SKYLUX Skycom Skymax CE 24V/5A, Skycom CE MASTER, Skycom CE SLAVE User Manual And Installation Instructions

Page 1

Release: 10-2016

SMOKE AND HEAT EXTRACTION CONTROL

EN

Skycom Skymax CE

24V/5A

User manual and installation instructions

ENGLISH

Page 2

E_MH_Installation_instruction_Skycom_Skymax_CE 01/10/2016

2/26

YOUR SHE-SYSTEM DESCRIPTION

Address of installation

Name: ...............................................................................................................................................................................

Address: ........................................................................................................................................................................

Phone no.: ........................................................................................................................................................................

Contact person: .................................................................................................................................................................

Date of installation: ............................................................................................................................................................

System Description

Number of SHE control: Number of opening system(s):

Master(s) (24V/8A): .................................. Skylux 160° CE: ..................................

Slave(s) (24V/8A): .................................. Skymax CE: ..................................

Skymax (24V/5A): .................................. Skymax Standard: ..................................

Cintramax CE: ..................................

Skyvent CE: ..................................

other systems: ..................................

External controls (AFA: Automatic Fire Alarm - CCS: Climate Control System): ..................

230V power supply from circuit N°: ..................

Your SHE-System description............................................................................................................................. p. 2

Table of contents.................................................................................................................................................. p. 2

Introduction........................................................................................................................................................... p. 3

SHE survey AG.Plastics ...................................................................................................................................... p. 4

Safety & warnings................................................................................................................................................ p. 5

General description.............................................................................................................................................. p. 6

Installation.......................................................................................................................................................... p. 6

Connection, operation and settings................................................................................................................ p. 8

Motor (actuator)....................................................................................................................................... p. 8

Fire switches............................................................................................................................................ p. 10

External priority switch............................................................................................................................. p. 11

Smoke-/heat detectors............................................................................................................................. p. 12

Comfort ventilation + setting roof access................................................................................................ p. 12

Weather sensor / Close all functions....................................................................................................... p. 13

External signal output, re alarm panel and other systems..................................................................... p. 13

More control units linked to one re group (bus connection)................................................................... p. 14

Special functions...................................................................................................................................... p. 15

Electrical schemes............................................................................................................................................. p. 16 - 18

Main scheme (control PCB with factory settings)................................................................................... p. 16 - 17

Skymax CE (with positive safety)............................................................................................................ p. 18

Settings (jumpers, dip switch, ... ) ...................................................................................................................... p. 19

Frontpanel............................................................................................................................................................ p. 20

LED indication (external & internal)................................................................................................................... p. 21

Cables................................................................................................................................................................. p. 22

Maintenance........................................................................................................................................................ p. 23

Spare parts and accessories............................................................................................................................... p. 24

CE Declaration of conformity............................................................................................................................... p. 25

Technical specications.................................................................................................................................... p. 26

Revisions.............................................................................................................................................................. p. 26

TABLE OF CONTENTS

Page 3

01/10/2016

3/26

E_MH_Installation_instruction_Skycom_Skymax_CE

INTRODUCTION

Why do you need to foresee Smoke and Heat Extraction (SHE)?

In case of re, it is not the re itself, but the smoke gasses that make most victims. The heat and smoke gasses ll the

building, which complicates evacuation. Skylux developed different natural SHE systems which create smoke free zones

and bring down temperature during re, which enables a quick and safe evacuation.

SHE systems are legally required in specic buildings. In such buildings, only CE certied systems, in accordance with

European (and Belgian) norms, are allowed to be used.

At the same time, our SHE systems provide free natural daylight and daily ventilation.

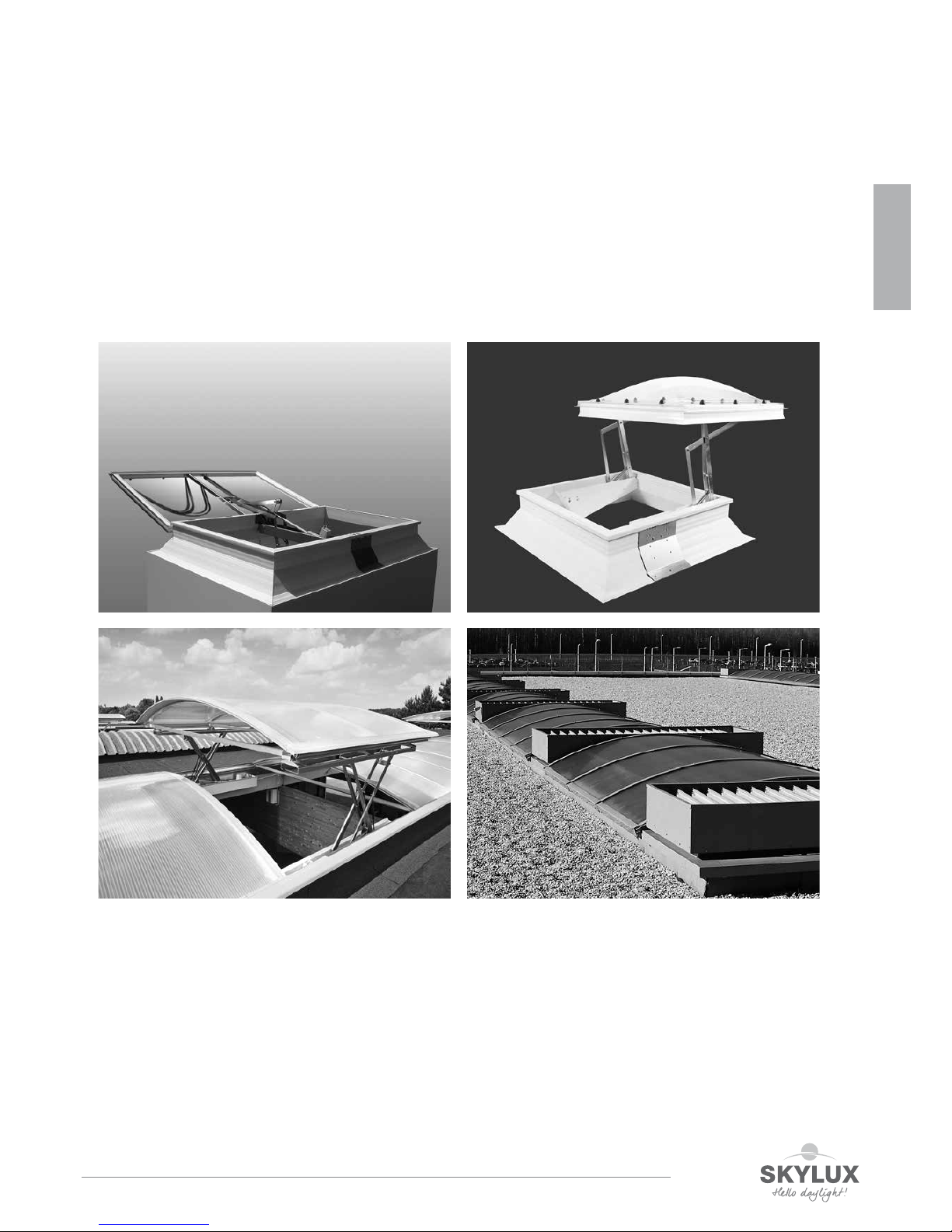

Skylux‘ SHE systems:

Each of these SHE systems can be operated by a Skycom® CE Master control, possibly in combination with a Skycom®

CE Slave control.

We developed also a control unit fort he Skymax® CE : the Skycom® Skymax® CE control.

The SHE survey (p. 4) mentions the combinations of control units and smoke hatches allowed and supported by Skylux.

Skyvent® CE

Skylux® 160° CE Skymax® CE

Cintramax® CE

ENGLISH

Page 4

E_MH_Installation_instruction_Skycom_Skymax_CE 01/10/2016

4/26

SHE TABLE

1. The SHE-control must be installed or serviced by a qualied person, authorised for working at electrical Smoke and Heat

Extraction systems. The control and accessories must be installed according to the local norms.

2. Service!

Before installation or service disconnect electrical power and remove the indicated terminal of the battery. Afterwards

reconnect the terminal, mount the housing before switching on electrical power. Now you can test the complete installation.

3. Service of opening system:

Before servicing the opening system, make sure the opening system can not start to move unexpectedly. Therefore

remove the 8 A glass-fuse before starting service at the opening system. This disables the main supply and the battery

supply of the opening system.

4. Batteries:

- To avoid explosion danger follow these safety rules:

• Never short circuit a battery.

• Do not use external chargers. Explosive gasses can be released.

• Always handle batteries with care as they contain strong acids.

- Avoid to store controls with batteries for a long time. Batteries which are not used must be recharged (unload & load)

every 3 months to slow down the capacity loss.

- Don’t discharge batteries to deep as they might be damaged.

- There is no guarantee on batteries.

5. Guarantee expires:

• If controls or cables (especially motor cable) are wrongly dimensioned;

• If non-original parts are used. Use only original parts delivered by AG.Plastics. Especially take care to use a

control which is suitable for the SHE opening system;

• If opening systems are not connected according the installation instructions. Most opening systems must be

connected through a limit switch. Please consult thoroughly the electric scheme of the appropriate SHE system

before connection.

6. Next to the installation of a SHE system, make sure you take all necessary steps to be able to proceed to a smooth

evacuation. Foresee several escape routes, make sure the remen can reach easily the re place. See to the possibility

of a quick signal to the re department in case of re by a full re detection system,… Consult your architect, constructor

and re-department.

7. The SHE-system needs mains voltage. In case of power failure, the system will continue to operate on its batteries in a

limited period of time (min 72 h).

8. Mains power failure g putting out of service:

If the mains voltage is switched off for a longer period of time (> 1 day), disconnect the indicated pin of the battery and

insulate the wire end. Otherwise, you will risk that the batteries discharge and will be damaged.

9. There is a possibility that the smoke does not reach the detector due to chimney effects through walls, shafts, roofs. Also

behind a closed door or at another oorlevel may the smoke not be detected. A detector may be less sensitive to certain

types of re so that the signal is given in a later phase. Make sure to install sufficient detectors at right places.

10. It may occur that the opening system is not correctly operated due to a panic situation in case of re.

11. The SHE-control does not protect people or objects from being stuck when the actuators are activated. This must be

done externally.

12. The manufacturer is not responsible for the loss of a life or materials caused by re, smoke, wind, rain, … even when

the rain- and wind detector is connected. Make sure no damage (wind, rain, …) can be caused during uncontrolled open-

ing of the system.

13. The SHE-control and accessories must not be used as connector box for cables ! Use an external connector box.

14. The wiring for the accessories (re push buttons, detectors, prior key contact, ...) must be at least 1 m off other current

wires (not in the same wire drain) to prevent from interference.

15. We reserve the right to modify this manual or the products without prior notice. You can always check the newest ver-

sion on www.agplastics.com.

16. The responsible person must keep this manual, if possible near the control unit.

17. In particular cases due to fall-through safety, it’s forbidden to open the smoke hatches more than 30 cm for ventilation.

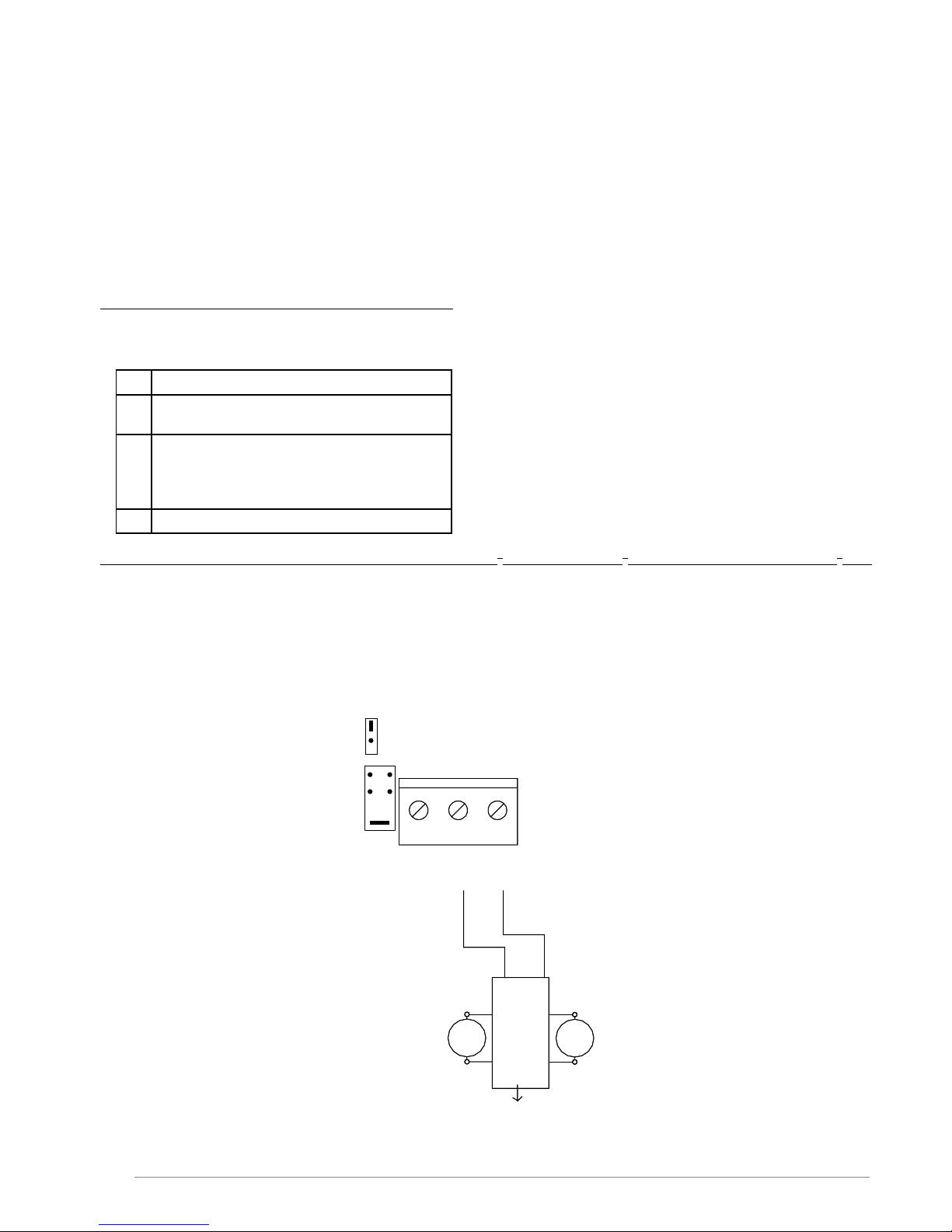

SKYCOM

SKYMAX®*

Art.nr. 34072

PRIOR SWITCH

Art.nr. 32569

with Skymax CE

with positive safety (opens automatically)

SKYCOM

MASTER

Art.nr. 30975

with Skymax CE

without positive safety

(does NOT open automatically)

Cable sections in function of the distance

SKYCOM

MASTER

Art.nr. 30975

SKYCOM

SLAVE*

Art.nr. 30977

with Skylux 160° CE

SKYCOM

SLAVE*

Art.nr. 30977

with Cintramax CE

SKYCOM

MASTER

Art.nr. 30975

* Important: with positive safety: always install a Skycom control unit (Slave or Skymax) at the

ceiling, as near as possible to the opening system (max 5m).

Other combinations are usually NOT COMPLIANT!

Page 5

01/10/2016

5/26

E_MH_Installation_instruction_Skycom_Skymax_CE

SAFETY & WARNINGS

1. The SHE-control must be installed or serviced by a qualied person, authorised for working at electrical Smoke and Heat

Extraction systems. The control and accessories must be installed according to the local norms.

2. Service!

Before installation or service disconnect electrical power and remove the indicated terminal of the battery. Afterwards

reconnect the terminal, mount the housing before switching on electrical power. Now you can test the complete installation.

3. Service of opening system:

Before servicing the opening system, make sure the opening system can not start to move unexpectedly. Therefore

remove the 8 A glass-fuse before starting service at the opening system. This disables the main supply and the battery

supply of the opening system.

4. Batteries:

- To avoid explosion danger follow these safety rules:

• Never short circuit a battery.

• Do not use external chargers. Explosive gasses can be released.

• Always handle batteries with care as they contain strong acids.

- Avoid to store controls with batteries for a long time. Batteries which are not used must be recharged (unload & load)

every 3 months to slow down the capacity loss.

- Don’t discharge batteries to deep as they might be damaged.

- There is no guarantee on batteries.

5. Guarantee expires:

• If controls or cables (especially motor cable) are wrongly dimensioned;

• If non-original parts are used. Use only original parts delivered by AG.Plastics. Especially take care to use a

control which is suitable for the SHE opening system;

• If opening systems are not connected according the installation instructions. Most opening systems must be

connected through a limit switch. Please consult thoroughly the electric scheme of the appropriate SHE system

before connection.

6. Next to the installation of a SHE system, make sure you take all necessary steps to be able to proceed to a smooth

evacuation. Foresee several escape routes, make sure the remen can reach easily the re place. See to the possibility

of a quick signal to the re department in case of re by a full re detection system,… Consult your architect, constructor

and re-department.

7. The SHE-system needs mains voltage. In case of power failure, the system will continue to operate on its batteries in a

limited period of time (min 72 h).

8. Mains power failure g putting out of service:

If the mains voltage is switched off for a longer period of time (> 1 day), disconnect the indicated pin of the battery and

insulate the wire end. Otherwise, you will risk that the batteries discharge and will be damaged.

9. There is a possibility that the smoke does not reach the detector due to chimney effects through walls, shafts, roofs. Also

behind a closed door or at another oorlevel may the smoke not be detected. A detector may be less sensitive to certain

types of re so that the signal is given in a later phase. Make sure to install sufficient detectors at right places.

10. It may occur that the opening system is not correctly operated due to a panic situation in case of re.

11. The SHE-control does not protect people or objects from being stuck when the actuators are activated. This must be

done externally.

12. The manufacturer is not responsible for the loss of a life or materials caused by re, smoke, wind, rain, … even when

the rain- and wind detector is connected. Make sure no damage (wind, rain, …) can be caused during uncontrolled opening of the system.

13. The SHE-control and accessories must not be used as connector box for cables ! Use an external connector box.

14. The wiring for the accessories (re push buttons, detectors, prior key contact, ...) must be at least 1 m off other current

wires (not in the same wire drain) to prevent from interference.

15. We reserve the right to modify this manual or the products without prior notice. You can always check the newest version on www.agplastics.com.

16. The responsible person must keep this manual, if possible near the control unit.

17. In particular cases due to fall-through safety, it’s forbidden to open the smoke hatches more than 30 cm for ventilation.

ENGLISH

Page 6

E_MH_Installation_instruction_Skycom_Skymax_CE 01/10/2016

6/26

The Skycom CE controls are intended for opening of skylights, smoke hatches, ... for Smoke and Heat Extraction (SHE)

and comfort ventilation of 1 re zone.

The Skycom Skymax CE control is typically used to command 1 Skymax smoke hatch in a staircase.

The Skycom Skymax control has the following operation possibilities (upon accessories):

Operation for Smoke and Heat Extraction (control in Alarm-status):

1. Automatically activated: by smoke or heat detectors. Each control has also an internal T-sensor which generates

alarm at 75°C.

2. Activated by passer-by: on ‘break-glass’ re-switches

3. Operation by remen: possibility for priority open and close on the priority switch for remen

Operation for comfort ventilation:

Activated by opening-closing switches (push buttons) or by weekly timer, room thermostat,

outdoor weather sensor.

The operation status (OK / alarm / fault / smoke hatch open) is indicated by Led’s and is also available on outputs for connection with other systems (AFA-systems, Air-gates, buzzer, ...) in the building.

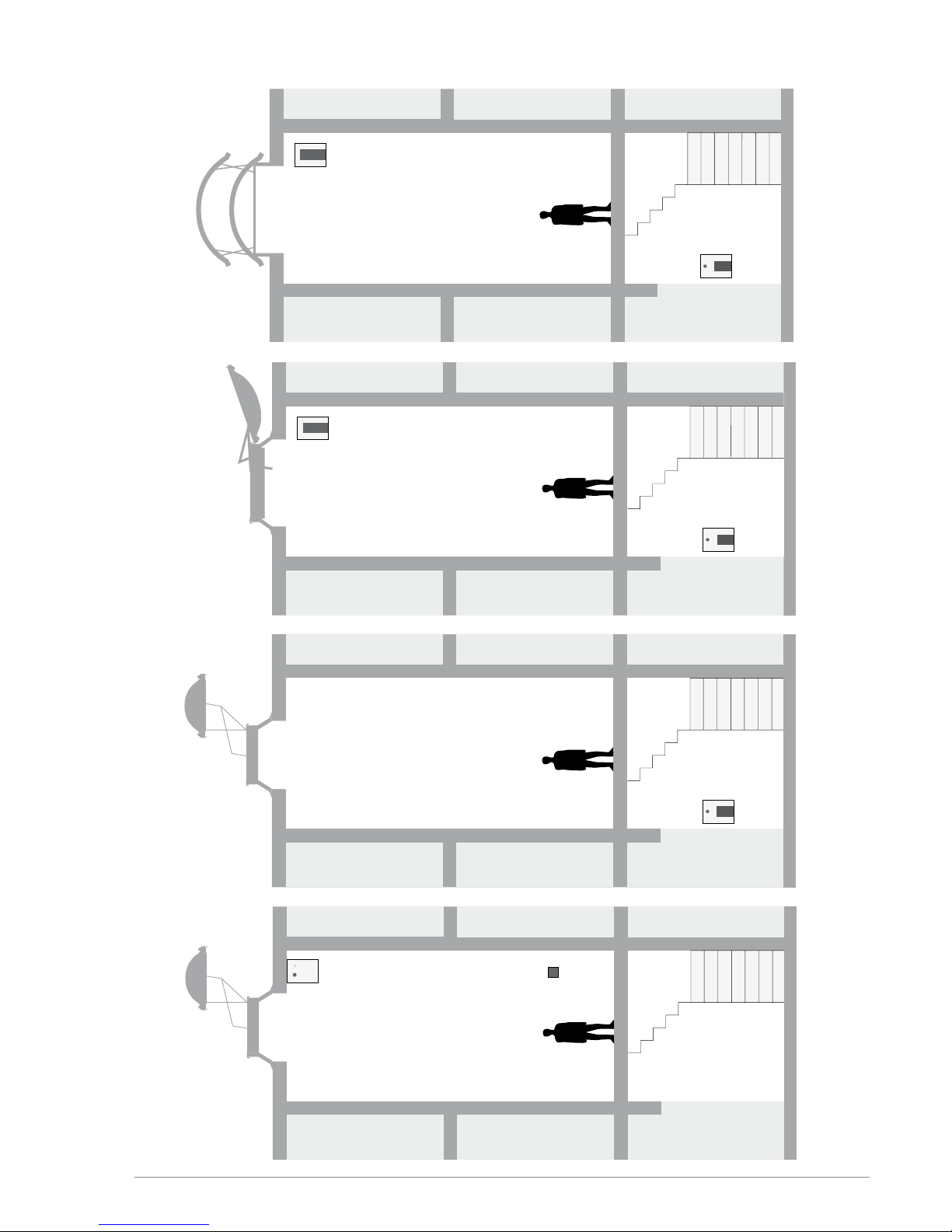

We advise to consult your re department to choose the best installation place fort all SHE accessories. You’ll nd an

example on page 7. Generally, install the control panel for the remen (prior switch) at a visible place and easy to be

reached, on the access road of the remen with the bottom at 1,35 - 1,45 m above the oor in the entrance hall of the

(main) building.

The Skycom Skymax CE Slave control must be installed as close as possible (max. 5 m) to the opening system, i.e. at

the ceiling of the building or against the roof opening.

The control unit weights 7,5 kg and must be installed on a stable underground. The mounting holes for wall mounting

are placed on the metal plate underneath the plastic lid.

Foresee (at least) a separate 230V power circuit with its own automatic circuit breaker for each re zone. Don’t connect

other devices to this circuit!

It is sometimes required to supply the control unit with a 230V circuit with separate earth leakage circuit breaker and that

a circuit breaker is installed on the actuator line.

GENERAL DESCRIPTION

INSTALLATION

Page 7

01/10/2016

7/26

E_MH_Installation_instruction_Skycom_Skymax_CE

n

SCHEME

SKYMAX® CE

SKYCOM

SKYMAX CE

FIRE SWITCH

RAIN – AND WIND DETECTOR

COMFORT VENTILATION

SMOKE AND HEAT SENSOR

*1

*2

*3 *4 *6*5 *

7

4 x 0,5 mm

2

fireproof

6 x 0,5 mm22 x 0,5 mm23 x 0,5 mm23 x 0,5 mm

2

standard

standard

fireproof

fireproof

Max. 5m

fireproof

2 x 1,5 mm

2

PRIORITY SWITCH

only for firemen

option

standard

*1

*2

*3

*4

*4

*4*6

*5

*5

*5

*7

at the ceiling, as near as possible to the smoke hatch

ENGLISH

Page 8

E_MH_Installation_instruction_Skycom_Skymax_CE 01/10/2016

8/26

Connection, operation and settings

Motor (actuator)

The actuators must be connected to output terminals 2-3. The max. load is 5A.

It is possible to disable the line monitoring on the motor output. The cables can be connected in series or parallel or a

combination of these (see drawings motor and electrical schemes).

It is important to keep the right polarity. The motors of most systems must be connected via a limit switch - see electrical

scheme of the specic opening system.

See table at the end for cable sections and max. motor cable length.

Cable monitoring (line monitoring) on the motor output

The control is equipped with 3 possible settings for cable monitoring (line monitoring), which can be congured by

means of jumper J2.

a. Jumper J2 mounted in pos. “Motor line” (Setting for Skylux® 160° CE, Skymax® CE old and new and Cintramax® CE)

Known motor: line monitoring (2-3) with double wired motor connexion.

Jumper J3 (actuator output) is set according to the number of termination resistors (27KΩ) to be detected – 1 to max. 4

lines can be detected by moving jumper J3 – this means that the cable installation between the control unit and the motors

can be established in series connection (cable connection from smoke hatch 1, further to smoke hatch 2, etc.), or parallel

connection (cable connection from each smoke hatch to the control), or a combination of these. However, as mentioned

max. 4 different lines can be detected, each of them connected to the end resistor of 27KΩ.

Jumper description

J3

Number of connected 27Kohm terminal

resistors for actuator output

J2

Chooses line monitoring through motor

terminals 2-3 (Mot Mon) or separate

wire terminals 1-3 (Ext Li Mon), or no

line monitoring when J2/J3 is removed

F1

Fuse 8A for actuator output

Line 1

1

CH 1

24V Out

Actuator

23

+-

5

LIP

2

1

4

6

3

M1

24V Out

Actuator

2

1

Actuator

Motor line monitor

Ext 3 wire monitor

(line 1)

Blue

Next LIP

Brown

Blue

J2

1

J3

4

3

2

1

M2

Blue

Brown

Page 9

01/10/2016

9/26

E_MH_Installation_instruction_Skycom_Skymax_CE

b. Jumper J2 in pos. “Ext 3 wire” (Setting for Skymax® standard / Cintramax® CE (old) / Skyvent® CE)

Unknown motor: line monitoring (1-3) with 3 wired motor connexion.

With jumper J3 (actuator output): you choose how many lines (number of 27KΩ)

you wish to detect - the same way as the motor line.

This setting demands 3 wire cable from motor output to motor.

c. Jumper J2/J3 is not mounted - No line monitoring for actuator output

Electronic current limiter, type LIP function and setting (Skylux 160°CE, Cintramax CE, Skymax CE)

The current limiter type LIP (mounted on the opening system) is used as current limiter for the actuator. On the LIP5, and

younger version max. 3 times overload cut outs in the same direction is allowed. After which it will not be possible to run

in this direction again, before the motor has run in the opposite direction. Please note that when opening, the red LED in

the LIP must light. This indicates that polarity of the actuator is correct.

Table of LIP settings

* SA Power LM Large - parallel operation: Jumper OPT mounted - both motors stop at the same time if one stops

because of overload.

** When DIP4 is OFF = Tandem Mode - both motors stop at the same time if no current ows in one (1,5 sec. reaction

time).

*** Required: an actuator with “read” sensor (3-wire sensor black cable included).

Actuator

24V Out

1

+

21

Line 1

-

3

2

3

4

J2

J3

Mn M2 M1

Actuator

Motor line monitor

Ext 3 wire monitor

(line 1)

27K Ohm

(Only last

actuator)

Opening system

Skylux 160° LM Skylux 160° LM Skylux 160°: Mini + RM

Cintramax Skymax

current limit

3A 4A 2,5A

DIP 1 ON OFF ON

DIP 2 OFF ON ON

Type DIP 1 DIP 2 DIP 3 DIP 4 DIP 5 DIP 6 DIP 7 DIP 8

LIP5

Single

See diagram

above

27K

ON

not present

LIP6 *

Double

ON OFF ** =

Tandem

27K ON M1-M2 delay=OFF not present

LIP7

Single

Basic

27K

ON

not present

LIP7

Single

Tandem

27KONON =

COM

OFF = Slave

ON = Master

OFF = Synchro Mode

ON = Tandem Mode

off: no delay

on: 7s delay

no function

1

2

13

2

3

4

J2

J3

M1

Actuator

Motor line monitor

Ext 3 wire monitor

(line 1)

ENGLISH

Page 10

E_MH_Installation_instruction_Skycom_Skymax_CE 01/10/2016

10/26

Fire switches

The re switch will contain the following:

• Breakable glass window and red control button, activated by pressure - this puts

the control unit in ALARM status, by which the motor output is activated (for

normal service and testing the lid can be opened with a key).

• RESET button which brings the control unit out of the alarm status and starts

the closing sequence for about 180 seconds. Please note that RESET does

not cancel errors in the system, e.g. line errors etc. These must be found and

corrected. When a detector is still alive after reset, the control will go immediately

in alarm status again.

• RED LED indicates that the control unit is in ALARM status and that the motor

output either is or has been activated.

• YELLOW LED indicates faults on the system - please call for a service

technician.

• GREEN LED indicates that the system is in normal operation status without

errors.

The master control has an integrated priority re switch.

Additional connection of the external re switches are made as shown on the

drawing.

When the control is fully loaded, max. 8 external re switches can be connected.

When there is no load (Master), max. 10 re switches can be connected.

The installation with re switches must be terminated with a resistor (10kΩ 27kΩ) in the last switch in order to establish the line monitoring correctly – this

can either be done by moving the factory mounted resistor from the terminal

strip to the last re switch or connect jumper J1 in the re switch (by this a

10KΩ resistor is also connected).

By means of DIP switches the control unit has different possibilities of settings

for the input to the re switch:

DIP 1 (Con.Fire.Sw):

On = ALARM status from 500-3KΩ, (indication of line error by direct short circuit

or open circuit).

Off = ALARM status from 0-3KΩ (indication of line error by open circuit).

DIP 2 (Fail Safe):

On = Any line error on re switch or smoke detector puts the control unit in

ALARM status. This function can be used if cables to re switches and smoke

detectors are not reproof.

Off = An error status does not report ALARM status.

Terminals BVT

1. green LED OK (lights when OK and while closing)

2. yellow LED (lights on error)

3. red LED alarm (emergency opening)

4. ground (-)

5. not used

6. re switch reset

7. re switch emergency opening

Jumper J1 must only be set in

the last or only re switch

Fail. 24V

ALARM

OK 24V

6

4

3

2

1

4

3

2

1

J1

7

6

4

3

2

1

Gnd

11 12

24V

10 13

7

J1

7

6

FIRE15Reset

14

21

FAIL SAFE

Con. Fire. Sw

DIP

NO

OFF

ON

Red LED

Yellow LED

Green LED

2,2 kΩ

2,2 kΩ

10

K

Ω

Last manual control

point

Fit Jumper J1 for line

monitoring

Manual control point.

Break glass (BVT) No. 1

10

K

Ω

Break glass (BVT)

1

Buzzer

3

4

6

7

LED

OK

LED

2

i

LED

Alarm

GND

Reset

24V

24V

Green

Yellow

Red

24V

2,2k

Ω

J1

Jumper

10k

Ω

Reset

Alarm

doorswitch

FIRESWITCH

SKYCOM CE

10 1512

11 14

13

Page 11

01/10/2016

11/26

E_MH_Installation_instruction_Skycom_Skymax_CE

External priority switch for remen

The optional add-on PCP (SVM AddOn) is already connected. With correct SW (Version 042 or higher), LD3 + LD2 ash

for 5 sec. when communication has started. Connect the priority switch as shown on the electrical scheme. Line monitoring is done on the close (1-3) and open (1-4) outputs of the “add-on” PCB and is indicated by LD3 and LD2. Therefore

in the priority switch 10kΩ resistors are integrated. To avoid confusion there can be only one priority switch.

Information about the LED-indications: see page 21.

SVM addon

54321 6

CLOSE OPEN

16

GND

OPEN

CLOSE

LED

AL

MAIN PCB

If present, remove resistors

when connecting priority switch

LED

CLOSE

OPEN

GND

GND

GND

POWER

OPEN

CLOSE

PRIOR

external priority switch

CONTROL

LINK

PROGRAM

LD1

LD2

LD3

GRE

RED

RED

ComfortWeather

24V

Gnd

Weather

22 23

Gnd

20 21

PRIOR

ENGLISH

Page 12

E_MH_Installation_instruction_Skycom_Skymax_CE 01/10/2016

12/26

Nr.2-20

L2

L2

Nr.1

16

Gnd17Smoke

10

K

Ω

L1 Out

Smoke or heat sensors

L1 In

L1 Out

L1 In

(only last sensor)

Smoke- / heat detectors

Smoke- and heat detectors are connected as shown.

Line monitoring: Correct line monitoring can only be guaranteed with detectors delivered

from the supplier. Other detectors may have different internal resistances and stand by

power consumption.

Connect max 20 pc per control.

Comfort ventilation

The motor output can be controlled separately with comfort switch(es).

The master control has already integrated comfort open/close buttons.

Additionally external comfort switches can be connected as shown on the scheme.

It’s possible that due to fall-through safety, it’s forbidden to open the smoke hatches more than

30 cm for ventilation.

For comfort ventilation there are the following possibilities:

Potentiometer in Puls position:

It is possible to press the »up« button 3 times, which each gives 10 seconds of opening time after that nothing happens – Continuous »up« signal gives 3x10 sec.= 30 sec. - One press on

»down« closes the actuator completely; it takes 18s longer compared to fully closing time - In

order to avoid »actuator pumping« max. 3 successive closing attempts will be allowed.

Potentiometer in Constant position:

As long as »up« signal or »down« signal are given, the actuators are running. This is the

recommended position in case of e.g. roof access

Potentiometer in Puls variable position:

The time on the above mentioned pulse opening can be adjusted from 1-60 sec. on the

potentiometer.

When moving the potentiometer into the different positions the LED batt low will ash for about

4 sec. to indicate when in puls mode. LED line fail ashes 4 sec. when in Constant and AC fail

ashes when in puls Variable.

Put the potentiometer of all connected detection units (also Master) in the same position.

20

Gnd

18Up19

Down

Puls

variable

Min

Const.

Max.

Puls

YELYEL YEL

AC FAIL LINE FAIL BATT LOW

Up

Down

Switch Ch

1

Comfort

Potmeter for

comfort features

Room thermostats, weekly timers, CCS and other external control equipment for comfort ventilation can be connected to

the input of the comfort control.

Page 13

01/10/2016

13/26

E_MH_Installation_instruction_Skycom_Skymax_CE

6

NO

4

COM5NC

89

NO

NC

7

COM

Alarm Out Failure Out

Po

tential free F

ailure

contac

t.

C

om + NC connec

ted by

failure.Max 48V 0,5A

Po

tential free ALARM

contac

t.

C

om + NO connec

ted by

alarm.

Max 48V 0,5A

External signal output, Fire Alarm Panel and other control systems

The control panel can forward alarm situation to external connected systems by

means of potential free contacts on the terminals 4 (com), 5 (NC) and 6(NO).

The control panel can forward failure condition to external connected systems by

means of potential free contacts on the terminal 7 (com), 8(NO) and 9(NC).

Alarm and error contacts work parallel on all controls connected with bus connection.

DIP6 (fail relay):

On = Fail relay changes function to indicate open/closed smoke hatches.

How to make a connection from a Fire Alarm Panel

The control panel can receive potential free alarm signals from e.g.

AFA systems on the input to re switch or smoke-/heat detector.

Terminal 16 and 17.

Line monitoring resistor must be tted over the contact of the AFA system.

GND

16 17

Smoke

10 kΩ

Normally open

10 kΩ

Supplied with Panel

Weather sensor / Close all function

Install the rain- and wind detection as close as possible to the smoke hatch, at a place, where

the wind speed is equal to the wind speed of the smoke hatch (do not install the detector at eg

the outside of the roof edge trim).

The smoke hatches should be closed when the wind is above 6 m/s.

LED LD3 on the main board indicates active weather sensor - lights as long as input is active.

As long as the weather sensor is active, the smoke hatches cannot be opened with comfort

switches.

The weather sensor closes on all controls which are connected through bus connection.

On the input to weather station a weekly timer can be connected which makes sure that

everything is closed, e.g. by end of a working day.

The 24V power supply (terminal 22 & 23) for the weather sensor is standard set this

way (J11) that it does not function on batteries.

If battery functioning is needed, then mount J11.

This is possible at PCB V5 and the following versions (as from March 2015).

Be aware of the reduced standby time due to current consumptions.

Factory setting weather sensor = test = Pos 0 = delay 10s + highest sensibility.

Recommended settings weather sensor: Pos 4 = 4m/s (delay = 10 min)

For more details, consult the installation instructions of the wind-and

rain detector AWR-24/250.

Weather

24V

Gnd

Weather

22 2321

NC

NO

COM

24V

AC/DC

WIND & RAIN

AWR-24/250

ENGLISH

Page 14

E_MH_Installation_instruction_Skycom_Skymax_CE 01/10/2016

14/26

More controls connected in one re group (bus connection)

When there is only 1 control unit in the re group, terminals

A 1 2 3 and B 1 2 3 are not used. The communication is

interrupted by removing all the jumpers.

By means of a bus communication it is possible to make 2 – 35 control units to work as a complete system. The control

units communicate with each other via a 3 wire bus connection.

Terminal no. A1, A2, A3 are for the incoming connection and B1, B2, B3 for the outgoing connection.

In the rst control unit start Bus J4 has to be on. This control is Master and J5 must therefore also be on. Following control unit is a slave and therefore J6 must be connected. In the last slave unit, J7 and J6 must be connected to terminate

the bus cable.

ALARM: Alarms from Manuel Control Point smoke-/heat detectors are controlled locally. When DIP11 is set, the control

will go into alarm state if another control connected on the BUS enters alarm state.

RESET: If the reset button on one control or in one re switch is activated, the reset function on all connected controls is

activated and starts the closing function on all motor output for approx. 180 sec.

COMFORT: The comfort operation can work locally on each control. When DIP10 is set the control will react on any

comfort signal send on the bus from another control.

If a wind- and rain sensor is connected, it will work on all control on the bus matter dip settings.

Function description for control units connected with bus connection

If more control units are connected by means of a bus connection, the following are monitored/communicated between

the control units:

- A detected bus error makes the LED LD7 on the main board light/ash.

- A detected bus error brings all controls on the bus connection in error condition (line error).

- If one of the control units in the network goes into alarm status, all go into alarm status.

- If one of the control units goes into a certain error status (line error, AC error, battery error or bus error), the

other control units also go into error status – the type of the error is indicated on the board of the front plate of

all control units – on the control unit(s) which have not caused the error, the ok LED on the board of the front plate

ashes at the same time as the error. On the control unit(s) which have caused the error, the OK LED is switched

off.

Factory settings of Master, Slave & Skycom Skymax CE

J4 J5 J6 J7

Master ON ON OFF OFF

Slave OFF OFF ON ON

Skycom Skymax OFF OFF OFF OFF

START TERM.

START termination

J4

END termination

BUS Slave

BUS Master

MASTER SLAV E

J6J5

END TERM.

J7

Serial OutSerial In

A2

A1

B2

B1

A3 B3

BUS Master

START termination

BUS Slave

END termination

START termination

BUS Slave

BUS Master

END termination

A1

Serial Out

A3

B1

A2

Serial In

B3B2

Serial Out

B1

B2 B3

START TERM.

J4

SLAVE

J6

MASTER

J5

END TERM.

J7 J5

MASTER

J4

START TERM.

J7

END TERM

.

J6

SLAVE

A1

Serial In

A2 A3

Master

First control on BUS

Slaves

Middle controls on BUS

Slave

Last control on BUS

Please notice

mounted jumpers

BUS connection

3x 0,5mm2

Fireproof

BUS connection

3x 0,5mm2

Fireproof

START TERM.J4MASTER SLAVE

J6J5

END TERM

.

J7

Page 15

01/10/2016

15/26

E_MH_Installation_instruction_Skycom_Skymax_CE

Special functions

Sprinkler function:

DIP 9 On - a special function comes in use where sprinkler systems are installed. With this function activated, the actuator

output closes, if smoke-/heat detector input is activated.

If the re switch is activated, the actuator output opens.

Weekly open/close:

DIP 7 On - the motor output opens shortly (3 seconds) once a week and closes immediately after -

This function is used to give the right tension on the smoke vents to keep them airtight.

Function of heat detector in LIP:

DIP 3 On - a heat detector 70-100° can be mounted in each LIP. If the temperature is exceeded, the control unit goes into

alarm status and the opening system opens.

Special mode:

DIP 12 On - possible to use comfort switch also during line fault, low batt., no AC, Alarm only as long as re input is active

or detector is activated.

ENGLISH

Page 16

E_MH_Installation_instruction_Skycom_Skymax_CE 01/10/2016

16/26

24V Out

Actuator

5

LIP #1

3

M1

6

4

L1

PE

13 A Autofuse

3

N1

2

1

Line 1

+

21

J2

4

J3

FUSE F1 - fast

Max. 8A

Nr.2-20

L2

L2

Nr.1

10

OK 24V

-

3

6

NO

4

COM5NC

89

NO

NC

7

COM

14

Reset

15

Gnd

FIRE

11 12

Fail. 24V

ALARM

24V

13

19

Gnd16Smoke17Up

18

J4

BUZZER

24V

- 24VDC +

-

+

+

-

PS -

PS +

BAT -

BAT +

YELYEL

AC FAIL LINE FAIL

RESET

YEL

variable

Puls

BATT LOW

Const.

Min

Con. Fire. Sw

Max.

Puls

RED

GRE

RED

RED

RED

RED

RED

BUZZER ON /OFF

J1

FAILURE

YEL

OK

GRE

ALARM

RED

Skycom Skymax CE 24V - 5A

OFF

ON

TEMP

T

Actuator

Motor line monitor

Ext 3 wire monitor

(line 1)

10

KΩ

DIP

NO

Next LIP

Brown

Blue

(only last sensor)

Comfort

L1 Out

Down

Smoke or

heat sensors

Up

L1 In

L1 In

L1 Out

Red 2,5mm2

Batteries

2x 12V - 7,2 Ah

Black 2,5mm2

Potential free NO/NC

contacts : Max 48V 0,5A

PS1

Power Supply 180-250

VAC

24VDC 150W/200W

Potmeter for

comfort features

Foil

Without keyboard jumper mounted

J9

BLUE

DOME OPEN

7

8

M2

7

4

3

2

1

4

3

2

1

J1

6

7

4

3

2

1

6

J1

7

6

10

K

Ω

2,2 kΩ

Red LED

Yellow LED

Green LED

Last manual control

point

Fit Jumper J1 for line

monitoring

Manual control point.

Break glass (BVT) No. 1

Break glass (BVT)

2,2 kΩ

10

K

Ω

Battery backup

Terminal 23

Alarm Out Failure Out Fire switch

Sensor ComfortWeather

Motor

NTC

LED 1 Smok

e vent opens 2-3

LED 2 Smok

e vent closes 2-3

LED

3Wind & rain sensor active 21-22

LED 4 Line er

ror motor 1-2-3J2-J3

LED 5

Flashes: Line error PRIOR switch (see Add-on PCB)

LED 6 Line er

ror smoke/heat sensor 16-17

LED

7Bus-signal from other control is missing

Flashes: bus-signal from Add-on PCB is missing

1

2

Page 17

01/10/2016

17/26

E_MH_Installation_instruction_Skycom_Skymax_CE

Nr.2-20

L2

L2

Nr.1

Reset

Down

19

Gnd16Smoke17Up

18

J4

A2

24V

Gnd

Weather

22 23

Gnd

20 21

A1

B2

B1

A3

J5

B3

START termination

21

Const.

Min

FAIL SAFE

Con. Fire. Sw

Puls

END termination

BUS Slave

BUS Master

10911857

643

12

BUS FIRE

BUS COMFORT

SPRINKLER

AG MODE

WEEK OPEN

FAIL RELAY M.

SNITCH

SERVICE TIMER

TEMP DETECT

DSW

OFF

ON

Factory mounted

resistors on terminals:

TEMP

T

Options (accessories)

10

KΩ

DIP

NO

Switch Ch 1

(only last sensor)

Comfort

L1 Out

Down

Smoke or

heat sensors

Up

L1 In

L1 In

L1 Out

tmeter for

ort features

= OFF

= ON

J9

+ 2-3 : 27kΩ

+ 13-14 : 10kΩ

+ 16-17 : 10kΩ

+ 1-3 : 10kΩ

+ 1-4 : 10kΩ

POWER

OPEN

CLOSE

SVM addon

54321 6

PRIOR

CLOSE OPEN

16

GND

OPEN

CLOSE

LED

LED

CLOSE

OPEN

GND

GND

GND

external priority switch

CONTROL

LINK

PROGRAM

Serial In Serial Out

Busconnection

J7J6

J11

Battery backup

Terminal 23

Sensor ComfortWeather

Relevant

Terminals

Relevant

Jumpers

(&

resistors)

ent opens 2-3

ent closes 2-3

ve 21-22

r motor 1-2-3J2-J3

Line error PRIOR switch (see Add-on PCB)

13-14

r smoke/heat sensor 16-17

om other control is missing

: bus-signal from Add-on PCB is missing

A123/B123

BL

J4-J5-J6-J7

LD1

LD2

LD3

GRE

RED

RED

PRIOR

NC

NO

COM

24V

AC/DC

WIND & RAIN

AWR-24/250

ENGLISH

Page 18

E_MH_Installation_instruction_Skycom_Skymax_CE 01/10/2016

18/26

J5 J6 J7J4

J3

412

3

J2

N

L

230V

16A

PE

L1NPE

SKYMAX CE (from 2015)

3x1,5mm²

24VDC

12

3

4

limit

switch

'LIP'

2x1,52mm

Fireproof

Max 5m

5

6

M

Blue

Brown

7

8

M

Blue

Brown

POWER

OPEN

CLOSE

SVM addon

54321 6

Priority switch

Remove resistors when

mounting priority switch

CLOSE OPEN

16

GND

OPEN

CLOSE

LED

Skycom Skymax CE control

Skymax CE

4 x 0,5 mm2

Fireproof

17 2216

13 14

23

10KΩ

10KΩ

Skymax CE

from 2015

Page 19

01/10/2016

19/26

E_MH_Installation_instruction_Skycom_Skymax_CE

Settings (factory setting: marked in bold)

By means of jumpers and dip switches it is possible to enable/disable several functions.

Factory settings are for 1 opening system Skymax CE with 1 Skycom Skymax control.

Text on board Factory

mounted

Mounted / ON function Dismounted / OFF function

DIP 1 Conf. Fireswitch OFF

Fire switch active from 500-3KΩ

Fire switch active from 0-3KΩ

DIP 2 Failsafe OFF Line error on re switch or detector puts

the control in alarm

Normal mode

DIP 3 Temp. Detekt OFF Line error on motor line (upper resistor

area) = alarm

Normal mode

DIP 4 Service T OFF Active Inactive

DIP 5 Snitch OFF LED’s “remember” errors (line errors,

AC/Batt. error, bus error). The LED’s

can only be switched off/reset again by

setting dip switch off

Normal mode

DIP 6 Fail Relay OFF Failure relay works as indication that

skylight is open

Normal mode (works as failure relay)

DIP 7 Week open OFF Weekly open (2 sec.) /close

(5 sec.) cycle activated

Weekly open/close not activated

DIP 8 AG Mode special ON Priority “close” button enabled +

10 s comfort pulse

Normal mode + 6 s comfort pulse

DIP 9 Sprinkler OFF Motor output closes by active detector

(opens by activating the re switch) or

internal T-detection

Normal mode - motor output opens

by ative detectors or re switches

DIP 10 Bus comfort ON The control reacts on comfort signal

via bus activity

The control does not react on comfort

signals via bus activity //

Always reaction

on weather signal and failures via bus activity and

own comfort signal

DIP 11 Bus re ON The control reacts on alarm signal

via bus activity

The control does not react on alarm

signal via bus activity

//Always reaction on weather signal and failures

via bus activity and own alarm signal (detector or

fire switch)

DIP 12 BR Mode special OFF comf. active at all failures

Alarm only as long as input is activated

Normal mode

J1 ON Buzzer functional Buzzer off

J2 Mot Mon act. yes Known actuator: line monitoring

(motor) with 2-wired motor connexion No line monitoring

Ext Li Mon act. no Unknown actuator: line monitoring

with 3-wired motor connexion.

J3

(motor)

1 - 2 - 3 - 4 Pos. 1 Set up according to number of

27KΩ resistors on actuator exit

No line monitoring

(J3 and J2 not connected)

J4(Bus) Start term.

+

No

First control unit in the bus network

which is also master

See section concerning connection of

controls units in bus connection, page

14

J5(Bus) Master No

J6(Bus) Slave No Middle and last control unit in the bus

network

J7(Bus) End term. No Last control unit in the bus network

J9 * FOIL Ye s Line monitoring of keypad foil Line error ashes

J11 * BatSup -> Ø 23 No Battery backup of terminal 23 Terminal 23 only AC supplied

Others: Reset time = 180 sec. closing // Cut-off motor output and loading after 360 sec. // Comfort variable (potentiometer): 1-60

sec.

* As from new edition (March 2015)

ENGLISH

Page 20

E_MH_Installation_instruction_Skycom_Skymax_CE 01/10/2016

20/26

FRONT PANEL: LED’s (MASTER & SLAVE) & BUTTONS (MASTER ONLY)

RESET

SKYMAX

Page 21

01/10/2016

21/26

E_MH_Installation_instruction_Skycom_Skymax_CE

LED INDICATIONS

Front panel

Main board (Internal PCB)

Add-on PCB (option PCB for Priority switch)

Symbol Colour &

Visibility

Operation possibilities for: Alarm/

re

Comfort

operation

OK Green

lights if everything is ok

switched off by local error on this control

ashes by error message from other controls received by bus

Ye s Ye s

Red Alarm: Control in alarm via own entry

Flashes: Control in alarm via other control

Ye s No

Yellow

(ashes)

Fault: AC or DC or line error. Ye s Only close

Yellow *

(ashes)

AC error: No Mains voltage

- Circuit breaker switched off?

- Internal 24V supply defect?

Ye s Only close

Yellow *

(ashes)

DC error: Battery low, charging

- Mains voltage disconnected?

- Battery not connected?

- More than 1 day => batteries defect

Ye s Only close

Yellow *

(ashes)

Line error

- See Led 4-7 for details

- No other Led: connector keypad fail (J9)

- Check settings (arrows) and connections according the

schemes

Ye s Only close

Blue lights when smoke vents are open

ashes when the smoke hatch opens or closes

Ye s Ye s

lights with * time for yearly service - please contact SHE service (running light) Yes Ye s

Relevant

Terminals

Relevant

Jumpers

Operation possibilities:

(&

resistors)

Alarm:

- re

- prior

Comfort

LED 1 Smoke vent opens 2-3

LED 2 Smoke vent closes 2-3

LED 3 Wind & rain sensor active 21-22 Ye s No

LED 4 Line error motor 1-2-3 J2-J3 Yes Only close

LED 5 Line error reswitch

Flashes: Line error PRIOR switch (see Add-on PCB)

13-14 J1 in

re button

Ye s Only close

LED 6 Line error smoke/heat sensor

Flashes : temperature exceeds 75°C

16-17 Ye s Only close

LED 7 Bus-signal from other control is missing

Flashes: bus-signal from Add-on PCB is missing

A123/B123

BL

J4-J5-J6-J7

Ye s Only close

LD 1 Supply voltage connected Link Ye s Ye s

LD 2 Line error prior open (+LED5 from main PCB ashes) 1- 4 Ye s Only close

LD 3 Line error prior close (+LED5 from main PCB ashes) 1- 3 Ye s Only close

ENGLISH

Page 22

E_MH_Installation_instruction_Skycom_Skymax_CE 01/10/2016

22/26

Cables

It is very important to use the correct cable sections and sizes to make sure that the Smoke and Heat Extraction system

meets the standards and works correctly in case of emergency.

The two most important factors are the ability of the cables to resist heat and to make sure that the voltage drop in the

cables to the actuators does not exceed the max. value (15% for most systems) at full load of the SHE-hatches.

Fire resistant cables according to IEC 60331 must be used for the following functions:

Normal cables can be used for the following functions:

Nominal motor current for each opening system (current per system):

Max. motor cable length:

Opening systems with actuators 24V 2 or 3 wires: section: see table “Max

motor cable length”

Fire switch 6 x 0,5 mm²

Smoke detector 2 x 0,5 mm²

Heat detector 2 x 0,5 mm²

Cable between control units (bus) 3 x 0,5 mm²

Priority switch 4 x 0,5 mm²

Supply for control 230VAC 3 x 1,5 mm²

Comfort ventilation button 3 x 0,5 mm²

Wind- and rain sensor 3 x 0,5 mm²

* Only to be used to determine the

max motor cable length with the

table below.

* * Generally use 1 Slave control per

opening system. This results in

short motor cables.

I total (theoretical) 1 A 2 A 3 A 4 A 5 A 6 A 7 A 8 A

Cable 3 (2) x 1,5 mm² 109 m 54 m 36 m 27 m 21 m 18 m 15 m 13 m

Cable 3 (2) x 2,5 mm² 181 m 90 m 60 m 45 m 36 m 30 m 26 m 22 m

Cable 3 (2) x 4 mm² 292 m 146 m 97 m 73 m 58 m 48 m 41 m 36 m

Cable 3 (2) x 6 mm² 439 m 219 m 146 m 109 m 87 m 73 m 62 m 54 m

Cable 3 (2) x 10 mm² 759 m 379 m 253 m 189 m 151 m 126 m 108 m 94 m

NOMINAL Max. Systems

per Control

THEORETICAL *

system E (1A) 1 A 8 1,25 A

Skymax standard 1,1 A 7 1,1 A

Skymax CE (old version) 4 A 2 4 A

Skymax CE ** 2 x 2,5 A (1) 3,75 A

Skylux 160°CE LM ** 4 A (2) 3 A

Skylux 160°CE LM (2 motors) ** 2 x 4 A (1) 6 A

Skylux 160°CE RM ** 2,5 A (3) 1,875 A

Cintramax ** (old version) 2 x 1,1 A (3) 2,2 A

Cintramax CE ** 2 x 4 A (1) 6A

Skyvent ** 0,8 A (10) 0,8 A

£

Page 23

01/10/2016

23/26

E_MH_Installation_instruction_Skycom_Skymax_CE

The functions of the control unit and the opening system must be tested by authorized personnel at least once a year.

The control unit informs when the maintenance should be done. The external LEDs on the front panel ashes fast (running light). The control unit and opening system are of course still full operating. Please call a service technician at your

earliest convenience in order to carry out the maintenance and to test the control and opening system, in order to prepare it for another year of operation. The legal requirements for this must be observed and the testing and control must

as a minimum include the following:

• Control that all opening systems move to full opening when the re function is activated - should not be carried out if

the wind is more than 6 m/sec. as there might be a risk that the opening system cannot close automatically.

• Control of the batteries. If the batteries are replaced it is important to use the correct type.

• Control of in- and outputs on the control.

• Control of re switches and smoke- and heat detectors.

The batteries should be replaced as required, however at least every third year!

Clean dust from components (fan, ...) inside.

Clean wind & rain sensor as required.

Please contact our SHE service for more information or inquiries: Tel: +32 (0)56 24 81 05 - Email: service@agp.be

Maintenance

Date

MaintainedbySystem

Check

Battery

Check

Remarks

Year 0

............./............/20........

Year 1

............./............/20........

Year 2

............./............/20........

Year 3

............./............/20........

Year 4

............./............/20........

Year 5

............./............/20........

Year 6

............./............/20........

Year 7

............./............/20........

Year 8

............./............/20........

Year 9

............./............/20........

Year 10

............./............/20........

Year 11

............./............/20........

Year 12

............./............/20........

Year 13

............./............/20........

Year 14

............./............/20........

Year 15

............./............/20........

Year 16

............./............/20........

Year 17

............./............/20........

Year 18

............./............/20........

Year 19

............./............/20........

Year 20

............./............/20........

Year 21

............./............/20........

Year 22

............./............/20........

Year 23

............./............/20........

Year 24

............./............/20........

Year 25

............./............/20........

Year 26

............./............/20........

MAINTENANCE

ENGLISH

Page 24

E_MH_Installation_instruction_Skycom_Skymax_CE 01/10/2016

24/26

Part no. Description

25774 Wind and rain sensor 24VAC/DC: closes everything if rain or strong wind

25776 Heat detector

25775 Optical smoke detector

25773 Comfort switch Opus complete with housing

25772 Fire switch

30391 Replacement glass for re switch (also for PRIORITY switch

31441 WCP111720: Key for re switch for operation without breaking glass (until 2014)

31440 IP65 protection box for re switch

32567 PRIOR set with Add-on PCB and external priority switch

32568 Add-on PCB for external priority switch

32569 External priority switch

31021 Battery 12V/7,2AH 151x65x98mm (always order 2 pieces per control)

31782 Main board Skycom CE Master - all versions until 2014

35370 Main board Skycom CE all versions from 2015

31786 Main Board Skycom CE Slave until 2014 - until stock lasts

31783 Power supply 230 VAC / 28,5 VDC 8A

31784 Circuit breaker 10A (input terminal)

31442 Set Spare parts for Skycom CE (10x jumper / 10x R27k / 10x R10k / 2x Fuse 8A)

35347 Plastic Housing for Skycom CE master Belgium until 2014

35351 Plastic Housing for Skycom CE master Belgium from 2015

35349 Plastic Housing for Skycom CE slave

35350 Plastic Housing for Skycom CE Skymax

32541 Sticker ‘Hide comfort switches’ (for public places)

28662 LIP 5: Electronic limit switch for Skylux 160° CE with 1 motor

26811 LIP 6: Electronic limit switch for Skymax CE, Cintramax CE and Skylux 160 CE with double motor

31439 IP65 Protection box for limit switch (LIP)

19794 LA 1: Electronic limit switch for Skymax standard

20653 LA-TR: Electronic limit switch for Cintramax (old version)

SPARE PARTS AND ACCESSORIES

Page 25

01/10/2016

25/26

E_MH_Installation_instruction_Skycom_Skymax_CE

DECLARATION OF CONFORMITY

We, AG.Plastics

Spinnerijstraat 100

8530 Harelbeke-Stasegem

Belgium

declare under our sole responsibility that the product:

Skycom Skymax CE 24V-5A

(name, type or model, lot, batch or serial number, possible sources and numbers of items)

to which this declaration relates is in conformity with the following standard(s) or other normative

document(s).

EN12101-10:2006

EN61000-6-2:2005 EN61000-6-4:2001

EN61000-3-2:2005 EN61000-3-3:1995

(Title and/or number and date of issue of the standard(s) or other normative document(s)

following the provisions of Directive 73/23/EEC - 89/336/EEC and 93/68/EEC.

Stasegem 1 January 2011 Tom Vandamme

(Place and date of issue) (Name and signature or equivalent marking of authorized person)

ENGLISH

Page 26

E_MH_Installation_instruction_Skycom_Skymax_CE 01/10/2016

26/26

Power supply : 230V AC / max. 1,2A

Operating conditions : - 5 °C to + 60 °C / Humidity max 90%, non- condensing/

internal use without aggressive vapers & gases

Protection degree : IP54

Colour : RAL 9003 (white)

Dimensions WxHxD : 286x238x113 mm

Weight incl. batteries : 7,5 kg

Autonomy battery : Min. 72 hours

Internal T-sensor : Alarm generated at 75°C

Max. load : 24V / 5A (Fuse F1: 8A Fast acting)

Motor output : 1 pc. (terminals 6mm²) – line detection: 1-4 lines

Fire switches & zones * : 1 re zone, 8 - 10 pcs. external re switches,

depending on the load

Comfort zones * : 1 comfort zone - unlimited number of switches

Smoke- and heat detectors : 1 input - max. 20 pcs. detectors per control

Priority switch : 1 input for an external Priority switch

Wind- and rain sensor * : Input for close all

Connection of control units : Bus connection integrates most functions -

Max. 35 controls in the same bus connection

Alarm output * : Potential free SPDT change over max. 48V 0,5A

Fault output * : Potential free SPDT change over max. 48V 0,5A

Supply output * : 24VDC 0,5A at 230VAC operation

Line surveillance on : Motor lines, re switches,smoke detector Priority switch,

and communication bus

Visual indication (LED) : OK, AC fault, Low battery, Line fault, Alarm, comfort open

*

not present on Slave

Manufacturer:

AG.PLASTICS, Spinnerijstraat 100, B-8230 Harelbeke, Belgium, website: www.skylux.be

SHE service: Tel.: +32 (0) 56 24 81 05 I e-mail: service@skylux.be

Skycom Skymax CE Control:

Skycom CE Manual:

Version Production date Description

01 June 2014 First release

02 March 2015 New PCB with low consumption, keypad, J9, J11, T-sensor, ...

03 October 2016 EMC update: ferrite + GND 22-G+SW

Version Release date Description

01 December 2015 First release

02 October 2016 New wind and rain detector AWR-24/250 added

SHE survey added + EMC update

TECHNICAL SPECIFICATIONS

CONTROL FOR 1 FIRE ZONE AND 1 COMFORT ZONE

REVISIONS

Loading...

Loading...