of wheels and shafts, such as for internal combustion engine

ignition timing or tachometers. They are used in brushless DC electric motors to detect the position of

the permanent magnet.

After power up the motor analyzer or after the STOP key is pressed to stop the motor running, it will

enter to the Hall Effect Sensor Test mode automatically. If the motor sensor harness is connect to the

sensor connector of the unit, one or two of the sensor LEDs will be light up that show the corresponding

sensors are function correctly.

Rotate the rotor for a step, and then the light up sensor LED will be changed. For example, if the sensor

A LED is light up, after the rotor is rotated by a step, then the sensor A and B LEDs will be fight up at the

same time. If rotating the rotor by a step again, sensor A LED will be light off and sensor B LED will be

light up only.

For a proper sensor operation, LED should be light up according to the below sequence:

A

B

C

LED A -> LED A,B -> LED B -> LED B,C -> LED C -> LED C,A -> this sequence will be repeated if the

hall effect sensors are functioned properly.

The following phenomenons that show the motor Hall Effect Sensor do not work properly.

-The LED light up sequence is not correct

-All LEDs light up at the same time

-All LEDs light off at the same time

SAFETY PRECAUTIONS

Please read the Instruction Manual before starting to operate the motor analyzer. For those users that

do not have experience to use it, please seek help from the professional users.

Please make sure the voltage apply to the unit is within the required range. (7.4V-8.4V) and polarity

should be connected properly.

IF THE INPUT POWER POLARITY IS REVERSED, THE UNIT MAY BE BURNT OUT.

For some high KV motor, long time no loading working is not suggested.

Motor and this unit will generate heat during operation.

ERROR MESSAGE

When the message RUN ERROR is appeared, please check and reconnect the sensor cable and A, B,

C motor wires to the unit again. Make sure A, B, C motor wires are connected to the corresponding A, B,

C socket on the unit. And please make sure there is no short circuit of A, B, C connector. If the error

message still appeared, the tested motor may be failure.

WARRANTY AND SERVICE

We guarantee this product to be free of manufacturing and assembly defects for a period of one year

from the time of purchase. The warranty only applies to material or operational defects, which are

present at the time of purchase. During that period, we will repair or replace free of service charge for

products deemed defective due to those causes.

For any repair or replace service, please contact your dealer in the first instance, who is responsible for

processing guarantee claims. This warranty is not valid for any damage or subsequent damage arising as a

result of misuse, modification or as a result of failure to observe the procedures outlined in this manual.

Manufactured by

SKYRC TECHNOLOGY CO., LTD.

RoHS

www.skyrc.com

2014.12

7504-0532-02

Loading...

Loading...