TABLE OF

CONTENTS

Operating Instructions ........................................ 01

How the SkyHydrant Works ................................ 04

How to Maintain Water Quality ........................... 06

Ultrafiltration Removal Criteria ............................ 08

Data Sheet ........................................................ 11

Operating Log ................................................... 15

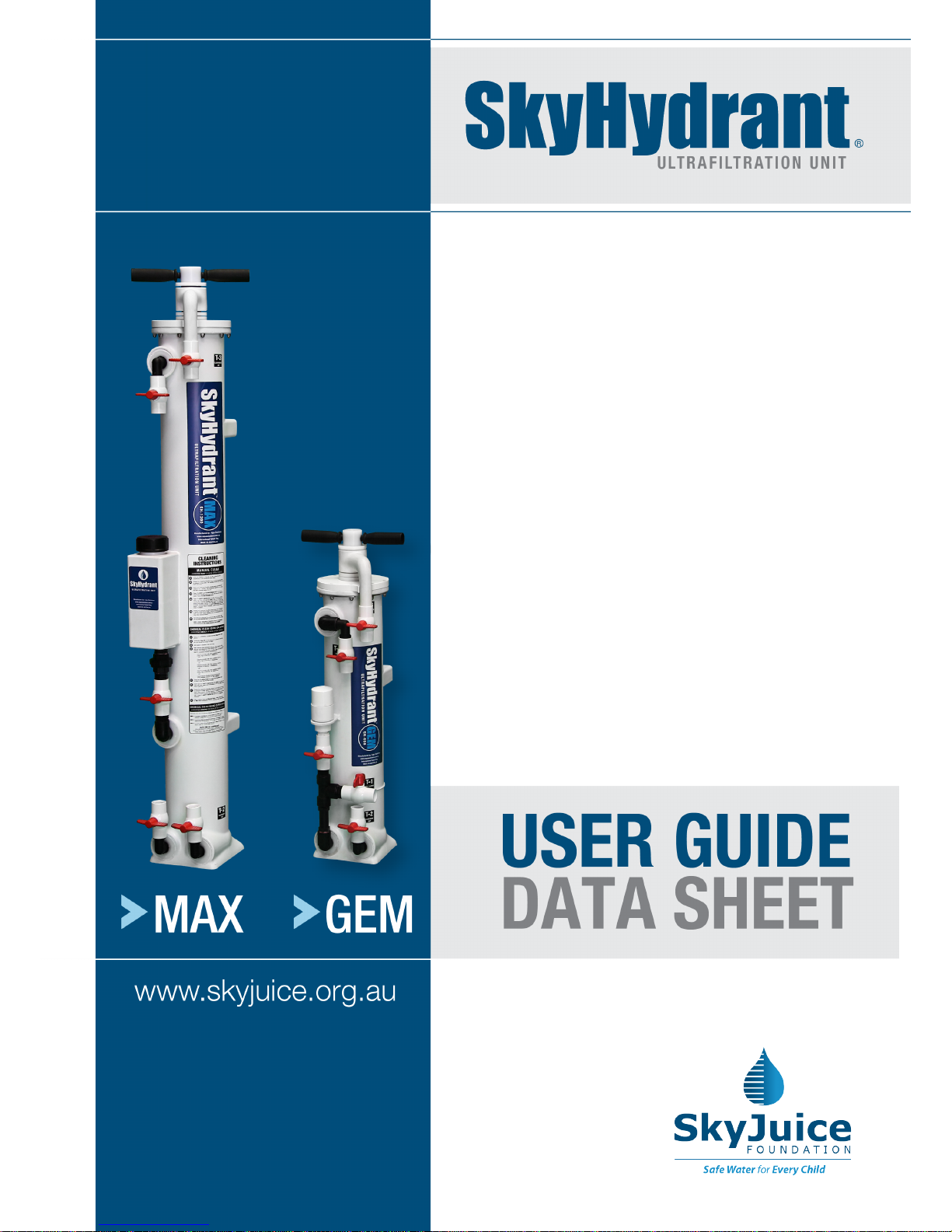

SkyHydrant-GEM

Nominal 6,000 litres per day

SkyHydrant-MAX

Nominal 12,000 litres per day

Height - 143 cm

Depth - 18 cm

Width - 25 cm

Mass (dry) - 13 kg

Mass (wet) - 32 kg

Height - 82 cm

Depth - 18 cm

Width - 25 cm

Mass (dry) - 9 kg

Mass (wet) - 21 kg

1

SKYHYDRANT - USER GUIDE & DATA SHEET

OPERATING INSTRUCTIONS

SkyHydrant ultrafiltration units are ideal for supplying drinking water in remote

locations from both surface and ground water supplies. SkyHydrants can be setup

and operated by non-technical persons and require no power or replacement filters.

SKYHYDRANT SETTING UP

Select a secure undercover location for the SkyHydrant

sheltered from sun and rain and install in an upright position.

The site should be located in a well-drained position with access

to a disposal area for the discharge of backwash water.

A maintenance person should undertake daily cleaning and

servicing of the unit to ensure it’s continuous operation. Log

sheets should also be completed to record water production

and to schedule servicing of the unit.

SKYHYDRANT ASSEMBLY

Connect the Cleaning Handles

Unwind the head shaft a few turns anticlockwise to release

pressure and remove the two temporary bolts used during

shipping. Next, screw the two cleaning handles into the top

of the SkyHydrant making sure they are firmly seated into

position.

Attach Legs and/or Wall Brackets

Use fasteners provided to screw the legs onto the base of

the unit and/or attach the wall mounting brackets to the back

of the SkyHydrant which in turn can be secured to a wall or

upright (see Fittings & Accessory Sheet for details).

Connect Plumbing Fittings

All outlets use 20mm (3/4”) BSP connectors and quick

connect fittings. The taps numbers T1 “Dirty Water In” and T2

“Backwash Out” can be folded down level for use.

Setup Ancillary Connections

Connect hoses and fittings to allow the SkyHydrant to function

i.e. Taps, pipes, tanks, pumps or other equipment (see How

the Ultrafiltration Unit Works for details).

• Connect “dirty water in” hose to T1 “Dirty Wash In”.

• Connect “backwash out” hose to T2 “Backwash Out”.

• Connect drinking water “clean water out” hose to T3

“Clean Water Out”.

2

SKYHYDRANT - USER GUIDE & DATA SHEET

COMMENCE USING THE SKYHYDRANT

Before start up, read section “Water Pipes and

Containers - Keep Free Of Contamination”.

1. Fill the Unit with Water

Open T1 “Dirty Water In” and T4 “Vent”. Wait

until water flushes out T4 and Close T4 “Vent”.

2. Removing Trapped Air

Rotate cleaning handles anticlockwise until

water leaks from the head. This releases

any trapped air, gently turn the cleaning handles

clockwise with just enough pressure to reseal

the “O” rings (do not over tighten).

3. Produce Drinking Water

Open T3 “Clean Water Out” to commence the

flow of drinking water.

INTERNAL FILTER MODULE

The SkyHydrant does not need to be opened or

accessed internally for cleaning or maintenance.

Regular cleaning is however essential to prevent the

filter module becoming clogged. This is undertaken

by moving handles on the top of the SkyHydrant

back and forth as part of the cleaning process

which only takes a couple of minutes to complete.

The SkyHydrant should function for many years

without replacement of the internal filter module

providing correct maintenance is undertaken. Also

raw water entering the unit should be pre-filtered to

remove suspended solid material and be free of any

damaging chemicals.

SKYHYDRANT MANUAL CLEANING

(UNDERTAKE DAILY OR MORE OFTEN IF NEEDED)

Mechanical cleaning of the SkyHydrant is essential to remove day-to-day accumulations of

contaminate.

Do this by moving the cleaning handles on top of the unit back & forth at least daily and throughout the

day. This is necessary to maintain the correct flow of drinking water and prevent the filtration module from

clogging. Follow the process below:

Close all valves T1,2,3,4,5. At this time the ultrafiltration unit should

be full of water.

Rotate the Cleaning Handle about 3 turns anti-clockwise to release the

internal “O” rings seals. The handles should now move freely back &

forth.

Agitate the Cleaning Handles quickly back and forth (90° rotation) for

about 1 minute. This movement cleans the filter module inside the unit.

Open T4 VENT and T2 BACKWASH OUT and continue moving the

cleaning handles back and forth until the unit drains of water Close T2

BACKWASH OUT.

Open T1 DIRTY WATER IN and allow the unit to fill with water and

flush through T4 VENT. Continue moving the cleaning handles back

and forth.

Continue this action until water flushing from T4 VENT is the same

colour as water entering through T1 DIRTY WATER IN (generally

about 1 minute).

When complete, cease moving handles and close T4 VENT.

Rotate the Cleaning Handles about three turns clockwise to gently

reseal the “O” rings. Use just enough pressure to seal until water stops

dripping. Do not over-tighten as this may strip the internal thread.

The Manual Cleaning Procedure is now complete. Open T3 CLEAN

WATER OUT to resume the flow of drinking water.

M1

M2

M3

M4

M5

M6

M7

Note: Water pipes and equipment should be flushed with a chlorine solution before use to eliminate contamination.

3

SKYHYDRANT - USER GUIDE & DATA SHEET

SKYHYDRANT SOLUTION CLEANING PROCEDURE

(Undertake weekly/monthly)

Solution cleaning removes accumulated organic matter and other contaminates from the

SkyHydrant not removed by the regular manual cleaning. To do this, follow the process below:

Undertake Steps M1 to M6 of the MANUAL CLEAN PROCEDURE (listed on previous page)

REPEAT Step M4 of the MANUAL CLEAN PROCEDURE (this will leave the unit empty of water).

Fill the Solution Tank with water (3/4 full).

Add chlorine (see amount below) to the solution tank and stir until dissolved. This should create

a 0.2% chlorine solution inside the filter housing. The chlorine manufacturer will state the chlorine

concentration on the label, this will determine how much chlorine to add using the information below.

Open tap T5 SOLUTION and allow the solution tank to drain, close tap T5-SOLUTION.

Open taps T1 DIRTY WATER IN & T4 VENT and allow the unit to fill with water and immediately

close T4 VENT when water spills out.

Rotate the Cleaning Handles about 3 turns anti-clockwise to unseal the internal “O” rings then move

the Cleaning Handles quickly back and forth a few times, this mixes the chlorine inside the unit. A

small amount of chlorine solution should also discharge from the top. Close T1 DIRTY WATER IN

and leave to soak for 4 hours or longer

After soaking carry out Manual Clean, follow Steps M1 to M8. After completion the unit can be

returned back to producing drinking water again.

C1

C2

C3

C4

C5

C6

C7

C8

Solution Cleaning Using Citric Acid – Undertake Monthly

Citric acid is used to remove iron and manganese deposits from inside the filtration unit.

STEP 1 Complete a SOLUTION CLEAN USING CHLORINE (as above) followed by step M4

of the MANUAL CLEAN procedure (to make sure the unit is empty of water).

STEP 2 Undertake steps C3 and C4 (as above) and follow the table below for the amount of Citric

Acid powder to add to the chemical tank in step C4 (instead of chlorine).

STEP 3 Complete steps C5 to C8 (as above), however in step C4 leave the citric acid to soak

for 12 hours (not 4 hours). This procedure is now complete.

Safe Use of Chemicals:

Follow manufacturer’s safety instructions. Avoid contact with skin and wear protective gloves, eyeglasses

and clothing. Do not inhale fumes.

Chlorine is used to remove deposits of organic matter form inside the filtration unit.

Follow steps C1 to C8 below and see step C4 for the amount of chlorine to use:

4

6

8

10

200 ml

Chlorine powder with 65% available chlorine (700g/kg of chlorine)

Chlorine powder with 55% available chlorine (550g/kg of chlorine)

Chlorine powder with 35% available chlorine (350g/kg of chlorine)

Chlorine powder with 25% available chlorine (250g/kg of chlorine)

Liquid chlorine (Sodium Hypochlorite) with 12% available chlorine

teaspoons

CHLORINE

MAX

2

3

4

5

100 ml

teaspoons

SH1200

GEM

SH600

CITRIC ACID SOLUTION

500 gms

Fine Granular Citric Acid

250 gms

GEM

SH600

MAX

SH1200

4

SKYHYDRANT - USER GUIDE & DATA SHEET

HOW THE SKYHYDRANT WORKS

The SkyHydrant requires no power to operate; instead it relies on the flow of water from gravity pressure.

Raw water flows through the unit with a water head pressure of between 2 metres and maximum 4 metres

(20kPa to 40kPa or 3psi to 6psi).

The SkyHydrant can be set up in a number of different ways to best accommodate site needs. A popular

method is to pump raw water (using mechanical or hand pump) to a 1,000 litre header tank located on a

3 meter high tank-stand and allow the water to gravity feed through the ultrafiltration unit and collect in a

1,000 litre drinking water tank located on a 1 meter high tank stand.

The drinking tank can be connected with taps or be fitted with pipes for supplying water directly to houses

through a distribution network.

Never pump or connect mains water pressure directly to the ultrafiltration unit without using a suitable

water pressure regulating or control device as excessive water pressure may damage the filter fibres.

SKYHYDRANT SITE EQUIPMENT

For the SkyHydrant to function it requires additional operating equipment. This may include hoses, pipes,

pumps, taps, tap stands, float valves, water bladders, tanks and tank stands.

The amount of additional equipment depends on the installation being undertaken and individual sites

requirements.

Installations where existing roof top water tanks are available allows the ultrafiltration unit to become an “in

line filter”. Simply connect to the existing water supply system. Other types of installations will require more

extensive site work and equipment.

It is important when setting up the ultrafiltration unit to ensure correct sizing of pipes, pumps and other

equipment.

5

SKYHYDRANT - USER GUIDE & DATA SHEET

MULTIPLE SKYHYDRANT UNITS

Multiple SkyHydrant can be connected together

(2 or more) to increase water production when

required.

Multiple connection kits are available or alternatively

obtain local plumbing fittings to manifold multiple

SkyHydrants together.

Water production will vary significantly depending

on the quality of the raw water available. Turbid and

highly contaminated water will reduce output as

well as increasing the frequency needed of cleaning

cycles.

SKYHYDRANT UNIT SETUP

The SkyHydrant can be set up to operate as single stand-alone

unit (picture to the left) or manifolded together into multiple units

for high flow production (above).

The supply of raw water to SkyHydrant can be sourced from

gravity feed overhead tanks or by using pressure reducing

devices when supplied directly from pumps or pressure supply

pipes.

Operating pressure should be limited to (20kPa to 40kPa or

3psi to 6psi) or about 2 to 4 meters head pressure to produce

a typical flow rate of about 500 to 700 litres per hour per unit.

Drinking water produced from the SkyHydrant can be stored in

tanks and connected to taps or be piped to household supplies.

PERFORMANCE MONITORING

At start up it is recommended the flow rate of the SkyHydrant be measured and recorded. This will

determine if the flow rate decreases in the future.

To undertake this procedure, allow water to flow into T1 (dirty water in) from a measured height (say 2

metres) and use a stopwatch to time how long it takes to fill a measured bucket of water (say 10 litres) out

of T3 (clean water out).

On a regular basis repeat this procedure. If the flow rate decreases it may indicate more frequent cleaning

of the ultrafiltration unit be undertaken.

Over the lifetime of the ultrafiltration unit there will be a natural loss of flow due to ageing of the filter fibres.

OPERATION LOG SHEETS

It is good practice to keep a daily operational log-sheet (see Log Sheet on the last page) to record drinking

water production flow rates and when cleaning procedures were undertaken.

This is useful to identify a pattern of use when monitoring on-going performance trends or to determine if

operational problems may be occurring. It is also useful as a convenient reminder of when the next cleaning

cycle is due to be undertaken, particularly when a cleaning roster is being used.

6

SKYHYDRANT - USER GUIDE & DATA SHEET

HOW TO MAINTAIN WATER QUALITY

FEED WATER SUITABILITY FOR ULTRAFILTRATION

Not all water is suitable for filtering through the SkyHydrant ultrafiltration unit (UF) and testing for unsuitable

contaminates should be undertaken before use.

• YES – Diseases Removed

The SkyHydrant will significantly remove biological contaminates and pathogens including bacteria,

viruses, protozoa, cysts, parasites etc. making water safe to drink.

• YES – Turbidity Removed

The SkyHydrant will remove turbidity and dirt from water. Dirty water can however damage the filter fibres

and it is recommended to install a pre-filter.

• NO – Chemicals NOT Removed

The SkyHydrant will not remove salt or dissolved chemicals and minerals from water.

WATER PIPES AND CONTAINERS KEEP FREE OF CONTAMINATION

Use a chlorine solution to sanitise and eliminate any residual post contamination, which may spread disease

in water pipes, drinking containers, hoses, taps, and other equipment.

Use a 0.1% (1,000 parts per million) chlorine solution (add approximately 1 teaspoon of chlorine powder to

5 litres of water) and flush through pipes or wash drinking water containers.

It is also recommended to regularly flush a chlorinated solution through the SkyHydrant together with

drinking water hoses and pipes to eliminate any post contamination.

PRE-FILTRATION TREATMENT

It is recommended that a pre-filter be installed to reduce solids from fouling the internal filter module when

using a highly turbid water source.

A pre-filter (300-micron) will provide good protection, pre-filters will also require regular cleaning to maintain

a good water flow.

SKYHYDRANT LONG TERM STORAGE

When the SkyHydrant is placed into storage for use again in the future, the filter fibres must remain wet at

all time to prevent permanent damage.

When placing the ultrafiltration unit into storage:

• Undertake a chemical clean and leave at least 1 litre of clean water inside the unit (or preferably

leave the unit full of clean water with 5 to 10ppm chlorine) to maintain a wet environment.

• Turn all valves off before placing the unit into storage. Do not store in conditions below freezing.

After storage undertake a chemical clean to restore the filter module back to normal operation condition.

7

SKYHYDRANT - USER GUIDE & DATA SHEET

PREVENTING POST CONTAMINATION OF DRINKING WATER

Water produced from the SkyHydrant is free of biological contaminates and safe to drink. Over time

however, water quality can deteriorate - in hot climates water can remain safe for a few days while in colder

climates it may stay safe for weeks.

To maintain water quality it is good practice to regularly disinfect drinking water tanks and water pipes by

adding a small amount of chlorine to prevent the growth of unwanted organisms and pathogens in the

stored water.

To achieve this, as a guide add about 3/4 teaspoon of chlorine powder (at 65% available chlorine) or 1½

teaspoons of chlorine powder (at 35% available chlorine) for every 1,000-litres of tank water. First, mix the

chlorine in a small bucket of water to make a solution before adding the chlorine solution to the tank.

It is recommended to use a water testing kit to maintain a free residual chlorine level of between 0.2 to 0.5

milligrams per litre (mg/l) which is equivalent to 2 to 5 parts per million (PPM). Water should be tested every

few days to maintain the chlorine levels and make adjustments as necessary.

8

SKYHYDRANT - USER GUIDE & DATA SHEET

ULTRAFILTATION REMOVAL CRITERIA

A patented low-pressure ultrafiltration technology meeting and exceeding World Health

Organisation requirements for safe drinking water.

Proprietary and patented low-pressure ultrafiltration membrane technology is highly effective in removing all

non-dissolved species in feed waters. Ultrafiltration is classified by the World Health Organisation (WHO) as

effective removal of disease causing pathogens and exceeds requirements for key criteria to produce safe

drinking water. However, it is important to test the water and validate the composition of the feed water.

Please refer to the Technical Bulletins and Specifications to obtain specific information on performance.

Ultrafiltration (to 0.04um nominal) WILL REMOVE

Pathogens (disease causing organisms) and Turbidity (dirt):

1. PATHOGENS removed (to log reduction value >4) by ultrafiltration include:

2. TURBIDITY

NTU (Nephelometric Turbidity Units) is removed by ultra-filtration to levels below <0.1 NTU. Turbid

water contains suspended matter such as clay, slit, fine fragments of organic matter, and similar

material. TURBIDITY levels of up to 1000 NTU can be removed however levels below 500 NTU are

preferred.

3. TOTAL SUSPENDED SOLIDS (TSS) will be removed. TSS is similar to turbidity.

4. IRON AND MANGANESE if first oxidised or if colloidal can be removed by ultrafiltration.

5. ARSENIC MANGANESE if first oxidised can be removed by ultra iltration.

The World Health Organisation (WHO) reports that ultrafiltration provides complete removal of bacteria and viruses

(disease causing pathogens) as outlined in WHO document “GUIDELINES FOR DRINKG WATER

QUALITY” under “Treatment Process” as referenced in the WHO website.

• Total Coliform TC

• Total Coliform FC

• Ecoli

• Virus (significantly reduces virus levels)

• Bacteria

• Protozoa

• Cysts

• Helminths

Note: mg/L (milligrams per litre) also equals ppm (parts per million); WHO (World Health Organisation)

1. Chemicals not removed by ultrafiltration include:

• Arsenic (unless first oxidised) (WHO safe drinking standard - Max 0.01 mg/L)

• Cadmium (WHO safe drinking standard - Max 0.003 mg/L)

• Chromium (WHO safe drinking standard - Max 0.05 mg/L)

• Copper (WHO safe drinking standard - Max 2.0 mg/L)

• Cyanide (WHO safe drinking standard - Max 0.07 mg/L)

• Fluoride (WHO safe drinking standard - 1.5 mg/L)

• Lead (WHO safe drinking standard - Max 0.01 mg/L)

• Mercury (WHO safe drinking standard - Max 0.006 mg/L)

• Nickel (WHO safe drinking standard - Max 0.07 mg/L)

• Nitrate (WHO safe drinking standard - Max 50 ml/L as NO3)

• Nitrite (WHO safe drinking standard - 3 mg/L as NO2)

• Sulphate (Safe Drinking Levels: 250 mg/L but up to 500mg/L can be tolerated

Ultrafiltration (to 0.04um nominal) WILL NOT REMOVE

Chemicals or Minerals or Salinity (salt) from water:

9

SKYHYDRANT - USER GUIDE & DATA SHEET

2. Minerals (hardness) is not removed by ultrafiltration, this includes:

• Total Hardness, hard water is mainly calcium and magnesium and is not considered a health

risk but can be unpleasant to taste and cause a build up of scale in pipes (WHO safe drinking

standard-Max 500 mg/L)

• Calcium, Carbonate (WHO safe drinking standard- Max 250 mg/L)

• Iron and Manganese (unless first oxidised) (WHO safe drinking standard- 0.4 mg/L;

Note: exceeding this level is not unsafe but is unpleasant to taste - max 1.0 mg/L)

• Magnesium (WHO safe drinking standard- Max 150 mg/L)

3. Salinity and salts are not removed by ultrafiltration include:

• Salinity (WHO safe drinking standard - Max 250 mg/L)

• Chloride and Sodium (WHO safe drinking standard - Max 600 mg/L)

• Conductivity (WHO safe drinking standard - Max 2000 uS/cm)

4. Total dissolved solids (TDS) cannot be successfully removed by ultrafiltration:

• TDS (WHO safe drinking standard - Max 1000 mg/L)

• TDS contain a wide range of substances including organic and inorganic (chemicals)

5. Unpleasant tastes are not successfully removed in most cases using ultrafiltration.

Ultrafiltration will have NO effect on ph levels:

• pH Scale (WHO safe drinking standard 6.5 – 9.0)

• Total Alkalinity (WHO safe drinking standard max 500)

• pH levels are not considered a health issue but may cause corrosion or encrustation of plumbing

fittings and pipes.

10

SKYHYDRANT - USER GUIDE & DATA SHEET

T4

T1

T2

S

T

E

P

O

N

E

S

T

E

P

T

W

O

CONNECT

CONNECT

HANDLES

CONNECT

LEGS

WALL BRACKETS

(OPTIONAL)

ULTRAFILTRATION UNIT

ACCESSORY KIT

ULTRAFILTRATION UNIT

11

SKYHYDRANT - USER GUIDE & DATA SHEET

DATA SHEET

Turbidity will also be removed and as turbidity rise the

SkyHydrants will require more frequent cleaning cycles

to remove accumulated contaminates. A pre-filter to 200

microns is highly recommended to reduce module fouling in

areas where high levels of solids are found.

The backwash cleaning cycle is easily undertaken requiring

no tools or the need to access internal components of the

SkyHydrant. Handles on top of the unit are simply moved

back and forth for the mechanical agitation cleaning process

which takes about one minute to complete before the back

flush valve is opened to release contaminates.

BACKGROUND

Small communities require robust, reliable water treatment

solutions often from difficult water sources. The treatment

systems must provide pathogen free water economically and

with minimal operator attendance.

SkyHydrant Water Filtration Units require no power or replacement filters and can be operated by nontechnical persons. SkyHydrants are lightweight and portable making them ideal for supplying drinking

water in most remote locations from both surface and ground water supplies.

They can operate as single standalone units or be manifolded together to increase water flow to create

large-scale water production plants.

SkyHydrants will significantly remove pathogens from feed water including bacteria, viruses, protozoa,

cysts and parasites to a level as classified by the World Health Organisation (WHO) as suitable for drinking

water.

TYPICAL APPLICATIONS

• Decentralised water treatment systems

• Community small-scale systems

• Remote and rural

• Communities

• Point-of-entry filtration

• Emergency and temporary water supplies

• RO (reverse osmosis) pre-treatment

12

SKYHYDRANT - USER GUIDE & DATA SHEET

THE SOLUTION

The SkyHydrant is a patented low cost, low maintenance ultra water filtration solution.

It affords practical, small-scale potable water treatment using proven ultrafiltration (UF) membrane

technology.

The hollow fibre membrane filtration module is mounted inside a potable rated moulded plastic pressure

housing which is compact, robust, easy to transport and simple to install.

The UF barrier filtration process provides primary disinfection by removing pathogens and particulates to

supply safe drinking water from the majority of non-saline surface and ground waters.

Additional post filtration treatment including ultra violet (UV) or chlorine disinfection can be utilised if desired.

OPERATING DESCRIPTION

Raw water flows into the SkyHydrant housing under low pressure. As it passes through the porous walls of

the hollow fibre membranes inside the unit, solids are retained on the membrane surface. The SkyHydrant

is suitable for use in either pumped feed or gravity feed applications.

The secret to the successful operation of the SkyHydrant is the effectiveness of its patented backwash

system, which uses a mechanical agitation process to clean membrane surfaces.

Backwashing is initiated manually by an operator, on a frequency as determined by site conditions and at

least once a day.

Periodically the SkyHydrant also requires a chemical clean to remove residual fouling that cannot be

removed by the daily backwash process alone and helps to limit biological growth in the system.

Typically chlorine and occasionally citric acid is used for the chemical cleaning process, which requires an

operator to attend. Chemical cleaning frequency is application specific but generally between weekly and

monthly.

MEMCOR® MEMBRANE MODULES

The membrane filtration modules use high permeability, low fouling PVDF hollow fibre membranes for

optimum performance and long life. The modules are simple in design and easy to install and maintain.

MEMBRANE CLEANING

A simple low pressure patented mechanically agitated backwash sequence together with periodic chemical

cleaning for quality performance at low differential pressure, even with turbid feed waters.

Note: Design, data and dimensions are subject to modification without notice.

13

SKYHYDRANT - USER GUIDE & DATA SHEET

TECHNICAL DATA

Filtration of potable non-saline surface water or groundwater for small

communities. Not suitable for use with seawater or brackish water or other water

sources containing contaminants such as heavy metals.

Typical filtrate production capacity treating clear surface water¹

3 metres to 4 metres head pressure

Pressurised outside to inside filtration

500µm or finer

50 NTU

< 0.1 NTU

> 4 LRV (for particles 2 to 5µm)

> 0 to 35˚C ( > 32 to 95oF)

> 0 to 35˚C (> 32 to 95oF)

Note: The unit must not be allowed to freeze

6.0 to 9.0pH Note: Exposure to chlorine or chloramines is not recommended

in feeds below 6.5pH

100kPa

MEMCOR® membrane filtration module polyvinylidene fluoride (PVDF) hollow

fibre ultrafiltration membrane with nominal pore size 0.04µm. Filter direction

outside to inside.

Food grade polyethylene (PE)

Various including PVC and PP

EPDM typical

Various including PE, ABS, Nylon and PVC

Typical Application

Typical Feed Inlet Pressure Range

for Gravity Feed

“Filter” Mode Operation

Feed Pre-Screen Mesh Size

Recommended

Max. Recommended Feed Turbidity

Filtered Water Turbidity

Typical Log Reduction Value

Operating Feed Temperature Range

Temperature Range for

Tansportation and Storage

Feed pH Range

Maximum Housing Operating

Pressure

Membrane Module Details

Materials of Construction:

Module Housing Assembly

Valves

Seals and Gaskets

Pipe and Fittings

Model Number

SkyHydrant MAX (SH1200)

SkyHydrant GEM (SH600)

Nominal litres per day using low turbidity feed water

Nominal 12,000 litres per day

Nominal 6,000 litres per day

2 to 10pH typical

Note: Occasional brief exposure during chlorine cleans to 10.5pH is acceptable

Approximately 15 litres

Gravity drain waste outlet to be provided adjacent to unit

300 to 500mg/L / 300 to 500ppm

Typically about 300 grams of citric acid powder will be used

Mechanical Agitation

Allowable pH Range for Cleaning

Waste Water Volume Per Backwash

Typical Target Chlorine

Concentration During a Chlorine

Clean

Cleaning Concentrate and Volume

Required for an Acid Cleaning Cycle

Backwash

2.0 to 2.2pH

(not less than 2.0pH)

Not Required

Installed under cover with protection from direct sunlight and rainfall

Typical Target Acid Concentration

During an Acid Clean

Electricity Supply

Recommended Installation Location

¹ Feed water quality will affect production capacity.

² Unscreened or coarsely screened raw water may reduce membrane operating life.

³ Capacity and backwashing/cleaning frequency will typically vary with feed turbidity.

14

SKYHYDRANT - USER GUIDE & DATA SHEET

WEIGHT & DIMENSIONS

UNIT DIMENSIONS & MASS (Approximate)

SHIPPING DIMENSIONS & MASS (Approximate – Shrink Wrapped

Model Number

SkyHydrantMAX (SH1200)

SkyHydrantGEM (SH600)

Model Number

SkyHydrantMAX (SH1200)

SkyHydrantGEM (SH600)

Height (cm)

143

82

Depth (cm)

18

18

Width (cm)

25

25

Mass (kg-dry)

13

9

Mass (kg-wet)

32

21

Height (cm)

150

90

Depth (cm)

20

20

Width (cm)

28

28

Mass(kg-dry)

18

12

FILTRATE QUALITY

TERMINOLOGY

IMPORTANT OPERATING INFORMATION

Ppm = Parts per Million

NTU = Nephelometric Turbidity Units (a measurement of turbidity)

Um = Micron

M = Metre

• The filter sub-modules located inside the SkyHydrant is to remain in a wet environment to avoid the

membrane drying which would result in total and permanent loss of performance. If long-term storage is

necessary after operation, the unit is to be rinsed with a solution of sodium hypochlorite (100ppm) and stored

at a temperature not above 40˚C, out of direct sunlight.

• When SkyHydrants are being used for the first time it is recommended that a chlorinated backwash be carried

out before the filtrate is used.

• The filter sub-module is resistant to oxidising agents such as chlorine, chloramines, bromine, bromamine,

and potassium permanganate. Maximum exposure of sub-modules to bromine, bromamine, potassium

permanganate, and other oxidants should be checked prior to starting operation.

• The SkyHydrant comprises a single MEMCOR® membrane sub-module located inside in a low-pressure

housing. The unit is suitable for operation under low positive or negative head pressure. Raw water flows

along the length of the hollow fibres before being forced through the walls of the fibre to produce a filtrate

virtually free of suspended solids. The unit removes virtually all solids and bacteria and significantly

reduces virus levels. Filtrate flow rate is controlled manually.

Parameter

Bacteria

Virus

Coliform

Cryptosporidium

Parameter

Giardia

Algae

Turbidity

Log Reduction Value

>6 99.9999%

>3 99.9%

>6 99.9999%

>6 99.9999%

Log Reduction Value

>6 99.9999%

>6 99.9999%

<0.02

15

SKYHYDRANT - USER GUIDE & DATA SHEET

TIME DATE DRINKING

WATER

PRODUCTION (L)

MANUAL

CLEANING

UNDERTAKEN

CHEMICAL

CLEANING

UNDERTAKEN

AMOUNT

CHLORINE

USED

OTHER

INFORMATION

OR NOTES

OPERATING LOG

16

SKYHYDRANT - USER GUIDE & DATA SHEET

Loading...

Loading...