Page 1

1

Nynja Build Manual 1.4d

Nynja Build

manual

Version 1.4d

Page 2

2

Nynja Build Manual 1.4d

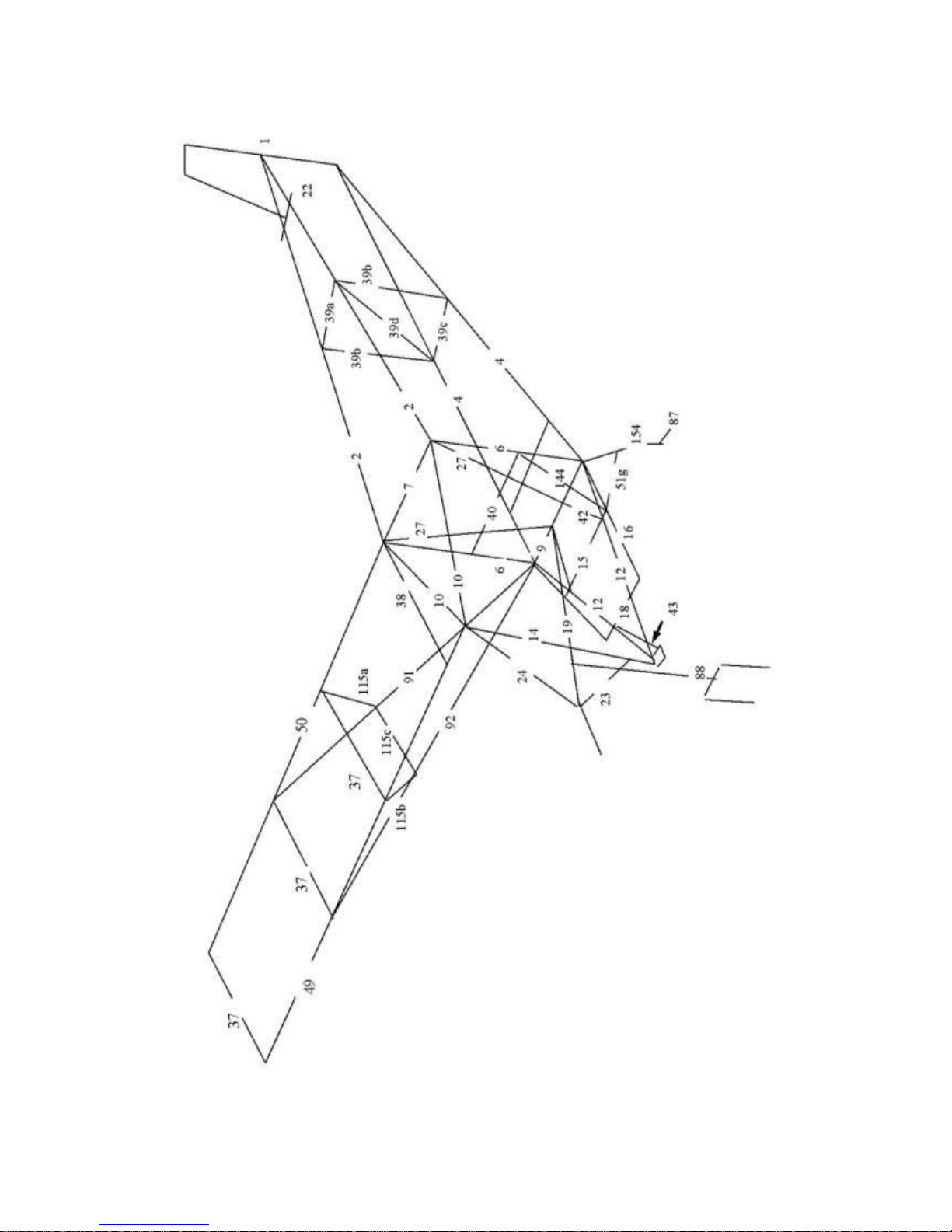

Figure 1 tube numbering scheme.

Page 3

3

Nynja Build Manual 1.4d

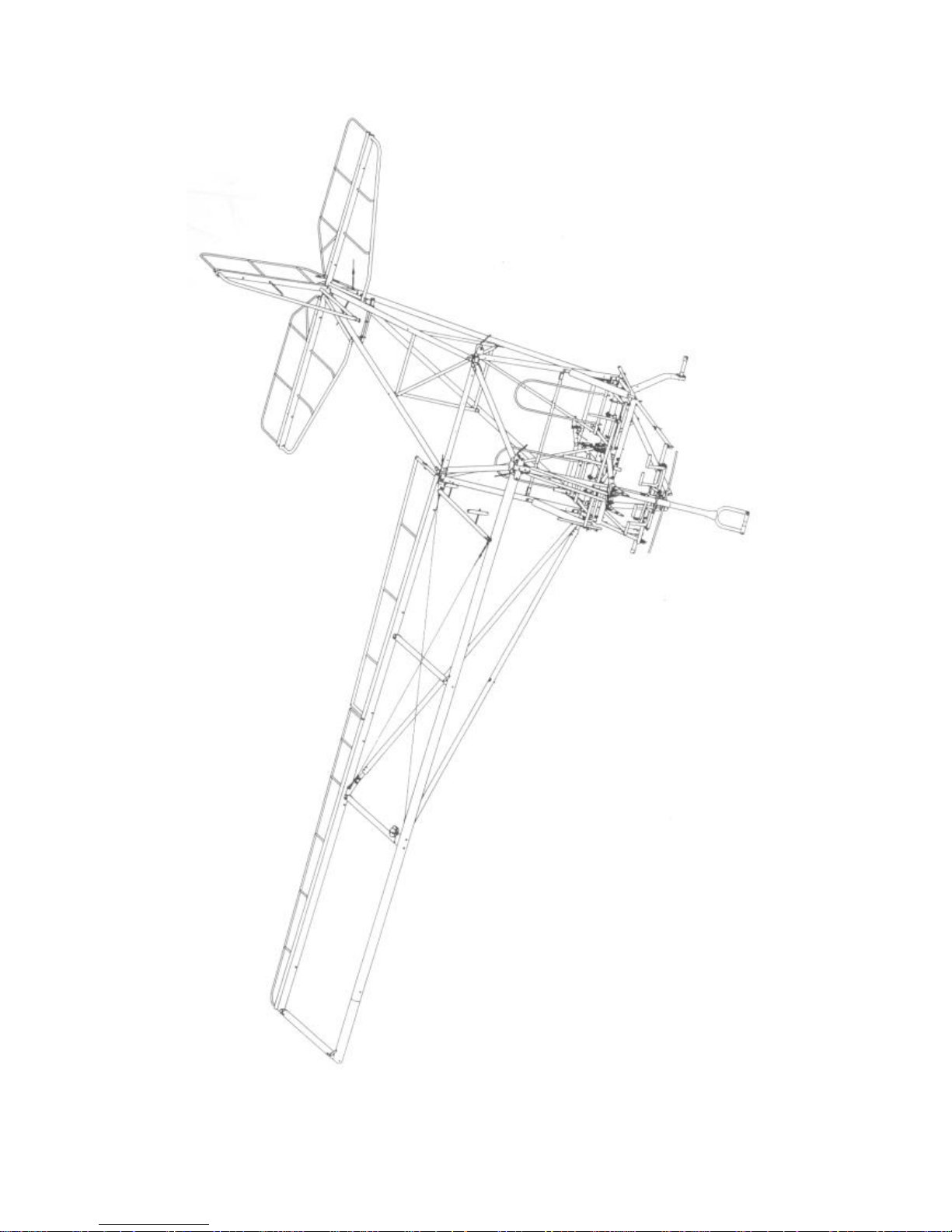

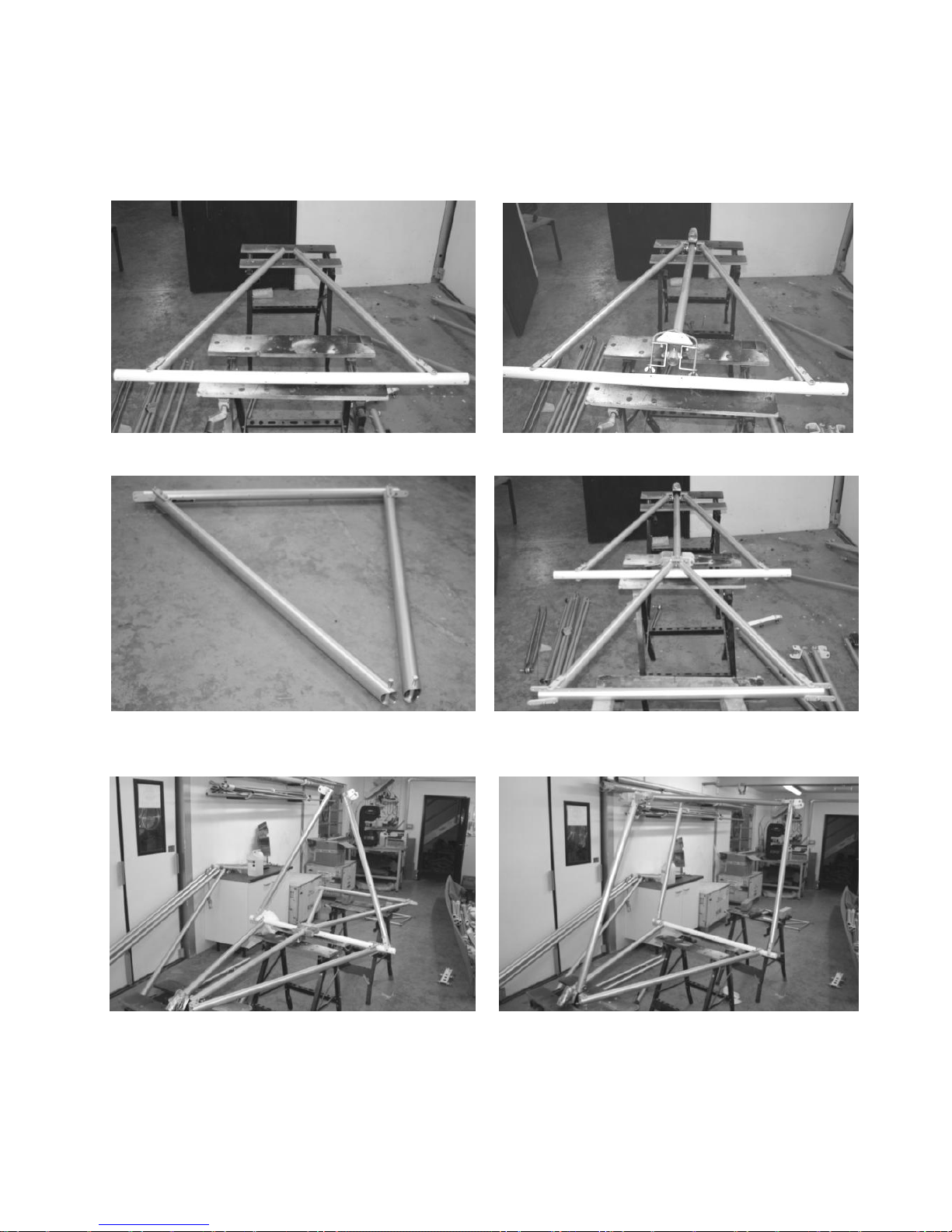

Figure 2 Basic frame (Skyranger).

Page 4

4

Nynja Build Manual 1.4d

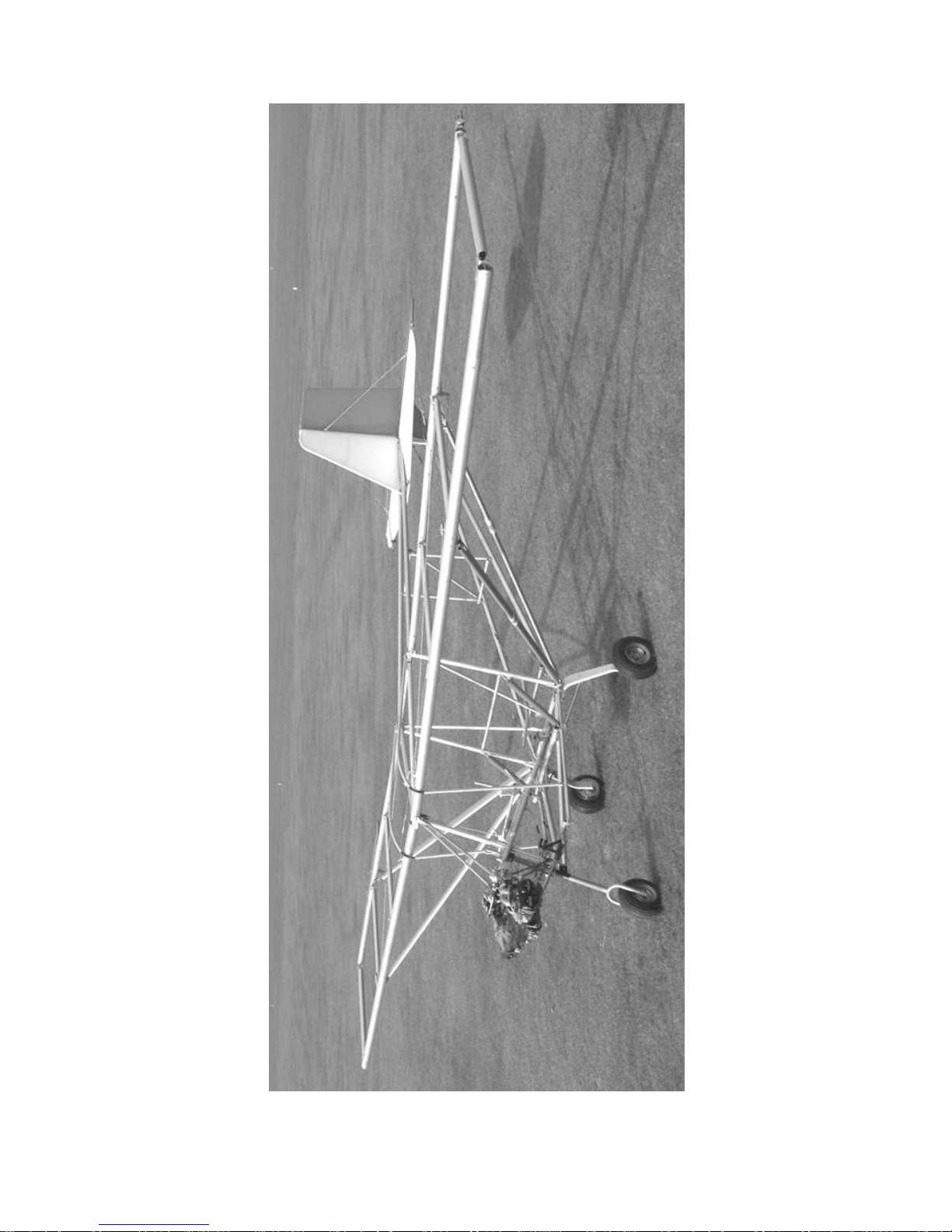

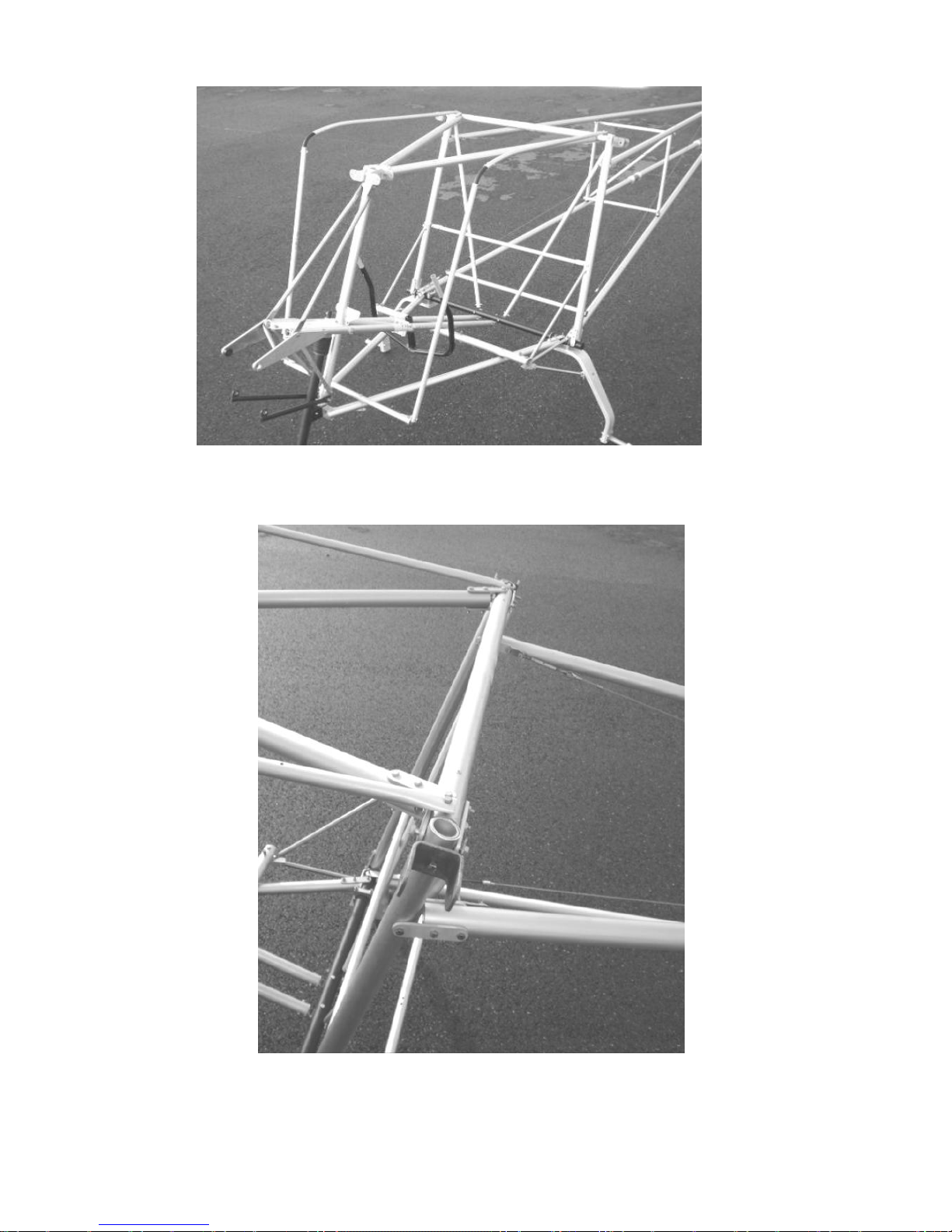

Figure 3 uncovered Skyranger frame.

Page 5

5

Nynja Build Manual 1.4d

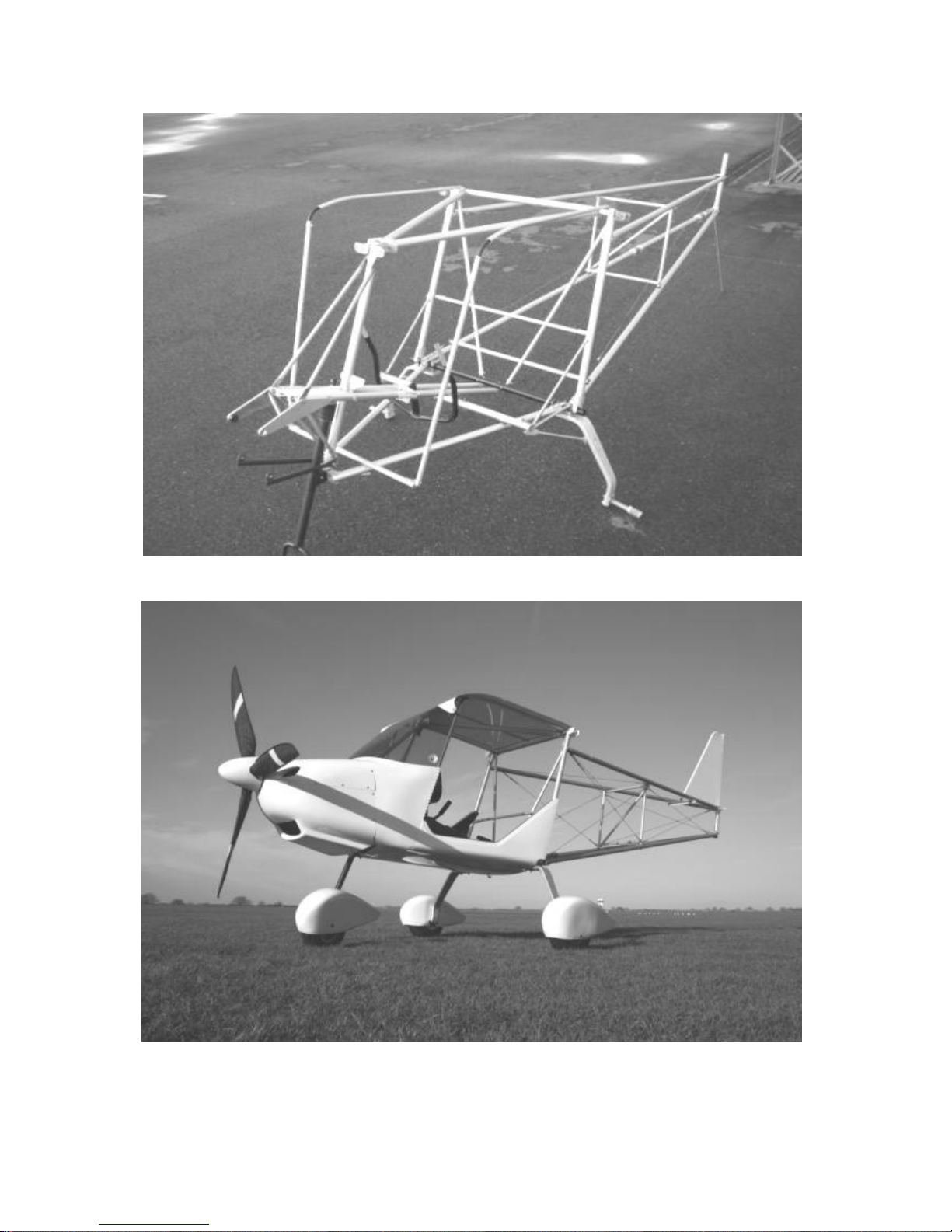

Figure 4 Uncovered Nynja frame

Figure 5 Nynja fuselage with rear fairings removed

Page 6

6

Nynja Build Manual 1.4d

Figure 6 Nynja fuselage with rear fairings removed – rear view

Figure 7 simply assemble thus!

Page 7

7

Nynja Build Manual 1.4d

Contents

Introduction ............................................................................................................. 10

1.1 How to Build Your Aircraft .................................................................................................... 10

1.2 The BMAA Homebuilt Aircraft System ....................................................................................... 12

1.3 General Assembly Notes ........................................................................................................... 14

1.4 Finish .......................................................................................................................................... 18

1.5 Weight ........................................................................................................................................ 20

2. Forward Fuselage ............................................................................................ 21

2.1 Tube Numbering .................................................................................................................. 21

2.2 Fuselage frame assembly overview ........................................................................................... 23

2.3 Lower Cabin Triangle .................................................................................................................. 25

2.4 Upper Cabin Triangle ................................................................................................................. 30

2.5 Rear Cabin Frame ................................................................................................................ 33

2.6 Rear cabin frame bracing. .................................................................................................... 34

2.7 Engine Supports ................................................................................................................... 37

2.8 Floor ..................................................................................................................................... 46

2.9 Rudder Pedals ..................................................................................................................... 48

2.10 Control Stick Assembly ........................................................................................................ 49

2.11 Finishing the Forward Fuselage ........................................................................................... 52

3 Rear Fuselage .................................................................................................. 54

3.1 Tail End ................................................................................................................................ 54

3.2 Bracing Frame ............................................................................................................................. 56

3.3 Front End.............................................................................................................................. 57

3.4 Fuselage bracing cables ............................................................................................................. 58

3.5 Tailplane Front Mounting ..................................................................................................... 63

3.6 Fuel Tank Support and Flap Handle ........................................................................................... 64

Not Tightening the Bolts and cables! ................................................................................................ 66

4 Undercarriage .................................................................................................. 67

4.1 Wheels ................................................................................................................................. 67

4.2 Main Undercarriage .............................................................................................................. 69

4.3 Nose Gear ................................................................................................................................... 73

4.4 Brakes .................................................................................................................................. 77

5. Tail Surfaces ....................................................................................................... 80

5.1 Tensioning the Rear Fuselage ............................................................................................. 80

5.2 Elevator Trim Tab ................................................................................................................. 81

5.3 Tailplane ...................................................................................................................................... 83

5.4 Rudder .................................................................................................................................. 87

5.5 Control Cables ..................................................................................................................... 90

6 Fitting the Rear Fuselage Fairings ............................................................... 100

6.1 Preparing the rear fuselage fairings ................................................................................... 100

6.2 Fitting the rear fuselage fairings ......................................................................................... 101

7. Engine Installation Rotax 912UL/912ULS .................................................... 105

8. Wings .............................................................................................................. 110

8.1 Wing Frame ........................................................................................................................ 110

8.2 Aileron Horn Assembly ....................................................................................................... 119

8.3 Attaching the Wings to the Fuselage ................................................................................. 121

8.4 Aileron Control Cables ....................................................................................................... 122

8.5 Flaps ................................................................................................................................... 126

8.6 Covering the Wings ............................................................................................................ 128

8.7 Inserting the Battens .......................................................................................................... 135

9. Windscreen Frame and Throttles ................................................................. 138

9.1 Windscreen Frame ............................................................................................................. 138

9.2 Throttles ............................................................................................................................. 143

Page 8

8

Nynja Build Manual 1.4d

10. Floor pan, firewall and cowlings .................................................................. 147

10.1 Floor pan ............................................................................................................................ 147

10.2 Firewall and scuttle moulding ............................................................................................. 150

10.3 Engine cowlings ................................................................................................................. 153

11. Engine Ancillaries ......................................................................................... 158

11.1 CKT twin outlet exhaust fitting ........................................................................................... 158

11.2 Oil cooling ................................................................................................................................ 160

11.3 Water cooling ..................................................................................................................... 164

12 Fuel System ................................................................................................... 167

12.1 Fuel lines and connections ...................................................................................................... 167

12.2 Engine compartment ............................................................................................................... 168

12.3 Fuel Tanks............................................................................................................................... 169

12.4 Fitting instructions for HADS Optional Mod 33 – Large diameter balance pipe between fuel

tanks ................................................................................................................................................ 170

Overview ......................................................................................................................................... 170

Parts: ............................................................................................................................................... 170

Fitting ............................................................................................................................................... 171

12.5 Fuel tank load spreader bars .................................................................................................. 172

12.6 Fuel tank securing straps ........................................................................................................ 172

12.7 Fuel tank connections ........................................................................................................ 173

12.8 Fuel filler .................................................................................................................................. 175

13 Instrument panel .............................................................................................. 176

14 Throttle and Choke cables .............................................................................. 180

15 Instruments .................................................................................................... 184

15.1 Pitot-Static System ............................................................................................................. 184

16 Electrical System ........................................................................................... 186

16.1 Soft start wiring .................................................................................................................. 190

16.2 Wiring General Points ........................................................................................................ 191

16.3 Low Current and Instrument Wiring ................................................................................... 191

16.4 Battery ................................................................................................................................ 193

17 Windscreen and rear windows ..................................................................... 195

17.1 Windscreen ........................................................................................................................ 195

17.2 Rear windows ..................................................................................................................... 202

18 Doors .............................................................................................................. 205

18.1 Keeping out the drafts. ....................................................................................................... 205

18.2 One Piece Door .................................................................................................................. 207

18.3 Two Piece Door .................................................................................................................. 213

19 Tail surfaces again ........................................................................................ 224

19.1 Trimmer system ................................................................................................................. 224

20 Centre console. ............................................................................................. 230

21 Seats and Seatbelts....................................................................................... 234

21.1 Seats .................................................................................................................................. 234

21.2 Seatbelts ............................................................................................................................ 237

22 Wheel Spats – Standard ................................................................................ 238

22.1 Nose Wheel ........................................................................................................................ 238

22.2 Main Wheels ...................................................................................................................... 239

23 Fitting the teardrop spat option. .................................................................. 241

Nose Wheel ..................................................................................................................................... 241

Main Wheel spats ............................................................................................................................ 242

24 Fairings .......................................................................................................... 246

Page 9

9

Nynja Build Manual 1.4d

24.1 Lower Fin Fairing ............................................................................................................... 246

24.2 Upper Fin Fairing ............................................................................................................... 246

24.3 Wing Root Fairings ............................................................................................................. 248

24.4 Cable Exit Fairings ............................................................................................................. 248

24.5 Tailplane Leading Edge Fairings ....................................................................................... 249

24.6 Wingstrut end Fairings (Socks) .......................................................................................... 249

24.7 Wingtip Fairings ................................................................................................................. 250

25 Aerofoil Profile Support Blocks ................................................................... 252

26 Fitting the heater option ............................................................................... 254

27 Fitting the storage side pockets................................................................... 256

28 Preparing for Flight ....................................................................................... 257

28.1 Airframe .............................................................................................................................. 257

28.2 Aerofoil Jury struts ............................................................................................................. 257

28.3 General checks .................................................................................................................. 259

28.4 Baggage Bag ..................................................................................................................... 259

28.5 Controls .............................................................................................................................. 260

28.6 Powerplant ......................................................................................................................... 263

28.7 Weight and Balance ........................................................................................................... 265

28.8 Placards ............................................................................................................................. 266

28.9 Test Flying .......................................................................................................................... 266

27 Additional Information .................................................................................... 268

27.1 Example BMAA Homebuilt Registration Form ........................................................................ 268

27.2 Wire-locking........................................................................................................................ 270

28 Index ................................................................................................................. 274

28 Amendments .................................................................................................. 277

Page 10

10

Nynja Build Manual 1.4d

Introduction

1.1 How to Build Your Aircraft

Building the Nynja is a fairly straightforward process, but it can be made much more

difficult than necessary if one basic rule is not followed:

READ THE INSTRUCTIONS!

Figure 8 A rare sight, but essential for successful building (the manual that is, not Rob)!

The Build Manual

Reading the whole manual before starting is suggested. Reading ahead by at least

the section being worked upon, as each section is reached, is recommended.

Reading the instructions for the components under your spanners is essential! It is

remarkable how often the instructions are over-looked or misread, remembering that

you are going to fly in your finished aircraft!

Instructions, however, are never as good as they could be, and so corrections and

suggestions for improving the instructions are welcome, preferably in writing by

email. These can then be included in future updates of the manuals.

If you have errata or receive updates to the manual, mark these immediately in

your copy of the manual so that you do not forget them when you reach that

stage.

An electronic copy of the build manual is available on request via dropbox, and any

updates will be published there as soon as they are made.

Don’t rush things, work carefully, and don’t forget to enjoy building your aeroplane!

Page 11

11

Nynja Build Manual 1.4d

In case of difficulty

If you cannot find a part, ensure that you have determined what it looks like, and that

it is not already attached to a sub-assembly in the area you are working on. Often

parts are hidden by the packaging, or lurking in the bottom of a box of bits in the

corner of the garage, rather than being missing from the kit.

If you have a problem that you cannot resolve by a careful read of the instructions

with the appropriate parts in front of you please have a look in the Skyranger internet

discussion group, send an email, or if all else fails ring:

01604 494459

Note that most enquiries can be answered by a careful read of the manual, so

do give it some thought before calling.

Email is preferred and more convenient than the telephone, as it makes it simple to

communicate answers to other builders and allows time for a better more researched

reply to your questions. Please use paul@flylight.co.uk

Figure 9 We await your call on the Nynja Hotline! – but consider email please!

Photographs

The manual has lots of drawings and photographs to help you build your aeroplane.

The photographs are chosen to illustrate each point, but often include other areas of

the aeroplane in the background. However, due to the number of modifications made

during the UK certification phase you should be cautious about assuming that

background items are shown as they should be on UK specification aircraft. Many

parts are common to the Skyranger and Skyranger Swift, and these may be shown in

some of the photos and drawings where commonality exists.

Page 12

12

Nynja Build Manual 1.4d

1.2 The BMAA Homebuilt Aircraft System

Before starting the build of your Nynja you must register the project with the BMAA.

The required forms are downloadable from the BMAA website at www.bmaa.org, go

to the Technical Information section, click on Forms, and download form

BMAA/AW/022.

An example form for a Nynja fitted with a Rotax 912ULS and standard Kiev prop 283

is shown towards the end of this manual.

You will have to find a BMAA Inspector to oversee the project. A list of Inspectors is

available from the BMAA if required. Fill in the form with information about your

aircraft and Inspector.

Send this form, along with the certificate of conformance for the aircraft, engine and

propeller, with the current fee to the BMAA.

The BMAA will then register the project and issue you with a project number. They

will send you a pack of paperwork with information about building a BMAA homebuilt,

and a stage inspection form to be completed during the build by yourself and your

Inspector.

Please read all the paperwork that the BMAA send you when you receive it –

this may prevent stress later!

You can also register the aircraft with the CAA and order registration letters

(available from Flylight) to save time later.

Your Inspector is required to visit prior to commencing any real building to inspect

your workshop and the kit. This forms the first stage inspection.

Your Inspector has to sign off several key stages of the build. Get his signature on

the form at the time, just in case! He can be a very useful source of knowledge and

advice, and should be your ‘mentor’ during the build. Also, a second pair of eyes and

an experienced mind can often solve problems for you in an instant.

Inspectors will vary somewhat in their likes and dislikes, and so requirements may

vary from what you may consider to be adequate. It is best to listen to your

inspector’s views, but in case of specific queries either you or your inspector may

contact Flylight or the BMAA directly to discuss matters.

Please respect the stage inspections and do not present him with a fully built aircraft

for the first visit! It is not his fault if you have to undo a lot of building to make right

something that should have been checked in a stage inspection before continuing

further. If there is a delay in having an inspection it is better to get on with building

bits and pieces like wheels and wing frames than to continue adding to the main

assemblies.

When your aircraft is complete and to your Inspector’s satisfaction, the completed

stage inspection form is sent to the BMAA. Also required to be sent at the same time

is the Engine Installation Check Sheet (either the Rotax version or the generic BMAA

version for non-Rotax engines). This details tests required to ensure correct

installation and set up of the engine, such as the fuel-flow test described towards the

end of this manual. Again your inspector has to witness the tests and sign the form.

The BMAA will then process the paperwork and raise a BMAA AW029 giving

permission to test fly, along with a draft MAAN (Microlight Aircraft Approval Note) for

Page 13

13

Nynja Build Manual 1.4d

specific clearance and flight testing of your aircraft. This will require checking and

returning to the BMAA for an authorisation signature to make it valid.

Initially your aircraft must be flown by a BMAA Test Pilot, or a specially authorised

check pilot. He/She will fly the aircraft to the flight test schedule to ensure that your

aircraft is set up and flying as it should. You can accompany them for the flight tests

as observer / secretary. When the aircraft is flying satisfactorily (some trimming /

adjustments may be required), then if you have suitable experience you may fly the

aircraft. 5 hours of flying are required to prove reliability and debug the aircraft,

before an application can be made for a full permit to fly. Whilst waiting for this to

arrive you are normally permitted to fly the aircraft, continuing to obey the restrictions

of the test flying clearance contained in the AW029.

If you are the first with a new engine or propeller type, or have made any major

modifications to your aircraft, then 25 hours of reliability testing are usually required.

If you plan any modifications then it is essential that the BMAA is informed at the

beginning of the project, so that a technical investigation can be made and approval

for you to go ahead can be given.

It is likely that you are keen to begin construction, and are waiting impatiently for the

paperwork and your inspector to allow you to do so. However, this short delay can be

used very productively to familiarise yourself with the instructions and the

components, and prepare them for use.

Modifications

You may desire to install equipment such as a radio, strobes etc.. These will

constitute modifications to the standard aircraft and therefore must be done in

accordance with BMAA procedures. Details of the most common modifications are

included in the TIL’s, and Standard Minor Mods (SMM) available on the BMAA

website ( www.bmaa.org ) . If these are done at the time of construction no additional

modification fees are payable.

For modifications not covered by the TIL’s, or SMM’s, it is probably better to

complete the standard aircraft and commence flying before proceeding with the

modification. This is because non-standard modifications will introduce complexity

and delays into getting you aircraft flying, and so these are best done at leisure when

you already have your aircraft in the air.

Note that the Nynja succeeds in providing a capable aeroplane at an excellent price

by following the principle of simplicity. Some areas may look basic at first glance, but

meet the stringent requirements of BCAR Section S without adding cost and weight.

Any modifications you make must also meet Section S, but it is up to you how much

cost you are willing to bear and where you spend your weight. However, increased

cost and less fuel carrying capacity are difficult to avoid.

Do not begin any modifications without first speaking to your inspector, the

BMAA, or Flylight Airsports.

Page 14

14

Nynja Build Manual 1.4d

1.3 General Assembly Notes

Before starting to assemble anything, read the whole of this manual to get an overall

impression of the order and methods of assembly. The sequence of construction is

the one used to build the importer’s aircraft, and should be adhered to. If you wish to

change the sequence, you may find difficulty in fitting other parts later, so read ahead

carefully to determine the effects of your changes. Flylight Airsports cannot advise

on, nor be responsible for, the consequences of not following the instructions, as if

we have not tried something we cannot comment upon it with any experience.

Unpacking

To familiarise yourself with the kit components it is useful to unpack the kit and sort it

into groups for each assembly stage, such as wing parts, fuselage parts,

undercarriage etc.. Do this in conjunction with the packing list and the instruction

manual to determine that you have all the required parts.

If you cannot find a part, check under the packaging on related assemblies,

and make sure you know what it is that you are looking for, as parts may be

rolled up or transported inside other parts. For instance smaller tubes may be slid

inside larger ones.

Don’t forget to check all the boxes, in case you’ve put a box aside somewhere. Some

small parts may be hidden within packaging foam ‘snow’ in the bottom of boxes, so

don’t throw any boxes or packaging away until you have ascertained for certain that

you have all the parts – we have stories of unloading skips to retrieve parts that have

gone with the rubbish!

We also pack some parts in the engine box – so remember to look in there.

This may all sound obvious, but we know from past experience that even big parts

like propellers can be thought missing when they are there all the time!

Don’t try and remove the glassfibre parts from the big wood box without first

removing at least one of the metal side rails on the box – or the gap will be too

small and you will flex and crack the big side panels!

Initial assembly with non locking nuts

During initial assembly it may be helpful to use wing nuts or normal nuts (wing nuts

are preferred as they are more obvious and less likely to be forgotton!) rather than

Nyloc nuts for test fitting pieces, or on pieces which need to be removed later to fit

the coverings or other parts. Alternatively, only tighten the Nyloc nuts up to the Nyloc

section until ready to apply threadlock and tighten properly.

Assembly

If in doubt about a part, or an assembly, read ahead and pay particular attention to

drawings and photographs. Note that the direction of bolts (up/down, pointing

forwards/backwards) may differ between drawings and photographs. Normally, the

bolts will be inserted from the top or the front, unless other considerations apply,

such as coverings or access.

Remember to replace any non locking nuts with Nyloc nuts before final assembly,

and also:

REMEMBER TO USE LOCTITE 243 ON ALL NUTS.

Page 15

15

Nynja Build Manual 1.4d

This is usually available from your local fastenings company, look them up in the

Yellow Pages under “Fixings and Fasteners”, and you will never be stuck for nuts

and bolts again!

Loctite should be used very sparingly. A common mistake is to overuse it. Loctite

smeared over the outside of fasteners acts as a corrosive agent. Any surplus should

be immediately removed with a soft cloth.

A good tip is to paint a red stripe across the nut and bolt end after final tightening.

This way it will be easy to inspect and spot any nuts not finally tightened.

Main tools needed for assembly

Spanners and sockets in the range of: 6, 8, 10, 12, 13, 14, 17mm

Allen keys: 4, 6, 8mm

Metal saw

Drill and bits for metal

Rivet pliers

Cutting pliers

General pliers

Screwdrivers, flat and cross-head

Hammers, metal and rubber/plastic

Mouse tail file with diameter less than 6mm

Flat file

Engineers Rule

Tape measure

6mm reamer (desirable)

Wire-locking pliers (desirable)

Cleco’s or Skin pins for 4mm holes

Dremel Multi tool or equivalent small cutting / sanding tool

Soft faced clamps

Rivnut installation tool and 4 and 5mm Rivnuts (these can be really useful to make a

tidier alternative to nuts or captive nuts on things like instrument panel fixings)

Products needed for assembly

Loctite 243, to be used on all bolts

Silicon grease

Oil for general use

Oil for engine and gearbox, see engine documents

Epoxy adhesive (Araldite or similar)

Lock-wire

Holes

All the holes have been drilled to a high accuracy, however it may sometimes be

necessary to use a round file or reamer to ease the insertion of some bolts. Be

careful not to make a hole too large however, sometimes all that is required is to

loosen other bolts nearby, or to apply pressure to some other part. Generally bolts

should not be tightened up until all the parts in a particular sub-assembly are

assembled, to avoid the common problem of the final bolt not fitting!

Page 16

16

Nynja Build Manual 1.4d

Washers

Metal washers should be used to prevent scratching of the surface as a nut is

tightened.

Nylon washers, or similar plastic washers, should be used to:

a) fill spaces between parts, such as between tubes and U-brackets

b) avoid friction between two moving metal parts, such as the stick and its

supporting bracket

c) avoid contact between parts of different materials, especially stainless-steel

and aluminium

The final point above is primarily to prevent the hard steel wearing through the soft

aluminium due to vibration, rather than for electrolytic reasons, as the bolt passing

through both materials will still complete the electrical connection.

Saddle washers

Normally they are shown on the drawings and photos.

Generally they are used between two crossed tubes or between a tube and a flat

bracket.

Take care not to overtighten bolts which pass through plastic saddle washers as you

may cause them to split.

Nuts and washers

Standard nuts and washers in the main kit are metric zinc plated steel. An acceptable

alternative is to use A2 stainless nuts and washers. These can be purchased from a

fastener supplier for relatively low cost and provide protection form corrosion. Note

that bolts supplied are a mix of 8.8, 10.9 and 12.9 and Eastern European Mil spec

and some smaller bolts are stainless steel. These may NOT be changed for other

specification or to stainless steel as strength, malleability and dissimilar metal

corrosion can be problems.

Bolts

Generally all bolts should bear on their unthreaded lengths, not on the threaded

portions.

It is also important that nuts are not screwed on so far as to become ‘threadbound’

by reaching the limit of the threaded portion. You can use an extra washer or two to

adjust the effective length and prevent this where required.

Turn nuts, not bolts whenever possible, when tightening, as this may damage the

plating and encourage corrosion. Washers are only needed under nuts to allow them

to be turned, whereas bolt heads should not be turned.

Do not over-tighten bolts, avoid deformation of tubes or brackets.

Page 17

17

Nynja Build Manual 1.4d

IMPORTANT: tubes must not be visibly deformed.

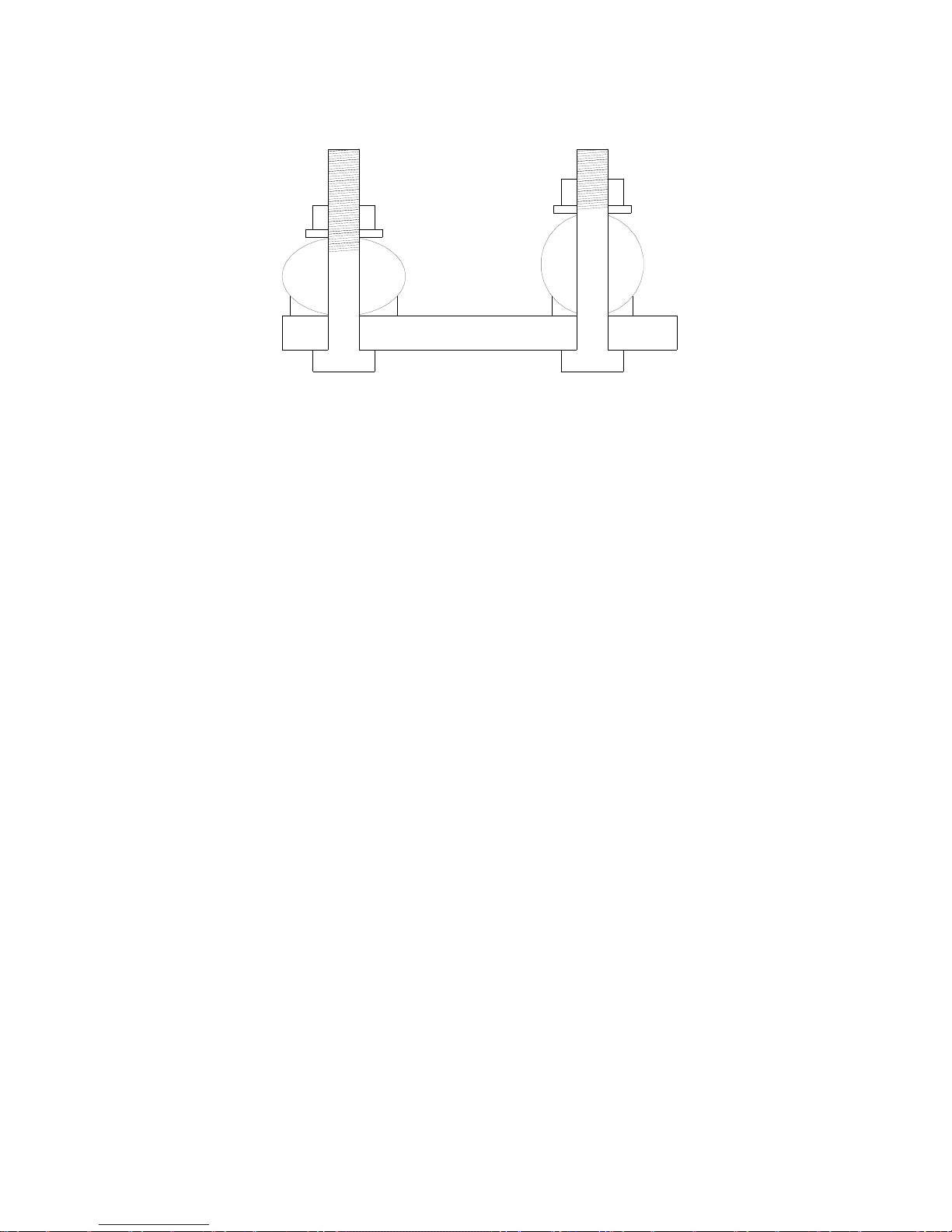

Figure 10 Left - WRONG – squashed tube, thread in tube. Right – RIGHT – tube still round,

thread stops in washer(s).

Every wing nut has to be fastened by a security ring or aviation ‘nappy pin’.

Nyloc nuts should be used only once.

When cutting bolts short, a minimum of two threads should protrude from the nut.

Paint the cut end to prevent rusting.

Bolts subject to rotation should be drilled and locked with a split pin. Examples

include stick pivot bolt, torque-tube pivot bolt, rudder link bolts.

Wire-locking

Certain parts require securing with lock-wire, such as engine bolts and turnbuckles. If

you have not done this before, discuss how to do it with your inspector. A basic guide

to wire-locking bolts and turnbuckles is included at the end of this manual.

Stainless-steel parts

A number of tubes have flattened steel end-fittings which may require slight “tweaks”

to align them as required. This should be done carefully in a vice, with wooden jaw

pieces to protect the surfaces.

Avoid bending the parts back and forth repeatedly, and avoid bending them at

the hole position.

The finish on the stainless-steel parts is quite varied. If desired these parts can be

polished to a shiny finish, although those positioned in the pilot’s line of sight may be

covered in anti-reflection black coatings or plastic sleeving if desired. Scotchbrite

pads can be used to provide a pleasing, even, cosmetic finish.

Coverings

Handle the coverings with care, pay attention to the risk of bolt heads, corners and

reinforcements/stiffeners damaging the covering as it is put on.

Dacron coverings need care to avoid getting dirty and becoming stained. Keep your

hands and tools clean and oil-free when working with or near these coverings.

Page 18

18

Nynja Build Manual 1.4d

You can remove most dirty marks on Dacron with a sponge soaked with tepid water

and a mild detergent, followed by rinsing using only tepid water.

Part numbering

Numbers in bold italics refer to a part number, either as shown on the relevant

drawing or a universal part number with a prefix. Prefixes refer to the following:

tu tube

tual aluminium tube

tuac steel (acier in French) tube

u U-bracket

ual aluminium U-bracket

me metal plate piece

meal aluminium metal plate piece

meac steel (acier) metal plate piece

ca cable, wire rope

The material-type part of the number is not always used.

During assembly follow the drawings and photographs corresponding to the text.

Drilling and cutting

When drilling holes or cutting parts be very careful to measure and mark the correct

positions. Check these a second time before proceeding to cut or drill.

The old adage of measure twice, cut once still applies!

Otherwise, you won’t be the first to ring up to order a new bit, having chopped

something too short!

If you find a part which you think is wrong, in terms of size etc., be very sure that this

is so before cutting or drilling etc. to correct the problem. For instance, over-long

bolts may have extra parts to be fitted later. Leave irreversible actions until the end of

the build!

When drilling holes in metal, use a centre punch to prevent the drill wandering, and

start with a small pilot drill working up to the required hole size.

It can be useful to use masking tape on fibreglass gel surfaces to help prevent

cracking, and to reduce the risk of marking the surface if the drill should slip.

1.4 Finish

All Aluminium parts are supplied anodised or powder coated. Do not be alarmed if

some marks are present in the finish of the tubular parts, this is a result of the

suspension method at the anodising plant. You may also notice areas on tubing that

may appear to have fine sanding marks. This is done prior to the anodising process

to polish out any small scratches. It is also not unusual to find small areas of silver

paint applied at the final stage over any small remaining marks prior to leaving the

factory. Some light scuff marks may be present as a result of storage and transit.

Page 19

19

Nynja Build Manual 1.4d

This is normal. Deep scratches or dents are not acceptable – ask you inspector for

advice, and refer the problem to the importer.

Aluminium plate parts may be painted to improve their cosmetic appearance if

desired. Use a Scotchbrite pad or lightly sand with fine wet and dry before using a

suitable aluminium primer and top coat. Ensure that all painting operations result in a

thin covering that will not hide defects from inspection.

Steel components are all supplied plated and / or powder coated, for corrosion

resistance. Again they may be painted for extra protection or cosmetic reasons if

desired.

Further protection from corrosion can be beneficial for longevity, and to resist the

ravages of operation near the sea or storage in damp hangars. Aluminium and steel

parts can be treated with corrosion protection products such as the excellent ACF50.

This should be squirted in all tube ends and around fittings and applied to the outside

with a soft cloth. An initial thorough application before covering is recommended

(don’t do this if you have Dacron covers that you intend to paint), followed by periodic

repeat application.

‘Wax oil’ or similar propriety products may also be used inside tubes and around

fittings.

Glassfibre fairing parts are supplied in a white finish. This can be polished with T cut

or similar to a high sheen. Alternatively they can be painted, but avoid using dark

colours on the rear fuselage fairings as strong sun can generate high temperatures

that will soften the glass fibre. None of the fairings carry structural loads so this does

not have any safety implications, but this may result in cosmetic damage in the form

of permanent distortion / waves in the fairings.

Self adhesive vinyl graphics may be applied, but again avoid large areas of dark

colour.

Dacron coverings may be lacquered with a special process using Automotive

Polyester or Acrylic Lacquer mixed with a flex agent. Refer to the importer for more

information. Advantages are stronger colours and a sealed shiny finish which allows

oil etc to be wiped off without leaving marks. Disadvantages include extra weight and

the loss of the ability for the coverings to be re-used in the event of removal for

damage repair.

Xlam coverings can be decorated with Vinyl graphics. Take care to degrease the

surfaces prior to application and use good quality Vinyl with good adhesive

properties. Application in low temperatures is to be avoided, and some work with a

heat gun and application of pressure will be required to work the Vinyl into the weave

and stitching to ensure good long term adhesion. Seek specific advice before

application.

Page 20

20

Nynja Build Manual 1.4d

1.5 Weight

The UK prototype Nynja with Xlam coverings, Rotax 912ULS and standard ‘console’

dash, basic analogue instrument fit, installed intercom box, aerial and radio, and

including doors (see note below***), has been found to have a basic empty reference

weight of approximately 258kg. Options such as, wheel spats, spinner, thick carpet,

etc will have a weight penalty. Painting metal parts, cowlings and applying lacquer to

Dacron coverings will have a weight penalty. Additional avionics or strobes are also

surprisingly heavy.

It may be necessary to make choices in these options to ensure that the weight

remains inside the maximum permitted Zero Fuel weight (ZFW) for the aircraft. The

ZFW will vary according to the fuel burn of the chosen engine option. Max ZFW for

the 912ULS engine Nynja is 268Kg

Refer to the Homebuilt Aircraft Data Sheet (HADS) or the BMAA for further

information on the rules regarding weight for this class of aircraft.

Below is an approximate guide to the weight of specific options:

Wheel spat kit + 4.0Kg

Nynja wingtip fairings + 2.0Kg

Skyranger wing tip fairings (alternative to above) +1.5Kg

Carb heat (912 engines) +0.7Kg

Heater option + 1.0Kg

Spinner +0.5Kg

912UL engine - 1.5Kg

Slipper Clutch on 912/912ULS gearbox +1.5Kg

Large starter motor on 912 / 912ULS +0.5Kg

****Items that are non essential for flight and are easily removable may be eligible for

non inclusion in the ZFW calculation and be considered as payload. These items

may include:

Baggage hammock 1.5Kg

Doors 5.5Kg

Other items may be eligible – See latest version Of HADS or refer to BMAA.

If a total aircraft parachute recovery system is fitted, then the max permitted MTOW

rises to 472.5Kg and Max ZFW also rises 22.5Kg to 290.5Kg. These systems can

typically be installed for around 12 - 15kg, allowing the remainder of the allowance to

be used for payload, or additional fixed items.

Weight is surprisingly cumulative and dividends will be gained by ‘thinking light’

during every stage of the build. The benefits of an aircraft kept well under the

maximum permitted weight will be better performance and payload capacity.

Page 21

21

Nynja Build Manual 1.4d

2. Forward Fuselage

Note: During assembly of the fuselage, hand tighten the bolts only as far as the

Nyloc section. After the fuselage is complete and you are sure it is correct, you

can go back and tighten all of the nuts.

If you wish plain nuts, or even better wing nuts, can be used in the initial construction,

to be replaced with Nylocs when the time comes to tighten the nuts up. However,

note that it is often beneficial to have the nuts loose anyway, to ease any alignment

difficulties.

2.1 Tube Numbering

Refer to these drawings for tube numbers throughout the forward fuselage assembly

sequence.

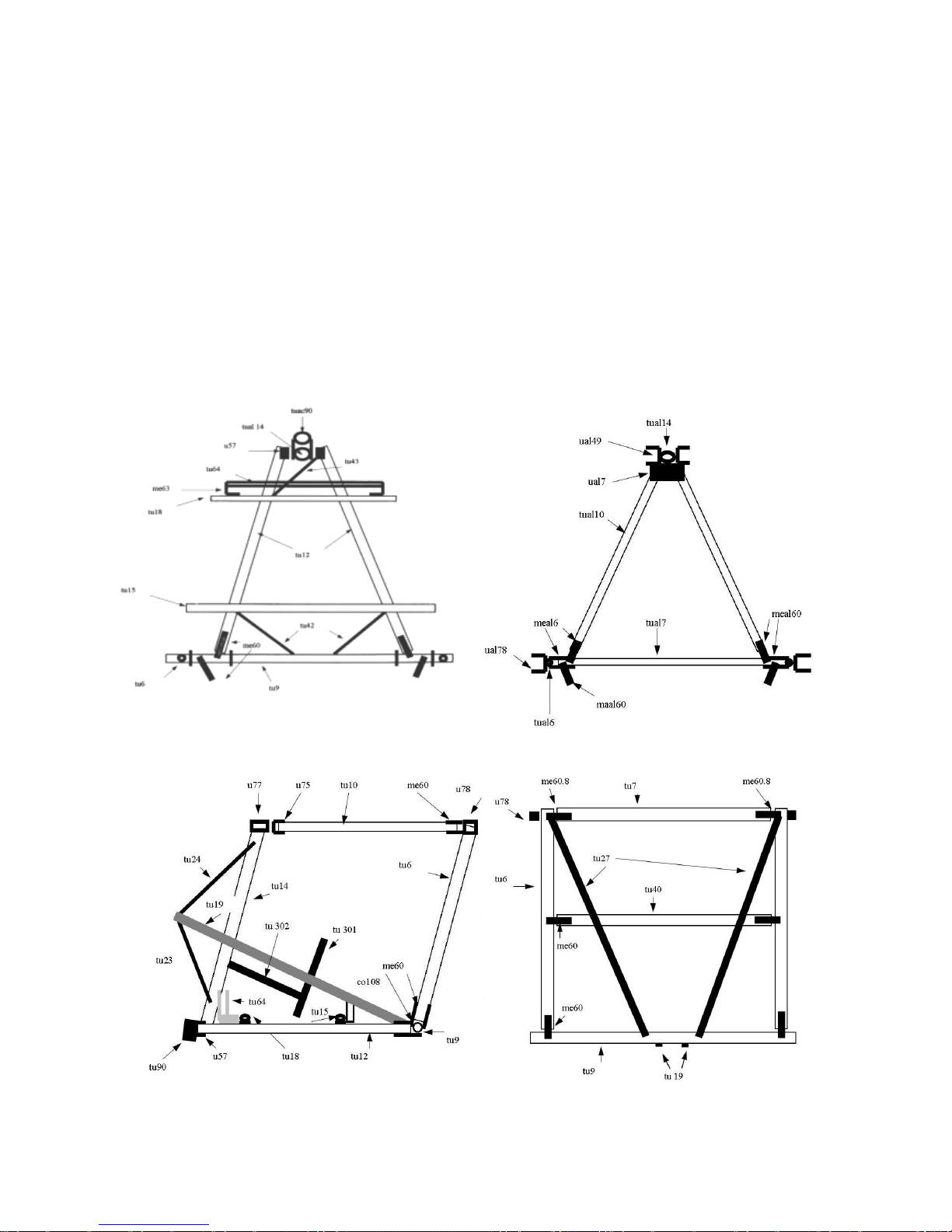

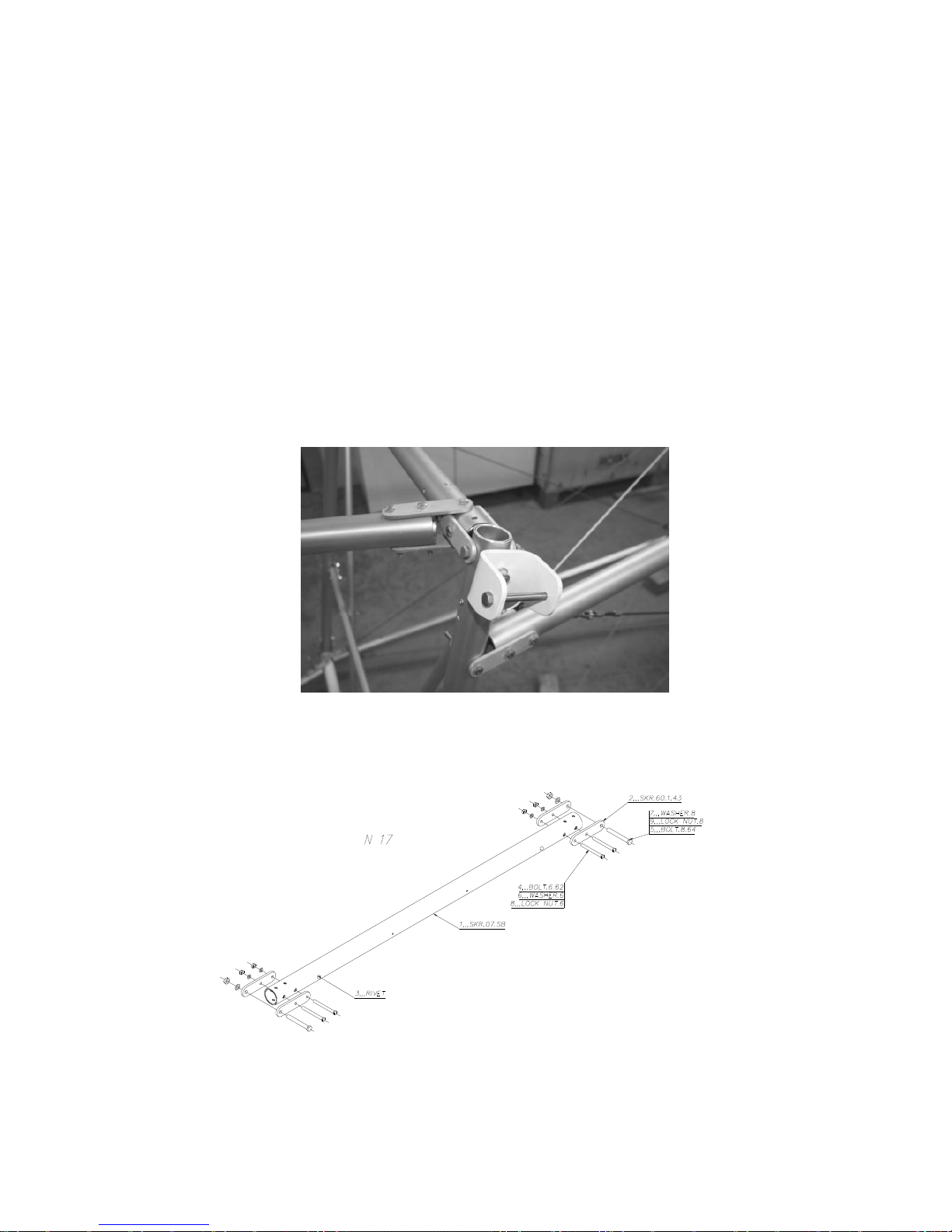

Figure 11 cabin lower and upper triangle tube numbering.

Figure 12 cabin viewed from port side, and rear cabin frame viewed from rear.

Page 22

22

Nynja Build Manual 1.4d

Figure 13 forward fuselage from front quarter.

Figure 14 Cabin upper rear corner

Page 23

23

Nynja Build Manual 1.4d

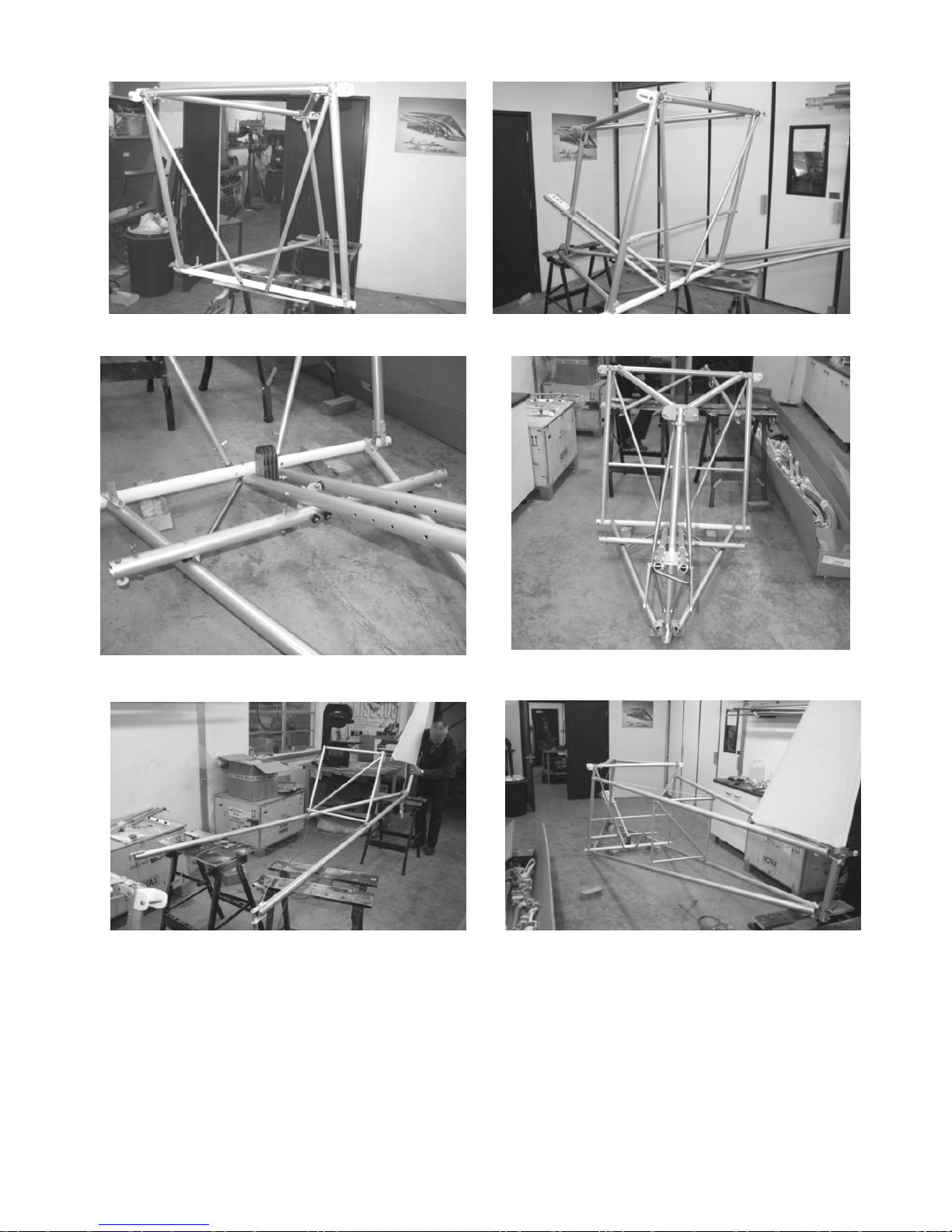

2.2 Fuselage frame assembly overview

Lower triangle assembly Attaching TU14

Upper triangle assembly Attaching upper triangle to TU14

Attaching rear cabin uprights TU6 Attaching Upper triangle to uprights

Page 24

24

Nynja Build Manual 1.4d

Cabin diagonals TU27 attached Twin TU19 tubes in position

Front seat support TU15 and braces Forward engine mount assembly fitted

Assembling tailcone Tailcone fitted to cabin

Figures 15 – assembly overview

Page 25

25

Nynja Build Manual 1.4d

2.3 Lower Cabin Triangle

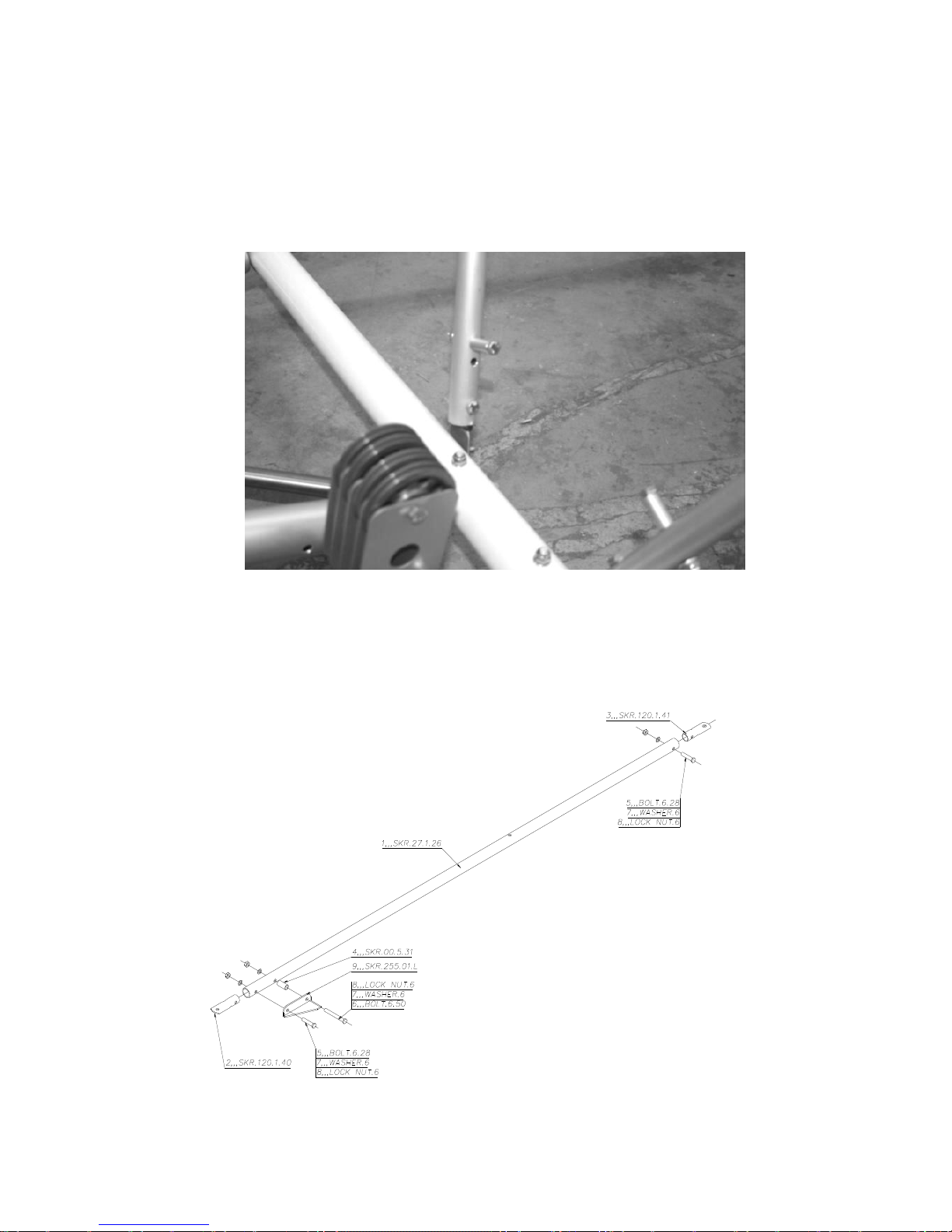

2.3.1 Orienting the main undercarriage cross-beam tu9.

The main undercarriage cross-beam tu9 is made of steel.

Flip the beam over until satisfied that the holes are in the correct positions.

The holes in the steel main undercarriage cross-beam tu9 are drilled at

an angle through the beam so that the tail section of the fuselage,

which attaches to the third set of holes in from the ends, tilts upwards

from the beam whilst the lift-strut attachment bolts, nearest the ends,

remain horizontal.

Figure 16 Tu9 (The big white tube), looking from above, front of aircraft to left

2.3.2 Fitting the sides of the lower cabin triangle to the main

undercarriage cross-beam.

a) Assemble the aluminium linking plates 9 onto the pair of lower cabin triangle

tubes tu12, including the seat support brackets (Figure17)

The linking plates are drilled with three 6mm holes, not at equal

intervals. The centre hole is offset away from the single mounting hole.

Remember the anti-crush spacers on the bolts (inside the tubes).

The middle bolts have the seat support bracket, an L-shaped piece, on

their upper ends, with the upstanding part of the bracket in front of the

bolt. A piece of fuel tube may be slit to fit over the support, and secured

with silicone sealant, to make a better rest for the seat base later.

The bolts should pass from bottom to top (contrary to the drawing, but

as per the photographs), to clear the undercarriage legs later.

Page 26

26

Nynja Build Manual 1.4d

11,,,SKR.254

Figure 17 lower cabin triangle, rear of tube tu12 (note, find SKR254 in assembly bag A9)

b) Assemble the pair of lower cabin triangle tubes tu12 to the main undercarriage

cross-beam tu9 using the fourth set of holes inwards from the ends of tu9.

The front ends of the lower cabin triangle tubes tu12 should have the

cut-outs on the inside, visible in Figure 19.

Bolt spacers are not needed in the steel undercarriage tube.

The bolts should pass upwards, to clear the undercarriage legs later.

Figure 18 starboard end of tu9, looking from front.

Page 27

27

Nynja Build Manual 1.4d

2.3.3 Fitting the front vertical to the lower cabin triangle.

Figure 19 forward ends of the lower cabin triangle viewed from below and above. Note non-

UKMOD nose leg lower guide.

a) Fix the lower guide SKR90 for the nose-leg to the lower part of the front

vertical tu14, between the two U-brackets SKR76.

Note these U-brackets are slightly different from those used elsewhere

in the kit, with the holes on the side parts further from the end (16mm

from the end to the hole centre).

The front vertical tu14 has a row of three 6mm holes at its upper end

(amongst others), and a row of three 8mm holes at the lower end.

UKMOD: a spacer tube is used on the U-bracket and nose leg guide

securing bolt as it passes through the front vertical tu14.

UKMOD: The guide SKR90 has additional webs welded onto it top and

bottom, Figure 20

Figure 20 UKMOD nose leg lower guide.

Page 28

28

Nynja Build Manual 1.4d

Figure 21 forward end of lower cabin triangle.

Note: Stud shown

may also be

supplied as a bolt,

and should be fitted

head up.

Page 29

29

Nynja Build Manual 1.4d

b) Apply threadlock to the bolt securing guide SKR90 to the front vertical tu14

and tighten firmly, but take care not to distort or crush the tube.

This should be done at this stage as the bolt holding this bracket is not

easily accessible later.

Whilst the spacer should prevent crushing of the tube, it is better not to

rely on it. It is permissible for the spacer to remain slightly loose, as

under load it will still prevent excessive deformation of the tube.

Do not distort the tube.

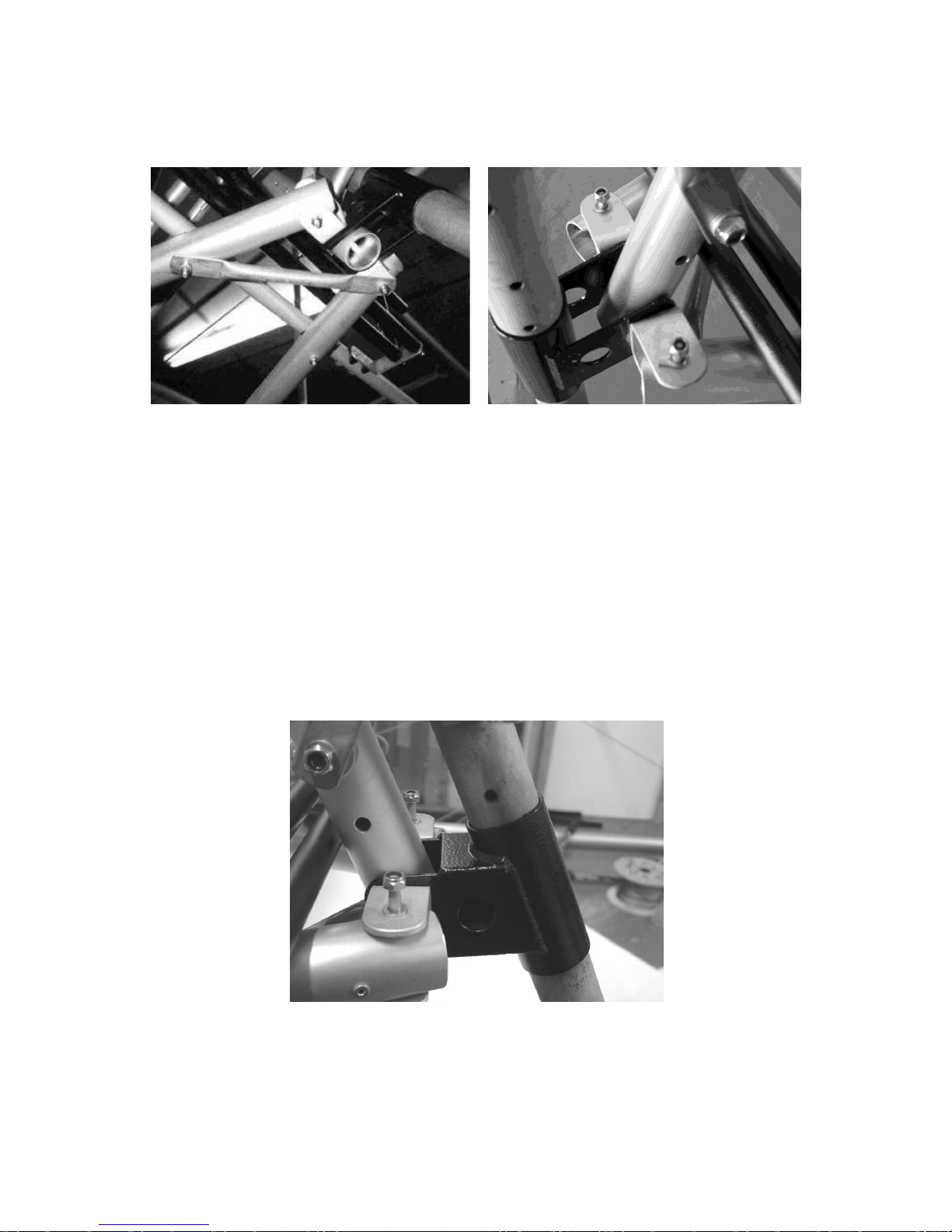

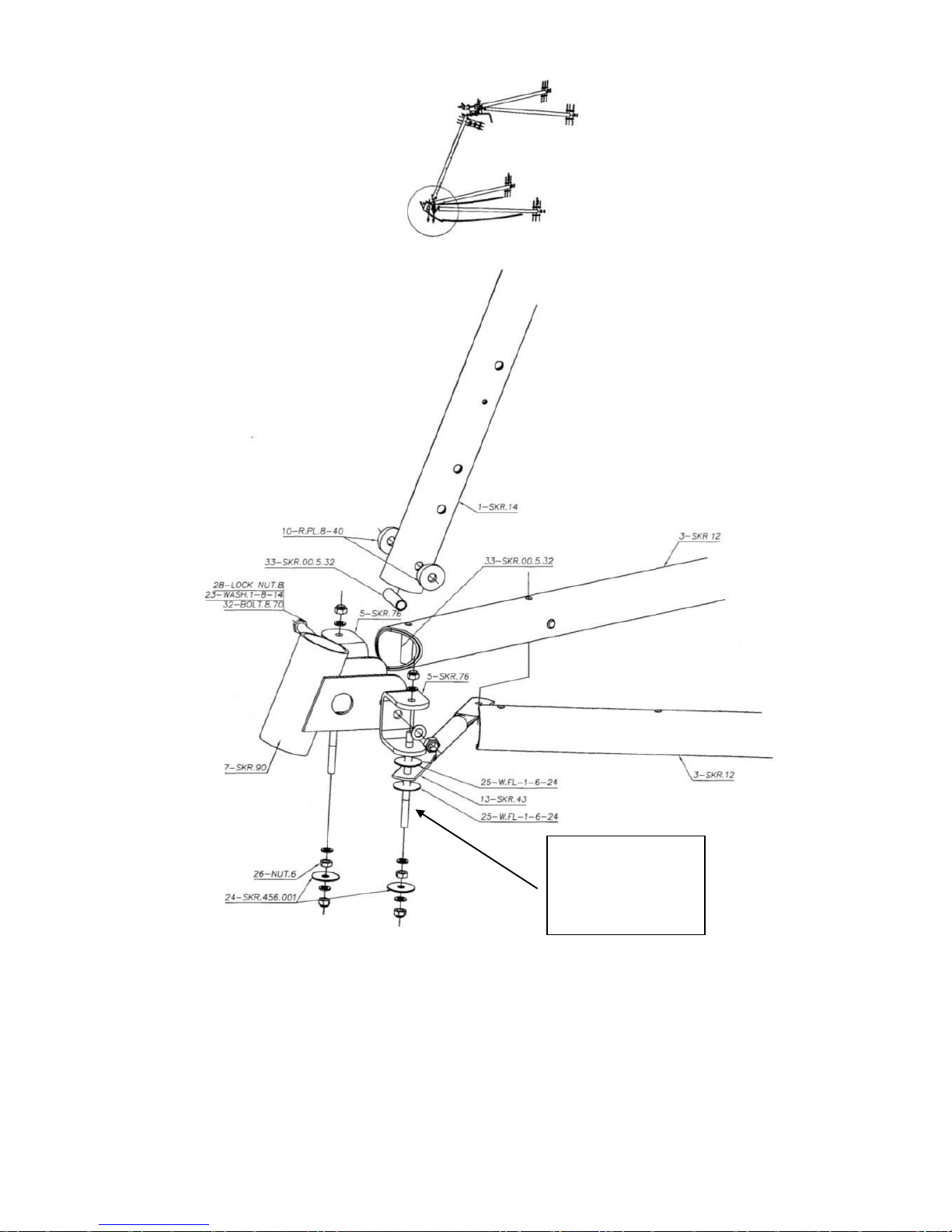

c) Mount the U-brackets SKR76 to the lower cabin triangle tubes SKR12

Note the use of a spacer sleeve in the tubes.

The studs should be long end downwards to mount the bottom of the

firewall and the front of the fuselage covering later.Discard the curved

metal washer if fitted – as this is a Skyranger part not used for the

Nynja.

If the bolt thread sticking out of the nut securing the U brackets to the

TU14 fouls the TU12 end file the end of the TU12 to provide clearance

d) Mount the steel diagonal-brace SKR43 to the bottom of the stud through the

port tube. Use thin plastic washers W.FL-1-6-24 and steel washers

SKR456.001

The other end of the brace will be attached to the rudder pedal mounts

later. The brace may be supplied attached to the mounts, have a look

under the packaging.

Thin plastic washers may be used to take up any slack between the

tubes and U-brackets.

Page 30

30

Nynja Build Manual 1.4d

2.4 Upper Cabin Triangle

2.4.1 Fitting the sides of the upper cabin triangle to the upper rear cabin

cross-piece.

Refer to Figure 23 and 24.

a) Fix the aluminium linking-plates SKR60 on the upper rear cabin cross-piece

tube tu7, which links the trailing-edges of the wing.

These linking plates are drilled at one end with an 8mm hole and at the

other with two 6mm holes.

The row of small holes should point forwards, whilst the bolts point

rearwards.

The bolts will be tilted down and backwards compared to the vertical

bolt holes for the cabin upper triangle and tail cone tubes, as the rear

cabin frame is raked backwards.

Figure 22 Port end of the upper rear cabin cross-piece.

Figure 23 upper rear cabin cross-piece.

Page 31

31

Nynja Build Manual 1.4d

b) Assemble the upper cabin triangle tubes tu10 with aluminium linking-plates to

the upper rear cabin cross-piece tu7.

The drawing shows the lower cabin triangle tubes tu12, however the

fittings are the same on the upper cabin triangle tubes tu10. Note that

the tubes themselves are not the same.

The cut-outs at the front of the upper cabin triangle tubes tu10 should

face outwards.

Figure 24 rear of upper cabin triangle tube tu10.

2.4.2 Assembling the top of the front vertical tube.

a) Fix the U-bracket SKR75 and the pair of U-brackets SKR78 for the leading-

edges on the front vertical tube SKR14.

b) Mount the aileron cable pulleys.

c) Assemble the two upper cabin triangle tubes SKR10, linking them to the

double U-bracket SKR75.

Page 32

32

Nynja Build Manual 1.4d

8,,,SKR.94.SB

24,,,WASHER.8

30,,,CASTLENUT.8

31,,,SAFETY PIN

8,,,SKR.94.SB

24,,,WASHER.8

30,,,CASTLENUT.8

31,,,SAFETY PIN

Figure 25 forward end of upper cabin triangle.

Figure 26 forward end of upper cabin triangle.

Page 33

33

Nynja Build Manual 1.4d

2.5 Rear Cabin Frame

2.5.1 Preparing the rear cabin uprights.

Figure 27 rear cabin uprights and correct handing for attachment of SKR2 fuselage longerons

a) Fix the steel U-brackets for the trailing-edges with the taper downwards, using

an aluminium saddle washer under each, against the rear cabin uprights

SKR6.

The rear cabin uprights SKR6 have inner sleeves at their upper end,

and are handed in that the holes that connect the upper rear fuselage

longerons TU2 should be angled for the tailcone taper.

The nuts may foul the upper rear cabin cross-piece SKR7, in this case

file away a little from the TU7 to provide clearance.

A spacer should be used on the bolt inside the tube.

Page 34

34

Nynja Build Manual 1.4d

b) Apply threadlock and tighten the bolts holding the trailing edge U-brackets, as

they are not easily accessible later, but not so tight as to prevent easy rotation

of the fittings by hand pressure.

2.5.2 Fitting the rear cabin uprights.

Refer to figure 27

a) Assemble the rear cabin uprights SKR6 to the main undercarriage cross-beam

SKR9, using the second set of holes from the end.

Remember the bolt spacers on the two bolts at the bottom of SKR6.

The bolts should all point rearwards through the main undercarriage

cross-beam SKR6.

b) Lift the upper triangle into position on the rear cabin uprights SKR6 and

temporarily secure with an 8mm diameter bolt.

c) Secure the bolts through the rear cabin uprights SKR6 and the upper cabin

triangle tubes SKR10 including the proper spacers etc..

This is easier now the upper cabin triangle is in place, although it is still

worth leaving all the accessible bolts loose until more of the fuselage is

assembled.

The 8mm bolts securing the rear cabin uprights SKR6 are fitted with

spacers and the nut must not be done up yet as there are more pieces

to fit to it.

2.6 Rear cabin frame bracing.

Figure 28 lower and upper ends of rear cabin frame diagonals.

a) Bolts and fittings for the SKR9 tube are packaged separately – in a bag

marked ‘9’, Find these now.

b) Assemble the steel end pieces into the rear cabin frame diagonals SKR27.

The one with the 8mm hole goes at the upper end and the one with the

6mm hole goes at the lower end.

Page 35

35

Nynja Build Manual 1.4d

c) Install the bolt and spacer to support the seat a short distance above the lower

ends of the rear cabin frame diagonals SKR27, Figure 29

These should be oriented with the supporting part towards the middle of

the aircraft. Note that the spacer tube is also shown on Figure 30 as

well as the small bracket piece. The Nynja should be supplied with

round peg support as per picture below.

Figure 29 seat support peg.

d) Stiffen the cabin back with the two rear cabin frame diagonals SKR27 .

These are positioned behind the rear cabin uprights SKR6, with the

seat supports pointing inwards and upwards, and their supporting part

towards the front.

Figure 30 rear cabin frame diagonal, port side viewed from rear.

Page 36

36

Nynja Build Manual 1.4d

Figure 31, tu40, rear cabin frame cross-piece, looking from the front.

e) Fit the upper ends to the end of the 8mm bolts at the top of the rear cabin

uprights SKR6.

The upper end of the round tube part of SKR27 will touch the rear cabin

uprights SKR6. If interference appears great, it is permissible to flatten

or file the upper ends of the SKR27 to ease this. A steel washer may be

placed under the steel end piece on the rear cabin frame diagonals

SKR27, to further help, but don’t be concerned at some interference.

Attach the lower ends to the rear of the main undercarriage cross-beam SKR9.

The final attachment be quite tight to get on and an additional person or

a ratchet strap may be necessary to provide tension to the frame to

help.

Assemble the rear cabin frame cross-tube SKR40 and attach to the rear of the rear

cabin uprights SKR6, but in front of the rear cabin frame diagonals SKR27.

The bolts should point rearwards, and pass through the upper ends of

the stainless braces SKR144 before the rear cabin uprights SKR6 and

finally the attachment plate on the rear cabin frame cross-tube SKR40.

Include a thin plastic washer between the brace and the aluminium rear

cabin uprights.

2.6.1 Fuel tank upper mounting pieces.

Refer to Figure 32

Page 37

37

Nynja Build Manual 1.4d

a) Where the rear cabin frame cross-tube SKR40 crosses the rear cabin frame

diagonals SKR27 they should be connected with a bolt, pointing backwards.

UK MOD – the holes will need drilling out to 6mm. Suitable 6mm bolts

are included with the wooden spreader bar pieces.

b) Paint the wooden tank spreader pieces with fuel-proof paint.

Fuel proof paint is available from model aircraft shops, an enjoyable but

potentially expensive visit!

c) Assemble the wooden fuel tank load spreading pieces on the rear end of

these bolts and tighten, but do not crush the wood excessively.

Ensure that the end of the bolt is below the level of the rear surface of

the wooden pieces. Long side faces outwards

Figure 32 fuel tank wooden tank spreader pieces.

2.7 Engine Supports

2.7.1 Rotax 912.

Figure 33 Rotax 912 engine mounts

Page 38

38

Nynja Build Manual 1.4d

Figure34 Rotax 912 mounting bracket – note position of TU310 is reversed for Nynja – as

shown correctly below

Fig 35 Nynja engine mount assembly

Remove

this washer

Page 39

39

Nynja Build Manual 1.4d

Fig 36 Nynja firewall support brackets, should be fitted on the engine mount bolts at the front

of the SKR19’s at this stage as shown (normally found packaged with firewall)

Fig37 liaison of TU19’s, TU14 and SKR8

a) Locate the two central cabin tubes SKR19 onto the front vertical SKR14

including the steel engine mounting bracket 98 between them. Loosely bolt in

place using the washers and saddle washers.

Aluminium washers – Note

that TU14 is a different

diameter – make sure the

correct saddle washers are

used!

7mm and 1mm plastic

washers

Page 40

40

Nynja Build Manual 1.4d

Fig 38 Rear of SKR19 – ends must be bent to align like his

b) It is worth trial fitting the central cabin tubes to the underside of the main

undercarriage cross-beam to allow the stainless steel brackets to be bent in a

vice to align properly, Fig 38

Before fitting the SKR98 steel engine mount it saves time later if you

drill a 6mm hole near the front to fit an earth connection, picture in

wiring section of manual Figure 236

The two plastic rings which form the aileron stops may be slid over the

tubes at this stage (see the section on the ailerons in the Wing

chapter), although they may require removal later by cutting them off if

adjustment of the aileron movement is required.

c) Attach the two central cabin tubes SKR19 onto the main undercarriage cross-

beam SKR9.

Remove the pulley set from the assembly and put to one side for now.

This makes fitting the TU19’s to the undercarriage cross beam much

easier. But leave the long bolt (stud) in position through the two tubes, which will help ensure alignment and prevent possible difficulty fitting

later.

Note the bolts through SKR9 should point upwards, and should pass

through the stainless-steel under-seat diagonal tubes SKR42 before

passing through the central cabin tubes SKR19 and the main

undercarriage cross-beam SKR9.

The steel end pieces on the central cabin tubes SKR19 may require

bending slightly to allow them to sit flat against the underside of the

main undercarriage cross-beam SKR9.

d) Loosely fix the two stainless-steel upper triangulation tubes SKR24 to the top

of the front vertical SKR14, including saddle washers.

Page 41

41

Nynja Build Manual 1.4d

e) Loosely attach the upper and lower stainless-steel triangulation tubesSKR23

to the central cabin tubes and the engine mounting brackets, including the

alloy side pieces 298, Figure 35 and Figure 39.

It will be necessary to tweak the ends of the steel triangulation tubes to

position them flat against the engine mount and the front vertical tube

SKR14.

UKMOD: the front pair of mounting bolts should have a spacer tube

fitted as they pass through the two central cabin tubes SKR19. This

allows them to be done up reasonably tight, without ovaling the tubes.

This should result in thread protruding from the Nylocs.

If no thread is showing, the washers shown under the nuts may be

omitted (washers under bolt heads should have been removed earlier)

Check the alignment of the stainless-steel parts, and tweak as

necessary to get them to all lie flat against each other. This will reduce

the space they occupy along the bolts.

Note the presence of the steel diagonal brace SKR310 on the

starboard side, and a corresponding additional thick plastic washer on

the port side to assure symmetry between sides.

Note that the 298 plates are handed and the starboard one has a

recess machined in, as shown below.

Fig 39 handing the 298 plates

Note recessed section

on starboard 298 plate

only

Page 42

42

Nynja Build Manual 1.4d

Fig 40 Forward end of SKR19 and Liaison of engine mount plates 298BK, SKR310, upper

triangulation tubes SKR24’s and lower triangulation tubes SKR23. Note arrangement of plastic

washers – only fit them where shown.

Figure 41 upper engine mount triangulation tubes.

1mm plastic washer

TU24

TU23

TU310

3mm plastic washer

Page 43

43

Nynja Build Manual 1.4d

Figure 42 lower engine mount triangulation tubes.

f) Leave the bolt holding SKR310 slack enough to rotate it out of the way when

fitting the engine.

Figure 43 lower triangulation tubes TU23 and lower engine mounts

g) Loosely fix the two stainless-steel lower triangulation tubes SKR23 to the front

vertical tube SKR14, including saddle washers, Figure 42 and 43.

Page 44

44

Nynja Build Manual 1.4d

It may be necessary to apply some weight to the engine mount to fit the

bolt holding the lower triangulation tubes SKR23 to the front vertical

tube, or to use a twisted rope as shown in figure 44.

Figure 44 twisted rope used to pull down on engine mount.

h) The bolts around the engine mount may now be tightened, starting with those

on the mount itself before tightening the bolts holding the top and bottom ends

of the triangulation tubes.

Leave the bolt holding SKR310 loose enough to turn it.

i) Check engine mount plates spacing:

the distance between the plates should be 175-180mm, measured at

the front set of holes where the rubber engine mounts fit. It may be

necessary to adjust the spacer size under the rear bolts that hold the

plates in position adding or subtracting 1or3mm plastic washers, to get

this measurement.

Figure 45 Rotax 912 engine mounts, front view.

175-180mm

Page 45

45

Nynja Build Manual 1.4d

j) With this measurement verified, the diagonal brace SKR310 can be bent to fit

in position and sit flat against the port engine plate. The plate can then be

drilled and the SKR310 fixed into position with a 6mm bolt.

The SKR310 upper edge should be approximately 0-5mm from the upper

edge of the engine mounting plate.

Check that the distance between the plates has not changed during this

process.

Figure 46 fixing position for TU310

k) The lower engine mounts, Figure 43 and 47, should be attached to the front

vertical SKR14.

Figure 47 Rotax 912 lower engine mounts.

0-5mm

Page 46

46

Nynja Build Manual 1.4d

2.8 Floor

a) The floor is supplied pre made out of composite. The grey side is the upper

side. It may be surfaced with vinyl or carpet, or left as is.

Cut a hole in the floor for the battery box:

The hole is located on the centreline, approximately 1cm back from the

rudder pedal mounting bar SKR18. The hole is 15cm long by 9cm wide.

Figure 48 battery location.

Figure 49 view of installed floor.

Page 47

47

Nynja Build Manual 1.4d

b) Slide the floor in before fitting the SKR15 but first:

Apply some of the supplied thin 2x10mm self-adhesive foam in strips along

the tops of the tubes which the floor rests on, to prevent it rattling.

c) Fit the seat front support tube SKR15, above the lower cabin triangle tubes

SKR12 with a pair of saddle washers per bolt between the two tubes.

Note the tapered ends of the tube taper towards the front.

Figure 50 TU15 assembly

d) The forward ends of the steel under-seat diagonal tubes SKR42, which were

attached to the main undercarriage cross-beam, should be attached to the

bottom of the bolts securing the seat front support tube SKR15 to the lower

cabin triangle tubes SKR12 with a thin plastic washer or saddle washer

between the steel tube and the aluminium tube.

Figure 51 SKR15 seat front support tube.

Page 48

48

Nynja Build Manual 1.4d

e) The floor should be slid back against the front of the seat front support tube

SKR15.

It should butt up against the underside curve of the tube, but not

actually pass beneath it, thus preventing the floor from lifting upwards

along its rear edge in negative-g situations.

Mark through from the bottom the positions of the holes for the rudder

pedal mounting bar, and drill the floor to suit.

The floor passes beneath the rudder pedal mounting bar.

f) To further stiffen the floor in the middle of the cockpit, fit the small piece of L-

section aluminium to support the floor, see Figure 56.

This is attached by the bolts which hold the central bracing pieces,

which are fitted later.

g) Install the battery box, and secure it with four bolts with penny washers.

h) Fit the webbing strap, passing right around the box through the slots in the

side of the box, with the buckle at the top.

Leave fitting the battery until later.

2.9 Rudder Pedals

Refer to figure 52.

a) Fit the rudder pedals orientated as shown on the drawing, before attaching the

second of the two L-brackets if they are not already in place.

b) Fit the rudder pedal mounting bar SKR18 to the top of the lower cabin triangle

tubes SKR12, over the top of the floor.

c) Make sure that there are saddle washers between the pedal bar and the floor

but NOT between the floor and the lower cabin tubes – this may mean

removing a set from the assembly

Figure 52 rudder pedals.

Page 49

49

Nynja Build Manual 1.4d

d) Attach the rear end of the steel diagonal-brace SKR43 to the bottom of one of

the bolts, including a plastic washer between the steel brace and the

aluminium tube.

e) If no floor is fitted, put pieces of prop-tape on the lower cabin triangle tubes

SKR12 beneath the rudder pedals to protect the tubes from abrasion from the

pedals when under load.

f) Cut off any protruding ends of the rudder pedal mounting bar bolts beneath

the aircraft, to prevent them rubbing on the coverings. Nut caps may also be

fitted.

2.10 Control Stick Assembly

Figure 53 control stick and torque-tube parts

Page 50

50

Nynja Build Manual 1.4d

a) If not already done, attach the aileron horn to the machined ‘top hat’ with 4mm

bolts.

Rivets must not be used here, as the fitting carries all the tension loads

from the elevator controls. Use the bolts supplied, do not use any

unknown strength bolts. Attach the top hat to the front vertical SKR14

by the pivot bolt through the aileron horn, inserted from the rear.

The pivot bolt must be assembled in the following order:

Bolt head

Large metal washer

Plastic washer

Aileron horn

Rubber grommet

Plastic saddle washer

Front vertical SKR14

Plastic saddle washer

Large metal washer

Small metal washer if necessary for spacing)

Castle nut and split pin

b) When all is in final position, this should be done up tight enough to remove

excess play but without discernible friction.

c) Fit the stick to the stick pivot fork with thin nylon washers either side of the

stick in the stick pivot fork.

d) The pivot bolt should be done up just tight enough to remove any play but

allow movement of the stick without discernible friction.

e) Rubber rings are is supplied to act as elevator stops. They should be

positioned on the stick so as to engage on the edge of the fork jaws,

They may be secured by glue and/or cable ties above and below them.

f) Fit the plastic torque-tube bearing into the rear pivot support.

The bearing is inserted from the front. Then if the forward pivot bolt were to

fail, the stick would still be held in place by this bearing.

Figure 54 torque-tube bearing.

Page 51

51

Nynja Build Manual 1.4d

g) The stick pivot fork end should be fitted through the plastic torque-tube

bearing and into the torque-tube.

Note that the plastic bearing fits over the fork end and is trapped in

position by the torque-tube. This should be an easy fit with 0.5mm free

play along the axis of the torque-tube. If this is tight it may be necessary

to file the end of the torque-tube a little to prevent binding.

If the bearing is tight on the stick pivot piece when positioned correctly,

the bearing should be abraded lightly until a smooth action is achieved.

h) The torque-tube can now be fitted onto the front pivot (attached to the aileron

horn), and the rear pivot can be bolted to the central cabin tubes SKR19.

Note that the rudder stop cables will be fitted between the rear pivot

support and the central cabin tubes, do not tighten these bolts up

without the stops in place.

It may be necessary to slot the holes horizontally in the rear pivot where

it attaches to the central cabin tubes SKR19 to allow it to take up the

exact alignment of the torque-tube, but note the rudder stop cables will

have some effect on this alignment.

i) Insert and secure the bolts holding the fittings into the ends of the torque-tube.

Page 52

52

Nynja Build Manual 1.4d

2.11 Finishing the Forward Fuselage

2.11.1 Tightening bolts

At this stage it is permissible to tighten most of the bolts, as the cabin frame now

forms a well braced structure. The exceptions are the bolts securing the lower ends

of the rear verticals to the main undercarriage cross-beam, as these will be undone

when fitting the undercarriage.

Check the basic alignment of the structure as you tighten the bolts, trying not to work

in such a fashion as to introduce any unnecessary distortions into the structure (e.g.

don’t do all the bolts up along one side and then along the other).

Some slight misalignment is inevitable in a pre-drilled structure of this type, and

unless this is severe it is probably best to live with it rather than to open out too many

bolt holes. A slightly asymmetrical but well defined shape is preferable to a perfectly

aligned shape with sloppy bolts.

Remember to apply threadlock, and do not over tighten the bolts. The tubes should

not be visibly distorted. Remember the bolts are not relying on their tightness to stay

done-up, they only need to be tight enough to avoid the parts rattling against each

other. The Nyloc and the Loctite are responsible for keeping the bolts done-up.

2.11.2 Central brace

a) Fit the aluminium angles 2 and 3 linking the central cabin tubes SKR19 to the

seat front support tube SKR15.

These are not pre-drilled, as the exact hole positions are affected by

the general alignment of the rest of the fuselage.

b) Bolt the angles to the seat front support tube SKR15 first, then drill them to

match the holes in the central cabin tubes SKR19.

To aid clearance for the rudder and elevator cables, it is recommended

that (if supplied) both the lower saddle washers on the seat front

support tube SKR15 are omitted. This leaves only the side ones

against the central cabin tubes SKR19.

An additional thin plastic washer may be fitted between the central

brace and the starboard central cabin tube to increase clearance for the

rudder cable.

The bolts should pass from the middle towards the outside, to clear the

elevator cables.

Page 53

53

Nynja Build Manual 1.4d

Figure 55 central bracing pieces. Note the bolts should be the other way around (as shown in

photo fig 56).

Figure 56 central bracing pieces.

Page 54

54

Nynja Build Manual 1.4d

3 Rear Fuselage

The rear fuselage is composed of four longitudinal tubes, connected by the vertical

fin at the tail end and braced by a single frame half way down. Steel cables are used

diagonally to stiffen the structure, with tension applied by turnbuckles fitted to two of

the cables.

Once again, do not tighten the nuts until the assembly has been completed.

3.1 Tail End

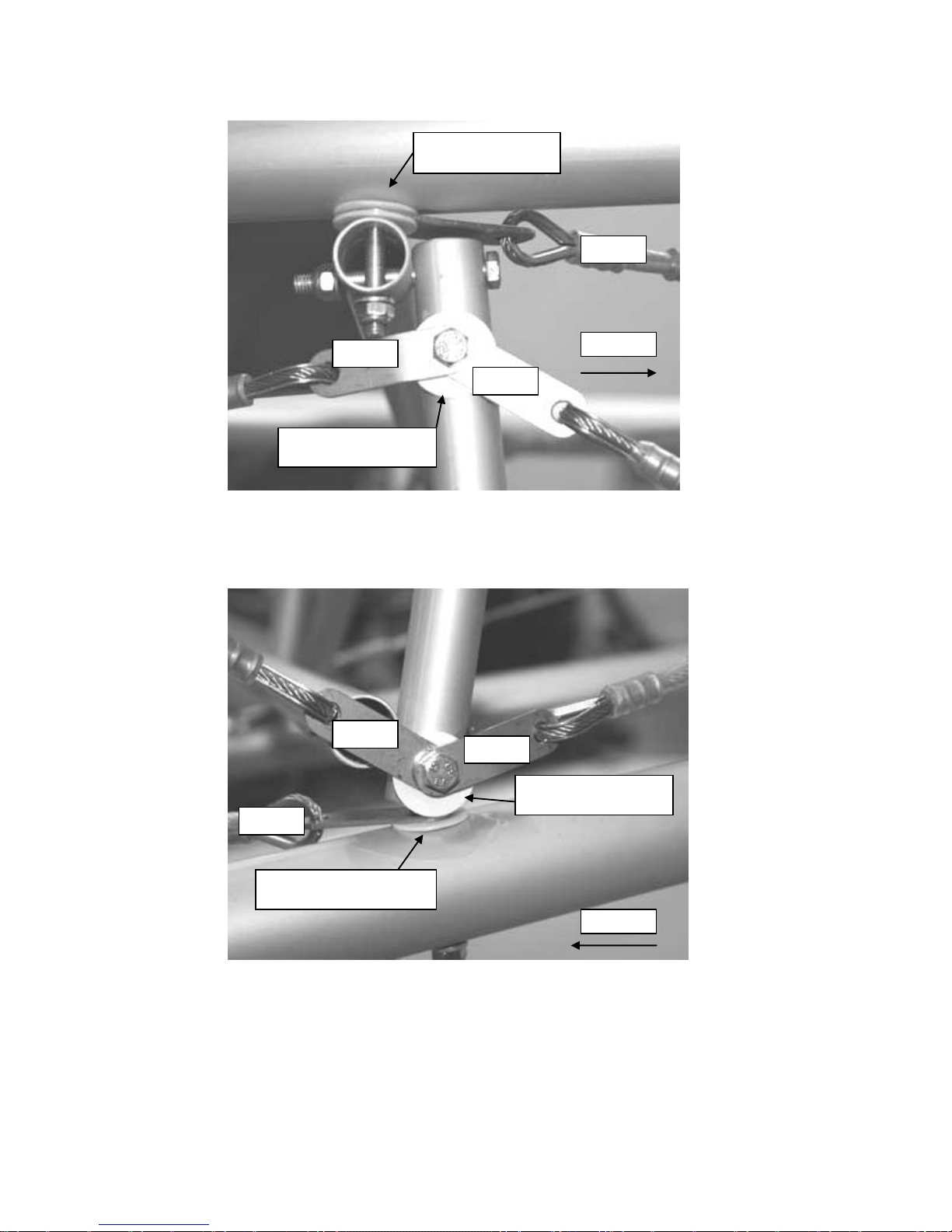

a) Fit the rudder post (the trailing edge of the vertical fin) between the two pairs

of saddle washers shown in Figure 57,58, 59.

Do not forget the steel T-piece to which the horizontal stabiliser halves

attach, and the extra flat washer on the lower bolt,

Some difficulty may be encountered with access to the various nuts in

this area. A useful trick to hold a nut to the end of a spanner is a piece

of sticky tape placed over the end of the spanner.

Tighten these particular nuts now using Loctite, as they are very difficult

to reach later.

b) Fit the stainless-steel bracket in front of the rudder post, and attach the upper

pair of longitudinal tubes SKR2.

Figure 57 vertical fin and horizontal stabiliser rear mountings.

c) Attach the bottom end of the vertical fin to the bracket and longitudinal tubes

SKR4 in a similar manner Figure 58.

If you do not have suitable supports or a helper to hold the front ends of

the tubes at this stage it can be helpful to mount the bracing frame (as

detailed below) to the lower pair of longitudinal tubes, followed by

Page 55

55

Nynja Build Manual 1.4d

resting the upper pair of tubes on it whilst they are attached to the

bracing frame and the rudder post is attached to the lower pair of tubes.

Figure 58 rear end of upper rear fuselage tubes.

Figure 59 rear end of lower rear fuselage tubes.

Page 56

56

Nynja Build Manual 1.4d

3.2 Bracing Frame

a) Fit the rear fuselage bracing frame SKR39 to the upper and lower rear

fuselage tubes using the holes approximately mid-way down the tubes.

b) Check the orientation of this frame against the drawing below, as examples

have been delivered assembled the wrong way around.

Figure 60 rear fuselage bracing frame. Note orientation arrow.

b) Attach the Upper and lower bracing cables A and B to the central frame at this

point. – see section 3.4 for details

Page 57

57

Nynja Build Manual 1.4d

3.3 Front End

a) Prepare the front ends of the lower tubes.

b) Prepare the front ends of the upper tubes.

Figure 61 forward end of lower rear fuselage tubes Note upper tubes have brackets orientated

at 90 degrees from that shown and cables are arranged differently on Nynja. See Figure(s) 62